Production technique of m-bromofluorobenzene

A production process and a technology for m-fluorobromobenzene are applied in the field of production technology of m-fluorobromobenzene, can solve problems such as low reaction efficiency, complicated operation, easy to cause accidents, etc., achieve simple process steps, high reaction yield, and avoid accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with specific examples.

[0023] The processing steps of producing m-fluorobromobenzene are as follows:

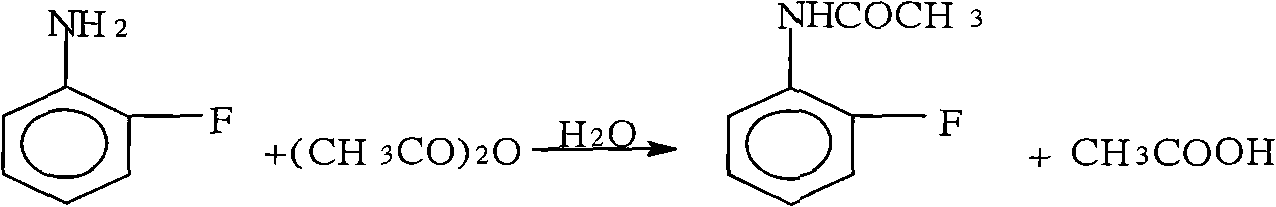

[0024] (1) Acetylation: Check that the inner wall of the bromination kettle, the stirring, and the sleeve of the thermometer are intact without porcelain drop, and close the valve at the bottom of the kettle. Add 1000kg of water and 800kg of o-fluoroaniline to the kettle, start stirring, and add 4100kg of dichloromethane. Add 875kg of acetic anhydride dropwise between 20 and 30°C, keep the temperature for 0.5h after the addition is complete.

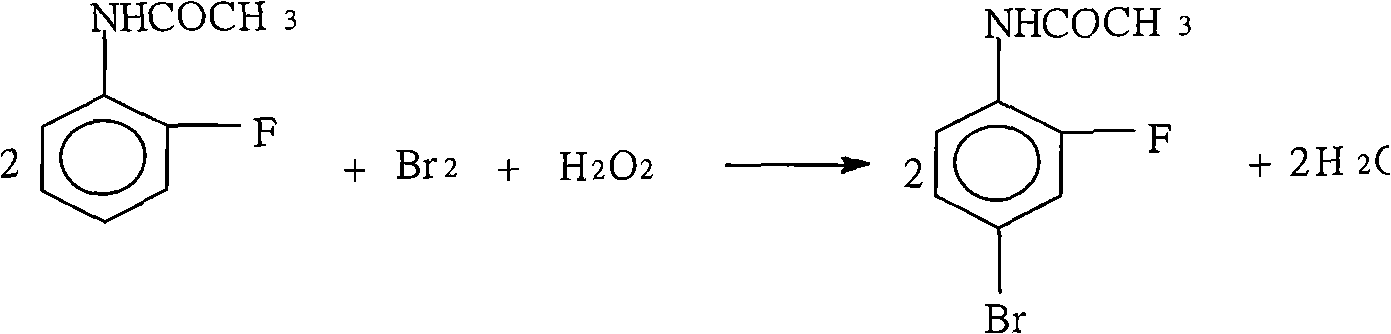

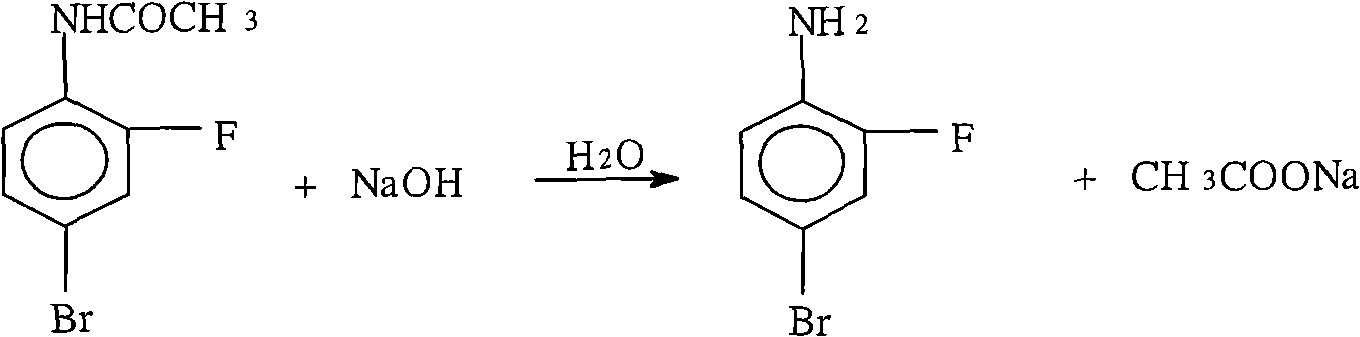

[0025] (2) Bromination: Add 673kg (217L) of bromine dropwise into the bromination kettle at a rate of 15-20L / h, control the temperature of the kettle at 25-30°C, and keep the temperature for 0.5h after the addition is complete. Add 465kg of 27% hydrogen peroxide dropwise into the bromination kettle, control the temperature of the kettle at 25-35°C, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com