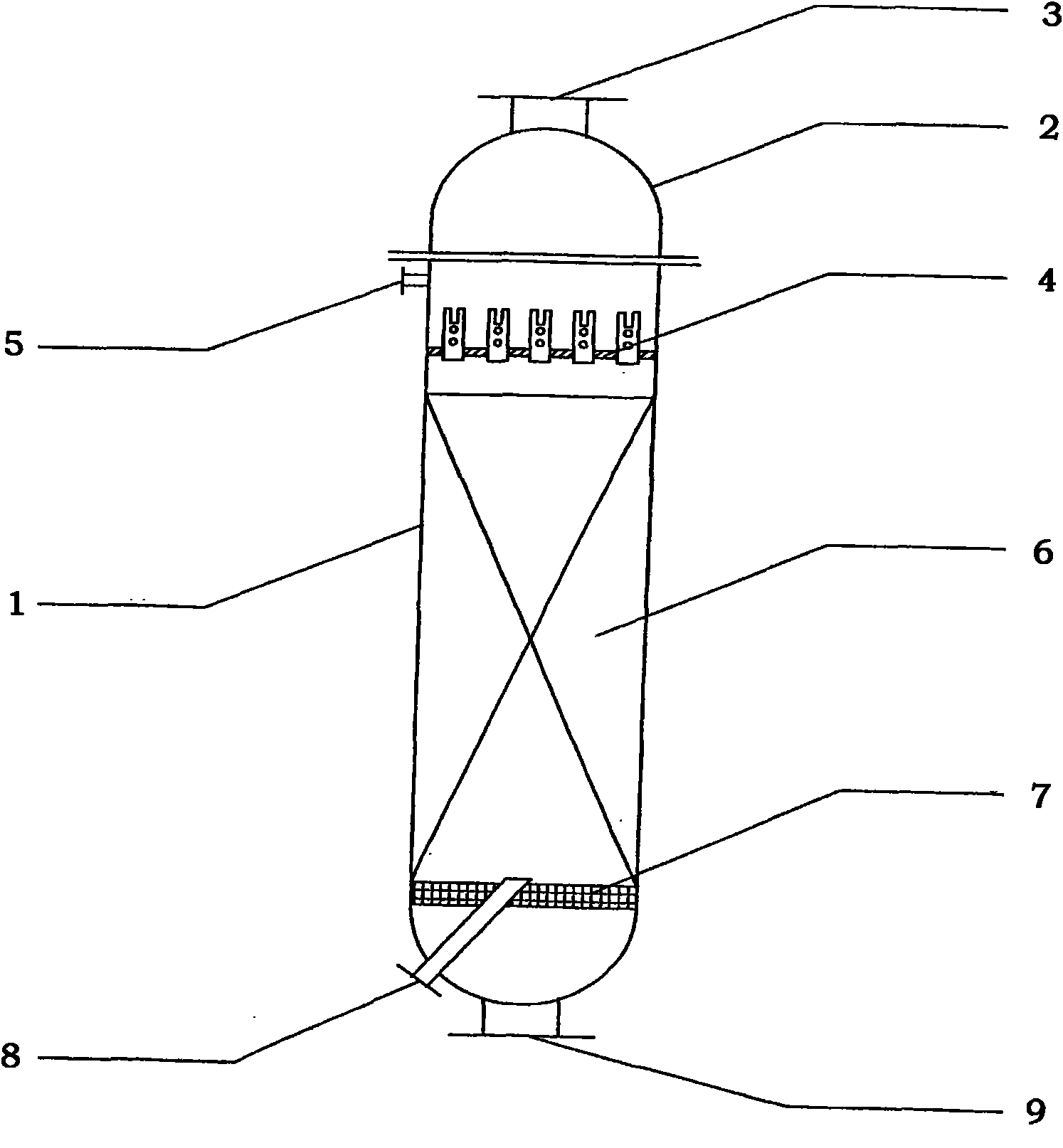

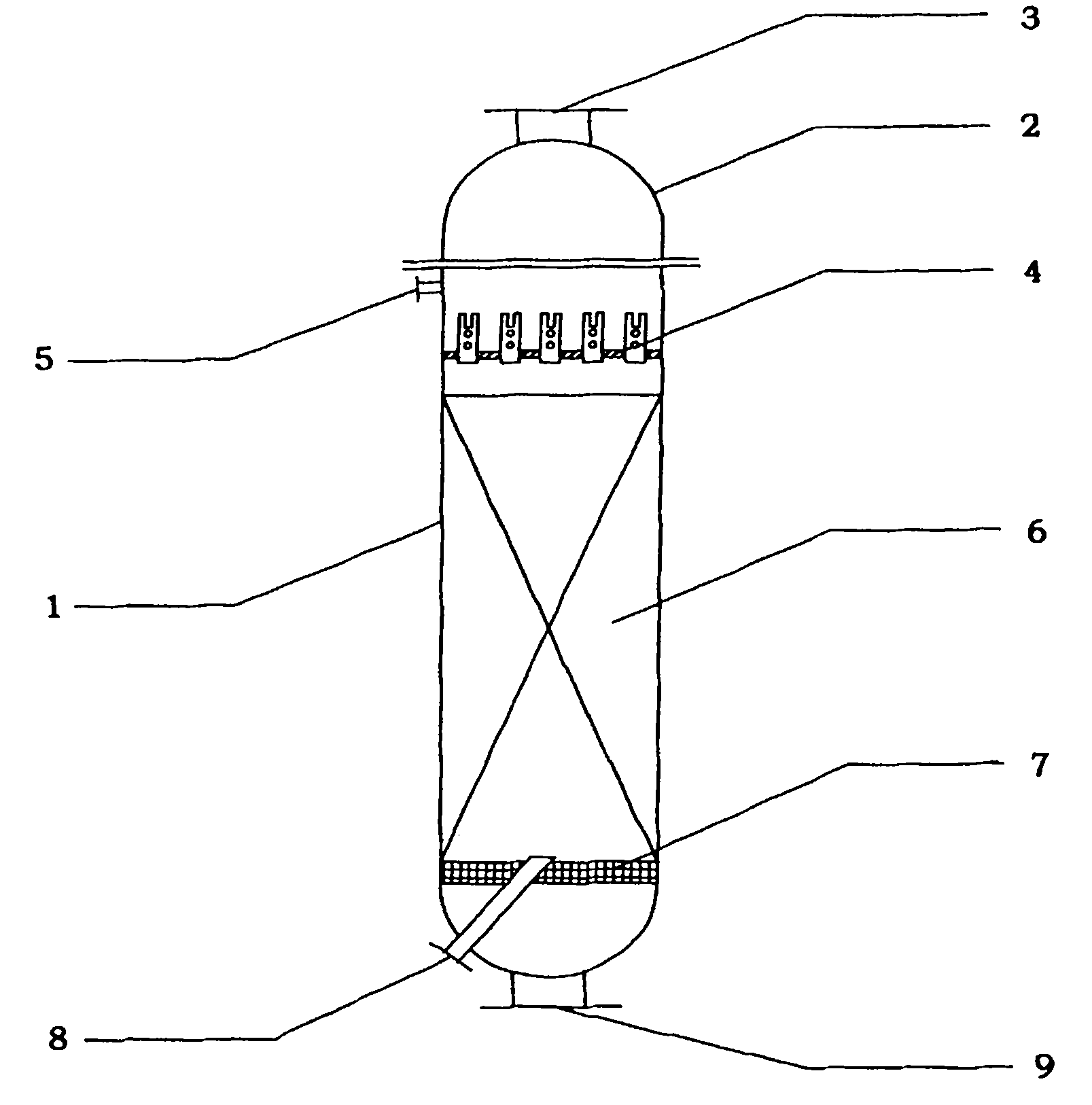

Reactor for preparing succinyl oxide by maleic anhydride hydrogenation

A technology for producing succinic anhydride and a reactor, which is applied in the field of trickle bed catalytic reactors and can solve problems such as low efficiency, unsuitability for large tonnage, large-scale production, and difficulty in separating products and catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The production device with an annual output of 10,000 tons of succinic anhydride is equipped with a trickle bed reactor equipped with a bubble-cap distributor 4 and a grid-type distribution plate 7 with an opening ratio of 15%, and is filled with 3.75 tons of the aforementioned Ni / Al 2 o 3 -SiO 2 Catalyst (made into strips with a diameter of 2mm and a length of 8-12mm), after being reduced with nitrogen and hydrogen containing about 1% hydrogen, the system is replaced with hydrogen, the pressure is increased to 8.0Mpa, and the circulating compressor is started for hydrogen circulation; at the same time, press the solvent The weight ratio of maleic anhydride and maleic anhydride is 4.9:1. Add maleic anhydride into the dissolving tank filled with γ-butyrolactone (used as a solvent), and after it dissolves, it can be transferred to the metering tank; when in the reactor When the temperature of the catalyst material layer 6 drops to 40-50°C, the feed pump can be started to...

Embodiment 2

[0017] In the trickle bed catalytic reactor, a vertical pipe distributor 4 and a grid distribution plate 7 with a 30% opening ratio are configured, and the remaining operation steps and indicators are the same as in Example 1, and the same effect can be obtained.

Embodiment 3

[0019] In the trickle-bed catalytic reactor, a CZ type distributor 4 and a porous plate type distribution plate 7 with a 5% opening ratio are configured, and the aforementioned granular Raney nickel catalyst is filled, and the remaining operation steps and indicators are the same as in Example 1, and can be obtained Same effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com