Patents

Literature

269results about "Carboxylic acid anhydrides preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

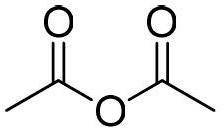

Addition of iridium to the rhodium/inorganic iodide catalyst system

InactiveUS6211405B1High rateReduce productionPhysical/chemical process catalystsOrganic compound preparationPtru catalystCarboxylic acid

The present invention provides a process for the carbonylation of an alcohol, ether or ester to products comprising a carboxylic acid, the anhydride thereof or coproduction of the carboxylic acid and anhydride. More particularly, the present invention provides a process for the carbonylation of methanol to produce acetic acid by reacting methanol with carbon monoxide in a liquid reaction medium containing a catalyst comprising rhodium, iridium, iodide ion, and said reaction medium further comprising water, acetic acid, methyl iodide, and methyl acetate and subsequently recovering acetic acid from the resulting reaction product.

Owner:CELANESE INT CORP

Continuous carbonylation process

InactiveUS6916951B2Improve heat removal efficiencyStable catalyst environmentOrganic compound preparationOrganic chemistry methodsAcetic acidGas phase

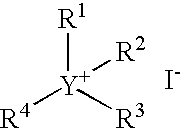

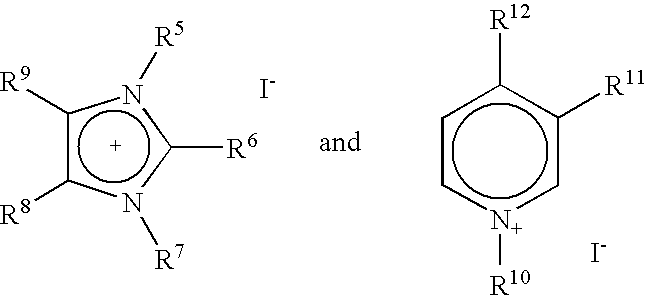

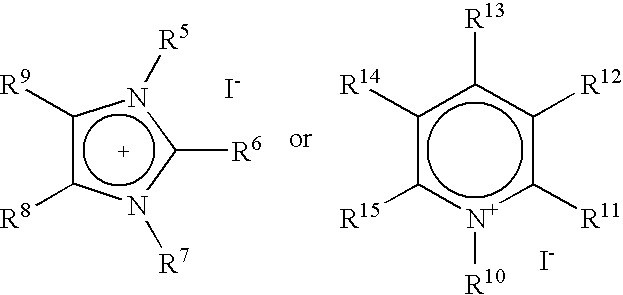

Disclosed is a continuous process wherein carbon monoxide, a carbonylatable reactant, and a halide in the gas phase are contacted with a non-volatile catalyst solution comprising an ionic liquid and a Group VIII metal to produce a carbonylation product in the gas phase. The process is useful for the continuous preparation of acetic acid by the carbonylation of methanol.

Owner:EASTMAN CHEM CO

Carbonylation process

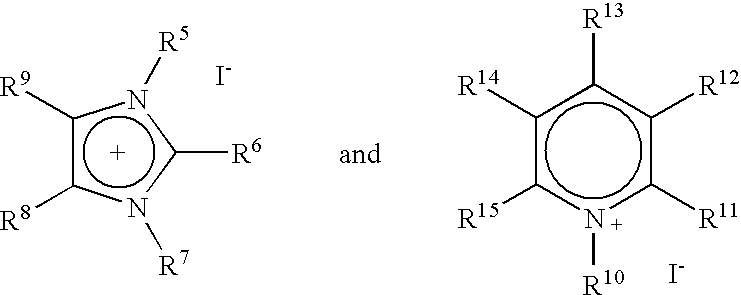

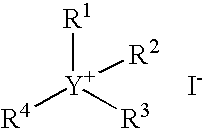

ActiveUS20070293695A1Organic compound preparationPreparation by carbon monoxide or formate reactionHydrogen halideCarboxylic acid

Disclosed is a carbonylation process for the production of carboxylic acids, carboxylic acid esters and / or carboxylic acid anhydrides wherein a carbonylation feedstock compound selected from one or more organic oxygenates such as alcohols, ethers, and esters is contacted with carbon monoxide in the presence of a carbonylation catalyst and one or more onium compounds. The carbonylation process differs from known carbonylation processes in that a halide compound such as a hydrogen halide, typically hydrogen iodide, and / or alkyl halide, typically methyl iodide, extraneous or exogenous to the carbonylation process is not fed or supplied separately to the process.

Owner:EASTMAN CHEM CO

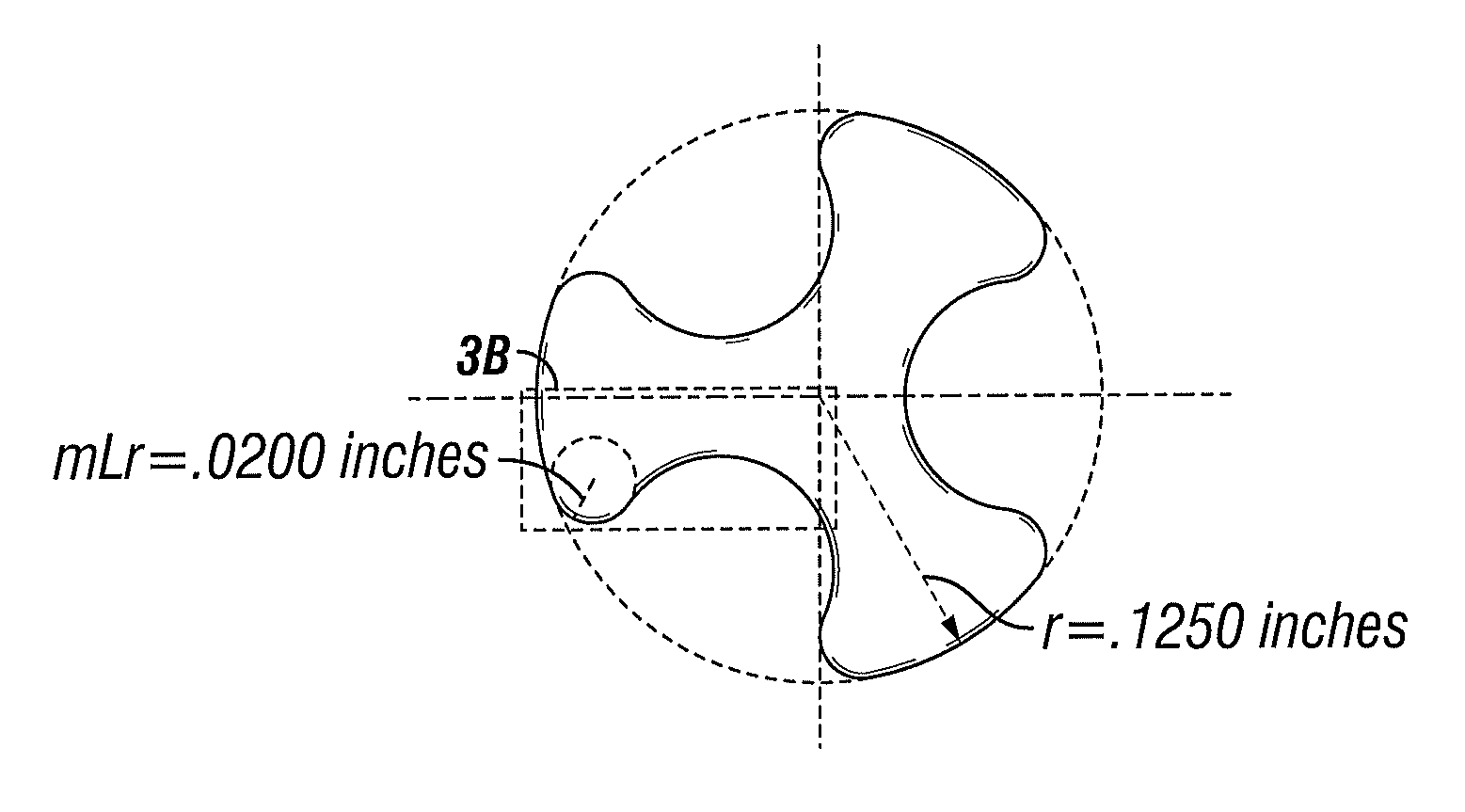

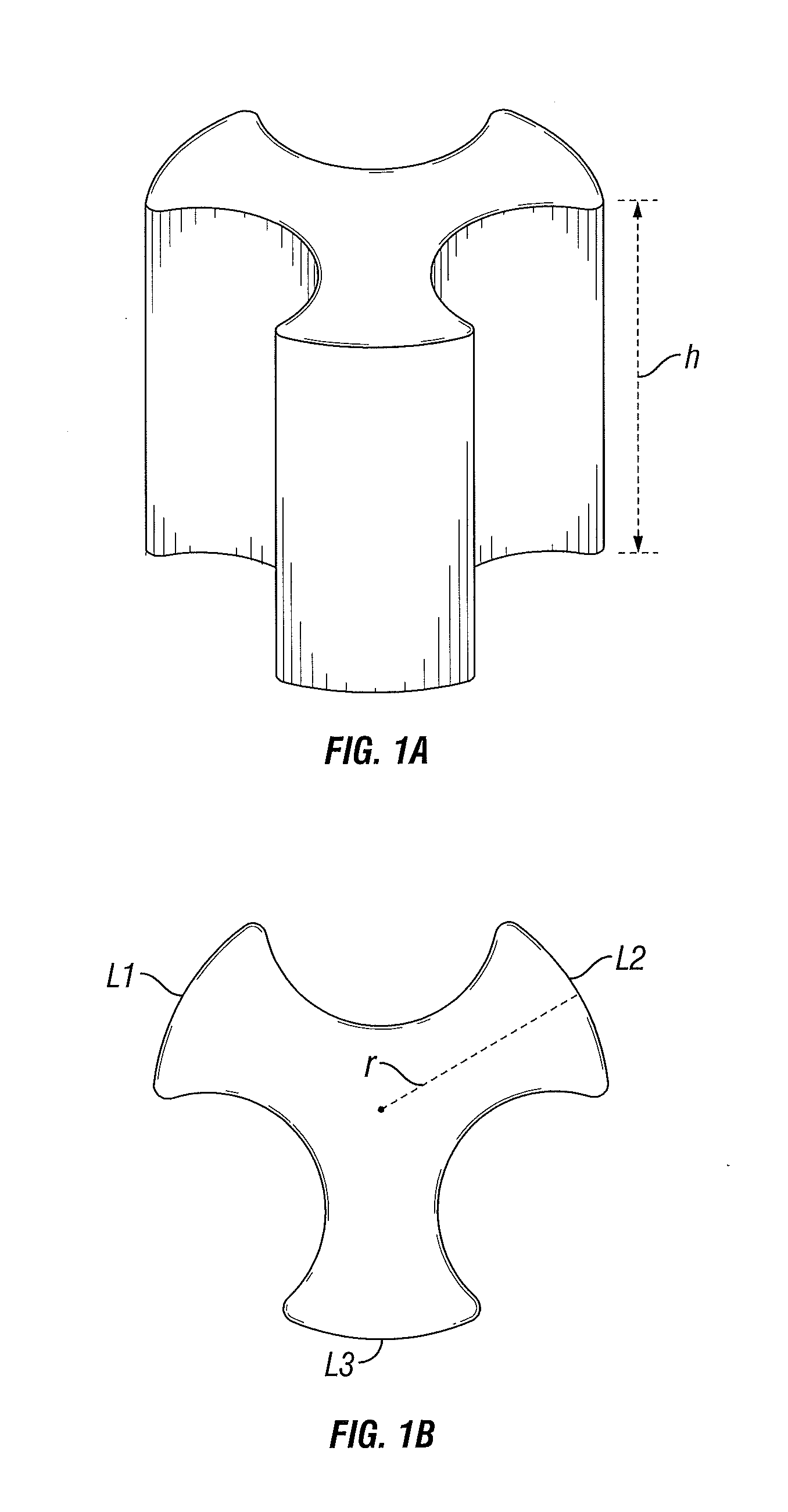

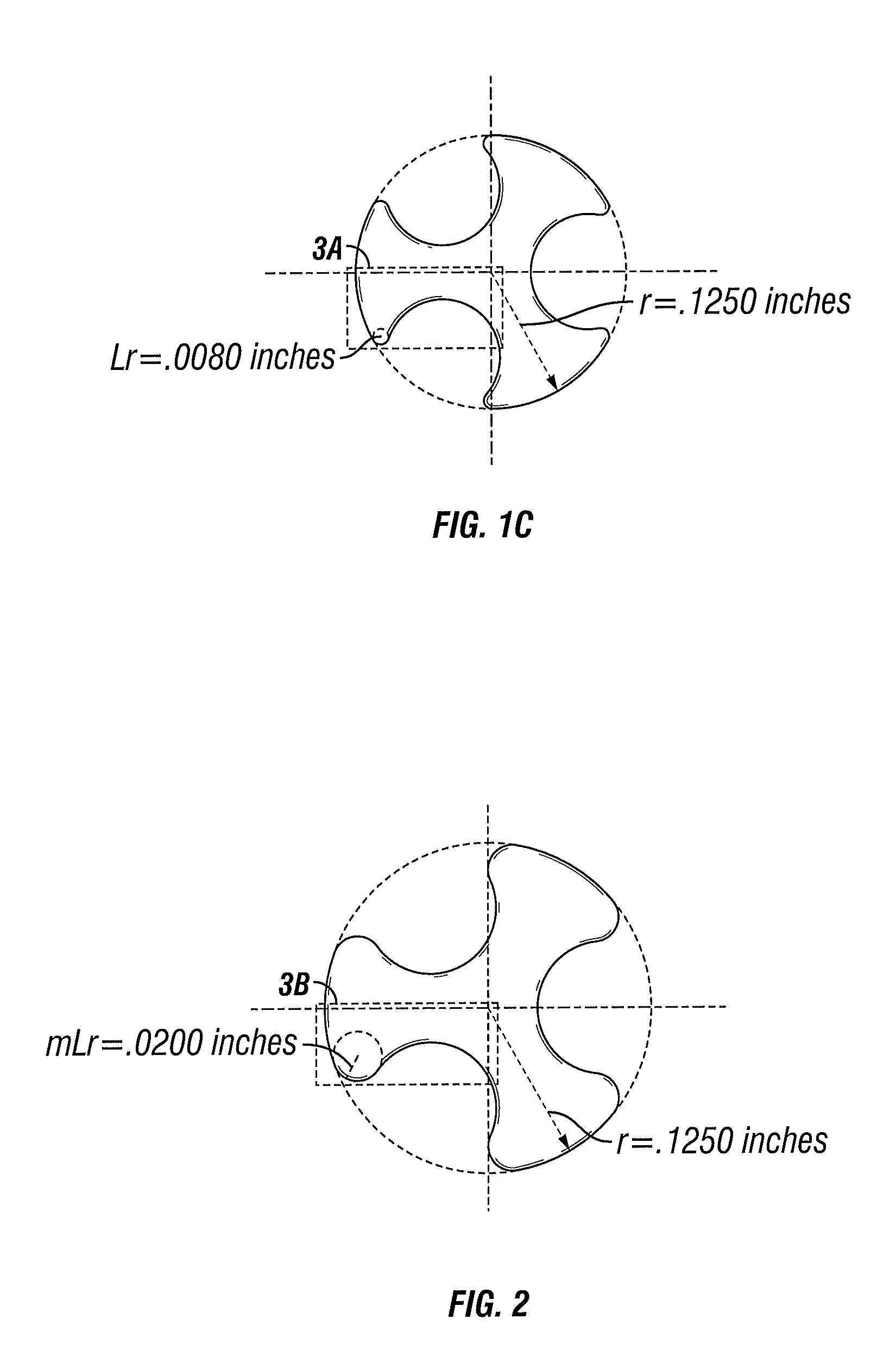

Modified trilobe shape for maleic anhydride catalyst

Embodiments of the present invention include improved shaped catalyst structures containing catalytic material comprised of mixed oxides of vanadium and phosphorus and using such shaped catalyst structures for the production of maleic anhydride.

Owner:HUNTSMAN PETROCHEMICAL LLC

Catalyst for hydrogenating cis-butenedioic anhydride to prepare butanedioic anhydride and its prepn and application

InactiveCN1453066AHigh surface areaImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCarboxylic acid anhydrides preparationButanedioic acidPtru catalyst

The catalyst has active component Ni and carrier SiO2 and Al2O3 in the molar ratio of 1 to 1.47-5.98 to 0-3.3. The catalyst is prepared with Ni(NO3)2, ethyl metasilicate with or without aluminum nitrate and ethanol, and through pH regulation to 3-5 or 7-9 with acetic acid, ammonia water or urea, heating at 80-120 deg.c to form gel, roasting at 400-550 deg.c and reduction at 400-580 deg.c. One technological process of catalytically hydrogenating cis-butenedioic anhydride to prepare butasnedioic anhydride in the state with or without solvent is provided. The catalyst has the features of highspecific surface area, high dispersion of metal in carrier, high heat stability, high catalytic activity, high selectivity, capacity of being reused, easy separation from the product, low cost, low consumption and mild reaction condition.

Owner:SHANXI UNIV

Method of making indeno-fused naphthol materials

ActiveUS20120157696A1Organic compound preparationPreparation from carboxylic acid esters/lactonesHydrogenPyran

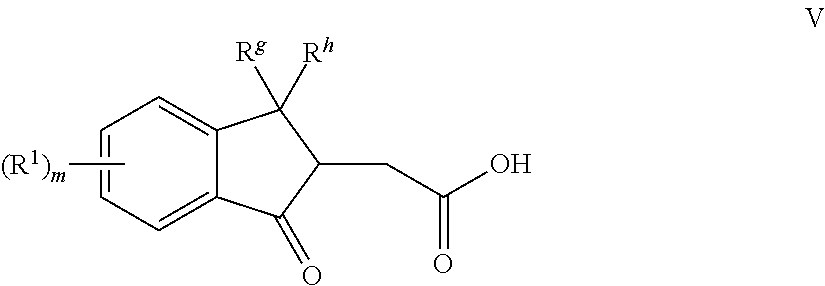

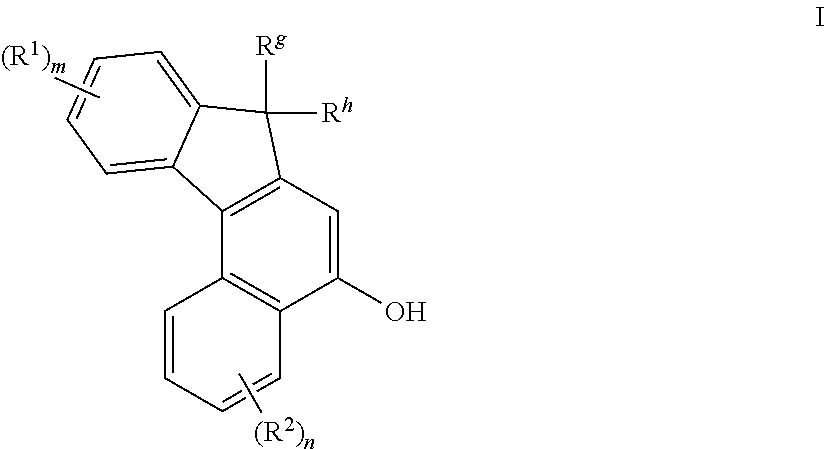

The present invention relates to a method of making indeno-fused naphthol materials, that involves, with some embodiments, forming an indanone acid intermediate, which can be represented by the following general Formula V,With Formula V, m is from 0 to 4, and R1 for each m, Rg and Rh can each be independently selected from, for example, hydrogen and hydrocarbyl. The present invention also relates to a method of making an indeno-fused naphthopyran that involves an indanone acid intermediate synthetic route.

Owner:TRANSITIONS OPTICAL INC

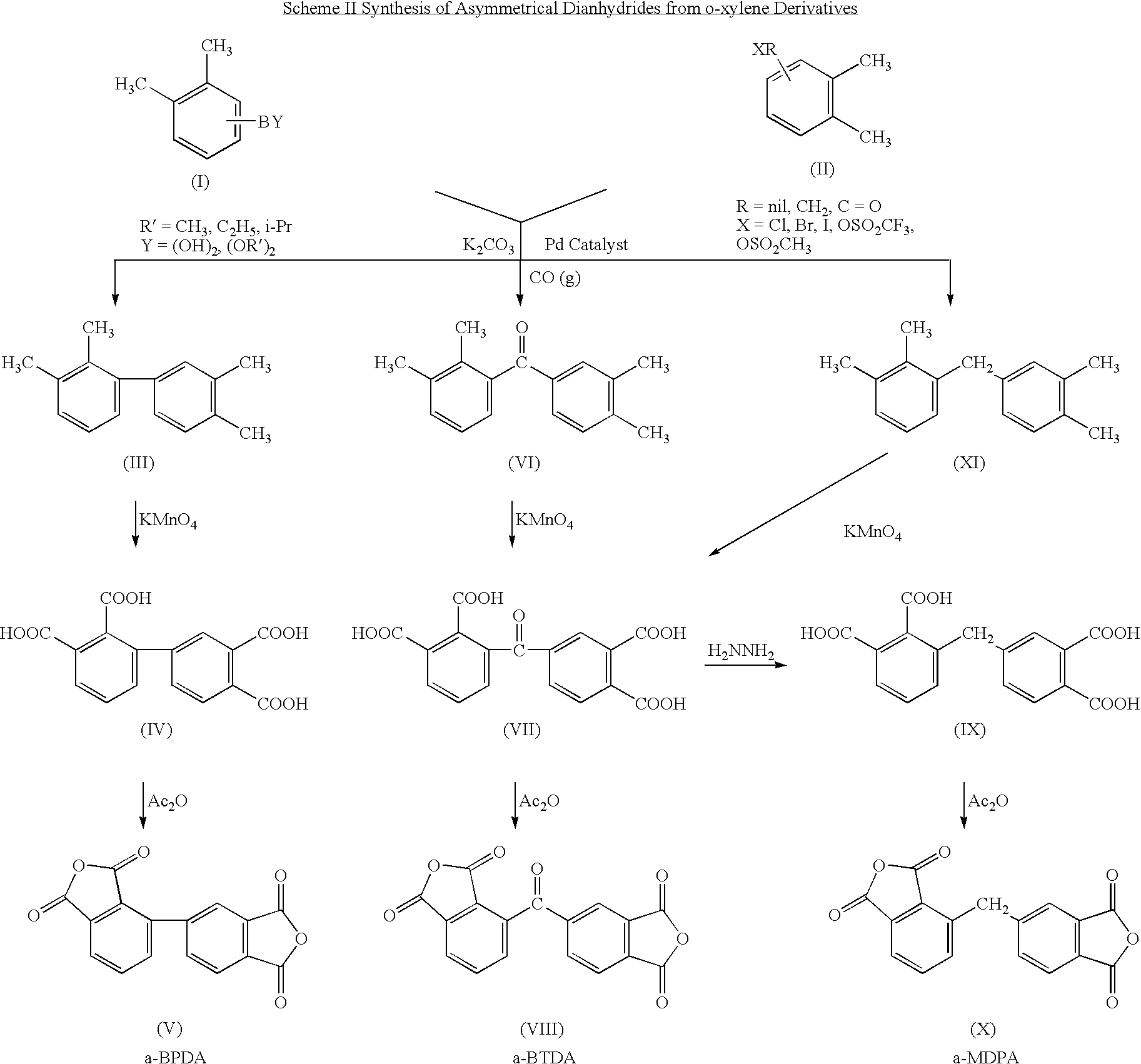

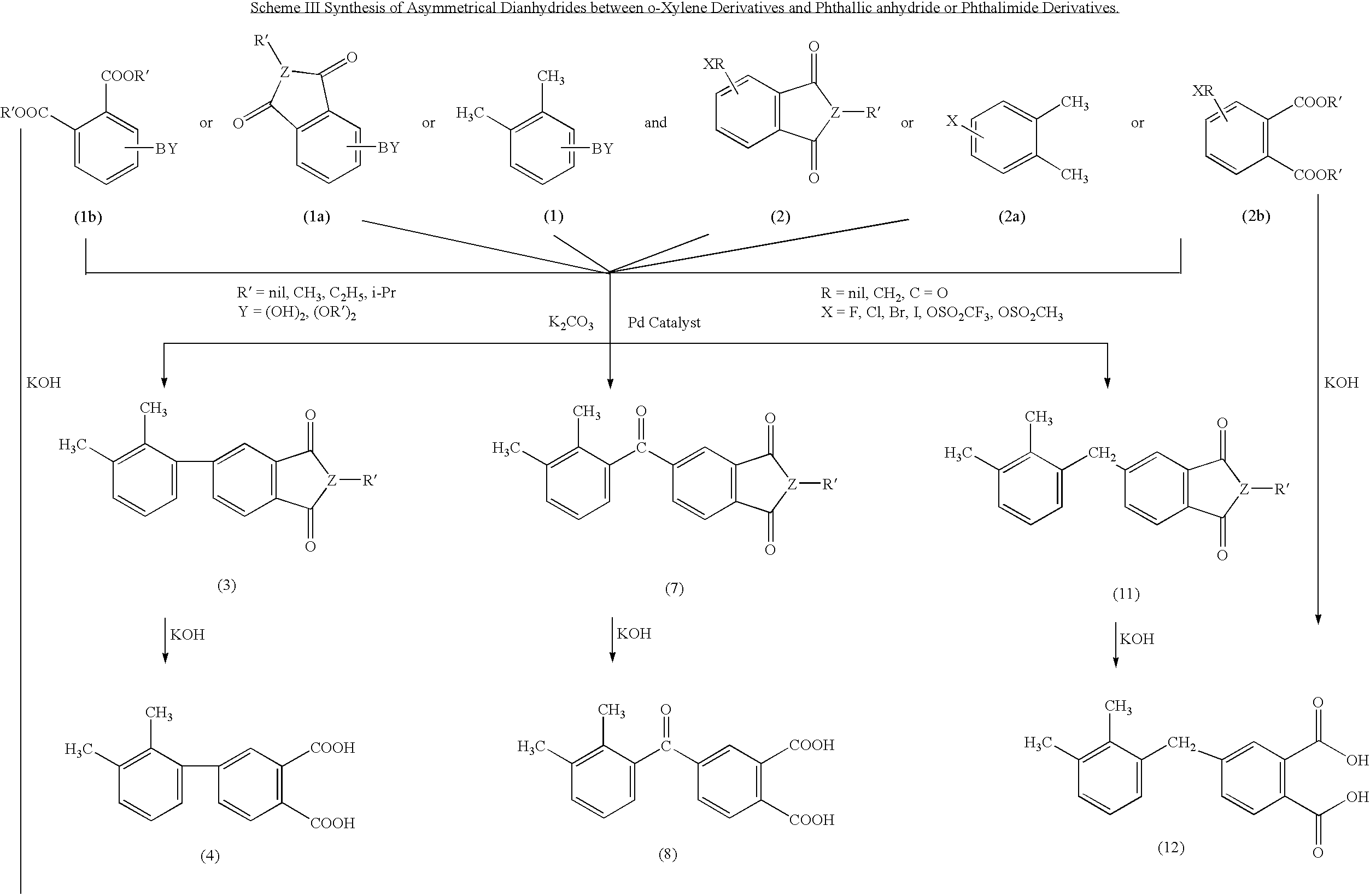

Synthesis of asymmetric tetracarboxylic acids and corresponding dianhydrides

ActiveUS7425650B1High yieldOrganic compound preparationPreparation from carboxylic acid amidesO-XyleneBPDA

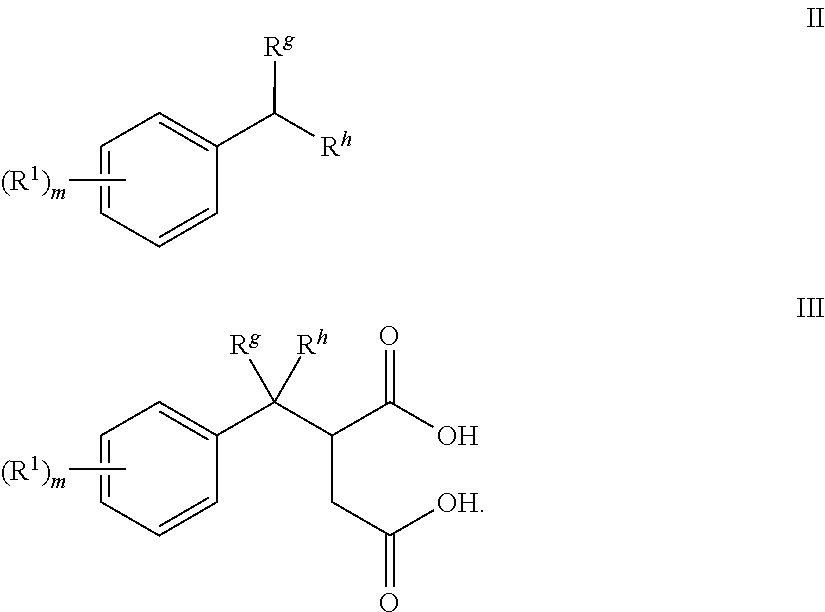

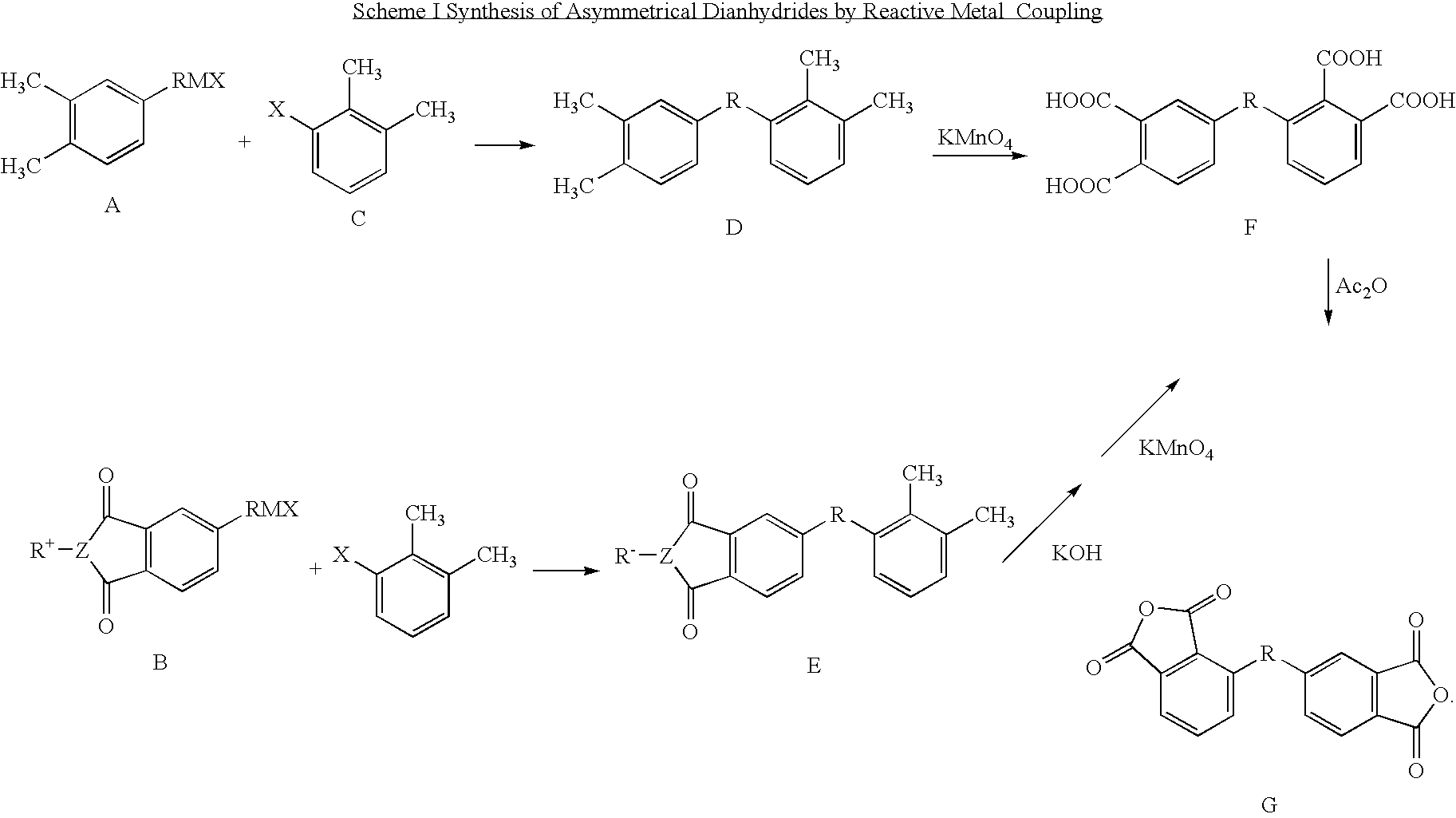

This invention relates to processes for preparing asymmetrical biphenyl tetracarboxylic acids and the corresponding asymmetrical dianhydrides, namely 2,3,3′,4′-biphenyl dianhydride (a-BPDA), 2,3,3′,4′-benzophenone dianhydride (a-BTDA) and 3,4′-methylenediphthalic anhydride (-MDPA). By cross-coupling reactions of reactive metal substituted o-xylenes or by cross-coupling o-xylene derivatives in the presence of catalysts, this invention specifically produces asymmetrical biphenyl intermediates that are subsequently oxidized or hydrolyzed and oxidized to provide asymmetric biphenyl tetracarboxylic acids in comparatively high yields. These asymmetrical biphenyl tetracarboxylic acids are subsequently converted to the corresponding asymmetrical dianhydrides without contamination by symmetrical biphenyl dianhydrides.

Owner:UNITED STATES GOVERNMENT ADMINSRATOR OF NAT AERONAUTICS & SPACE

Catalyst system for synthesizing acetic acid and acetic anhydride from carbonyl compound and its uses

ActiveCN1876239AImprove performanceGuaranteed stabilityCarboxylic preparation from carbon monoxide reactionMetal/metal-oxides/metal-hydroxide catalystsIodised saltAcetic anhydride

The related catalyst system comprises Rh compound as catalyst, all of alkyl iodide, heteropoly salt and alkali iodide together as promoter. This invention is fit to prepare acetyl oxide by carbonylating methyl acetate or acetic acid by methanol.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

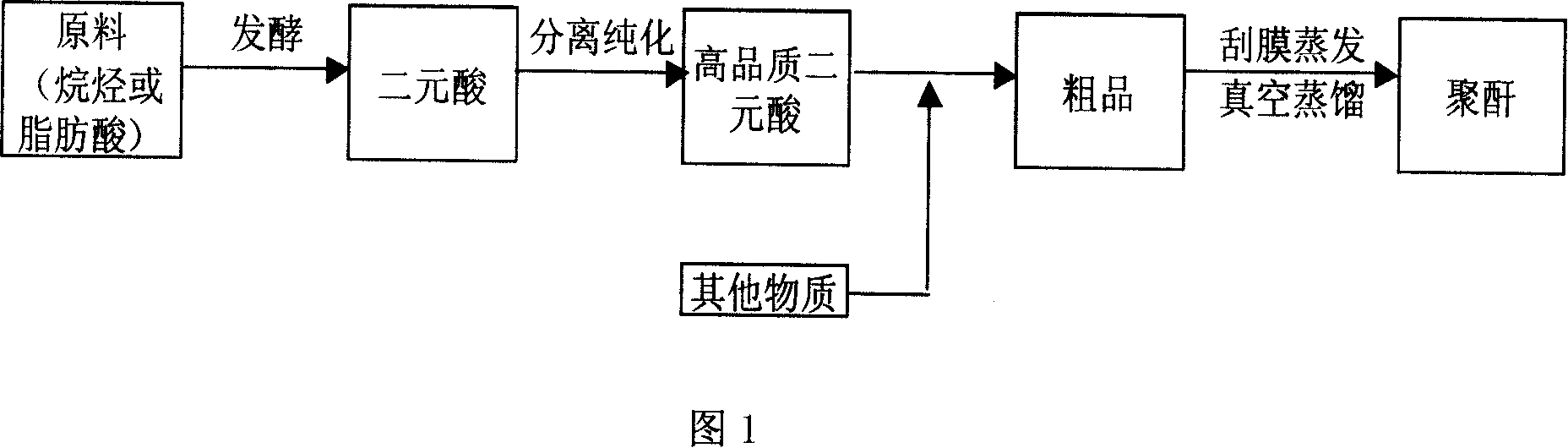

Powder paint solidifying agent and method of manufacturing used long chain carbon polyanhydride

InactiveCN101108928ALight colorGood yellowing resistanceOrganic compound preparationPowdery paintsAlkaneDistillation

The invention discloses the long carbochain biatomic acid polyanhydrides curing agent with high quality using the alkane or the fatty acid as raw material and prepared by biological method. The biatomic acid polyanhydrides curing agent can be used for the curing of the powder coating. The invention also provides the preparation process of the long carbochain biatomic acid polyanhydrides curing agent. The process is started from the alkane or the fatty acid. First the biological fermentation method is applied to produce the long carbochain biatomic acid to gain the biatomic acid conforming to the requirements after special purification process. The biatomic acid carries out dehydration under normal pressure with other reactant under the material temperature of 100 DEG C. to 140 DEG C. and distillation time of 1h to 6h, and is decompressed and distilled to gain the finished product under the condition of the vacuum degree less than 15mmHg and temperature of 110 DEG C. to 140 DEG C., or is distilled in a wiped film vaporization device to remove the substance with small molecules to gain the polyanhydrides curing agent finished product. The long carbochain polyanhydrides curing agent gained by the invention has product color less than (Gardner chroma), ash not higher than 80ppm and nitrogen content not higher than 60ppm, melting point capable of being adjusted according to the requirement of the actual application, good resistance to yellow changing and completely meets the requirement of the high-grade powder coating on the curing agent.

Owner:CATHAY R&D CENT CO LTD +1

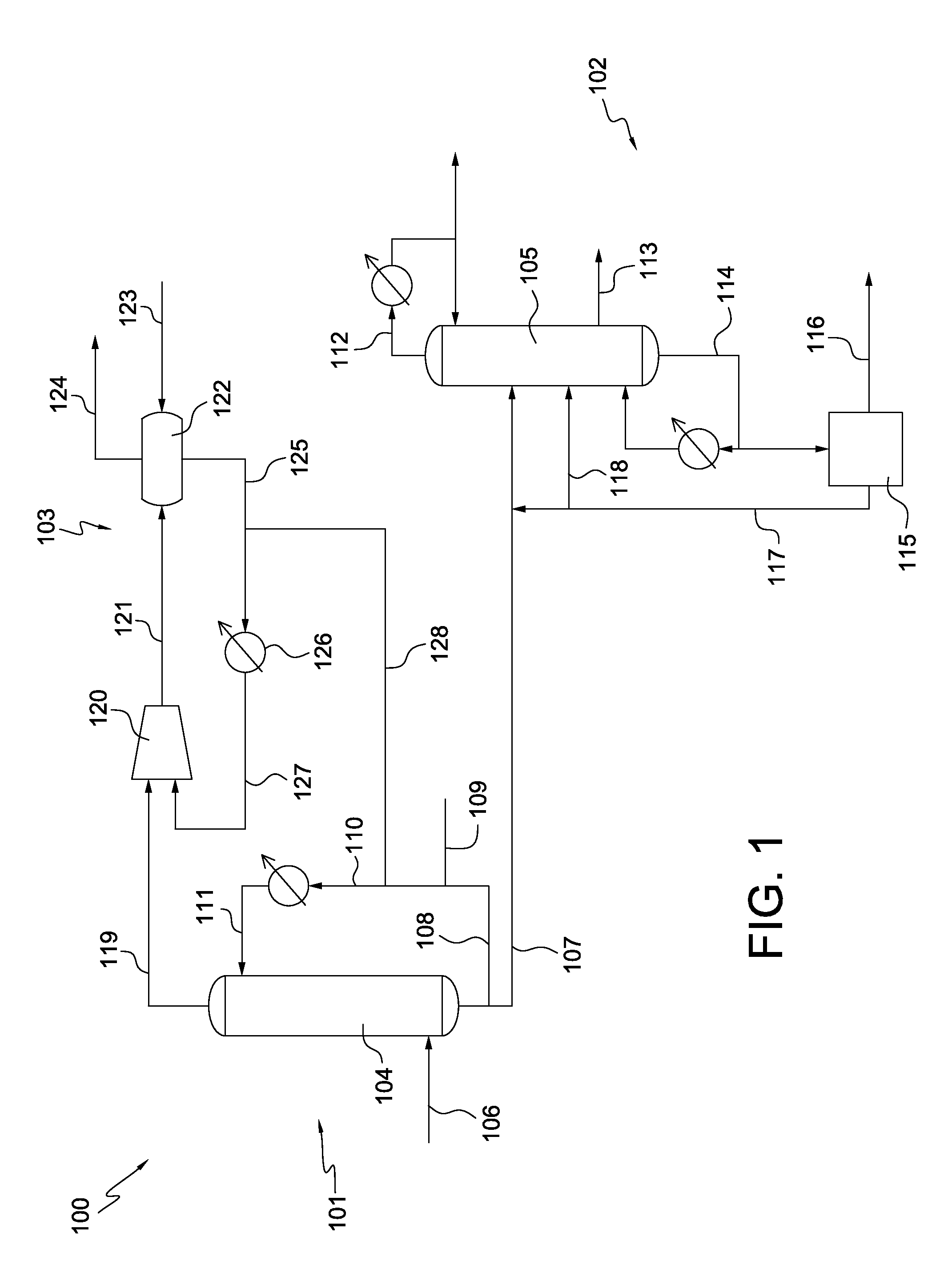

Processes For Purifying Acetic Anhydride and Method of Making Same

ActiveUS20140066653A1Organic compound preparationVacuum distillation separationAcetic acidAcetic anhydride

In one embodiment, the invention is to a process for purifying acetic anhydride. The process includes the steps of feeding a liquid crude acetic anhydride stream directly to a distillation column and separating the liquid crude acetic anhydride stream to produce a light ends stream, a sidedraw and a residue stream. The sidedraw comprises substantially pure acetic anhydride product. The distillation column is operated at a pressure less than 101 kPa. The substantially pure acetic anhydride product comprises greater than 98 wt. % acetic anhydride, has a permanganate time of greater than 10 minutes, and has an APHA color of less than 10.

Owner:CELANESE INT CORP

Catalyst system of catalytic methylester acetate or methylether synthetic acetoanhy dride and use thereof

ActiveCN1778468AImprove stabilityEasy to adjustOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic acid anhydrides preparationIodised saltAcetic anhydride

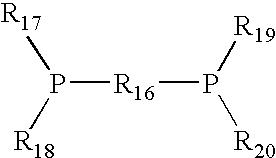

A catalyst system for synthesizing the acetic anhydride from methyl acetate or bimether by catalytic reaction contains active component (Rh matches) and cocatalyst (alkyl diodine, phosphate and iodine salt). Said catalytic reaction between methyl acetate or bimether, CO and H2 is conducted in acetic acid. Its advantages are high catalytic activity and high stability.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Technique of manufacturing trifluoro acetic anhydride

InactiveCN101108797AWill not polluteProcess parameters are clear and completeCarboxylic acid anhydrides preparationAcetic anhydrideGas phase

A trifluoroacetic anhydride processing technique is provided, which utilizes the trifluoroacetic acid and the phosphorus pentoxide as raw materials. The material usage rate (weight) of the trifluoroacetic acid and the phosphorus pentoxide is 1 : 1.5 to 1 : 0.65 and the phosphorus pentoxide is added twice. The entire operation process is done in the fully sealed state, the high boiling substance (after cut) and the tail gas are treated and recycled after collecting the finished products; the condensing water and the cooling water are water from deep well and the byproduct phosphoric acid are all recycled. The invention prepares the trifluoroacetic anhydride applied in the highly efficient liquid chromatogram and the derivating agent of the gas chromatogram, the solvent, catalyst, the condensation dehydration agent and the retention agent of various synthetic reaction, which has complete, canonical and reasonable process and convenient operation, therefore is suitable for industrial production, can effectively improve the purity and the yield of the products, has no environment pollution and reduces the production cost.

Owner:申厚宝

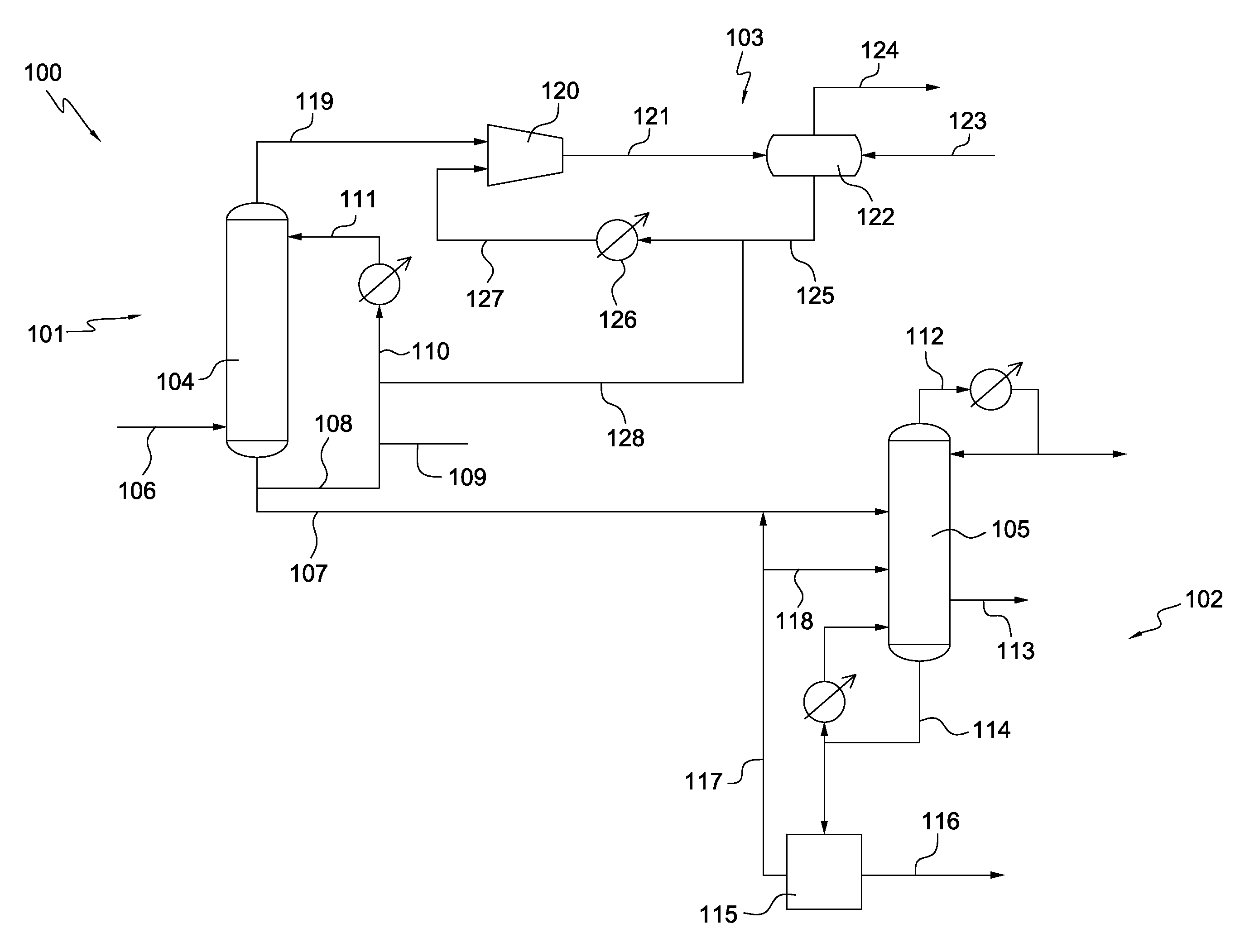

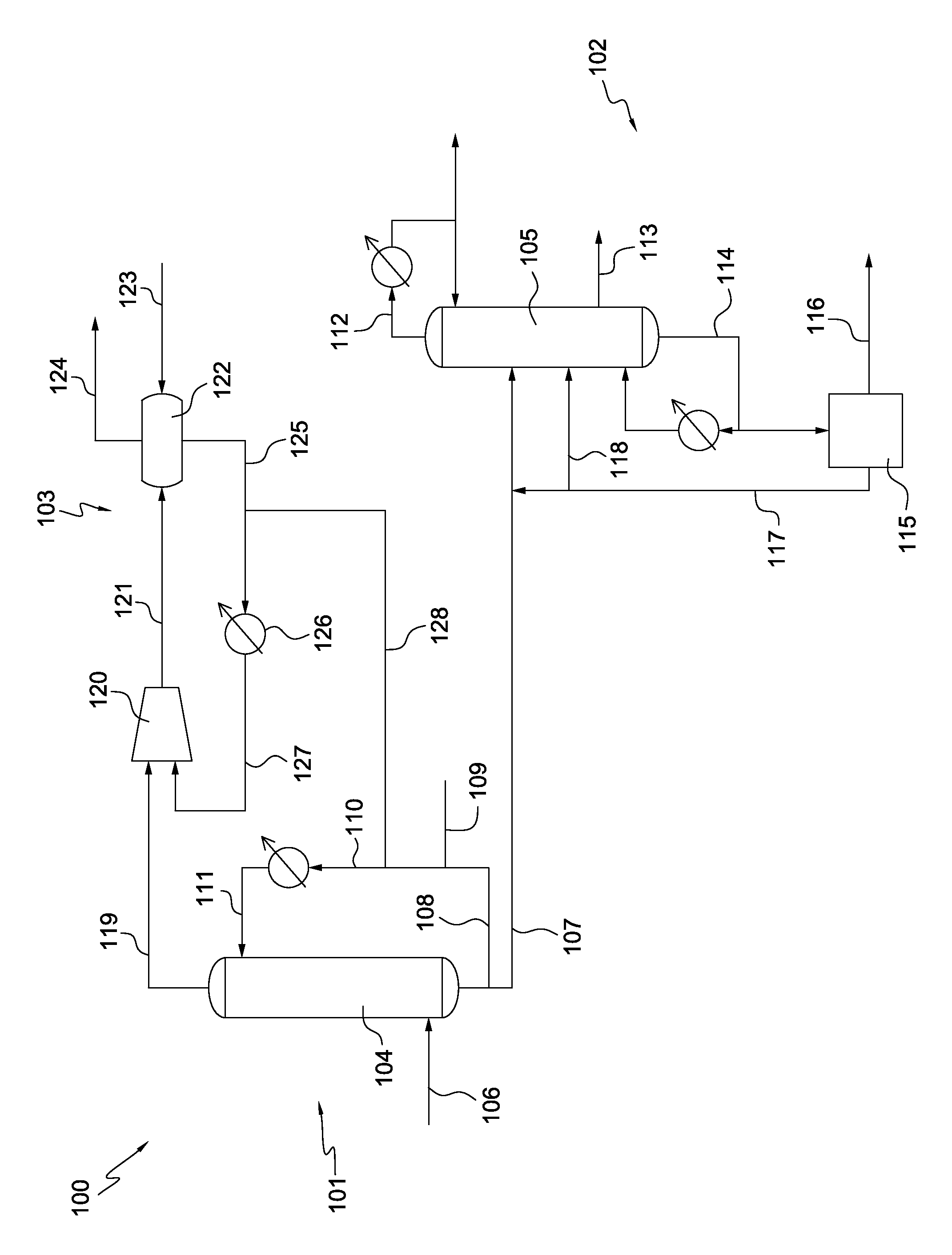

Production of acetic acid and mixtures of acetic acid and acetic anhydride

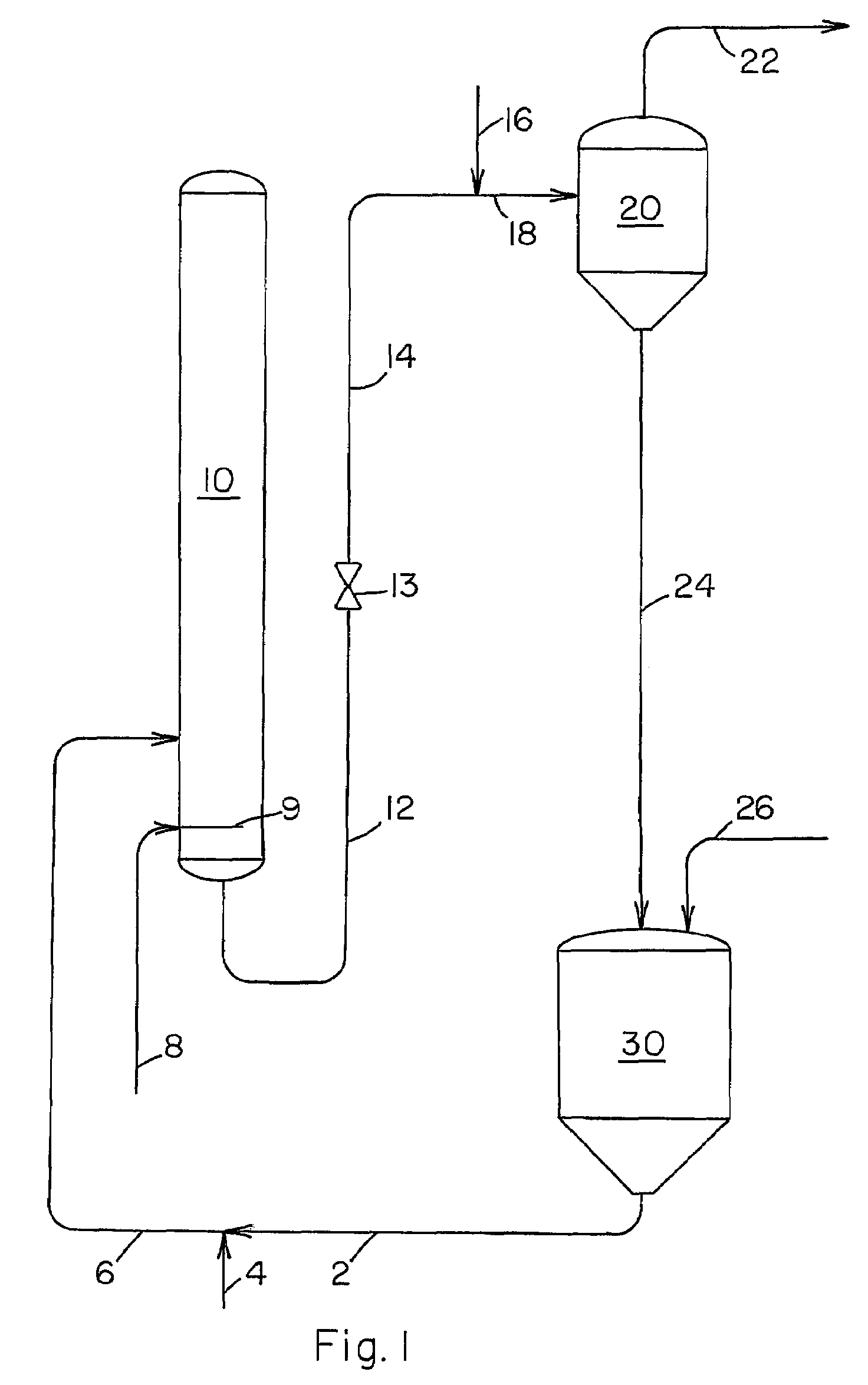

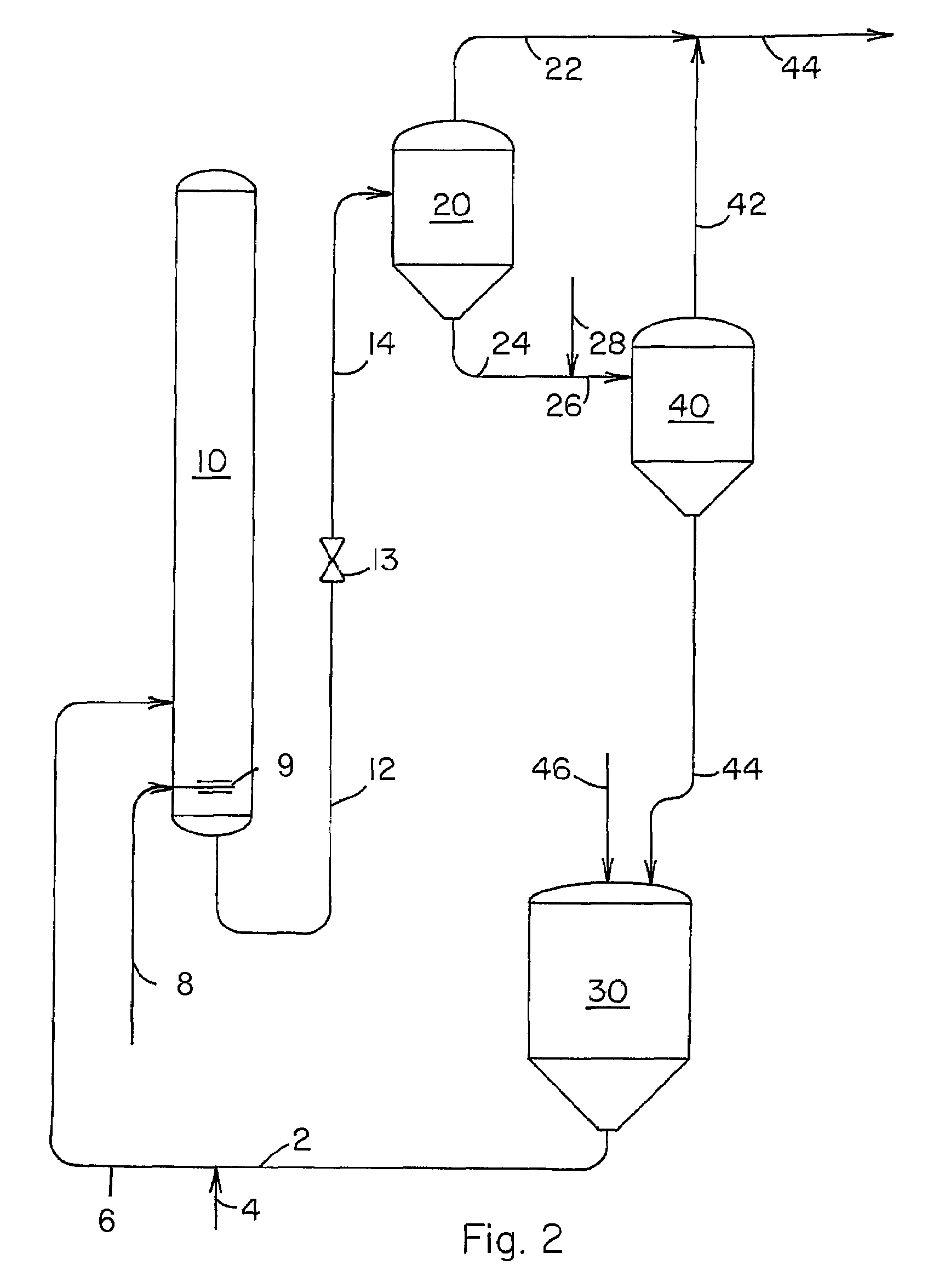

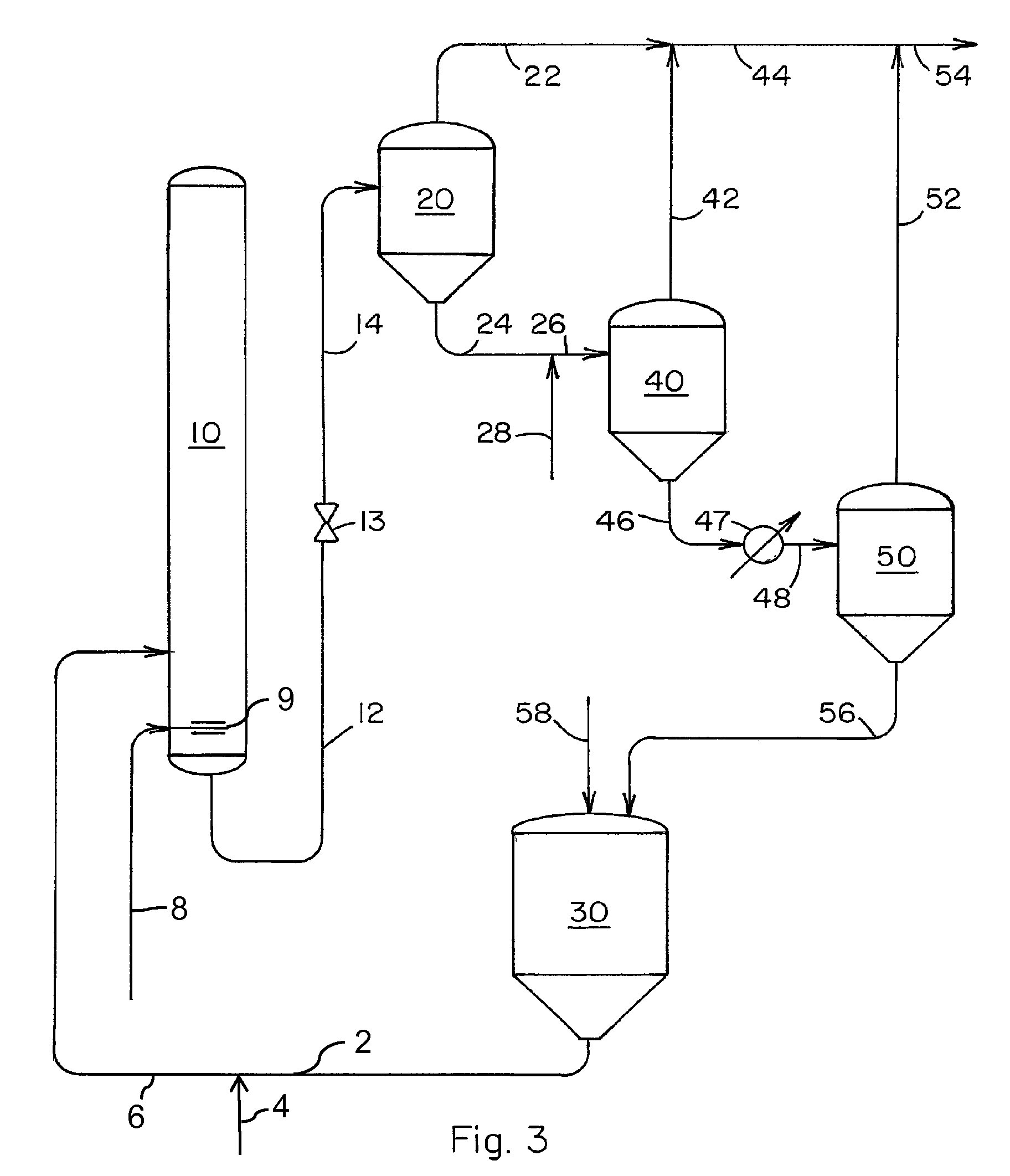

ActiveUS7737298B2Organic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic anhydrideEvaporation

Disclosed is a process for the production of acetic acid or mixtures of acetic acid and acetic anhydride in a carbonylation process wherein a mixture comprising methyl acetate and / or dimethyl ether and methyl iodide is contacting in the liquid phase with carbon monoxide in the presence of a carbonylation catalyst at elevated pressures and temperatures. Methanol, water, or a mixture thereof is added to an acetic anhydride-containing stream within a flash evaporation zone to convert some or all of the acetic anhydride to acetic acid and optionally methyl acetate and to provide heat for the evaporation of a portion of the product effluent produced by the carbonylation process.

Owner:EASTMAN CHEM CO

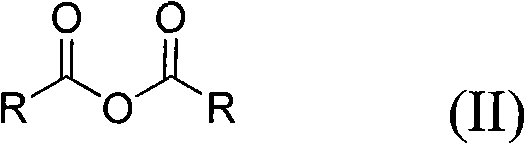

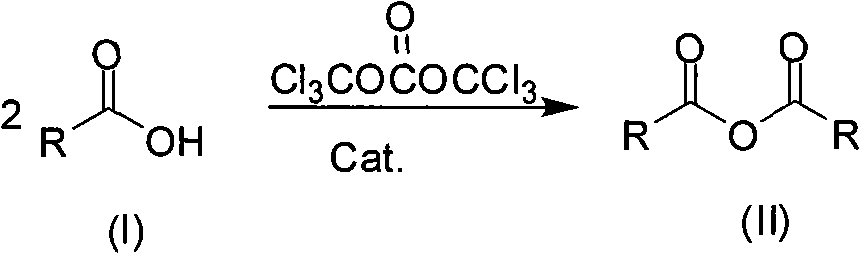

Method for preparing symmetrical acid anhydride

InactiveCN101357884AGet rid of the useAvoid pollutionFunctional group formation/introductionCarboxylic acid anhydrides preparationOrganic solventCarbonate ester

The invention discloses a preparation method for symmetric anhydride, which comprises the following steps: raw materials are corresponding carboxylic acid RCOOH and bis(trichloromethyl) carbonic ester, which react in organic solvent under the action of catalyst for 1 to 10h under the temperature of 40 to 100 DEG C. The reacted mixture is post-processed, and the symmetric anhydride indicated in formula (II) is obtained. The catalyst is tertiary amine with N-formyl group, and the molar ratio of the carboxylic acid, bis (trichloromethyl) carbonic ester and the catalyst is 1:0.17-0.19:0.005-0.1. The preparation method has the advantages of advanced technical route, mild reaction condition, high reaction yield, low three-waste, low catalyst consumption, and the like, and is the preparation method for symmetric anhydride with good popularization and application prospect.

Owner:ZHEJIANG UNIV OF TECH

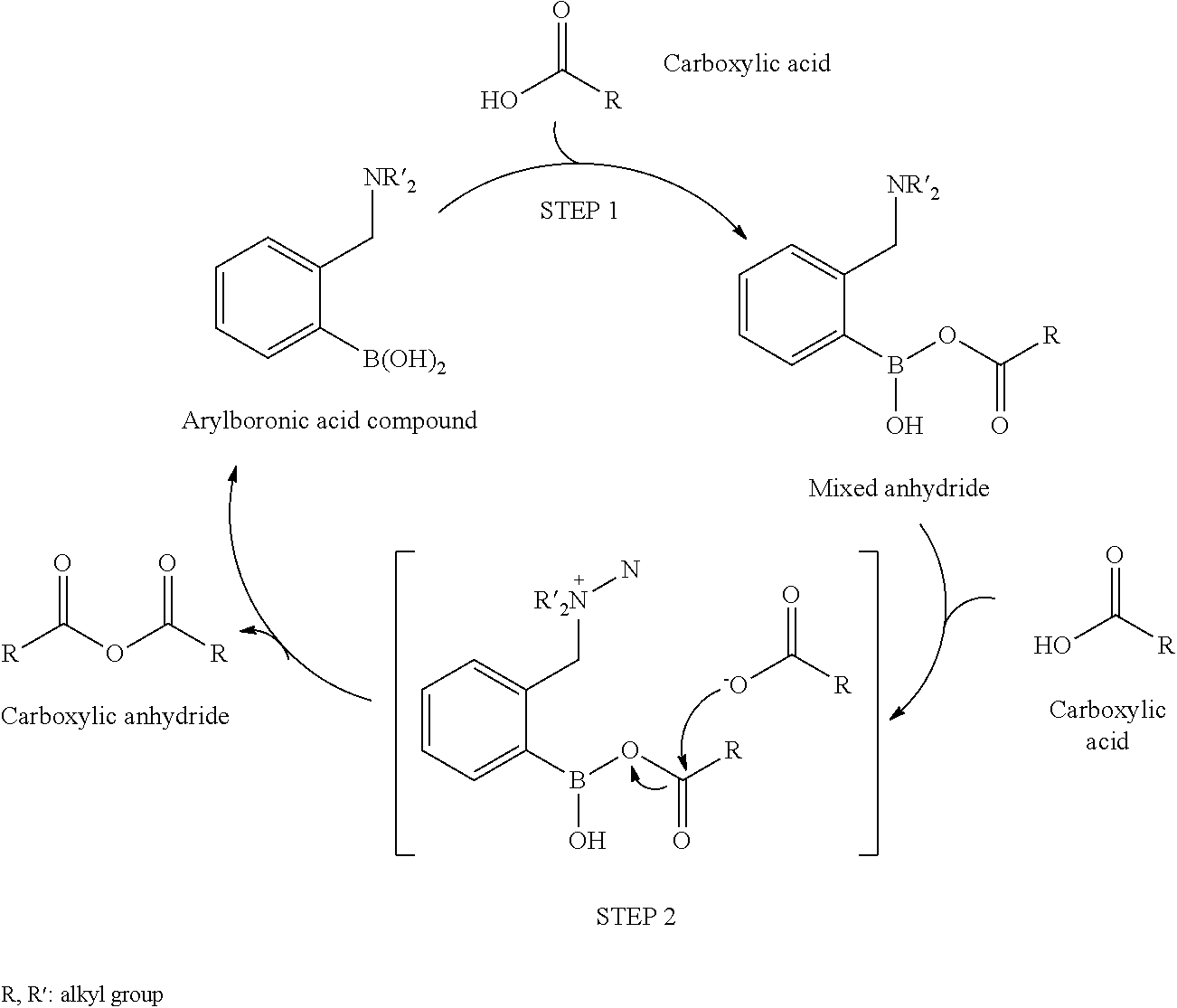

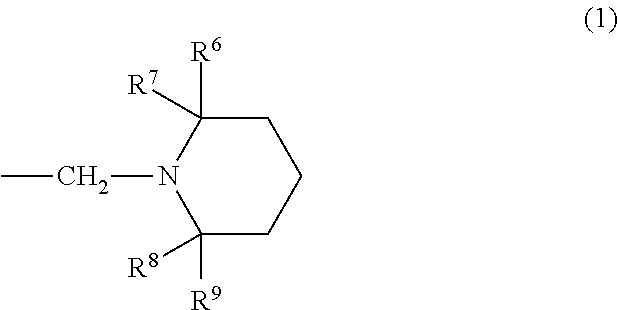

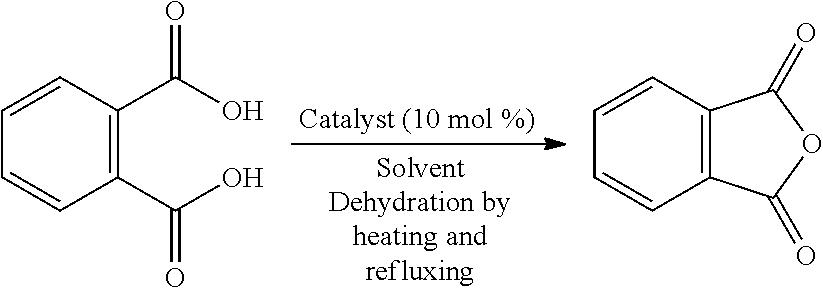

Method for producing carboxylic anhydride and arylboronic acid compound

InactiveUS20110319620A1High yieldEfficient advancementGroup 3/13 element organic compoundsCarboxylic acid anhydrides preparationPhenylboronic acidPhthalic anhydride

When phthalic acid is heated in heptane under azeotropic reflux conditions in the presence of a catalytic amount of an arylboronic acid compound (such as 2,6-(diisopropylaminomethyl)phenylboronic acid or 2,6-bis(diisopropylaminomethyl)phenylboronic acid), phthalic anhydride is obtained in high yield.

Owner:NAGOYA UNIVERSITY

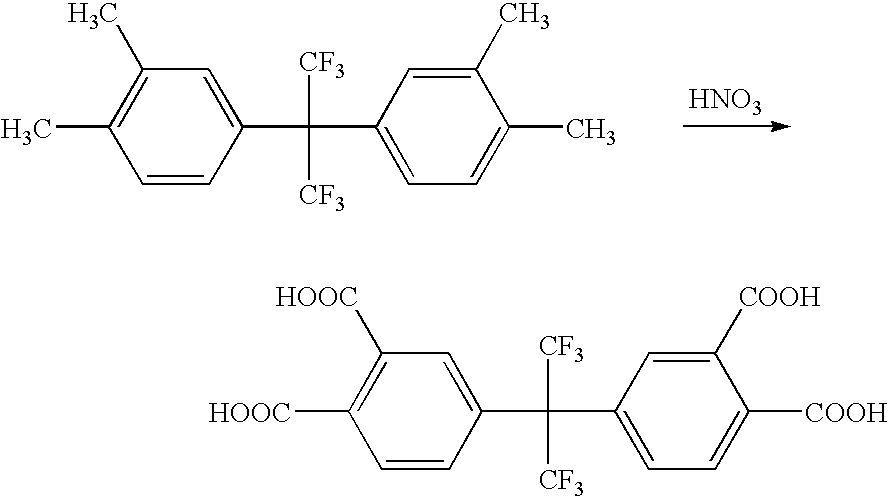

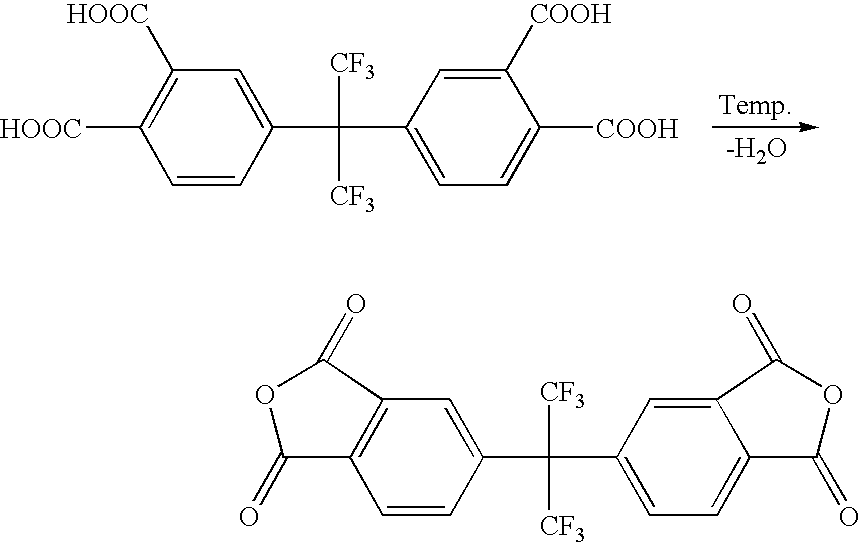

Process for making 2,2-bis (3,4-dicarboxyphenyl) hexafluoropropane

InactiveUS20090156834A1Organic compound preparationCarboxylic preparation by oxidationAqueous solutionNitric acid

There is provided a continuous process for making 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane. The process has the following steps: a) continuously feeding 2,2-bis(3,4-dimethylphenyl)hexafluoropropane and aqueous nitric acid into a reactor cell and b) heating the mixture to a temperature sufficient to effect reaction between the 2,2-bis(3,4-dimethylphenyl)hexafluoropropane and the nitric acid.

Owner:HONEYWELL INT INC

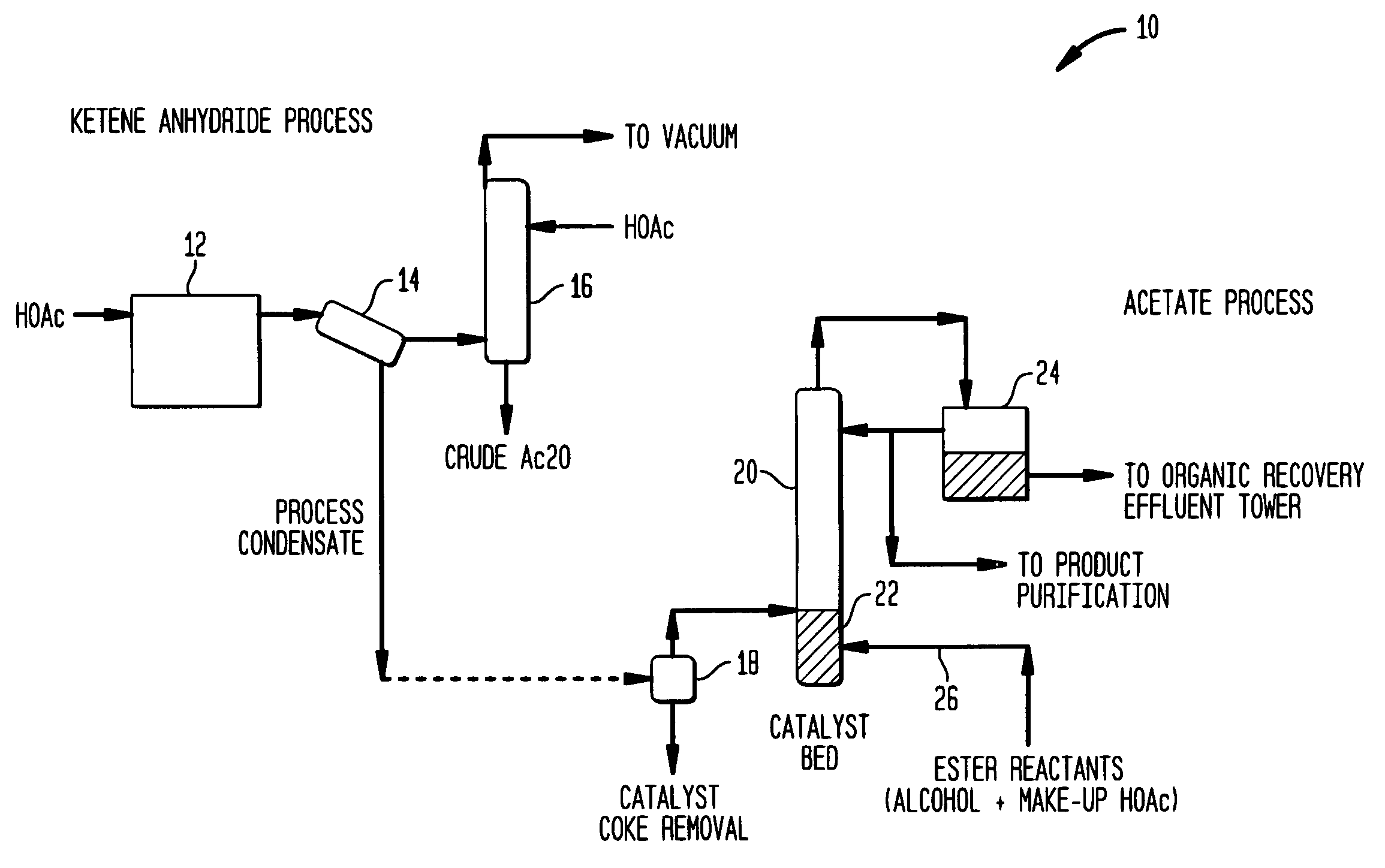

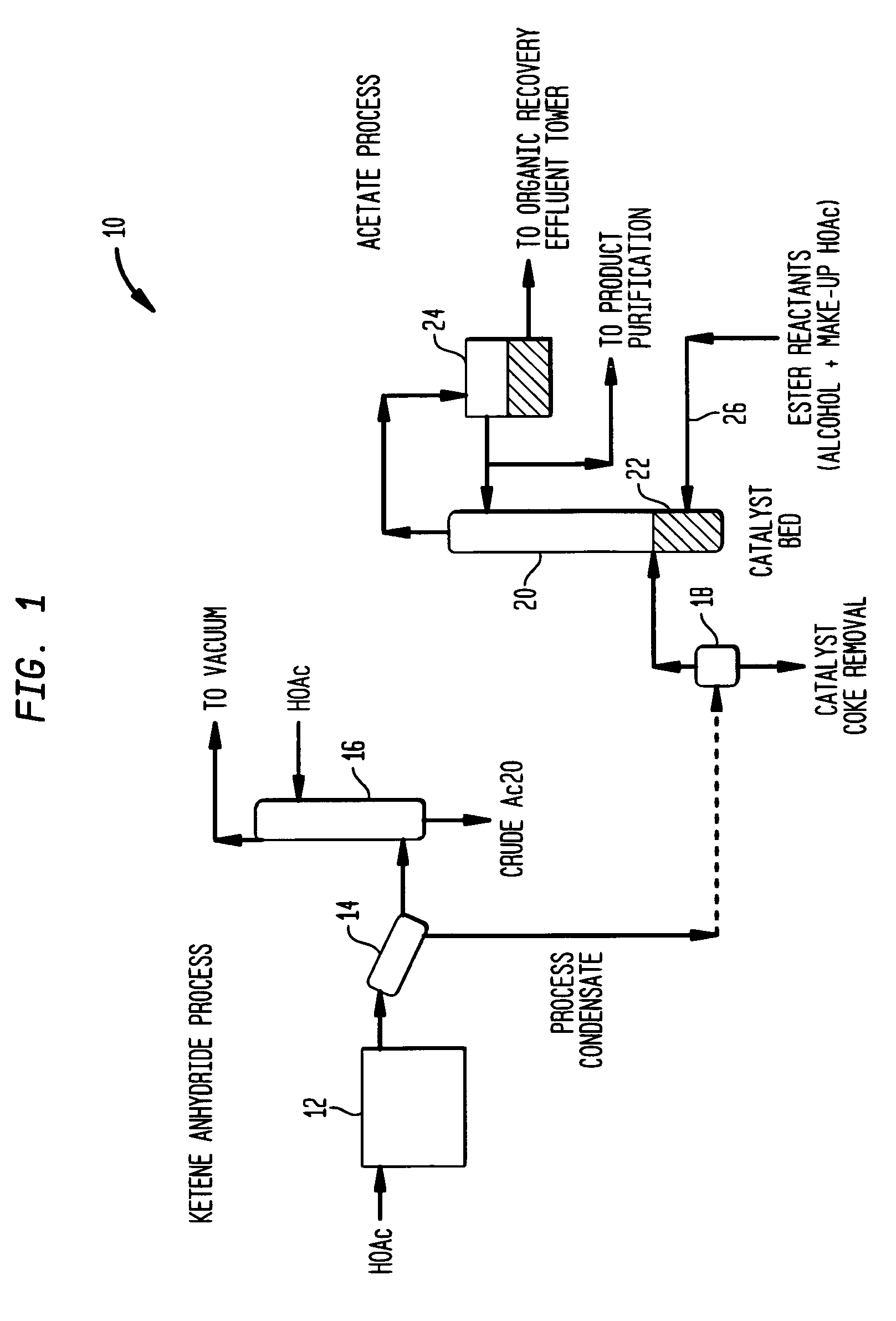

Acetic anhydride and acetate ester co-production

ActiveUS7199263B2Minimizes decompositionOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

A method of co-producing acetic anhydride and an acetate ester includes pyrolizing acetic acid at elevated temperature to produce a first ketene stream, the first ketene stream being a vapor phase stream comprising ketene, acetic acid and water; cooling the first ketene stream to condense acetic acid and water therefrom, thereby generating (i) a weak acid aqueous stream and (ii) a ketene feed stream; feeding the ketene feed stream to an acetic anhydride reactor where the ketene is reacted with acetic acid to produce acetic anhydride; concurrently with step (c), feeding the weak acid aqueous stream to an esterification reactor wherein acetic acid in the weak acid stream is reacted with an organic alcohol to produce an acetate ester. Preferably, the organic alcohol is selected from organic alcohols which (i) form acetate esters which esters and optionally alcohols provide azeotropic mixtures with water and (ii) wherein the azeotropic mixtures have a water content greater than the amount of water generated by reaction of the alcohol with acetic acid to facilitate azeotropically separating the acetate ester from the reaction mixture.

Owner:CELANESE INT CORP

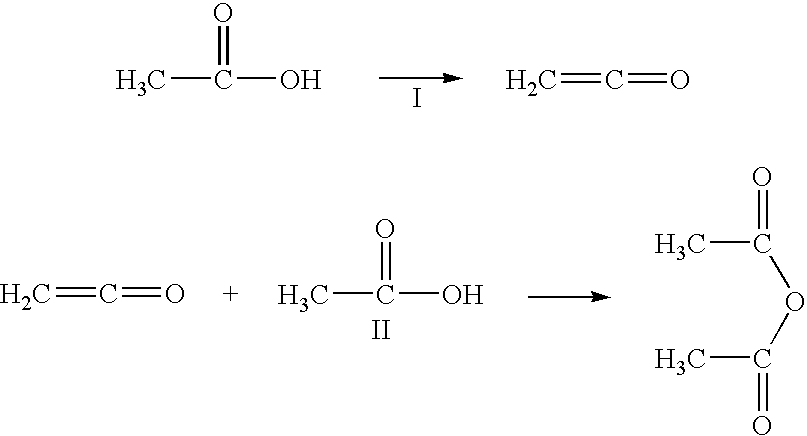

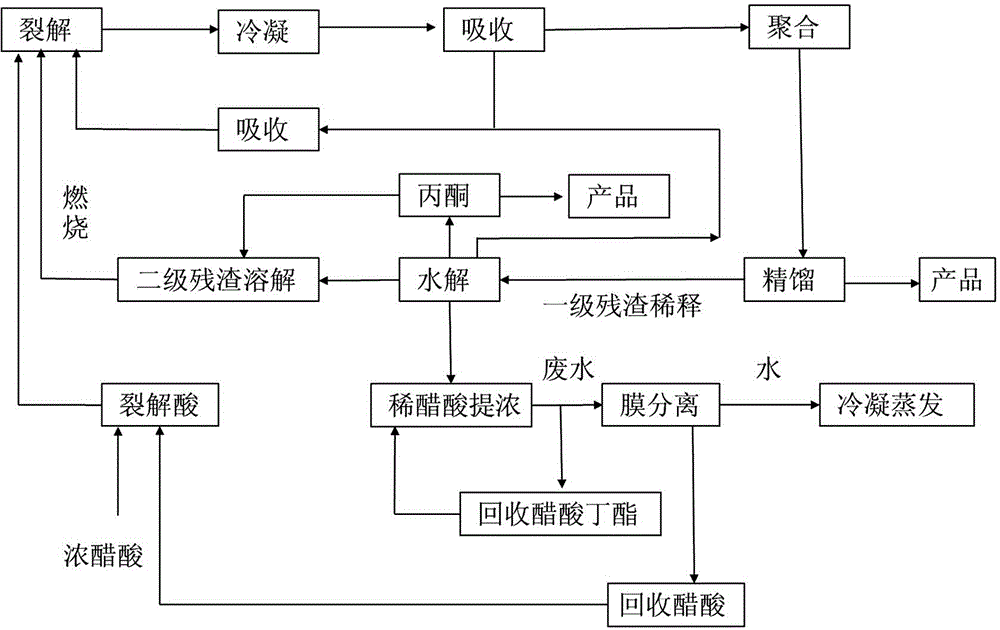

Clean production method of diketene

InactiveCN104402670ASolve the use problemOxygen-containing compound preparationOrganic compound preparationAcetic acidDistillation

The invention provides a clean production method for acetic acid cracking for preparation of diketene. The method comprises the steps of cracking, condensation, absorption, polymerization, distillation, and residue hydrolysis treatment. The method is characterized in that dilute acetic acid is added in the residue hydrolysis section to obtain acetone, acetic acid and secondary residue; the acetone is for recycling, part of the acetone is mixed with the secondary residue to provide heat for fuel production; and acetic acid is subjected to separation, extraction and concentration and enters the cracking section as a production raw material. The invention has the advantages that by optimizing the process and the circular route, the generated waste gas and residue in the production process are digested and absorbed in the system, so as to realize clean production.

Owner:ANHUI JINGHE IND

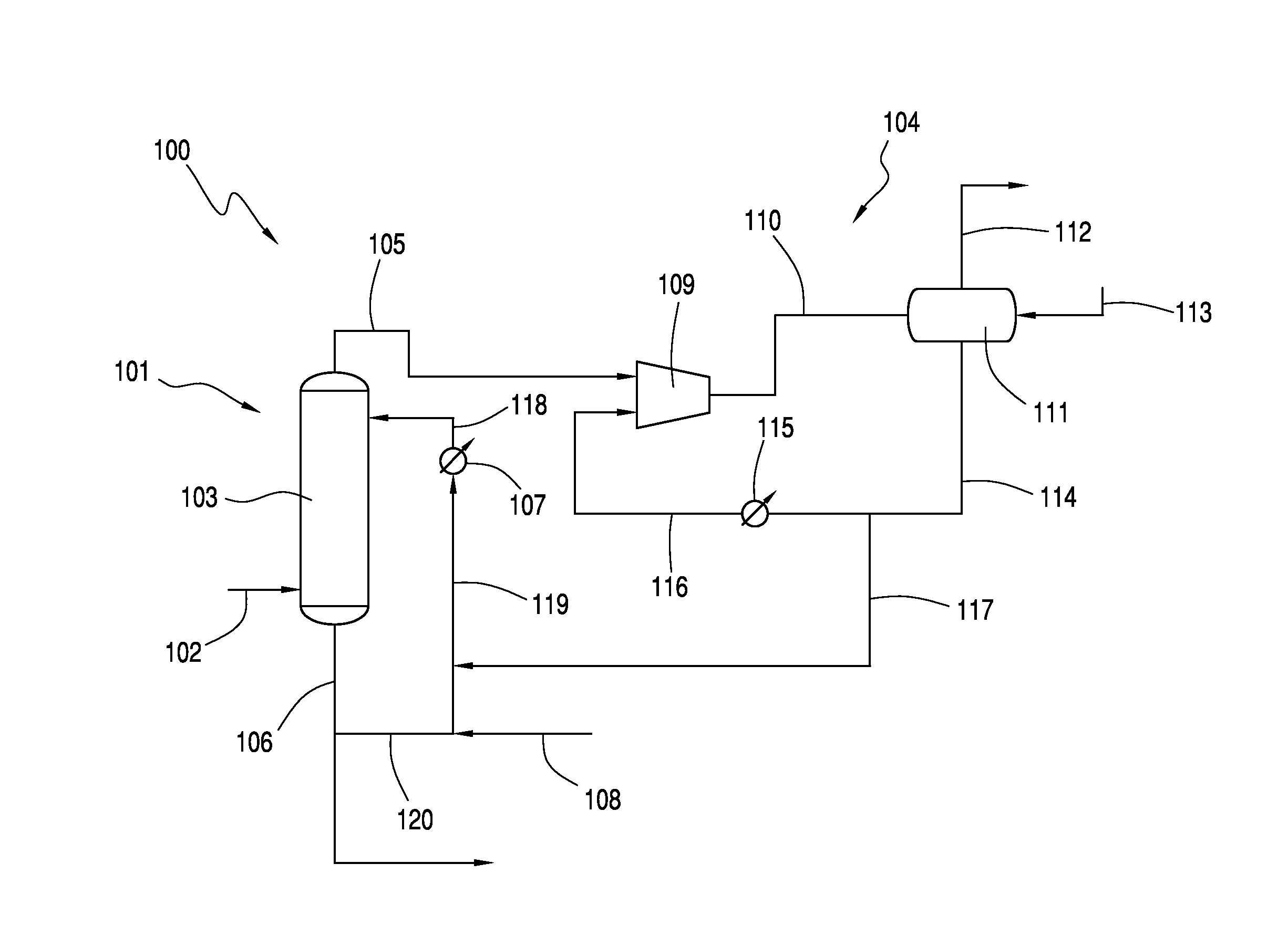

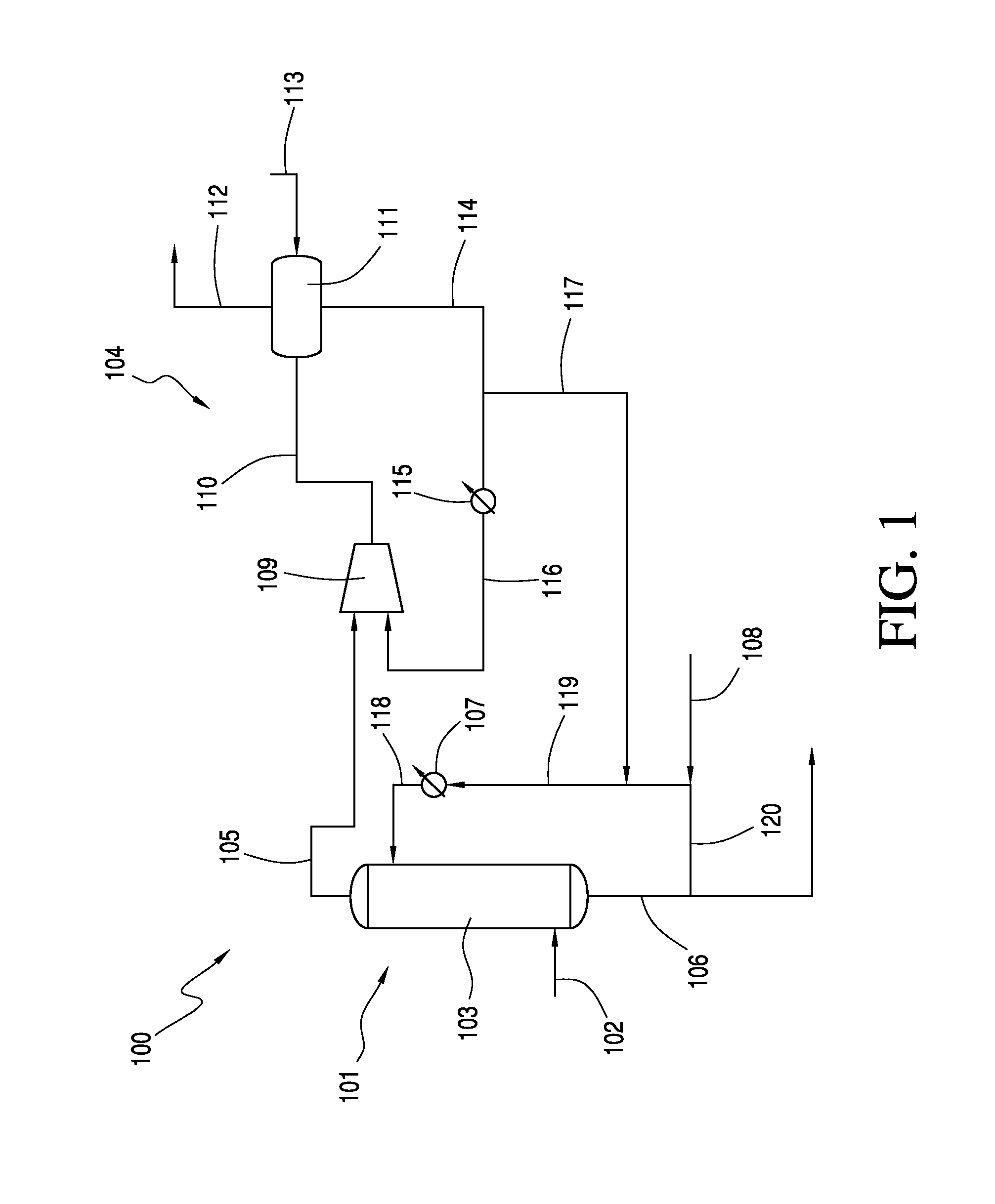

Processes for Preparing Acetic Anhydride

ActiveUS20130197267A1Organic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidAcetic anhydride

In one embodiment, the invention is to a process for producing acetic anhydride. The process includes at least a step of carbonylating methanol and / or a methanol derivative with carbon monoxide to form acetic acid, and contacting ketene with the acetic acid to form a crude acetic anhydride product stream and a vent stream having unreacted ketene. The process further comprises a step of directing at least a portion of the vent stream to a liquid ring vacuum compressor having a ring seal fluid comprising acetic acid The unreacted ketene in the portion of the vent stream contacts the ring seal fluid to form supplemental acetic anhydride.

Owner:CELANESE INT CORP

Processes for purifying acetic anhydride

ActiveUS8759576B2Organic compound preparationPreparation from carboxylic acid amidesAcetic acidAcetic anhydride

In one embodiment, the invention is to a process for purifying acetic anhydride. The process includes the steps of feeding a liquid crude acetic anhydride stream directly to a distillation column and separating the liquid crude acetic anhydride stream to produce a light ends stream, a sidedraw and a residue stream. The sidedraw comprises substantially pure acetic anhydride product. The distillation column is operated at a pressure less than 101 kPa. The substantially pure acetic anhydride product comprises greater than 98 wt. % acetic anhydride, has a permanganate time of greater than 10 minutes, and has an APHA color of less than 10.

Owner:CELANESE INT CORP

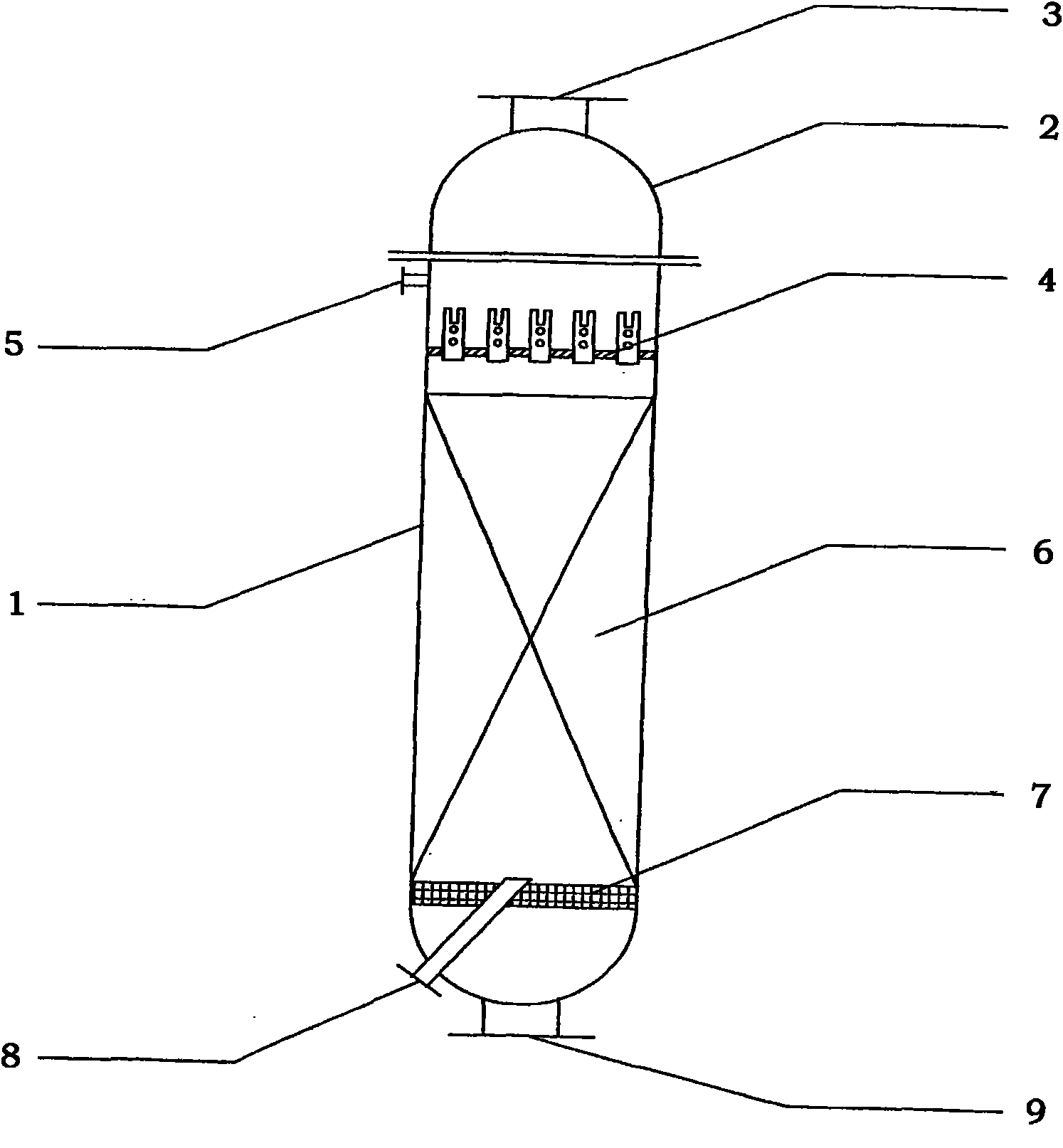

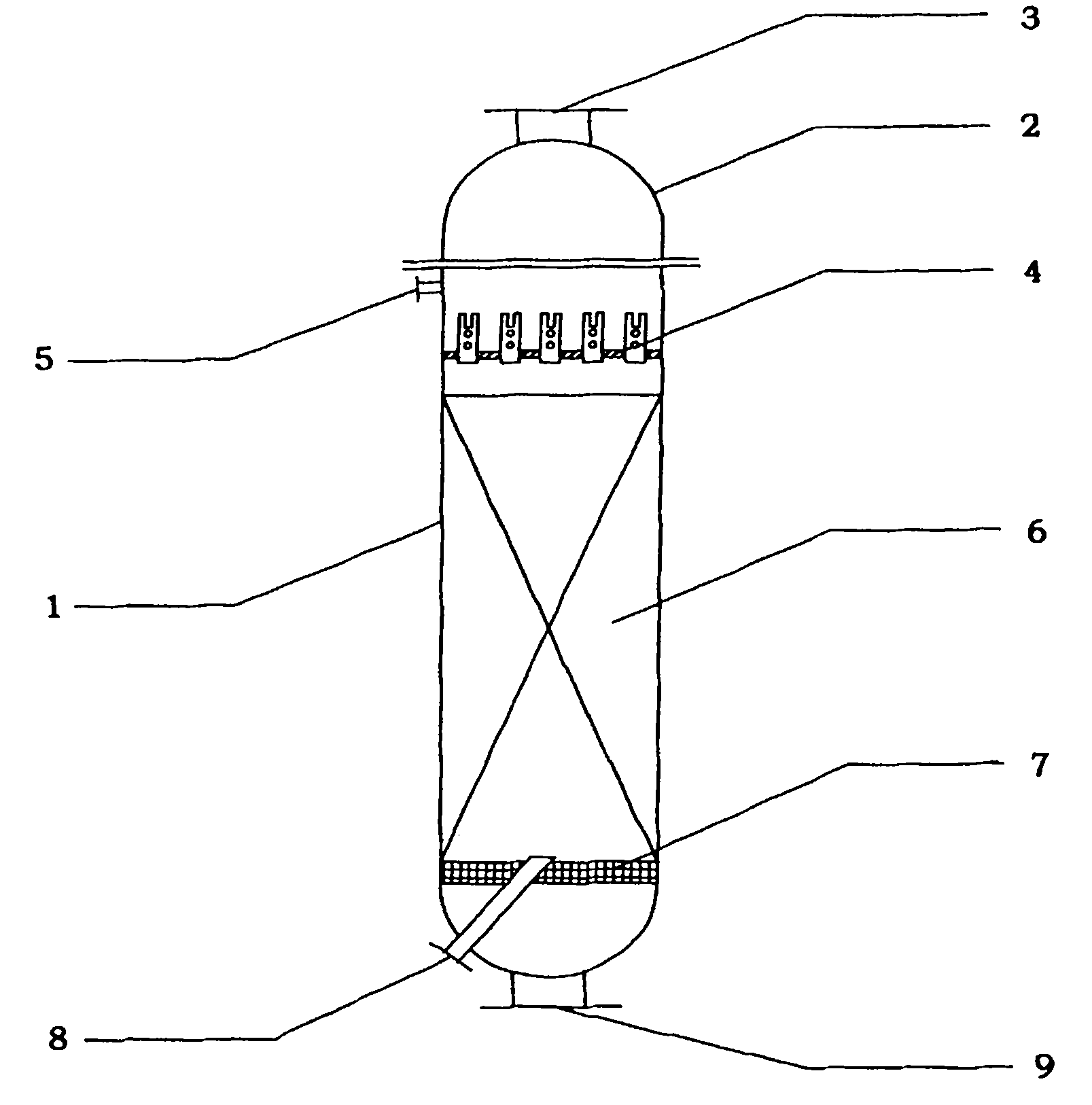

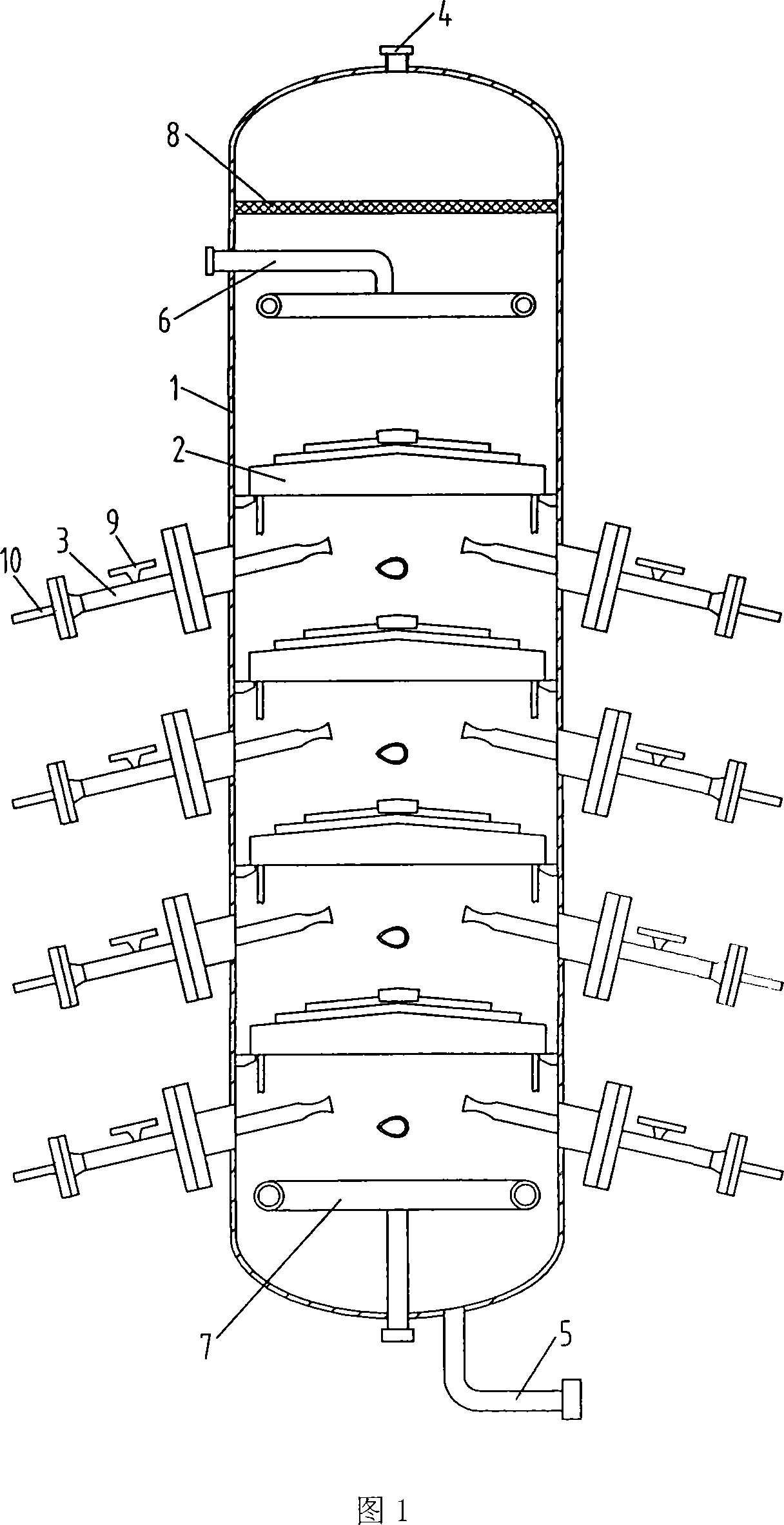

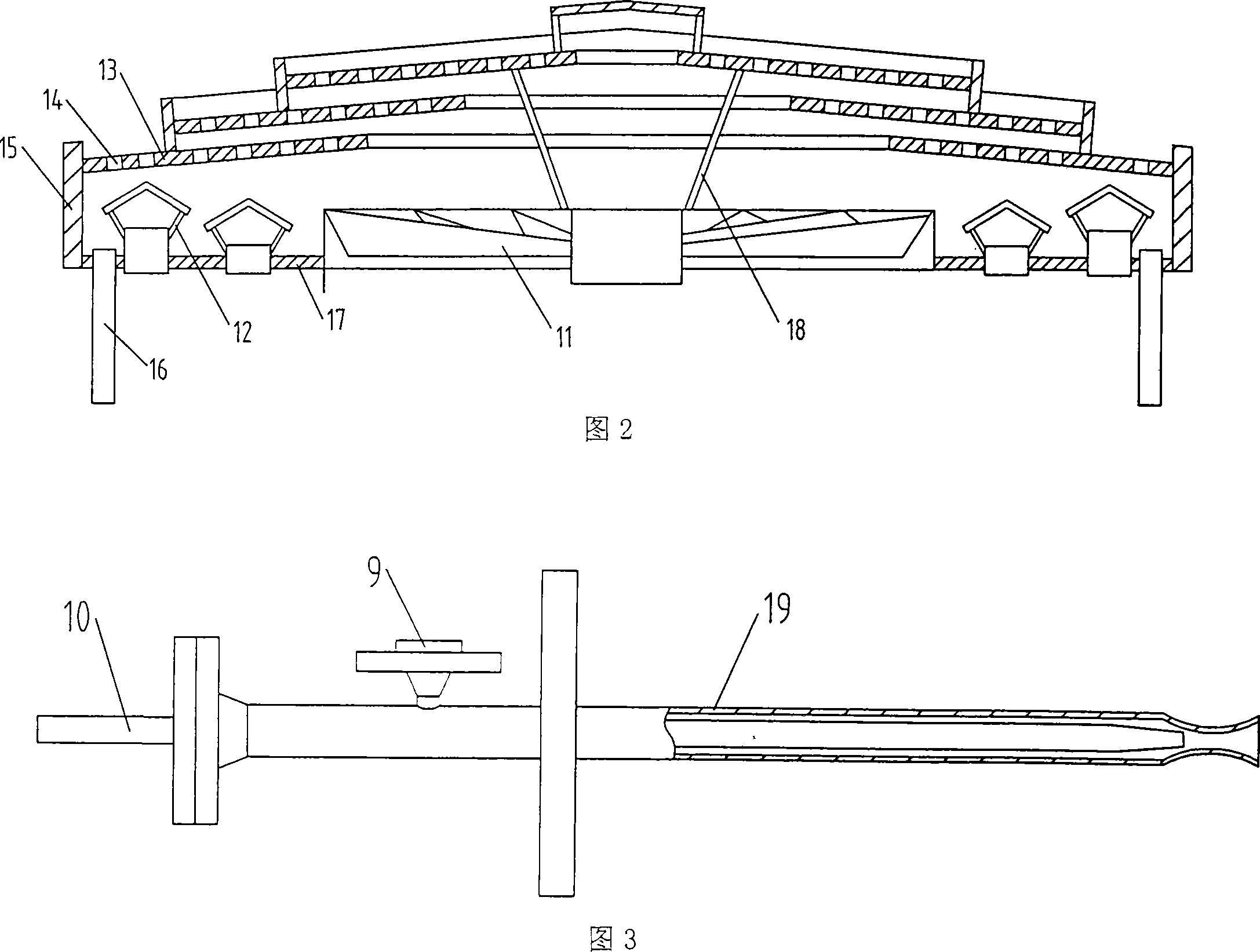

Reactor for preparing succinyl oxide by maleic anhydride hydrogenation

InactiveCN101890323AIncrease productivitySimple structureChemical/physical processesCarboxylic acid anhydrides preparationVertical tubeHydrogen

The invention relates to a reactor for preparing succinyl oxide by maleic anhydride hydrogenation. The invention is characterized in that a trickle bed catalytic reactor is adopted. The trickle bed catalytic reactor is provided with a tower body, a dismountable end socket arranged on the tower body, a hydrogen inlet and a catalyst charging hole which are arranged on the end socket, a distributor arranged at the upper part of the tower body, a maleic anhydride / solvent inlet arranged at the upper part of the distributor, a distribution plate arranged at the lower part of the tower body, a catalyst material layer which is composed of hydrogenation catalyst and is arranged on the distribution plate as well as a catalyst discharging hole and a product outlet which are arranged at the lower part of the tower body. The distributor is in bubble cap type, CZ type, vertical tube type, Technip type, injection type or Venturi type, the distribution plate is in grid type, porous plate type or grid bar type, and aperture ratio is 10-30%. 10 thousand ton class result shows that maleic conversion rate is 100%, selectivity of succinyl oxide is 98%, production efficiency is four times higher than that of stirring kettle reactor, and the service life of catalyst is prolonged by five times.

Owner:山西侨友化工股份有限公司

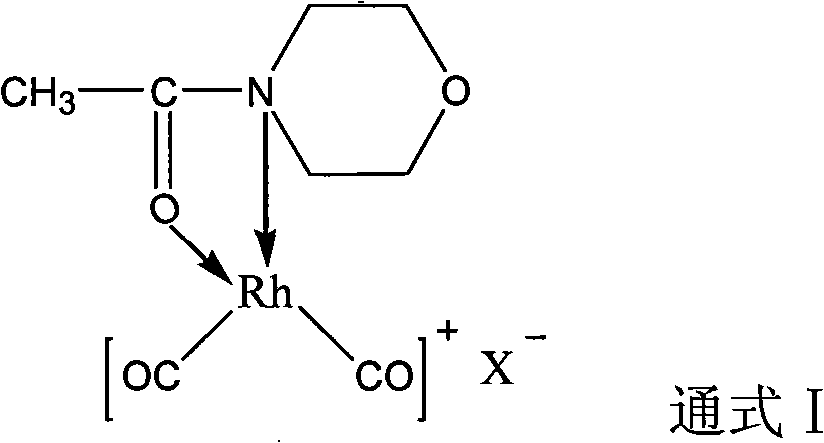

Acetic acid and acetic anhydride carbonyl reaction kettle for gas liquid ejecting combined slurry bed

InactiveCN101143814AFully contactedFully integratedCarboxylic acid anhydrides preparationAcetic acidAcetic anhydride

The invention discloses an acetic acid and acetic anhydride carbonyl reaction kettle of a gas-liquid injection combination type slurry bed, which includes a kettle body, fixed column trays and gas phase material injection pipes, wherein, a gas phase outlet is provided on the top of the kettle body, a liquid phase outlet is provided on the bottom of the kettle body, a liquid phase distribution pipe is provided on the upper part in the kettle body, a gas phase distribution pipe is provided on the lower part in the kettle body, at least one fixed column tray mounted in the kettle body is provided between the liquid phase distribution pipe and the gas phase distribution pipe, at least one gas phase material injection pipe extending into the kettle body from the outside is provided on the lower part of each fixed column tray, and each gas phase material injection pipe is radially distributed along the kettle body. The structure of the invention is reasonable, the effect of mass transfer is good, which is favorable to the sufficient contact between gas pahse material flow and liquid phase material flow, various materials can sufficiently merge with one another, the stability of uniform gas-liquid distribution is increased, processing ability is high, and various disadvantages of an externally hung dasher can be avoided.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

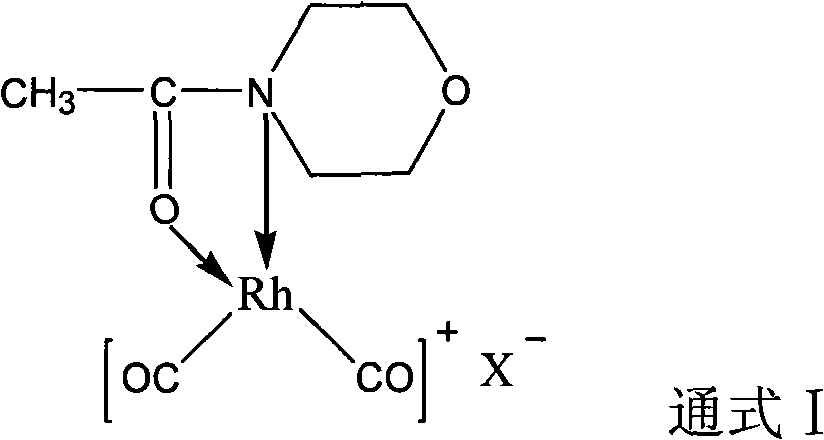

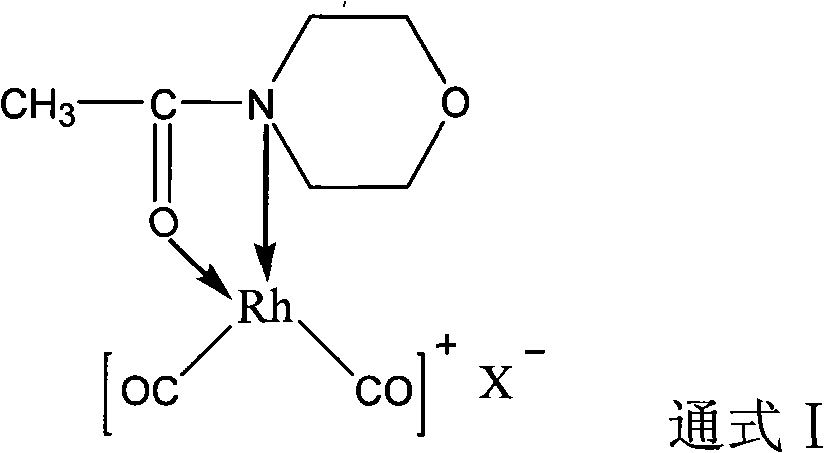

Rhodium catalyst for acetic oxide carbonyl synthesis from methyl acetate and preparation thereof

ActiveCN101279294AHigh activityImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsSolubilityAcetic anhydride

The present invention discloses a rhodium catalyst for synthesizing acetic anhydride by acid methyl carbonyl, which is a cis-dicarbonyl rhodium cation structural catalyst formed by carbonyl rhodium and ligand function; the catalyst is a chelate square plane complex; the cation part of the catalyst is cis-dicarbonyl rhodium cation and the ligand is acetyl morpholine. The catalyst not only shows excellent thermal stability, but also keeps excellent catalyzing activity during the reaction of synthesizing acetic anhydride by acid methyl carbonyl; simultaneously the solubility of the catalyst species can also be increased in a reaction system, thus avoiding the addition of acetic acid and / or acetic anhydride as a catalyst solvent in the industrial production, thus effectively reducing the load of flash evaporation and evaporation and improving the manufacture efficiency of acetic anhydride synthesis by acid methyl carbonyl. The present invention also discloses a preparation method of synthesizing acetic anhydride by acid methyl carbonyl by the rhodium catalyst..

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

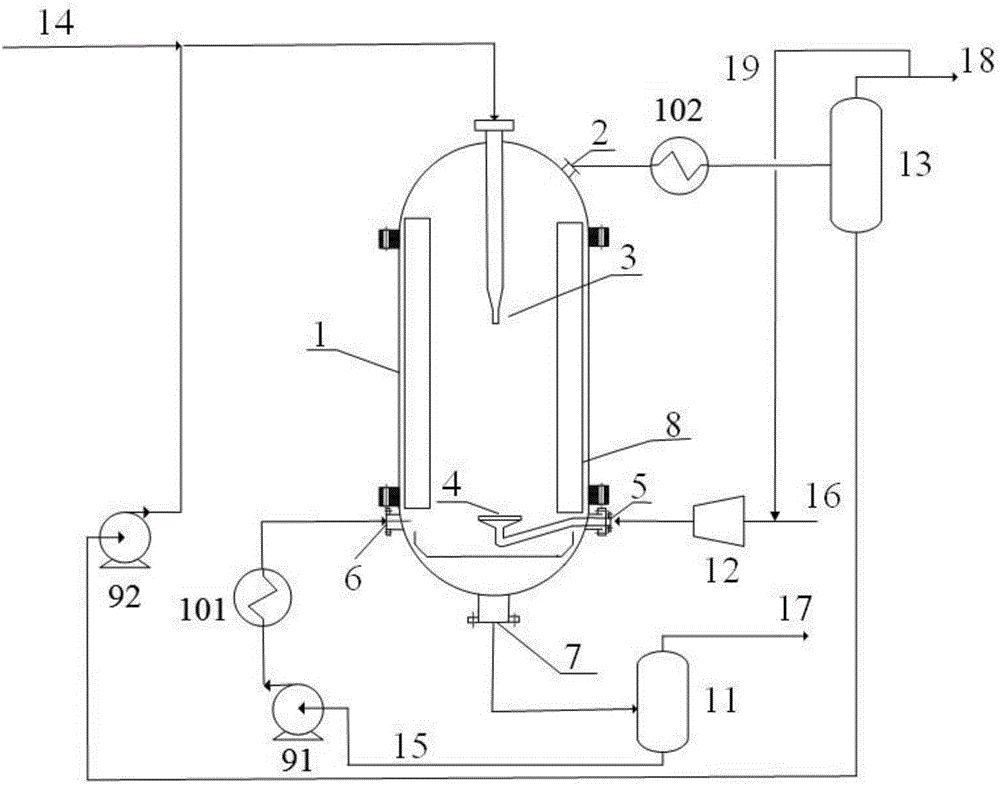

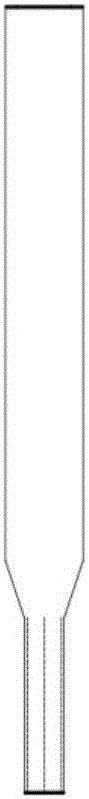

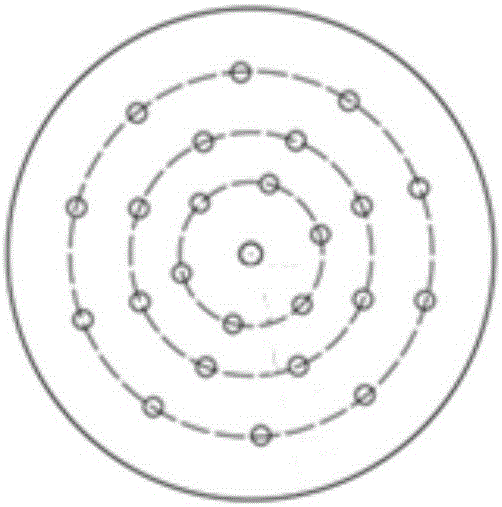

Gas-liquid two-phase jet flow reactor and gas-liquid two-phase jet flow reaction system

InactiveCN106076211ASimple structureSimple processLiquid-gas reaction as foam/aerosol/bubblesChemical/physical/physico-chemical nozzle-type rreactorsAcetic anhydrideSpray nozzle

The invention discloses a gas-liquid two-phase jet flow reactor which comprises a reactor cylinder, wherein a liquid jetting device is arranged at the top of the reactor cylinder, the liquid jetting device consists of a liquid inlet and a reduced nozzle extending into the reactor cylinder; a gas outlet is formed in the upper part of the reactor cylinder; a plurality of baffle plates are arranged on the inner wall of the reactor cylinder; a gas inlet and a circulating liquid inlet are formed in the lower part of the reactor cylinder, the gas inlet is communicated with a gas distributor positioned below the reduced nozzle; and a liquid drain outlet is formed in the bottom of the reactor cylinder. The invention further discloses a gas-liquid two-phase jet flow reaction system, which comprises the gas-liquid two-phase jet flow reactor, an evaporator and a flash evaporation tank. According to the gas-liquid two-phase jet flow reaction system, the high-efficiency dispersion and mixing of gas-liquid two phases can be realized by breaking bubbles through utilizing the shearing action of jet flow of high-speed liquid; the gas-liquid two-phase jet flow reaction system has the advantages that the flow is simple, the reactor has a simple structure, gas-liquid mixing effect is good, and the like; the gas-liquid two-phase jet flow reaction system is applicable to technology of producing acetic acid through the carbonylation of methanol or a technology of producing acetic anhydride through carbonylation of methyl acetate.

Owner:SINOPEC NANJING ENG & CONSTR +2

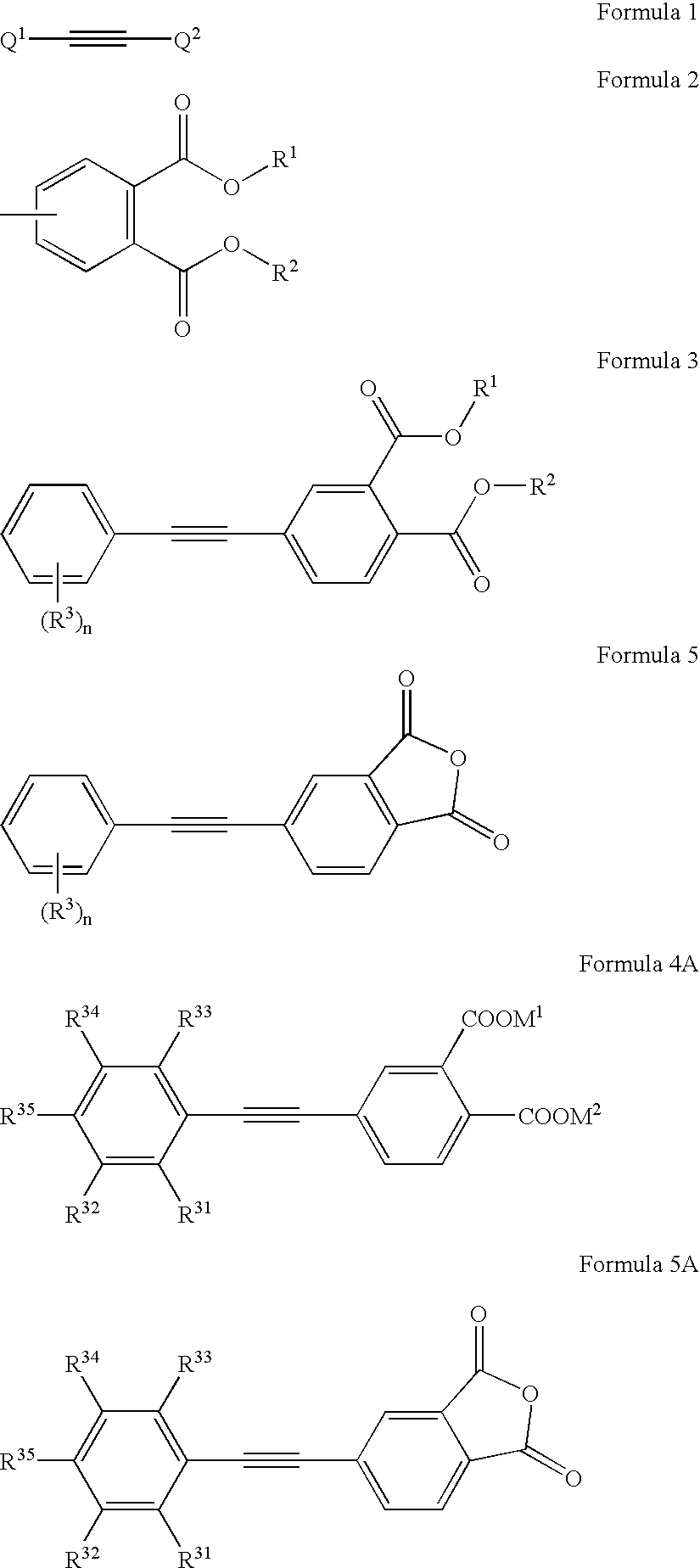

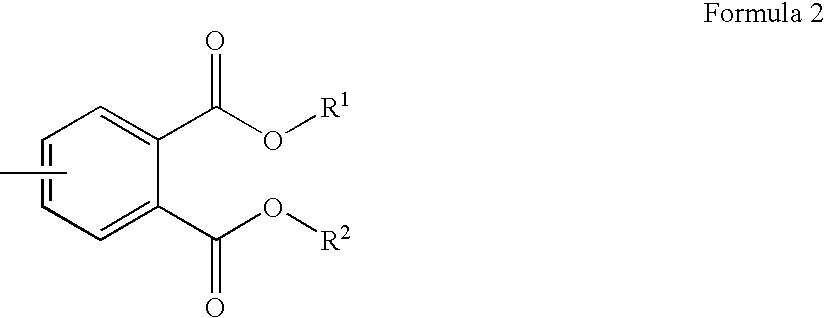

Aryl ethynyl phthalic acid derivative and method for producing the same

InactiveUS20050215820A1Easy to useStably produced on an industrial scaleOrganic compound preparationDiaryl/thriaryl methane dyesArylPhthalic anhydride

The invention provides an aryl ethynyl phthalic acid and derivatives thereof (including fluorine-containing compounds) represented by Formulae 1, 3, 5, 4A and 5A including the structure of Formula 2, and method of producing these compounds, in which an aryl ethynyl phthalic anhydride is formed by subjecting an aryl phthalic acid to ring closing:

Owner:FUJIFILM HLDG CORP +1

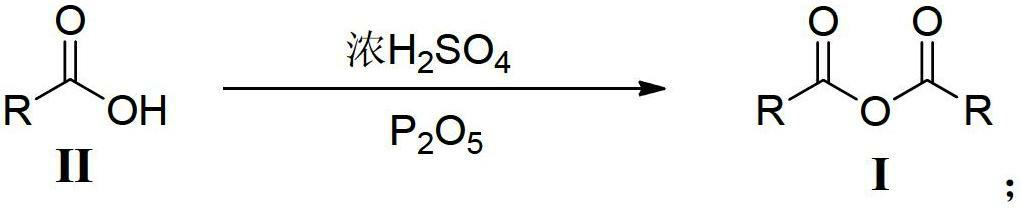

Preparation method of low-carbon chain symmetric anhydride

ActiveCN102675080AHigh purityHigh yieldCarboxylic acid anhydrides preparationCarbon chainCarboxylic acid

The invention discloses a preparation method of low-carbon chain symmetric anhydride (I). The preparation method comprises the following steps of: taking low-carbon chain carboxylic acid (II) as a raw material, performing reaction by concentrated sulfuric acid and phosphorus pentoxide, and distilling to obtain the high-purity low-carbon chain symmetric anhydride (I). The preparation method of the low-carbon chain symmetric anhydride, disclosed by the invention, only comprises one-step reaction, has the advantages of few reaction byproducts, high yield and simplicity and convenience in operation, and is suitable for industrial production; and the obtained low-carbon chain symmetric anhydride is high in purity.

Owner:NANJING ACCELEDEV TECH DEV

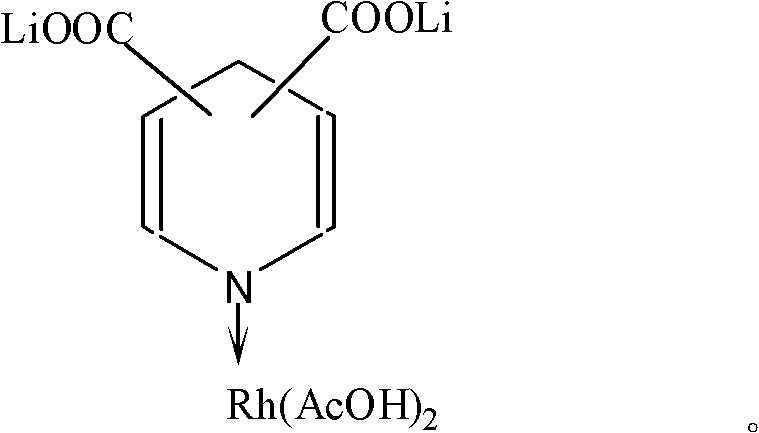

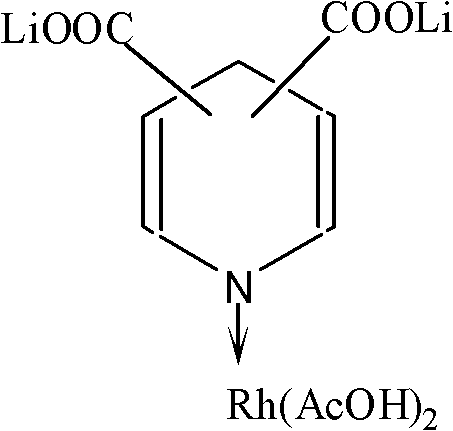

Lithium pyridine carboxylate-rhodium acetate complex catalyst for synthesizing acetic acid and acetic anhydride through carbonylation, and preparation method and application thereof

InactiveCN102218343AGood activity and stabilityImprove reaction stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationLithiumAcetic anhydride

The invention belongs to the field of synthesis of acetic acid and acetic anhydride through carbonylation, and relates to a lithium pyridine carboxylate-rhodium acetate complex catalyst for synthesizing acetic acid and acetic anhydride through carbonylation of methanol, and a preparation method and application of the catalyst. When the catalyst is used for catalyzing carbonylation reaction of the methanol to prepare the acetic acid and catalyzing carbonylation reaction of methyl acetate to prepare the acetic anhydride, the catalyst has good catalytic activity and reaction stability. Under the relative mild conditions, the catalyst can catalyze the carbonylation of the methanol to prepare the acetic acid and catalyze the carbonylation of the methyl acetate to prepare the acetic anhydride at high speed and high selectivity. The catalyst has an active ingredient of rhodium; and a coordination structure formed by the rhodium active ingredient and the lithium pyridine carboxylate is shown as the specifications.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Coproduction of acetic acid and acetic anhydride

ActiveUS20120123156A1Organic compound preparationCarboxylic acid esters preparationAcetic anhydrideAcetic acid ear

Disclosed is a process for the coproduction of acetic acid and acetic anhydride by producing in a first carbonylation reactor a carbonylation product mixture containing acetic anhydride, removing the carbonylation mixture from the first carbonylation reactor, contacting the carbonylation mixture with methanol to react with and convert some or all of the acetic anhydride contained in the mixture to acetic acid and methyl acetate, feeding the resulting reaction composition to a second carbonylation reactor and contacting the reaction composition to carbonylation.

Owner:EASTMAN CHEM CO

Carbonylation process

InactiveUS20090247783A1Increase carbonylation rateOrganic compound preparationPreparation by carbon monoxide or formate reactionHydrogen halideCarboxylic acid

Disclosed is an improved carbonylation process for the production of carboxylic acids, carboxylic acid esters, and / or carboxylic acid anhydrides wherein a carbonylation feedstock compound selected from one or more organic oxygenates such as alcohols, ethers, and esters is contacted with carbon monoxide in the presence of a carbonylation catalyst and one or more onium compounds. The carbonylation process differs from known carbonylation processes in that a halide compound, other than the onium salt, such as a hydrogen halide (typically, hydrogen iodide) and / or an alkyl halide (typically, methyl iodide), extraneous or exogenous to the carbonylation process is not fed or supplied to the process. The process can be improved by using a bidentate ligand comprising two functional groups selected from tertiary amines and tertiary phosphines, such as 2,2′-bipyridine and diphosphine derivatives.

Owner:EASTMAN CHEM CO

Method for recovering catalyst rhodium from industrial waste liquid of carbonyl synthesis of acetic anhydride

ActiveCN102247841AHigh recovery rateSimple processChemical recyclingMetal/metal-oxides/metal-hydroxide catalystsAcetic anhydrideZinc

The invention is a method for recovering catalyst rhodium from industrial waste liquid of carbonyl synthesis of acetic anhydride. The invention is characterized in that the method comprises the following steps: (1) waste liquid incineration and cineration, (2) melt oxidation transformation, water washing, (3) preparation of aqueous rhodium salt solution, (4) zinc powder displacement, (5) pickling for zinc powder removal. The content of the recovered rhodium is not less than 78%, and the recovery rate is not less than 98%. The invention provides a method for recovering catalyst rhodium from industrial waste liquid of carbonyl synthesis of acetic anhydride, which has high recovery rate, simple process, and low cost. The content of the recovered rhodium is not less than 78%, which not only meets the process requirements for the carbonyl synthesis of acetic anhydride, but also greatly reduces recovery cost; the recovery rate of rhodium is not less than 98%, and the method provides genuine goods at a fair price, and is convenient for a fair shake.

Owner:张超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com