Method for preparing levulinic acid and co-producing gamma-valerolactone from biomass

A technology of levulinic acid and biomass, which is applied in the preparation of organic compounds, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of solid acid catalyst deactivation, acid site loss, increased cost, etc., to improve the reaction Efficiency and product yield, increased contact area, and the effect of avoiding waste acid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

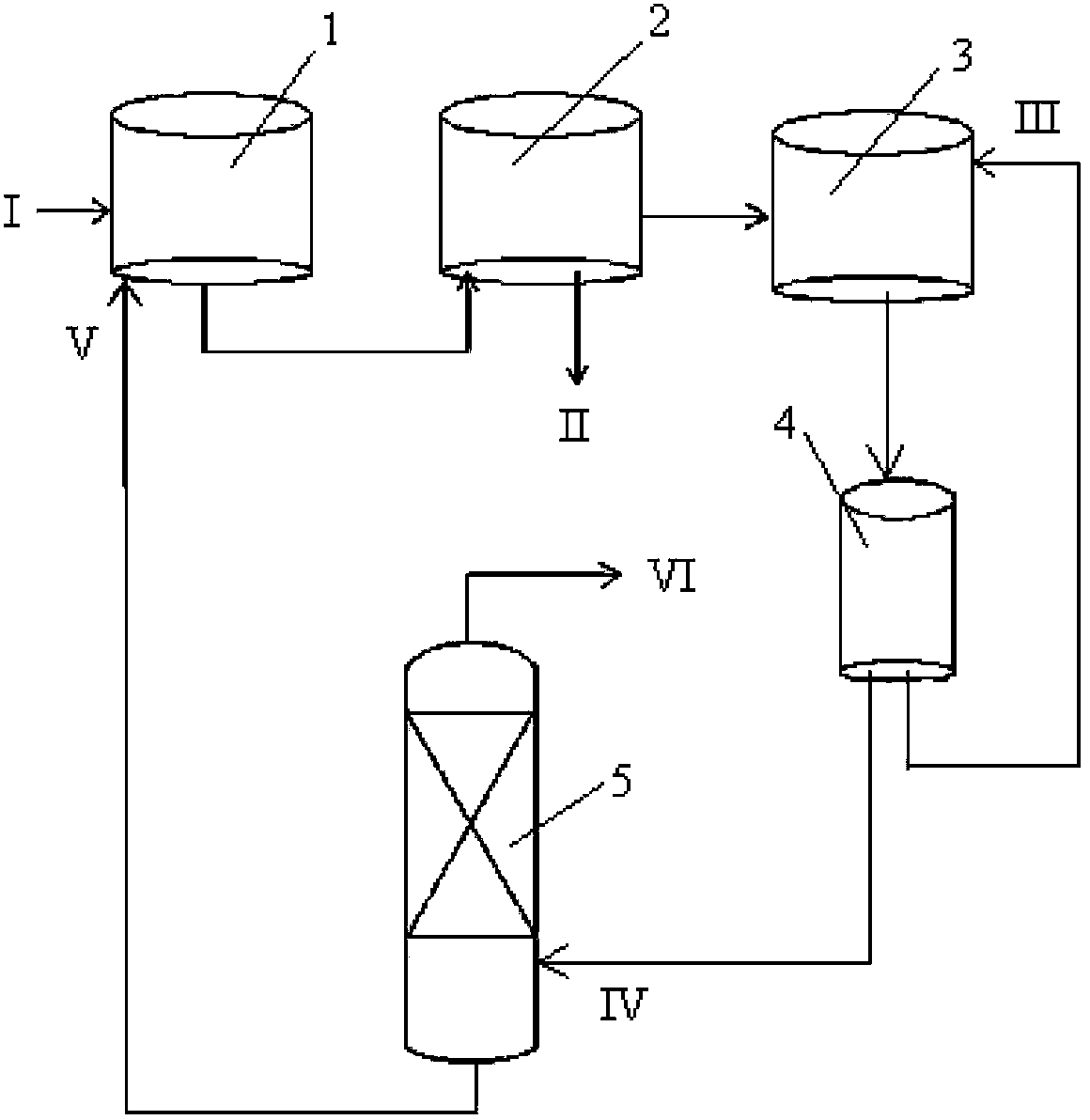

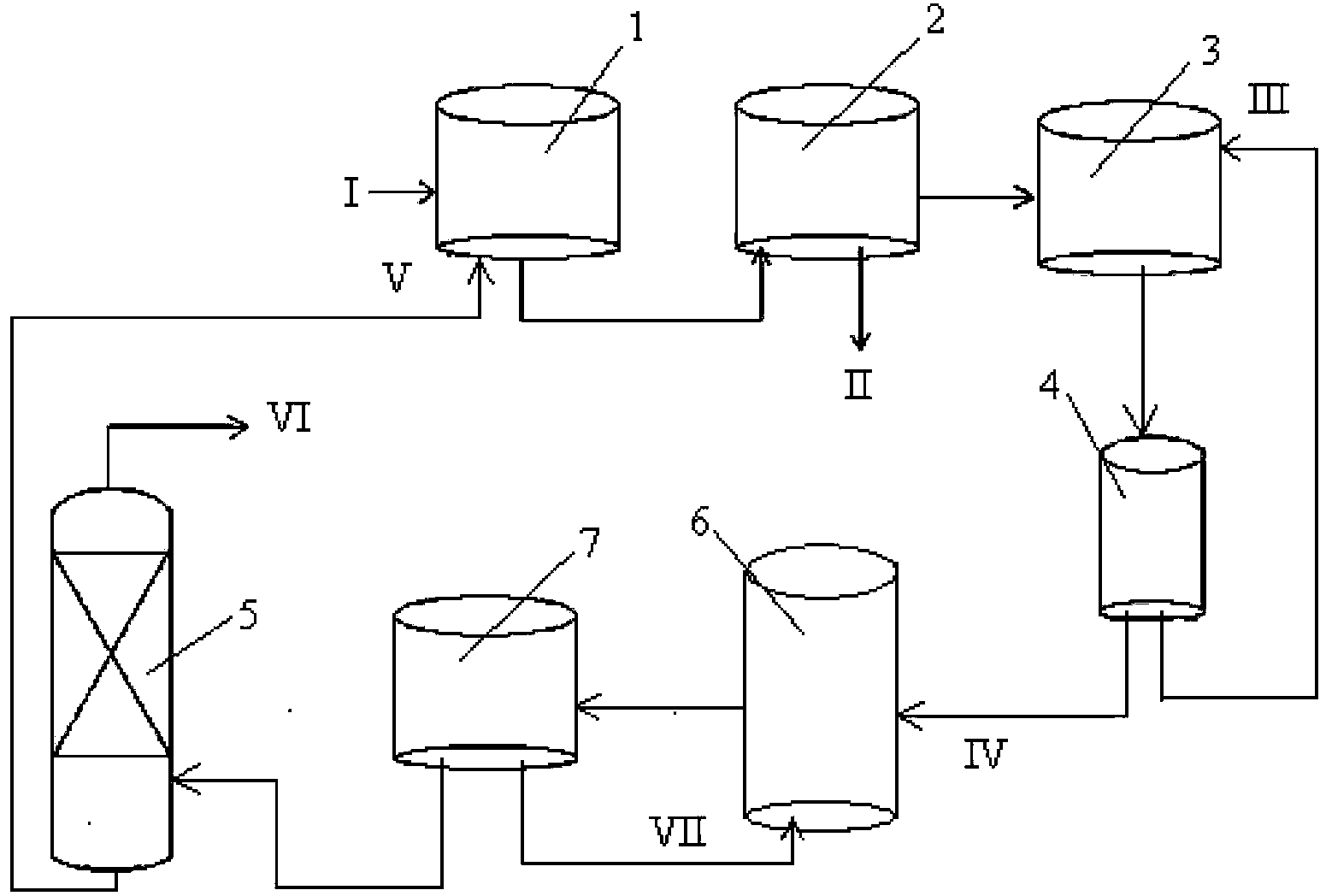

Method used

Image

Examples

Embodiment 1

[0030] This example is a process for preparing levulinic acid. Corn stalks are mixed with an aqueous solution with a content of 90% γ-valerolactone. The mixing ratio is 1:20 according to the weight ratio of corn stalks to γ-valerolactone. Dissolving, after the dissolution is completed, the obtained mixture is filtered, and a molecular sieve solid acid catalyst is added to the filtrate. The weight ratio of the molecular sieve solid acid catalyst to the filtrate is 1:20, and the catalytic reaction is carried out at 160 ° C. After the reaction, the obtained mixture Filtration is carried out, and the filtered molecular sieve solid acid catalyst is reused, and the filtrate is distilled to separate levulinic acid, water and γ-valerolactone. The process utilizes γ-valerolactone to dissolve corn stalks and then catalyzes the preparation of levulinic acid with a solid acid catalyst. The catalytic efficiency is high, and the yield of levulinic acid is greatly improved compared with the w...

Embodiment 2

[0032] This example is the preparation process of levulinic acid. Corncobs are mixed with an aqueous solution with a γ-valerolactone content of 95%. The mixing ratio is 1:5 according to the weight ratio of corncobs and γ-valerolactone. Dissolve, after the dissolution is completed, filter the obtained mixture, add an ion exchange resin solid acid catalyst to the filtrate, the weight ratio of the ion exchange resin solid acid catalyst to the filtrate is 1:4, carry out the catalytic reaction at 260 ° C, and the reaction ends The obtained mixture is filtered, and the filtered ion exchange resin solid acid catalyst is reused, and the filtrate is distilled to separate levulinic acid, water and gamma-valerolactone solution. In this process, the yield of levulinic acid is not less than 40%.

Embodiment 3

[0034] This example is the preparation process of levulinic acid, mixing wood chips with an aqueous solution with a content of 98% of γ-valerolactone, the mixing ratio is 1:200 by weight ratio of wood chips and γ-valerolactone, and dissolving at 100°C After the dissolution is completed, the obtained mixture is filtered, and a heteropolyacid solid acid catalyst is added to the filtrate. The weight ratio of the heteropolyacid solid acid catalyst to the filtrate is 1:100, and the catalytic reaction is carried out at 100 ° C. After the reaction, the obtained The mixture is filtered, and the filtered heteropolyacid solid acid catalyst is reused, and the filtrate is separated from levulinic acid, water and gamma-valerolactone solution by distillation. In this process, the yield of levulinic acid is not less than 50%. The filter residue in the reaction process can be used as fuel after being dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com