Magnetic dielectric resin composition and applications thereof

A resin composition and magnetic medium technology, applied in the field of copper clad laminates, can solve the problems of poor insulation performance, flame retardant effect, poor mechanical strength, small magnetic permeability coverage, etc., and achieve good insulation, low dielectric loss, bending high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of magnetic and dielectric resin composition of the present invention is:

[0033] The resin is dissolved in a solvent, an initiator is added, and then a magnetic filler and a nonmagnetic filler are added, and mixed at room temperature to obtain a glue solution, that is, the magnetic and dielectric resin composition of the present invention.

[0034] The reinforcing material is impregnated with the above glue solution, and then baked in an oven at 155°C for 5 minutes to be cured to stage B to obtain a reinforcing material prepreg.

[0035] The produced prepreg is placed between copper foils, laminated and cured in a press at 210°C to obtain a cured product, and the dielectric constant, magnetic permeability, resistivity and other properties are measured.

[0036] The preparation process of the magnetic filler of the present invention is as follows: a certain proportion of zinc oxide, iron oxide, nickel oxide, magnesium oxide and other substances a...

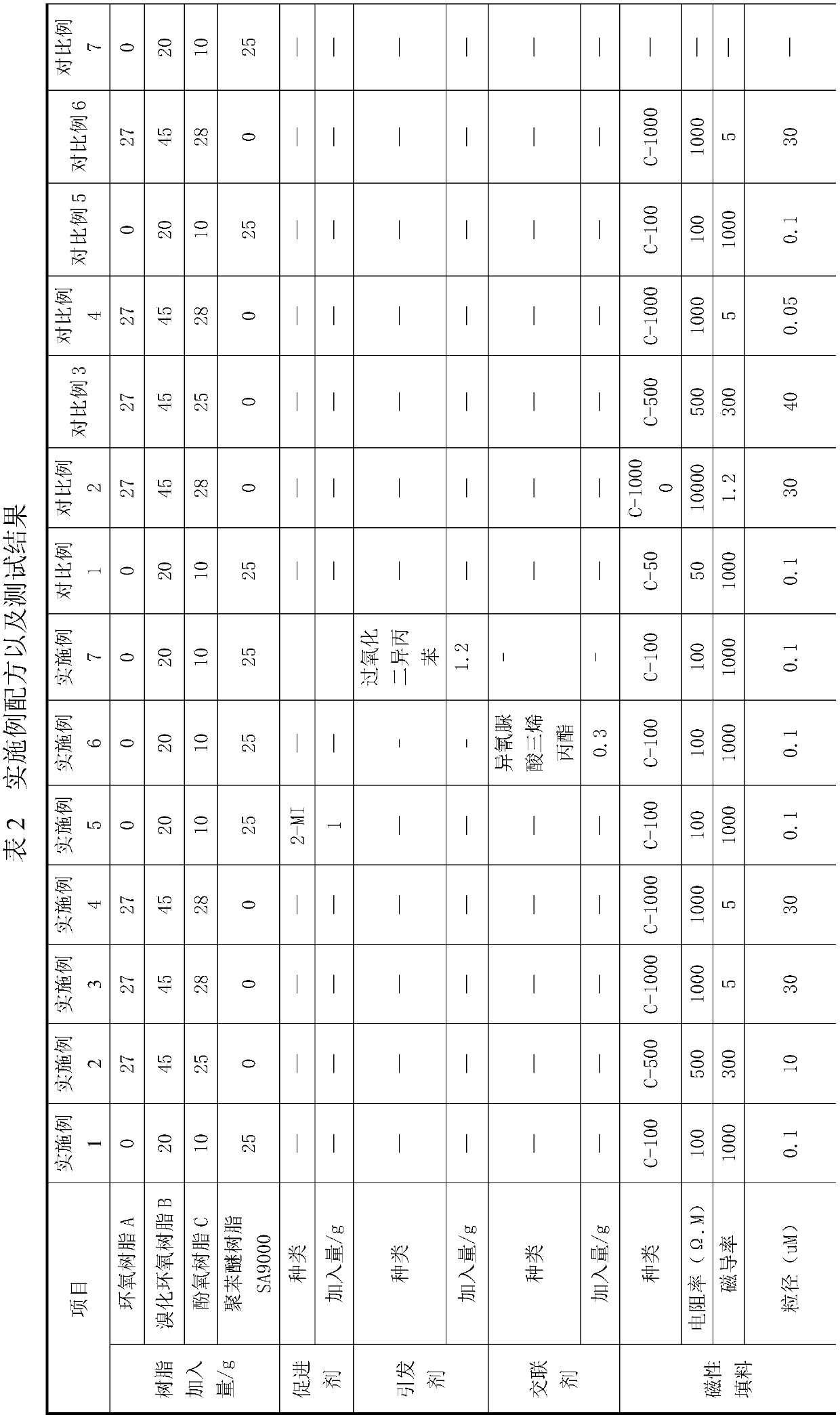

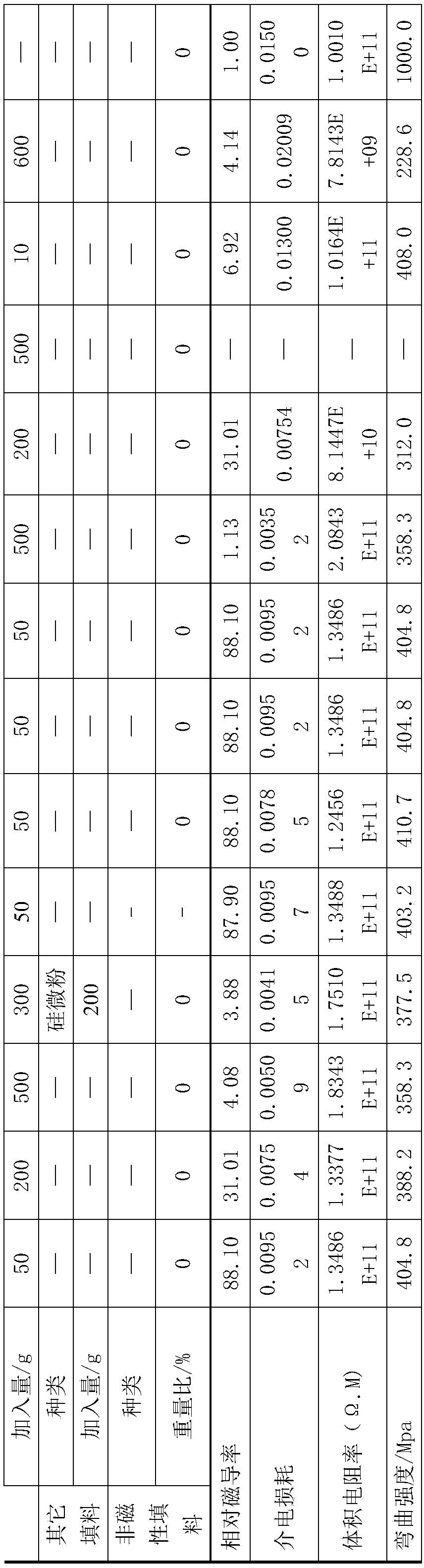

Embodiment 1

[0048] Dissolve 20g of brominated epoxy resin B, 10g of phenoxy resin C, and 25g of polyphenylene ether resin SA9000 in the solvent ethylene glycol methyl ether; then add magnetic filler, the type of magnetic filler is C-100, and the resistivity is 100Ω .M, a magnetic permeability of 1000, a particle size of 0.1uM, and an addition amount of 50g; mixed at room temperature to obtain a glue solution, that is, a magnetic-dielectric resin composition.

[0049] The reinforcing material is used to impregnate the above glue solution, and then baked in an oven at 155°C for 5 minutes to cure to stage B to obtain a reinforcing material prepreg. The produced prepreg is placed between copper foils, laminated and cured in a press at 210°C, and the dielectric constant, magnetic permeability, resistivity and other properties are measured after the copper clad laminate is obtained. The specific performance test results are shown in Table 2 .

Embodiment 2

[0051] The difference between this example and Example 1 is that the preparation raw materials include: 27g epoxy resin A, 45g brominated epoxy resin B, 25g phenoxy resin C, the type of magnetic filler is C-500, and the resistivity is 500Ω.M , The magnetic permeability is 300, the particle size is 10uM, and the addition amount is 200g.

[0052] The magnetic and dielectric resin composition prepared in this example was used to prepare a copper clad laminate, and the properties of the prepared copper clad laminate are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com