Method for preparing chitosan/ZSM-5 molecular compound film

A technology of ZSM-5 and chitosan, which is applied in the field of preparation of chitosan/molecular sieve composite membranes, can solve the problems of unreachable permeability and separation performance to be improved, and achieve good pervaporation separation performance and easy reaction modification , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

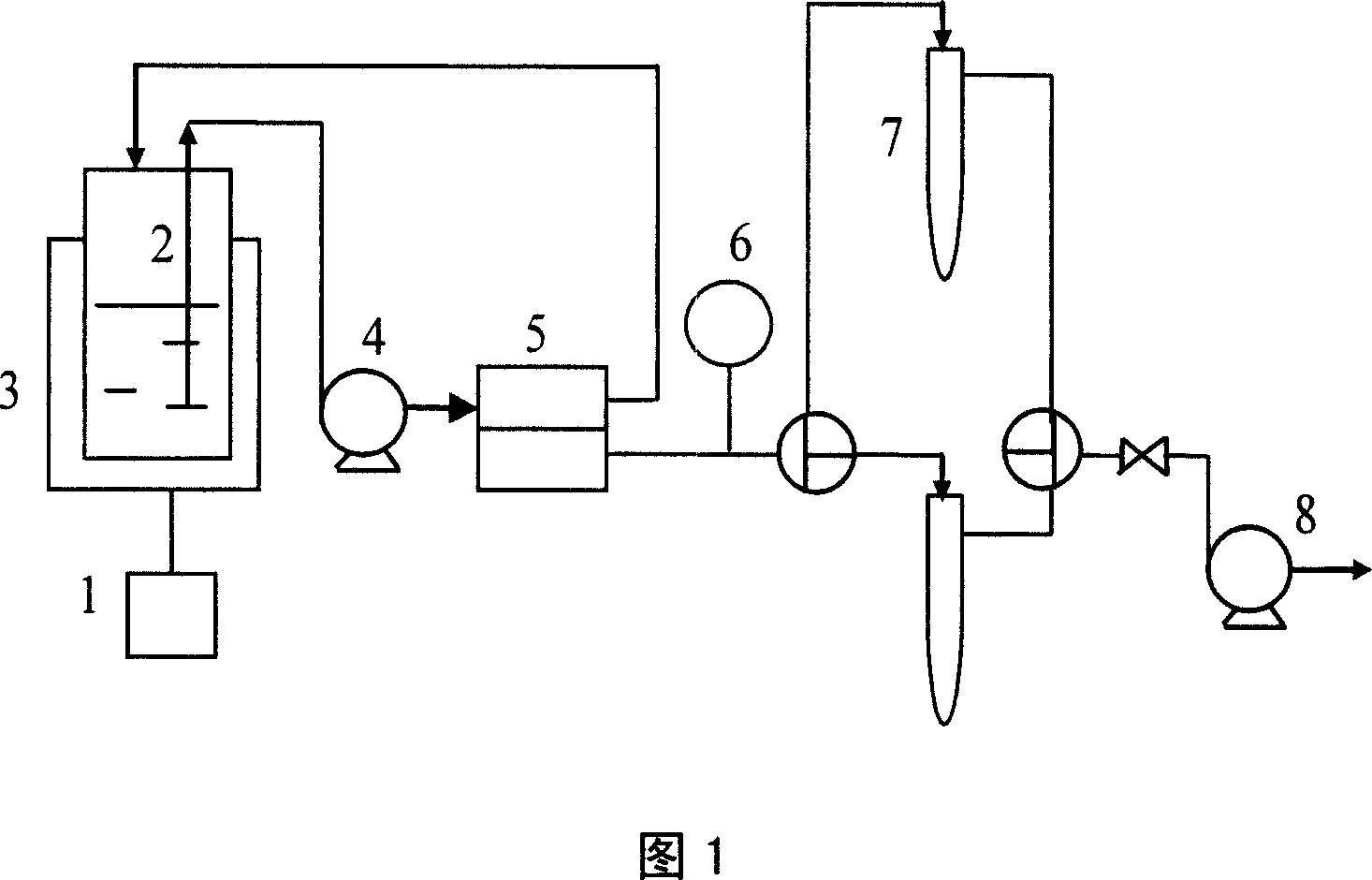

Method used

Image

Examples

Embodiment 1

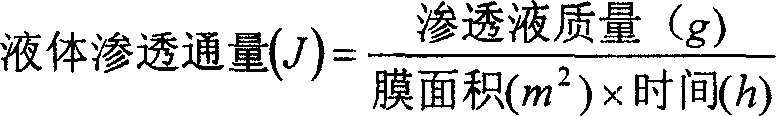

[0033] Accurately weigh 1.5g CS (molecular weight: 200,000, degree of deacetylation: 75%-85%) and dissolve it in 2% acetic acid aqueous solution at 25°C, stir evenly to prepare a 1.5wt% CS solution. Add 0.013g (5% of the mass of CS in the film) ZSM-5 molecular sieve into 17g of 1.5wt% CS solution that has been weighed, stir until the solution is evenly clarified, vacuumize and degas, and then cast the film The solution was poured on a clean glass plate, and after the solvent evaporated, the film was peeled off from the glass plate to obtain a CS / ZSM-5 composite film containing 5% ZSM-5 molecular sieve.

[0034] The membrane is pervaporated to separate methanol / DMC azeotrope (methanol 70wt%, DMC30wt%), the raw material side maintains normal pressure, the permeate side is vacuumed, the pressure on the downstream side is 2 h), separation coefficient 4.47, pervaporation separation index (PSI value) 1707.1g / (m 2 h).

Embodiment 2

[0036] Accurately weigh 1.5g CS (molecular weight: 500,000, degree of deacetylation: 75%-85%) and dissolve it in 2% acetic acid aqueous solution at 25°C, stir evenly to prepare a 1wt% CS solution. Add 0.025g (10% of the mass of CS in the film) ZSM-5 molecular sieve into the 25g 1wt% CS solution that has been weighed, stir until the solution is evenly clarified, vacuumize and degas, and then pour the casting solution Put it on a clean glass plate, and after the solvent volatilizes, peel off the film from the glass plate to obtain a CS / ZSM-5 composite film containing 10% ZSM-5 molecular sieve.

[0037] The membrane is pervaporated to separate methanol / DMC azeotrope (methanol 70wt%, DMC30wt%), the raw material side maintains normal pressure, the permeate side is vacuumed, the downstream pressure is 2h), separation coefficient 3.63, pervaporation separation index (PSI value) 1643.0g / (m 2 h).

Embodiment 3

[0039] Accurately weigh 1.5g CS (molecular weight: 200,000, degree of deacetylation: 75%-85%) and dissolve it in 2% acetic acid aqueous solution at 25°C, stir evenly to prepare a 1.5wt% CS solution. Add 0.039g (15% of the mass of CS in the film) ZSM-5 molecular sieve into 17g of 1.5wt% CS solution that has been weighed, stir until the solution is evenly clarified, vacuumize and defoam, and then cast the film The solution was poured on a clean glass plate, and after the solvent evaporated, the film was peeled off from the glass plate to obtain a CS / ZSM-5 composite film containing 15% ZSM-5 molecular sieve.

[0040] The membrane is pervaporated to separate methanol / DMC azeotrope (methanol 70wt%, DMC30wt%), the raw material side maintains normal pressure, the permeate side is vacuumed, the downstream pressure is 2 h), separation factor 2.81, pervaporation separation index (PSI value) 1250.5g / (m 2 h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com