Method for preparing magnetic shielding sheet for wireless charging and NFC

A magnetic shielding sheet and wireless charging technology, which is applied in the fields of magnetic field/electric field shielding, inductor/transformer/magnet manufacturing, shielding materials, etc., can solve the problem of high magnetic permeability loss of magnetic sheet, unsatisfactory fragmentation effect, and eddy current effect of magnetic sheet Large and other problems, to achieve the effect of reducing production cost, high appearance yield and performance yield, and low magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

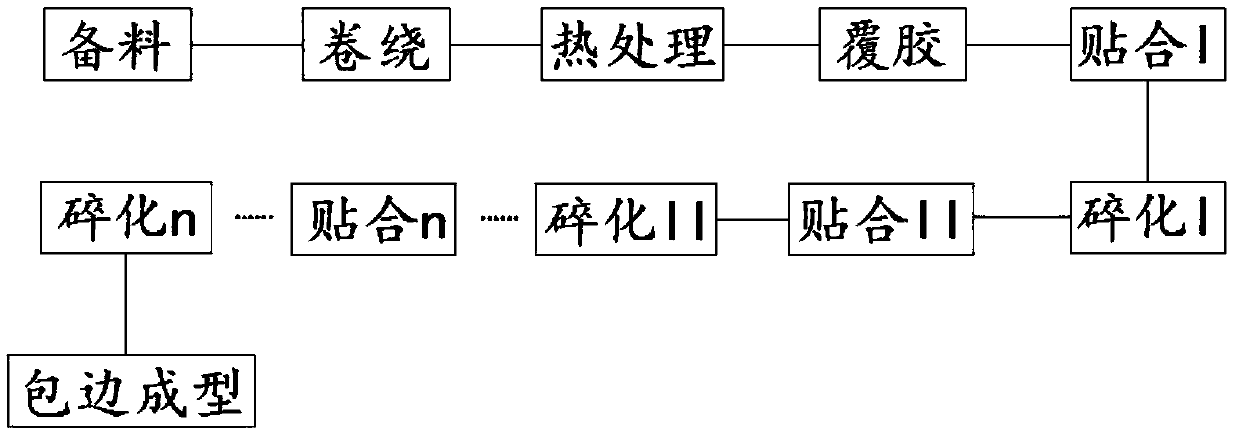

[0038] see figure 1 , the present invention provides a kind of preparation method for the magnetic shield sheet on wireless charging and NFC, and this method comprises the following steps:

[0039] 1) providing the magnetic material required for making the magnetic shielding sheet, and winding the magnetic material;

[0040] 2) heat-treating the magnetic material after winding;

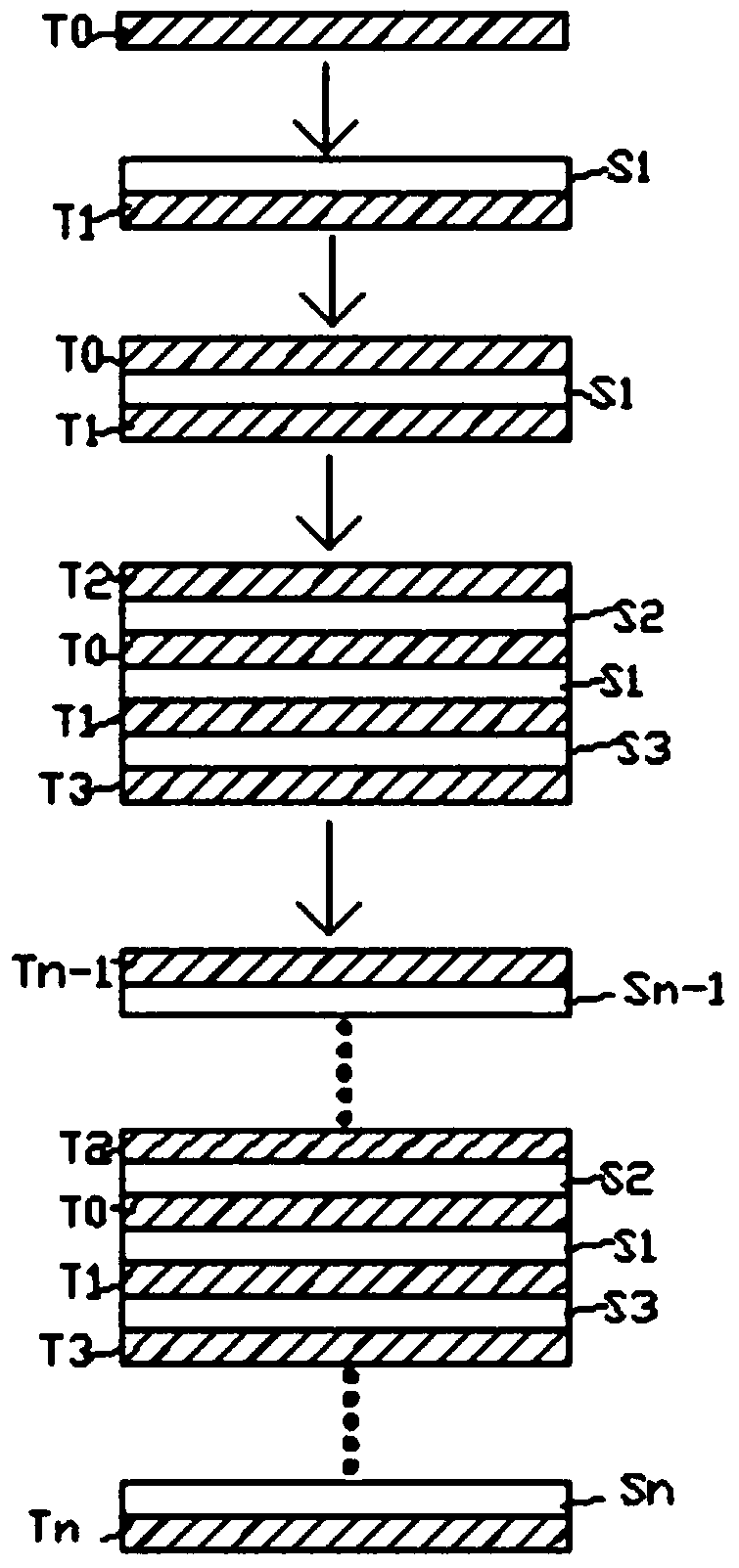

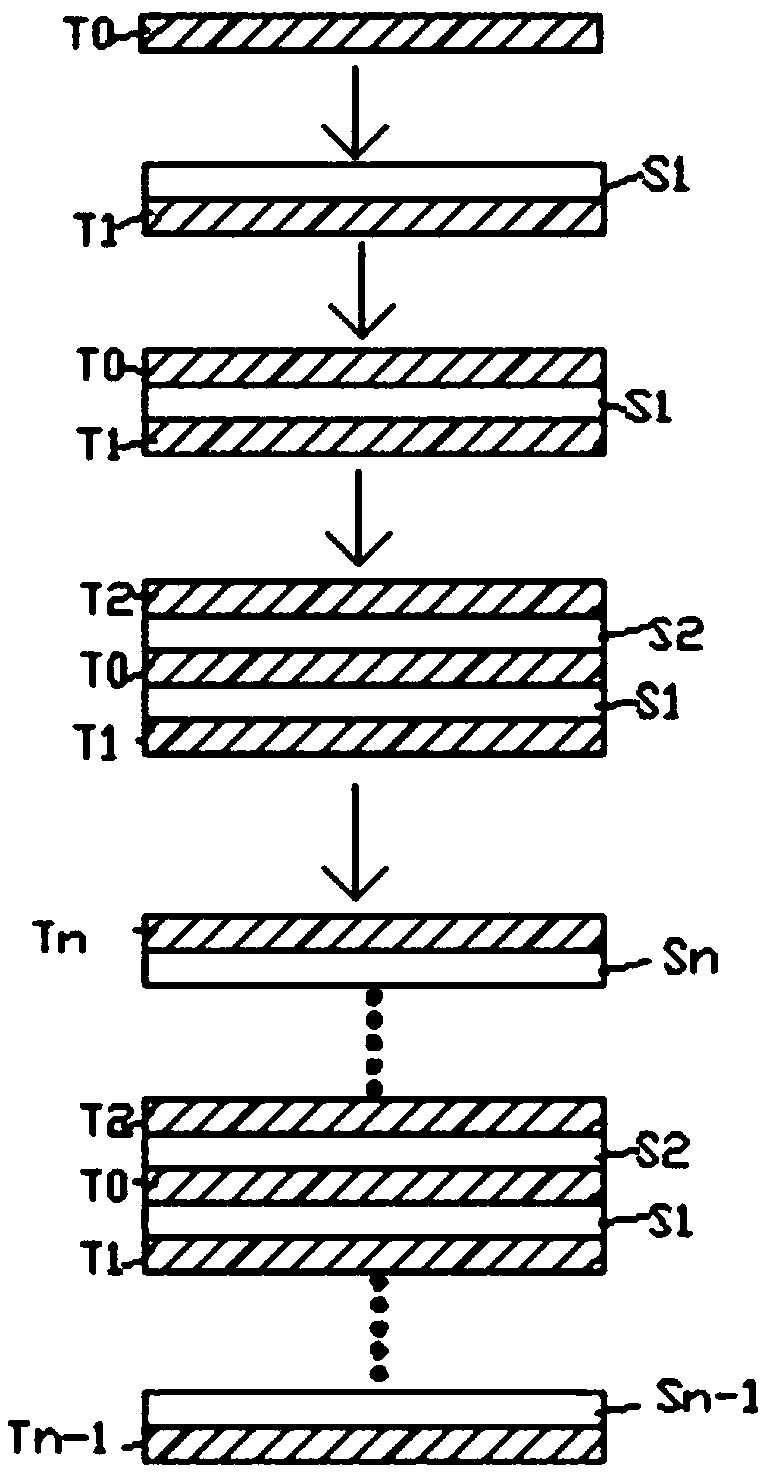

[0041] 3) taking at least one layer of the heat-treated magnetic material and performing one-side glue coating;

[0042] 4) pasting the two magnetic materials after the one-sided glue-coating process;

[0043] 5) crushing the bonded magnetic material;

[0044] 6) Carrying out secondary lamination of the magnetic material after crushing;

[0045] 7) Carrying out secondary crushing treatment on the magnetic material bonded for the second time, and so on, until the performance of the finally obtained magnetic sheet meets the requirements;

[0046] 8) Die-cut and edge-wrap the finally obtained magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com