Patents

Literature

233results about How to "Simplify the process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

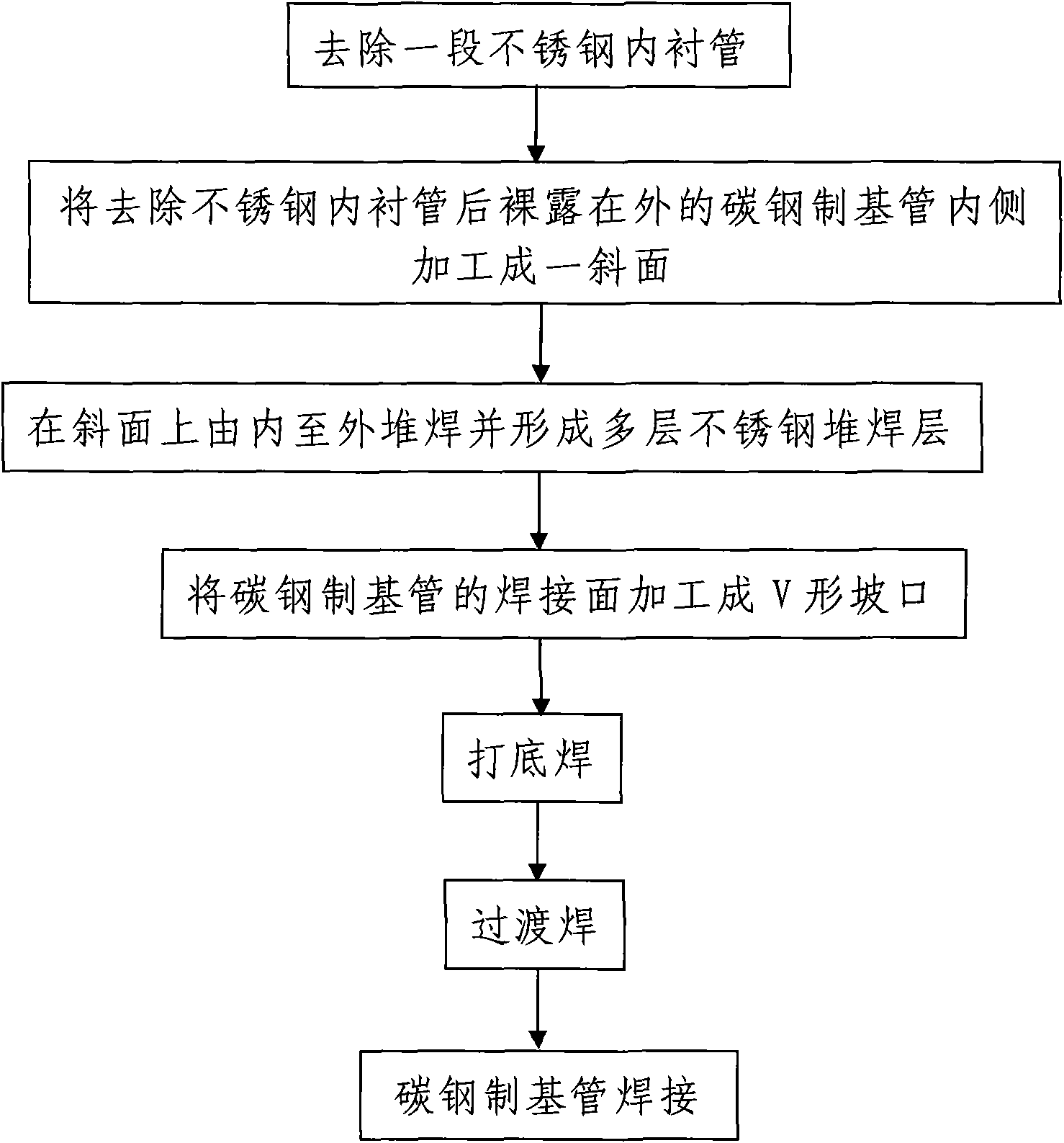

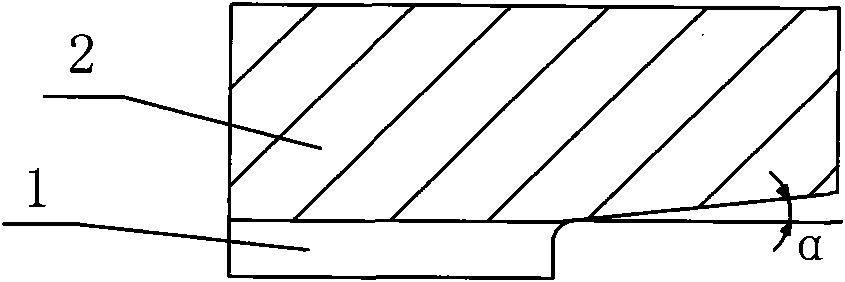

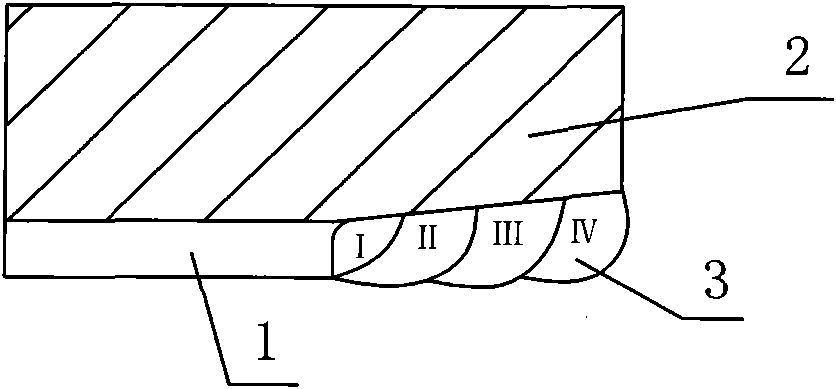

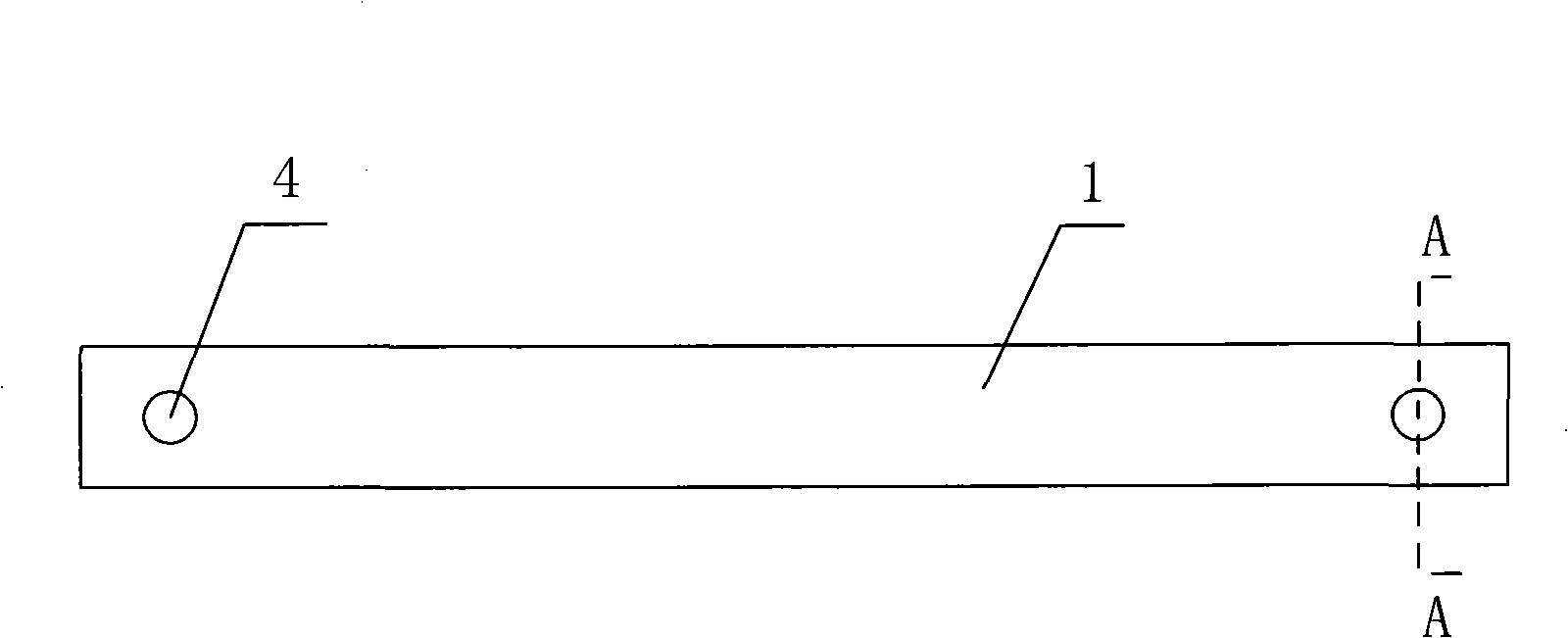

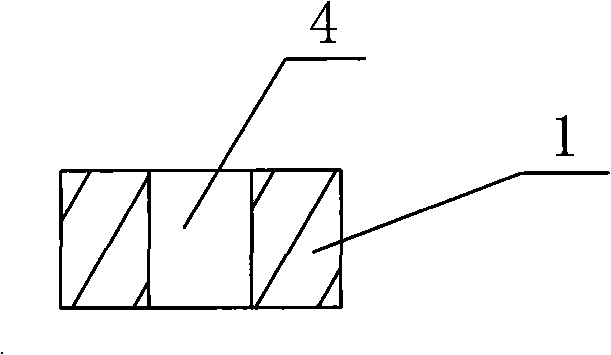

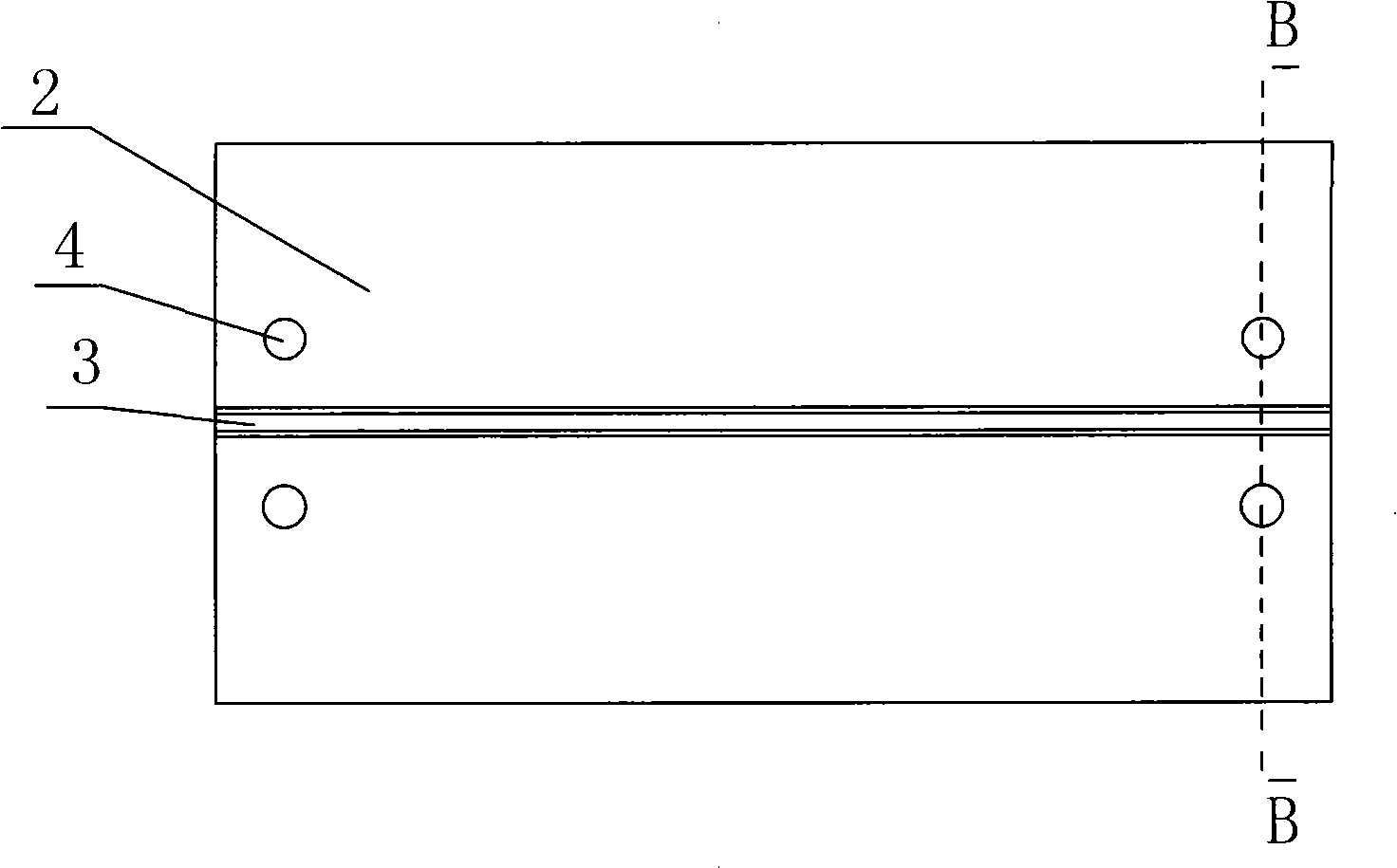

Method for welding composited tube at bonding interface of carbon steel/stainless steel machinery

ActiveCN101653855ASimple welding processExcellent weld mechanical properties and corrosion resistanceArc welding apparatusWelding/cutting media/materialsCarbon steelArc welding

The invention discloses a method for welding composited tube at the bonding interface of carbon steel / stainless steel machinery, comprising the following steps: 1. welding groove treatment as follows:removing a section of stainless steel lined tube; processing the interior of the carbon steel parent tube exposed outside after removing the stainless steel lined tube into an inclined plane inclinedinwards from exterior to interior; using a tungsten electrode argon arc welding machine to carry out bead weld on the inclined plane from interior to exterior and forming multiple stainless steel bead weld layers; processing the weld surface of the carbon steel parent tube into a V-shaped groove; 2. backing weld: when fitting up the stainless steel bead weld layers before backing weld, adopting the tungsten electrode argon arc welding machine to carry out fitting-up and fixing in a manner of spot welding; 3. transition weld; and 4. carbon steel parent tube weld. The invention features simpleprocedure steps, less used weld materials, high weld pass percentage, good welding line mechanical property, high weld quality and improved production efficiency simultaneously.

Owner:XIAN SUNWARD AEROSPACE MATERIAL

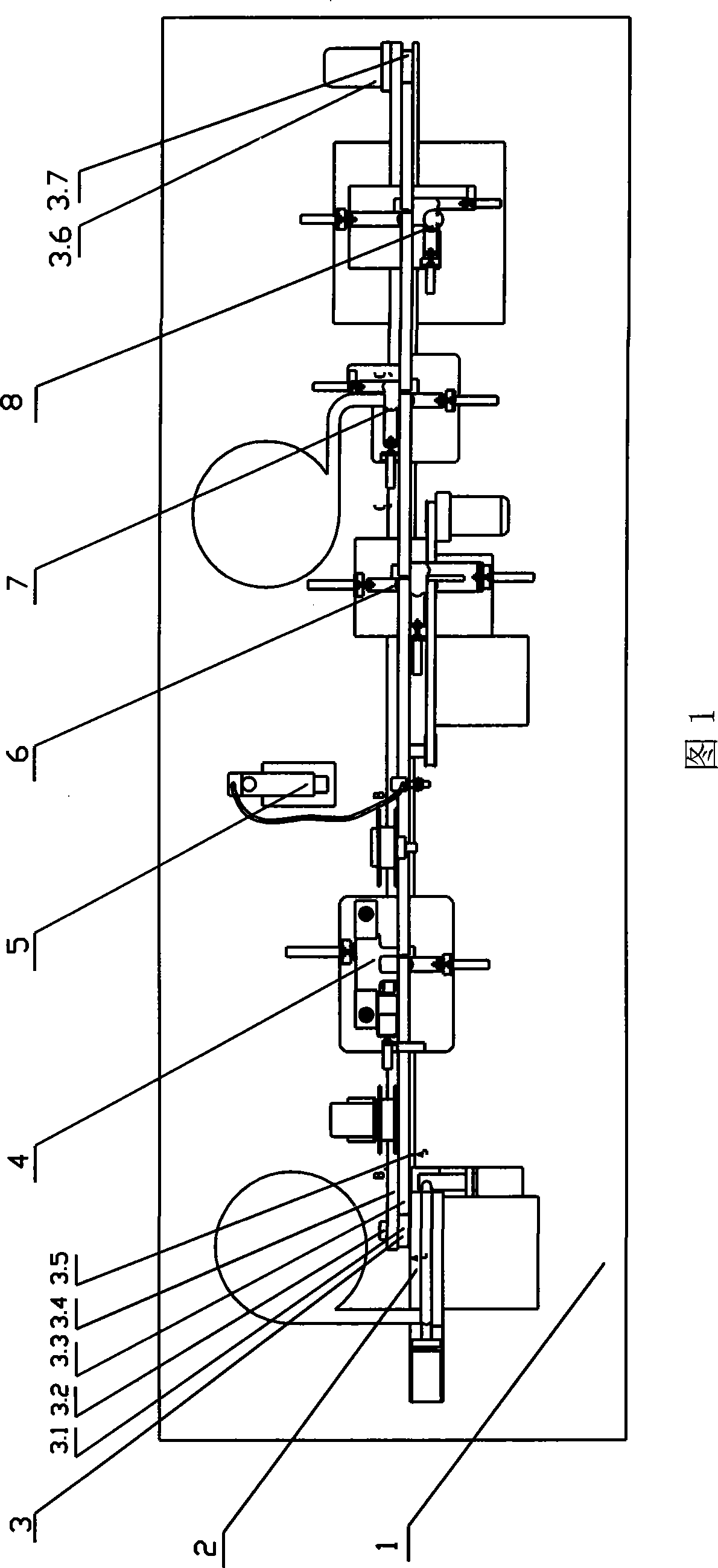

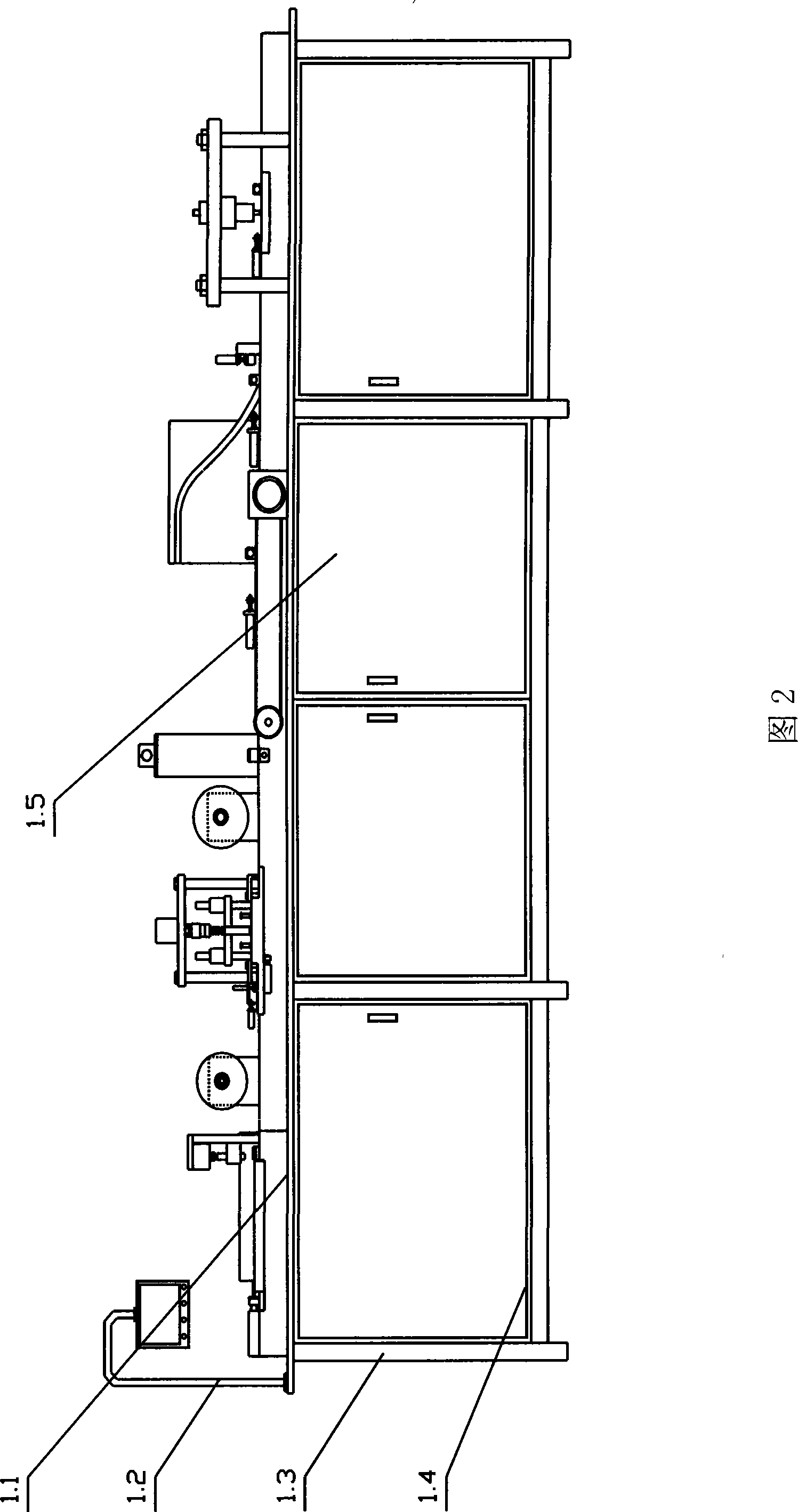

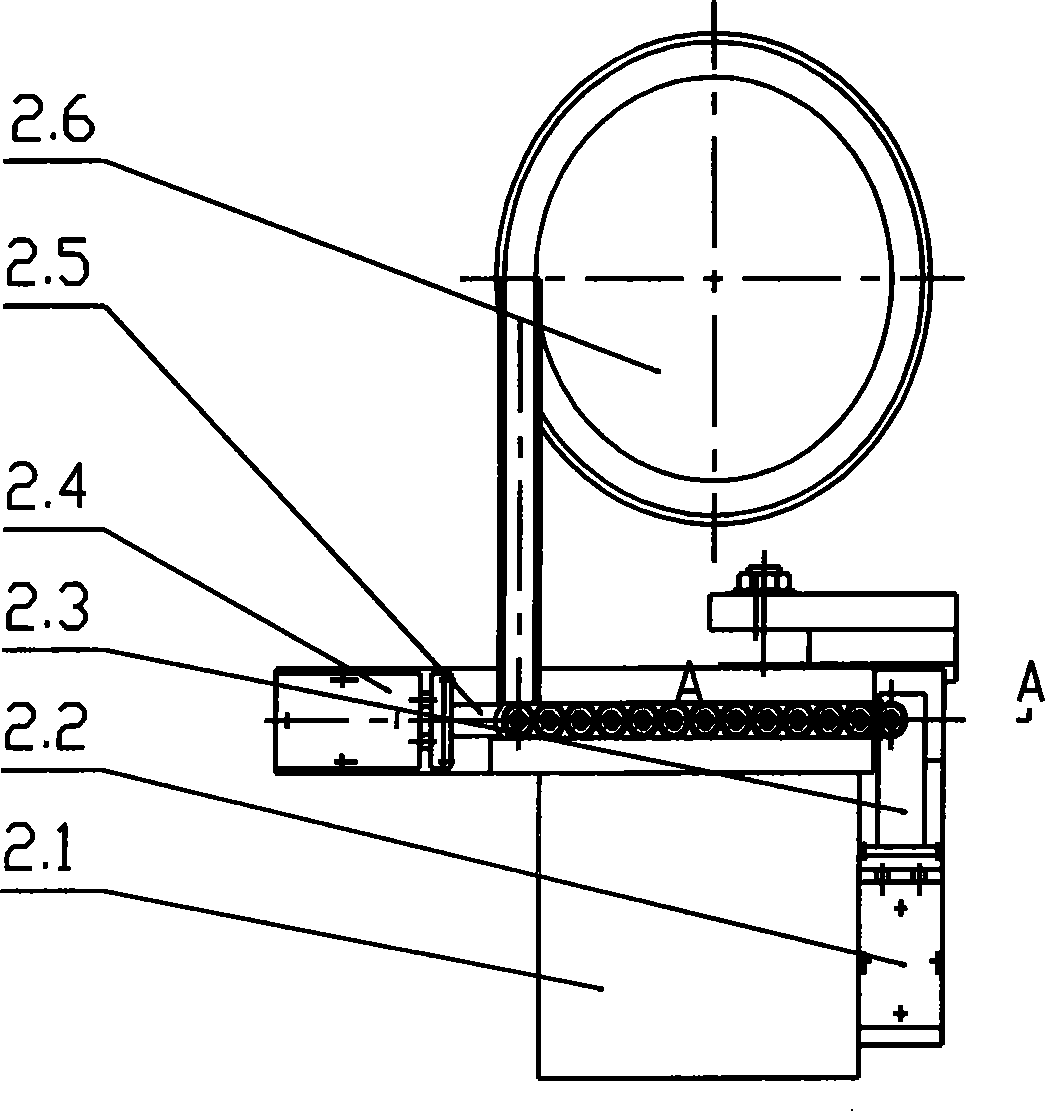

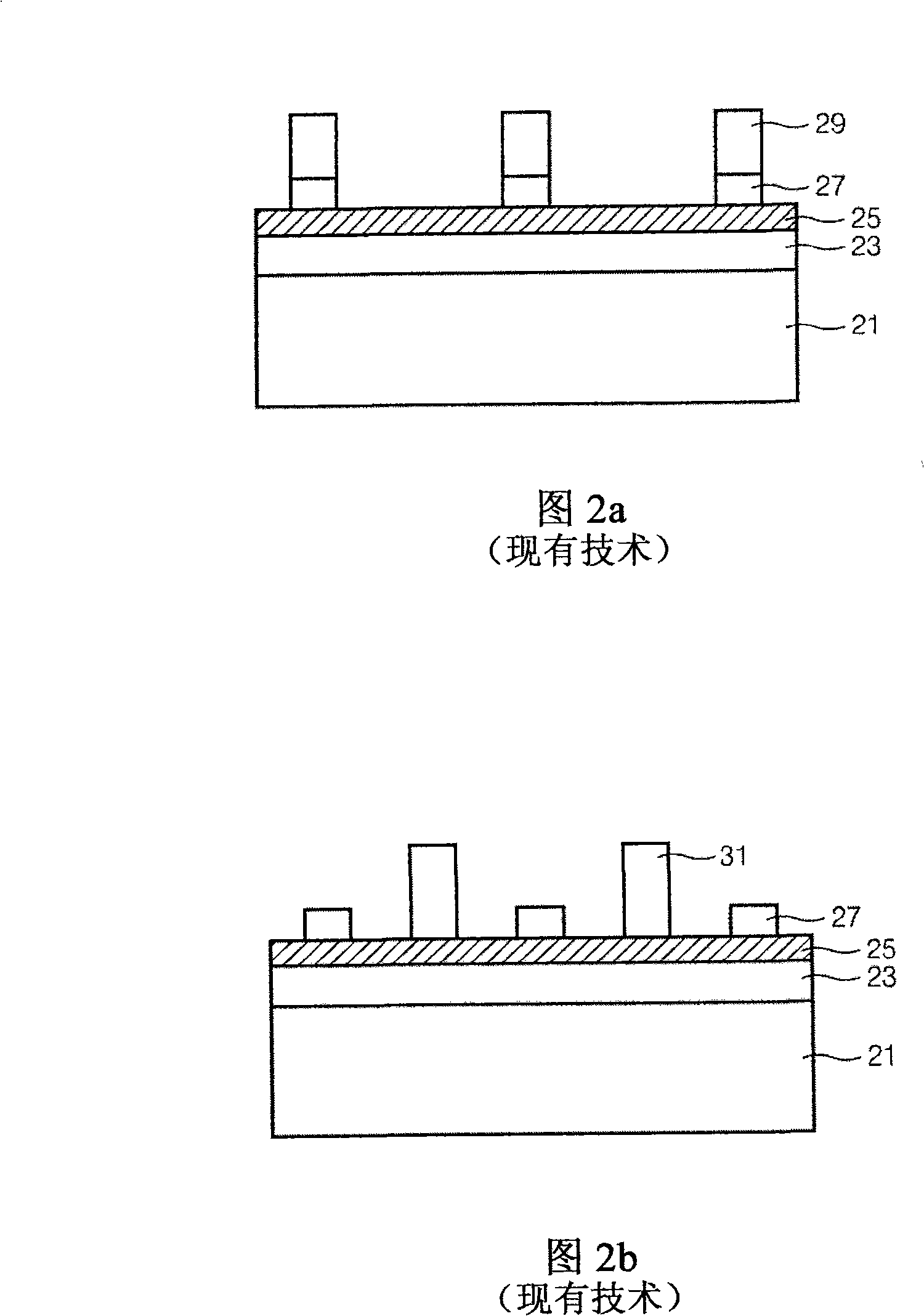

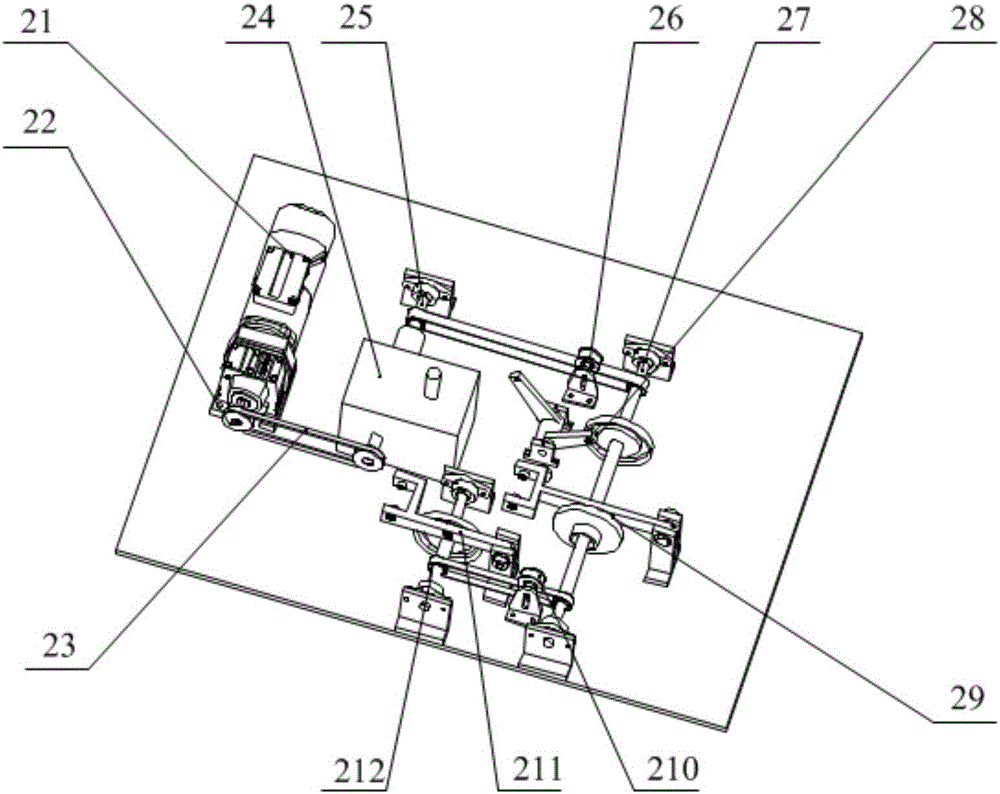

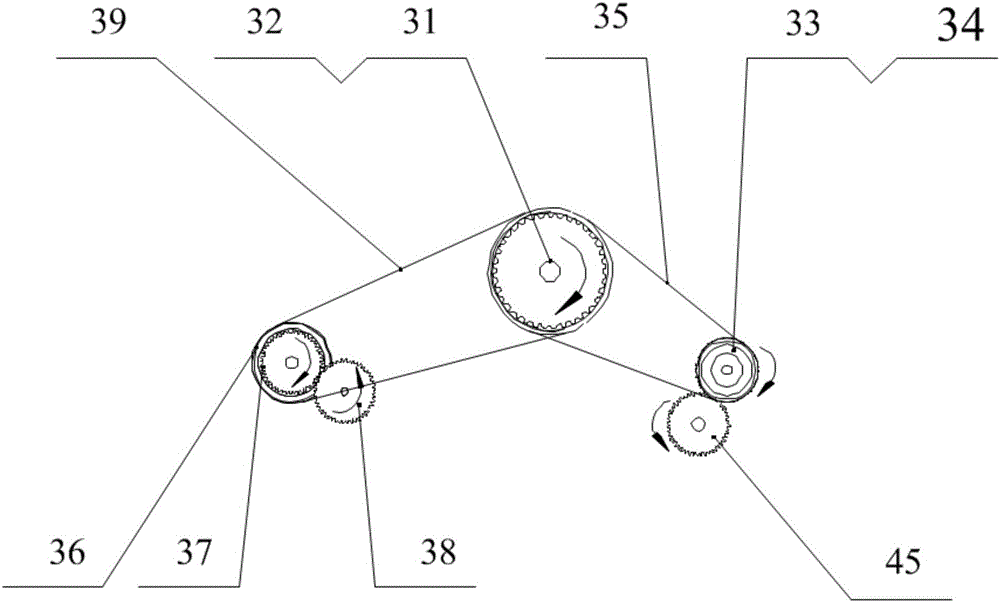

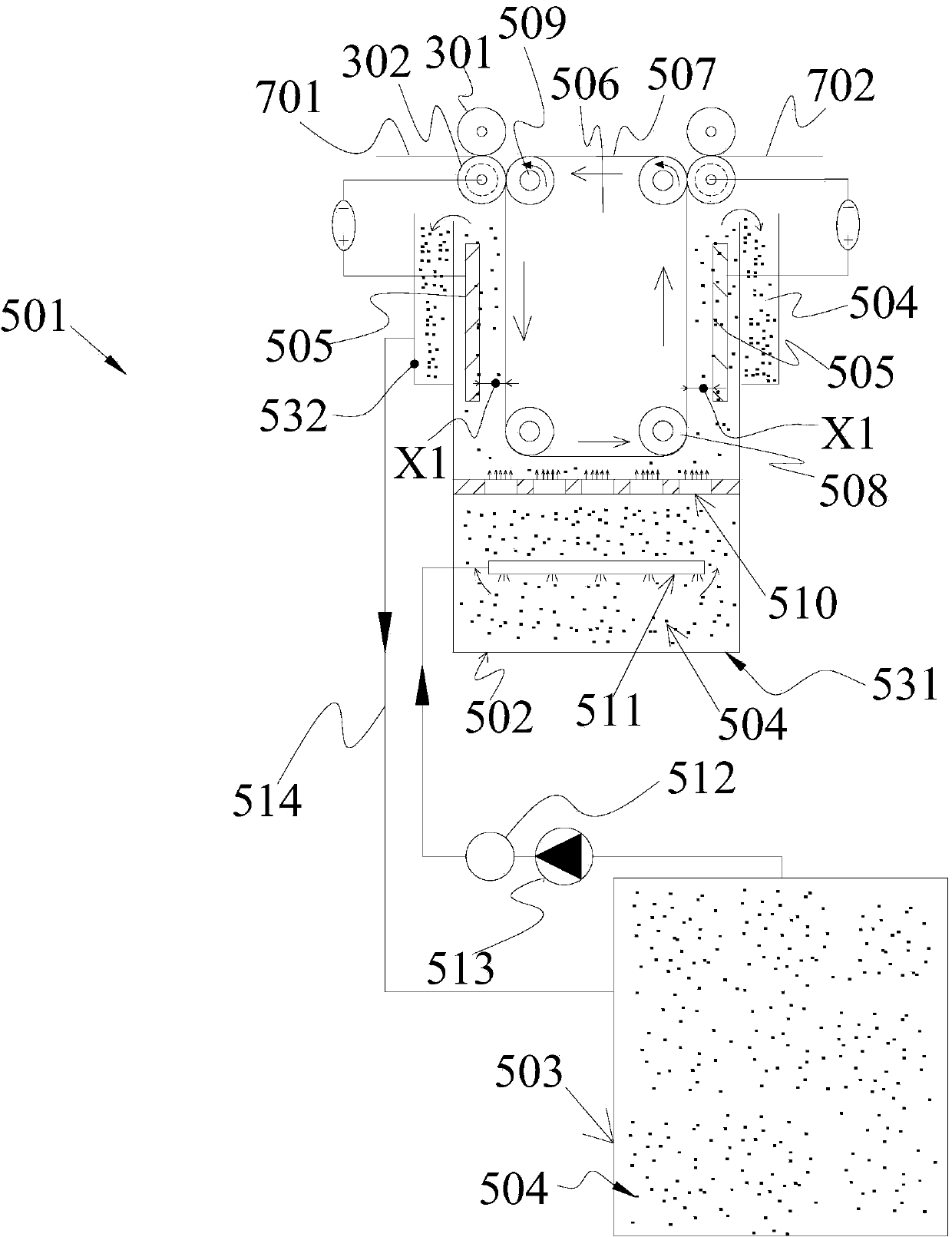

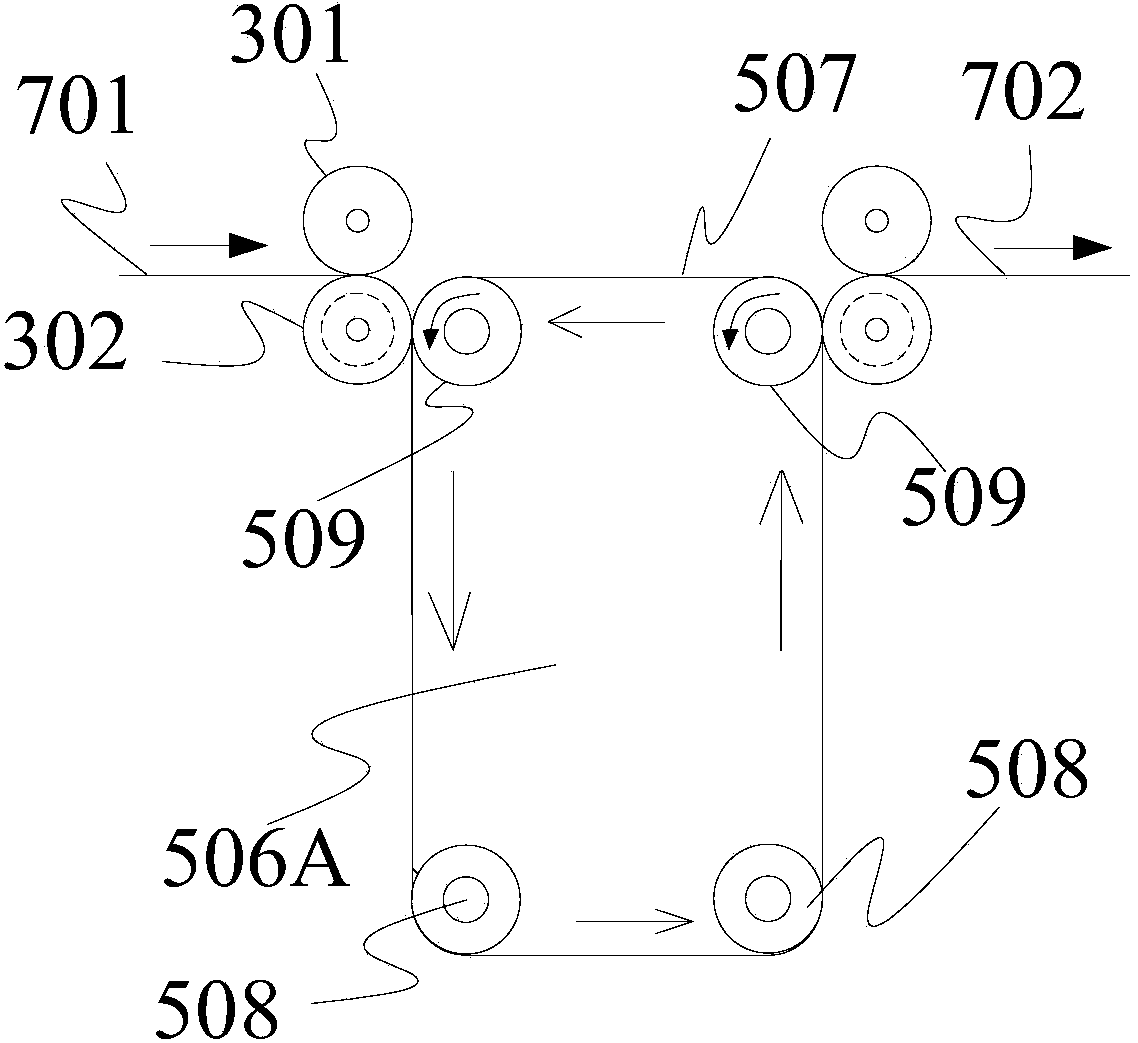

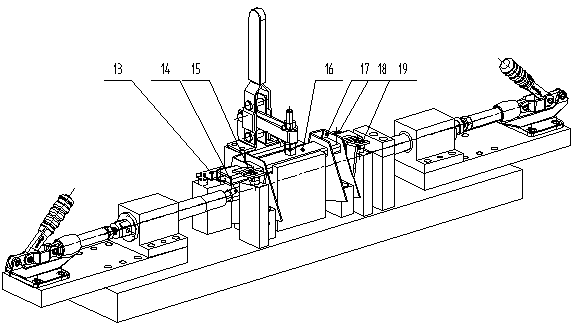

Button cell battery production line

InactiveCN101252194AAdvanced technologyEasy to controlFinal product manufactureNon-aqueous electrolyte cellsProduction lineLithium

The invention relates to a button cell production line, being characterized in comprising a rack component, a lithium chip loading mechanism, a paper cutting mechanism, a filling mechanism, a manganese chip loading mechanism, an anode case loading mechanism, a sealing mechanism, a main transmission mechanism, a pneumatic control system and an electrical apparatus control system as well as a control program; the rack component comprises a large worktable and a rack fastened on the lower surface of the large worktable, a lower base plate of the rack is arranged on a lower beam of the rack, a control cabinet is arranged on the upper part of the lower base plate of the rack; the lithium chip loading mechanism, the main transmission mechanism, the paper cutting mechanism, the filling mechanism, the manganese chip loading mechanism, the anode case loading mechanism and the sealing mechanism are arranged on the large worktable in turn; the pneumatic control system is arranged on the lower base plate of the rack; the electrical apparatus control system and the control program are arranged inside the control cabinet; a touch screen support is vertically arranged on the upper surface of the large worktable close to one end of the lithium chip loading mechanism.

Owner:TIANJIN POLYTECHNIC UNIV

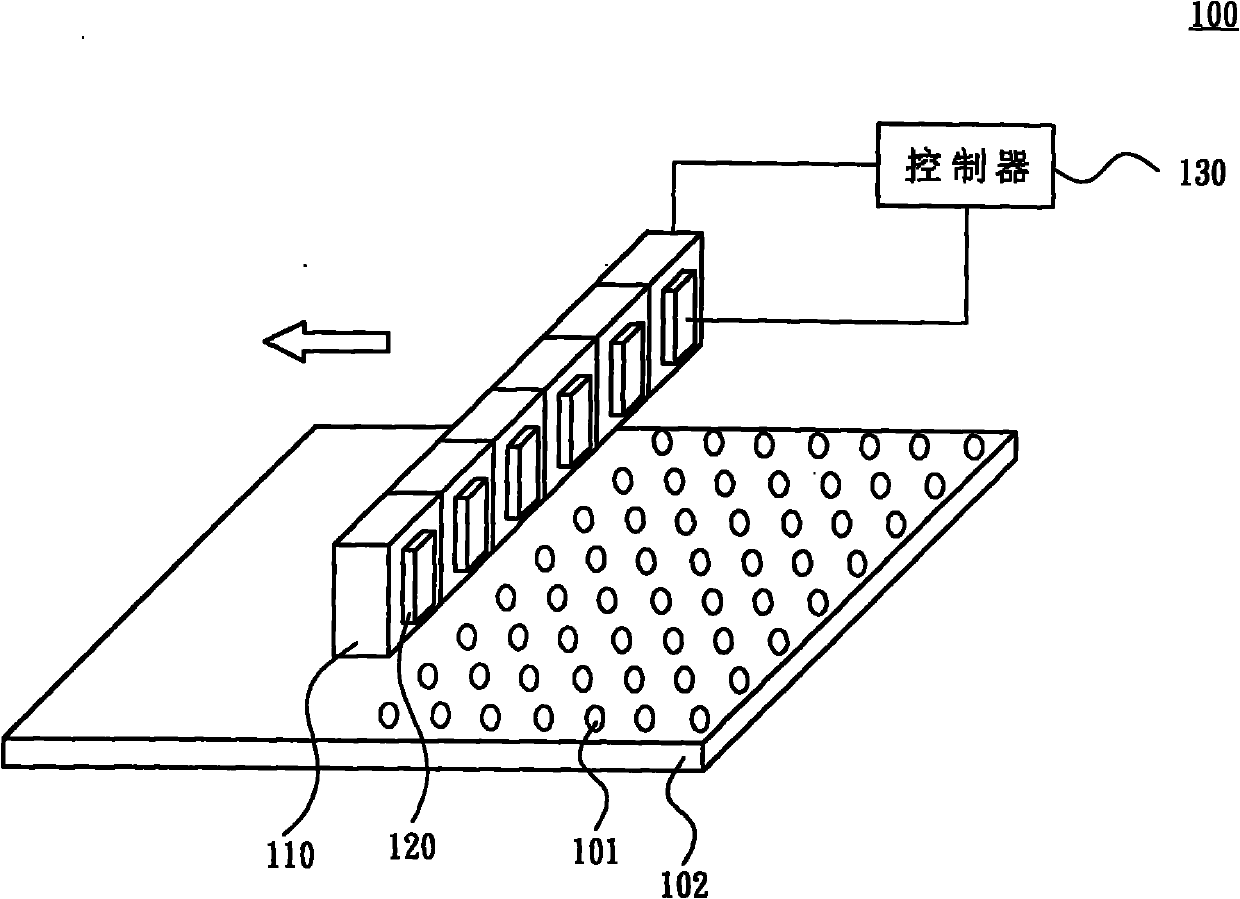

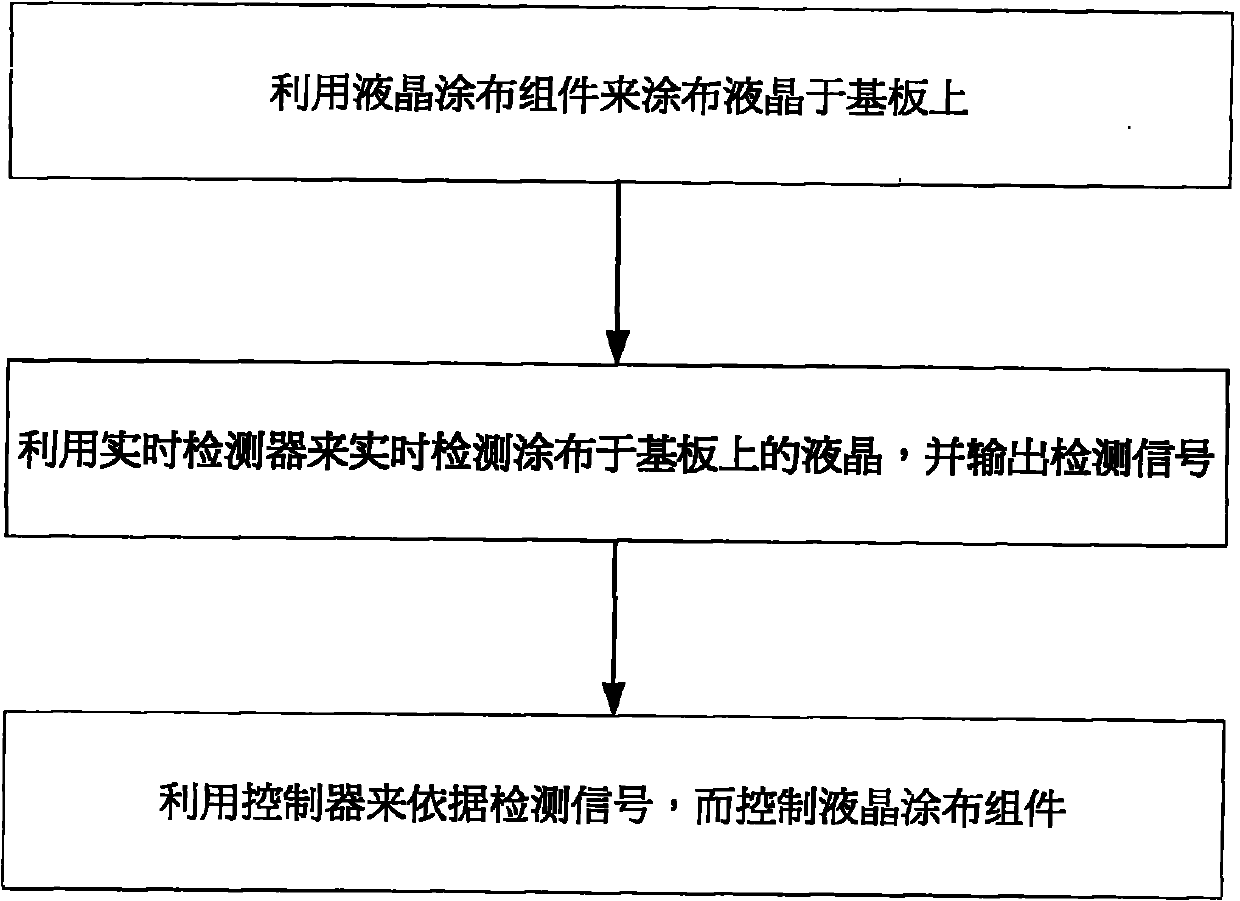

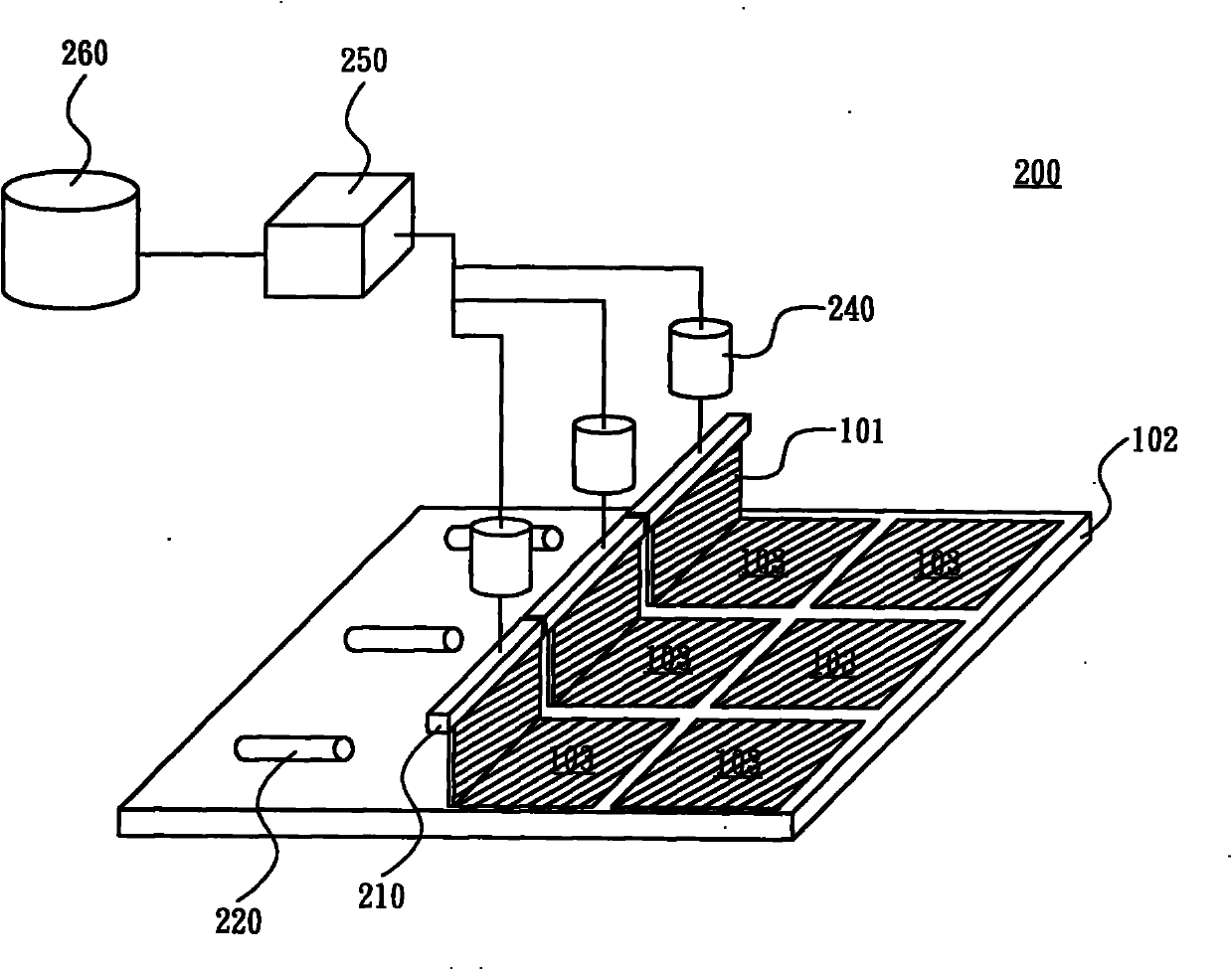

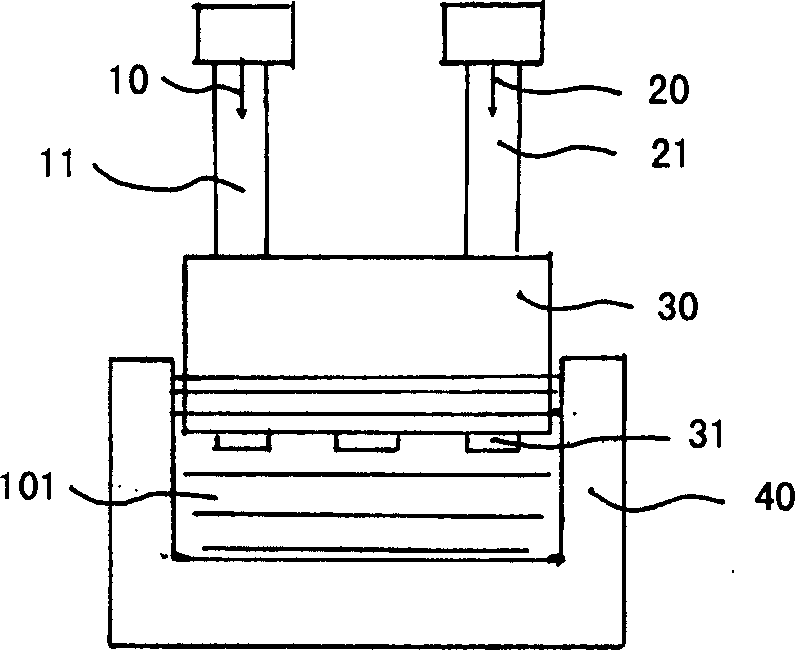

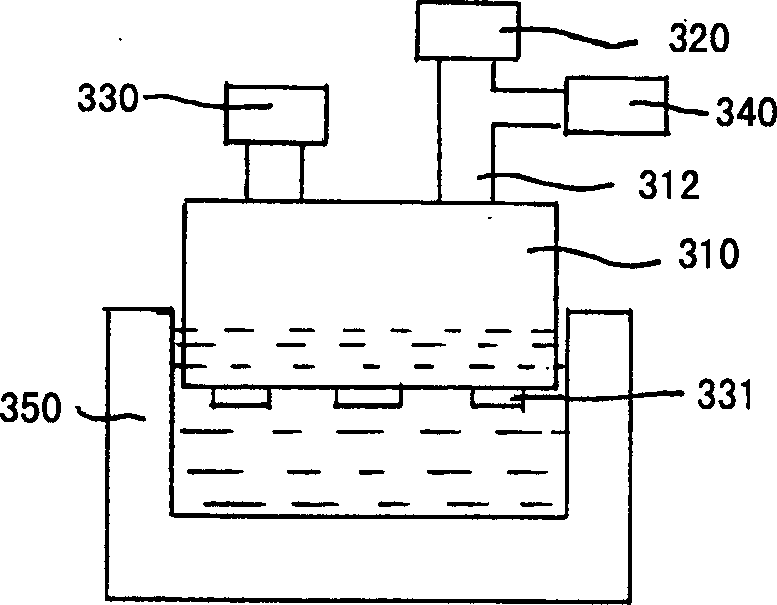

Liquid crystal coating device and liquid crystal coating method

ActiveCN102000652AControl coating amountControl thicknessLiquid surface applicatorsCoatingsLiquid-crystal displayMaterials science

The invention provides a liquid crystal coating device and a liquid crystal coating method. The liquid crystal coating device comprises a liquid crystal coating component, a real-time detector and a controller. The liquid crystal coating method comprises the following steps of: coating a liquid crystal onto a substrate by using the liquid crystal coating component; detecting the liquid crystal coated onto the substrate in real time by using the real-time detector, and outputting a detection signal; and controlling the liquid crystal coating component according to the detection signal by usingthe controller. By the liquid crystal coating device and the liquid crystal coating method, liquid crystal coating situations can be monitored in real time, and uniform liquid crystal films can be coated and formed.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

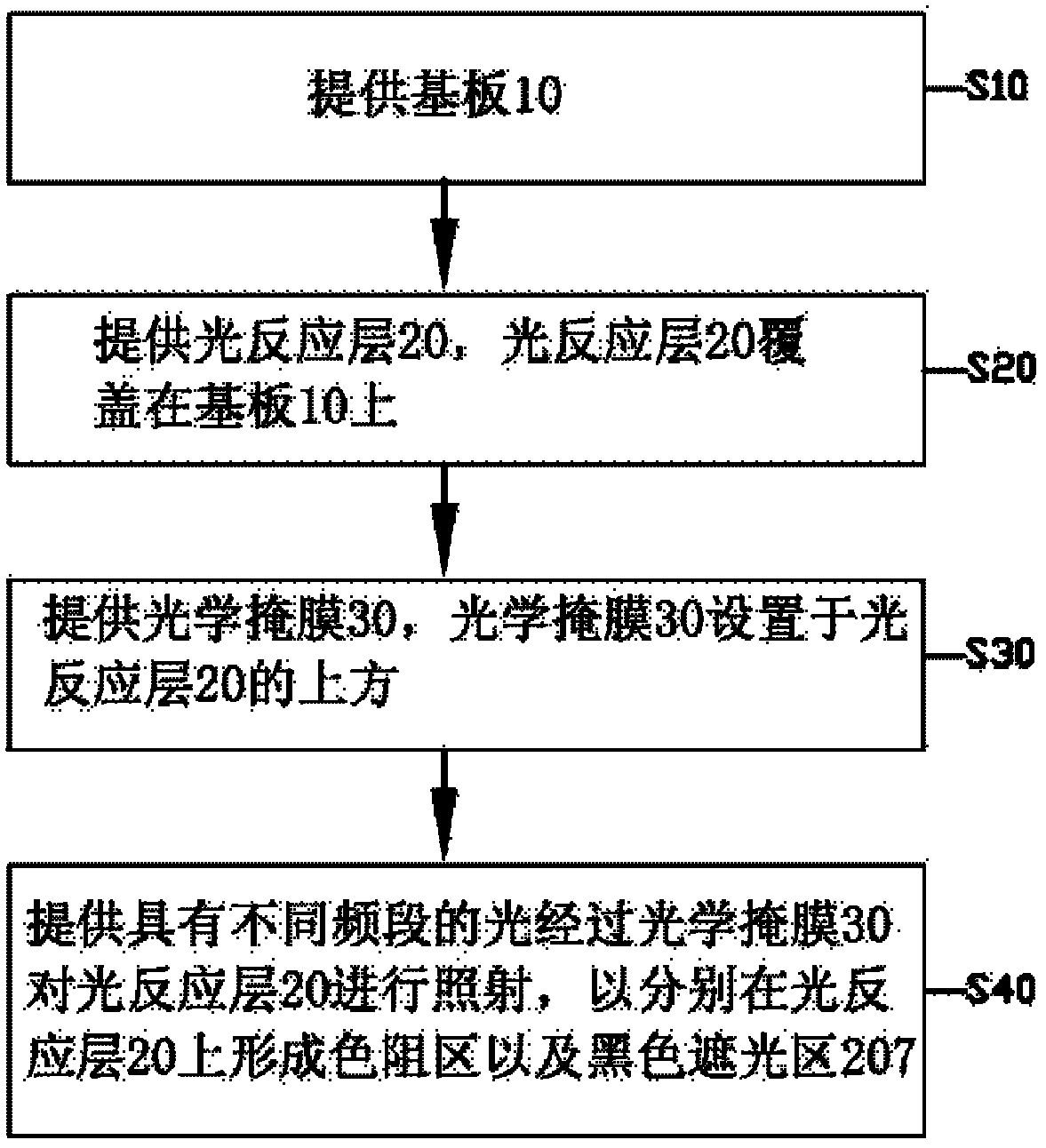

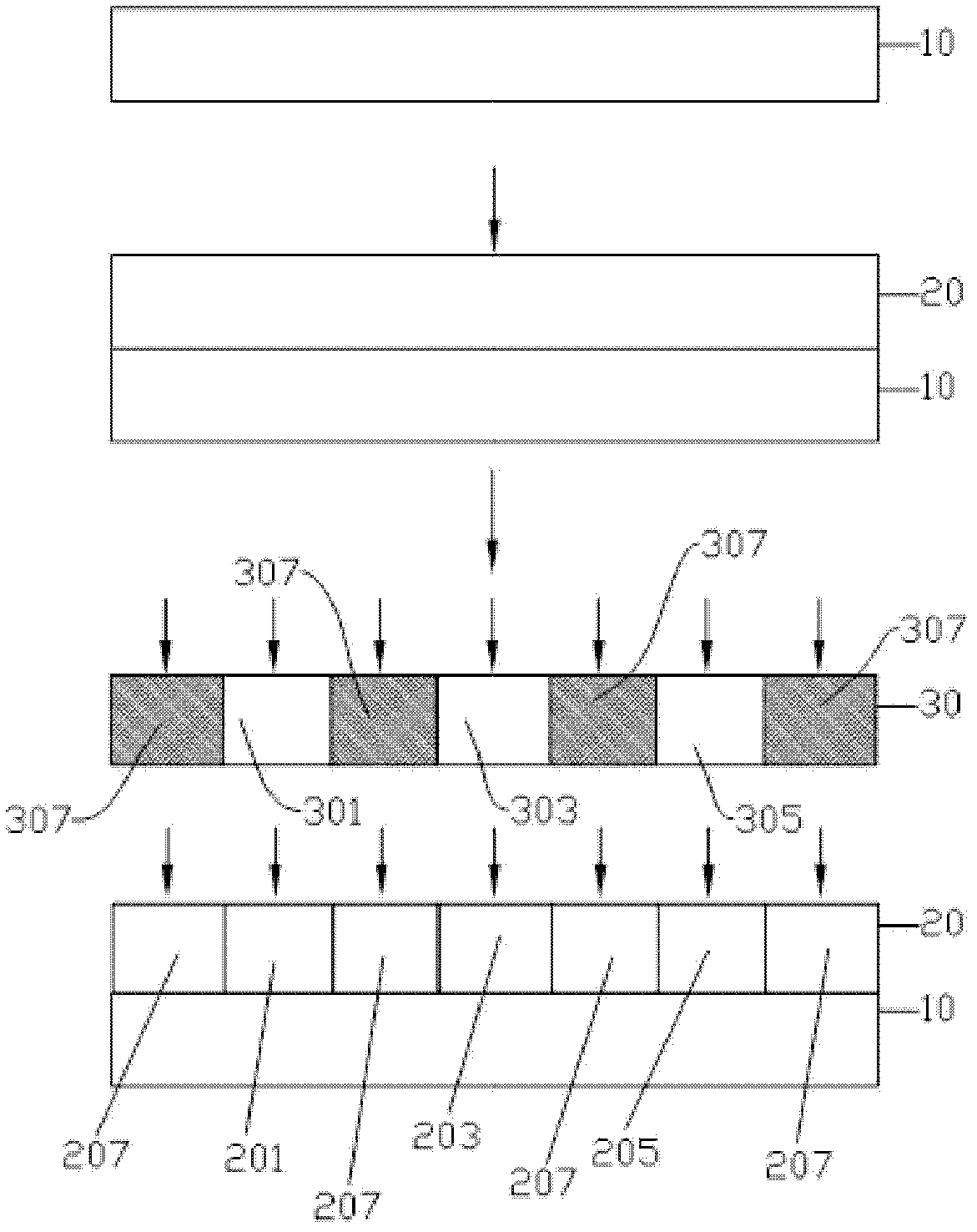

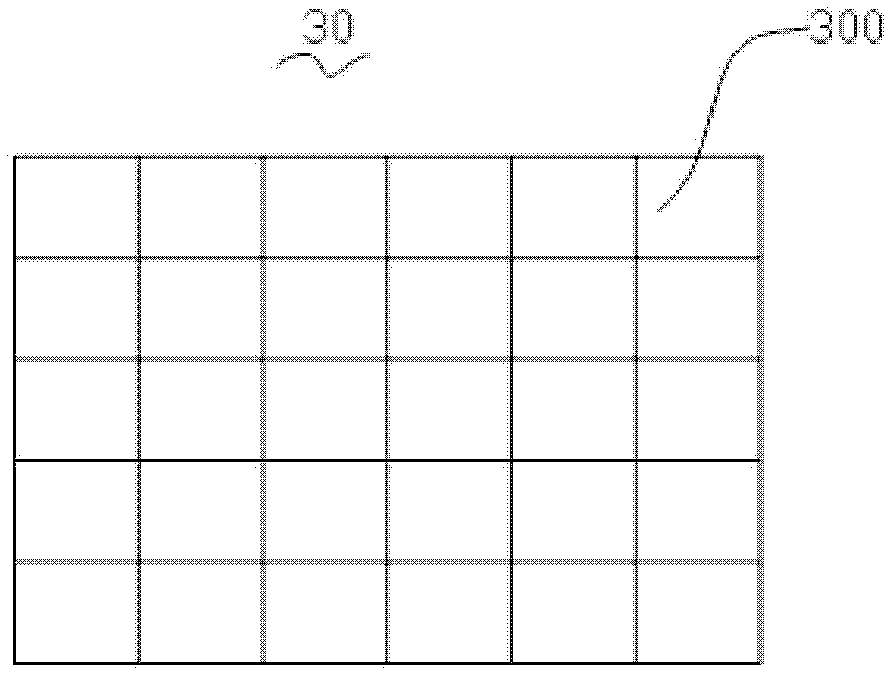

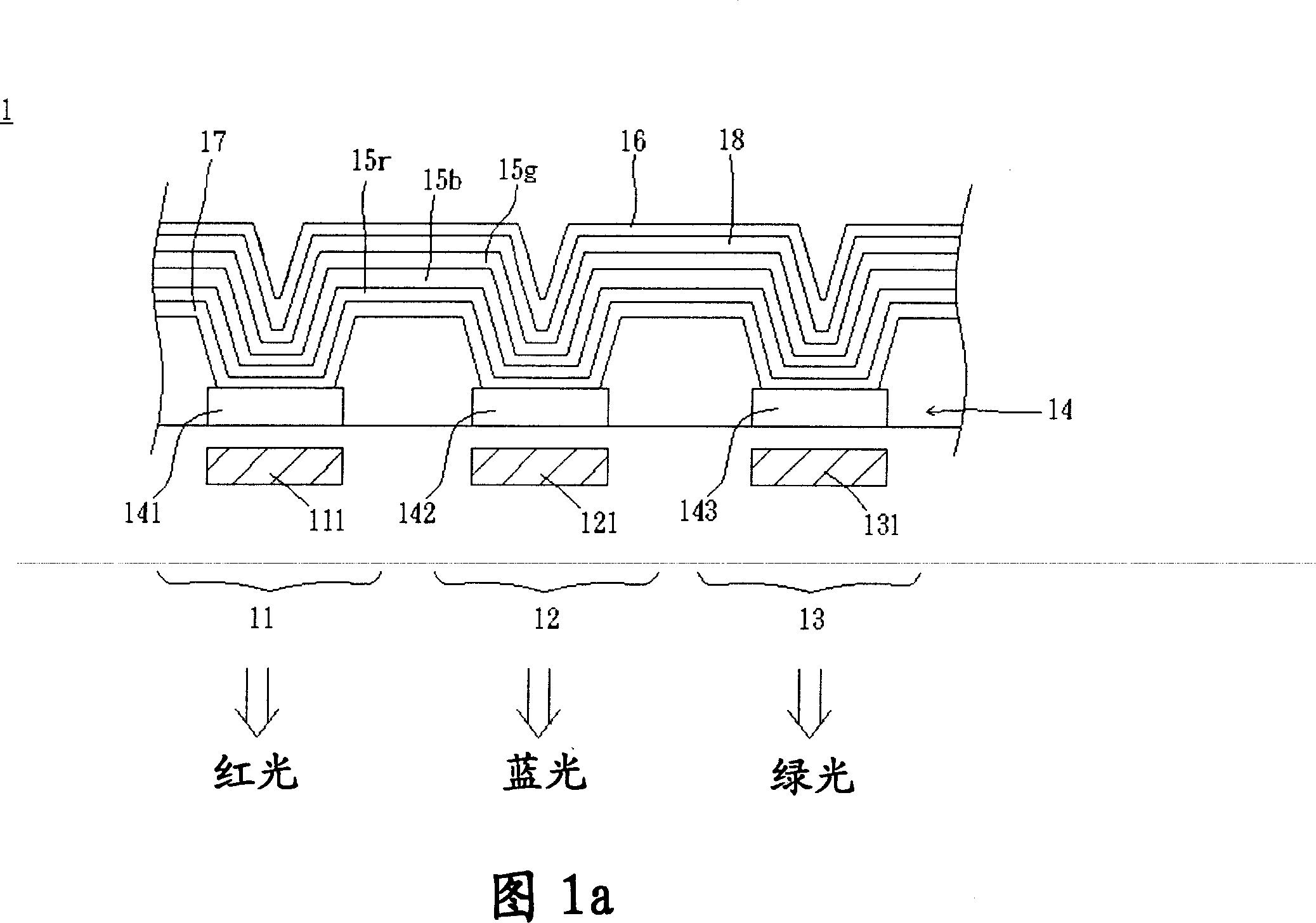

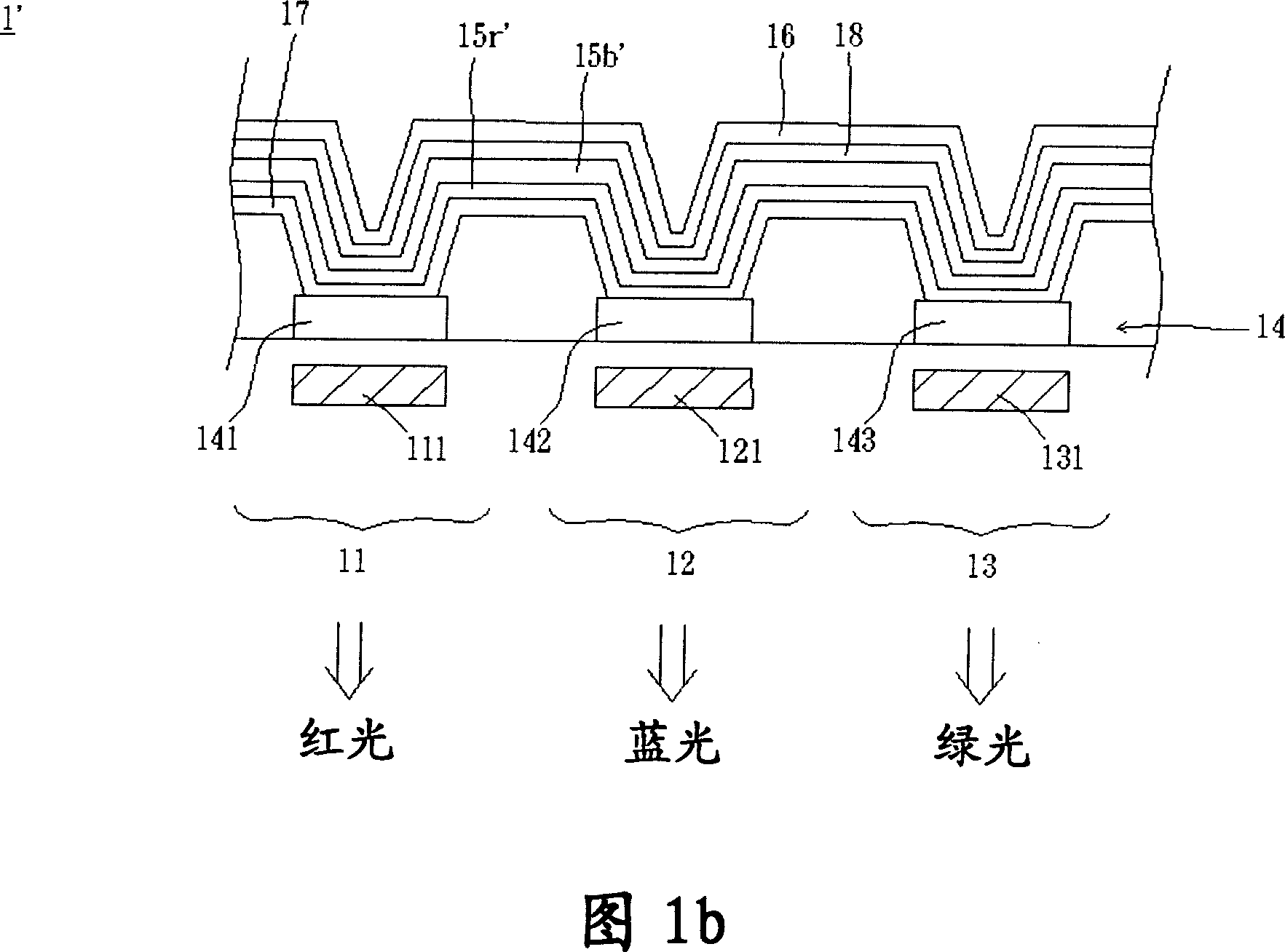

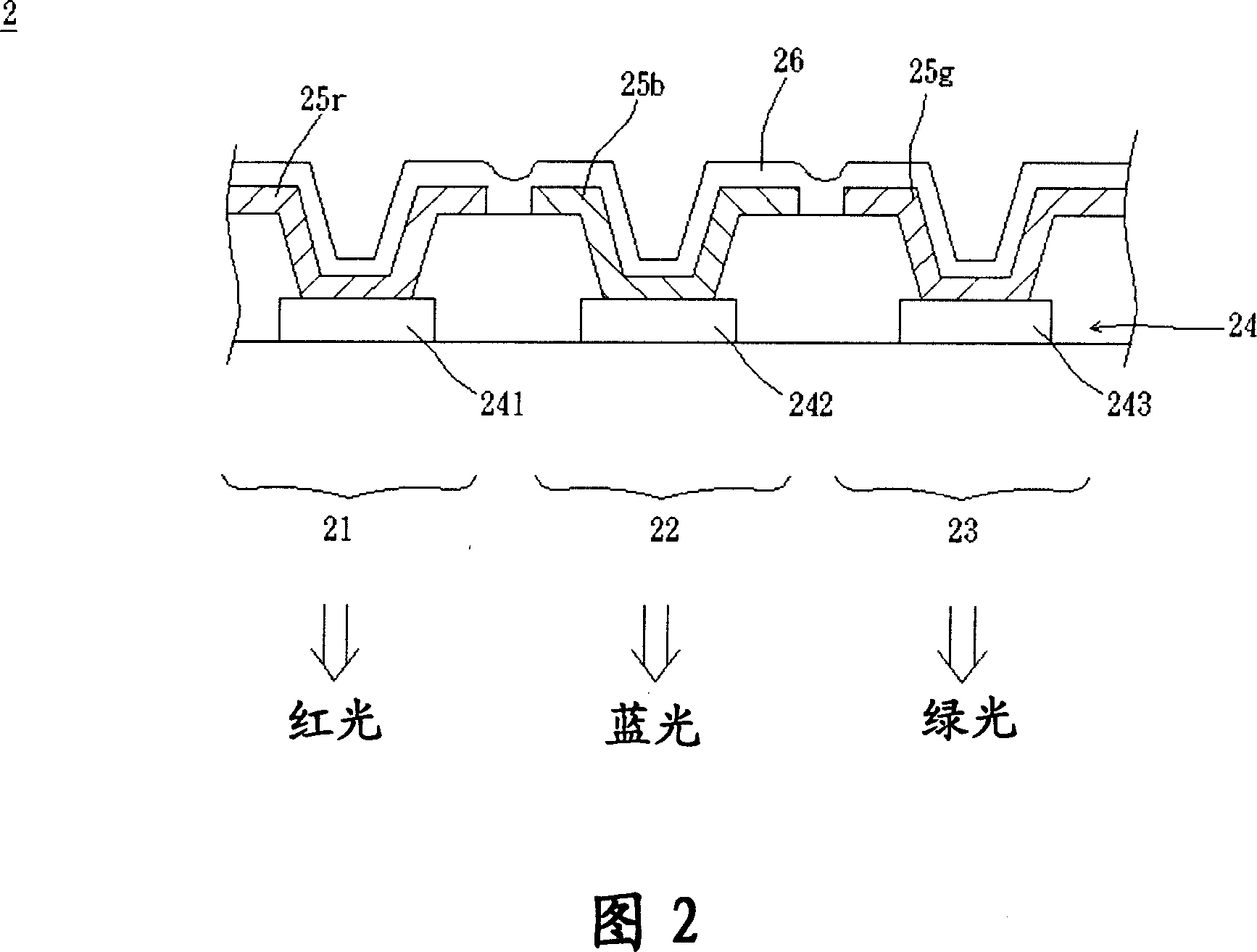

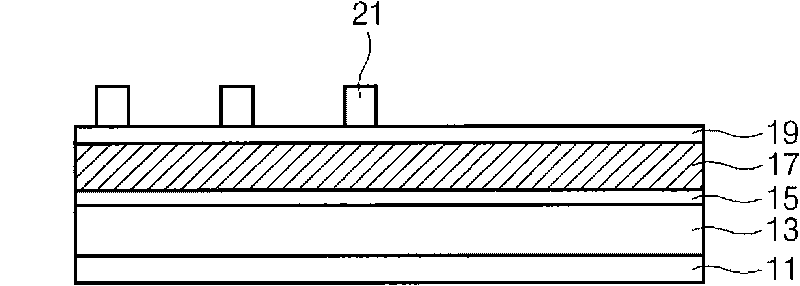

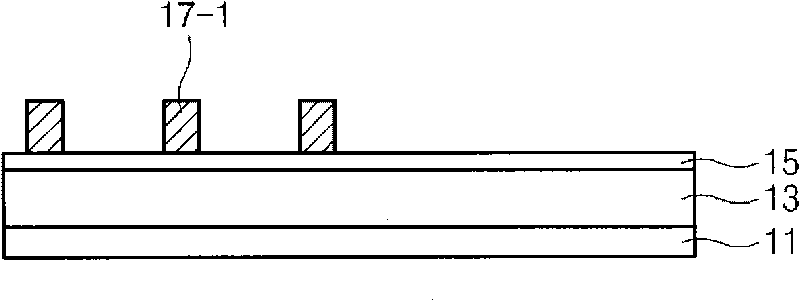

Method, optical mask and photoreaction layer for making substrate of color filter

InactiveCN102213785AShorten the cycle timeStrong penetrating powerOptical filtersOriginals for photomechanical treatmentDisplay contrastColor gel

The invention discloses a method, an optical mask and a photoreaction layer for making a substrate of a color filter. The method comprises the following steps of: providing the substrate; providing the photoreaction layer, wherein the photoreaction layer is coated on the substrate; providing the optical mask, wherein the optical mask is arranged above the photoreaction layer; and providing light of different frequency ranges to irradiate the photoreaction layer through the optical mask so as to respectively form a color resistance area and a black shading area on the photoreaction layer. The invention also provides the optical mask and the photoreaction layer for making a color resistance layer of the substrate of the color filter. By adopting the mode, the method has the advantages of shortening the cycle period of processing and improving the aperture opening ratio and the display contrast ratio.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Connecting rod machining technique

InactiveCN103495847AImprove productivityReasonable arrangementConnecting rodsProduction rateMachining

The invention relates to the technical field of mechanical part machining and in particular discloses a connecting rod machining technique. The connecting rod machining technique mainly comprises a rough machining stage, a semi-fine machining stage and a fine machining stage. The coarse machining stage is that a blank part is forged, the large end and the small end of the blank part are both in cake shapes, and the surface of the blank part is roughly ground. The semi-fine machining stage is that a boring cutter is utilized to turn a large end hole and a small end hole of a connecting rod, an oil groove is formed, an external angle of the oil groove is chamfered, and an internal angle of the oil groove is chamfered. The fine machining stage is that the surface of the blank part is finely ground, and the large end hole and the small end hole of the connecting rod are honed. The connecting rod machining technique has the advantage being reasonable in arrangement of all technologic stages, greatly simplifying technologic machining steps, improving connecting rod production rate, well reducing the weight of the connecting rod, enhancing the strength of the connecting rod and effectively improving the bearing capacity of the connecting rod.

Owner:QINGDAO CONNECTINROD MACHINERY

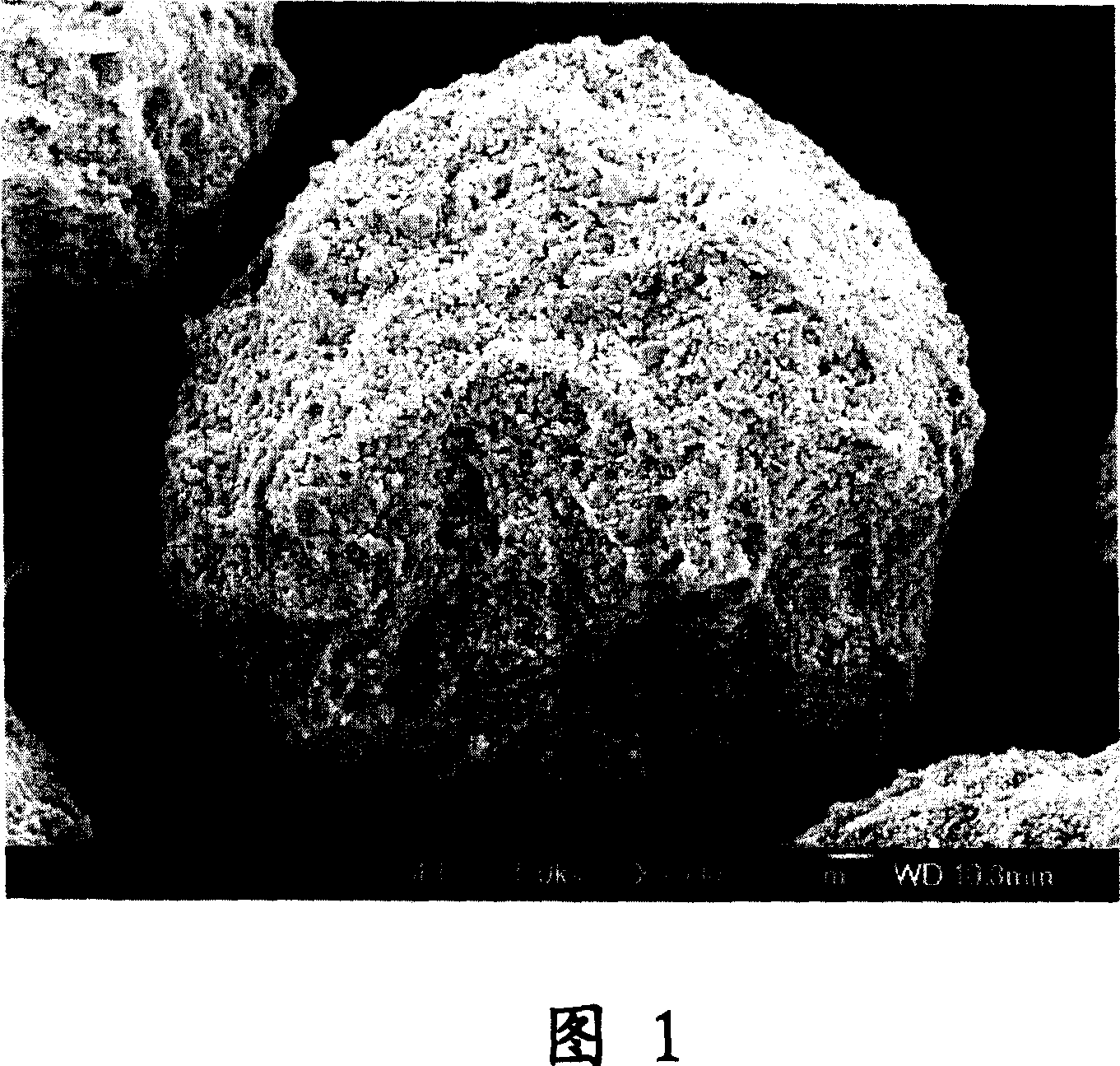

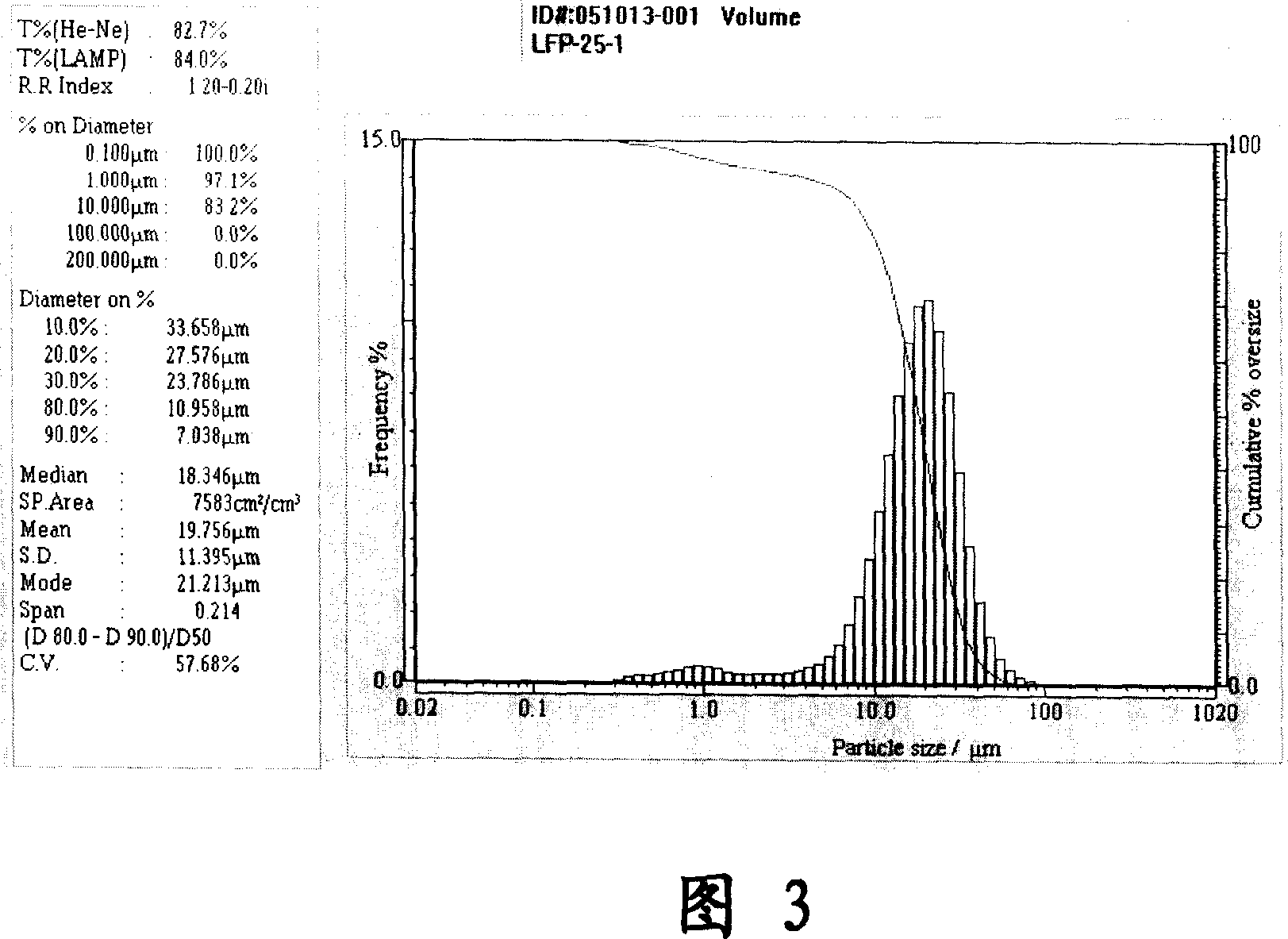

Compound material of anode fit for producing secondary battery and its produced battery

ActiveCN101064367AGood adhesionSimplify the process stepsMaterial nanotechnologyActive material electrodesHigh rateElectrical battery

The invention relates to composite material which is used to produce positive pole of second battery and the produced battery. The composite material which is used to produce positive pole of second battery is powder and with olivine structure or NASICON structure, the powder of composite material is primary particle with 10-500 nanometer, and the secondary particle with 1 mm consists of the primary particle. The second battery includes negative pole, electrolyte, and positive pole produced by composite material, and composite material is powder and with olivine structure or NASICON structure, the powder of composite material is primary particle with 10-500 nanometer, and the secondary particle with 1 mm consists of the primary particle. The invention can improve the surface area of material, and increase the capacity, and easy to be produced, and the formed battery has high rate of charge and discharge, high capacity, and reduce the overcharge or overdischarge to increase the battery life.

Owner:ADVANCED LITHIUM ELECTROCHEMISTRY CO LTD

Electro-beam welding method of niobium alloy and titanium alloy thick plate

InactiveCN101274388ASimplify the process stepsSimple and efficient operationWelding/cutting auxillary devicesAuxillary welding devicesSmooth surfaceHigh pressure

The invention discloses an electron-beam welding method for welding niobium alloy and titanium alloy thick plates, which comprises steps of: welding surface processing: the welding surfaces of two welding pieces which need welding are processed into smooth surfaces with the roughness Ra less than or equal to 1.6 Mum and the surface being vertical to each adjacent surface of plate material; washing with acid: HF, HNO3 and H2O or HF, H2SO4, HNO3 and H2O are used for preparing an acid solution in a container resisting acid corrosion, and the two welding pieces are respectively put into the acid solution for being washed at normal temperature; welding: a middle or high voltage vacuum electron-beam welding machine is used for welding one face of the each of the two welding pieces, and the depth of a welding line is one second to three fourths of the thickness of the plate material; after the concreting of the welding line and under the same welding condition, the other faces of the two welding pieces are welded, and the depth of the welding line is one fourth to three fourths of the thickness of the plate material. The process of the method has the advantages of simple steps, convenient operation, high welding quality and good straightness of the welded plate and solving the problem of great warp and deforming of the plate material existing in the welding of the thick plate materials.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

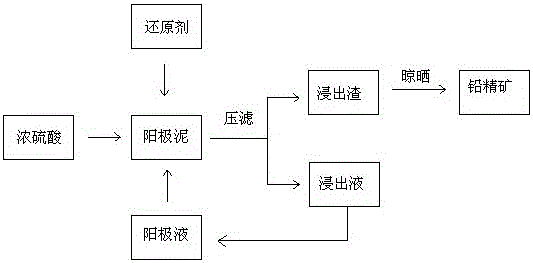

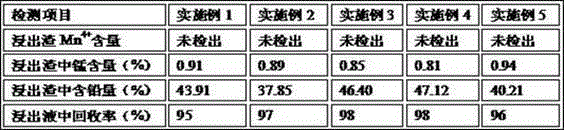

Method for recycling manganese and lead in electrolytic manganese anode mud

InactiveCN105039703ASimplify the process stepsReduce manufacturing costPhotography auxillary processesProcess efficiency improvementSulfuric acidManganese

The invention discloses a method for recycling manganese and lead in electrolytic manganese anode mud. The method is characterized by comprising the following steps that (1) the electrolytic manganese anode mud is subjected to reduction leaching, anode liquor, reducing agents and a concentrated sulfuric acid solution are sequentially added into the electrolytic manganese anode mud to be subjected to a reduction reaction for 6-10 h, then filter pressing is conducted, and leaching residues containing PbSO4 and leaching liquor containing MnSO4 are obtained; (2) the leaching residues are processed, the obtained leaching residues are aired at the temperature of 30-35 DEG C until the moisture content is smaller than or equal to 5%, and then a lead concentrate product can be obtained; and (3) the leaching liquor is processed, the leaching liquor obtained in the step (1) is collected and then is reused as anode liquor to be recycled according to the step (1). The problem of stacking pollution of the electrolytic manganese anode mud is solved, separation of manganese and lead can be achieved, valuable lead is recycled, and economic value is created. The method is easy to operate, has feasibility and has certain popularization value in the production of the field.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

Production process of personalized implant tooth abutment

InactiveCN105105857ASimplify the process stepsShort timeDental implantsDental prostheticsIntraoral scannerPersonalization

The invention discloses a production process of a personalized implant tooth abutment. The process comprises the steps of: a. conducting three-dimensional data scanning on a plaster mold by an extraoral scanner, locking a scanning rod at a part for imitative implantation of an implant into a patient's dentale in the plaster mold; or, carrying out three-dimensional data scanning on the patient's mouth by an intraoral scanner, and locking the scanning rod to the implant; b. transmitting the three-dimensional data to a computer by the extraoral scanner or intraoral scanner, and performing data pairing by the computer; c. according to the pairing result, conducting denture design automatically by the computer; d. transmitting the well designed denture data to a 3D printer or grinding machine by the computer, letting the 3D printer complete denture 3D printing and the grinding machine complete denture grinding; and e. matching the 3D printing molded denture or grinding treated denture with the implant implanted into the patient's dentale. The production process provided by the invention can complete denture processing only by scanning data without a component entity, and has the advantages of simple process, short time, high efficiency and low cost.

Owner:王运武

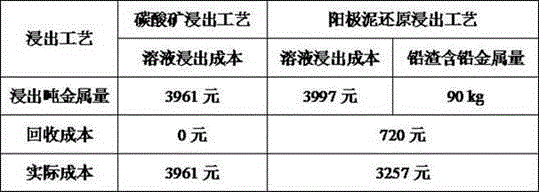

Method for manufacturing optical compound film structure with controllable transparency pattern changes

InactiveCN107045220ASimplify the process stepsRealize large-scale continuous productionNon-linear opticsComposite filmPolymer

The invention provides a method for manufacturing an optical composite membrane structure capable of controlling a change in light transmission pattern includes the steps of first providing an optical composite film comprising a polymer liquid crystal dispersion layer, a transparent conductive layer formed on the polymer liquid crystal dispersion layer, Transparent conductive layer; and then, the optical composite film is patterned to remove portions of the transparent conductive layer to form a conductive line pattern and a plurality of leads extending from the conductive line pattern side, and forming a transparent substrate A transparent substrate, a transparent conductive layer and a polymer liquid crystal dispersion layer; and then, at least a sub-surface repair program for the patterned optical composite film; and finally, an electrical contact is formed at the wiring gap.

Owner:NANOBIT TECH

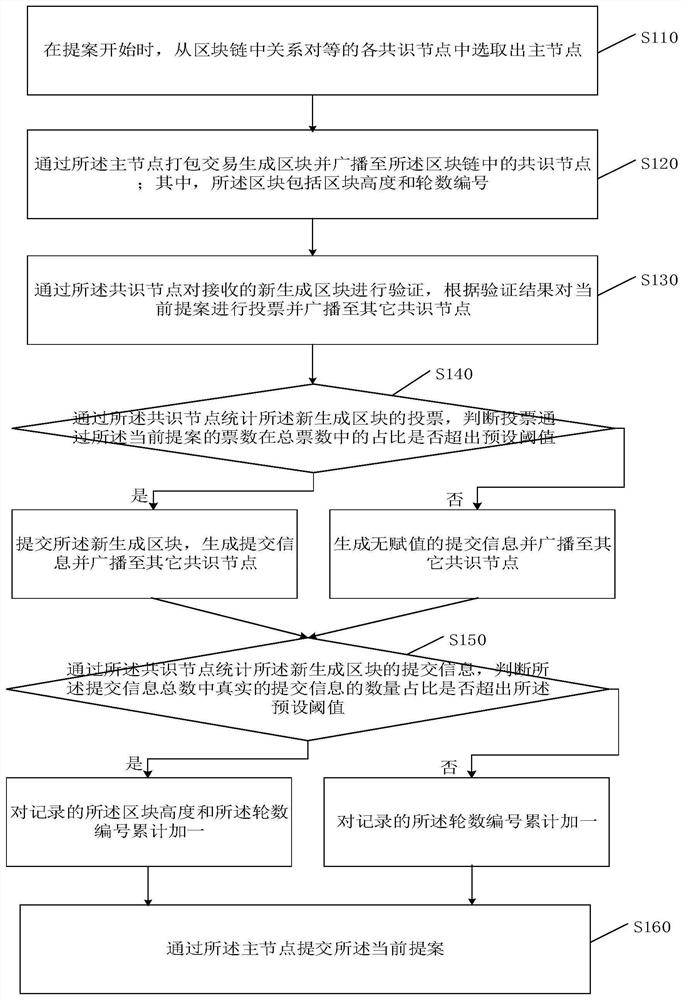

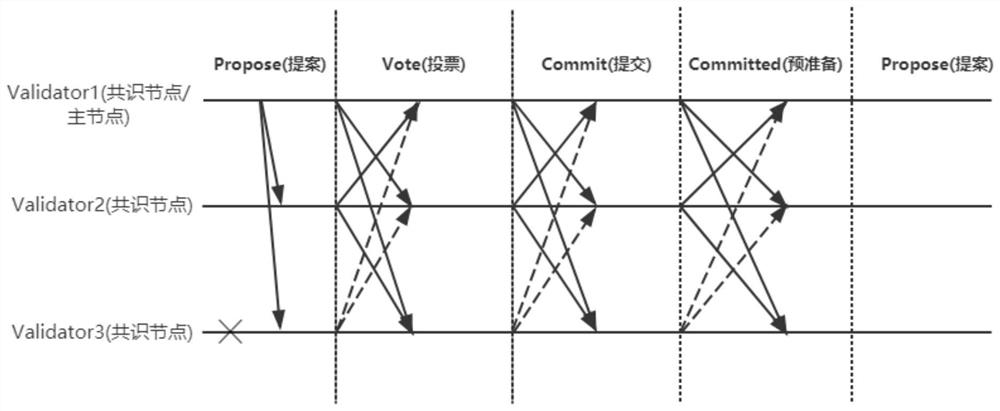

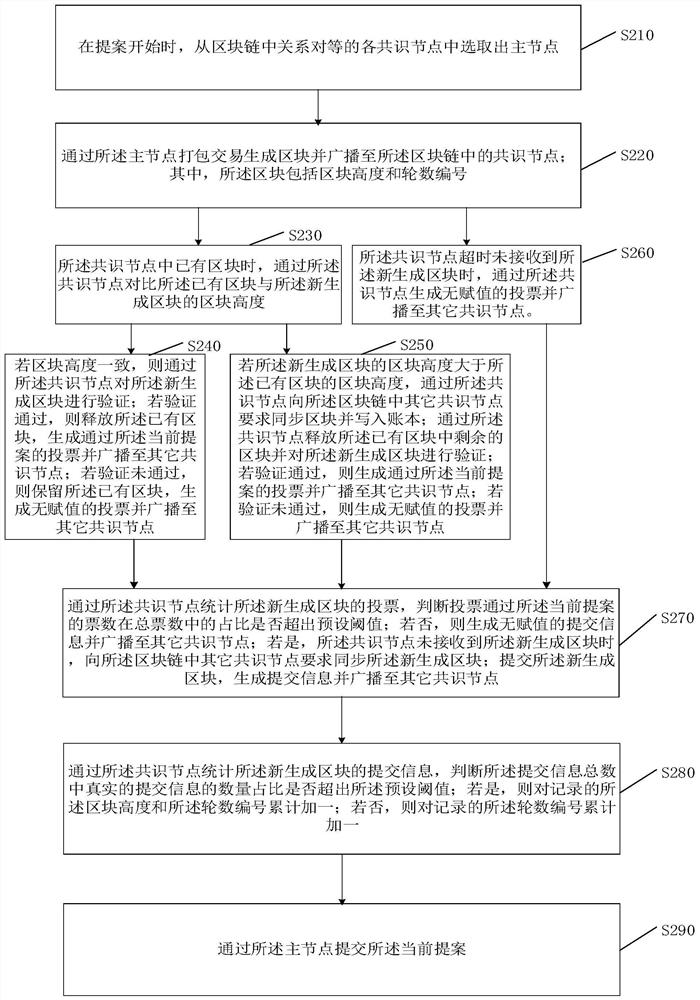

Byzantine fault-tolerant consensus method and system

ActiveCN112187490AResolve issues where agreement cannot be reachedImprove fault toleranceData switching networksSecuring communicationByzantine fault toleranceEngineering

The invention belongs to the technical field of block chains, and provides a Byzantine fault-tolerant consensus method and system. The Byzantine fault-tolerant consensus method comprises the steps of:generating a block through a packaging transaction of a main node, and broadcasting the block to a consensus node in a blockchain; verifying the received newly generated block through using the consensus node, voting a current proposal according to a verification result, and broadcasting the voted current proposal to other consensus nodes; counting votes of the newly generated block through usingconsensus node, and judging whether the proportion of votes voting through in total votes exceeds a preset threshold value or not; if so, submitting the newly generated block, generating submission information and broadcasting the submission information to other consensus nodes; if not, generating non-assigned submission information and broadcasting the non-assigned submission information to other consensus nodes; and counting the submission information of the newly generated block through using the consensus node. According to the Byzantine fault-tolerant consensus method and the system of the invention, the fault-tolerant rate of the Byzantine fault-tolerant consensus method is improved, the tolerableness of network partition is realized, and the problem that states of the consensus nodes in the blockchain cannot be consistent due to the network partition is solved.

Owner:深圳法大大网络科技有限公司

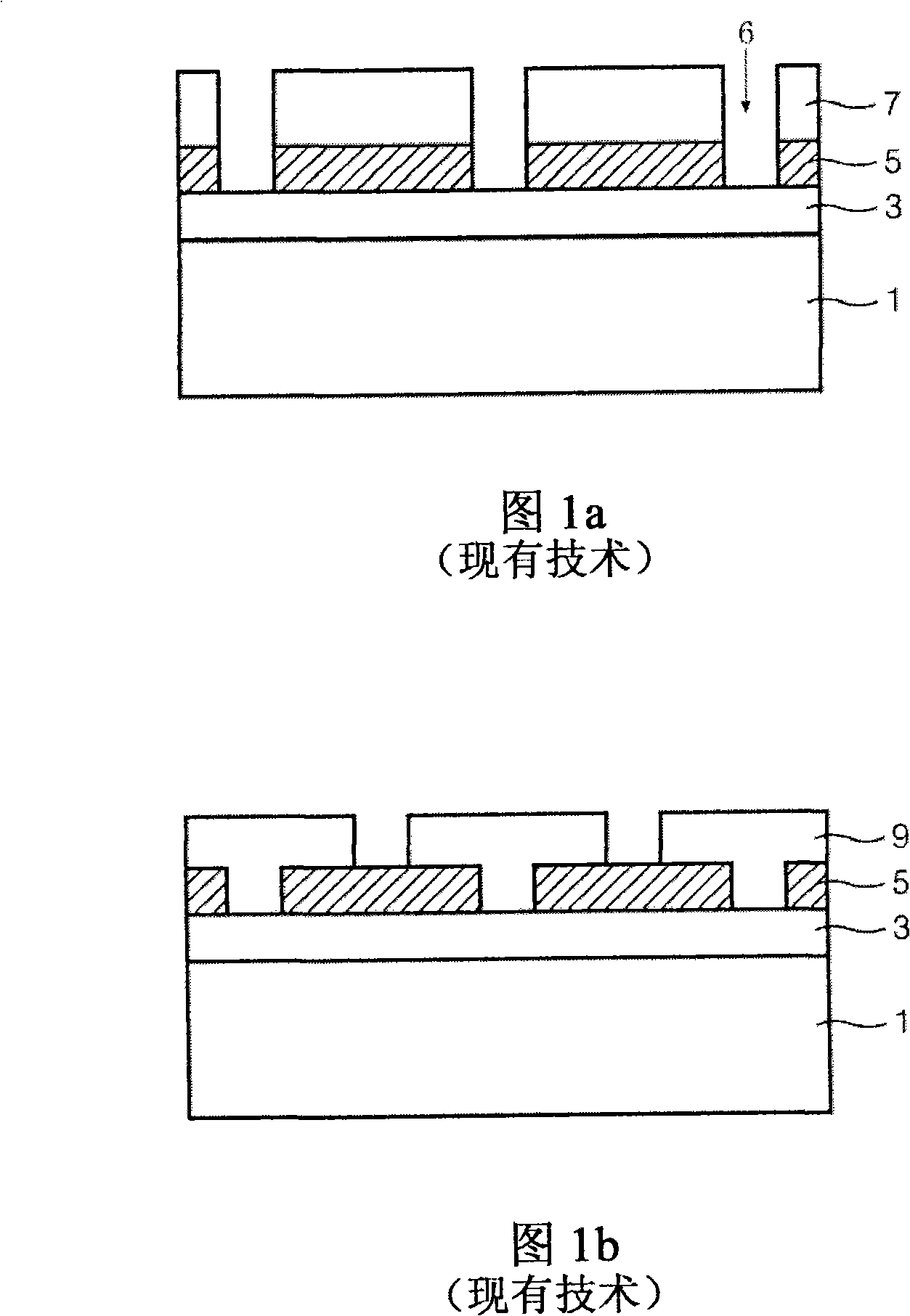

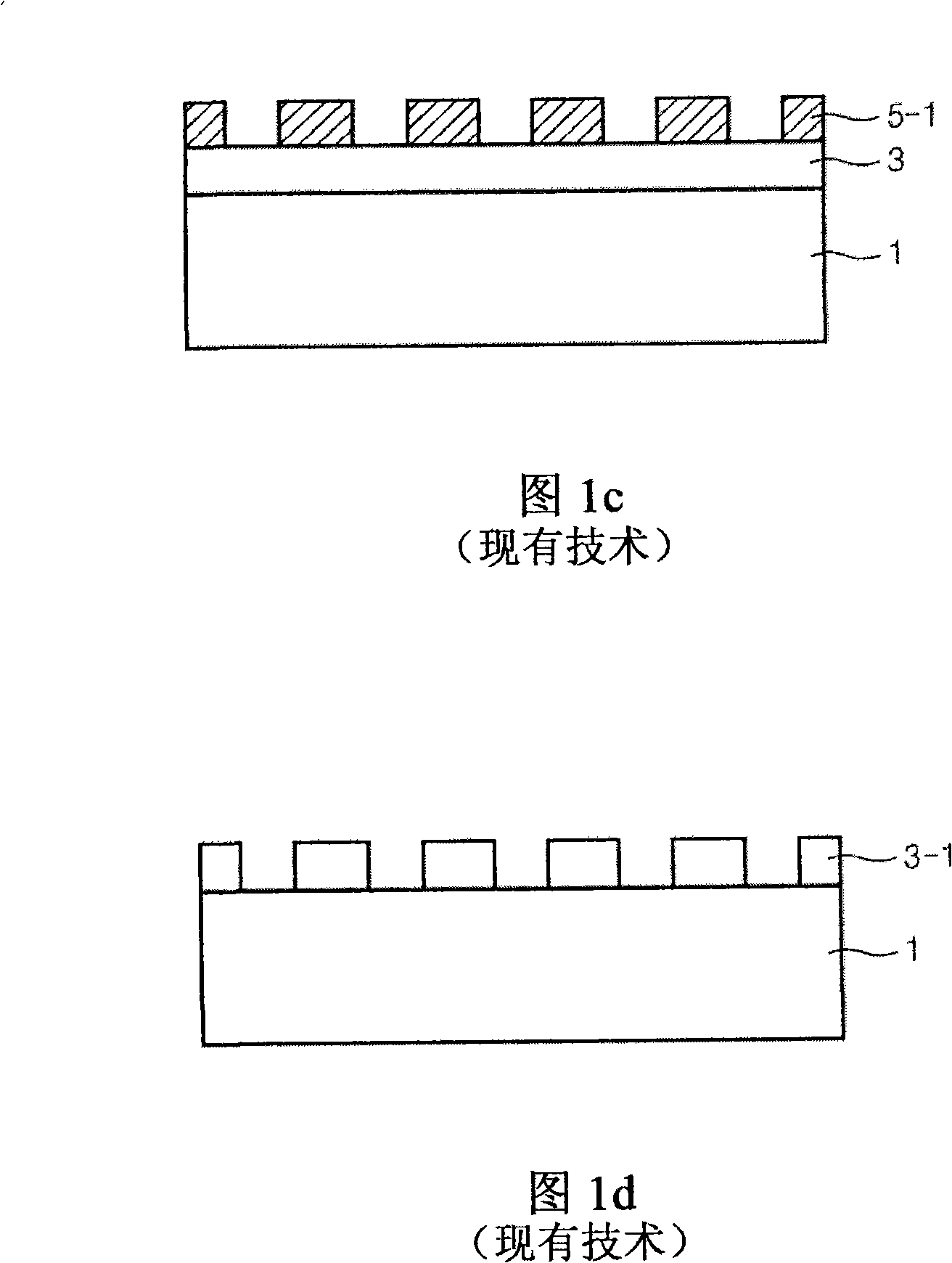

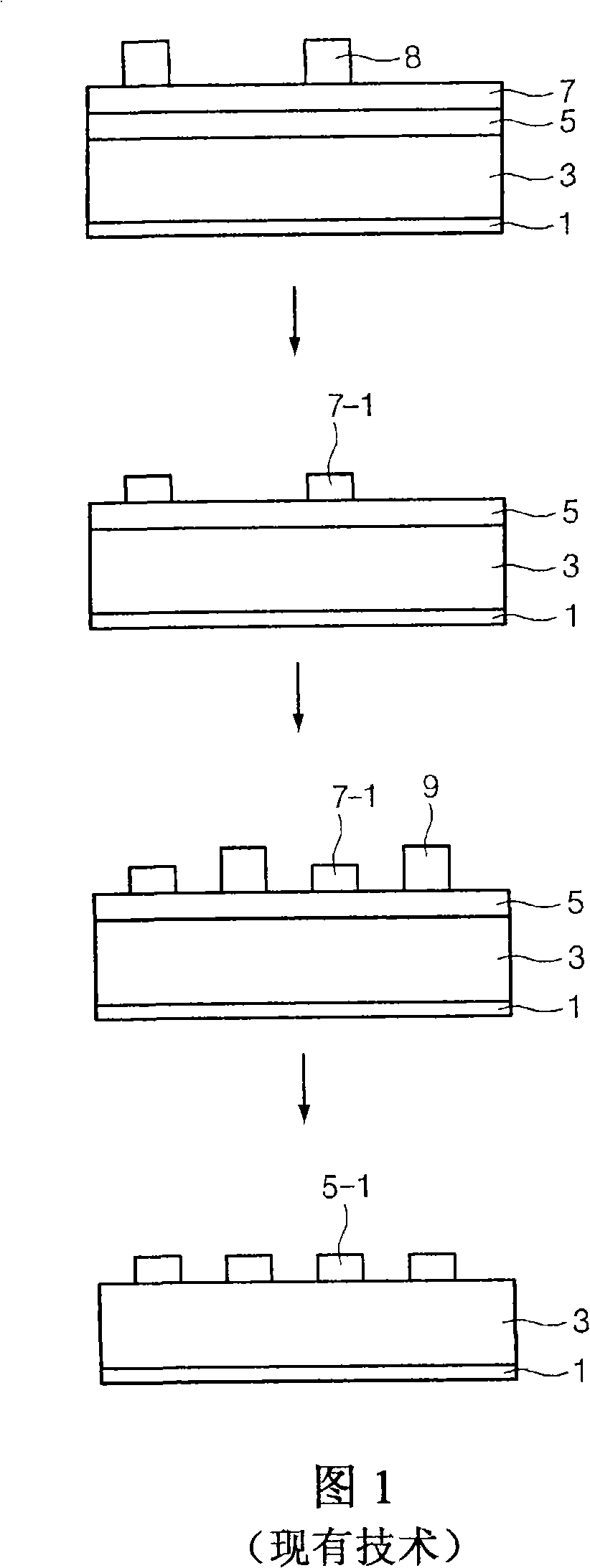

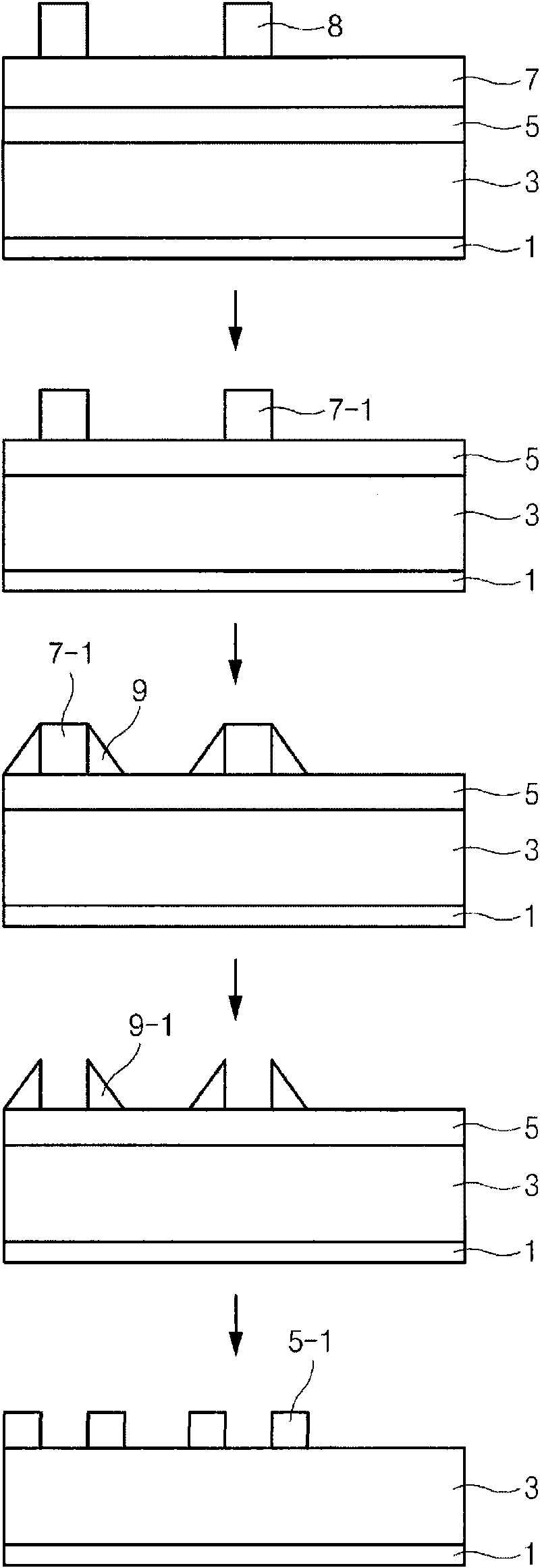

Method for forming fine pattern of semiconductor device

InactiveCN101299408AExcellent Overlay AccuracyReduce manufacturing costSemiconductor/solid-state device manufacturingSemiconductor devicesCarbon layerSemiconductor

A method for forming a fine pattern of a semiconductor device includes forming a deposition film over a substrate having an underlying layer. The deposition film includes first, second, and third mask films. The method also includes forming a photoresist pattern over the third mask film, patterning the third mask film to form a deposition pattern, and forming an amorphous carbon pattern at sidewalls of the deposition pattern. The method further includes filling a spin-on-carbon layer over the deposition pattern and the amorphous carbon pattern, polishing the spin-on-carbon layer, the amorphous carbon pattern, and the photoresist pattern to expose the third mask pattern, and performing an etching process to expose the first mask film with the amorphous carbon pattern as an etching mask. The etching process removes the third mask pattern and the exposed second mask pattern.; The method also includes removing the spin-on-carbon layer and the amorphous carbon pattern, and forming a first mask pattern with the second mask pattern as an etching mask.

Owner:SK HYNIX INC

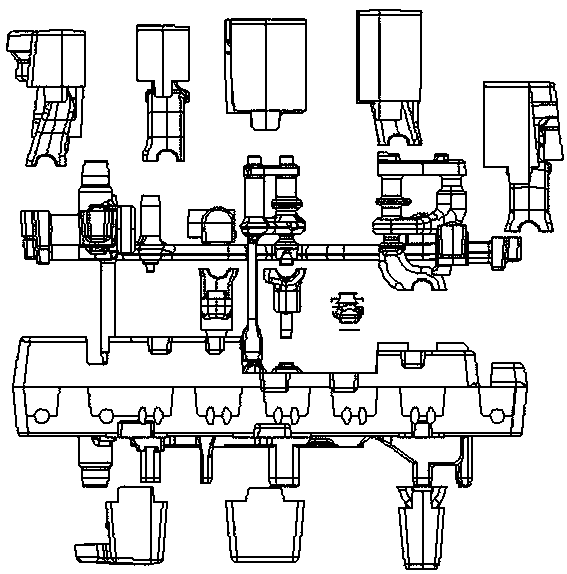

Filling and sealing machine for syringes

ActiveCN106697419AAvoid damageSimple structureLiquid materialPackaging machinesOutput deviceEngineering

The invention discloses a filling and sealing machine for syringes. The filling and sealing machine comprises a main disc capable of doing intermittent rotation motion, an upper syringe device, a downward pressing device, a filling device, a pre-screwing device, a cap screwing device and an output device, wherein the upper syringe device, the downward pressing device, the filling device, the pre-screwing device, the cap screwing device and the output device are sequentially distributed on the periphery of the main disc. A groove for containing the syringes is formed in the main disc. The syringes are transferred to the groove of the main disc through the upper syringe device and are moved to stations where corresponding devices are located along with rotation of the main disc. A filling pump assembly through which the syringe is filled with liquid is arranged on the filling device. The pre-screwing device is used for hanging a cone-head cap on the syringe filled with the liquid in advance. The cap screwing device is used for screwing up the cone-head cap hung on the syringe. The output device outputs the syringes obtained after filling and sealing are completed by outputting the rotary disc. By the adoption of the filling and sealing machine for the syringes, the secondary pollution is reduced effectively, and the transfusion safety is improved.

Owner:SHINVA MEDICAL INSTR CO LTD

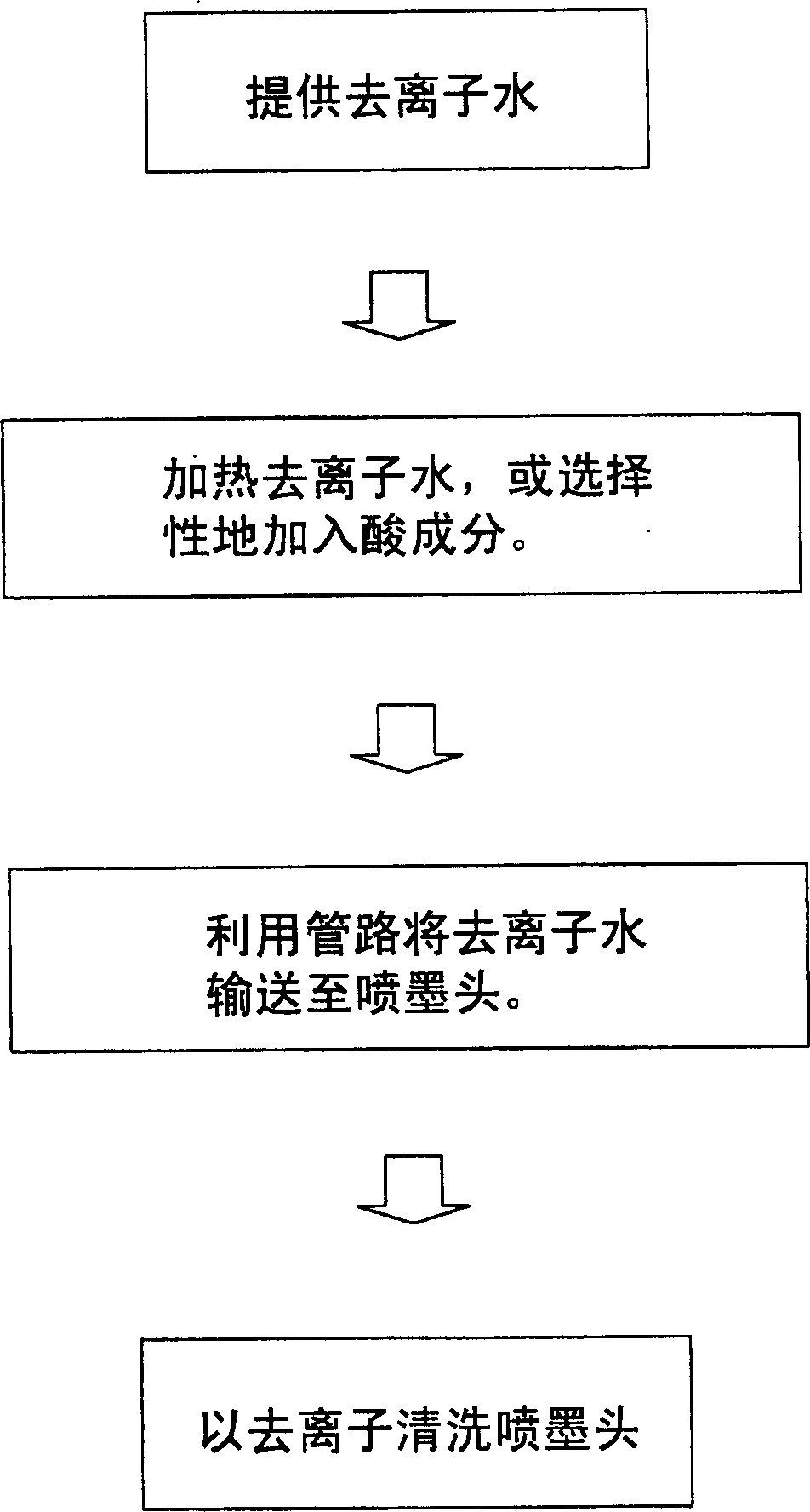

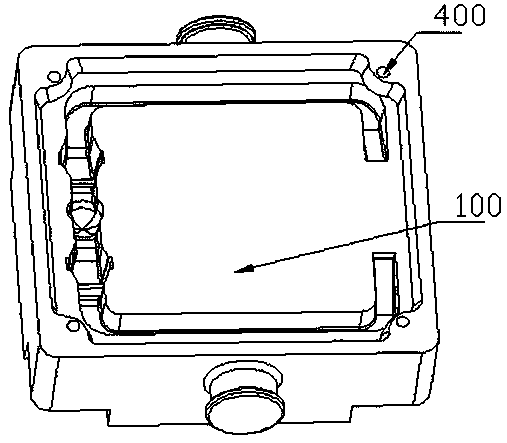

Ink jetting head cleaning device

The ink jet head cleaning device for reducing or avoiding ink jet jamming and ink concentration change and reducing consumption of solvent and ink has simplified making process and lowered production cost. The ink jet head cleaning device includes one ink jet head with at least one nozzle and several holes; one multiple joint duct with at least one joint connected to the holes in the ink jet head; one ink supplying element; one solvent supplying element; and one gas supplying element connected to the ink jet head through the multiple joint duct to provide gas to the inside of the ink jet head to eliminate residual ink or solvent, with the gas supplying element being connected with one joint of the multiple joint duct.

Owner:RITDISPLAY

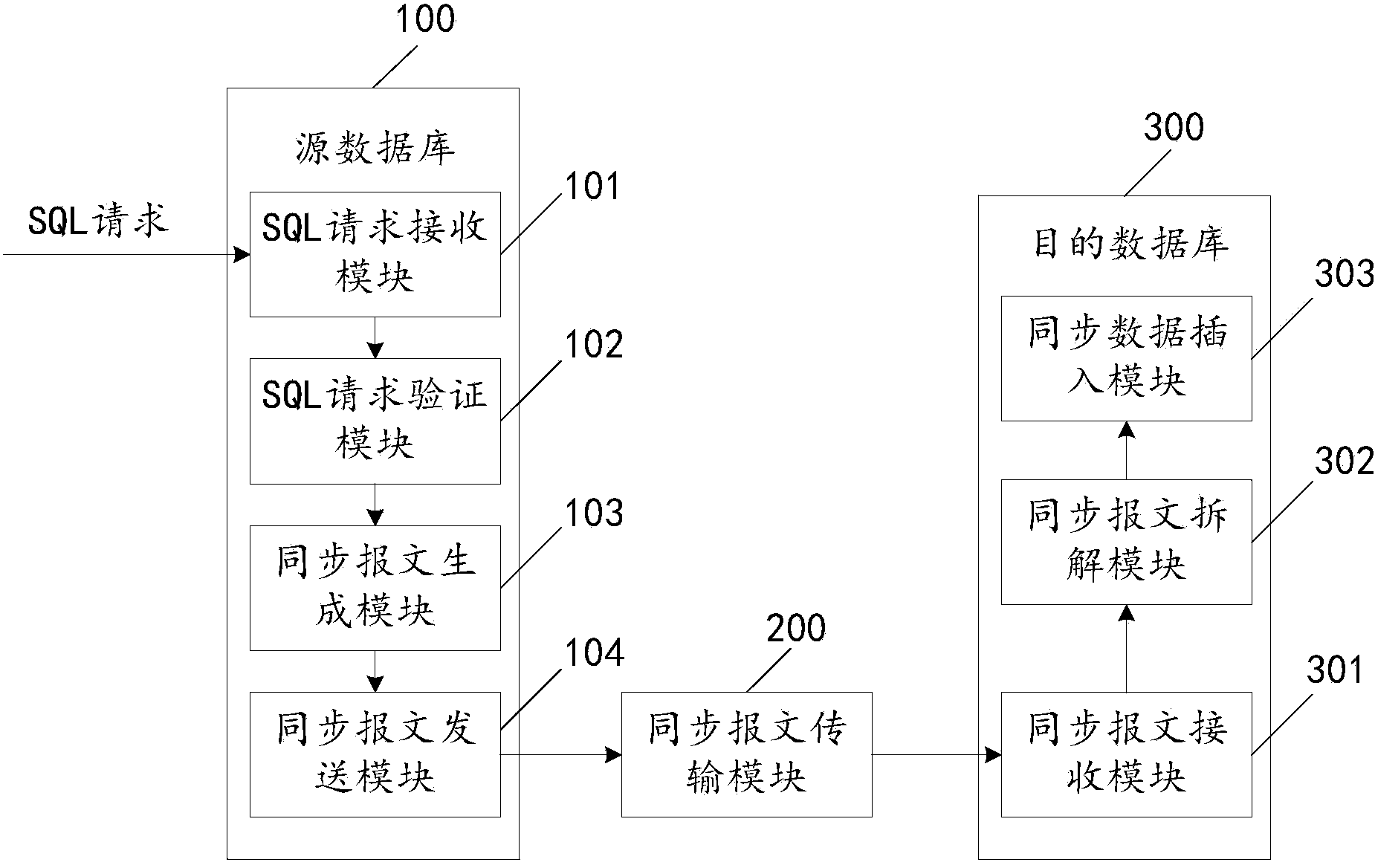

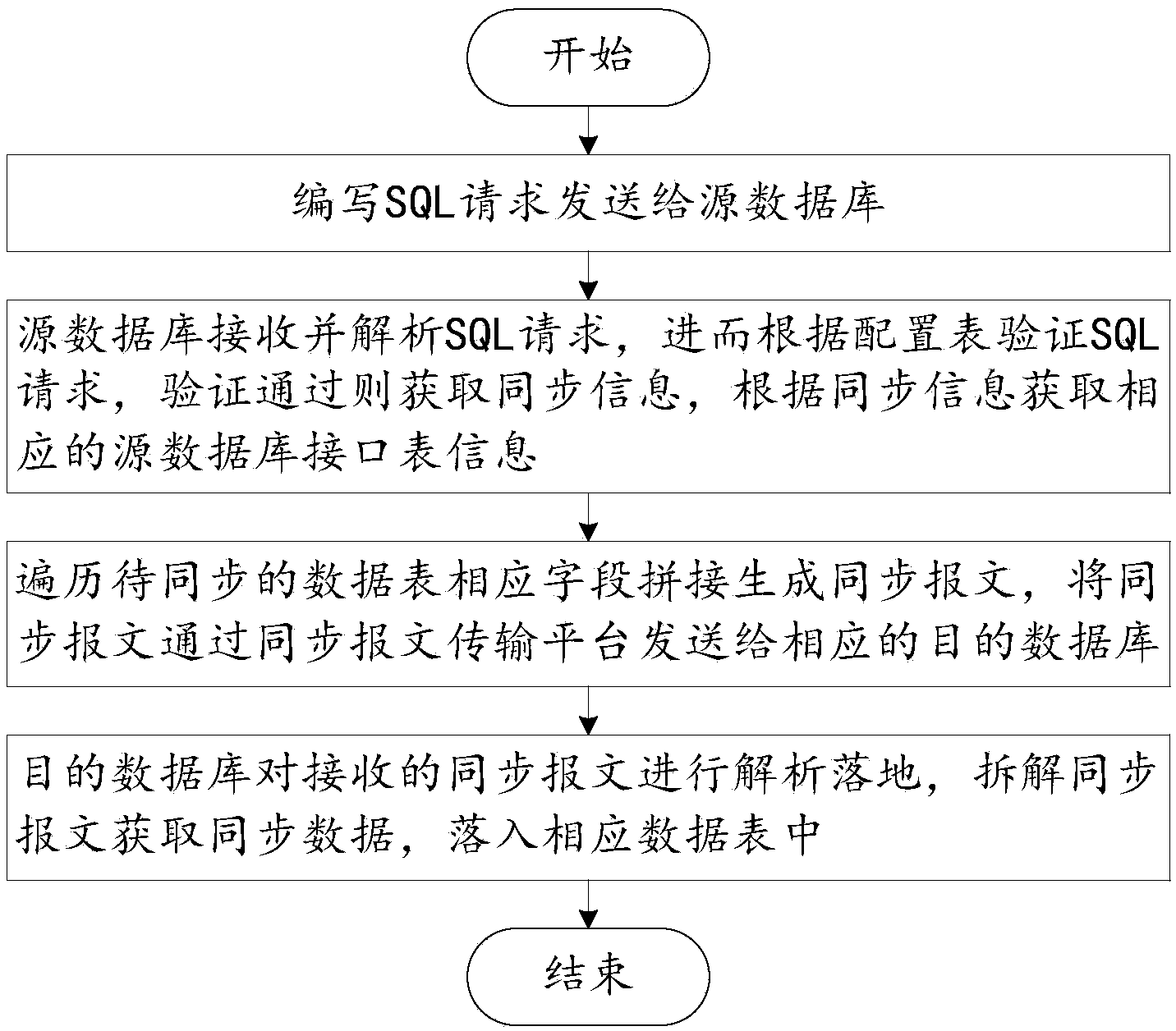

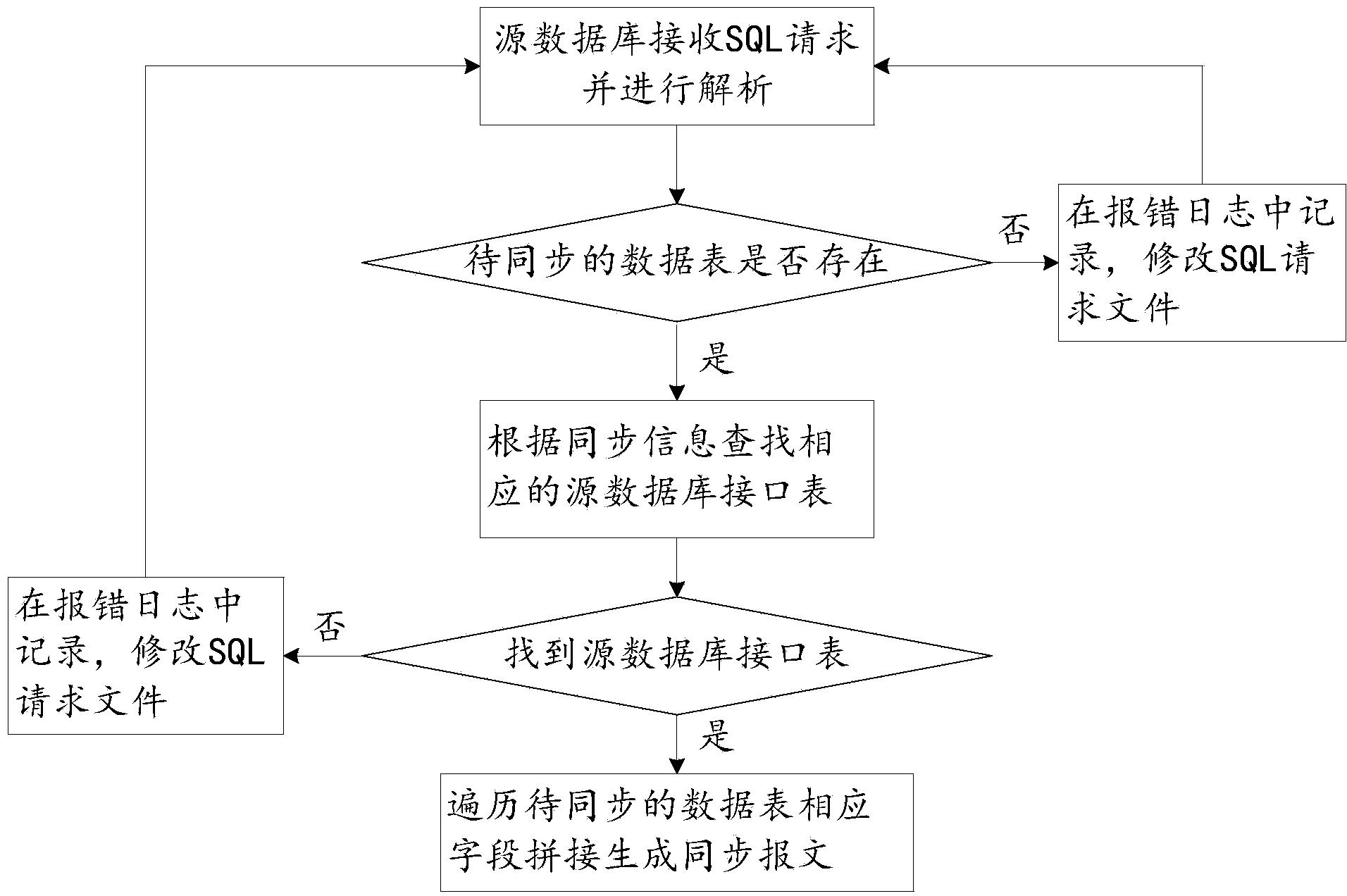

Cross-database data synchronizing system and method

ActiveCN104317921ASimplify the process stepsReduce investmentDatabase distribution/replicationSpecial data processing applicationsSQLSystem maintenance

The invention relates to a cross-database synchronizing system and method. The system comprises a source database, a synchronization message transmission module and a target database. The method includes: the source database uses a configuration table to verify an SQL request, synchronization information and source database interface table information are acquired according to the SQL request, the corresponding fields of a to-be-synchronized data table are traversed to splice and generate a synchronization message, and the synchronization message is inserted into the source database interface table; the synchronization message transmission module carries the synchronization message in the source database interface table to the interface table of the target database; the target database performs parsing falling on the synchronization message in the interface table of the target database, and data falls into the corresponding data table. By the system and the method, cross-database data synchronization flow steps are simplified, system maintenance staff input is reduced, SQL scripts compiling times are reduced, the message is automatically spliced and transmitted to the target database, the target database parses the message, risks caused by manual execution are reduced greatly, and error rate and cost consumption are lowered.

Owner:北京思特奇信息技术股份有限公司

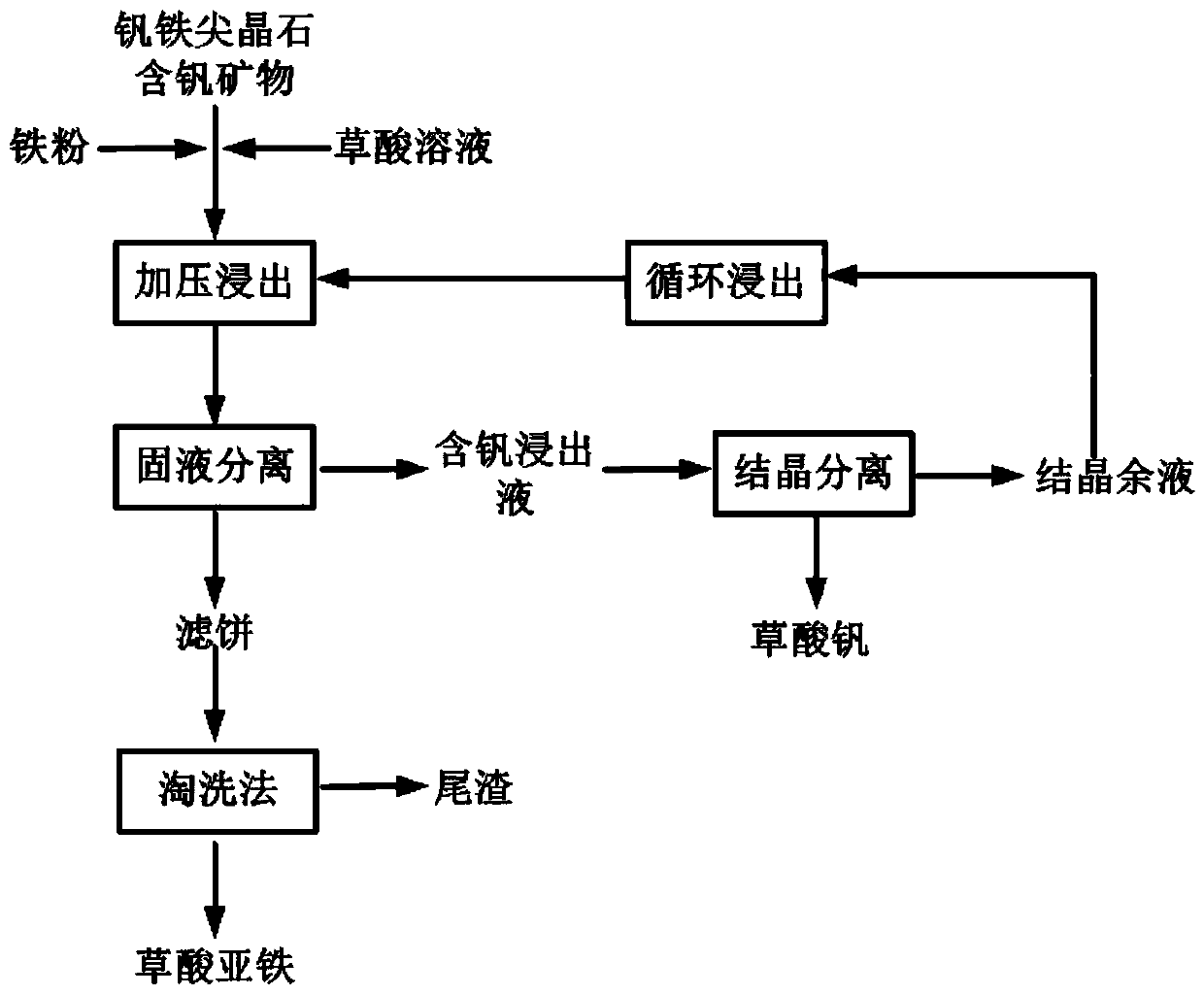

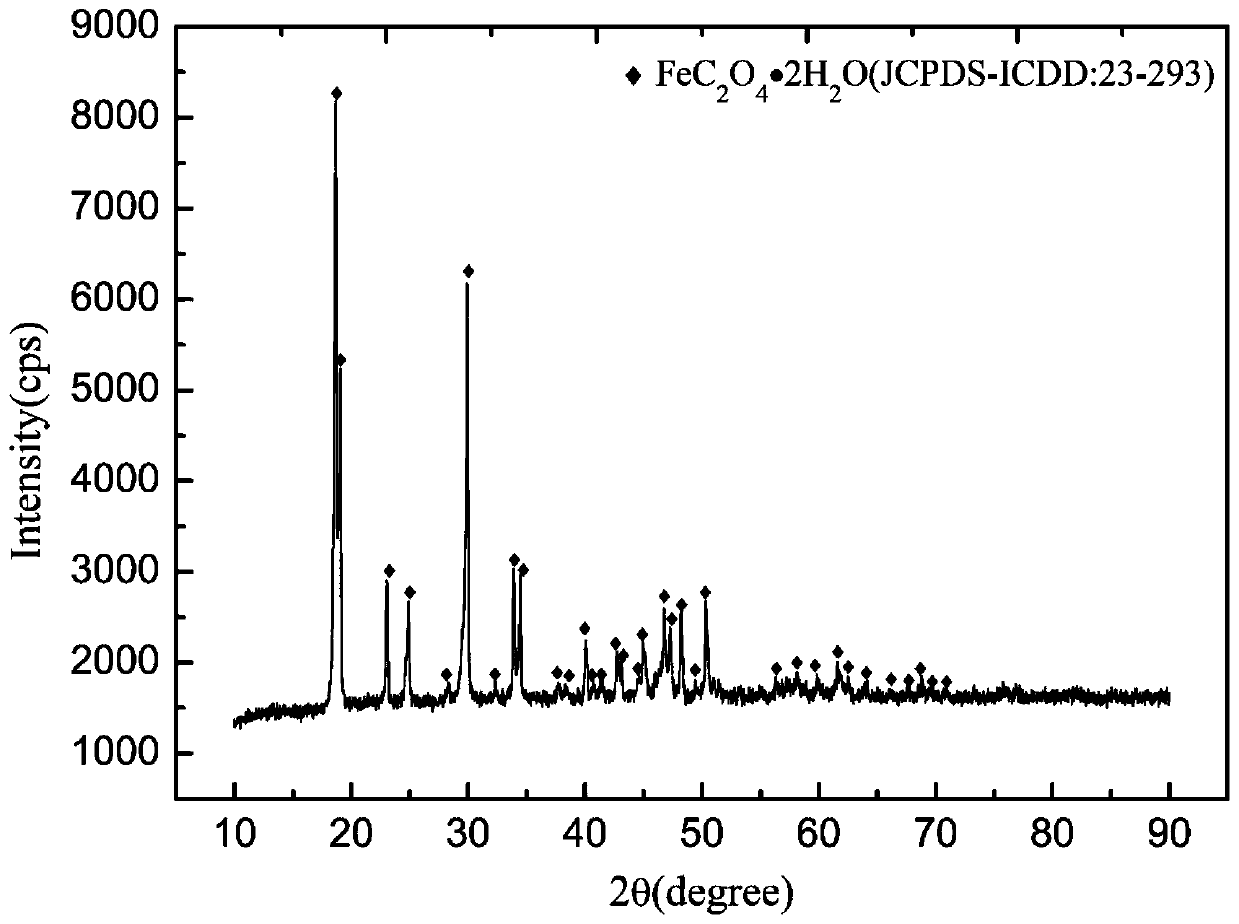

Method for leaching vanadium in ferrovanadium spinel vanadium-containing minerals through complexing of hydrothermal oxalic acid

ActiveCN110306044AAchieve separationSimplify the process stepsProcess efficiency improvementReaction rateSlurry

The invention provides a method for leaching vanadium in ferrovanadium spinel vanadium-containing minerals through complexing of hydrothermal oxalic acid, and belongs to the field of leaching of vanadium in ferrovanadium spinel vanadium-containing minerals through a hydrothermal method. According to the method, the ferrovanadium spinel vanadium-containing minerals are used as raw materials, ferrumpowder is used as a reducing agent, an oxalic acid solution is used as a leaching agent, and the ferrovanadium spinel vanadium-containing minerals, the ferrum powder and the oxalic acid are mixed into slurry to react under a hydrothermal condition; and solid-liquid separation is conducted on the slurry obtained after the reaction, so that clean vanadium-containing leachate and a ferrous oxalate by-product are obtained. According to the method, oxalate ions with a the strong complexing effect react with vanadium and ferrum in ferrovanadium spinel to form [V(C2O4)3]<3-> and [Fe(C2O3]<3-> to enter the solution; and the formed [Fe(C2O3]<3-> reacts with the Fe powder to form ferrous oxalate sediment, so that proceeding of the reaction is facilitated, and the leaching reaction rate is increased. By adoption of the method, vanadium in the ferrovanadium spinel vanadium-containing minerals can be effectively extracted, vanadium and ferrum are separated in the leaching process, the process steps are simplified, and the by-product, namely the ferrous oxalate, with high added value is obtained.

Owner:UNIV OF SCI & TECH BEIJING

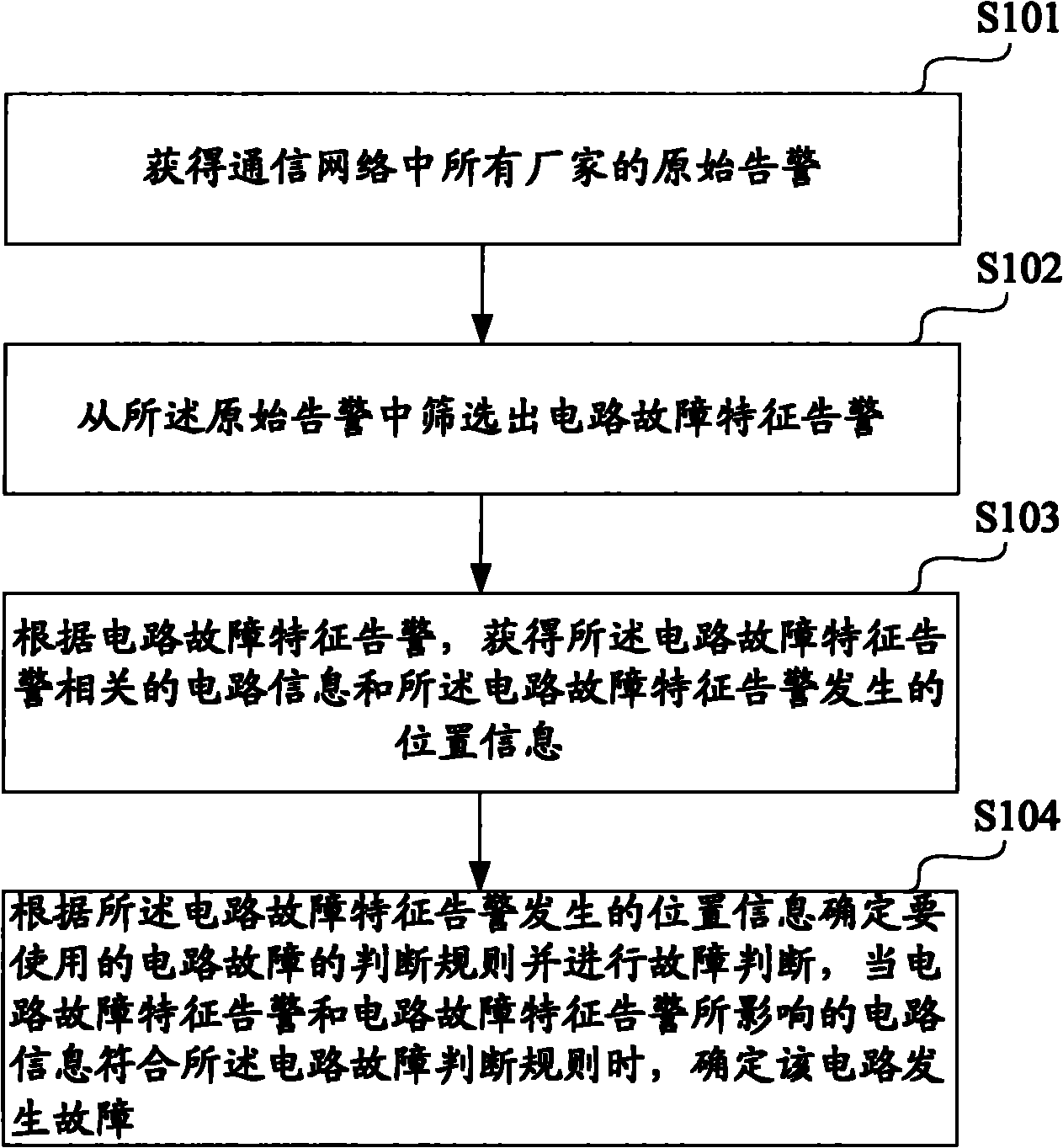

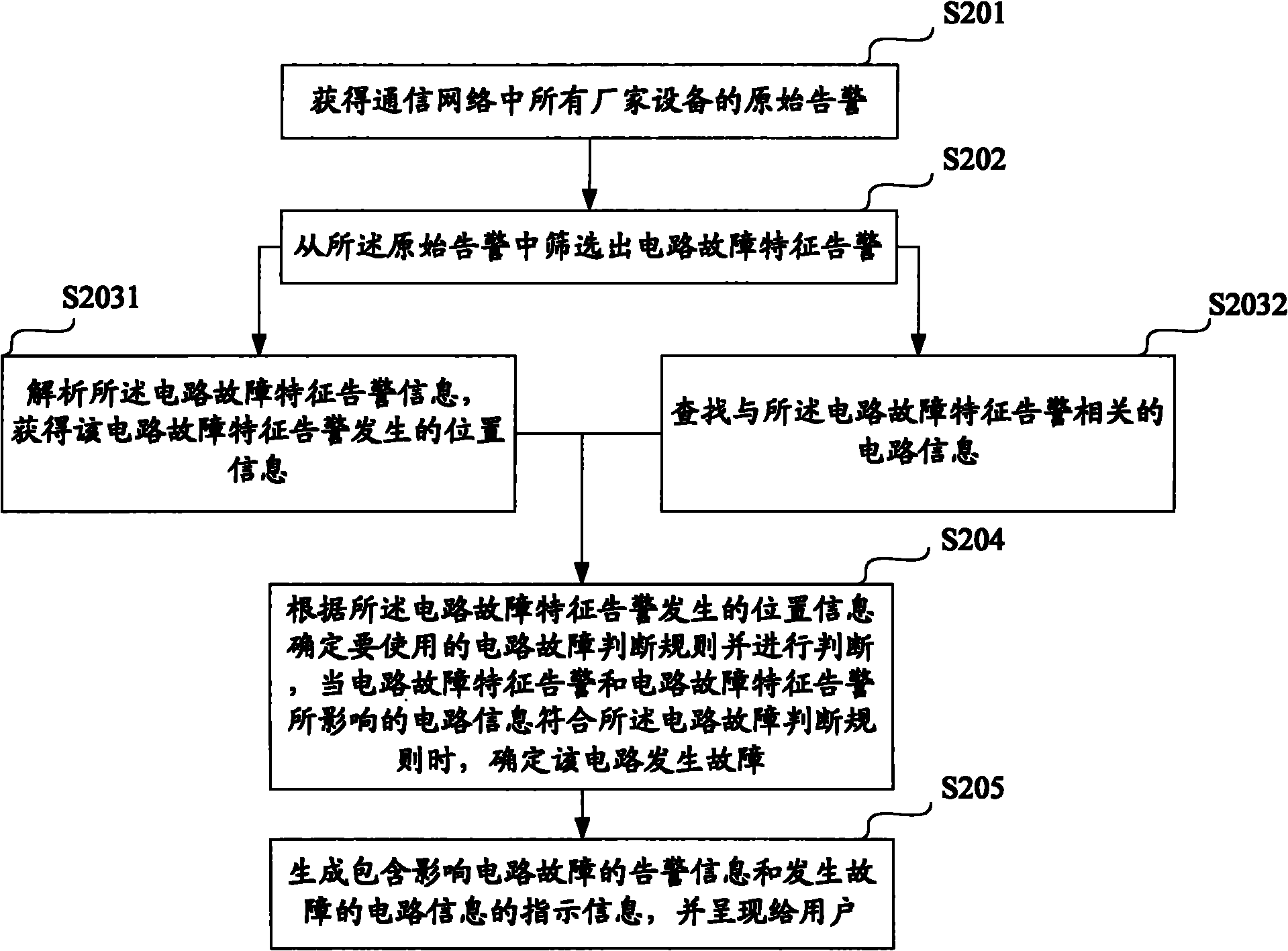

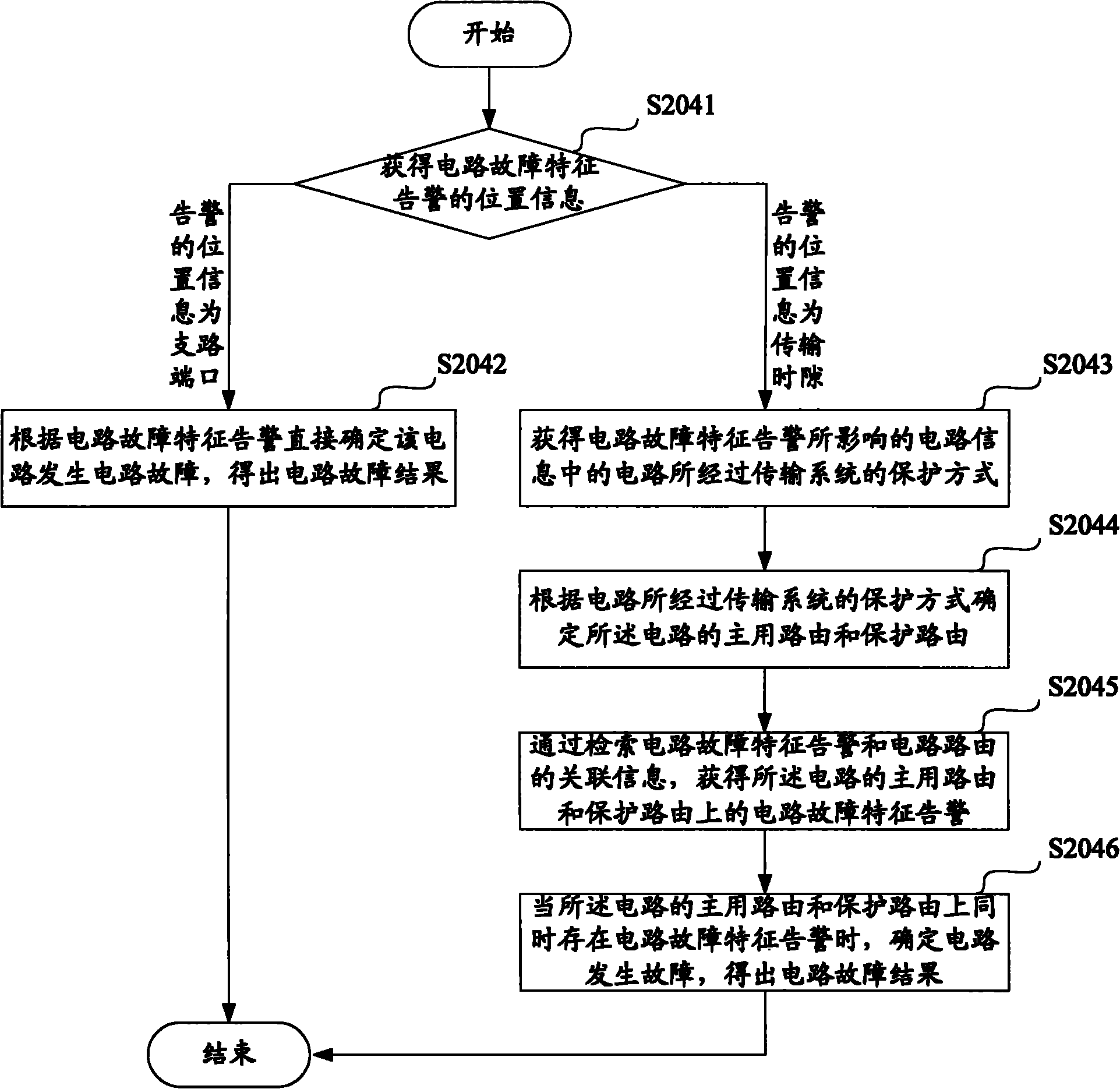

Synchronous digital hierarchy (SDH) circuit fault diagnosing method and device

ActiveCN101771466ASave human effortSimplify the process stepsTime-division multiplexFault recovery arrangementsFailure diagnosisService quality

The invention discloses a synchronous digital hierarchy (SDH) circuit fault diagnosing method comprising the following steps of: obtaining original alarms of the equipment of all companies in a communication network; screening circuit fault characteristic alarms from the original alarms; obtaining circuit information influenced by the circuit fault characteristic alarms and position information of the circuit fault characteristic alarms according to the circuit fault characteristic alarms; judging by determining judgment rules of circuit faults according to the position information of the circuit fault characteristic alarms; and when the circuit fault characteristic alarms and the circuit information influenced by the circuit fault characteristic alarms accord with the judgment rules of the circuit faults, determining that a circuit is out of order. The invention also discloses a circuit fault diagnosing device. The invention can fast and automatically diagnose the circuit faults by utilizing the conventional alarms and resource libraries, prevent the lag of circuit fault processing, enhance the service quality and efficiency of a telecommunication network and ensure the normal operation of the telecommunication network.

Owner:成都亿阳信通信息技术有限公司

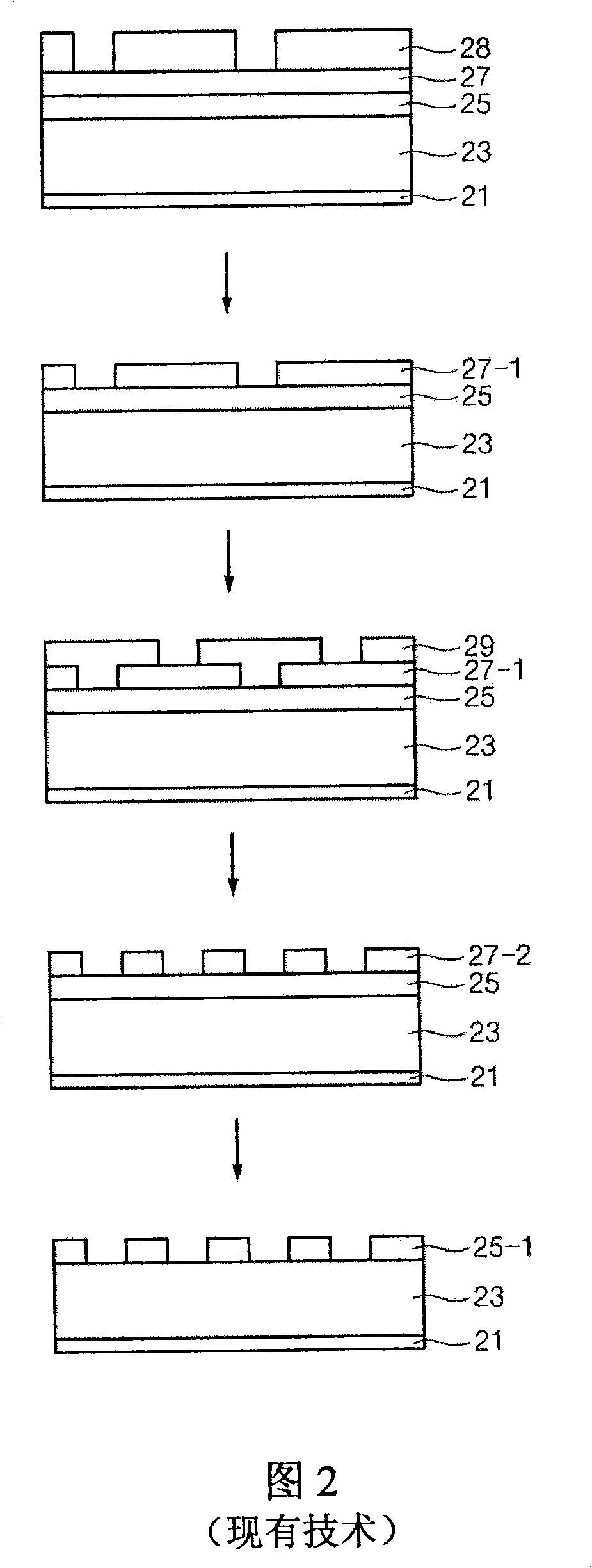

Method for forming fine pattern of semiconductor device

InactiveCN101320673AReduce manufacturing costSimplify the process stepsSemiconductor/solid-state device manufacturingCarbon layerOptoelectronics

A method for forming a fine pattern of a semiconductor device comprises forming a deposition pattern including first, second, and third mask patterns over a semiconductor substrate having an underlying layer, side-etching the second mask pattern with the third mask pattern as an etching barrier mask, removing the third mask pattern, forming a spin-on-carbon layer that exposes the upper portion of the second mask pattern, performing an etching process to expose the underlying layer with the spin-on-carbon layer as an etching barrier mask, and removing the spin-on-carbon layer.

Owner:SK HYNIX INC

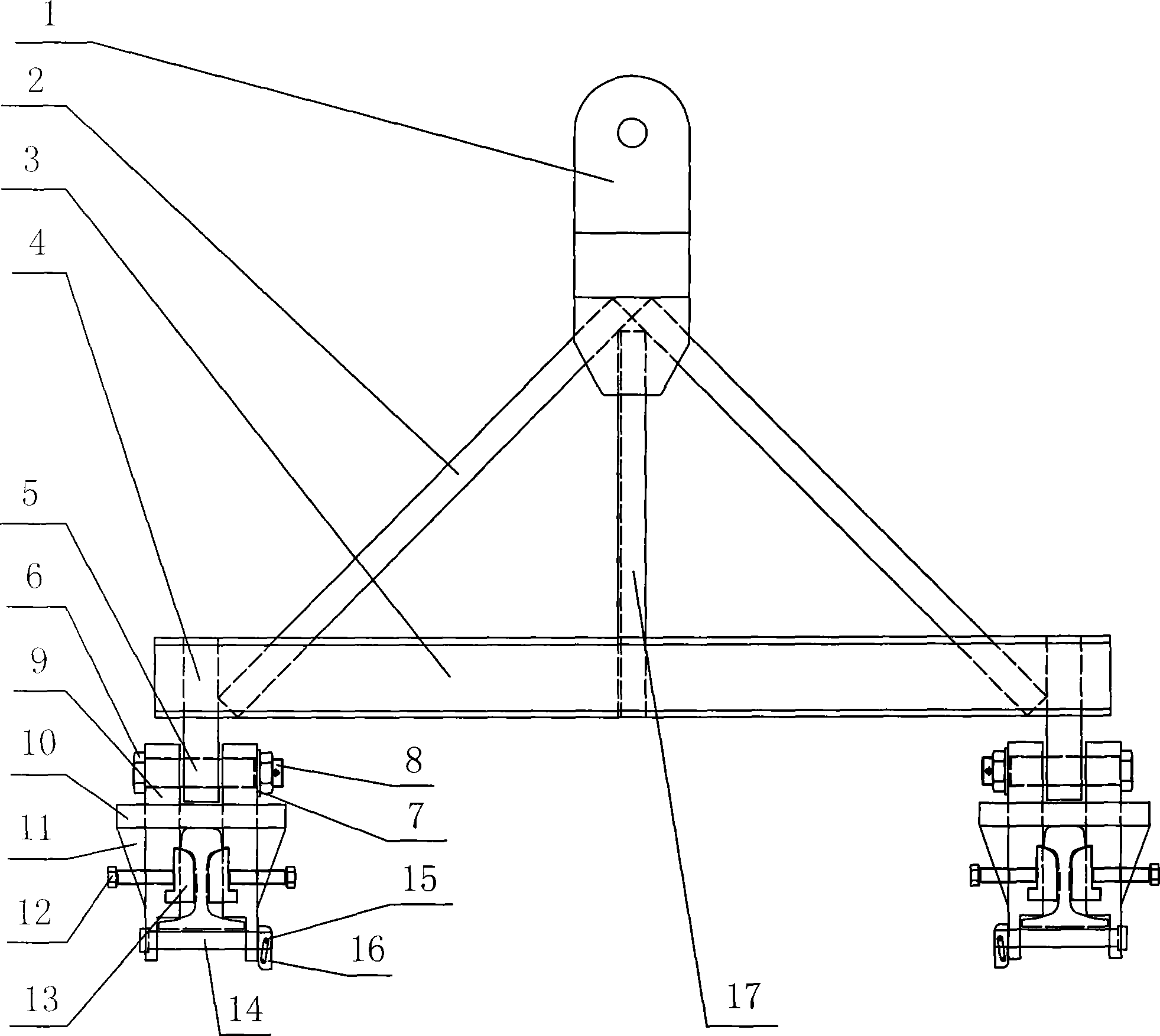

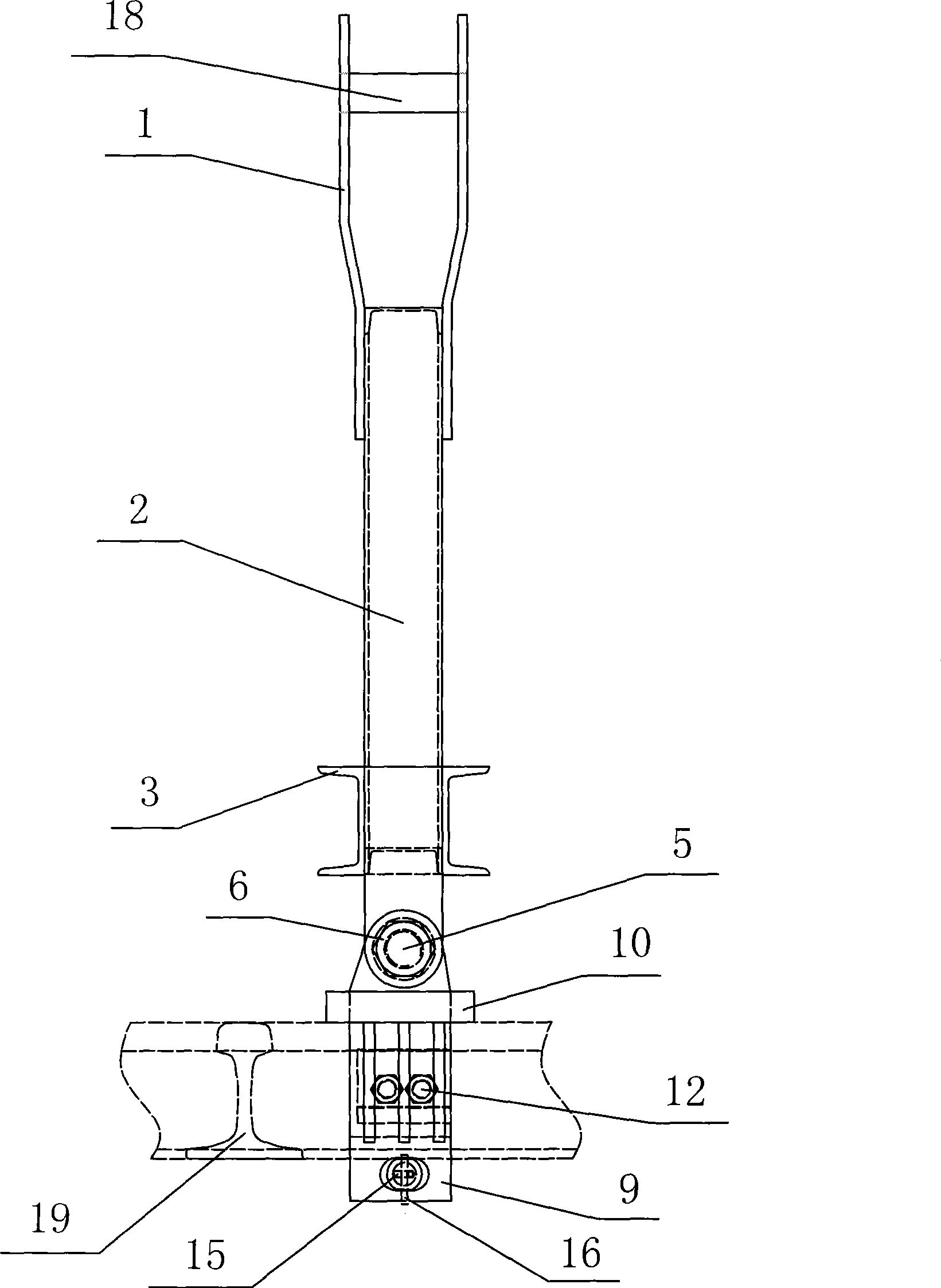

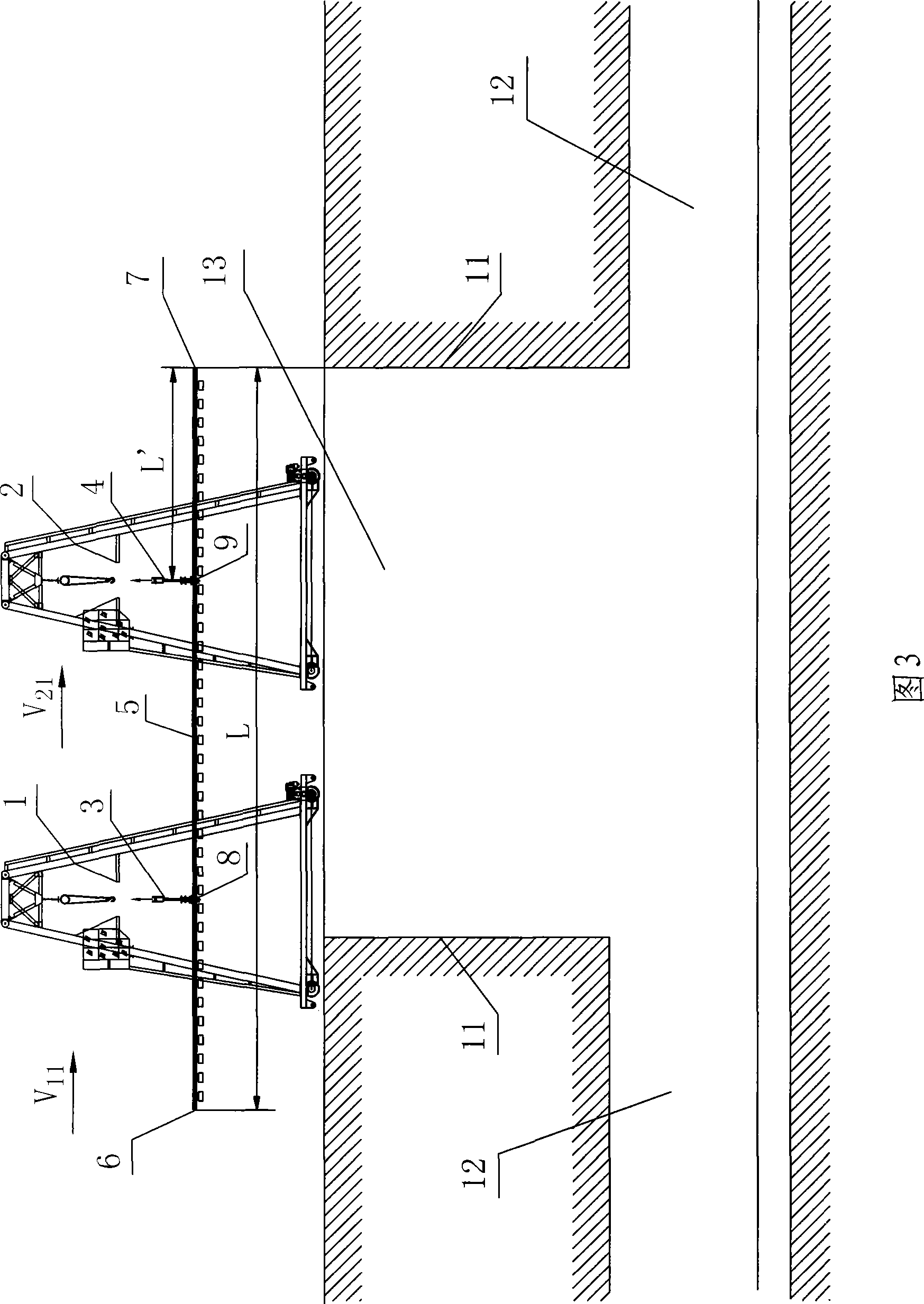

Arranging construction method of subway narrow shield well inclined hoisting rail

ActiveCN101413234ASimple structureSimple and fast operationRailway track constructionArchitectural engineeringGantry crane

The invention discloses a construction method for inclinedly and downward hoisting a track panel of a narrow shield well of a subway, which comprises the following steps: (a) a shield well is selected according to the length of the track panel; and (b) a left gantry crane and a right gantry crane are adopted to inclinedly and downward hoist the track panel through a track panel hoisting device respectively, wherein 1. after the horizontal hoisting, the left gantry crane and the right gantry crane synchronously move to the position above a feed opening from left to right; 2. the left gantry crane is still, and the right gantry crane travels toward the left and synchronously ensures that a large hook of the right gantry crane descends to cause the track panel to have an inclination angle of alpha; 3. the two gantry cranes synchronously move toward the right, and large hooks simultaneously descend; 4. the two gantry cranes continue moving synchronously toward the right, and the large hooks simultaneously descend; 5. the two gantry cranes move toward the right, and the running speed of the left gantry crane and the descending speed of the large hook of the left gantry crane are greater than those of the right gantry crane; and 6. the right gantry crane is still, and the large hook of the left gantry crane descends when the left gantry crane travels toward the left. The construction method has simple working procedures, simple and convenient operation, low construction cost, and high efficacy, and can effectively solve the construction problem of inclinedly and downward hoisting the track panel in the narrow shield well.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

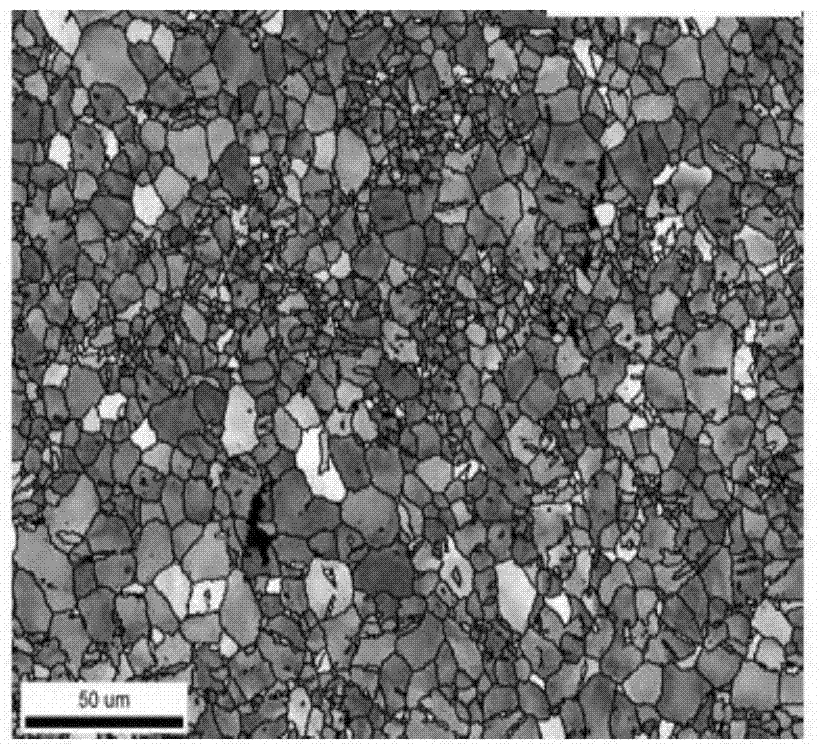

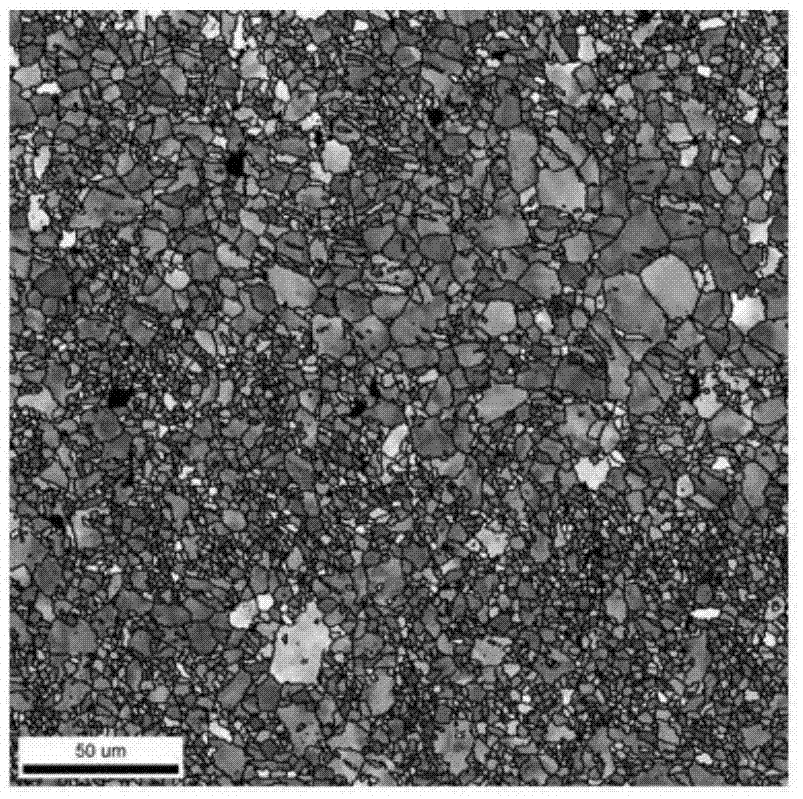

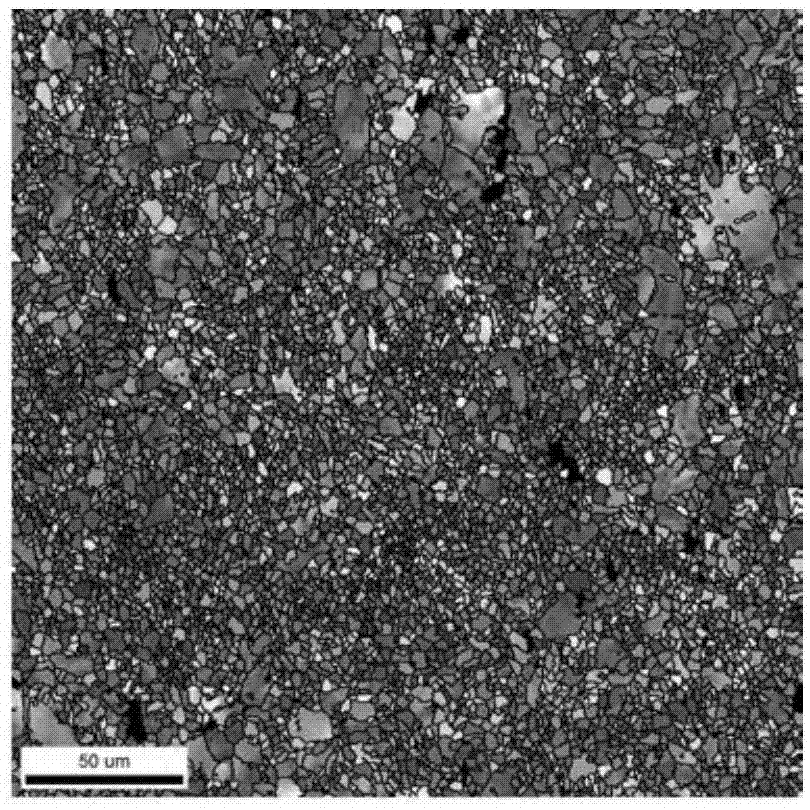

High-efficiency rolling technology for high-strength and high-ductility magnesium alloy sheet and preparation method

ActiveCN106862272AHigh strengthImprove plasticityTemperature control deviceMetal rolling arrangementsHigh intensityParameter control

The invention discloses a high-efficiency rolling technology for a high-strength and high-ductility magnesium alloy sheet. The high-efficiency rolling technology is a technology used for rolling a rolled blank. According to the parameter control of the rolling technology, the rolling speed of each rolling pass is 10-50m / min, the rolling reduction of each rolling pass is controlled to be 40%-90%, and the preheating temperature and rolling temperature in each rolling pass before rolling are both 250-450 DEG C. The invention further discloses a preparation method of the high-strength and high-ductility magnesium alloy sheet. The method includes the steps that (1) the rolled blank is prepared; (2) high-efficiency hot rolling is carried out, the rolling speed of each rolling pass is controlled to be 10-50m / min, the rolling reduction of each rolling pass is 40%-90%, and the preheating temperature and rolling temperature in each rolling pass before rolling are both 250-450 DEG C; and (3) annealing is performed. By the adoption of the high-efficiency rolling technology for the high-strength and high-ductility magnesium alloy sheet, the mechanical property level of the sheet can be effectively improved, and the strength and ductility of the sheet can be greatly improved particularly.

Owner:BAOSHAN IRON & STEEL CO LTD

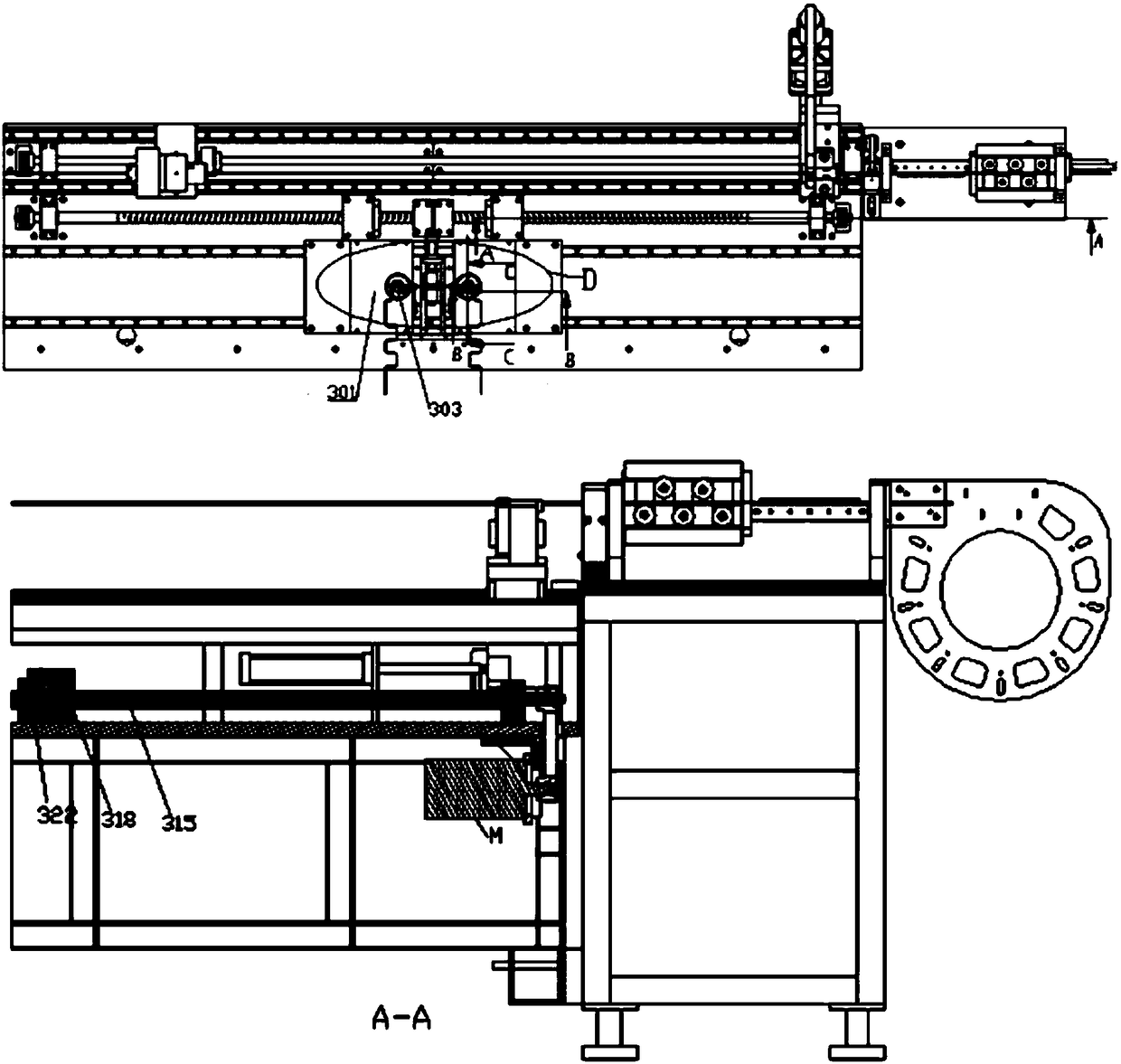

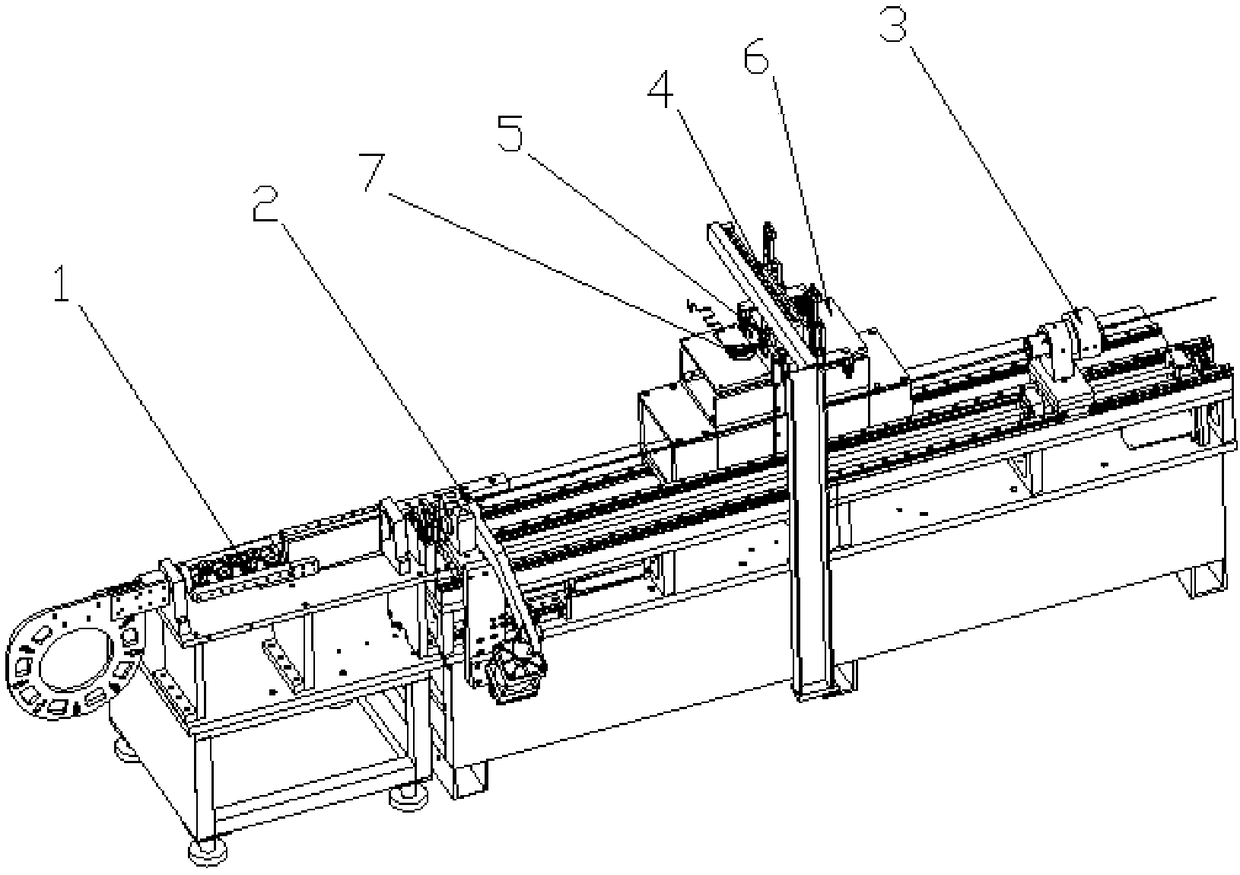

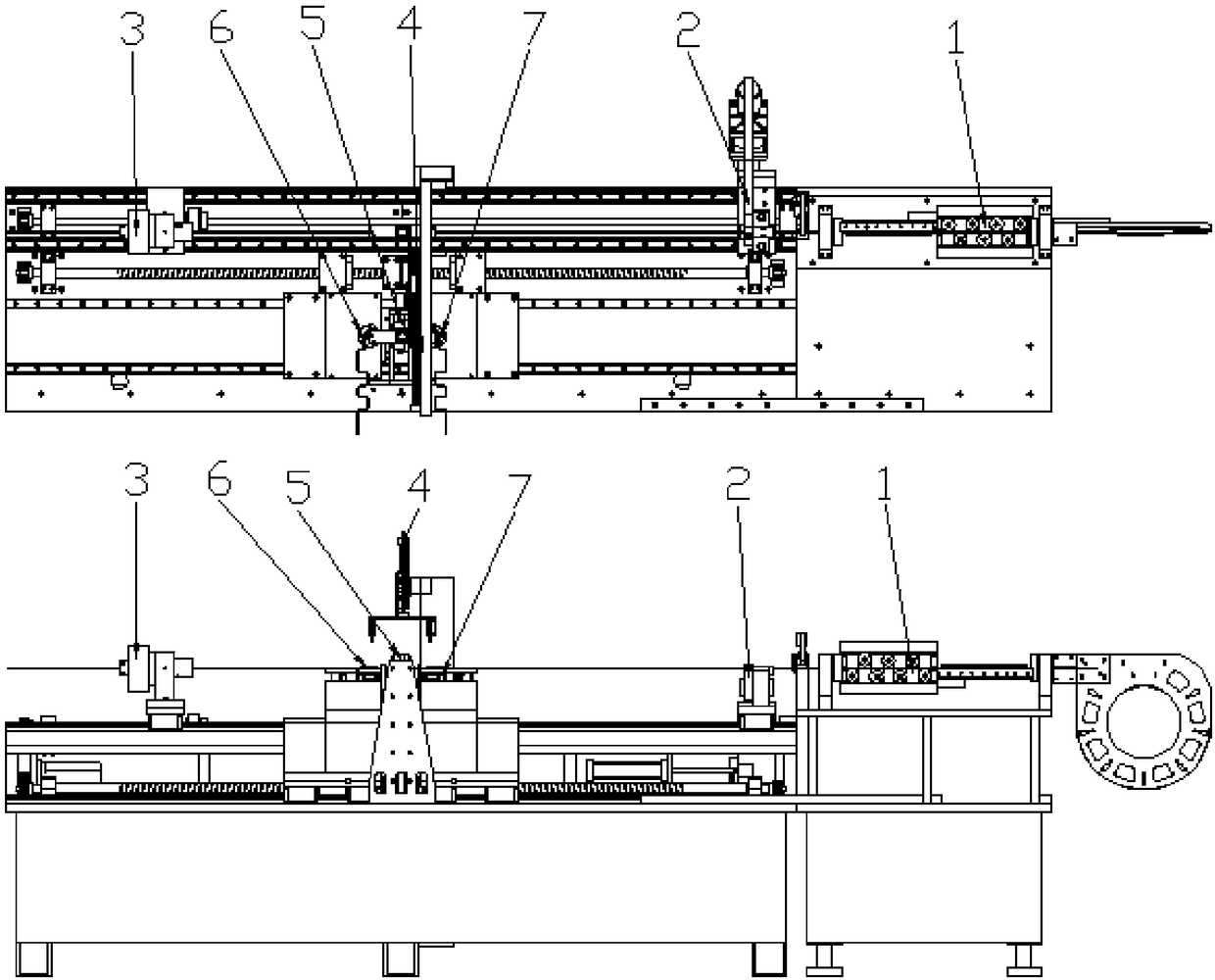

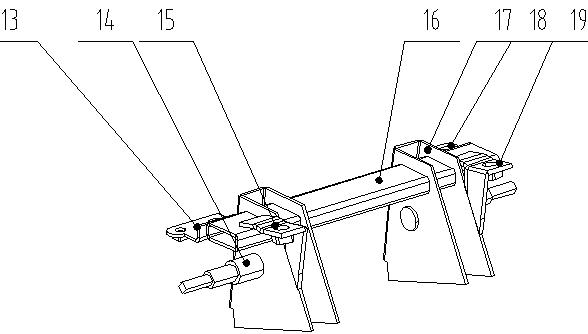

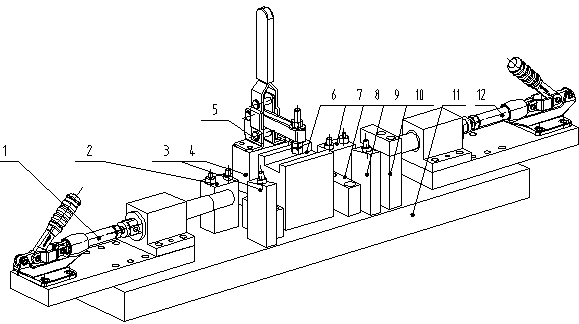

Double-head seven-axis forming machine

The invention discloses a double-head seven-axis forming machine. The double-head seven-axis forming machine comprises a bottom frame and a rack platform arranged on the bottom frame and further comprises a material counting mechanism, a linear mechanism, a cutting-off mechanism, a feeding mechanism, a wire changing mechanism used for adjusting the angle of a wire, a left forming mechanism, a right forming mechanism, and a wire pulling mechanism which are all arranged on the rack platform, wherein the left forming mechanism and the right forming mechanism are used for bending the wire; the left forming mechanism and the right forming mechanism are arranged on the left side and the right side of the wire changing mechanism correspondingly; and the wire changing mechanism is fixed to the rack platform of the double-head seven-axis forming machine. According to the double-head seven-axis forming machine, the structure is integrally designed, the process steps are simplified, the bending forming time is shortened, the structures of front stations and rear stations are compact, cooperation is tight, machining debugging is easy, convenient and easy to operate, and one-time complex linearbending operation can be achieved; the bending efficiency is high, the manufacture process is good in stability, the bending quality is greatly improved, more convenience is realized, the manual handoperation error is reduced, manpower is saved, a computer is utilized to control multiple axes to conduct an action simultaneously, and debugging is easy; and the cost is reduced, the resources are saved, and the production efficiency is improved.

Owner:GUANGZHOU CAIHONG HARDWARE SPRING CO LTD

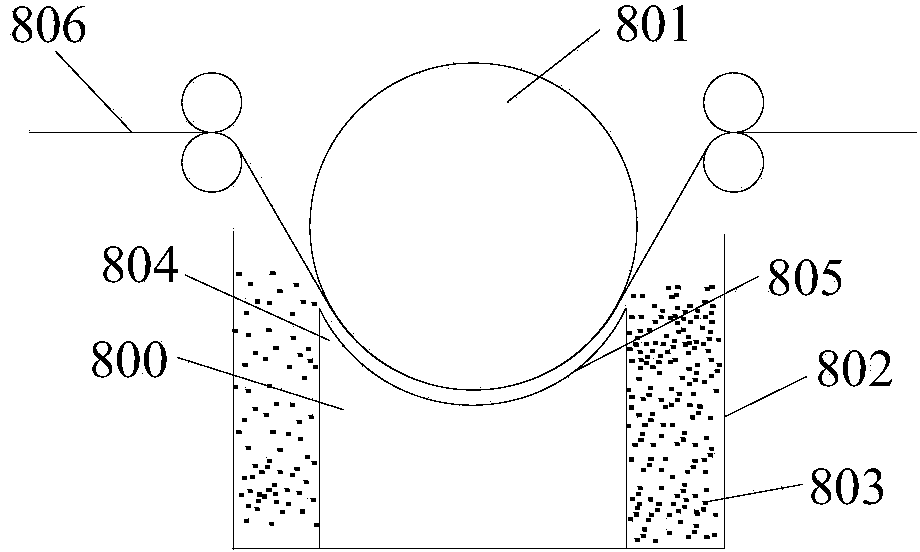

Electroplating bath

ActiveCN103789806AReduce in quantityImprove uniformityTanksFinal product manufactureProduction lineIndium

The invention belongs to the technical field of preparation of solar cells, and in particular relates to an electroplating bath, which is used for depositing elemental copper, gallium, indium or selenium or a copper, gallium, indium or selenium alloy on the surface of a substrate. The electroplating bath comprises an electroplating branch bath and a master bath, wherein the electroplating branch bath is provided with an accommodation cavity for containing an electroplating solution; anodes immersed in the electroplating solution are hung on the lateral surfaces of the electroplating branch bath; a conveying device for carrying the substrate to synchronously move is arranged on the middle part of the electroplating branch bath; the anodes are arranged on the two sides of the conveying device; parts, opposite to the anodes, on the two lateral surfaces of the conveying device are immersed in the electroplating solution; the substrate is attached to the lateral surfaces of the conveying device, and is opposite to the anodes when passing through the electroplating branch bath. According to the electroplating bath, the length of an electroplating production line is reduced, and a small space is occupied; the elemental copper, gallium, indium or selenium or the copper, gallium, indium or selenium alloy is deposited on the front surface of the substrate only, so that few process steps are required; the anodes are opposite to the substrate, so that the uniformity and smooth finish of the surface of a deposited CIGS (copper, indium, gallium and selenium) absorption layer are ensured.

Owner:SOLTRIUM TECH LTD SHENZHEN

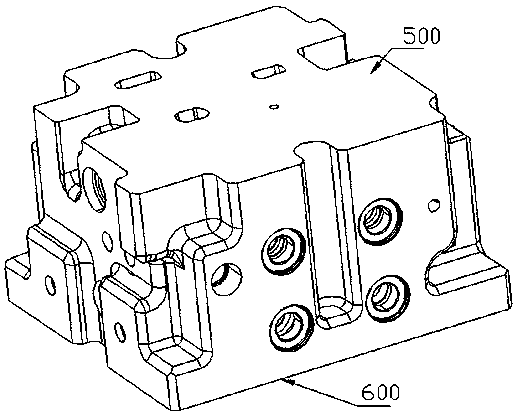

Casting method of hydraulic valve casting

InactiveCN109128010AHigh strengthGuaranteed StrengthFoundry mouldsFoundry coresIntegrated design3d printer

The invention relates to a casting method of a hydraulic valve casting. The casting method is characterized by comprising the following steps: designing a mold core including a hydraulic valve; selecting the bottom surface of the hydraulic valve and the top surface of the hydraulic valve as split surfaces of the mold core and dividing the mold core into a bottom core, an intermediate core and an upper cover core; printing the intermediate core by adopting a 3D printer; printing the bottom core and the upper cover core by adopting the 3D printer and / or preparing the bottom core and the upper cover core by adopting a wooden pattern; assembling the bottom core and the intermediate core; assembling the upper cover core on the intermediate core. The casting method of the hydraulic valve casting, provided by the invention, has the benefits that the intermediate core of the hydraulic valve and the external contour are combined together, so that the quantity of sand cores is reduced, and the process step is simplified; through the integrated design of the intermediate core, the sand core strength of the intermediate valve core is enhanced, so that the problems of sand core deformation andthe like are solved.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

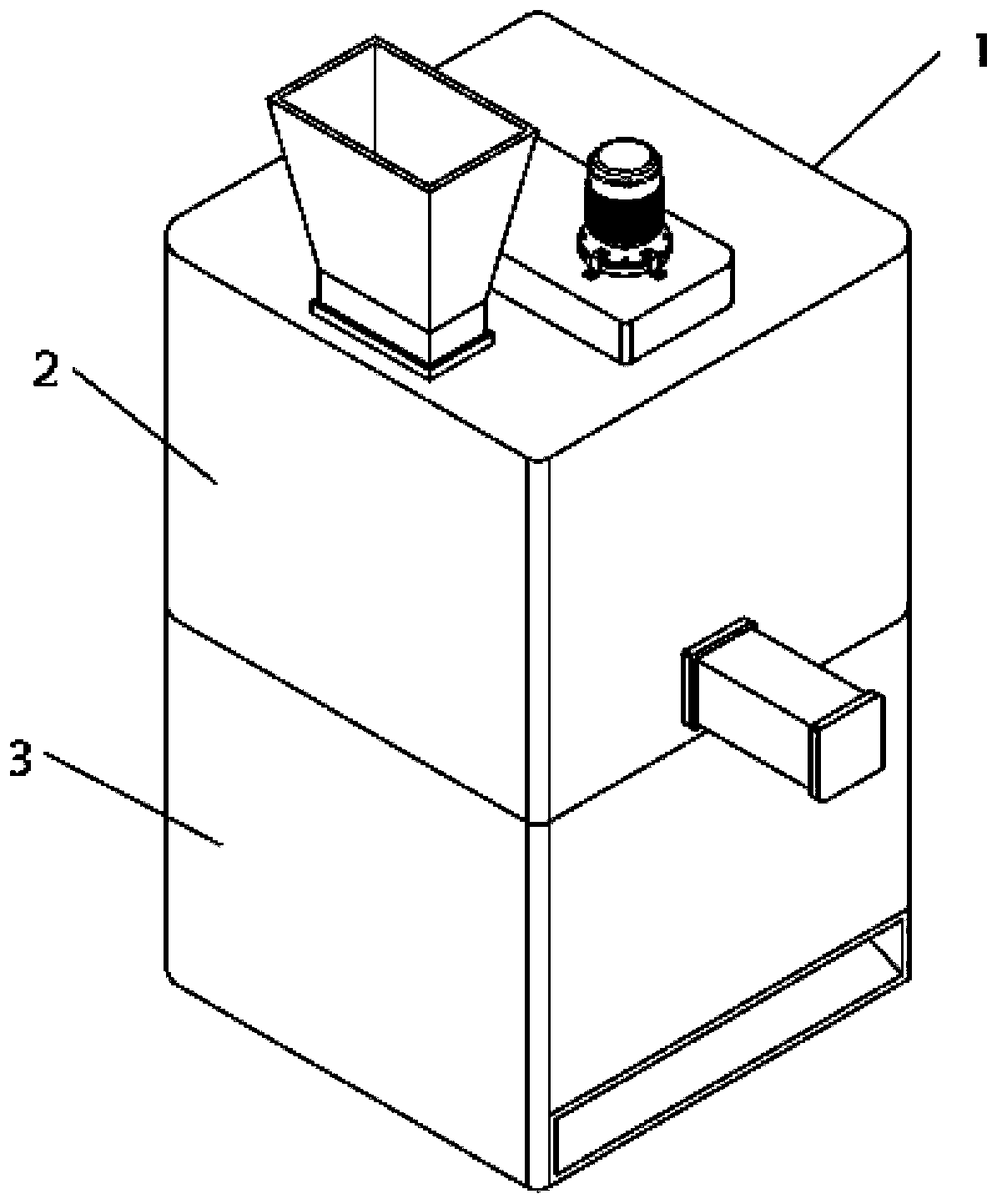

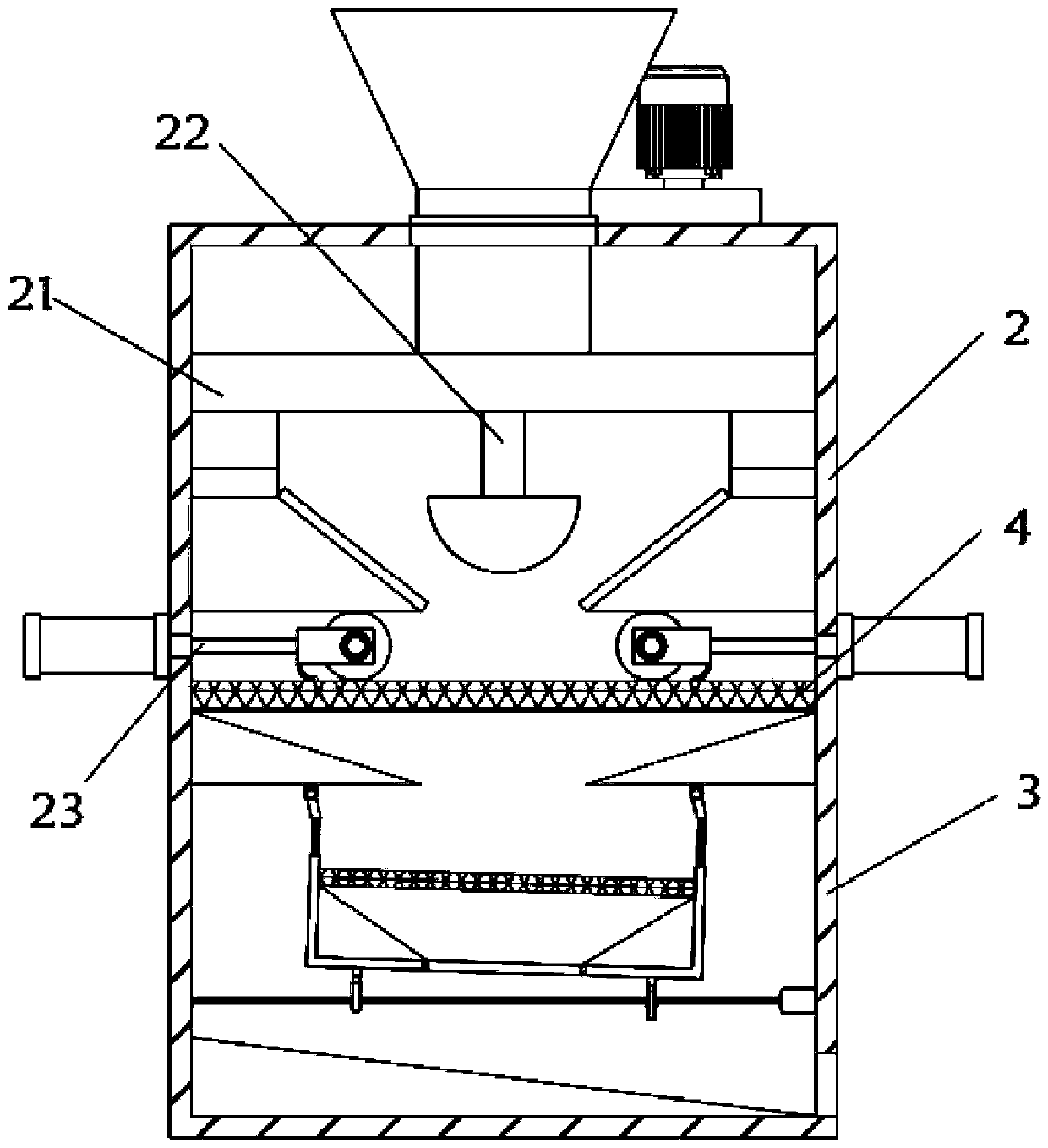

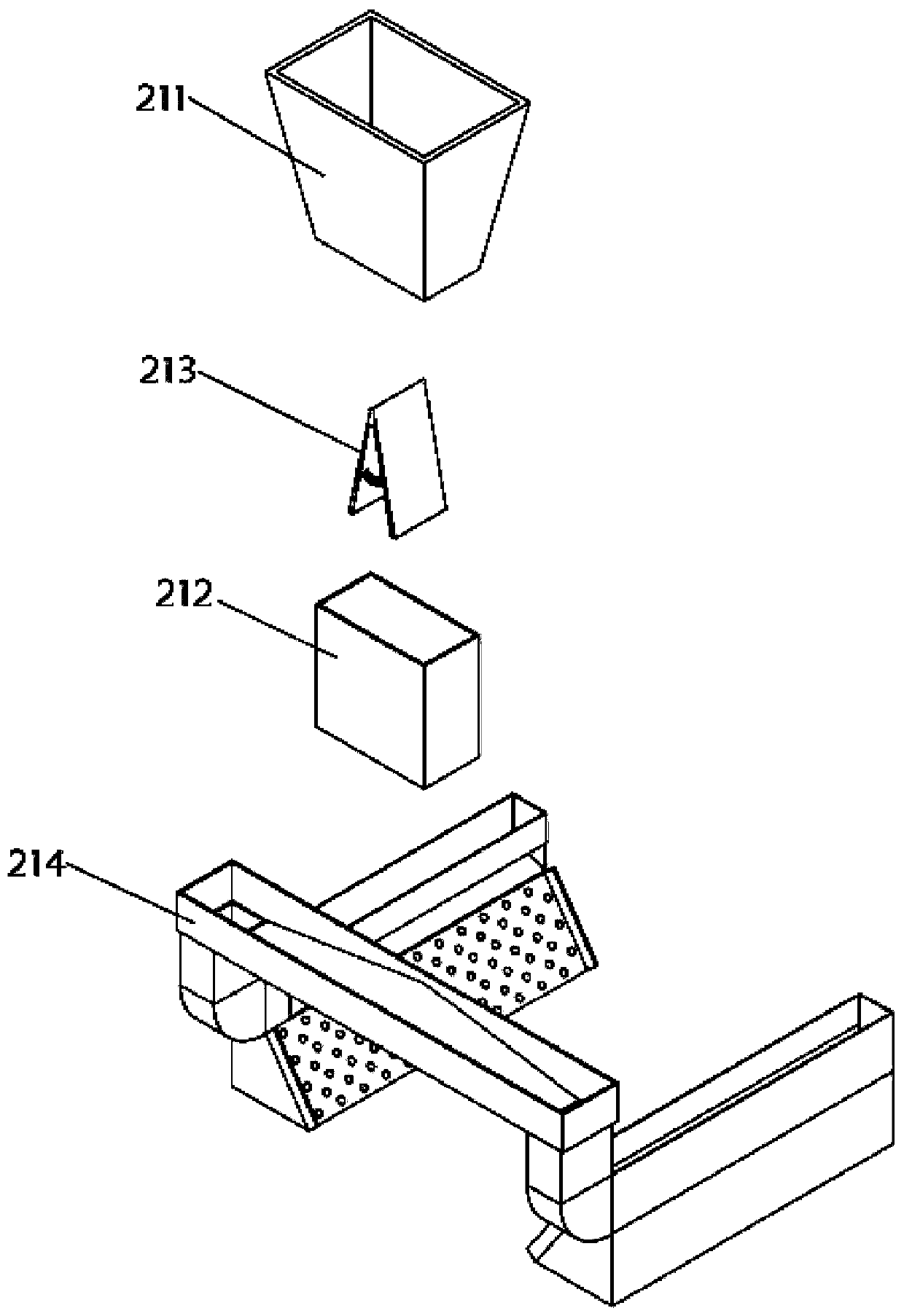

Grinding and screening integrated traditional Chinese medicine processing device

ActiveCN110935543ASimplify the process stepsImprove work efficiencySievingScreeningReciprocating motionElectric machinery

The invention relates to the technical field of traditional Chinese medicine processing, and particularly relates to a grinding and screening integrated traditional Chinese medicine processing device.The grinding and screening integrated traditional Chinese medicine processing device comprises a processing box body, wherein the processing box body comprises a grinding box body and a screening boxbody, a filter screen is mounted between the grinding box body and the screening box body, and a material distributing device, a grinding device and a rolling device are arranged in the grinding boxbody. According to the grinding and screening integrated traditional Chinese medicine processing device, the filter screen is arranged in the processing box body, the processing box body is divided into the grinding box body and the screening box body, so that grinding and screening are carried out in the same process, the process steps are simplified, and the working efficiency is improved; an electric push rod pushes a grinding block to do up-down reciprocating motion, meanwhile, a connecting shaft drives the electric push rod to rotate, so that the mechanical grinding work of traditional Chinese medicines is realized; and a working motor drives a rotating shaft to rotate, so that two elliptical teeth rotate synchronously, the two elliptical teeth are attached to a fixed pulley to slide,and the two elliptical teeth are different in height, so that a screening box can shake up and down, and the mechanical screening work is completed.

Owner:安徽豪门国药股份有限公司

Processing method and auxiliary device of curved-beam motorcycle damper assembly

InactiveCN103192217AGuaranteed positioning accuracyGuaranteed installation requirementsWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameBaseboard

The invention discloses a processing method and an auxiliary device of a curved-beam motorcycle damper assembly. The auxiliary device comprises a plurality of positioning mechanisms such as a rectangular baseboard, a connecting pipe fixing seat arranged on the floor, a connecting pipe limiting seat, a quick clamp, a damper box limiting seat, a left support lug fixing seat for oil-tank mounting, a right support lug fixing seat for oil-tank mounting, a left support lug fixing seat for storage-rack mounting, a right support lug fixing seat for storage-rack mounting and a quick clamp device. The processing method includes positioning various components by the auxiliary device, welding the components again to form the damper assembly, and then welding the assembly on a frame. Synchronous positioning of multiple components of the curved-beam motorcycle damper assembly is realized by the auxiliary positioning device; by means of positioning and then welding multiple components, the damper assembly is formed in one step; and effects of simplifying procedures and improving processing efficiency are achieved. The auxiliary device has the advantages of simple structure, positioning reliability and convenience in operation, and is capable of improving mounting accuracy of an oil tank, a storage rack and a damper.

Owner:力帆科技(集团)股份有限公司

Display image system

InactiveCN101083275AImprove yieldImprove performanceSolid-state devicesSemiconductor devicesOptoelectronicsImage system

The invention relates to a video display system, comprising plural pixels, each having first, second and third organic light-emitting component and comprising a first electrode layer, a first organic light-emitting layer, a second organic light-emitting layer, a second electrode layer and a filtering component, where the first organic light-emitting layer is arranged on the first electrode layer and inside the first and second organic light-emitting components; the second organic light-emitting layer is arranged on the first electrode layer, and inside the second and third organic light-emitting components, so as to make the first and second organic light-emitting layers overlap in the second organic light-emitting component; the second electrode layer is arranged on the first organic light-emitting layer and the second one; the filtering component is arranged in the second organic light-emitting component.

Owner:INNOLUX CORP

Non-silicone magnesium alloy pressure casting mould release agent

ActiveCN103567375ASimplify the process stepsReduce manufacturing costFoundry mouldsFoundry coresGlycerolPolyethylene glycol

The invention discloses a non-silicone magnesium alloy pressure casting mould release agent which comprises the following components in percentage by weight: 10%-20% of polyol ester, trimethylolpropane complex ester or pentaerythritol complex ester, 1%-8% of polyacrylate, polyisobutene or ethylene-propylene copolymer, 5%-20% of sorbitan monooleate, alkyl alcohol polyoxyethylene ether, polyoxyl oleate or polyethylene glycol dilaurate,6-15% of triethanolamine, triisopropanolamine, decanedioic acid or C11-C14 binary acid, 1%-5% of magnesium alloy dedicated water-soluble corrosion inhibitor, 1%-5% of ethylene glycol, diglycol or glycerol, and the balance of deionized water. According to the non-silicone magnesium alloy pressure casting mould release agent, no organic silicon compound is contained, the production cost is reduced, the product is long in storage period and convenient to transport; no ash is in the raw materials of the product, so that no residue and bright surface of the processed part are ensured; the product is stored without being added with antiseptics, so that the product is safe in use and environment-friendly; compared with a similar product, the product effectively reduces the mould abrasion times and prolongs the service life of a mould.

Owner:DONGGUAN PENGRUN CHEM PROD

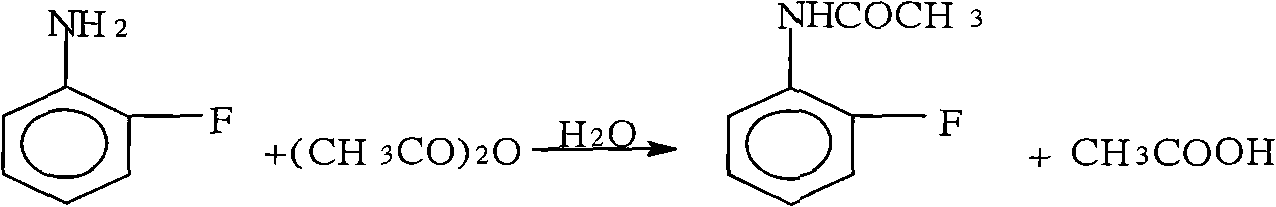

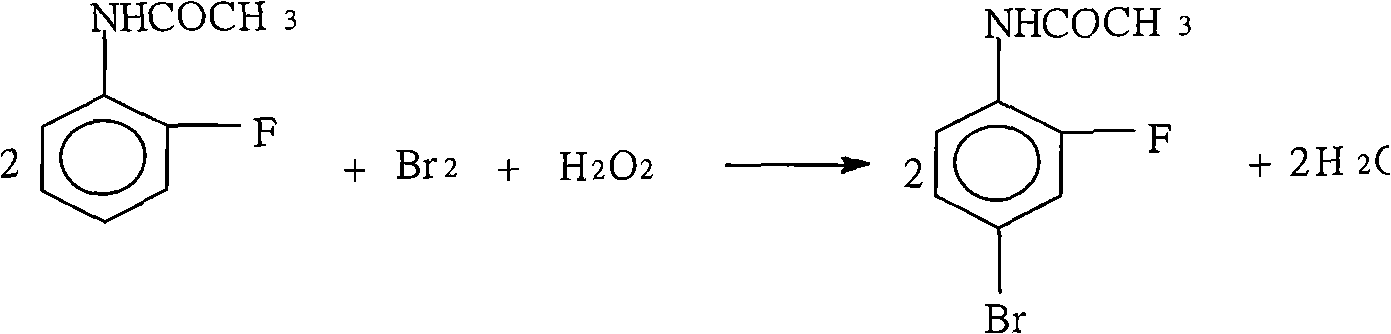

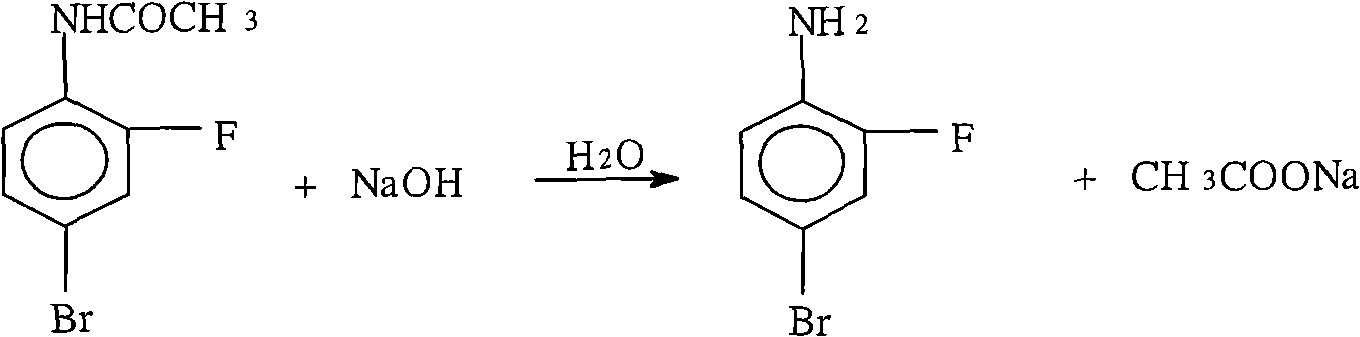

Production technique of m-bromofluorobenzene

ActiveCN101838180ASimplify the process stepsReduce pollutionHalogenated hydrocarbon preparationMethylene DichlorideWater vapor

The invention discloses a production technique of m-bromofluorobenzene, which takes o-fluoroaniline as main raw material and produces the m-bromofluorobenzene according to the process route of acetylation, bromination, hydrolysis, diazotization, deamination, water vapor rectification and rectification. The production technique introduces methylene dichloride solvent in the working procedure of acetylation, leads the product solid to be changed into solution which is not needed to be separated and is directly hydrolyzed; and the solvent is distilled out by the heat of neutralization reaction in the hydrolysis process, so that the problems of separation intoxication, low production capacity and low hydrolysis yield can be solved. The production technique of the m-bromofluorobenzene not onlyhas simple working procedure steps, greatly improves the safety and reduces the hurt for the people, but also has high reaction yield and low environmental pollution.

Owner:营口兴福化工有限公司

CFB boiler inlaid type hood air distributing device and improving method thereof

InactiveCN106122952AAvoid the risk of cokingThe situation of ash leakage is solvedFluidized bed combustionApparatus for fluidised bed combustionSlagEngineering

The invention discloses a CFB boiler inlaid type hood air distributing device and an improving method thereof, and belongs to the technical field of heat-engine plant circulating fluidized bed boiler air distribution plate transformation. The CFB boiler inlaid type hood air distributing device comprises a tube nest, air distribution plate castable and the like. The tube nest is located at the upper portion of an air chamber. Hearth water wall tubes are evenly arranged below the tube nest. The air distribution plate castable is laid on the tube nest with reserved gaps. An air pipe B is inlaid in an air pipe A, penetrates the tube nest and extends into the air chamber. The air pipe A and the air pipe B are fixed through welding points. A strengthening casing pipe is fixed to the intersection position of the air pipe A and the tube nest. Small air holes of the air pipe B are formed in the upper portion, above the air pipe A, of the air pipe B. An I-shaped hood is buckled at the upper portion of the air pipe A, and I-shaped hood air outlet holes are formed in the I-shaped hood. According to the CFB boiler inlaid type hood air distributing device and the improving method thereof, welding and fixing points are broken by dismounting the hood, part of air pipes are cut, new air pipes are inserted, welding and fixing are conducted, and therefore the running resistance of an air distribution plate can be adjusted; and the problems that the air distributing uniformity is poor, temperature distribution is uneven, slag leaks in the air chamber, and the power consumption of a primary draught fan is large are solved.

Owner:山西平朔煤矸石发电有限责任公司

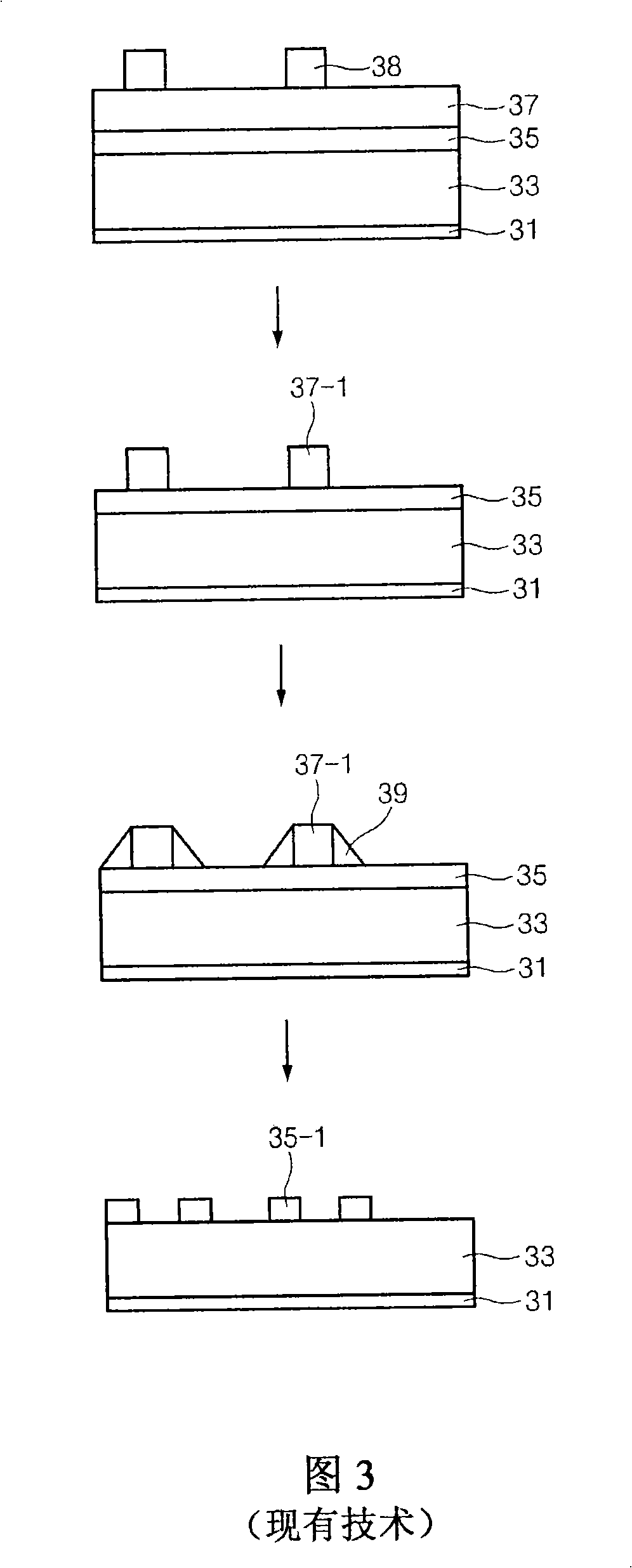

Method for formlng pattern of semiconductor device

InactiveCN101728324AAvoid damagePrevent notch phenomenonTransistorSolid-state devicesPhotoresistSemiconductor

Owner:SK HYNIX INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com