Patents

Literature

221 results about "Amyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amyl acetate (pentyl acetate) is an organic compound and an ester with the chemical formula CH₃COO[CH₂]₄CH₃ and the molecular weight 130.19 g/mol. It has a scent similar to pears and apples. The compound is the condensation product of acetic acid and 1-pentanol. However, esters formed from other pentanol isomers (amyl alcohols), or mixtures of pentanols, are often referred to as amyl acetate.

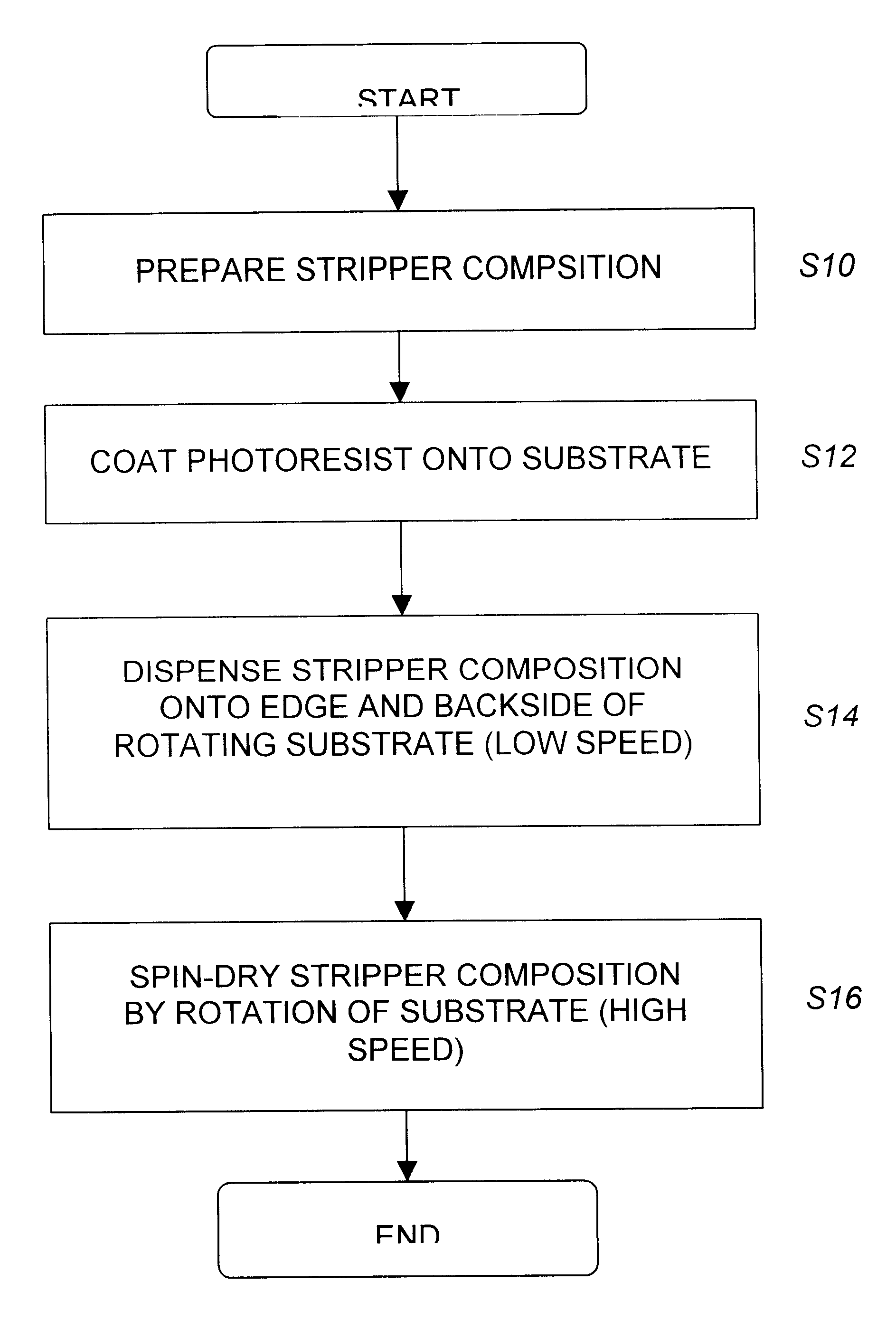

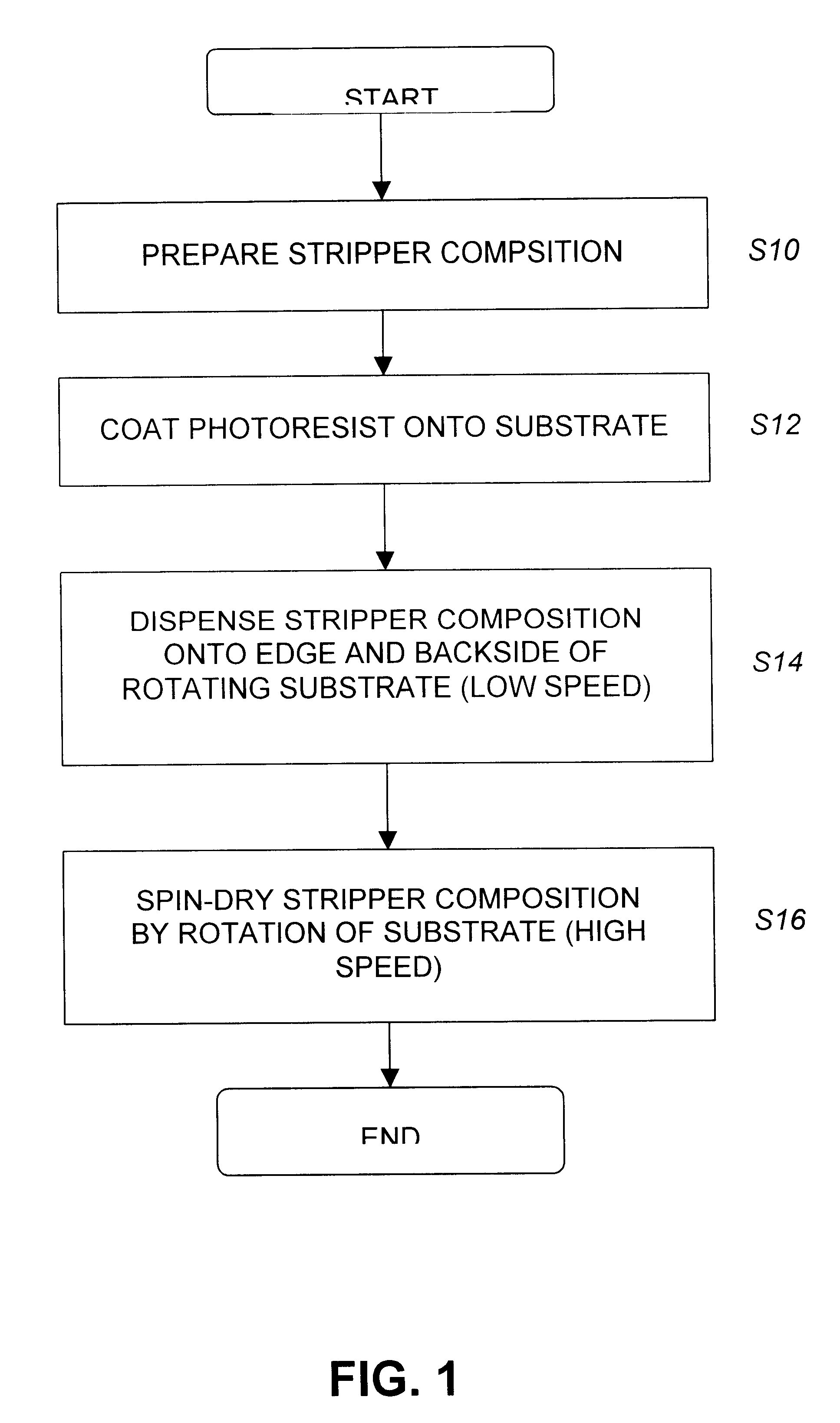

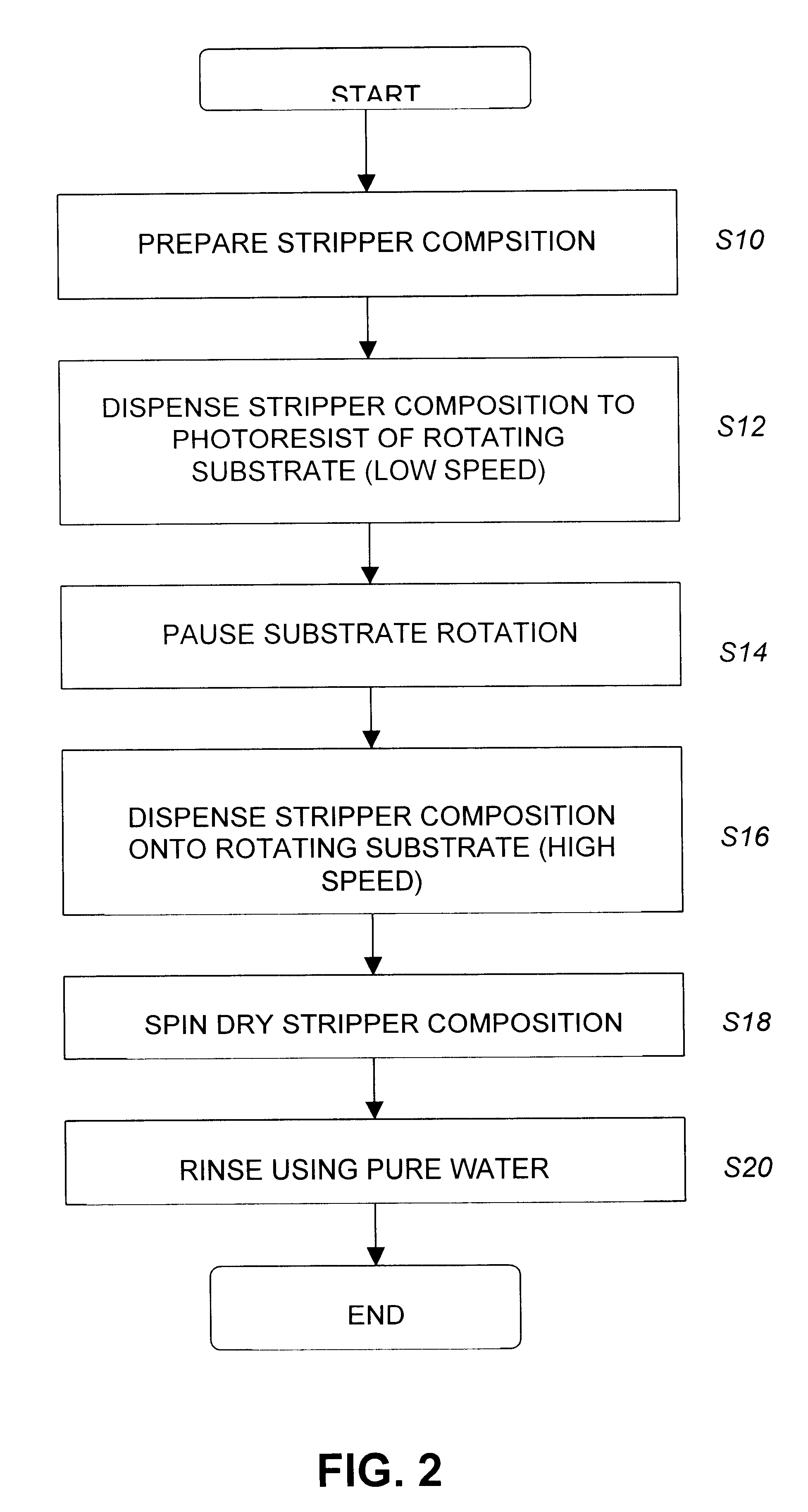

Photoresist stripper compositions

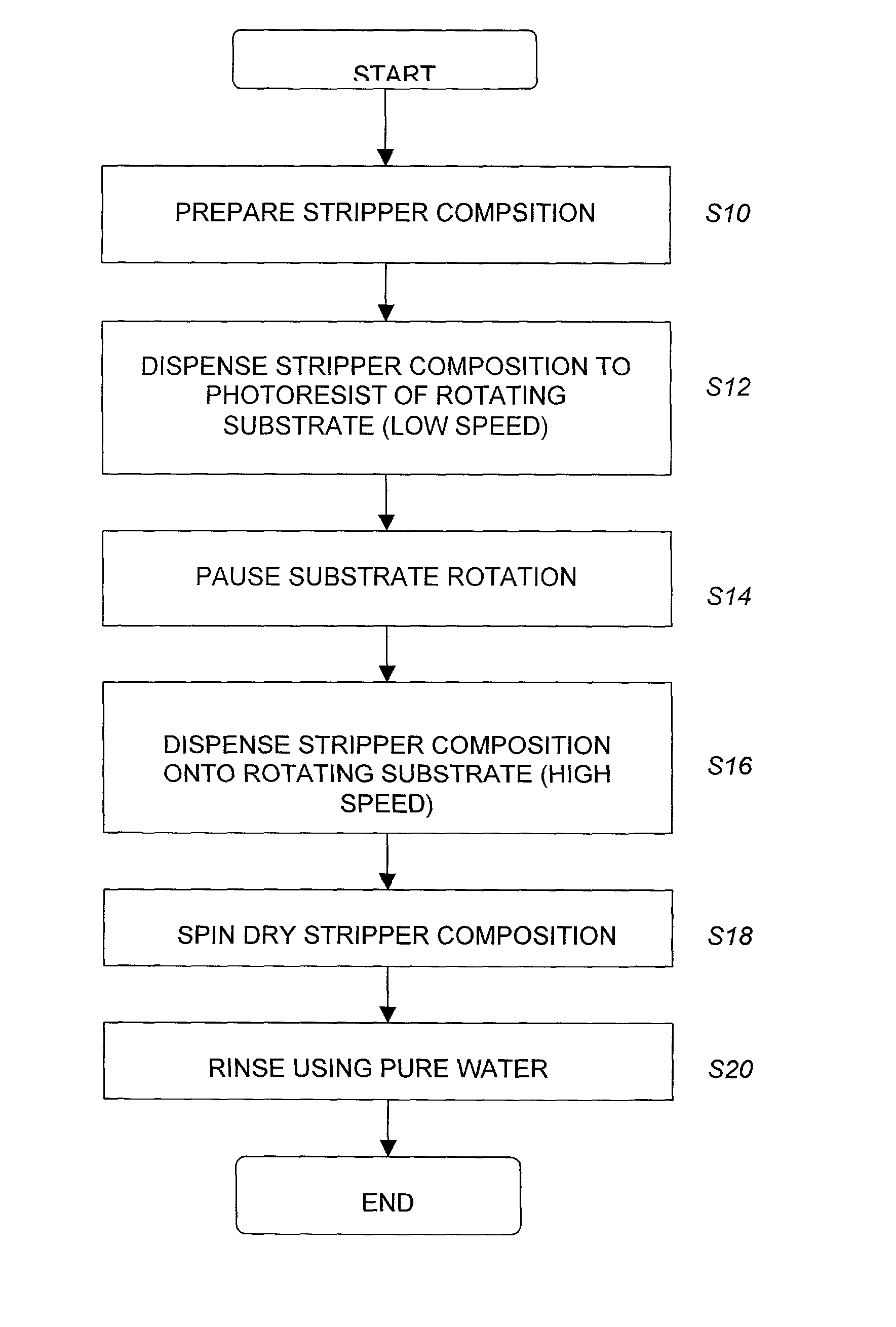

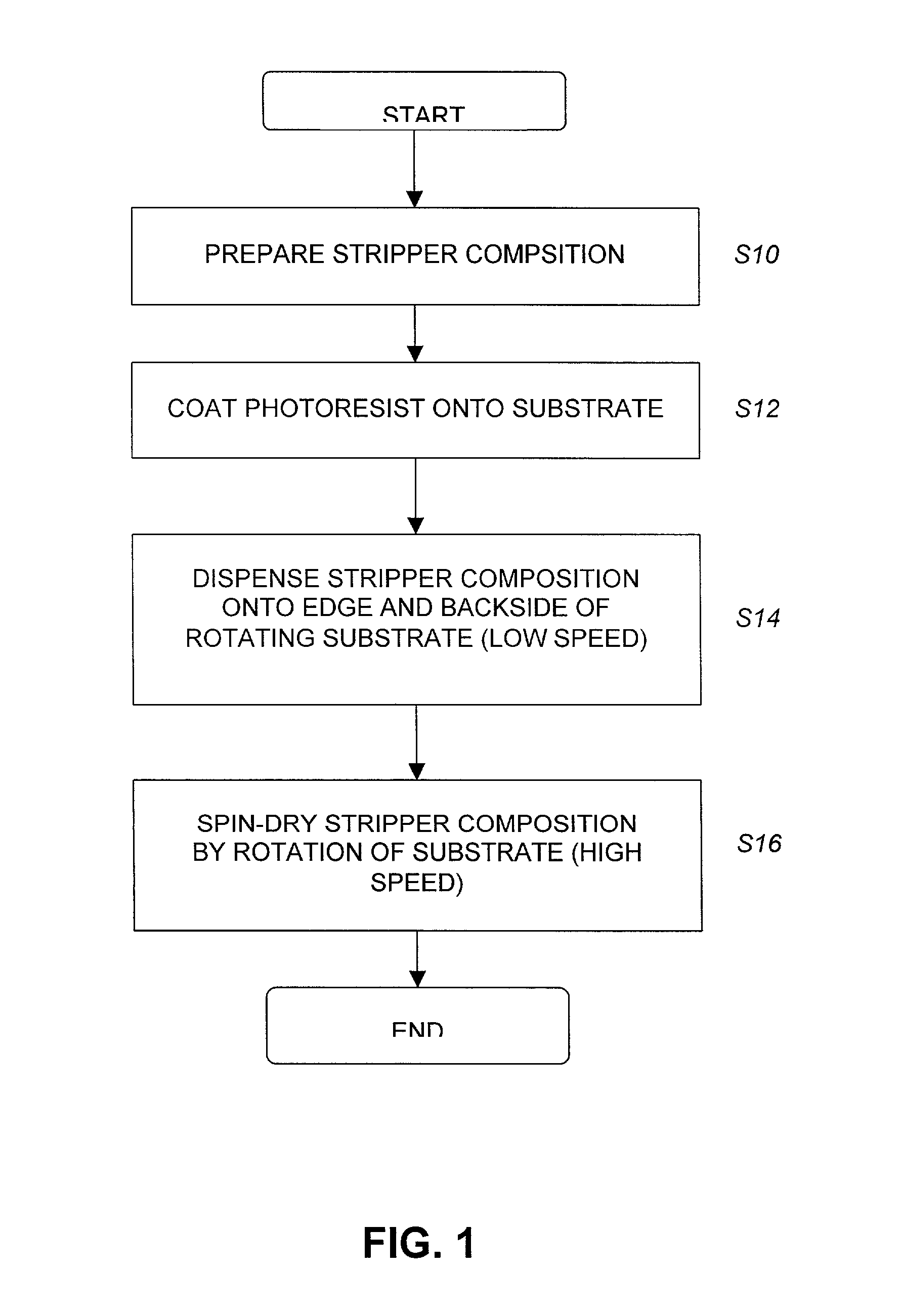

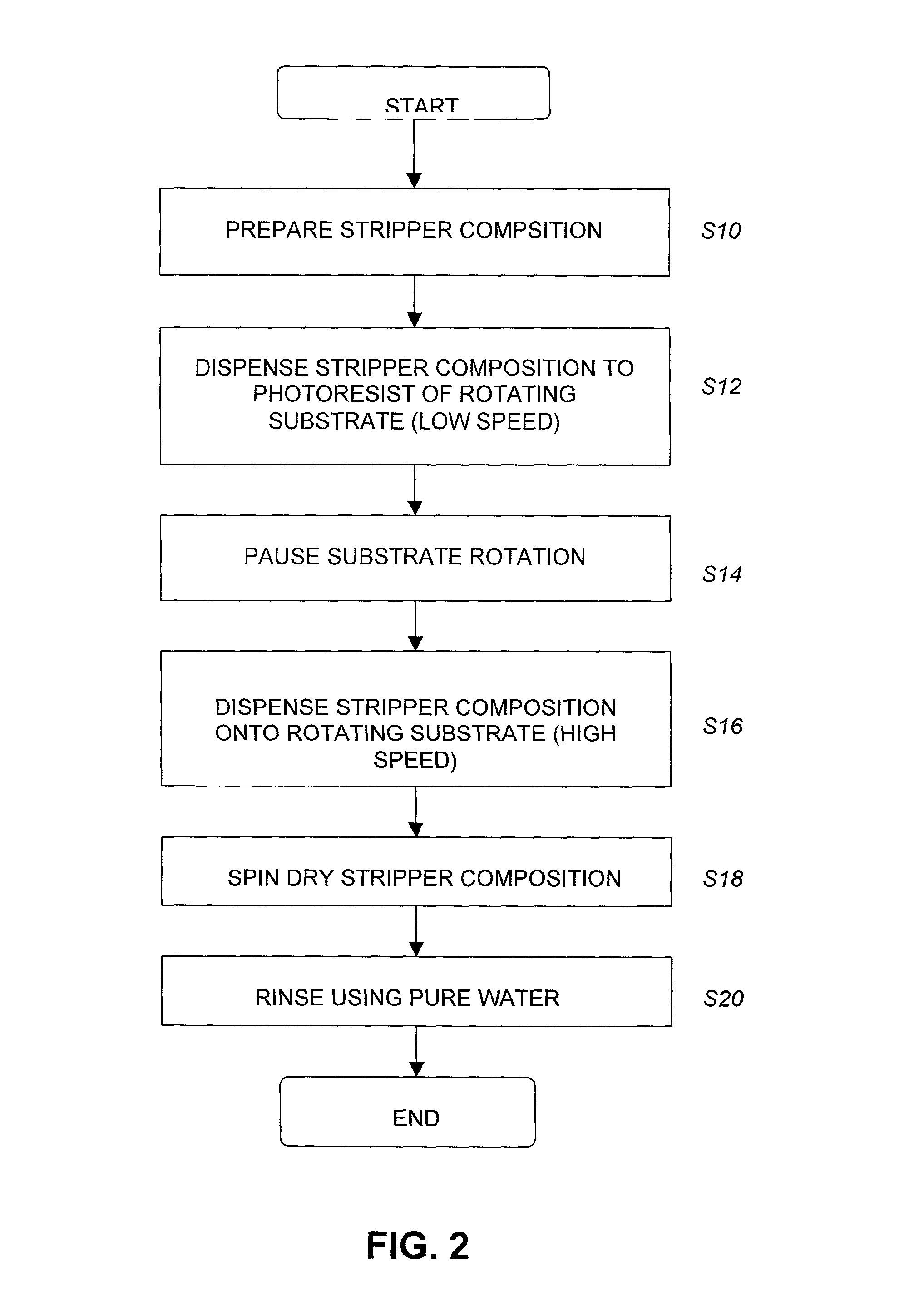

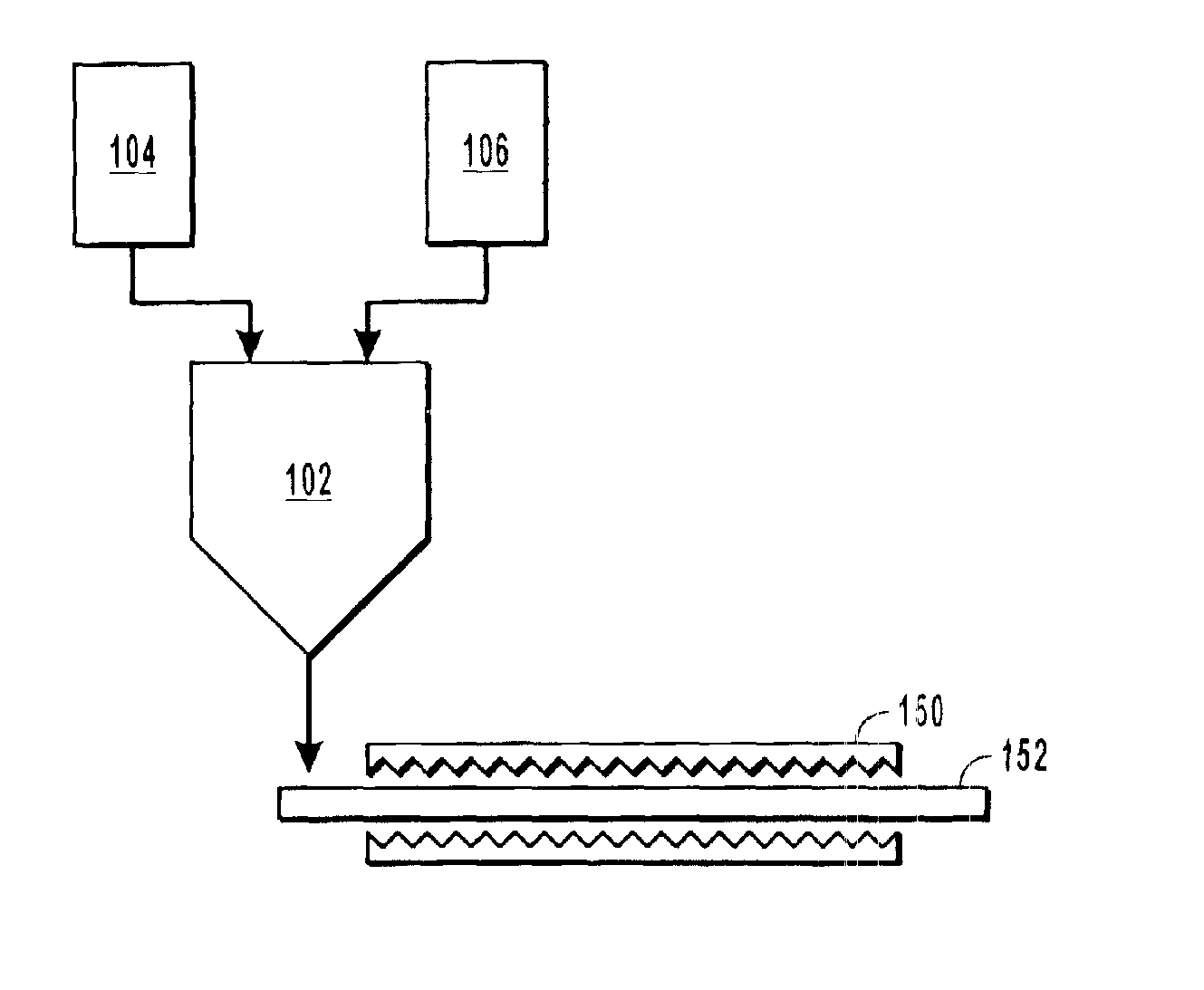

InactiveUS20030113673A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusAmyl acetateMethyl group

A photoresist stripper composition is made up of a mixture of an acetic acid ester, gamma-butyrolactone (GBL), and a non-acetate ester or a poly alkyl alcohol derivative. The acetic acid ester may be at least one of n-butyl acetate, amyl acetate, ethyl aceto-acetate, and isopropyl acetate. The non-acetate ester may be at least one of ethyl lactate (EL), ethyl-3-ethoxy propionate (EEP) and methyl-3-methoxy (MMP). The poly alkyl alcohol derivative may be at least one of propylene glycol monomethyl ester (PGME) and propylene glycol monomethyl ester acetate (PGMEA).

Owner:SAMSUNG ELECTRONICS CO LTD

Sulfur additives for paving binders and manufacturing methods

Sulfur, useable in as an additive to asphalt in the preparation of asphalt binders can be plasticized by addition of carbon and further treated with amyl acetate. This plasticized sulfur can be formed into solid particles and then added to asphalt as either a minority or majority component to create desired paving binder compositions. The solid plasticized sulfur has non-stick non-flow properties within a wide range of ambient temperatures, and it can be stored solid for subsequent use in paving applications.

Owner:SHELL CANADA ENERGY

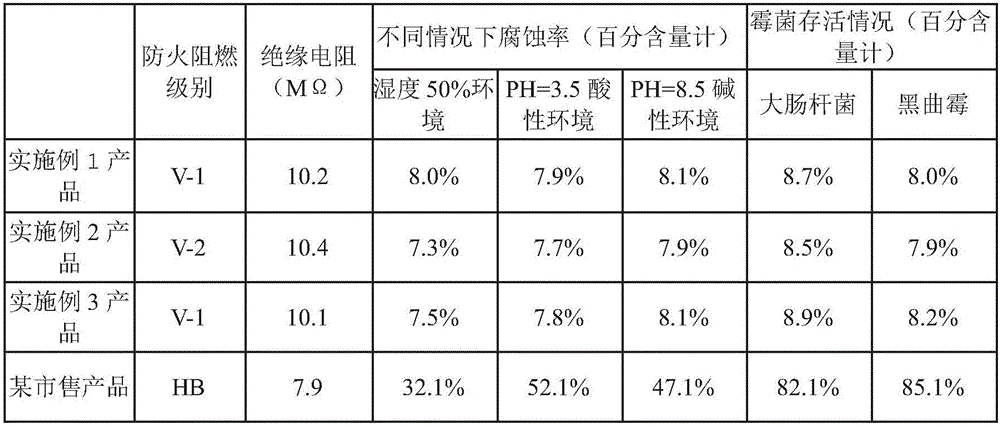

Antimicrobial moldproof agent for silk fabrics

ActiveCN103757893AWon't breakHas antibacterial and antifungal effectsAnimal fibresFiberPhosphoric acid

The invention discloses an antimicrobial moldproof agent for silk fabrics, which is prepared from the following components in parts by weight: 8-12 parts of citric acid, 7-11 parts of polyoxyethylene trimethyl ammonium chloride, 6-10 parts of vinyl siloxane, 5-9 parts of chitosan quaternary ammonium salt, 4-8 parts of tetrasodium metaphosphate, 3-7 parts of tin tetrachloride, 3-7 parts of potassium oxalate, 3-7 parts of sodium alginate, 5-9 parts of phenyl salicylate and 10-14 parts of amyl acetate. The antimicrobial moldproof agent has favorable antimicrobial and moldproof effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:上海福晏精细化工有限公司

Vinyl acetate/acrylic emulsion waterproof paint

InactiveCN102408794AEasy constructionImprove waterproof performanceCoatingsBenzoyl peroxideAmyl acetate

The invention discloses a vinyl acetate / acrylic emulsion waterproof paint, which is prepared by the following raw materials according to weight ratio by stirring: 85 parts of vinyl acetate / acrylic emulsion , 20 parts of carboxymethyl cellulose, 25 parts of barium sulfate, 20 parts of benzoyl peroxide, 30 parts of amyl acetate, 15 parts of tourmalinite powder, 10 parts of carboxymethyl cellulose, 40 parts of magnesium silicate, 60 parts of water, 6 parts of binder, 6 parts of film forming auxiliary agent, 6 parts of dispersant and 5 parts of antifoaming agent. The product of the present invention has good application property, water resistance, insulation effect and high cost performance.

Owner:SUZHOU MEIYAMEI CONSTR COATINGS

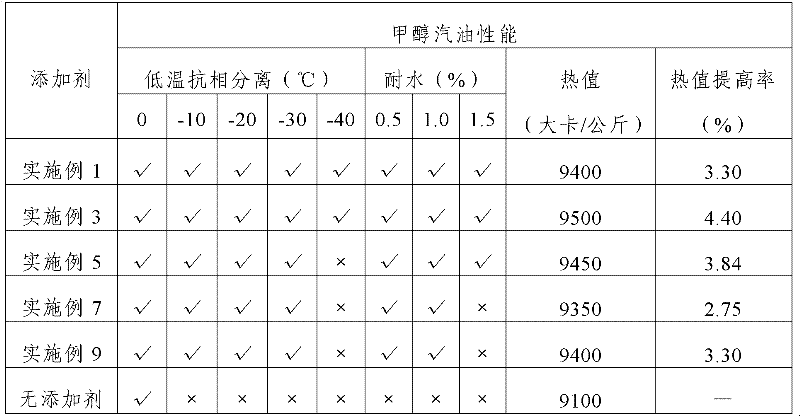

Additive for improving resisting phase separation performance and heat value of methanol gasoline

InactiveCN102344837AImprove oilinessReduce fuel consumptionLiquid carbonaceous fuelsAmyl acetateN-Butyl Alcohol

The invention discloses an additive for improving resisting phase separation performance and a heat value of methanol gasoline. The additive consists of the following raw materials in percentage by weight: 35-45 percent of aliphatic alcohol, 10-20 percent of aliphatic ether, 15-30 percent of aliphatic ester, 5-15 percent of aliphatic acid, 1-5 percent of aliphatic amine and 0.1-3 percent of emulsifier OP, wherein the aliphatic alcohol is one or more of isopropyl alcohol, n-propanol, n-amyl alcohol, isoamyl alcohol and n-butyl alcohol; the aliphatic ether is one or more of ethylene glycol methyl ether, ethylene glycol ethyl ether and ethylene glycol butyl ether; the aliphatic ester is one or more of butyl acetate, n-amyl acetate and isoamyl acetate; the aliphatic acid is oleic acid and / or naphthenic acid; the aliphatic amine is dimethylamine and / or diethylamine; and the emulsifier OP is emulsifier OP-15 and / or emulsifier OP-20. The methanol gasoline in which the additive is added has superior low-temperature resisting phase separation and water resisting phase separation performances and an obviously improved heat value.

Owner:西安祺祥能源科技发展有限公司

Photoresist stripper compositions

InactiveUS6589719B1Multicolor photographic processingSemiconductor/solid-state device manufacturingAmyl acetateN-Butyl acetate

A photoresist stripper composition is made up of a mixture of an acetic acid ester, gamma-butyrolactone (GBL), and a non-acetate ester or a poly alkyl alcohol derivative. The acetic acid ester may be at least one of n-butyl acetate, amyl acetate, ethyl aceto-acetate, and isopropyl acetate. The non-acetate ester may be at least one of ethyl lactate (EL), ethyl-3-ethoxy propionate (EEP) and methyl-3-methoxy (MMP). The poly alkyl alcohol derivative may be at least one of propylene glycol monomethyl ester (PGME) and propylene glycol monomethyl ester acetate (PGMEA).

Owner:SAMSUNG ELECTRONICS CO LTD

Illegal bill scavenger and special spraying and bushing tank

InactiveCN101020871ANot easy to damageEasy to removeOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsScavengerKerosene

The illegal bill scavenger is compounded with amyl acetate 90-97 wt%, acrylic acid and / or ethanol 3-8 wt%, and kerosene 2-3 wt%. The illegal bill scavenger is used via matching with one special spraying and brushing tank, which includes one spraying tank filled with pressurized gas and hydroscopic brushing fins fixed to the outer wall of the spraying tank. The illegal bill scavenger is sprayed to the surface contaminated by illegal bill before brushing with sponge brush and water flushing. It has fast eliminating effect, low cost and no damage to the base material.

Owner:颜军科

Flavour compositions

InactiveUS20060153959A1Material efficiencyPrevent bacterial growthCosmetic preparationsToilet preparationsEthyl salicylateBenzaldehyde

A flavour composition comprises at least 0.5% by weight of one or more of the following group A materials: cinnamic aldehyde, basil oil, tarragon, cis-3-hexenyl acetate, cis-3hexenol, orange oil, lime, citral, and damascone; and at least 3% by weight of one or more of the following group B materials: anethole synthetic, alcohol C10, eucalyptol, methyl salicylate, clove bud oil, carvone laevo, benzyl benzoate, thymol, benzaldehyde, benzyl formate, ethyl salicylate, eucalyptus oil, ionone alpha, iso amyl acetate, rosemary oil, cardamom oil, ginger, eugenol, camomile oil, spearmint, and peppermint. These materials have been identified as being capable of inhibiting the growth of Porphyromonas gingivalis or the protease (arg-gingipain) activity of Porphyromonas gingivalis, and so to possess hitherto unappreciated antimicrobial properties. The invention thus enables compositions to be defined comprising flavour materials that enhance the antimicrobial efficacy of known antimicrobial agents against micro-organisms or metabolic processes associated with gum diseases. The invention also provides a consumer product, particularly an oral or dental care product, including such a flavour composition; a method for reducing or preventing gum disease; and use of the flavour compositions for reducing or preventing gum disease.

Owner:QUEST INTERNATIONAL

Easy-to-print circuit board silver paste and preparation method thereof

ActiveCN103996432AEasy curing moldingImprove printing yieldNon-conductive material with dispersed conductive materialCable/conductor manufactureAmyl acetatePolytetrafluoroethylene

An easy-to-print circuit board silver paste is made of the following raw materials by weight portion: 6-8 parts of saturated polyester resin, 3-5 parts of polyurethane resin, 0.1-0.2 parts of polytetrafluoroethylene wax, 3-5 parts of amyl acetate, 8-12 parts of silver-coated glass powder, 65-70 parts of ultrafine silver powder, 3-5 parts of glass powder, 4-6 parts of graphite, 7-10 parts of dimethylbenzene, 0.2-0.4 parts of rosin acid aluminum soap, 5-8 parts of propylene glycol, 1-2 parts of polyisobutene, 1-2 parts of aminopropyltriethoxysilane, 2-3 parts of dipropylene glycol butyl ether, 2-3 parts of capric acid, and 0.2-0.4 parts of fluorine-containing surfactant. Graphite is added to the silver paste of the invention, which increases the conductivity. The easy-to-print circuit board silver paste has good dispersion performance, good lubricity and good printing performance. Through the adding of the silver-coated glass powder, the silver paste has good wetting property and can be well combined with a circuit board, and the circuit board is durable and firm. An organic carrier of the silver paste is resistant to high temperature, the circuit can be kept in good condition before the glass powder is melt, and the yield of circuit board printing is high.

Owner:浙江巨力宝纺织科技有限公司

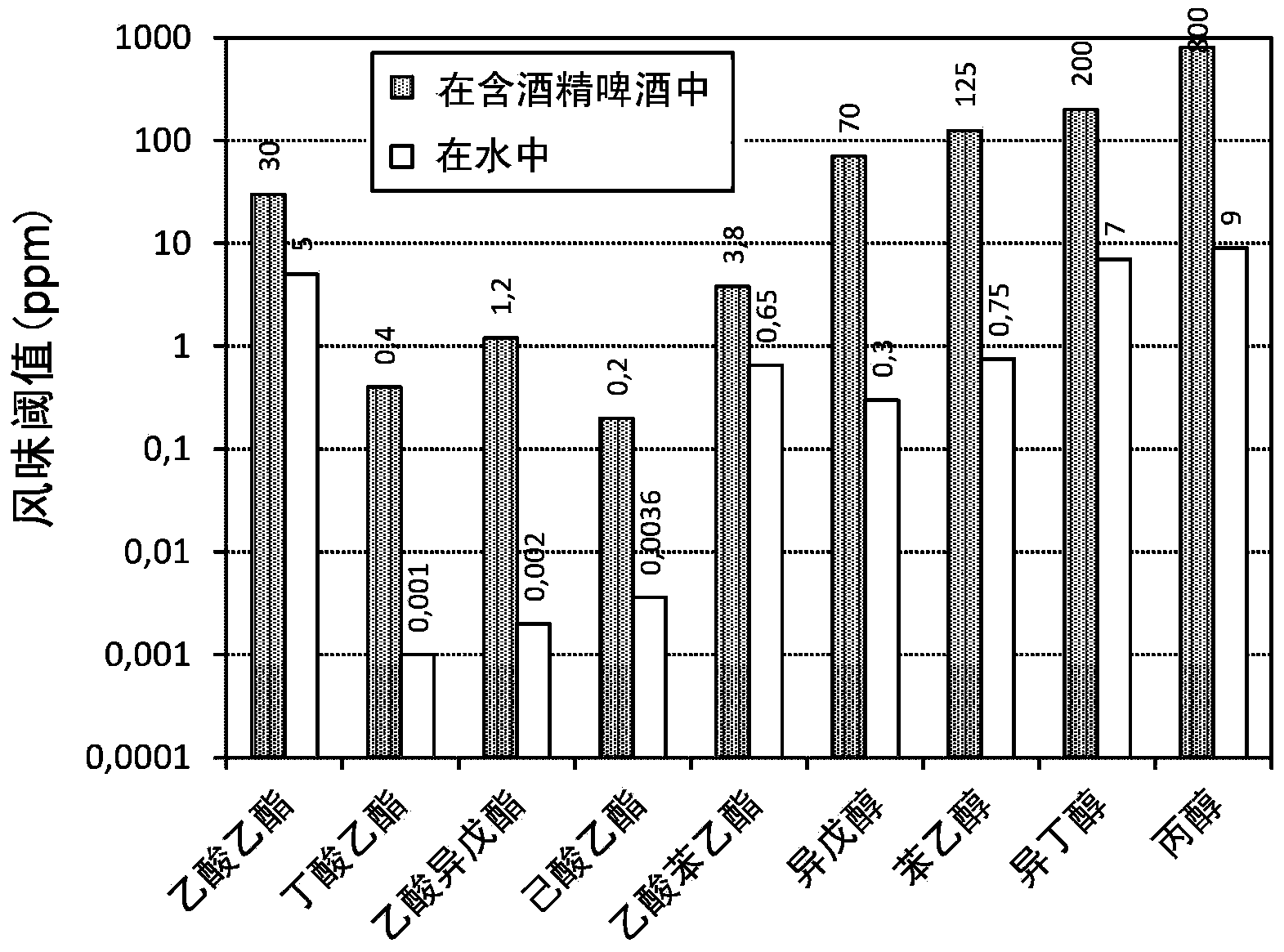

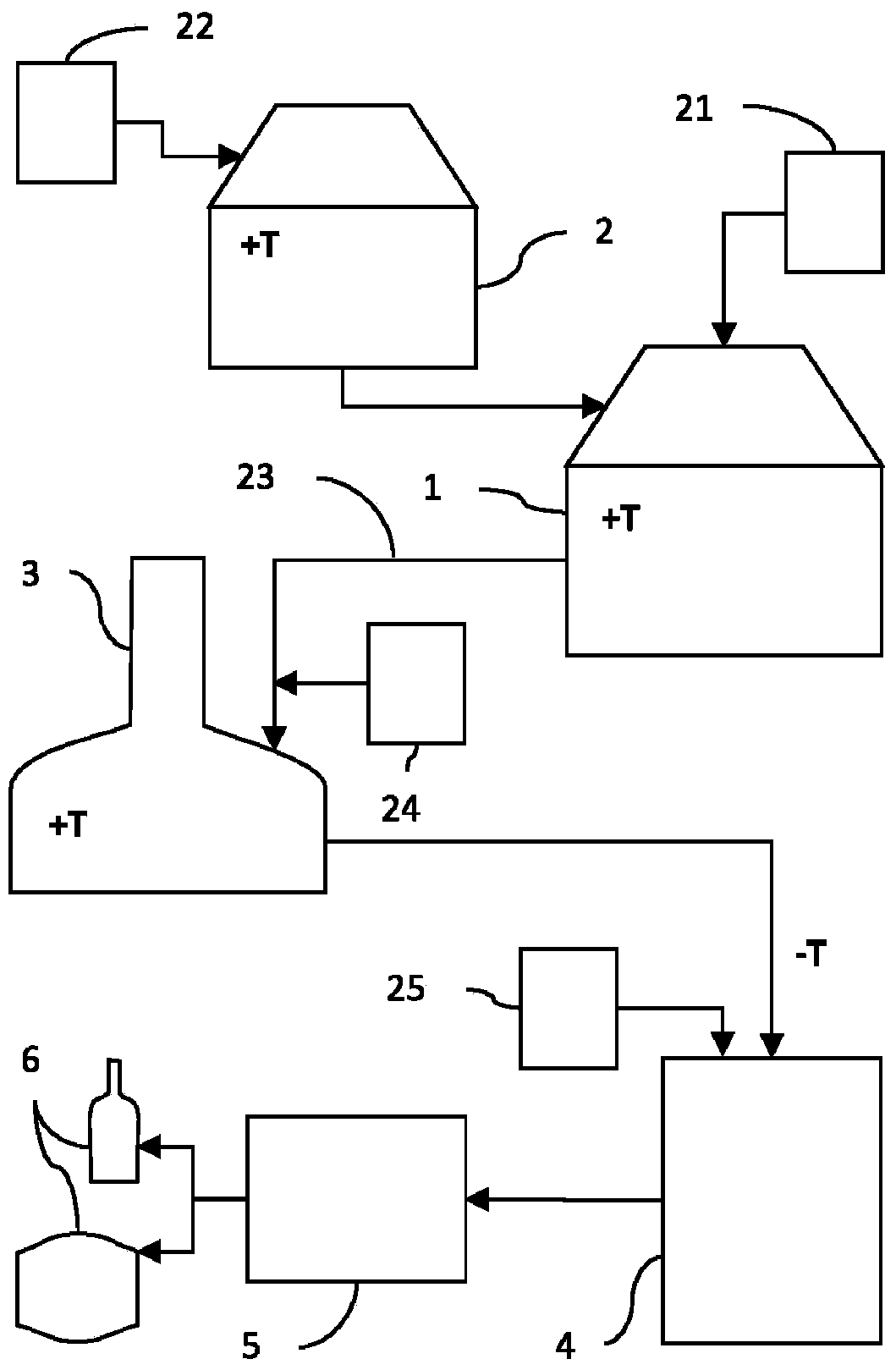

Low alcohol or alcohol free fermented malt based beverage and method for producing it

The present invention concerns an alcohol free or low alcohol fermented malt based beverage having an alcohol content of not more than 1.0 vol%, preferably not more than 0.7 vol%, having an aroma profile close to the one of alcoholic lager beers, characterized in that, it comprises 7.00-30.00 ppm ethyl acetate and 0.01-0.20 ppm ethyl butyrate. It preferably also comprises the following esters: 0.05-2.00 ppm (iso)amyl acetate; 0.01-0.10 ppm ethyl butyrate; 0.01-0.05 ppm ethyl hexanoate; and the following higher alcohol: 5.00-30.00 ppm (iso)amyl alcohol, wherein (iso)amyl alcohol is defined as the sum of 3-methyl butanol and 2-methyl butanol.

Owner:ANHEUSER BUSCH INBEV SA

Method for reaction rectification coupling continuous preparation of and series acetate

ActiveCN1837183AReduce unit consumptionHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsobutanolDistillation

The invention discloses a reaction-distillation coupling preparing acetic acid series ester method, which comprises the following steps: using glacial acetic acid and alcohol with lower five carbons (alcohol, optal,alcohol isopropylicum, butanol, isobutanol, amyl alcohol and isoamyl alcohol ) for raw material; adopting modified strong acidic phenylethene series basic ion exchange resin for accelerant; preparing by reaction-distillation coupling; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate; making glacial acetic acid and alcohol with lower five carbons to carry on esterification reaction by solid acid catalysis in trickle bed reactor; adding reaction product (acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate), water and cycle still liquor in fractionating tower; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate by separating at the top of the tower. The conversion rate of alcohol with lower five carbons is more than 96%, the recovery ratio of acetic acid ethyl ester (propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate) is more than 95%. The invention has high alcohol conversion rate, which simplifies the operation.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Method for preparing solid acid catalyst by microwave solid phase method and application thereof

InactiveCN101703949AEasy to separateSimple post-processingMolecular sieve catalystsOrganic compound preparationSolid acidAmyl acetate

The invention discloses a method for preparing a solid acid catalyst by a microwave solid phase method and application thereof. A catalyst is synthesized into the solid acid catalyst by using a manganese oxide octahedral molecular sieve as a carrier, using tin tetrachloride or ferric chloride as an active component and adopting the microwave solid phase method. The method efficiently implements even solid load of the active component on the surface of the carrier; the method used in a reaction for synthesizing iso-amyl acetate can implement the separation of a solid catalyst, a liquid reactant and a product more easily, and simplify the post treatment process for synthesizing the iso-amyl acetate; and the yield of ester can reach 85 percent at most.

Owner:GUANGDONG UNIV OF TECH

Alkyd resin coating for industrial outer wall and preparation method thereof

InactiveCN105038543AImprove adhesion performanceImprove adhesionAnti-corrosive paintsPolyester coatingsResin coatingDimethyl siloxane

The invention discloses an alkyd resin coating for an industrial outer wall. The alkyd resin coating comprises, by weight parts, 60-68 parts of drying oil alkyd resin, 20-50 parts of epoxy modified alkyd resin, 15-30 parts of acyclic acid modified alkyd resin, 2-4 parts of propylene glycol monomethyl ether acetic ester, 5-10 parts of propylene glycol, 5-10 parts of alcohol etherification melamine resin, 2-8 parts of urea resin, 1-3 parts of 2-amino-2-methyl-1-propanol, 20-25 parts of carboxymethyl cellulose, 1-3 parts of silane coupling agent, 1-4 parts of sodium dodecylbenzene sulfonate, 1-3 parts of polyoxyethylene polyoxypropylene ether, 1-2 parts of wetting agent, 1-3 parts of solydimethyl siloxane, 0.5-1.5 parts of preservative, 1-2 parts of hydroxypropyl guar gum, 40-60 parts of water, 5-20 parts of amyl acetate, 5-10 parts of super fine calcium carbonate, 2-8 parts of magnesium silicate, 6-10 parts of kaolin and 2-8 parts of china clay. The invention further discloses a method for preparing the alkyd resin coating for the industrial outer wall. The alkyd resin coating for the industrial outer wall is good in adhesive force and excellent in corrosion resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

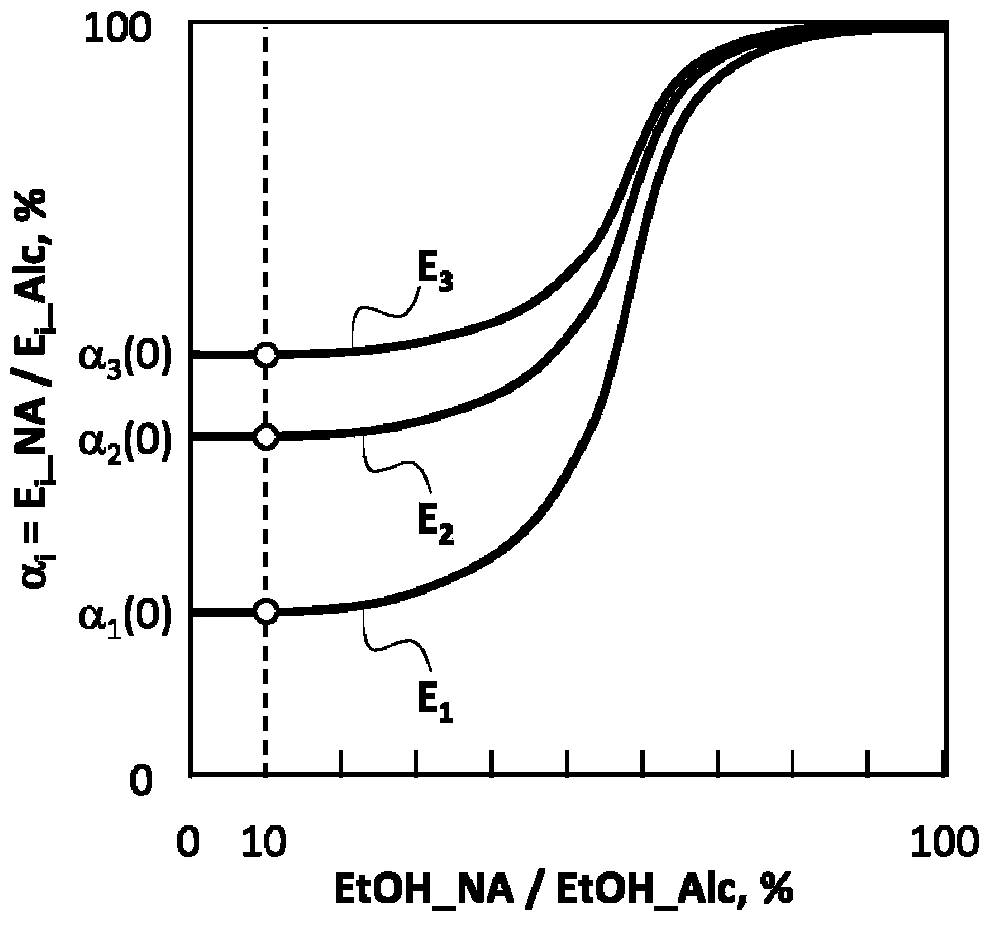

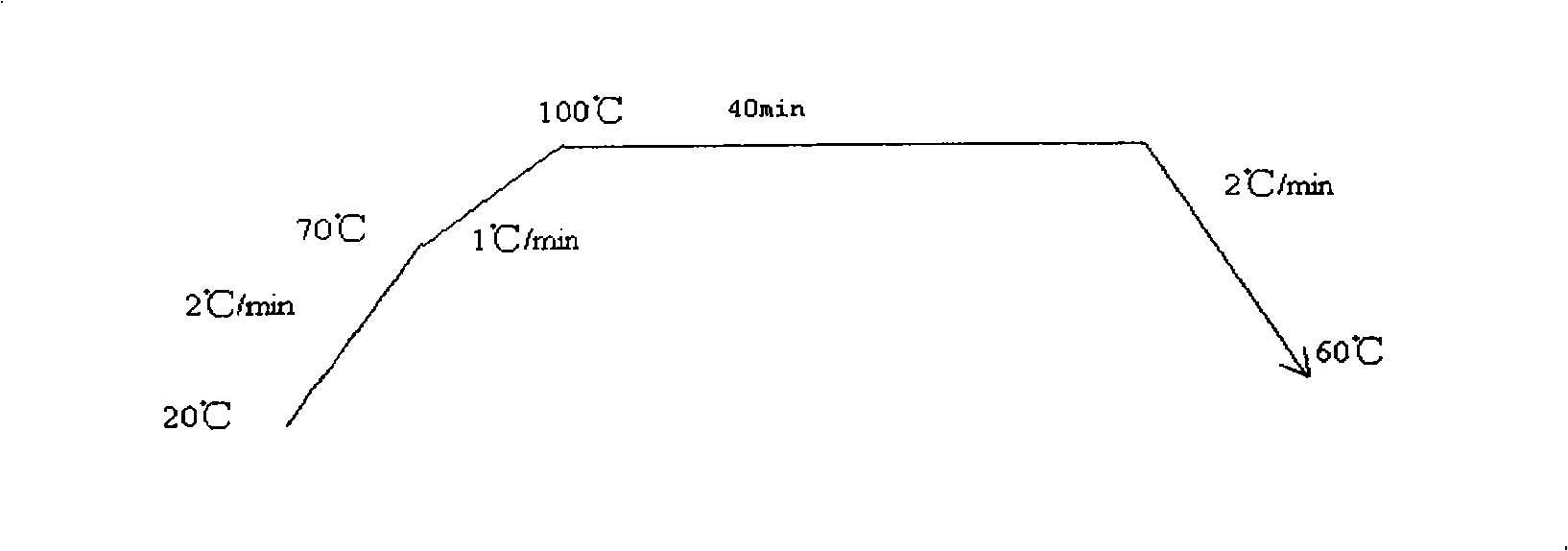

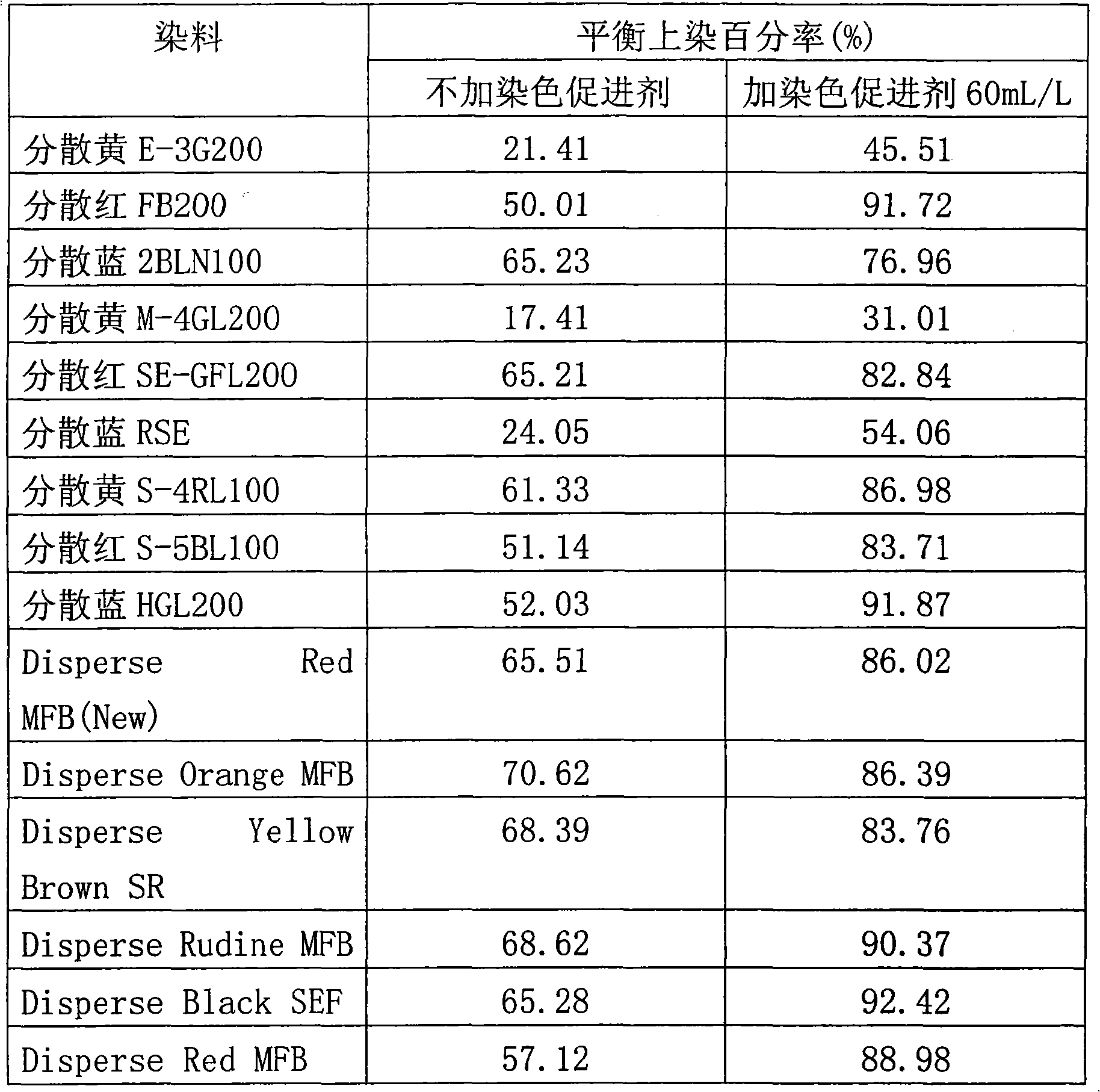

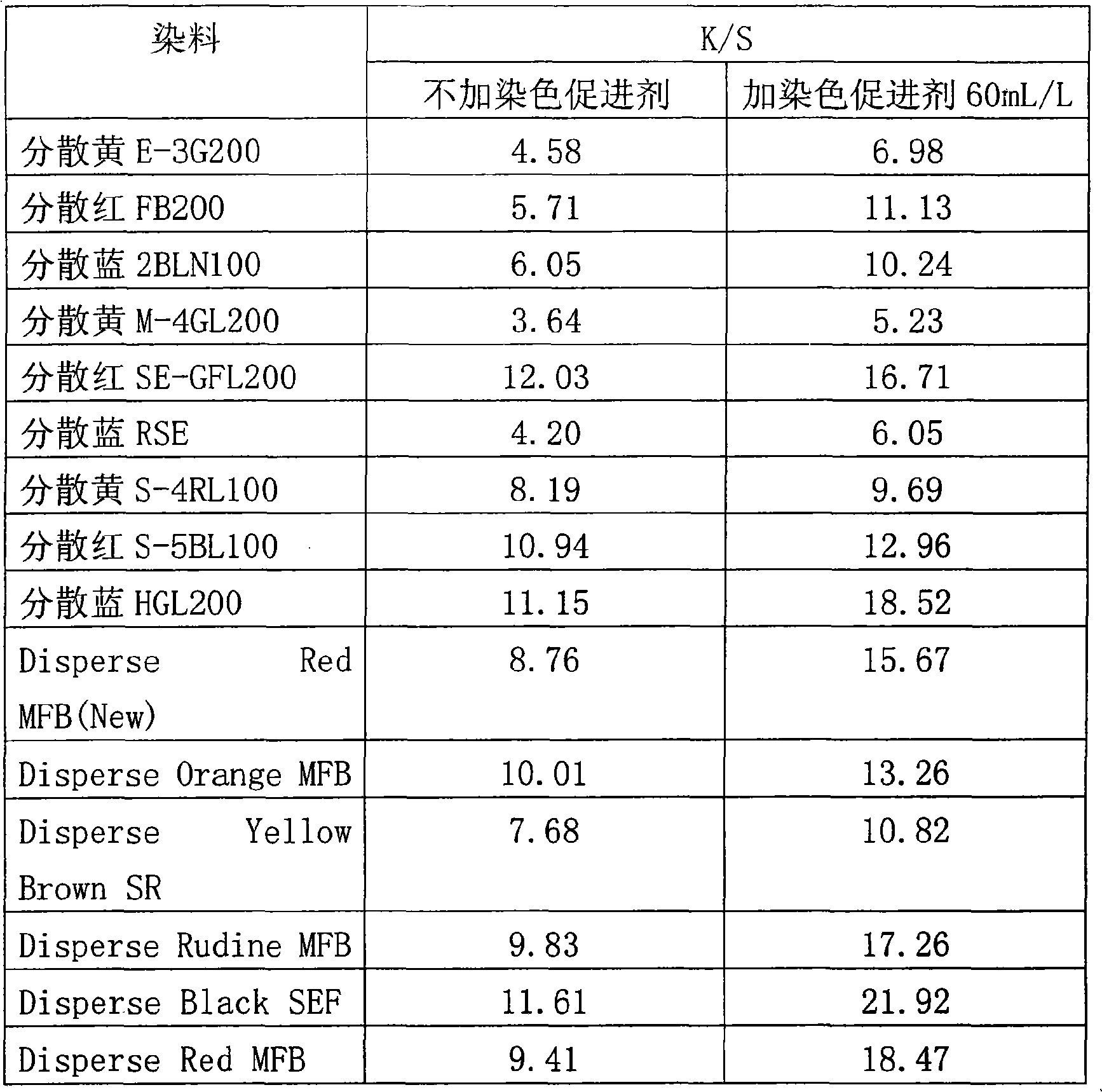

Polylactic acid fibre disperse dyeing accelerant

The invention discloses a polylactic acid fiber loose dye dyeing accelerant, which consists of n-amyl acetate, compound emulsifier and water with a volume percentage of 10:0.3 to 0.6:89.4 to 89.7; wherein, the compound emulsifier consists of a Span type non-ion surface activator, a Tween type non-ion surface activator and a low molecular organic alcohol with volume percentage of 2 to 60: 35 to 98: 9 to 5. The polylactic acid fiber loose dye dyeing accelerant of the invention has the advantages of environment protection and good stability, playing the role of remarkably improving the dye uptake of polylactic acid fiber loose dye dyeing, being able to lighten the pollution to the water resource by the waste liquid of dyeing, besides, having a higher dyeing color fastness and having little effect on the breaking strength of a polylactic acid fiber fabric.

Owner:ZHEJIANG SCI-TECH UNIV

Mildew-proof wear-resistant asphalt paint and preparation method thereof

InactiveCN104293069AGood weather resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesXylyleneTitanium isopropoxide

The invention discloses mildew-proof wear-resistant asphalt paint which is characterized by being prepared from the following raw materials in parts by weight: 17-23 parts of E-22 epoxy resins, 6-9 parts of benzyl transparent silicon resins, 8-11 parts of polyether acrylate, 4-7 parts of tetraethylenepentamine, 3-5 parts of tricresyl phosphate, 1-3 parts of nano bamboo fibers, 2-4 parts of zinc chromate, 37-43 parts of modified asphalt, 5-7 parts of modified waste resin sand, 1-2 parts of ammonium bromide, 2-4 parts of fungacetin, 3-4 parts of catechinic acid, 4-6 parts of epoxy linseed oil, 8-11 parts of amyl acetate, 6-9 parts of xylene, 5-7 parts of glycol, 1-2 parts of tri(dioctylphosphoryloxy) titanium isopropoxide and 2-4 parts of powdered aluminum. The mildew-proof wear-resistant asphalt paint is prepared by adding the epoxy resins on the basis of the modified asphalt, so that the characteristics of high corrosion resistance, weather fastness, waterproofness and thermal stability of the pain are ensured; the added tricresyl phosphate has the characteristics of favorable wear resistance, weather fastness, mildew resistance and radiation resistance; and the added modified waste resin sand has favorable fire resistance, antifouling property and anti-ageing property, so that the quality of the paint is improved and the waste is recycled to solve the problem of environment pollution.

Owner:TIANCHANG YINHU PAINT

Aluminum alloy door and window protection coating layer material used for smart homes

InactiveCN105925123AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsCobaltDibromomethane

The invention relates to an aluminum alloy door and window protection coating layer material used for smart homes. The material comprises melamine copolycondensation resin, fluoroether rubber, modified phenolic resin, nanometer zinc oxide, potassium titanate whisker reinforcement, nanometer magnesium hydroxide, polyethylene wax, zinc pyrithione, 10,10'-oxybisphenoxarsine, carbendazim, tetramethylthiuram disulfide, dibromomethane, titanium nitride powder, zeolite powder, sodium dihydrogen phosphate, disodium hydrogen phosphate, barium sulfate powder, lead oxide powder, barite powder, molybdenum disulfide powder, sodium carbonate, lead iodate powder, diethylene glycol butyl ether, soybean oil, amyl acetate, petroleum sulfonate, vinyl benzene, cobalt isooctoate, sulfamic acid and isopropyl titanate. The material has superior flame, acid-alkali, mildew and bacterium resistance, and improved performances.

Owner:梁方英

Antimicrobial antistatic agent for silk fabrics

ActiveCN103757897AHas antibacterial and antistatic effectsGood effectAnimal fibresFiberHexamethylenetetramine

The invention discloses an antimicrobial antistatic agent for silk fabrics, which is prepared from the following components in parts by weight: 16-19 parts of dimethyl terephthalate, 11-14 parts of fatty alcohol polyethenoxy ether sodium sulfate, 8-12 parts of sodium tripolyphosphate, 18-22 parts of ethylene glycol, 10-12 parts of polyethyleneglycol, 5-9 parts of zinc acetate, 5-7 parts of ethoxylated straight-chain primary alcohol, 4-6 parts of potassium oxalate, 2-4 parts of amyl acetate, 5-8 parts of white soap powder and 2-5 parts of hexamethylenetetramine. The antimicrobial antistatic agent for silk fabrics has favorable antimicrobial and antistatic effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:烟台力量知识产权服务有限公司

Modified FEVE fluorocarbon resin coating

The invention discloses a modified FEVE fluorocarbon resin coating. The modified FEVE fluorocarbon resin coating comprises the following raw materials in parts by weight: 20 to 50 parts of modified FEVE fluorocarbon resin, 30 to 40 parts of epoxy modified alkyd resin, 10 to 25 parts of acrylic modified alkyd resin, 2 to 6 parts of melamine resin, 5 to 10 parts of isocyanate curing agent, 5 to 12 parts of high-substituted hydroxy propyl cellulose, 0.5 to 1.5 parts of sodium dodecyl benzene sulfonate, 2 to 8 parts of polyoxyethylene polyoxypropylene ether, 10 to 18 parts of super fine calcium carbonate, 10 to 16 parts of gas-phase silicon dioxide, 2 to 9 parts of kaolin, 5 to 10 parts of organobentonite, 1.5 to 2.8 parts of graphene, 0.5 to 1.8 parts of polydimethylsiloxane, 0.5 to 1.5 parts of polyamide wax, 0.5 to 1.5 parts of calcium sulfonate, 5 to 10 parts of amyl acetate, 2 to 10 parts of propanediol, 3 to 6 parts of methyl ethyl ketone and 20 to 55 parts of water. The modified FEVE fluorocarbon resin coating is excellent in adhesion capability, resistant to corrosion and good in mould-proof effect.

Owner:合肥市易远新材料有限公司

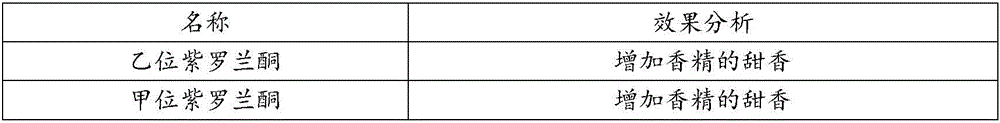

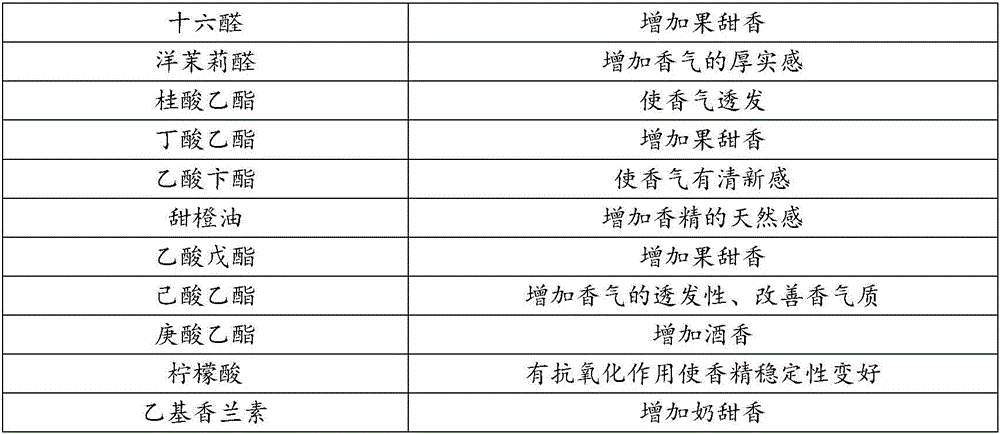

Blueberry essence for cigarette paper

InactiveCN106398868AStrong noveltyObvious blueberry aromaTobacco preparationEssential-oils/perfumesBlueberry extractAlcohol

The invention provides blueberry essence for cigarette paper. The blueberry essence is prepared from, by weight, 1-2 parts of blueberry essence and 8-9 parts of blueberry extract, the blueberry essence is prepared by mixing, by mass, 1%-2% of beta-ionone, 1%-2% of alpha-ionone, 5%-10% of hexadecanal, 10%-15% of heliotropin, 3%-5% of ethyl cinnamate, 8%-10% of ethyl butyrate, 8%-10% of benzyl acetate, 3%-5% of sweet orange oil, 1%-3% of amyl acetate, 1%-2% of ethyl hexanoate, 1%-2% of ethyl oenanthate, 1%-3% of citric acid, 3%-5% of ethyl vanillin and 26%-54% of 95% ethyl alcohol. The blueberry extract is extracted through a supercritical extraction process and has aroma components and natural anthocyanin of blueberries. The blueberry essence is added into the cigarette paper, so that cigarettes have obvious blueberry fragrance and meanwhile have the distinctive blue of the blueberries.

Owner:HUBEI CHINA TOBACCO IND

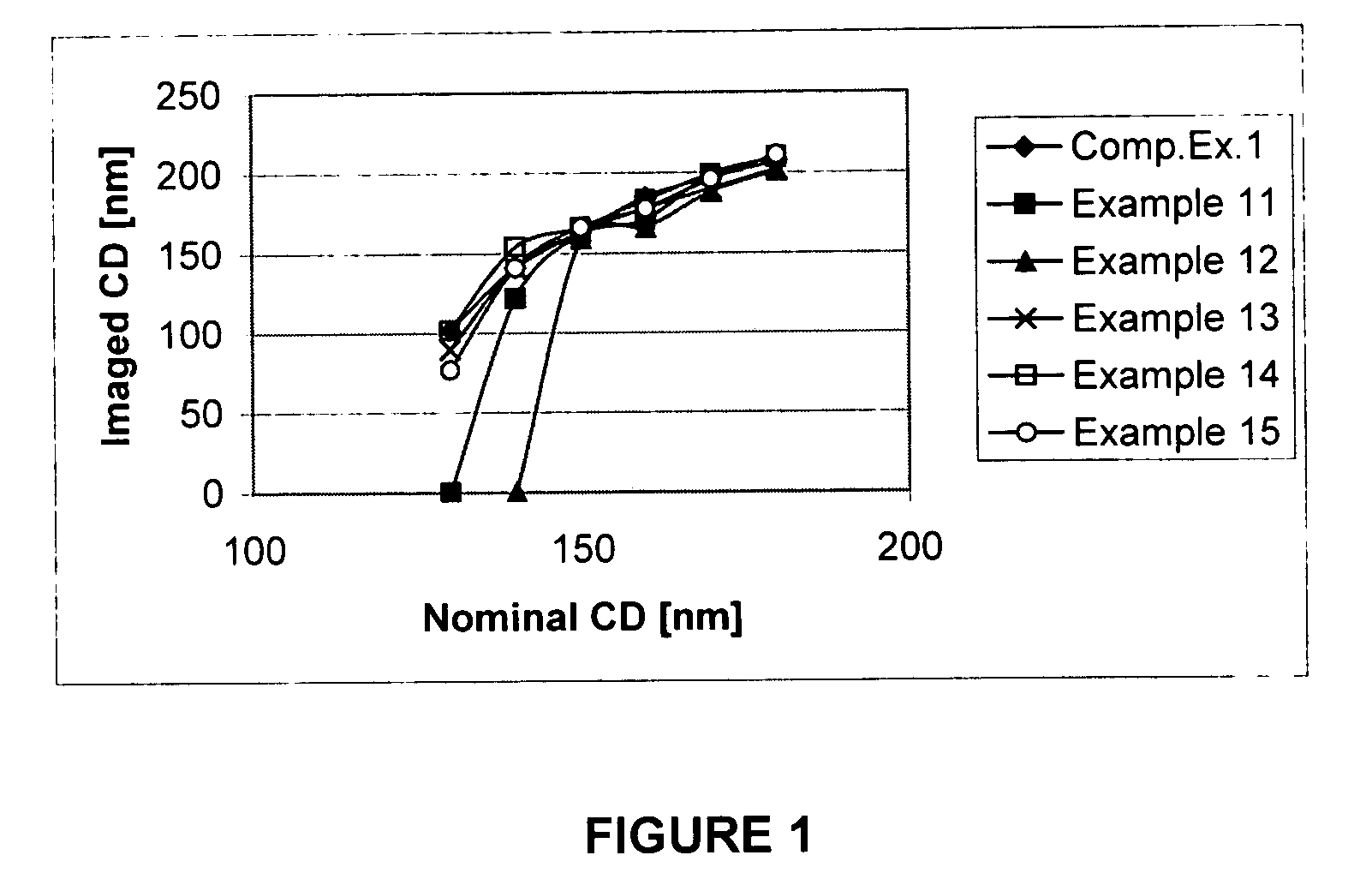

Method for the removal of an imaging layer from a semiconductor substrate stack

InactiveUS7011935B2Surface-active detergent compositionsNon-surface-active detergent compositionsFeature DimensionKetone

Processes to overcome mistakes, such as, incorrect film thicknesses, poor coating quality, and incorrect feature dimensions made during the lithographic process in multilayer imaging systems are provided. To optimize manufacturing efficiency, it is desirable to be able to remove the top layer (an imaging layer) without having to remove, recoat, and usually cure the bottom layer (undercoat or underlayer). A rework process for removing an imaging layer from a substrate stack is such a process. The stack comprises a substrate, an underlayer adjacent to the substrate, and an imaging layer comprising silicon adjacent to the underlayer. The process comprises the steps of:(a) contacting the substrate stack with an imaging layer removal solvent;(b) removing the imaging layer with the imaging layer removal solvent thereby forming a substrate / underlayer stack, wherein the imaging layer removal solvent is selected from the group consisting of: glycol ethers, ketones, esters, lactates, dimethylsulfoxide (DMSO), dimethylformamide (DMF), tetrahydrofuran (THF), methyl tetrahydrofuran, dioxane, tetrahydropyran, ethyl tetrahydropyran-4-acetate, methyl tetrahydropyran-4-methanol, tetrahydropyran-4-one, n-butyl acetate, n-amyl acetate, and any combinations thereof; and(c) removing the imaging layer removal solvent from the substrate / underlayer stack after the imaging layer is removed.

Owner:ARCH CHEM INC

Cleaner

InactiveCN1526805AEasy to useEasy to cleanOrganic non-surface-active detergent compositionsPolyesterOxalate

The cleaner is prepared through dissolving oxalic acid in absolute ethyl alcohol and adding industrial ethyl acetate, butyl acetate or amyl acetate, and consists of oxalic acid 5-18 wt%, absolute ethyl alcohol 30-45 wt%, and industrial ethyl acetate, butyl acetate or amyl acetate 50-65 wt%. The cleaner of the present invention has excellent effect of scrubbing down scratches on surface of city building, especially those of polyester paint and sprayed paint.

Owner:闫振武 +1

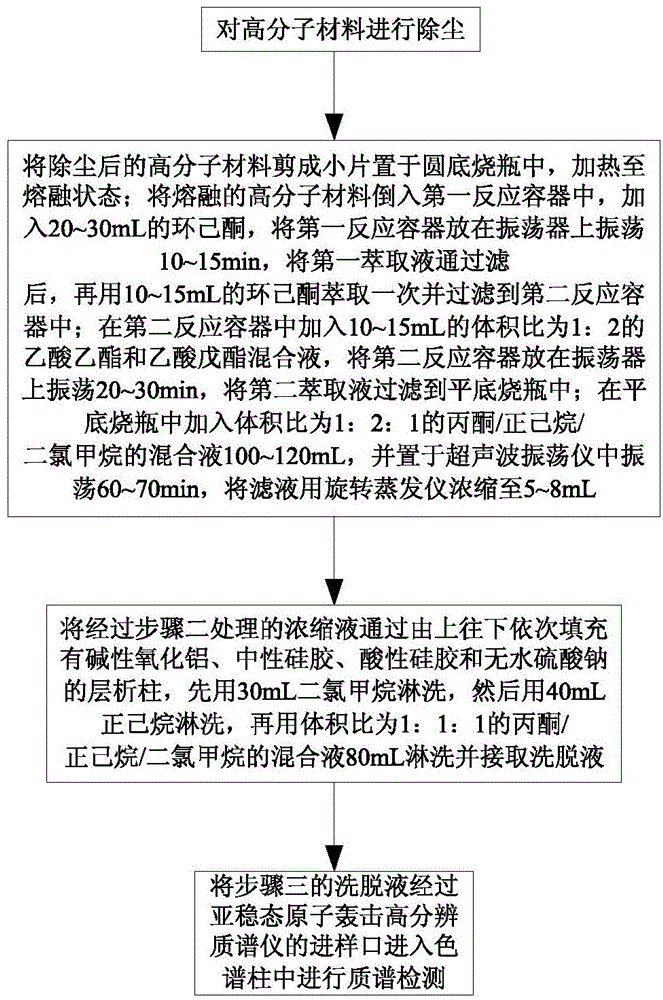

Method for measuring short chain chlorinated paraffin in high polymer material

The present invention relates to the field of measurement of short chain chlorinated paraffin and particularly relates to a method for measuring short chain chlorinated paraffin in a high polymer material. The method comprises the following steps: dedusting the high polymer material; shearing the dedusted high polymer material into pieces, putting the pieces in a round-bottom flask, and heating the pieces to a molten state; pouring the molten high polymer material into a first reaction container, adding cyclohexanone in twice, oscillating and filtering; adding mixed liquor of ethyl acetate and amyl acetate into a second reactor, oscillating and filtering; adding mixed liquor of acetone / normal hexane / dichloromethane with a volume ratio of 1:2:1, and oscillating and concentrating the mixed liquor in an ultrasonic oscillator; spraying the concentrated solution onto a chromatographic column, leaching and receiving eluant; feeding the eluant into a chromatographic column from the sample feed opening of a metastable atom bombardment high-resolution mass spectrometer to realize mass spectrometric detection. According to the invention, the main components and the added components in the high polymer material are fully separated to improve the detection efficiency and accuracy of the short chain chlorinated paraffin.

Owner:通标标准技术服务(天津)有限公司

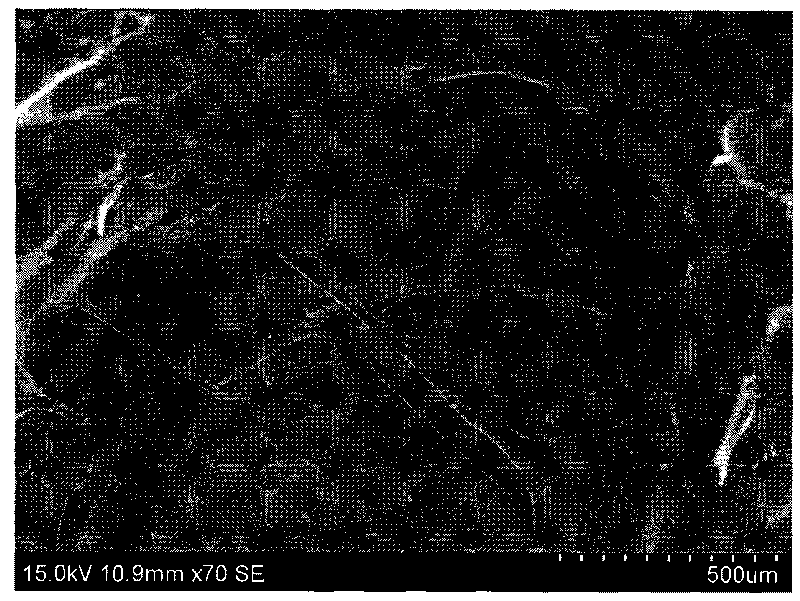

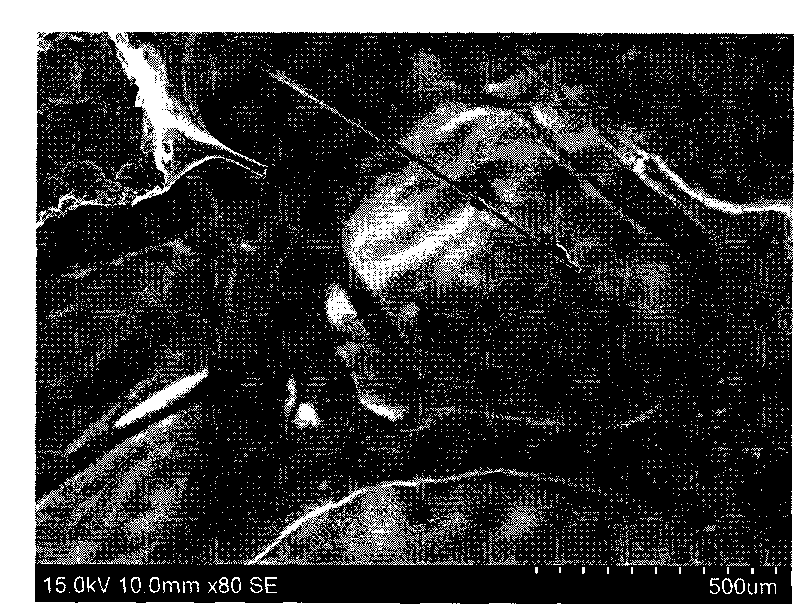

Micro grating for transmissive electron microscope and its making process

InactiveCN1433044AEasy to makeIncrease productivityElectric discharge tubesCold cathode manufactureGratingAmyl acetate

The present invention relates to a micro grating for transmissive electronic microscope and its making process and aims at simplifying its production process, raising production efficiency and heat stability. In the technological scheme, the micro grating is made with acetone, n-pentyl acetate and collodion. The production process includes mixing n-pentyl acetate and collodion and adding acetone to prepare mixed liquid; dropping one drop of the mixed liquid to culture dish and covering the liquid surface with copper net; spreading filter paper on the film formed on the liquid surface and lifting the filter paper with the copper net and film; cutting the film and setting fil mwith copper net into the sample chamber of transmissive electronic microscope; and applying high voltage to the microscope to form the micro grating.

Owner:ZHONGBEI UNIV

Laundry cleaning delivery system

InactiveUS20070042923A1Satisfies needOrganic detergent compounding agentsSurface-active detergent compositionsAlcoholLaundry

A laundry cleaning delivery system that dispenses cleaning liquid into laundry machines is disclosed. A cleaning solution is impregnated into a sheet that has a fabric substrate sufficient to contain the correct amount of cleaning solution to clean a particular load of laundry. The fabric substrate comprises hydraulically entangled nonwoven fibrous material periodically perforated to create sheets of a desired size and roll count and wound into rolls that are placed into resealable containers. The active ingredients of the cleaning solution comprise amyl acetate and alcohol etoxylate. Also, methods of using and manufacturing a laundry cleaning delivery system are disclosed herein.

Owner:JANKURA AKOS +1

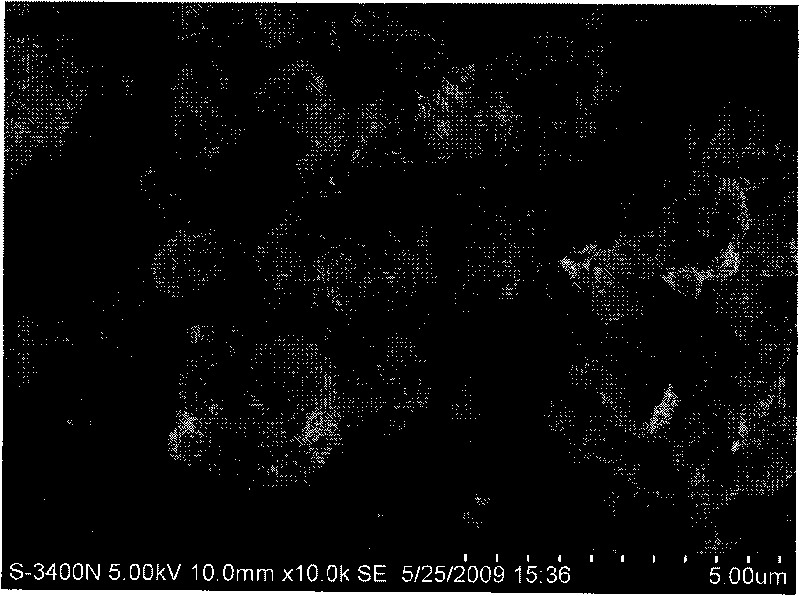

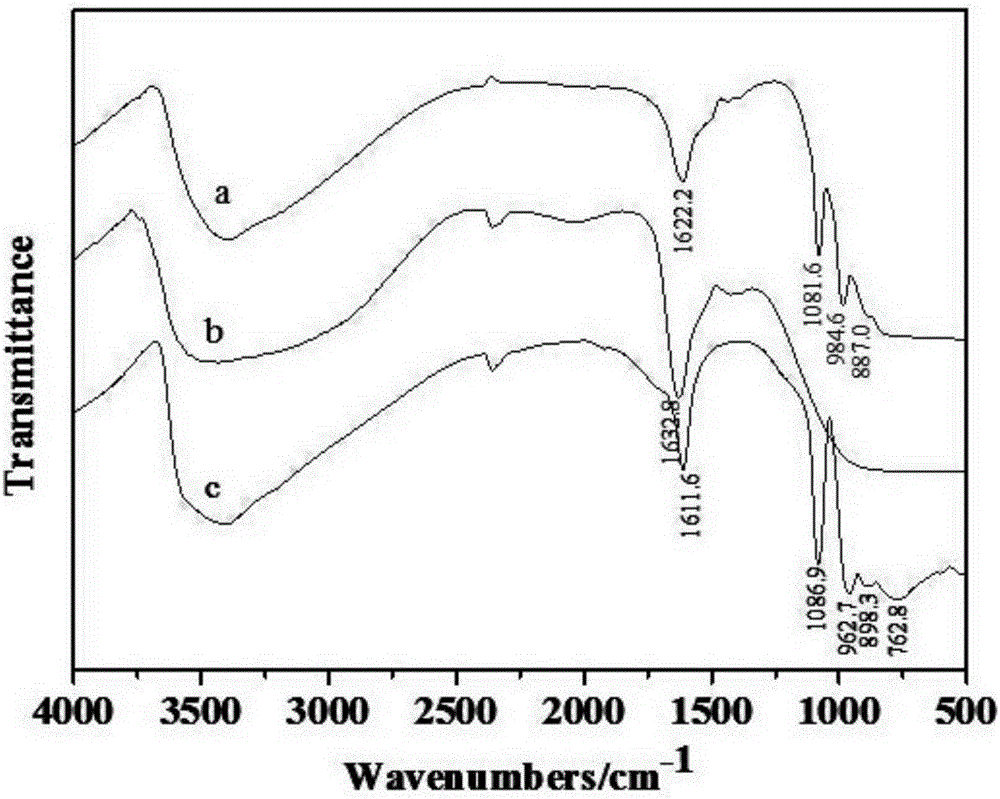

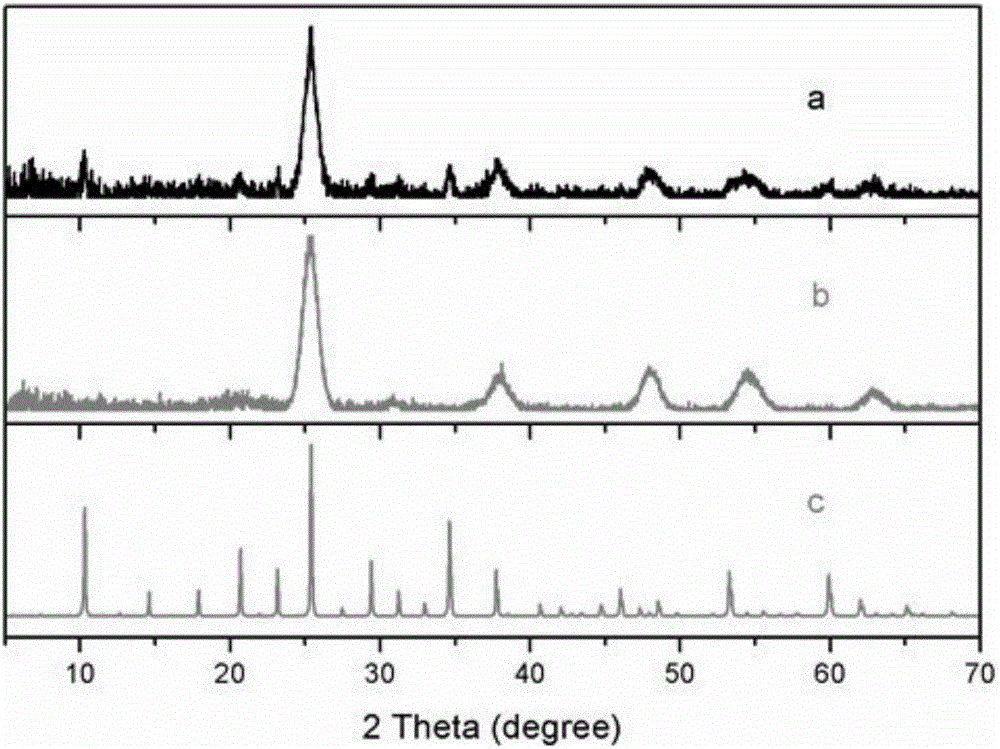

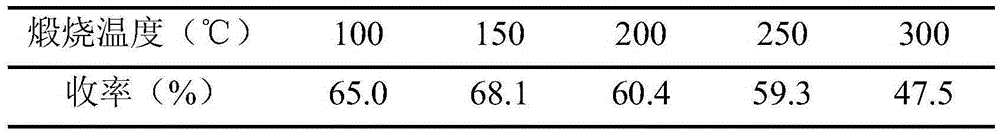

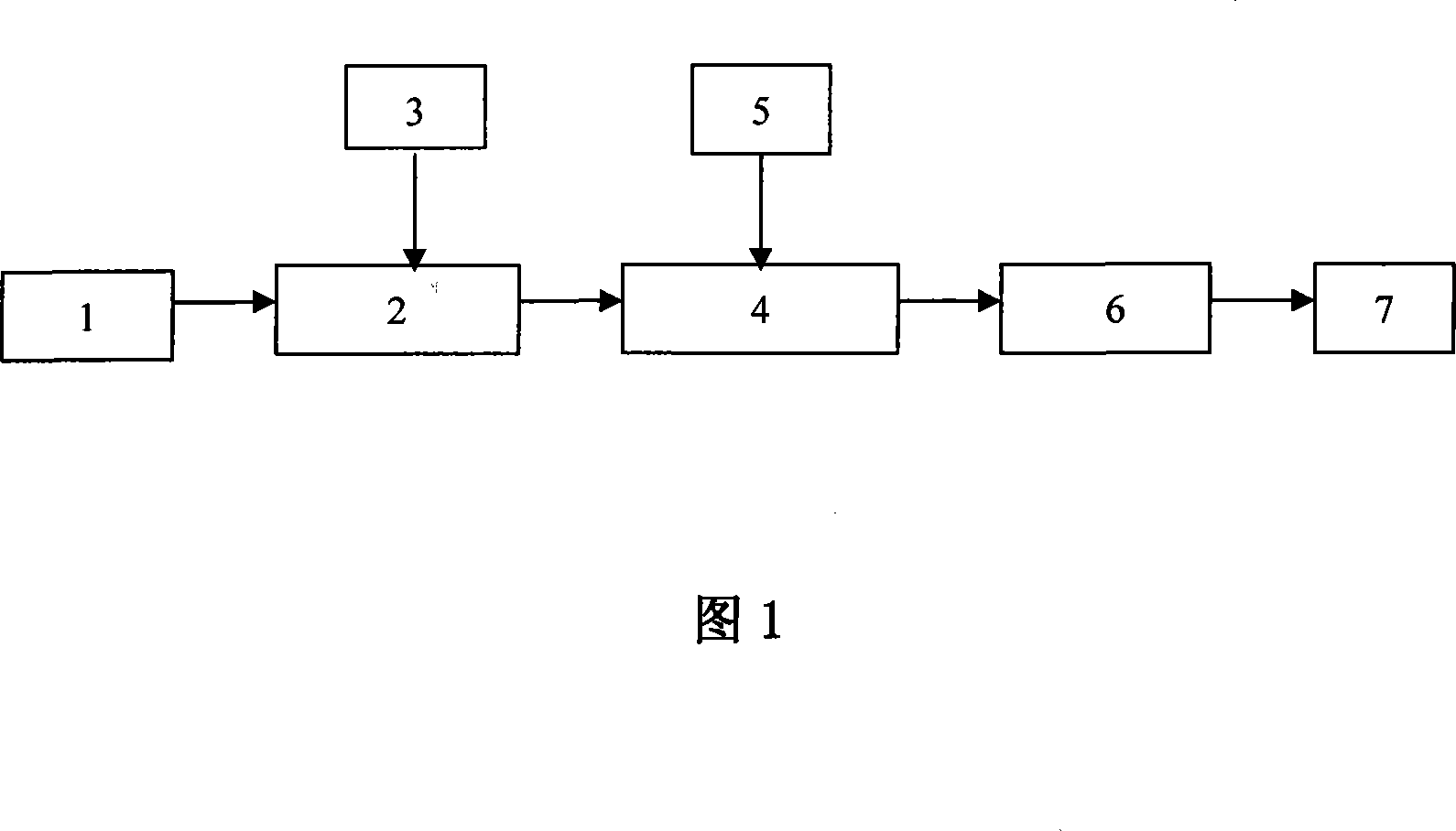

Preparation method of catalyst H6P2W15Mo3O62/TiO2 and n-pentyl acetate

InactiveCN105251538AHigh catalytic activityHigh reusabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidPentyl acetate

The invention discloses a preparation method of catalyst H6P2W15Mo3O62 / TiO2 and n-pentyl acetate. Dawson H6P2W15Mo3O62 is prepared with a hydrothermal method, then TiO2 loaded Dawson type P-W-Mo-heteropolyacid catalyst H6P2W15Mo3O62 / TiO2 is prepared with an impregnation method, the structure of the TiO2 loaded Dawson type P-W-Mo-heteropolyacid catalyst H6P2W15Mo3O62 / TiO2 is characterized with FT-IR and XRD methods, and the catalytic activity of catalytic activity on esterification reaction is studied. The optimized conditions for preparing the catalyst are that the activation temperature is 150 DEG C, the calcination time is 4.5 h, and the load of the H6P2W15Mo3O62 / TiO2 is 40%. The n-pentyl acetate synthesized by the catalyst of the H6P2W15Mo3O62 / TiO2 has the advantages of excellent catalytic activity, mild reaction condition, high product yield, no environmental pollution and better recycling performance. Therefore, the H6P2W15Mo3O62 / TiO2 is an excellent catalyst for synthesizing the n-pentyl acetate and has an excellent application prospect.

Owner:HUBEI NORMAL UNIV

Method for producing reclaimed thermoplastic resin and thermosetting resin multi-layer composite coated controlled-release fertilizer

InactiveCN101182264AReduce dosagePrecise Controlled ReleaseFertilizer mixturesResin coatingAmyl acetate

The invention relates to a multi-layer composite coated controlled-release fertilizer with recycled thermoplastic resin as the inner coating and thermosetting resin as the outer coating and a production method thereof. In this invention, the recovered thermoplastic resin and a certain proportion of mineral powder and grain powder are mixed in a mixed solvent of n-butyl acetate and amyl acetate, and then sprayed on the fertilizer particles through a two-fluid nozzle in a heated fluidized bed. , forming a thermoplastic resin film with nutrient controlled release function. Then it is transferred to the heated drum fluidized bed, and the mixture of thermosetting resin, curing agent and diluent is sprayed in stages. Under the condition of rotating and heating, a rapid curing reaction occurs on the outer layer of the thermoplastic resin film to form a dense and bright film. thermosetting resin film. This product integrates the advantages of two types of resin films, realizes the perfect combination of toughness and elasticity, and can reduce the amount of film materials by 20-50% to achieve the same controlled release effect, which not only reduces the cost, but also improves the internal controlled release effect of the product and Appearance quality, suitable for large-scale industrial production and promotion.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Plastic cleaning agent and preparation method thereof

InactiveCN104046523AEfficient removalStrong detergencyOrganic detergent compounding agentsSurface-active detergent compositionsDisodium EdetateThiourea

The invention discloses a plastic cleaning agent and a preparation method thereof and belongs to the technical field of plastic cleaning. According to the plastic cleaning agent and the preparation method thereof, the plastic cleaning agent has the advantages that discharge pollution is reduced and the cleaning cost is low. The plastic cleaning agent is characterized in that the plastic cleaning agent per liter contains the following ingredients by weight: 100-200g of nonylphenol polyoxyethylene ether, 60-80g of oxalic acid, 5-10g of fatty alcohol-polyoxyethylene ether, 1-5g of alkylphenol polyoxyethylene ether, 3-7g of thiourea, 20-50g of propylene glycol methylether, 5-10g of disodium edetate, 10-20g of amyl acetate and the balance of water. The preparation method of the plastic cleaning agent comprises the steps: (1) weighing all the ingredients; (2) putting the ingredients weighed in the step (1) in a flask, adding water until the volume is 1L, and then, stirring for 2-5 minutes at normal temperature, thereby obtaining the plastic cleaning agent.

Owner:WUZHOU HENGSHENG ELECTRONICS

Composite fluorocarbon resin coating with excellent adhesion

The invention discloses composite fluorocarbon resin coating with excellent adhesion. The coating is prepared from the following raw materials in parts by weight: 15-35 parts of modified FEVE fluorocarbon resin, 20-60 parts of epoxy modified alkyd resin, 20-35 parts of epoxy resin, 1-3 parts of dicyandiamide, 1-2 parts of sodium dodecyl benzene sulfonate, 3-8 parts of carboxymethylcellulose, 1-5 parts of ethylene glycol monoethyl ether acetate, 5-15 parts of super fine calcium carbonate, 2-10 parts of magnesium silicate, 5-15 parts of kaolin, 2-8 parts of talc powder, 2-6 parts of graphene, 2-8 parts of amyl acetate, 4-10 parts of propylene glycol, 1-3 parts of a wetting agent, 1-3 parts of preservative, 2-10 parts of ethyl acetate, 2-7 parts of butylated amino resin, 2-6 parts of methylated amino resin and 40-80 parts of water. The composite fluorocarbon resin coating has good adhesion and excellent corrosion resistance.

Owner:合肥市易远新材料有限公司

Method for preparing fiber reinforced foam glass

The invention relates to a method for preparing fiber reinforced foam glass, comprising the following steps: washing, drying and grinding waste glass into glass powders, then putting glass powders, calcium carbonate, potassium permanganate, ferric oxide, boric acid and sodium nitrate into a mixer for uniformly mixing, adding aluminum silicate fiber into the mixer, adding polyvinyl alcohol, n-amyl acetate, alcohol, distilled water and polyethylene glycol 2000 based on the above mixture in the mixture and fibers as the reference, mixing uniformly and pouring slurry into a mould; then pushing the mould filled with the slurry into a foaming kiln, heating for drying, volatilizing organic compounds, foaming, cooling and annealing to obtain fiber reinforced foam glass. As the invention adopts a slurry suspension method to prepare the fiber reinforced foam glass, fibers are distributed uniformly in foam glass, and the mechanical strength of samples is high; and the fiber reinforced foam glass has wider use range than the common foam glass and long service life, and can absorb main parts of explosion energy when facing shock waves.

Owner:SHAANXI UNIV OF SCI & TECH

Pyrophyllite and bone black blended and modified heat dissipating coating material

InactiveCN103773130AImprove thermal conductivityImprove mechanical propertiesCoatingsSodium lactatePyrophyllite

The invention discloses a pyrophyllite and bone black blended and modified heat dissipating coating material. The pyrophyllite and bone black blended and modified heat dissipating coating material is prepared from the following raw materials in parts by weight: 93-100 parts of chlorinated polyethylene, 0.1-0.2 part of potassium dihydrogen phosphite, 2-3 parts of calcium fluoride, 1-2 parts of amyl acetate, 4-6 parts of maleic anhydride grafted polypropylene, 5-7 parts of wollastonite powder, 2-4 parts of graphite powder, 1-2 parts of benzotriazole, 2-3 parts of guar gum, 2-3 parts of mannitol, 1-2 parts of sodium lactate, 0.8-1 part of dimethylethanolamine and 7-10 parts of modifying filler. According to the heat dissipating coating material disclosed by the invention, the heat conducting effect of a coating is enhanced through adding the modifying filler and blending and modifying pyrophyllite and bone black, so that the heat dissipating performance is enhanced, and the physical and mechanical properties of the surface of the coating are improved.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com