Method for blasting big boulder in artificially dug pile

An artificial digging pile, large-scale technology, applied in the field of blasting, can solve the problems of poor treatment effect, labor and time-consuming, low efficiency, etc., and achieves the effect of good demolition effect, improvement of project quality, and improvement of construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

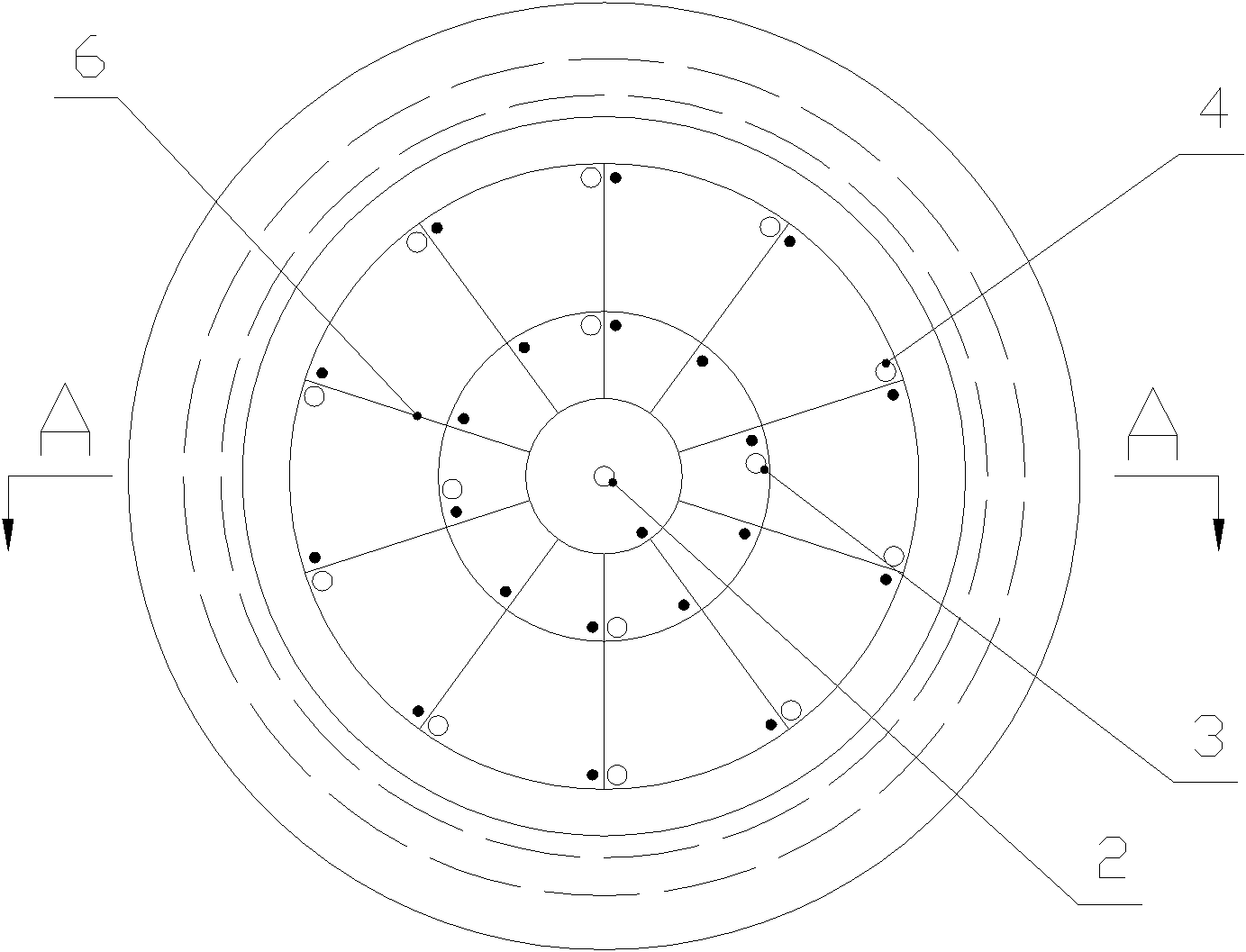

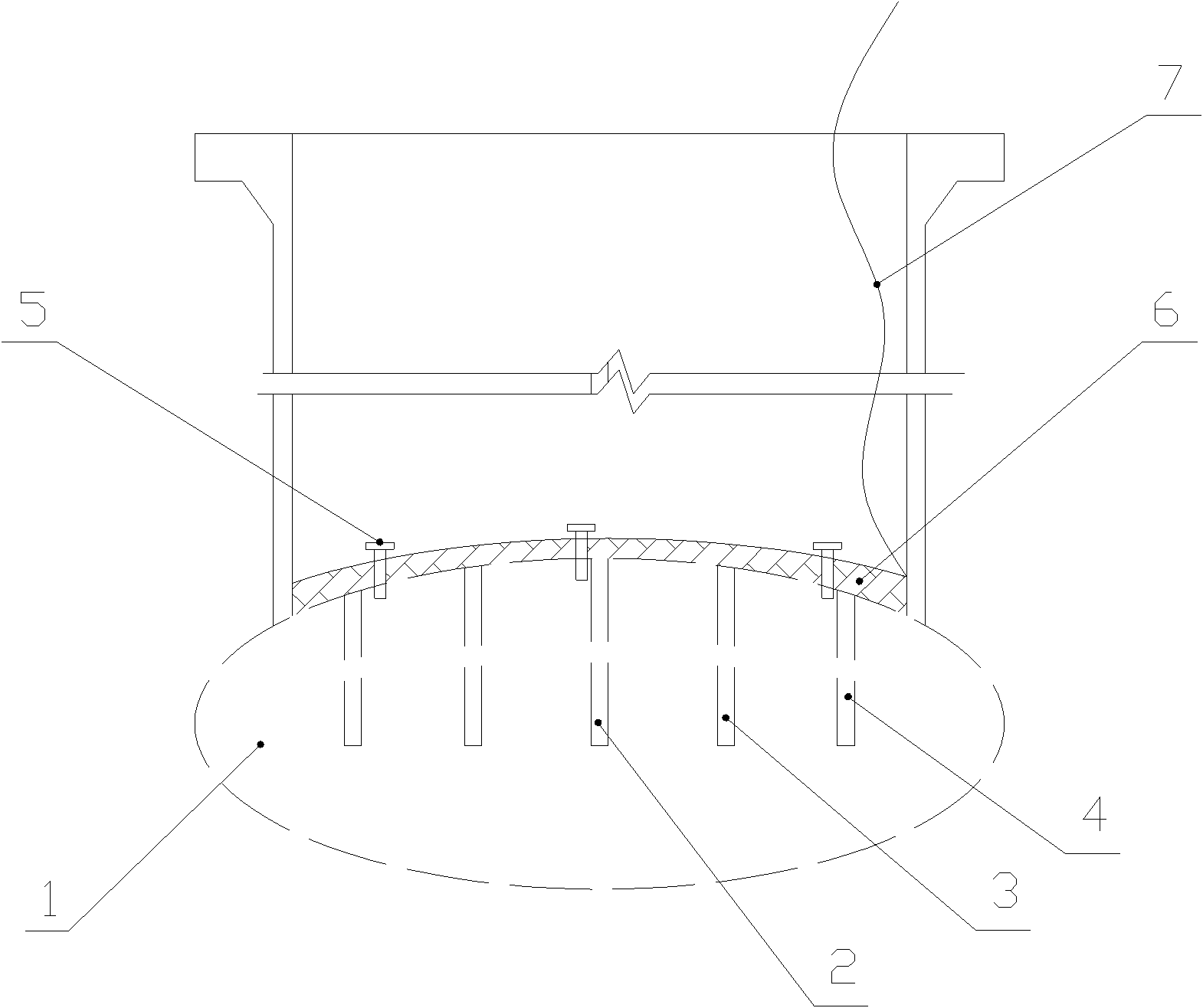

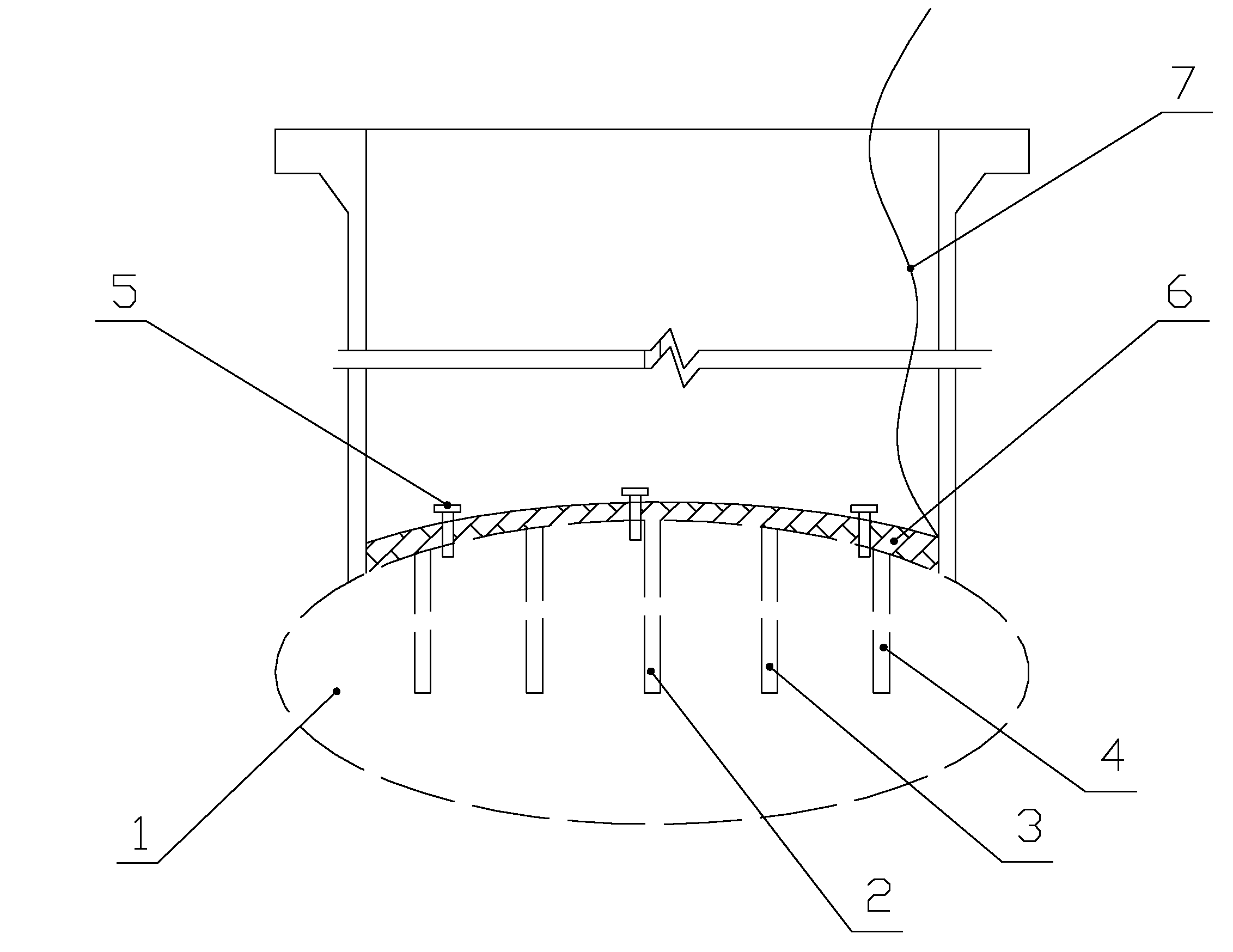

[0031] Embodiment 1: the central blasthole 2 is set to one, and the depth of the central blasthole 2 is 250mm; the distance between two adjacent middle ring blastholes 3 is set to 400mm, and the depth of the middle ring blasthole 3 is set to 200mm; the adjacent two outer ring blastholes 4 The distance is set to 300mm, and the depth of the outer ring blast hole 4 is set to 200mm. After the detonation is completed, the gravel barrier layer 6 of the reinforced grid structure can lift up the blasting part of the large boulder 1 as a whole, and at the same time, no gravel flies out of the artificially dug pile well, and the blasting safety is relatively high.

Embodiment 2

[0032] Embodiment 2: the central blasthole 2 is set to one, and the depth of the central blasthole 2 is 250mm; the distance between two adjacent middle ring blastholes 3 is set to 430mm, and the depth of the middle ring blasthole 3 is set to 200mm; the adjacent two outer ring blastholes 4 The distance is set to 340mm, and the depth of the outer ring blast hole 4 is set to 200mm. After the detonation is completed, the gravel barrier layer 6 of the reinforced grid structure can lift up the blasting part of the large boulder 1 as a whole, and at the same time, no gravel flies out of the artificially dug pile well, and the blasting safety is relatively high.

Embodiment 3

[0033] Embodiment 3: the central blasthole 2 is set to one, and the depth of the central blasthole 2 is 250mm; the distance between two adjacent middle ring blastholes 3 is set to 450mm, and the depth of the middle ring blasthole 3 is set to 200mm; the adjacent two outer ring blastholes 4 The distance is set to 400mm, and the depth of the outer ring blast hole 4 is set to 200mm. After the detonation is completed, the gravel barrier layer 6 of the reinforced grid structure can lift up the blasting part of the large boulder 1 as a whole, and at the same time, no gravel flies out of the artificially dug pile well, and the blasting safety is relatively high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com