Patents

Literature

85results about How to "Settlement yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing levulinic acid and co-producing gamma-valerolactone from biomass

InactiveCN103435577AAvoid emissionsAvoid separationOrganic compound preparationCarboxylic compound preparationSolid acidGamma-Valerolactone

The present invention provides a method for preparing levulinic acid and co-producing gamma-valerolactone from biomass. The method comprises: mixing biomass and a gamma-valerolactone aqueous solution according to a weight ratio of the biomass to the gamma-valerolactone of 1:5-1:200, and dissolving the biomass under a heating condition; adding a solid acid catalyst to the filtrate to prepare levulinic acid; and adding a Ru, Ni or Pt base catalyst to prepare gamma-valerolactone. According to the present invention, after cellulose and hemicellulose in the biomass are dissolved in the gamma-valerolactone, the contact area with the solid acid is substantially increased so as to improve reaction efficiency and a product yield; the solid acid can be reused after recycling, such that waste acid emission can be avoided, cost can be reduced, and pollution on the environment can not be caused; the final product is the gamma-valerolactone so as to avoid separation of the product and the solvent; and difficult problems of low product yield, easy catalyst deactivation and low product separation cost due to existing of a large amounts of water during a levulinic acid and gamma-valerolactone preparation process using biomass in the prior art are solved.

Owner:TIANJIN UNIV

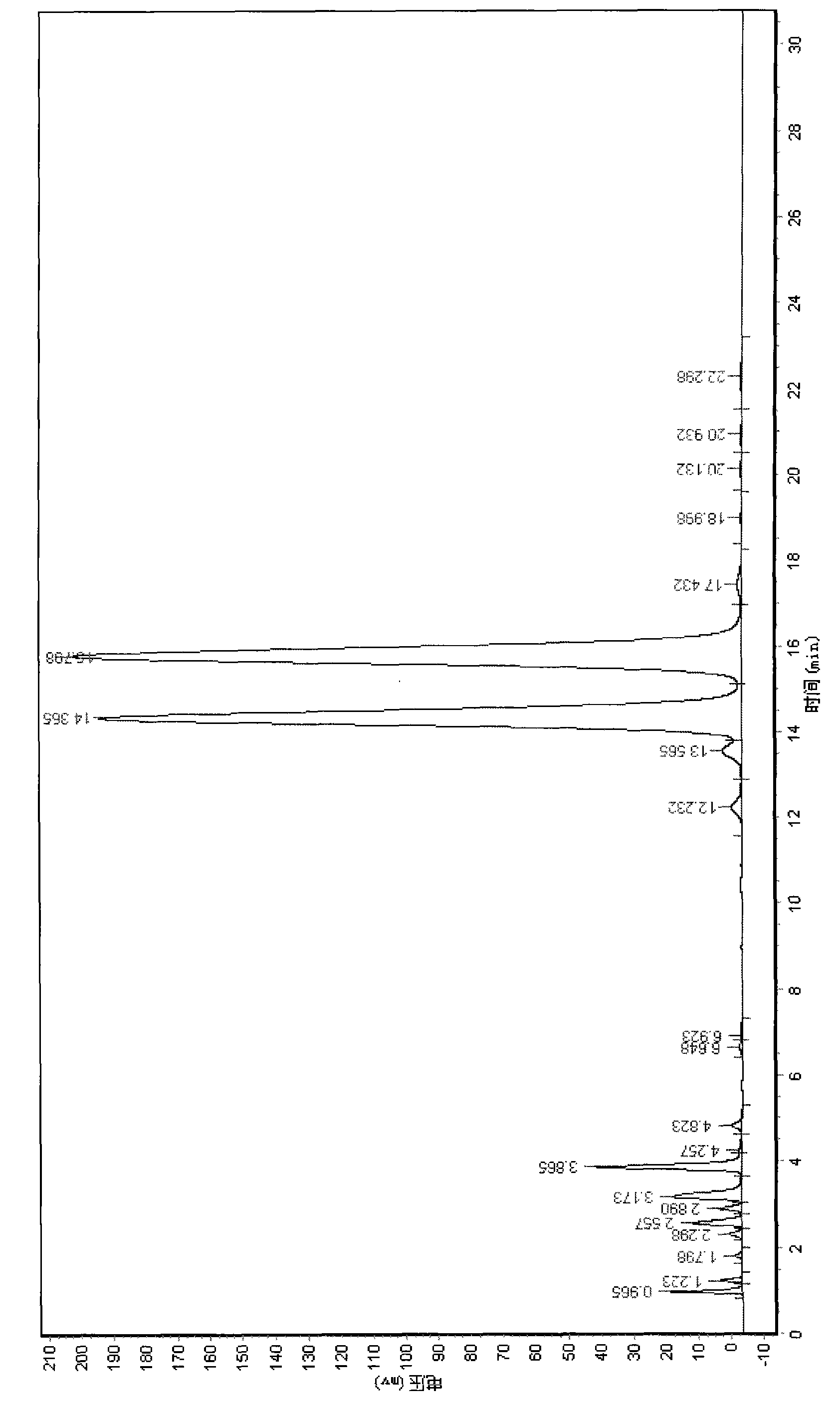

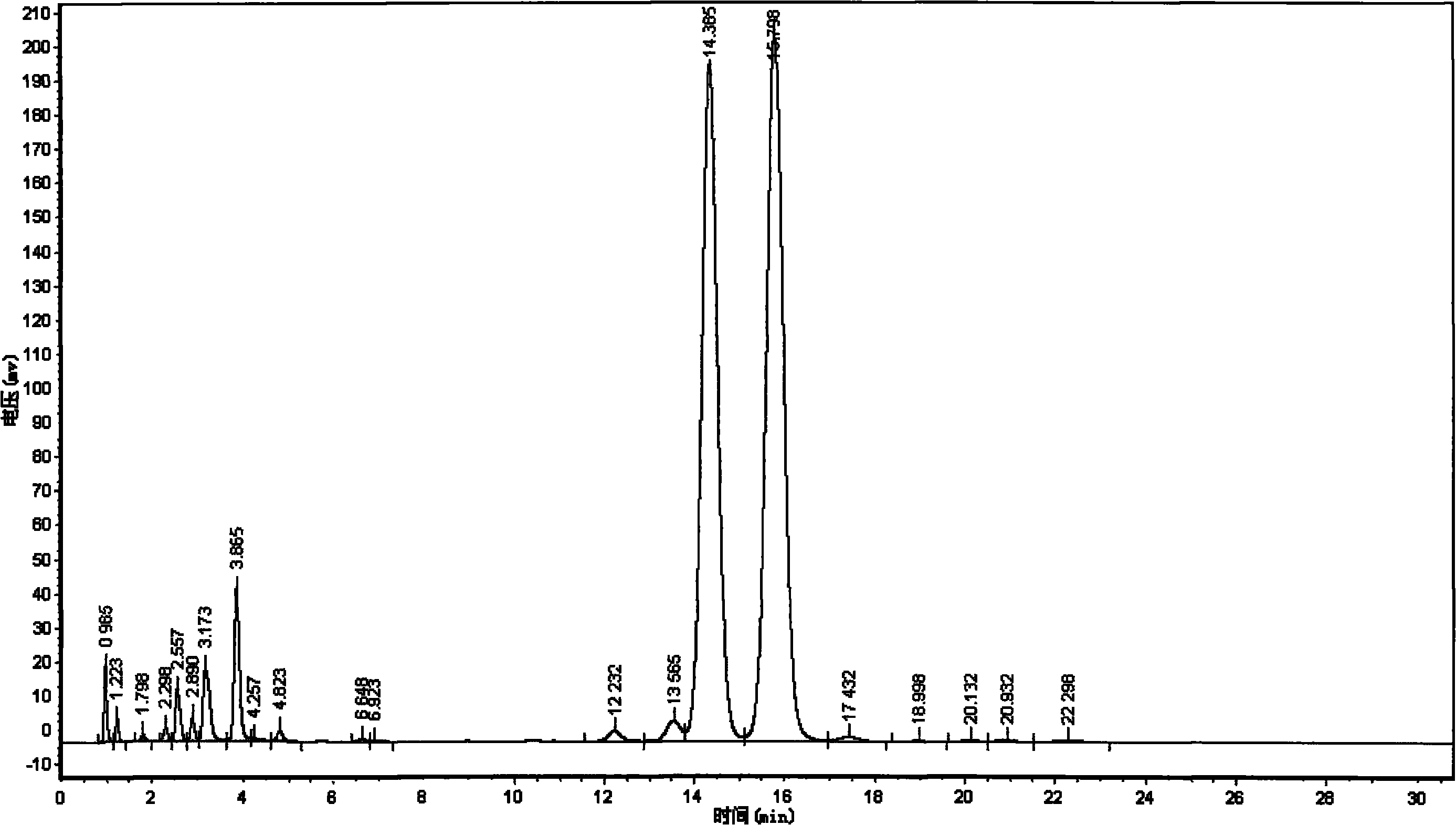

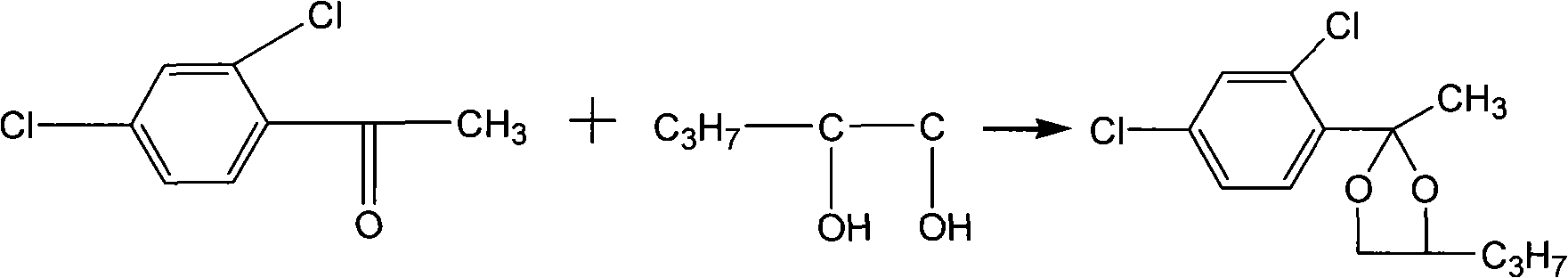

New method for producing propiconazole

ActiveCN101781290ASolve the problems of long reaction time, high water content and sticky materialsSimple processOrganic chemistryPropiconazoleBromine

The invention discloses a new method for producing propiconazole, comprising the following steps of: cyclizing 2,4-dichloroacetophenone and 1,2-pentanediol, brominating with bromine to generate 2-brooethyl-(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane, then condensing with 1,2,4-tolyltriazole sylvite to prepare a crude product, and desolventizing, washing and distilling the crude product in vacuum to obtain the propiconazole. When the brominating reaction is carried out after the cyclizing reaction is finished, the bromine is added for twice, firstly the bromine accounting for 1%-10% of the total weight of the bromine is added in a reaction system for brominating induction reaction, and then the residual bromine is added. The bromine is added for twice during brominating reaction, firstly the bromine accounting for 1%-10% of the total weight of the bromine is added for initiating the whole system, the brominating induction reaction guides the direction of the brominating reaction so that monobromides and dibromides generating ketone due to the repeated resolution of cyclized matter are reduced, and finally the method achieves the purpose of improving the yield of the brominating reaction; and the conversion rate of the bromides is high and can be greater than 97%.

Owner:利民化学有限责任公司

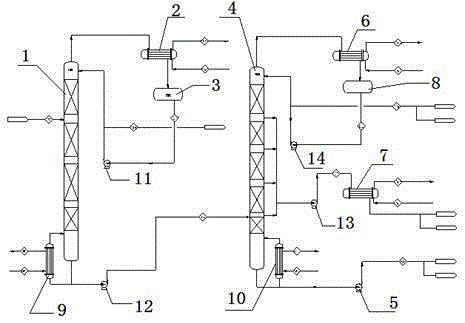

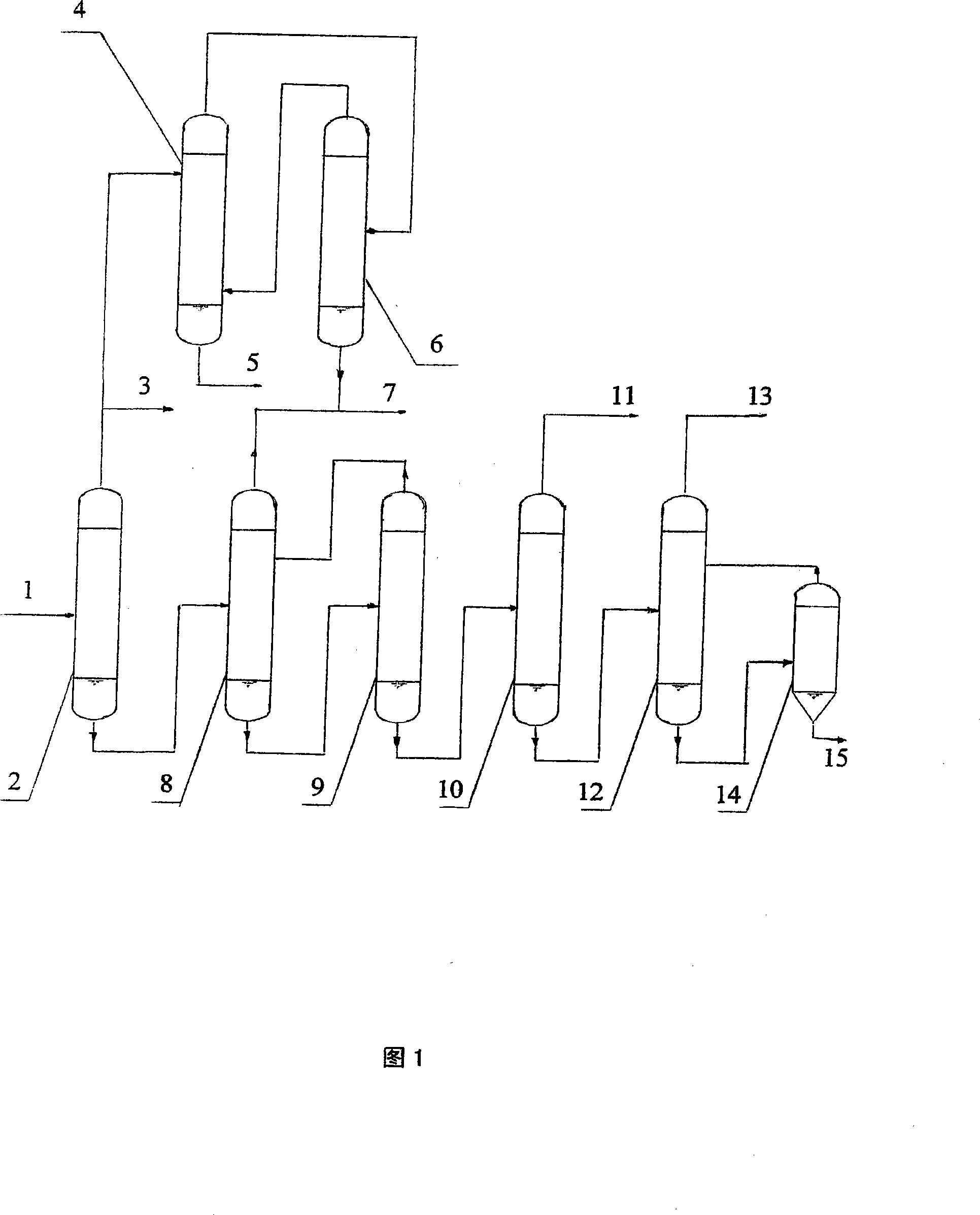

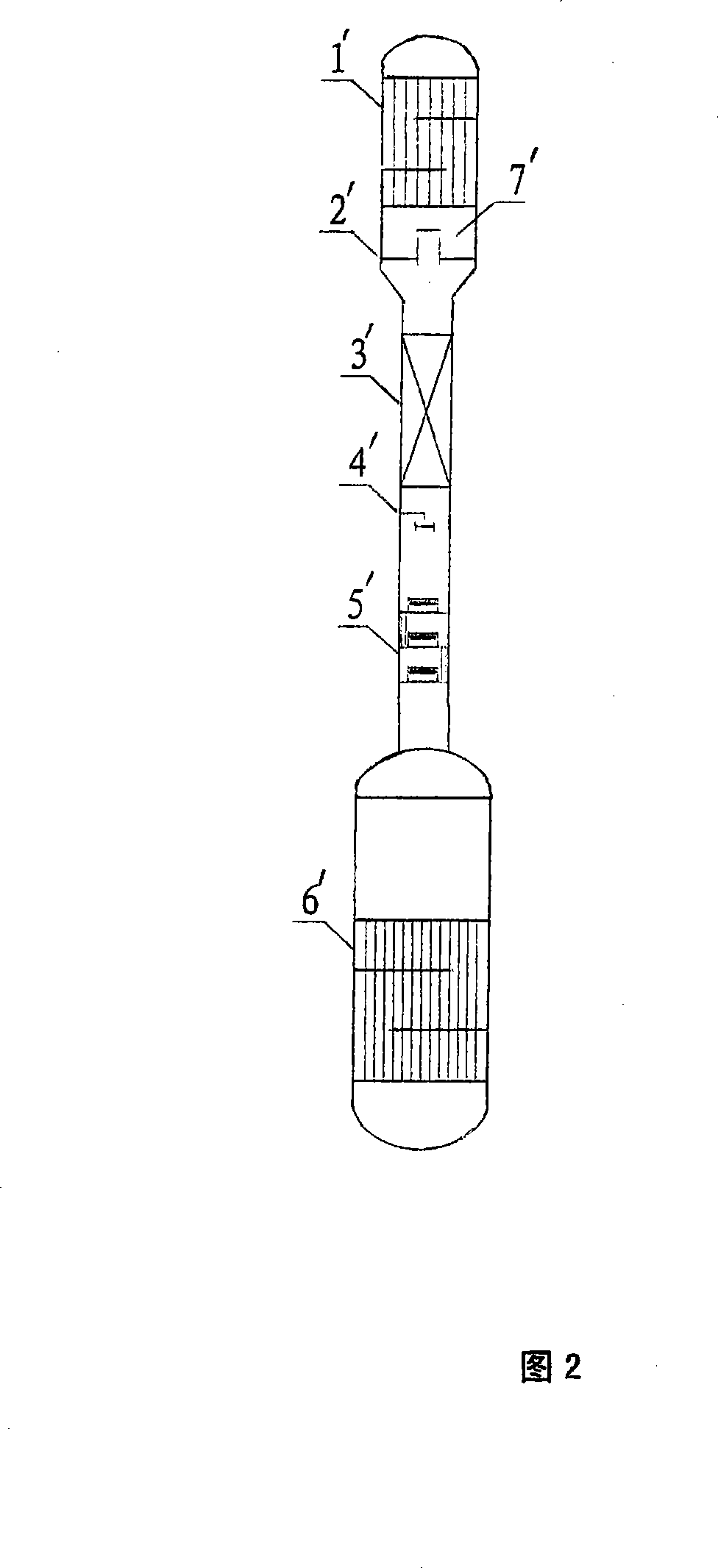

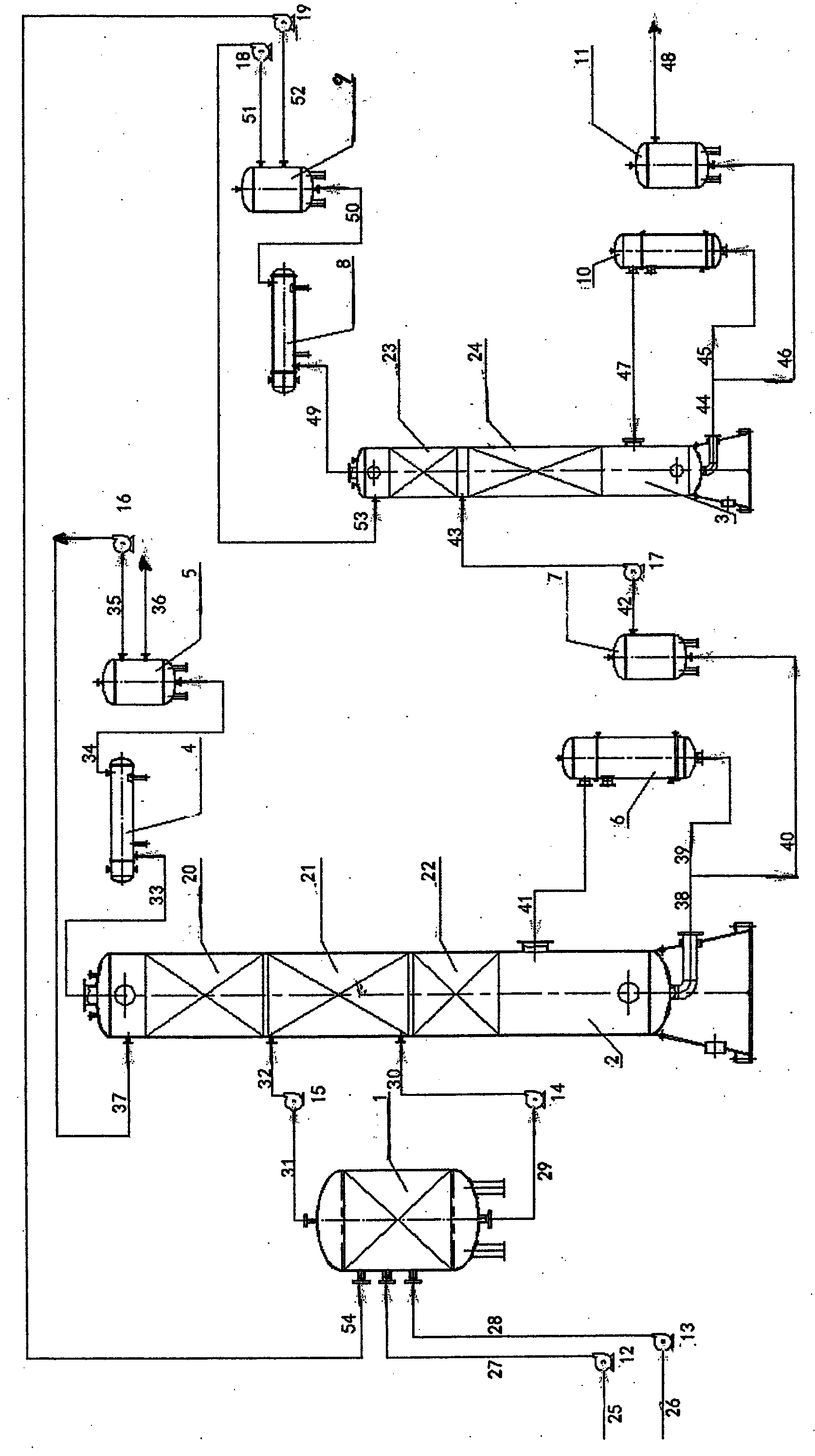

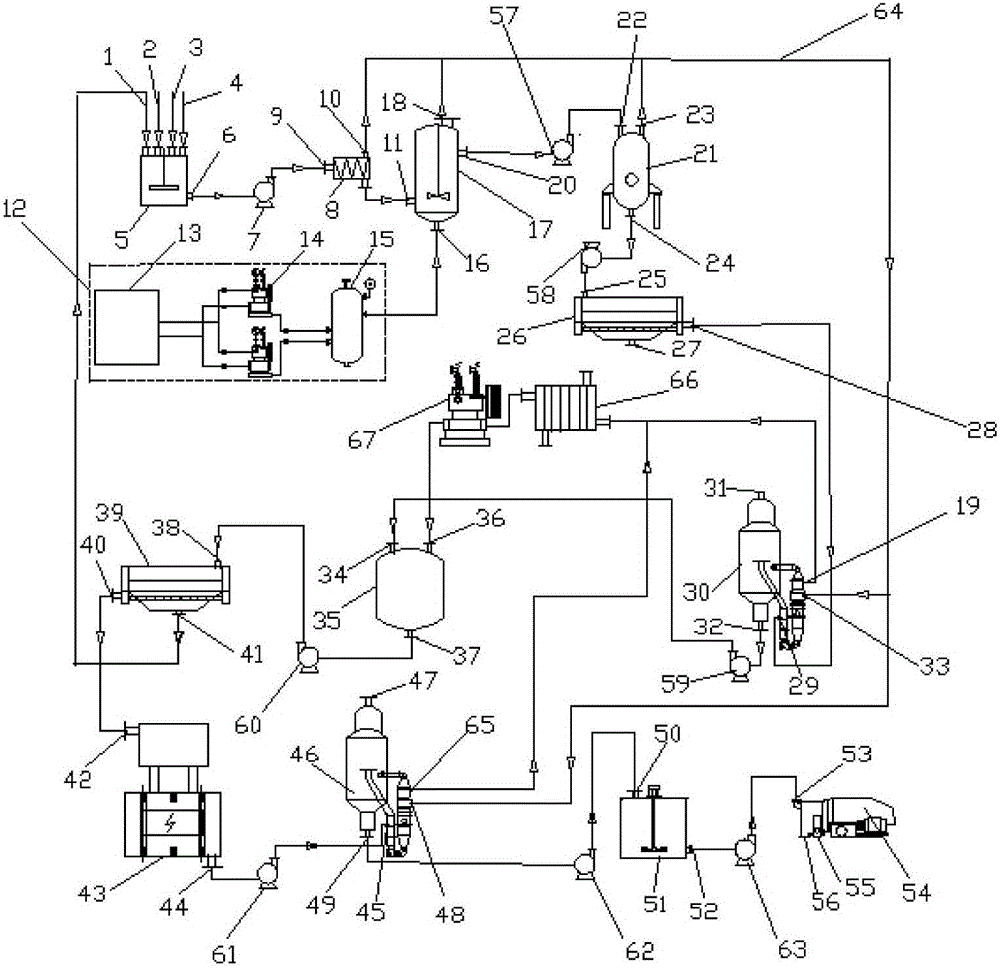

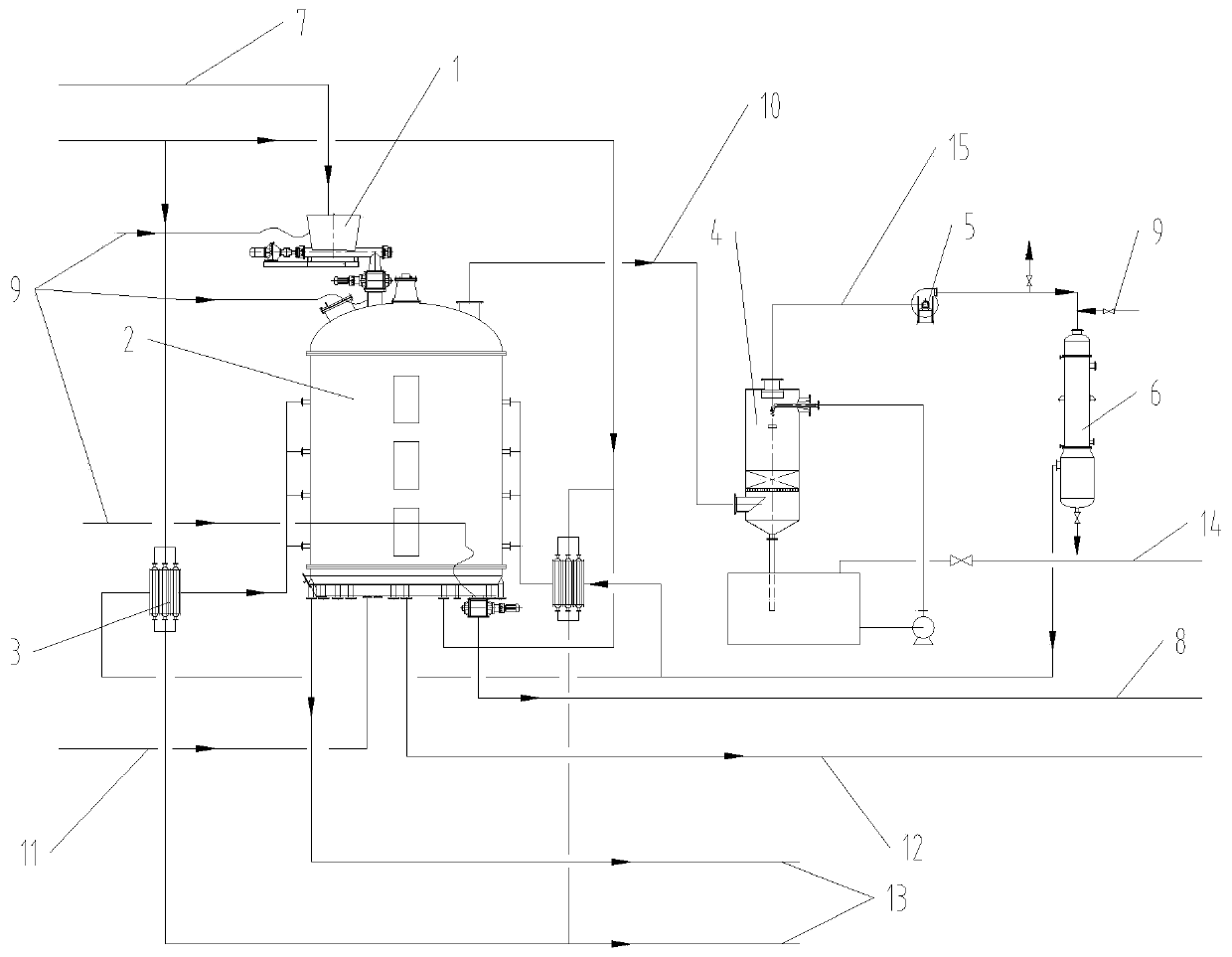

Refining purifying device and method used for continuously producing battery grade dimethyl carbonate

ActiveCN105384639AAddressing Purity IssuesSettlement yieldCarbonic/haloformic acid esters purification/separationHigh energyReboiler

The invention relates to a refining purifying device and method used for continuously producing battery grade dimethyl carbonate. The device is characterized in that the top of a light component removal column is connected with an overhead condenser; the overhead condenser is connected with the light component removal column by a first reflux drum and a first reflux pump and is connected with a light component removal outlet; the bottom of the light component removal column is connected with a first reboiler; the first reboiler is used for conveying raw materials subjected to light component removal to a rectifying column via a column reactor pump; the rectifying column is connected with a second reflux drum by a rectifying column condenser; the second reflux drum is connected with the rectifying column by a second reflux pump; the bottom of the separate column reactor is connected with a second column reactor pump by a second reboiler; the middle part of the separate column reactor is connected with a side condenser by a side withdrawing pump. The device and the method have the beneficial effects that the problems of low product purity, low yield, high energy consumption and generation of solid waste pollutants in traditional production processes are solved; the purity of the dimethyl carbonate product is improved 99.99% or more after removing light components by the light component removal column and then carrying out purifying refining by the rectifying column.

Owner:DONGYING HI TECH SPRING CHEM IND

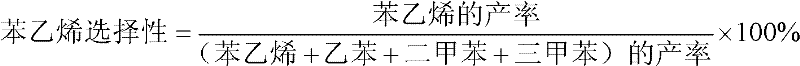

Alkaline molecular sieve catalyst for preparation of styrene, and preparation method thereof

InactiveCN102380413AHigh catalytic activityHigh yieldMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAlkyl transfer

The invention discloses an alkaline molecular sieve catalyst for preparation of styrene, and a preparation method thereof. The alkaline molecular sieve catalyst adopts an IM-5 molecular sieve as a carrier, and can carry at least one of compounds containing alkali metal, alkaline earth metal, B, P, Zn or Fe through an ion exchange method and an immersion method. The alkaline molecular sieve catalyst has good catalytic performances and high stability, can be utilized for side chain alkylation reaction of toluene and methanol, and solves the problems that based on the prior art, a styrene yield is low; a molecular sieve structure is easy to be destroyed; and catalyst stability is poor.

Owner:SHANGHAI HUAYI GRP CO

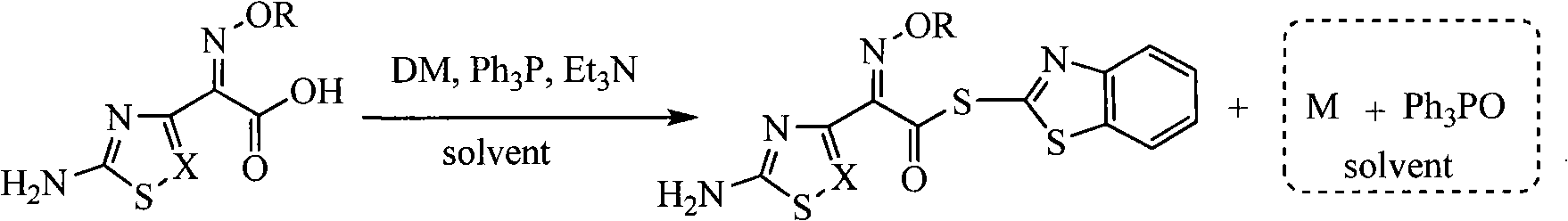

Process for recovering triphenyl phosphine oxide and 2-mercaptobenzothiazole from production waste liquid of cephalothin active ester

The invention discloses a method for recycling triphenyl phosphine oxide and 2-mercaptobenzothiazole from the production waste liquid of cephalosporin active ester, which includes the following steps: 1 to 10 percent sodium hydroxide solution is added drop by drop into the production waste liquid of the cephalosporin active ester under 0 to 80 DEG C; the pH value of the system is adjusted to be 10 to 12, and then the waste liquid is mixed fully for 0.5 to 6 hours, standing still and layering; an organic layer is decompressed to recycle an organic solvent; the solid waste slag is recrystallized directly to obtain the triphenyl phosphine oxide; the 2-mercaptobenzothiazole is extracted and obtained from water layer by a using acid neutralization method. The recycling method of the invention has the advantages of the simple operation, the high recycling rate, the good product purity, the good atom economy, etc., which effectively solves the problems existing in the prior art, such as the complicated operation, the high energy consumption, the low yield rate, the serious environment pollution, etc., thus having a wide implementary value and potential social economic benefits.

Owner:ZHEJIANG UNIV OF TECH +2

Extraction technology of artemisinin

The invention relates to an extraction technology of artemisinin, and belongs to the technical field of natural plant extraction. The extraction technology comprises the following steps: (1) drying raw materials: putting the raw materials in a drying facility to dry the raw materials; (2) primary preparation of artemisinin: putting the dried raw materials in an extraction tank, adding petroleum ether into the extraction tank, heating, carrying out reflux extraction, discharging the liquid extract from the extraction tank after the reflux extraction, allowing the liquid extract to stand still for a while, collecting the supernate, making the supernate go through a silica gel column, then washing the silica gel column by petroleum ether, collecting the fractions containing artemisinin, transferring the fractions to a condensing tank, condensing the fractions, transferring the condensed liquid to a crystallization tank when the liquid in the condensing tank start to crystallize, carrying out crystallization in the crystallization tank, filtering to obtain the crystals, and drying the crystals so as to obtain crude artemisinin; (3) artemisinin refinement: placing the crude artemisinin in an alcohol-precipitation tank, dissolving the crude artemisinin by ethanol with a concentration of 85-95%, wherein the volume of the ethanol is 60 to 70 times of that of the crude artemisinin, allowing the solution to stand still for a while, collecting the supernate, subjecting the supernate to fine filtration, transferring the filtrate to a condensing tank, condensing the filtrate, allowing the condensed filtrate to stand still so as to carry out crystallization, filtering to obtain the crystals, and finally drying the crystals in vacuum so as to obtain refined artemisinin.

Owner:QINGDAO ZHONGREN ZHIYE BIOTECH

Method for separating catechol/hydroquinone from phenol hydroxylation reaction solution

ActiveCN101225025AImprove liquidityAvoid carbonizationOrganic chemistryOrganic compound preparationReboilerHydroquinone products

The invention discloses a method of separating catechol / hydroquinone in phenol hydroxylation reaction solution, which is characterized in that: phenol and hydrogen peroxide are reacted under catalyst action to produce reaction solution comprising water, phenol, catechol, hydroquinone and tar; vacuum rectification dehydration, de-phenol, catechol separating, hydroquinone separating and tar removing are made upon the reaction solution to prepare the catechol and the hydroquinone product; thermal medium oil independent circulation stepwise condensation / heat mode is adopted for the distillation system separating the catechol and the hydroquinone; vertical sieve plate is adopted for stripping section of the distillation tower; high-efficiency structured packing is adopted for the distillation section; embedded type structure in the tower is adopted for the condenser and the reboiler of the distillation tower. The method of separating catechol / hydroquinone in phenol hydroxylation reaction solution has the advantages of solving the problems of difficultly liquefying the catechol and the hydroquinone for the condenser at the top part of the distillation tower and easily causing material condensing or gasifying due to small difference value between the boiling point and the freezing point during vacuum rectifying for the catechol and the hydroquinone, prolonging production period, lowering unit consumption of product and reaching more than 99% for product purity of the catechol and the hydroquinone.

Owner:SHANGHAI HUAYI NEW MATERIAL

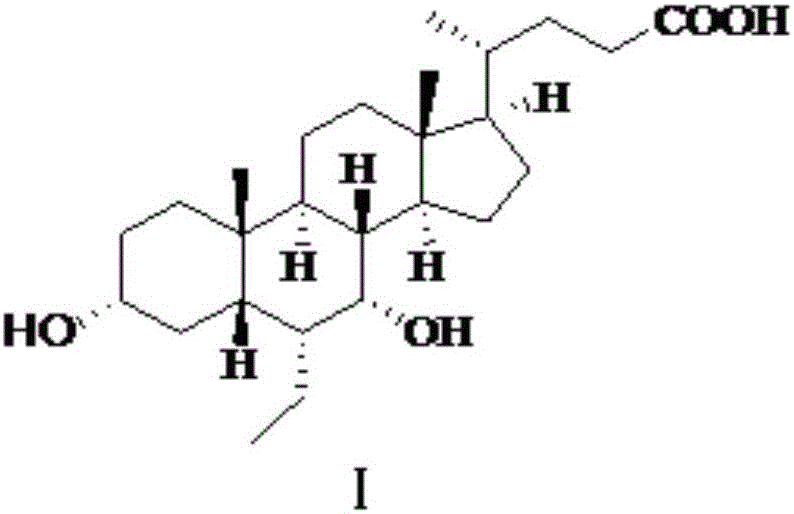

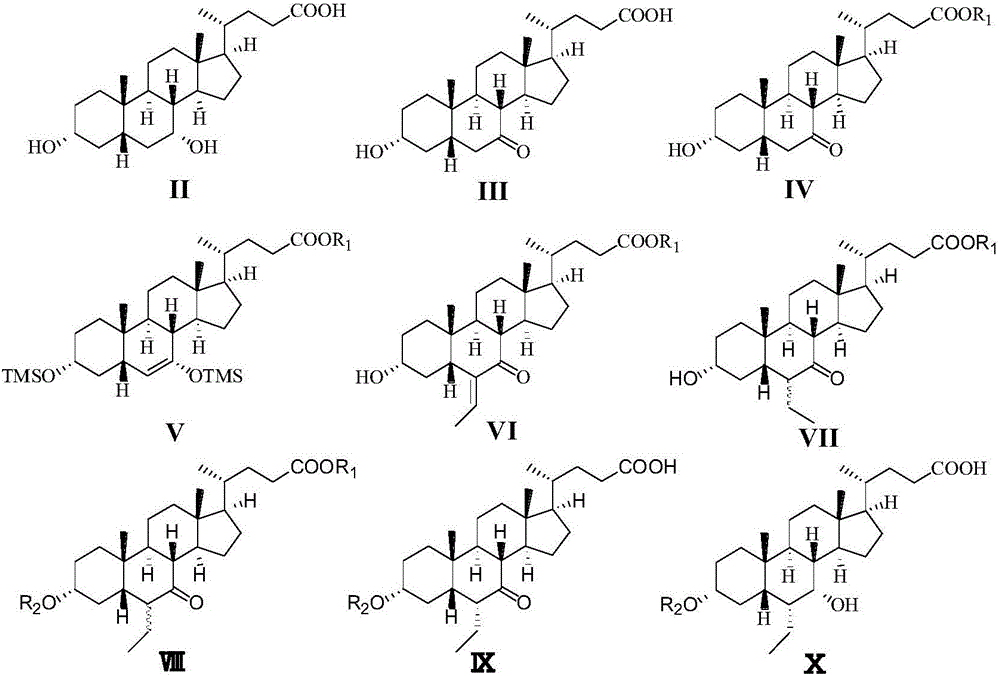

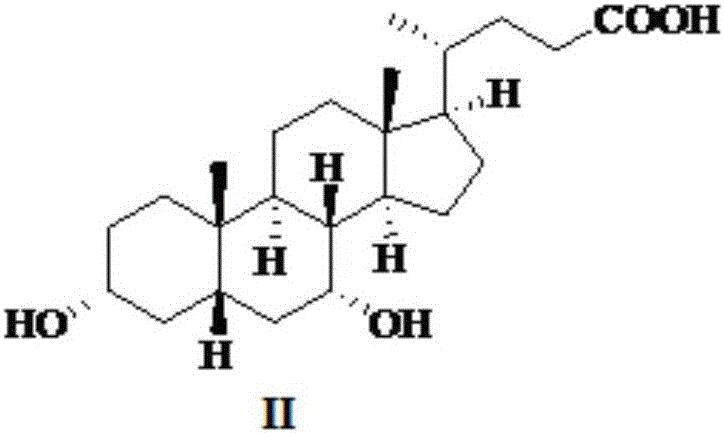

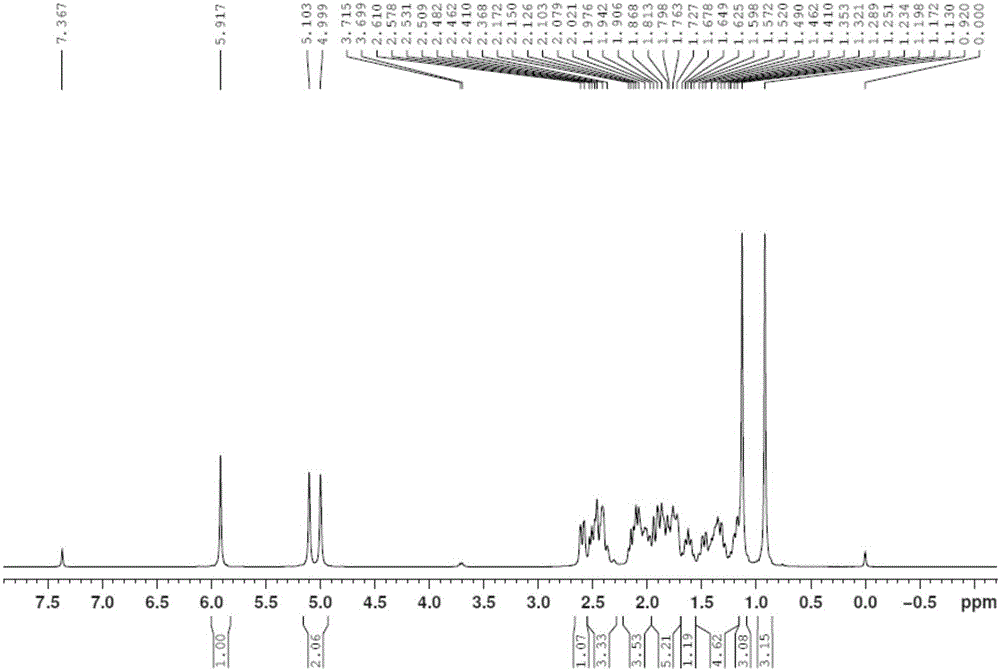

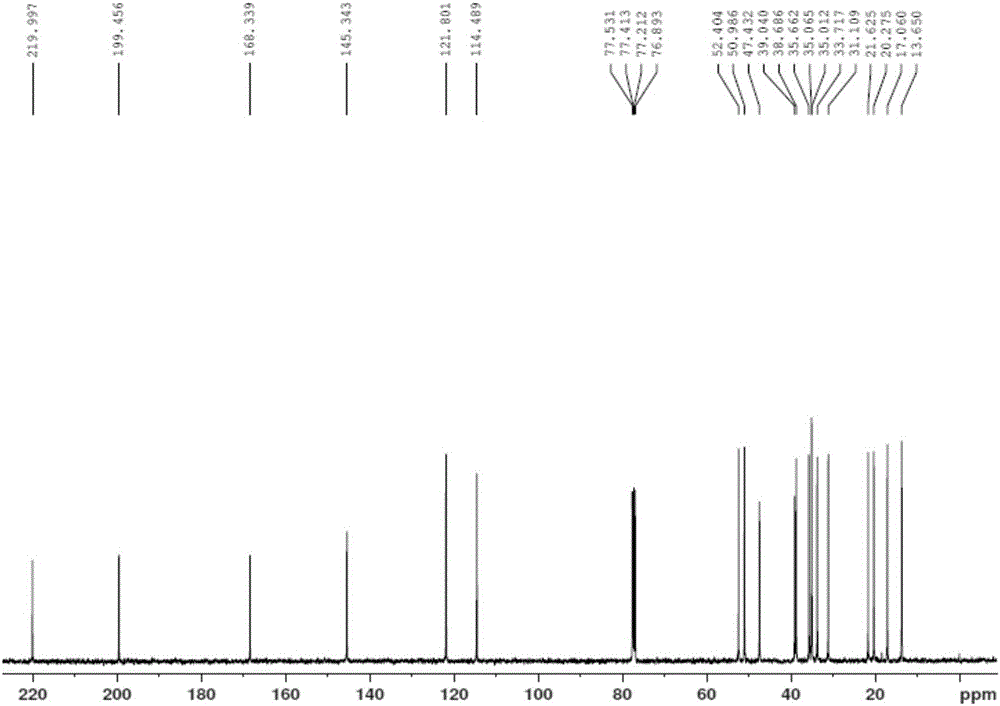

Synthesis method of obeticholic acid

InactiveCN106279336AHigh yieldLess impuritiesSteroidsBulk chemical productionSynthesis methodsCarboxylic acid

The invention discloses a synthesis method of obeticholic acid. The synthesis method takes 3alpha,7alpha-dihydroxyl-5beta-cholestane-24-acid as a starting material and comprises the following steps: carrying out hydroxyl oxidation and carboxylic acid ethyl esterification, and reacting with trimethylsilyl chloride to synthesize silyl enol ether; then enabling the silyl enol ether and acetaldehyde to subject to Mukaiyama hydroxyaldehyde condensation to obtain 6-ethylidene-3alpha-hydroxyl-7-one-5beta-cholestane-24-ethyl; carrying out catalytic hydrogenation, hydroxyl protection and ester group hydrolysis; carrying out selective reduction through sodium borohydride; finally, carrying out de-protection to obtain the obeticholic acid. By optimizing synthesis steps and selecting different protection reagents to protect hydroxyl and carboxyl for a plurality of times, and adopting a selective hydrogenation reduction reaction, the problems in a synthesis reaction of the obeticholic acid that more impurities are caused, a structure is easy to overturn, the yield in a 6alpha-ethylation process is low, purification is difficult to realize and the like are effectively solved; the total yield of an obeticholic acid product is greatly improved; the synthesis method has good economical efficiency and is suitable for industrial production.

Owner:合肥诺瑞吉医药科技有限公司

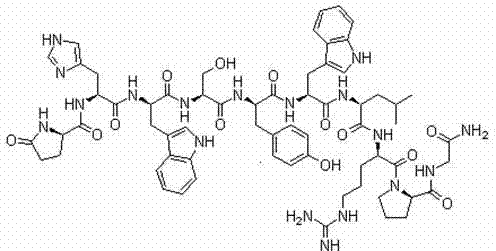

Cetrorelix purification and separation method

InactiveCN107312073AEfficient separationHigh yieldLuteinising hormone-releasing hormonePeptide preparation methodsFreeze-dryingEvaporation

The invention discloses a cetrorelix purification and separation method. The method includes steps: dissolving a crude product of cetrorelix in acetonitrile water solution, and filtering through a filter membrane to obtain crude solution for standby application; adopting a mobile phase A for balancing a reversed phase column, loading the crude solution into the reversed phase column, performing gradient eluting for separation and purification, wherein the mobile phase A refers to sodium dihydrogen phosphate aqueous solution, and a mobile phase B refers to acetonitrile; subjecting target peptide solution with purity higher than 99.5% to vacuum rotary evaporation and concentration at a water temperature not higher than 38 DEG C; adopting acetic acid aqueous solution for balancing the reversed phase column, loading a sample of concentrated liquid into the reversed phase column, and adopting an acetic acid aqueous solution / acetonitrile system for salt conversion; subjecting the converted acetate and the target peptide solution with purity higher than 99.5% to vacuum rotary evaporation and concentration at a water temperature not higher than 38 DEG C, and performing freeze drying to obtain powdery cetrorelix. The obtained cetrorelix is high in purity and yield, meets industrial production requirements and has a high economic value and a promising application prospect.

Owner:ZHEJIANG PEPTITES BIOTECH CO LTD

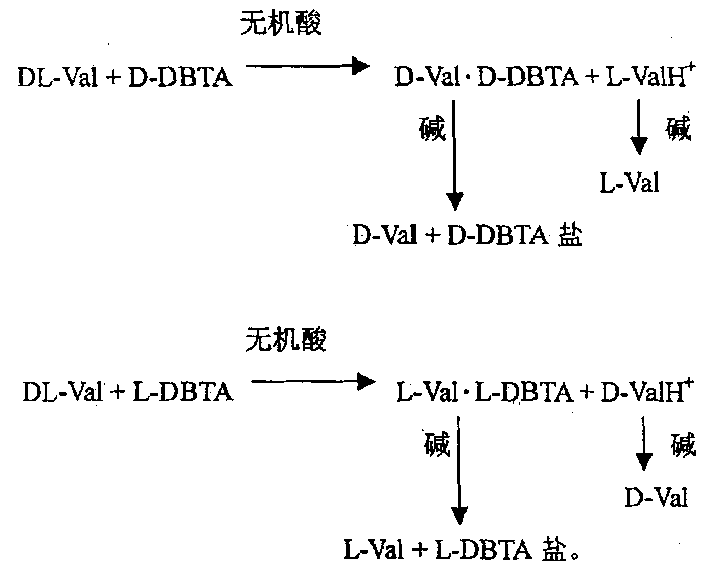

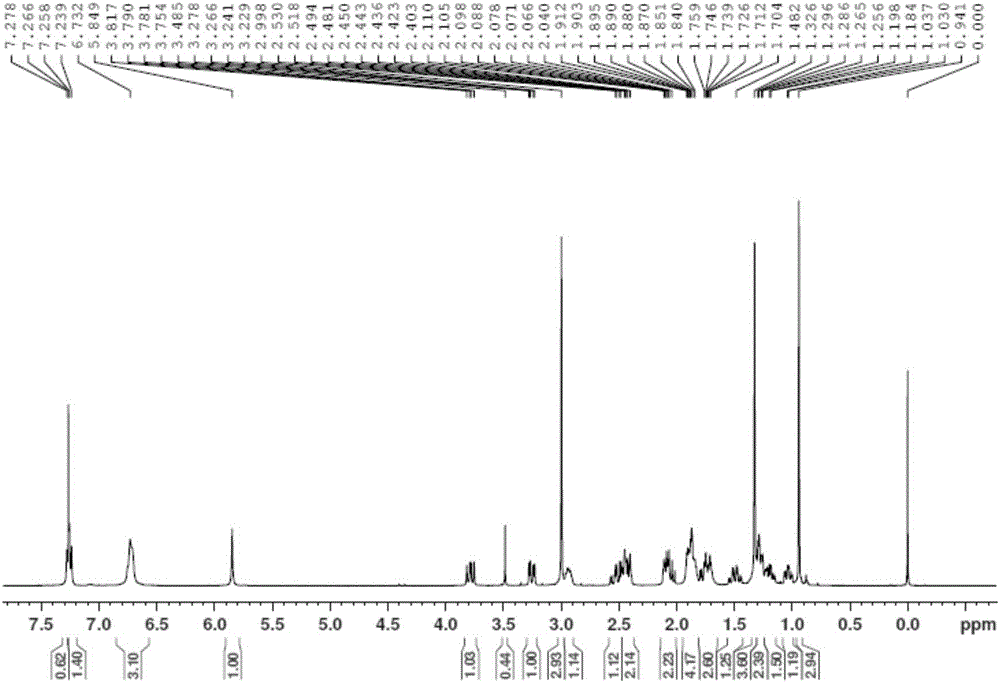

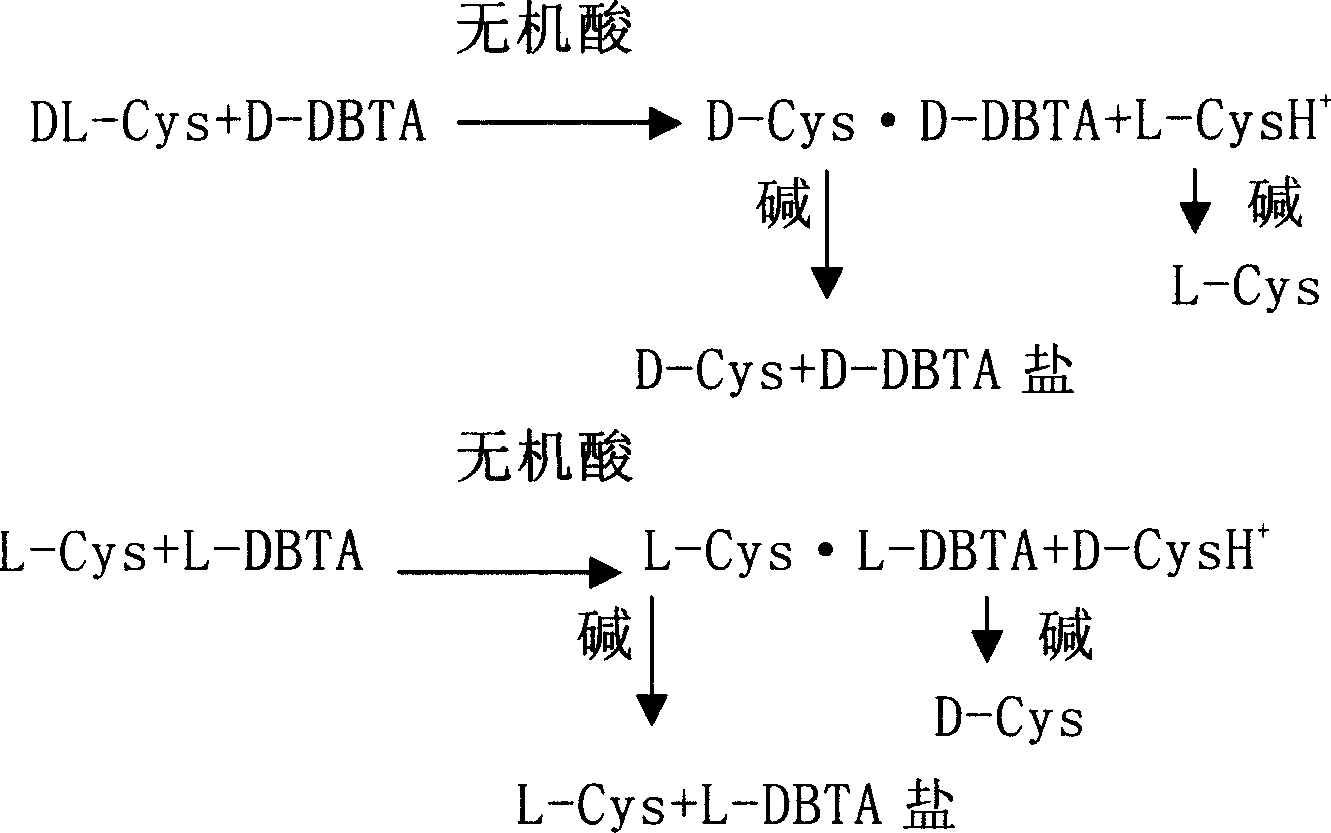

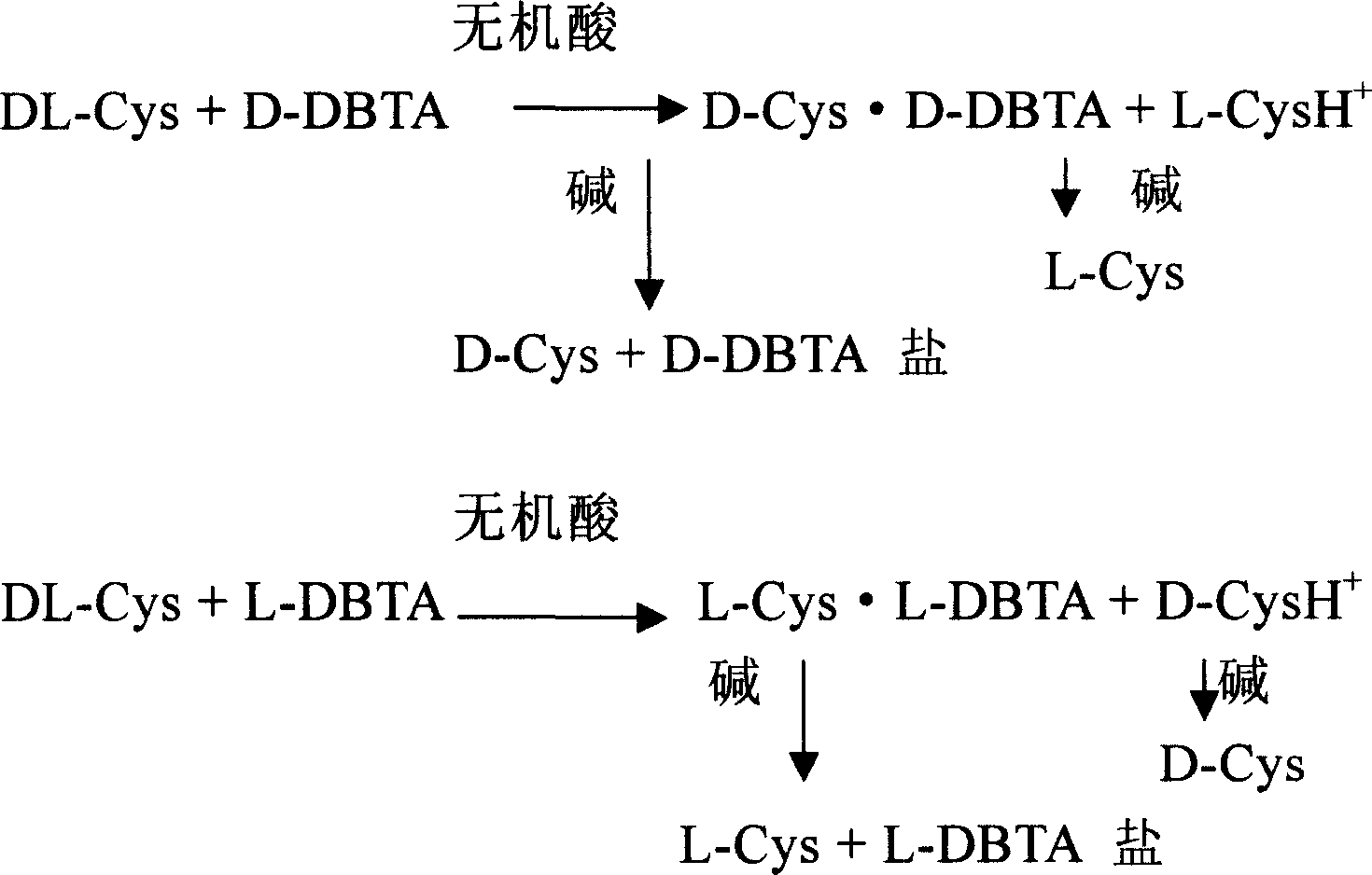

Methof for preparing l-valine and d-valine by using chemical resolution process

InactiveCN1477096AReduce dosageReduce pollutionOrganic compound preparationAmino-carboxyl compound preparationAlcoholSolvent

The present invention uses racemic valine (DL-Val) as raw material, uses inorganic acid as solvent, uses dextral dibenzoyl tartaric acid (D-DBTA) and levo-dibenoyl tartaric acid (L-DBTA0 as resolution agent according to the ratio of 1:0.5-1.2 in dilute inorganic solution, stirring for 0.5-2.0 hr. at 60-100 deg.C, then progressively cooling to room temp., filtering out crystal salt, using alkali to neutralize said crystal salt and mother liquor respectively in water and ethyl alcohol so as to respectively obtain the invented dextral valine (D-Val) and levo-valine (L-Val).

Owner:SOUTHEAST UNIV

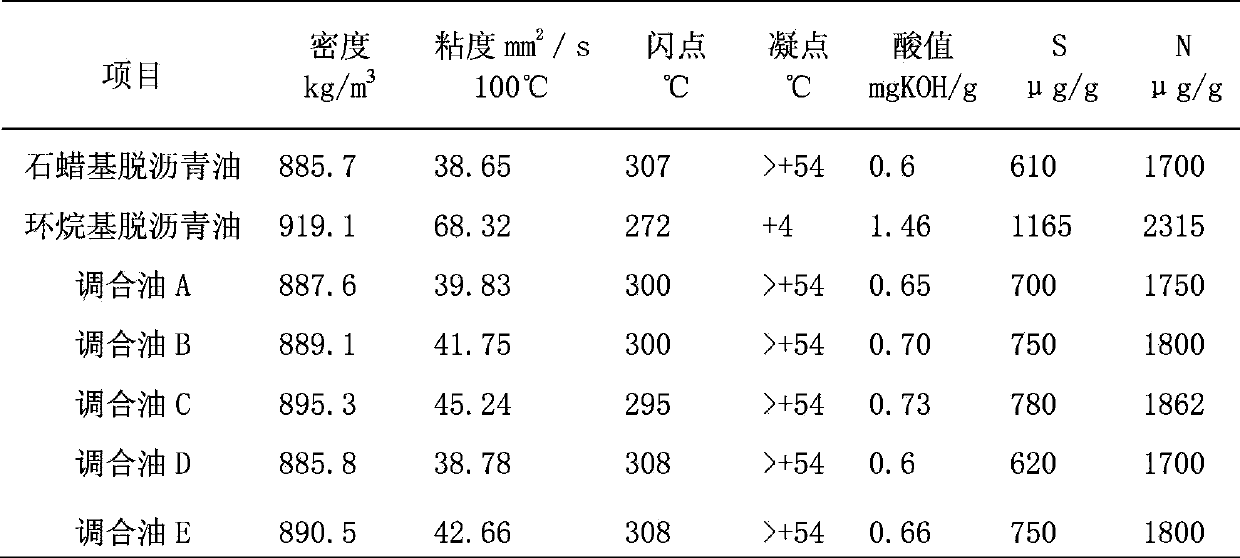

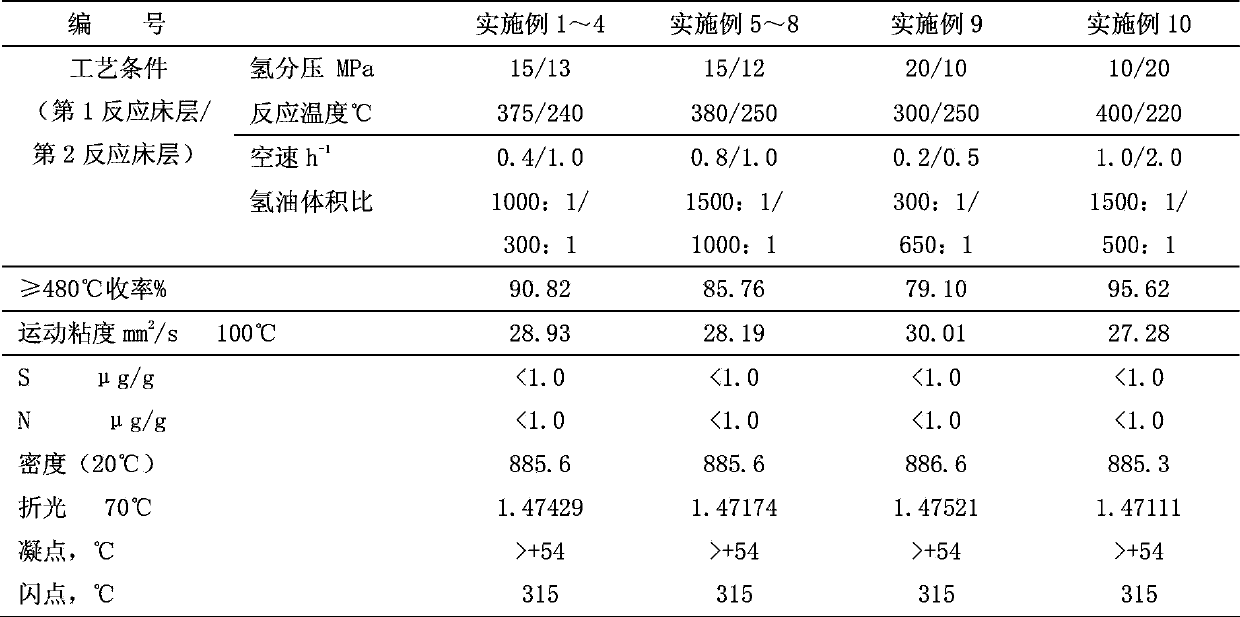

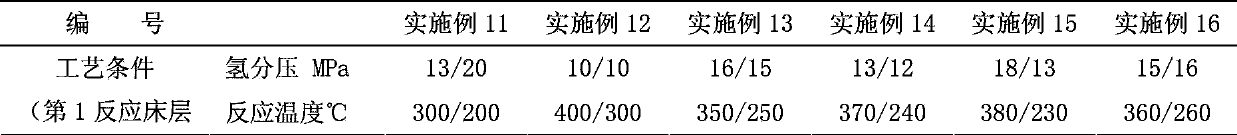

Preparation method of food-grade microcrystalline wax

InactiveCN103865580AExtended service lifeChange the rate of the hydrogenation reactionPetroleum wax refiningMicrocrystalline waxSlag

The invention relates to a preparation method of food-grade microcrystalline wax. The preparation method comprises the following steps that blended oil comprising paraffin-based slag-reduced deasphalted oil and naphthenic base slag-reduced deasphalted oil is used as a raw material, is fed into a first reaction bed layer and then undergoes a hydrotreatment modification reaction; the reaction product is fed into a stripping tower and the stripped product is fed into a second reaction bed layer and undergoes a hydrofining reaction to produce hydrofined product oil; the hydrofined product oil is cut by atmospheric and vacuum fractionation equipment to form a heavy lubricant component having a temperature of 480-750 DEG C; the heavy lubricant component and an acetone-benzol dewaxing solvent are mixed; the mixture is cooled to below -15 DEG C; the cooled mixture is filtered so that dewaxed filtrate and deoiled wax are obtained; the deoiled wax is mixed with carclazyte by stirring; and the mixture is filtered so that the carclazyte is removed and the food-grade microcrystalline wax is obtained. The food-grade microcrystalline wax has Seybolt color number greater than +25, a drop melting point of 67-92 DEG C, a needle penetration degree of 15-35(1 / 10mm), oil content of 0.85-3.0%, sulfur and nitrogen content less than 1 microgram per gram and heavy metal and arsenic content less than 1mg / kg.

Owner:PETROCHINA CO LTD

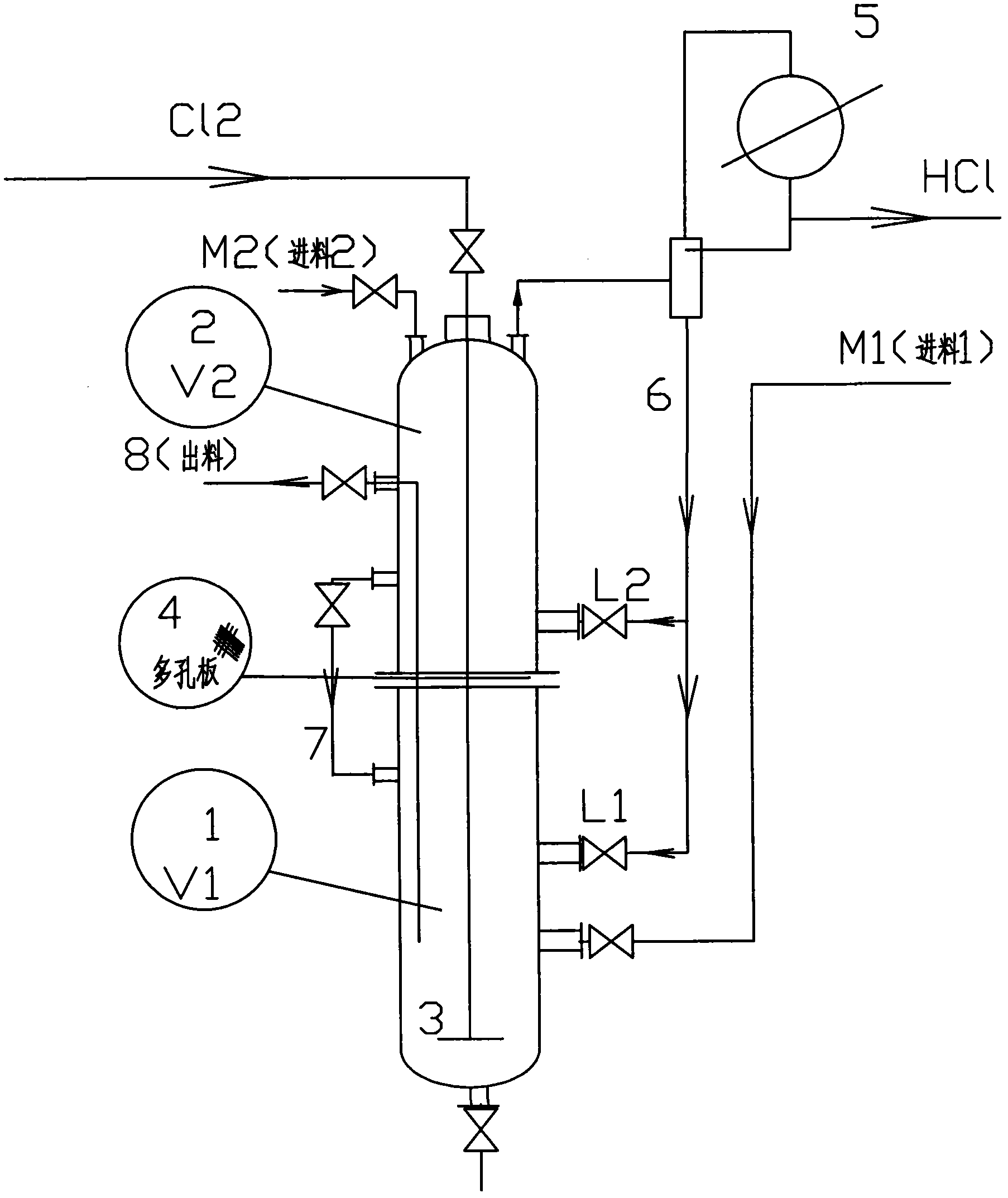

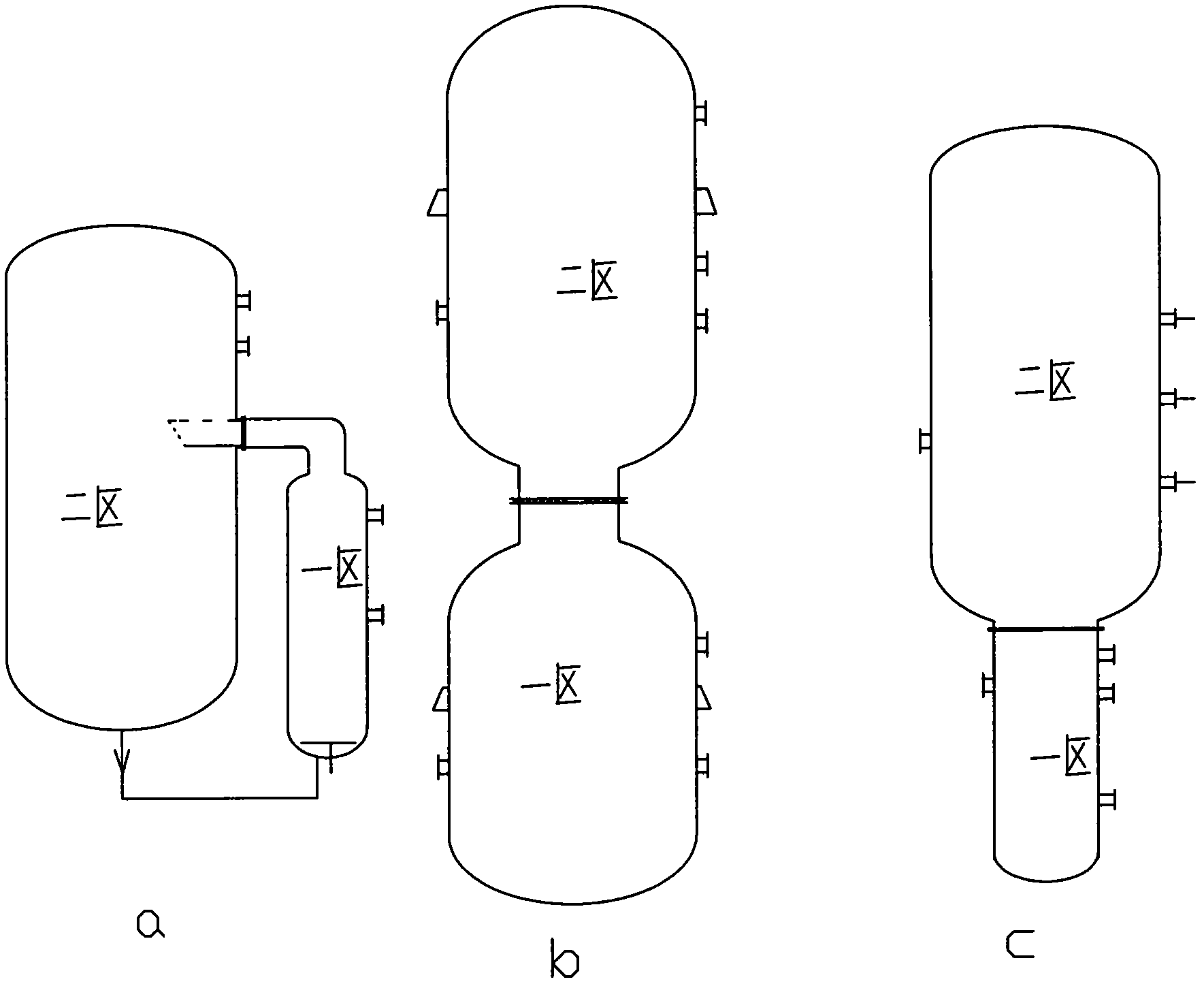

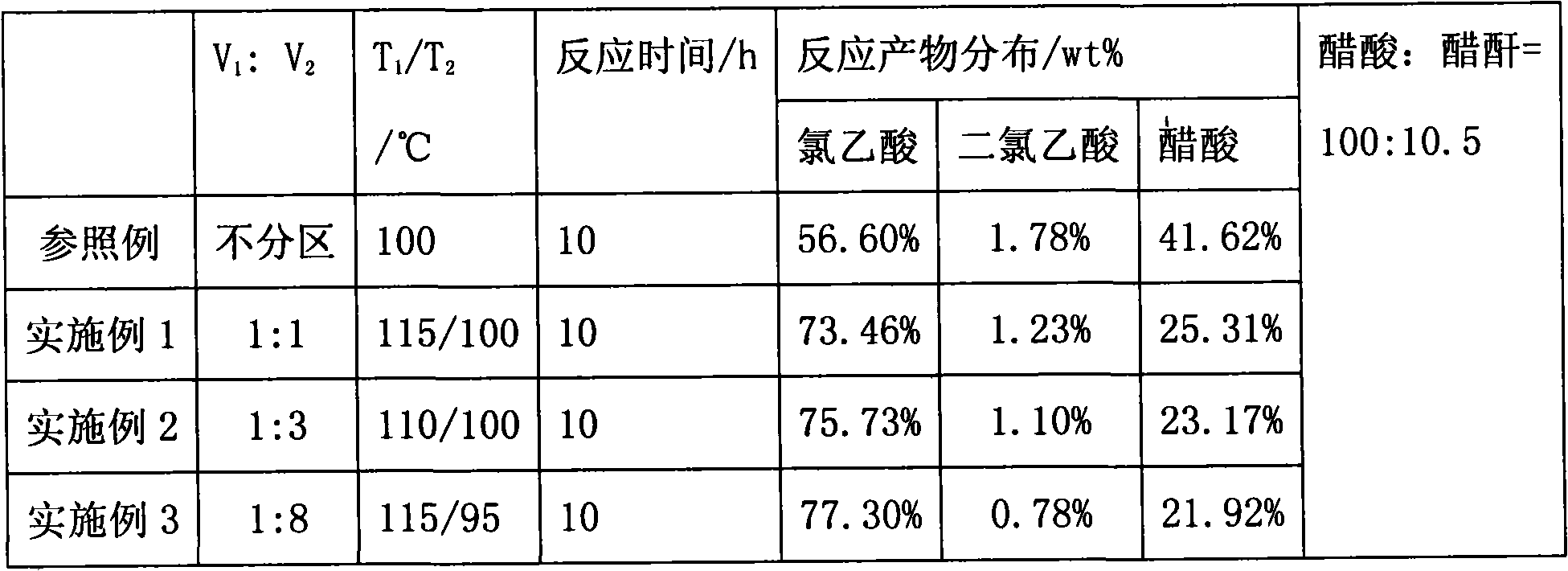

A kind of acetic acid chlorination reactor and reaction process method

InactiveCN102274708APromote absorptionQuick responseOrganic compound preparationCarboxylic compound preparationAcetic acidHigh energy

The invention discloses an acetic acid chlorination reaction process and a complete reactor. The acetic acid chlorination reactor are divided into two reaction regions, namely a second (upper) reaction region and a first (lower) reaction region, which are separated by a porous partition board; and the upper and lower two reaction regions can be heated or cooled under independent control and both have enough feed inlets or discharge holes. By controlling a feeding mode and reaction temperatures, the catalyst concentration and reaction temperatures in the two reaction regions are differentiated; by controlling the material exchange amounts in the upper and lower reaction regions, the reaction speeds in the two regions are different; and thus, the chloroacetic acid concentrations in the two reaction regions are different. The acetic acid chlorination reaction process and the complete reactor have the advantages of solving the problems of low reaction speed, high energy consumption, big investment, low chloroacetic acid yield and the like in the prior art.

Owner:TAIYUAN UNIV OF TECH +1

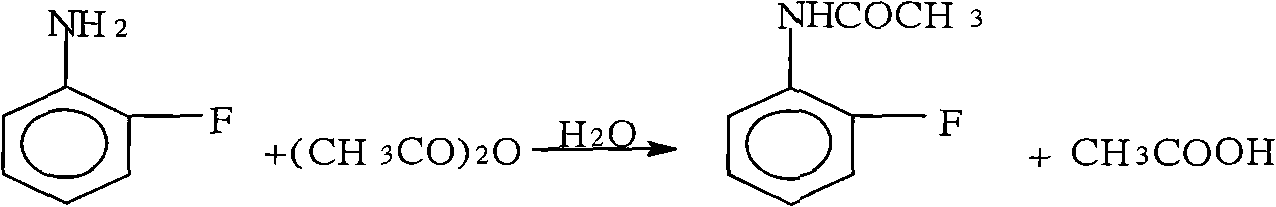

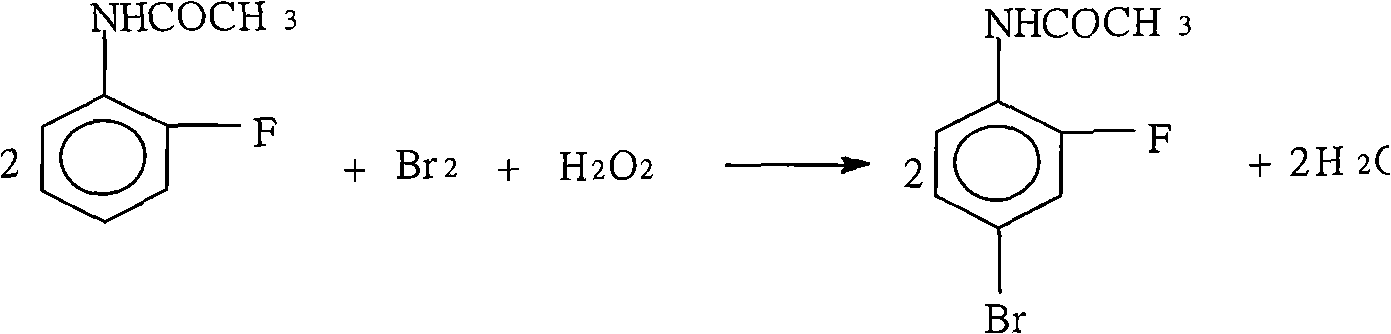

Production technique of m-bromofluorobenzene

ActiveCN101838180ASimplify the process stepsReduce pollutionHalogenated hydrocarbon preparationMethylene DichlorideWater vapor

The invention discloses a production technique of m-bromofluorobenzene, which takes o-fluoroaniline as main raw material and produces the m-bromofluorobenzene according to the process route of acetylation, bromination, hydrolysis, diazotization, deamination, water vapor rectification and rectification. The production technique introduces methylene dichloride solvent in the working procedure of acetylation, leads the product solid to be changed into solution which is not needed to be separated and is directly hydrolyzed; and the solvent is distilled out by the heat of neutralization reaction in the hydrolysis process, so that the problems of separation intoxication, low production capacity and low hydrolysis yield can be solved. The production technique of the m-bromofluorobenzene not onlyhas simple working procedure steps, greatly improves the safety and reduces the hurt for the people, but also has high reaction yield and low environmental pollution.

Owner:营口兴福化工有限公司

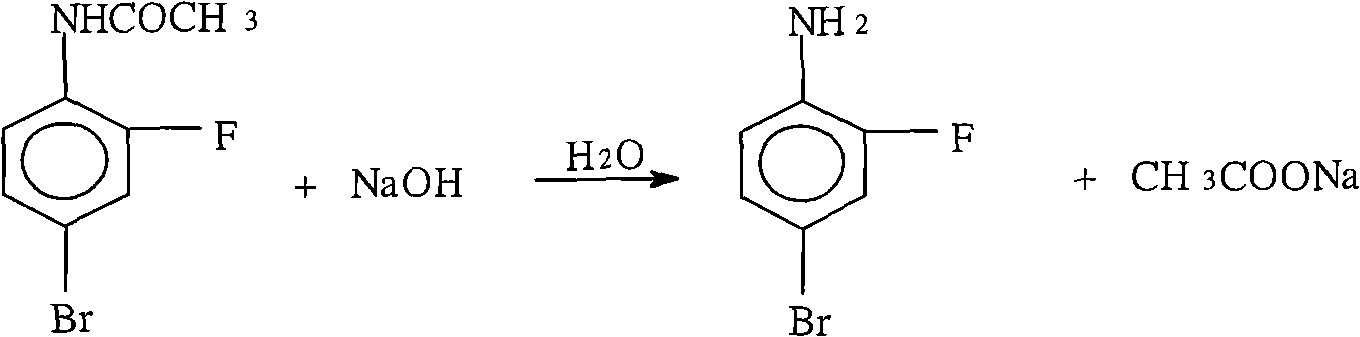

Technique for preparing L-homoserine

InactiveCN101100438AReduce dosageReduce generationOrganic compound preparationAmino-carboxyl compound preparationL-homoserineReducing agent

Production of L-homoserine is carried out by taking L-asparto as raw material to prepare L-asparto methyl ester or ethyl ester, taking them as raw materials, taking metal complex hydrogen compound as reducer, and preparing final product under normal pressure in organic solvent. It's convenient, has gentle reactive condition and can be used for industrial production.

Owner:安徽省恒锐新技术开发有限责任公司

Method for producing amino acids through efficiently treating fermentation broth

ActiveCN108084041ASettlement yieldSolve the costOrganic compound preparationOrganic chemistry methodsPurification methodsUltrafiltration

The invention discloses a method for producing amino acids through efficiently treating a fermentation broth. The method comprises (1) filtering a fermentation broth through a ceramic membrane havingpore sizes of 0.2-0.4 micrometers, (2) carrying out decolorization and impurity removal on the filtrate through an organic ultrafiltration membrane or activated carbon, (3) carrying out concentrationon the liquid obtained in the step 2 through a reverse osmosis membrane, (4) carrying out multistage flash evaporation concentration crystallization on the concentrate obtained in the step 3 to obtaina crystalline intermediate product and (5) mixing the crystalline intermediate products with purity of less than 90% and washing the crystalline intermediate products through a crystal washing agent.The method is easy to operate, has high efficiency, saves energy, is environment-friendly, realizes a low cost and solves the problem that the existing amino acid separation and purification method has a low yield and a low cost and produces more three wastes. The prepared amino acid crystal product has purity of more than 95% and a pure yield of more than 85%.

Owner:黑龙江诺潽生物科技有限公司

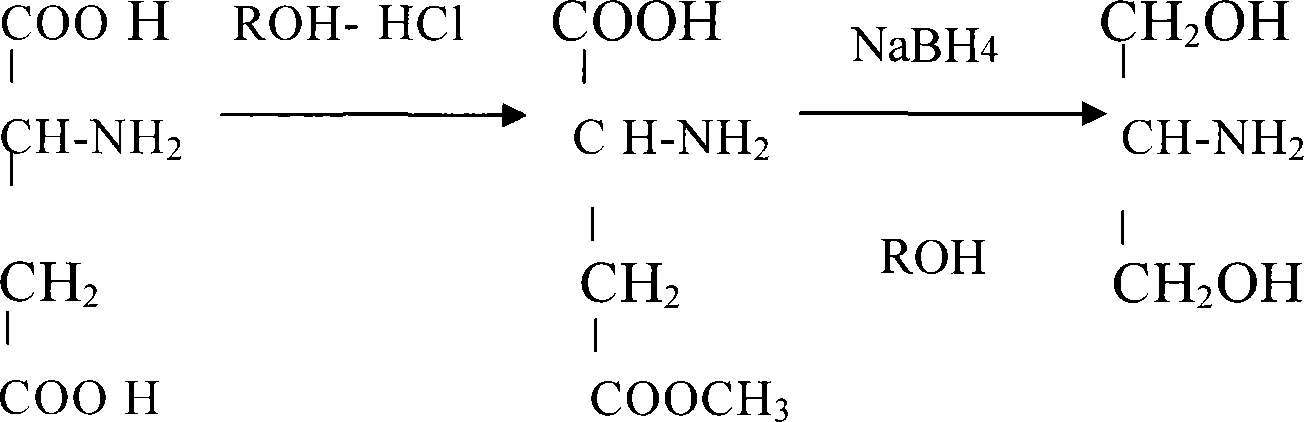

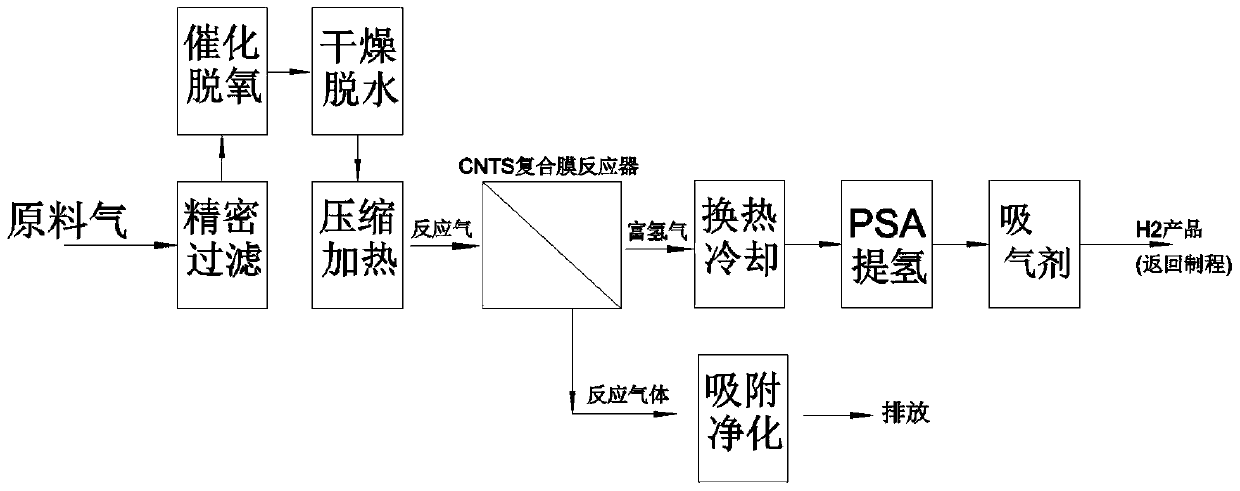

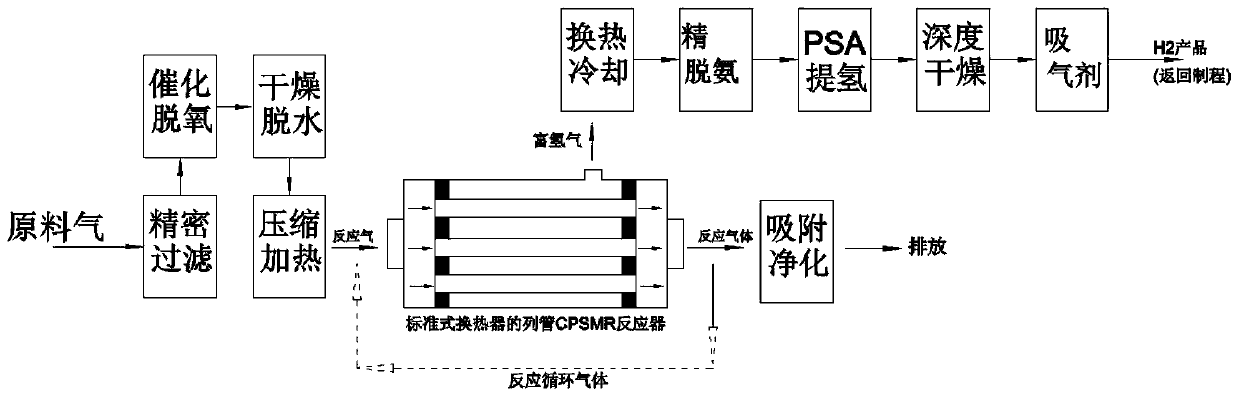

Catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in MOCVDprocess as well as preparation method and application of the catalytic permeable membrane reactor

InactiveCN111137853ASolve the conversion rateSettlement yieldHydrogen separation using solid contactHydrogen productionOxide ceramicCarbon nanotube

The invention discloses a catalytic permeable membrane reactor for producing hydrogen from ammonia-containing tail gas in an MOCVD process. In the membrane reactor, a porous gamma-aluminum oxide ceramic circular tube containing 5-10% (w / w, similarly hereinafter) of metal palladium is dispersed is used as a support body; an inorganic carbon nano-membrane, which contains 10-30% of cobalt and 5-20% of molybdenum as active components, 1-10% of lanthanum serving as an auxiliary catalytic component and 1-5% of potassium serving as an accelerant, is embedded into pretreated carbon nanotubes (CNTs) and coats the inner wall of an alumina ceramic round tube, has thickness of 10 nm to 1 [mu]m and pore diameter of 0.20 to 10 nm; thus forming the catalytic permeable membrane reactor which simultaneously has catalytic activity and separation selectivity. Ammonia-containing tail gas in the MOCVD process is pretreated and then enters a membrane reactor; at the reaction temperature of 400-600 DEG C, an ammonia thermal cracking catalytic reaction is performed under the reaction pressure of 2.0-5.0 MPa; and hydrogen-rich gas generated by the reaction is subjected to adsorption refining deamination,pressure swing adsorption purification and metal getter purification to obtain a hydrogen product with the purity of more than 6-7 N, and the hydrogen product is returned to the MOCVD process to be recycled, thereby filling the blank for green and circular economy development of the LED industry.

Owner:SICHUAN TECHAIRS

Method for preparing threonine crystal by threonine fermentation liquid

InactiveCN101759580AQuality improvementHigh yieldOrganic compound preparationAmino-carboxyl compound preparationUltrafiltrationThreonine

The invention relates to a method for preparing threonine crystal by threonine fermentation liquid, comprising the steps of: sterilizing the threonine fermentation liquid, and the carrying out plate-type or tube-type film ultrafiltration, concentration, azeotropic crystallization and other steps to prepare the threonine crystal; and the prepared threonine crystal has the purity of 98.5%, the threonine film ultrafiltration yield of more than 96%, and the azeotropic crystallization yield of more than 95%. The preparation method is an environment-friendly new production technique which has high efficiency, low energy consumption, low cost, simple method and easy popularization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Exemestane intermediate and preparation method therefor and application thereof

InactiveCN105017370AClear structureClear physical and chemical propertiesSteroidsStructural formulaMethyl group

The invention relates to an exemestane intermediate, particularly 6-(N-methyl-N-phenyl)-amine methyl-4-ene-3,17-androstanedione and a preparation method therefor and application thereof. The structural formula of the exemestane intermediate is a formula shown in the description. The 6-(N-methyl-N-phenyl)-amine methyl-4-ene-3,17-androstanedione prepared by the method provided by the invention can be used for preparing 6-methylene-4-ene-3,17-androstanedione through elimination reaction and the 6-methylene-4-ene-3,17-androstanedione is further oxidized to prepare exemestane. By using the intermediate provided by the invention to prepare exemestane, the purity and yield of exemestane are remarkably improved, the long-term troubled problem on the yield and purity of synthesized exemestane in the field is solved, and industrial practices verify that the exemestane intermediate has extreme value.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY +1

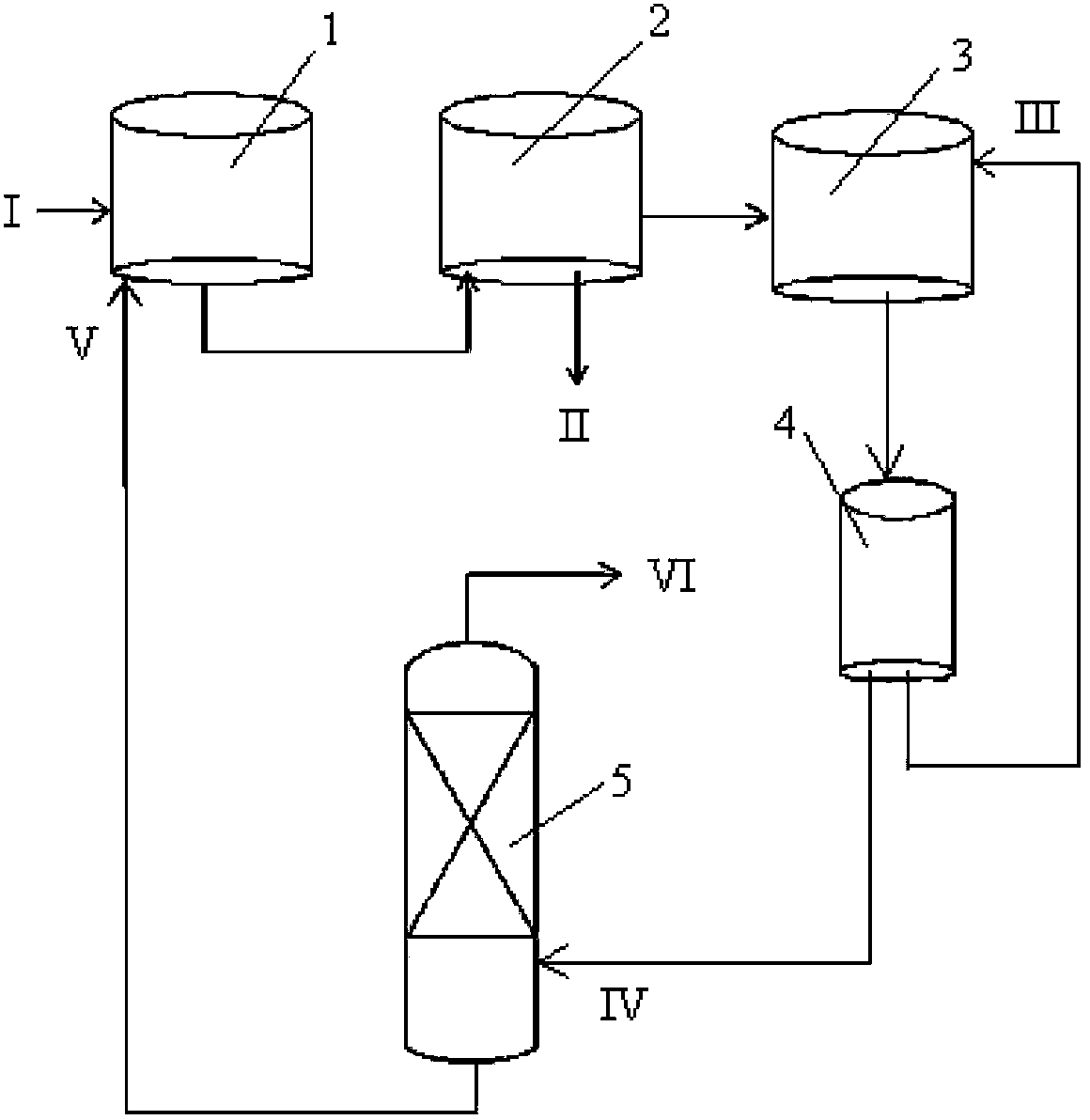

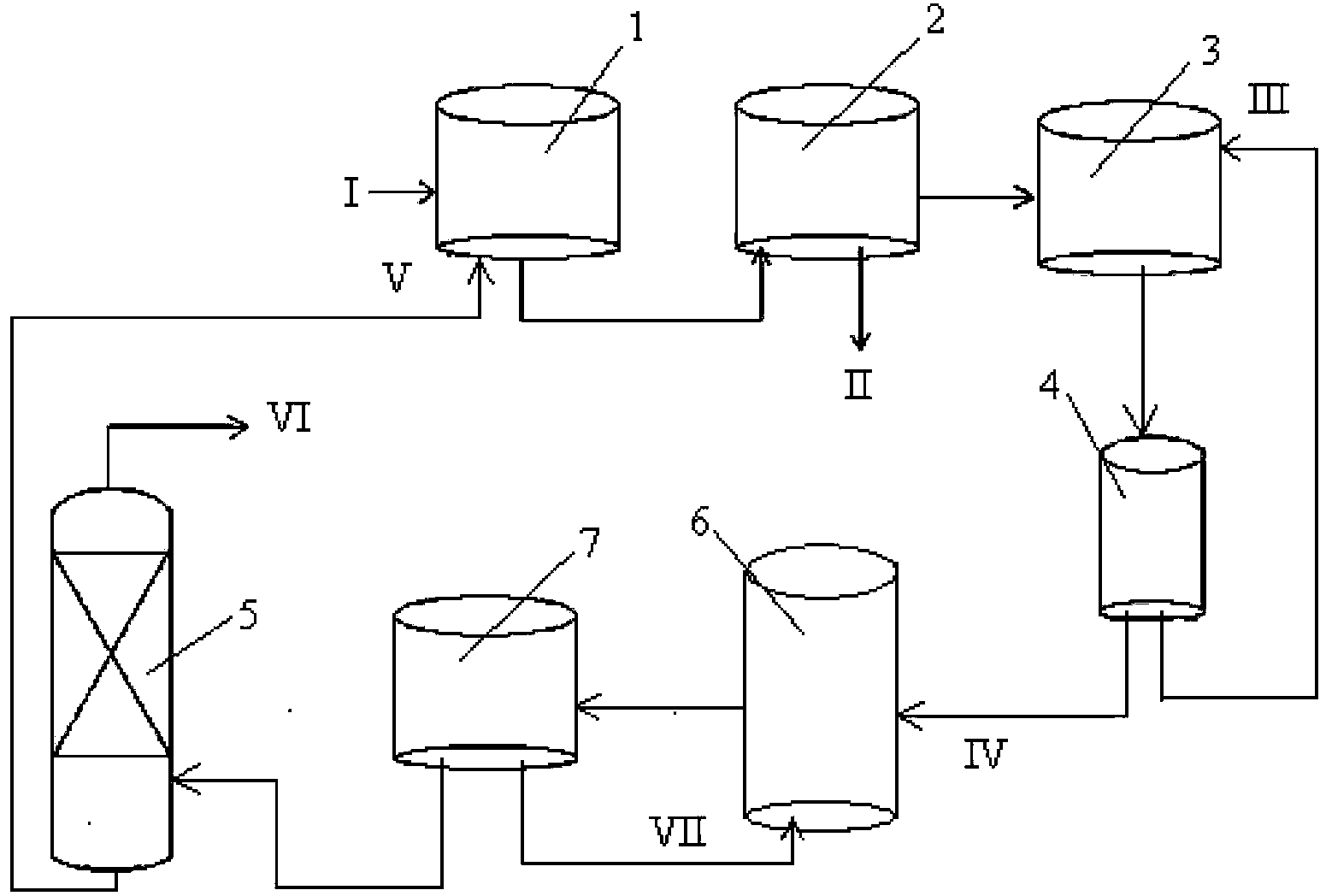

Device and method for preparing propionic anhydride through reactive distillation of acetic anhydride and propionic acid

InactiveCN104072359AFix stability issuesSettlement yieldChemical industryCarboxylic acid anhydrides preparationAcetic acidPropanoic acid

The invention discloses a device and method for preparing propionic anhydride through reactive distillation of acetic anhydride and propionic acid. The device comprises a reactor, a reactive distillation tower, a propionic anhydride refining tower, a condenser, a reboiler, a reflux tank, a kettle outlet tank, a pump and a pipeline. A process flow combining the reactive distillation tower with the reactor and the propionic anhydride refining tower is adopted. The method comprises the following steps: the acetic anhydride and propionic acid enter the reactor and react, and the acetic anhydride and propionic acid flowing into the reactive distillation tower react and are distilled on each layer of a tower plate of the section; the material flowing from the reaction section is distilled by a stripping section; the material rising from the reaction section is distilled by a distillation section, and 80-100% acetic acid is extracted from the tower top; the tower kettle discharge of the reactive distillation tower is pressurized and enters the propionic anhydride refining tower for distillation; several of acetic acid, acetic anhydride, propionic acid, propionic anhydride acetate and propionic anhydride are obtained from the tower top of the propionic anhydride refining tower, and the propionic anhydride with purity of 80-100% is obtained from the tower kettle of the distillation tower. The problems of unstable quality, relatively low yield and relatively low production efficiency of the products in batch production of propionic anhydride are solved.

Owner:TIANJIN PULAI CHEM TECH

Method for preparing levocysteine and dextral cysteine using chemical resolution method

InactiveCN1876628AReduce dosageReduce pollutionOrganic compound preparationOptically-active compound separationSolventInorganic acids

The invention relates the method of preparing L-Cys and D-Cys with chemical resolution method, comprising the following steps: using DL-Cys as raw material, using inorganic acid as dissolvent, using D-DBTA and L-DBTA as resolution agent, dissolving the DL-Cys and resolution agent at the rate of 1:0.5-1.2 in the dilute inorganic acid solution, stirring for 0.5-2.0 hours at the temperature 60-100Deg.C, cooling, filtering, neutralizing crystallization salt and mother liquid with alkali, and separately getting L-Cys and D-Cys. The invention has the advantages of simple technology. The resolution agent can be recovered.

Owner:安徽省恒锐新技术开发有限责任公司

Preparation method of 2,4-disubstituted benzenesulfonyl chloride

InactiveCN108084062ASuppress generationAvoid overdoseSulfonic acid preparationChlorosulfuric acidSolvent free

Owner:TIANJIN RUILING CHEM CO LTD

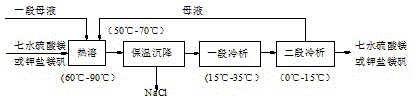

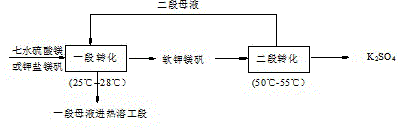

Potassium sulphate preparing method through thermal melting, refrigeration and double decomposition crystallization method

InactiveCN104692420ASolve the problem of low one-time yieldIncrease valueSulfate/bisulfate preparationDecompositionTwo step

The invention relates to the technical field of salt chemical engineering, in particular to a potassium sulphate preparing method through thermal melting, refrigeration and a double decomposition crystallization method. The potassium sulphate preparing method includes the following steps of 1 raw material preparation, 2 thermal melting, 3 cold separation crystallization and 4 potassium sulphate preparation through a two-stage two-step method, wherein magnesium sulfate heptahydrate or kainite reacts with potassium chloride through a traditional two-stage two-step method to prepare a potassium sulphate product. The potassium sulphate preparing method has the advantages that the problem that subtype magnesium sulfate salt lake brine is low in one-time production rate of raw materials in a traditional process is solved, the problems that in a flotation technology, the one-time yield is low, a product contains a poison potion, and the product granularity is thin are solved, a potassium sulphate product does not contain medicament and is in a particle shape, and the value of the potassium sulphate product is enhanced. The method is mainly used for the process for preparing potassium sulphate through the subtype magnesium sulfate salt lake bittern or through coastal acrid bittern or the like, good in effect and capable of generating larger economical benefits and social benefits.

Owner:MANGYA XINGYUAN POTASH FERTILIZER

Moisturizing and anti-aging cosmetic formula and preparation method thereof

PendingCN111643383ALow cost of treatmentReduce riskCosmetic preparationsToilet preparationsGlycerolEthyl group

The invention discloses a moisturizing and anti-aging cosmetic formula and a preparation method thereof. The cosmetic is in a double-dosage form and is divided into an agent A and an agent B. The agent A is prepared from deionized water, butanediol, p-hydroxyacetophenone, sodium hyaluronate, hydroxyethyl piperazineethanesulfonic acid, oligopeptide-1, nonapeptide-1, glycerin, 1, 2-hexanediol and ethylhexylglycerin; the agent B is prepared from deionized water, p-hydroxyacetophenone, copper gluconate, hydroxyethyl piperazine ethane sulfonic acid and 1, 2-hexanediol. The preparation method comprises the following steps: respectively preparing the agent A and the agent B, respectively filling different bottle bodies with the prepared agent A and the prepared agent B, and packaging the agent Aand the agent B in a packaging box. The cosmetic has the beneficial effects that the cosmetic is low in treatment cost and small in risk, and each consumer can bear the cosmetic; oligopeptide-1 is selected to be combined with copper ions, and glycine-histidine-lysine-copper and hydroxyethyl piperazine ethane sulfonic acid are combined, so that the problems that the absorption rate and the effect are not obvious are effectively solved; the preparation process is simple and high in efficiency.

Owner:杭州创纬科技有限公司

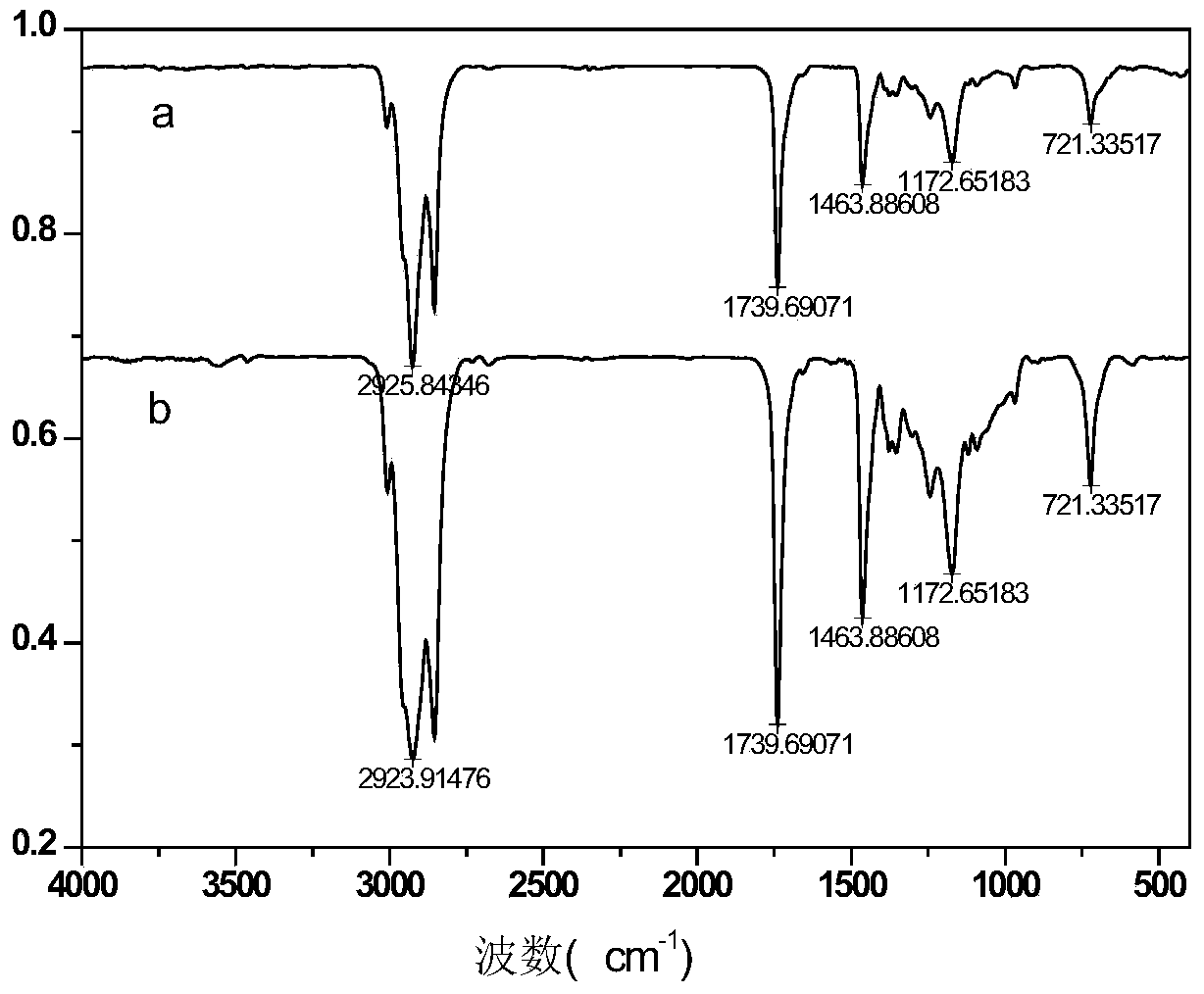

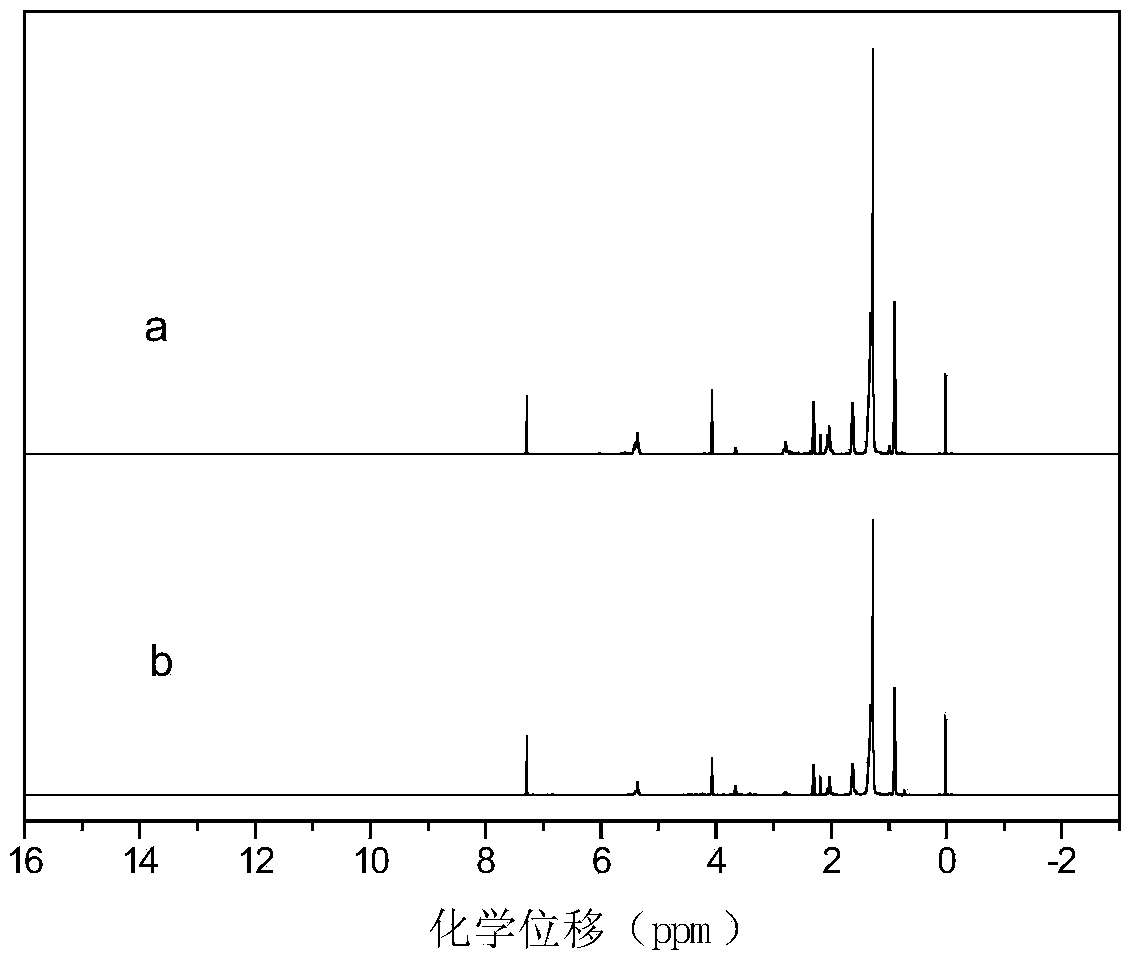

Method for catalytic synthesis of lauryl oleate by using twin-ion liquid microemulsion and application thereof

InactiveCN104003869ASolve the costSolve corrosiveOrganic compound preparationCarboxylic acid esters preparationOligomerReaction rate

The invention belongs to the technical field of preparation of lauryl oleate, and discloses a method for catalytic synthesis of lauryl oleate by using a twin-ion liquid microemulsion and an application thereof. The method comprises the following steps: (1) adding a non-polar solvent to a surfactant, dropwise adding imidazolium ionic liquids after mixing, and evenly mixing, so as to obtain the twin-ion liquid microemulsion; and (2) adding an oleic acid and laurinol to the twin-ion liquid microemulsion, carrying out heating reaction, and purifying to obtain lauryl oleate. According to the method, the twin-ion liquid microemulsion with good high-temperature stability is utilized as a reaction medium, the contact area of a catalyst and an oligomer is increased, the generated water is solubilized into a core of the ionic liquid microemulsion, the reaction rate is quickened, the used catalyst is high in activity, small in corrosion on equipment, and low in demands on equipment, the problems of high catalyst cost, serious equipment corrosion, low reaction rate, poor product quality, rigorous reaction condition and the like in the prior art are solved, and the method can be popularized and applied to catalytic esterification reaction.

Owner:SOUTH CHINA UNIV OF TECH

Efficient self-recycling system for continuously preparing sodium bichromate by wet method

ActiveCN105129852ACleaner production achievedFully enclosedChemical industryChromates/bichromatesSodium bicarbonateThermal energy

The invention discloses an efficient self-recycling system for continuously preparing sodium bichromate by a wet method. The system comprises a beating tank, an oxygen supply device, and a first delivery pump, a preheating device, a liquid-phase oxidation reaction device, a flash evaporation device, a first separation device, a first concentration device, a carbonization device, a second separation device, an electrolytic bath, a second concentration device, a cooling crystallization device and a centrifugation device, which are sequentially connected with the beating tank through a feed liquid delivery pipeline, wherein the oxygen supply device is used for introducing oxygen into the liquid-phase oxidation reaction device; CO2 generated by preheating decomposition, CO2 and steam, which are generated by oxidation, and steam generated by flash evaporation can be delivered to the concentration devices, the steam is used for feed liquid concentration, and CO2 is led into the carbonization device for carbonization reaction; chromium-containing sodium bicarbonate obtained by separation in the second separation device can be delivered to the beating tank as an ingredient. According to the system, the byproducts CO2 and steam are used for carbonization and feed liquid concentration and the product sodium bicarbonate is used as the ingredient, so that sodium, CO2 and heat are efficiently self-recycled, and energy waste is reduced.

Owner:SICHUAN YINHE CHEM

Method for synthesizing L-ascorbyl palmitate

The invention discloses a method for synthesizing L-ascorbyl palmitate, which comprises the following steps: grinding L-ascorbyl palmitate into fine powder; at 25 to 20 DEG C, slowly adding the L-ascorbyl palmitate fine powder into pure sulfuric acid so that the L-ascorbyl palmitate fine powder dissolves in the sulfuric acid; adding L-ascorbyl palmitate in an amount which is 0.95 times the molar number of L-ascorbyl palmitate into the reaction solution, adding dehydrating agent into the reaction solution, and continuing reaction for 6 to 7 hours; pouring the generated reaction solution into broken ice, filtering out coarse product, drying and washing with water; heating the prepared coarse L-ascorbyl palmitate, dissolving the coarse L-ascorbyl palmitate in ethyl acetate, and decolorizing and purifying the solution by particle active carbon; and subjecting the obtained solution to reduced-pressure distillation and concentration, cooling feed liquid to 0 DEG C and discharging to obtain L-ascorbyl palmitate white powder. When the method disclosed by the invention is used, the production efficiency can be improved greatly, the production period is shortened, the product yield is increased, the product quality is improved, and the dose of palmitic acid is reduced (only 5 percent more is required).

Owner:HEBEI WELCOME PHARMACEUTICAL CO LTD

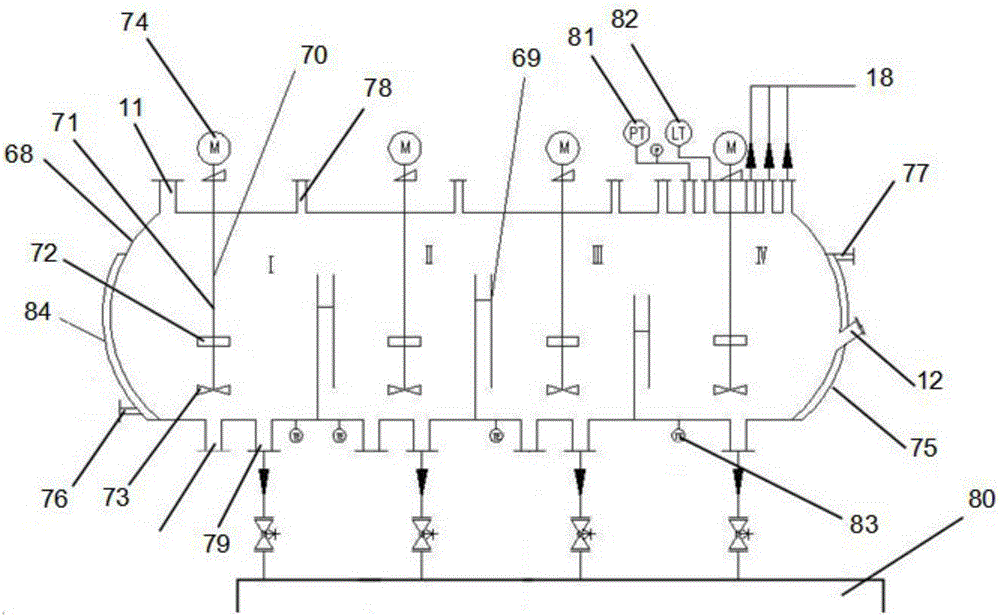

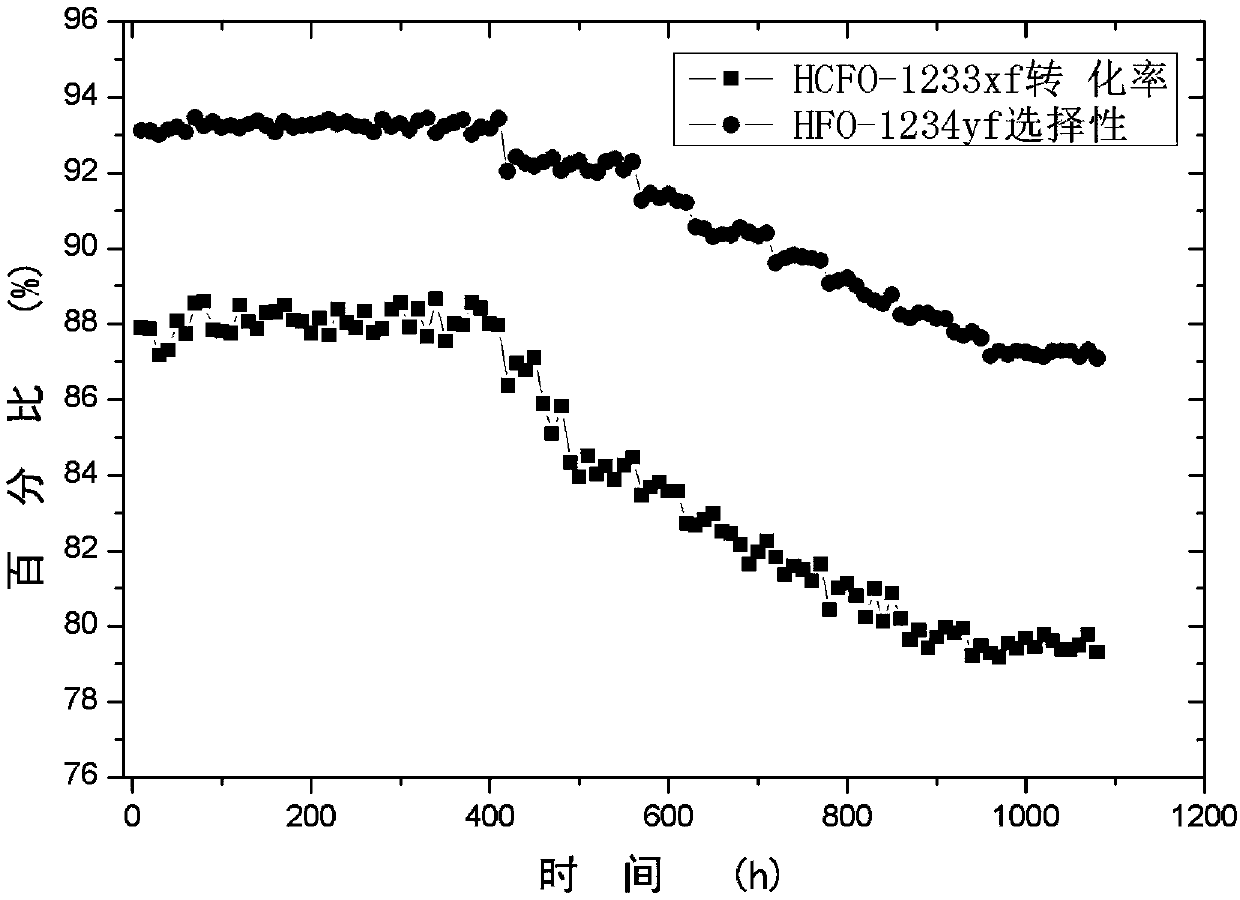

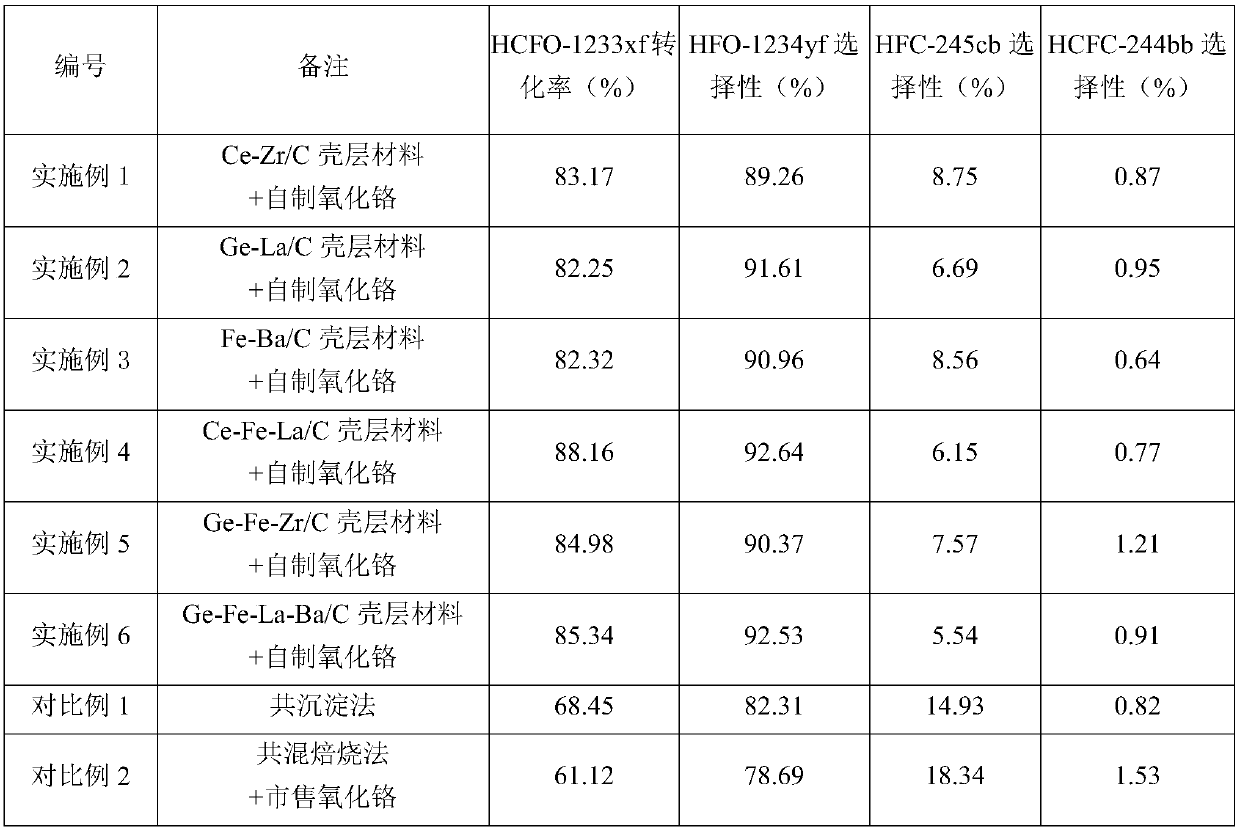

Fluorination catalyst and preparation method and application thereof

ActiveCN109569674ASolving activitySolve the conversion ratePhysical/chemical process catalystsPreparation by halogen replacementMicrowave methodHFO-1234yf

The invention provides a fluorination catalyst and a preparation method and application thereof. The preparation method comprises the steps of using a microwave combined blending method, preparing a metal aid / organic ligand compound by a microwave method at first, then roasting to prepare a metal aid / carbon shell layer material, and finally, blending the metal aid / carbon shell layer material with self-made chromium oxide, tabletting, roasting, and carrying out fluorination to prepare the fluorination catalyst. The fluorination catalyst is particularly suitable for being used for preparing and synthesizing HFO-1234yf from HCFO-1233xf.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

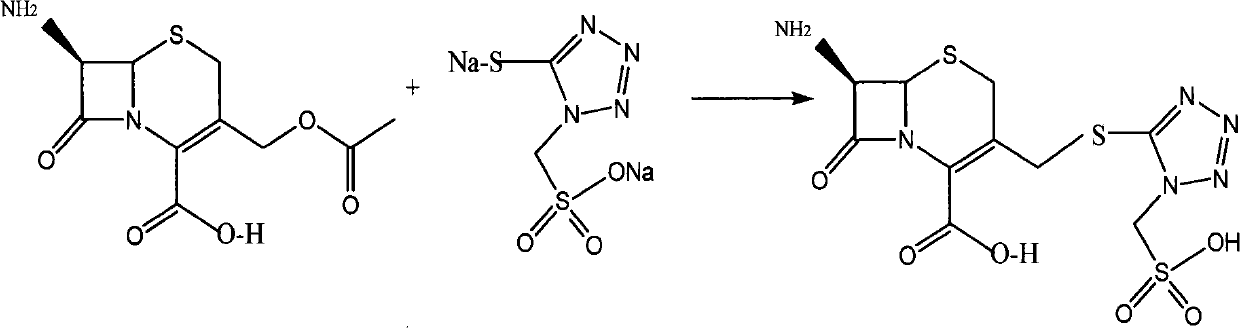

Method for preparing 7-amino-3-sulfotetrazolthiomethylcephalosporanic acid

InactiveCN101792453AConvenient storage and transportationSimple and mild reaction conditionsOrganic chemistryFiltrationSolvent

The invention discloses a method for preparing 7-amino-3-sulfotetrazolthiomethylcephalosporanic acid, which comprises: adding solution of boron trifluoride and dimethyl carbonate in a dimethyl carbonate solvent, stirring the solution, adding 7-aminocephalosporanic acid and 5-mercapto-1H-tetrazole-1-methanesulfonic acid disodium salt in turn to perform an reaction; when reactant residue is less than or equal to 0.5 percent, adding purified water to continue the reaction; cooling the reaction solution, filtering the reaction solution, and washing the product obtained by filtration to obtain a coarse crystal product; and dissolving the coarse crystal product, adding an organic solvent, adjusting the pH value, stirring the solution, cooling and standing the solution, filtering the solution, washing the product obtained after filtration and drying the product to obtain the finished product. Compared with the traditional process, the method has the advantages of mild and simple reaction conditions, easy solvent recovery and recycling, reaction yield up to 90 to 91.2 percent, purity up to 98.0 percent and light color as the solution of boron trifluoride and dimethyl carbonate is used as a catalyst. The method is suitable for large-scale production and overcomes the drawbacks of high price, difficult recovery, low yield, low purity and high production cost of the process using solution of boron trifluoride and acetonitrile as a catalyst.

Owner:河北九派制药股份有限公司

Anhydrous lithium hydroxide production device and use method thereof

PendingCN110762961AAvoid energy consumptionSolve the problem of energy consumptionDrying gas arrangementsDrying solid materialsLithium oxideLithium hydroxide

The invention relates to an anhydrous lithium hydroxide production device. The device comprises a disc type continuous dryer, a dust remover and a dehumidifier, wherein the disc type continuous dryeris connected with the dust remover, the dust remover is connected with the dehumidifier, a pipeline between the dust remover and the dehumidifier is connected with an inert gas pipeline, a plurality of inert gas inlets are formed in the side wall of the disc type continuous dryer, and a dehumidifier extraction pipeline is connected with the inert gas inlets. The invention further provides a use method of the device, wherein the method comprises the following steps that nitrogen gas is introduced into the inert gas pipeline, and the nitrogen gas is heated and then enters the disc type continuous dryer; evaporated moisture and a small amount of dust in wet materials are brought out through the hot nitrogen gas, and then the nitrogen gas returns to a system for recycling after dust removal and dehumidifying are carried out; and the dried materials are discharged after being cooled. The device and the method can achieve the purposes of stable product quality, high yield and low energy consumption while lithium hydroxide drying is completed.

Owner:河北云瑞化工设备有限公司

Triptorelin purification preparation method

InactiveCN104761620ASolve efficiency problemsSettlement yieldLuteinising hormone-releasing hormonePeptide preparation methodsWater bathsStationary phase

The invention discloses a triptorelin purification preparation method. The triptorelin purification preparation method comprises the following steps of preparing a triptorelin crude peptide solution, dissolving the triptorelin crude peptide solution in a warm water bath, and carrying out gradient elution by octadecylsilane bonded silica gel as a stationary phase, a purification mobile phase A which comprises a phosphoric acid aqueous solution with content of 0.2% and tetrabutylammonium phosphate and a phase B which is acetonitrile and has a mass percentage concentration of 12-52% in gradient elution, wherein the phosphoric acid aqueous solution with content of 0.2% is prepared from 1L of pure water, 2mL of phosphoric acid and 1mL of tetrabutylammonium phosphate, a warm water temperature is in a range of 25-28 DEG C and water bath time is in a range of 1-1.5h. The triptorelin purification preparation method solves the problem that the existing product production method produces low-purity crude peptide, has a low purification yield and cannot be controlled easily, and has the advantages of mild conditions, high reaction efficiency, high product purity, low cost, low dangerousness and pollution, high efficiency and large scale production feasibility.

Owner:苏州天马医药集团天吉生物制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com