Integral manufacturing method for tube section of large storage box based on numerical control mirror milling

A technology of mirror image milling and manufacturing methods, applied in the field of mechanical manufacturing technology, can solve problems such as difficult control of wall thickness tolerance, low processing efficiency, uneven corrosion, etc., and achieve the goals of improving measurement accuracy and efficiency, improving processing efficiency, and improving processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further description of the overall manufacturing method of a large tank barrel section based on CNC mirror milling according to the present invention with reference to the accompanying drawings and specific embodiments.

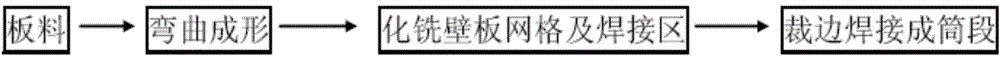

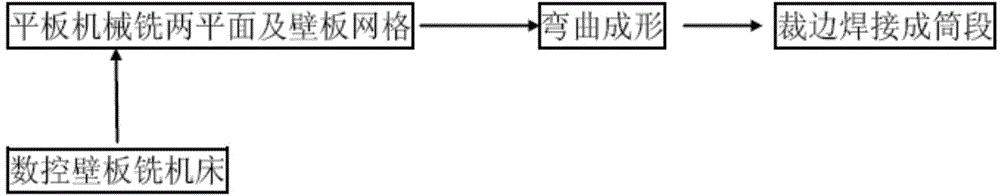

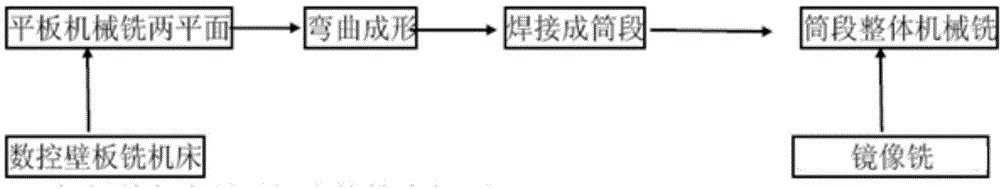

[0022] According to the present invention, a large-scale storage tank barrel segment integral manufacturing method based on numerical control mirror milling, such as image 3 As shown, it includes the following steps:

[0023] (1) CNC wall panel milling machine is adopted, and the plate mechanically mills the upper and lower sides of the storage box wall panel to ensure the total thickness accuracy of the panel is ±0.15mm;

[0024] (2) if Figure 4 As shown, the wall panel obtained in step (1) is bent and formed by the filler roll forming method, the straightness of the busbar is 1 to 1.5mm (for example: 1mm, 1.2mm or 1.5mm), and the non-perpendicularity of the busbar to the end surface is 1 to 1.5mm. mm (for example: 1mm, 1.2mm or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com