Potassium sulphate preparing method through thermal melting, refrigeration and double decomposition crystallization method

A potassium sulfate and metathesis technology, applied in the field of salt chemical industry, can solve the problems of rich chemicals, low recovery rate of potassium sulfate, poor quality, etc., and achieve the effect of improving comprehensive utilization of energy, good effect and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

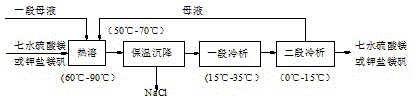

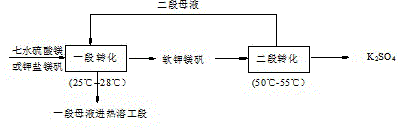

[0024] The invention uses magnesium sulfate subtype brine as raw material, and the magnesium sulfate or potassium mixed salt ore containing sulfate radical obtained by evaporation and drying in salt fields is harvested and transported to a hot melting workshop. Take a section of mother liquor (temperature 15°C) discharged from the potassium sulfate production workshop and exchange heat through a heat exchanger, so that the temperature of a section of brine reaches (80°C). Mix high-temperature brine (80°C-110°C) with magnesium sulfate or potassium containing sulfate The salt is added into the heat-dissolving tank according to a certain ratio (1:0.5), and the heat-melting reaction time (20 min) is melted. After the liquid is melted, the feed liquid enters the heat preservation settler to settle, and the separated solid is tailing salt, which is discharged to the tailing salt dam, and the liquid is pumped into the The flash tank is cooled by negative pressure, the vacuum degree is...

Embodiment 2

[0026] The invention uses magnesium sulfate subtype brine as raw material, and the magnesium sulfate or potassium mixed salt ore containing sulfate radical obtained by evaporation and drying in salt fields is harvested and transported to a hot melting workshop. Take a section of mother liquor (temperature 25°C) discharged from the potassium sulfate production workshop and pass it through a heat exchanger to exchange heat so that the temperature of a section of brine reaches (95°C). The high-temperature brine (95°C) is mixed with magnesium sulfate or potassium sulfate. The ratio (1:0.9) is added to the hot-melt tank for hot-melt reaction time (40min). After hot-melting, the feed liquid enters the heat preservation settler to settle, and the solid is separated into tail salt, which is discharged to the tail salt dam, and the liquid is pumped into the flash tank for further processing. The vacuum degree of negative pressure cooling is (0.6 Mpa), and the temperature is controlled a...

Embodiment 3

[0028] The invention uses magnesium sulfate subtype brine as raw material, and the magnesium sulfate or potassium mixed salt ore containing sulfate radical obtained by evaporation and drying in salt fields is harvested and transported to a hot melting workshop. Take a section of mother liquor (temperature 35°C) discharged from the potassium sulfate production workshop and exchange heat through a heat exchanger, so that the temperature of a section of brine reaches (110°C) and mix high-temperature brine (110°C) with magnesium sulfate or potassium sulfate The ratio (1:2) is added to the hot-melt tank for hot-melt reaction time (60min). After hot-melt, the feed liquid enters the heat preservation settler to settle, and the solid is separated into tail salt, which is discharged to the tail salt dam, and the liquid is pumped into the flash tank for further processing. The vacuum degree of negative pressure cooling is (0.8 Mpa), the temperature is controlled at (65°C), and the feed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com