A three-dimensional constrained ceramic composite bulletproof panel

A ceramic composite, panel technology, applied in protective equipment, armor plate structure, offensive equipment and other directions, can solve the problem of poor anti-multiple elastic performance, improve the integrity, improve the anti-multiple elastic performance, and improve the anti-delamination ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

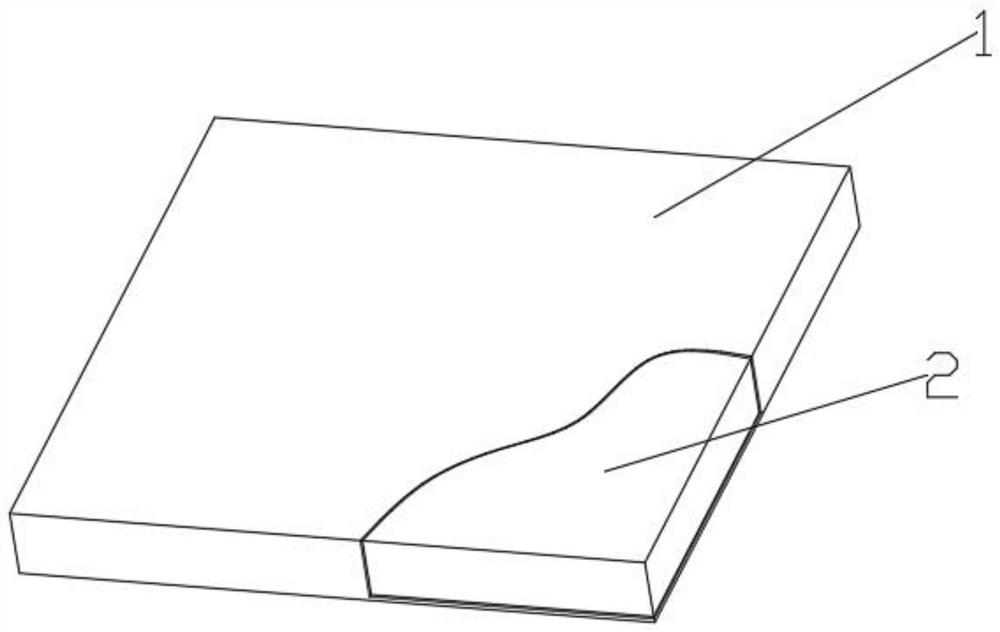

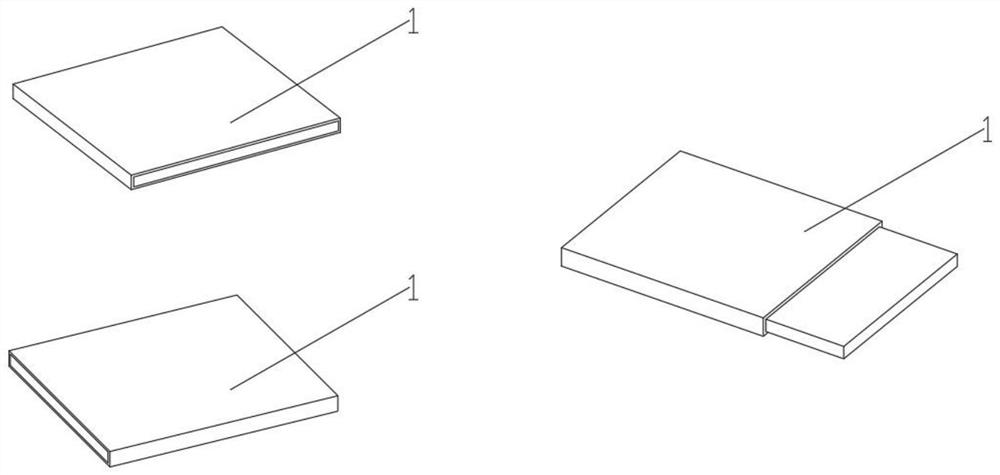

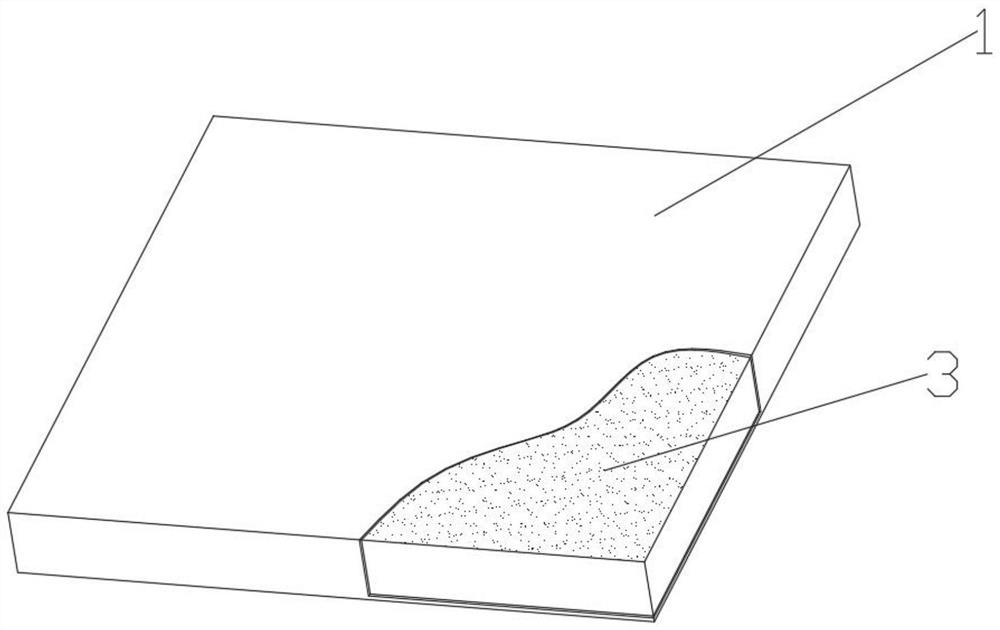

[0029] Such as Figure 1-Figure 3 Shown:

[0030] A three-dimensional constrained ceramic composite bulletproof panel, including a ceramic composite bulletproof panel 2 and a cladding layer 1, the cladding layer 1 is made of aramid fiber tubular fabric with a thickness of 0.1mm, and the aramid fiber tubular fabric is a woven structure, covering Layer 1 is composed of 2-layer, 3-layer, and 4-layer aramid fiber tubular fabrics, which are orthogonally nested, and are respectively recorded as experimental group A, experimental group B, and experimental group C; coating layer 1 is coated on the ceramic composite bulletproof panel 2 Outer surface, the ceramic composite bulletproof panel 2 adopts a 300mm*300mm ceramic plate 3 with a thickness of 10mm. The material of the ceramic plate 3 is alumina to realize the three-dimensional constraint on the ceramic composite bulletproof panel 2. Both the layer 1 and the ceramic plate 3 are bonded by an adhesive, and are shaped by hot pressing...

Embodiment 2

[0032] Such as figure 1 and Figure 4 Shown:

[0033] A three-dimensional constrained ceramic composite bulletproof panel, including a ceramic composite bulletproof panel 2 and a cladding layer 1, the cladding layer 1 is made of a 0.5mm thick carbon fiber tubular fabric, the carbon fiber tubular fabric is a braided structure, and the cladding layer 1 is three layers The carbon fiber tubular fabric is formed by nesting orthogonally. The cladding layer 1 covers the outer surface of the ceramic composite bulletproof panel 2. The ceramic composite bulletproof panel 2 adopts a composite ceramic plate 4 with a thickness of 300mm*300mm and a thickness of 10mm. The composite ceramic plate 4 has a cross-section of The hexagonal alumina ceramic unit 6 is spliced to realize the three-dimensional constraint on the ceramic composite bulletproof panel 2. Between the cladding layers 1, and between the cladding layer 1 and the composite ceramic plate 4 are bonded by adhesives. After hot p...

Embodiment 3

[0035] Such as figure 1 and Figure 5 Shown:

[0036] A three-dimensional constrained ceramic composite bulletproof panel, including a ceramic composite bulletproof panel 2 and a cladding layer 1, the cladding layer 1 is made of a 0.25mm thick ultra-high molecular weight polyethylene fiber tubular fabric, and the ultra-high molecular weight polyethylene fiber tubular fabric is Woven structure, the cladding layer 1 is made of 4 layers of ultra-high molecular weight polyethylene fiber tubular fabric orthogonally nested, the cladding layer 1 is clad on the outer surface of the ceramic composite bulletproof panel 2, and the ceramic composite bulletproof panel 2 is made of 300mm*300mm , a composite armor 5 with a thickness of 15mm, the composite armor 5 is composed of a 10mm thick alumina ceramic panel 8 and a 5mm thick fiber reinforced composite material plate 7, and the fiber reinforced composite material plate 7 is made of ultra-high molecular weight polyethylene fiber and epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com