Magnetic field sensor arrangement and current transducer therewith

A magnetic field sensor and magnetic field technology, which is applied to the outer casing of the magnetic sensor, the measuring device, and the current-only measurement, can solve the problems of affecting the magnetic properties of the material, reducing the magnetic properties of the magnetic circuit, and achieving easy assembly and high magnetic permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

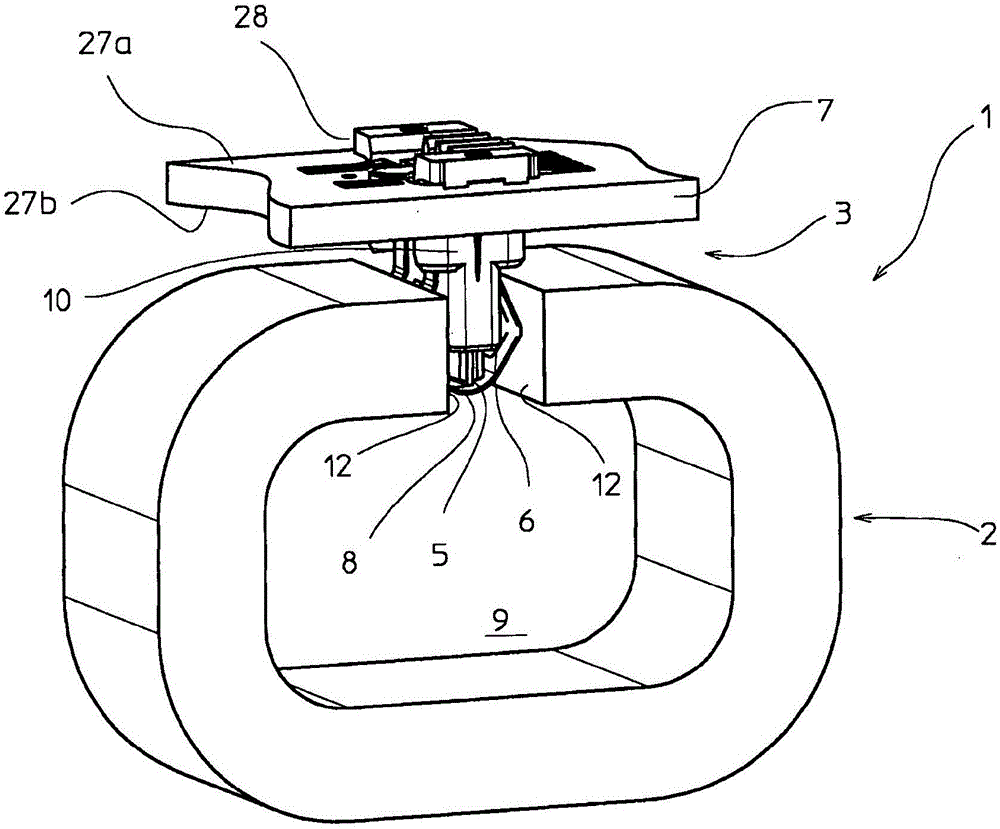

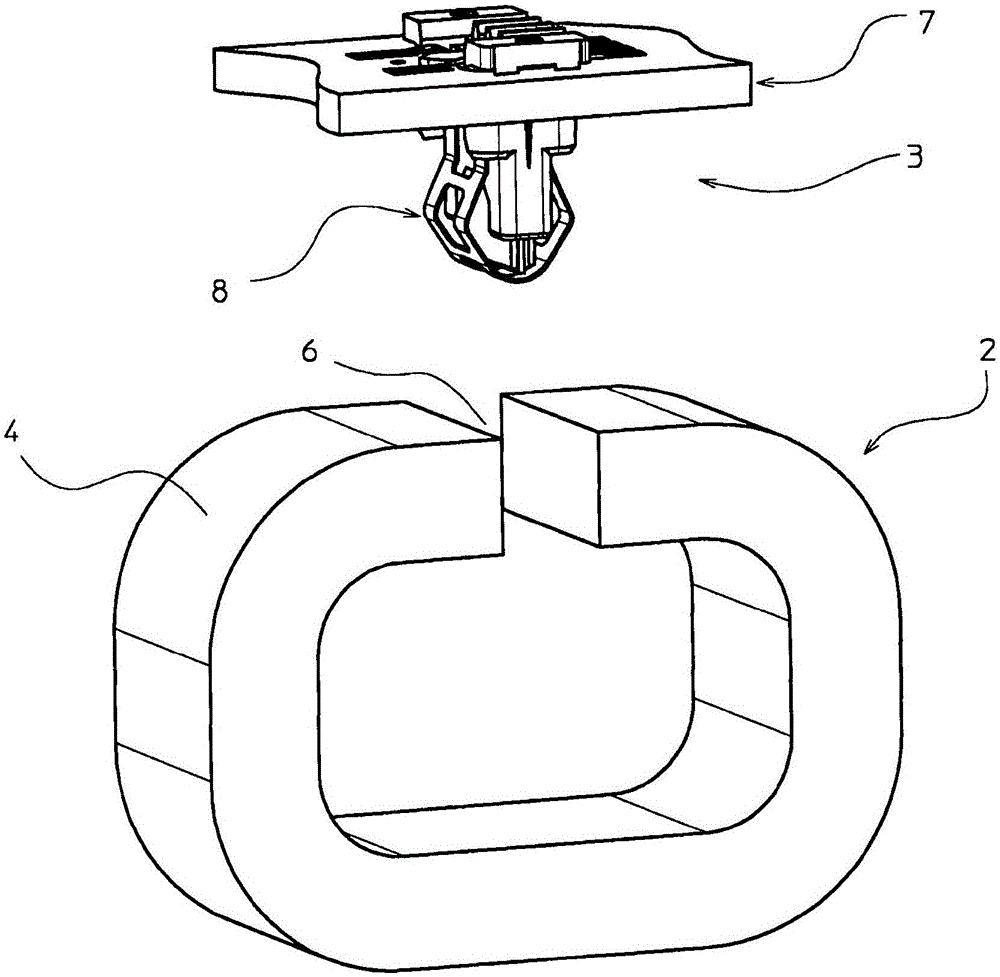

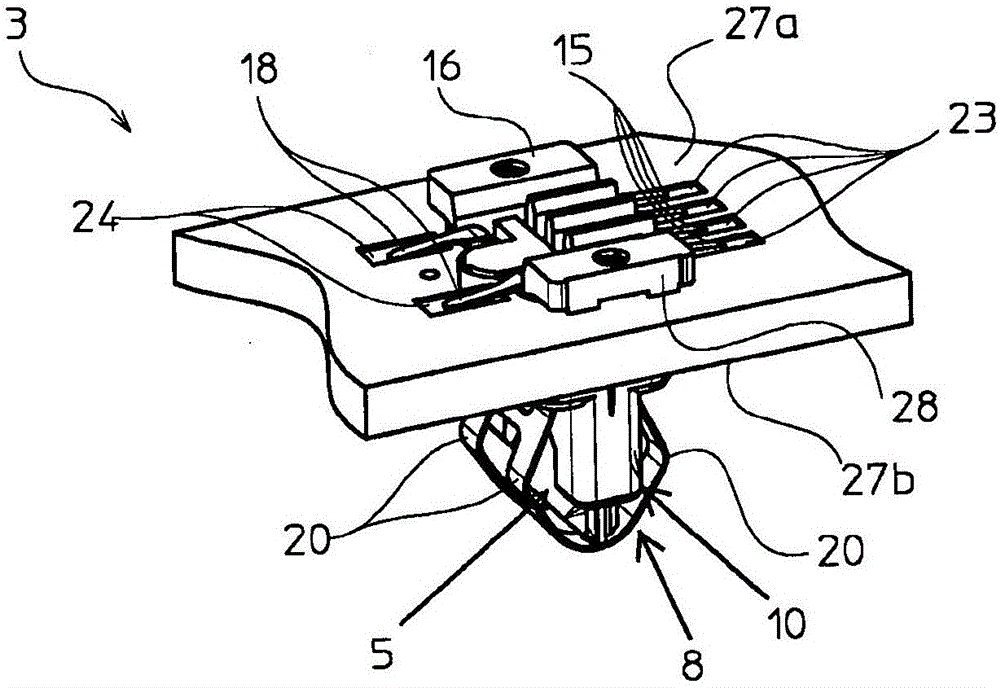

[0035] Referring to the drawings, a current converter 1 includes a magnetic circuit 2 and a magnetic field sensing device 3 . The magnetic circuit 2 comprises a toroidal core 4 with a gap 6 (often also referred to as an "air gap", although it may not be filled with air). A gap 6 is formed between opposite end faces 12 of the magnetic core 4 . The magnetic core 4 is made of a material with high magnetic permeability known in the art, for example, the material includes FeSi alloy or FeNi alloy. The central channel 9 of the magnetic core is configured to receive one or more primary conductors carrying one or more currents to be measured flowing therethrough.

[0036] In the illustrated embodiment, the magnetic field sensing device 3 includes a magnetic field detector 5 , a circuit board 7 , a housing 10 and a grounding device 8 . In a variation (not shown), the magnetic field sensing device may be constructed without a circuit board, but instead includes a connector to an exter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com