Patents

Literature

215 results about "Chemical milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperature-regulated etching chemicals to remove material to create an object with the desired shape. It is mostly used on metals, though other materials are increasingly important. It was developed from armor-decorating and printing etching processes developed during the Renaissance as alternatives to engraving on metal. The process essentially involves bathing the cutting areas in a corrosive chemical known as an etchant, which reacts with the material in the area to be cut and causes the solid material to be dissolved; inert substances known as maskants are used to protect specific areas of the material as resists.

Method for extruding and precisive roller forging thermal strength titanium alloy blades

InactiveCN1439467AReduce deformationPrevent oxidationEngine componentsMetal rollingHydrogenAir compressor

A technology for manufacuring Ti-alloy blade of air compressor by thermal sequence and precise forging includes such steps as blanking, coating glass lubricant, thermal squeezing, grinding for removing glass lubricant, chemical milling for removing polluted layer, vacuum recrystallizing, annealing, machining cog and arc corner hot forging removing glass lubricant and polluted layer again, vacuum dehydrogenating recrystallizing, annealing, calibrating, annealing and precise machining. Its advantages are simple process, low cost and high performance of product.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

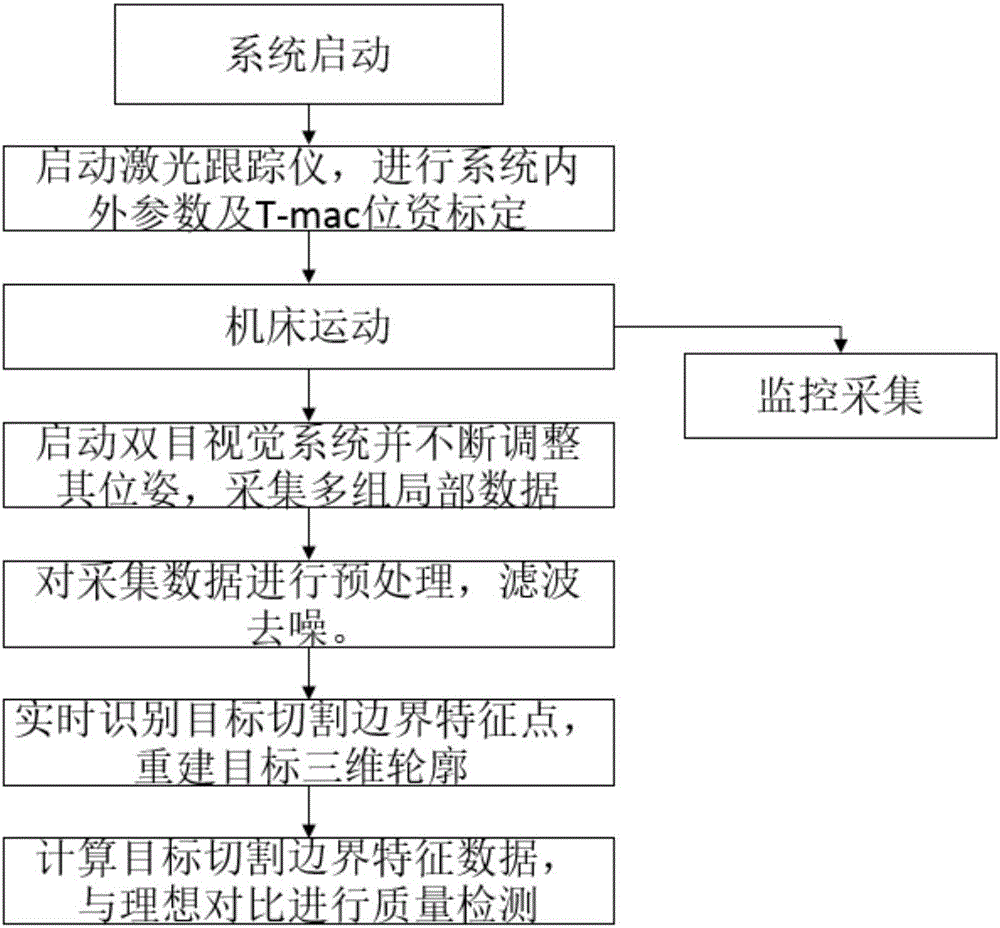

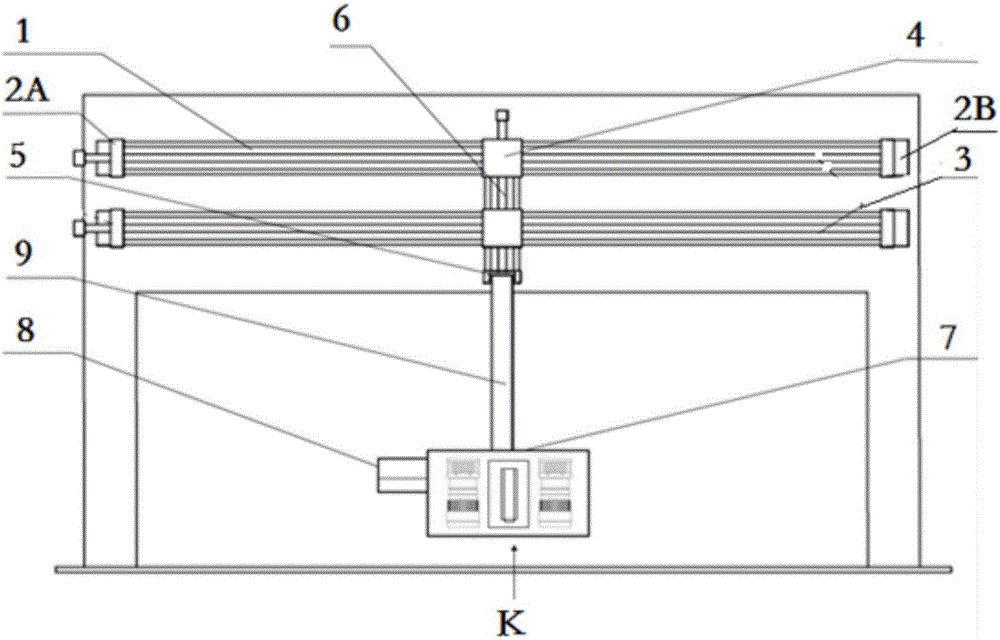

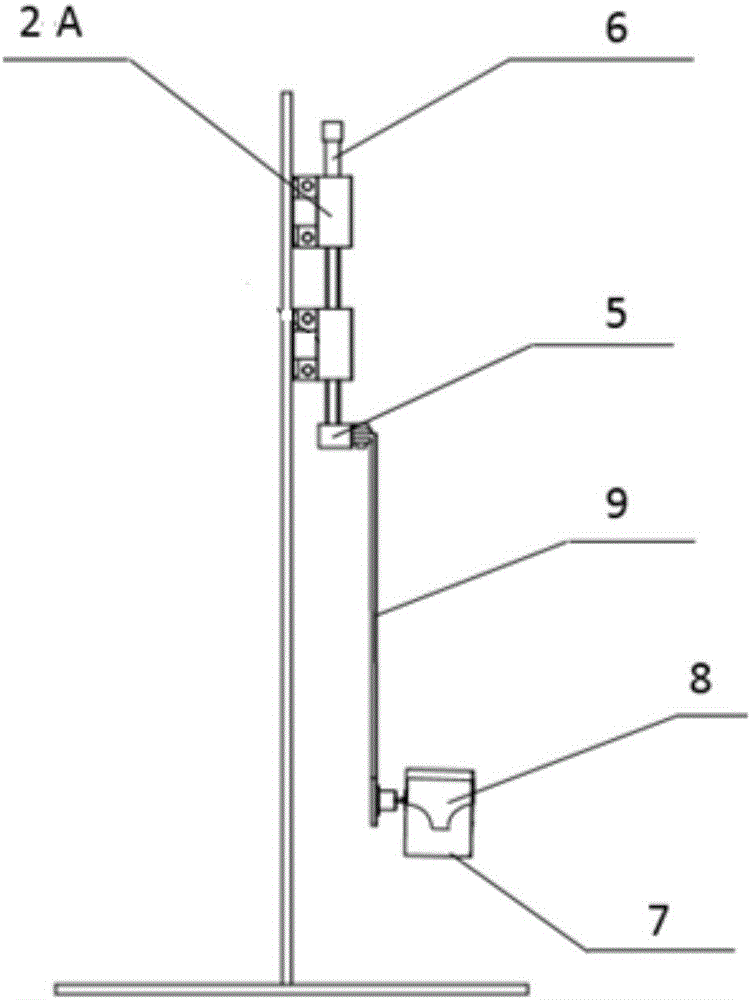

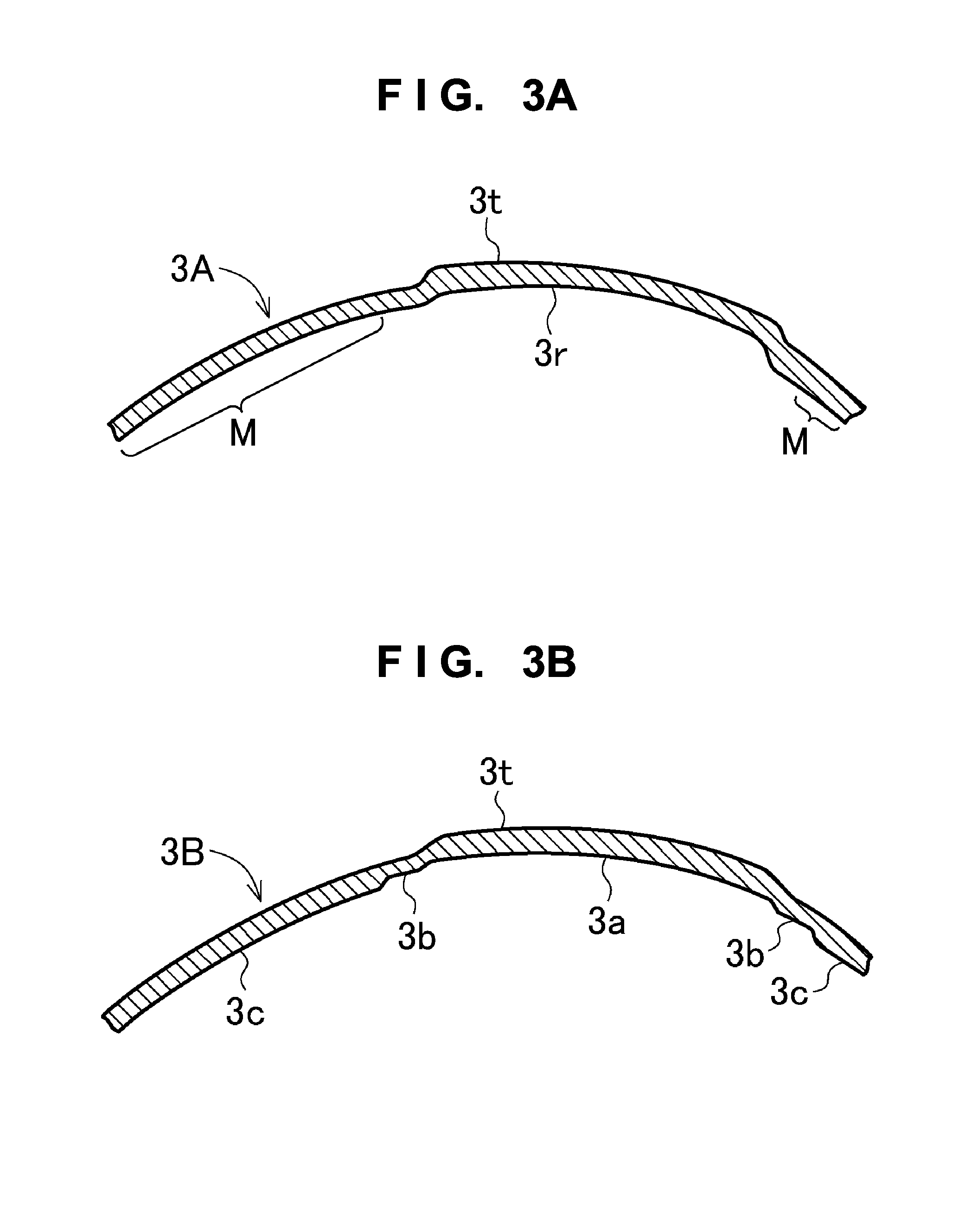

Non-contact online detection method for chemical milling cutting of large parts

InactiveCN106841206AMeet the requirements of chemical milling cutting quality inspectionMeet the requirements of cutting quality inspectionOptically investigating flaws/contaminationUsing optical meansVisual perceptionMachine tool

The invention discloses a non-contact online detection method for chemical milling cutting of large parts, belongs to the technical field of laser measurement, and relates to a non-contact online detection method for measuring the milling cutting quality of large parts. The detection method comprises the steps: integrating a binocular vision system onto a beam of a machine tool, and measuring local data of a boundary of a large part by adjusting the pose of the binocular vision system; calibrating internal and external parameters of a binocular camera and a T-Mac pose, acquiring measurement data, performing part boundary structure feature point extraction on the data and thus obtaining local three-dimensional information of the part boundary. The local measurement data is unified to a global coordinate system so as to achieve the overall three-dimensional information measurement and reconstruction. The detection method is high in measurement efficiency and convenient in pose adjustment, an original structure of the machine tool is not destroyed during installation, no contact with parts occurs, and the precision is high. The non-contact online detection method has the advantages of real-time measurement, thereby meeting the requirements of milling cutting quality inspection of large parts.

Owner:DALIAN UNIV OF TECH

Titanium alloying milling solution and milling technique used for the same

The present invention discloses a titanium alloy chemical milling solution and its application milling process, which mainly contains nitric acid and hydrofluoric acid as the main components of mixed acid acidic corrosion solution, sodium lauryl sulfate, ethylene glycol n-butyl ether and / or or urea additives. The surface tension of the solution is maintained at a stable value by using the present invention. The adsorption of ethylene glycol n-butyl ether can reduce the interfacial tension and increase the chemical milling rate. Sodium lauryl sulfate, which improves the fluidity of the solution, can eliminate excessive corrosion of the metal at the root of the chemical milling fillet, and prevent the appearance of "grooves", "slopes" and "ripples". Sodium nitrate prevents the formation of scale of alloying elements on the surface of the chemical milling groove, improves the surface finish of the chemical milling surface and facilitates maintenance of the equipment. Urea can effectively absorb the nitrogen-containing gas produced in the chemical milling process, reduce the volatilization of acid liquid, and avoid pollution to the environment. The invention does not need heating equipment, the amount of hydrogen added is less than 9ppm, the service life of the solution is long, hydrogen embrittlement does not occur, and the process has little influence on the fatigue performance of the material.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

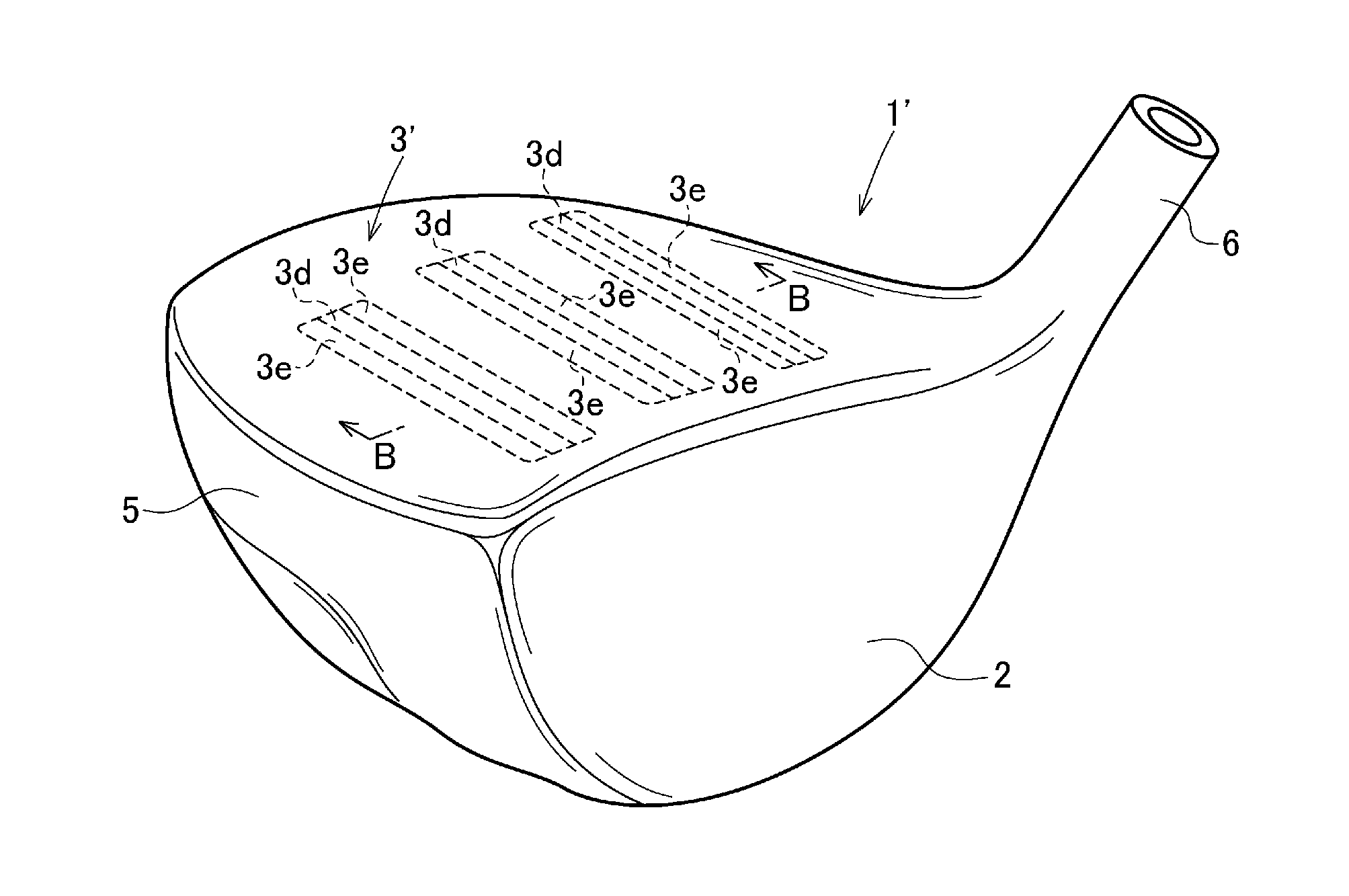

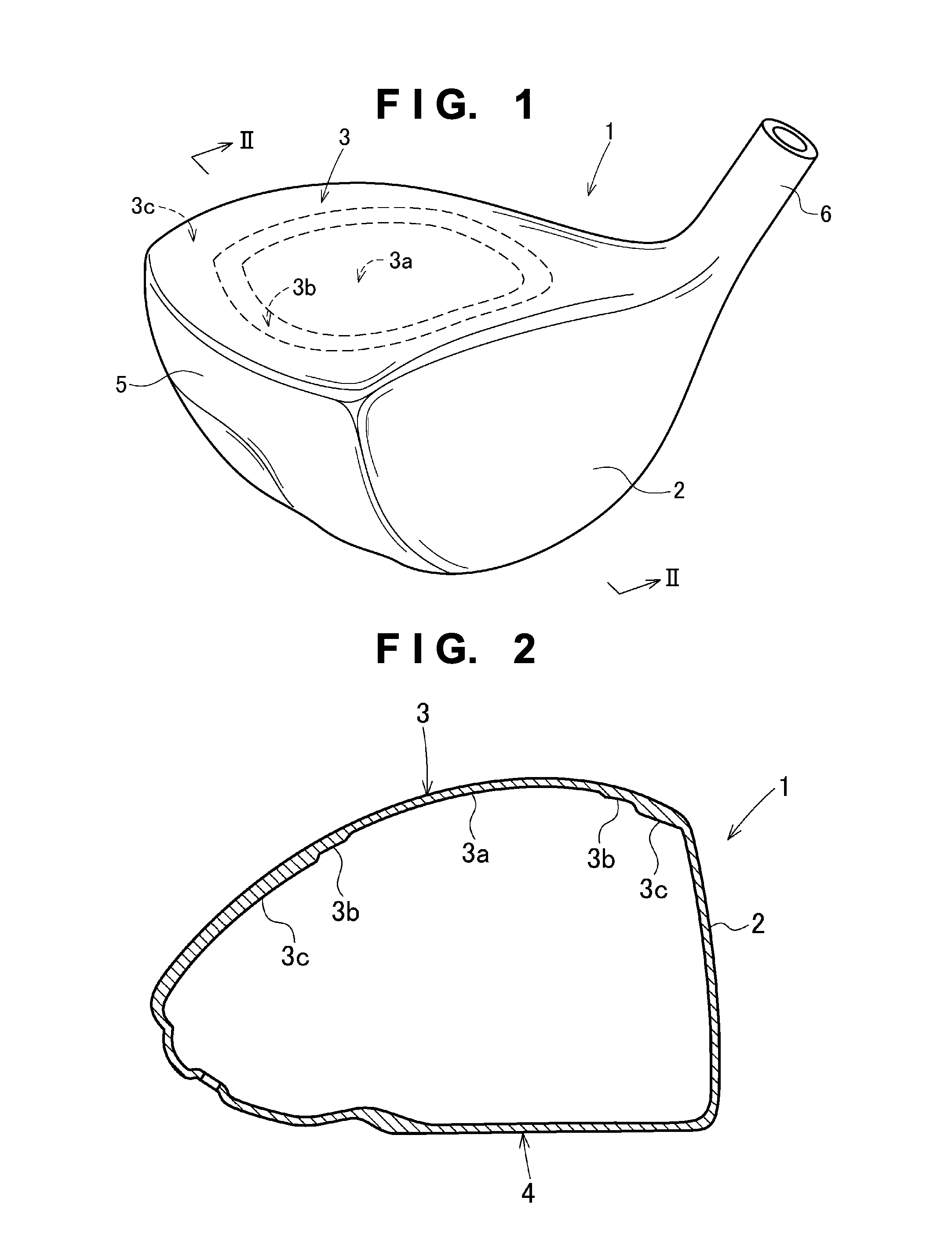

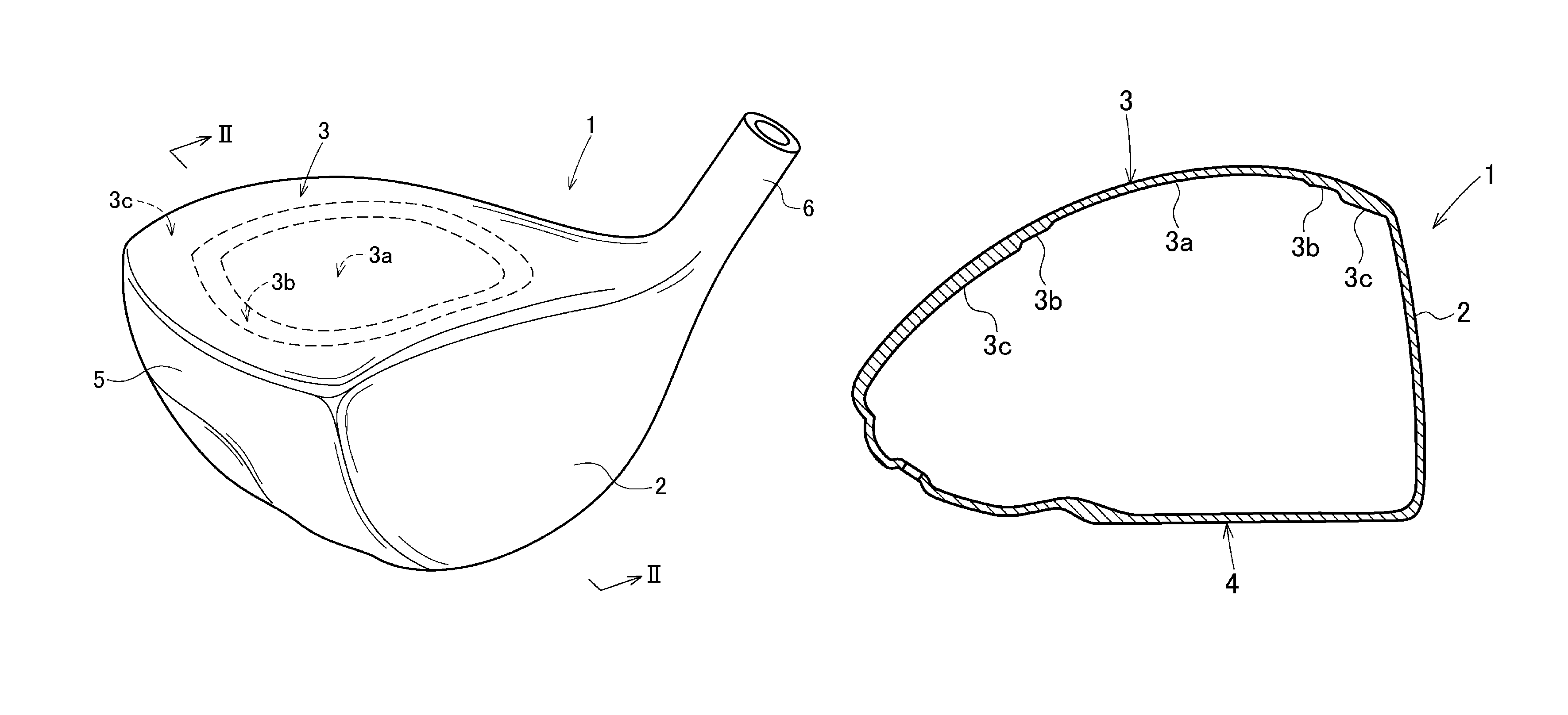

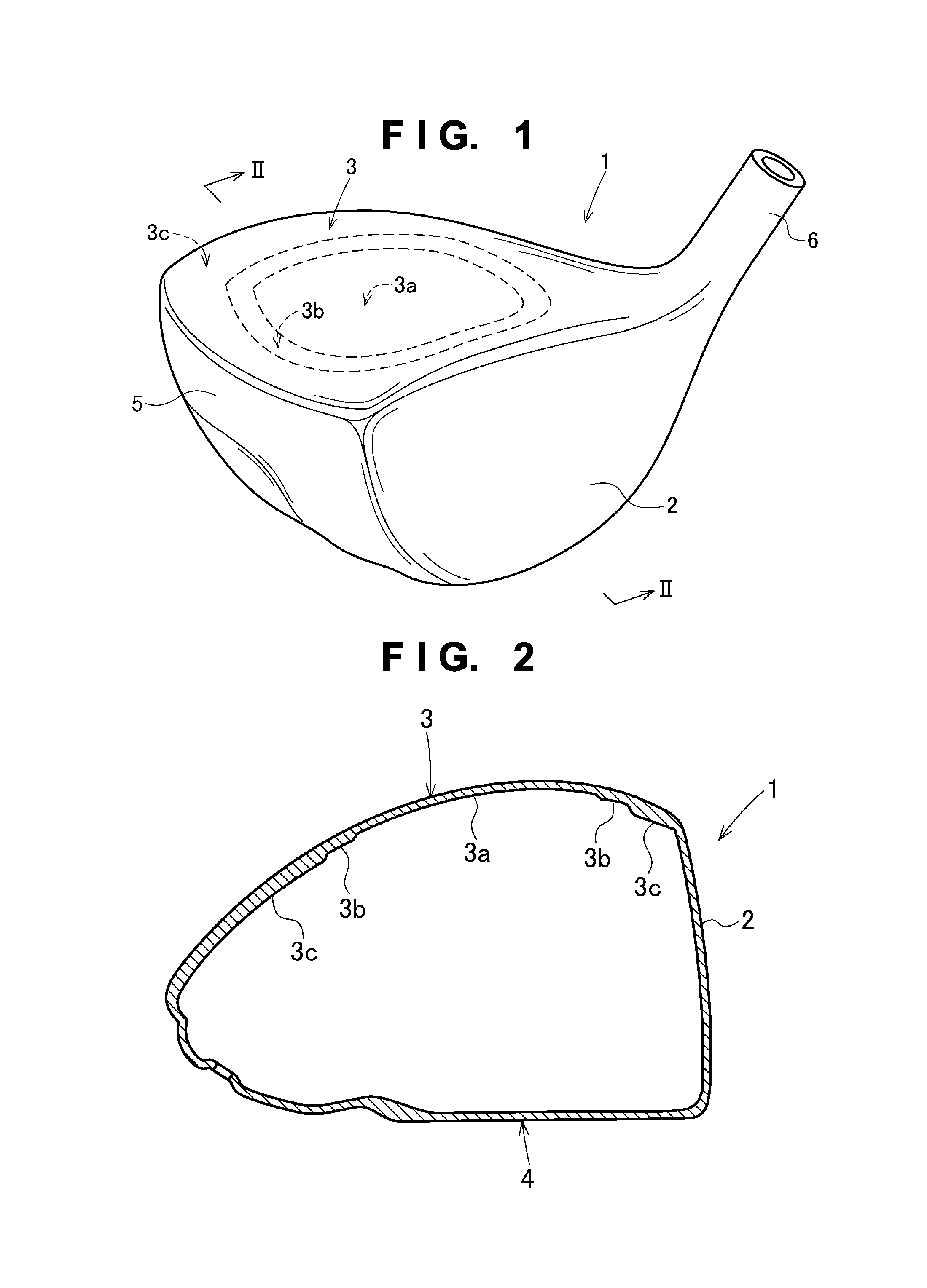

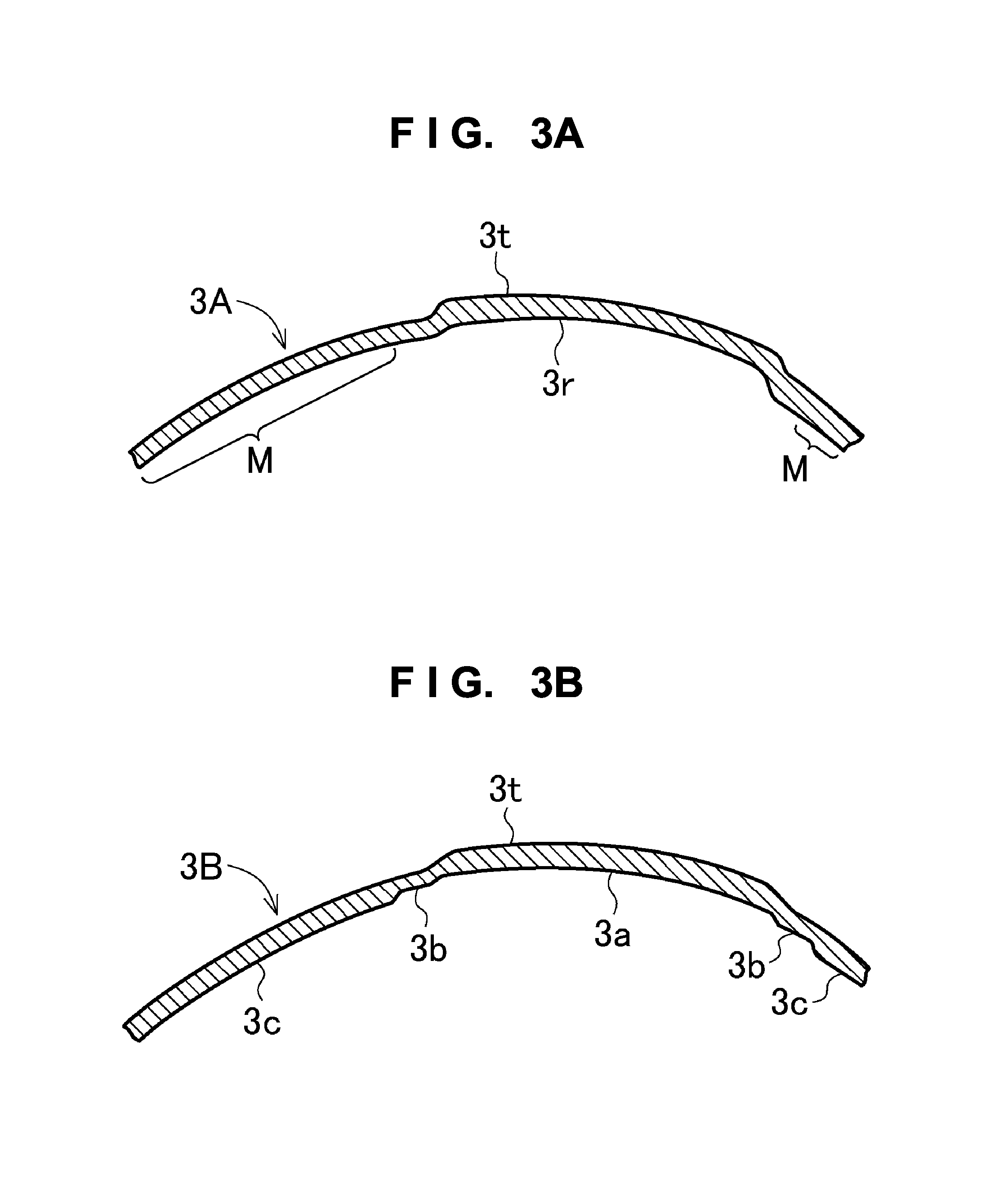

Hollow golf club head and method of manufacturing the same

ActiveUS20130344987A1Easy to manufactureLow costMetal rolling stand detailsMetal working apparatusEngineeringGolf Ball

This invention provides a hollow golf club head including a metal plate portion provided with thin and thick portions. A medium thick portion having an intermediate thickness between the thicknesses of the thin and thick portions is formed at the boundary portion between the thin and thick portions. The thin and medium thick portions are formed by the steps of pressing the metal plate portion to form a recess in one surface of the metal plate portion and a projection on its other surface, performing chemical milling of the recess and a portion surrounding it, and removing the projection by grinding.

Owner:BRIDGESTONE SPORTS

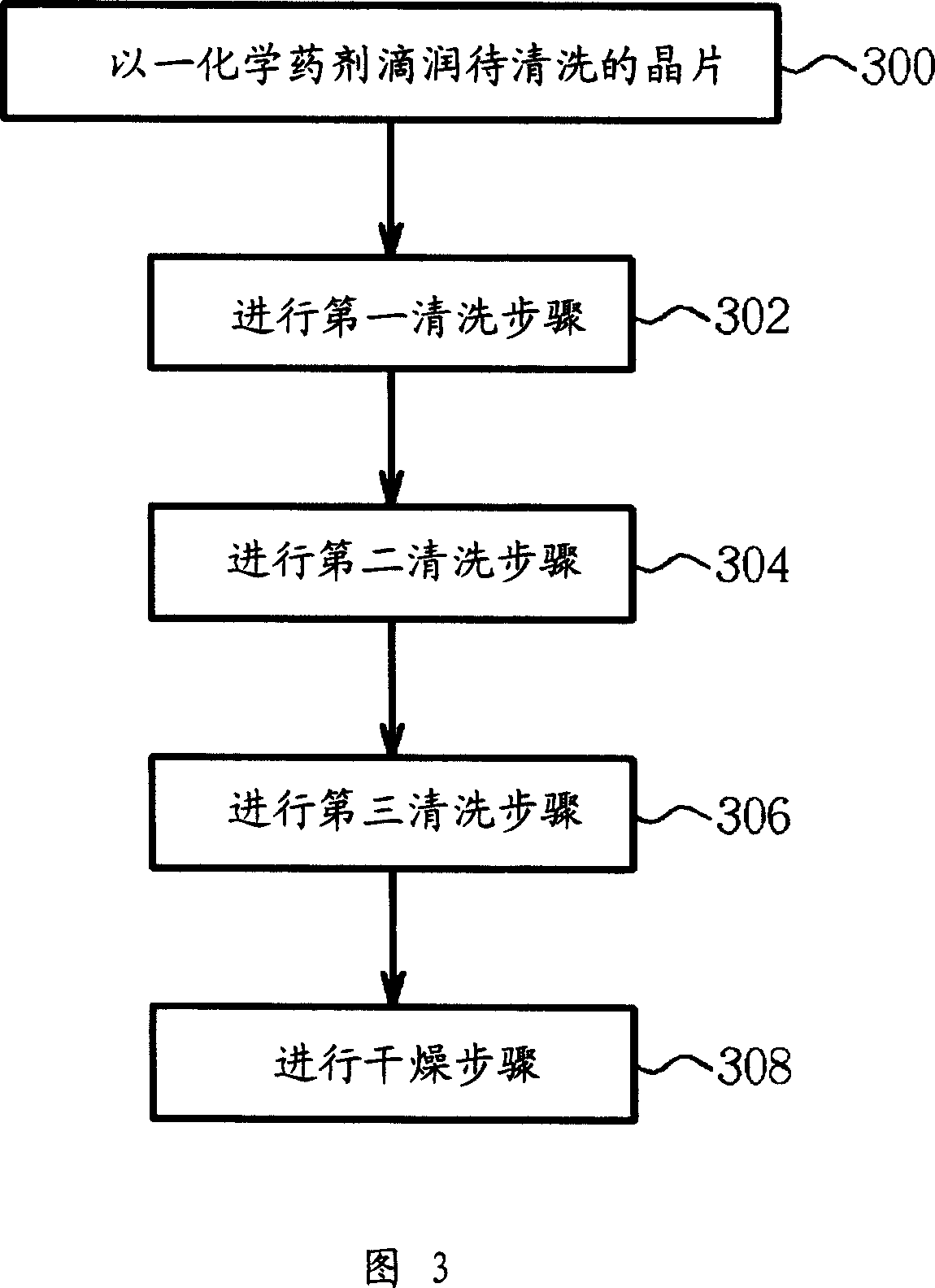

Wafer cleaning method after chemical milling

InactiveCN101062503AReduce viscositySemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsCompound (substance)Cleaning methods

The invention relates to the wafer cleaning after chemical grinding. It loads the wafer from buffer unit to cleaning unit. Through the added chemical agent to the buffer unit, it can reduce the stickiness of the BTA surface to reduce it completely in the following process.

Owner:UNITED MICROELECTRONICS CORP

Method for machining aircraft skin part

InactiveCN104972282AImprove manufacturing precisionIncrease profitAircraft componentsProduction rateEngineering

The invention discloses a method for machining an aircraft skin part. The method comprises the following steps that (1) process digital-analog information is extracted; (2) a neutral layer is projected; (3) the neutral layer is unfolded; (4) the unfolding face of the neutral layer is projected; and (5) a chemical milling sample plate and the skin part are machined. The sample plate meeting process requirements is directly produced through three-dimensional unfolding digital-analog calculation. According to the method for machining the aircraft skin part, the manufacturing precision of the part is effectively improved, machining accumulated errors are reduced, and the machining process meets the process manufacturing requirement. Meanwhile, the delivery cycle of the skin part is greatly shortened, and the material utilization rate is improved. An MMS mirror image milling matching edge flexible clamping system is adopted, and the method adapts to skins of various specifications; the space locating and clamping rigidity of workpieces is guaranteed, and productivity and production flexibility are greatly improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

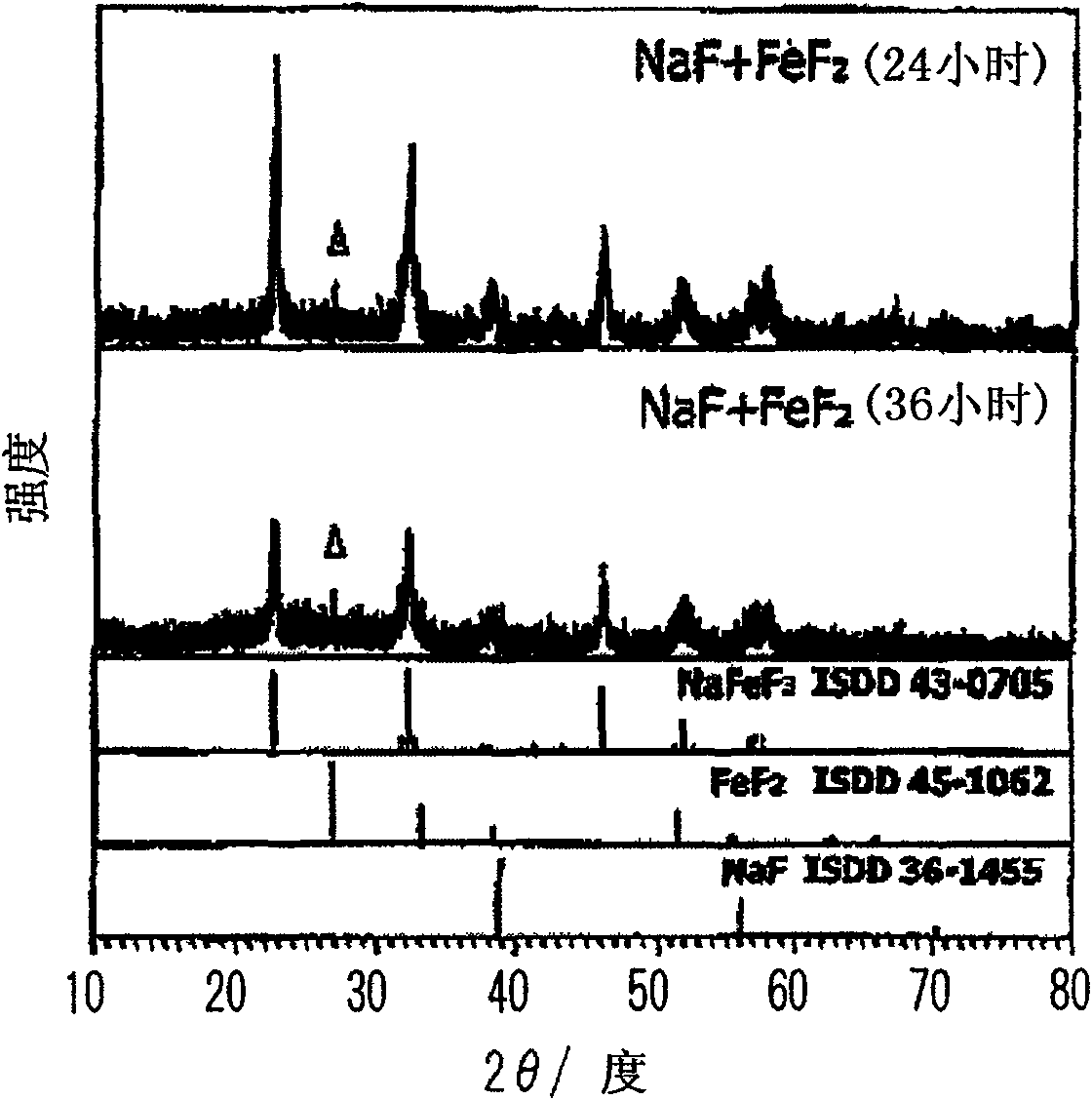

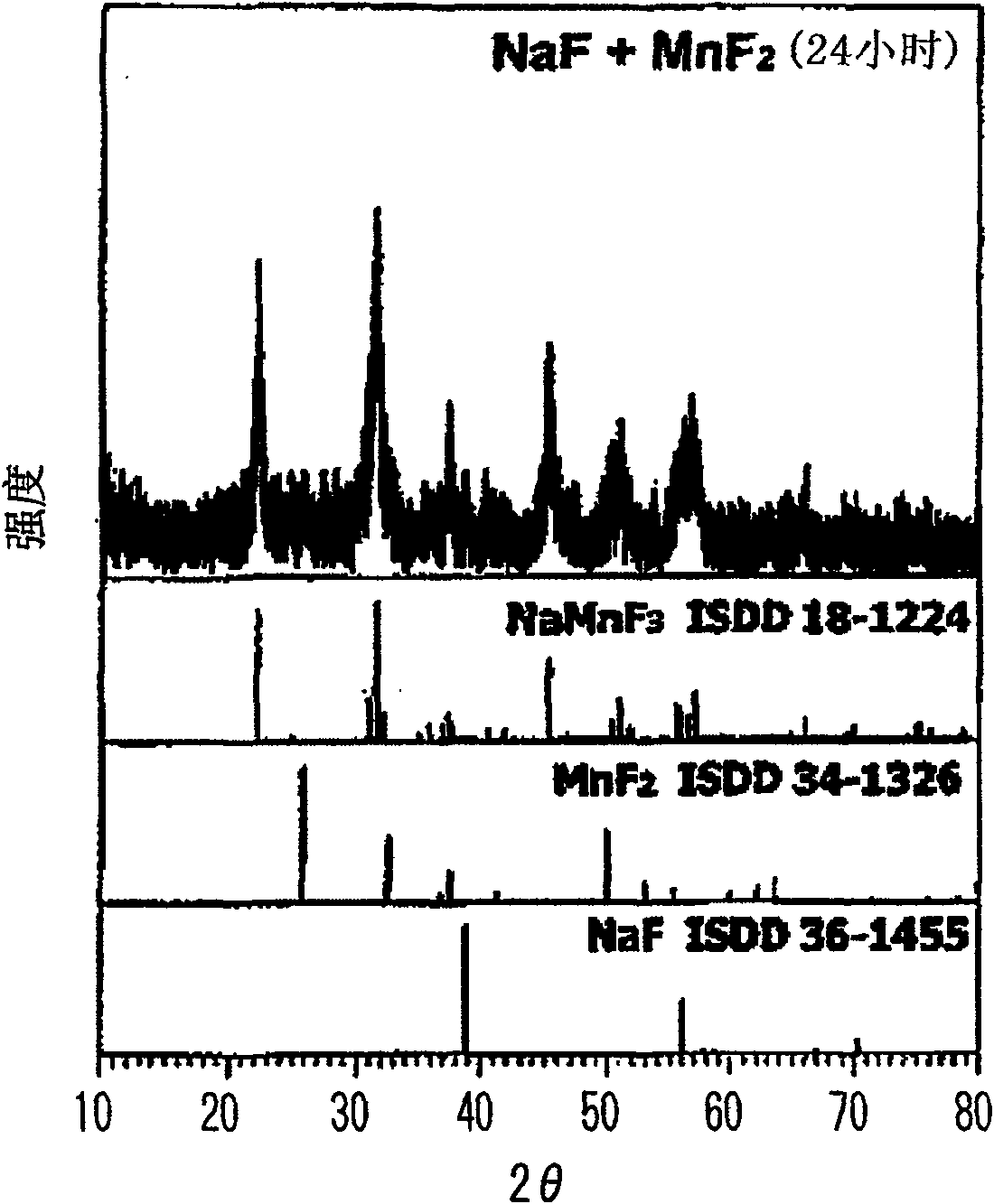

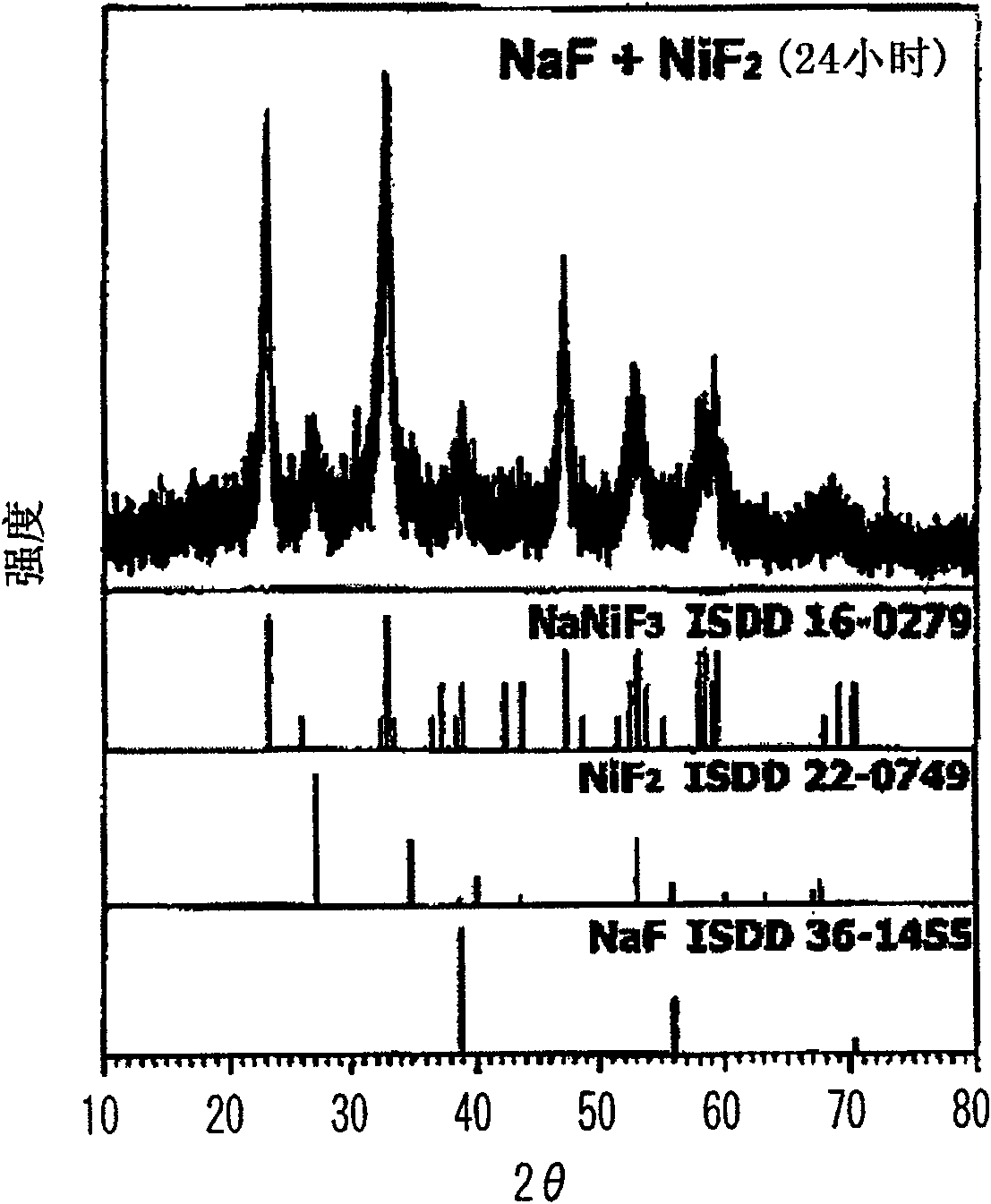

Cathode active material for nonaqueous electrolyte secondary battery and method of producing cathode active material for nonaqueous electrolyte secondary battery

To prepare a fluorinated cathode active material having a guest cation comprising sodium or lithium included therein in a nonaqueous electrolyte secondary battery, an alkali metal fluoride represented by the formula AF and a transition metal fluoride represented by the formula M'F2 are treated by chemical milling to thereby give a fluoride AM'F3. A satellite ball mill is preferably employed in the chemical milling treatment.

Owner:MITSUBISHI HEAVY IND LTD +1

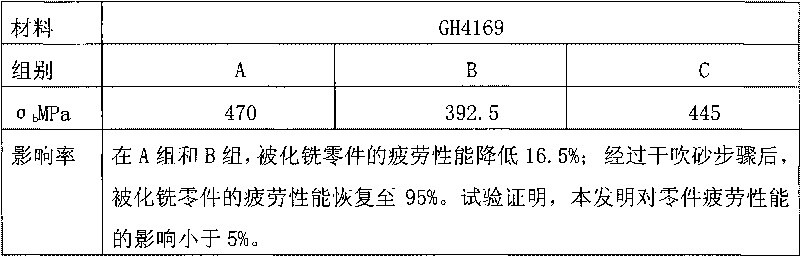

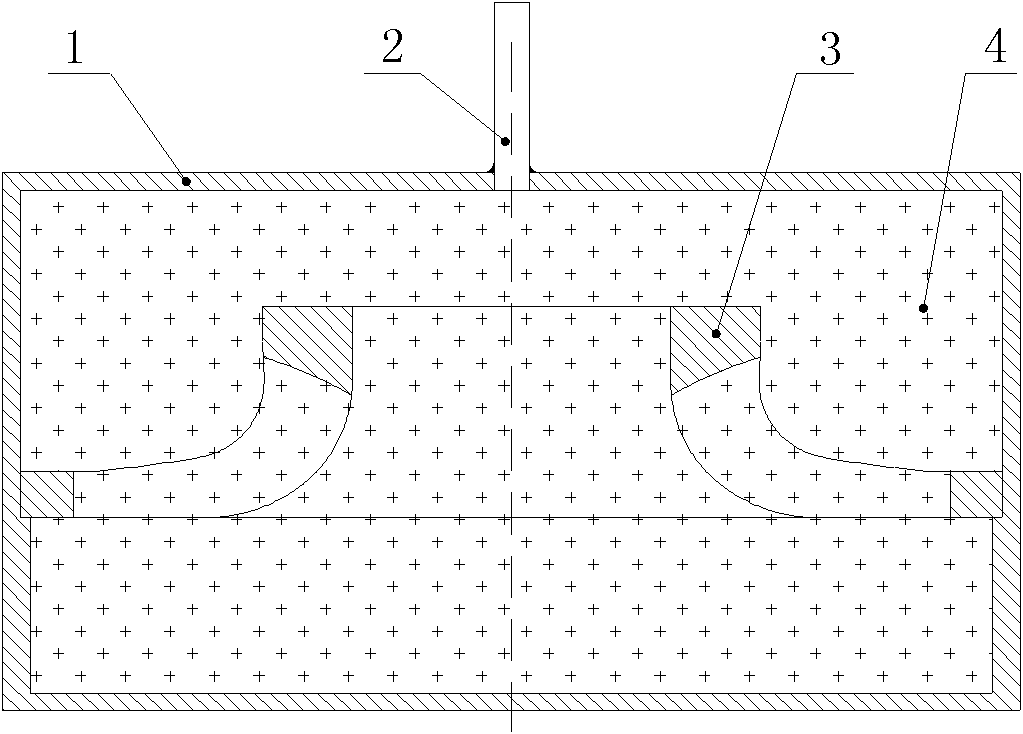

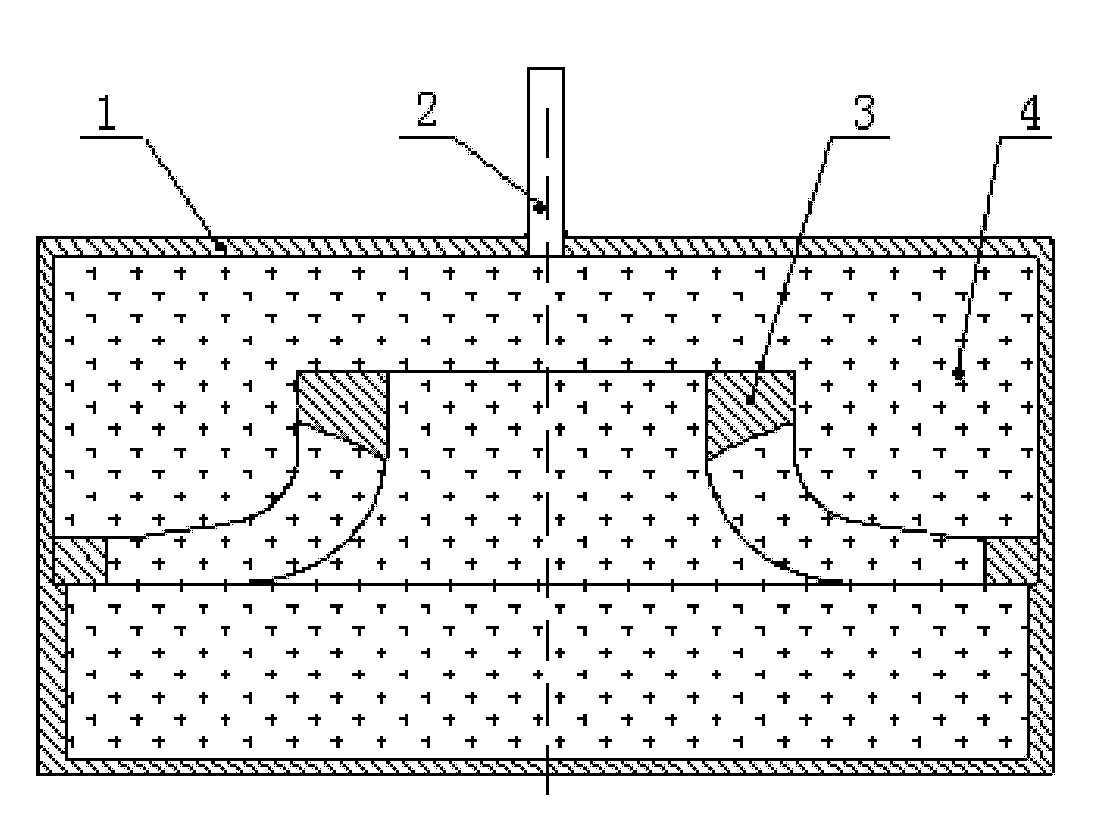

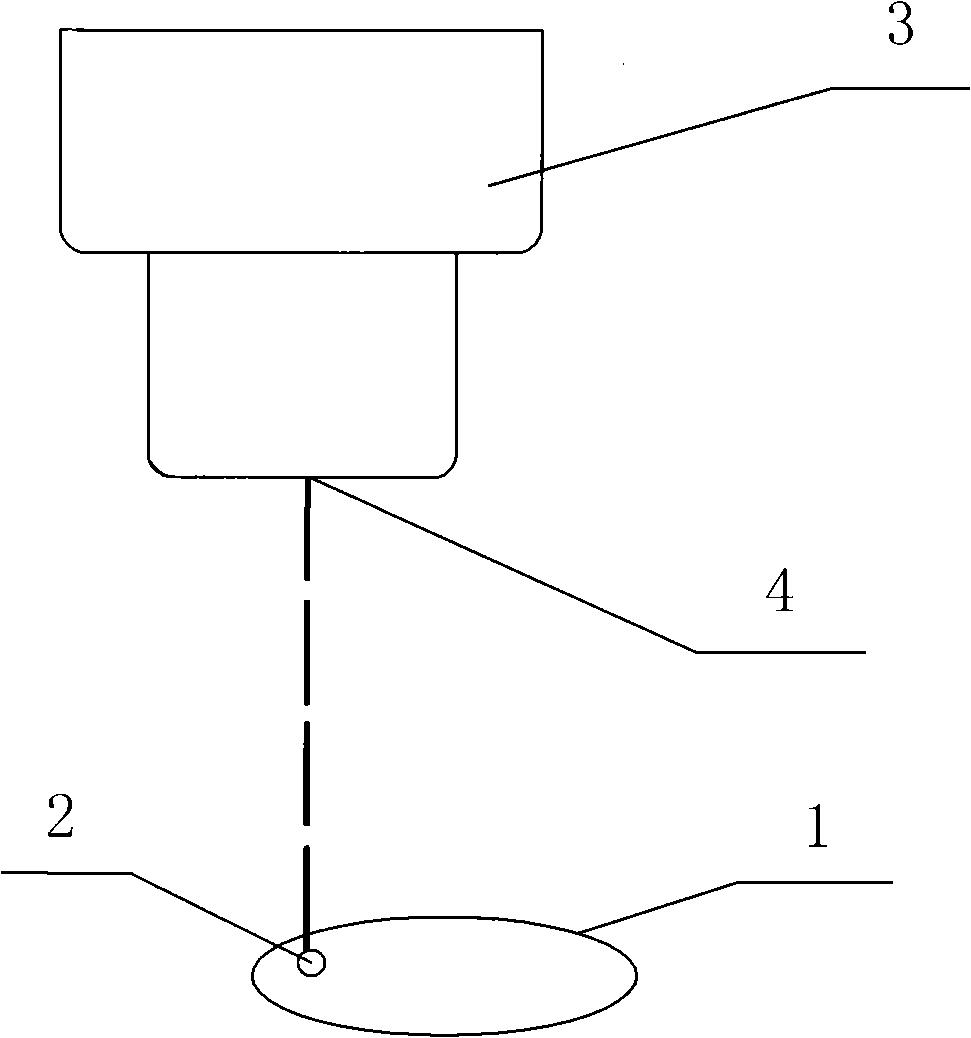

Precision-forging chemical-milling solution for high-temperature alloy blades and chemical milling method

The invention provides a precision-forging chemical-milling solution for high-temperature alloy blades and a chemical milling method. 55 to 75 g / L of hydrochloric acid, 100 to 135 g / L of nitric acid and 400 to 500 g / L of ferric chloride are adopted to be prepared with water into a chemical milling solution, and precision-forging parts of high-temperature alloy blades are chemically milled through size grouping, oil removal, hot washing, activation, hanging ash removal, repeated chemical milling and restoring performance. The solution can effectively remove metal, and the parts chemically milled are easy to clean. The method has the chemical-milling temperature lower than 50 DEG C, has the material-removing speed approximately between 0.02 and 0.05 mm / min, and can minimize the fatigue properties of materials. The method has the advantages of little influence on material properties and capability of effectively removing metal, and the solution is low in use temperature and little in environmental pollution and has the characteristics of simple operation, safety and reliability.

Owner:AECC AVIATION POWER CO LTD

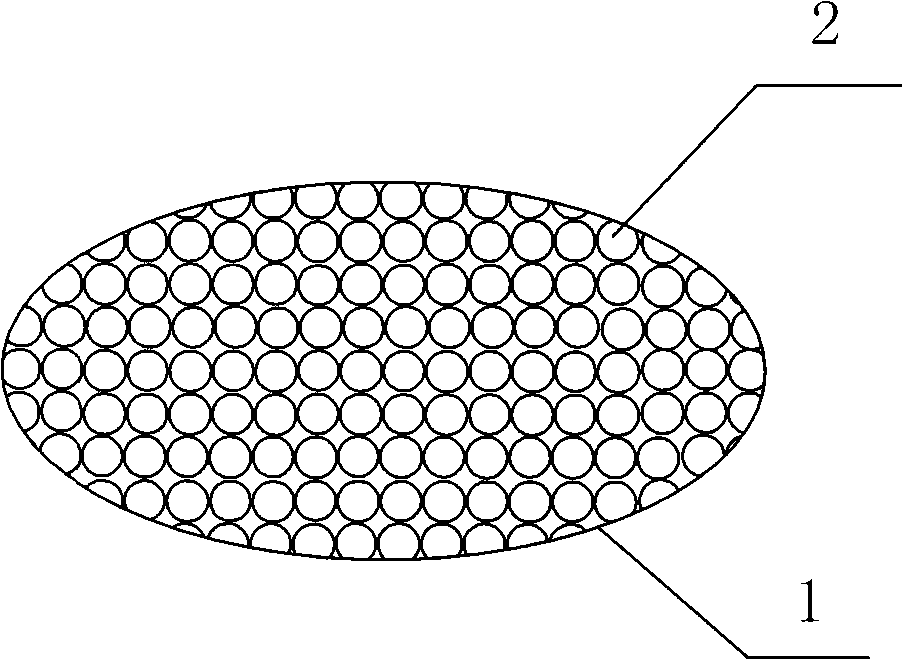

Titanium alloy rotor near-net manufacturing method

ActiveCN101954481AOptimizing Process Parameters of Hot Isostatic PressingImprove material performanceSpherical shapedHigh surface

The invention provides a titanium alloy rotor near-net manufacturing method, which comprises the following steps of: (a) machining a core mould and a sheath; (b) preparing spherical titanium alloy powder; (c) assembling the core mould, filling the powder and performing deaeration; (d) performing hot isostatic pressing processing; and (e) removing the sheath and performing chemical milling and de-molding. In the method, a plasma rotating electrode is adopted to prepare the low-temperature spherical titanium alloy powder, the core mould and the sheath are made from a metal material, hot isostatic pressing process parameters are optimized, the sheath is mechanically removed, and the core mould is chemically milled and removed so as to manufacture the high-performance titanium alloy rotor with a complex, thin-walled and semienclosed structure. The titanium alloy rotor manufactured by the method has the characteristics of high material performance reaching the performance level of a forged piece, high yield, high net-formed blade size accuracy, high surface quality, and isotropy.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

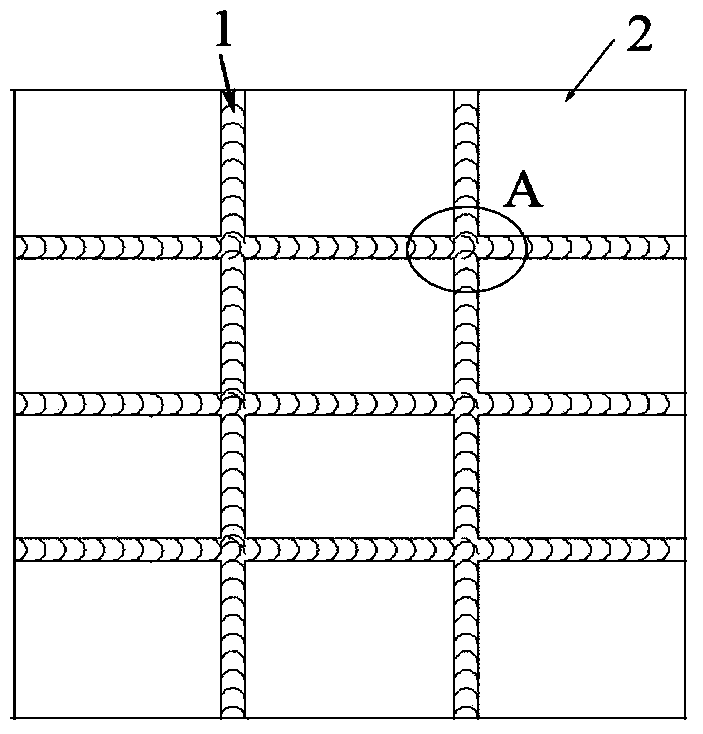

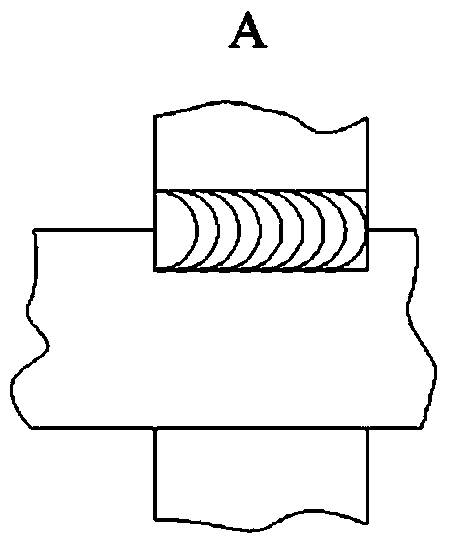

Micropore processing method of bone repairing body rough surface

ActiveCN101254138AGood adhesionProliferation effect is goodBone implantSurgeryControllabilityMaterials science

The invention discloses a micropore processing method for an open surface of a bone-prosthesis. The micropore processing method comprises the steps as follows: in the step of laser ablation, a plurality of micropores which are distributed uniformly and continuously are etched on the surface of the bone-prosthesis to be processed by using a laser engraving machine according to the conventional laser ablation method, the laser output power is 10 to 25W, the distance between a laser eradiating port and the etched surface is 1.5 to 2.5 mm when in etching, the cross-sectional area of each micropore is 1950 to 200000 micrometers<2>, and the depth is 5 to 500 micrometers; in the step of chemical milling, acid solution used for chemical milling is prepared by using HF, HNO3 and H2O, or HNO3, HF, H2O2 and H2O in an acid corrosion resistance container, then the etched bone-prosthesis is put in the acid solution to act the chemical milling on the open surface of the micropores, and then is washed by water. The steps are simple, the operation is simple and convenient, the controllability is good, the manufacturing cost is low, and the micropore processing method solves the difficult problem that the uniform and continuous micropore structure is formed on the surface of surgical implants.

Owner:XIAN CONTINENTAL BIOMATERIALS CO LTD

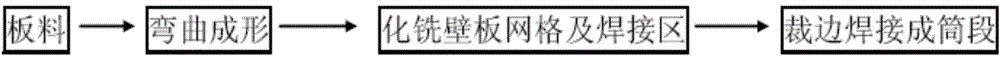

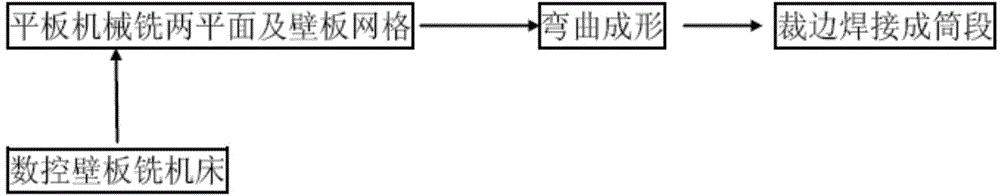

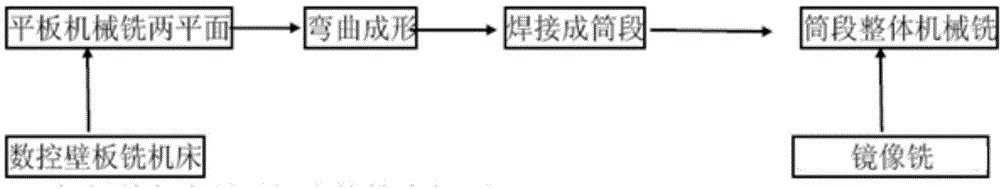

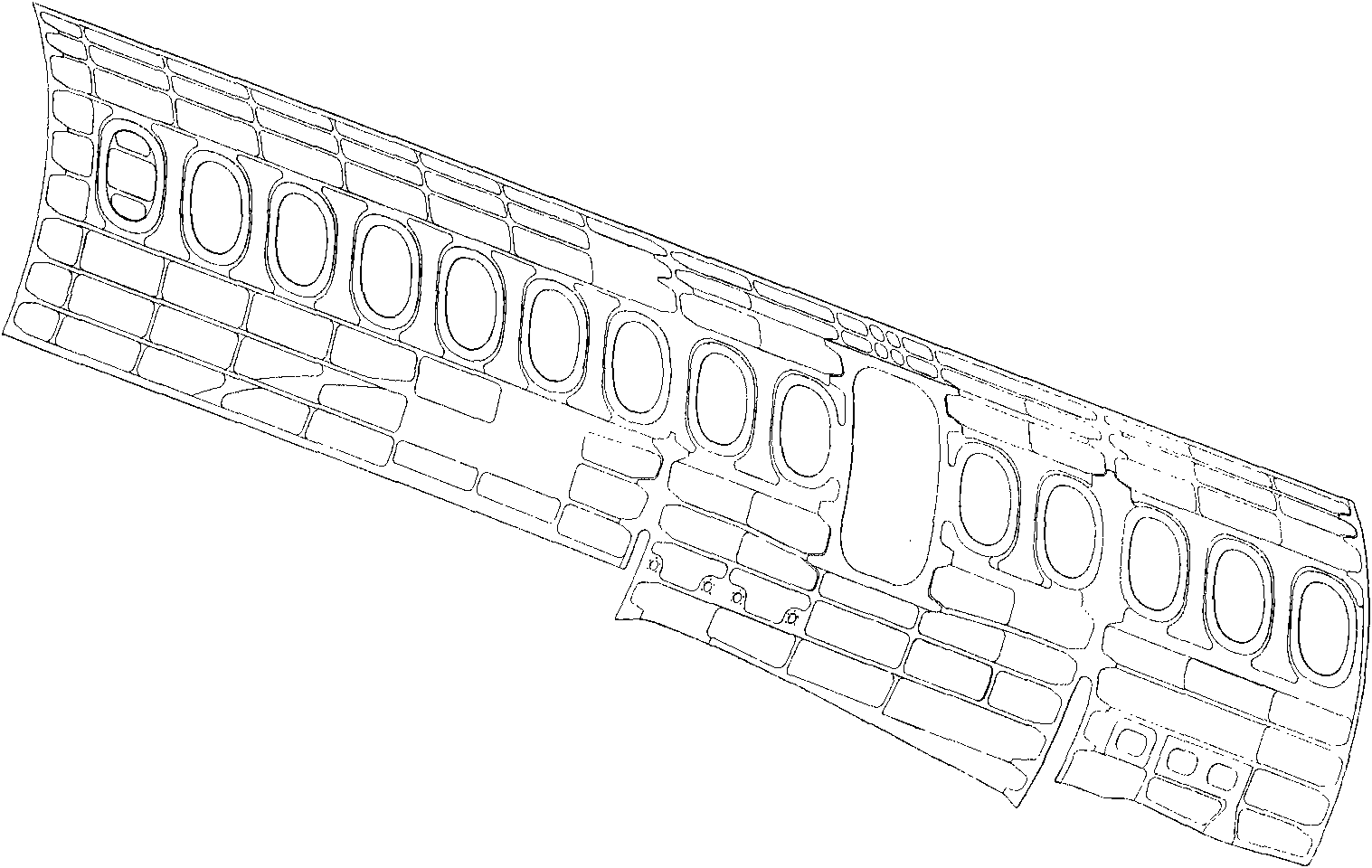

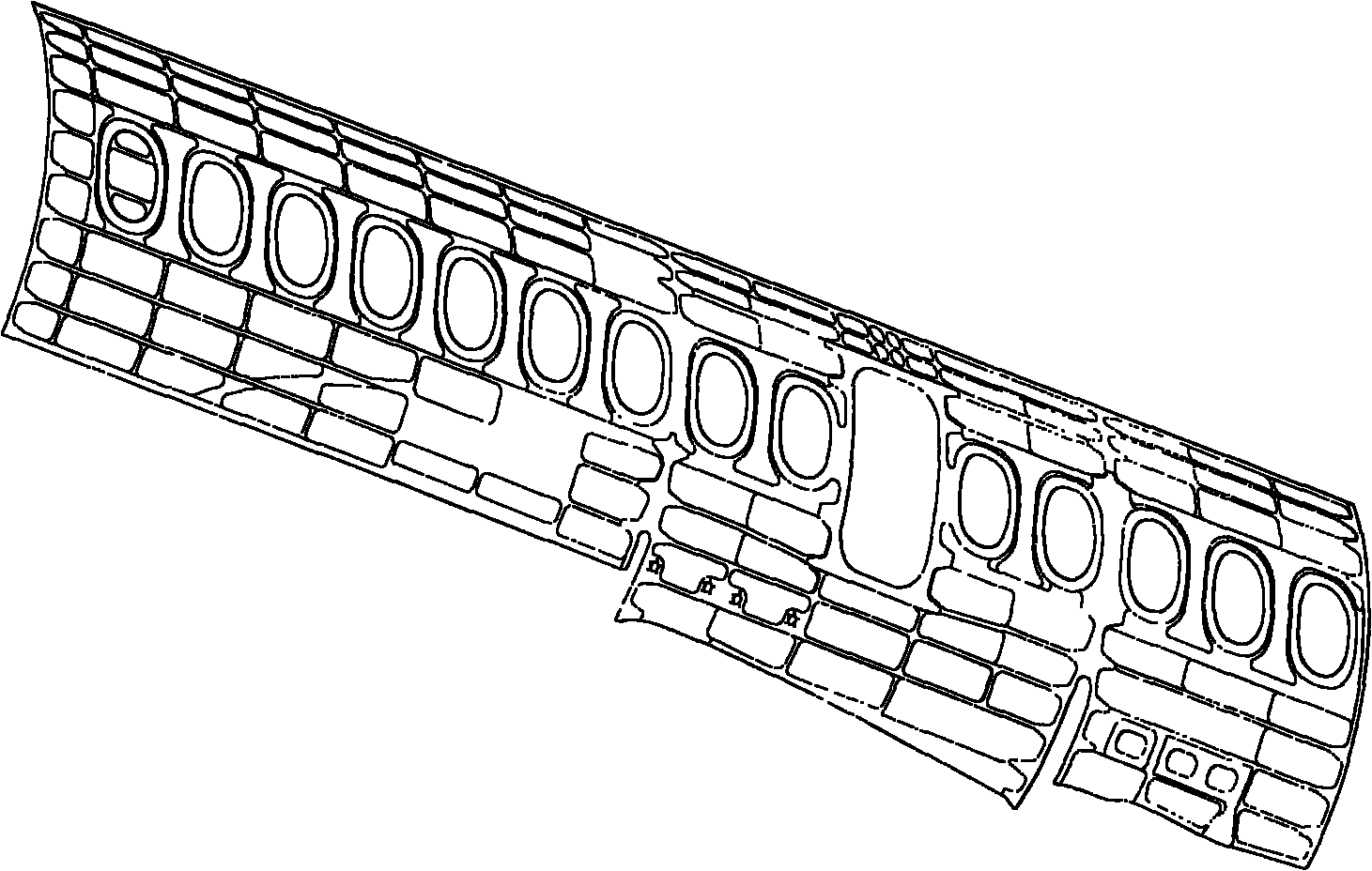

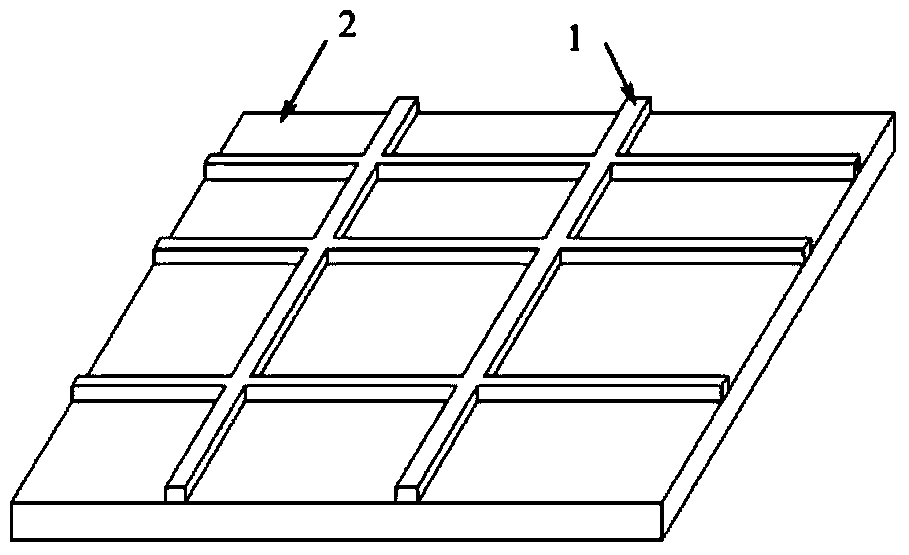

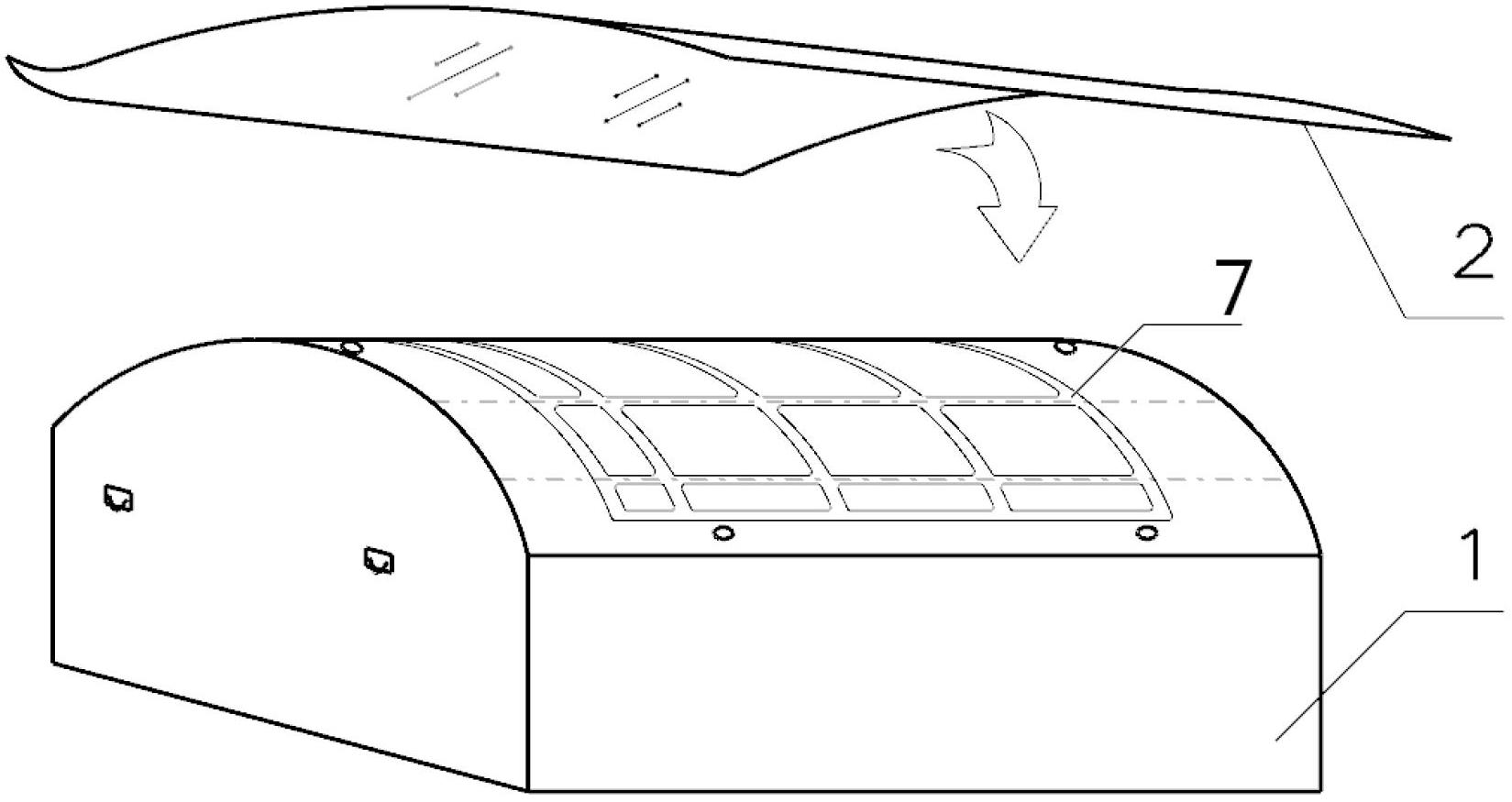

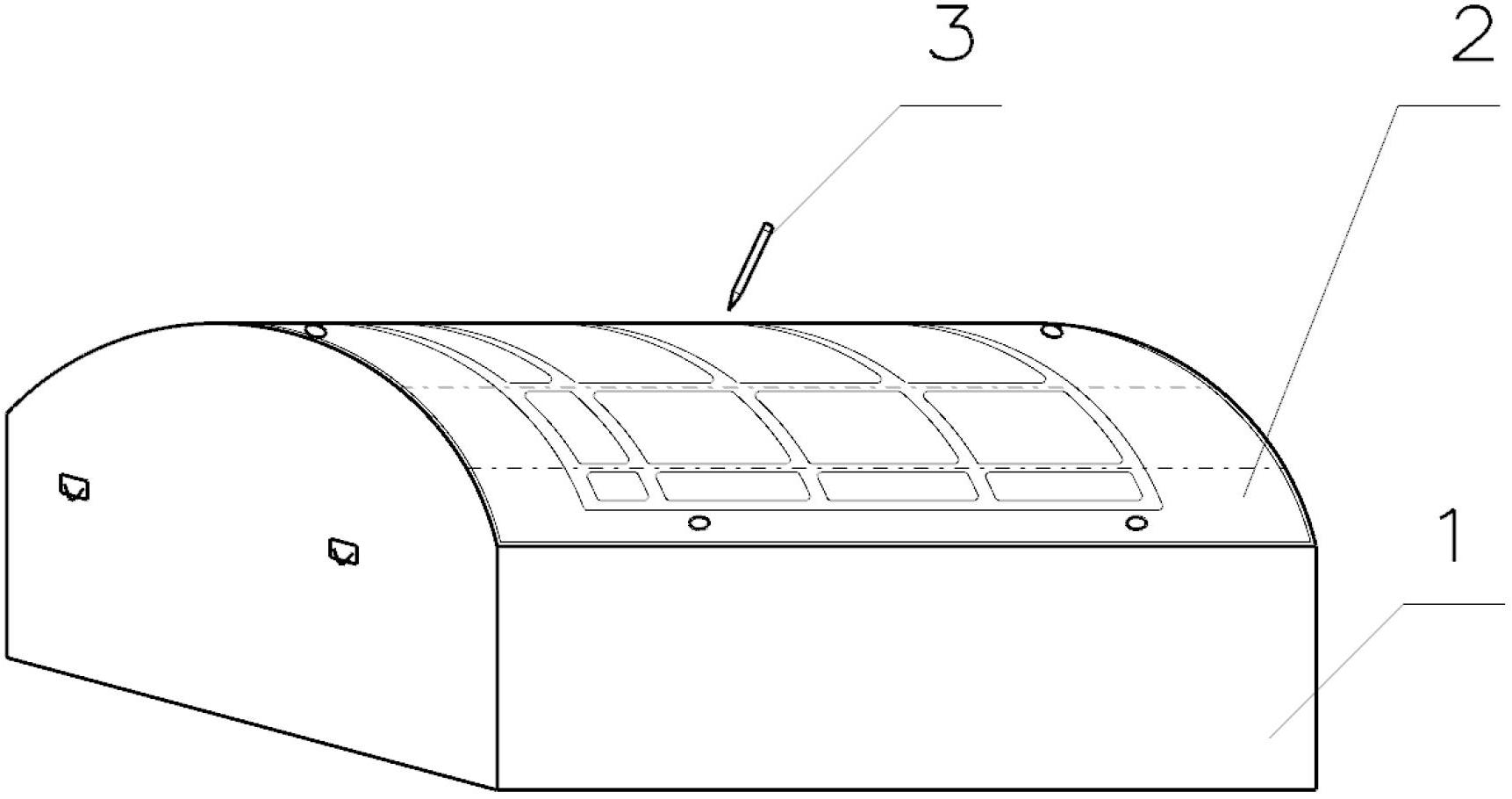

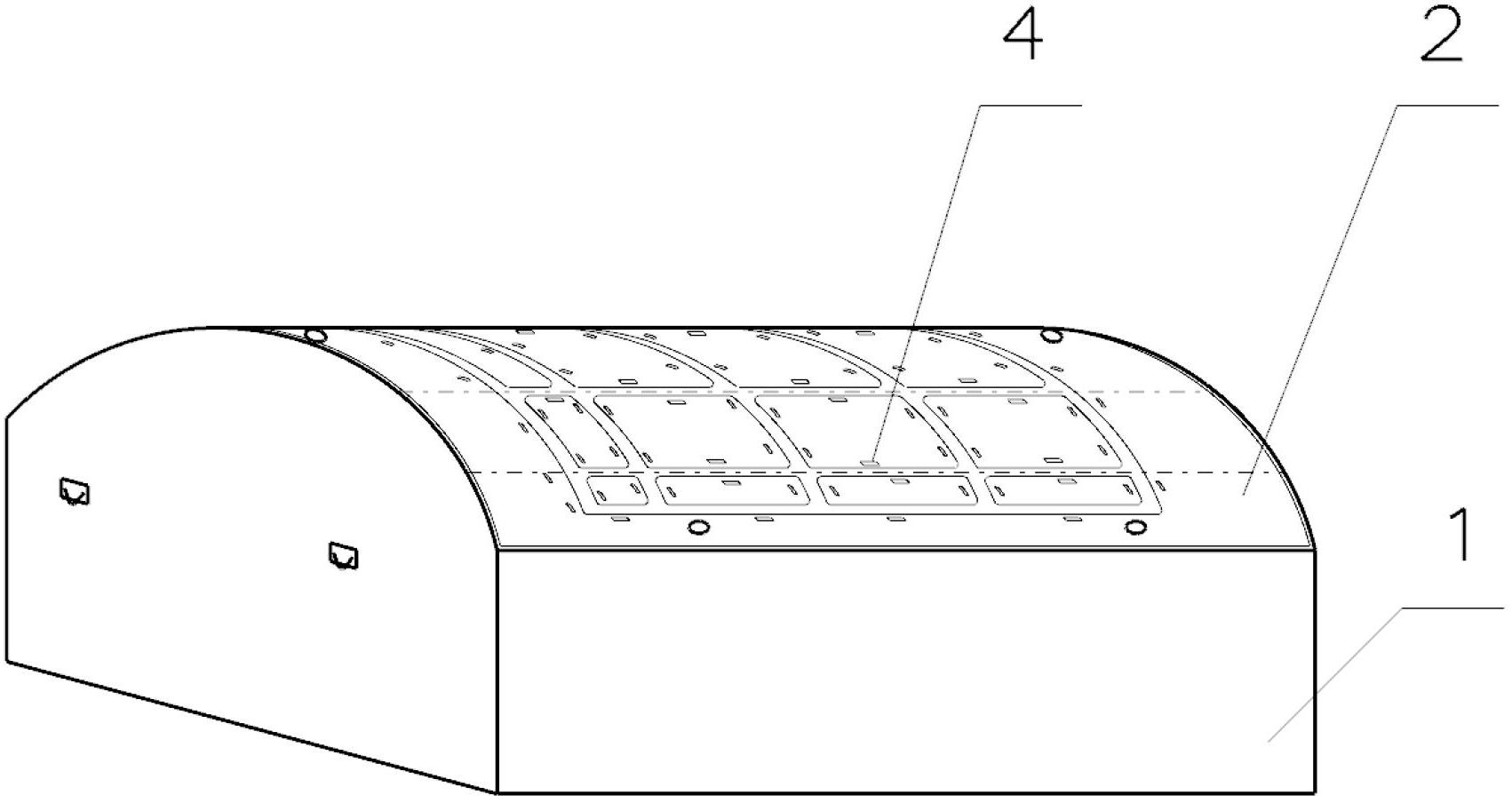

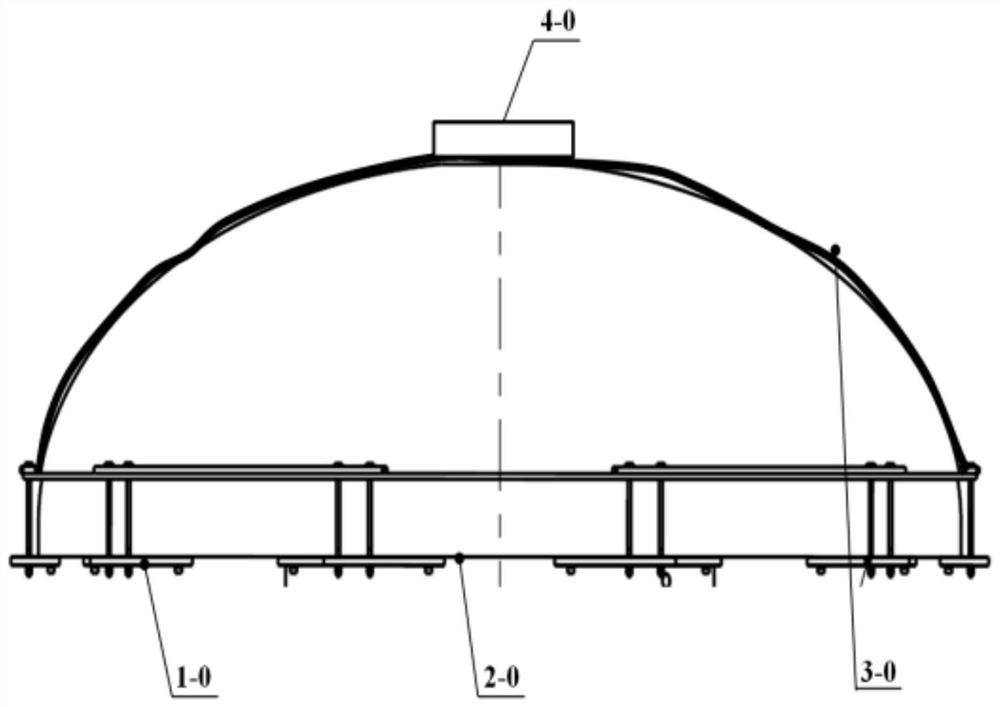

Integral manufacturing method for tube section of large storage box based on numerical control mirror milling

ActiveCN104439968AImprove machining accuracyImprove processing efficiencyMilling equipment detailsNumerical controlMechanical milling

The invention provides an integral manufacturing method for the tube section of a large storage box based on numerical control mirror milling. The method comprises the following steps: (1) milling the upper faces and the lower faces of wall boards of the storage box in a flat board mechanical milling mode through a numerical control wall board milling machine; (2) bending and forming the wall boards through a filling rolling and bending forming method; (3) welding the bent and formed wall boards into the tube section through friction stir welding; (4) carrying out mechanical milling on the tube section integrally, and gridding of the wall boards forming the tube section is machined through numerical control mirror milling. The tube section integral mirror milling is adopted in the integral manufacturing method to replace traditional chemical milling, flat plate mechanical milling and the single curve wall board numerical control gridding milling technology, the manufacturing method of the tube section of the gridding storage box that first a tube is formed and then the tube is milled is achieved, the demand is met, and the machining precision and the machining efficiency of the tube section of the storage box are improved.

Owner:CAPITAL AEROSPACE MACHINERY +2

Method for forming integral panel of main body

The invention provides a method for forming an integral panel of a main body. The method comprises the steps as follows: firstly, the radian measure of the integral panel of the main body is formed through a roll bending forming device; secondly, the radian measure is unbent by utilizing the elastic deformation property of material after the integral panel is processed through roll bending forming, and then multi-stage steps, cut cavities and outlines are formed on the integral panel through mechanical milling; and thirdly, the restored outline / radian measure conditions of the integral panel are checked when in roll bending forming, and part of the integral panel is processed through sizing. By adopting the invention, the method that single-curved parts are processed through three-dimensional milling (comprising chemical milling and mechanical three-dimensional milling) after being formed over the years can be replaced, the manufacturing accuracy and the fatigue strength of products can be improved, the pollution on environment caused by chemical-milling solution as well as the high pollution discharge treatment cost can be avoided, and dedicated three-dimensional milling clamps and equipment for mechanical three-dimensional milling can also be avoided.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Method for removing strained layer on surface of single crystal blade casting through chemical milling

The invention discloses a method for removing a strained layer on the surface of a single crystal blade casting through chemical milling. The method comprises the following steps of: (1) tightly plugging a blade window of the single crystal blade casting by using paraffin; (2) removing degreasing fluid on the surface by washing, and putting into chemical milling fluid for corrosion; (3) after the chemical milling is finished, putting into neutralization solution for neutralization; and (4) removing the neutralization solution on the surface by washing, and removing the paraffin which is used for plugging the blade window. In the invention, the surface of the single crystal blade casting is corroded through chemical milling treatment, so that recrystallization can be effectively prevented, rejection rates are reduced, and the method is easy to operate.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

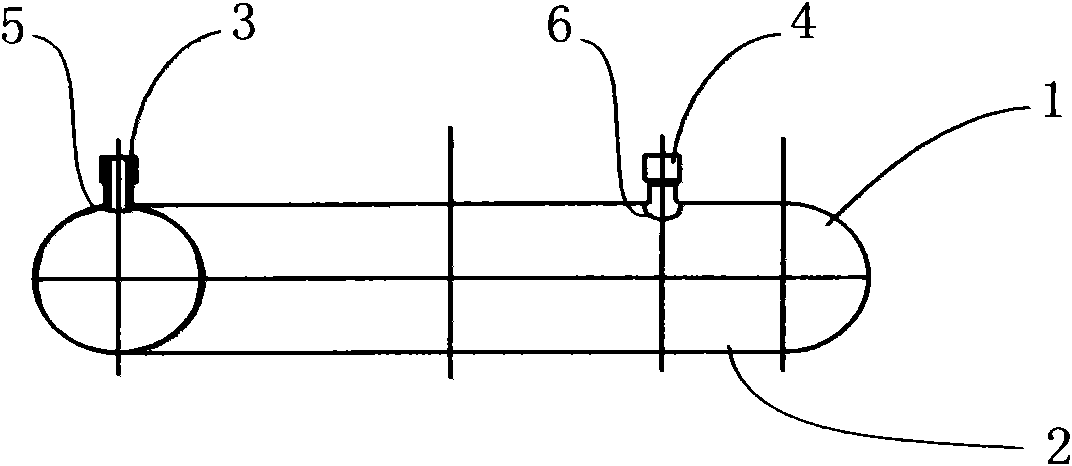

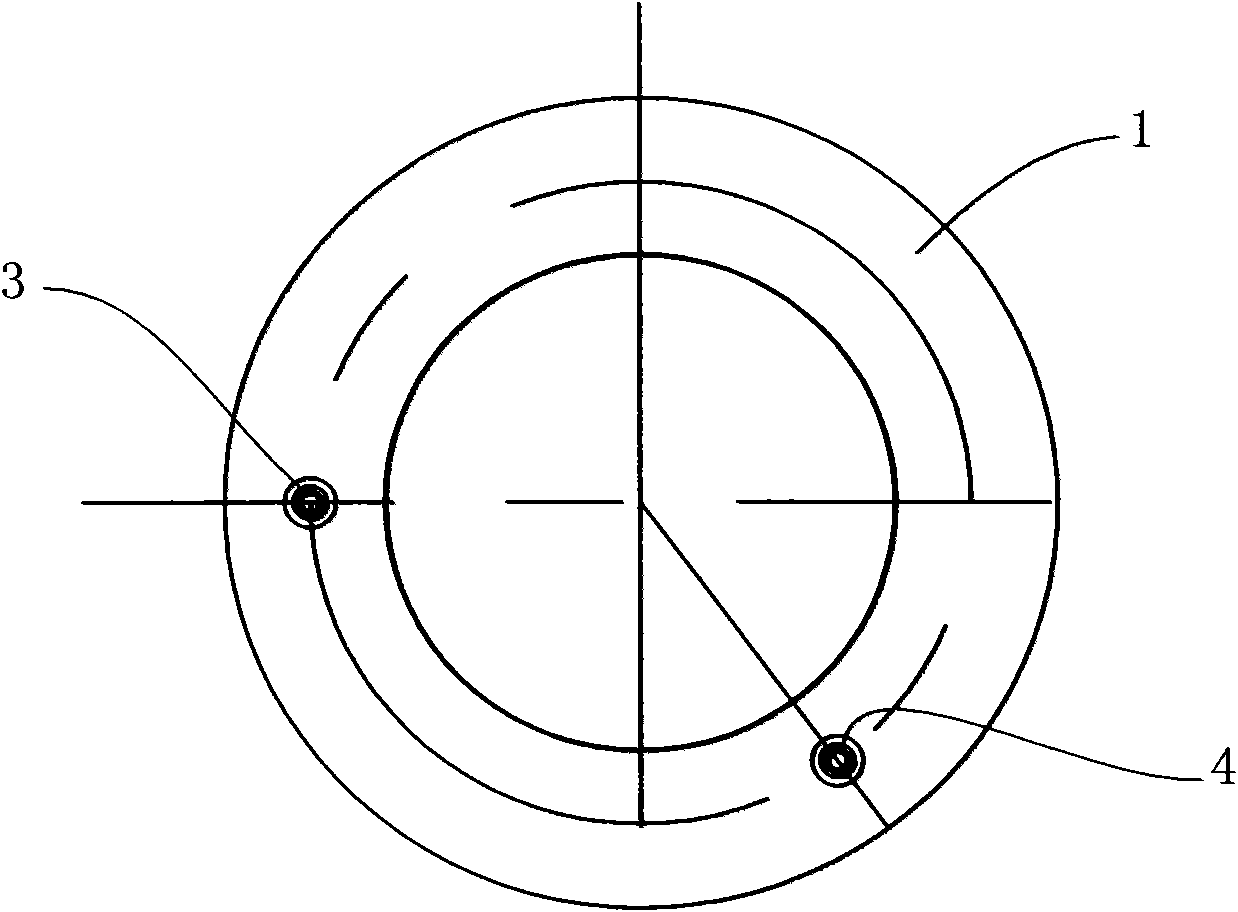

Manufacturing method of internal bladder of annular titanium alloy gas cylinder

ActiveCN101850494AThe inner and outer ring welds are formed beautifullyMeet the design requirementsWelding/cutting auxillary devicesAuxillary welding devicesGas cylinderWeld seam

The invention relates to a forming processing technology for an annular metal gas cylinder, in particular to a manufacturing method of an internal bladder of an annular titanium alloy gas cylinder, which comprises the following steps: (1) forging a titanium alloy plate to form two annular half-round tubes; (2) turning holes at the air inlet hole and air outlet hole positions of the annular titanium alloy half-round tubes; (3) welding an air inlet pipe nozzle and an air outlet pipe nozzle respectively on the turned holes in a vacuum argon filling protective chamber; (4) chemically milling the inner walls of the two annular titanium alloy half-round tubes to the required thickness; (5) welding the inner ring weld seam and outer ring weld seam of the two annular titanium alloy half-round tubes to form the sealed internal bladder; and (6) carrying out vacuum heat treatment. The weld seam has beautiful appearance, does not have welding defects such as air holes and has good high pressure resistant performance; the strength meets the design requirements; simultaneously the appearance of the internal bladder does not have deformation after welding, does not need correction, and meets the design tolerance requirement; and chemical milling is substituted for turning for the inner wall of the internal bladder to effectively solve the deformation caused by turning.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

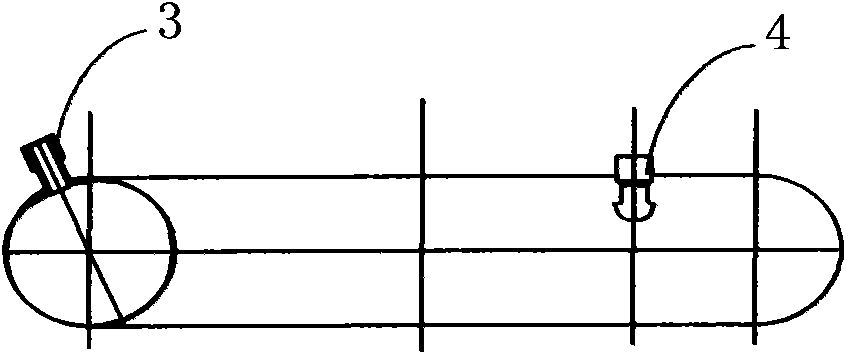

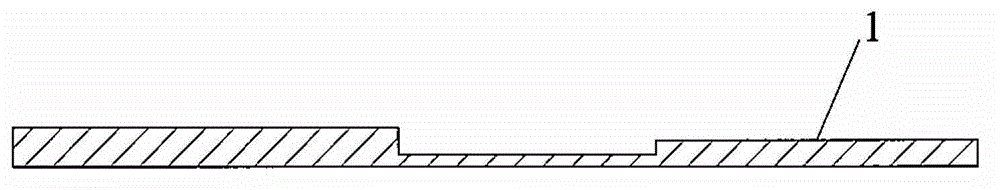

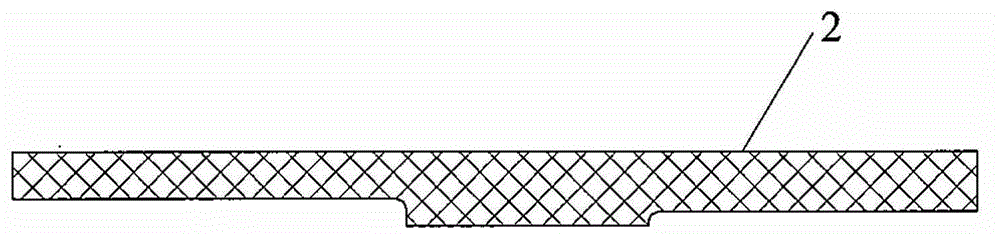

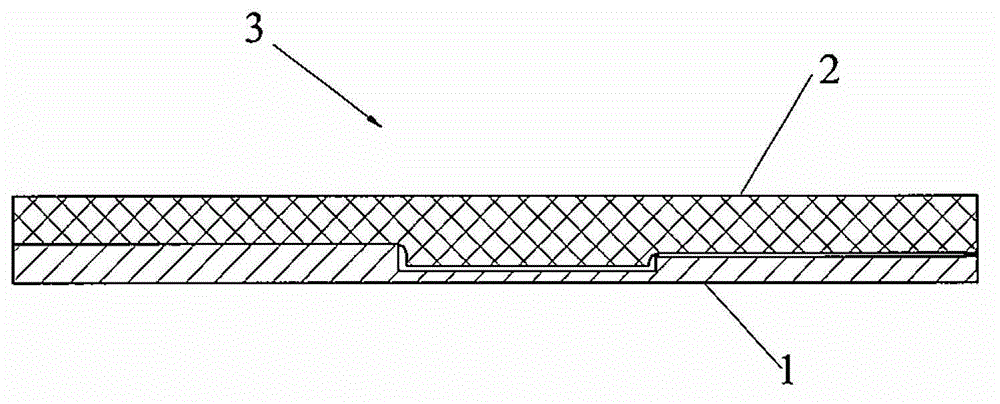

Rolling forming method of metal plate component

The invention discloses a rolling forming method of a metal plate component. The rolling forming method comprises the steps that (1) a wall plate part of a machine body is unfolded into a flat plate structure, and one side of the part is provided with a step; (2) a metal plate blank is prepared according to the unfolded flat plate structure; (3) a padding structure is designed, and the padding structure and the metal plate blank are complementary structures; (4) an elastic padding plate is prepared according to the designed padding structure; (5) the metal plate blank and the elastic padding plate are assembled, and a combined plate blank is formed; (6) rolling parameters of the combined plate blank are determined; (7) the combined plate blank is subjected to numerical control rolling forming; and (8) the metal plate component is extracted. The rolling forming method has the advantages that the precise forming of the component in the great-step-ratio and variable thickness structure can be realized, in addition, the limitation of the thickness and the intensity of processed parts is avoided, meanwhile, the rolling forming method can be utilized for replacing the traditional manufacture method of carrying out chemical milling after forming on the wall plate part of the machine body, the manufacture precision of products is improved, and the environment pollution caused by the chemical milling is also avoided.

Owner:SHANGHAI AIRCRAFT MFG

A method for processing and preparing a hemispherical metal storage tank for spacecraft fuel

The invention discloses a method for processing and preparing a semi-spherical metal storage tank used for an astrovehicle fuel. The method adopts pure titanium thin plates as the preparation material to prepare a metal semi-membrane type storage tank used for the astrovehicle fuel through cutting, trimming, lubricating, room-temperature deep drawing, flanging, chemical milling and other processing techniques, the semi-spherical storage tank free from the defects of drapes and scratches on the surface of the tank can be realized by adopting the method, and the requirements of tapered wall thickness or uniform wall thickness and smooth surface can be realized through chemical milling. By adopting the method for preparing the metal semi-membrane type storage tank disclosed by the invention,the processing is simple, the quality control is easy, and the product yield rate is high and reaches 90 percent above.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

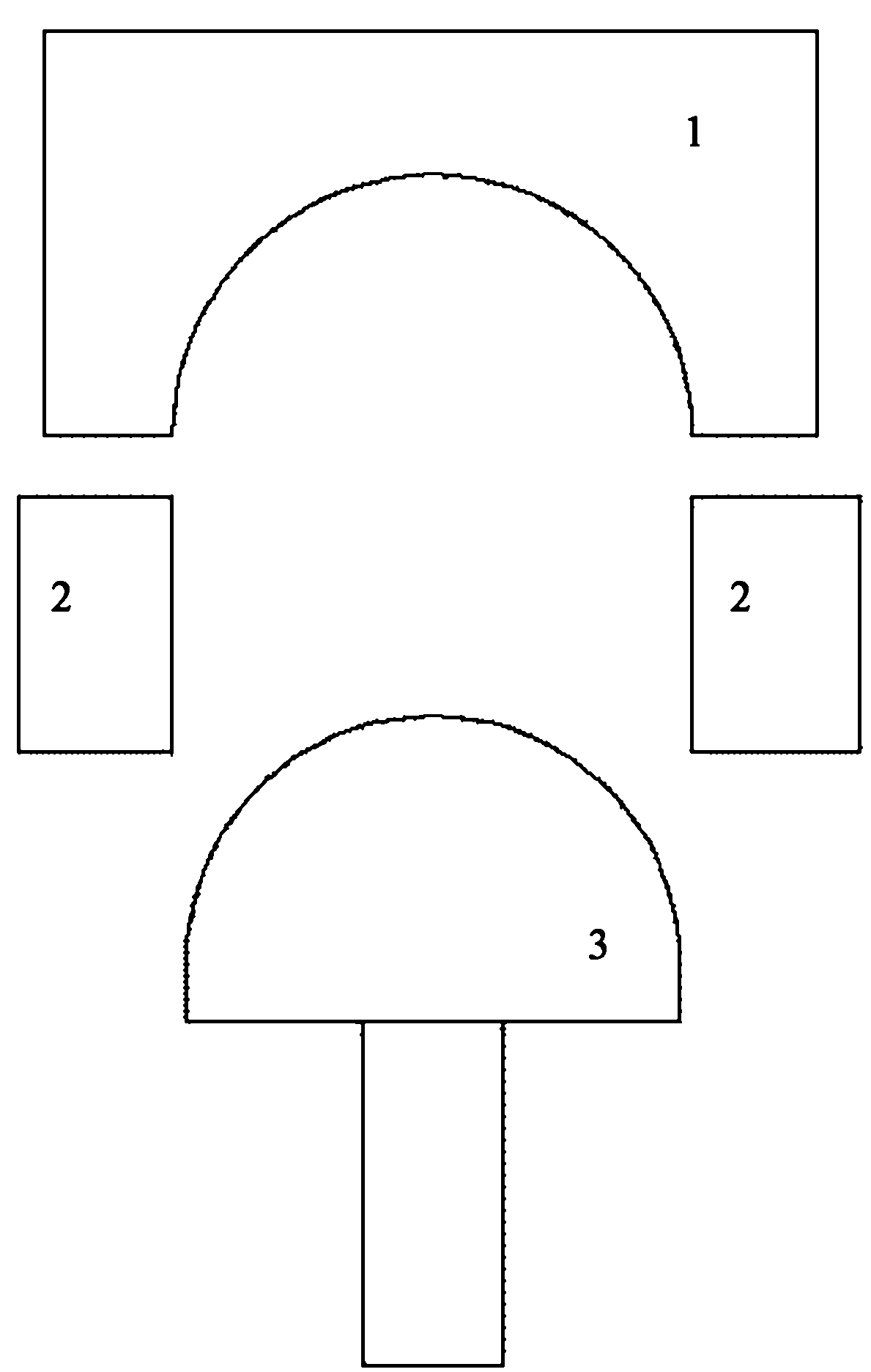

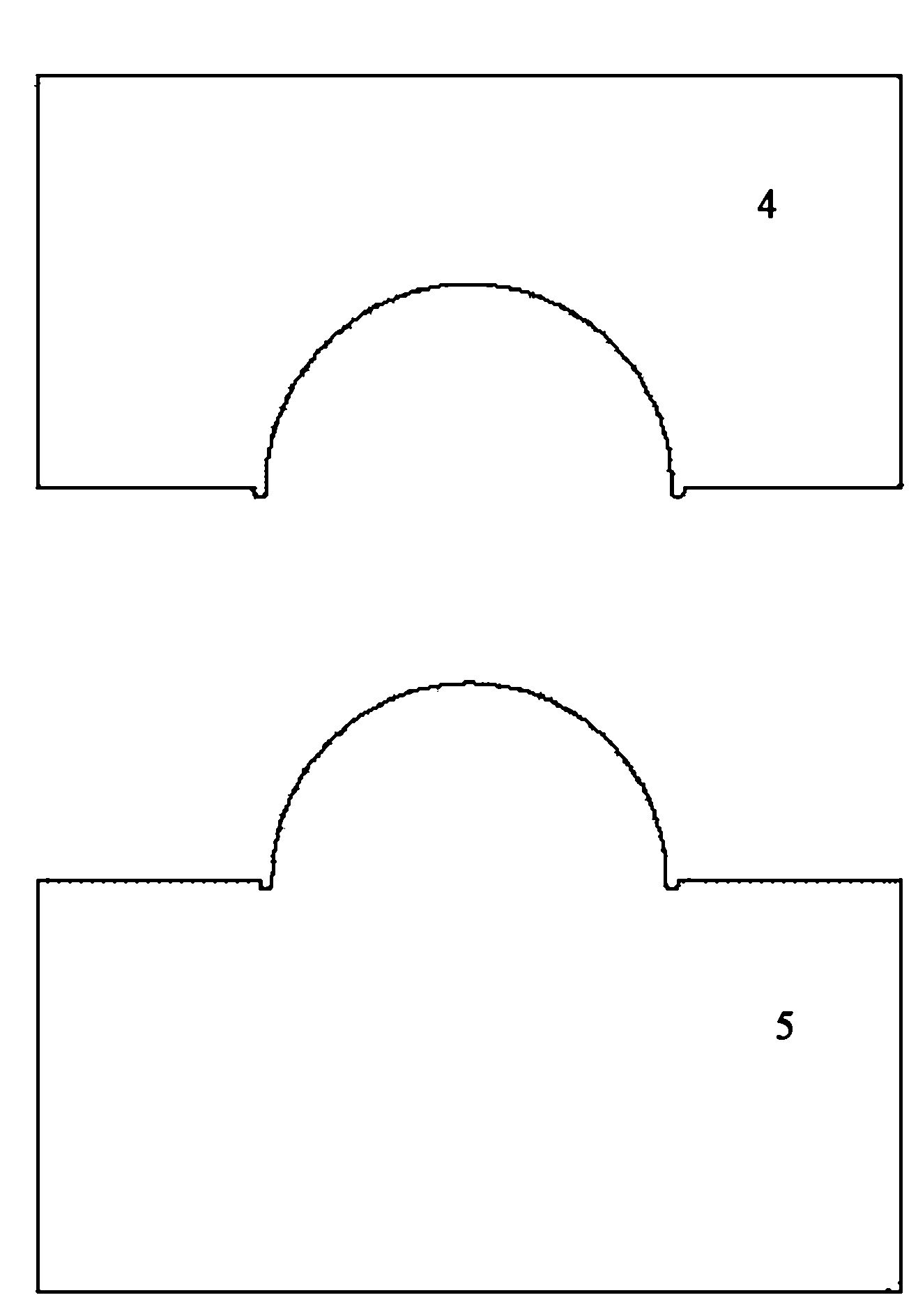

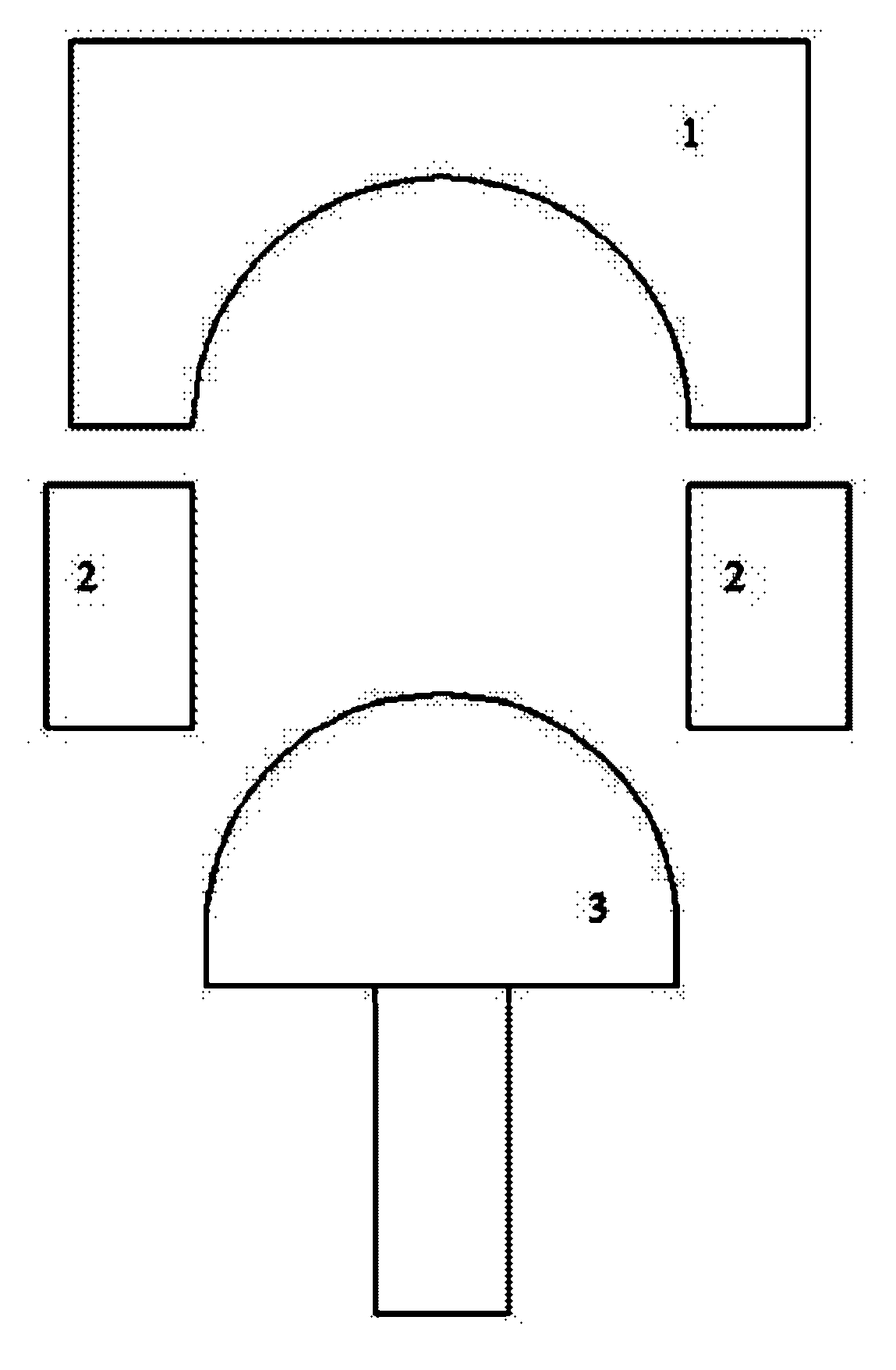

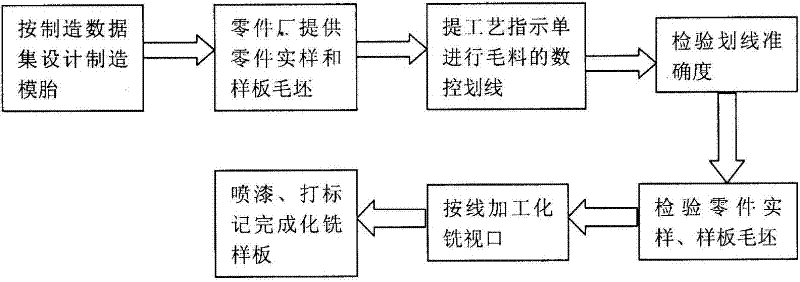

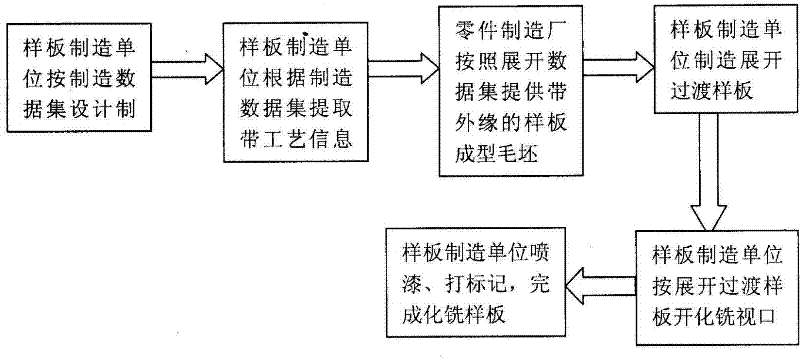

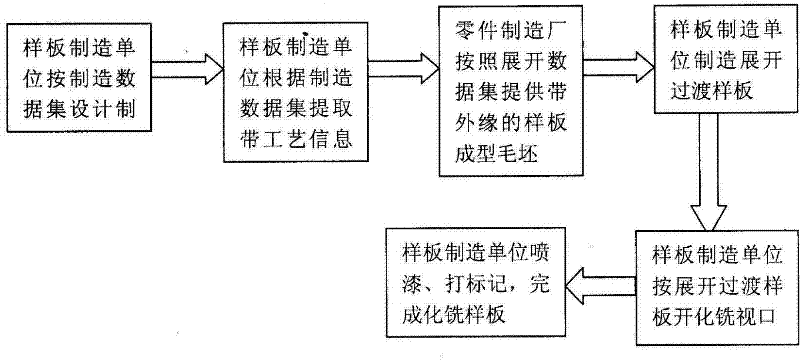

Processing method of chemical milling template

The invention relates to a processing method of a chemical milling template, which comprises the following steps: 1) preparing a data set; 2) expanding the data set; 3) expanding the data set and manufacturing a chemically milled blank; 4) unfolding a transitional template and transferring the transitional template to the formed blank; 5) forming a view port on the blank; and 6) forming the chemical milling template. By adopting the method, the production procedures can be simplified, the manufacturing cycle of the chemical milling template can be shortened, the step of treating excessive chemical milling threads through a numerically controlled integrated machine can be eliminated, molds for outer edge cutting of parts and outer edge cutting procedures for the parts can be eliminated, and thus the processing speed can be increased greatly.

Owner:SHENYANG AIRCRAFT CORP

Hollow golf club head and method of manufacturing the same

ActiveUS9174100B2Easy to manufactureLow costMetal rolling stand detailsMetal working apparatusGolf BallGolf club

This invention provides a hollow golf club head including a metal plate portion provided with thin and thick portions. A medium thick portion having an intermediate thickness between the thicknesses of the thin and thick portions is formed at the boundary portion between the thin and thick portions. The thin and medium thick portions are formed by the steps of pressing the metal plate portion to form a recess in one surface of the metal plate portion and a projection on its other surface, performing chemical milling of the recess and a portion surrounding it, and removing the projection by grinding.

Owner:BRIDGESTONE SPORTS

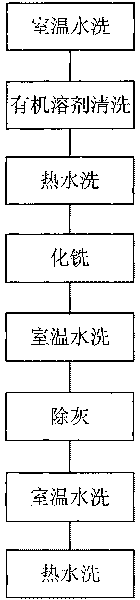

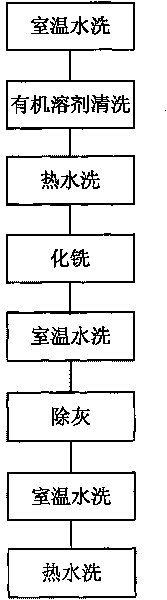

Chemical milling method for titanium alloy blades

ActiveCN101709471AMeet the precision requirementsMeet the design drawing requirementsOrganic solventRoom temperature

The invention provides a chemical milling method for titanium alloy blades. The method is implemented according to the following steps: (1) washing a titanium alloy blade subjected to finish forging with water in order to remove surface dust, adopting organic solvent to remove surface oil stain and then removing the organic solvent; (2) immersing the titanium alloy blade after the organic solvent is removed in chemical milling solution for 3 to 15 minutes; (3) cleaning the obtained product with room-temperature water to remove residual acid solution on the surface and then immersing the obtained product in dust-removing solution for 3 to 15minutes; and (4) removing the residual acid solution on the surface of the titanium alloy blade after dust removal. The method can effectively control the rate of corroding the surface of the blade by preparing the chemical milling solution so as to allow titanium alloy blades to meet precision requirements. The whole chemical milling process is simple in method and easy to control, and can meet design requirements without machining blade discs, blade backs, inner edges and surfaces of the titanium alloy blades.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Toughness porous anodic aluminium oxide film and preparation method thereof

InactiveCN1920108AUniform pore size distributionImprove toughnessAnodisationPhosphoric acidCrystal cell

The invention provides the porous anode pellumina and preparing method. The porous anode pellumina is composed by hexagon crystal cells, the bore diameter range is 5-200nm, the bores are parallel, and the bore diameter is distributed homogeneously. The film has good tenacity. The method comprises the following steps: aluminium sheet degreasing, removing the surface oxidate with alkali, then carrying out chemical milling, using aluminum sheet as anode, platinum filament as cathode, carrying out electrolytic oxidation in acide, then film aluminium base is electrolyzed in the electrolytic solution of dilute hydrochloric acid and anhydrous ferric chloride, soaking the film in the phosphoric acid, and getting the product. The film can be used for separating film of hyperfiltration and microfiltration and form board for making functional material and nanometer line.

Owner:DALIAN UNIV OF TECH

Rapid manufacturing method used for outer storing box gridding wallboard of aerospace craft

InactiveCN103639668AGuaranteed bonding strengthStrong shear resistanceVehicle componentsMetal working apparatusMechanical millingMachining

The invention discloses a rapid manufacturing method used for an outer storing box gridding wallboard of an aerospace craft, the outer storing box gridding wallboard comprises a bottom board and gridding ribs and is machined by the adoption of friction stir welding equipment. The rapid manufacturing method includes the following steps that (1), a bottom board plate is machined in advance; (2), material of stitch welding plates is selected following the principle of component matching between the stitch welding plates and the bottom board or the principle of performance complementation; the size of the stitch welding plates is determined according to the gridding number, the gridding size and the rib width on the bottom plate; (3), a friction stir stitch welding clamp used for the structure is designed; (4), the manufacturing concept of layering material increase-partial milling is achieved through the friction stir stitch welding gridding ribs; (5), finish machining is performed. The manufacturing concept of layering material increase is combined with the friction stir welding technology, and not only can gridding rib wallboards in various shapes and heights be manufactured, but also a heterogeneous aluminum alloy ribbed bar gridding wallboard can be manufactured and machined on a thin aluminum sheet, which can not be achieved through existing chemical milling and mechanical milling methods.

Owner:TIANJIN UNIV

Method for manufacturing sheet metal part stereo chemical milling sample plate

The invention discloses a method for manufacturing a sheet metal part stereo chemical milling sample plate. Based on the advantages of flexibility, transparency and high sticking performance, a gelatin plate is attached to a die tire, line drawing is carried out, then the gelatin plate is transferred to a blank; a chemical milling graphic is transferred to the blank; and the chemical milling sample plate is manufactured. By adopting the manufacturing method, the sample plate blank and the die tie are only required to be positioned once; the method has the advantages of simple operation, high practicability and high efficiency; and convenience is supplied to manufacturing of the stereo chemical milling sample plate.

Owner:XIAN AIRCRAFT IND GROUP

Chemical milling technology for surface plasticity deformation layer of single crystal cast blade

InactiveCN102817034AInhibition of recrystallizationImprove reliabilityAfter-treatment detailsChemical treatmentDehydrogenation

The invention relates to the field of surface treatment of blades, in particular to a chemical milling technology for a surface plasticity deformation layer of a single crystal cast blade. The chemical milling technology comprises the following steps of: firstly, carrying out surface treatment on the blade; secondly, carrying out chemical milling treatment on the blade: carrying out chemical milling treatment on the blade by adopting a chemical milling liquid at the chemical milling temperature of 30-40DEG C, the chemical milling speed of 3.0-4.5mum / min and the chemical milling depth of 30-60mum, wherein the chemical milling liquid in unit volume comprises the following components of 150-250ml / l of nitric acid, 80-130ml / l of hydrochloric acid, 80-130ml / l of hydrofluoric acid, 150-250ml / l of ferric trichloride, 40-60ml / l of acetic acid, 0.3-1.0g / l of lauryl sodium sulfate and 15-30g / l of activated carbon; and finally, carrying out dehydrogenation treatment on the blade in dehydrogenation furnace. According to the chemical milling technology, the treated engine blade meets the requirement of the design and the use reliability of the single crystal cast blade is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Forming method capable of guaranteeing quality of chemically-milled thick skin workpieces

The invention provides a forming method capable of guaranteeing quality of chemically-milled thick skin workpieces. The method specifically includes the steps: selecting a non-prestretched plate for producing a skin blank, and reserving jaw clamping allowances in two jaw directions of the skin blank; preparing four process aluminum rods with sizes equal to the reserved jaw clamping allowances in the jaw directions; adhesively bonding the process aluminum rods with the skin blank; adopting a skin stretching machine for prestretching the skin blank to enable the skin blank to form a pre-stretched plate with low internal stress; in a part forming process, adopting an aluminum rod bonding method for guaranteeing clamping force of a jaw of the skin stretching machine on the blank, performing chemical milling after forming, and cutting off the process aluminum rods and the jaw clamping allowances reserved in the jaw directions to form a skin workpiece; and finishing, painting and inspecting. The blank is pre-stretched to enable the internal stress of a skin material to be decreased, so that deformation of chemical milling is reduced, plasticity is excellent during forming, and forming quality of the chemically-milled thick skin workpieces is guaranteed.

Owner:SHENYANG AIRCRAFT CORP

Large irregular bus-shaped surface shell uniform thinning machining method and device

ActiveCN112589133AUniform thinningThinning meetMeasurement/indication equipmentsLarge fixed membersNumerical controlSpinning

The invention discloses a large irregular bus-shaped surface shell uniform thinning machining method and device. According to the large irregular bus-shaped surface shell uniform thinning machining method and device, a programmable uniform thinning model is generated, the blank curvature change rule is combined, and a sectional type turning method and a layered turning method are utilized to complete a certain aluminum alloy dry cutting process; and a set of shell blank uniform thinning machining device system is designed and directly added on numerical control equipment, so that the requirements of uniform thinning machining of blanks in a forming mode such as spinning / casting can be met, the requirements of the sectional type turning process and the layered turning process are met, the requirements of the large-end rigid clamping process are met, the error caused by main shaft jumping in the turning process is solved, precision compensation is realized, uniform thinning machining ofparts is realized, the problems of low chemical milling efficiency and heavy pollution after the parts are taken down through spinning and subjected to heat treatment deformation are solved, and the requirements of weight and precision are met.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Single-curvature cover machining method

InactiveCN103921068AImprove processing efficiencyImprove machining accuracyAircraft componentsMechanical millingEngineering

The invention discloses a single-curvature cover machining method. The single-curvature cover machining method comprises the following steps of feeding, rolling bending, flattening and milling. Secondary rolling bending is required to be performed on a single-curvature three-radian cover with high machining difficulty and a single-curvature thick cover with high machining difficulty after the single-curvature three-radian cover and the single-curvature thick cover are milled. The single curvature cover machining method can be used for machining a simple single-curvature cover or a complex single-curvature cover, chemical milling can be changed into mechanical milling, the single-curvature cover machining efficiency and the single-curvature machining precision are guaranteed, and the machining cost is effectively saved.

Owner:AVIC SAC COMML AIRCRAFT

Chemical milling method for monocrystalline high temperature alloy precision casting

InactiveCN103451657AEasy to operateEasy to controlAfter-treatment detailsStress concentrationSingle crystal superalloy

The invention relates to a chemical milling method for monocrystalline high temperature alloy precision casting. The method is as below: first cleaning impurities on the surface of the precision casting; then putting a corrosion liquid and a precision casting in a corrosion groove, putting in a test piece with known thickness, immersing the precision casting and the test piece in the corrosion liquid, heating the corrosion groove from outside to maintain the temperature of the corrosion liquid at 20-60 DEG C, corroding for 90-200 min to shed off the corrosion products; taking out the precision casting and the test piece from the corrosion groove, flushing the precision casting and the test piece with clear water, brushing off residual corrosion products, air-drying the precision casting and the test piece, measuring thickness change of the test piece and determining the removal amount of the casting; and if the removal amount is not enough, repeating the above steps until a required removal amount is reached. The method provided by the invention is mainly suitable for chemical milling of Re-containing nickel base monocrystalline high temperature alloy. The chemical milling method is mainly used for removal of local stress concentration on the surface layer of the casting in a casting technology, and can effectively alleviate defect of recrystallization in a subsequent heat treatment process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

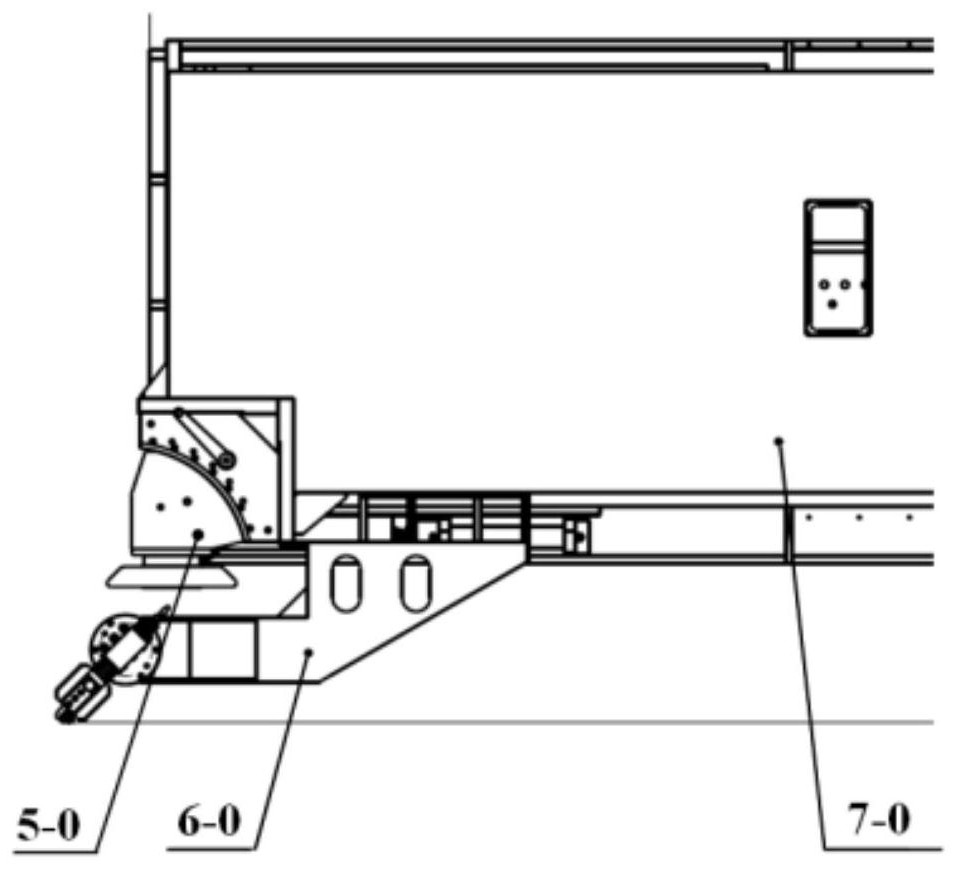

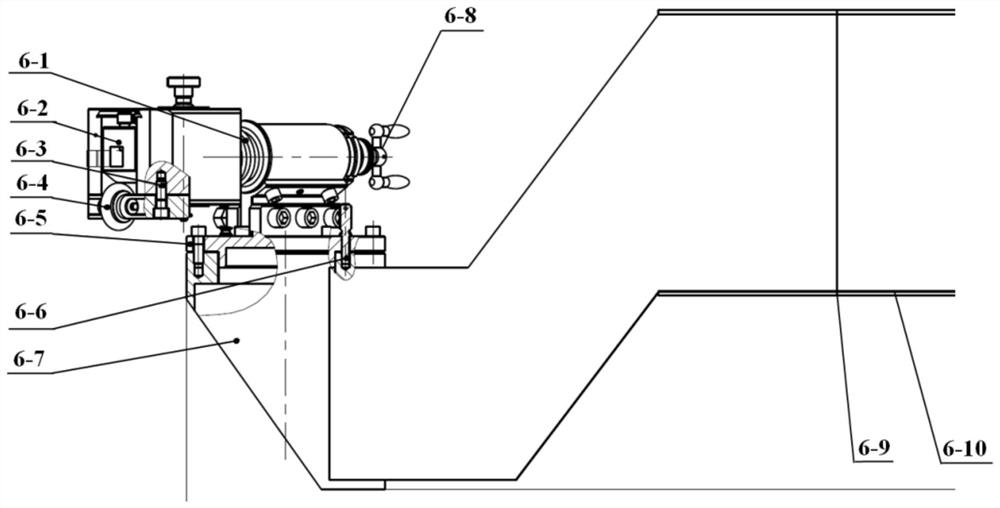

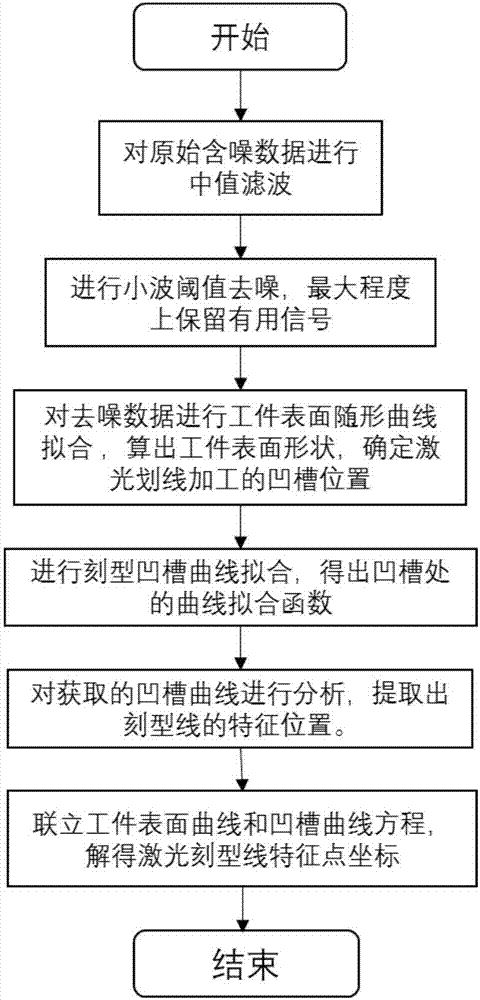

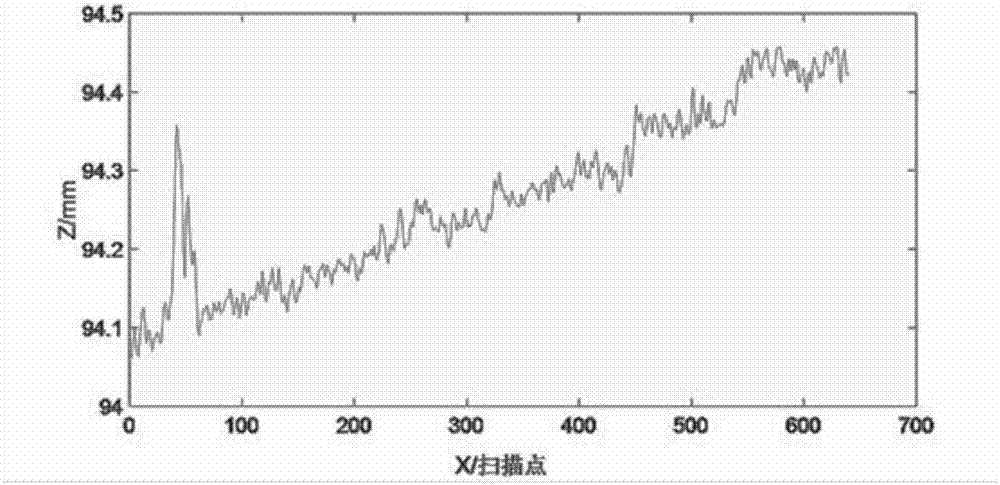

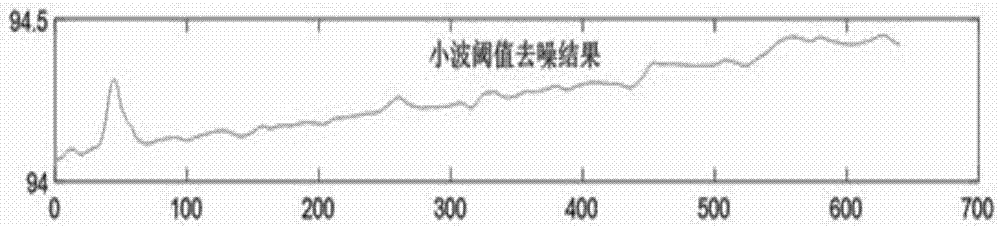

Line laser based laser engraving line feature extraction method

InactiveCN107133565AAccurate feature point locationRealize the processing effectImage enhancementImage analysisAviationFeature extraction

The invention belongs to the technical field of laser measurement, and relates to a line laser based laser engraving line feature extraction method. The method is provided in allusion to line laser detection for the laser engraving machining position of chemical milling regions of large aviation wall plate parts, and data preprocessing is performed on acquired original signals based on median filtering and wavelet threshold denoising so as to acquire smooth and stable signals. The accurate shape of a workpiece shape follow-up curve and an engraving groove curve at the line laser position is restored by adopting adaptive curve fitting; determining top edge boundary feature points of a groove according to an acquired workpiece shape follow-up curve equation and an engraving groove curve equation, and acquiring an accurate feature point of the groove by adopting a centering and averaging mode. The method has very high robustness, the extracted feature point of an engraving line is accurate in position, and a finally fit engraving line profile curve also meet a requirement of performing comparison with a mathematical model, thereby having great significance for guiding workpiece machining and assembling.

Owner:DALIAN UNIV OF TECH

Magnesium alloy chemical milling and processing technique

The invention provides a chemical polishing treatment technology for magnesium alloy, which mainly comprises the following steps: a) pretreatment for surface cleaning of the magnesium alloy workpiece such as cleaning and degreasing, which can comprise the steps of mechanical treatment, alkali washing, acid pickling and cleaning; b) chemical polishing, that is, impregnation of the treated magnesium alloy workpiece into the chemical polishing solution; c) post treatment such as cleaning and drying of the workpiece after polishing; wherein, in step b, water is adopted as solvent of the chemical polishing solution which mainly comprises 40 to 100 g / L nitric acid, 0 to 50 g / L oxalic acid and 1 to 10 g / L thiourea. The invention has the advantages that the chemical polishing solution with simple components and convenient management and control is prepared from the mixture of a plurality of common acids and organics; the obtained chemical polishing surface has good glossiness and smooth surface; and the chemical polishing solution can be used in combination with other chemical treatment steps, and can also be used as the fine polishing solution in mirror finishing.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Titanium alloy chemical milling engraving process

ActiveCN102995019ATroubleshoot size margin issuesGuaranteed distanceTectorial membraneLaser engraving

The invention relates to a titanium alloy chemical milling engraving process. According to the invention, laser and digital technologies are combined; laser energy and protective film thickness are controlled, and programming is carried out according to chemical milling process characteristic values, such that chemical milling and engraving can be accomplished in one step. Aiming at different film thicknesses, laser engraving is carried out. Through film penetrating tests, laser energy is determined, and a relationship between laser energy and film thickness is established. Through determining chemical milling axial and radial erosion ratio, laser engraving size allowance is determined, and a laser engraving size allowance problems is solved. The process provided by the invention has the advantages that: laser and digital technologies are combined; laser energy and protective film thickness are controlled, and programming is carried out according to chemical milling process characteristic values, such that chemical milling and engraving can be accomplished in one step; a traditional engraving technology is replaced, production period is shortened, and size precision is improved. Also, a template is not needed, such that large amounts of materials used for manufacturing templates can be saved, and cost is reduced. Also, operator labor intensity can be greatly reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com