Patents

Literature

255 results about "Mechanical milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

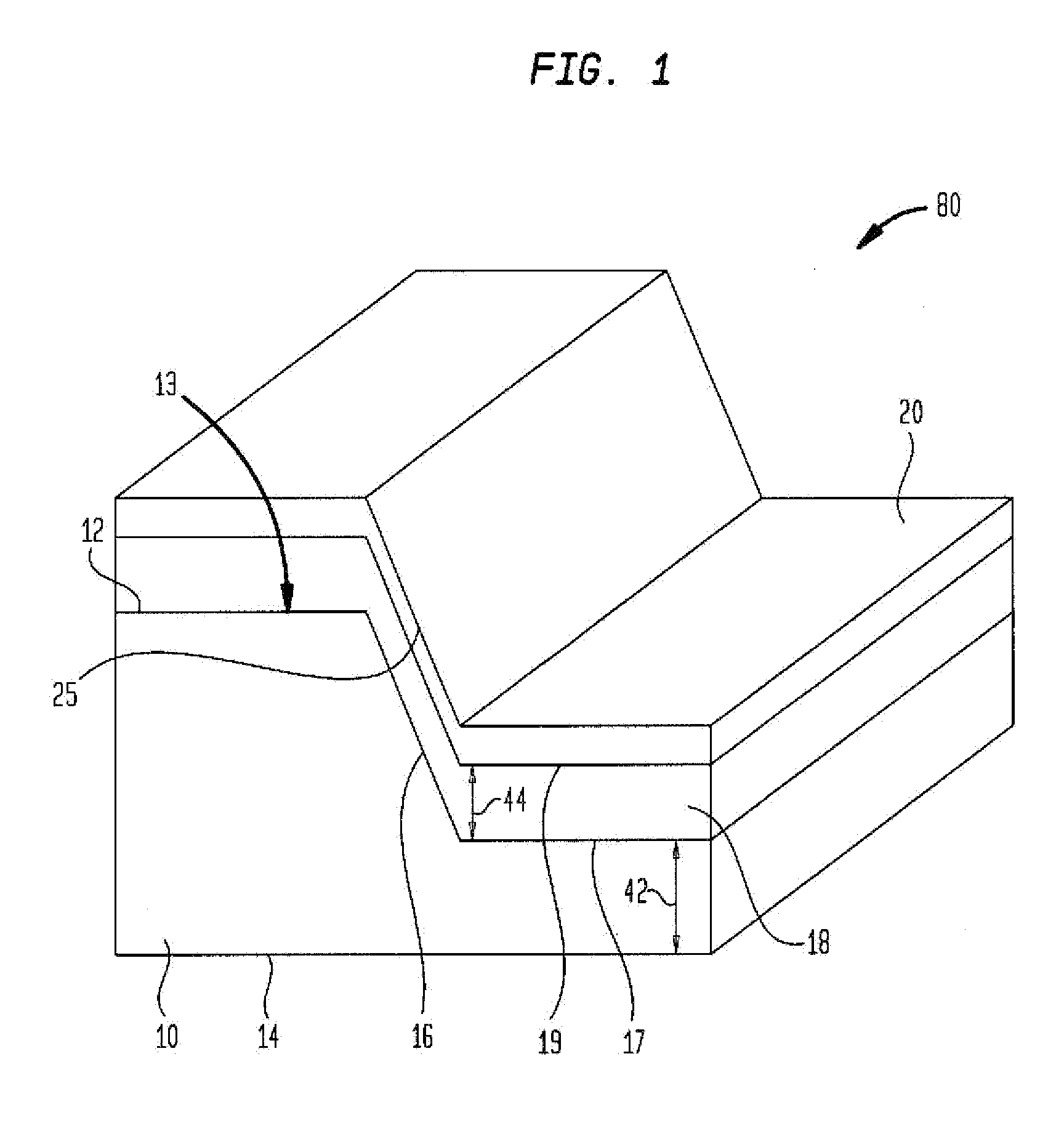

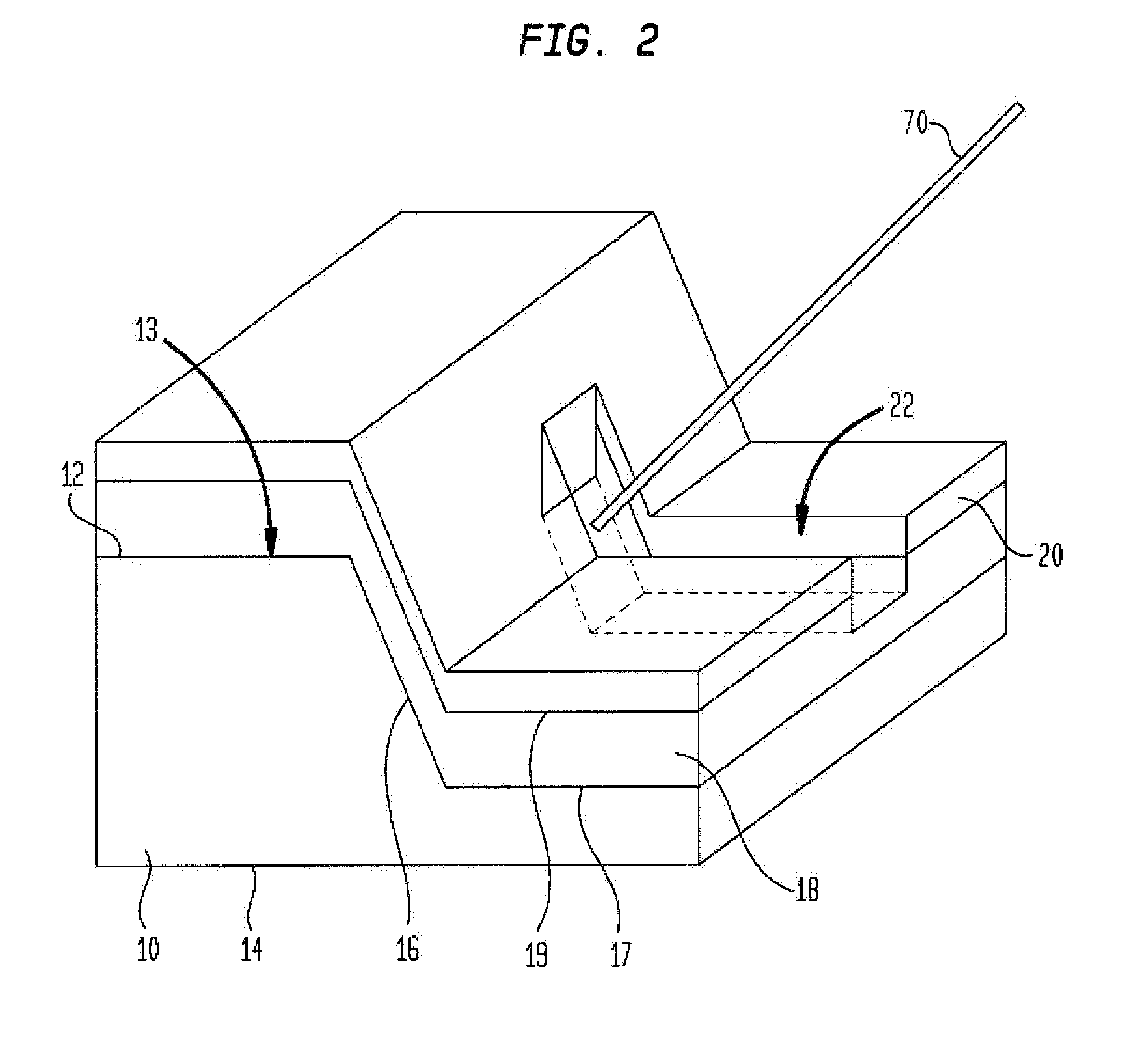

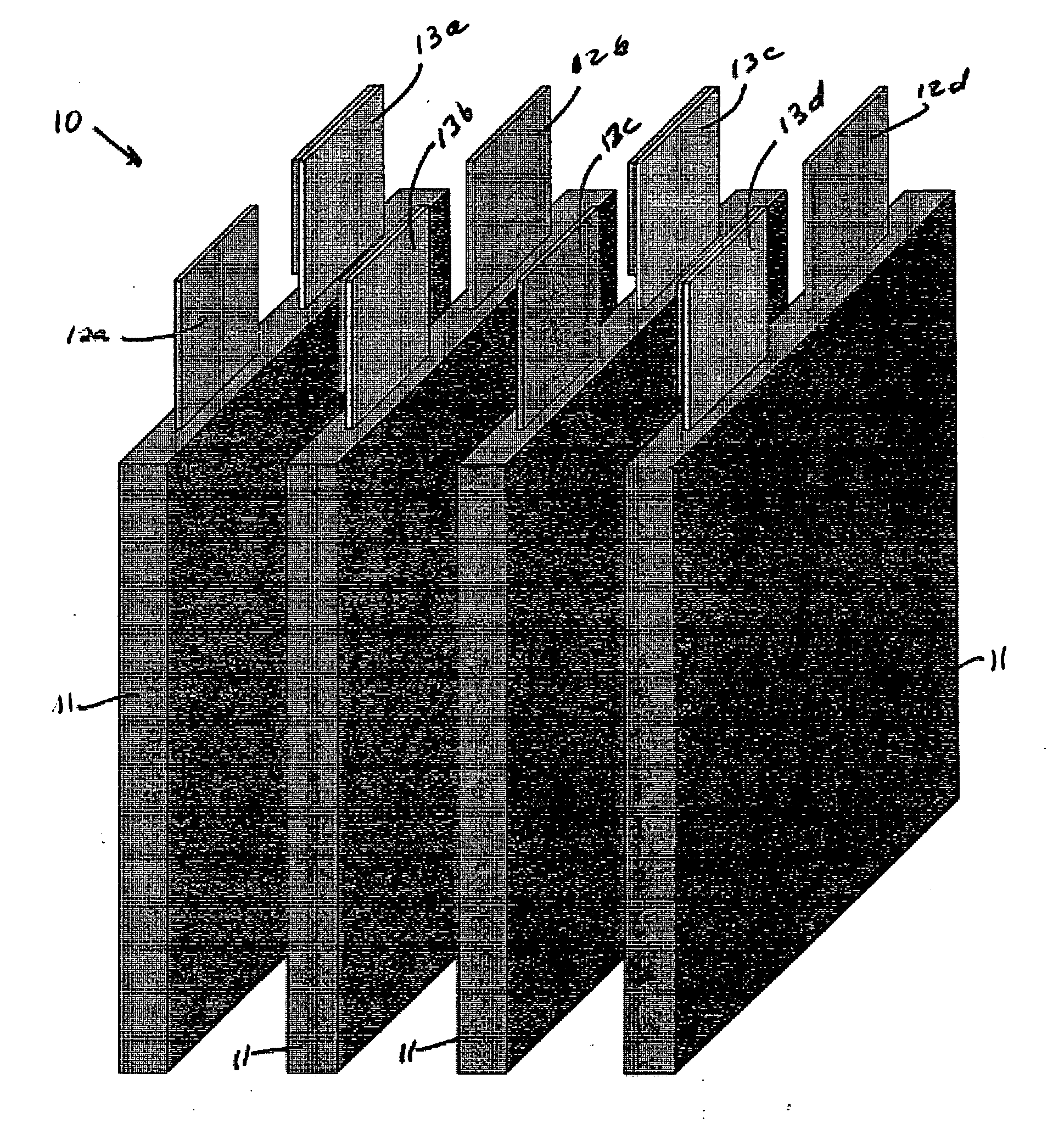

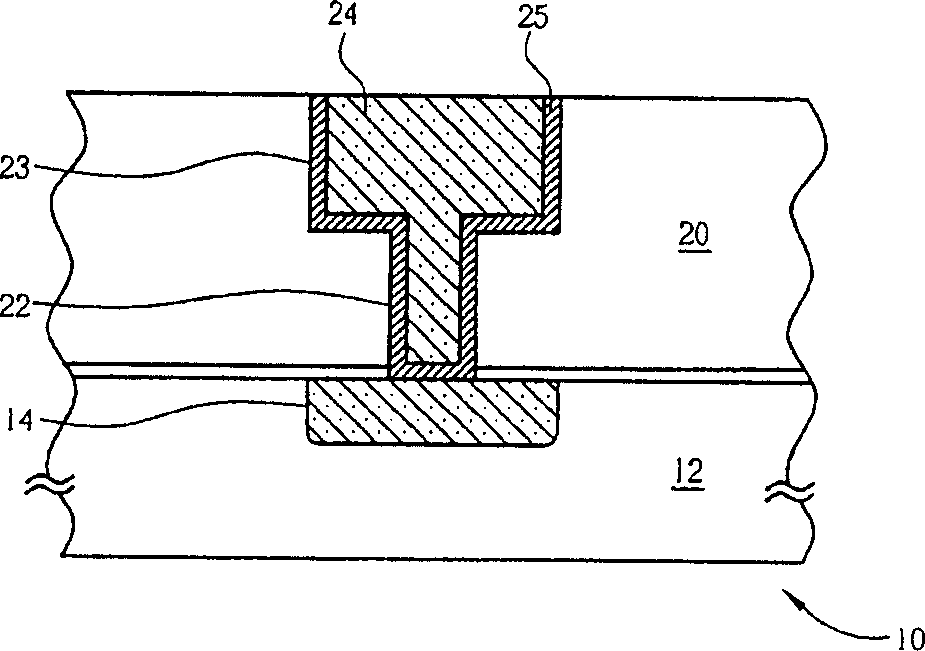

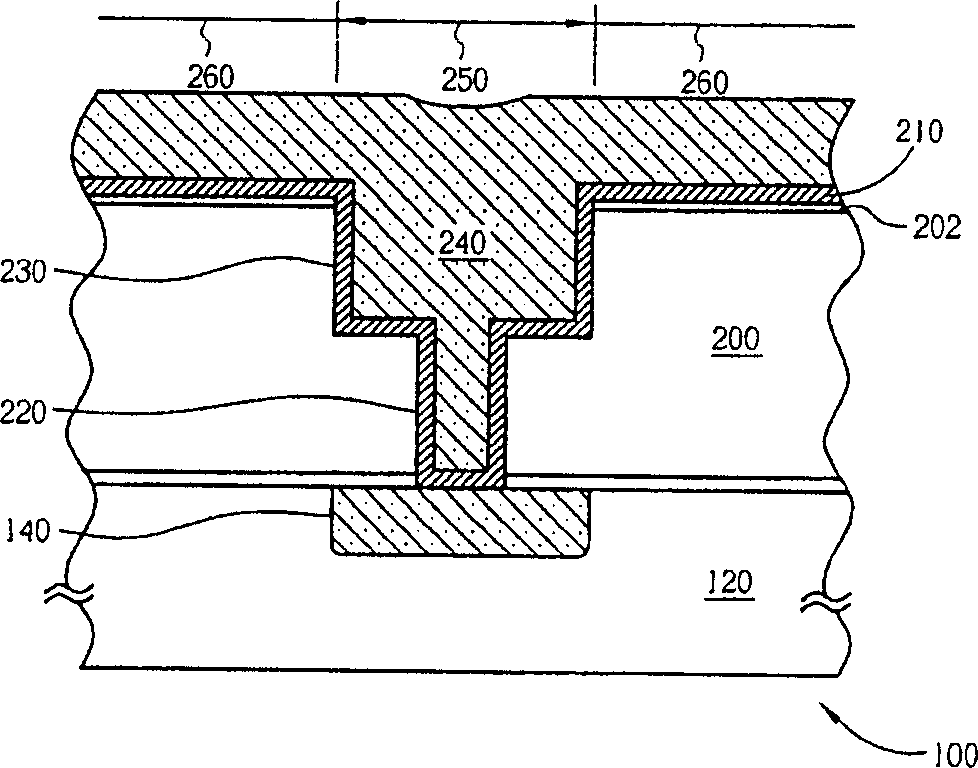

Non-lithographic formation of three-dimensional conductive elements

ActiveUS20120018894A1Semiconductor/solid-state device detailsSolid-state devicesMechanical millingElectroplating

A method of forming a conductive element on a substrate and the resulting assembly are provided. The method includes forming a groove in a sacrificial layer overlying a dielectric region disposed on a substrate. The groove preferably extends along a sloped surface of the substrate. The sacrificial layer is preferably removed by a non-photolithographic method, such as ablating with a laser, mechanical milling, or sandblasting. A conductive element is formed in the groove. The grooves may be formed. The grooves and conductive elements may be formed along any surface of the substrate, including within trenches and vias formed therein, and may connect to conductive pads on the front and / or rear surface of the substrate. The conductive elements are preferably formed by plating and may or may not conform to the surface of the substrate.

Owner:TESSERA INC

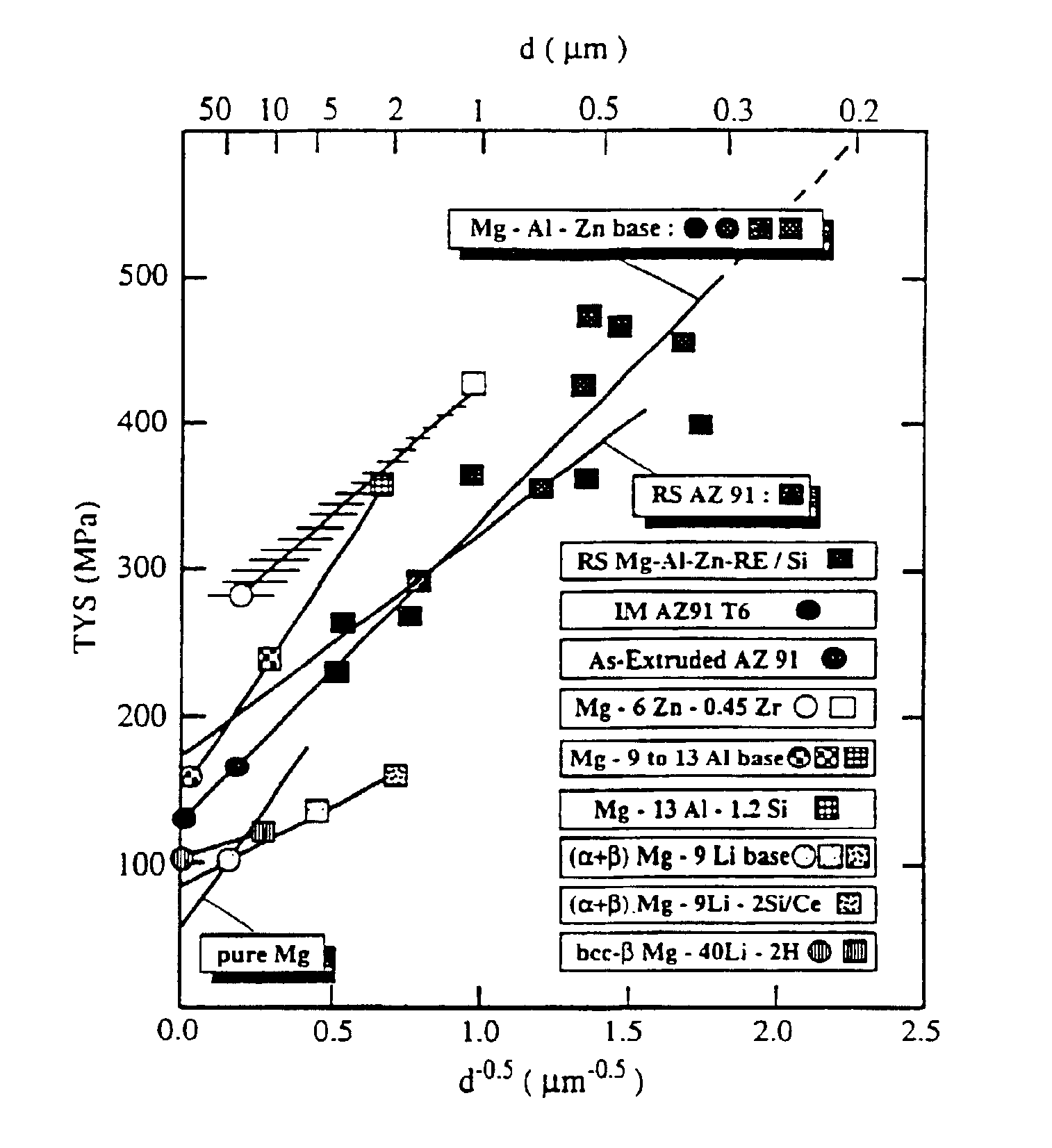

Selected processing for non-equilibrium light alloys and products

InactiveUS6908516B2Reduce resistanceMultiplies numberVacuum evaporation coatingSputtering coatingGas phaseMaterials science

A new class of light or reactive elements and monophase α′-matrix magnesium- and aluminum-based alloys with superior engineering properties, for the latter being based on a homogeneous solute distribution or a corrosion-resistant and metallic shiny surface withstanding aqueous and saline environments and resulting from the control during synthesis of atomic structure over microstructure to net shape of the final product, said α′-matrix being retained upon conversion into a cast or wrought form. The manufacture of the materials relies on the control of deposition temperature and in-vacuum consolidation during vapor deposition, on maximized heat transfer or casting pressure during all-liquid processing and on controlled friction and shock power during solid state alloying using a mechanical milling technique. The alloy synthesis is followed by extrusion, rolling, forging, drawing and superplastic forming for which the conditions of mechanical working, thermal exposure and time to transfer corresponding metastable α′-matrix phases and microstructure into product form depend on thermal stability and transformation behavior at higher temperatures of said light alloy as well as on the defects inherent to a specific alloy synthesis employed. Alloying additions to the resulting α′-monophase matrix include 0.1 to 40 wt. % metalloids or light rare earth or early transition or simple or heavy rare earth metals or a combination thereof. The eventually more complex light alloys are designed to retain the low density and to improve damage tolerance of corresponding base metals and may include an artificial aging upon thermomechanical processing with or without solid solution heat and quench and annealing treatment for a controlled volume fraction and size of solid state precipitates to reinforce alloy film, layer or bulk and resulting surface qualities. Novel processes are employed to spur production and productivity for the new materials.

Owner:HEHMANN FRANZ

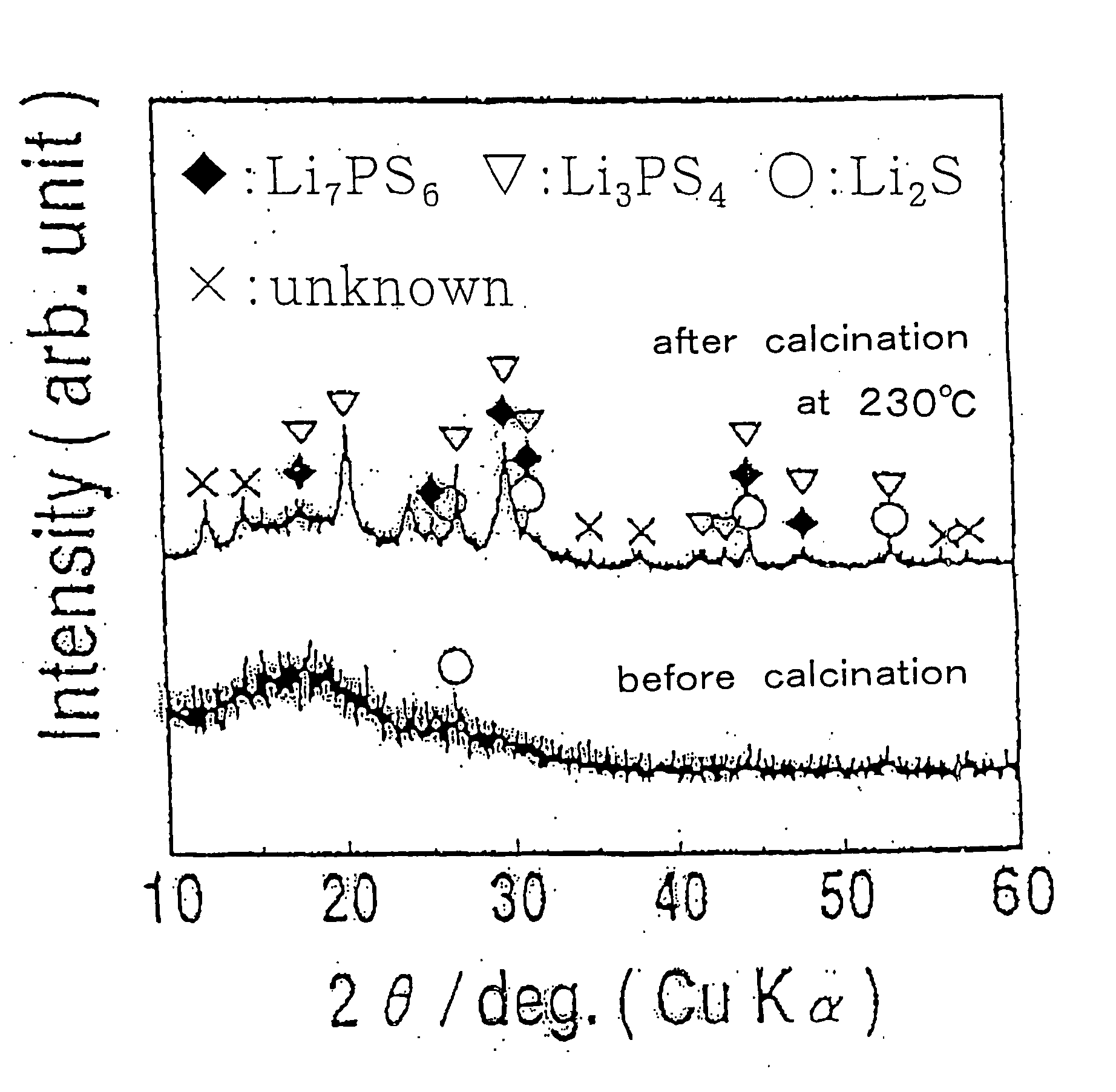

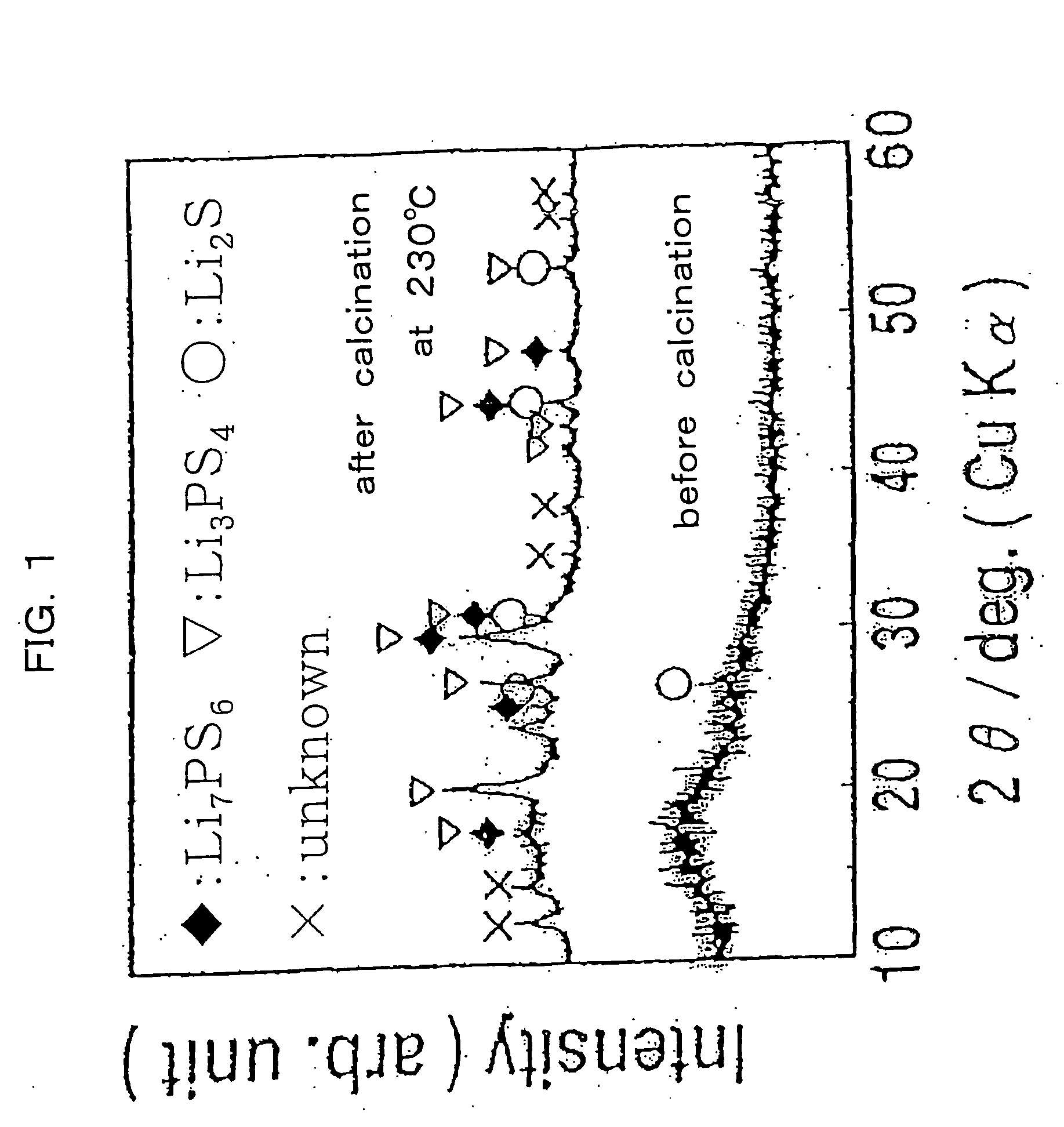

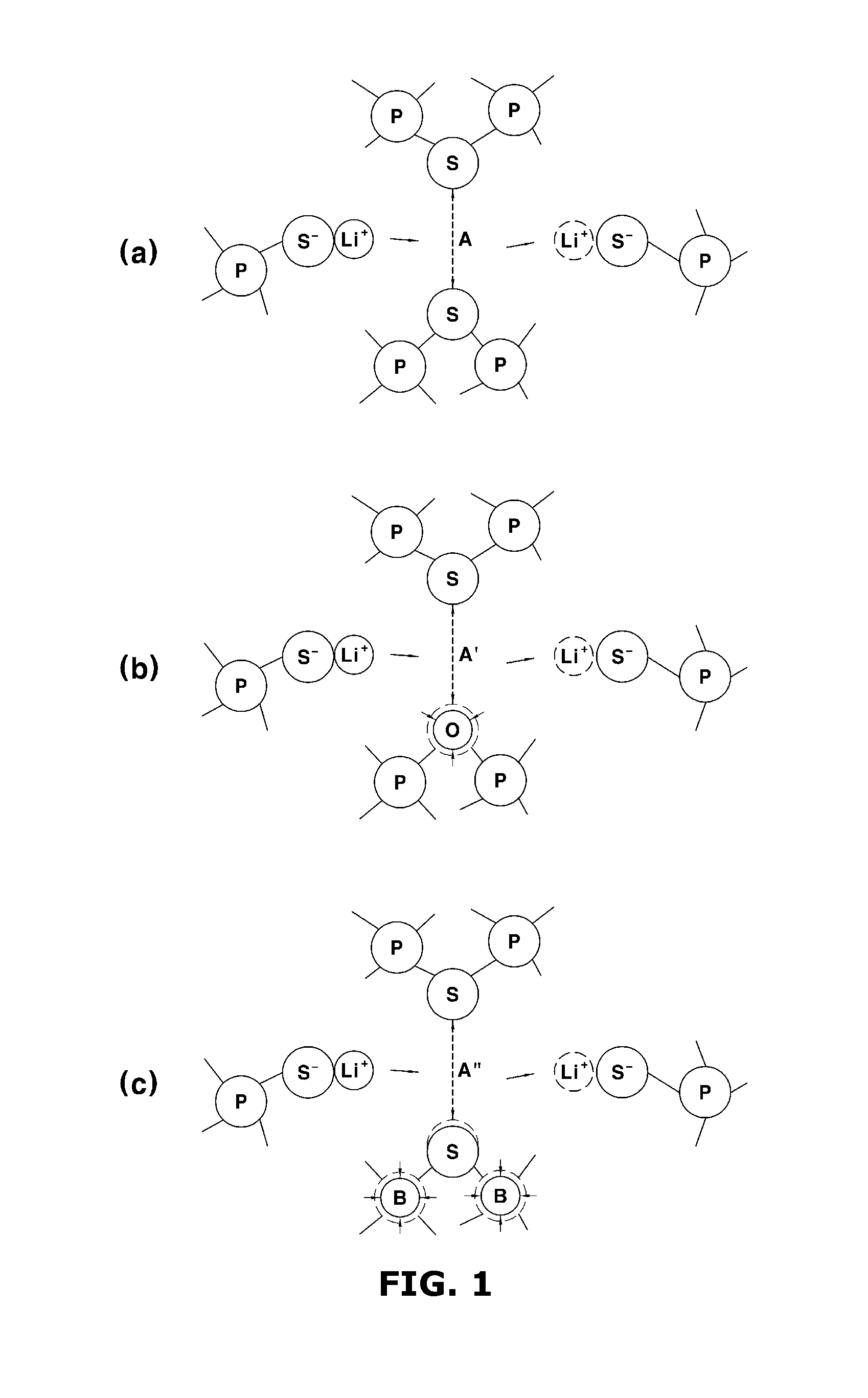

Method for producing sulfide glass or sulfide glass ceramic capable of conducing lithium ion, and whole solid type cell using said glass ceramic

InactiveUS20050107239A1Simple and convenient and easily availableSolid electrolytesConductive materialMetallic lithiumSulfur

The present invention relates to a process for producing sulfide glass or sulfide glass ceramic each capable of conducting a lithium ion, comprising subjecting metallic lithium, sulfur as a simple substance and phosphorus as a simple substance as starting raw materials, which constitute the sulfide glass and sulfide glass ceramic, to mechanical milling to thereby convert them into sulfide glass or sulfide glass ceramic; and a whole solid type cell using the above-mentioned sulfide glass ceramic as a solid electrolyte. According to the present invention, it is made possible to produce sulfide glass and sulfide glass ceramic which are each capable of conducting a lithium ion and which have high electroconductivity at room temperature by a simple and advantageous process from starting raw materials being easily available and inexpensive.

Owner:IDEMITSU KOSAN CO LTD +1

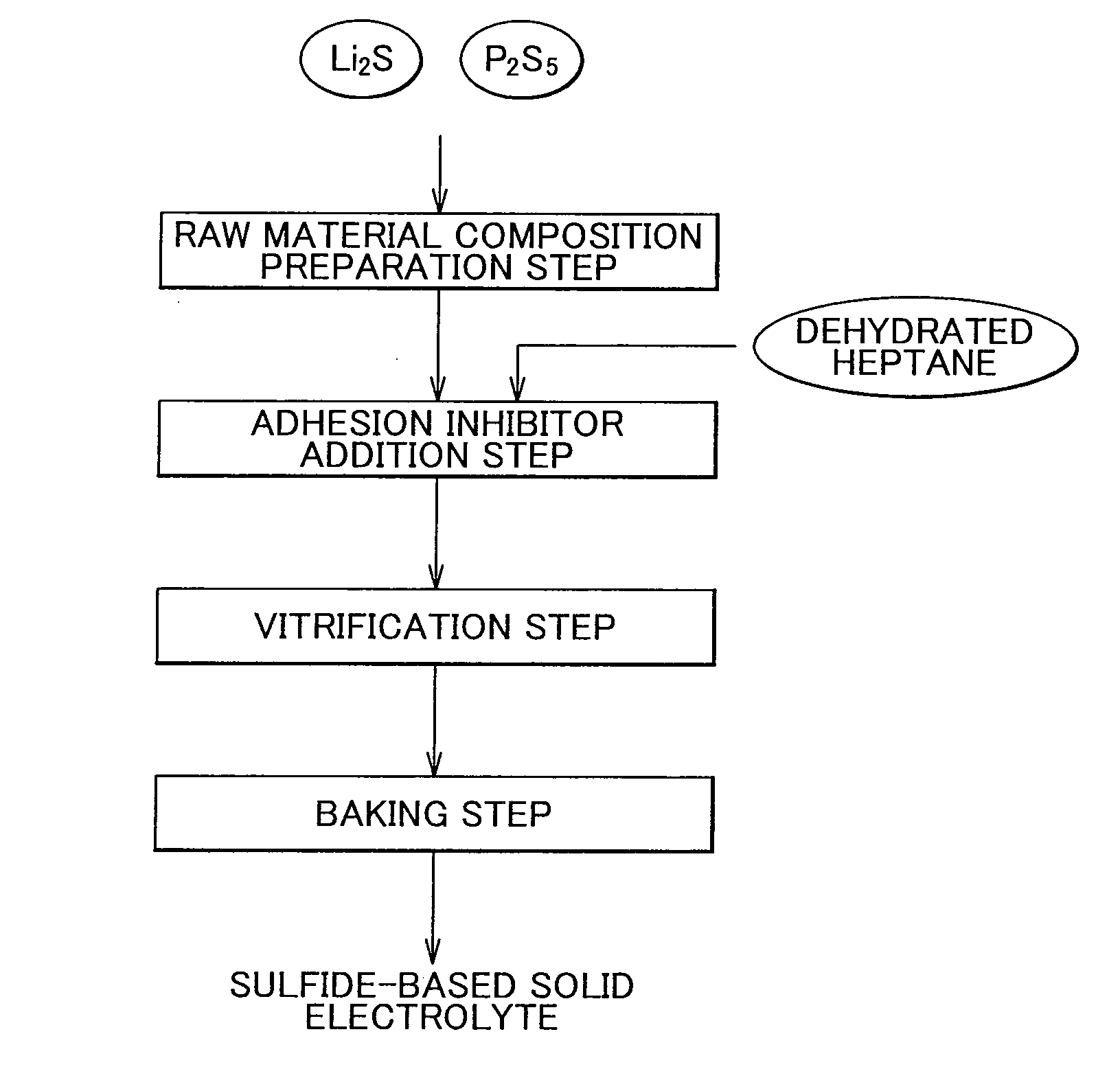

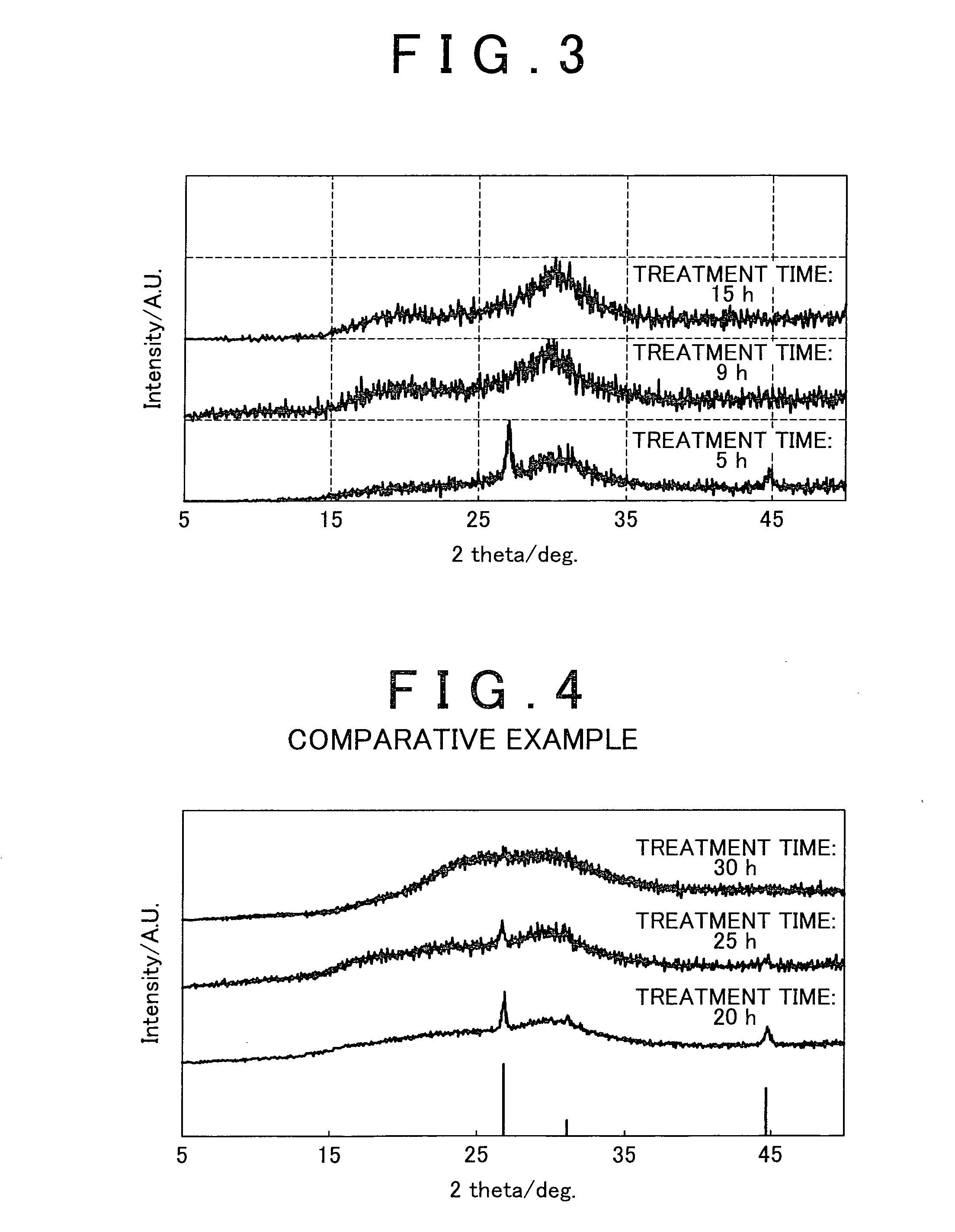

Process for producing sulfide-based solid electrolyte

ActiveUS20110108642A1Shorten the compositing timeImprove production efficiencyLi-accumulatorsCentrifugesVitrificationMechanical milling

The invention provides a process for producing a sulfide-based solid electrolyte, the process having: a raw material composition preparation step for preparing a raw material composition containing at least sulfur (S), an adhesion inhibitor addition step for adding to the raw material composition an adhesion inhibitor that inhibits formation of adhered substances including the unreacted raw material composition, on the inner surface of a milling pot during mechanical milling, and a vitrification step for synthesizing sulfide-based glass by carrying out mechanical milling on the raw material composition to which the adhesion inhibitor has been added.

Owner:TOYOTA JIDOSHA KK

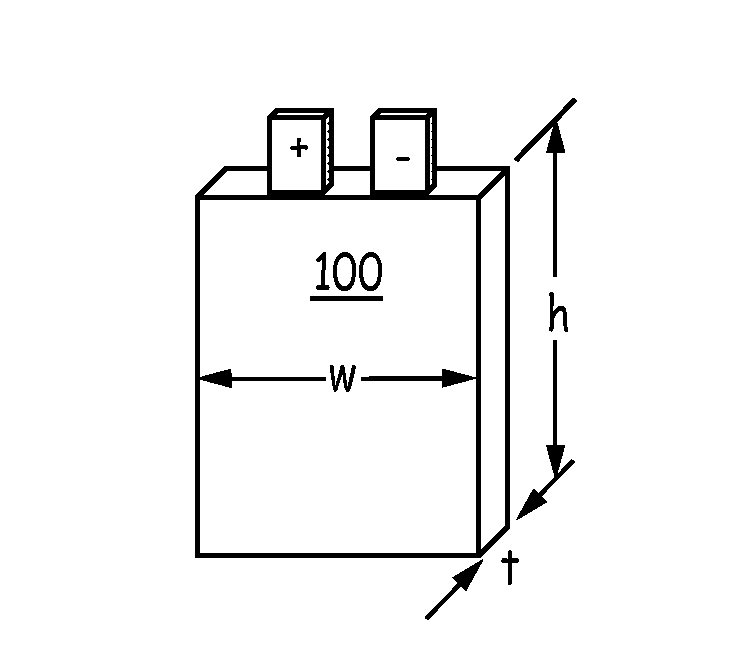

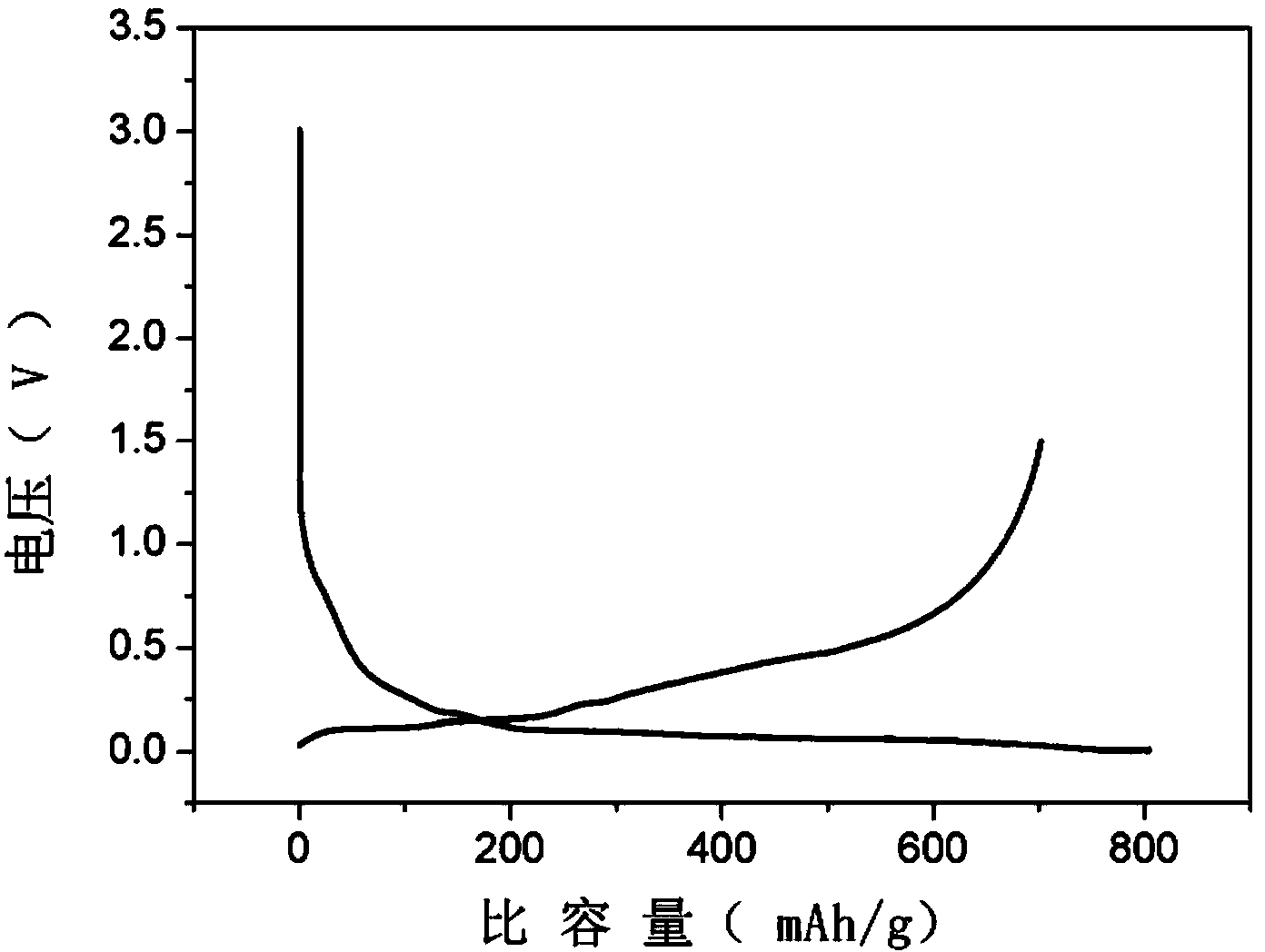

Low crystallinity silicon composite anode material for lithium ion battery

An electrode composition that includes the combination of a finely ground silicon mixture, a partially carbonized polymeric material, and a buffering agent is disclosed. The silicon mixture can be formed by mechanical milling of crystalline silicon to create amorphous silicon particles, while the polymeric material can be formed from polymers such as polystyrene, polyethylene, polypropylene, polyacrylonitrile, polyvinyl chloride, polyethylene oxide that are heated under inert gasses to slightly decompose the polymers.

Owner:ACTACELL ENERGY SYST

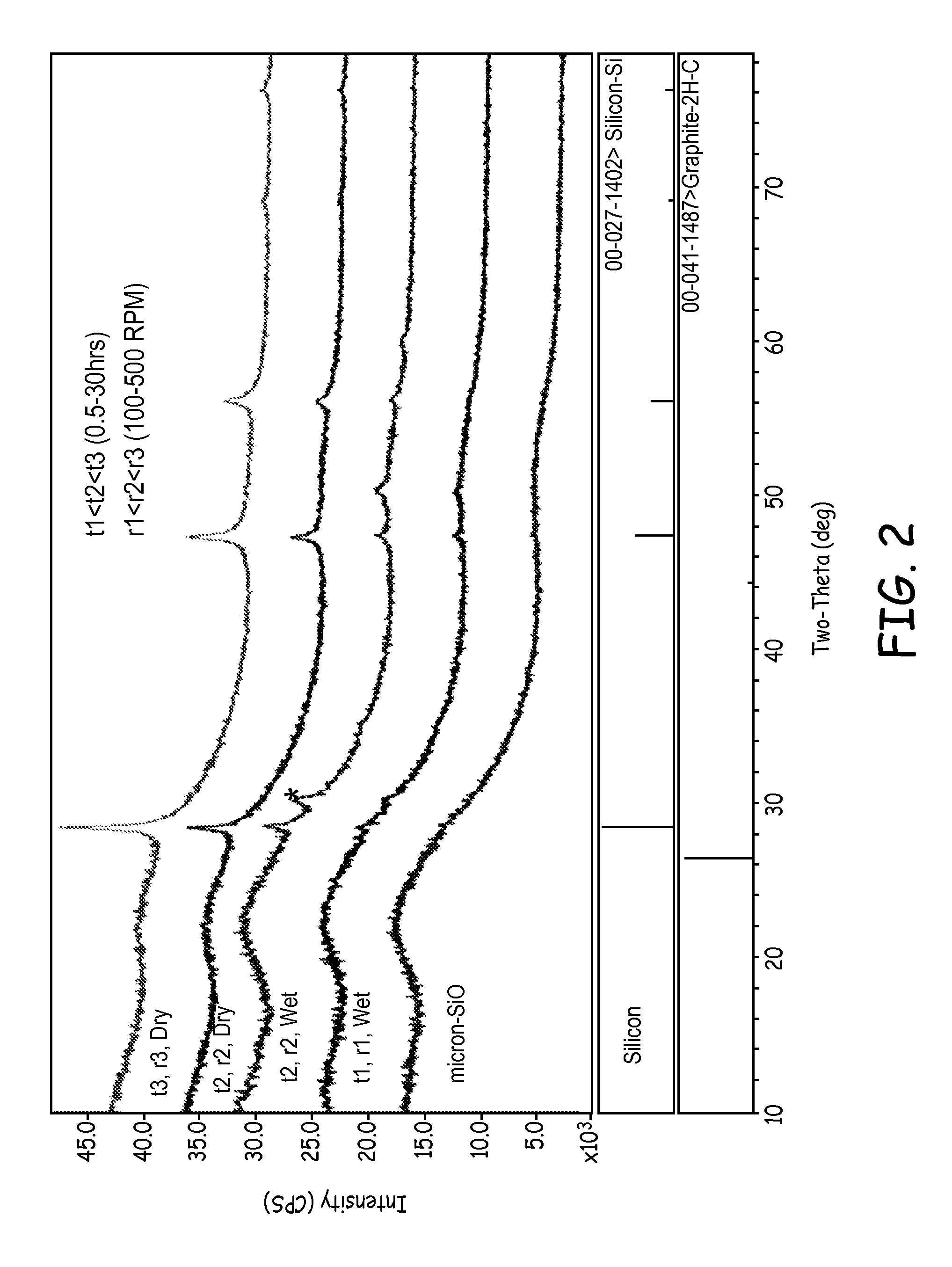

Silicon-silicon oxide-carbon composites for lithium battery electrodes and methods for forming the composites

ActiveUS20140370387A1High energyElectrode manufacturing processesLi-accumulatorsCarbon compositesHigh energy

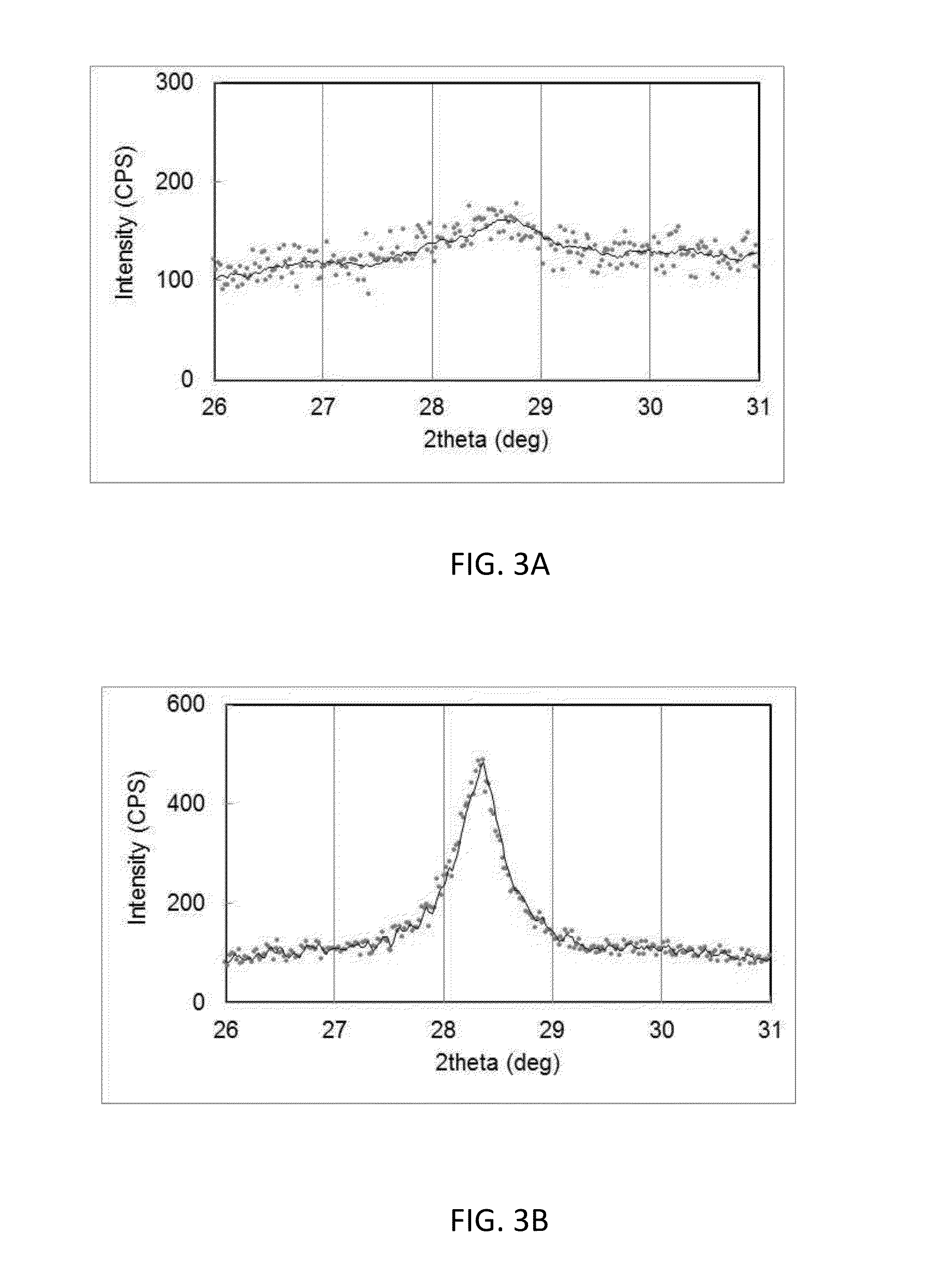

Composite silicon based materials are described that are effective active materials for lithium ion batteries. The composite materials comprise processed, e.g., high energy mechanically milled, silicon suboxide and graphitic carbon in which at least a portion of the graphitic carbon is exfoliated into graphene sheets. The composite materials have a relatively large surface area, a high specific capacity against lithium, and good cycling with lithium metal oxide cathode materials. The composite materials can be effectively formed with a two step high energy mechanical milling process. In the first milling process, silicon suboxide can be milled to form processed silicon suboxide, which may or may not exhibit crystalline silicon x-ray diffraction. In the second milling step, the processed silicon suboxide is milled with graphitic carbon. Composite materials with a high specific capacity and good cycling can be obtained in particular with balancing of the processing conditions.

Owner:IONBLOX INC

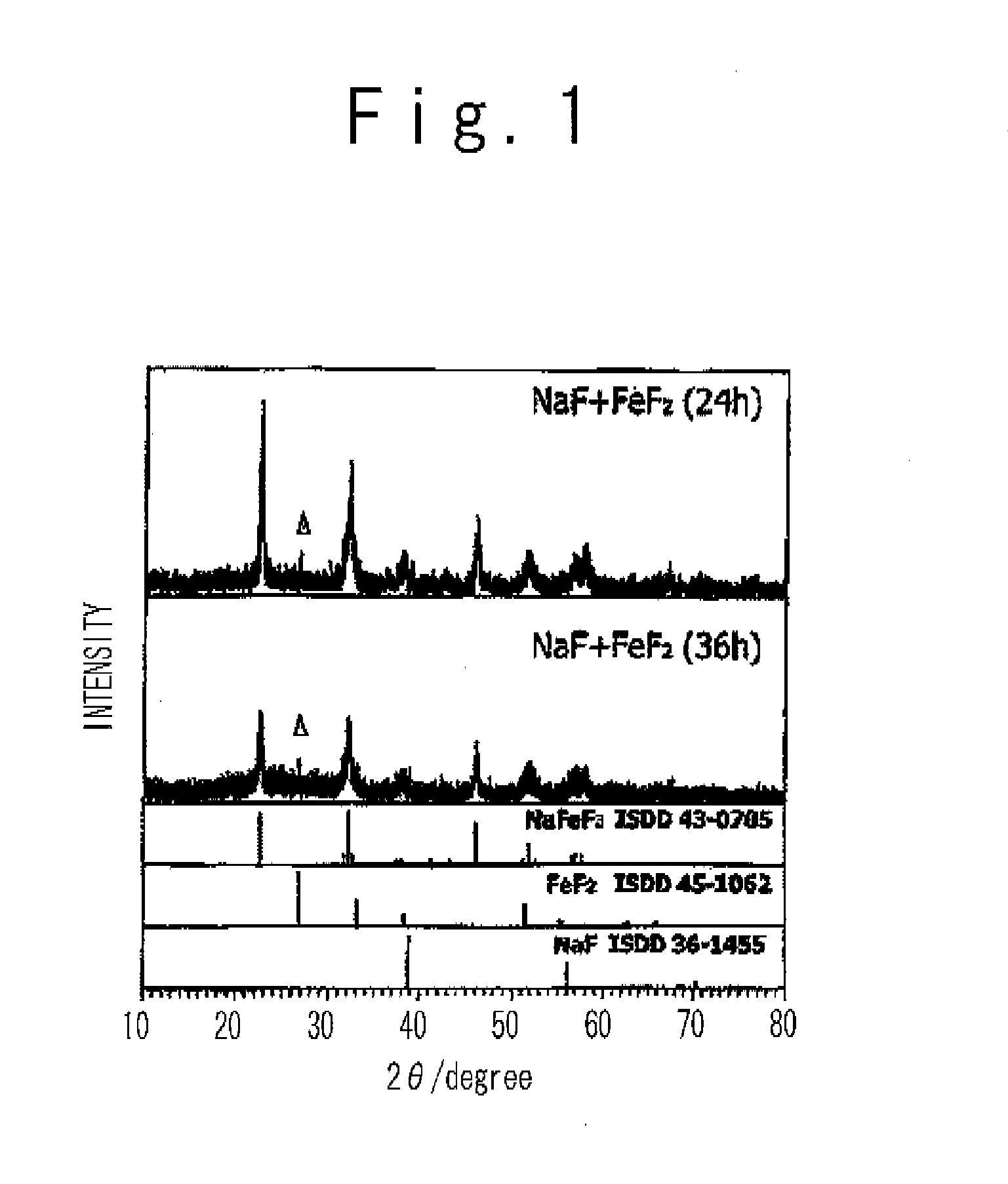

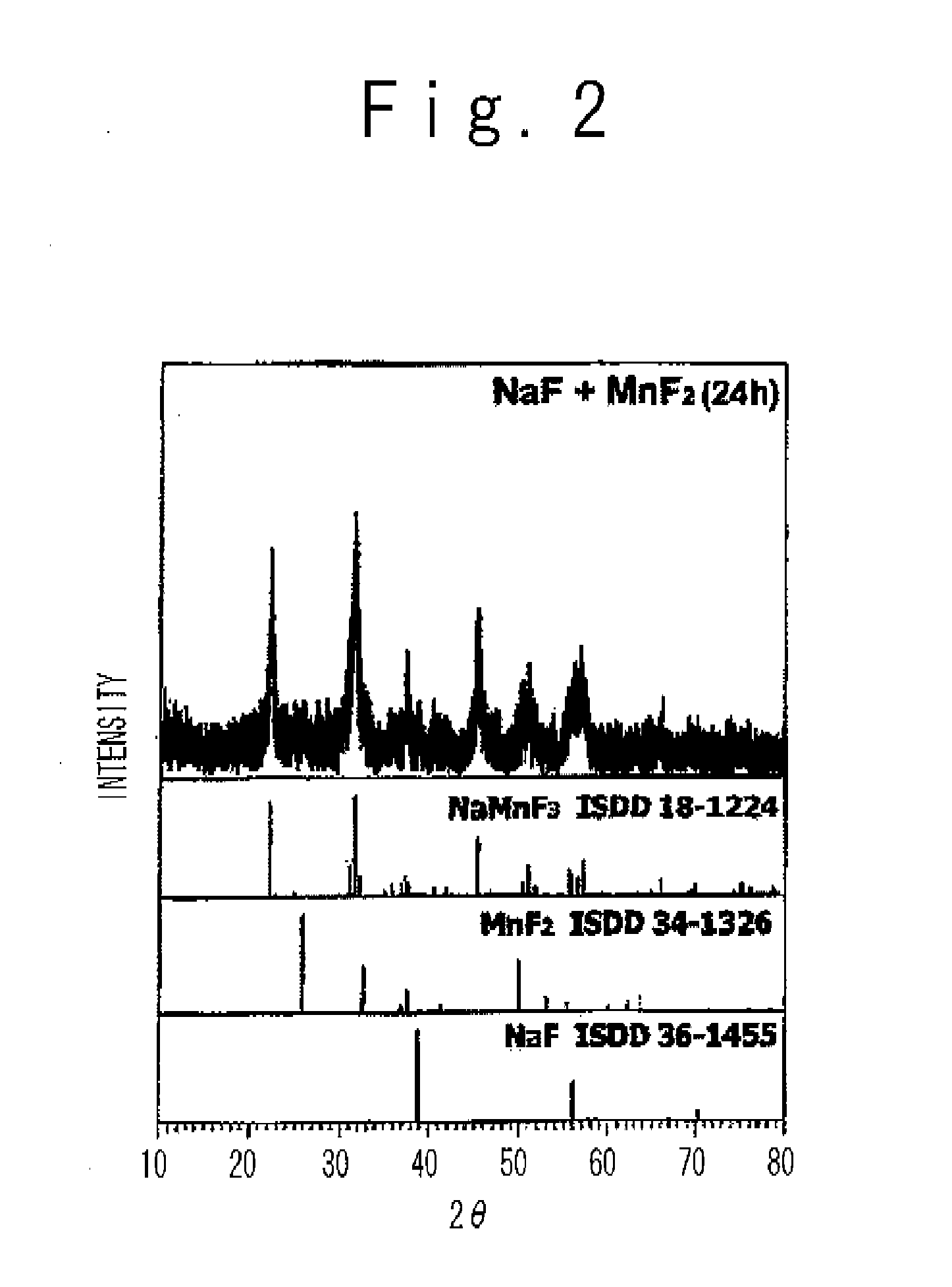

Cathode active material for non-aqueous electrolyte secondary battery and manufacturing method of the same

InactiveUS20100035155A1Increase energy densityElectrode manufacturing processesFluoride preparationMechanical millingFluoride

In a non-aqueous electrolyte secondary battery, in order to adjust a cathode active material in which guest cation such as Na and Li is included, alkaline metal fluoride which is expressed by a general formula AF and transition metal fluoride which is expressed by a formula M′ F2 are subjected to a mechanical milling process to produce metal fluoride compound AM′ F3. The mechanical milling process desirably uses a planetary ball mill.

Owner:MITSUBISHI HEAVY IND LTD +1

Hybridized particle, polymer-based composite material, their preparation methods and use of polymer-based composite material

The invention discloses hybridized particles, a polymer-based composite material, their preparation methods and a use of the polymer-based composite material. The hybridized particles comprise insulating ceramic particles and conductive microparticles loaded on the surfaces of the insulating ceramic particles. The conductive microparticles are granularly and discretely distributed on the surfaces of the insulating ceramic particles. The preparation method of the hybridized particles adopts an in-situ chemical-reduction technology, a sol-gel technology, an in-situ polymerization technology, a high-temperature heat treatment technology or a mechanical milling technology. The polymer-based composite material comprises the hybridized particles and a polymer filled with the hybridized particles. The polymer-based composite material comprises 20-80wt% of the hybridized particles. The hybridized particles have stable structures and stable performances. The polymer-based composite material has the excellent performances such as high dielectric constant, low dielectric loss and stable performances. The preparation methods of the hybridized particle and the polymer-based composite material have the advantages of simple process, easy control of conditions, high production efficiency and industrial production applicability.

Owner:SHENZHEN INST OF ADVANCED TECH

Graphite silicon-based composite anode material and preparation method thereof

InactiveCN104362307ASmall granularityHigh specific surface energyCell electrodesSecondary cellsCarbon compositesHigh carbon

The invention relates to a graphite silicon-based composite anode material for a lithium ion battery and a preparation method thereof. The graphite silicon-based composite anode material comprises a nano-silicon cracked carbon composite material, graphite and a carbon material coating layer. The preparation method comprises the following steps: firstly, nano-silicon is obtained by a high-energy wet mechanical milling method; secondly, nano-silicon and a polymer with high carbon residue are compounded by dispersion polymerization so as to form a polymer / nano-silicon composite microsphere emulsion with nano-silicon inlaid in polymeric microspheres; thirdly, the microsphere emulsion and graphite are compounded; and finally, solid-phase coating is carried out by the use of an organic carbon source, and heat treatment is conducted to obtain the graphite silicon-based composite anode material for a lithium ion battery. By the above method, the problem that nano-silicon is liable to agglomeration, especially agglomeration of nano-silicon from a liquid disperse state to a dry state, due to low granularity and high specific surface energy is solved. The anode material has characteristics of high specific capacity (greater than 550mAh / g), high initial charge discharge efficiency (greater than 80%) and high conductivity.

Owner:南京毕汉特威高分子材料有限公司

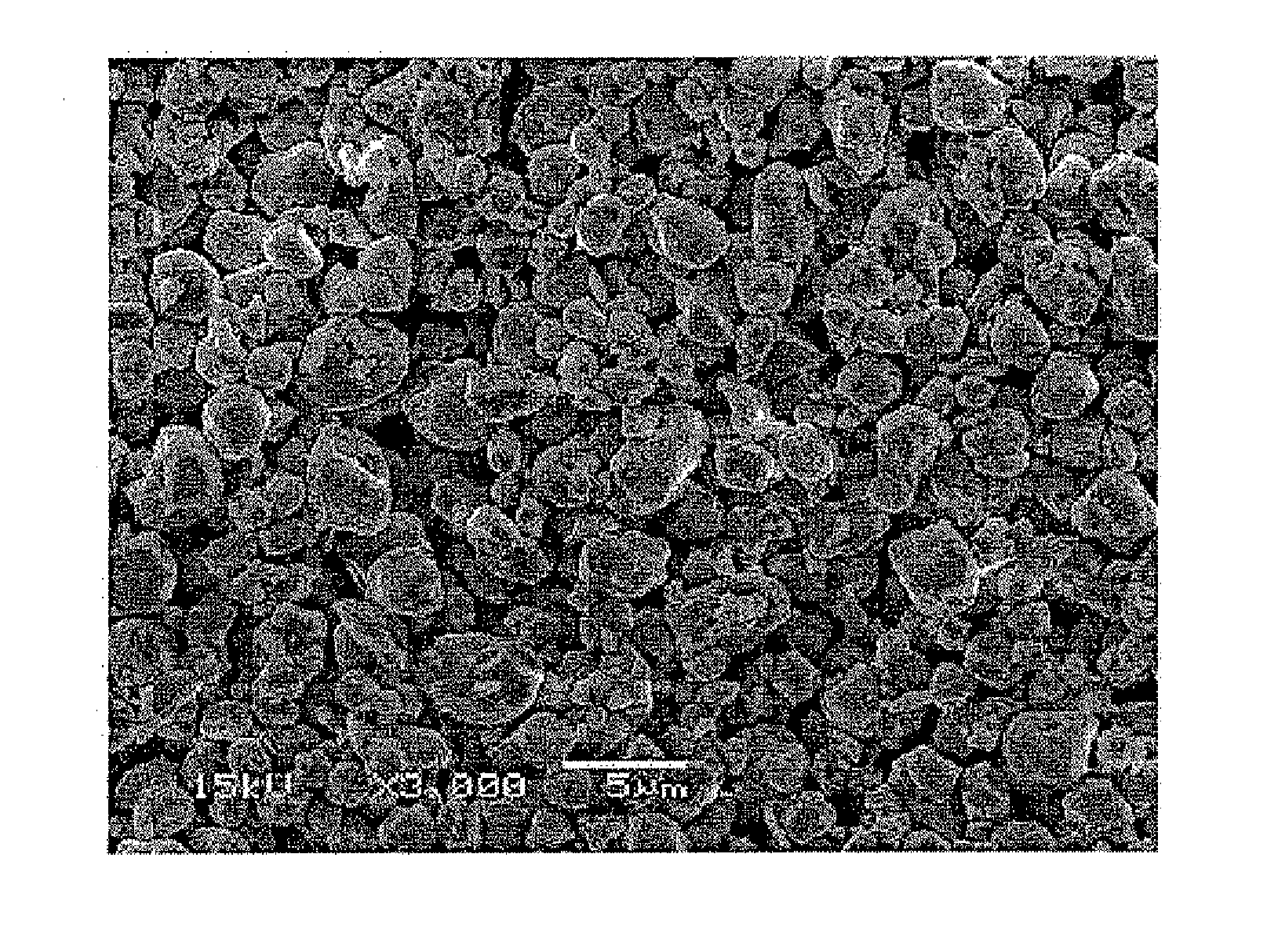

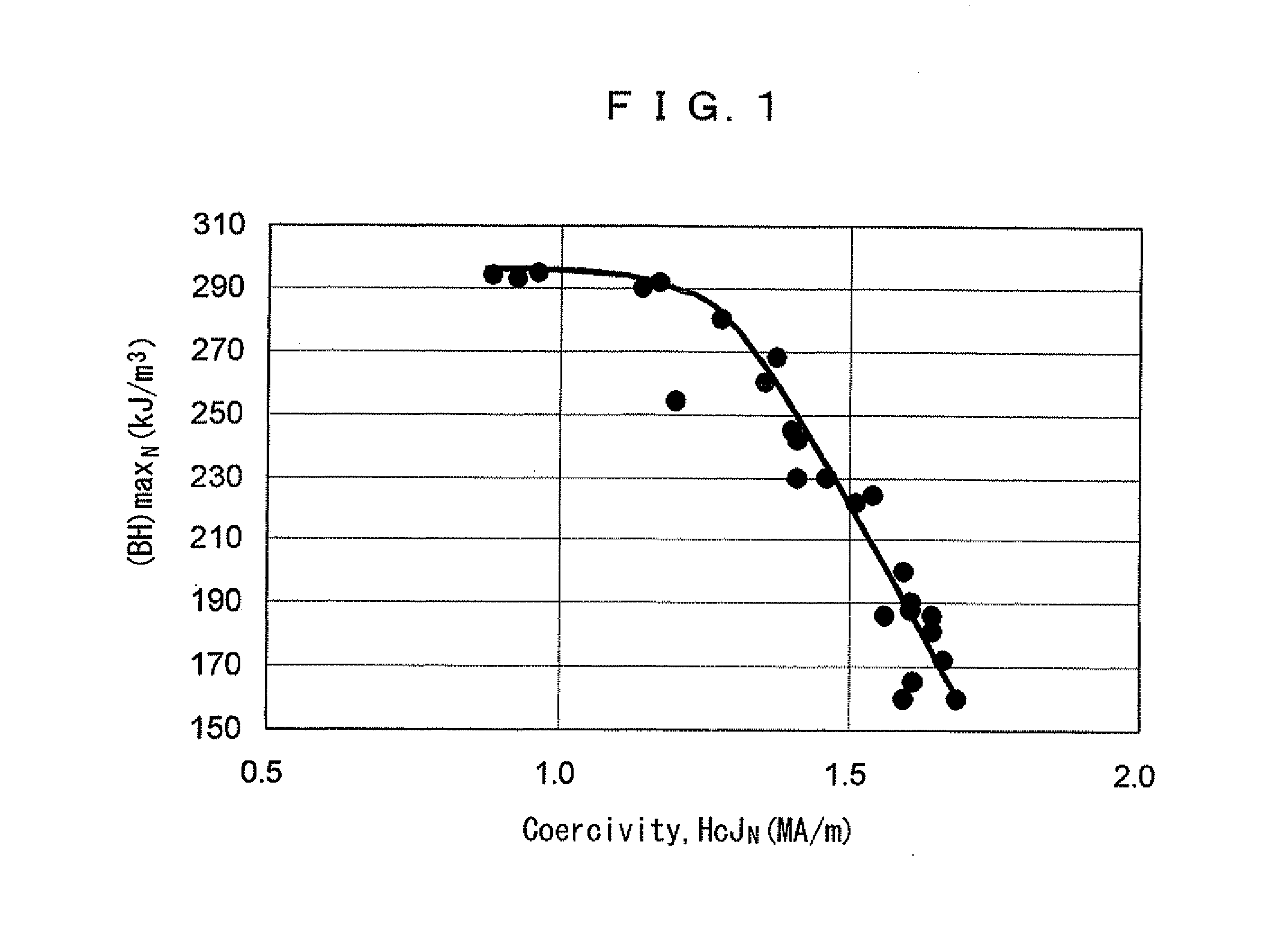

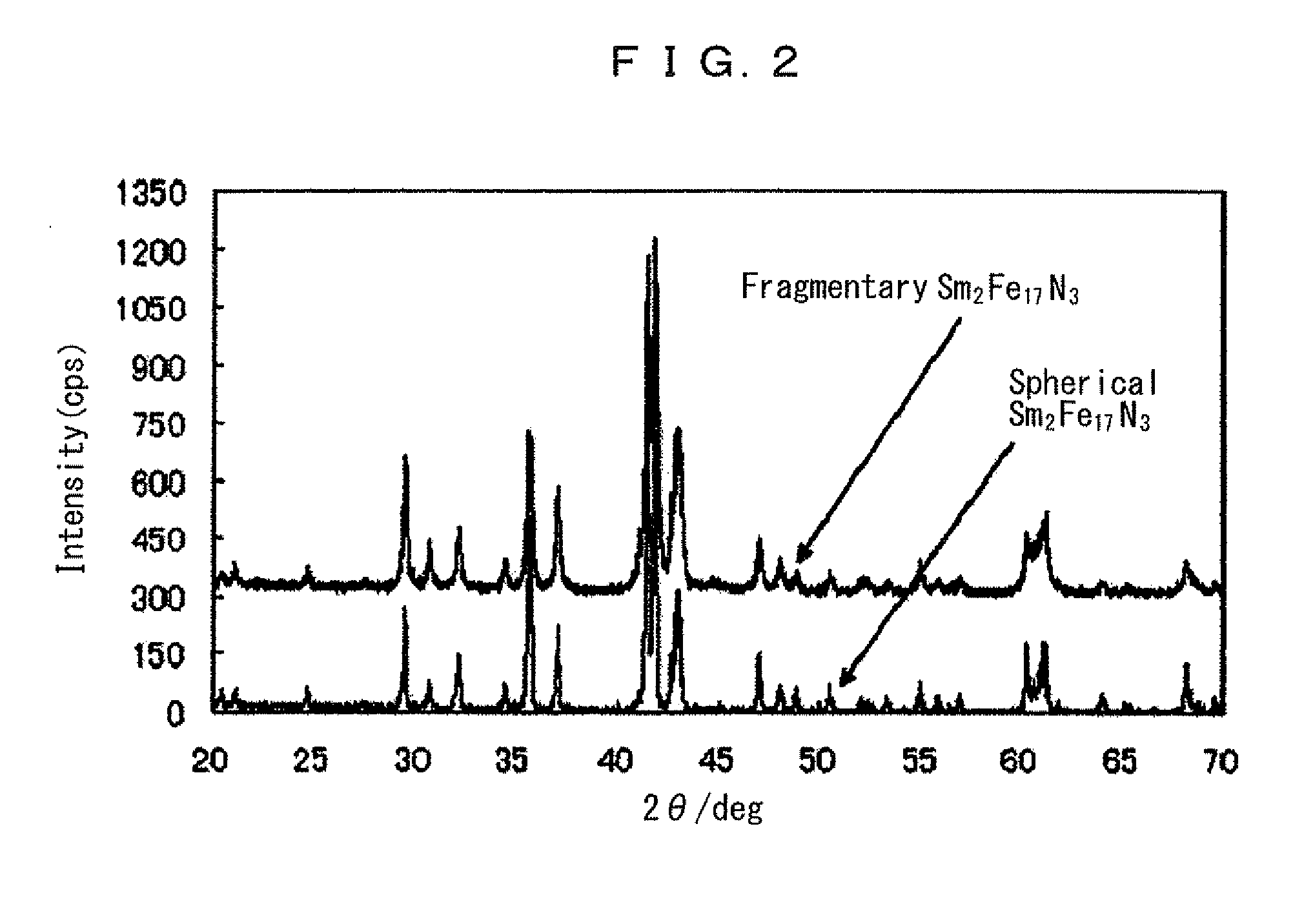

Anisotropic rare earth-iron based resin bonded magnet

InactiveUS20110074531A1Effectively secure magnetic stabilityGood magnetic stabilityPermanent magnetsInorganic material magnetismEpoxyOligomer

Anisotropic rare earth-iron based resin bonded magnet comprises: [1] a continuous phase including: (1) a spherical Sm2Fe17N3 based magnetic material covered with epoxy oligomer where its average particle size is 1 to 10 μm, its average aspect ratio ARave is 0.8 or more, and mechanical milling is not applied after Sm—Fe alloy is nitrided; (2) a linear polymer with active hydrogen group reacting to the oligomer; and (3) additive; and [2] a discontinuous phase being an Nd2Fe14B based magnetic material coated with the epoxy oligomer where its average particle size is 50 to 150 μm, and its average aspect ratio ARave is 0.65 or more, further satisfying: [3] the air-gap ratio of a granular compound on the phases is 5% or less; and [4] a composition where crosslinking agent with 10 μm or less is adhered on the granular compound is formed at 50 MPa or less.

Owner:MINEBEAMITSUMI INC

Preparing method for fine sheet metal magnetically soft alloy powder

ActiveCN104858441AImprove permeabilityHigh strengthInorganic material magnetismMicrometerGranularity

The invention relates to a preparing method for fine sheet metal magnetically soft alloy powder and belongs to the technical field of metal and alloy powder preparation. The method comprises the steps that two or three of Fe, Si, Al, Ni and Mo are selected as raw materials to carry out alloy distributing; a medium-frequency induction furnace is adopted for carrying out alloy smelting; a two-flow atomization method is adopted for carrying out atomizing on a melt, and alloy powder approximately spherical is prepared; by means of mechanical milling, flattening is carried out on the alloy powder; annealing treatment is carried out on the obtained sheet powder, and by means of an ultrasonic vibrating sieve, the fine sheet metal magnetically soft alloy powder is prepared. The powder prepared through the method, the granularity ranges from 10 micrometers to 100 micrometers, the average thickness ranges from 0.1 micrometer to 5 micrometer, the radial thickness ratio ranges from 50 to 500, and the powder flattening rate reaches 90%. According to the method, the powder preparing process is simple, the production efficiency is high, the production cost is low, the quality of the magnetically soft powder core can be effectively improved, and the manufacturing cost is reduced.

Owner:有研增材技术有限公司

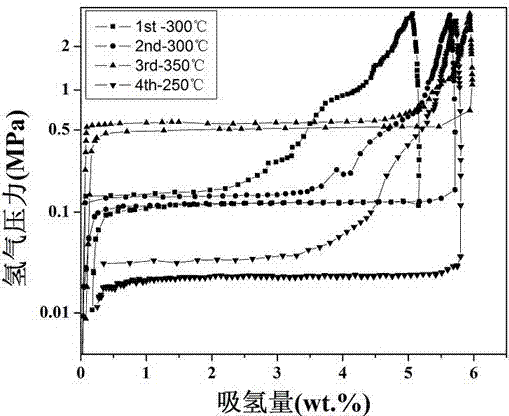

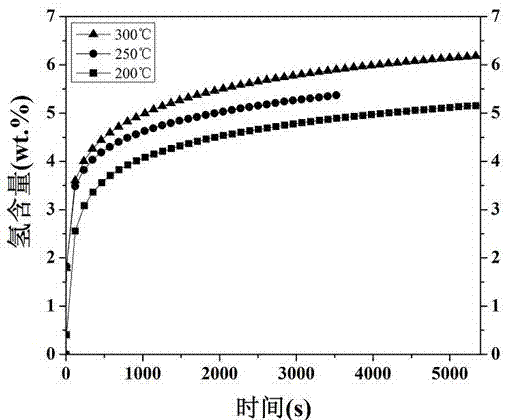

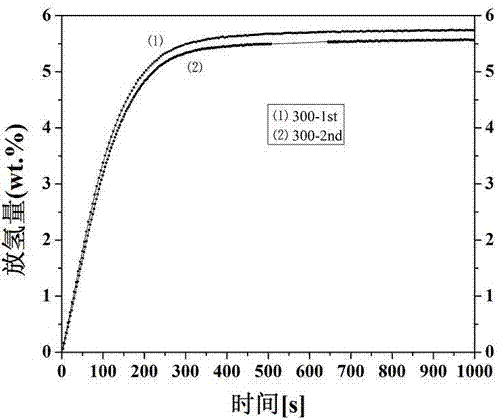

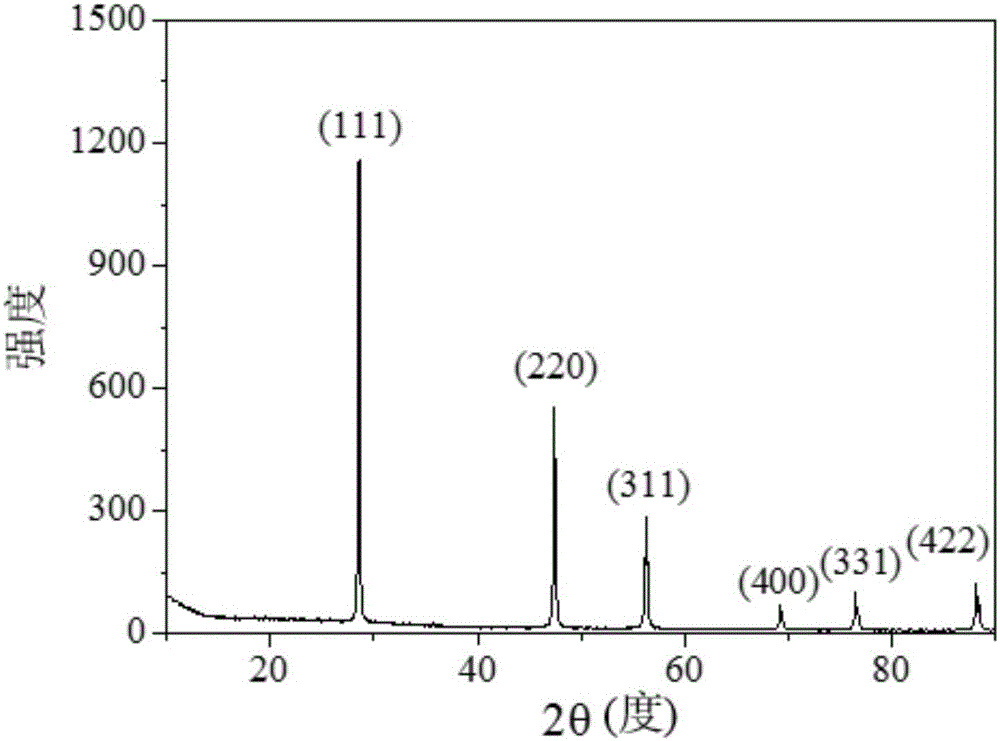

Magnesium-based hydrogen storage alloy with long period structure and preparation method thereof

ActiveCN102337438AHigh activityAbsorption and desorption of hydrogen are normalChemical compositionMechanical milling

The invention provides a magnesium-based hydrogen storage alloy with a long period structure and a preparation method thereof. The magnesium-based hydrogen storage alloy has the chemical composition of Mg100-(2x-4x)Nix-3xYx (x is not less than 2 and not more than 6), and has a 18R and 14H long period stacking ordered structure. The preparation method comprises the following steps of: taking pure magnesium and Ni-Y intermediate alloys according to the chemical composition, carrying out induction smelting to obtain magnesium-based alloy cast ingots, mechanically crushing, and then carrying out high-energy mechanical milling to finally obtain the magnesium-based hydrogen storage alloy. The magnesium-based hydrogen storage alloy provided by the invention has good activation property and hydriding / dehydriding kinetics property; Ni atoms and Y atoms in the long period structure form Mg2NiHx and YH2-3 in the hydriding process and are evenly distributed among Mg particles in nanoscale, therefore, the hydrogen storage property of the Mg-based hydrogen storage alloy is greatly improved. The preparation method provided by the invention is simple and applicable to industrialized production.

Owner:SOUTH CHINA UNIV OF TECH

Porous silicon material, and preparation method and application thereof

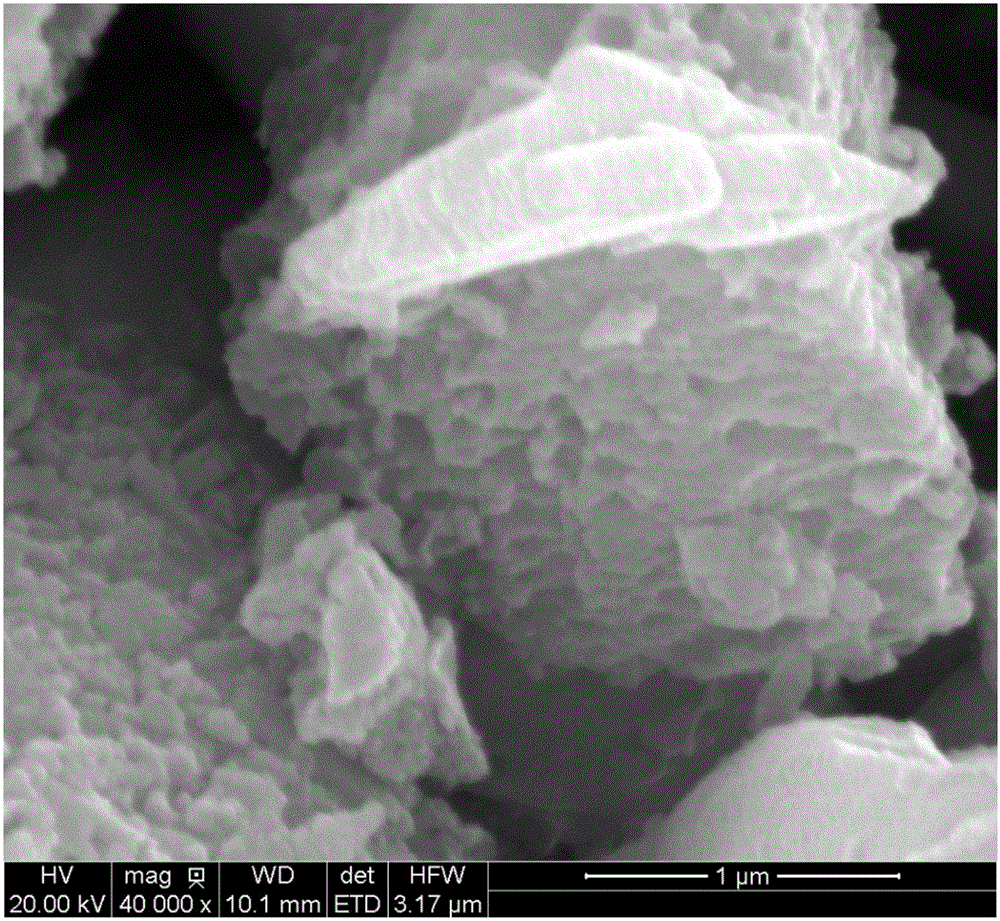

ActiveCN105047892AImprove cycle stabilityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAcid etchingSpace group

The invention discloses a porous silicon material, and a preparation method and an application thereof. The porous silicon material is mainly prepared by mechanical milling and acid etching of metallurgical iron-silicon alloy as a raw material; the dimension of the porous silicon material is in micron / submicron level; the porous silicon material has a diamond structure, belongs to an Fd-3m (227) space group, and has a reaction phase which can react with lithium (Li); a large number of hierarchical porous structures with different dimensions are evenly distributed in the surface and the inside of the porous silicon material; the porous silicon material can be used as a lithium ion battery anode active material, and shows the characteristics of high (first) coulombic efficiency, high capacity, excellent cycling stability and the like when applied to a lithium ion battery; meanwhile, the preparation technology of the porous silicon material is simple, and can be carried out only by conventional equipment; the used raw materials are cheap and available; the technological process is easy to control; and the porous silicon material is good in repeatability, high in productivity, stable in product quality and suitable for large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

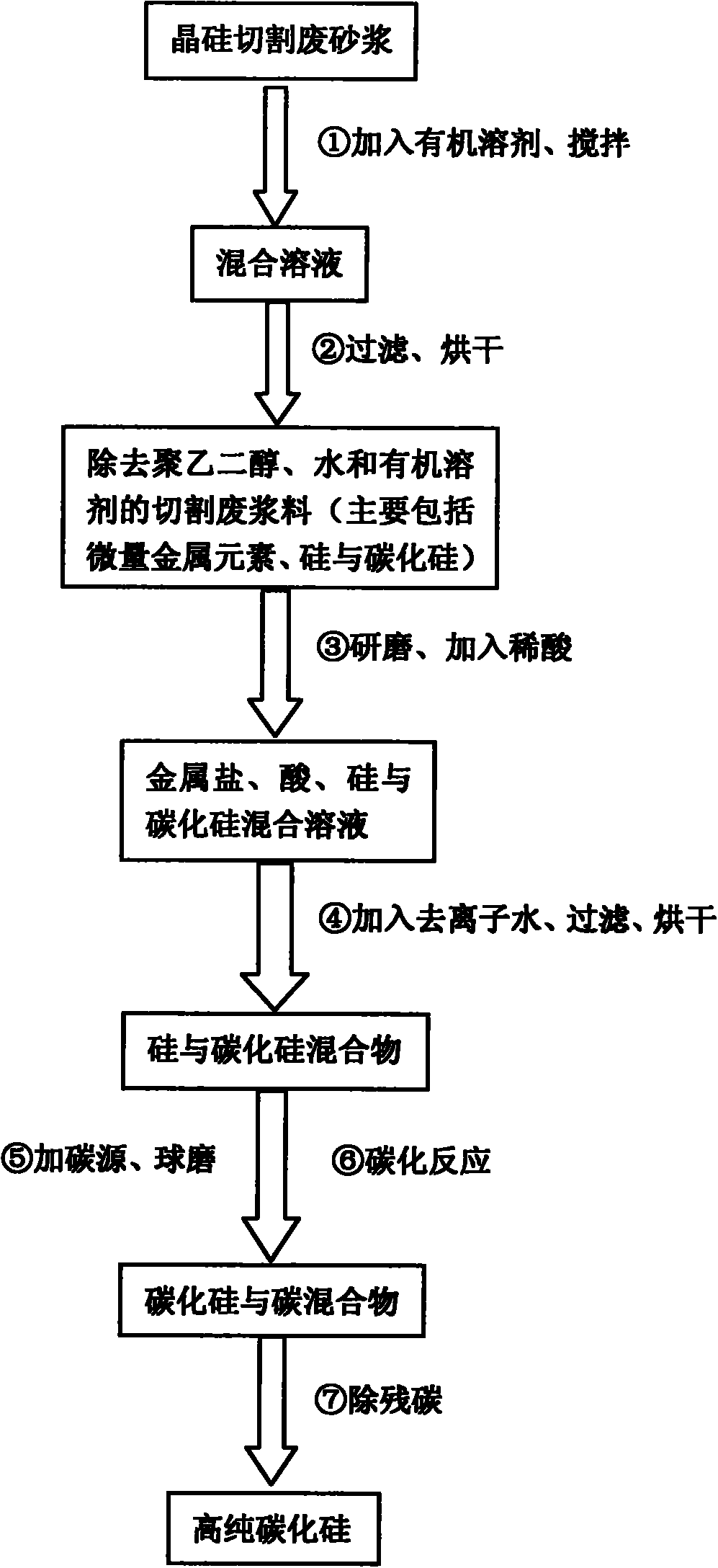

Method for purifying and preparing silicon carbide powder from crystalline silicon cutting waste mortar

The invention discloses a method for preparing silicon carbide powder by using crystalline silicon cutting waste mortar. The method comprises following concrete processes: firstly, adding an organic solvent to the crystalline silicon cutting waste mortar, dissolving polyethylene glycol in the waste mortar; filtering and drying a filter cake; then grinding the filter cake into powder; adding dilute hydrochloric acid to react, filtering after the reaction is complete, and removing trace metal impurities, so as to obtain mixed powder of silicon and silicon carbide; then adding excessive carbon source to the mixed powder; evenly mixing the powder in a mechanical milling manner; finally, carrying out thermal treatment on the mixed powder in vacuum or inert atmosphere within a certain temperature range, so that the silicon and the carbon are subjected to carbonization reaction; removing residual carbon in air after the reaction is complete; finally obtaining high-purity silicon carbide powder. By adopting the method, the complicated technological process in the traditional method for recovering the crystalline silicon cutting waste mortar is simplified; finally the silicon in the crystalline silicon cutting waste mortar is completely converted into silicon carbon by a simpler method; the resources are recycled; environmental pollution is also reduced.

Owner:HAINAN UNIVERSITY

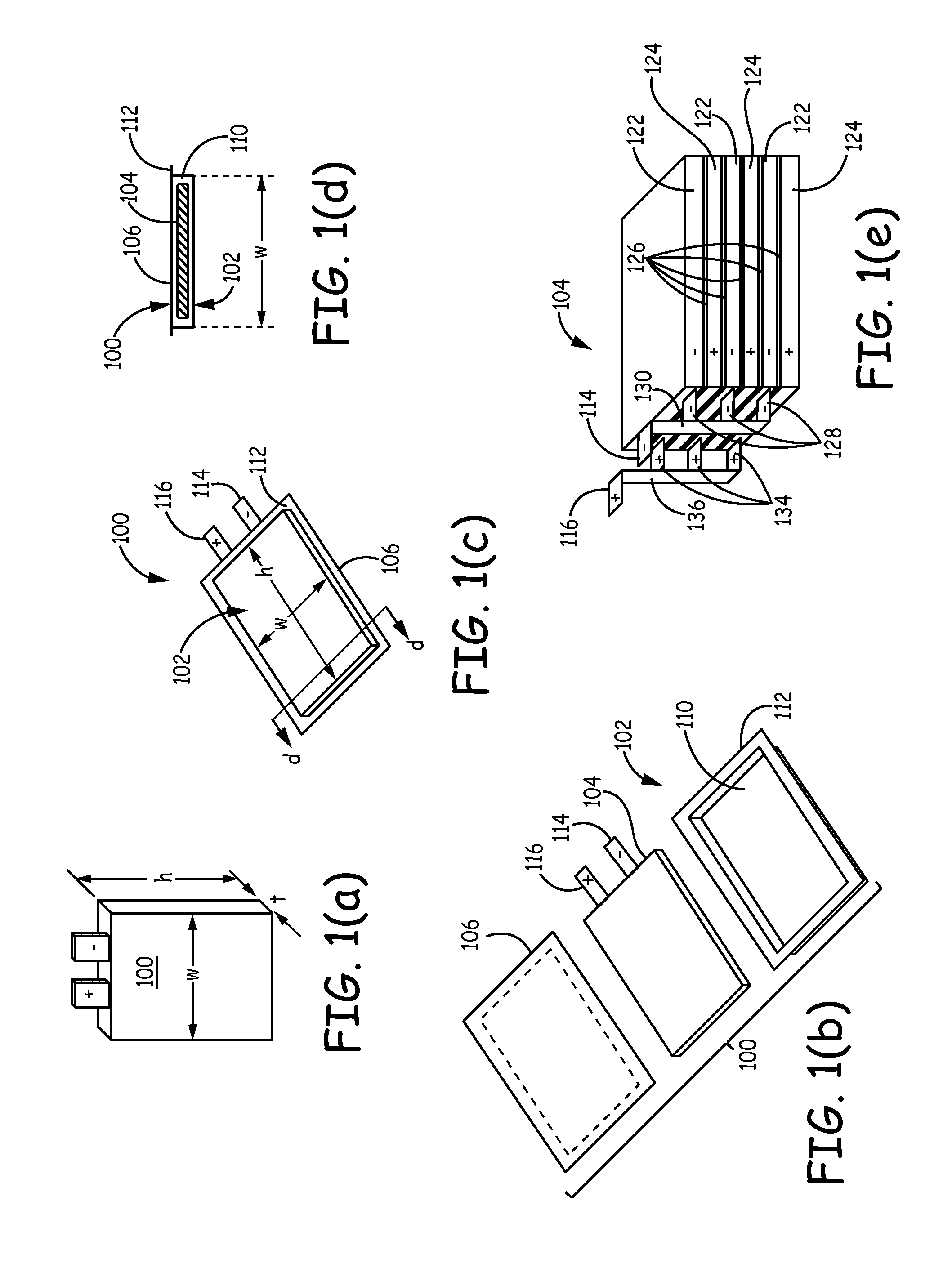

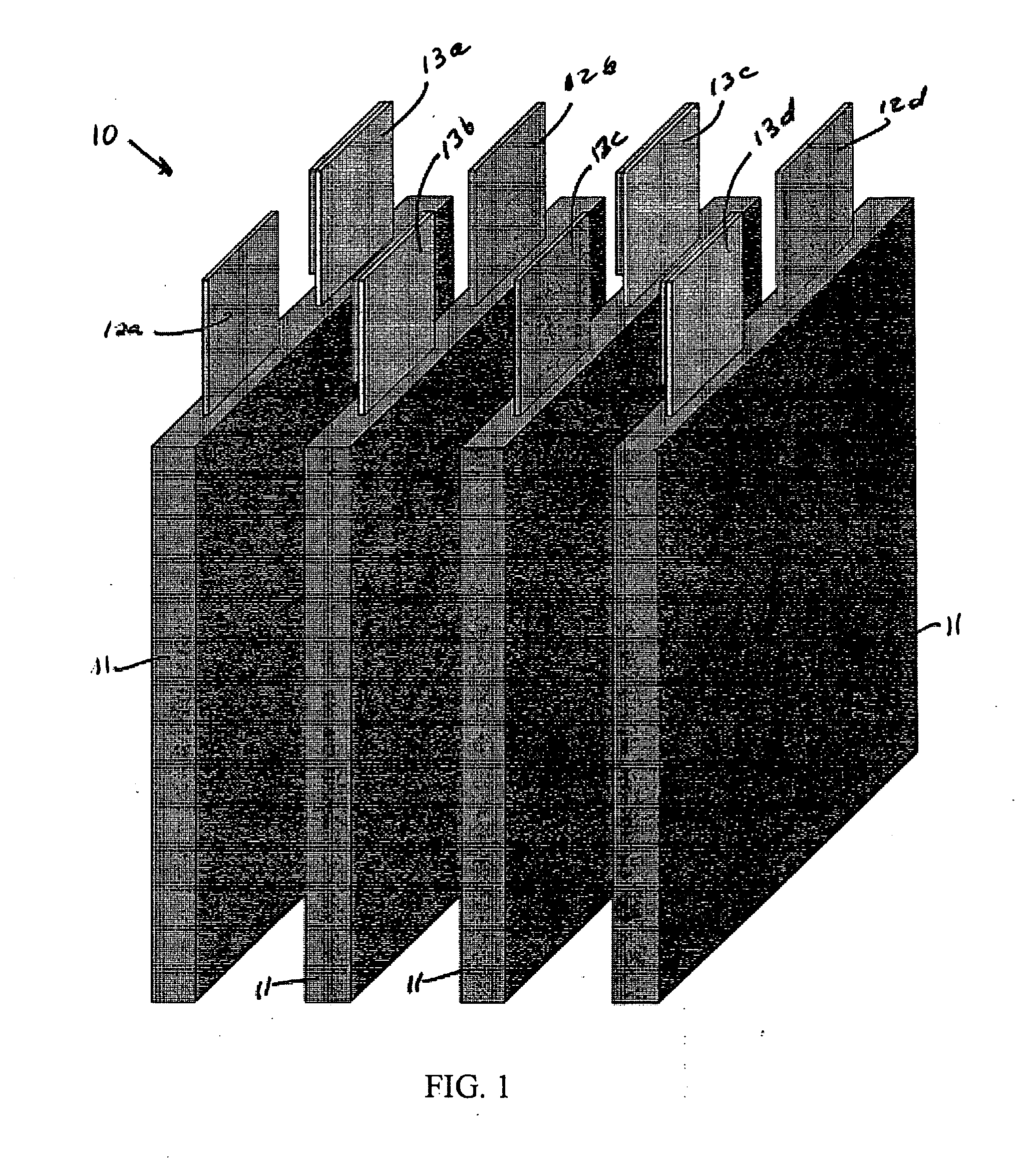

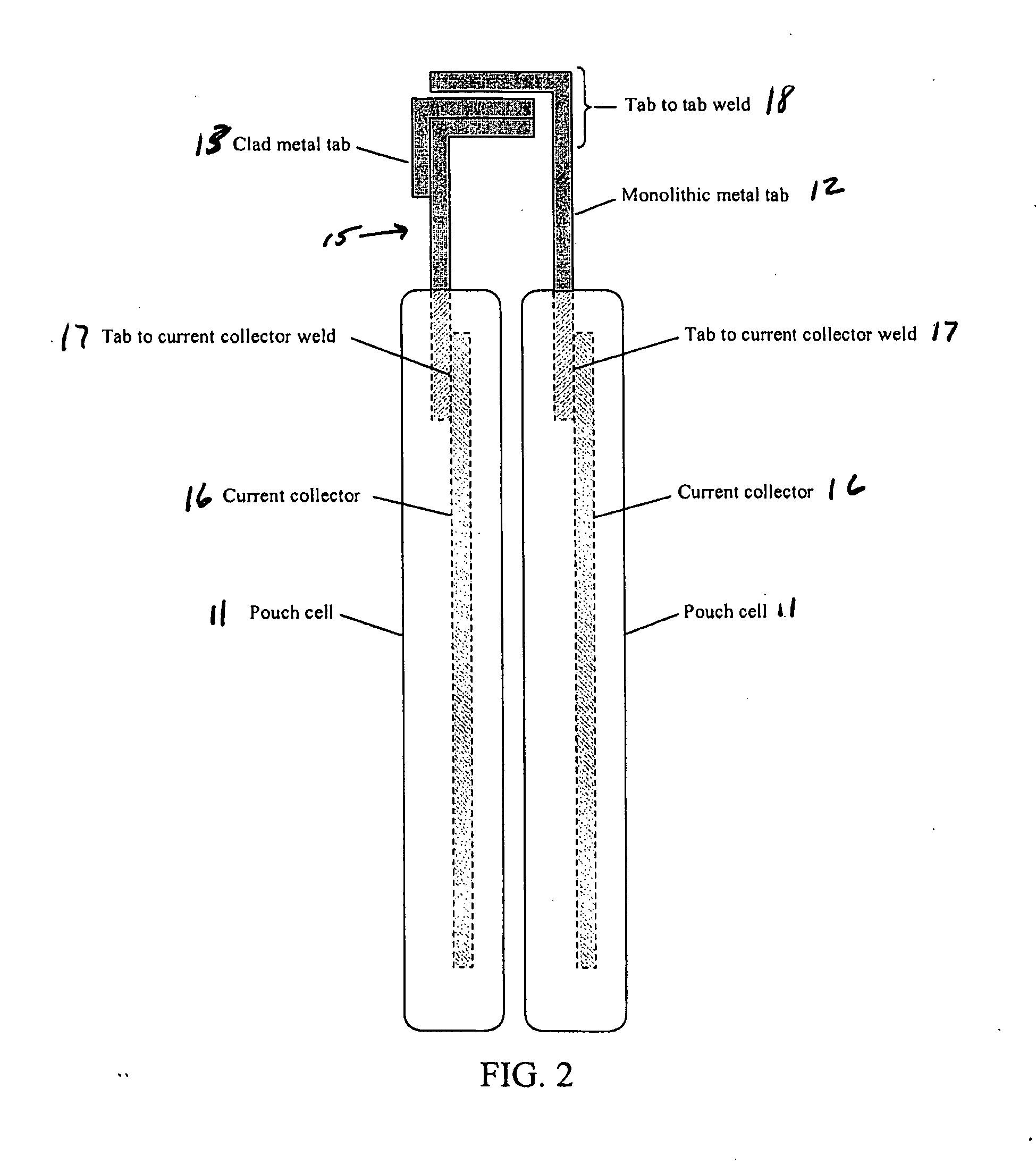

Battery Tabs and Method of Making the Same

InactiveUS20110274964A1Improve corrosion resistanceLess-robustPrimary cell to battery groupingCell electrodesMechanical millingEngineering

A terminal for a Li-ion battery cell utilizes a bimetallic strip formed from the materials used as the Li-ion cell current collectors, such as copper and aluminum. The bimetallic strip is to be used as, at least one, of the Li-ion pouch cell terminals. At least one portion of the bimetallic strip has one of the metallic components removed by such means as chemical or electrochemical etching, mechanical milling, skiving, or grinding, the remaining component being connected to the collector and the other end of the strip serving as the terminal.

Owner:EMS ENGINEERED MATERIALS SOLUTIONS LLC

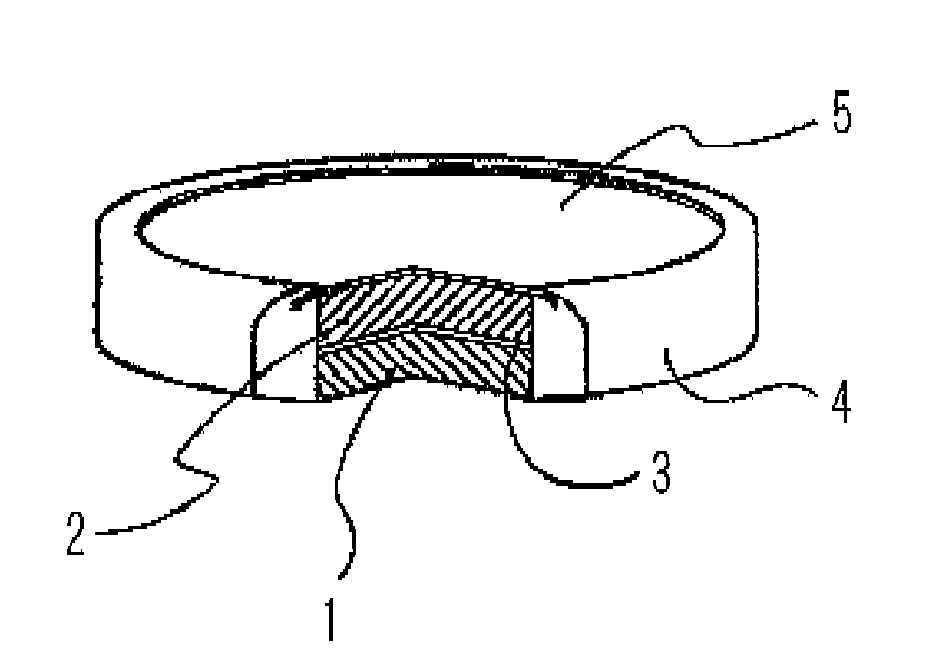

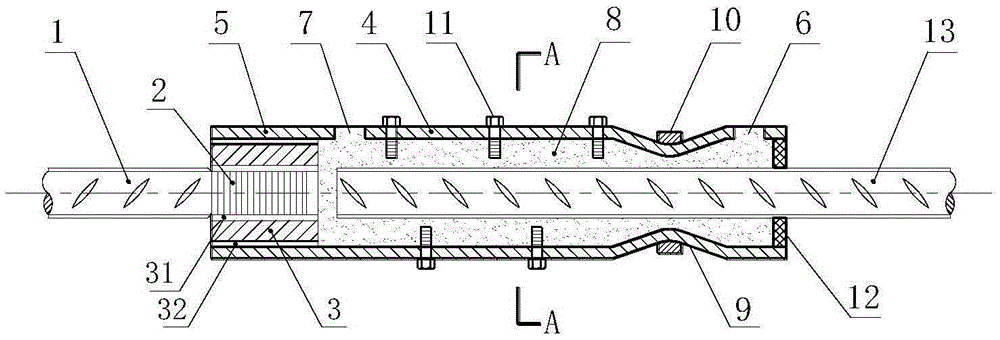

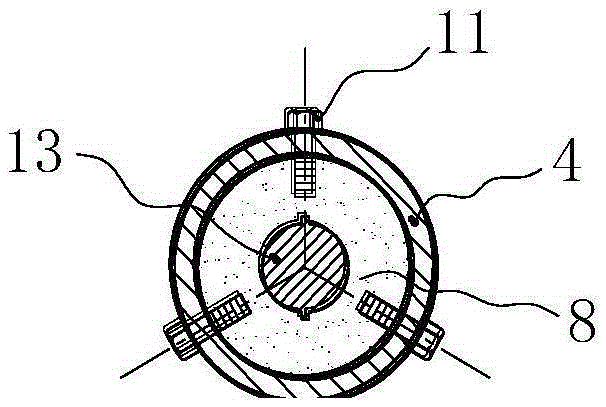

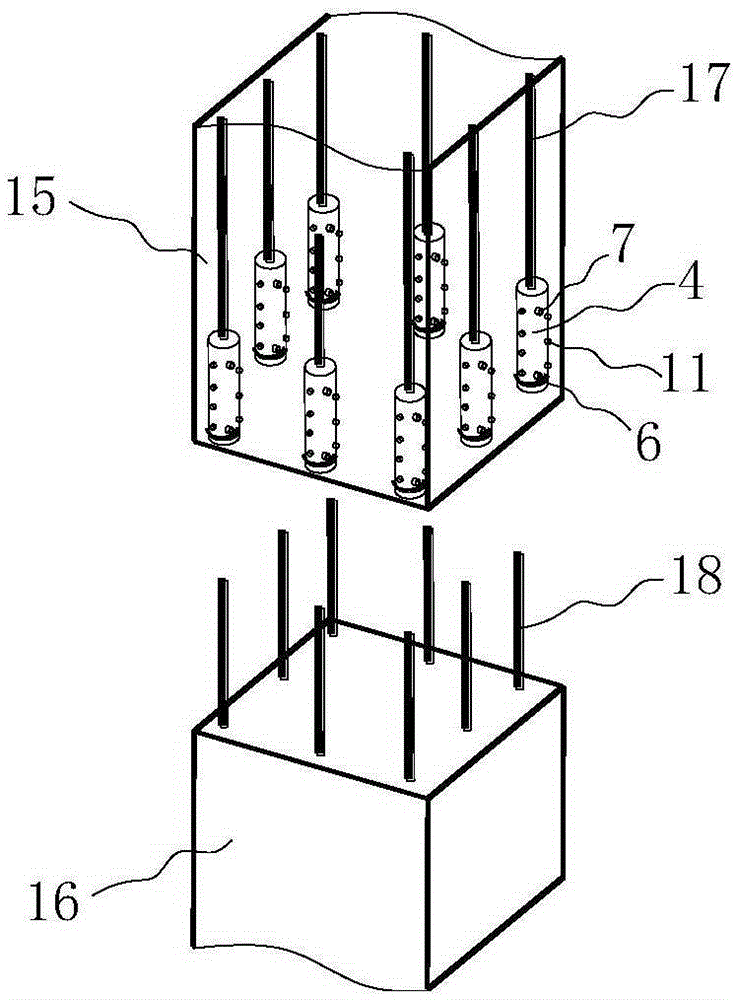

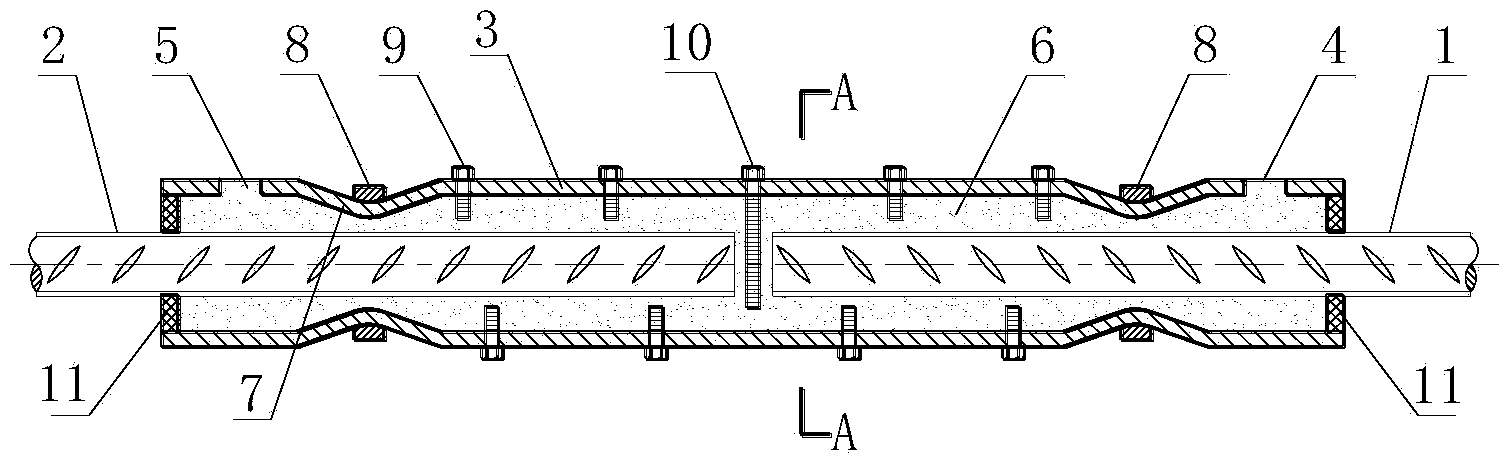

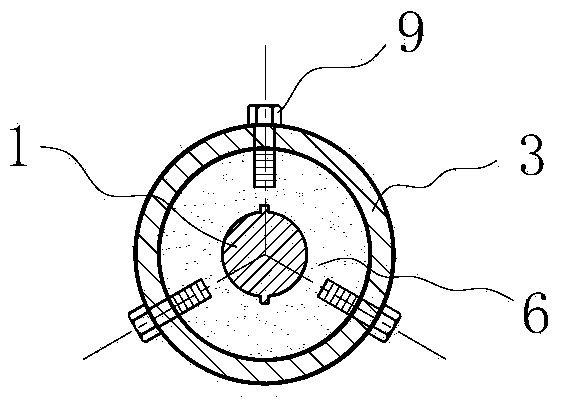

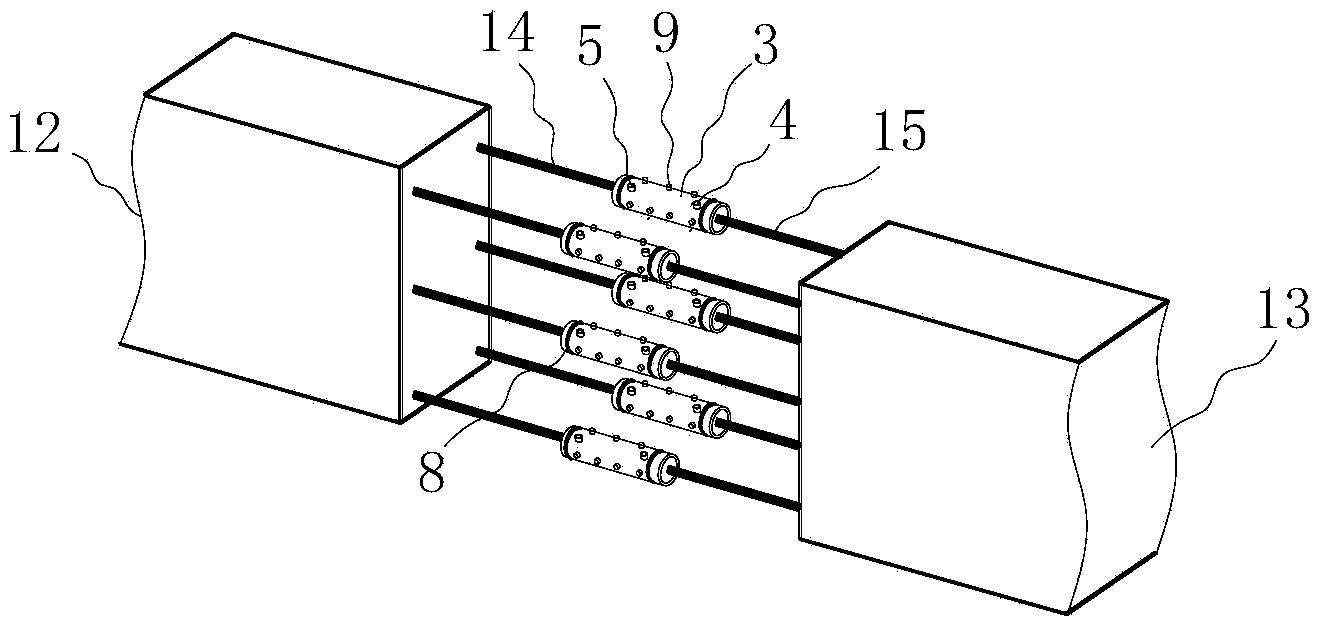

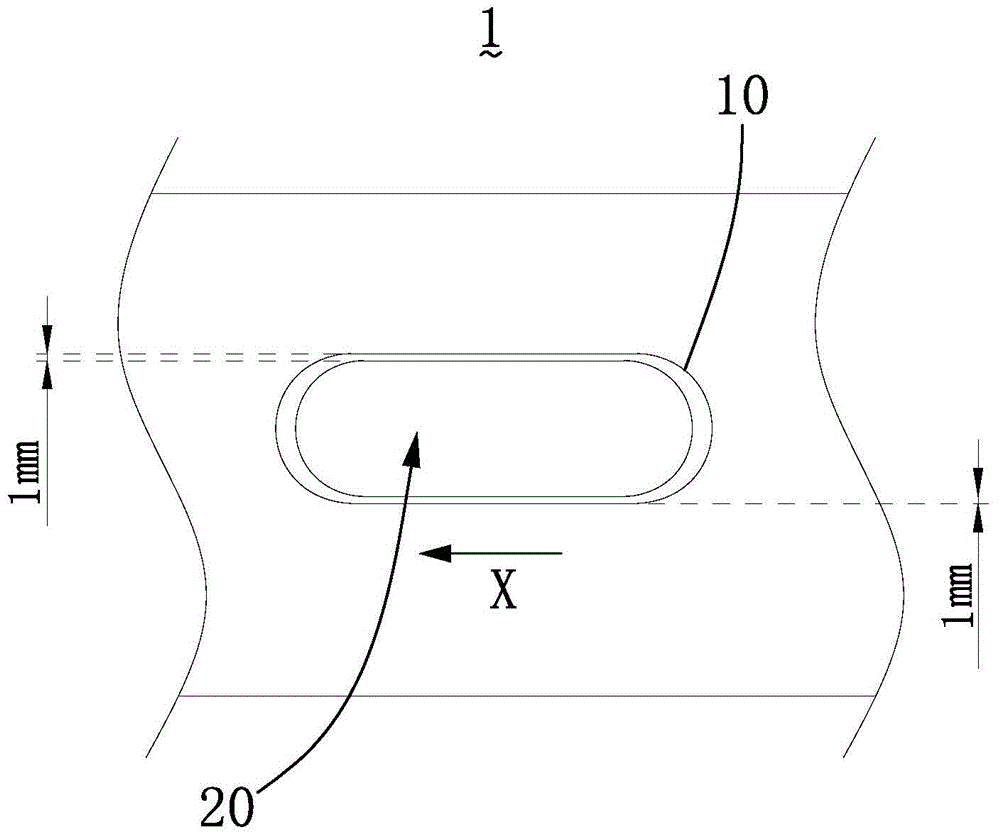

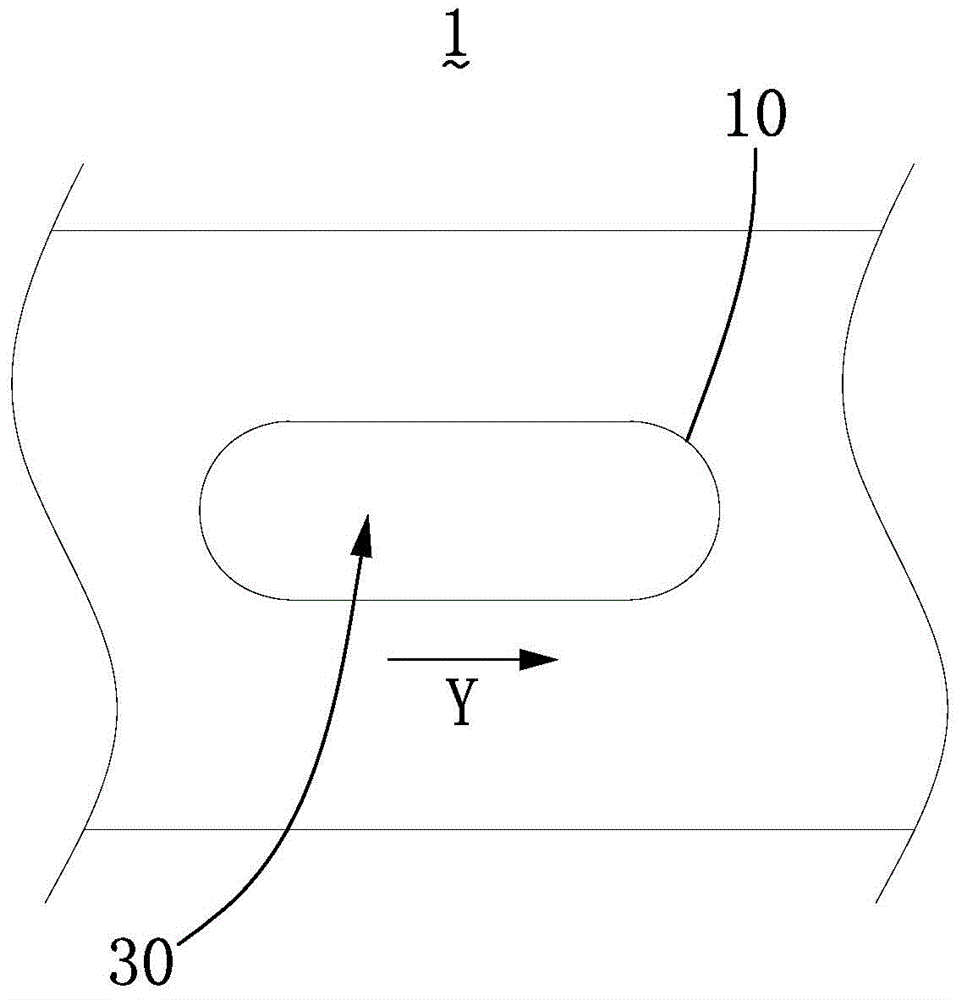

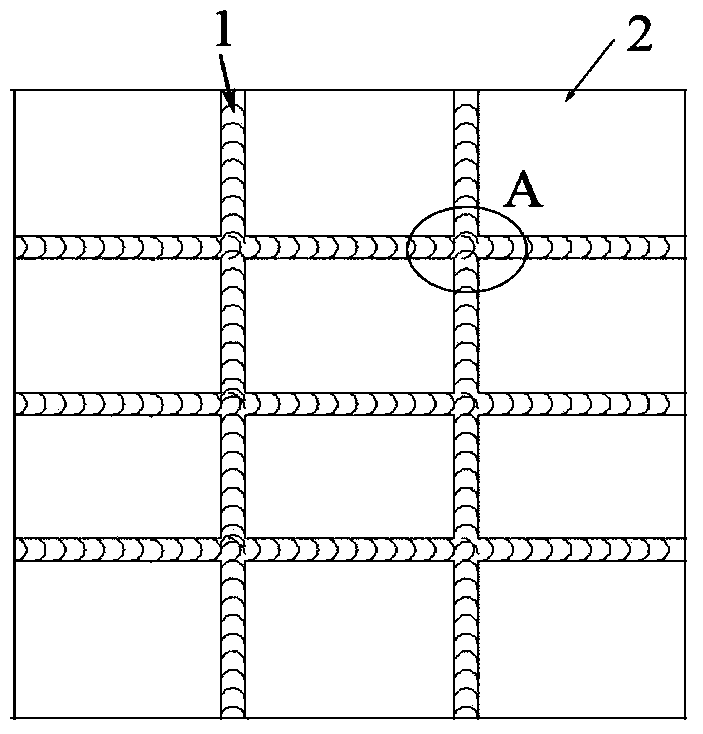

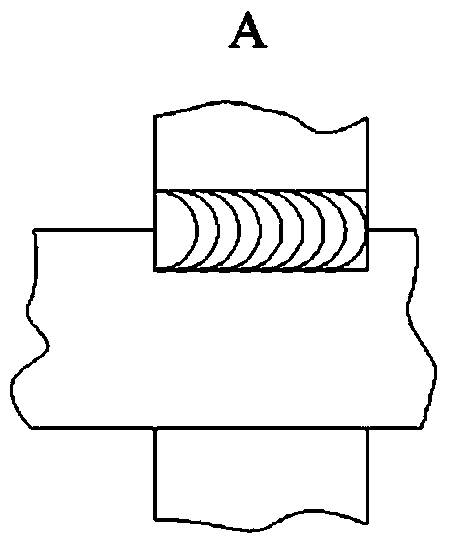

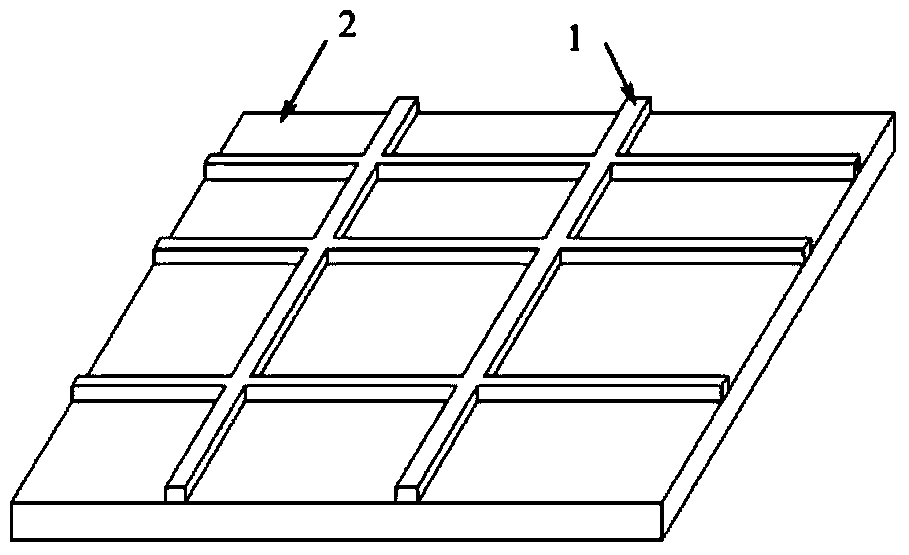

A Shear Enhanced Semi-grouting Sleeve

ActiveCN103758291BReduce manufacturing costWide variety of sourcesBuilding reinforcementsMechanical millingEngineering

The invention discloses a shearing reinforcing type semi-grouting sleeve which comprises a sleeve body, wherein the sleeve body is of a tubular structure; an elastic rubber sealing ring is arranged at the opening of one end of the sleeve body; a threaded connecting piece is arranged at the opening of the other end of the sleeve body; a grouting hole and a discharge hole are formed in side walls close to the end parts of the sleeve body; bolt holes are formed in the side wall along the sleeve body; anti-shearing bolts are arranged inside the bolt holes. The shearing reinforcing type semi-grouting sleeve has the advantages of wide material resource, simplicity in machining and manufacturing, reliability in property and the like, can greatly overcome the defects that the conventional cast iron or cast iron steel sleeve is complex to manufacture and high in cost, a mechanical milling sleeve is labor and time waste, and the like, can be widely applied to assembled type concrete structures, and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

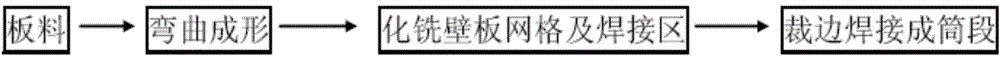

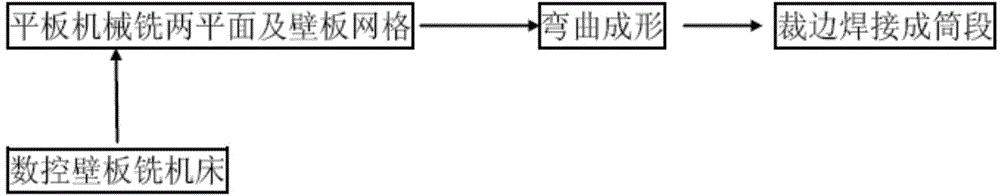

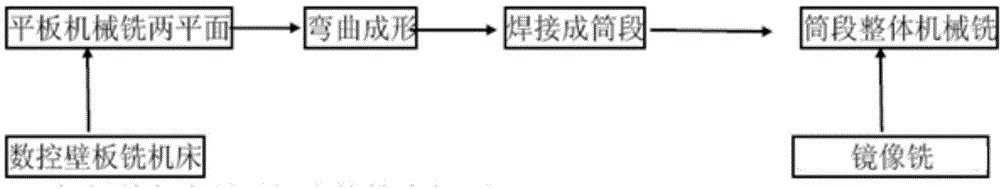

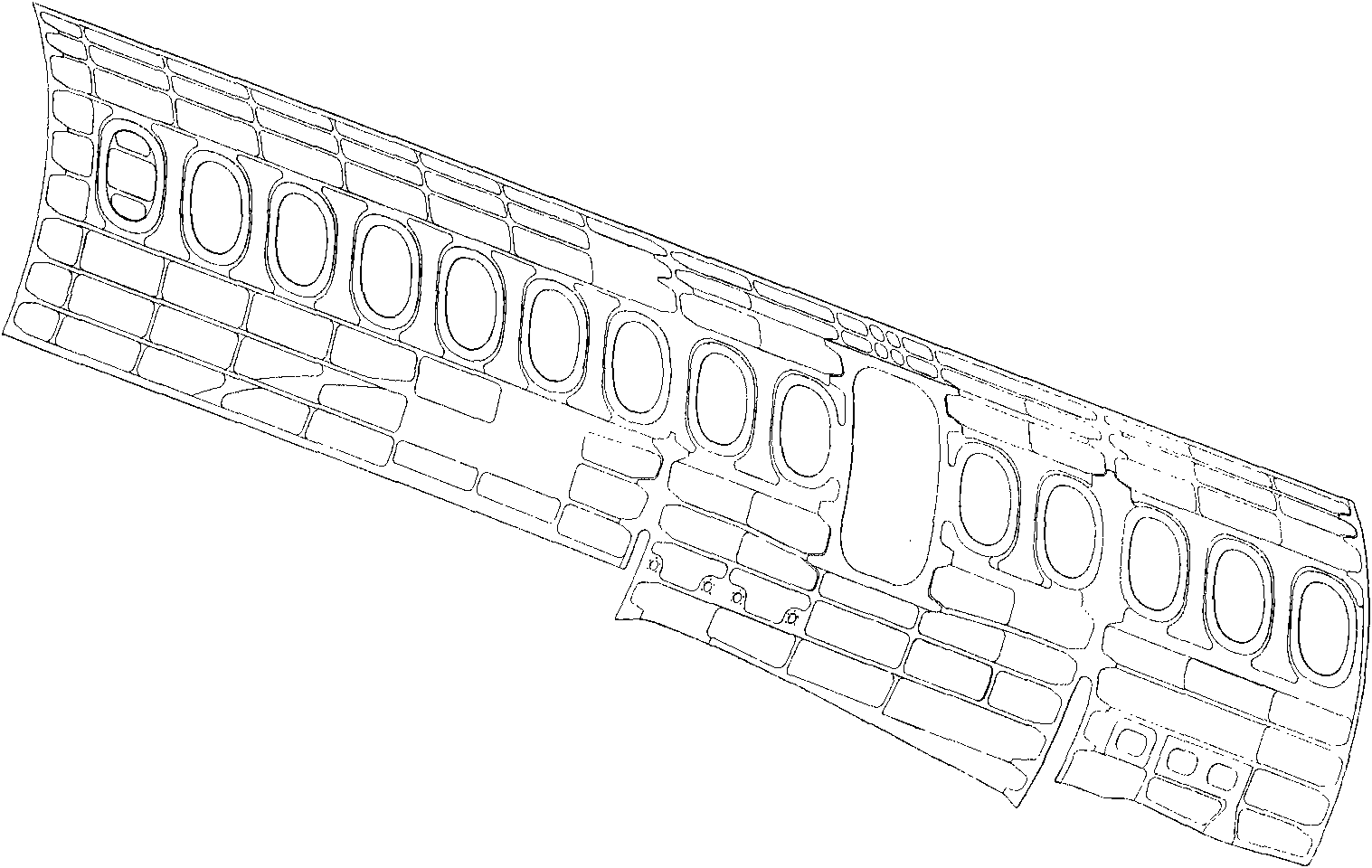

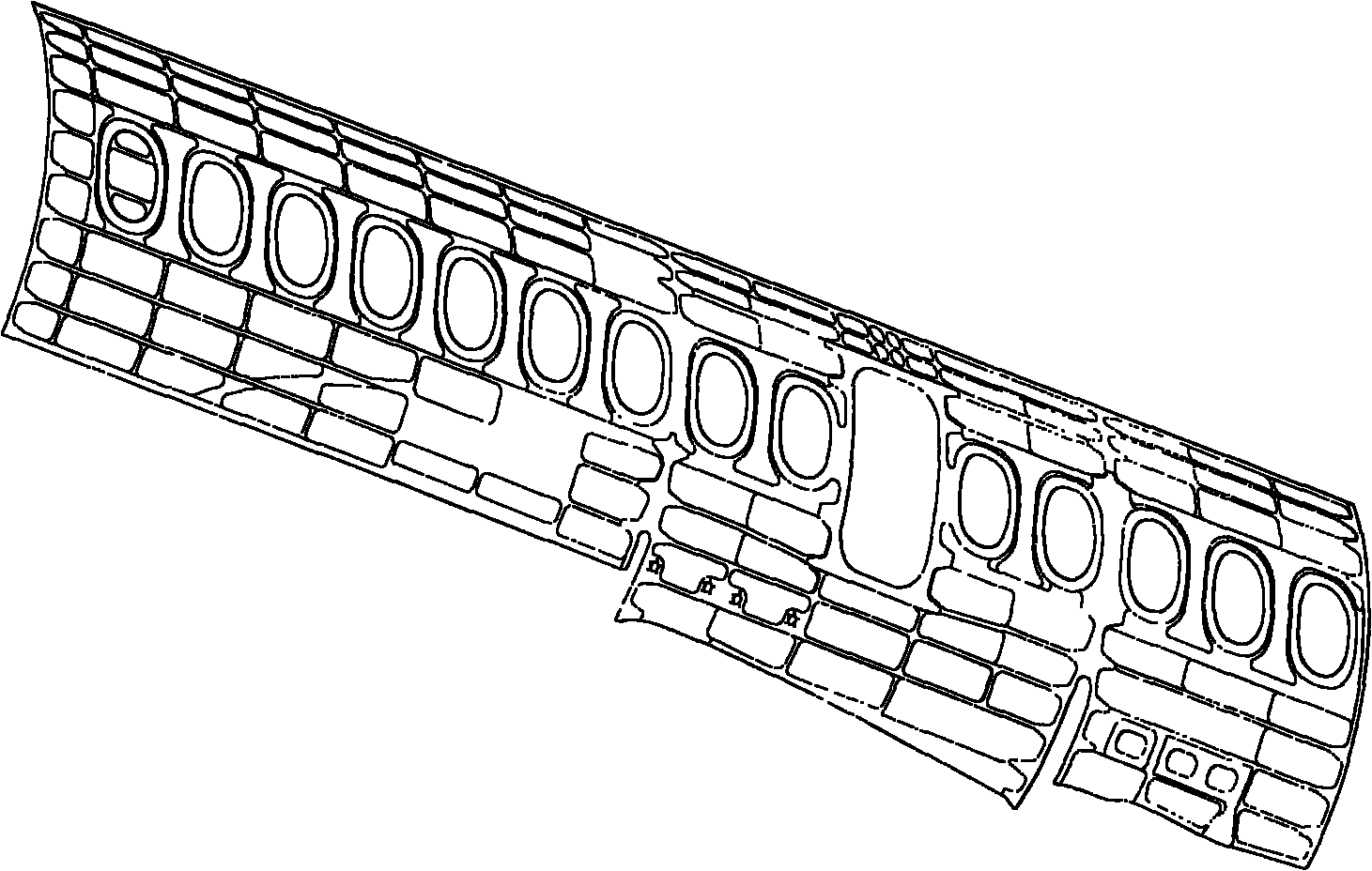

Integral manufacturing method for tube section of large storage box based on numerical control mirror milling

ActiveCN104439968AImprove machining accuracyImprove processing efficiencyMilling equipment detailsNumerical controlMechanical milling

The invention provides an integral manufacturing method for the tube section of a large storage box based on numerical control mirror milling. The method comprises the following steps: (1) milling the upper faces and the lower faces of wall boards of the storage box in a flat board mechanical milling mode through a numerical control wall board milling machine; (2) bending and forming the wall boards through a filling rolling and bending forming method; (3) welding the bent and formed wall boards into the tube section through friction stir welding; (4) carrying out mechanical milling on the tube section integrally, and gridding of the wall boards forming the tube section is machined through numerical control mirror milling. The tube section integral mirror milling is adopted in the integral manufacturing method to replace traditional chemical milling, flat plate mechanical milling and the single curve wall board numerical control gridding milling technology, the manufacturing method of the tube section of the gridding storage box that first a tube is formed and then the tube is milled is achieved, the demand is met, and the machining precision and the machining efficiency of the tube section of the storage box are improved.

Owner:CAPITAL AEROSPACE MACHINERY +2

Shearing reinforcing type full-grouting sleeve

ActiveCN103758292AReduce manufacturing costWide variety of sourcesBuilding reinforcementsMechanical millingEngineering

The invention discloses a shearing reinforcing type full-grouting sleeve which comprises a sleeve body, wherein the sleeve body is of a tubular structure; elastic rubber sealing rings are arranged at the openings of two ends of the sleeve body; a grouting hole is formed in the side wall close to the opening of one end; a discharge hole is formed in the side wall close to the opening of the other end; bolt holes are formed in the side wall along the sleeve body; anti-shearing bolts are arranged inside the bolt holes. The shearing reinforcing type full-grouting sleeve is wide in material resource, simple to machine and manufacture and reliable in property, greatly overcomes the defects that the conventional cast iron or cast iron steel sleeve is complex to manufacture and high in cost, a mechanical milling sleeve is labor and time waste, and the like, can be widely applied to assembled type concrete structures, and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

Method for forming integral panel of main body

The invention provides a method for forming an integral panel of a main body. The method comprises the steps as follows: firstly, the radian measure of the integral panel of the main body is formed through a roll bending forming device; secondly, the radian measure is unbent by utilizing the elastic deformation property of material after the integral panel is processed through roll bending forming, and then multi-stage steps, cut cavities and outlines are formed on the integral panel through mechanical milling; and thirdly, the restored outline / radian measure conditions of the integral panel are checked when in roll bending forming, and part of the integral panel is processed through sizing. By adopting the invention, the method that single-curved parts are processed through three-dimensional milling (comprising chemical milling and mechanical three-dimensional milling) after being formed over the years can be replaced, the manufacturing accuracy and the fatigue strength of products can be improved, the pollution on environment caused by chemical-milling solution as well as the high pollution discharge treatment cost can be avoided, and dedicated three-dimensional milling clamps and equipment for mechanical three-dimensional milling can also be avoided.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

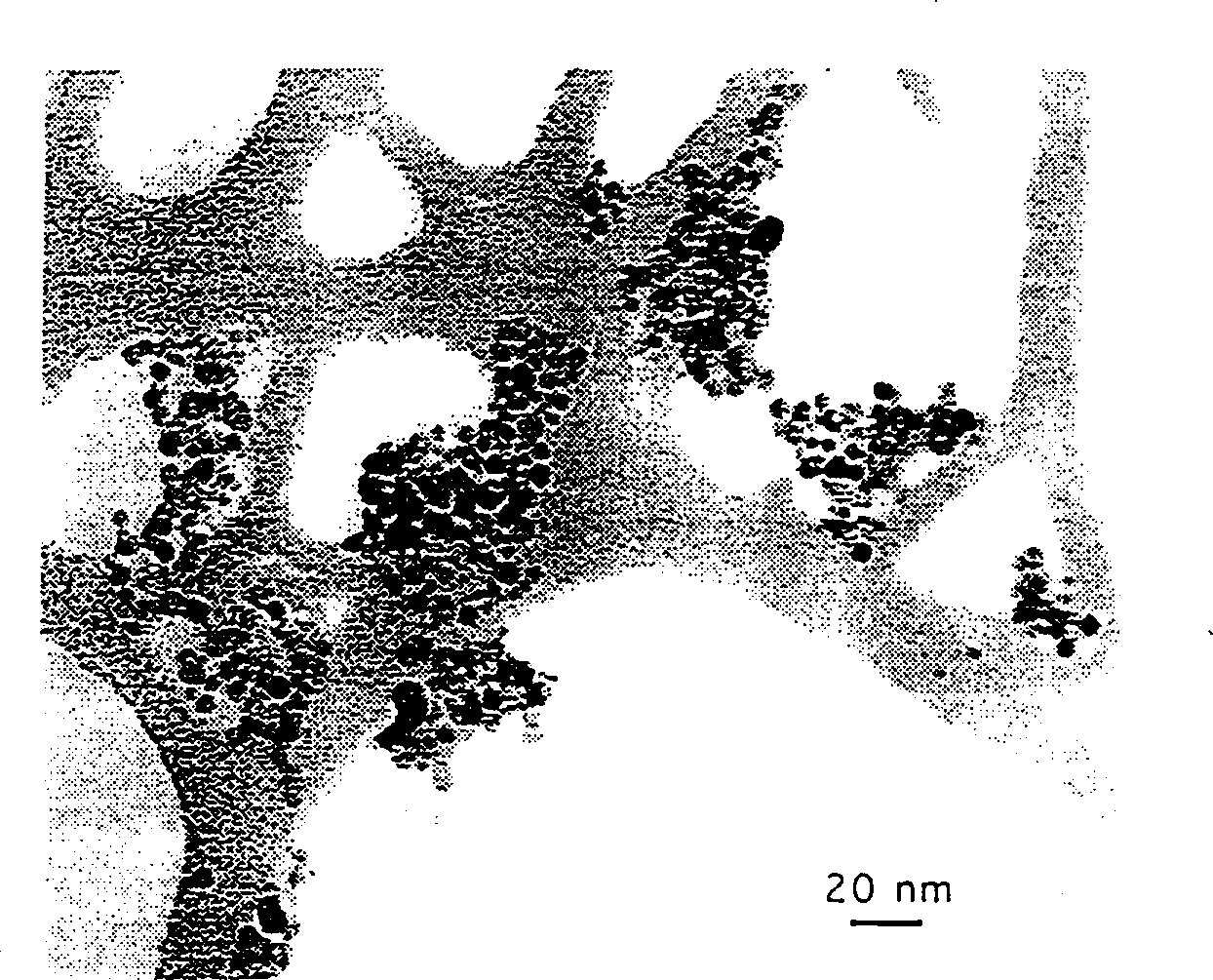

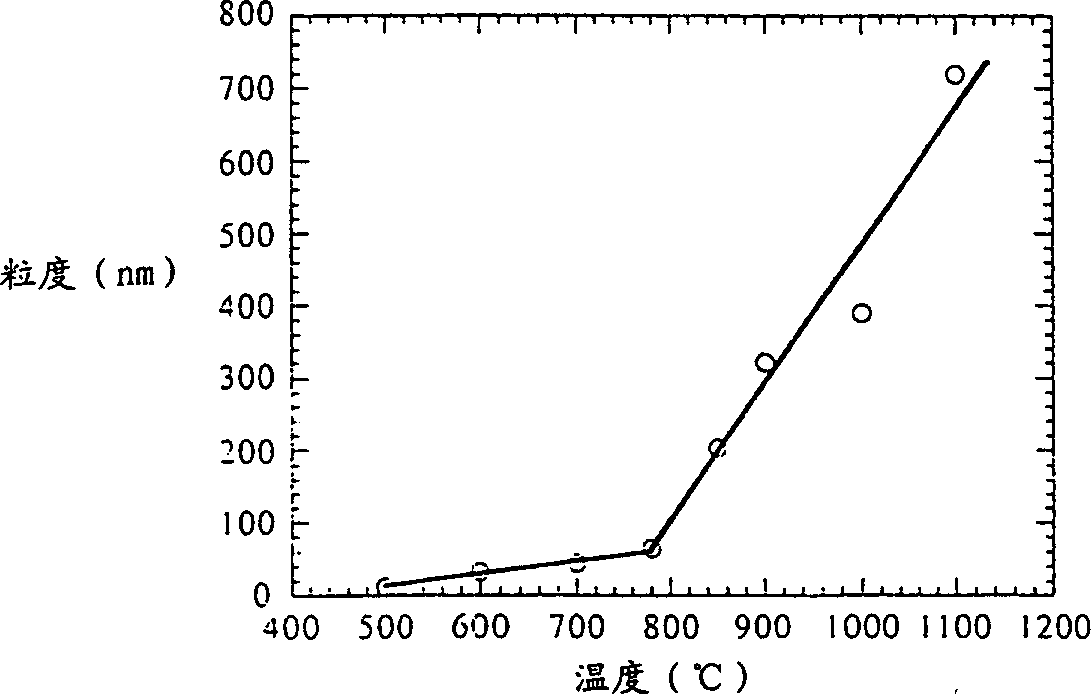

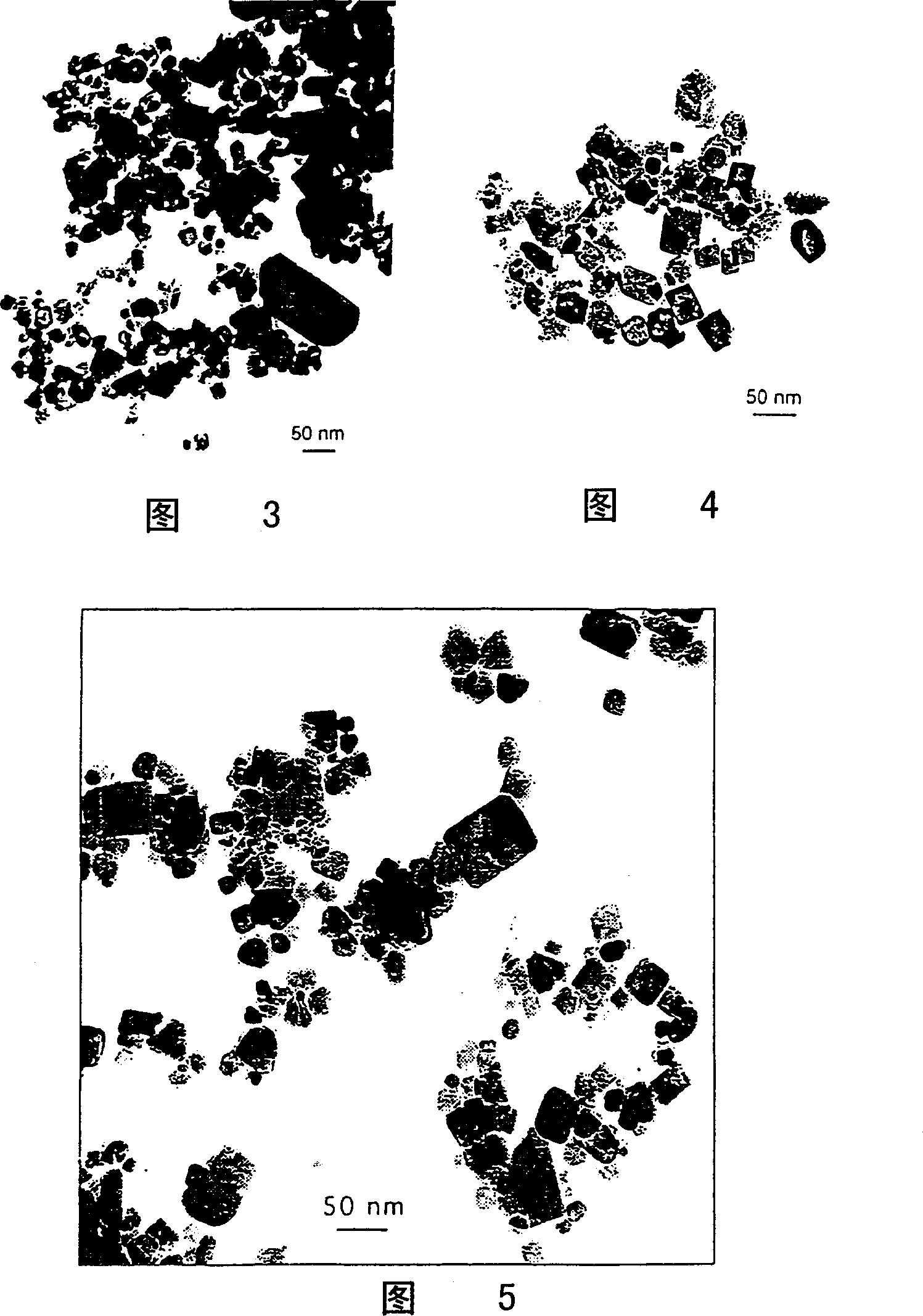

Process for the production of ultrafine powders

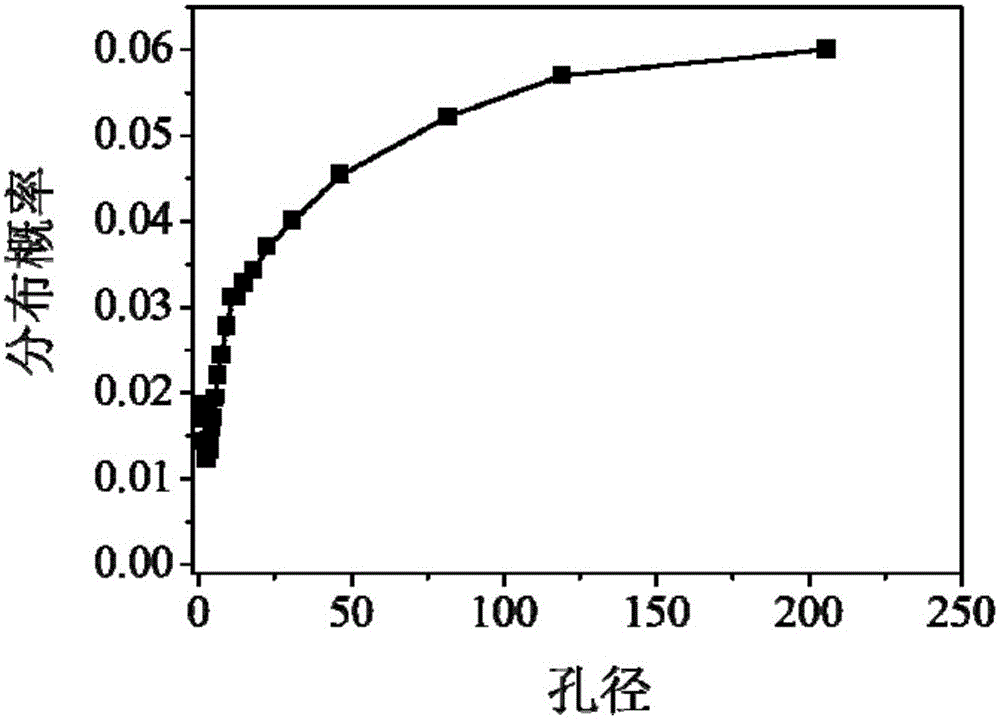

InactiveCN1300243ALow costHigh yieldAlkaline earth titanatesMaterial nanotechnologyMechanical millingParticle-size distribution

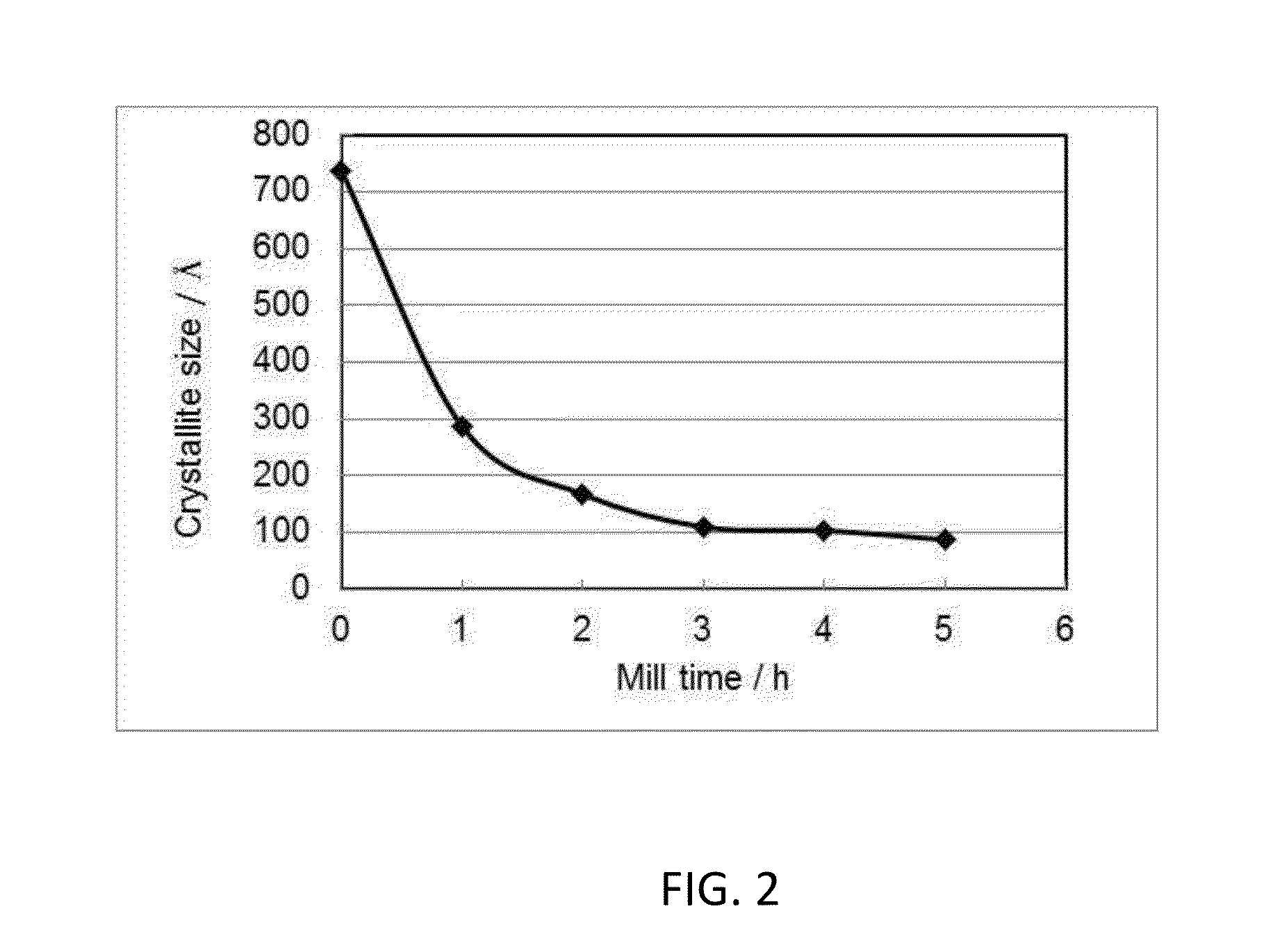

A process for the production of ultrafine powders consisting of individual particles with sizes in the range of 1 nm to 200 nm, which is based on the mechanical milling of two or more non-reacting powders. The process includes subjecting a suitable precursor metal compound and a non-reactant diluent phased to mechanical milling which through the process of mechanical activation reduces the microstructure of the mixture of the form of nano-sized grains of the metal compound uniformly dispersed in the diluent phase. Heat treating the milled powder converts the nano-sized grains of the precursor metal compound into a desired metal oxide phase. Alternatively, the precursor metal compound may itself be an oxide phase which has the requisite milling properties to form nanograins when milled with a diluent. An ultrafine powder is produced by removing the diluent phase such that nano-sized grains of the desired metal oxide phase are left behind. The process facilitates a significant degree of control over the particle size and size distribution of the particles in the ultrafine powder by controlling the parameters of mechanical activation and heat treatment.

Owner:ADVANCED NANO TECH +1

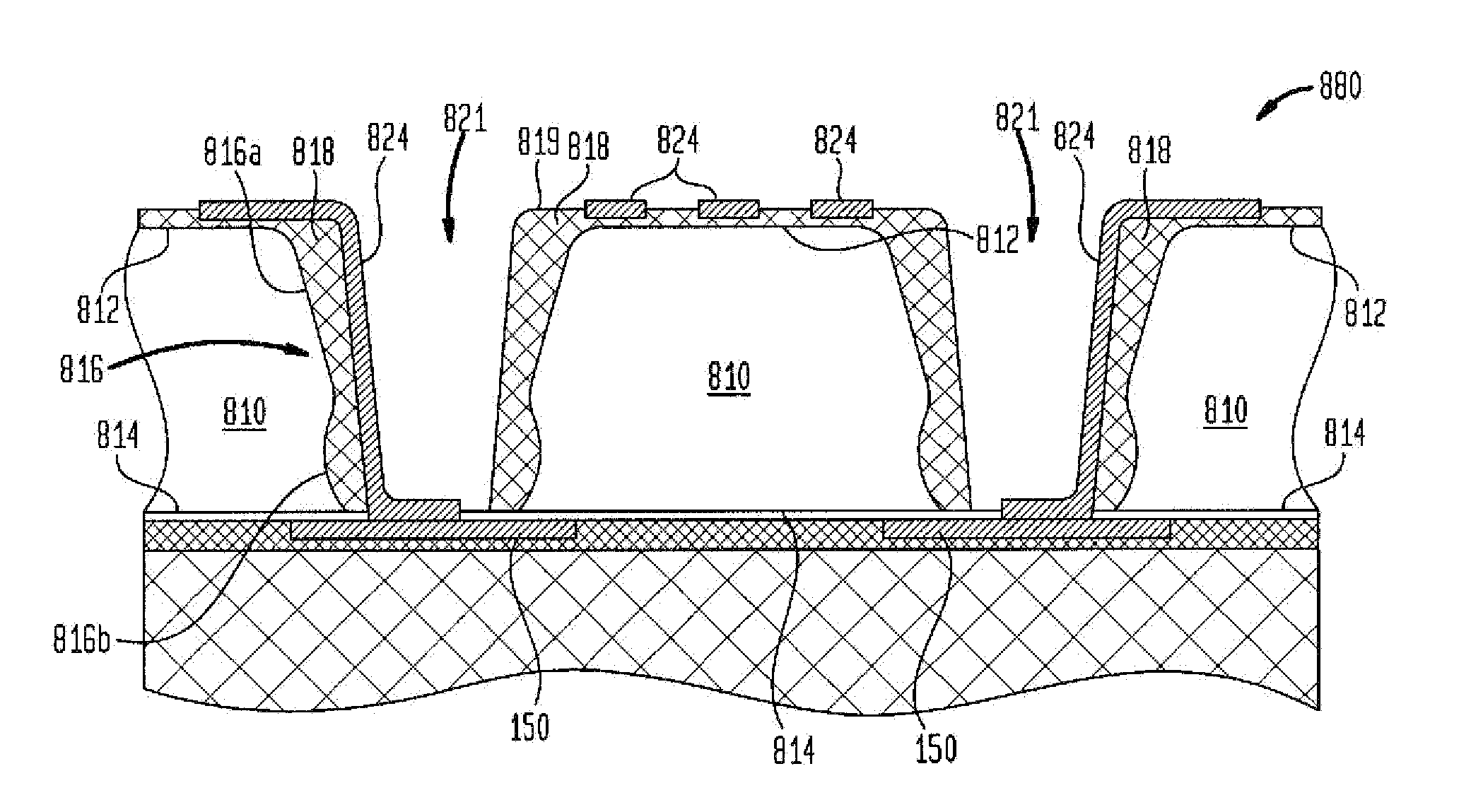

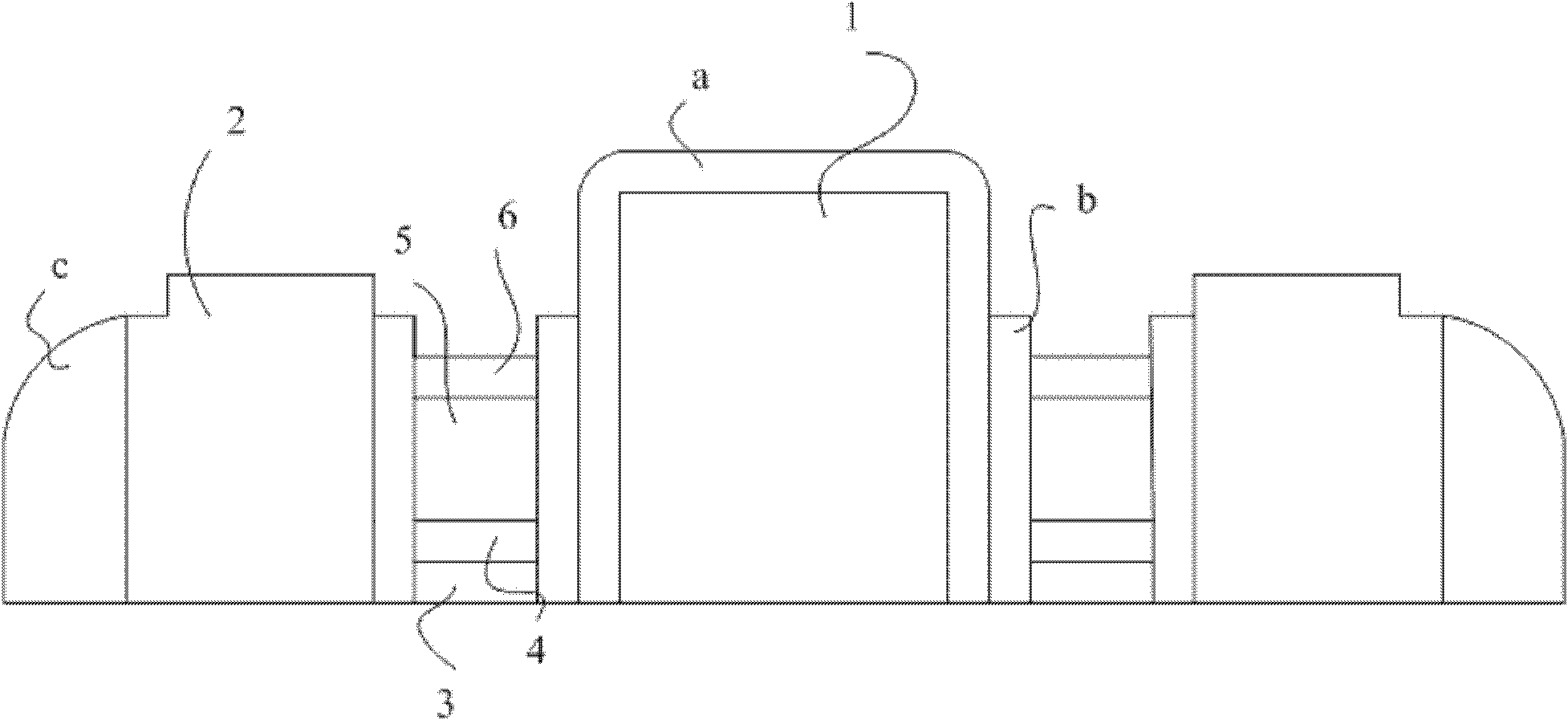

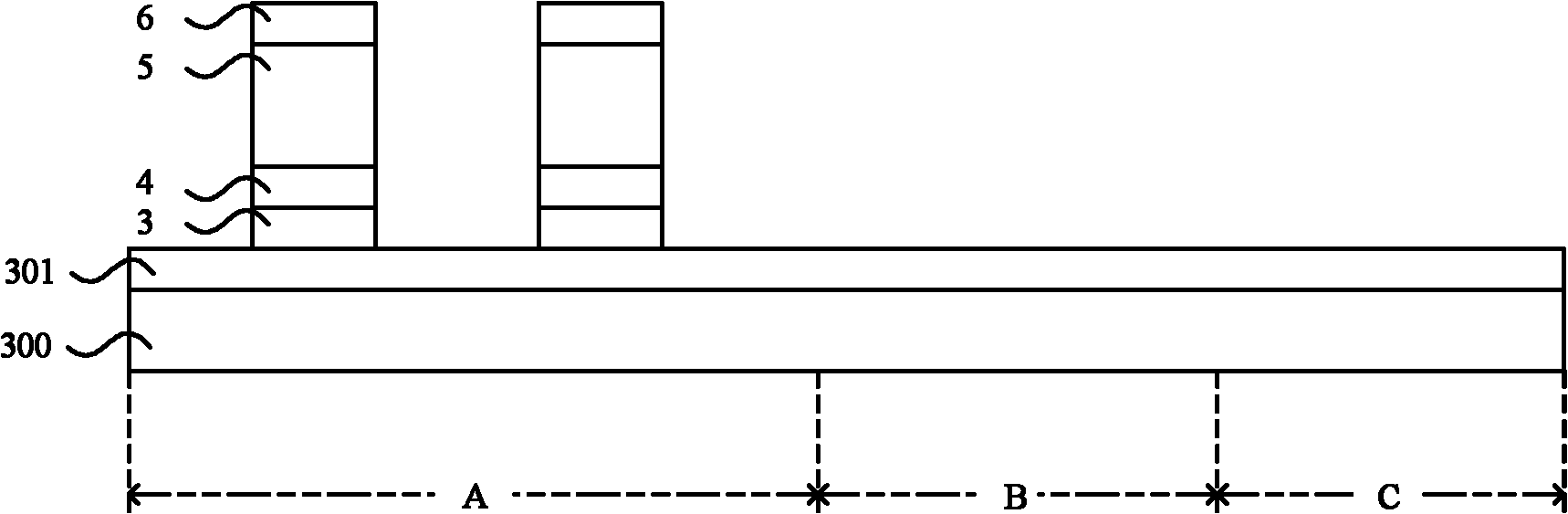

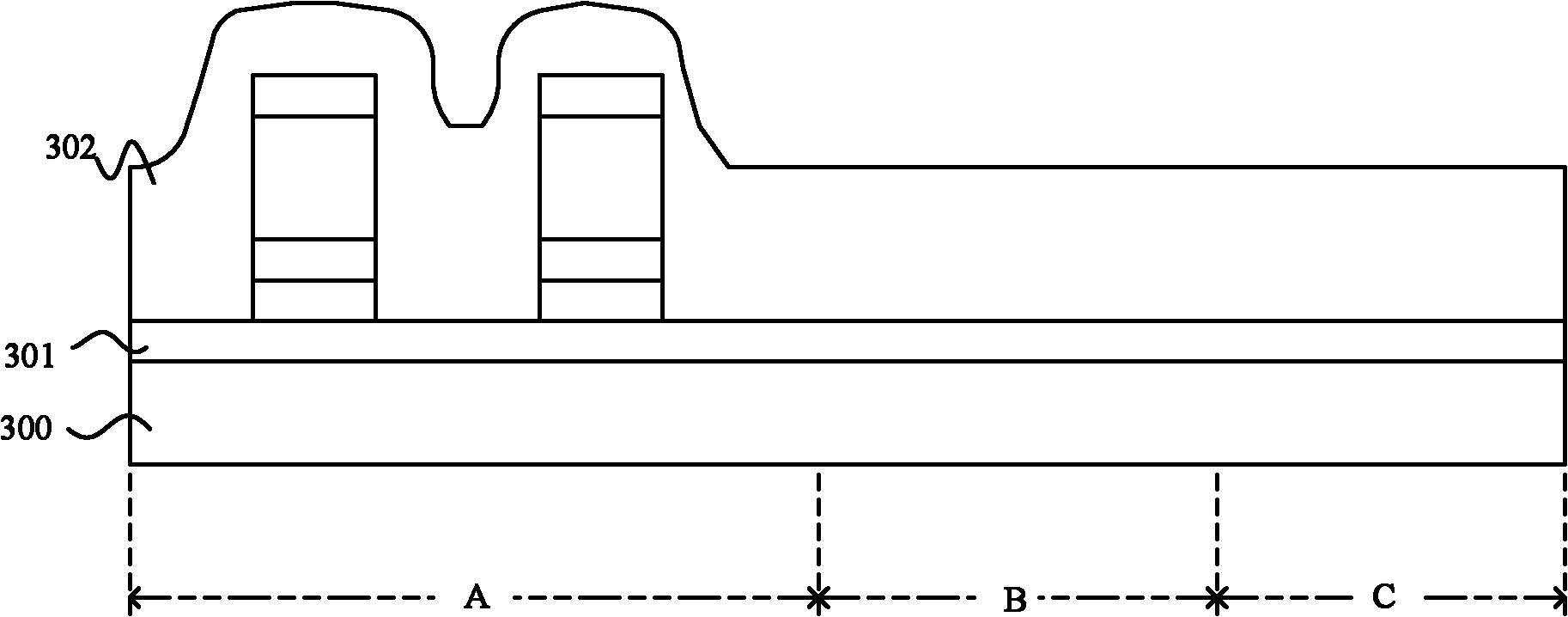

Flash memory and manufacturing method thereof as well as formation method of grids in different thicknesses

ActiveCN103021951AHigh speedHigh densitySolid-state devicesSemiconductor/solid-state device manufacturingHigh voltage transistorsMechanical milling

The invention provides a manufacturing method of a separate grid type flash memory used for an embedded logic circuit. Compared with a formation method of an individual separate grid type flash memory, the manufacturing method provided by the invention has the advantage that the separate grid type flash memory, a high voltage transistor and a logic transistor can be manufactured on one integrated circuit at the same time only by realizing formation of the grids in different thicknesses in an embedded separate grid type flash memory by virtue of chemical mechanical milling on two-layer polycrystalline silicon and oxidation of polycrystalline silicon, so that densities of the separate grid type flash memory, the high voltage transistor and the logic transistor can be increased, integration degree is high, operating speed is higher, and an integrated chip is smaller, so that cost of the whole integrated chip is reduced. The invention also provides a separate grid type flash memory used for the embedded logic circuit and a method for forming the grids in different thicknesses.

Owner:SEMICON MFG INT (SHANGHAI) CORP

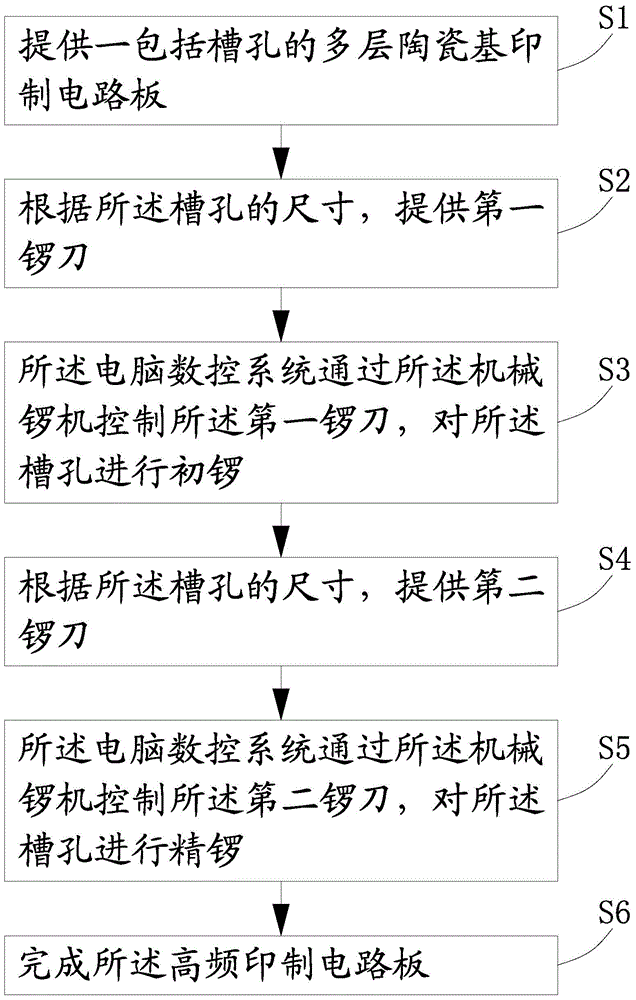

De-burring method for high-frequency printed circuit board

InactiveCN104354084AAchieve the purpose of removingEdge grinding machinesMechanical millingEngineering

The invention provides a de-burring method for a high-frequency printed circuit board. The method comprises the following steps of providing a multi-layer ceramic base printed circuit board with a slot; according to the size of the slot, providing a first milling knife, wherein a computer digital control system controls the first milling knife through a mechanical milling machine to crudely mill the slot; according to the size of the slot, providing a second milling knife, wherein the computer digital control system controls the second milling knife through the mechanical milling machine to finely mill the slot. Compared with the prior art, the de-burring method for the high-frequency printed circuit board provided by the invention has the advantages that the high-frequency board is molded in the mode that crude milling in the positive direction and fine milling in the negative direction are combined, i.e. the milling knife with the width smaller than the width of the slot is used for cutting the middle of the slot in the position where the slot is required to be molded to crudely mill, and then the milling knife with the width equal to the width of the slot is used for fine milling in the reversing direction, so that burrs generated when the knife is positively travelled are removed, and the aim of de-burring the surface of the high-frequency printed circuit board is fulfilled.

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

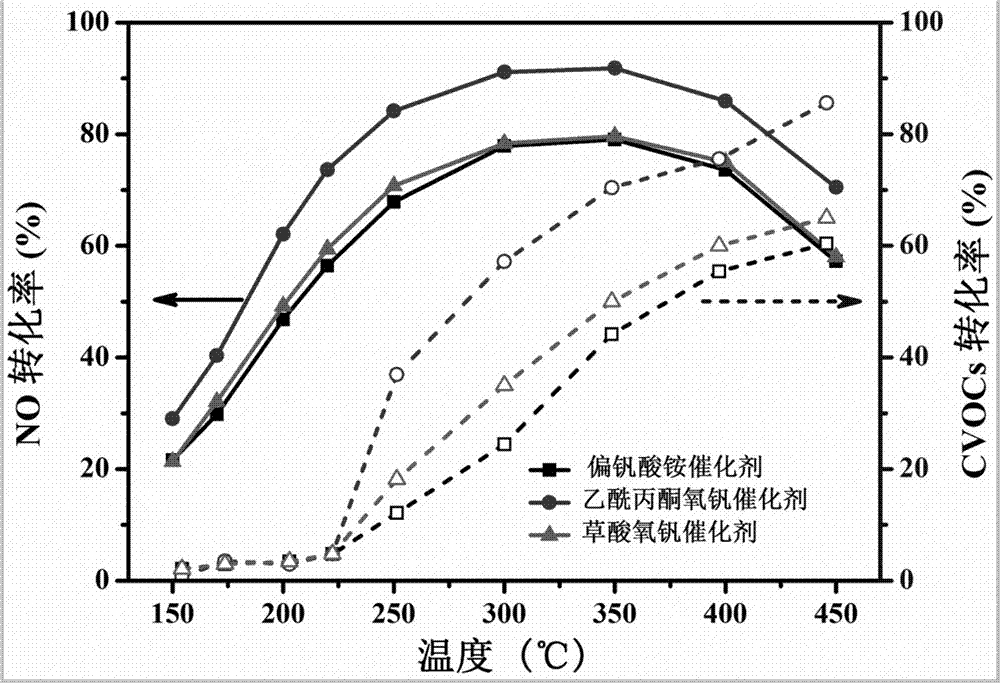

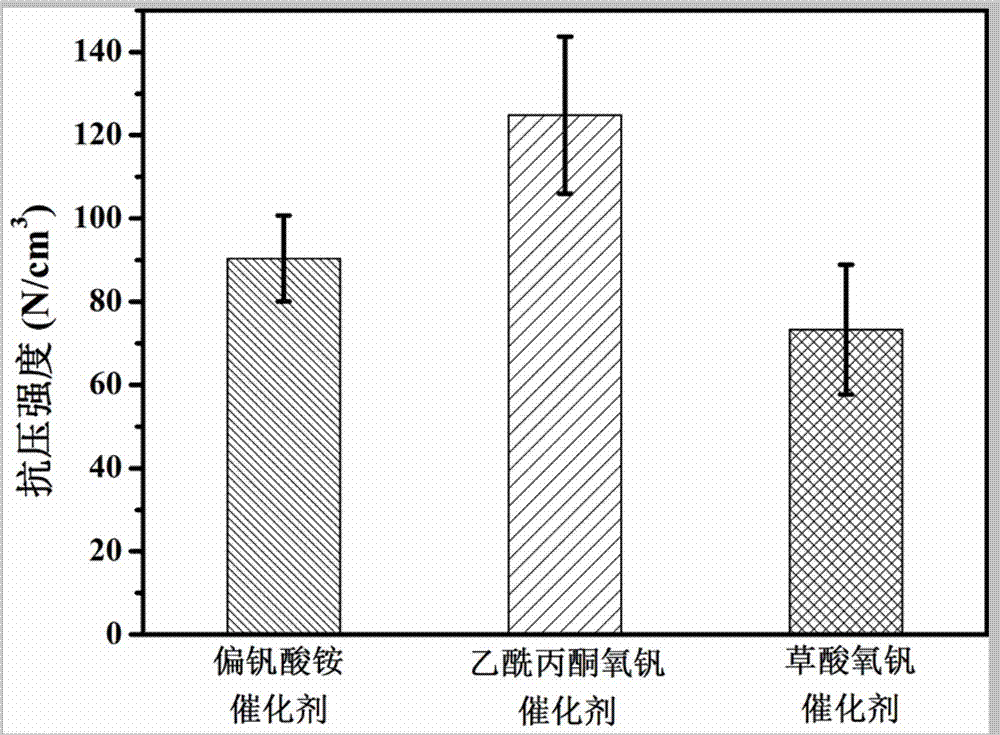

Preparation method and application of trifolium-shaped catalyst for cooperatively controlling NOx and CVOCs

ActiveCN107376895AImprove denitrification rateImprove removal efficiencyGas treatmentDispersed particle separationDenitrificationNOx

The invention discloses a preparation method and application of a trifolium-shaped catalyst for cooperatively controlling nitrogen oxide (NOx) and a chlorinated volatile organic compound (CVOCs). The catalyst adopts an organic vanadium compound as a vanadium precursor, and titanium dioxide or titanium tungsten powder as a carrier, and is prepared by utilizing a two-step method comprising the concrete steps of (1) utilizing a mechanical milling method for preparing a powder catalyst; (2) adopting an extrusion molding process for preparing the trifolium-shaped structured catalyst. The obtained catalyst is applicable to removing the NOx and the CVOCs of industrial flue gas of the industries such as waste incineration, steel iron sintering and nonferrous metallurgy, and is also applicable to cooperatively removing the NOx and the CVOCs. Compared with an existing commercial catalyst, a commercial vanadium-based catalyst system is rarely changed, the two-step method is adopted, and the obtained catalyst not only has high denitrification rate and CVOCs removal efficiency but only has higher mechanical strength and abrasion resistance, so that the preparation method is a preparation technology beneficial for commercially producing the trifolium-shaped catalyst for cooperatively denitrating and removing the CVOCs.

Owner:TSINGHUA UNIV

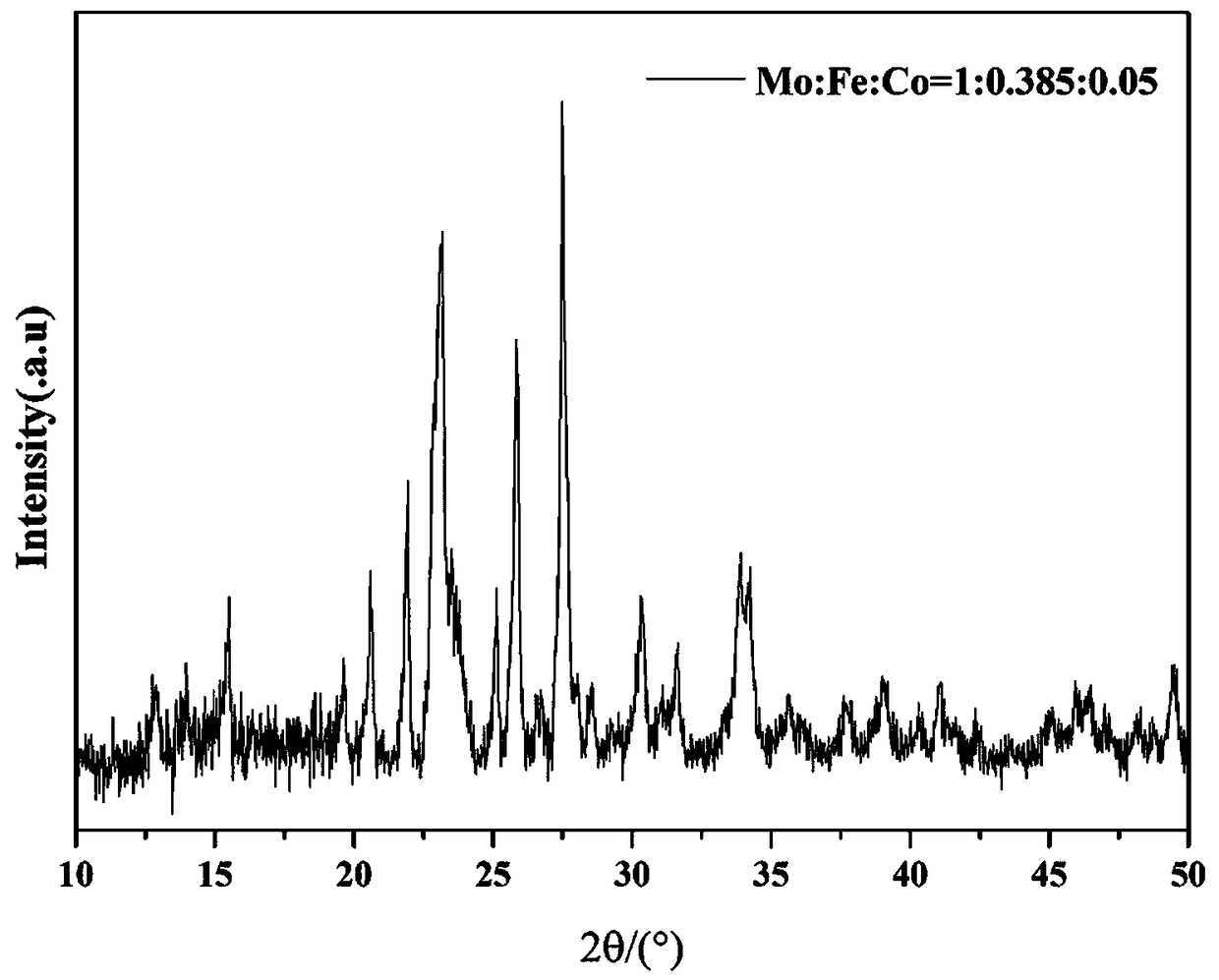

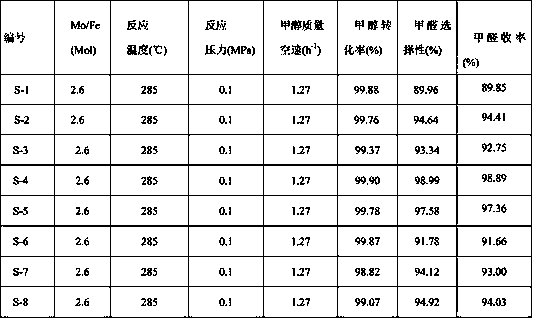

Method for modifying iron-molybdenum catalyst for oxidizing methanol to formaldehyde

InactiveCN109012682AImprove conversion rateHigh selectivityOrganic compound preparationCarbonyl compound preparationMolybdateMechanical milling

The invention belongs to the field of industrial catalysis, and relates to a method for modifying an iron-molybdenum catalyst for oxidizing methanol to formaldehyde, in particular to a method for modifying an iron-molybdenum catalyst with a metal additive salt by the utilization of a mechanochemical method. By the utilization of a mechanochemical method, corresponding molybdate, iron salt and metal additive salt are firstly weighed according to a certain molar ratio of molybdenum: iron: metal additive; then, the metal additive salt is directly mixed with the solid-phase iron salt and molybdate, and the mixture undergoes ball-milling, drying and calcining to prepare the metal additive modified iron-molybdenum catalyst raw-powder. In the invention, the metal additive salt, the iron source and the molybdenum source undergo the mechanical milling process to prepare the iron-molybdenum catalyst. In comparison with a method without addition of metal salt, methanol conversion rate and formaldehyde selectivity are obviously improved by the above method of the invention. The method has simple process, and solvent water and other precipitators are not required. By the method, discharge of industrial wastewater can be greatly reduced, and manufacture cost of the catalyst is lowered.

Owner:XINJIANG UNIVERSITY

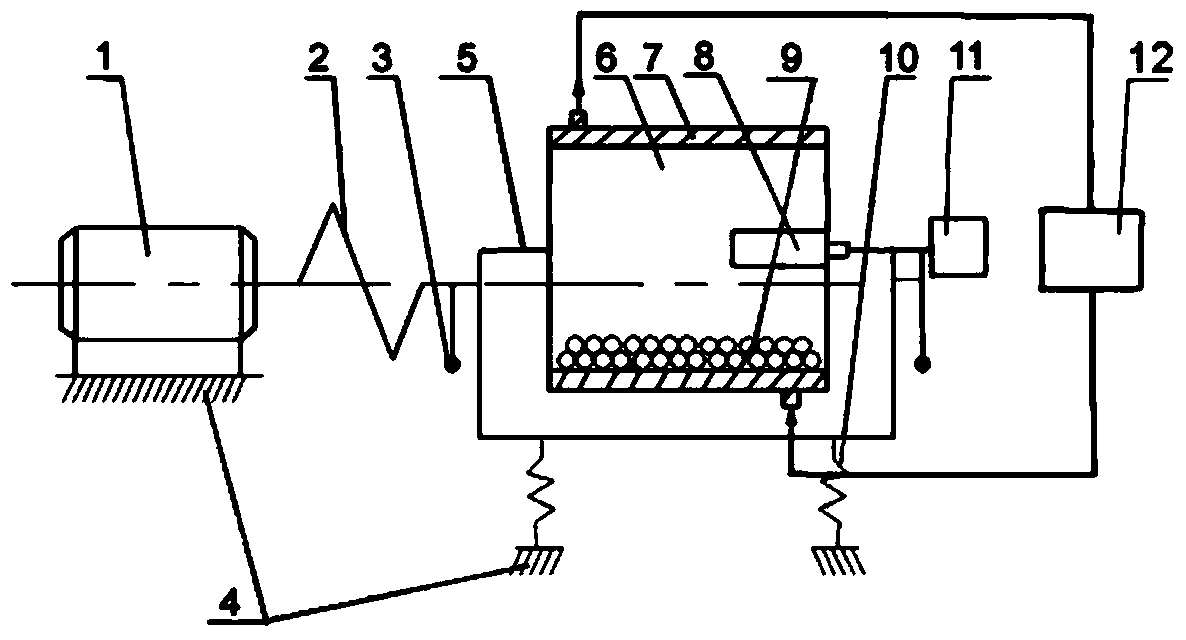

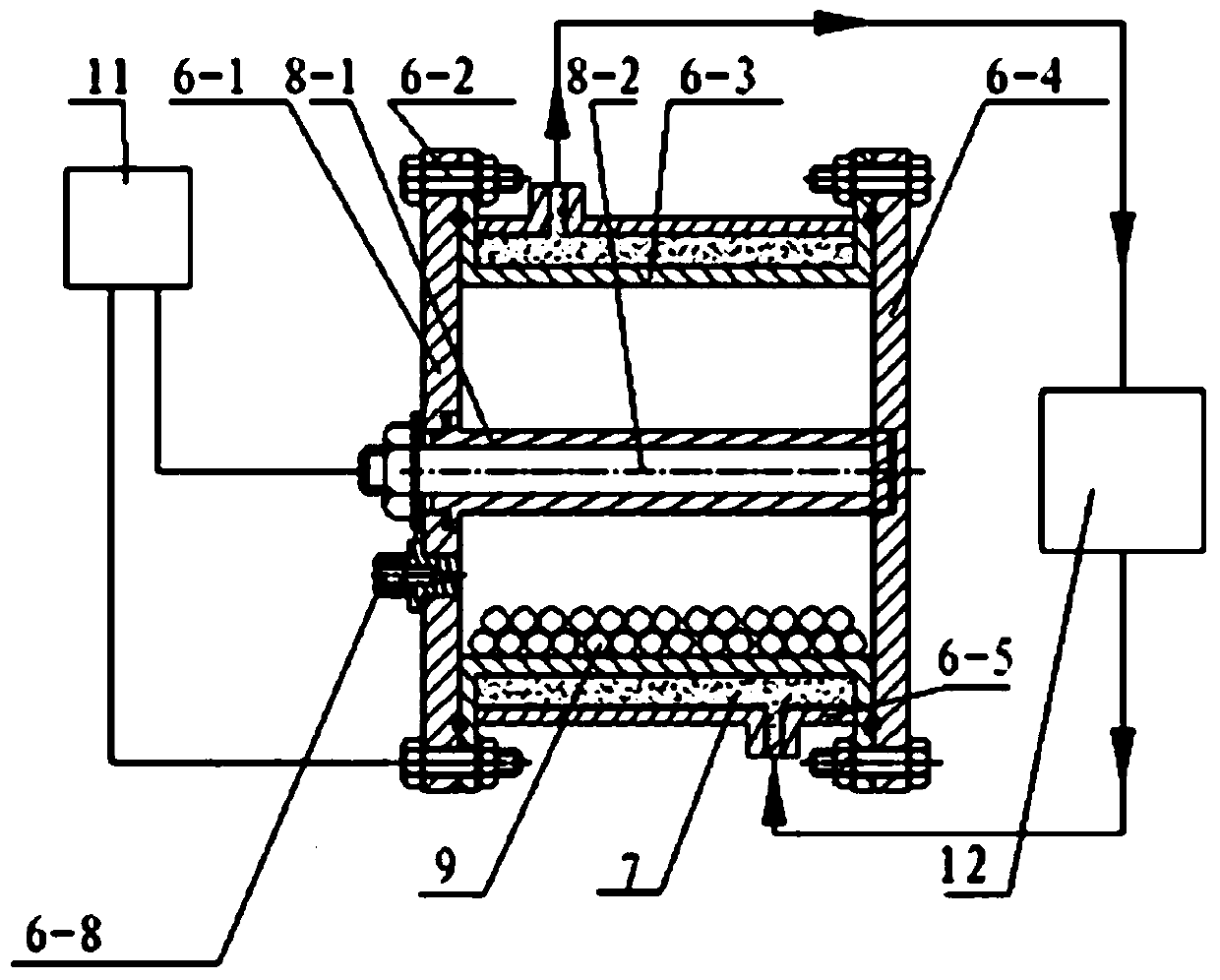

Surface modified nanometer material serving as lubricating oil additive as well as preparation method and application thereof

ActiveCN103804960AReduce the temperatureFast preparationAdditivesPigment treatment with macromolecular organic compoundsMechanical millingOil additive

The invention belongs to the technical fields of a nanometer material and lubricating oil, and discloses a surface modified nanometer material serving as a lubricating oil additive as well as a preparation method and an application thereof. The preparation method mainly comprises the following steps: putting a mixture of powder to be treated and a surface modification agent as well as grinding balls in a ball-milling tank of an improved dielectric barrier discharge plasma assisted mechanical milling device, feeding a discharge atmosphere medium, controlling the temperature of the ball-milling tank, adjusting discharge parameters, and starting the mechanical milling device so as to carry out dielectric barrier discharge plasma assisted mechanical milling, thus obtaining the surface modified nanometer material. The obtained powdery surface modified nanometer material can be added to the lubricating oil so as to improve the performance of the lubricating oil. The preparation method is simple to operate and good in controllability; the obtained surface modified nanometer material is small in particle size, high in activity, good in surface modification and extremely easy to deposit, flatly spread and diffuse on a mechanical friction surface and has excellent dispersion property in the lubricating oil, so that the friction of mechanical movement parts is reduced, and the worn surface is repaired.

Owner:麦卡伦(厦门)润滑油有限公司

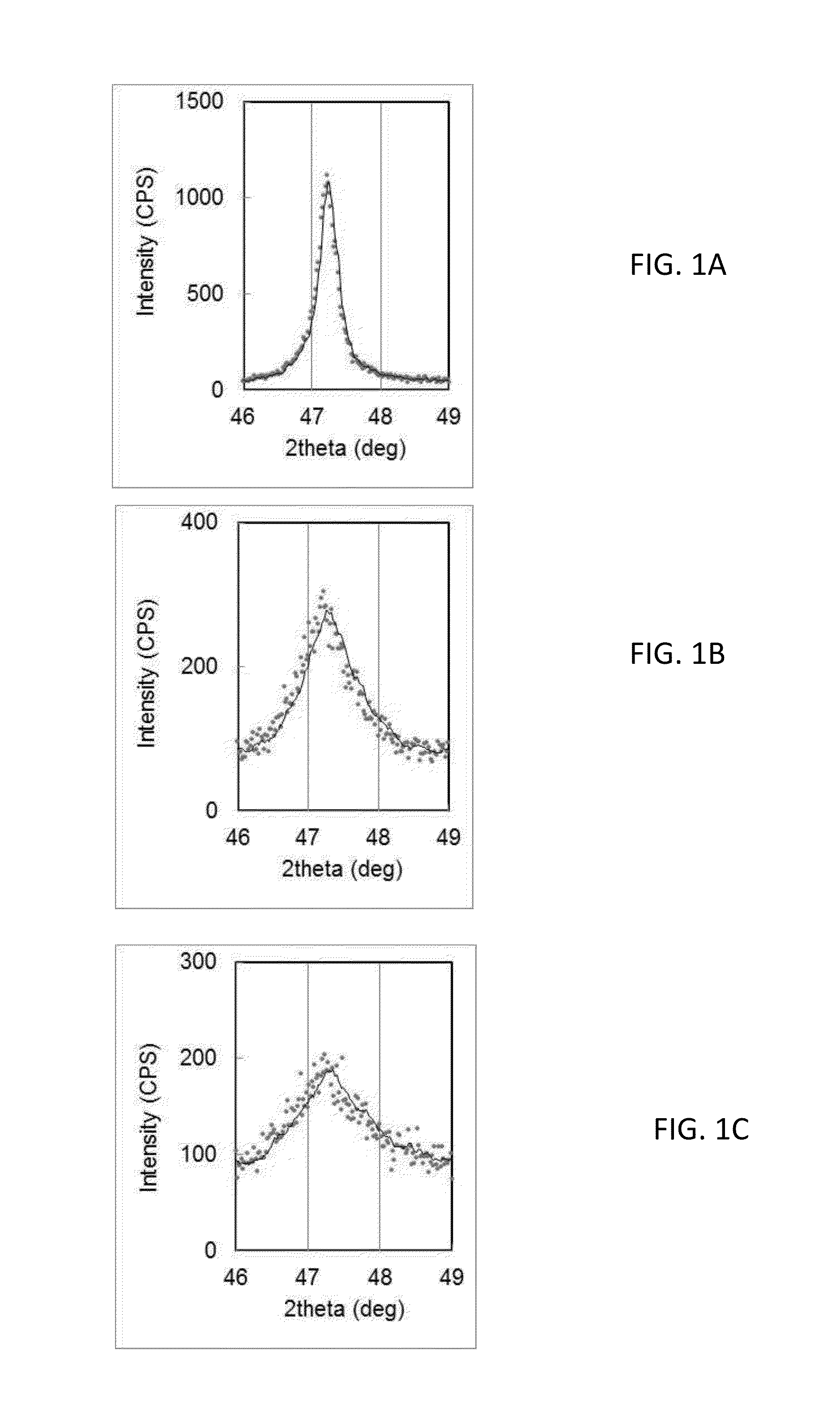

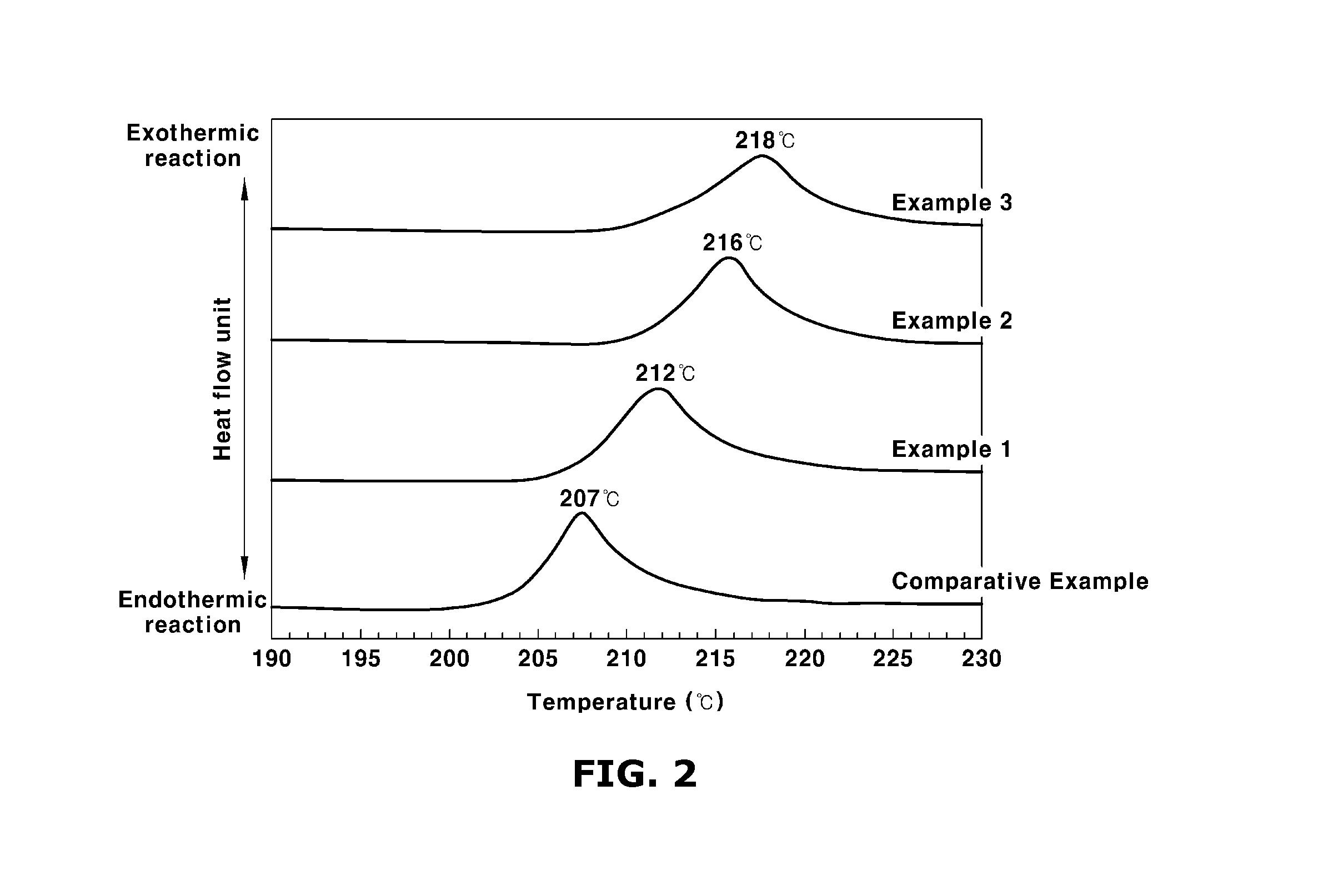

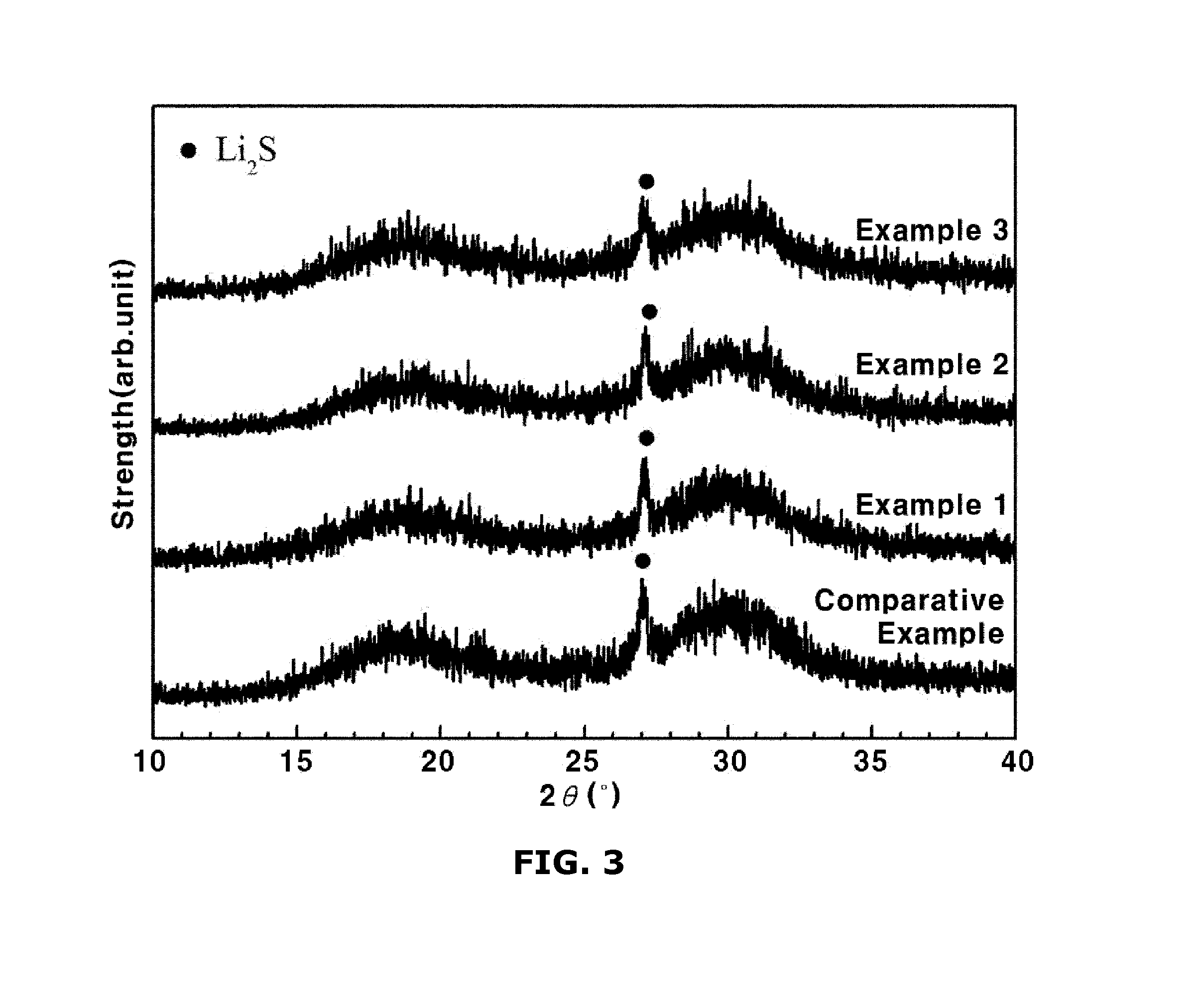

Sulfide-based crystallized glass for all-solid secondary battery and a method for manufacturing the same

ActiveUS20160181656A1Improved lithium-ionic conductivityEasy to addSolid electrolytesFinal product manufactureMechanical millingHeat treated

A sulfide-based crystallized glass for an all-solid secondary battery has a sulfide that includes Li2S and P2S5, wherein the sulfide-based crystallized glass consists of 1 to 5% by mole of Li3BO3. A method for manufacturing the sulfide-based crystallized glass comprises steps of mixing (1) 75 to 80% by mole of Li2S and 20 to 25% by mole of P2S5, and then mixing (2) 95 to 99% by mole of obtained mixture at (1) and 1 to 5% by mole of Li3BO3 with a mechanical milling method, and subjecting the mixture thus obtained to a heat-treatment process.

Owner:HYUNDAI MOTOR CO LTD +1

Rapid manufacturing method used for outer storing box gridding wallboard of aerospace craft

InactiveCN103639668AGuaranteed bonding strengthStrong shear resistanceVehicle componentsMetal working apparatusMechanical millingMachining

The invention discloses a rapid manufacturing method used for an outer storing box gridding wallboard of an aerospace craft, the outer storing box gridding wallboard comprises a bottom board and gridding ribs and is machined by the adoption of friction stir welding equipment. The rapid manufacturing method includes the following steps that (1), a bottom board plate is machined in advance; (2), material of stitch welding plates is selected following the principle of component matching between the stitch welding plates and the bottom board or the principle of performance complementation; the size of the stitch welding plates is determined according to the gridding number, the gridding size and the rib width on the bottom plate; (3), a friction stir stitch welding clamp used for the structure is designed; (4), the manufacturing concept of layering material increase-partial milling is achieved through the friction stir stitch welding gridding ribs; (5), finish machining is performed. The manufacturing concept of layering material increase is combined with the friction stir welding technology, and not only can gridding rib wallboards in various shapes and heights be manufactured, but also a heterogeneous aluminum alloy ribbed bar gridding wallboard can be manufactured and machined on a thin aluminum sheet, which can not be achieved through existing chemical milling and mechanical milling methods.

Owner:TIANJIN UNIV

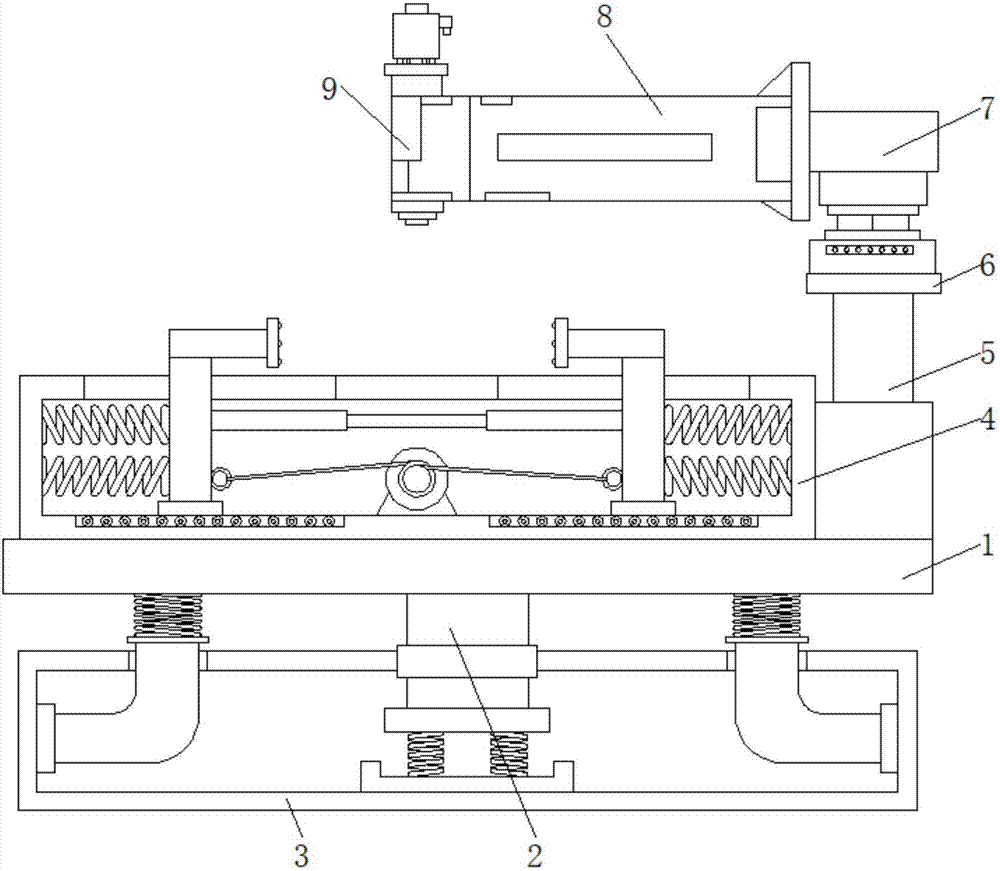

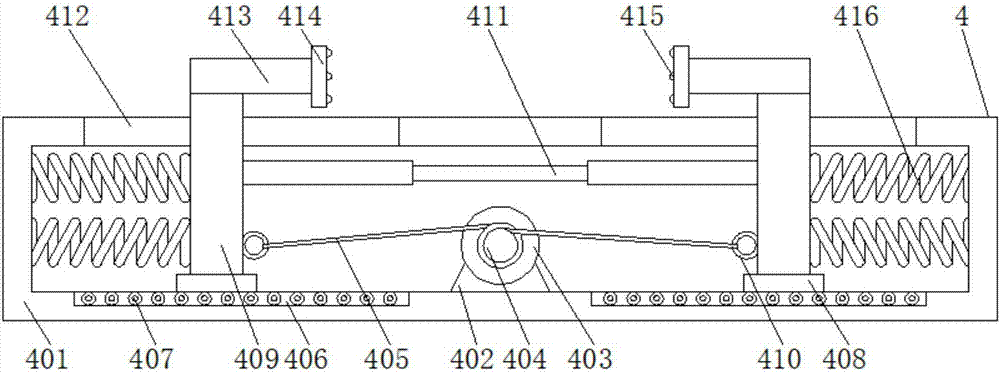

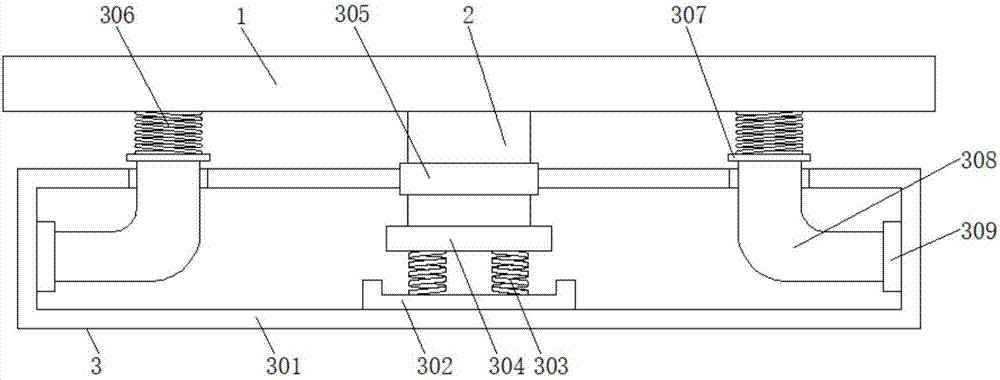

Mechanical milling machine with clamping function

InactiveCN107971784AEasy clampingImprove work efficiencyPositioning apparatusMaintainance and safety accessoriesMechanical millingMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a mechanical milling machine with a clamping function. According to the mechanical milling machine with the clamping function, the problem that the clamping effect is unsatisfactory can be solved. The mechanical milling machine with the clamping function includes a supporting table, a supporting column is fixedly connected at the bottom center of the supporting table, and a damping mechanism is fixedly connected at the bottom of the supporting column; and a clamping mechanism is fixedly connected at the topof the supporting table, a linear actuator which is located at the right side of the clamping mechanism is fixedly connected at the top of the supporting table, and a mounting block is fixedly connected at the top of the linear actuator. According to the mechanical milling machine with the clamping function, a motor runs to enable a rotating wheel to rotate, a pulling rope is used for pulling a connecting column to move to the inner side, so that two protruding blocks can move closer to clamp and fix workpieces and further the clamping effect is better, the time and the labor can be saved, andthe working efficiency during machining can be improved.

Owner:绍兴柯桥诚鑫精密铸造有限公司

Rare earth doping Mg2Si based thermoelectric material

InactiveCN101197420AExcellent thermoelectric performanceImprove thermoelectric performanceThermoelectric device junction materialsThermoelectric materialsRare-earth element

The invention discloses a rare earth doping Mg2Si based thermoelectric material. The invention utilizes rare earth doping to improve thermoelectric properties of the material. Rare earth is directly added during melting, then the melted material is hot pressed after mechanical milling, and thermoelectric material blocks Mg2-xSiREx are obtained, in which RE represents rare earth element, and x equals to 0.002 to 0.01. The invention, the rare earth doping Mg2Si based thermoelectric material, has better thermoelectric properties than non-doping Mg2Si2 thermoelectric material; the doped rare earth elements comprises heavy rare earth and light rare earth; the mechanism is that rare earth elements have similar properties as alkaline earth metal; Mg is easily substituted after rare earth elements are added as donor doping, which increases carrier concentration and thus improves thermoelectric properties of the material.

Owner:ZHEJIANG UNIV

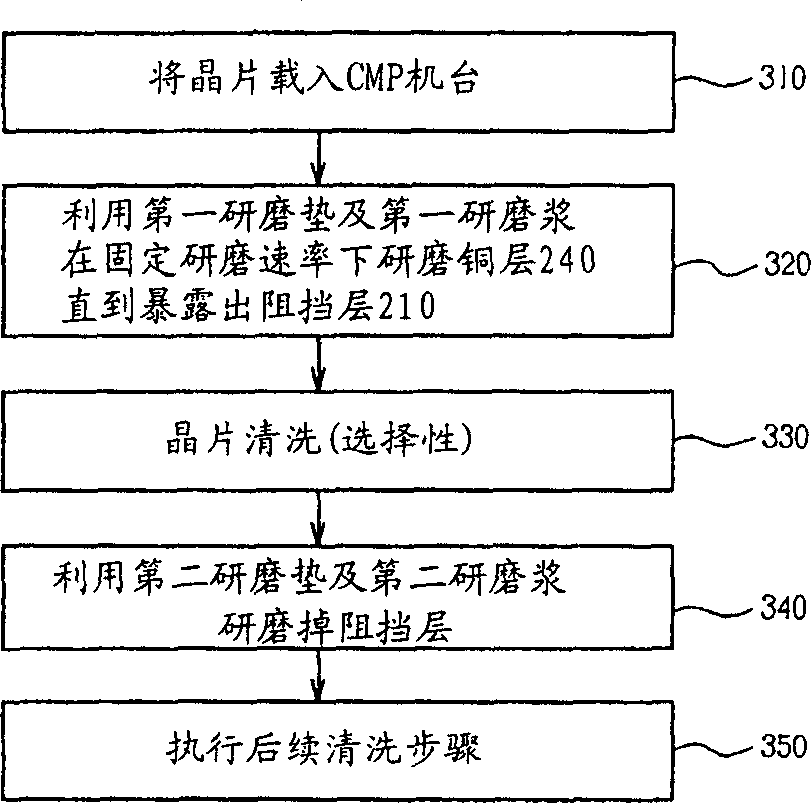

Chemical mechanical polishing technique

InactiveCN1755901AOther chemical processesSemiconductor/solid-state device manufacturingMechanical millingCopper

The invention provides a chemical mechanical milling process comprising following steps: first, loading the wafers which has lines of metal layer and baffle layer; then, via one first milling cushion, milling the metal layer in same milling speed to expose the lower baffle layer, wherein, the first milling paste distributed on the first milling layer has high milling selective rate to the baffle layer; the second milling step that utilizing one second milling cushion and the second milling past to mill and remove the exposed baffle layer. According to said invention, the milling selective rate (the copper to baffle layer) of first milling past is at least more than 30 while the better is more than 100.

Owner:UNITED MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com