Repair method for delamination damage of composite laminated plate

A composite material layer and composite material technology, which is applied in the field of repairing delamination damage of composite material laminates, can solve the problems of low reliability, complex process, influence on the aerodynamic surface of the structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0025] A method for repairing delamination damage of a composite material laminate, the composite material may be a solid composite material or a thermoplastic composite material, and the repair steps are as follows:

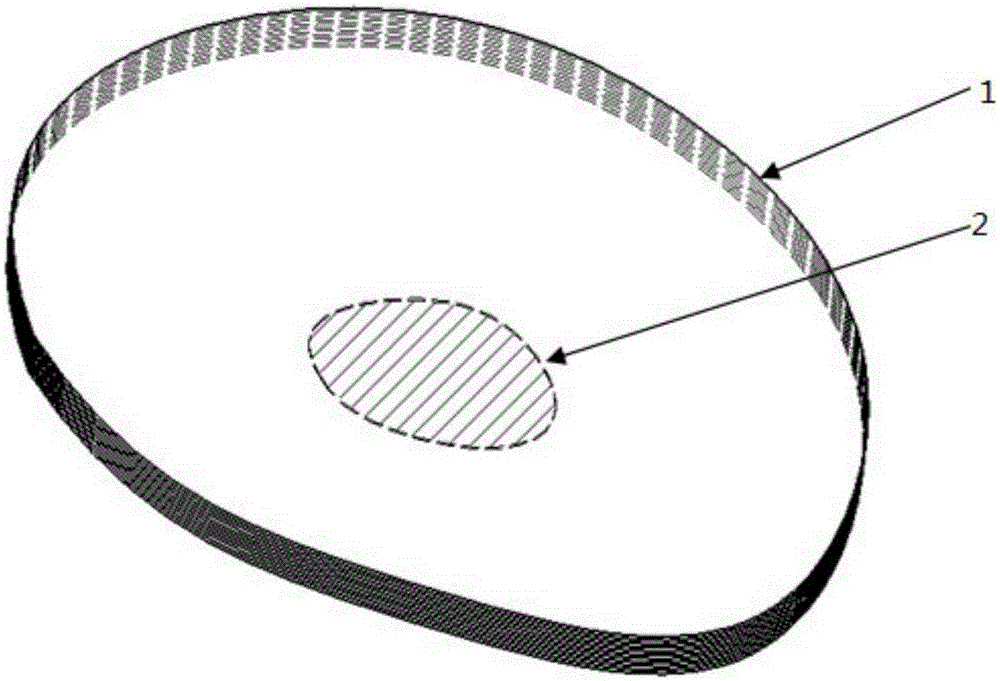

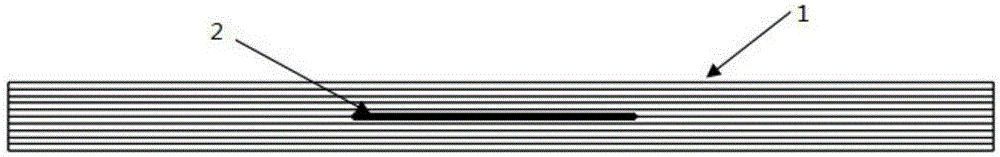

[0026] First, use non-destructive testing tools such as ultrasonic scanners to measure the delamination damage position 2 and its range inside the composite laminate 1, as shown in figure 1 and figure 2 shown. Wherein, the delamination damage location 2 may be one or more in the thickness direction of the composite laminate 1 , and the ranges of the multiple delamination damages may be the same or different.

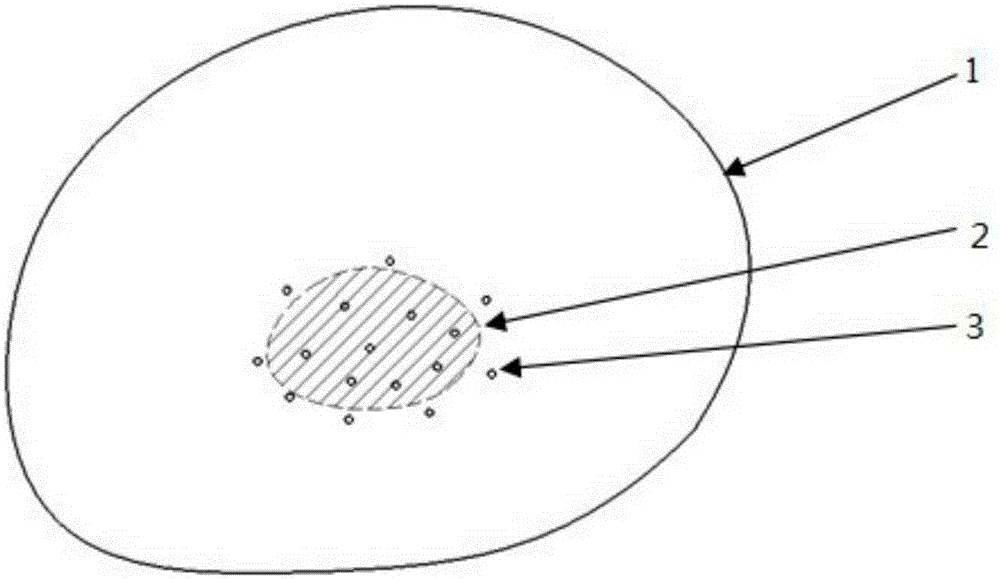

[0027] Secondly, a number of small holes 3 with a diameter of 0.1-1 mm are processed at the delamination damage position 2 of the composite material laminate 1 and its surroundings. The small holes 3 can be distributed paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com