Patents

Literature

94 results about "Trickle-bed reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A trickle-bed reactor (TBR) is a chemical reactor that uses the downward movement of a liquid and the downward (co-current) or upward (counter-current) movement of gas over a packed bed of (catalyst) particles. It is considered to be the simplest reactor type for performing catalytic reactions where a gas and liquid (normally both reagents) are present in the reactor and accordingly it is extensively used in processing plants. Typical examples are liquid-phase hydrogenation, hydrodesulfurization, and hydrodenitrogenation in refineries (three phase hydrotreater) and oxidation of harmful chemical compounds in wastewater streams or of cumene in the cumene process. Also in the treatment of waste water trickle bed reactors are used where the required biomass resides on the packed bed surface.

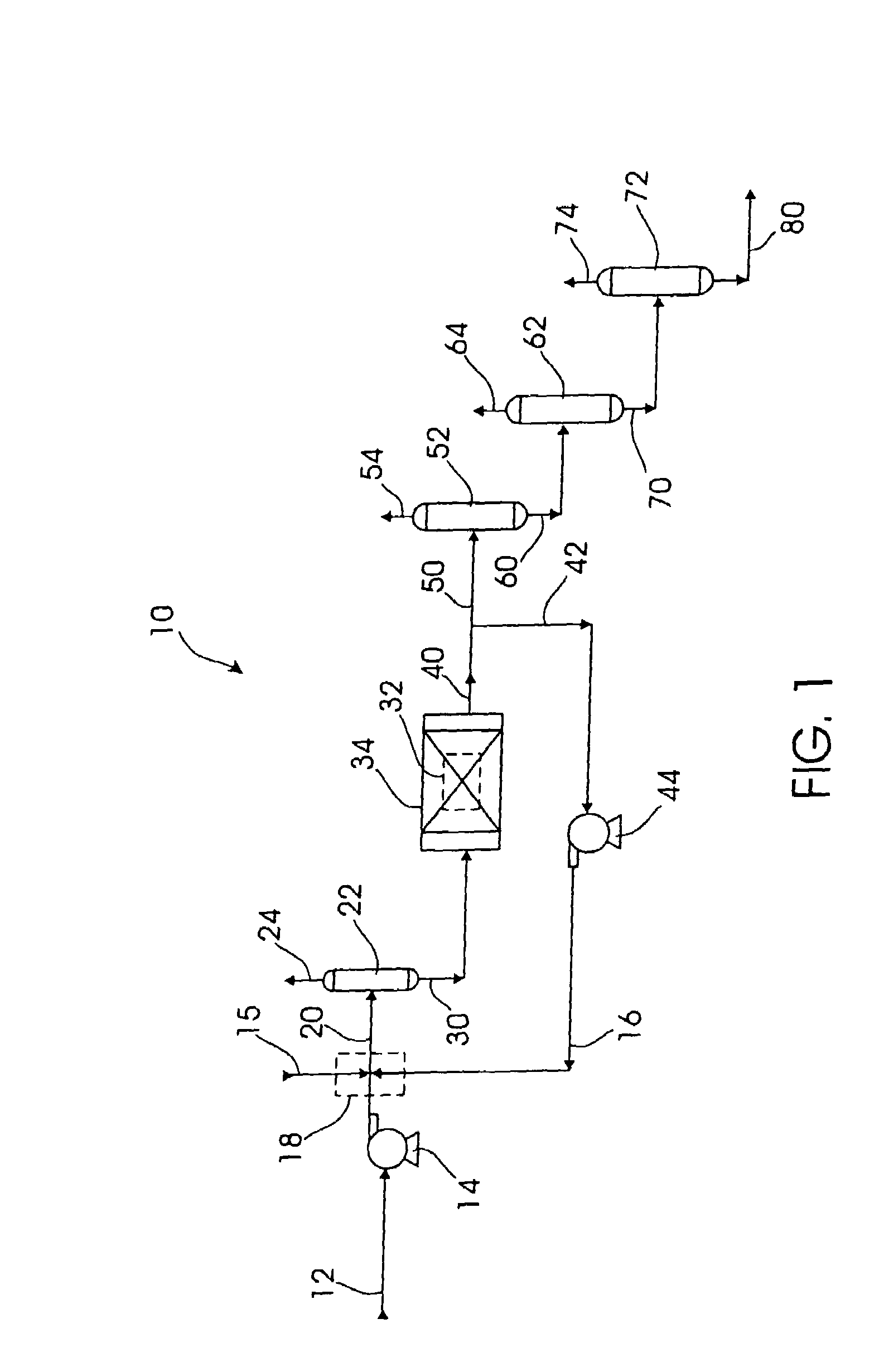

Two phase hydroprocessing

InactiveUS6881326B2Eliminate needHydrogen solubility is “Physical/chemical process catalystsOrganic compound preparationSolubilityHydrogen

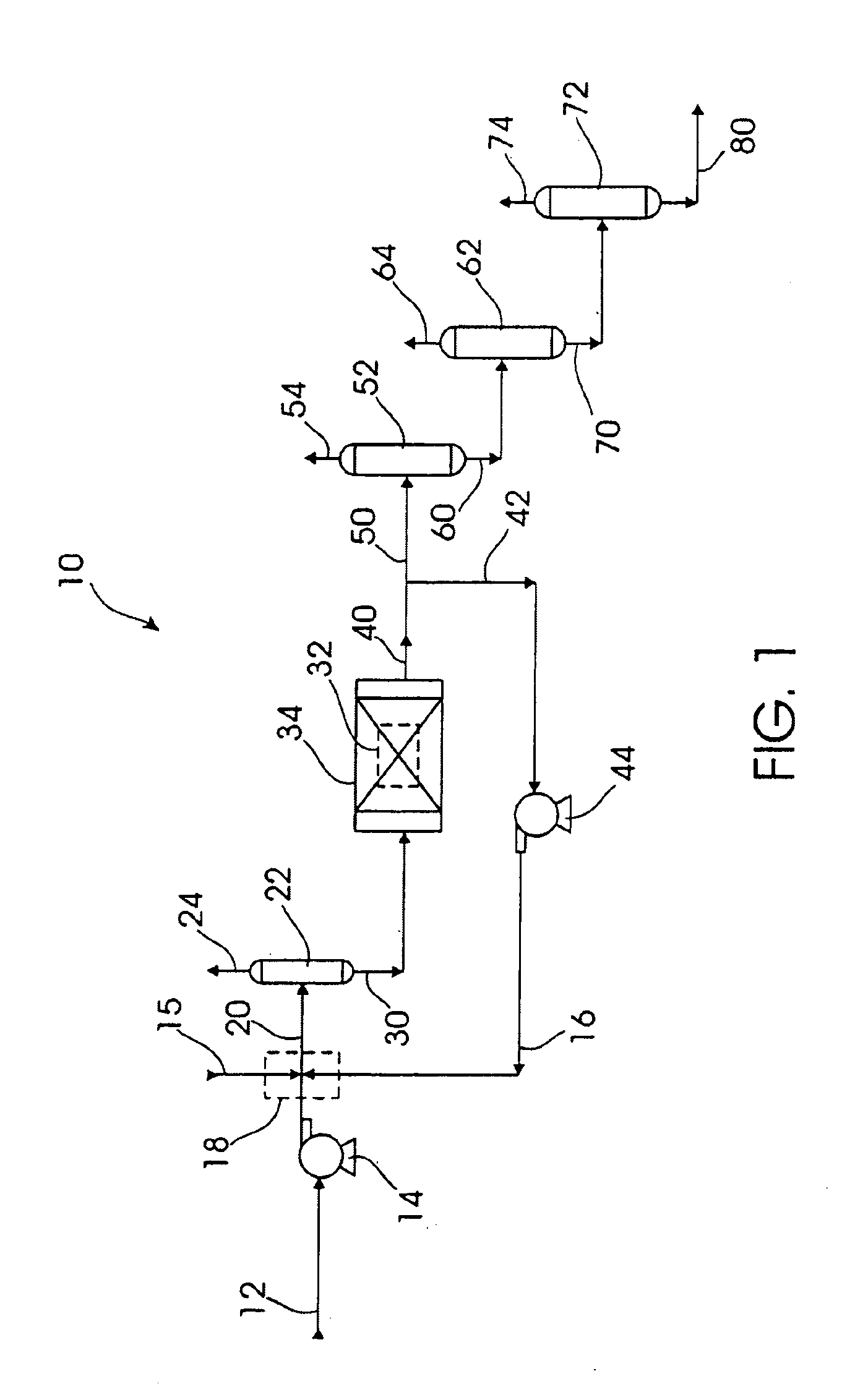

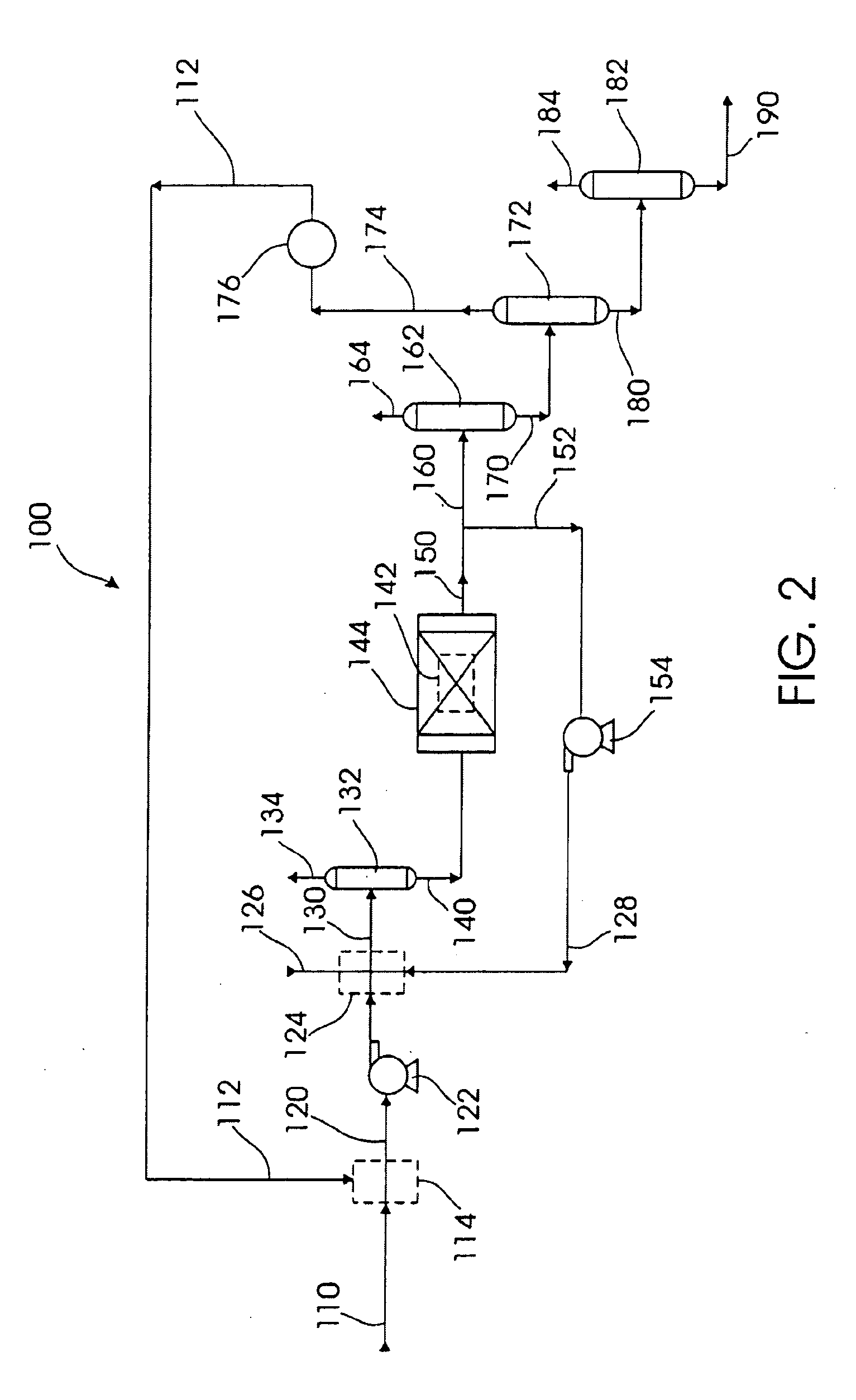

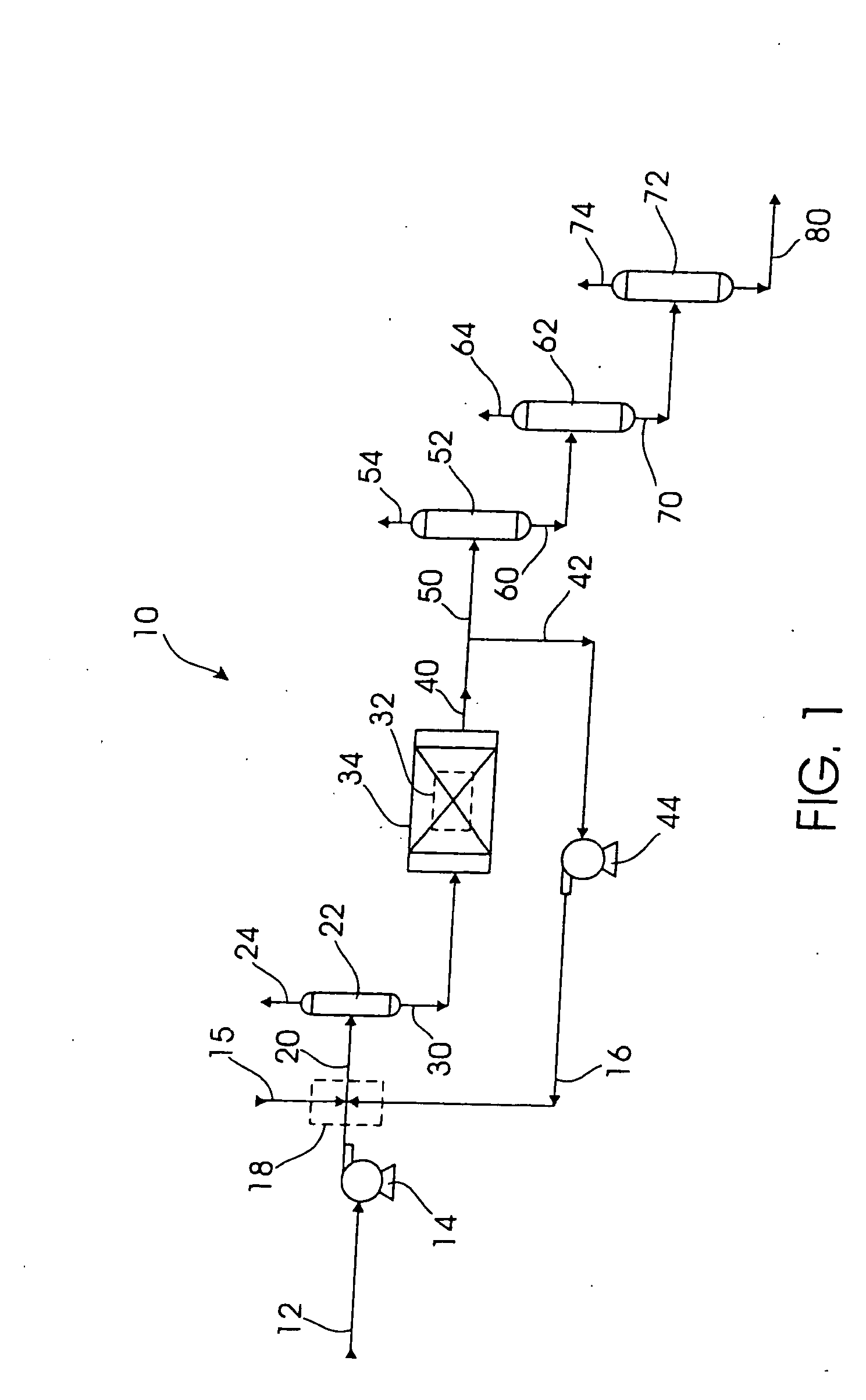

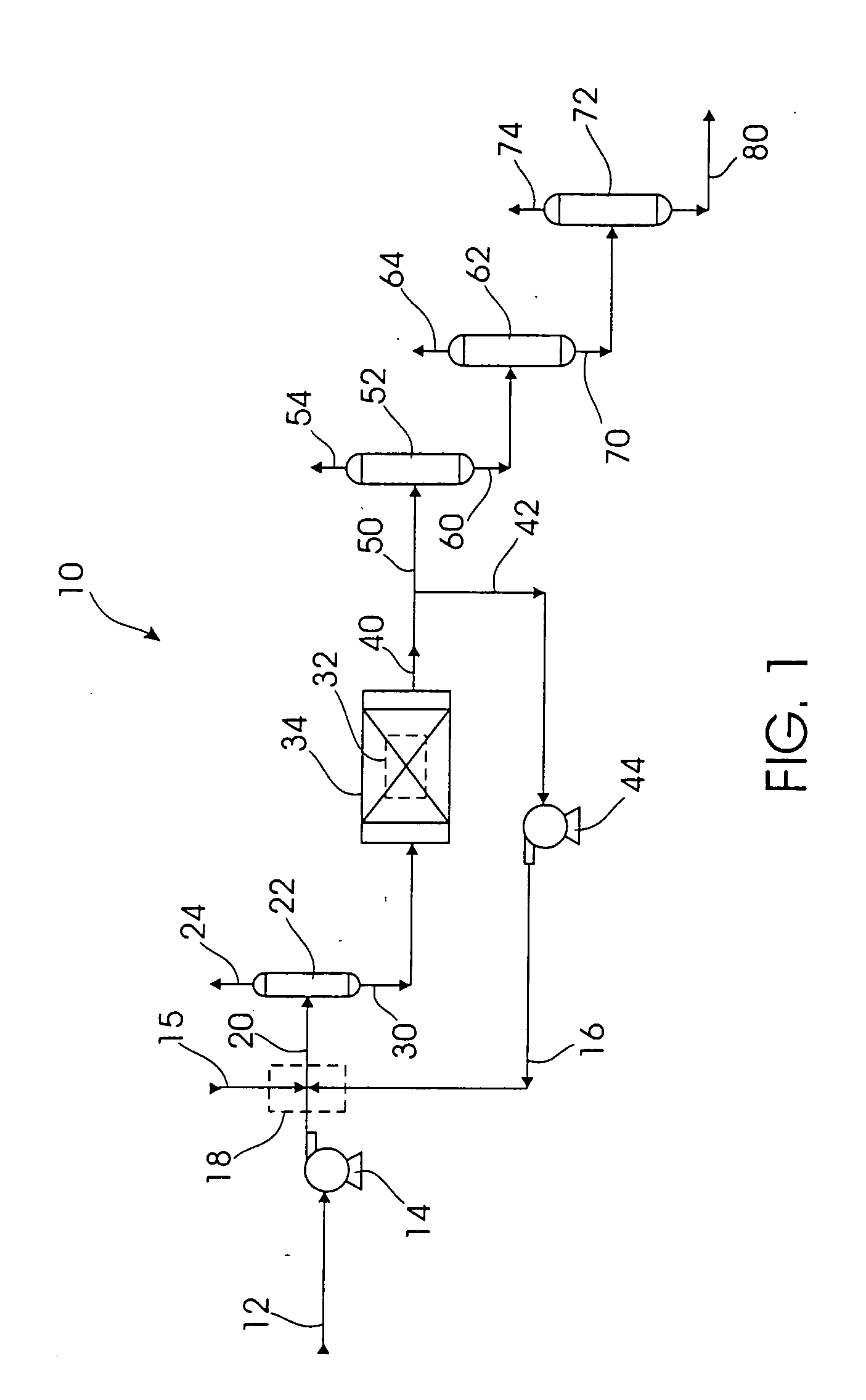

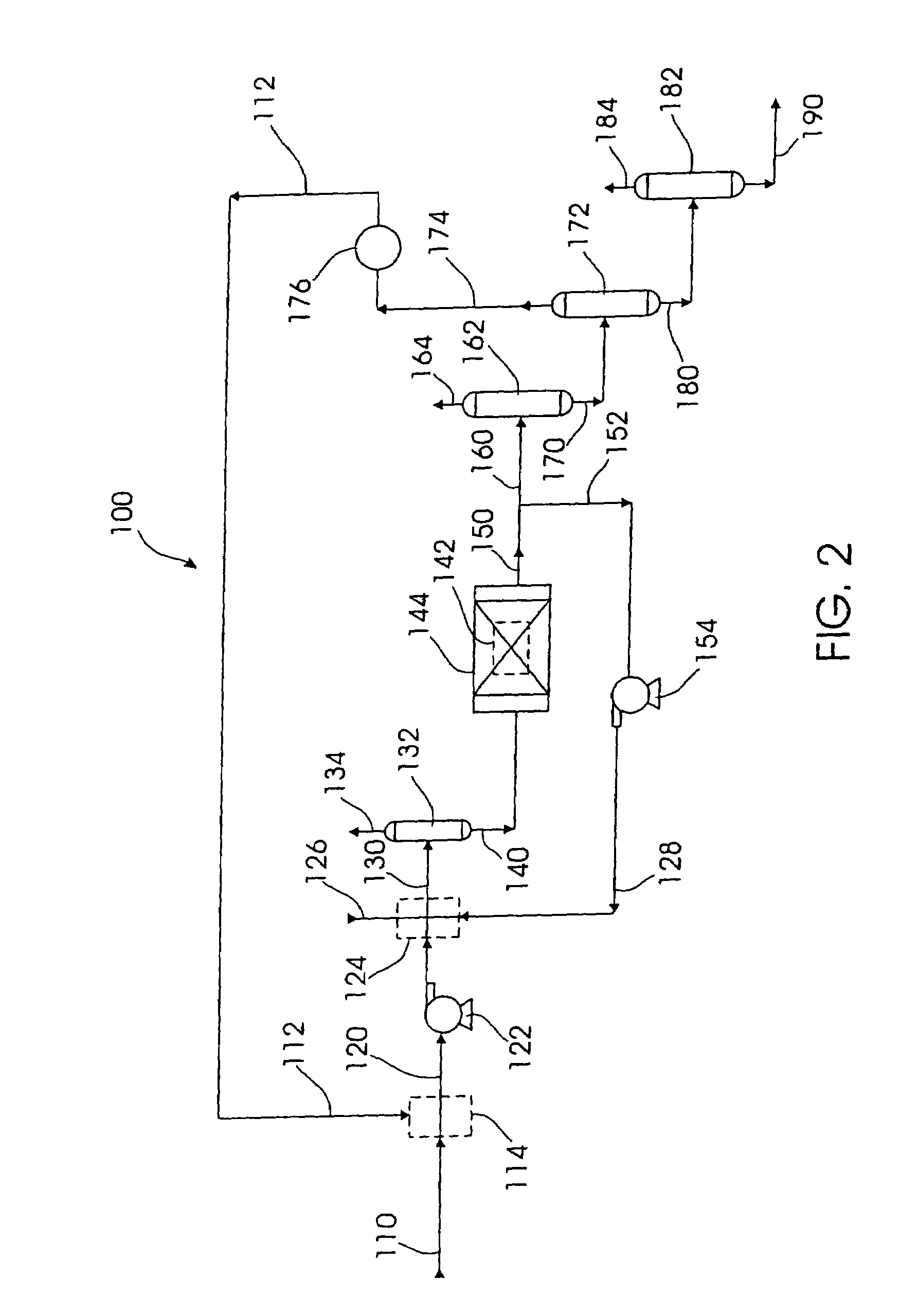

A process where the need to circulate hydrogen through the catalyst is eliminated. This is accomplished by mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is “high” relative to the oil feed. The type and amount of diluent added, as well as the reactor conditions, can be set so that all of the hydrogen required in the hydroprocessing reactions is available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required, therefore, hydrogen recirculation is avoided and trickle bed operation of the reactor is avoided. Therefore, the large trickle bed reactors can be replaced by much smaller tubular reactor.

Owner:EI DU PONT DE NEMOURS & CO

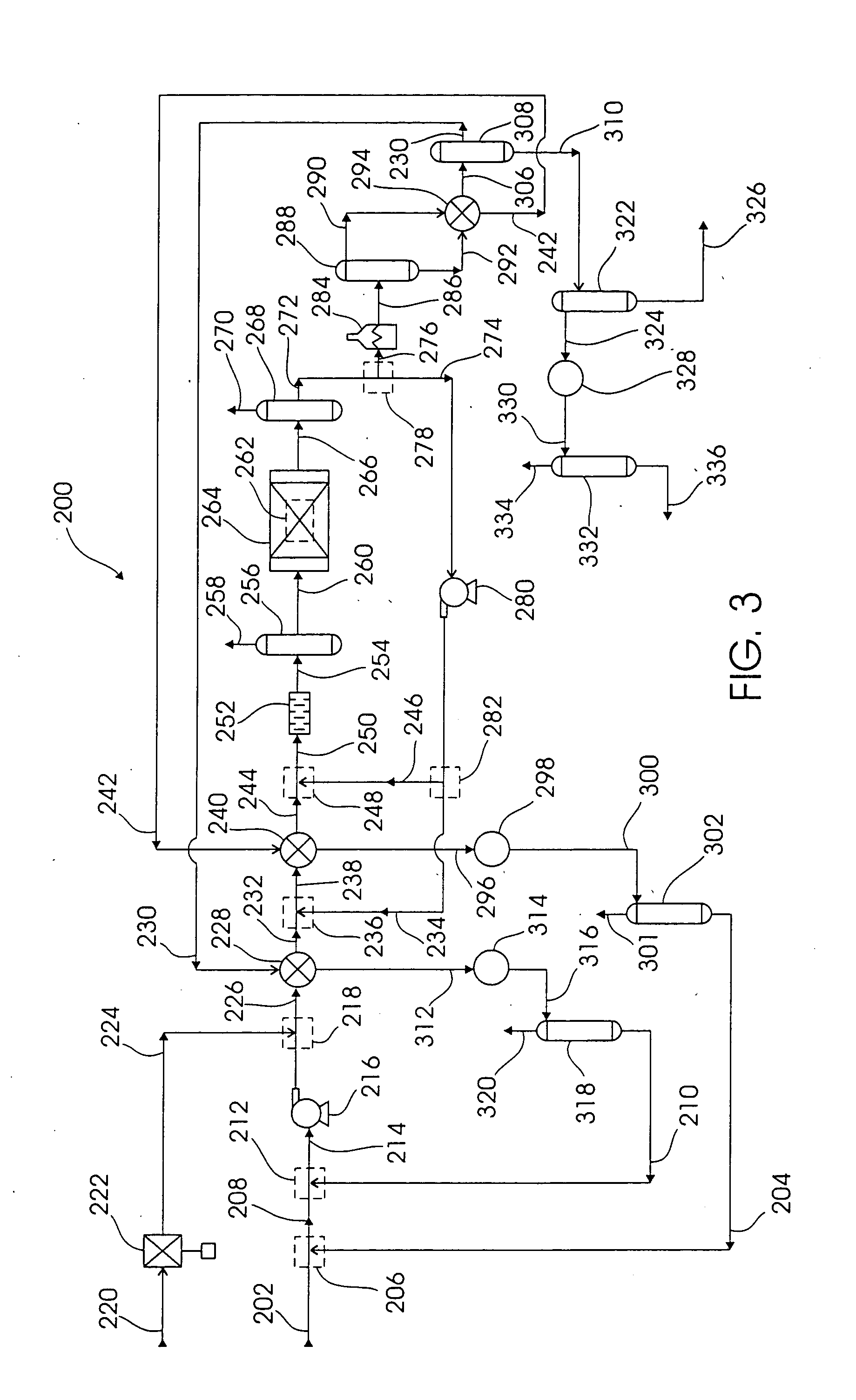

Control system method and apparatus for two phase hydroprocessing

InactiveUS20060144756A1Eliminate needHydrogen solubility is “Physical/chemical process catalystsHydrocarbon oils treatment control/regulationSolubilityHydrogen

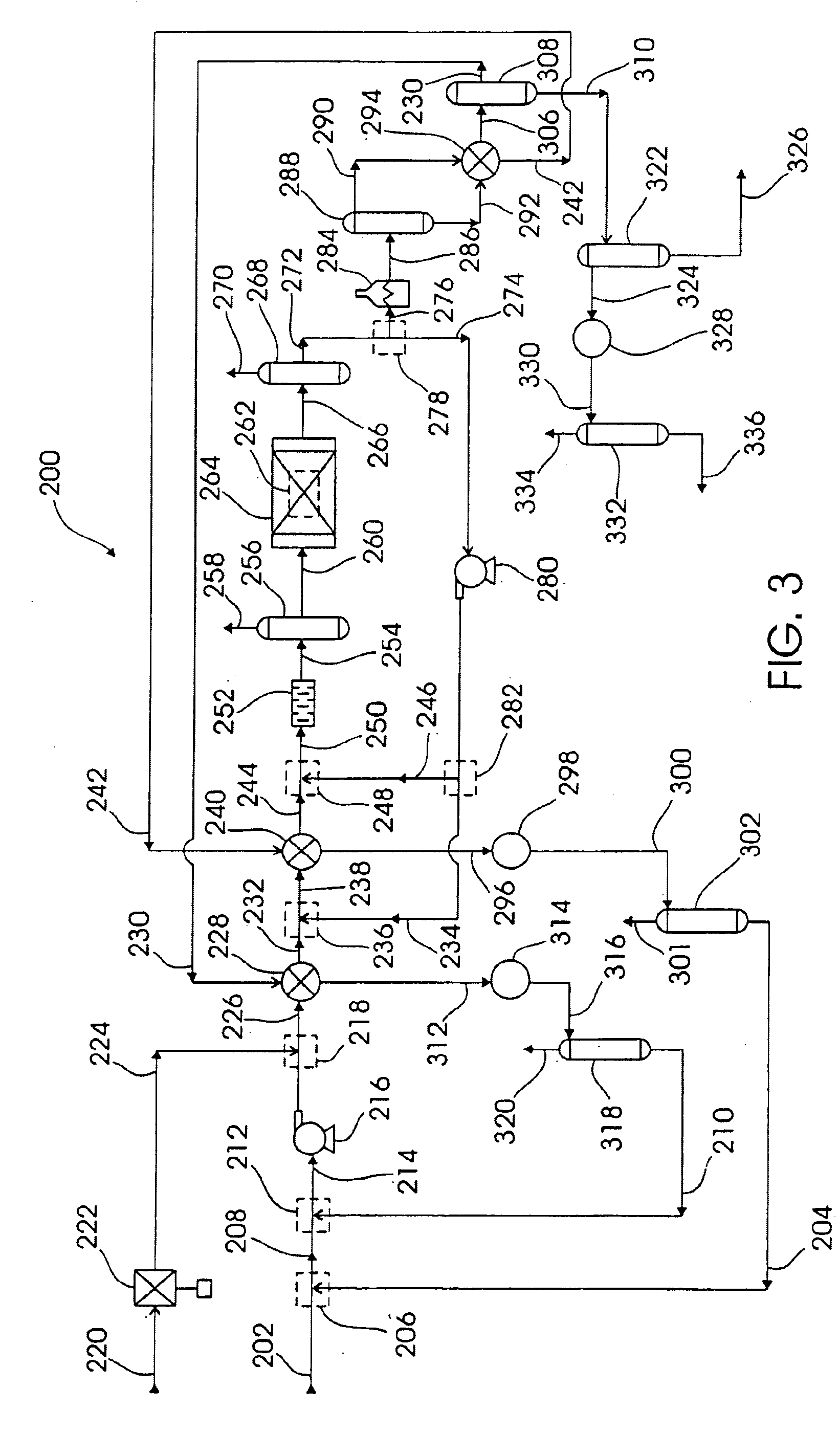

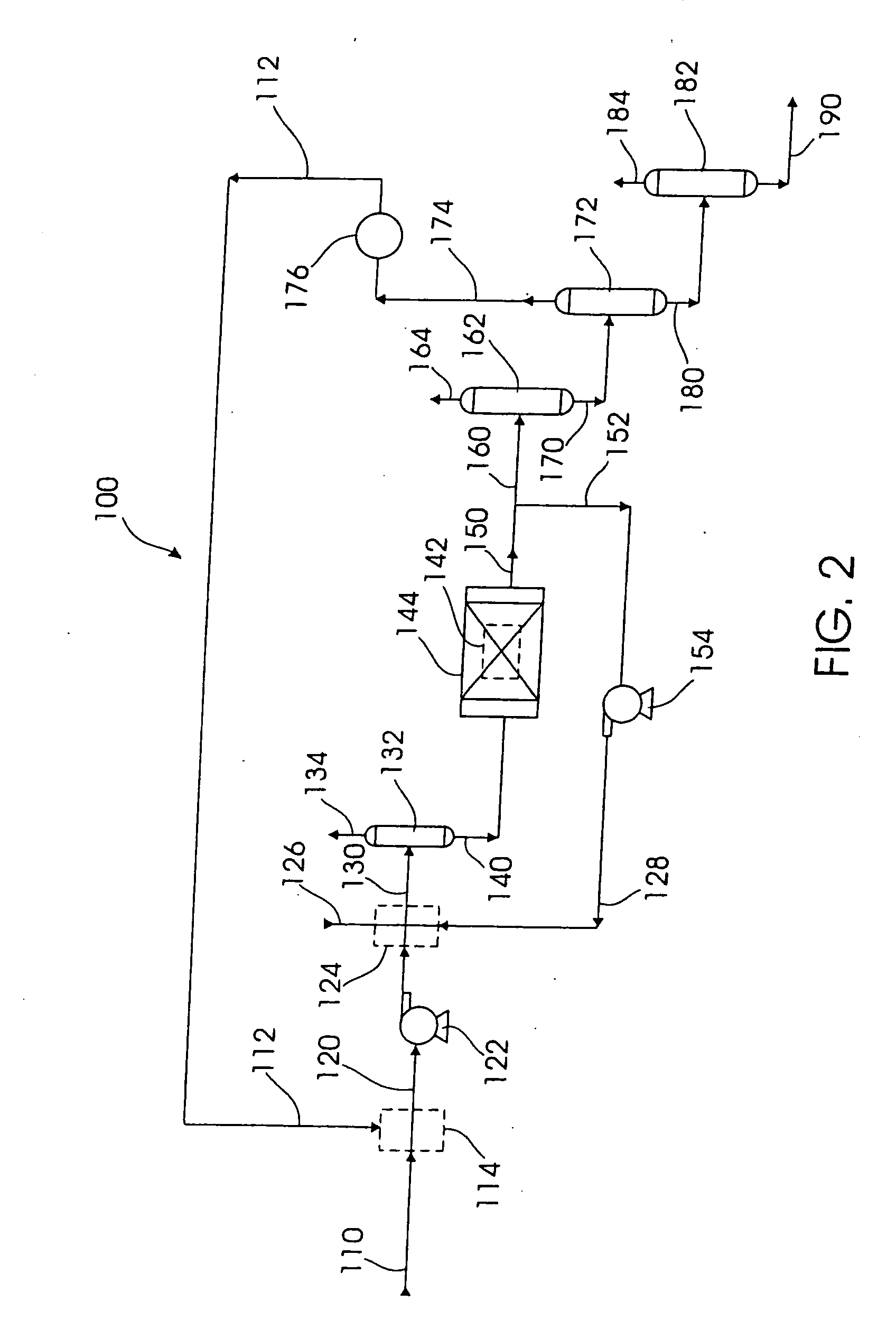

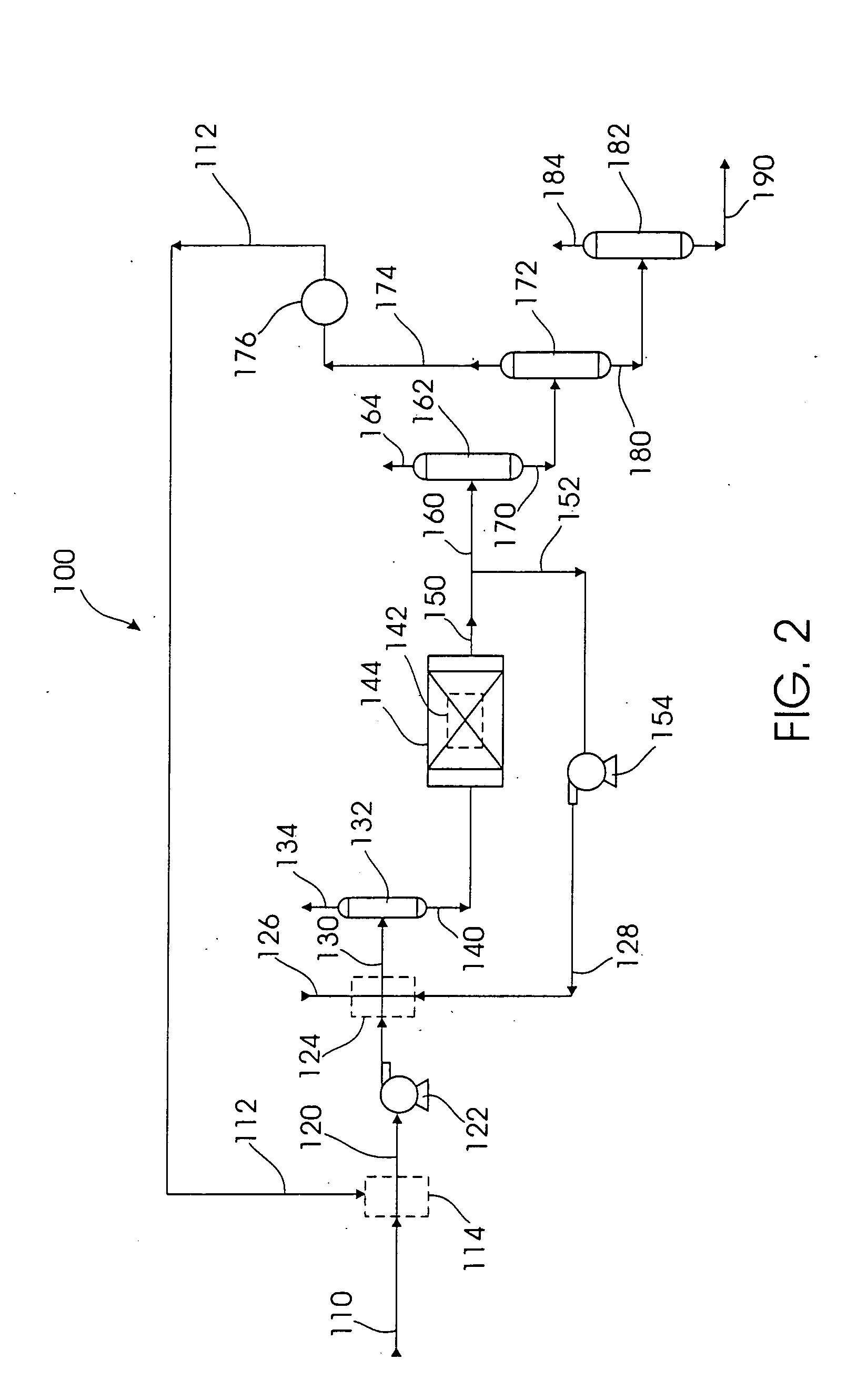

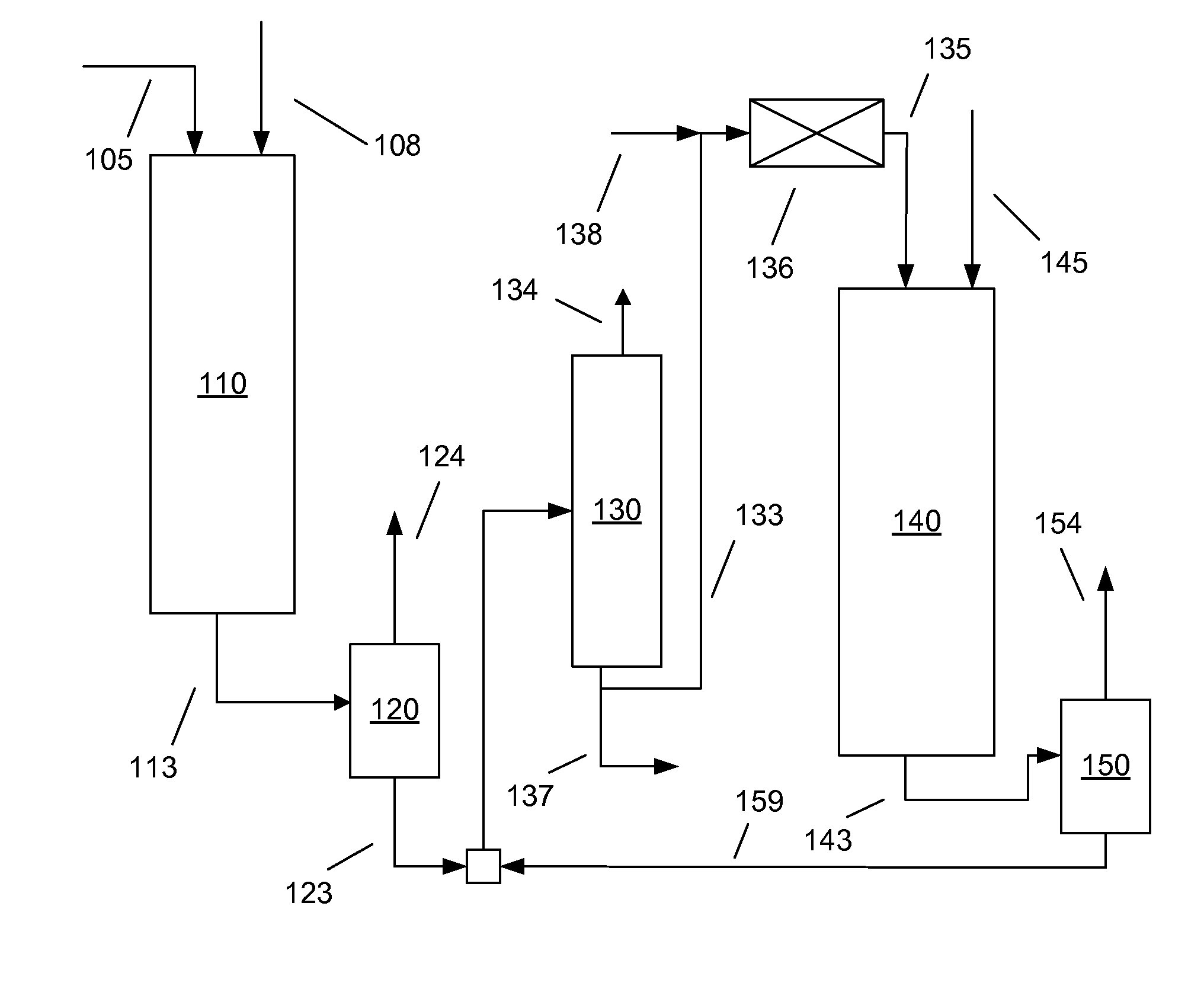

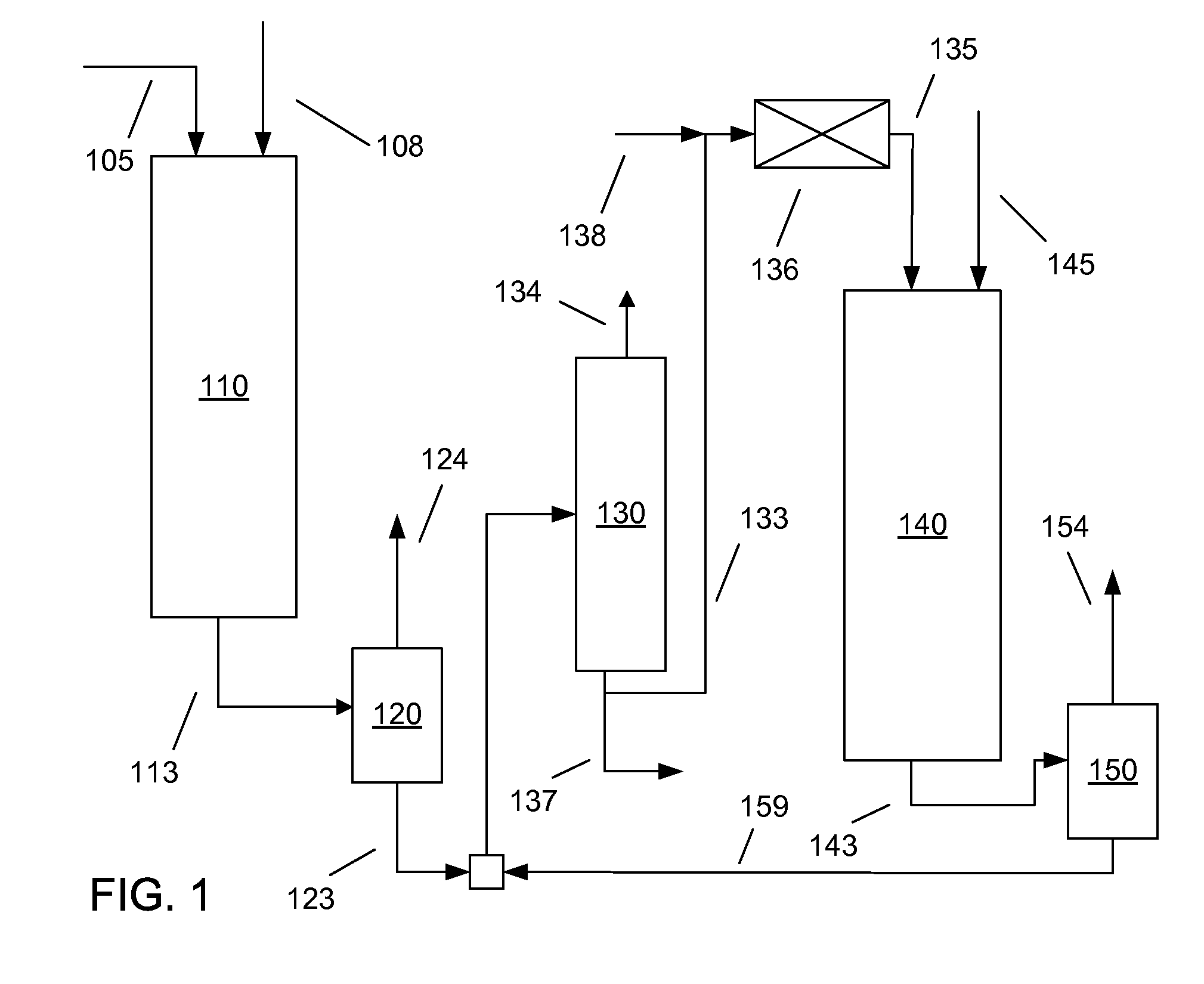

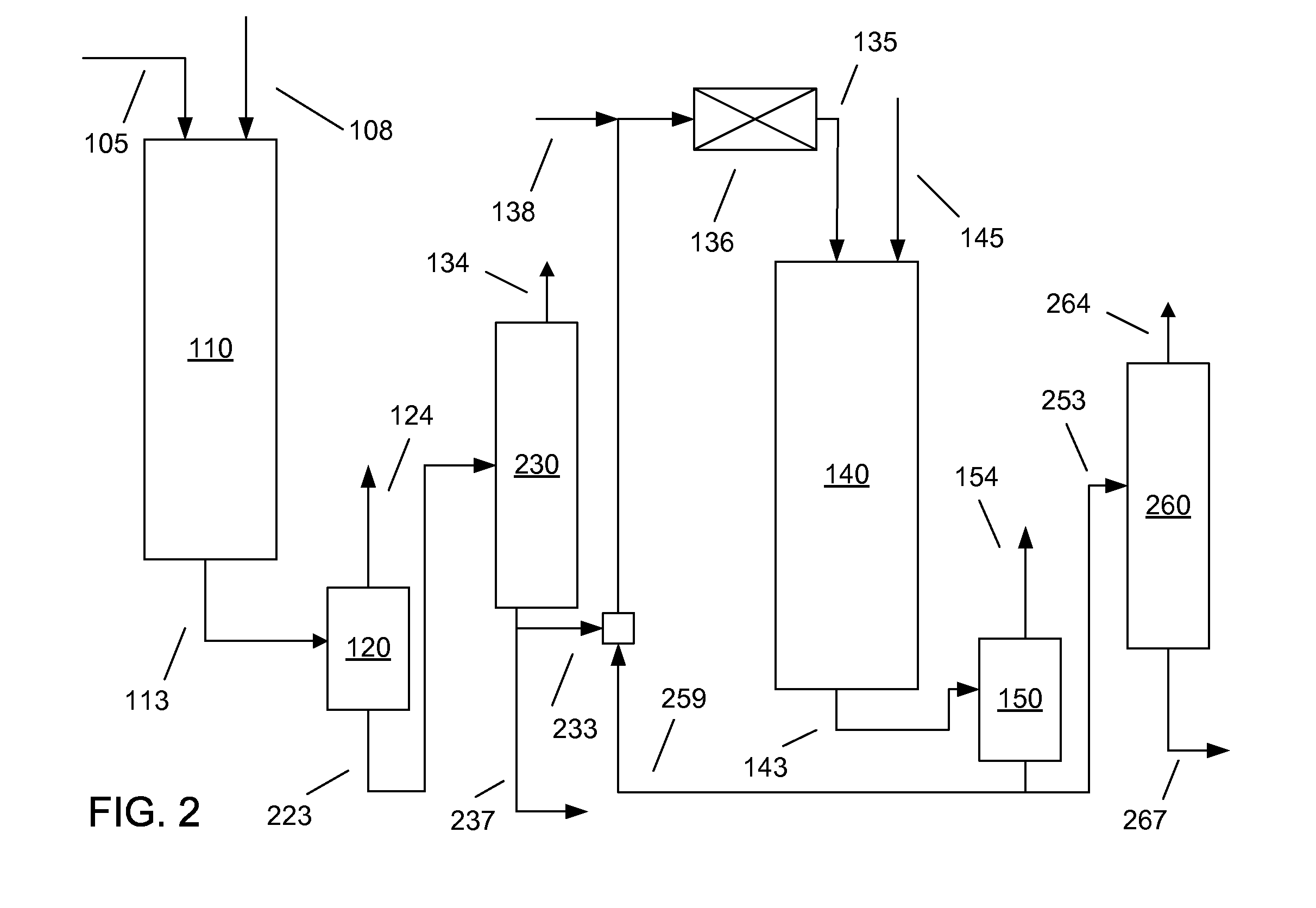

A continuous liquid phase hydroprocessing process, apparatus and process control systems, where the need to circulate hydrogen gas through the catalyst is eliminated. By mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is high relative to the oil feed, all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required; therefore, the large trickle bed reactors can be replaced by much smaller tubular reactors. The amount of hydrogen added to the reactor can be used to control the liquid level in the reactor or the pressure in the reactor.

Owner:EI DU PONT DE NEMOURS & CO

Two phase hydroprocessing

InactiveUS20050082202A1Eliminate needHydrogen solubility is “Physical/chemical process catalystsHydrocarbon oil crackingSolubilityHydrogen

A process where the need to circulate hydrogen through the catalyst is eliminated is provided. This is accomplished by mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is “high” relative to the feed. The type and amount of diluent added, as well as the reactor conditions, can be set so that all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required, therefore, hydrogen recirculation is avoided and trickle bed operation of the reactors is avoided. Therefore, the large trickle bed reactors can be replaced by much smaller tubular reactor.

Owner:EI DU PONT DE NEMOURS & CO

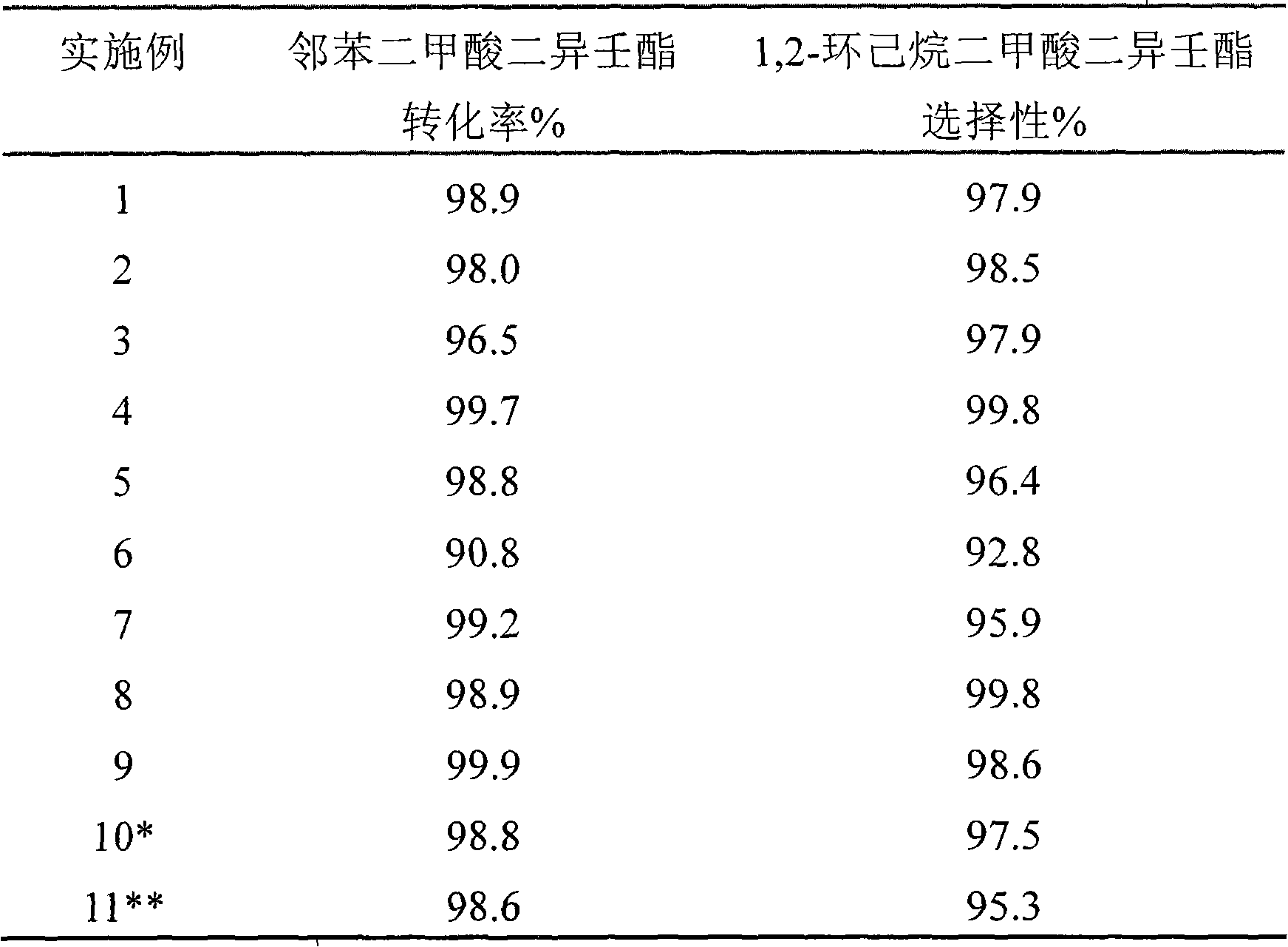

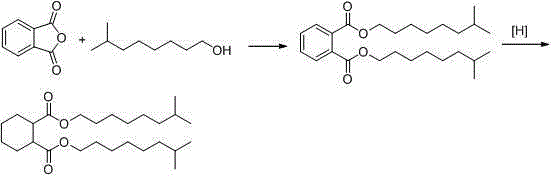

Catalyst for producing 1,2-cyclohexane dicarboxylic acid diesters

InactiveCN101406840AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationHydrogen pressureBULK ACTIVE INGREDIENT

The invention provides a catalyst for converting diisononyl phthalate, diisooctyl phthalate, dibutyl phthalate and other long-chain esters into corresponding 1, 2-cyclohexane dicarboxylic acid binary ester through hydrogenation. The catalyst for converting the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters into corresponding the 1,2-cyclohexane dicarboxylic acid binary ester through the hydrogenation consists of main active ingredients, additives and carriers, wherein the main active ingredients are noble metal Ru and Pd; the additives are Fe, Co, Ni, Cu and other metals or oxides; and macroporous Al2O3, ZrO2, TiO2 and the like are selected as the carriers. Under certain temperature, certain hydrogen pressure and the action of the catalyst, the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters in a trickle bed reactor can be converted into the corresponding the 1, 2-cyclohexane dicarboxylic acid binary ester with high activity and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Control system method and apparatus for two phase hydroprocessing

InactiveUS7569136B2Hydrogen solubility is “Eliminate needPhysical/chemical process catalystsHydrocarbon oils treatment control/regulationSolubilityHydrogen

A continuous liquid phase hydroprocessing process, apparatus and process control systems, where the need to circulate hydrogen gas through the catalyst is eliminated. By mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is high relative to the oil feed, all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required; therefore, the large trickle bed reactors can be replaced by much smaller tubular reactors. The amount of hydrogen added to the reactor can be used to control the liquid level in the reactor or the pressure in the reactor.

Owner:EI DU PONT DE NEMOURS & CO

Flexible glycerol conversion process

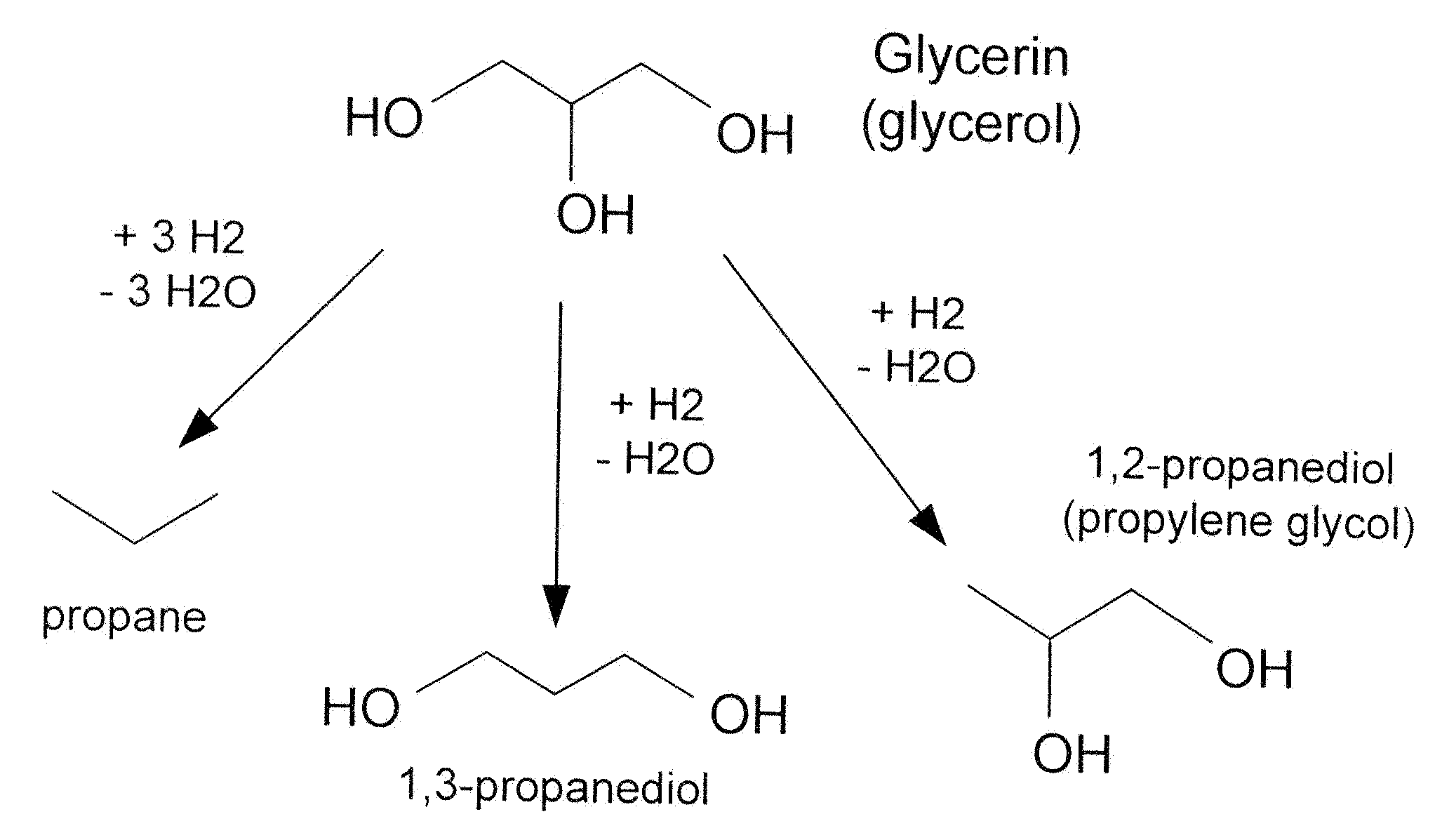

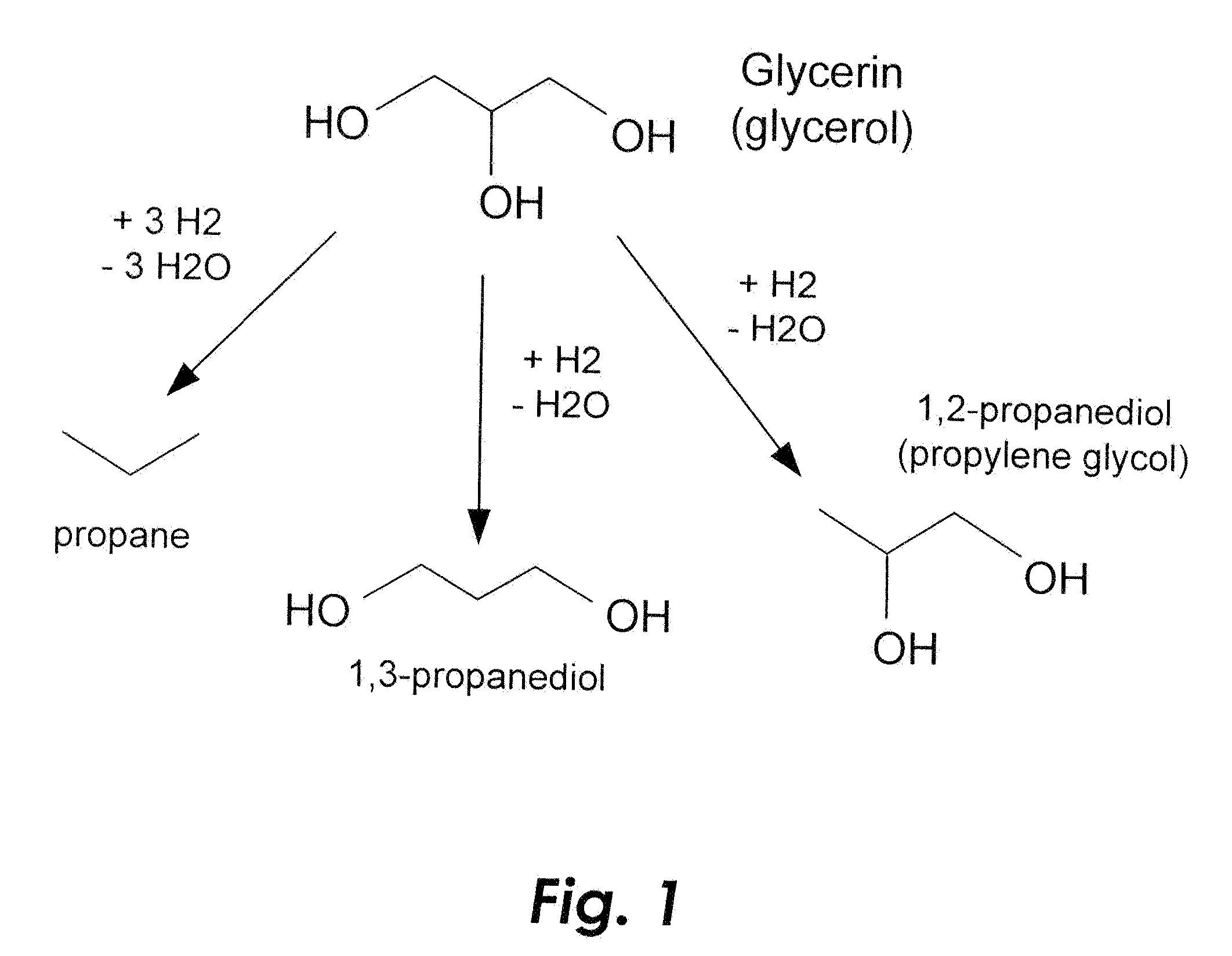

ActiveUS20090054701A1Oxygen-containing compound preparationOrganic compound preparationBiodieselHydrogen

The present invention relates to a process for converting byproducts of the manufacture of biodiesel into industrially useful oxygenated products of greater commercial value. The process includes a trickle bed reactor in which a glycerol-rich feedstock is reacted with hydrogen in the presence of a nickel-tungsten catalyst under typical refining condition of high temperature and pressure, yielding propane synfuel or propanediols.

Owner:REG SYNTHETIC FUELS LLC

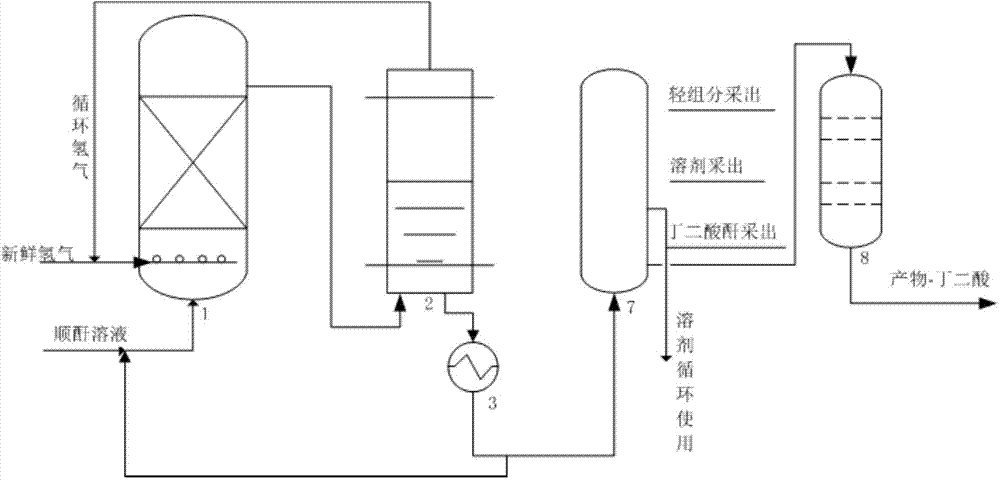

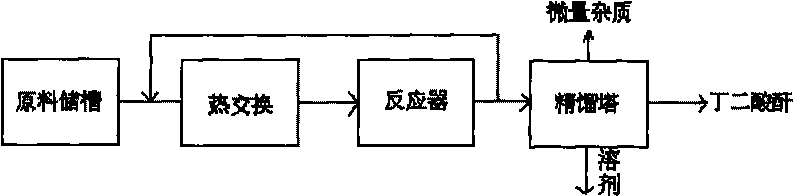

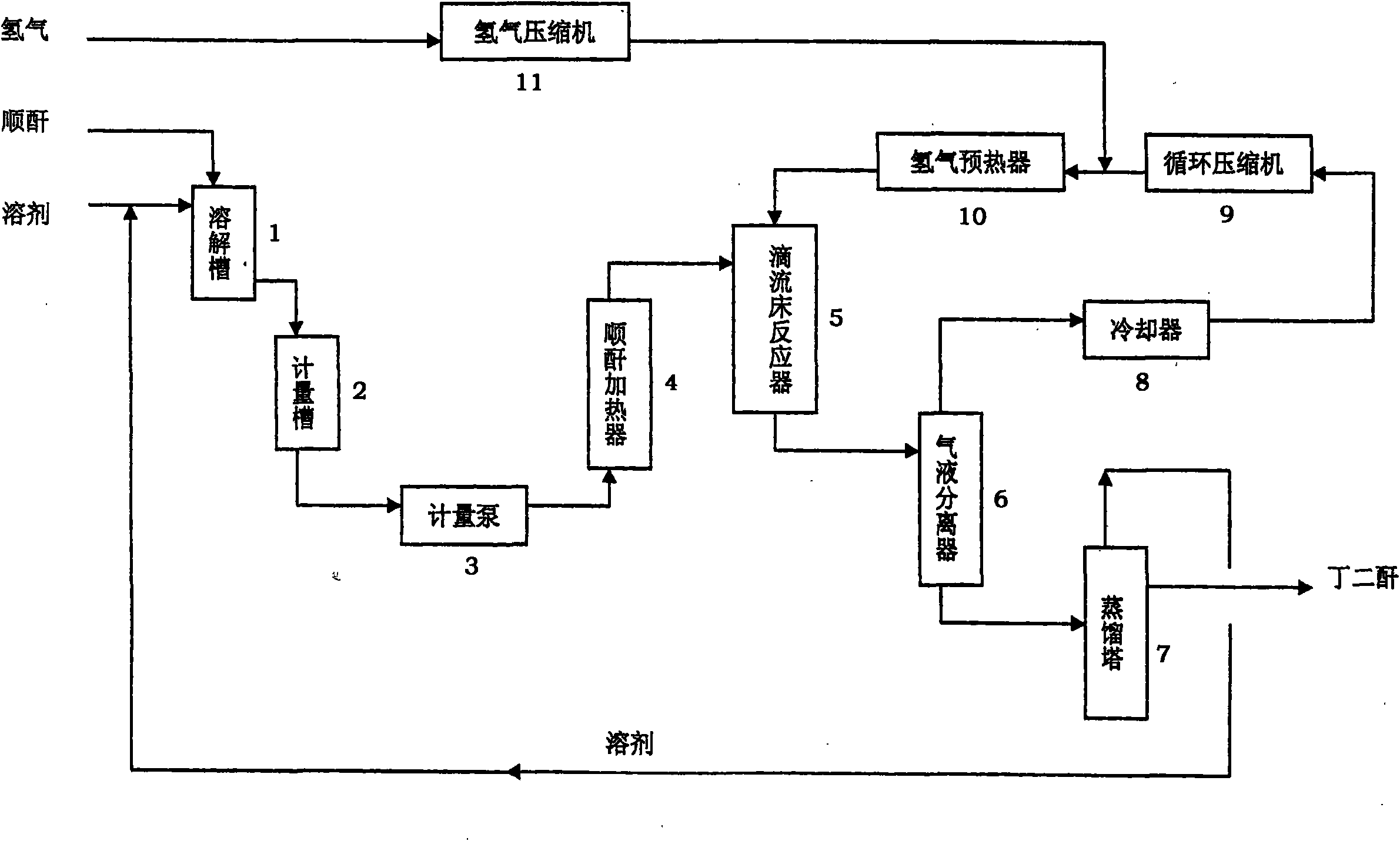

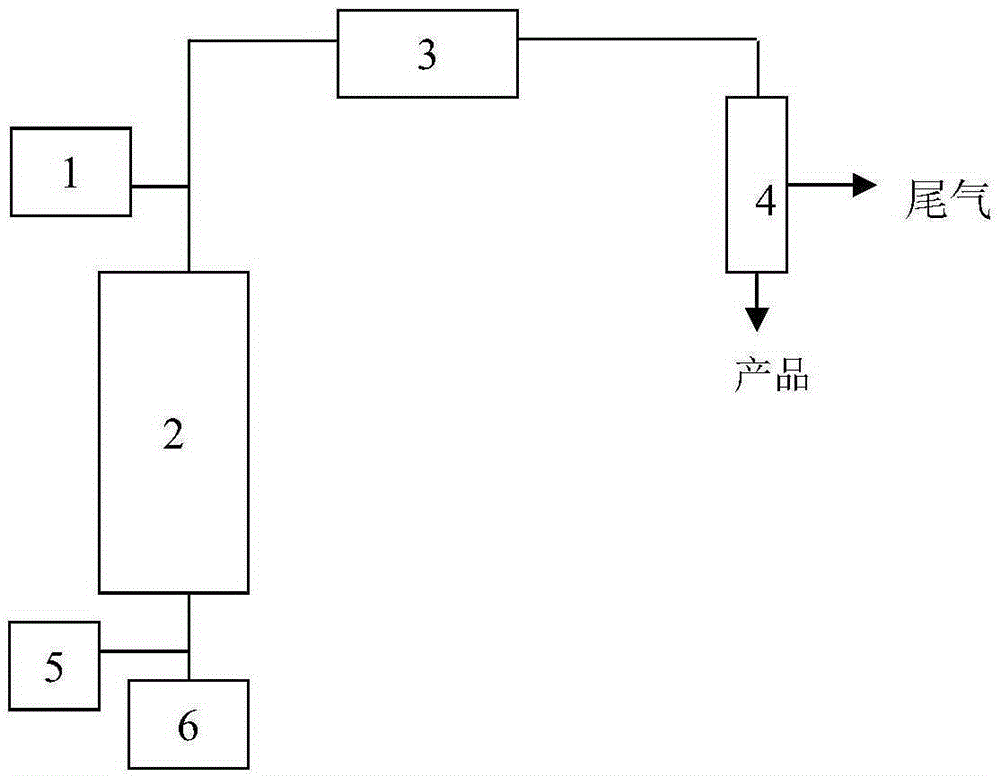

Technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride hydrogenation

ActiveCN103570650AControl the average operating temperatureUniform reaction temperaturePreparation from carboxylic acid anhydridesFixed bedReaction temperature

The invention discloses a technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride catalytic hydrogenation. The whole process comprises three steps, namely, reaction, rectification and hydrolysis, wherein two stages of hydrogenation reactors are used for reaction, a primary hydrogenation reactor is a fixed bed reactor with hydrogen entering from the lower part and reaction liquid exiting from the upper part, and a secondary hydrogenation reactor is a trickle bed reactor with hydrogen and reaction liquid entering from the upper part and exiting from the lower part. The technological process adopts an external circulating heat radiation manner, and reaction heat is uniformly removed, so that the average operation temperature of the whole reactor is effectively controlled, and the reaction temperature in the whole main reactor is balanced. Furthermore, the primary hydrogenation reactor adopts the manner that both the maleic anhydride solution and hydrogen flow upward simultaneously, so that the reaction temperature of the whole reactor is controlled to be balanced, local hot spot temperature is effectively controlled and lowered, and the reactants are prevented from polymerizing and depositing carbon or coking.

Owner:SHANXI UNIV

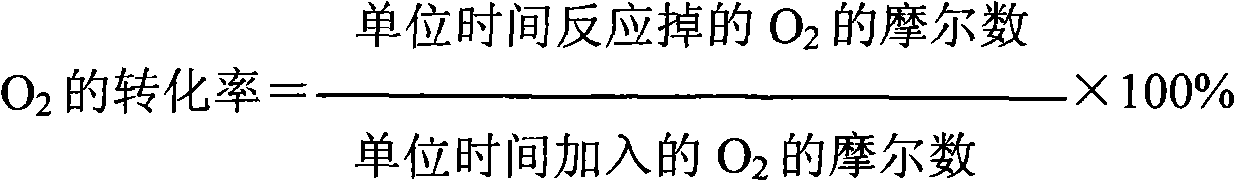

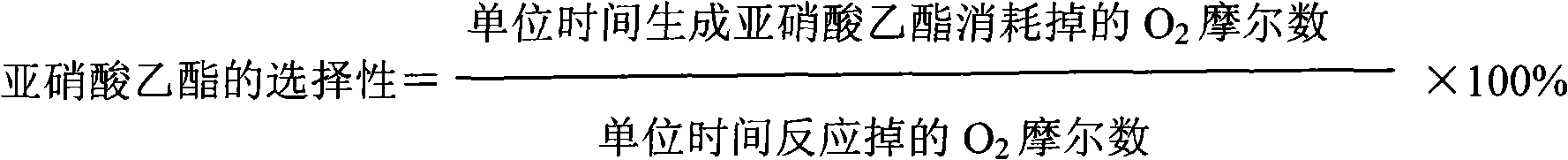

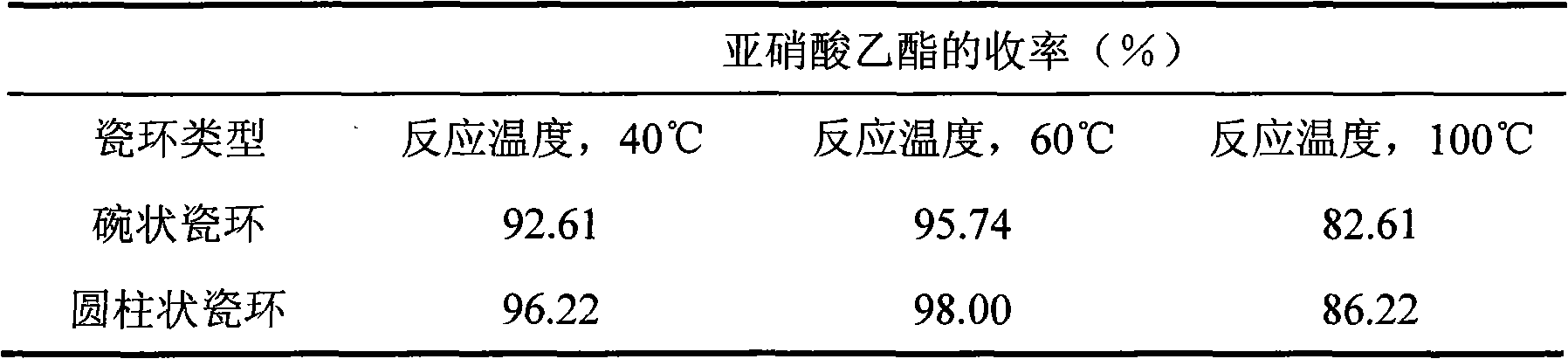

Reaction system and preparation method for nitrous alkyl ester

InactiveCN101314569AHigh yieldImprove efficiencyLiquid-gas reaction processesNitrous acid preparation ester preparationRetention timeGas phase

The invention relates to a reaction system for alkyl nitrite and a preparation method for the alkyl nitrite. The preparation method comprises the following steps that: a trickle-bed reactor is adopted and porcelain ring filler is filled into the trickle-bed reactor; liquid added into the reactor forms liquid membranes on the filler; alkyl alcohol is taken as a liquid-phase raw material and nitric monoxide, oxygen and nitrogen are taken as gas-phase raw materials; and gas and liquid phases are reacted in the trickle-bed reactor by means of co-current flow or countercurrent flow under the condition of nitrogen protection so as to generate the alkyl nitrite. The mol ratio of the alkyl alcohol to NO is between 2 to 1 and 7 to 1, and the mol ratio of the NO to O2 is between 4 to 1 and 8 to 1; the reaction temperature is between 40 and 100 DEG C, and the reaction pressure is between 0.1 and 1.0 MPa; and the retention time of continuous feeding of liquid-phase alkyl alcohol in the trickle-bed reactor is between 10 and 500 minutes, and the retention time of continuous feeding of gas phase in the trickle-bed reactor is between 0.02 and 1 minute. The reaction system and the preparation method have the advantages that: the operating condition is mild; the reaction time is short; the conversion rate of the raw materials, and the selectivity and the yield of products are high; and the whole reaction system is convenient for realizing continuous production, etc.

Owner:TIANJIN UNIV

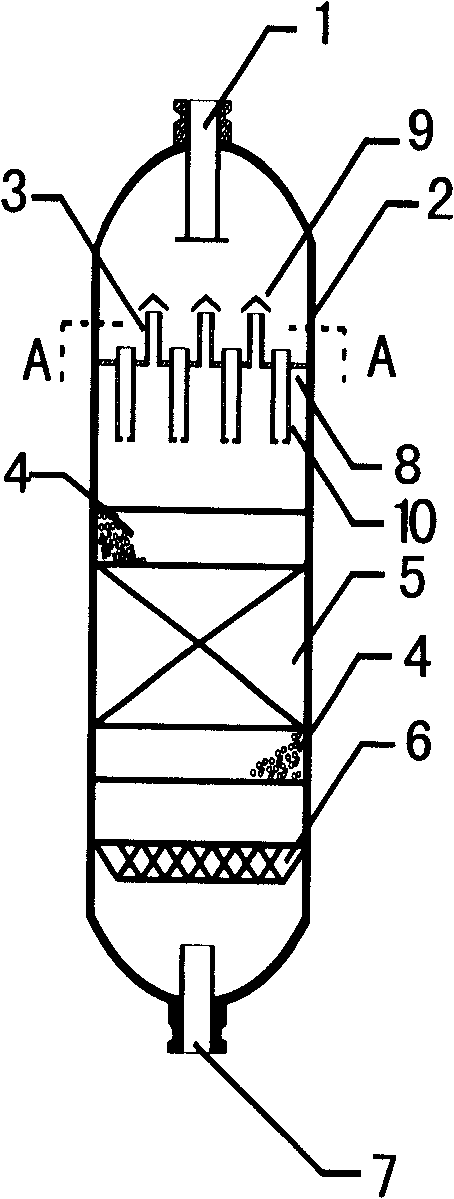

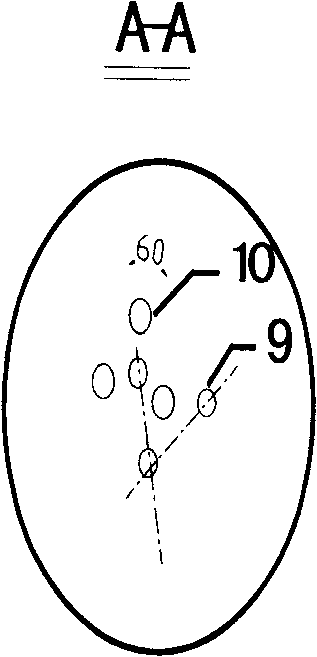

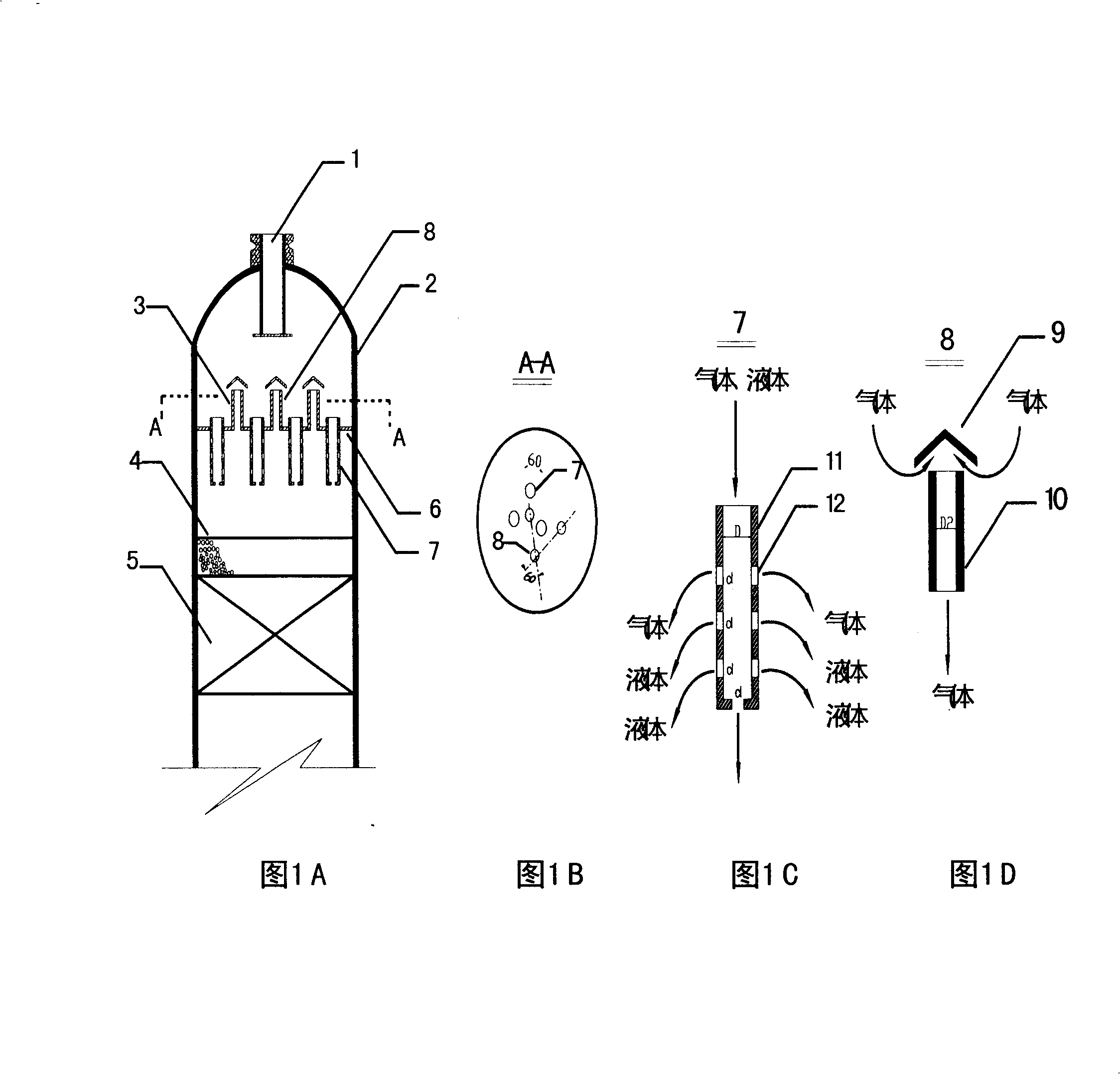

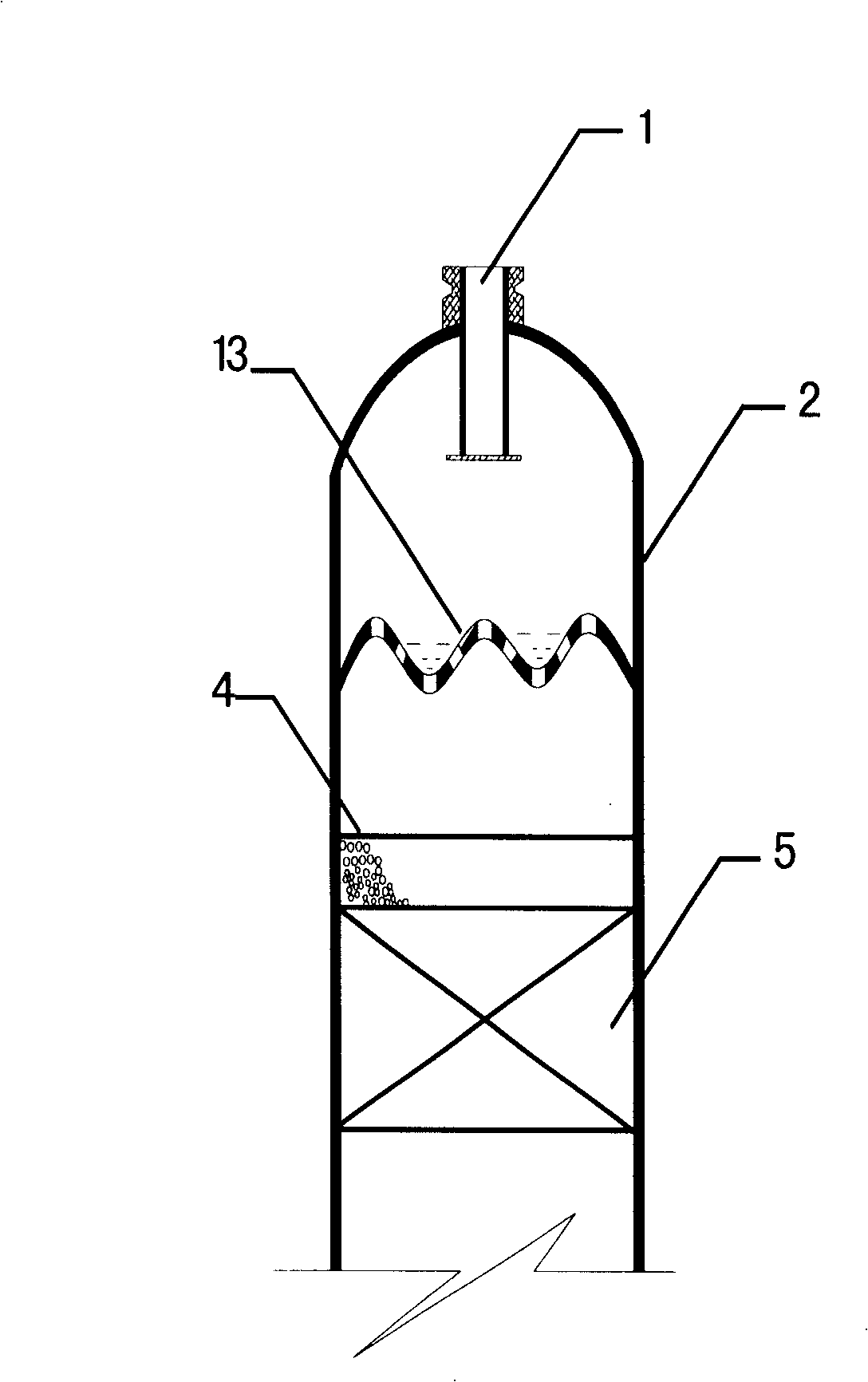

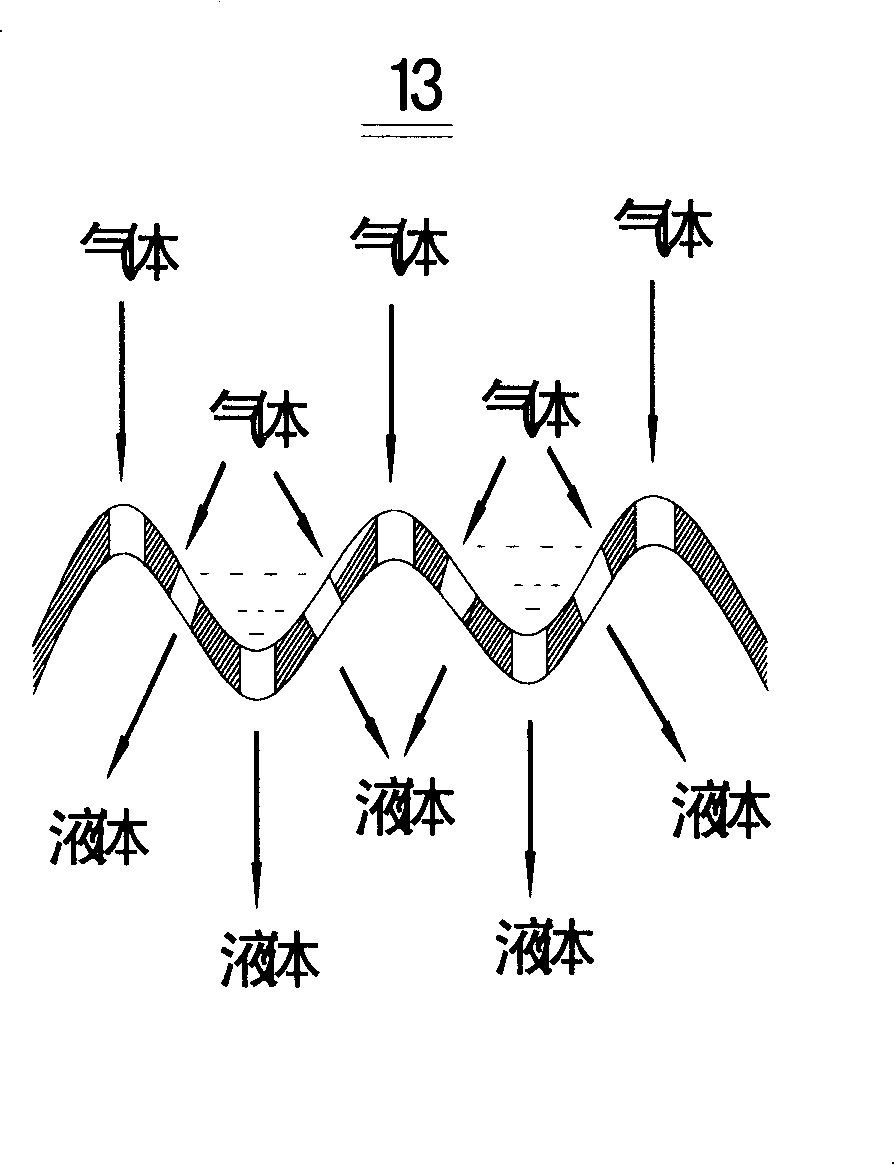

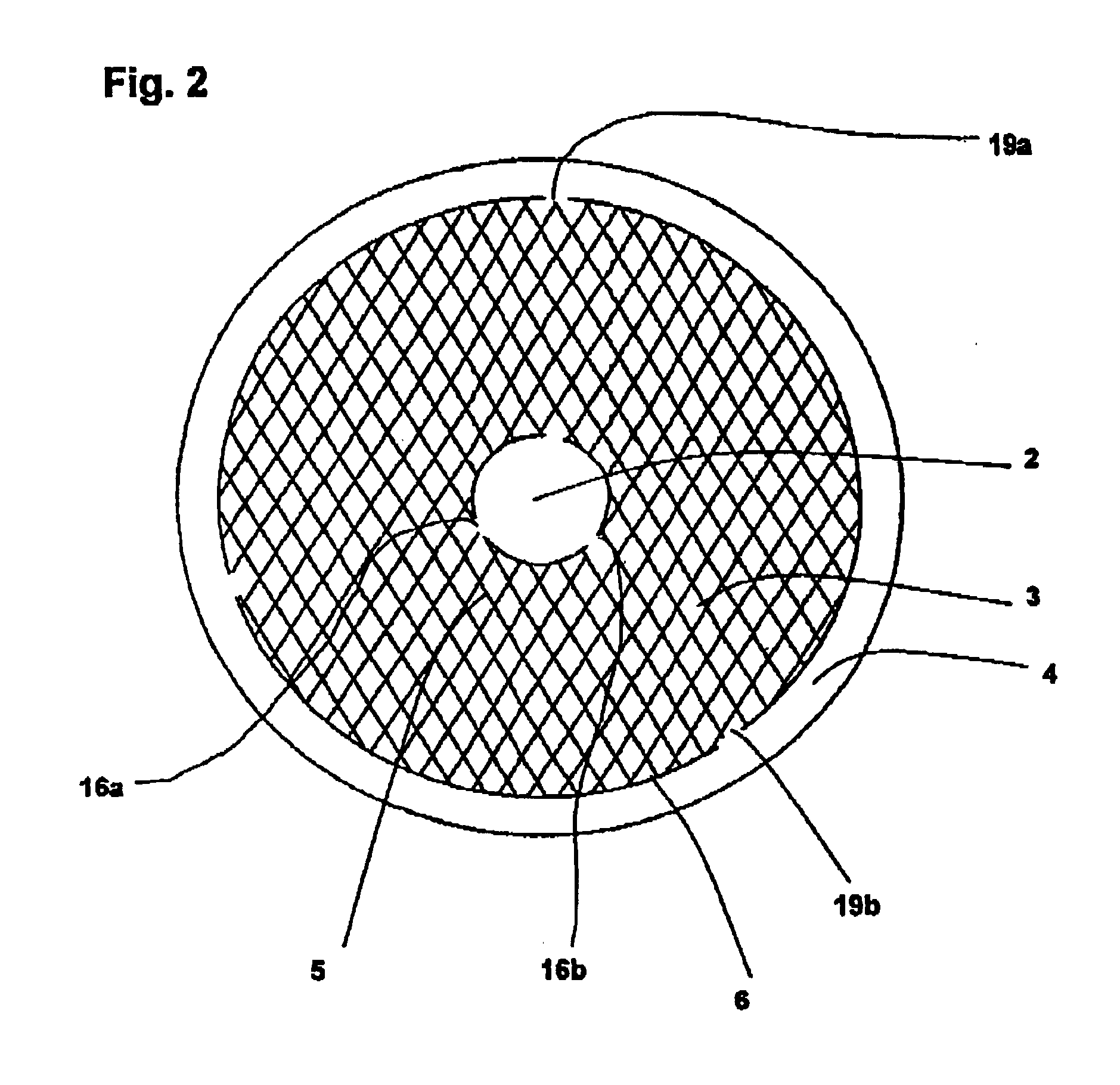

Trickle bed reactor

ActiveCN101279229AImprove gas-liquid distributionImprove reaction efficiencyChemical/physical processesProduct gasThree-phase

The invention relates to a trickle-bed reactor, which mainly aims at solving the problem that the uneven liquid-gas distribution of the trickle-bed reactor in the prior art results in the bad trickling effect of the reactor and low efficiency of the catalytic reaction. The trickle-bed reactor adopts the technical scheme that the trickle-bed reactor comprises an inlet orifice, a reactor shell, a liquid-gas distributor, a porcelain ball bed layer, a catalyst bed layer and an orifice ring, wherein the liquid-gas distributor is provided with a gas passage pipe and a liquid passage pipe on a distributing plate; the gas passage pipe is composed of a cone roof and a straight nozzle stub; the liquid passage pipe is a vertical nozzle stub with the upper end extending 10 to 100mm out of the upper part of the distributing plate and the lower end extending 200 to 1000mm out of the lower part of the distributing plate; a plurality of pinholes are evenly opened on the cross section at different positions along the axial direction to form the liquid-gas distributor. The technical scheme better solves the problem, greatly improves the reaction efficiency of the trickle-bed reactor and can be applied to various gas liquid and solids three-phase reactors.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

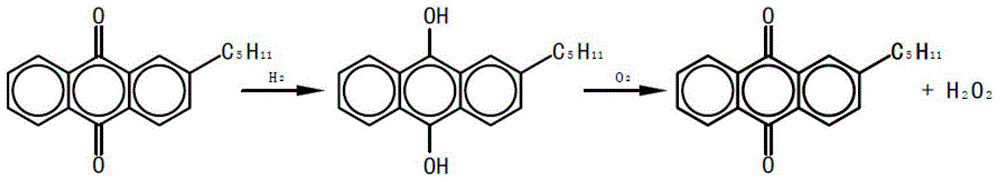

Monolithic catalyst for hydrogen peroxide production through pentylanthraquinone process and preparation method thereof

InactiveCN104368336AIncrease flow rateEasy to integratePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsSingle substanceHydrogenation reaction

The invention discloses a monolithic catalyst for hydrogen peroxide production through a pentylanthraquinone process and a preparation method thereof. The catalyst comprises an active component, a co-catalyst, and a carrier; wherein the active component is a combination of one or more elements of platinum group precious metals, the active component (calculated by single substance of precious metals) accounts for 0.01 to 5% of the total mass of the monolithic catalyst, and Pd (calculated by single substance) accounts for 50 to 100% of the total mass of the precious metals. Furthermore, the provided monolithic catalyst can be produced through a simple impregnation method, the preparation method is simple, the preparation process is easy to control, and the prepared monolithic catalyst has a high catalytic activity and selectivity in the hydrogenation reactions of 2-pentylanthraquninone. The provided monolithic catalyst integrates the advantages of conventional slurry bed reactor and trickle bed reactor together and discards the disadvantages of conventional slurry bed reactor and trickle bed reactor, so the efficiency of selective hydrogenation of 2-pentylanthraquinone is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

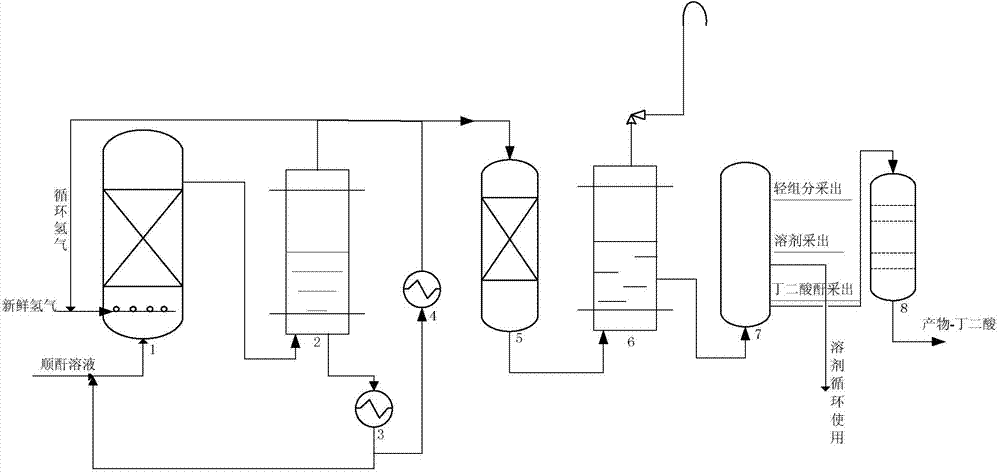

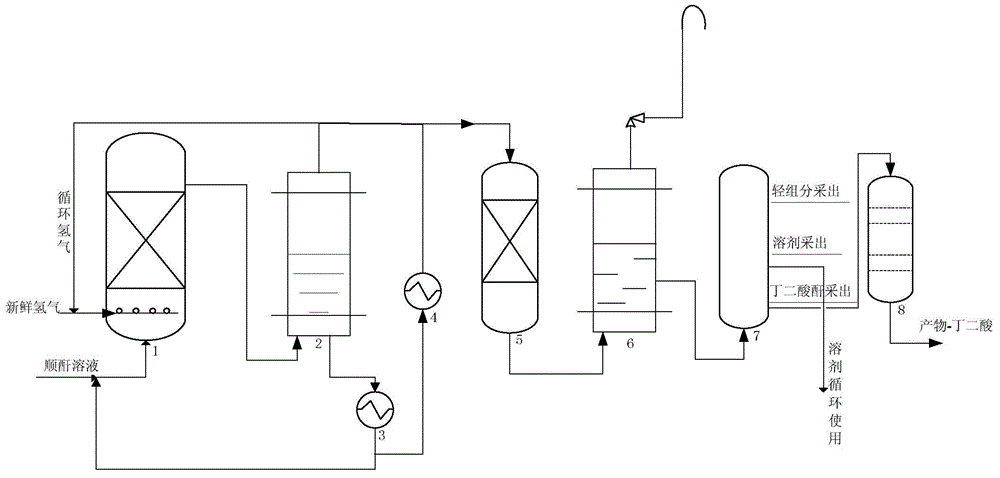

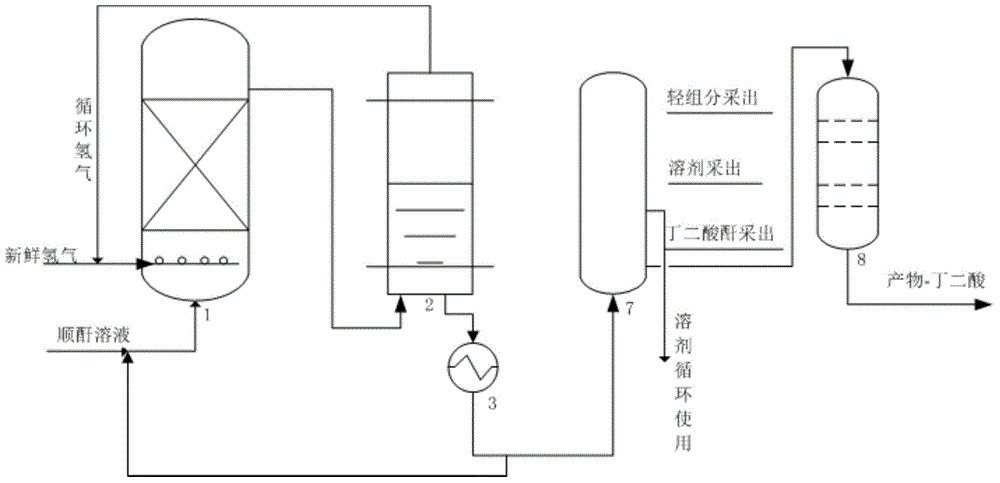

Process for continuously producing succinic anhydride through hydrogenation of maleic anhydride

The invention provides a process for continuously producing succinic anhydride through hydrogenation of maleic anhydride, which comprises the following steps of: shunting solution of maleic anhydride in a split ratio of 1 / 5-1 / 2 after hydrogenation is performed on the solution of maleic anhydride through a trickle bed reactor; rectifying partial shunted reaction liquid into a rectifying tower to obtain finished products succinic anhydride and a solvent, and recycling the solvent; mixing the other liquid with the solution of maleic anhydride; and returning to the reactor after eliminating heat through a heat exchanger. The process successfully solves the problem of exothermic effect in the process of preparing the succinic anhydride through the hydrogenation of the maleic anhydride, meanwhile realizes continuous production of the succinic anhydride, and greatly improves the production capacity of the succinic anhydride with above 97.5 percent of the yield of the succinic anhydride; the process has the advantages of simple flow, high utilization rate of devices and good quality of products; the solvent can be recycled, and the operation cost is low; and the process is suitable for clean production and has good environmental benefit.

Owner:SHANXI UNIV

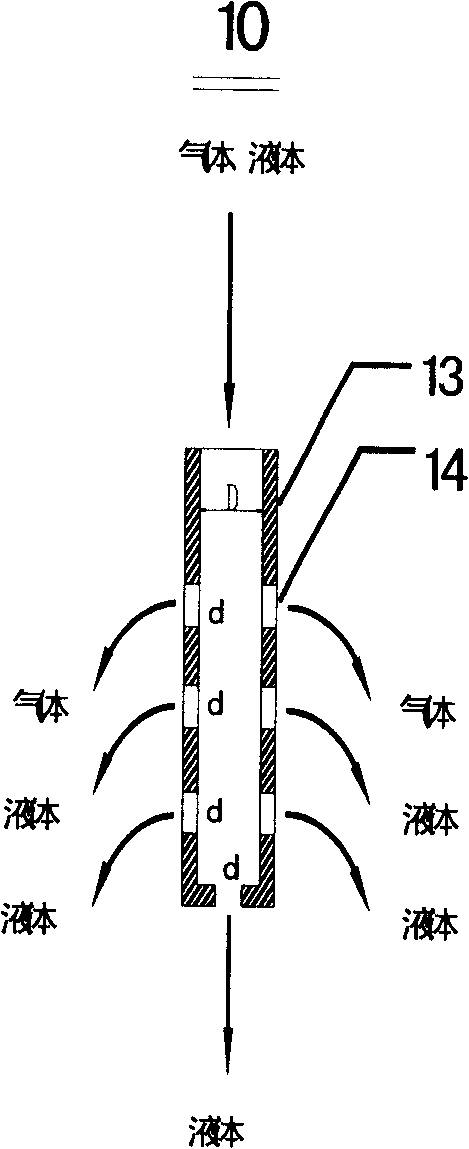

Gas-liquid distributor of trickle bed reactor

ActiveCN101279228AImprove reaction efficiencyImprove gas-liquid distributionChemical/physical processesHydrocarbon oils treatmentEngineeringProduct gas

The invention relates to a liquid-gas distributor of a trickle-bed reactor, which aims at solving the problems that the uneven liquid-gas distribution of the trickle-bed reactor in the prior art results in the uneven fluid distribution inside the layer of a catalyst bed; the trickling effect is not good; and the efficiency of the catalytic reaction is not well. The liquid-gas distributor adopts the following technical scheme: the liquid-gas distributor is provided with a gas passage pipe and a liquid passage pipe on a distributing plate; the gas passage pipe is composed of a cone roof and a straight nozzle stub; the liquid passage pipe is a vertical nozzle stub with the upper end extending 10 to 100mm out of the upper part of the distributing plate and the lower end extending 200 to 1000mm out of the lower part of the distributing plate; a plurality of pinholes are evenly opened on the cross section at different positions along the axial direction to form the liquid-gas distributor. The technical scheme better solves the problems, greatly improves the reaction efficiency of the trickle-bed reactor and can be applied to various trickle-bed reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

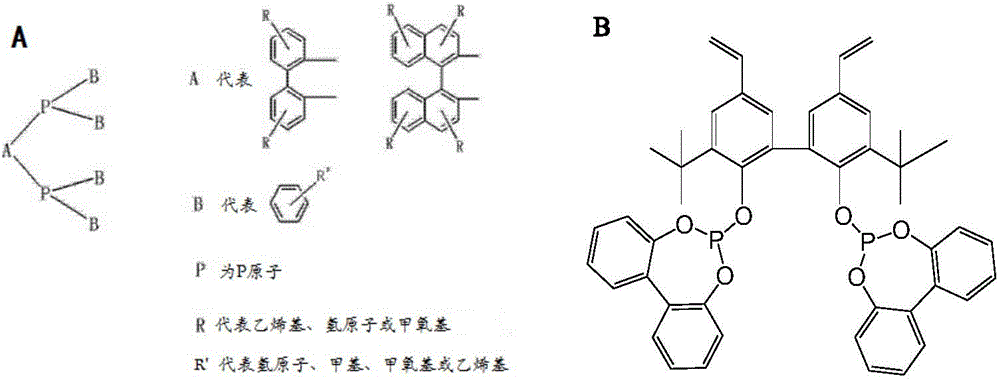

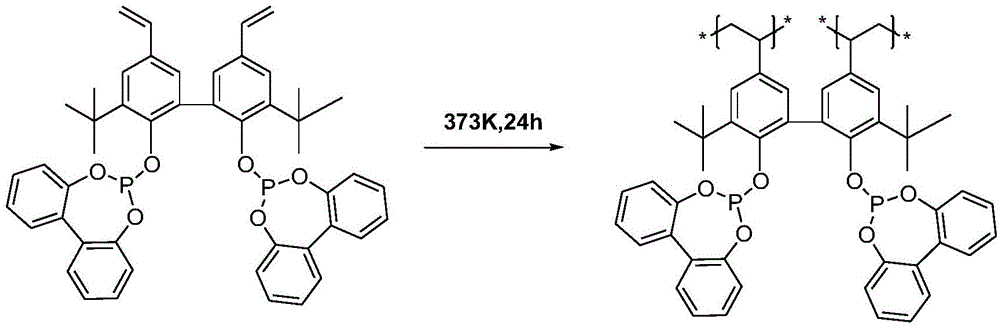

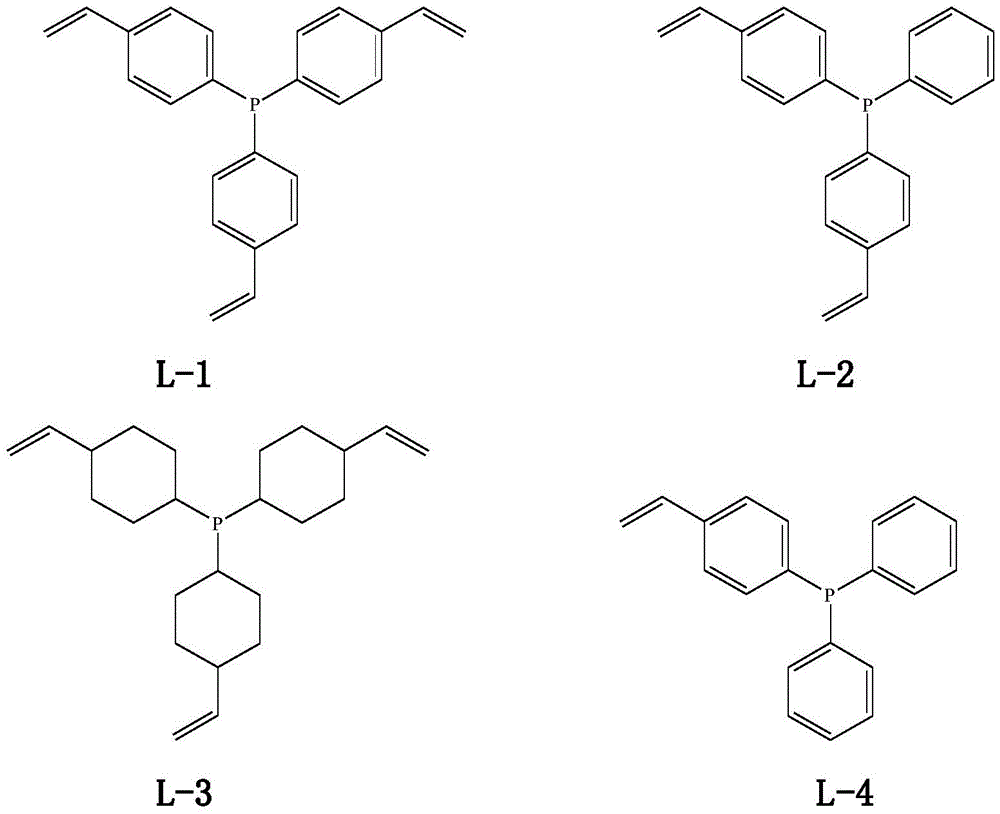

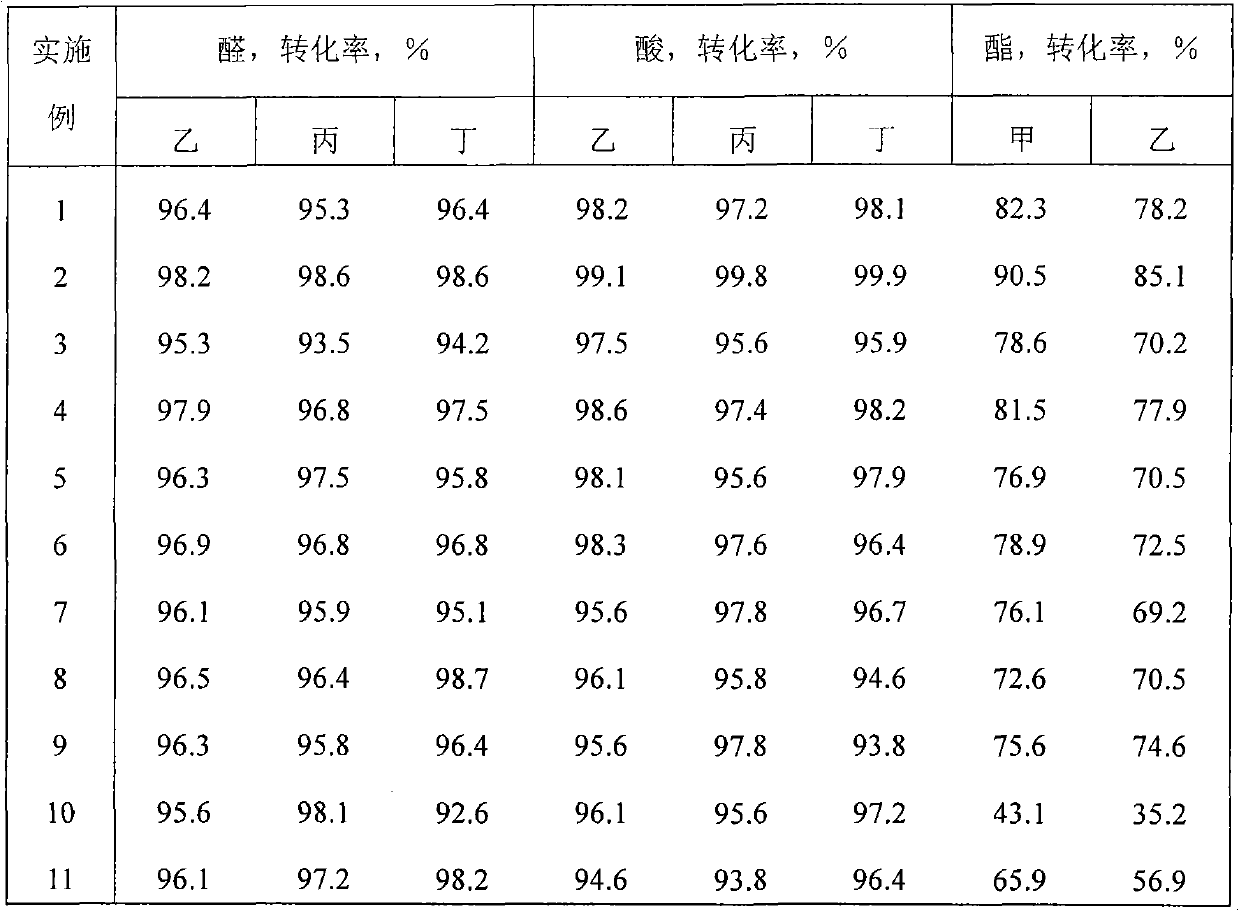

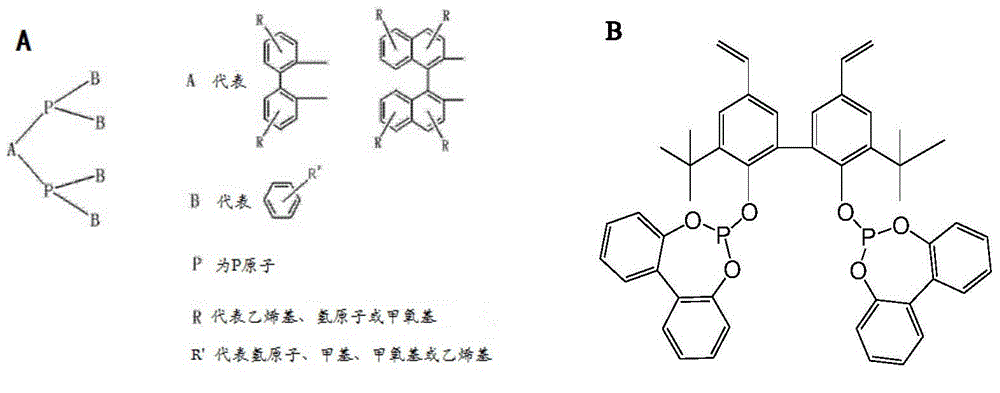

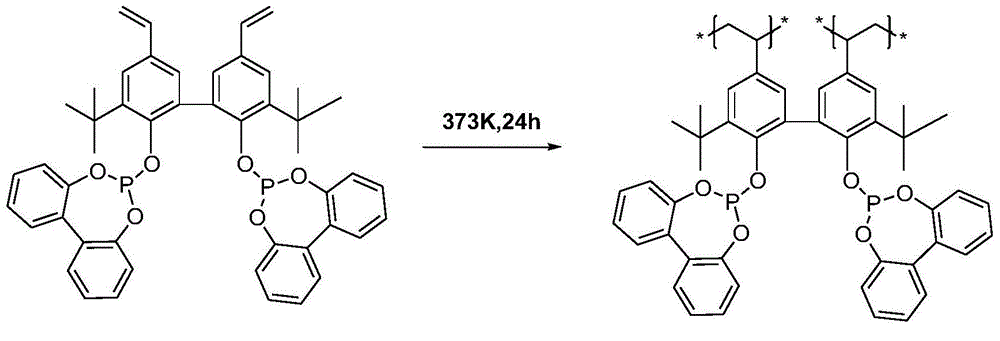

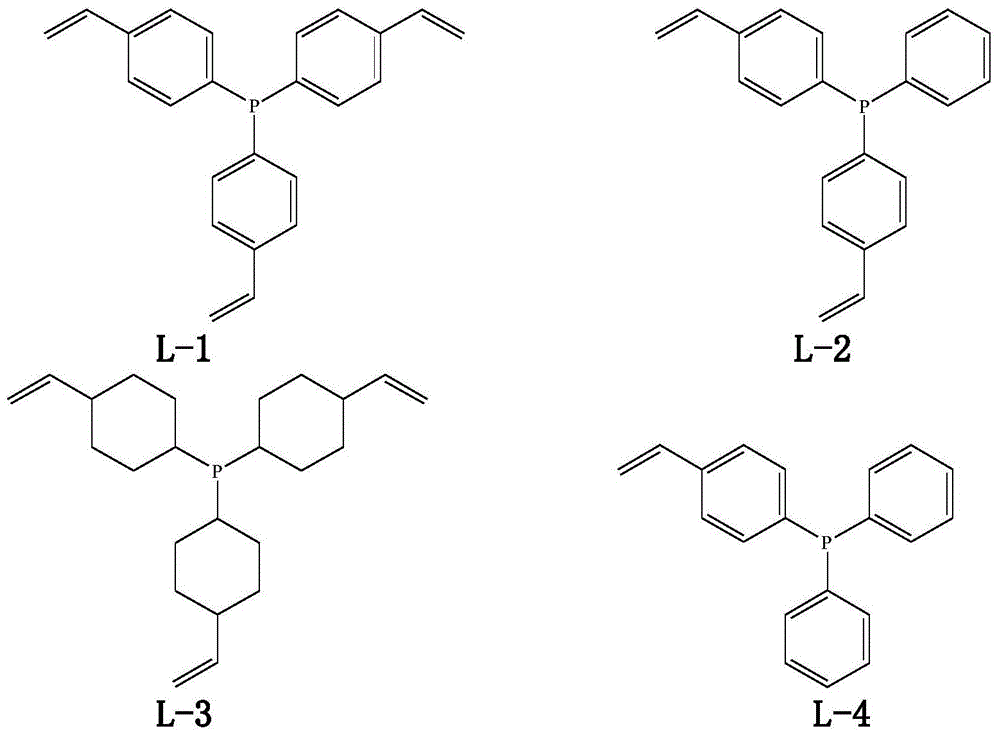

Heterogeneous catalyst adopting phosphine-containing organic mixed polymer-metal as well as preparation and application of heterogeneous catalyst

ActiveCN106140303ASolution to short lifeImprove utilization efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryAlkaneFormylation reaction

The invention discloses a heterogeneous catalyst adopting a hierarchical pore structure and adopting phosphine-containing organic mixed polymer-metal as well as preparation and an application of the heterogeneous catalyst in production of aldehyde with a high normal / isomeric ratio through internal olefin hydroformylation. In the heterogeneous catalyst, one, two or three of metal Rh, Co and Ir are taken as active components, and a phosphine-containing organic mixed polymer adopting the hierarchical pore structure is taken as a carrier and is prepared from multidentate organic phosphine ligands containing alkylene and monodentate organic phosphine ligands through copolymerization. The coordinate bond type heterogeneous catalyst is applicable to a fixed bed reactor, a slurry bed reactor, a bubble column reactor, a trickle-bed reactor and other reactors. The provided heterogeneous catalyst has good presentation in the internal olefin hydroformylation reaction, internal olefins are firstly isomerized to be terminal-group olefins under the action of the catalyst, a hydroformylation reaction is performed, corresponding normal aldehyde is selectively generated, accordingly, the normal / isomeric ratio of the product aldehyde is high and can be higher than 15, and the content of alkane in the obtained product is lower than 1%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for hydro-conversion of mixed aqueous solution containing alcohol, aldehyde, acid and ester into alcohols

The invention discloses a catalyst for hydro-conversion of a mixture aqueous solution containing alcohol, aldehyde, acid, ester and the like into corresponding alcohols. The catalyst mainly comprises three parts including a main active constituent, an auxiliary and a carrier. The main active constituent is one or more of precious metals including Re, Ru and Pd, the auxiliary is one or more of metals, including Ag, Ni, Cu and the like, or oxides thereof, and the carrier is selected from activated carbon, Al2O3, SiO2 and the like. Under the actions of the catalyst, the mixture aqueous solution containing alcohol, aldehyde, acid, ester and the like in a trickle bed reactor can be converted into a corresponding alcohol aqueous solution in high activity and high selectivity ways under the conditions with certain temperature and pressure.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

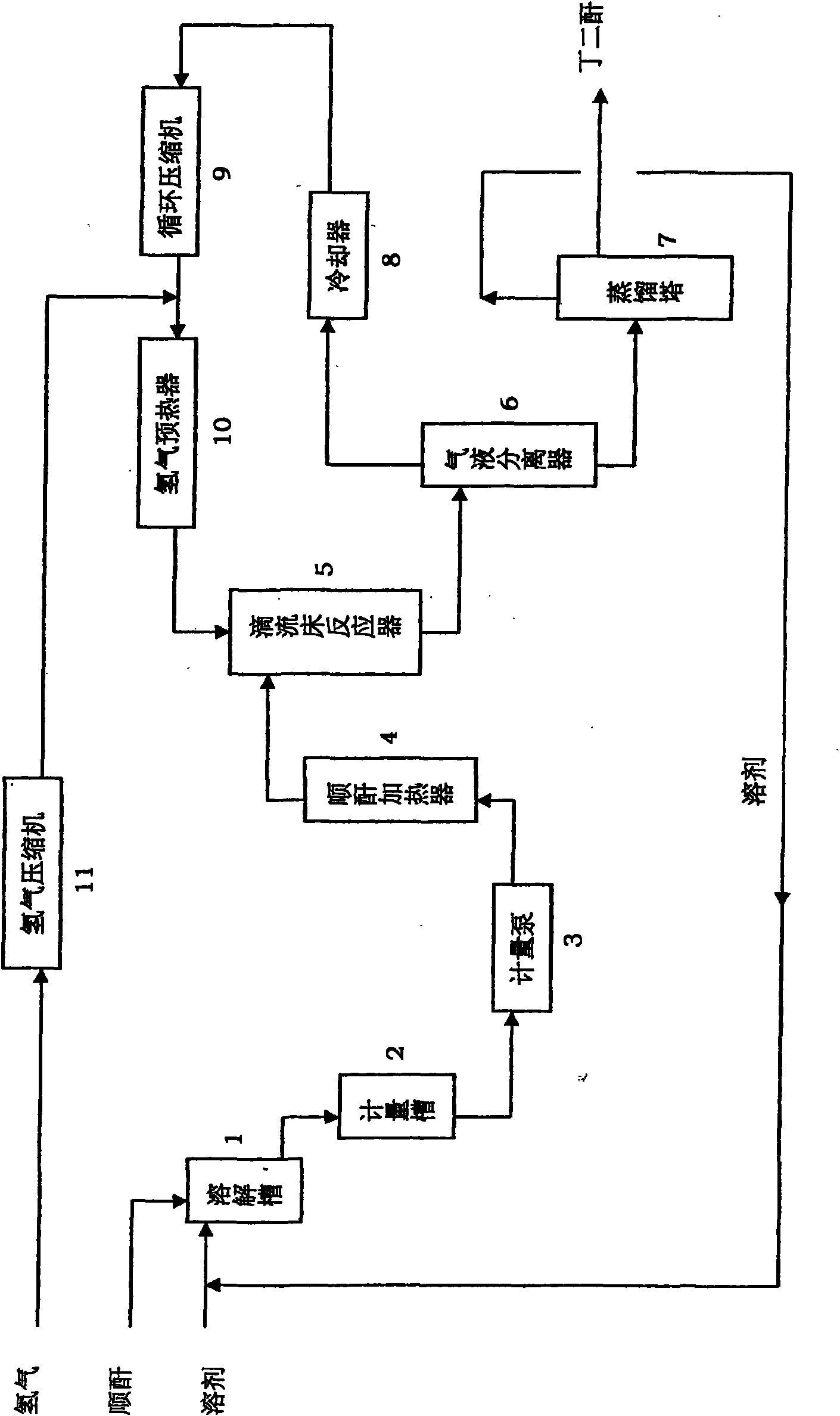

Continuous production process for preparing succinyl oxide by maleic anhydride hydrogenation

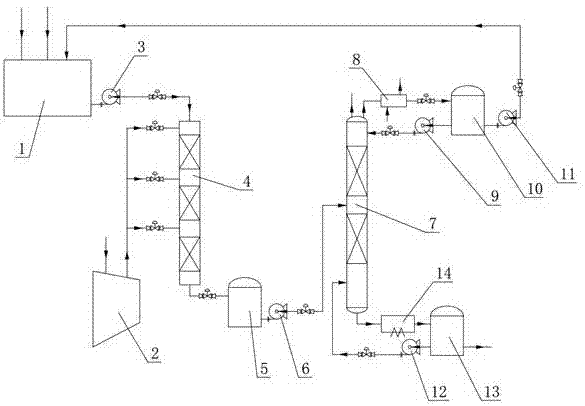

ActiveCN101891718AEasy to separateReduce lossesOrganic chemistryChemical/physical processesVapor–liquid separatorHydrogenation reaction

The invention relates to a continuous production process for preparing succinyl oxide by maleic anhydride hydrogenation, including the following steps: (1) maleic anhydride and solvent are dissolved in a dissolution tank, and preheating is carried out by virtue of a maleic anhydride heater; (2) maleic anhydride after preheating is mixed with hydrogen preheated by a hydrogen preheater, the mixture enters into a trickle bed reactor filled with hydrogenation catalyst, and maleic anhydride hydrogenation reaction is carried out; (3) reaction product and residual hydrogen pass through a gas-liquid separator, separated liquid phase product is conveyed into a distillation tower, and distillation is carried out, thus obtaining the finished product succinyl oxide; (4) solvent separated by the distillation tower is recycled; (5) the residual hydrogen separated by the gas-liquid separator is returned to the hydrogen preheater again. Result shows that maleic anhydride conversion rate is 100%, selectivity of product succinyl oxide is more than 98%, the production efficiency of continuous production process is four times higher than that of batch stirring kettle process, and the service life of catalyst is prolonged by more than five times.

Owner:山西侨友化工股份有限公司

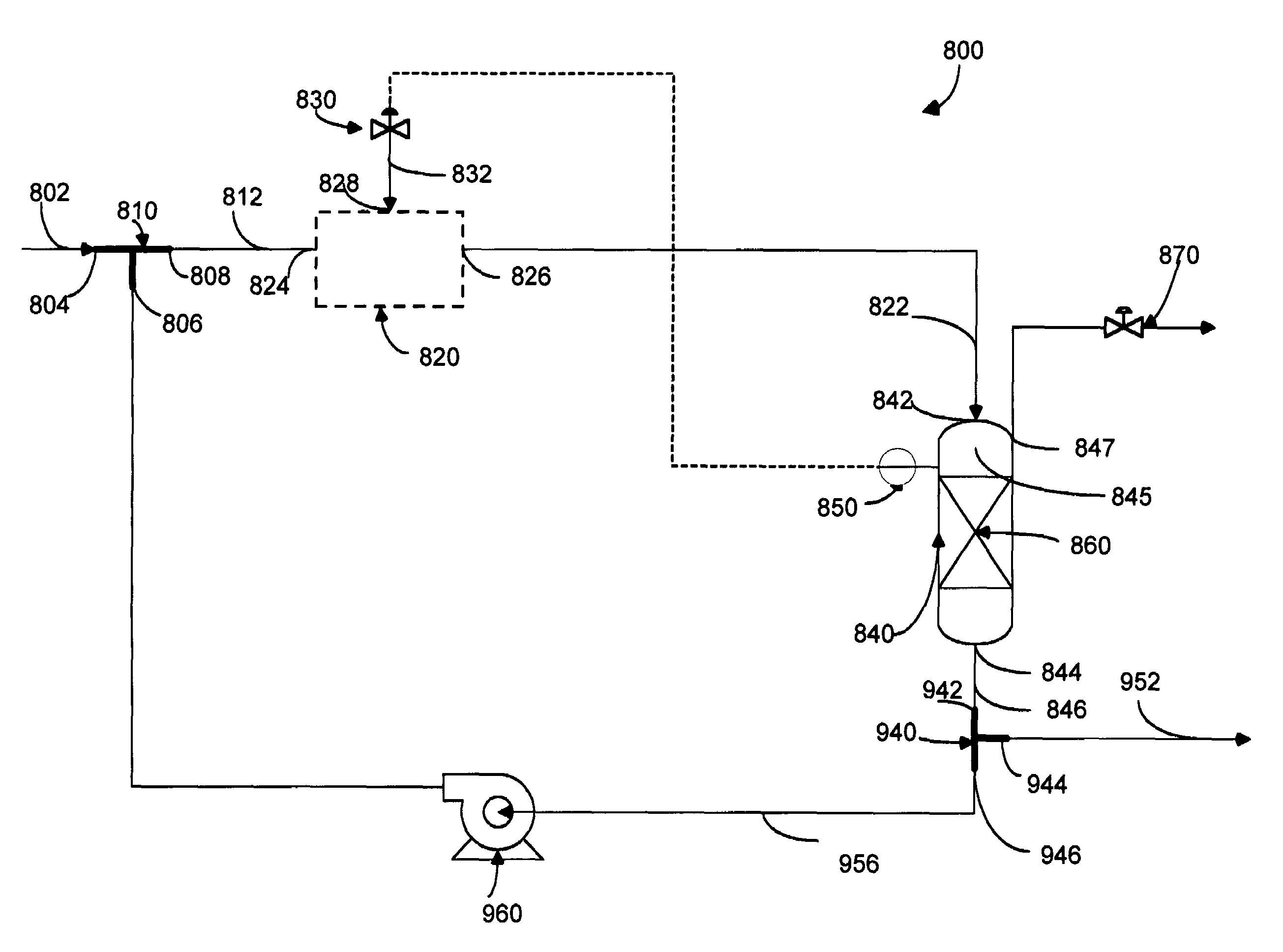

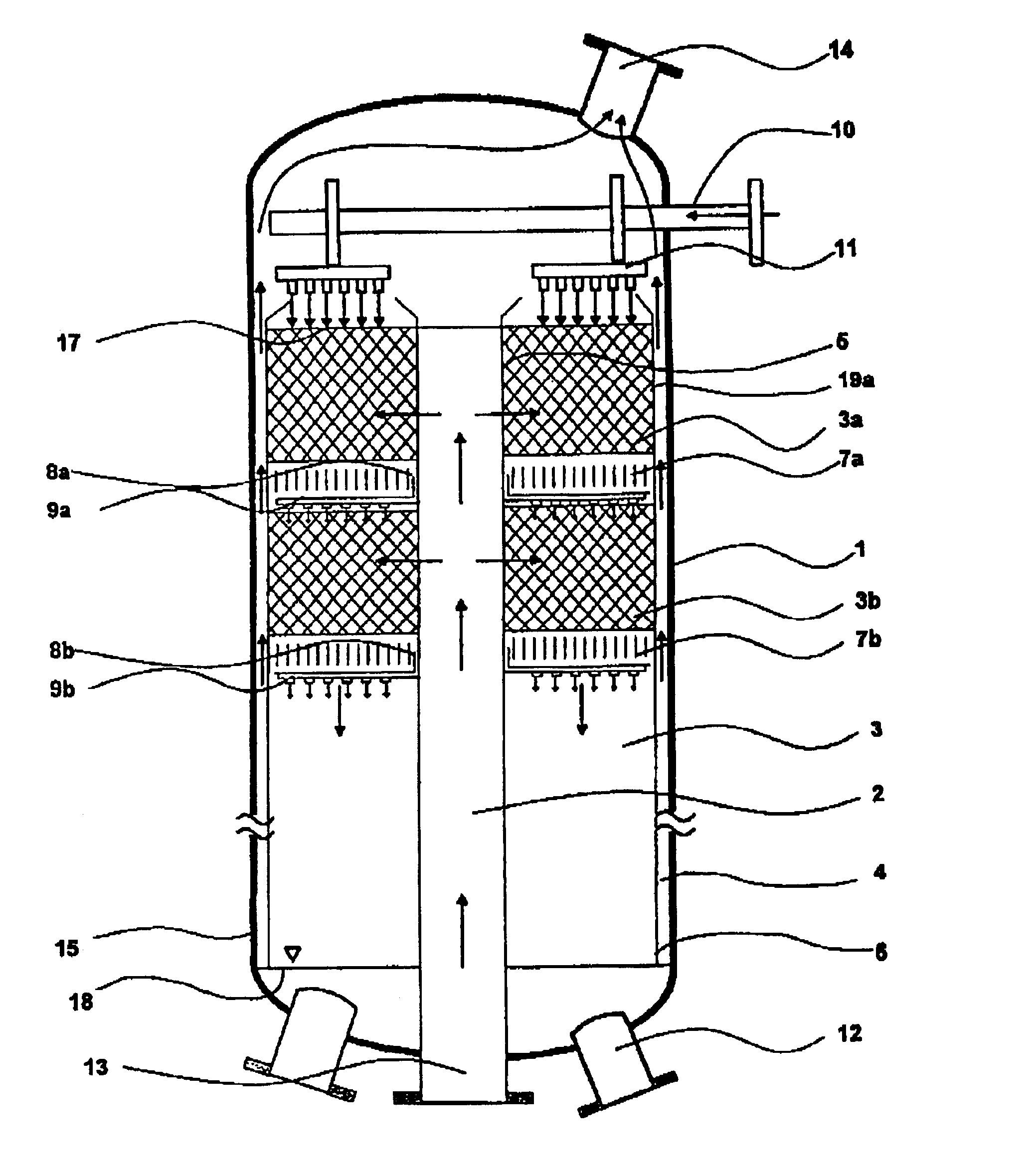

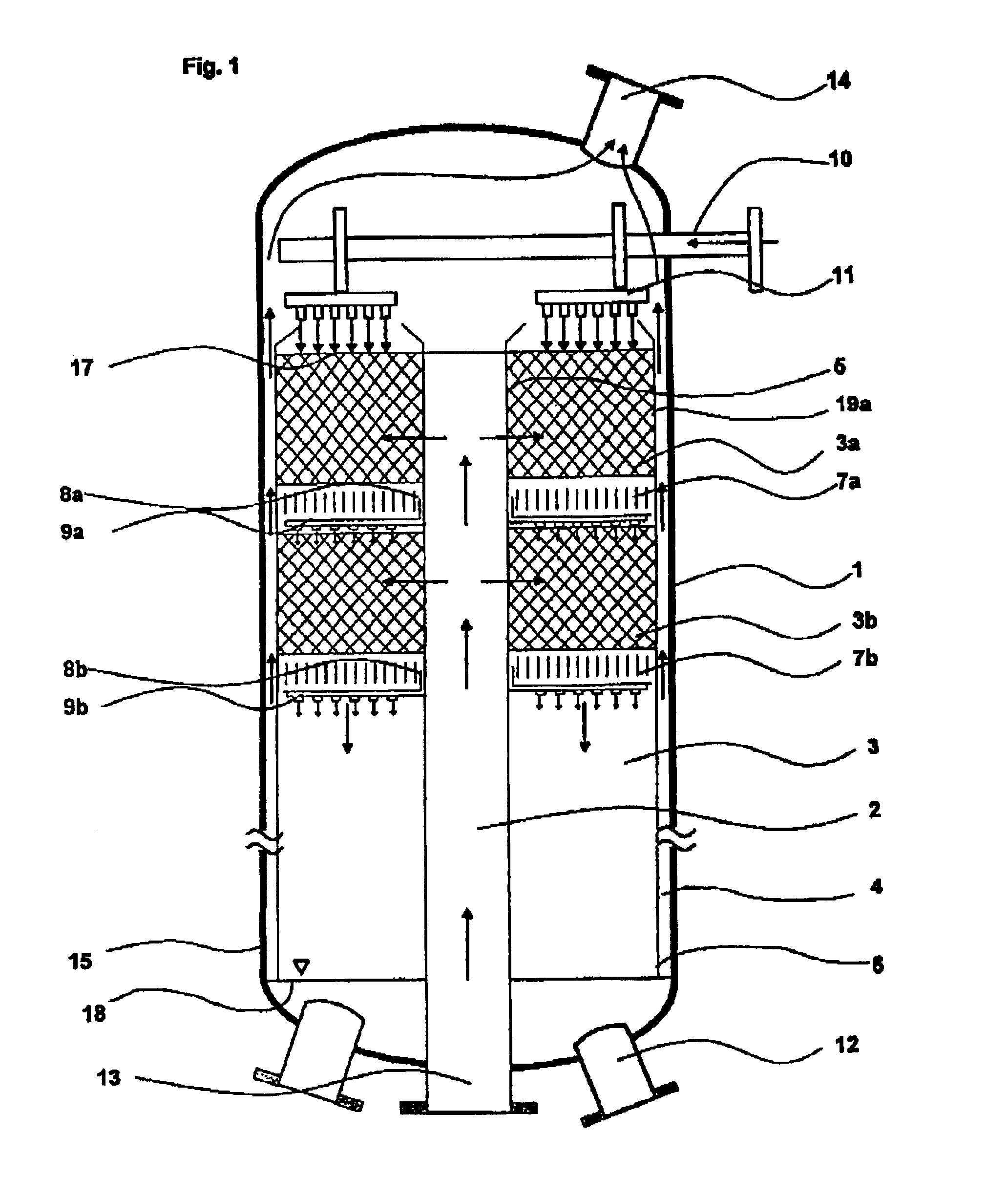

Preparation of hydrogen peroxide from hydrogen and oxygen

InactiveUS6872377B2Reduce pressureIncrease pointsHydrogen peroxideCatalyst activation/preparationHydrogenAlcohol

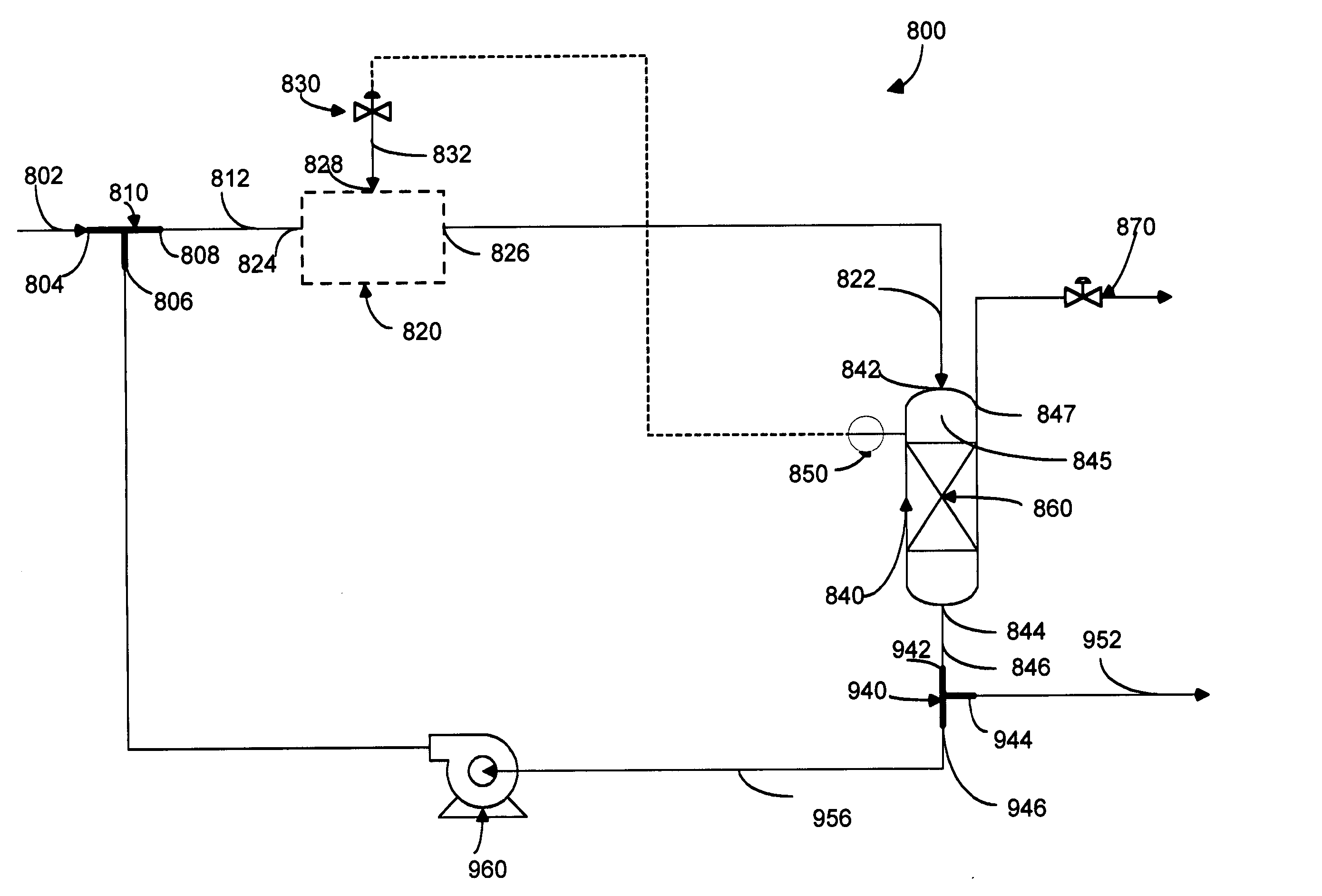

In a process for preparing an aqueous and / or alcoholic solution of hydrogen peroxide by reaction of hydrogen and oxygen in a trickle-bed reactor over a supported catalyst including a noble metal, the apparent flow direction of the gas stream and the apparent flow direction of the liquid stream are not parallel to one another. The apparent flow direction of the gas stream preferably runs radially from the longitudinal axis to the circumference of the reactor. The process allows high gas throughputs with a small pressure drop.

Owner:BASF AG

Phosphine-containing organic mixed polymer-metal heterogeneous catalyst and its preparation method and use

ActiveCN106140301ASolution to short lifeImprove utilization efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFixed bedSlurry

The invention discloses a phosphine-containing organic mixed polymer-metal heterogeneous catalyst and its use in butyraldehyde production. The heterogeneous catalyst comprises one, two or three of Rh, Co and Ir as active ingredients and utilizes a multistage pore-structure phosphine-containing organic mixed polymer as a carrier. The phosphine-containing organic mixed polymer is prepared from an alkylene-containing polydentate organic phosphine ligand and a single dentate organic phosphine ligand through copolymerization. The coordination bond-type heterogeneous catalyst is suitable for a fixed bed reactor, a slurry bed reactor, a bubbling bed reactor and a trickle-bed reactor. The heterogeneous catalyst has good effects in hydrogen-propene formylation preparation of butyraldehyde, can produce high-normal / isomeric ratio butyraldehyde with a normal / isomeric ratio of 25 or more and realizes product propane content less than 0.1%. The heterogeneous catalyst has good stability and can be simply and efficiently separated from reactants and products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

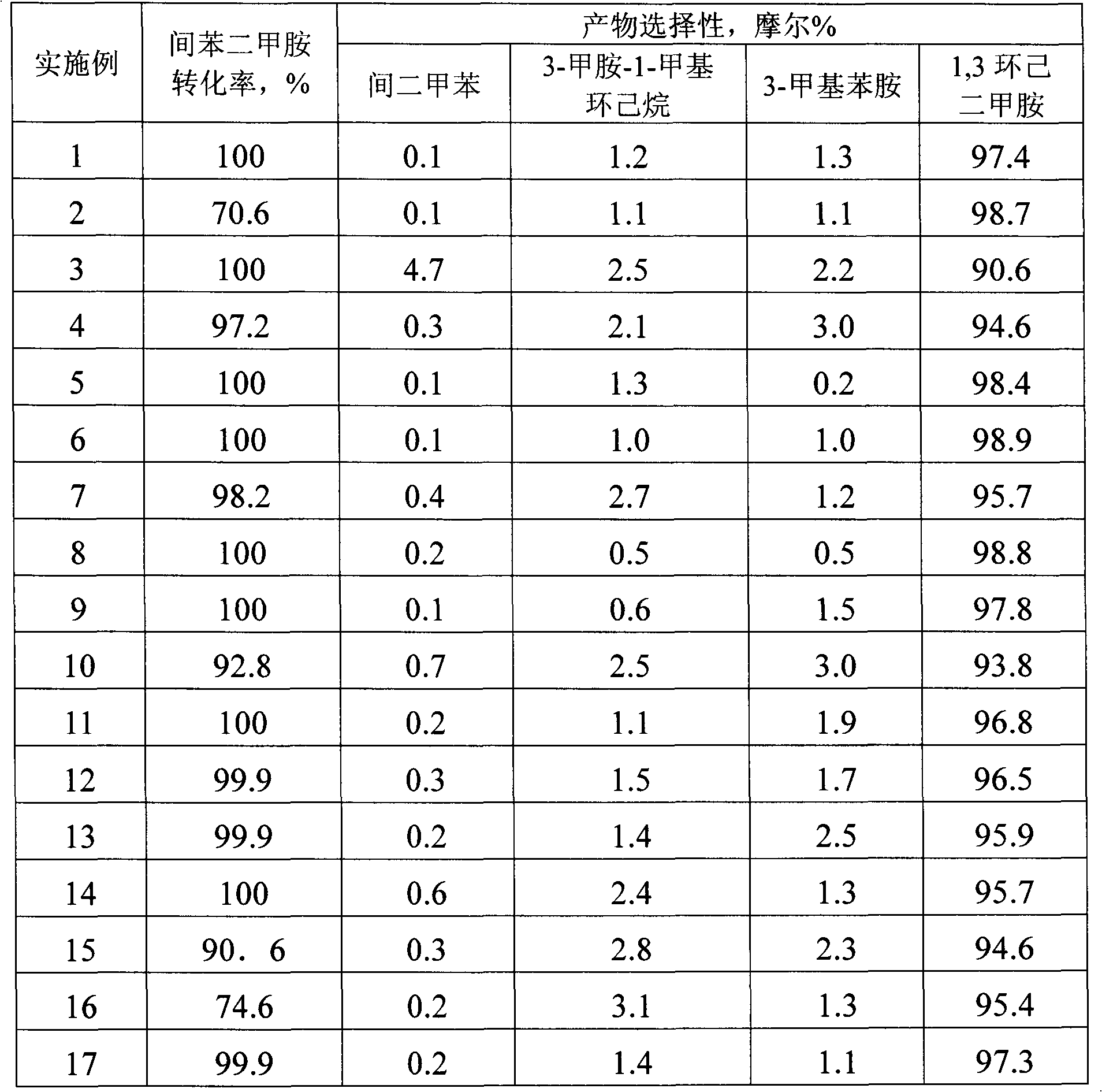

Method for preparing 1,3-cyclohexanebis(methylamine)

InactiveCN102690203ALow reaction pressureReduce reaction energy consumptionOrganic compound preparationCatalyst activation/preparationReaction temperatureBULK ACTIVE INGREDIENT

The invention discloses a method for preparing 1,3-cyclohexanebis(methylamine). The method is characterized in that a reaction system comprises m-xylylenediamine, ammonia (or an organic amine), hydrogen and a catalyst; a reaction temperature is in a range of 90 to 200 DEG C; reaction pressure is in a range of 1.0 to 20.0MPa; a mole ratio of H2 to m-xylylenediamine is in a range of 10-200; a weight ratio of m-xylylenediamine to NH3(or an organic amine) is (3 to 40): (60 to 94); an airspeed of a m-xylylenediamine liquid is in a range of 0.3 to 1.8h<-1>; the catalyst adopts Al2O3, active carbon or SiO2 as a carrier and is loaded with one or more of precious metals of Ru and Pd as active ingredients and preferably, is loaded with Ru; one or more auxiliary agents are selected from Ni, Cr, Co, Fe and their oxides; and in a trickle-bed reactor, under the ammonia (or an organic amine) reaction of the catalyst, the high activity and high selectivity transformation of a m-xylylenediamine liquid into 1,3-cyclohexanebis(methylamine) is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for producing propylene epoxide by trickle bed reactor

InactiveCN105330618AHigh selectivityGood choiceOrganic chemistryBulk chemical productionSolventPollution

The invention discloses a method for producing propylene epoxide by a trickle bed reactor. The method comprises steps as follows: a raw material, namely, propylene, flows out of a raw gas storage tank (5) under the conditions of the temperature ranging from 35 DEG C to 75 DEG C and the pressure ranging from 0 to 0.5 MPa and is introduced from the lower end of the trickle bed reactor (2), a solvent alcohol and hydrogen peroxide mixed liquid flows out of a mixed liquid storage device (1) and is introduced from the upper end of the trickle bed reactor (2), a reaction product is sequentially subjected to low temperature condensation by a condenser (3) and separation by a gas-liquid separator (4), and a product, namely, propylene epoxide, is obtained. With the adoption of the reaction device for propylene epoxidation, the conversion rate of propylene and the selectivity of propylene epoxide can be up to 60% and 99%. When the method is adopted to produce propylene epoxide, the reaction conditions are mild, the product selectivity is high, and pollution is avoided.

Owner:YANGZHOU UNIV

Method for reaction rectification coupling continuous preparation of and series acetate

ActiveCN1837183AReduce unit consumptionHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsobutanolDistillation

The invention discloses a reaction-distillation coupling preparing acetic acid series ester method, which comprises the following steps: using glacial acetic acid and alcohol with lower five carbons (alcohol, optal,alcohol isopropylicum, butanol, isobutanol, amyl alcohol and isoamyl alcohol ) for raw material; adopting modified strong acidic phenylethene series basic ion exchange resin for accelerant; preparing by reaction-distillation coupling; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate; making glacial acetic acid and alcohol with lower five carbons to carry on esterification reaction by solid acid catalysis in trickle bed reactor; adding reaction product (acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate), water and cycle still liquor in fractionating tower; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate by separating at the top of the tower. The conversion rate of alcohol with lower five carbons is more than 96%, the recovery ratio of acetic acid ethyl ester (propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate) is more than 95%. The invention has high alcohol conversion rate, which simplifies the operation.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride hydrogenation

ActiveCN103570650BControl the average operating temperatureUniform reaction temperaturePreparation from carboxylic acid anhydridesFixed bedReaction temperature

The invention discloses a technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride catalytic hydrogenation. The whole process comprises three steps, namely, reaction, rectification and hydrolysis, wherein two stages of hydrogenation reactors are used for reaction, a primary hydrogenation reactor is a fixed bed reactor with hydrogen entering from the lower part and reaction liquid exiting from the upper part, and a secondary hydrogenation reactor is a trickle bed reactor with hydrogen and reaction liquid entering from the upper part and exiting from the lower part. The technological process adopts an external circulating heat radiation manner, and reaction heat is uniformly removed, so that the average operation temperature of the whole reactor is effectively controlled, and the reaction temperature in the whole main reactor is balanced. Furthermore, the primary hydrogenation reactor adopts the manner that both the maleic anhydride solution and hydrogen flow upward simultaneously, so that the reaction temperature of the whole reactor is controlled to be balanced, local hot spot temperature is effectively controlled and lowered, and the reactants are prevented from polymerizing and depositing carbon or coking.

Owner:SHANXI UNIV

Startup sulfurization method for trickle bed class-II active center hydrogenation catalyst

ActiveCN102311765AForm a large numberImprove catalytic performanceHydrotreatment operations starting-upHydrocarbon oil crackingHydrogenClosed loop

The invention discloses a startup sulfurization method for a trickle bed class-II active center hydrogenation catalyst, which comprises the following steps: (1) preparing a class-II active center hydrogenation catalyst; (2) filling the class-II active center hydrogenation catalyst into a trickle bed reactor at normal temperature and normal pressure, introducing nitrogen to replace the air in a reaction system, sealing the nitrogen tightly, replacing the nitrogen with hydrogen, and sealing the hydrogen tightly; (3) regulating the temperature of a catalyst bed layer, introducing sulfurized oil from the bottom of the reactor, and wetting the class-II active center hydrogenation catalyst; (4) after the reactor is fully filled with sulfurized oil, introducing the sulfurized oil and hydrogen from the top of the reactor, forming closed-loop circulation in the reaction system, adding a sulfurizing agent into sulfurized oil gradually, and continuing to rise the temperature to complete sulfurization; and (5) after sulfurization is accomplished, introducing raw material oil from the top of the reactor. In the sulfurization method disclosed by the invention, the process is simple, the operation is convenient and quick, and the sulfurization effect is more ideal than the conventional method. Therefore, the method is more favorable for improving the number of class-II active center and consequently improving the activity of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous synthesis method of cyclohexane polyacid ester

ActiveCN105037161AQuick exclusionReduce complexityOrganic compound preparationCarboxylic acid esters preparationPtru catalystHydrogen pressure

The invention relates to a synthesis method of cyclohexane polyacid ester. The method specifically comprises the following steps of: adding benzene polycarboxylic acid or anhydride thereof and alcohol into a stirring tank reactor; adding in an acid catalyst and raising the temperature to 200-240 DEG C; carrying out some reaction until an acid value is less than 0.2 mg KOH / g; directly adding a crude product resulting from the esterification reaction into a trickle bed reactor for hydrogenation reaction, wherein the hydrogen pressure is 40-100 bar, the temperature is 70-250 DEG C, and a catalyst is a porous oxide loaded with VIII B group metal; and after the reaction, adding in alkali for neutralization and acid removal, performing distillation or evaporation to remove alcohol, removing by-products; and performing filtration and deliming to obtain cyclohexane polyacid ester. According to the method provided by the invention, after the esterification reaction generates the crude product, no purification step is not performed; excess alcohol is used as a solvent for subsequent hydrogenation reaction; and after the hydrogenation reaction, purification steps such as alcohol removing, acid removing and filtration are performed, thereby saving time and energy. Meanwhile, according to the method provided by the invention, the alumina-magnesia composite oxide is used as the catalyst carrier, and palladium or ruthenium is selected as the metal catalyst, enabling the phenyl ring hydrogenation rate to be greater than 99.9%.

Owner:中山联成化学工业有限公司

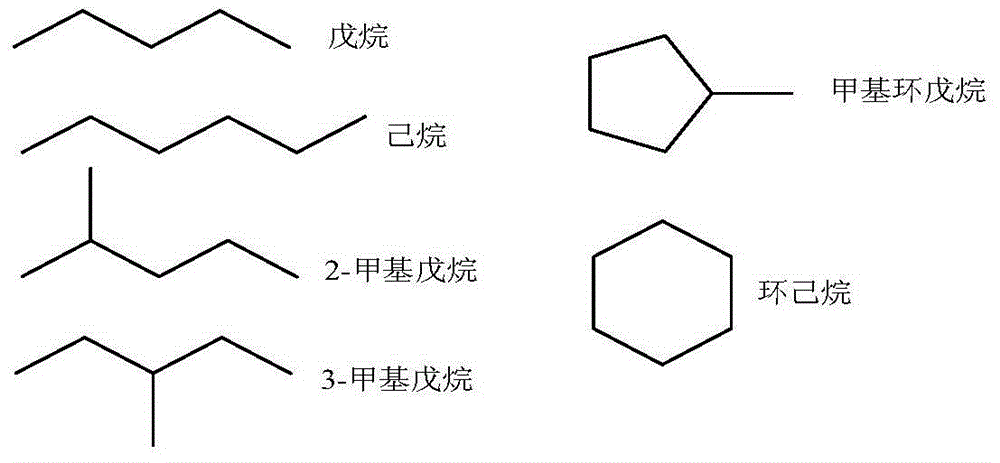

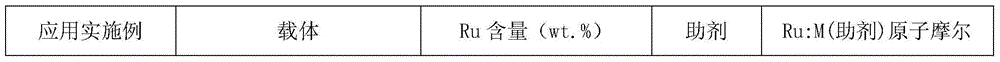

Catalyst for preparing C5 or C6 alkane from sugar or sugar alcohol via water-phase hydrogenolysis

InactiveCN104888775AHigh yieldImprove stabilityHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsAlkaneMolecular sieve

The invention discloses a catalyst for preparing C5 or C6 alkane from sugar or sugar alcohol via water-phase hydrogenolysis, and an application of the catalyst. The catalyst takes one or two of active carbon, ZrO2, TiO2, and Nb2O5 as a carrier, and takes a metal of Ru as an active metal. An oxide of Mo, Sn, or Mn is taken as an auxiliary agent. The metal of Ru takes 0.5-10.0% by mass percentage of the carrier. The atom mol ratio of Ru and Mo, Sn, or Mn is in a range of 0.2:1.0-5:1.0. The catalyst has excellent stability, can continuously stably operate more than 500h in a trickle bed reactor, and can be used for water-phase hydrogenolysis of sugar / sugar alcohol and is high in activity to obtain C5 / C6 alkane with a high yield. The problem that silicon-aluminum oxide or a molecular sieve supported catalyst is relatively poor in stability is solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Process for preparing hydantoin by one-step method

InactiveCN1616435ARealize continuous preparationThe synthesis process is simpleOrganic chemistryCyanideSolid acid

The one-step process of preparing hydantoin is that in a trickle bed reactor hydroxy methyl cyanide, CO2 and ammonia as material and solid acid as stuffing and catalyst are prepared into hydantoin through one-step process. Hydroxy methyl cyanide is made to flow into the trickle bed from the top in the flow rate of 100-300 ml / hr, CO2 and ammonia are made to flow into the trickle bed from the bottom in the flow rate of 0.01-0.1 cu m / hr and 0.005-0.06 cu m / hr separately, and through reaction at 40-120 deg.c for 2-5 hr, the reaction liquid is collected and processed through concentration, crystallization, filtering to obtain initial crystal, recrystallization and drying to obtain hydantoin. The synthesis yield may reach 74.85 %.

Owner:NANJING UNIV OF TECH

Integrated gas and liquid phase processing of biocomponent feedstocks

ActiveUS20120000824A1Liquid hydrocarbon mixture productionTreatment with hydrotreatment processesGas phaseDeoxygenation

A mineral feed can be hydrotreated in a trickle-bed reactor or other stage in a continuous gas-phase environment. The effluent from the hydrotreatment stage can be separated to remove gas-phase impurities. The remaining liquid effluent from the hydrotreating stage can then be introduced, in total or in part, into a second stage / reactor. A feed of biocomponent origin can also be introduced into the second stage / reactor. The second stage / reactor can be operated to perform deoxygenation of the mixture of biocomponent feed and hydrotreated liquid effluent in a continuous liquid phase environment.

Owner:EXXON RES & ENG CO

Preparation method for biological diesel oil

InactiveCN101168682AAvoid separationAvoid it happening againBiofuelsLiquid hydrocarbon mixture productionVegetable oilBiodiesel

The invention discloses a method for the biological diesel oil preparation by using anion exchange resin catalyzing vegetable oil, and the method is characterized in that catalyst is packaged in small packets to be filled into a trickle bed reactor to form a catalyst bed layer, methanol steam is accessed into the bottom part of the trickle bed, after the catalyst bed layer is heated to be 65 to 100 DEG C, vegetable oil is accessed from the top part of the trickle bed, and the residence time of the vegetable oil in the trickle bed is controlled for 100 to 300 min, thereby biological diesel oil is obtained through performing distillation reseparation on the reaction product obtained. The invention adopts gas-liquid mass transfer, and the mass transfer effect is good, thereby the working procedure of continuous blending and the energy consumption needed in the traditional method can be avoided; the invention adopts the anion exchange resin catalyzing vegetable oil as the catalyst, thereby avoiding the subsequent working procedures of catalyst separating, etc., and simultaneously avoiding a great amount of waste water generated when the basic catalyst is neutralized; the anion exchange resin can be reused, and the cost is reduced; the invention adopts the trickle bed reactor to produce the biological diesel oil, and is suitable for the continuous and large scaled production.

Owner:NANJING UNIV OF TECH

Process for preparing hexahydrophthalic anhydride (HHPA) by means of catalytic hydrogenation

ActiveCN107011304AReduce generationUniform and controllable response layoutOrganic chemistryHexahydrophthalic anhydrideMetal catalyst

The invention discloses a process for preparing hexahydrophthalic anhydride (HHPA) by means of catalytic hydrogenation. The process includes preparing Pd-NiO / SiO2 catalysts by the aid of impregnation processes by SiO2 used as a carrier; catalytically hydrogenating tetrahydrophthalic anhydride in a trickle-bed reactor to prepare the hexahydrophthalic anhydride (HHPA). The process has the advantages that the optimal reaction conditions and process parameters are explored; the SiO2-supported Pd and Ni binary-metal catalysts are adopted, the activity of the catalysts is appropriately deteriorated, the hydrogen partial pressures are increased, and accordingly the selectivity of the hexahydrophthalic anhydride (HHPA) which is a target product can be effectively improved; hydrogen can flow into the trickle-bed reactor from an upper location, a middle location and a lower location, accordingly, reaction layout is uniform and controllable, and side reaction can be reduced; heat generating reaction is carried out during catalyst hydrogenation, the internal circulation speed of the hydrogen in the reactor can be increased, the hydrogen is used as a heat transfer medium, accordingly, reaction heat can be timely transferred, local overheating phenomena can be effectively prevented, and the side reaction can be reduced.

Owner:PUYANG SHENGYUAN ENERGY TECH

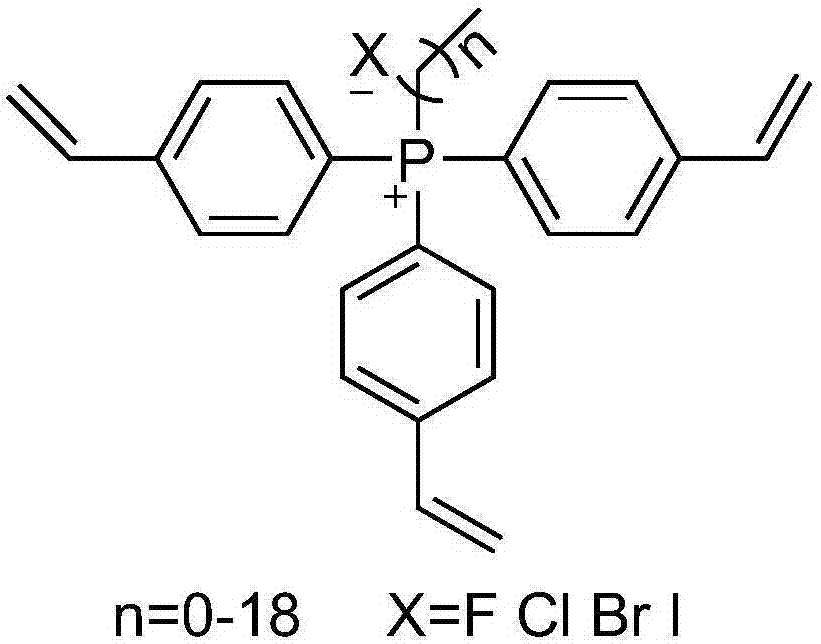

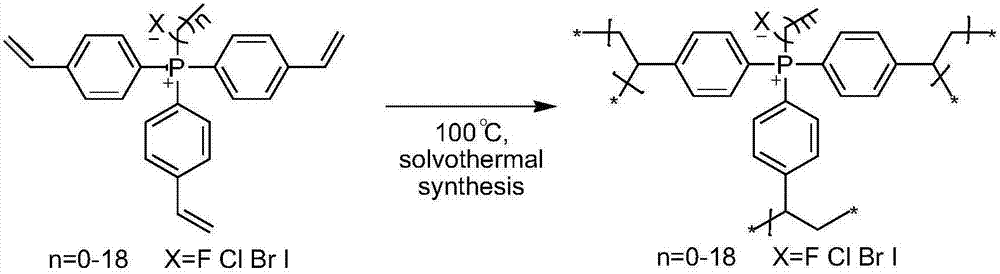

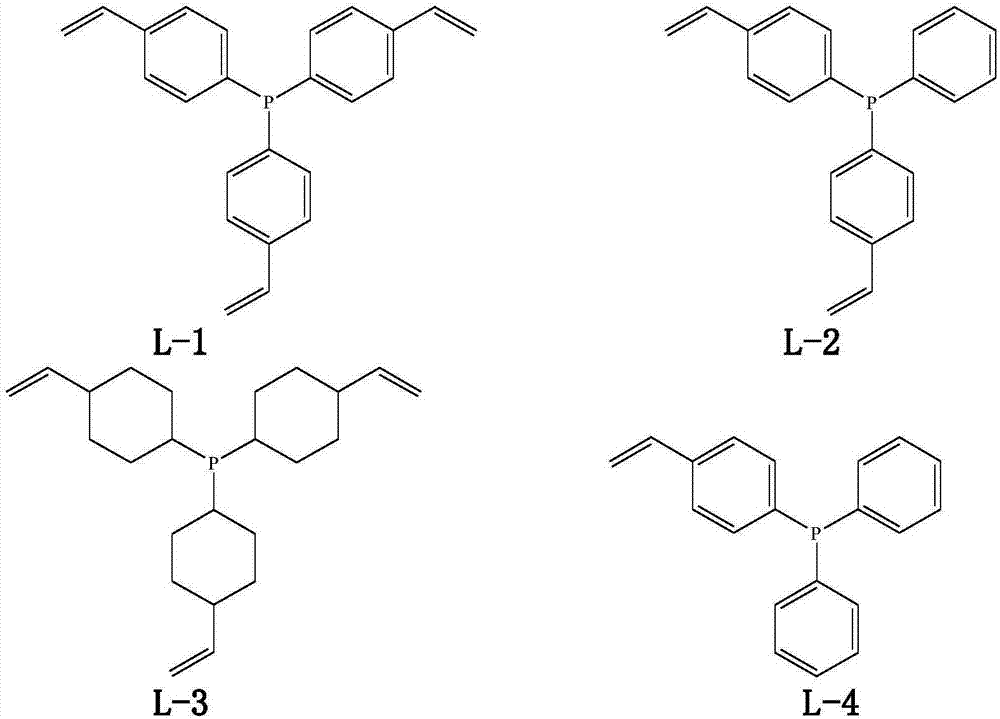

Quaternary phosphonium salt organic polymer catalyst, and preparation method and applications thereof

ActiveCN107537563AImprove stabilityImprove applicabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkPhosphonium salt

The invention relates to a quaternary phosphonium salt organic polymer catalyst, a preparation method thereof, and applications of the quaternary phosphonium salt organic polymer catalyst in cyclic carbonates production. The quaternary phosphonium salt organic polymer catalyst is prepared via following steps: self-polymerization of an olefin functionalized quaternary phosphonium salt or mixing-polymerization of the olefin functionalized quaternary phosphonium salt with a cross-linking agent is carried out so as to obtain an organic polymer; a Lewis acid is added into the organic polymer, or noLewis acid is added into the organic polymer, wherein when the Lewis acid is added, coordination reaction of metal ions in the Lewis acid with N and / or P in the quaternary phosphonium salt organic polymer is realized; and an obtained product is the quaternary phosphonium salt organic polymer catalyst. The quaternary phosphonium salt organic polymer catalyst is a heterogeneous catalyst, is suitable to be used in reactors such as fixed bed reactors, slurry bed reactors, kettle-type reactors, and trickle bed reactors, possesses excellent catalytic effect in production of cyclic carbonates via addition reaction of an epoxy compound with CO2, is relatively high in catalytic activity, high in selectivity in cyclic carbonates production, high in substance applicability, and high in catalyst stability, and can be separated from reactants and products easily.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Coal tar whole-fraction hydrogenation method

ActiveCN102796560ASimple processImprove conversion rateTreatment with hydrotreatment processesDistillationGasoline

The invention relates to a coal tar whole-fraction hydrogenation method. Medium / low-temperature coal tar whole-fractions are used as raw materials, catalytic hydrogenation and distillation treatments are carried out in a trickle bed reactor through a hydrogenation protective agent, a hydrodemetallization agent, a hydrodesulfurization agent, a hydrodenitrogenation agent and a hydrocracking agent, and then a gasoline fraction and a diesel oil fraction are cut. The coal tar whole-fraction hydrogenation method is simple in process flow; a product is high in conversion rate and high in quality; and the whole process is safe and stable in operation.

Owner:SHENMUFUYOU ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com