Micropore processing method of bone repairing body rough surface

A bone restoration and rough surface technology, applied in bone implants, medical science, laser welding equipment, etc., to achieve strong controllability, simple process steps, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] First preferred embodiment:

[0024] A microporous treatment method for a rough surface of a bone prosthesis of the present invention comprises the following steps:

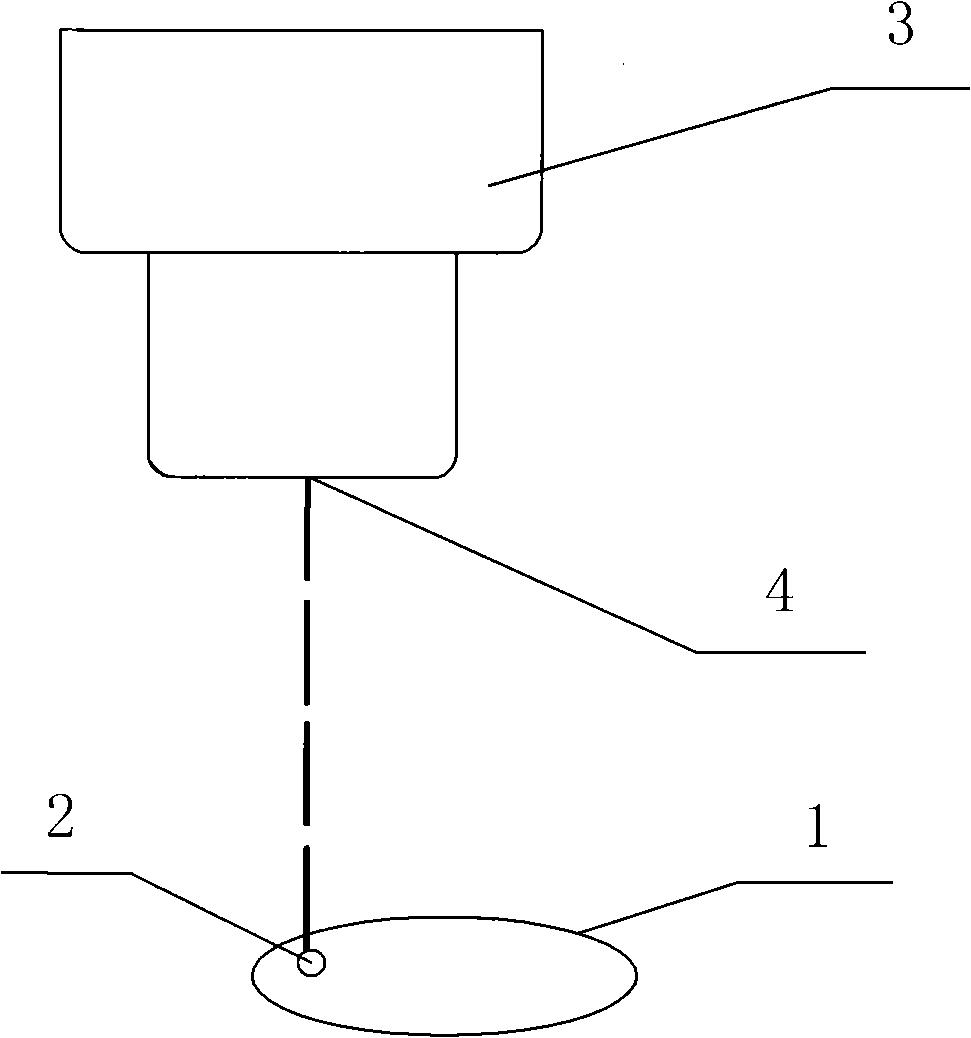

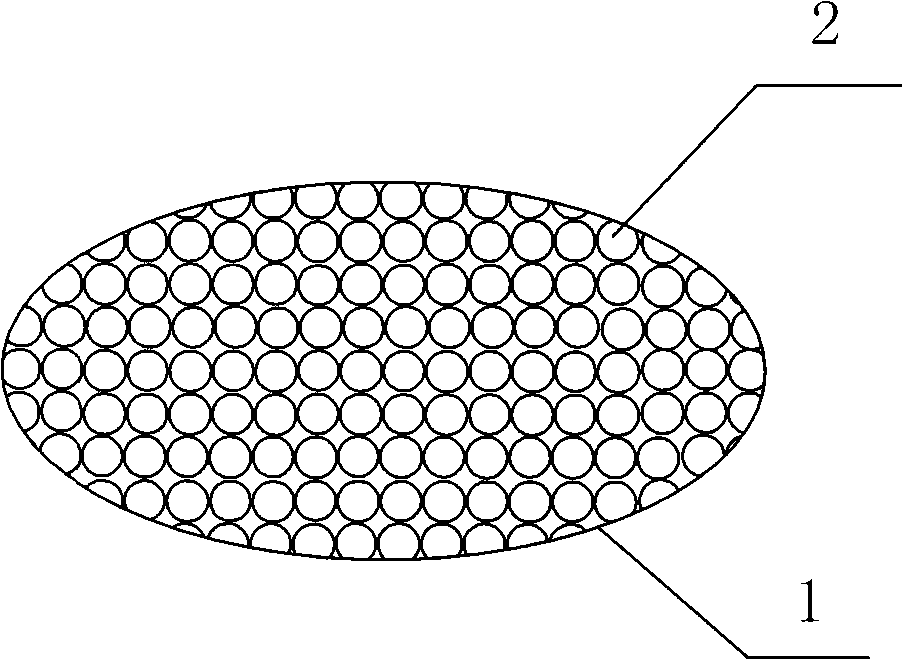

[0025] The first step, laser engraving: firstly, determine the surface 1 to be treated of the bone prosthesis, that is, the metal surgical implant. machine and etches a plurality of uniform and continuous micropores 2 on the surface 1 to be treated according to the conventional laser etching method. In this specific embodiment, the bone restoration to be processed is a craniofacial bone restoration made of a titanium alloy plate with a thickness of 2mm, and it is determined that the surface of the craniofacial bone restoration that is in long-term contact with human bone is to be treated. surface 1, and then laser etching can be started on the surface 1 to be treated.

[0026] The shape of the microhole 2 formed by laser etching is circular, triangular, square, rectangular or polygonal, and the cross-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com