Fire-resistant silicone rubber and preparation method thereof

A silicone rubber and fire-resistant technology, applied in the field of fire-resistant silicone rubber, can solve problems such as lack, flammability, and non-fire-resistant wires and cables, and achieve the effects of low cost, slowing down the transfer of materials and heat, and improving flame-retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw material composition (parts by weight): 150 parts of silicone rubber, 10 parts of white carbon black, 50 parts of glass fiber, 20 parts of glass microspheres, 5 parts of aluminum hydroxide, 3 parts of magnesium hydroxide, 1 part of copper oxide, 10 parts of heat stabilizer parts, 20 parts of refractory filler, 2 parts of vulcanizing agent DCP, 3 parts of catalyst and 1 part of hydroxyl silicone oil.

[0027] The catalyst is a catalyst with carbon black as a carrier and palladium, tungsten and platinum as active components, and the mass ratio of the palladium, tungsten, platinum and carbon black is 1:2:5:100;

[0028] Described refractory filler comprises quartz sand, mica powder, talcum powder and basalt, and mass ratio is 10:70:12:5;

[0029] The heat stabilizer includes calcium carbonate, magnesium stearate, calcium stearate, zinc oxide and phosphite, and the mass ratio is 60:10:15:7:3.

[0030] The silicone rubber is methyl vinyl silicone rubber.

[0031] A met...

Embodiment 2

[0033] Raw material composition (parts by weight): 200 parts of silicone rubber, 20 parts of white carbon black, 80 parts of glass fiber, 30 parts of glass microspheres, 12 parts of aluminum hydroxide, 7 parts of magnesium hydroxide, 3 parts of copper oxide, 15 parts of heat stabilizer parts, 30 parts of refractory filler, 5 parts of vulcanizing agent DBPMH, 7 parts of catalyst and 3 parts of hydroxyl silicone oil.

[0034] The catalyst is a catalyst with carbon black as a carrier and palladium, tungsten and platinum as active components, and the mass ratio of the palladium, tungsten, platinum and carbon black is 1:2:5:100;

[0035] Described refractory filler comprises quartz sand, mica powder, talcum powder and basalt, and mass ratio is 10:70:12:5;

[0036] The heat stabilizer includes calcium carbonate, magnesium stearate, calcium stearate, zinc oxide and phosphite, and the mass ratio is 60:10:15:7:3.

[0037] The silicone rubber is methylphenyl silicone rubber.

[0038] ...

Embodiment 3

[0040] Raw material composition (parts by weight): 170 parts of silicone rubber, 12 parts of white carbon black, 60 parts of glass fiber, 22 parts of glass microspheres, 7 parts of aluminum hydroxide, 4 parts of magnesium hydroxide, 1 part of copper oxide, and 11 parts of heat stabilizer 2 parts, 22 parts of refractory filler, 3 parts of vulcanizing agent BP, 4 parts of catalyst and 2 parts of hydroxyl silicone oil.

[0041] The catalyst is a catalyst with carbon black as a carrier and palladium, tungsten and platinum as active components, and the mass ratio of the palladium, tungsten, platinum and carbon black is 1:2:5:100;

[0042] Described refractory filler comprises quartz sand, mica powder, talcum powder and basalt, and mass ratio is 10:70:12:5;

[0043] The heat stabilizer includes calcium carbonate, magnesium stearate, calcium stearate, zinc oxide and phosphite, and the mass ratio is 60:10:15:7:3.

[0044] The silicone rubber is methyl vinyl silicone rubber.

[0045]...

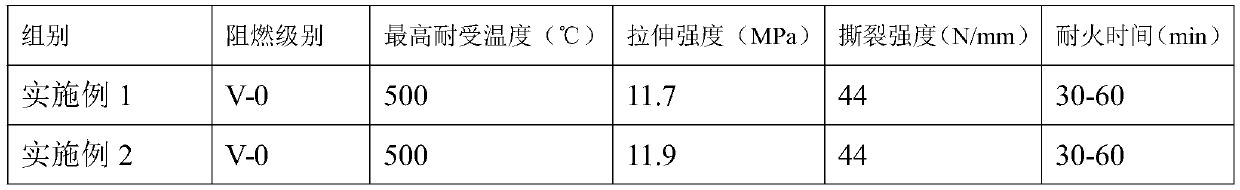

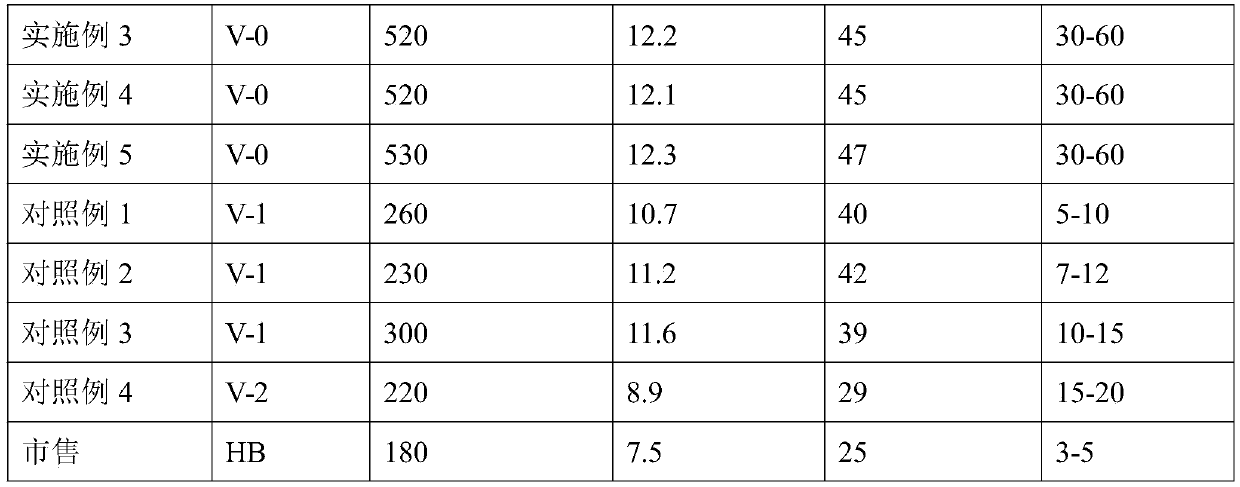

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum temperature | aaaaa | aaaaa |

| Fire resistance time | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com