Triptorelin purification preparation method

A technology of step 2, solution, which is applied in the field of purification and preparation of triptorelin, can solve the problems of difficult control, low purity of crude peptide, and low purification yield, and achieve the effects of improving efficiency, high product purity, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

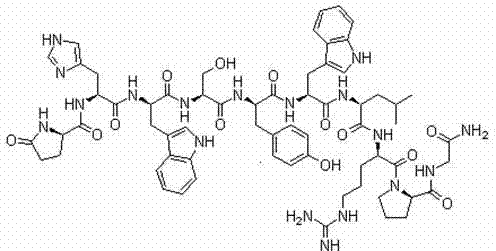

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of purification preparation method of triptorelin, comprises the following steps:

[0019] Add 800mmol of crude peptide to pure water at 25°C to dissolve, place in a water bath for 100min, stir well until completely dissolved, the solution is light yellow, clear, and free of particles;

[0020] The solution was filtered through a 0.45 μm aqueous filter membrane to remove insoluble matter to obtain a filtrate, which was purified by a 15 cm diameter silica gel reversed-phase high performance liquid phase preparative column. Purification preparation mobile phase is, A phase: 0.2% phosphoric acid aqueous solution plus tetrabutyl ammonium hydrogen phosphate, B phase: acetonitrile. The detection wavelength of the prepared mobile phase is 230nm, the flow rate is 80mL / min, the elution gradient B is from 12 to 52%, 40 minutes, the loading amount is 15g, and the samples with a purity of ≥99.0% are collected, and then detected and quantified according to HPLC ...

Embodiment 2

[0021] Embodiment 2: a kind of purification preparation method of triptorelin, comprises the following steps:

[0022] Add 1000mmol of crude peptide to pure water at 27°C to dissolve it, place it in a water bath for 93 minutes, stir well until it is completely dissolved, and the solution is light yellow, clear, and free of particles;

[0023] The solution was filtered through a 0.45 μm aqueous filter membrane to remove insoluble matter to obtain a filtrate, which was purified by a 15 cm diameter silica gel reversed-phase high performance liquid phase preparative column. Purification preparation mobile phase is, A phase: 0.2% phosphoric acid aqueous solution plus tetrabutyl ammonium hydrogen phosphate, B phase: acetonitrile. The detection wavelength of the prepared mobile phase is 230nm, the flow rate is 400mL / min, the elution gradient B is from 12 to 52%, 40 minutes, the loading amount is 15g, and the samples with a purity of ≥99.0% are collected, and then detected and quantif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com