Chemical milling method for titanium alloy blades

A titanium alloy blade technology, applied in the field of chemical milling of titanium alloy blades, can solve the problems of complex process steps, high temperature, low corrosion rate, etc., and achieve the effect of simple chemical milling process and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

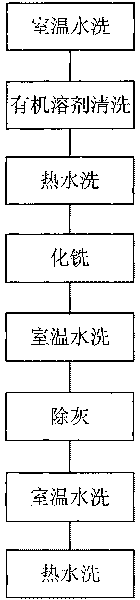

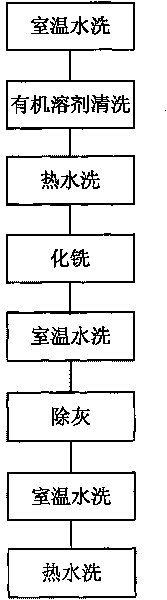

Method used

Image

Examples

Embodiment 1

[0016] The chemical milling solution is prepared by hydrofluoric acid, nitric acid and water, and the composition of the chemical milling solution is 30% by weight of HF, HNO 3 50%, the balance being water.

[0017] Wash the final forged titanium alloy blades with water to remove surface dust, then use organic solvents to remove surface oil stains, and then soak them in hot water at 40°C to remove organic solvents.

[0018] Place the titanium alloy blade from which the organic solvent has been removed in the chemical milling solution, and immerse it at 50°C for 15 minutes.

[0019] Wash the titanium alloy blades completed by chemical milling with room temperature water to remove the residual acid solution on the surface, and then immerse in the ash removal solution for 15 minutes, wherein the composition of the ash removal solution is 20% by weight of HF, HNO 3 25%, and the balance is water.

[0020] Clean the titanium alloy blades after dust removal with room temperature ...

Embodiment 2

[0023] The chemical milling solution is prepared by hydrofluoric acid, nitric acid and water, and the composition of the chemical milling solution is 50% by weight of HF, HNO 3 30%, and the balance is water.

[0024] Wash the final forged titanium alloy blade with water to remove surface dust, then use an organic solvent to remove surface oil, and then soak it in 45°C hot water to remove the organic solvent.

[0025] Place the titanium alloy blade from which the organic solvent has been removed in the chemical milling solution, and immerse it at 60°C for 10 minutes.

[0026] Wash the titanium alloy blades completed by chemical milling with room temperature water to remove the residual acid solution on the surface, and then immerse in the deashing solution for 11 minutes, wherein the composition of the deashing solution is 30% by weight of HF, HNO 3 35%, the balance being water.

[0027] Clean the titanium alloy blades after deashing with room temperature water to remove th...

Embodiment 3

[0030] The chemical milling solution is prepared by hydrofluoric acid, nitric acid and water, and the composition of the chemical milling solution is 40% by weight of HF, HNO 3 40%, the balance being water.

[0031] Wash the final forged titanium alloy blades with water to remove surface dust, then use organic solvents to remove surface oil stains, and then soak them in 50°C hot water to remove organic solvents.

[0032] Place the titanium alloy blade from which the organic solvent has been removed in the chemical milling solution, and immerse it at 70°C for 3 minutes.

[0033] Wash the titanium alloy blades completed by chemical milling with room temperature water to remove the residual acid solution on the surface, and then immerse in the deashing solution for 3 minutes, wherein the composition of the deashing solution is 25% by weight of HF, HNO 3 30%, and the balance is water.

[0034] Clean the titanium alloy blades after dust removal with room temperature water to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com