Patents

Literature

86results about How to "High permeability μ" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

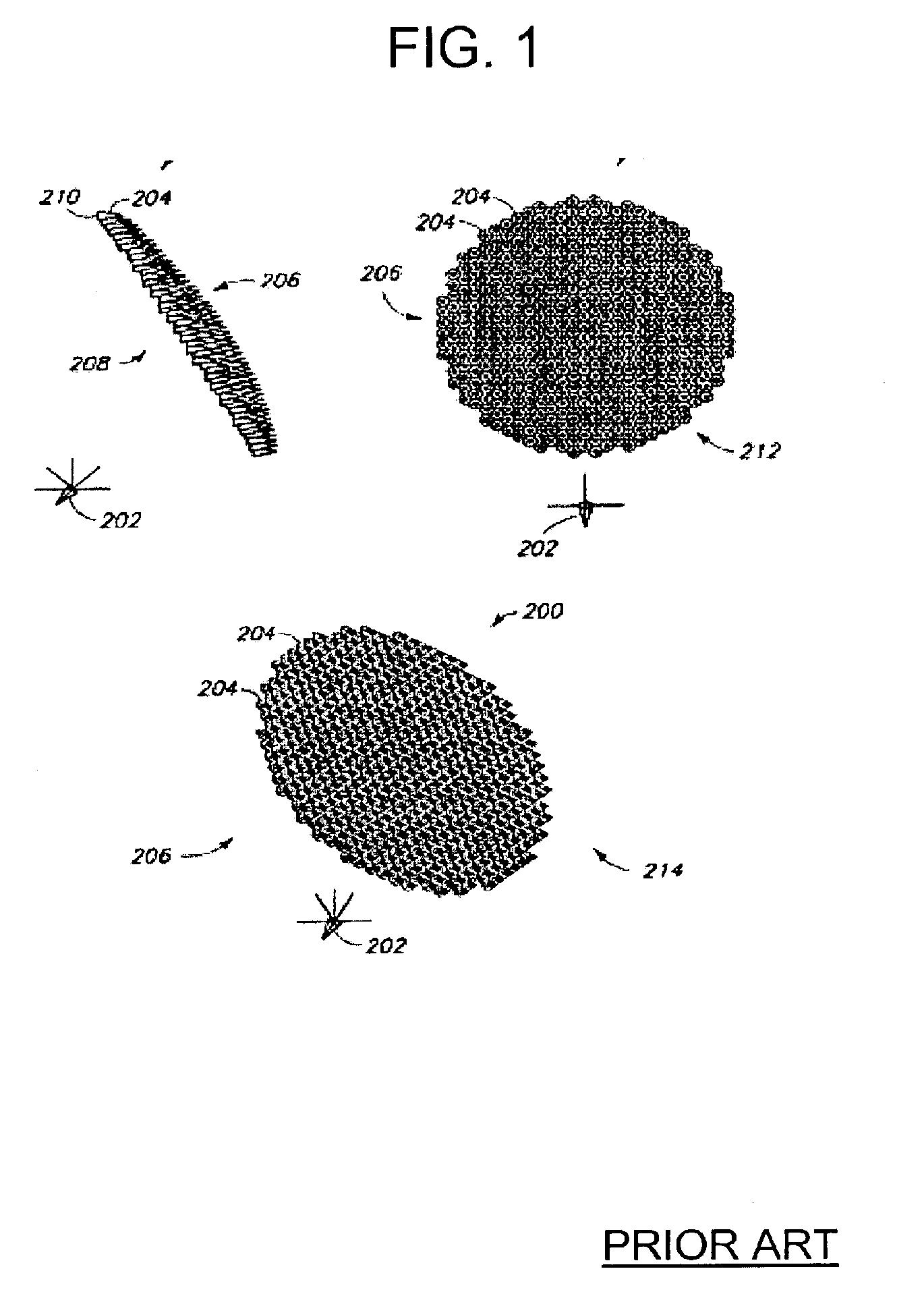

Micro and ultrafilters with controlled pore sizes and pore size distribution and methods for making

InactiveUS6309546B1High permeabilityMinimal pressure dropSemi-permeable membranesMembranesMicrometerPore diameter

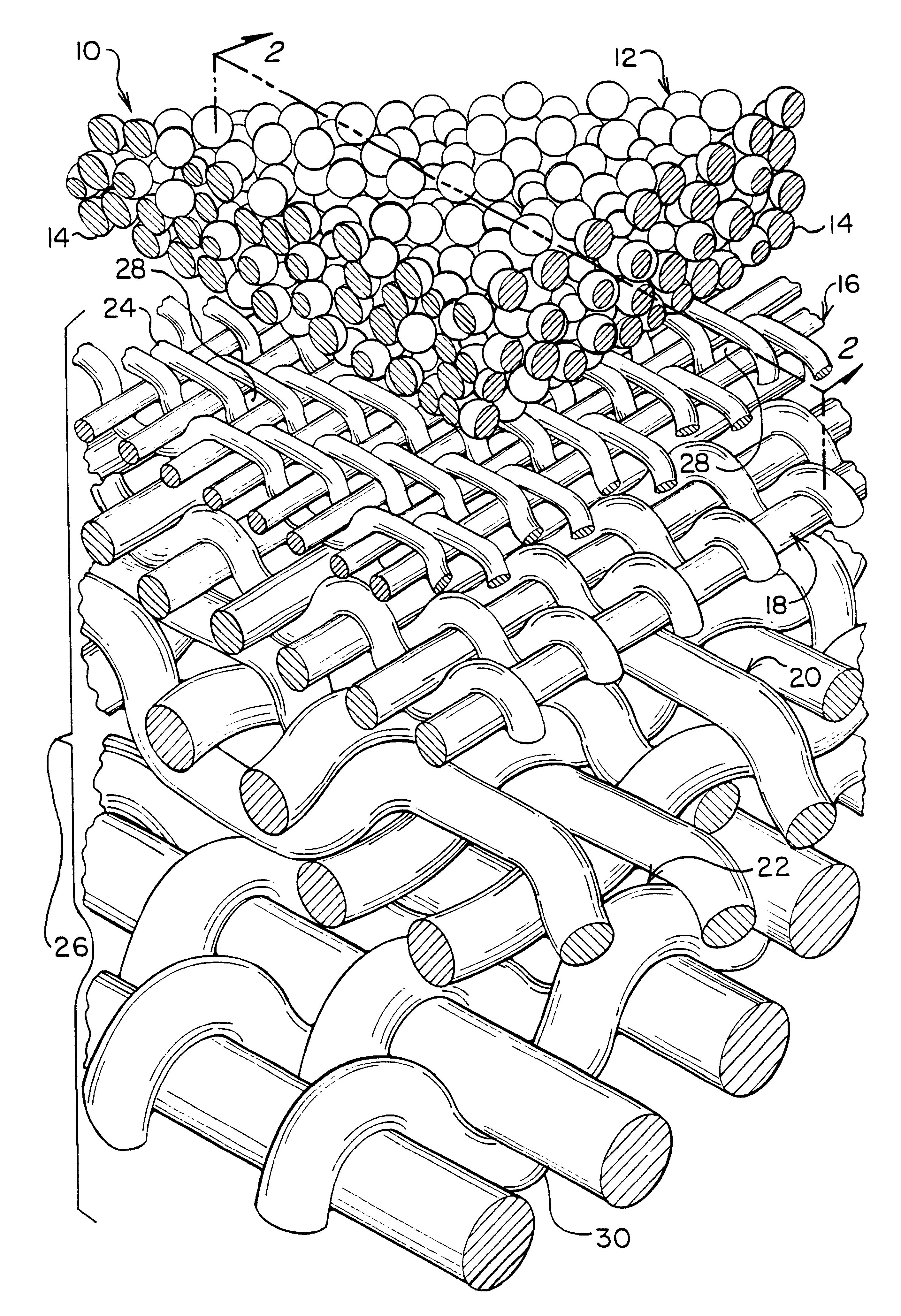

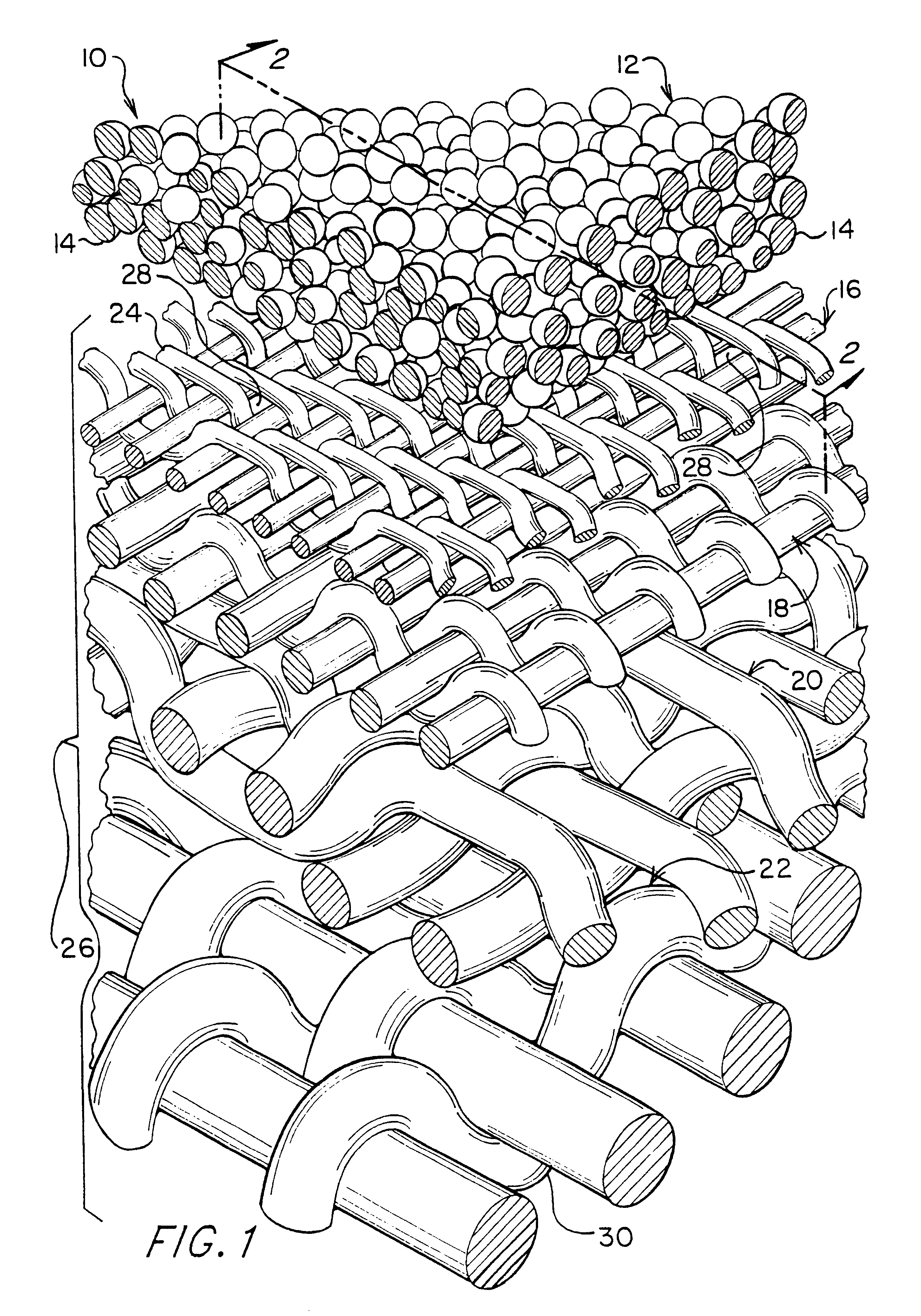

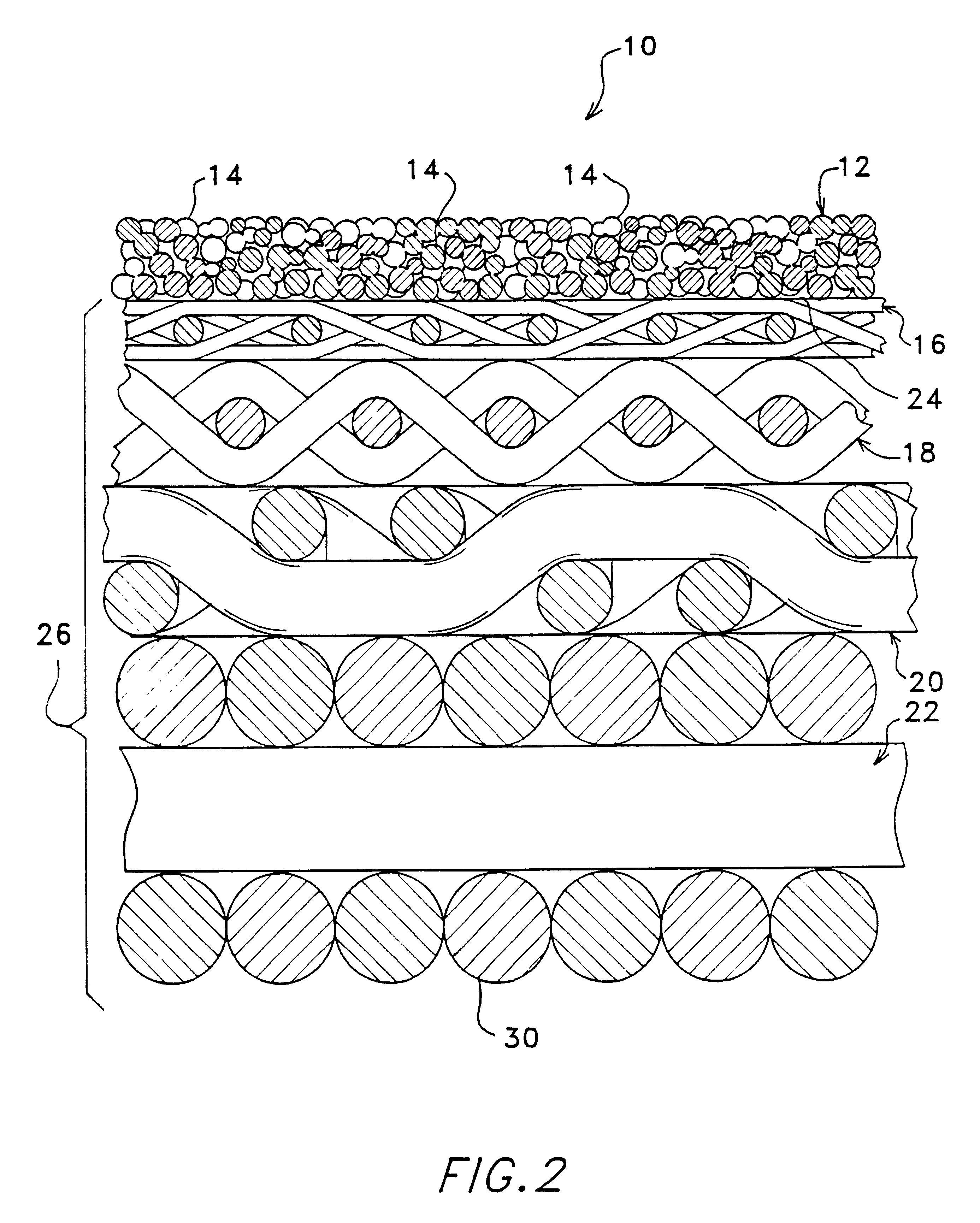

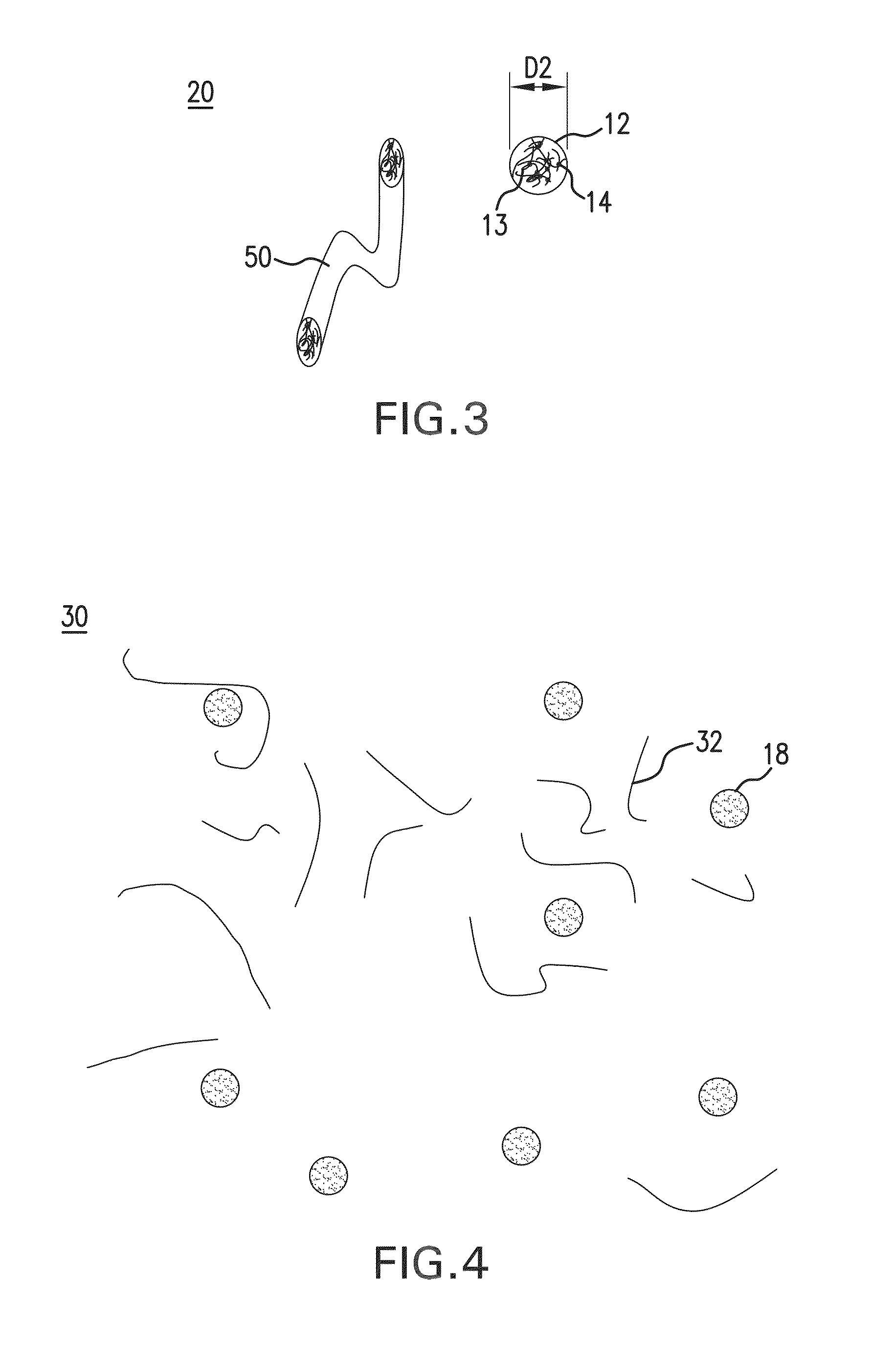

A micro / ultrafiltering element (10) and method for making a filter element are provided. The filtering element comprises a multi-level support (26) having a filtering membrane layer (12) formed thereon comprising sintered particles (14) of uniform diameter. The filtering membrane preferably has an average pore size of from about 0.005-10 micrometers. The filter element is capable of being formed in a variety of geometrical shapes based on the shape of the porous support,

Owner:ELLIPSIS CORP

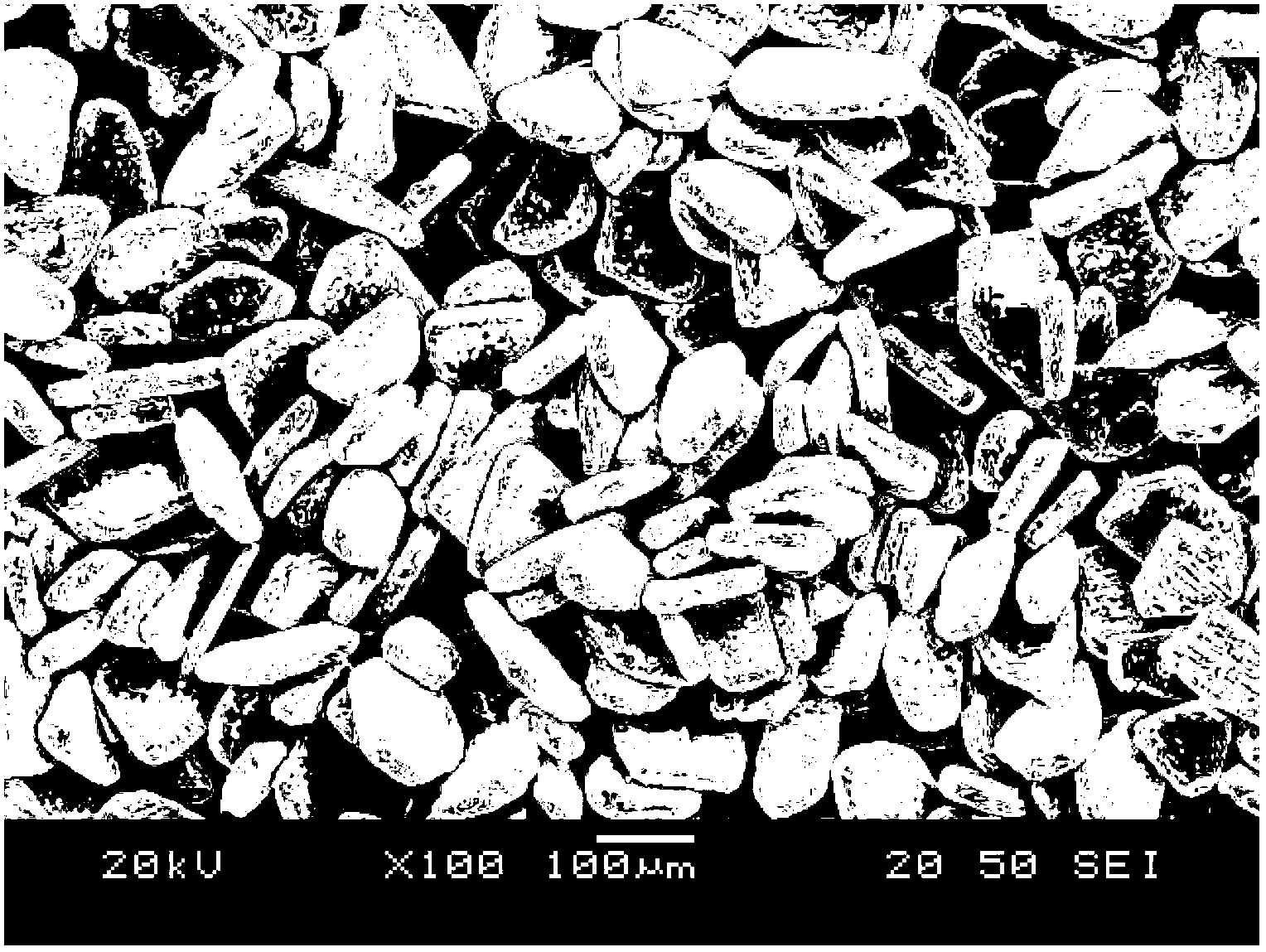

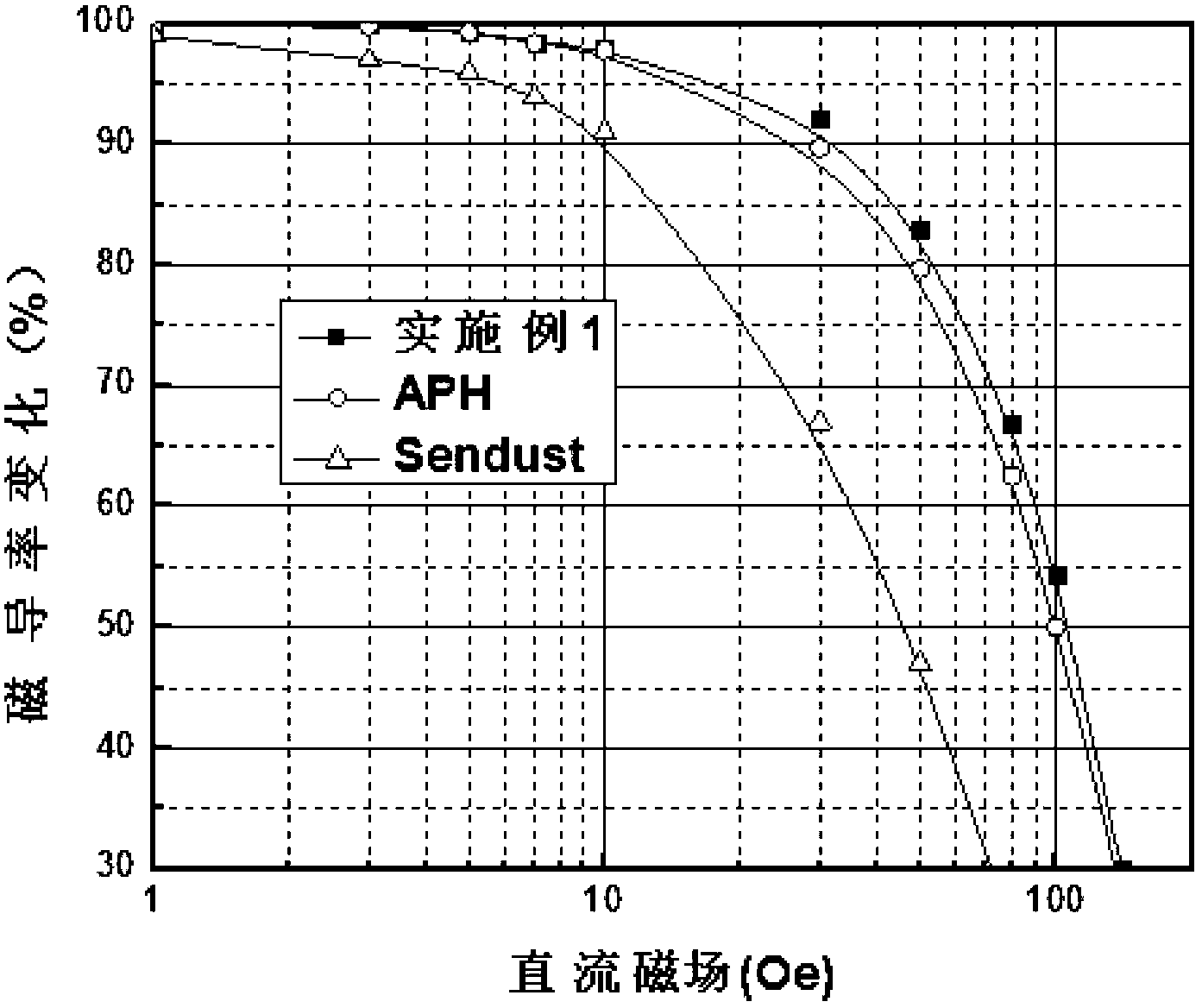

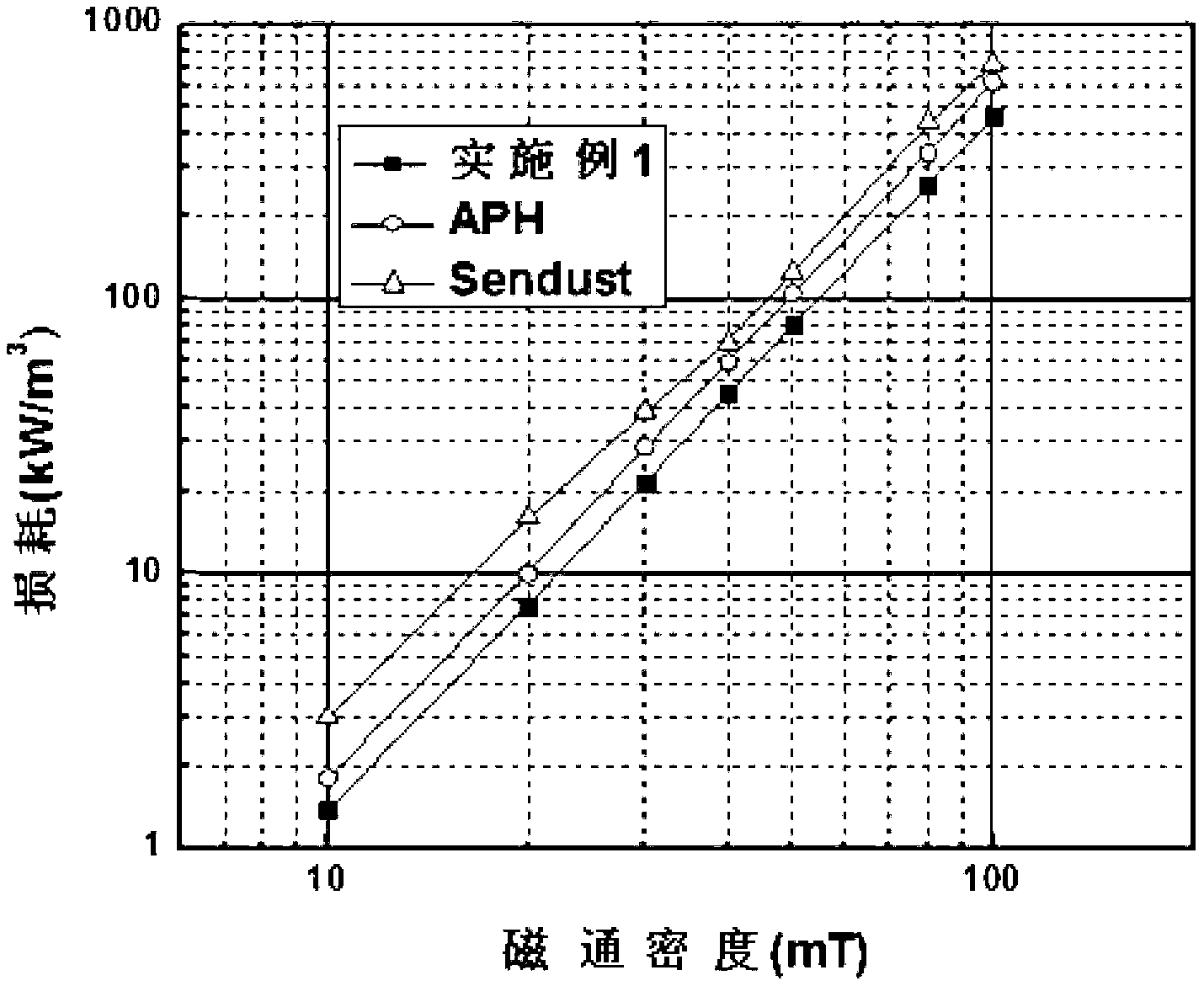

Preparation method of mu90 high-permeability Fe-based amorphous magnetic powder core

InactiveCN103219119AExcellent DC bias characteristicsHigh permeabilityInorganic material magnetismQuenchingMagnetic powder

The invention belongs to the field of Fe-based soft magnetic materials and particularly relates to a preparation method of a mu90 high-permeability Fe-based amorphous magnetic powder core. The preparation method comprises the steps of conducting preheating treatment to Fe-based amorphous ribbon which is prepared by adopting a single-roller rapid quenching method; crushing the amorphous ribbon by adopting a mechanical milling and air-current milling combination method; screening amorphous powder to obtain Fe-based amorphous powder with grain size being less than 100-mesh; conducting passivation and insulation treatment to the screened Fe-based amorphous powder, then mixing the Fe-based amorphous powder with adhesive and conducting coating granulation; molding the granulated coated powder to obtain the Fe-based amorphous magnetic powder core; and conducting stress relief annealing to the molded magnetic powder core. The Fe-based amorphous magnetic powder core which is prepared by adopting the method provided by the invention has high permeability and excellent loss and biasing characteristic.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Antifungal and/or antimycotic external preparation for nail

An antifungal and / or antimycotic external preparation for nail, which comprises neticonazole or a salt thereof and a basic substance.

Owner:HISAMITSU PHARM CO INC

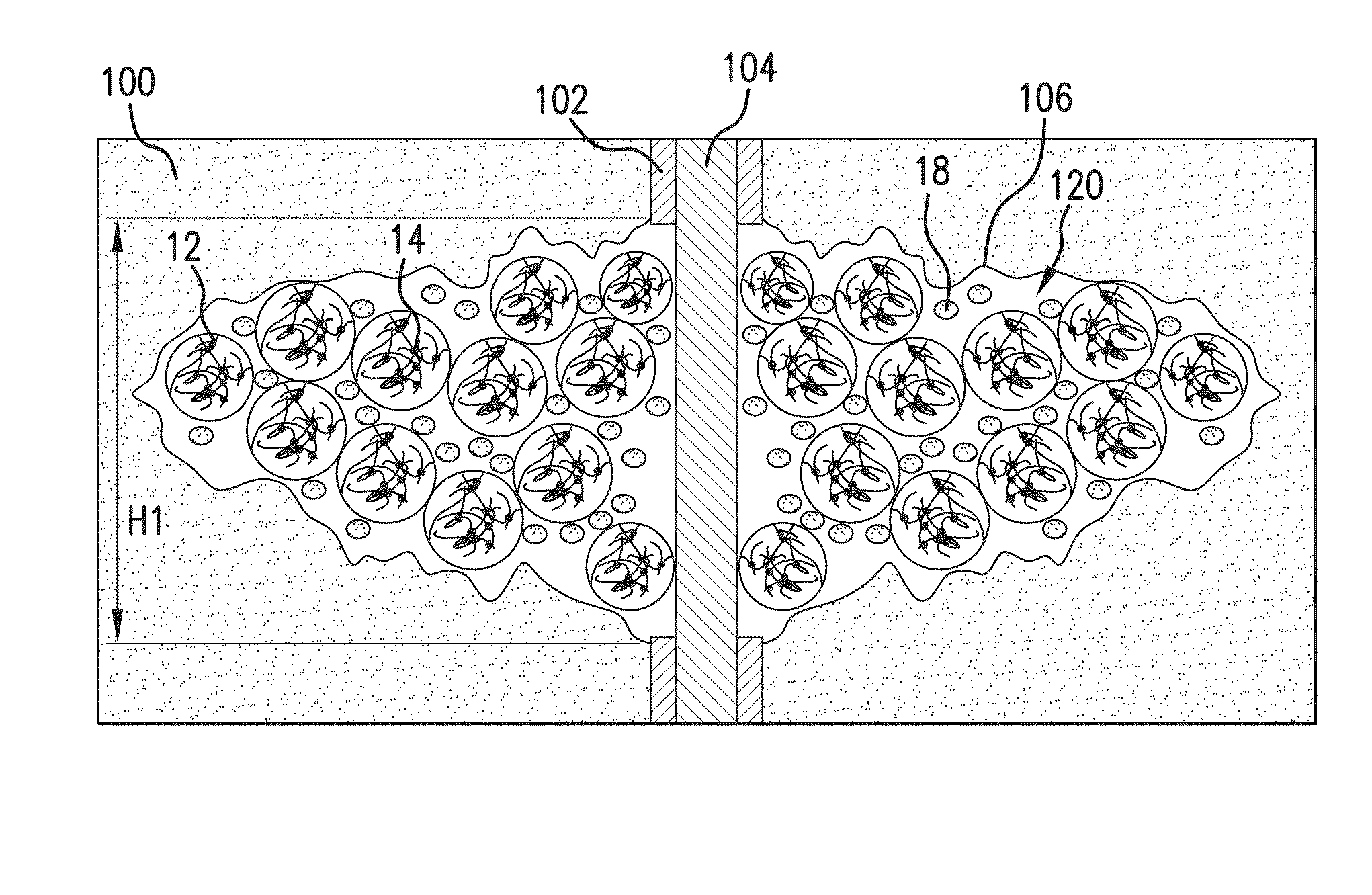

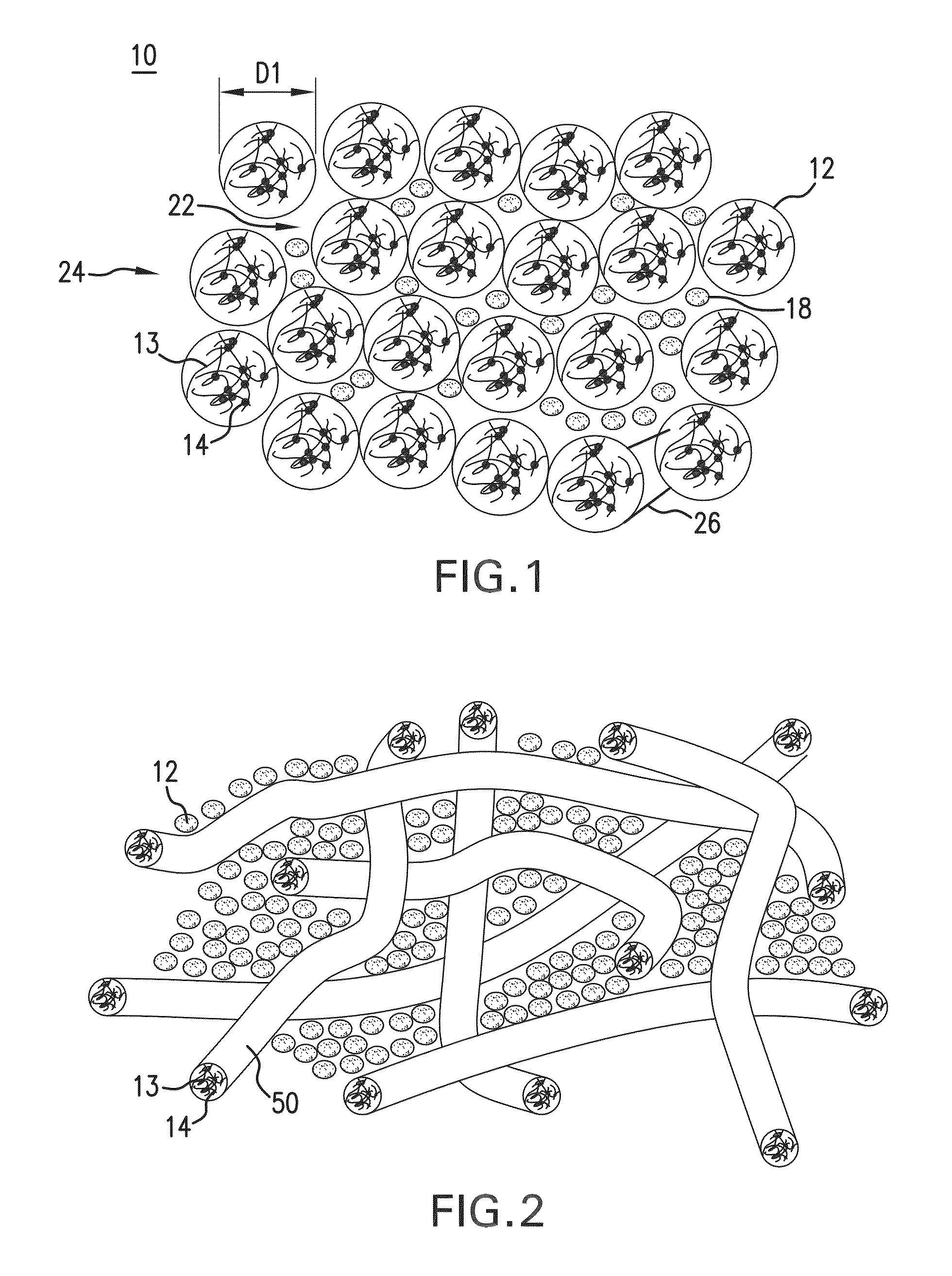

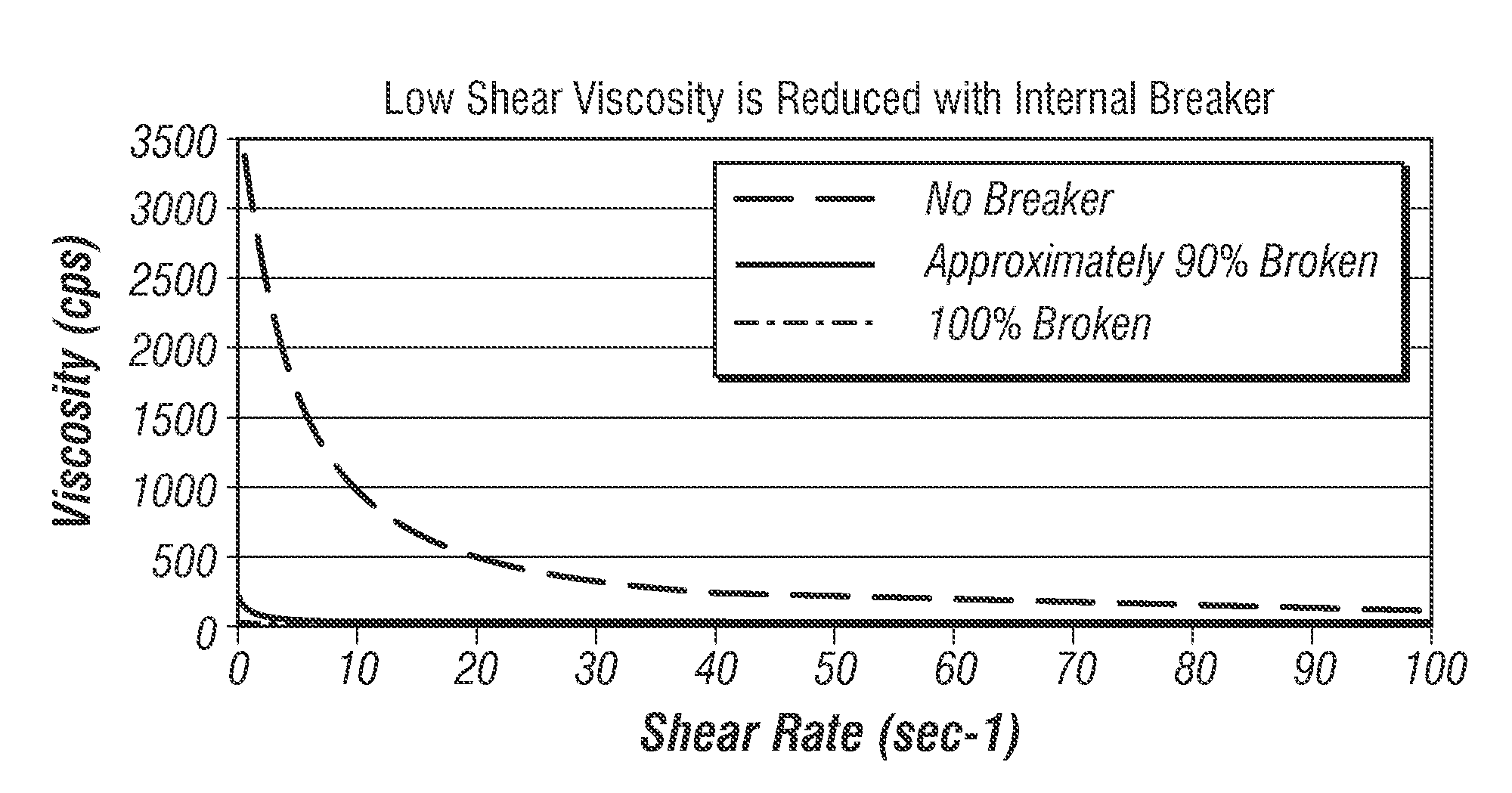

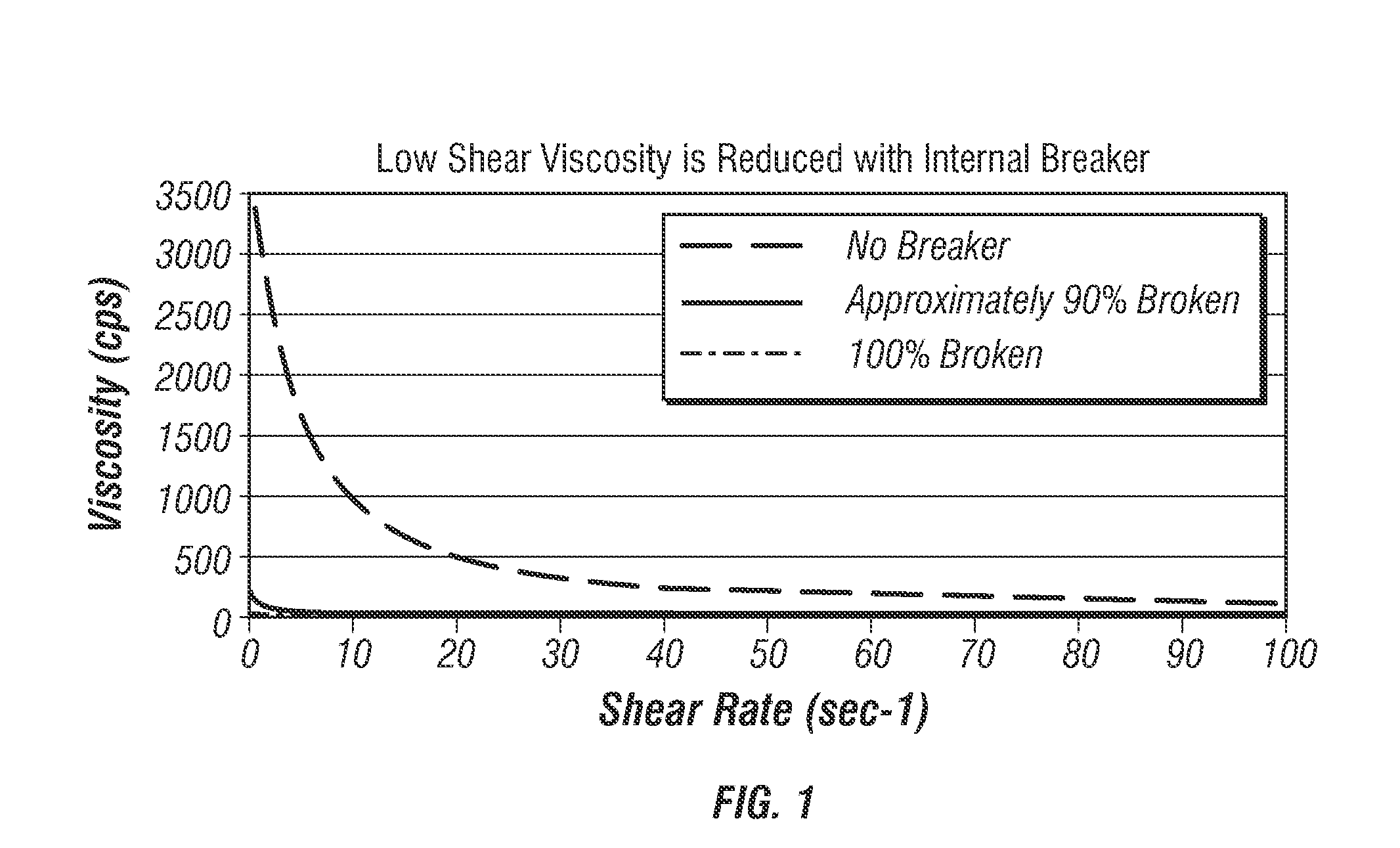

Hydraulic fracturing composition, method for making and use of same

ActiveUS20150096751A1High permeabilityEnhance productionFluid removalMixingSuperabsorbent polymerBuffering agent

A hydraulic fracturing composition includes: a superabsorbent polymer in an expanded state; a plurality of proppant particles disposed in the superabsorbent polymer; a well treatment agent, and a fluid to expand the superabsorbent polymer into the expanded state. A process for treating a well with well treatment agent includes disposing a hydraulic fracturing composition comprising the well treatment agent in a well. The well treatment agent can be a scale inhibitor, tracer, pH buffering agent, or a combination thereof.

Owner:BAKER HUGHES INC

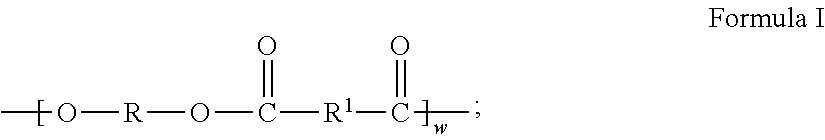

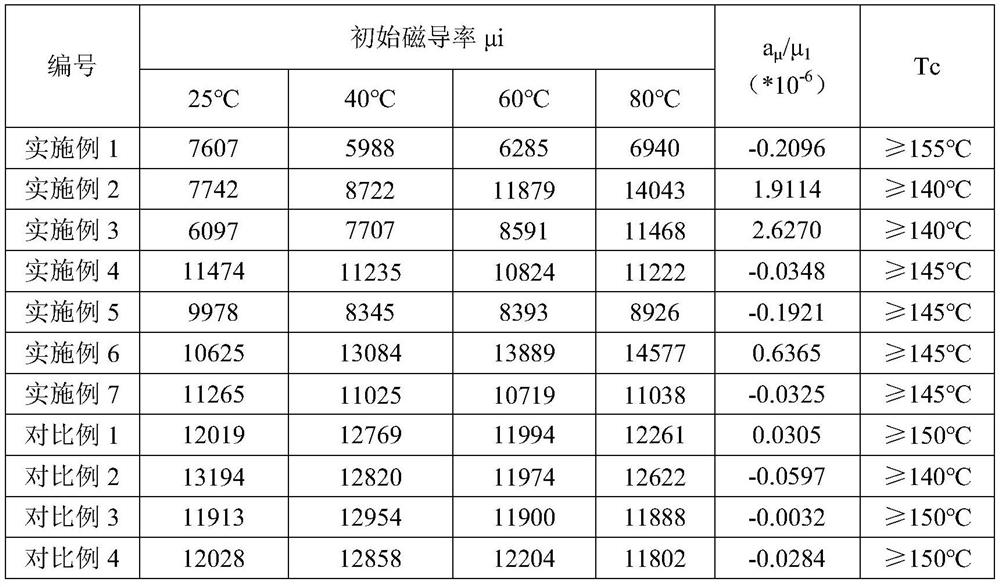

Magnetic powder core material with stable magnetic permeability and low loss and preparation method thereof

ActiveCN108335820AReduce porosityHigh permeabilityTransportation and packagingMetal-working apparatusMagnetic powderMagnetic dilution

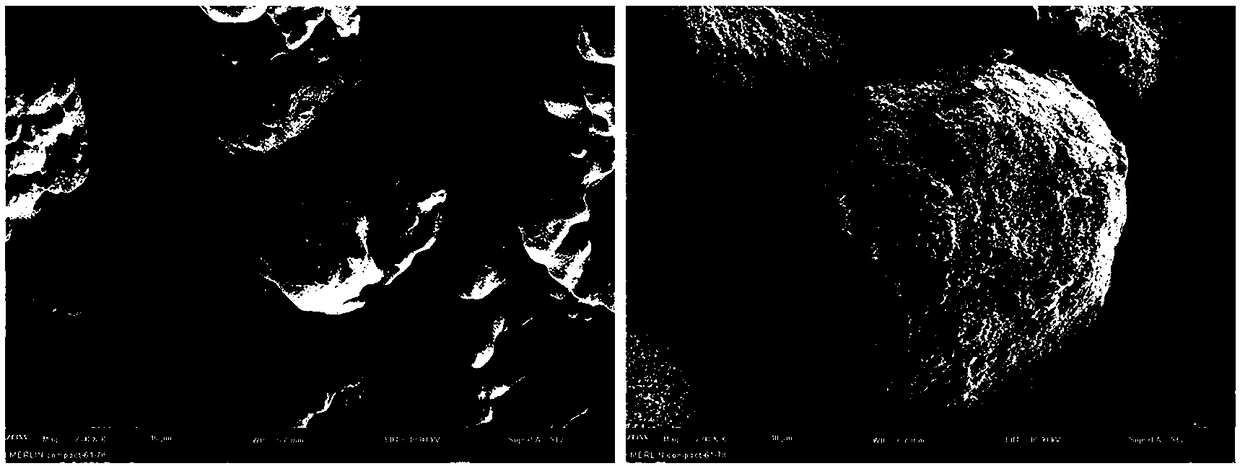

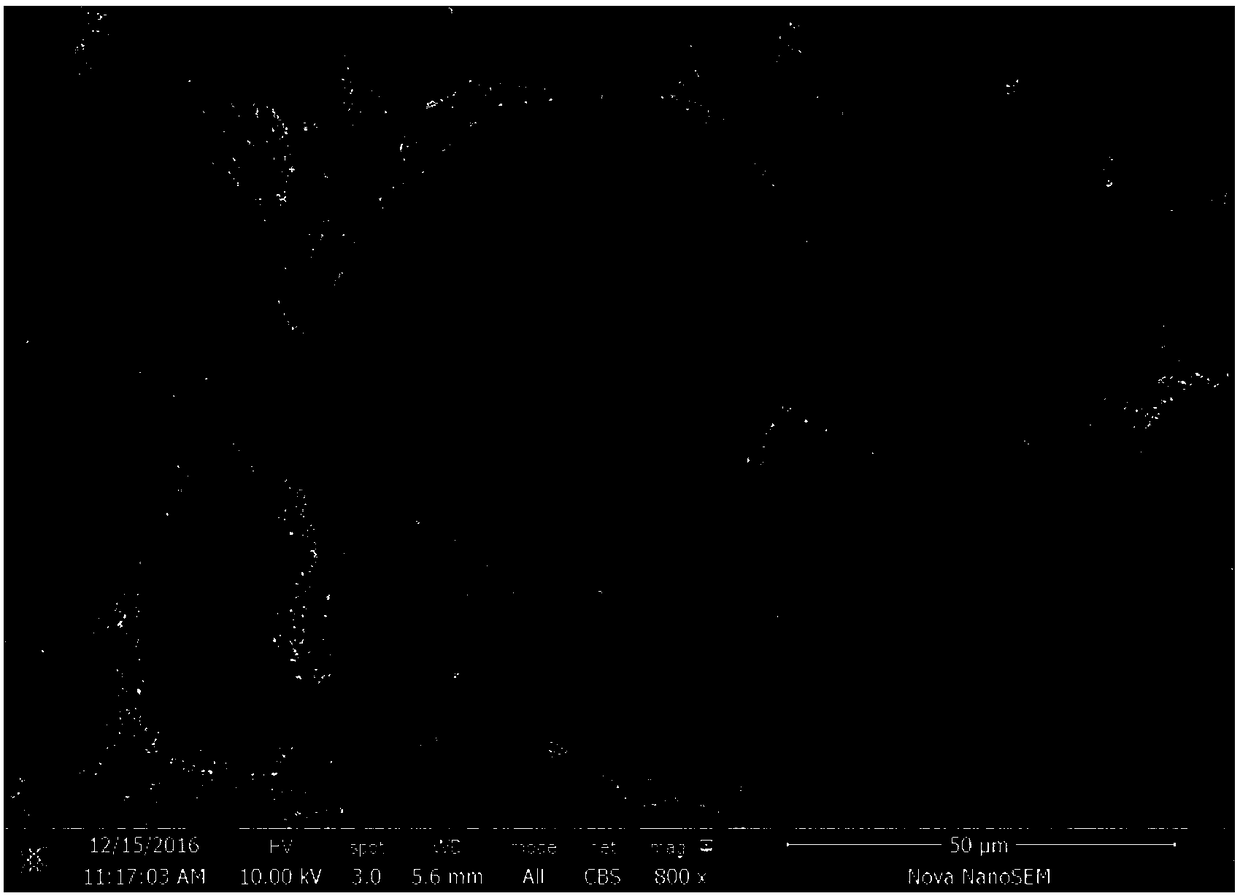

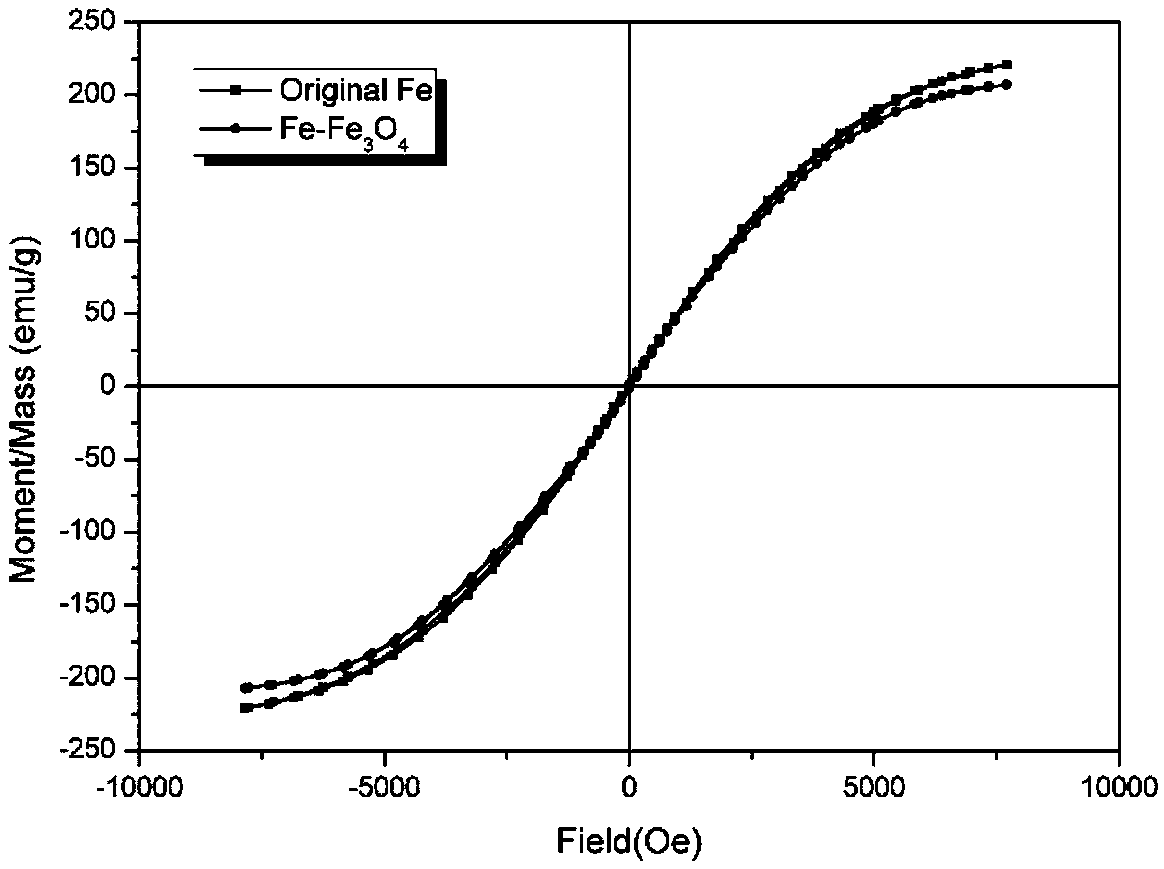

The invention relates to a magnetic powder core material with stable magnetic permeability and low loss and a preparation method thereof. First modifying the surface of the iron powder; preparing iron / ferrite composite powder with core-shell structure by high-energy ball milling; mixing the composite powder with the modified powder and then filling the mixture into an alloy steel mold for normal temperature pressing to obtain iron / ferrite soft magnetic composite magnetic powder cores; then performing subsequent heating treatment on the magnetic powder cores. Compared with the prior art, the present invention utilizes a ball milling method to prepare iron / ferrite coated powder. The process is short in time, uniform in coating, and simple in operation. At the same time, the present inventionuses a ferrimagnetic ferrite as an insulating coating agent, which reduces the magnetic dilution phenomenon caused by a non-magnetic substance as a coating agent. The suitable heat treatment temperature avoids the reaction between iron and ferrite during heat treatment to form magnetic disadvantageous components, ensures high saturation magnetization of magnetic powder core, high magnetic permeability, reduces loss, and obtains magnetic permeability of soft magnetic composite magnetic powder core.

Owner:TONGJI UNIV

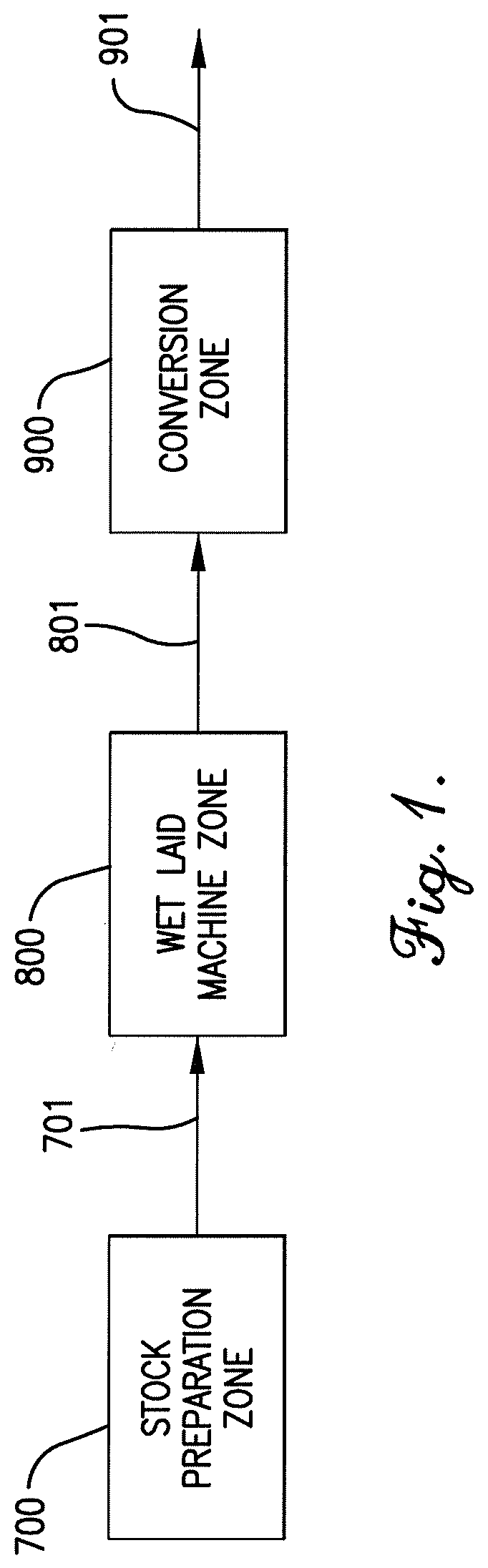

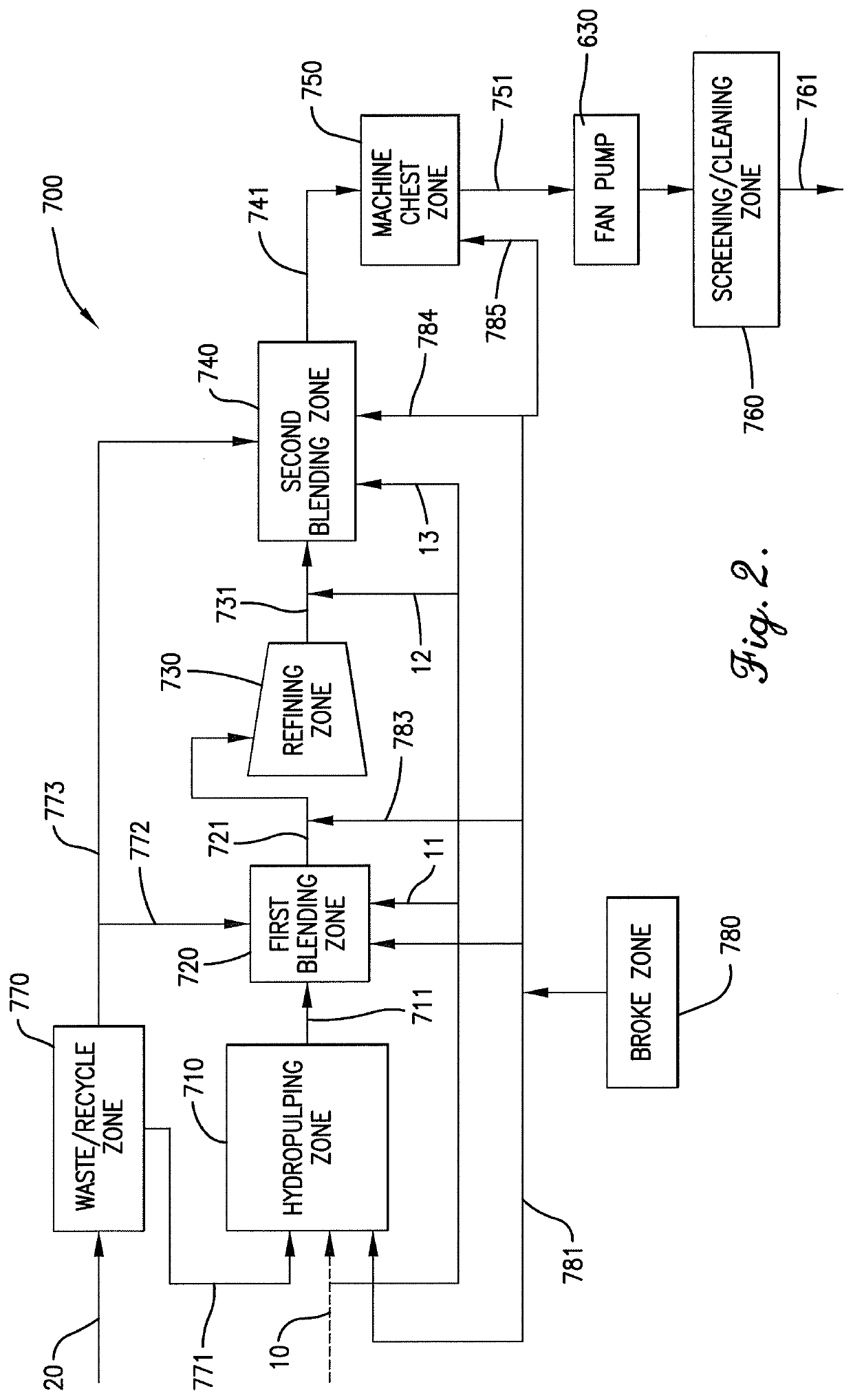

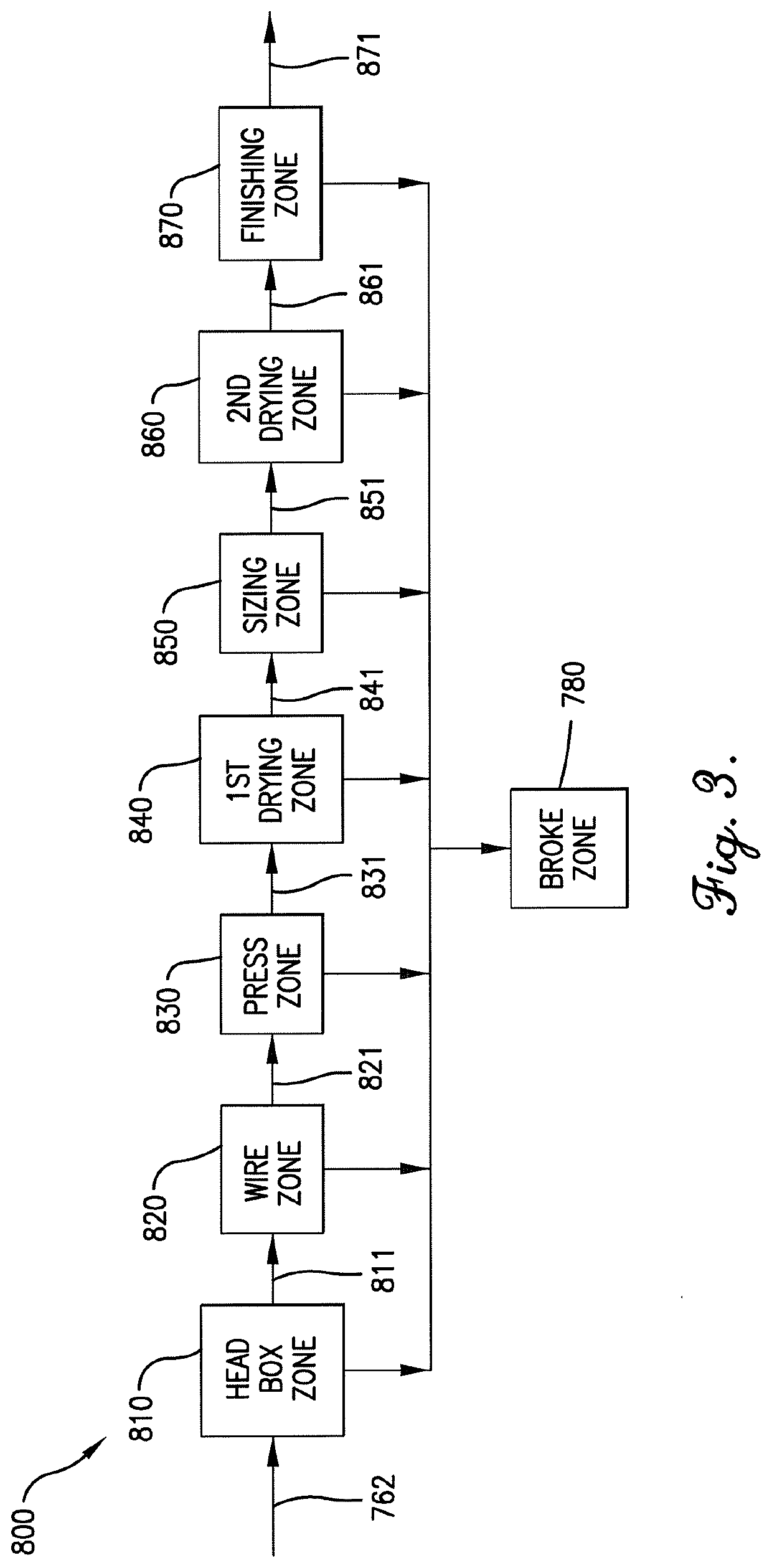

Paper product articles

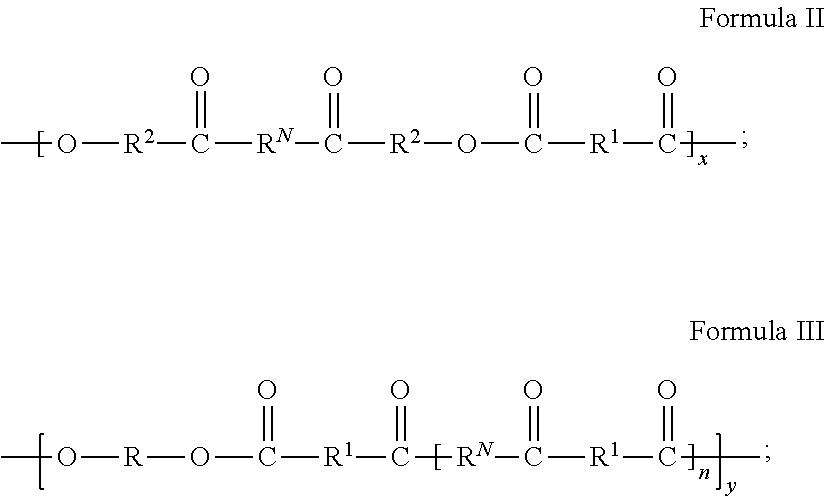

ActiveUS20200063351A1High air permeabilityHigh permeabilityPaper/cardboardMembrane filtersCellulose acetatePolymer science

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many the desired benefits. The Present invention also relates to a wet laid product having higher air permeability the same or lower pore size relative to a 100% cellulose comparative composition

Owner:EASTMAN CHEM CO

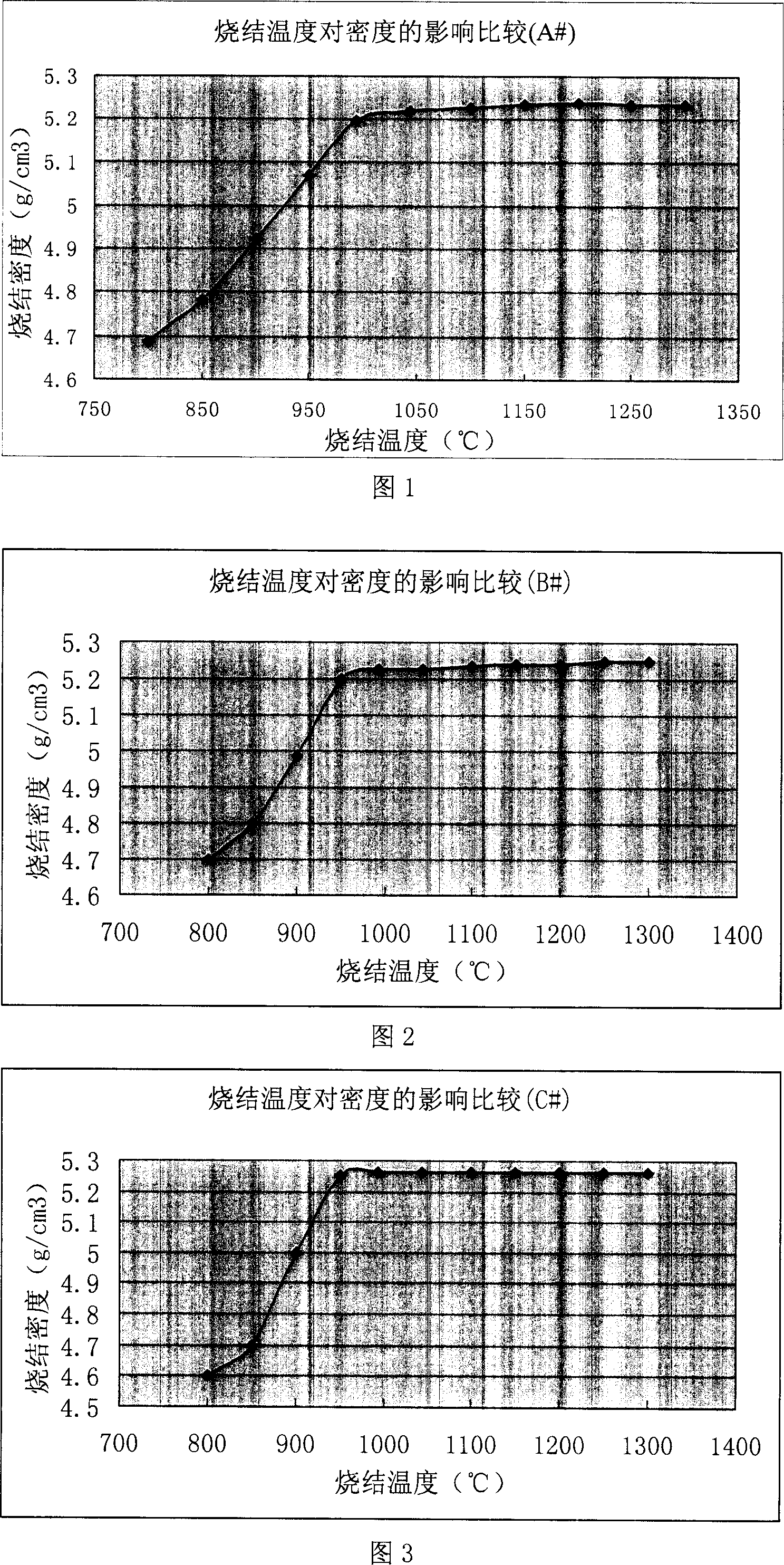

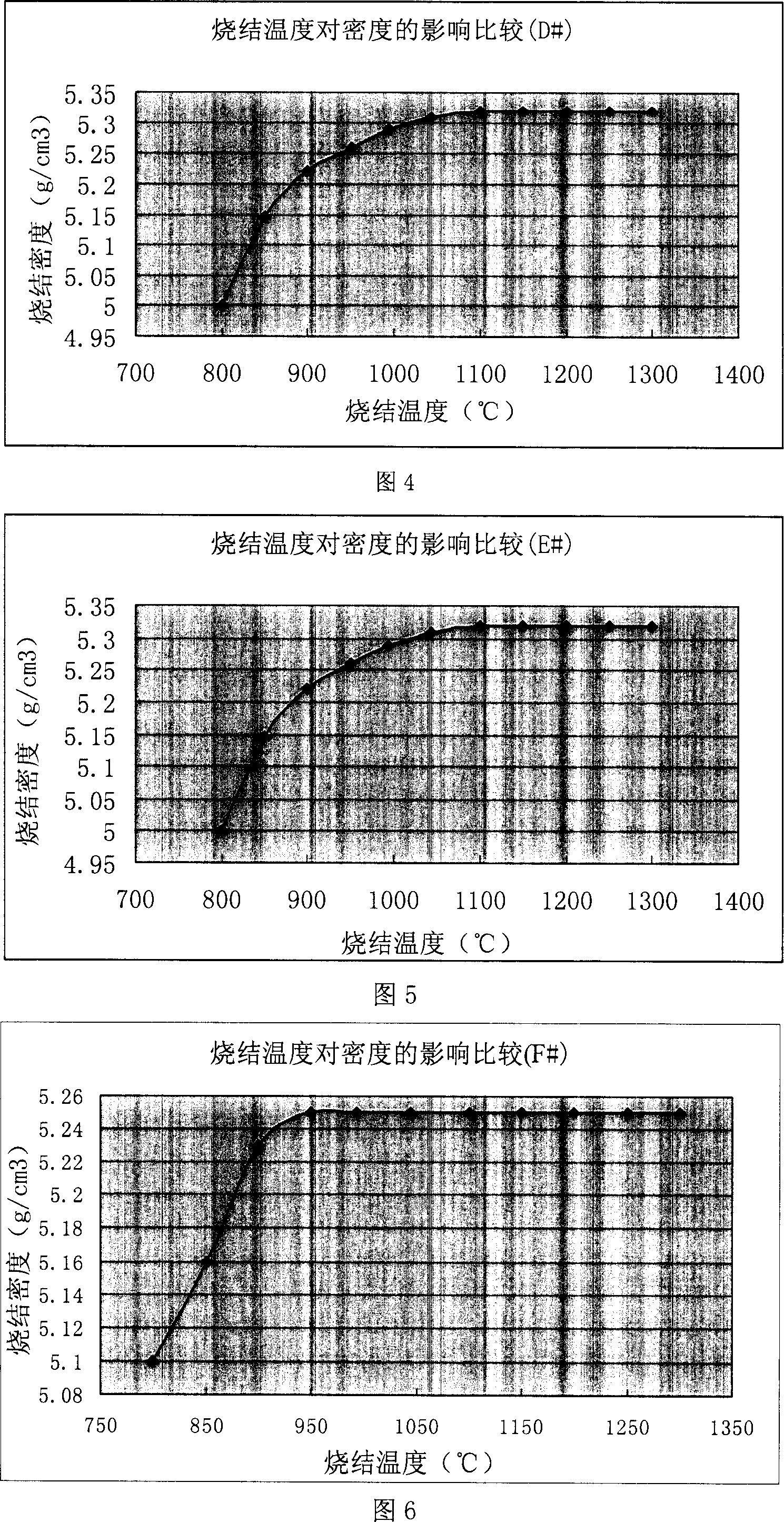

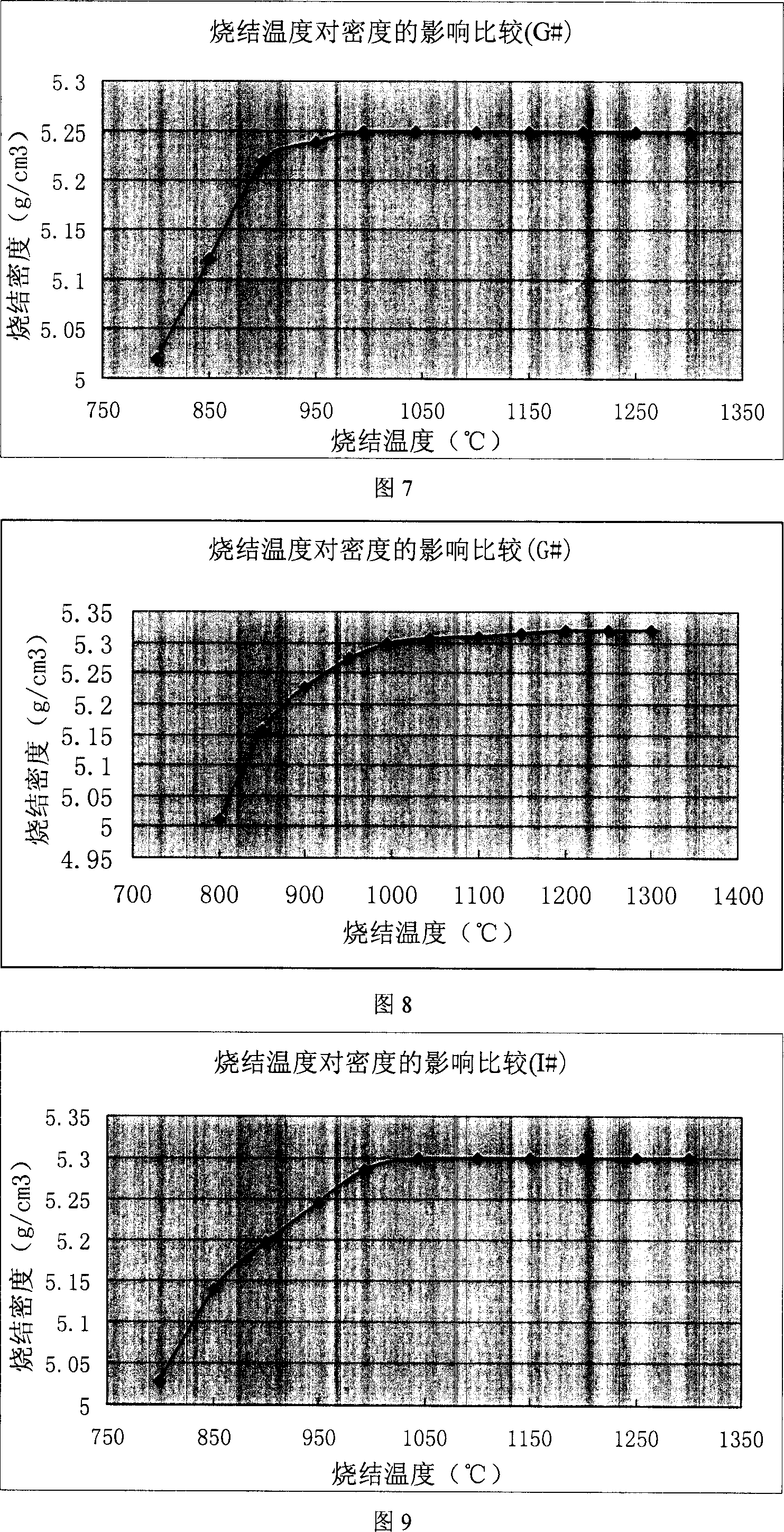

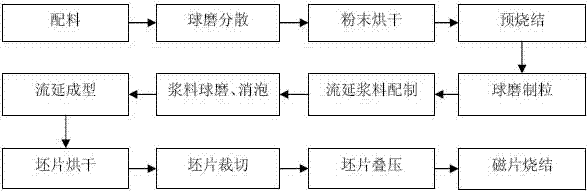

Nickel zinc ferrite low temperature high density production method and its product

InactiveCN101106000AHigh densityHigh permeabilityInorganic material magnetismInversion temperatureNickel

The invention discloses a method to produce nickel zinc ferrite with lower temperature and high intensity and nickel zinc ferrite with high magnetic permeability produced with the method. The main components of raw materials adopted in the method are converted into 47.5-49.5mol percent Fe2O3, 3.6-6.5mol percent CuO and 30-35mol percent ZnO, and the rest is NiO. Apart from the main components, the others are converted into one of the minor components, including.01-0.4wt percent Ti2O5, 0.01-0.5wt percent Bi2O3, 0.01-0.5wt percent V2O5, 0.01-0.5wt percent MoO3, 0.01-0.5wt percent Cr2O3, and 0.01-0.5wt percent Nb2O5. The finished product is obtained through steps of material batching, mixing, pre-heating, crushing, grain-making, molding, and sintering. Minor components are mixed after the main components are preheated. The method can realize as high intensity as 5.2g / cm3 and above to enhance the magnetic permeability at a sintering temperature of 200 DEG C lower than the current technique. The method can also increase magnetic inversion temperature and saturation magnetic sensing intensity.

Owner:TDG HLDG CO LTD

Super high magnetic conductivity, high courier temperature Mn-Zn ferrite and its preparation method

ActiveCN101106003AImprove display structureHigh permeabilityInorganic material magnetismInductances/transformers/magnets manufactureManganese oxideBrown iron oxide

The invention provides a Mn-Zn ferrite with high magnetic conductivity and high magnetic inversion temperature; major components of the ferrite include manganese oxide, zinc oxide, and iron oxide, and auxiliary components include bismuth oxide, molybdenum oxide, and niobium oxide; wherein, the constituents of the major components are: manganese oxide calculated by 23-27 Moore (percent) of Mno, zinc oxide calculated by 20-26 Moore (percent) of ZnO; the rest is iron oxide; constituents of the auxiliary components are: bismuth oxide calculated by 0-0.08 weight (percent) (excluding zero) of Bi2O, molybdenum oxide calculated by 0-0.12 weight (percent) (excluding zero) of MoO3, and niobium oxide calculated by 0.01-0.1 weight (percent) (excluding zero) of Nb2O5; the crystal particle of Mn-Zn ferrite is 50-180micron; under the condition of 25 DEG C, 10KHz, and 0.25mT, the initial magnetic conductivity of the Mn-Zn ferrite is 15000-18000; under the condition of 100KHz and 0.25mT, the initial magnetic conductivity is 13000-15000, and the magnetic inversion temperature is above or equal to 130 DEG C; in addition, the method provides the production method for the Mn-Zn ferrite.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

LED display screen display unit and automatic production method thereof

InactiveCN103065561AHigh permeabilityImprove permeabilitySolid-state devicesStacked PCBsPixel densityIntegrated circuit

The invention discloses an LED display screen display unit and an automatic production method thereof. The LED display screen display unit comprises a display unit main board, a drive IC (integrated circuit), and an LED lamp. The display unit main board comprises a first circuit board and a second circuit board. Pad sets consisting of a plurality of pads are disposed on the first side of the first circuit board and the first side of the second circuit board. The pad sets on the first circuit board and the pad sets on the second circuit board are in one-to-one correspondence and are mutually spaced. One pad set on the first circuit board and the corresponding pad set on the second circuit board form a pad matrix. The drive IC is disposed on the first circuit board and electrically connected with the pads of the pad matrix. Pins of the LED lamp are welded on the pads of the pad matrix. The LED display screen with the display unit has high transparency while having high pixel density, and the design meets the requirement for automatic batch production.

Owner:SHENZHEN NEXNOVO TECH CO LTD

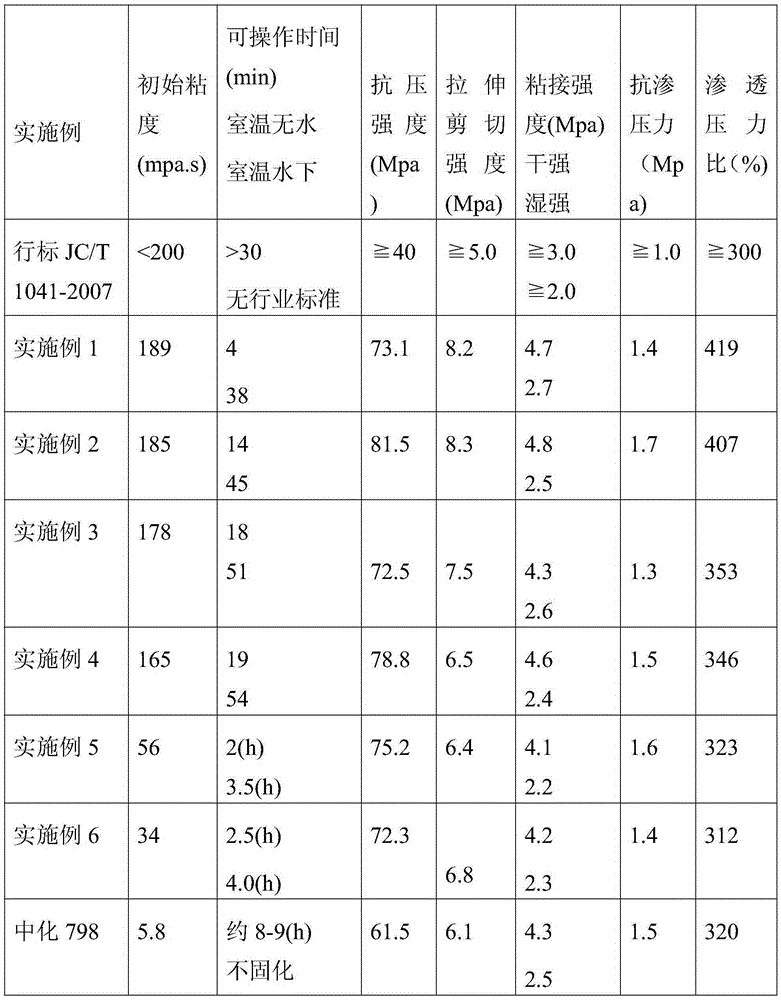

Transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material and preparation method and application thereof

The invention discloses a transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material. The transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material is prepared from a first component and a second component. The weight ratio of the first component to the second component is 100:(0.5-100). The first component is prepared from, by weight, 20-85 parts of epoxy resin, 25-80 parts of reactive diluent and 0.5-5 parts of interfacial modifier. The second component is prepared from, by weight, 10-95 parts of amine curing agent, 0-40 parts of waterproof dispersant and 0-20 parts of accelerant. The invention further discloses a preparation method and application of the transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material. The grouting material is high in strength, good in water plugging and leakage preventing effect, good in waterproof performance and comprehensive mechanical property and low in toxicity, the preparation method is simple, and the application range is wide.

Owner:GUANGZHOU YINGTIAN BUILDING MATERIAL TECH CO LTD

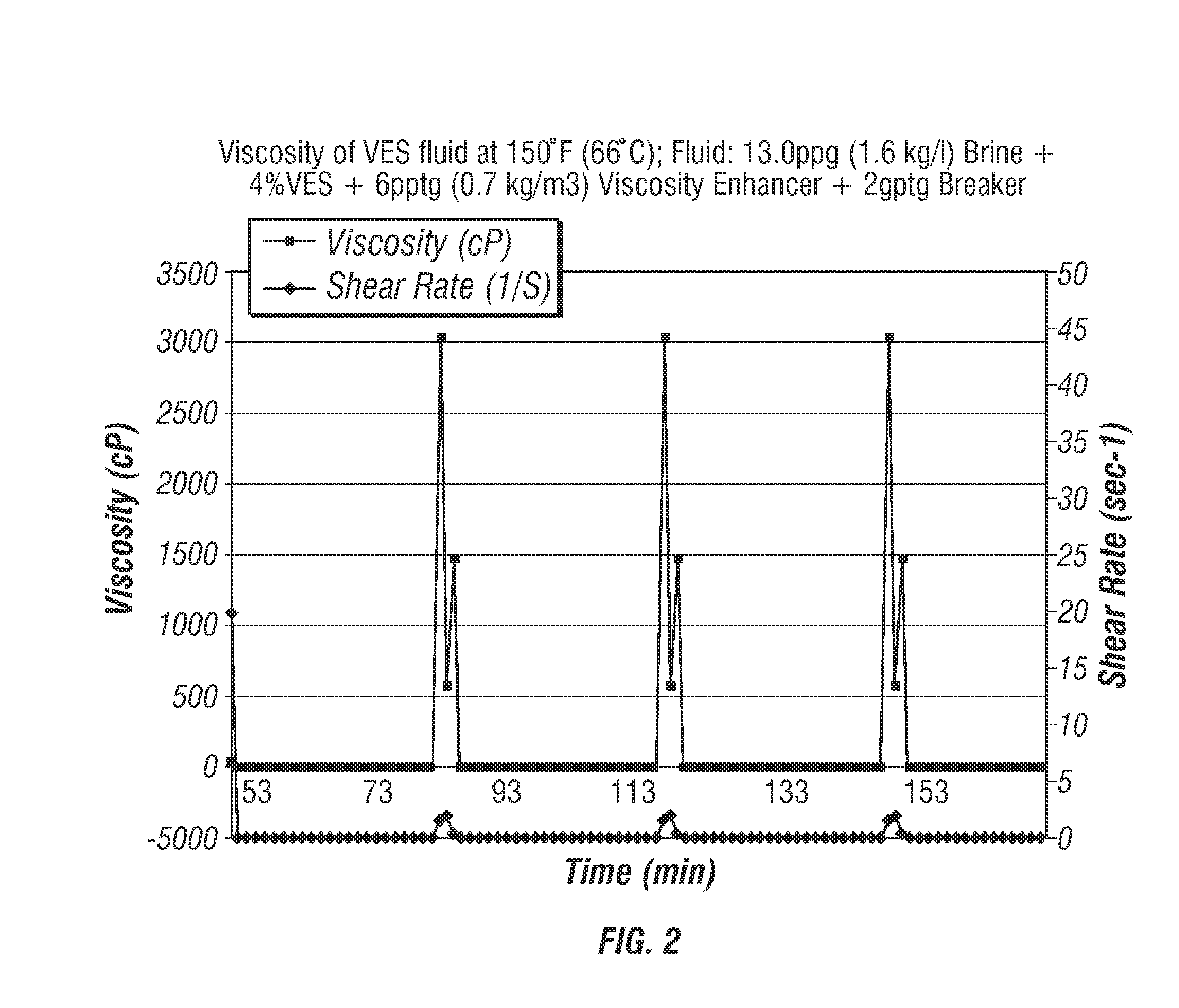

Methods of using viscoeleastic surfactant gelled fluids to pre-saturate underground formations

InactiveUS20090272534A1Increase viscosityHigh permeabilityFluid removalDrilling compositionAlkali hydroxideFluid system

Viscoelastic surfactant (VES) based fluid systems are effective to pre-saturate high permeability subterranean formations prior to a treatment operation that would undesirably suffer from high fluid leakoff. The fluid systems may include brine, a viscosity enhancer, as well as the VES, and a high temperature stabilizer. The stabilizer may be an alkaline earth metal oxide, alkaline earth metal hydroxide, alkali metal oxide, alkali metal hydroxide, Al2O3, and mixtures thereof. The viscosity enhancer may include pyroelectric particles, piezoelectric particles, and mixtures thereof. The fluid system is easy to pump into the formation, and after initial pumping, the fluid system will soak into and occupy or “pre-saturate” the pores of the formation prior to pumping of a second treating fluid for fracturing, gravel packing, frac-packing, and the like. The methods are practiced in the absence of acids typically used in acidizing operations, such as hydrochloric acid and hydrofluoric acid.

Owner:BAKER HUGHES INC

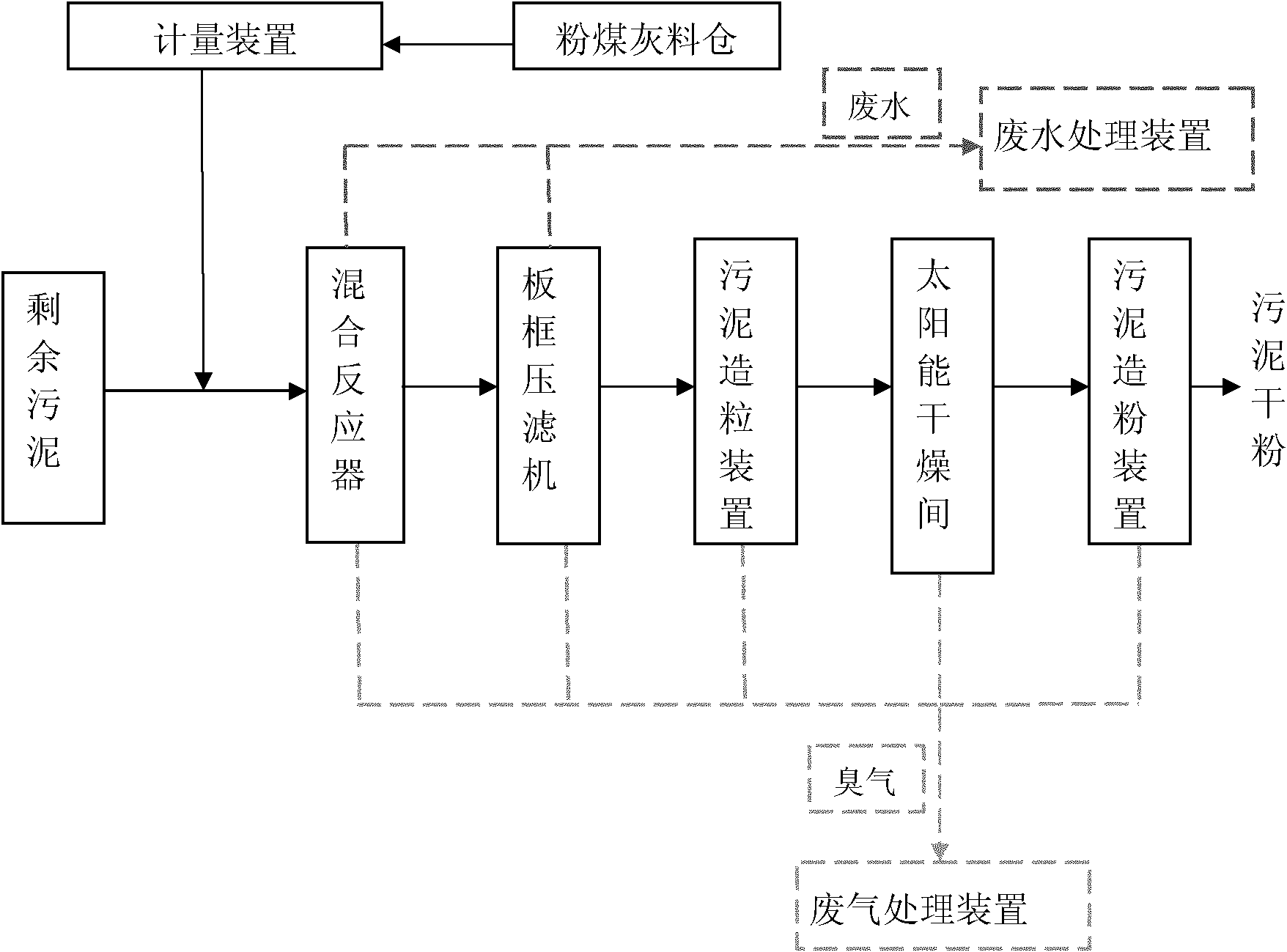

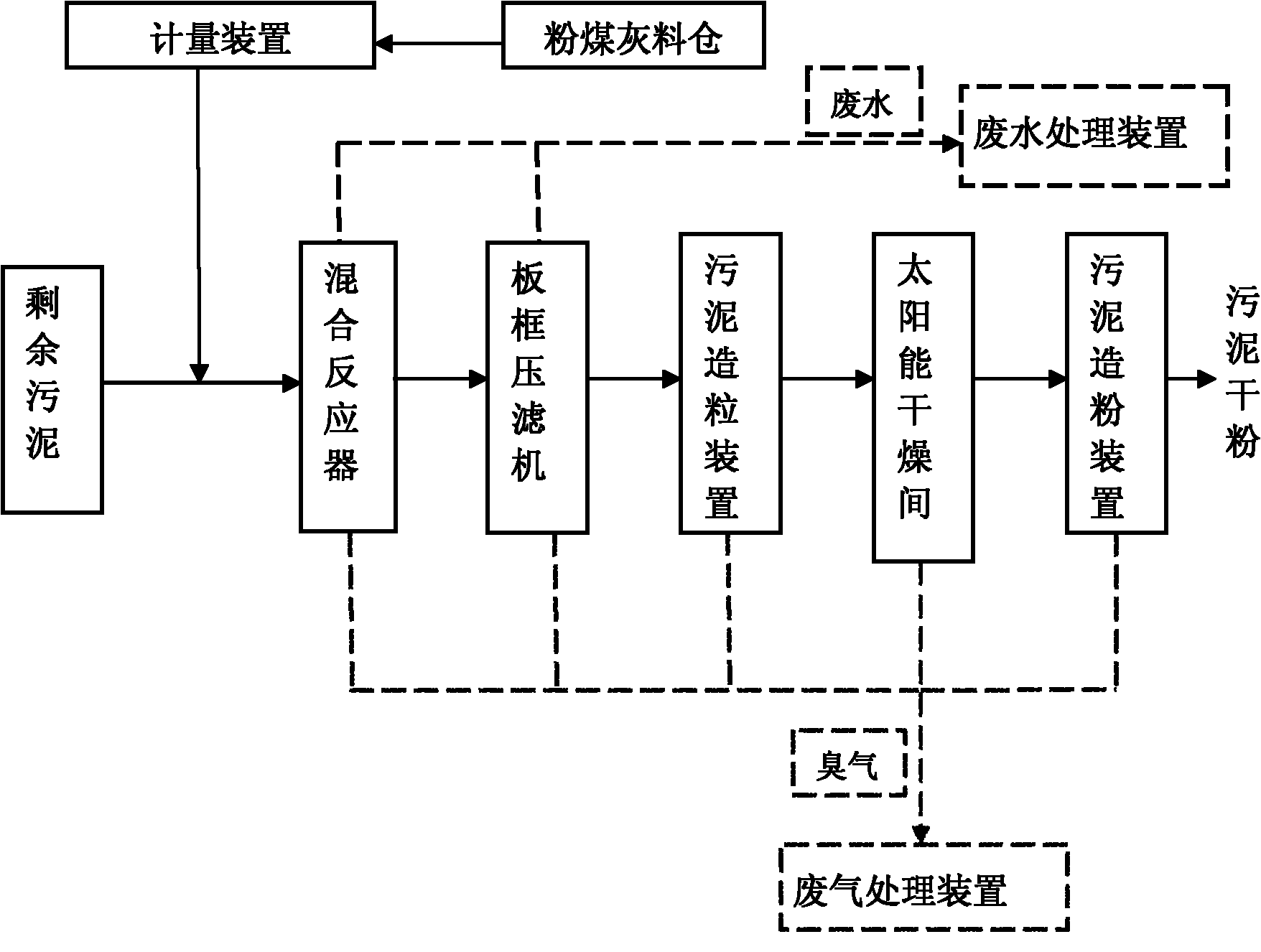

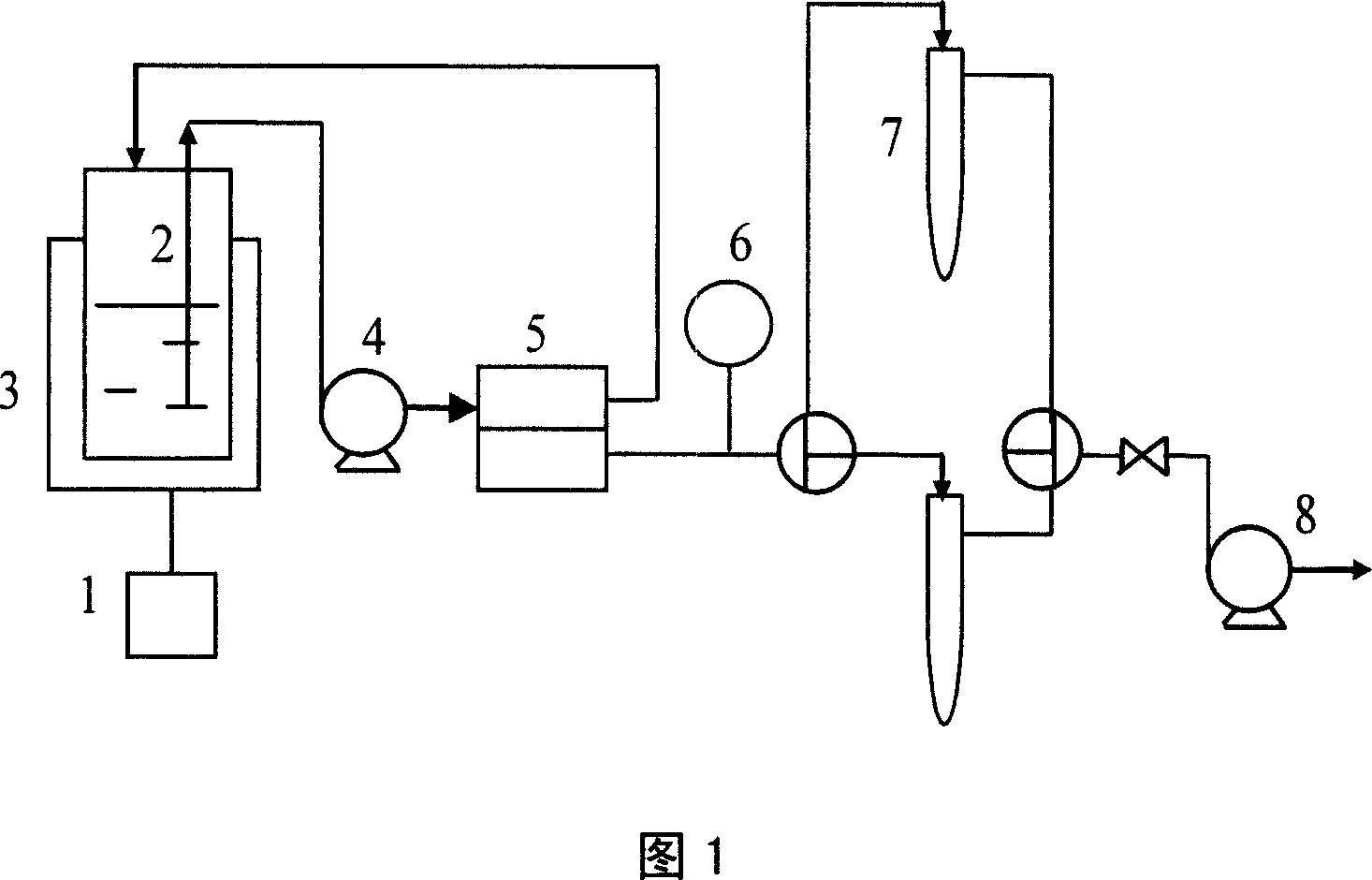

Process for treating excess sludge by utilizing fly ash

ActiveCN102161562ALoose textureWell-developed poresSludge treatment by de-watering/drying/thickeningWaste processingBound waterSolar drying

The invention relates to a process for treating excess sludge by utilizing fly ash. The method specifically comprises the following steps of: 1, feeding excess sludge to be treated which has the water content of between 80 and 90 percent, and fly ash in an amount which is 20 to 50 percent based on the mass of the excess sludge into a mixing agitator; fully mixing and reacting for 5 to 15min; feeding into a plate and frame dehydrator for dehydration to obtain sludge of which the water content is reduced to be between 35 and 45 percent; crushing the sludge into coarse particles with the particle size of between 3 and 5mm by using a sludge granulation device; feeding the sludge particles into a solar drying room, and drying for 24 to 48h at the temperature of above 40 DEG C and under the humidity of below 15 percent to ensure that the water content of the sludge is reduced to between 8 and 15 percent; and treating by sludge pulverization equipment and a high-speed airflow collision technology, wherein the particle size of sludge powder is 150 to 300 meshes and the water content is 5 to 10 percent after the treatment. The method has the advantages that: interstitial water, adsorbed water and capillary bound water in the excess sludge are absorbed into the fly ash; due to the characteristic of high permeability coefficient of the fly ash, the water in the fly ash is easily discharged; and the secondary pollution to the environment is avoided by appropriately treating the excess sludge.

Owner:北京方兴科创环境科技有限公司

Mn-Zn ferrite with high saturation flux density and high magnetic conductivity and preparation process thereof

The invention relates to ferrite and particularly relates to Mn-Zn ferrite with high saturation flux density and high magnetic conductivity and a preparation process thereof. The ferrite consists of main components and auxiliary components, wherein the main components include 52-54mol% of iron oxide calculated by Fe2O3, 18-21mol% of zinc oxide calculated by ZnO and the balance of manganese oxide calculated by MnO; relative to the main components, the auxiliary components include 100-500ppm of Ca calculated by CaO, 300-1000ppm of Bi calculated by Bi2O3, 100-400ppm of Sn calculated by SnO2 and 200-800ppm of Mo calculated by MoO3. The final ferrite product is finally obtained by the steps of mixing, vibrative grinding, presintering, ball milling, pelleting forming and sintering. According to the ferrite product, the saturation flux density Bs is improved to above 470mT on the basis that the 12000+ / -30% of magnetic conductivity is ensured.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

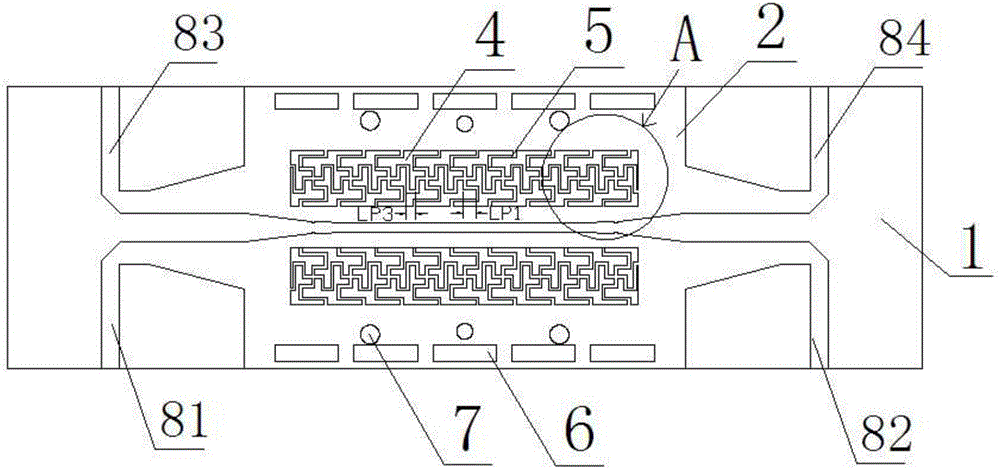

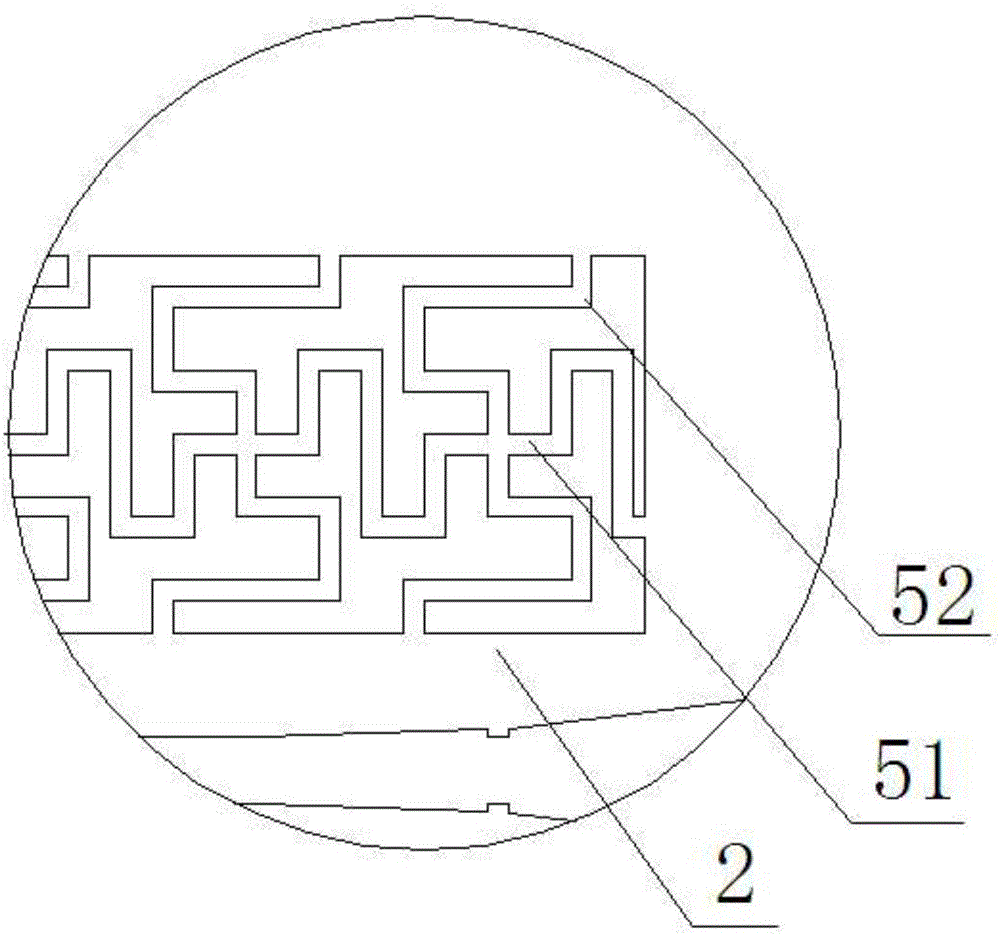

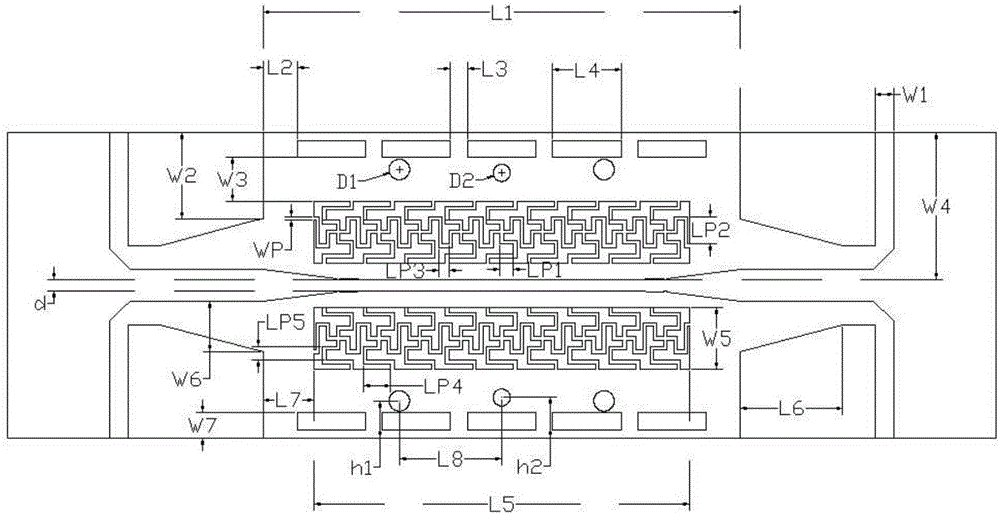

Miniaturized broadband slow-wave half-mode substrate-integrated waveguide coupler and design method thereof

The invention discloses a miniaturized broadband slow-wave half-mode substrate-integrated waveguide coupler and a design method thereof. An open edge of a half-mode substrate-integrated waveguide transmission line is utilized as a coupling part of the coupler and a microstrip multistage line network is formed by etching on the surface to replace a novel coupler structure formed by a traditional metal surface. Compared with a traditional substrate-integrated waveguide coupler, the miniaturized broadband slow-wave half-mode substrate-integrated waveguide coupler has the advantages that a slow wave effect is formed by introducing a microstrip multistage line into an inductive load, so that the physical size of a coupling edge is effectively reduced; the coupling characteristic of the coupler can be sensitively affected by a multi-parameter adjustable microstrip multistage line structure and the coupling coefficient and the coupling bandwidth can be more flexibly and effectively controlled; meanwhile, a new design freedom is provided for optimization of various performance indexes of the coupler by multiple parameters with adjustable structure sizes in the microstrip multistage line; and compared with a traditional substrate-integrated waveguide coupler, the formed novel coupler has a lower profile, a larger working bandwidth and better coupling performance.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

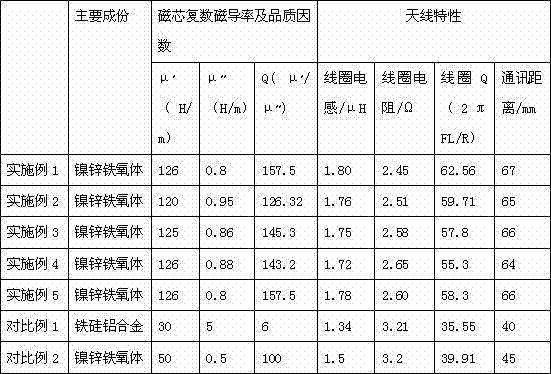

Nickel-zinc soft magnetic ferrite and preparation method thereof

InactiveCN103360042AImprove uniformityHigh permeabilityInorganic material magnetismIron compoundsMagnetNickel zinc

A nickel-zinc soft ferrite is provided. The nickel-zinc soft ferrite comprises: a main component comprising 51-52 mol% of Fe2O3, 14.5-16 mol% of NiO, 15-18 mol% of ZnO, and 14-18 mol% of CuO; and an auxiliary component comprising A12O3, V2O5 and CaO. A method of producing the nickel-zinc soft ferrite is also provided.

Owner:BYD CO LTD

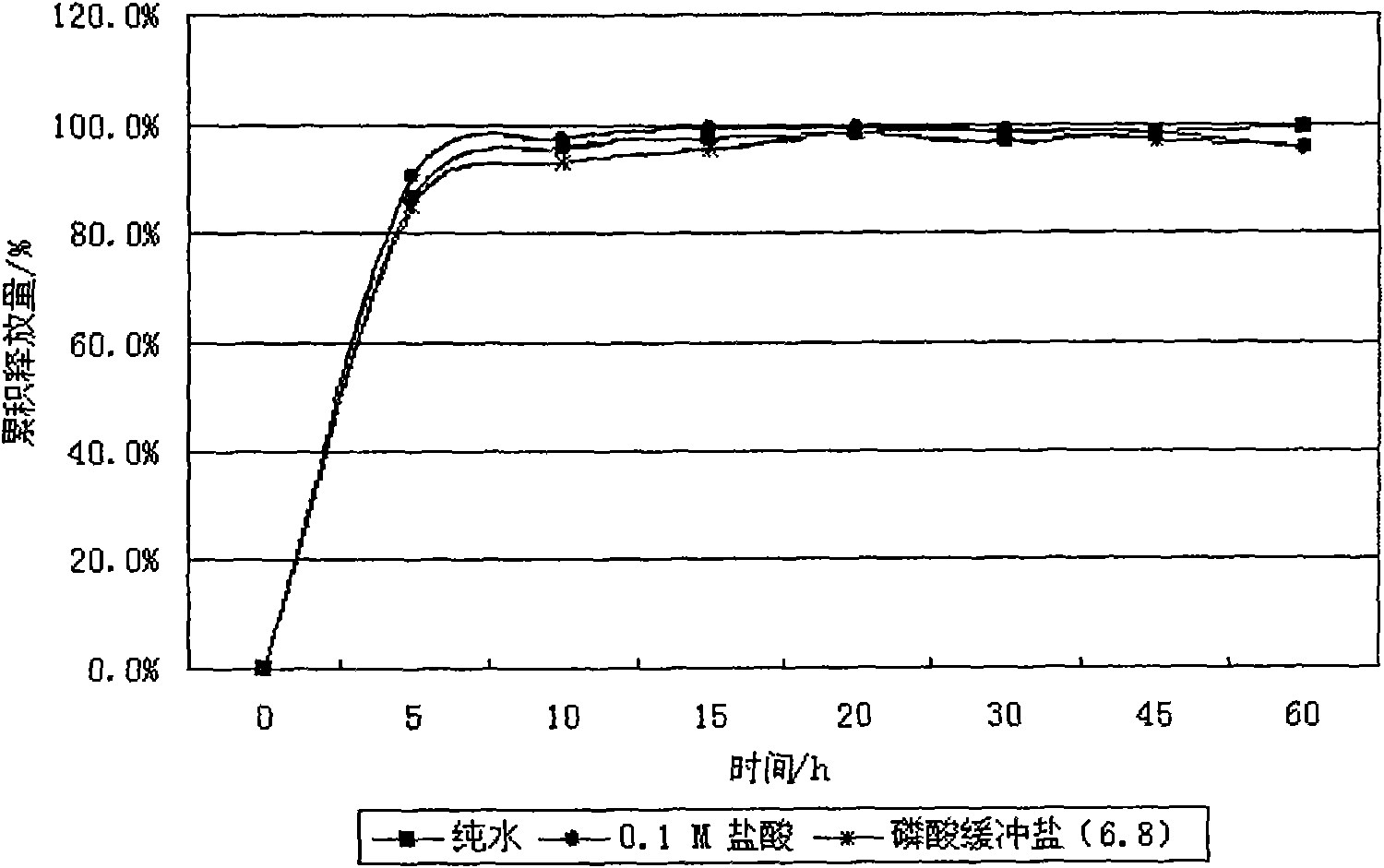

Propofol self-micro-emulsifying composition and preparation method thereof

InactiveCN101675917AProtection stabilityHigh permeabilityHydroxy compound active ingredientsAnaestheticsFat emulsionOil phase

The invention relates to a propofol self-micro-emulsifying composition and a preparation method thereof, mainly aiming at solving the technical problems of injection pain and extremely low oral bioavailability of the existing fat emulsion. The invention has the technical scheme that the propofol self-micro-emulsifying composition comprises the components by weight percent: 1-15% of propofol, 10-70% of emulsifying agent, 0-50% of auxiliary emulsifying agent and 0-30% of oil phase. The new formulation of propofol has the characteristics of low gastrointestinal metabolism, higher bioavailability,good stability and easy preparation.

Owner:WUXI APPTEC (TIANJIN) CO LTD +3

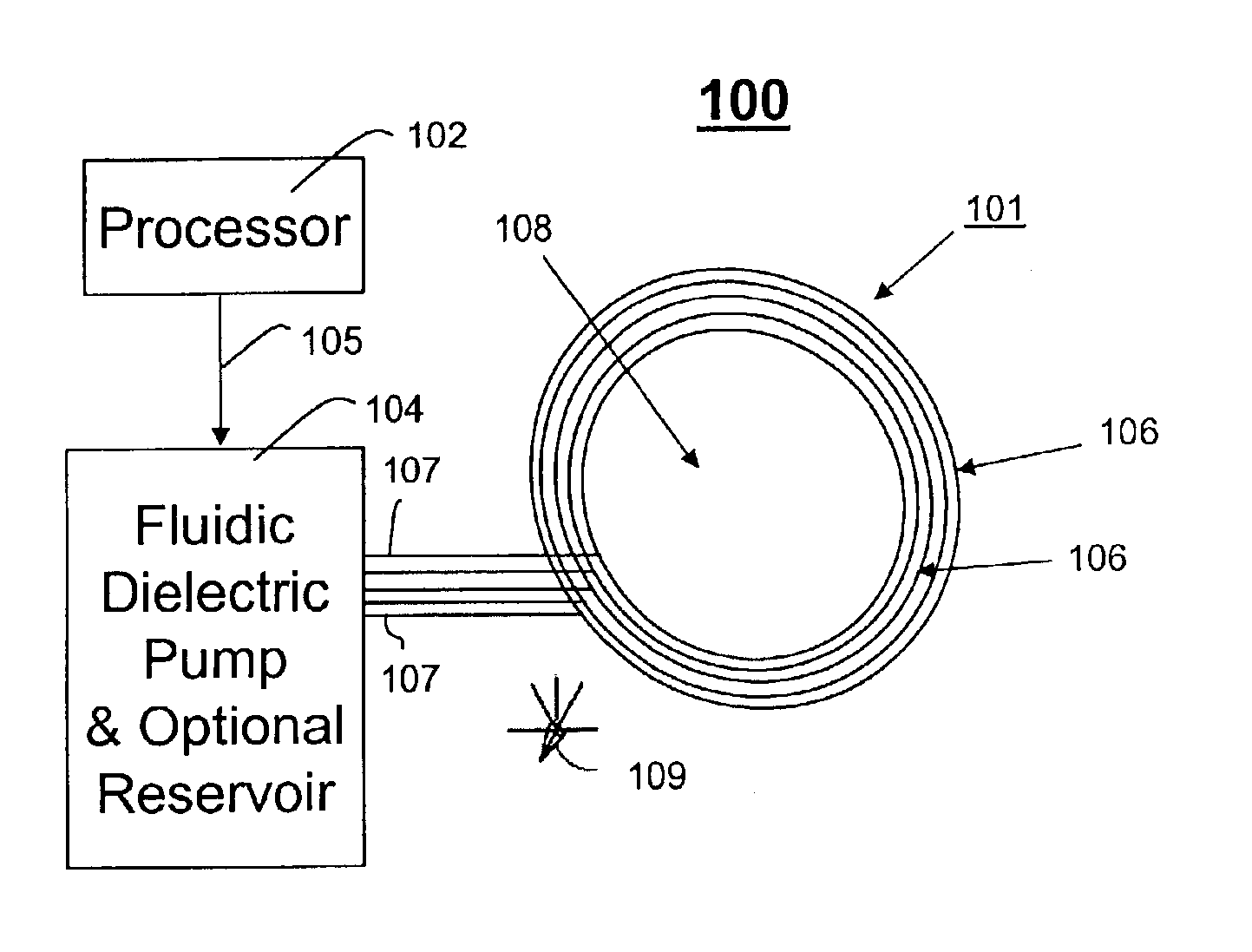

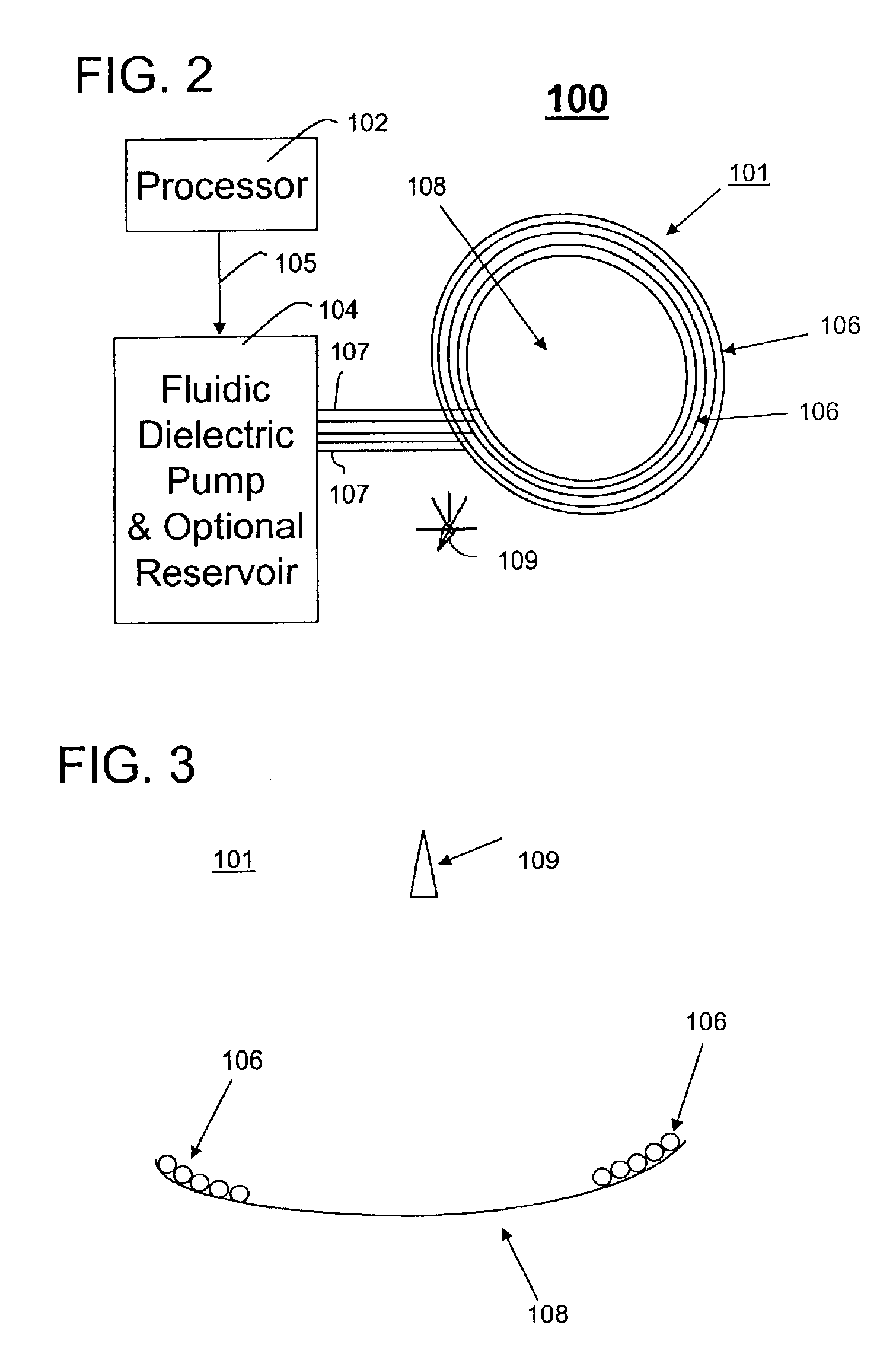

Taper adjustment on reflector and sub-reflector using fluidic dielectrics

A reflector antenna (100) includes a reflector unit (101) having at least one cavity (106) disposed on the reflector unit, at least one fluidic dielectric having a permittivity and a permeability, and at least one composition processor (104) adapted for dynamically changing a composition of the fluidic dielectric to vary at least the permittivity or permeability in at least one cavity. The antenna further comprises a controller (102) for controlling the composition processor to selectively vary at least one among the permittivity and the permeability in at least one of the cavities in response to a control signal.

Owner:HARRIS CORP

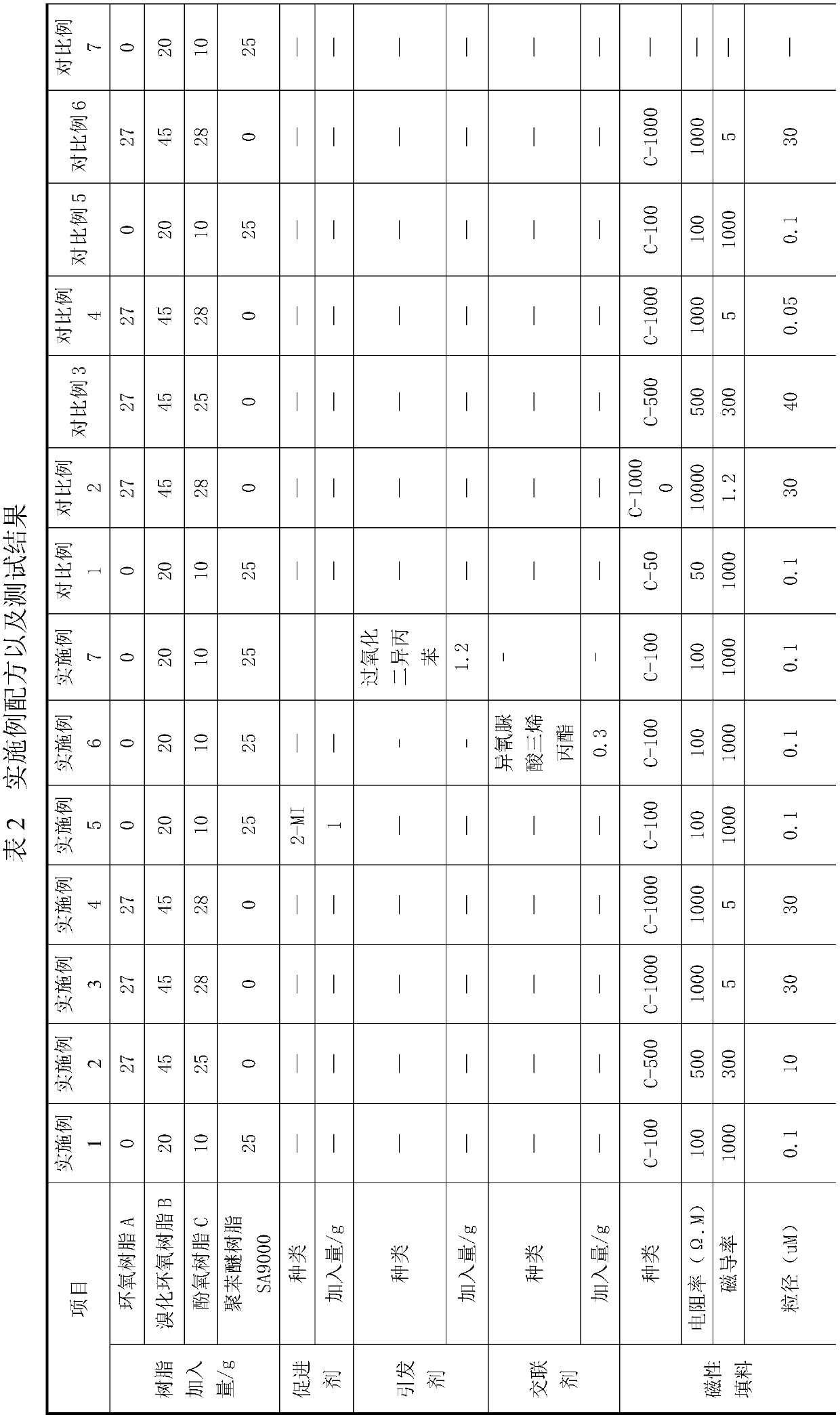

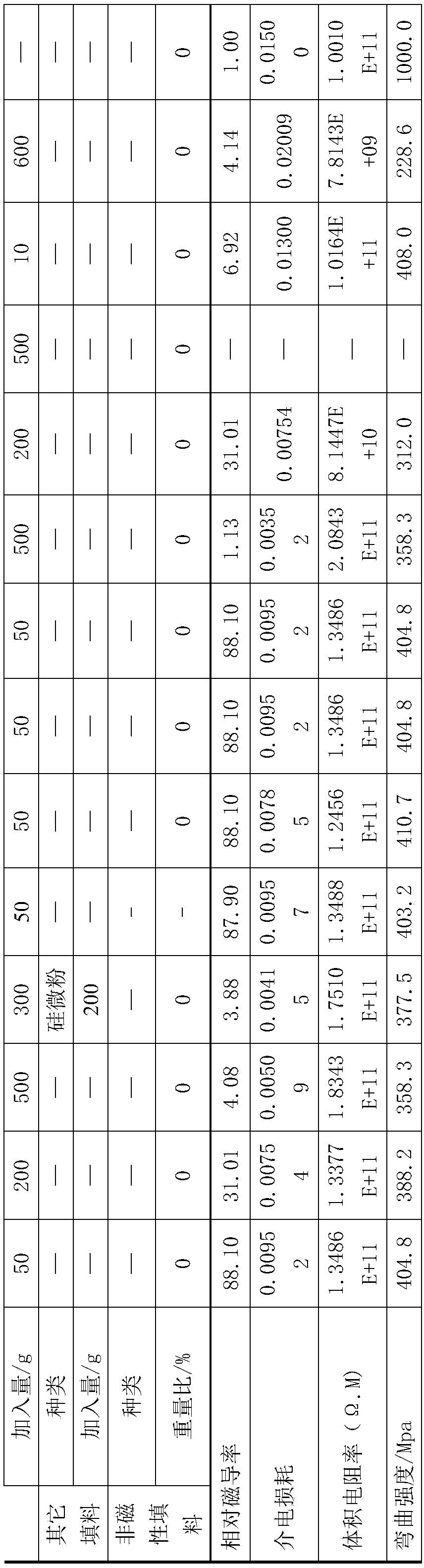

Magnetic dielectric resin composition and applications thereof

The present invention discloses a magnetic dielectric resin composition, which comprises, by weight, 30-100 parts by weight of a resin, 50-500 parts by weight of a magnetic filler, 0.1-7 parts by weight of an initiator, and 0.1-7 parts by weight of an accelerator, wherein the magnetic filler has resistivity of 100-1000 [omega].M. According to the present invention, the magnetic dielectric resin composition is used for the preparation of prepregs, laminates, copper clad laminates or circuit boards; and through the synergistic effect among different components in the magnetic dielectric resin composition, the prepared copper clad laminate has advantages of high magnetic permeability, good insulation property, low dielectric loss and high bending strength.

Owner:SHAANXI SHENGYI TECH

Method for preparing chitosan/ZSM-5 molecular compound film

ActiveCN101099924ALow priceNo pollution in the processSemi-permeable membranesCarbonic/haloformic acid esters purification/separationComposite filmMethyl carbonate

The present invention relates to process of preparing chitosan / molecular sieve composite film for separating methanol / dimethyl carbonate. The preparation process includes the following steps: 1. dissolving chitosan in solvent comprising glacial acetic acid and water at 20-40 deg.c to obtain 0.8-2.5 wt% concentration film casting chitosan solution; 2. adding certain amount of ZSM-5 molecular sieve to the film casting chitosan solution; 3. debubbling the solution after stirring; and 4. casting film on glass plate. Compared with traditional chitosan film, the chitosan / molecular sieve composite film has higher mechanical strength and higher infiltrating and vaporizing performance for separating methanol / dimethyl carbonate mixture.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

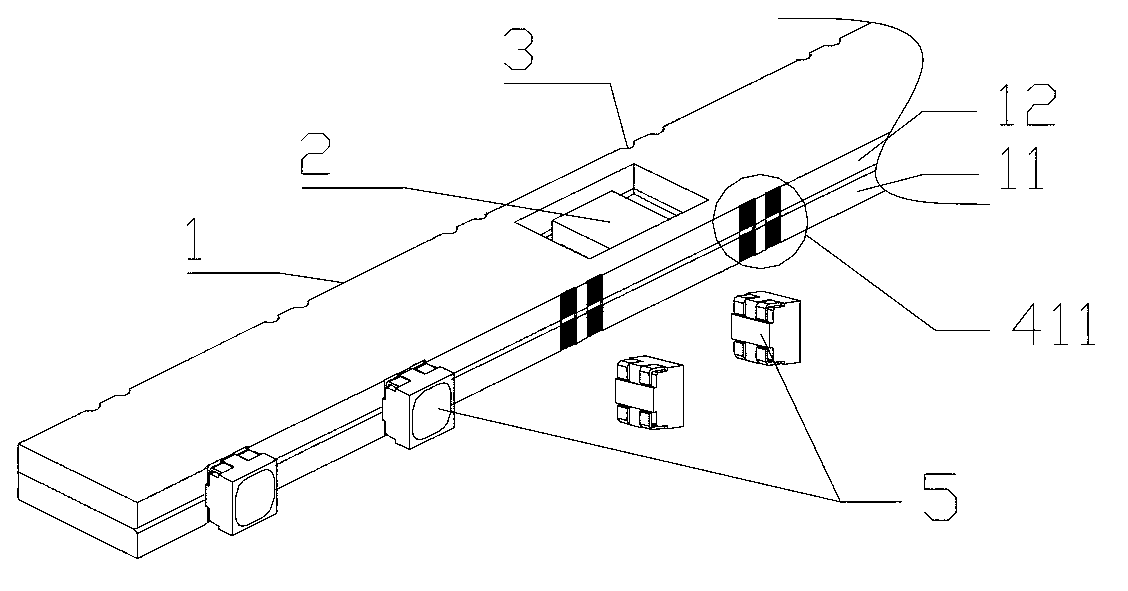

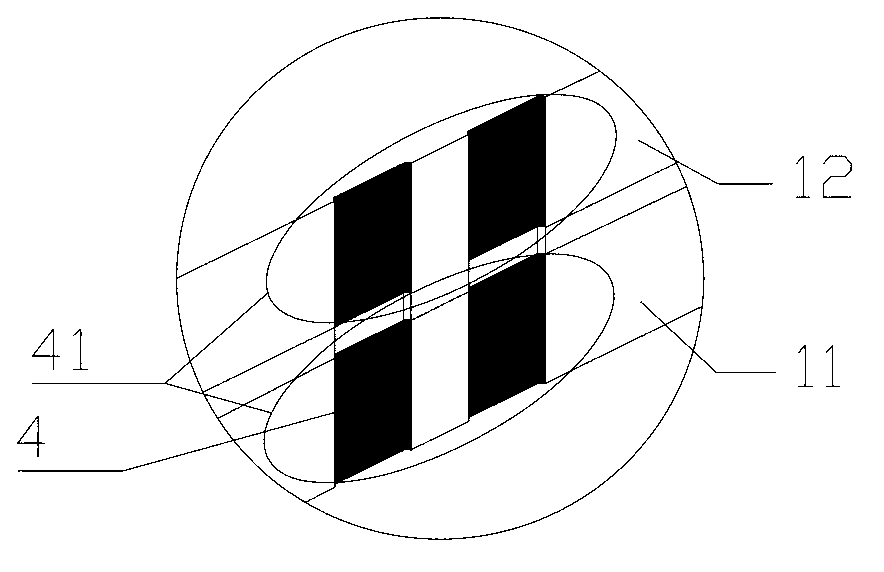

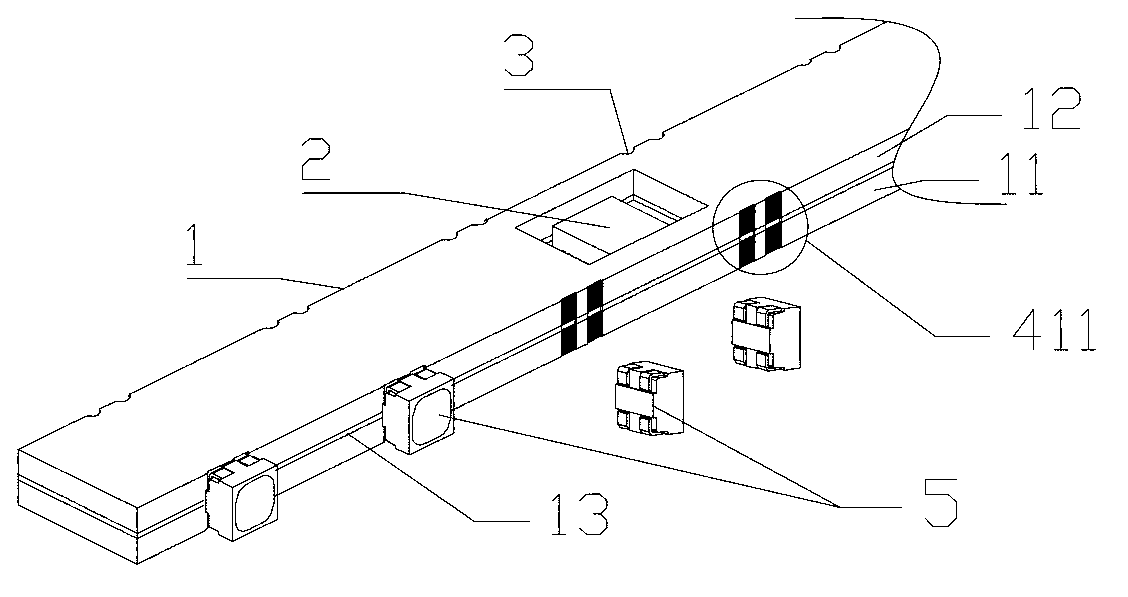

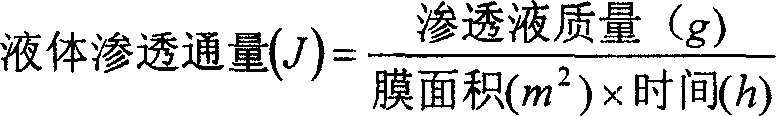

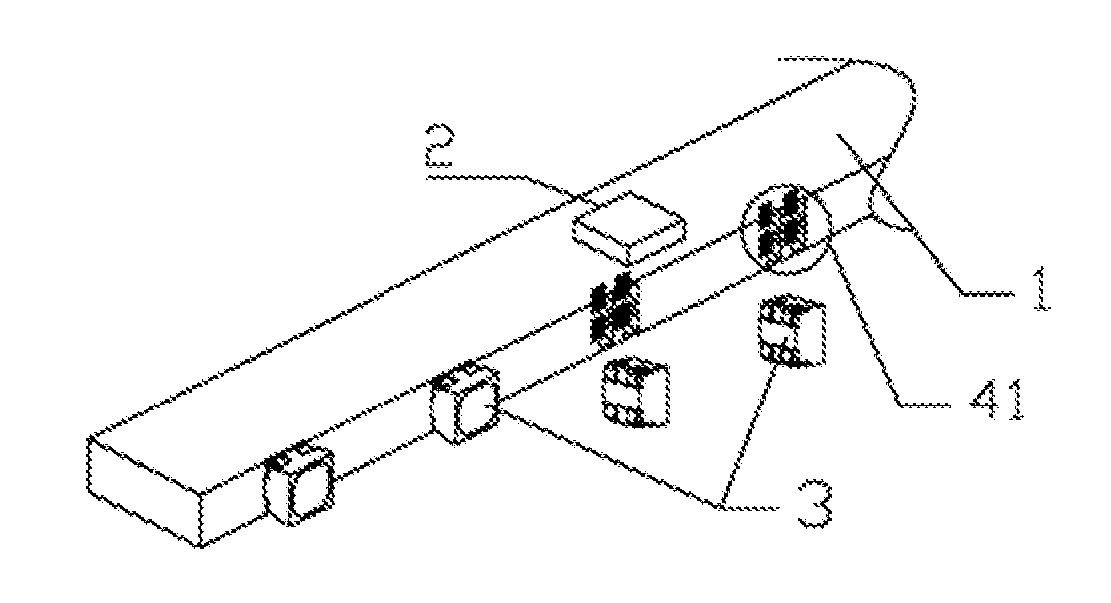

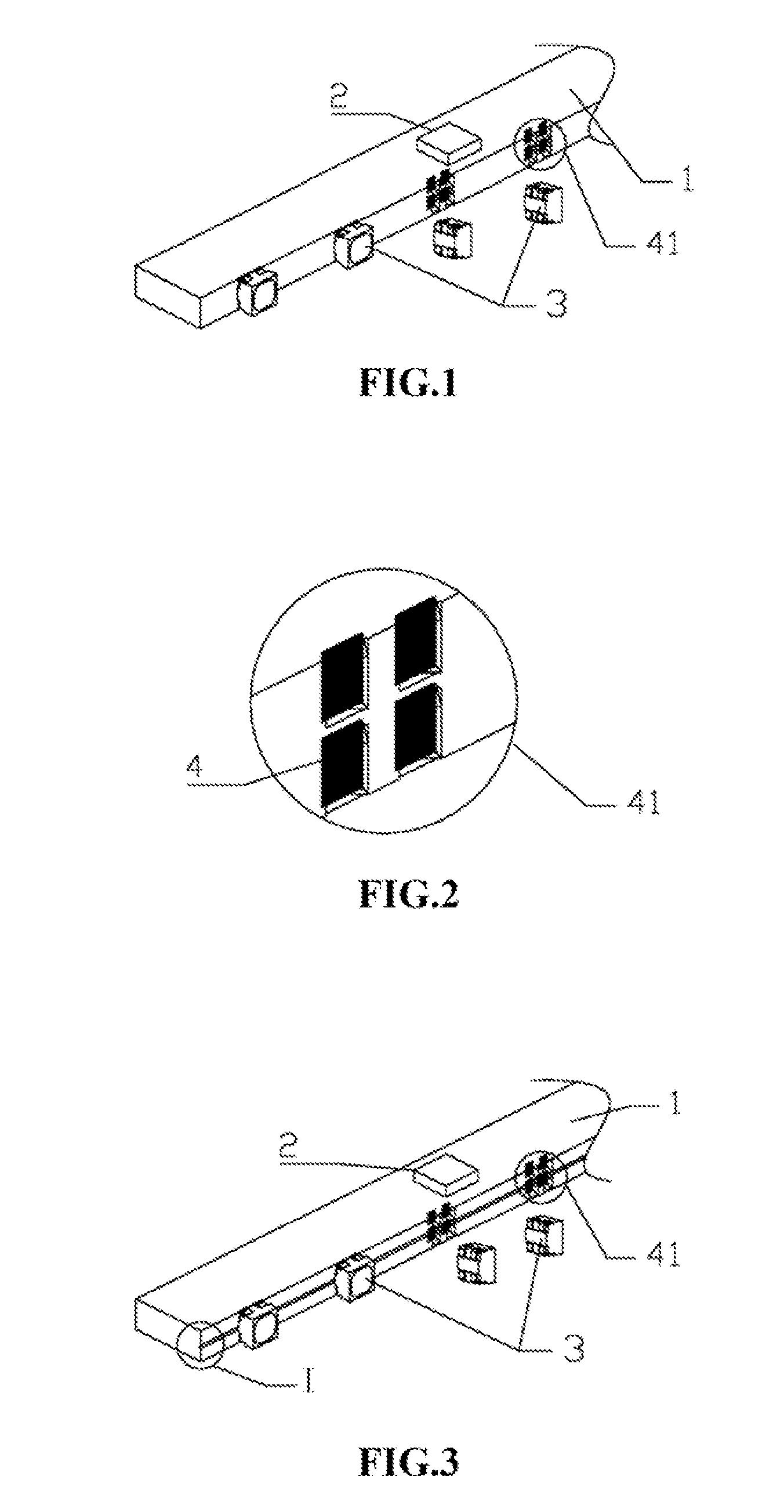

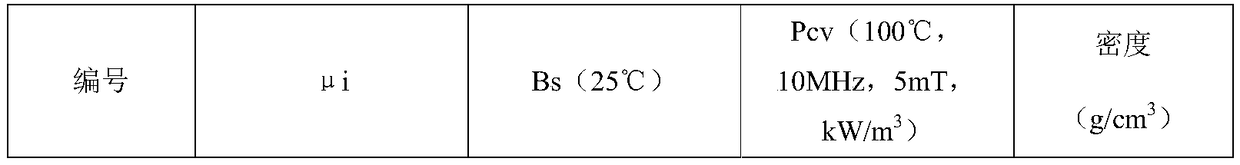

LED screen display unit and production method therefor

ActiveUS20150362133A1High efficiencyHigh permeabilityPrinted circuit assemblingLighting support devicesContact padPixel density

An LED screen display unit and production method therefor. The LED screen display unit comprises a circuit board (1), a driving IC (2) and LEDs (3); a first face of said circuit board (1) is provided with a contact pad matrix (41); the driving IC (2) is arranged on the circuit board (1) and is in electrical connection with contact pads (4) of said contact pad matrix (41); the pins (31) of the LEDs (3) are soldered to contact pads (4) of the contact pad matrix (41). The present display unit can ensure a higher permeability rate for LED display screens produced having high pixel density.

Owner:LI SHULING

Power-type nickel-zinc ferrite prepared by low-pressure and low-temperature sintering and preparation method thereof

The invention provides power-type nickel-zinc ferrite prepared by low-pressure and low-temperature sintering and a preparation method thereof. The preparation method comprises the following steps thatwhen a blank is sintered, the adopted air pressure is 1-100Pa, the sintering temperature is 750-930 DEG C, the insulation time is 1-8 hours and then a power-type nickel-zinc ferrite material is obtained. The power-type nickel-zinc ferrite is characterized in that the main components and the auxiliary components of the power-type nickel-zinc ferrite are also optimized, and the contents of the maincomponents and the types and the contents of the auxiliary components are limited, wherein the power-type nickel-zinc ferrite material comprises the following main components in percent by mole: 47.5%-55.5% of Fe2O3, 17%-27.5% of NiO, 16%-26% of ZnO and 7%-13% of CuO; the auxiliary components of the power-type nickel-zinc ferrite material are added according to the total mass of the main components, i.e., 4-7 types of the following oxides: 0.02-0.12wt% of Co, 0.05-0.35wt% of CaCO3, 0.02-0.05wt% of BaO, 0.02-0.08wt% of V2O5, 0.05-0.3wt% of Bi2O3, 0.05-0.2wt% of SnO2 and 0.02-0.2wt% of GeO2, and then the power-type nickel-zinc ferrite with higher magnetic conductivity and lower power loss can be obtained.

Owner:ZHEJIANG UNIV

Metal Organic Framework Filled Polymer Based Membranes

InactiveUS20130047843A1High permeabilityHigh CO2 permeabilitySemi-permeable membranesIon-exchanger regenerationMolecular self-assemblyMetal-organic framework

A membrane for separation of gases, the membrane including a metal-organic phase and a polymeric phase, the metal-organic phase having porous crystalline metal compounds and ligands, the polymeric phase having a molecularly self assembling polymer.

Owner:DOW GLOBAL TECH LLC

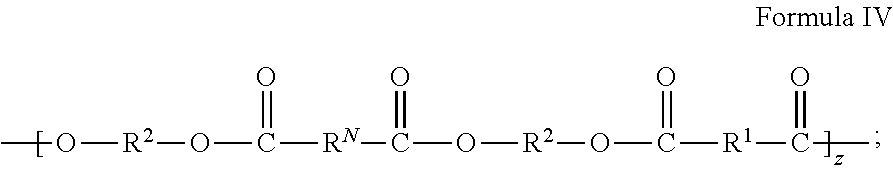

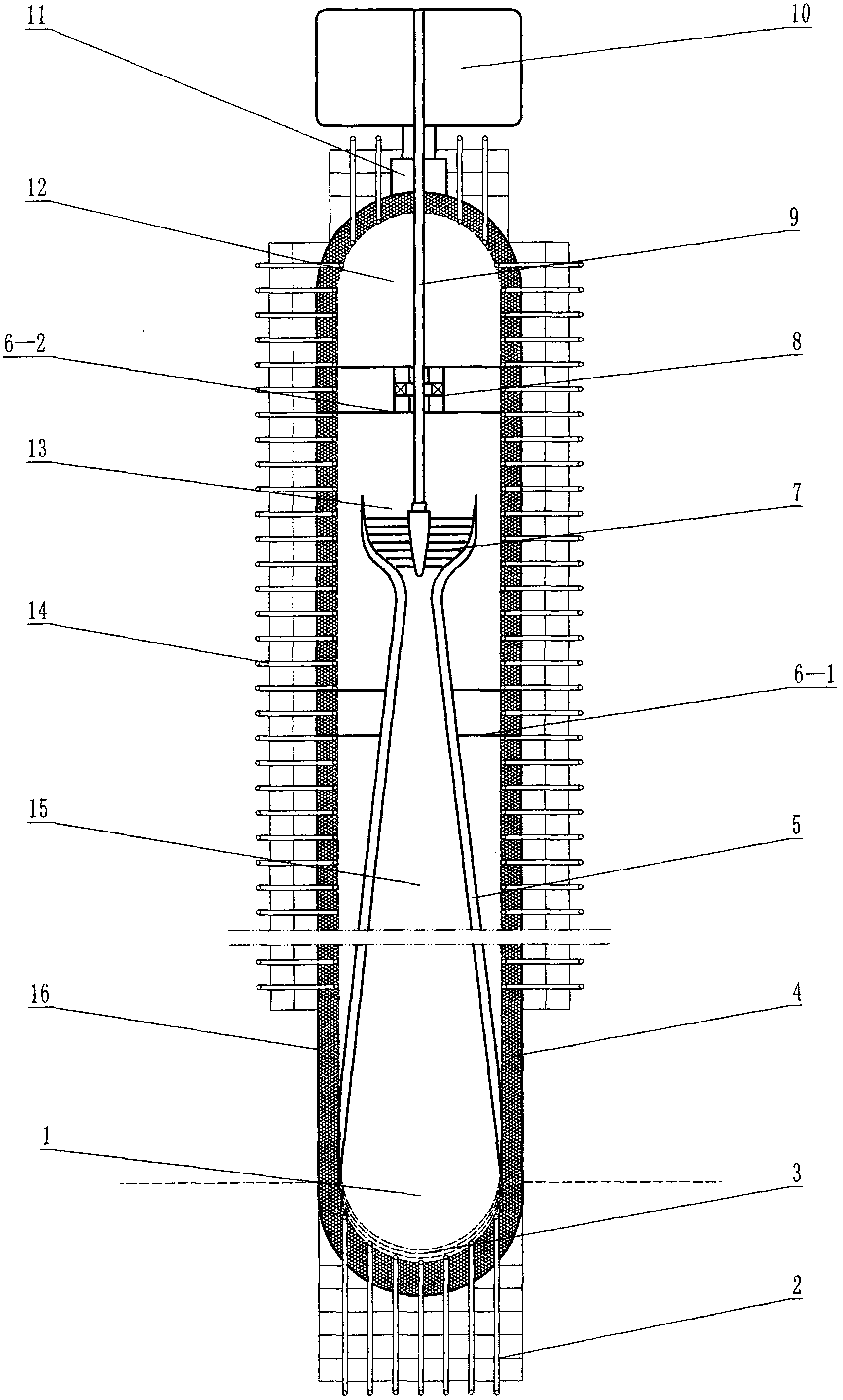

Heat pipe cyclic power machine

The invention discloses a heat pipe cyclic power machine consisting of a heat pipe and a turbine power generation system. The main body of the heat pipe consists of a pipe wall, a liquid absorption core and a working medium; the cavity body of the heat pipe consists of an evaporation cavity, a condensation cavity, a tapered pipe cavity, a vacuum heat insulation cavity and a nozzle; the liquid absorption core is arranged on the inner surface of the pipe wall of the heat pipe; the inner cavity of the lower part of the heat pipe is the evaporation cavity; the working medium is filled in the evaporation cavity; the inner cavity from the evaporation cavity to the nozzle is the tapered pipe cavity of which the cross sectional area is reduced gradually; the nozzle is formed on the upper part of the tapered pipe cavity; the vacuum heat insulation cavity is formed outside the tapered pipe cavity and the nozzle; the inner cavity of the upper part of the nozzle and the inner cavity outside the vacuum heat insulation cavity are condensation cavities; and the turbine power generation system consists of a multi-level blade, a supporting mechanism, a bearing, a rotating shaft, a magnetofluid sealing device and a power output system. The heat pipe cyclic power machine makes an actual contribution to aspects such as new energy power generation, energy saving and emission reduction, mechanical transmission and the like, and pushes the sustainable development of cyclic economy and the significant development of low-carbon economy and green economy.

Owner:舒明

High-permeability magnetic film and preparation method thereof

ActiveCN106601429AHigh permeabilityGood shielding performanceLiquid applicationFlat articlesLiquid polymerCopper

The invention discloses a high-permeability magnetic film and preparation method thereof. The high-permeability magnetic film comprises magnetic particles with weight ratio of 90-99.5% and polymer with weight ratio of 0.5-10%. The liquid-state polymer, the magnetic particles and the additives are uniformly mixed and then casted and dried by use of a casting machine to manufacture a rough belt, the obtained rough belt is repeatedly heated, insulated and rolled to finally manufacture a magnetic film product; the magnetic film manufactured by use of the method disclosed by the invention can be directly manufactured as a flexible copper-clade plate, or manufactured as a flexible circuit board through other manners; and meanwhile, the entire thickness off an electronic product is lowered since the material has high permeability and good shielding property, and the cost is lowered at the same time.

Owner:东莞易力禾电子有限公司

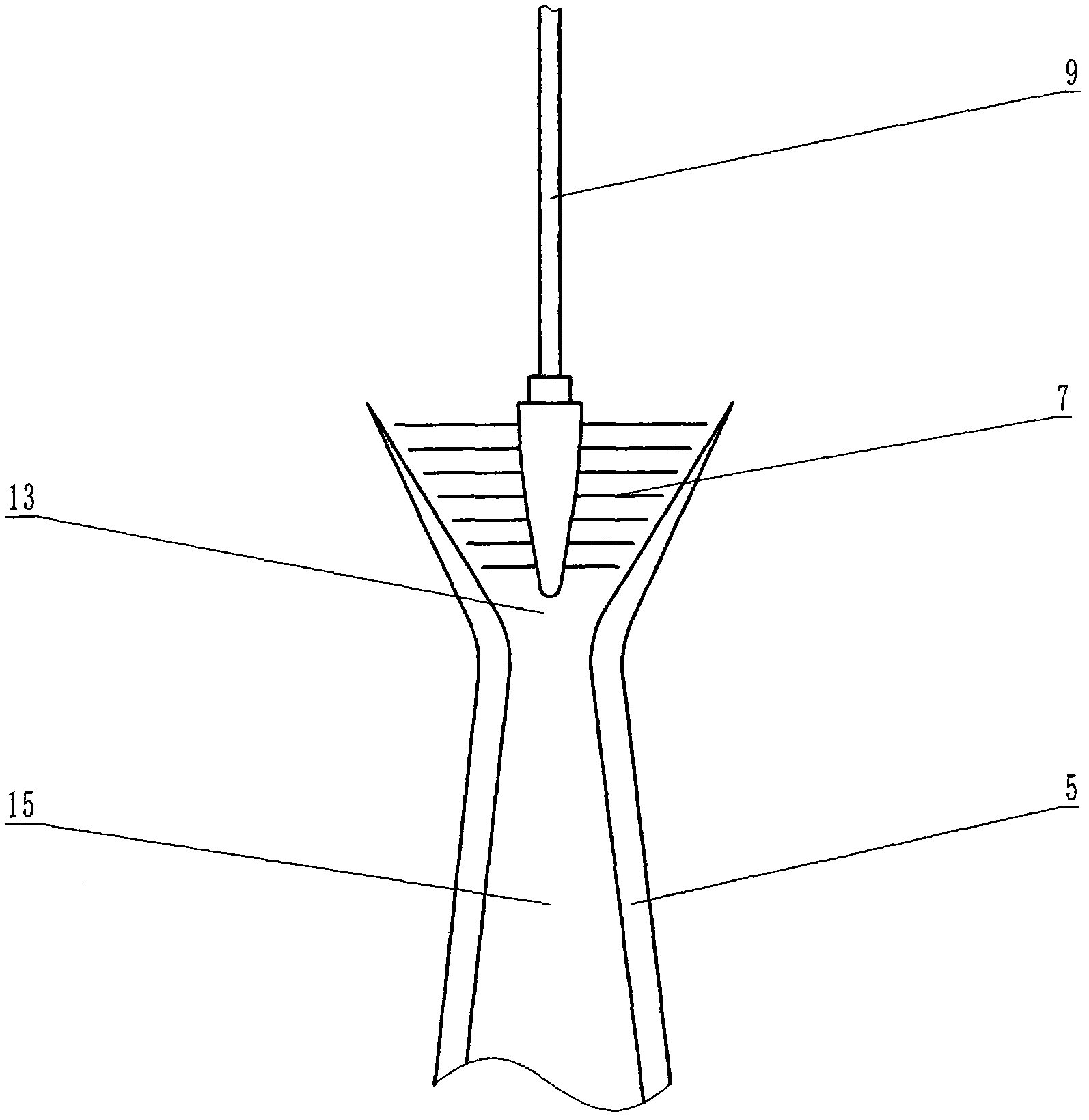

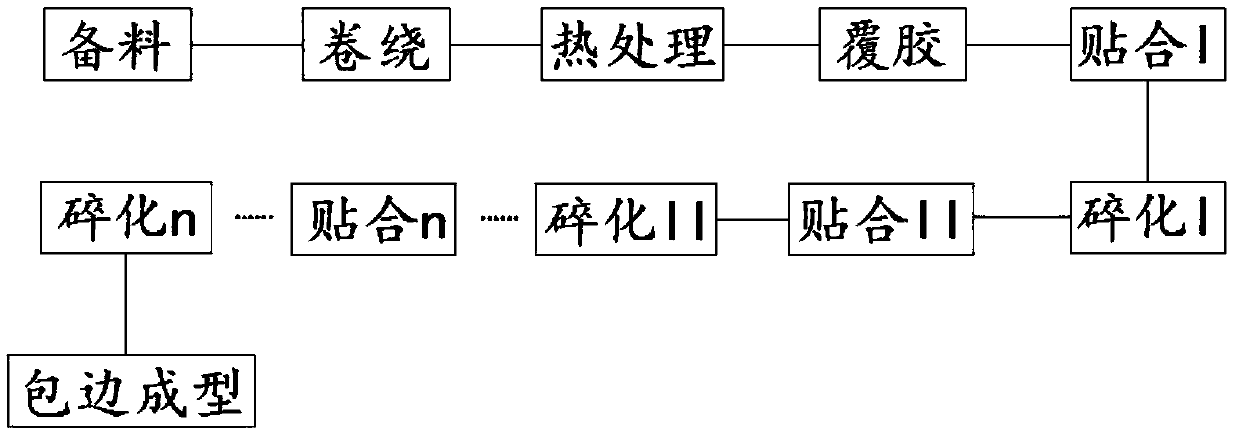

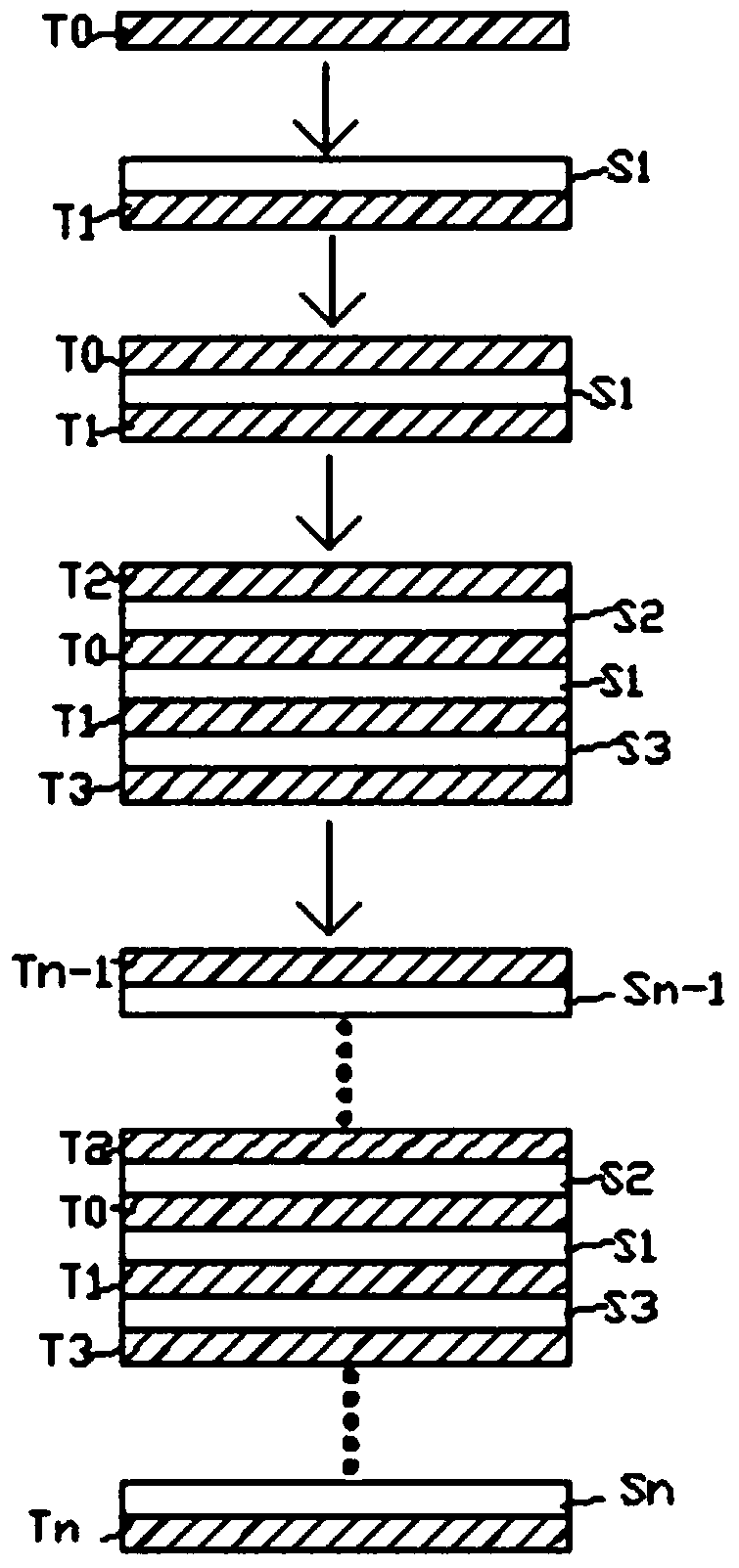

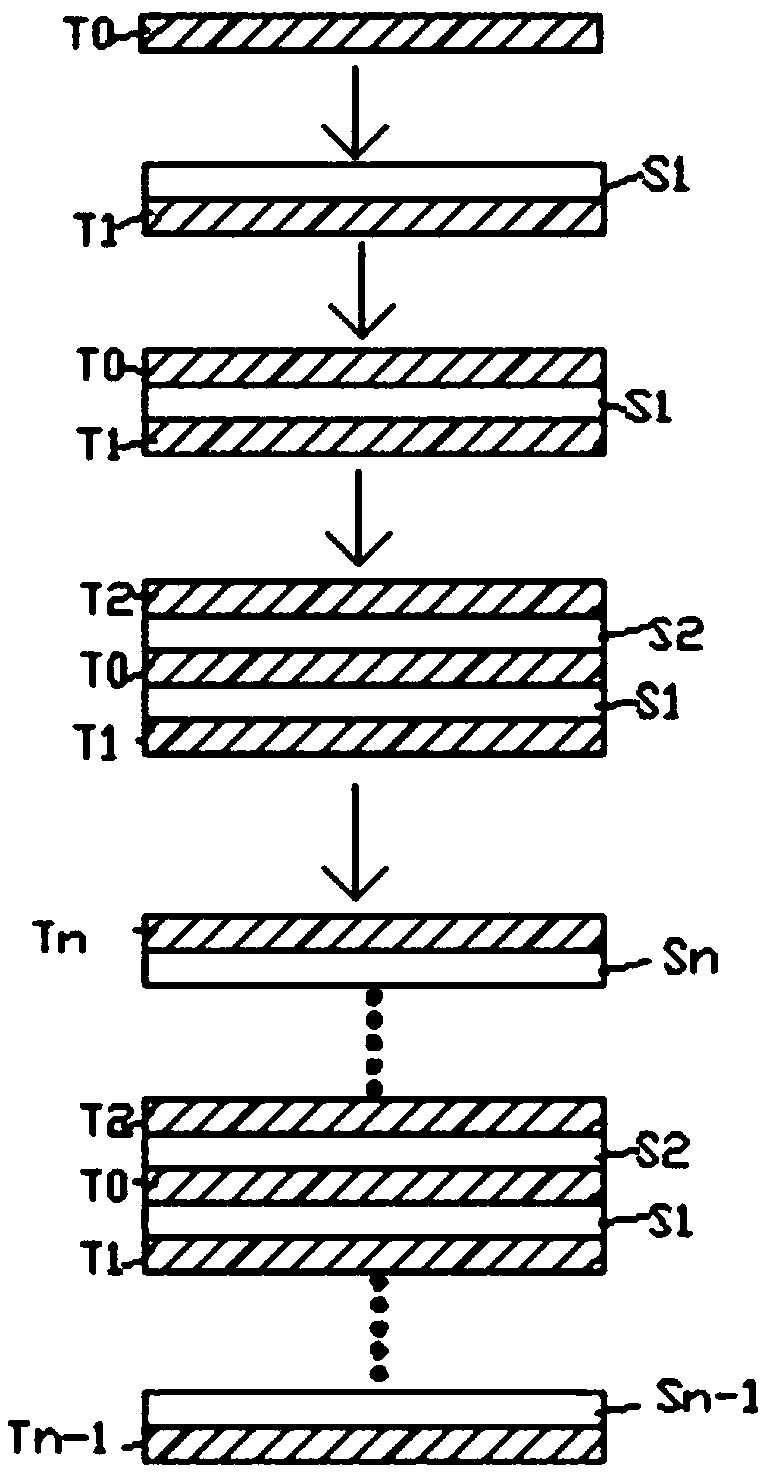

Method for preparing magnetic shielding sheet for wireless charging and NFC

InactiveCN109545535AHigh permeabilityReduce magnetic lossShielding materialsInductances/transformers/magnets manufactureForm processingForms processing

The invention discloses a method for preparing a magnetic shielding sheet for wireless charging and NFC. The method comprises steps that a magnetic material required for preparing the magnetic shielding sheet is provided, the magnetic material is subjected to winding processing, thermal processing, single-sided glue coating, fitting and shredding, secondary fitting and shredding, and the like tillthe magnetic performance reaches requirements, and lastly, edge forming processing is performed. The method is advantaged in that the stability and magnetic permeability of the nanocrystal can be maximized through the winding length and heat treatment process parameters, a new bonding mode can be adopted to reduce the risk of the magnetic material being stripped off by a release film in the filmstripping process, through the shredding method, that each layer of the magnetic material can be shredded to the maximum degree in a roll-to-roll mode is guaranteed, shredded particles are uniform, the surface of the magnetic sheet is smooth and flat, the appearance yield and the performance yield are high, compared with a conventional shredding method, not only various auxiliary materials required for shredding are saved, manufacturing cost of the magnetic sheet is reduced, and production efficiency is improved.

Owner:上海万兹新材料科技有限公司

Magnetorheological fluid for sealing

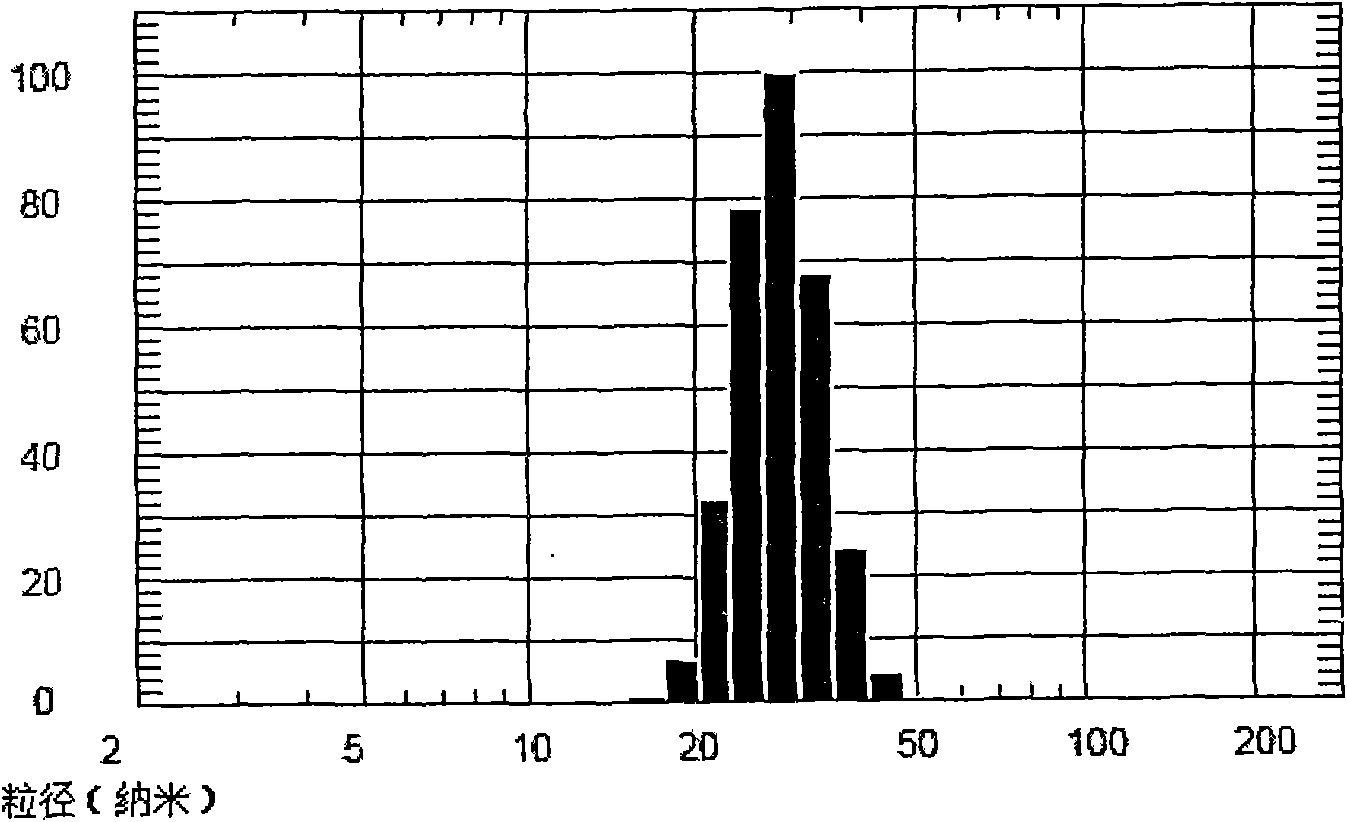

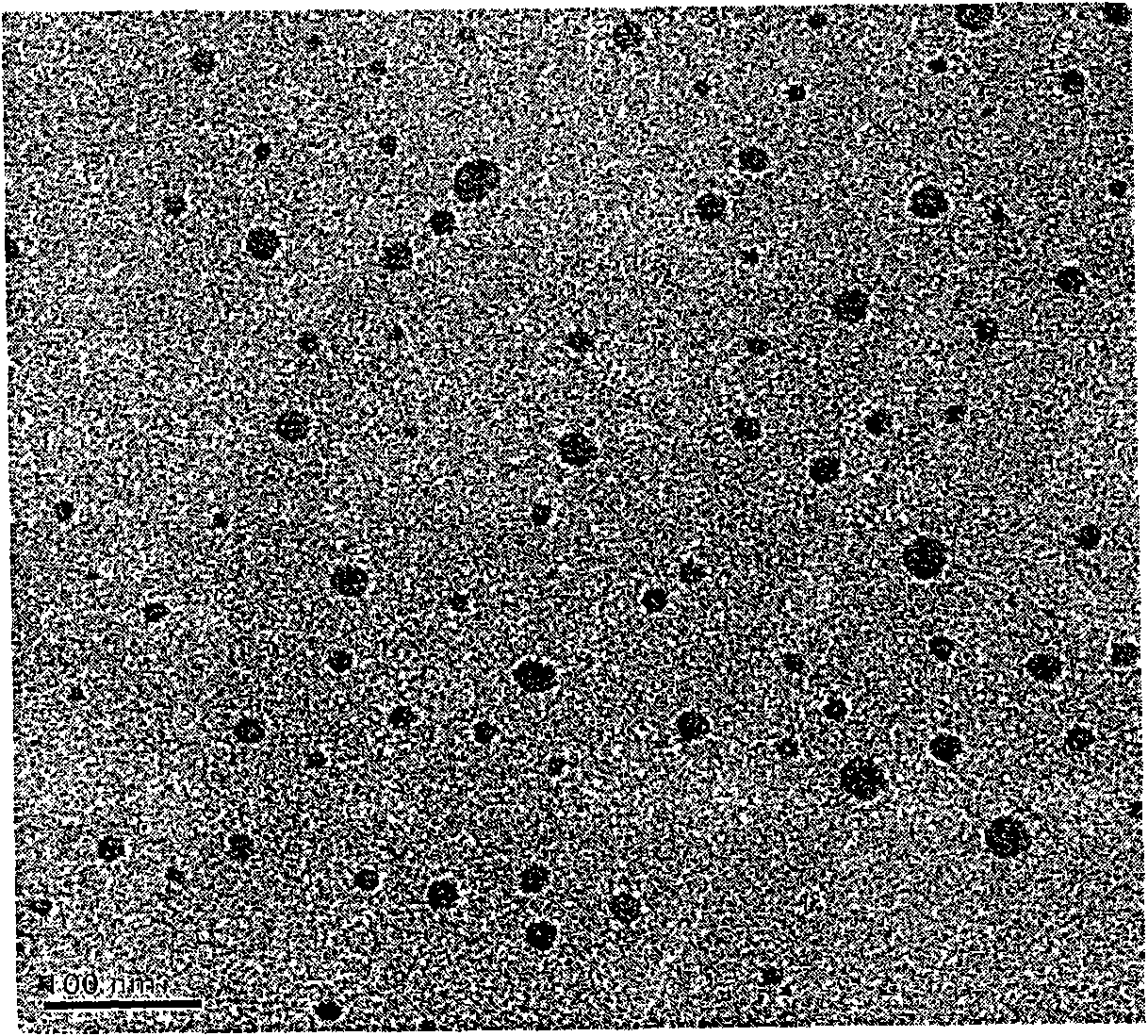

InactiveCN103789068AHigh permeabilityImprove pressure resistanceOther chemical processesMagnetic liquidsMicro nanoMagnetic liquids

The invention provides a magnetorheological fluid for sealing. The magnetorheological fluid is composed of micro / nano-scale magnetic particles, a basic carrier fluid and additives, wherein the mass percent of the micro-nano-scale magnetic particles is 47-89.5%, and the mass ratio of the micro-scale magnetic particles to the nano-scale magnetic particles ranges from 0.2: 1 to 4.5: 1, and moreover, the particle size range of the micro-scale magnetic particles is from 2 microns to 20 microns, while the particle size range of the nano-scale magnetic particles is from 1nm to 15nm; the mass percent of the additives is 0.5-3%, while the mass percent of the basic carrier fluid is 10-50%. The magnetorheological fluid is better in sealing effect than the magnetorheological fluid which is obtained from single micro-scale magnetic particles, and capable of meeting the requirement for zero leakage of sealing; the magnetorheological fluid has magnetic conductivity better than the magnetorheological fluid which is obtained from single nano-scale magnetic particles, and therefore, the pressure endurance capability of a magnetorheological fluid sealing device is obviously improved.

Owner:BEIJING JIAOTONG UNIV

Process for producing dried, singulated fibers using steam and heated air

InactiveUS20050086828A1Low knot contentHigh permeabilityDrying solid materials with heatSolid waste managementFiberNozzle

Dried, singulated cellulose pulp fiber is produced by introducing wet pulp steam and air into a jet dryer. The air is heated to a temperature of 250° C. to 600° C. Steam is injected at a nozzle pressure of from 344 KPa (50 psig) to 4,137 KPa (600 psig). The pulp is removed from the jet dryer and separated from the air. The product formed has advantageous properties such as low fines count, improved kink curl and twist, and high permeability.

Owner:WEYERHAEUSER NR CO

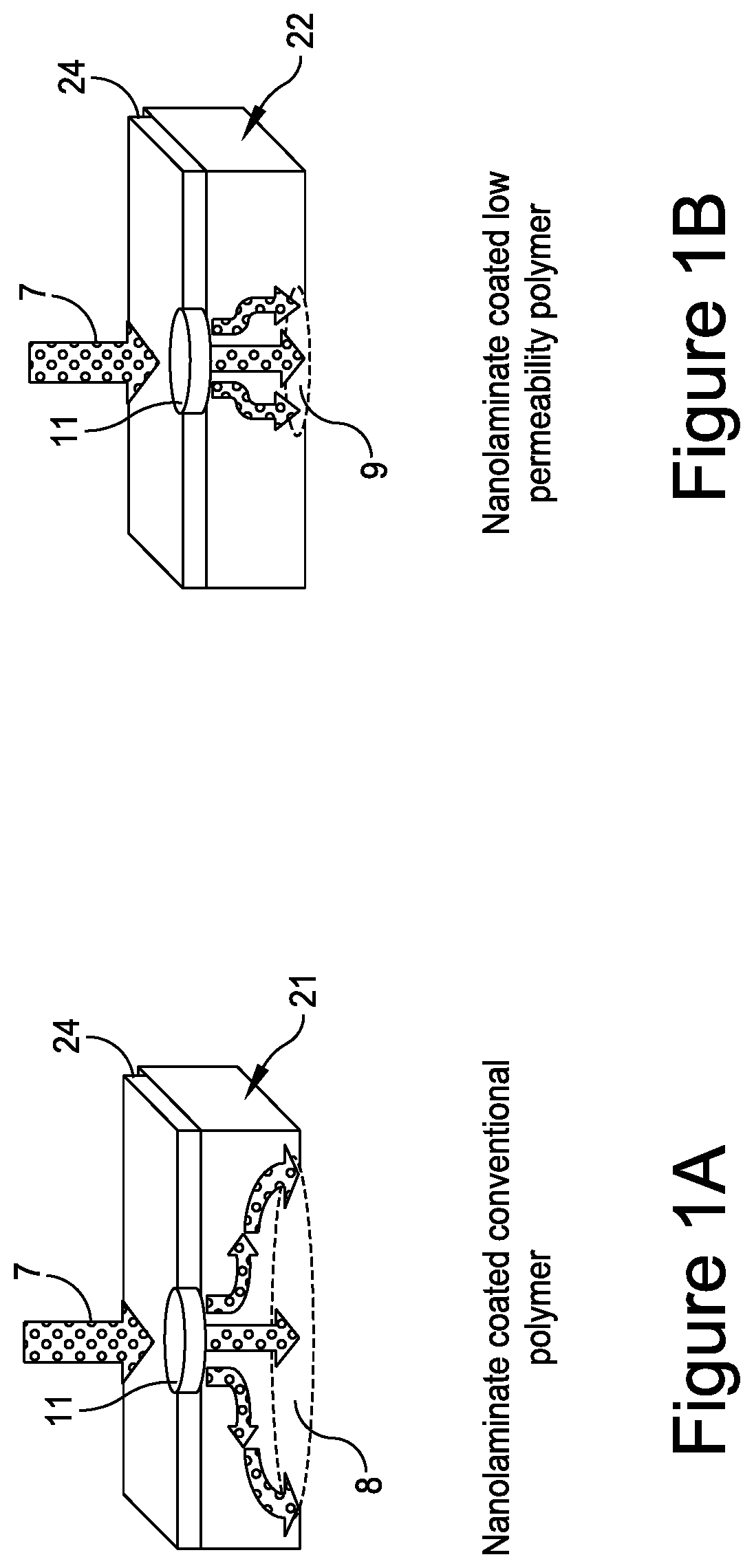

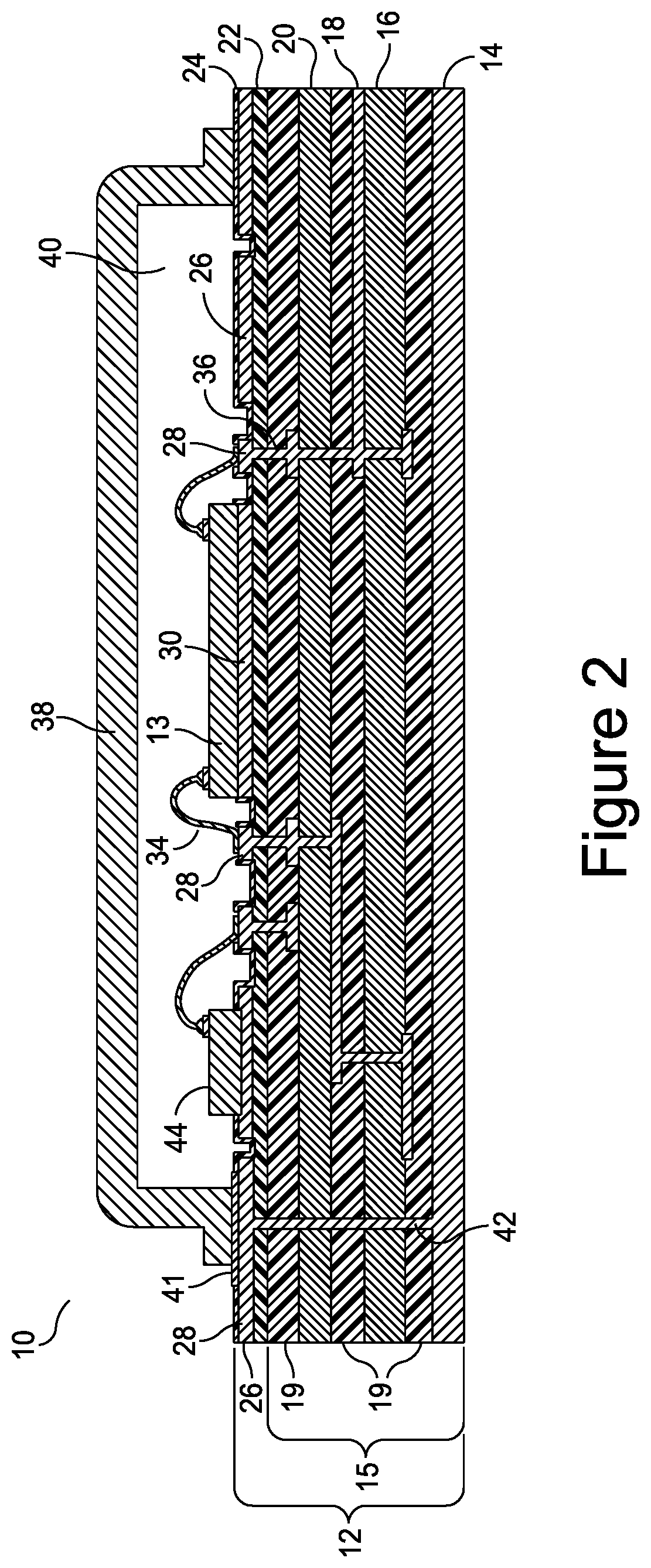

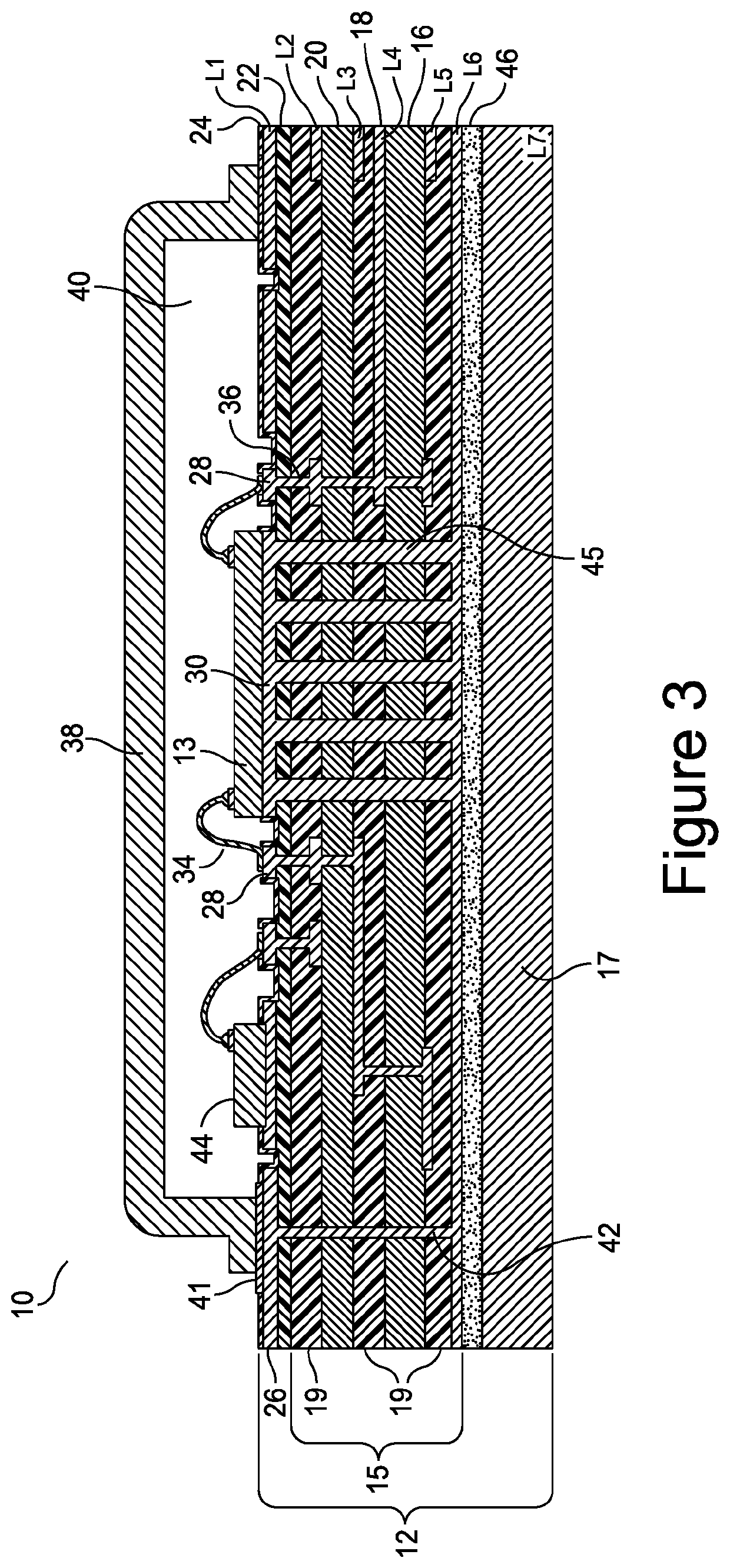

Hermetic chip on board

ActiveUS10834825B1Low permeabilityHigh permeabilitySemiconductor/solid-state device detailsSolid-state devicesThin membranePTFE - Polytetrafluoroethylene

A low permeability laminate film includes one or more low moisture permeability homogeneous polymer films with a total thickness between 0.5 and ten mils without glass or ceramic fillers and with a moisture permeability measured at 37° C. and 100% RH of less than 2.6 E-05 atm·cc·mm / in2·sec of air. The polymer film includes one of polychlorotrifluoroethylene, polytetrafluorethylene, fluorinated ethylene propylene, and perfluoro alkoxy alkane. The low permeability laminate film further includes a nanolaminate including alternate combinations of nanolaminate material that is selected from the group consisting of alumina, titanium dioxide, zirconium oxide, beryllium oxide, hafnium oxide, titanium oxide, silicon nitride, tantalum nitride, silica, parylene F, parylene AF-4, parylene HT® and PTFE (polytetrafluoroethylene). A resulting coated nanolaminate film has a moisture permeability less than an equivalent standard leak rate per square inch of 3.0 E-08 atm·cc / in2·sec of air.

Owner:RAYTHEON CO

High-permeability, high-frequency, high-impedance and high-Curie-temperature manganese-zinc ferrite material and preparation method thereof

InactiveCN112321293AHigh permeabilityLarge grain sizeInorganic material magnetismInductances/transformers/magnets manufactureZinc ferriteHigh impedance

The invention belongs to the technical field of soft magnetic ferrite materials, and discloses a high-permeability, high-frequency, high-impedance and high-Curie-temperature manganese-zinc ferrite material and a preparation method thereof. The high-permeability, high-frequency, high-impedance and high-Curie-temperature manganese-zinc ferrite material is composed of a main component and an auxiliary component. The main component is composed of the following raw materials in mole percentage: 52-54 mol% of Fe2O3, 18-22 mol% of ZnO and the balance of MnO. Based on the total amount of the main component, the auxiliary component is composed of the following raw materials: 200-1000 ppm of CaCO3, 200-1000 ppm of Bi2O3, 200-1000 ppm of Co2O3, and 200-1000 ppm of MoO3. The manganese-zinc ferrite material prepared by adopting the formula and the process has the characteristics of high magnetic conductivity, high frequency, high impedance and high Curie temperature: the initial magnetic rate [mu]i(25 DEG C) is more than or equal to 12000, the Tc is more than or equal to 150 DEG C, and the impedance coefficient is more than or equal to 26 ohm / mm within the range of 0.5-1.0 MHz.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

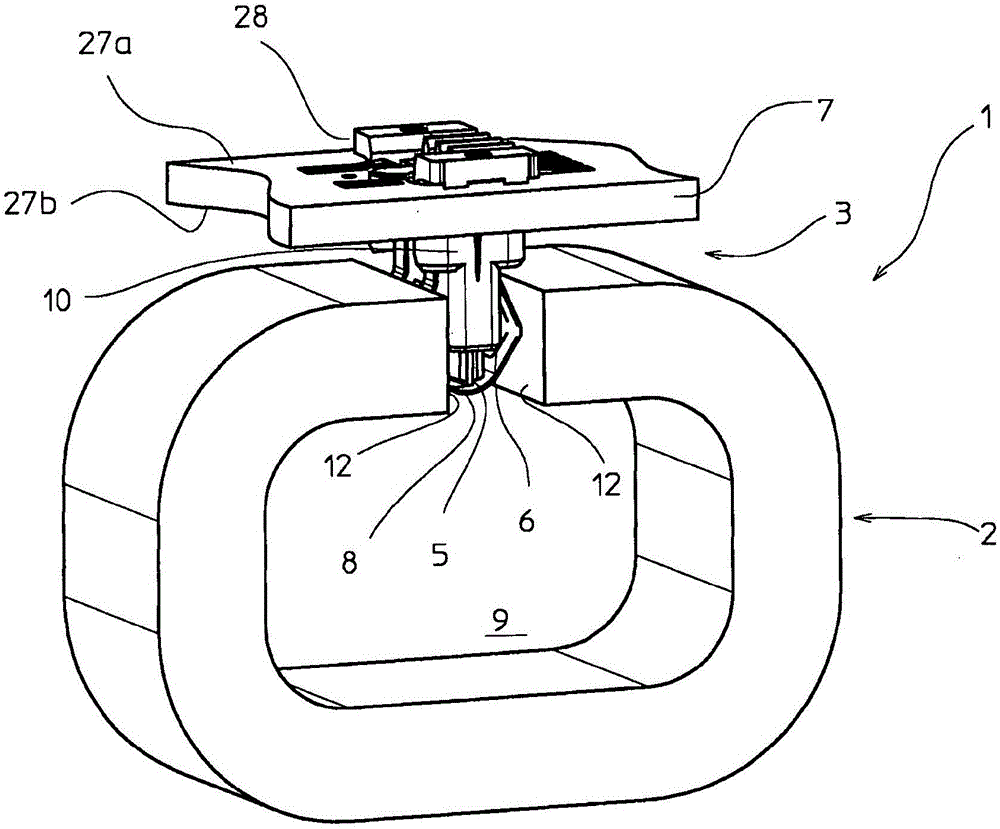

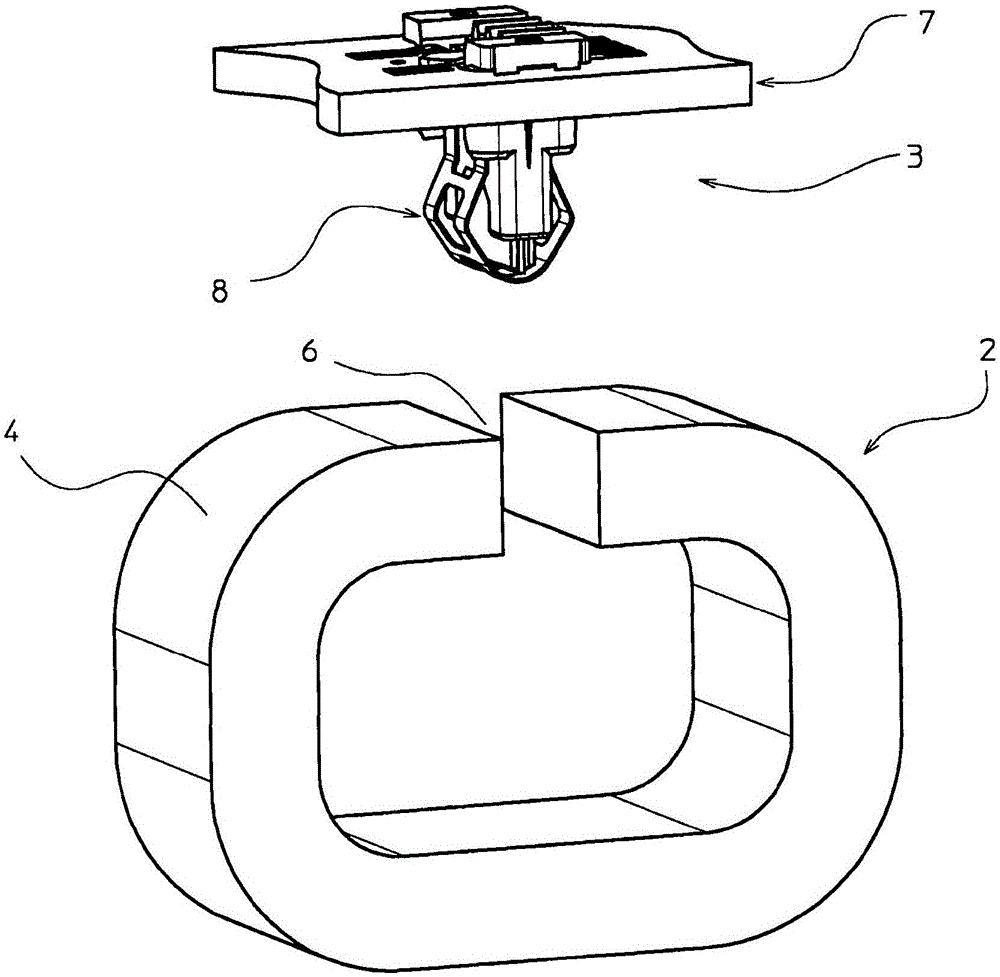

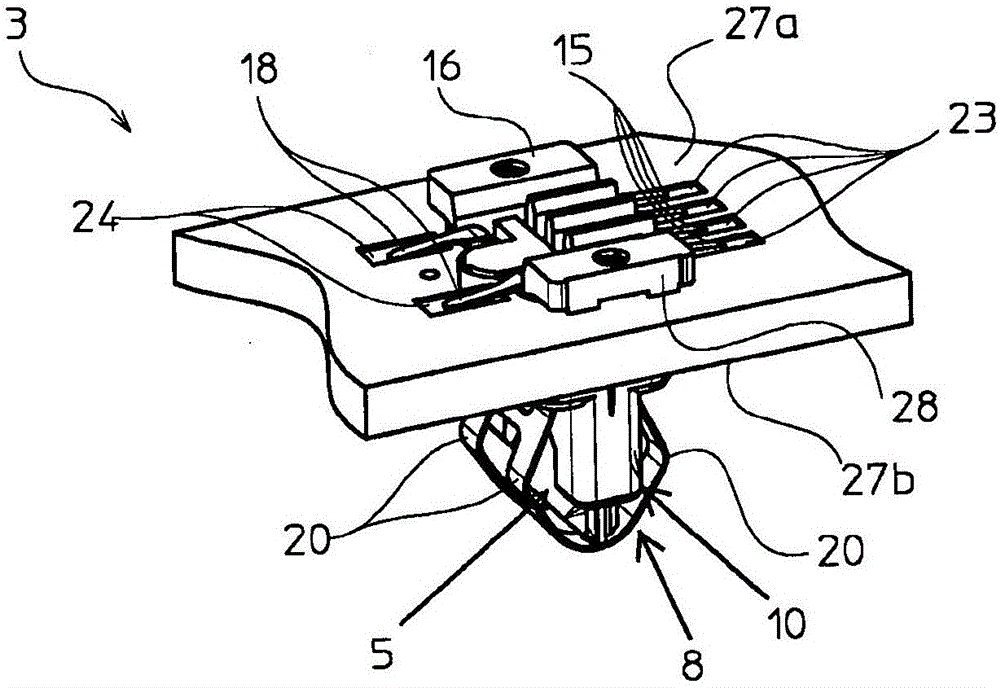

Magnetic field sensor arrangement and current transducer therewith

ActiveCN106104281AEasy to assembleHigh permeabilityMagnetic sensor packagingCurrent measurements onlyMagnetic coreElectricity

A magnetic field sensor arrangement is disclosed and is used for positioning in a gap formed between end faces (12) of a magnetic core (4). The magnetic field sensor arrangement comprises a magnetic field detector (5), a housing (10), and a grounding device (8), the magnetic field sensor and grounding device being mounted to the housing. The grounding device comprises at least one contact (20) elastically supported and configured for electrical contact with the magnetic core. The elastically supported contact is mounted adjacent a sensing portion of the magnetic field sensor and configured for insertion in the magnetic circuit core gap such that the contact elastically biases against the end face of the magnetic core.

Owner:莱姆电子(中国)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com