Patents

Literature

49results about How to "Improve printing yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

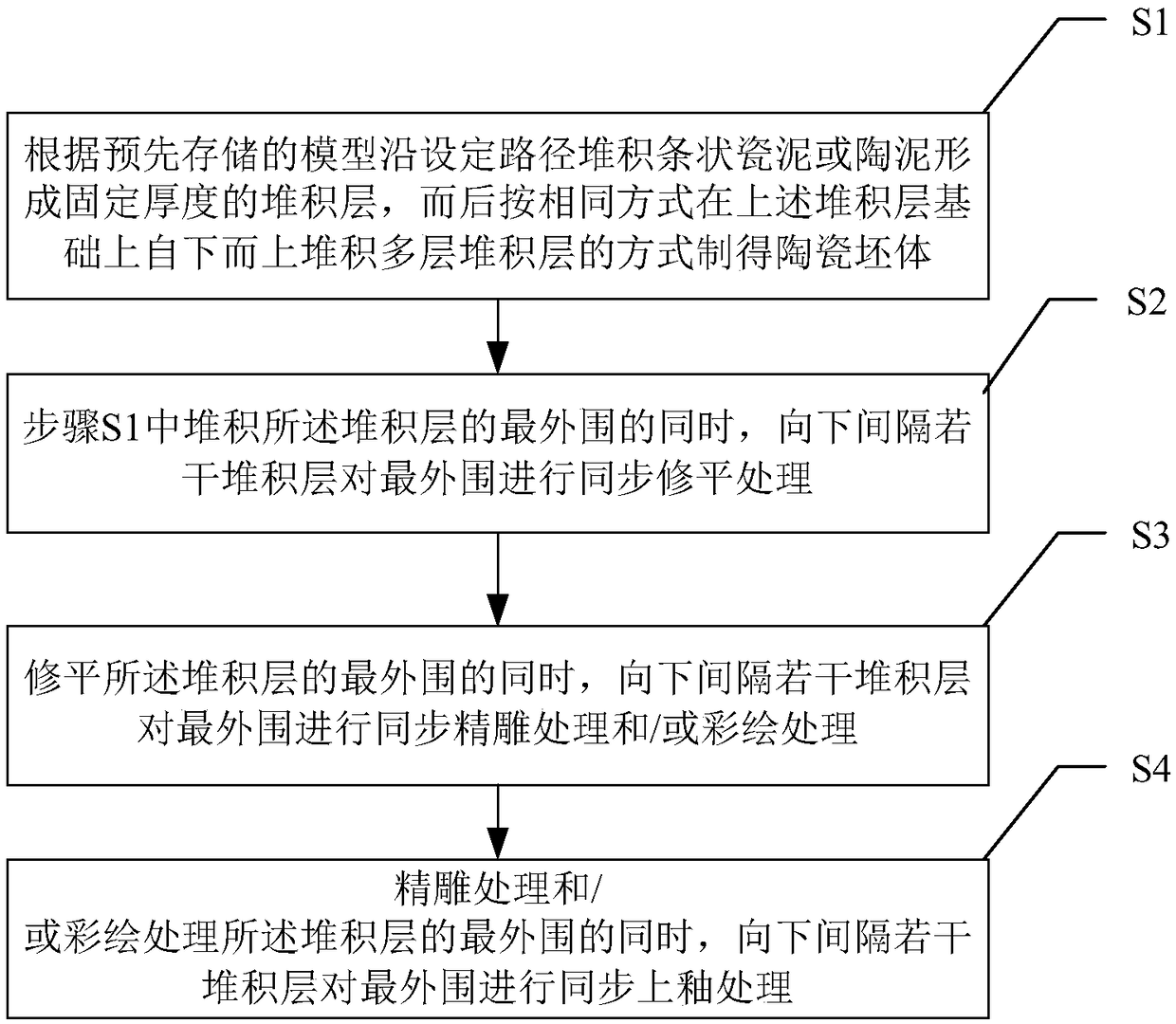

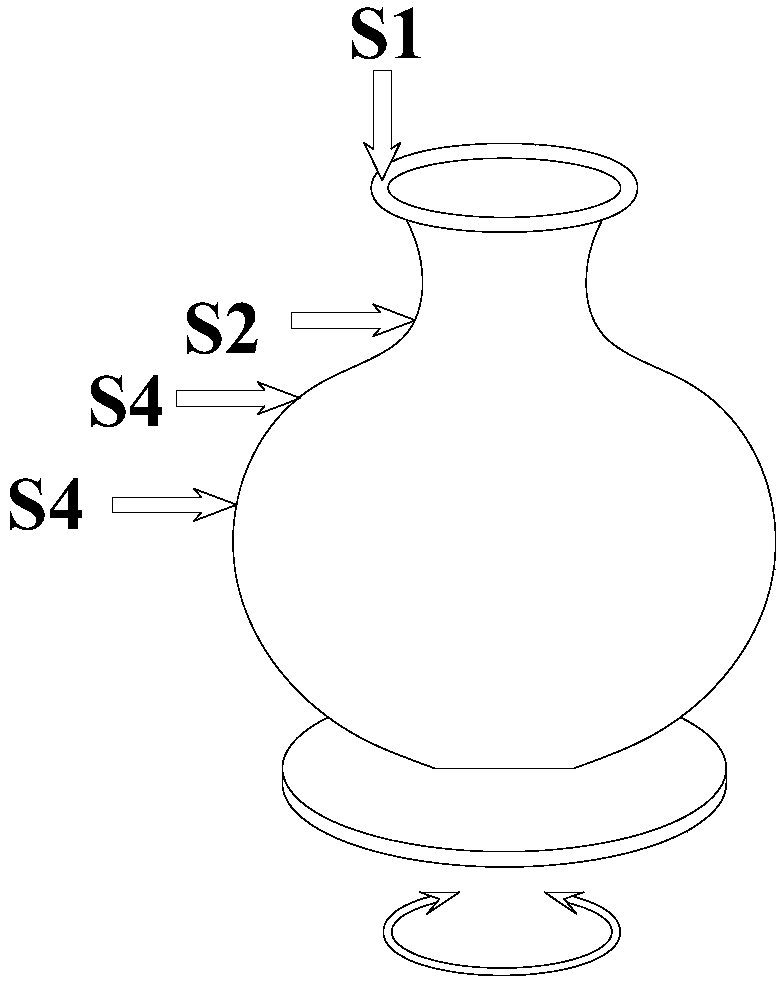

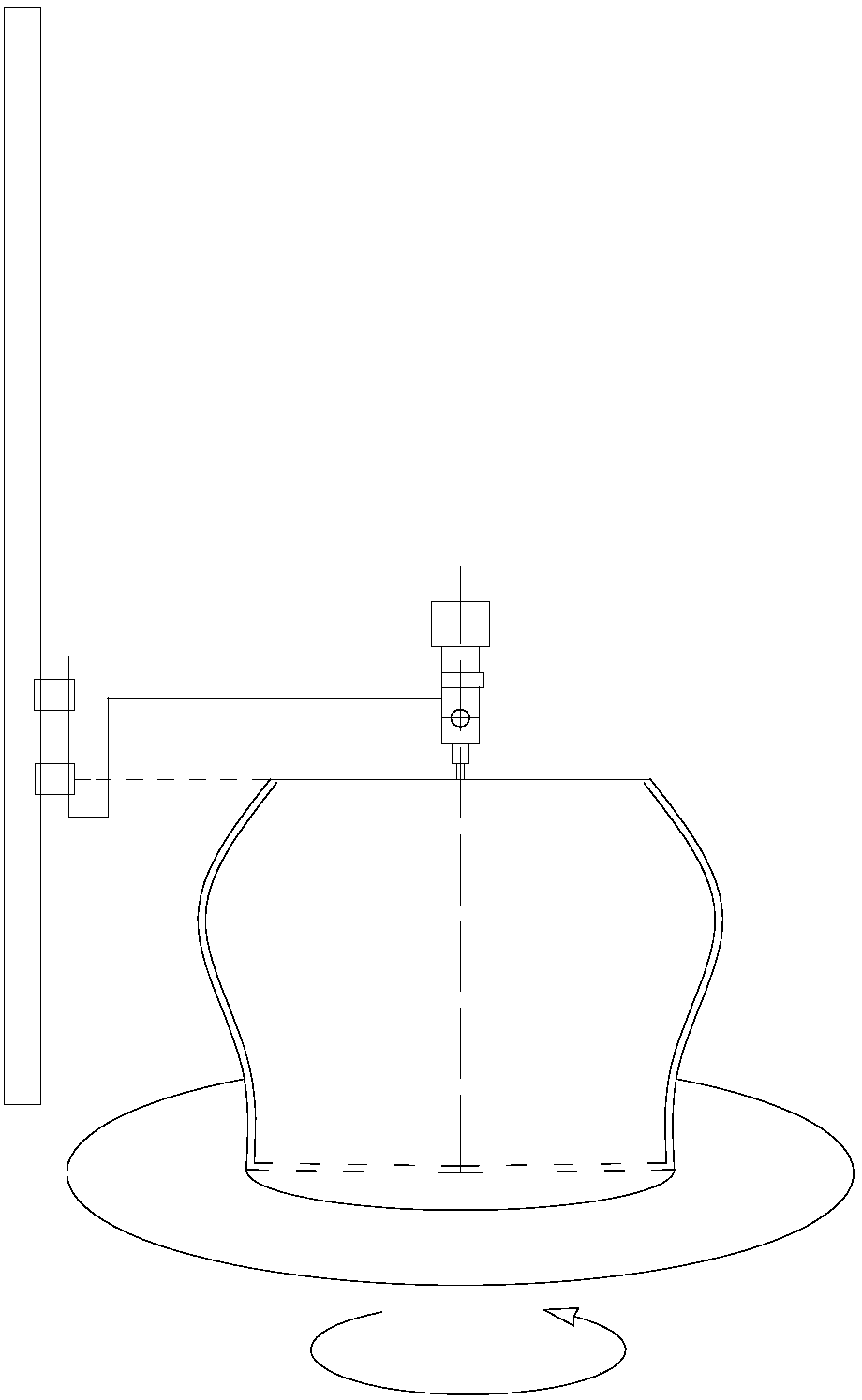

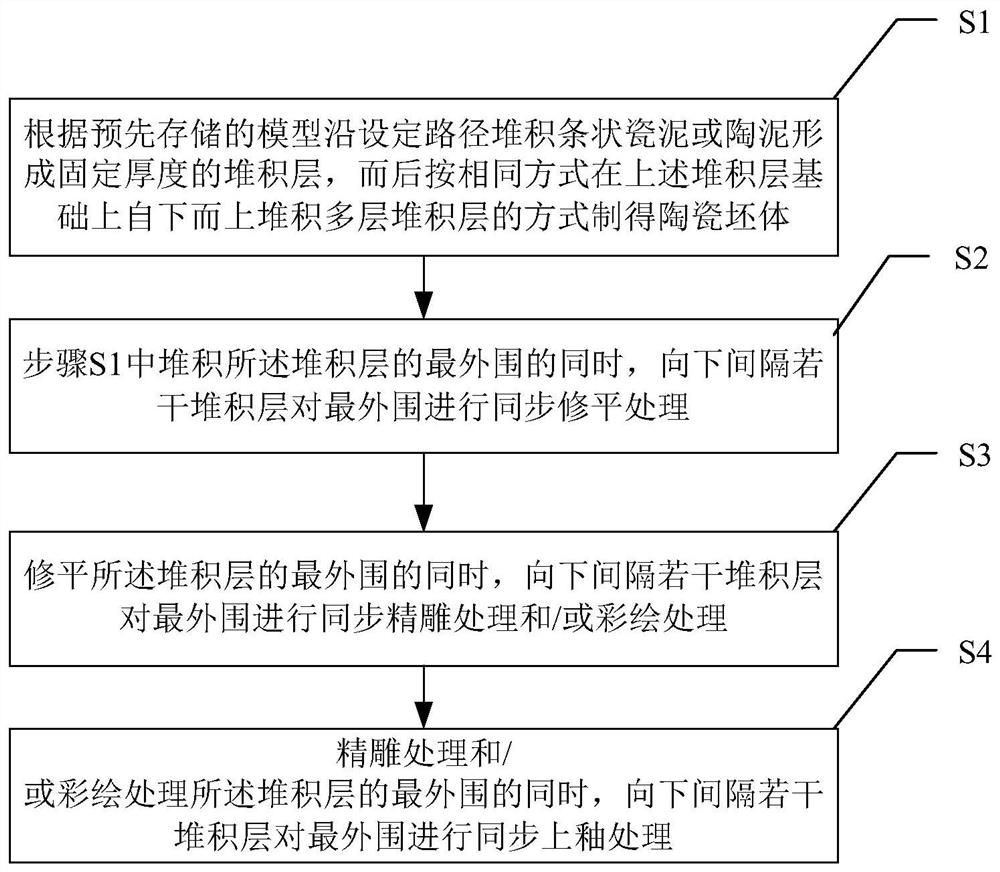

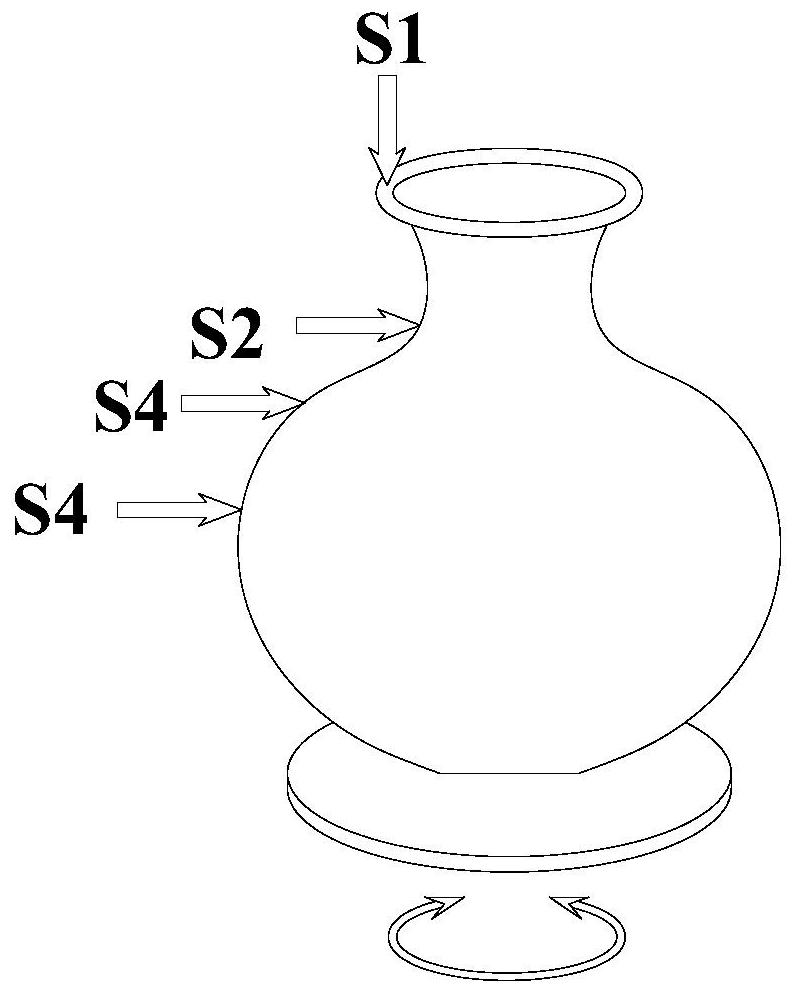

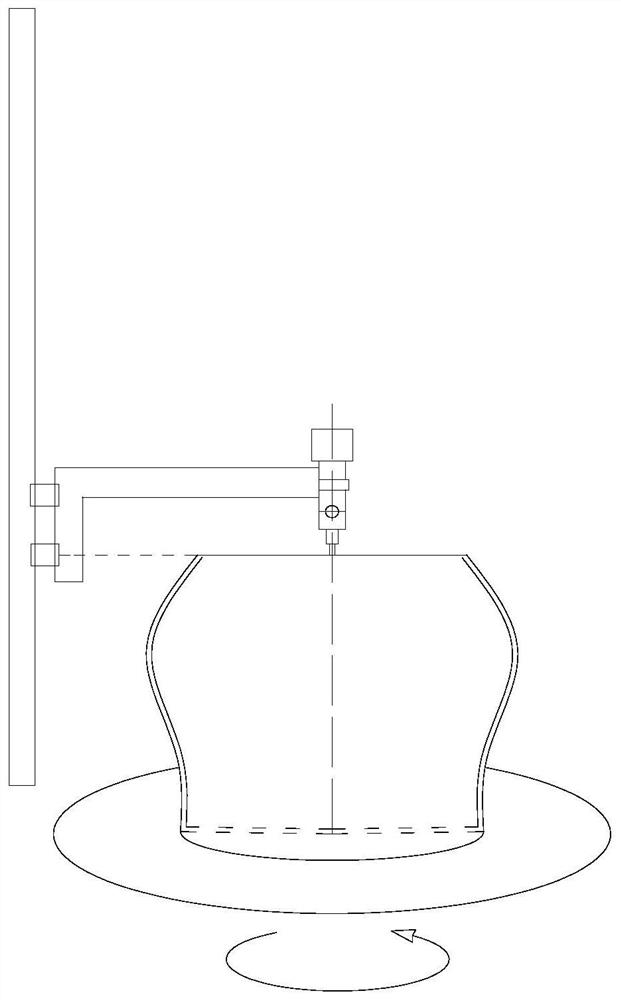

Large and medium chinaware manufacturing method

ActiveCN108582416ARich Applicable TypesReduce manufacturing costCeramic shaping apparatusClaywaresTime spaceCeramic

The invention discloses a large and medium chinaware manufacturing method. Compared with a traditional method, such subsequent treatment processes as outer surface finishing, finish carving treatmentand / or colored drawing treatment and glazing of large and medium chinaware ceramic blanks and production of chinaware outer profile surfaces belong to simultaneous asynchronous treatment spaced by specific space-time intervals, so that the problem of performing subsequent processes one by one after completion of previous treatment procedures in the traditional method is overcome, and saving of a lot of time and delication of the artistic effect can be both considered. In addition, the method can finish complex shapes, is more suitable for manufacturing of large and medium artistic shape chinaware, meanwhile, greatly enriches the shaping range of large and medium chinaware, and greatly reduces the manufacturing cost of large artistic porcelains.

Owner:湖南筑巢智能科技有限公司

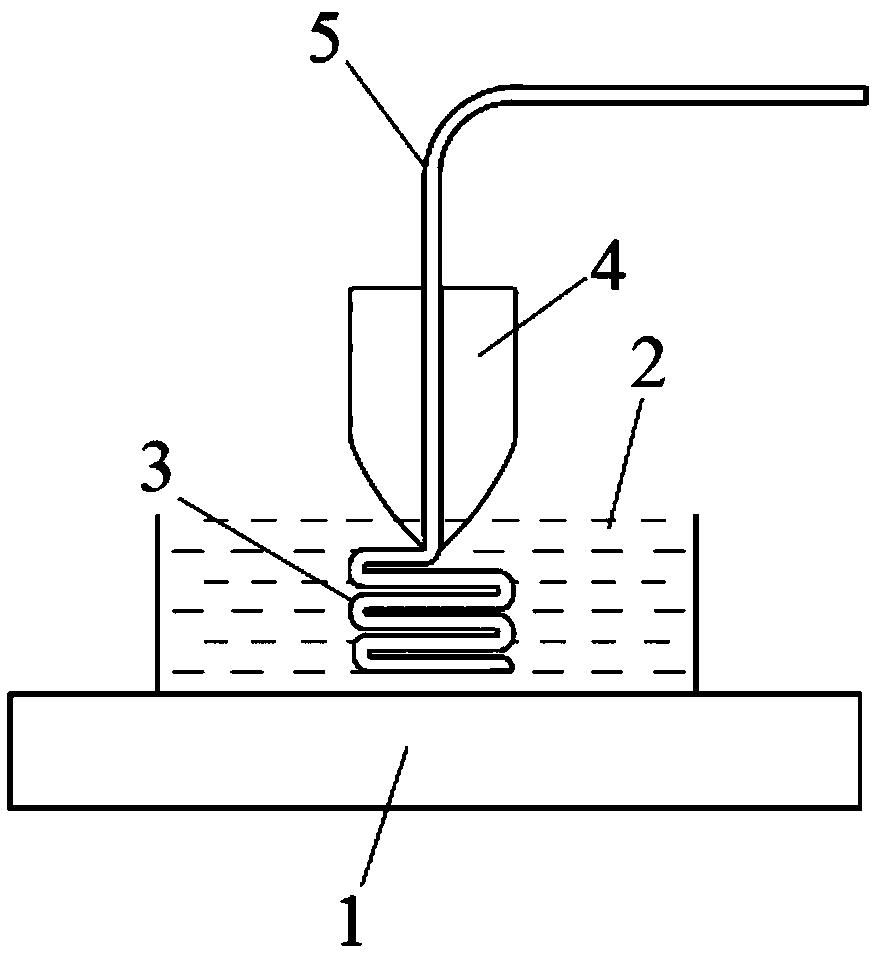

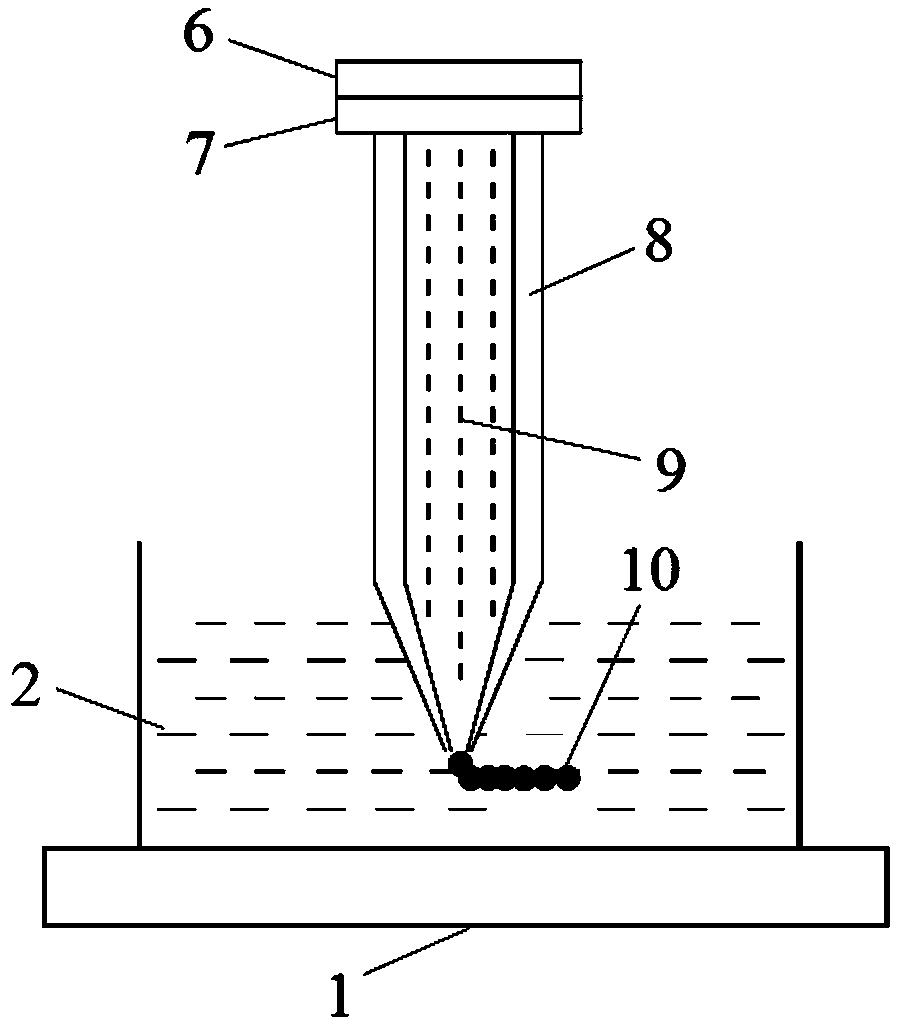

Three-dimensional printing method based on fluid support

InactiveCN108859097AExpand the scope of the structureImprove printing yieldManufacturing enclosuresAdditive manufacturing with liquids3 dimensional printingComputer engineering

The invention discloses a three-dimensional printing method based on fluid support. The printing method comprises the following steps that (1) a supporting fluid material is prepared, and then is putinto a container; (2) a three-dimensional model to be printed is sliced, and then a printer is used for printing a structure in the supporting fluid material in the step (1); (3) the structure which is printed in the step (2) is enabled to undergo post-curing in the supporting fluid material; and (4) after curing is completed, the printed structure is taken out by using a colander. According to the printing method, a supporting structure does not need to be designed and machined additionally, therefore, the structure range suitable for printing processing can be expanded, the printing yield isincreased, the post-processing process is simplified, and the printing cost is reduced.

Owner:NANJING UNIV

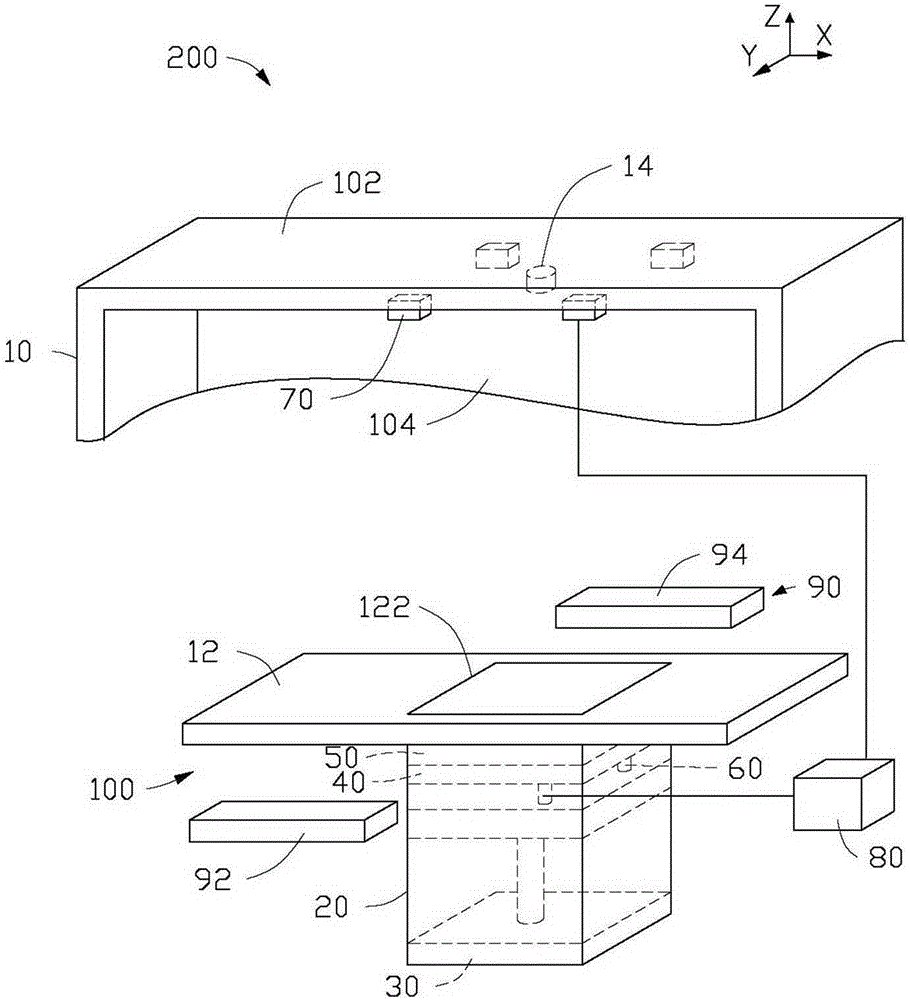

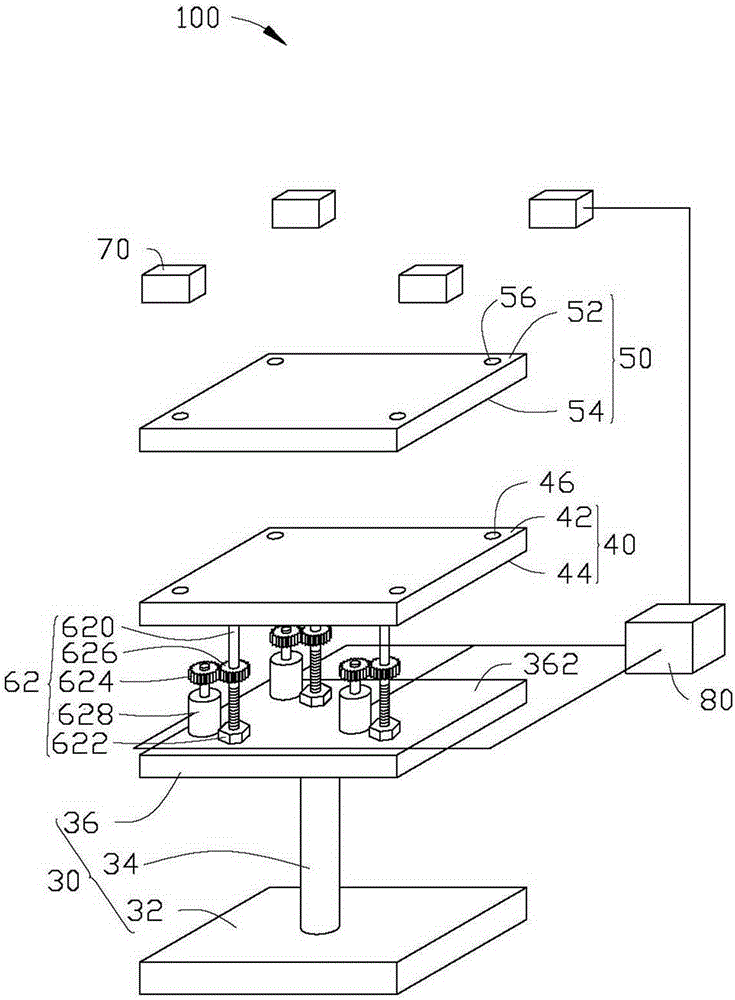

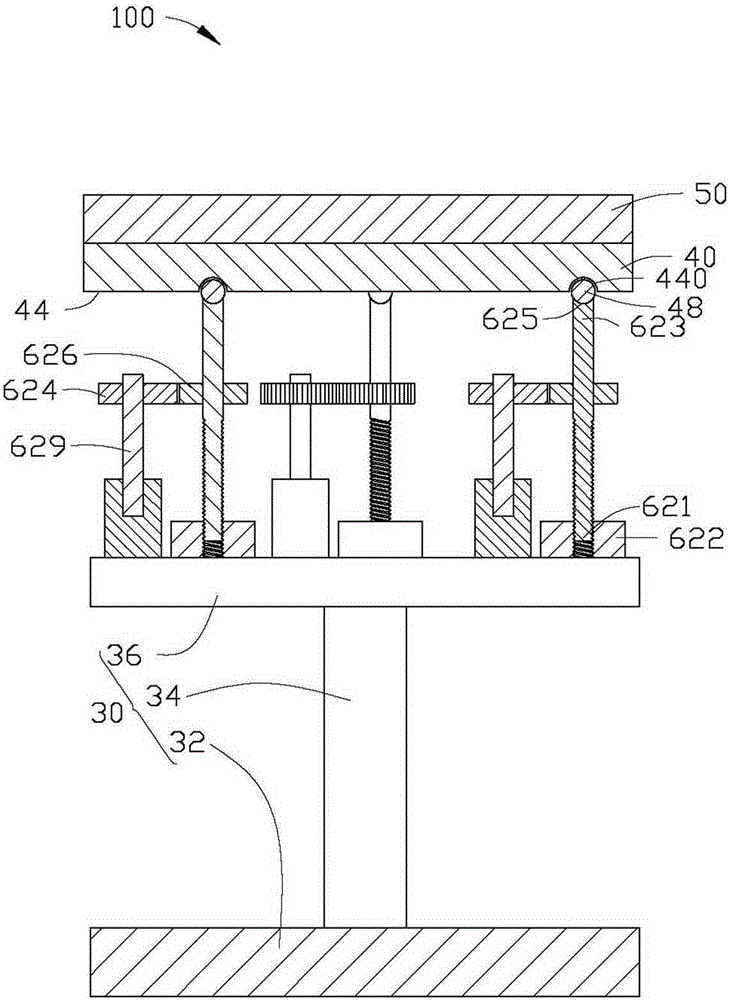

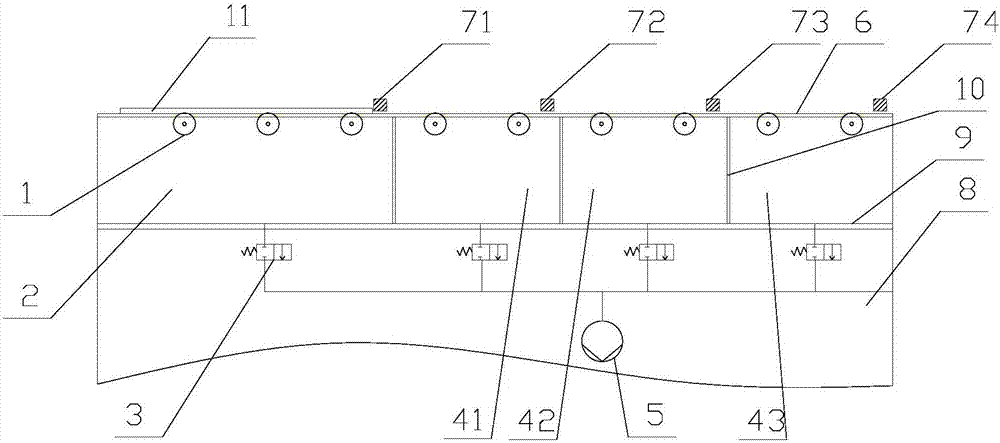

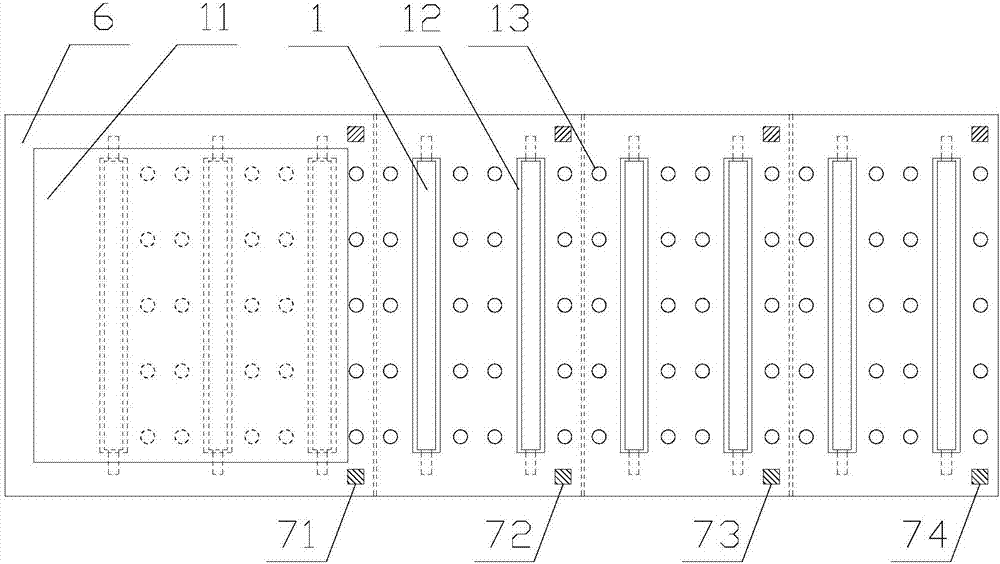

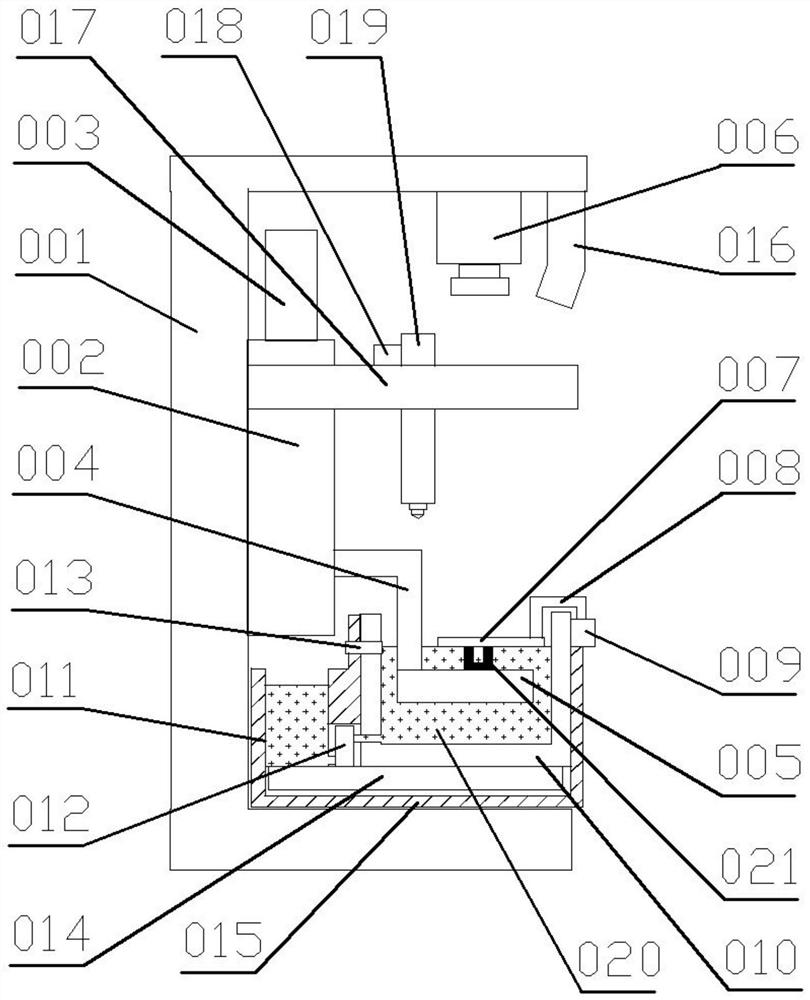

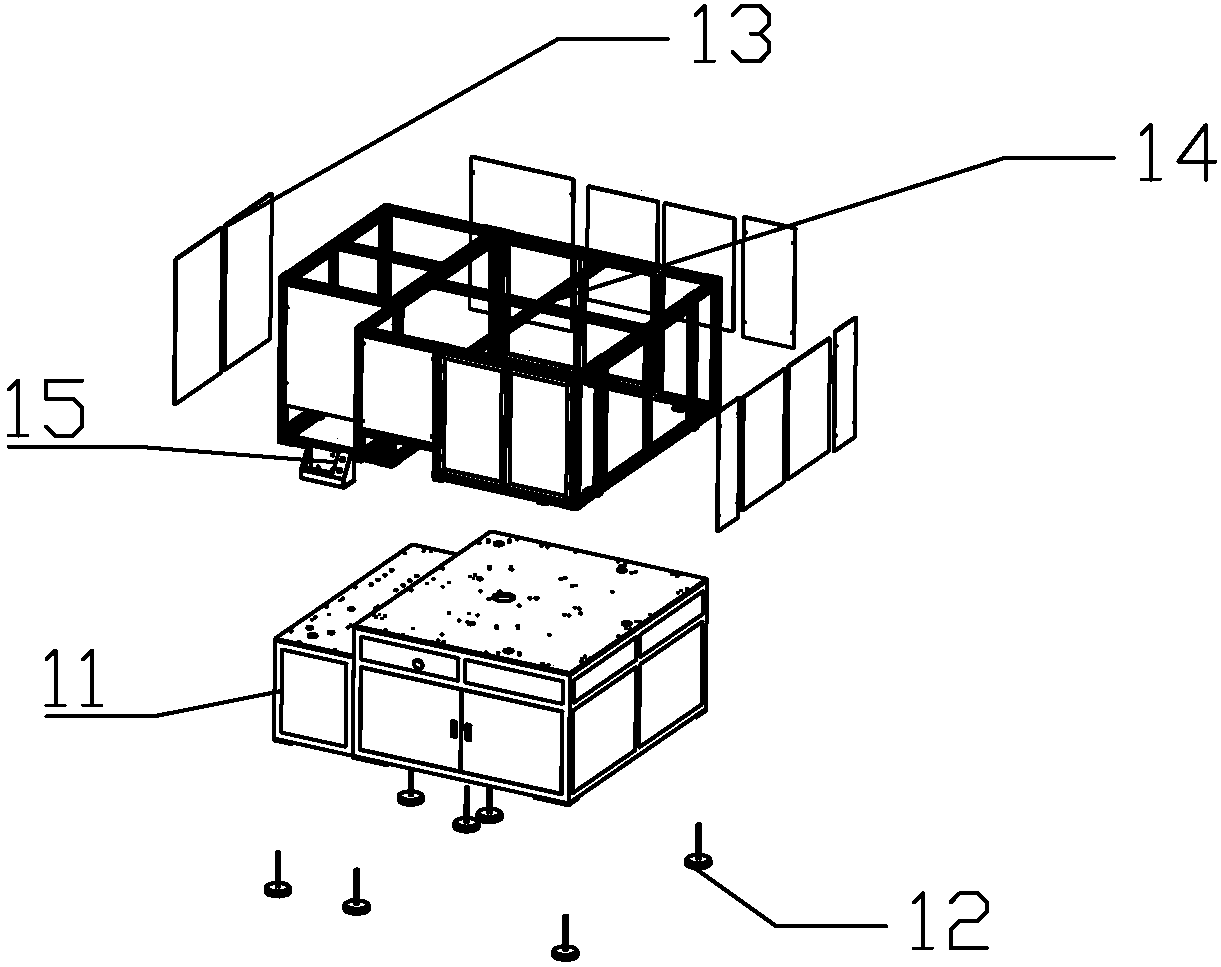

Intelligent 3D printing substrate leveling system and 3D printer

InactiveCN106553339AImprove printing efficiencyImprove printing yieldManufacturing platforms/substratesManufacturing data aquisition/processingNumerical control3d printer

The invention relates to an intelligent 3D printing substrate leveling system. The intelligent 3D printing substrate leveling system comprises a bearing substrate, a forming substrate fixed to the bearing substrate, four distance sensing devices located in the same horizontal plane, a numerical control unit storing a preset distance and a drive device. The plane is defined as a datum plane. The four distance sensing devices and the bearing substrate are located on the two back-to-back sides of the forming substrate correspondingly. The four distance sensing devices are aligned with the four corners of the forming substrate at intervals correspondingly and used for sensing the distance between the four corners of the forming substrate and the datum plane so as to output four distance signals. The numerical control unit receives four distance signals and calculates four distance deviations between the four distance signals and the preset distance. The drive device is movably connected with the bearing substrate, and at least three movable connecting positions are defined. The drive device drives the bearing substrate to ascend, descend or rotate relative to the movable connecting positions according to the four distance deviations so that the four distance deviations can be in the preset deviation range. The invention further provides a 3D printer.

Owner:GUANGDONG HANBANG 3D TECH CO LTD +1

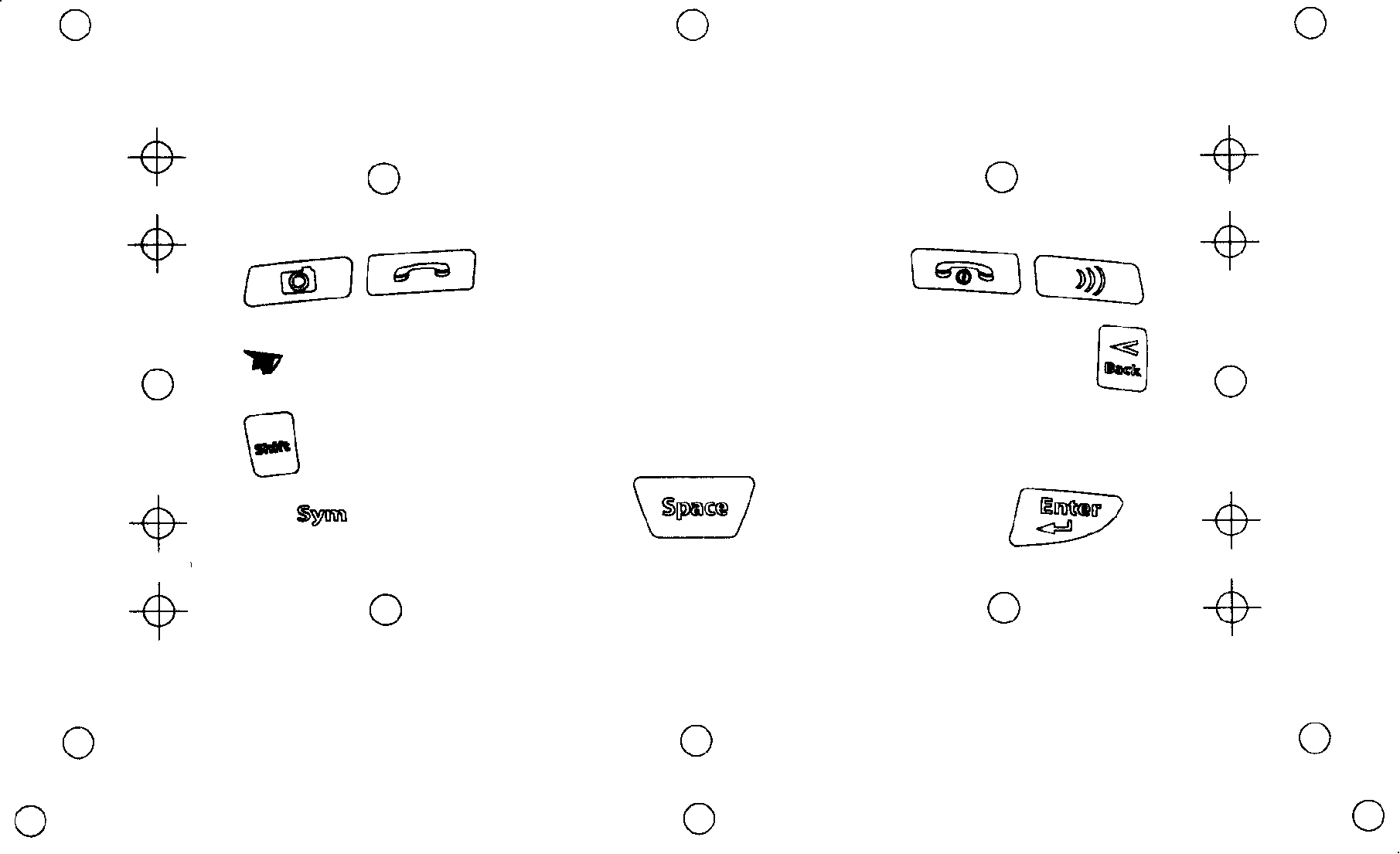

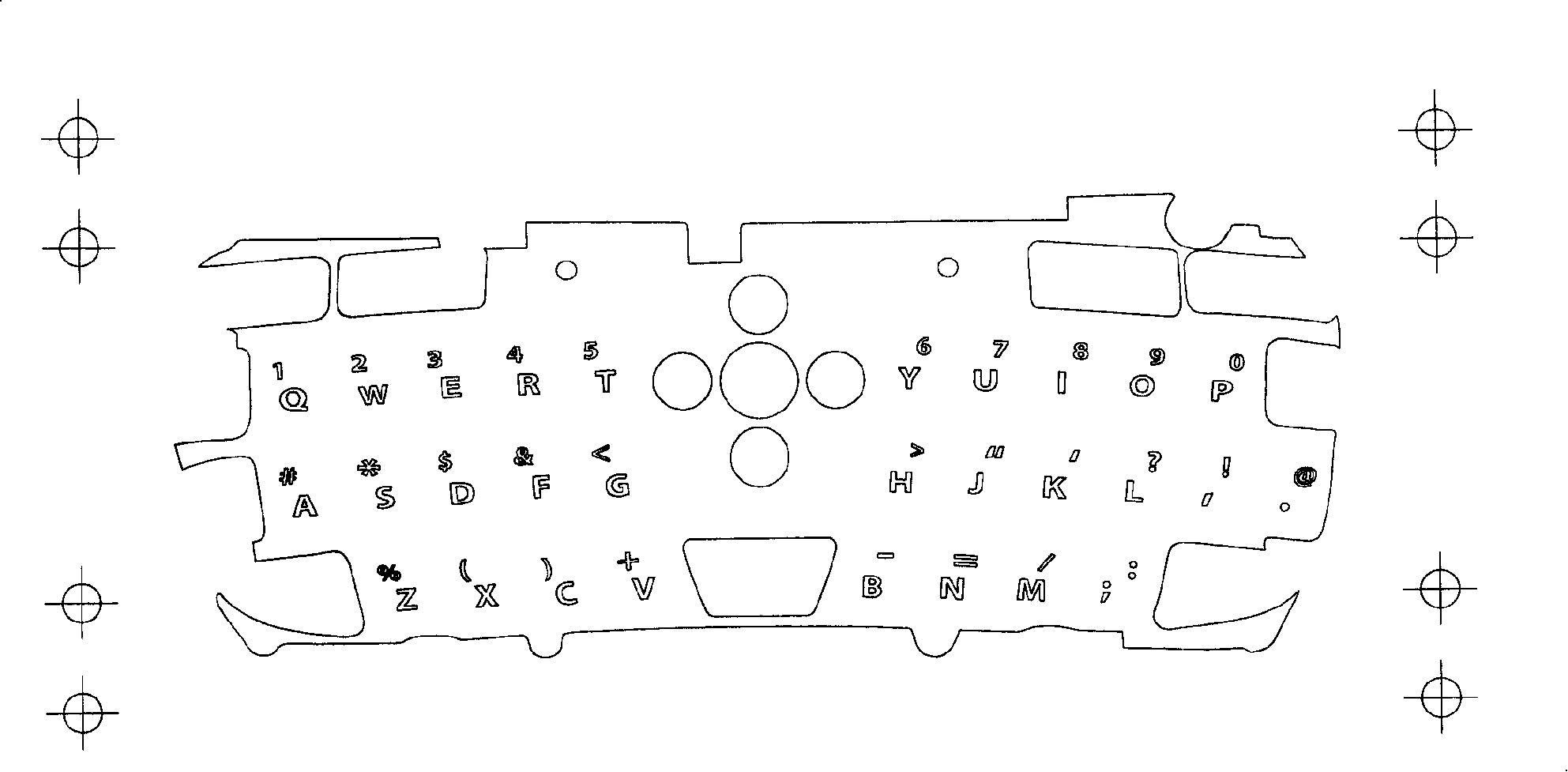

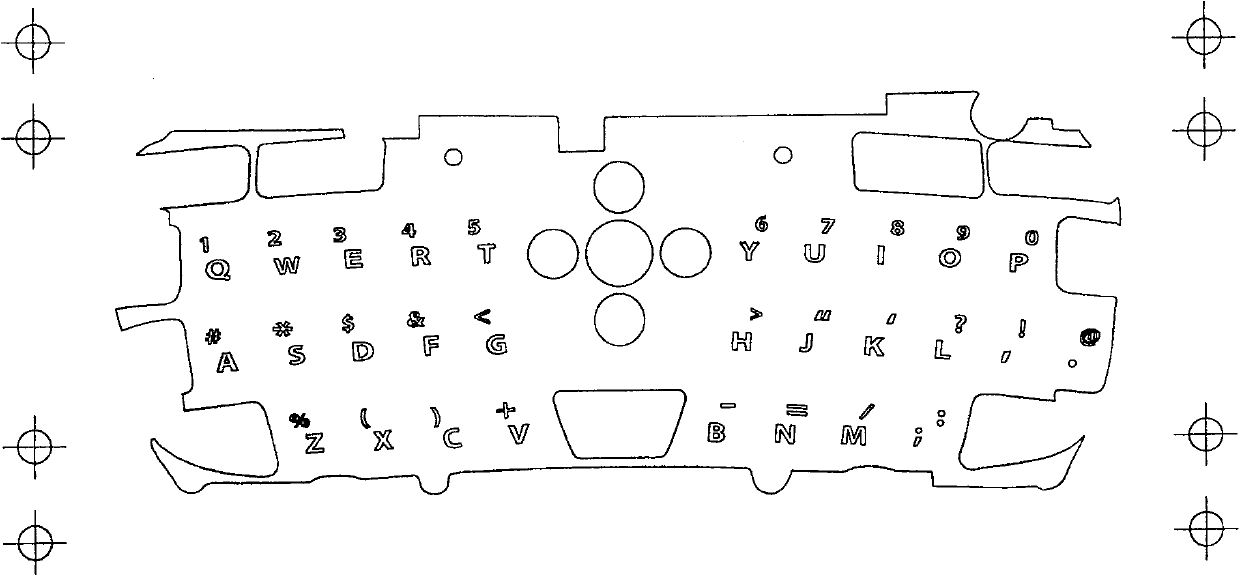

Chromaticity printing technique of in-mold label injection molding sheet material

ActiveCN101190615AReduce printing timesGuaranteed printing accuracyPattern printingOther printing apparatusPunchingAdhesive

The invention discloses an injection chromatic printing technique of a label in a mould, and the process is mainly to print a background color and a location hole simultaneously on a moldable sheet; the location hole is punched through by a digital controlling punching machine, then other colors are printed; after all ink is used out for printing, colorless adhesive or glossy oil is printed on a whole edition so as to prevent the ink from colliding when the injection is done; meanwhile, a level printing surface is formed, therefore any pressing trace can not appear on the surface of a keypad after the molding.

Owner:BYD PRECISION MFG

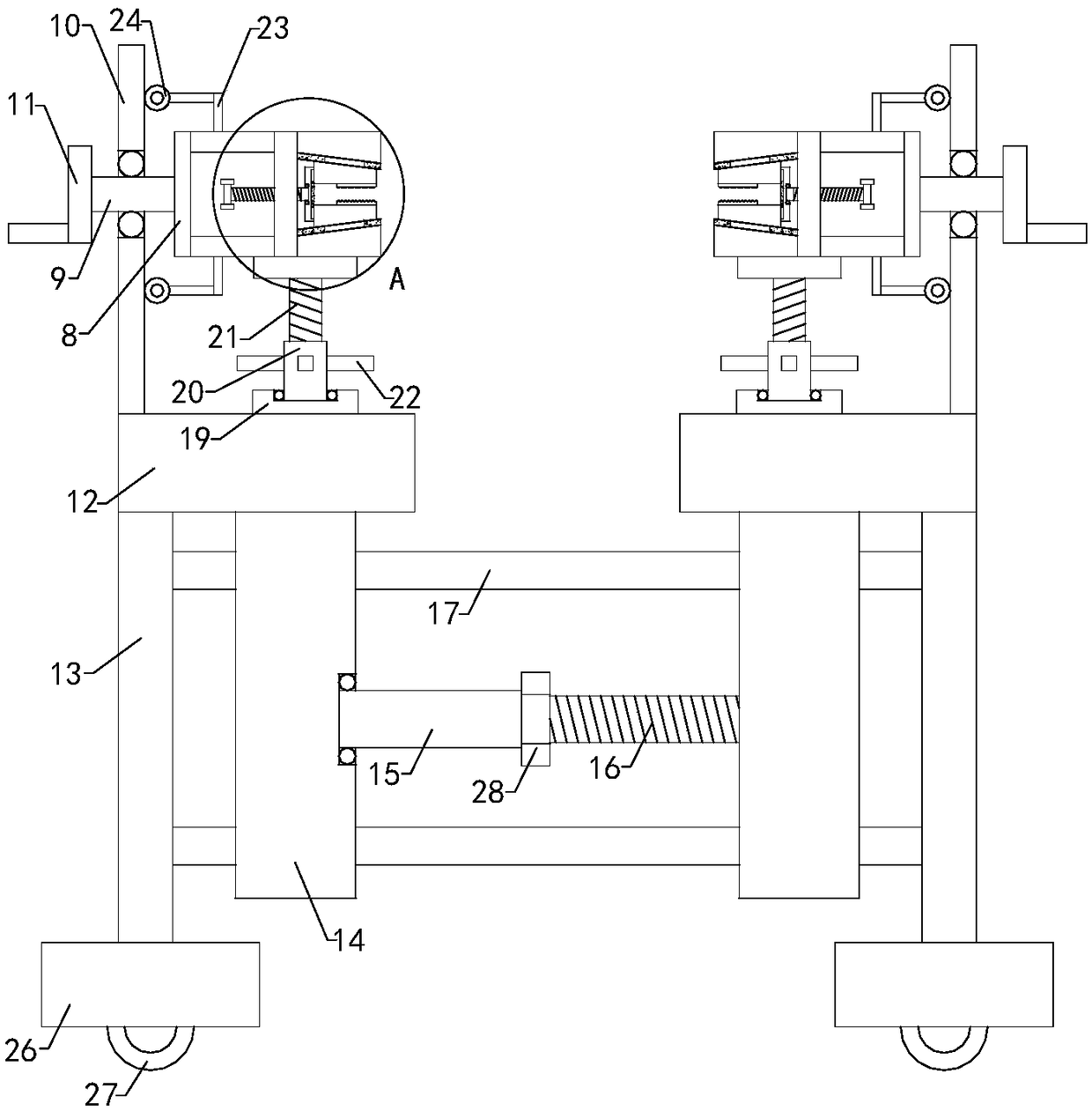

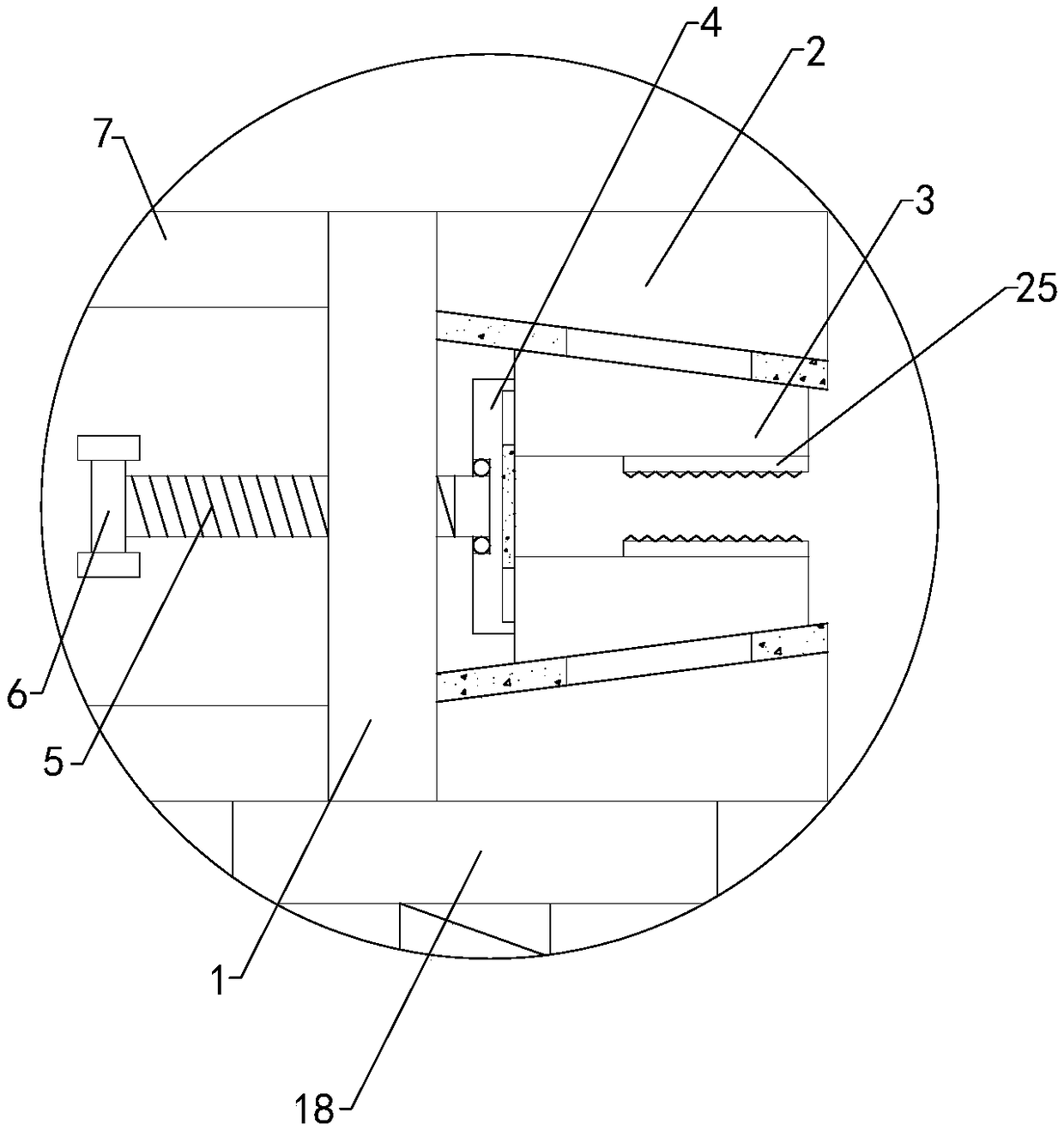

Auxiliary clamp for two-sided flexible circuit board printing correction

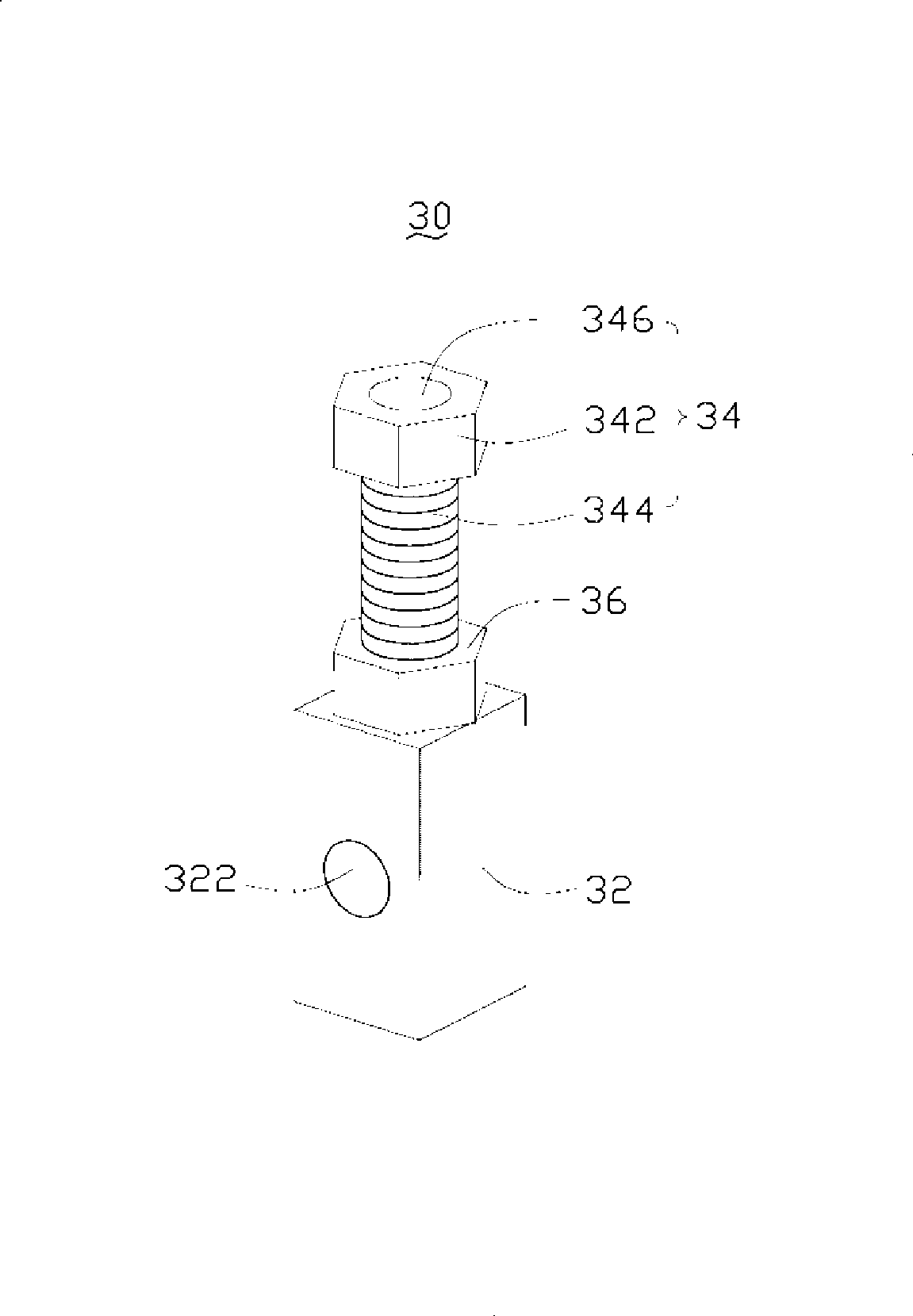

InactiveCN109327964AImprove clamping effectImprove use reliabilityPrinted circuit manufactureThreaded pipeFlexible circuits

The invention relates to the technical field of two-sided flexible circuit board accessory devices, in particular to an auxiliary clamp for two-sided flexible circuit board printing correction. The auxiliary clamp comprises a left fixing plate, a left upper retaining plate, a left lower retaining plate, a left upper clamping plate, a left lower clamping plate, a left push plate, a left adjusting screw rod, a left knob, a right fixing plate, a right upper retaining plate, a right lower retaining plate, a right upper clamping plate, a right lower clamping plate, a right push plate, a right adjusting screw rod, a right knob, a left upper side plate, a left blocking plate, a left lower side plate, a left rotating shaft, a left supporting plate, a left hand wheel, a right upper side plate, a right blocking plate, a right lower side plate, a right rotating shaft, a right supporting plate, a right hand wheel, a left placement plate, a right placement plate, a left supporting plate, a right supporting plate, a left adjusting block, a right adjusting block, a first threaded pipe, a first threaded rod, an upper connection slide column and a lower connection slide column. The auxiliary clamphas advantages that clamping effects can be improved, and reliability in use is improved; practicality is improved due to availability for direct turning; due to expansion adjustment, printing qualityis improved, and limitation in use is lowered.

Owner:YANCHENG HUAYU PHOTOELECTRIC TECH CO LTD

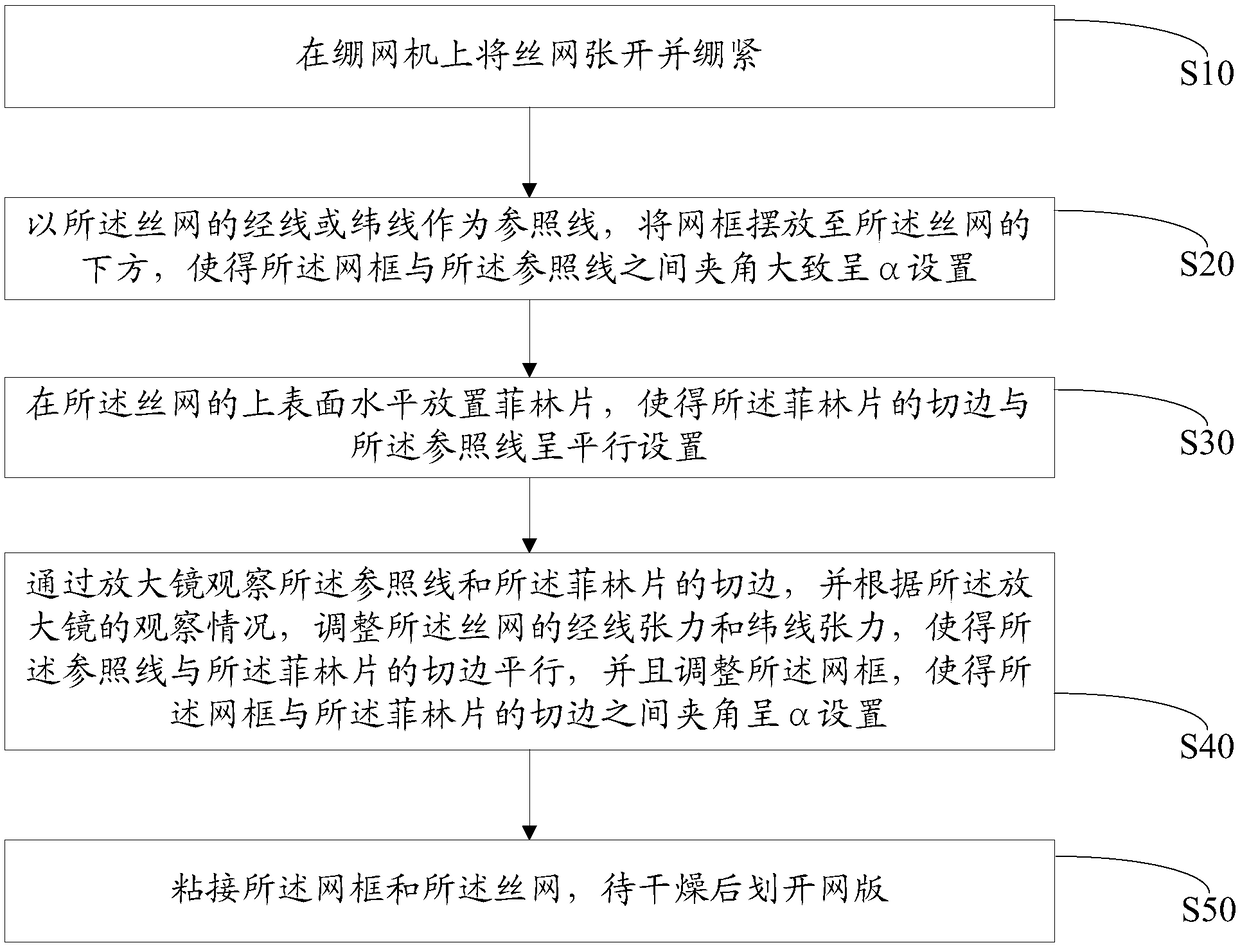

Tension method of printing polyester screen

ActiveCN108859390AImprove aliasing problemReduce the difference between peak and troughForme preparationPolyesterPulp and paper industry

The invention discloses a tension method of a printing polyester screen. By adopting the technical scheme, the tension method has the advantage that warp yarns, weft yarns and a screen framework of the screen are calibrated by films, so that the edges of the screen framework maintain the standard preset angle with the warp yarns or weft yarns of the screen, then the screen adhering and glue setting are performed, the difference between wave peak and wave valley of sawtooth after screen exposing is obviously reduced, the problem of sawtooth in screen and printing is greatly relieved, and the qualified rate in printing is improved.

Owner:SHENZHEN INKTOP INK TECH CO LTD

Low-temperature conductive printed circuit board silver slurry and preparation method thereof

InactiveCN103996429AReduce dosageLow melting pointNon-conductive material with dispersed conductive materialCable/conductor manufactureEpoxyIndium tin oxide

Disclosed is a low-temperature conductive printed circuit board silver slurry. The slurry is prepared by use of the following raw materials in parts by weight: 6-9 parts of indium tin oxide, 4-6 parts of 1-10 nm sheet-like silver powder, 4-6 parts of 40-50 nm spherical silver powder, 50-60 parts of 1-10 [mu]m sheet-like silver powder, 5-7 parts of an E-12 epoxy resin, 1-2 parts of a silicone resin, 12-15 parts of xylene, 7-10 parts of n-butanol, 1-2 parts of a polyurethane resin, 0.4-0.8 parts of isophorone diamine, 1-2 parts of dipentene, 2-4 parts of lignine, 0.4-0.8 parts of ethylene bis oleamide, and 11-14 parts of glass powder. According to the invention, the indium tin oxide is added to the slurry, less silver powder is consumed, the conductivity is good under the condition of a low temperature, and excellent conducting effect is achieved through matching of the silver powder in different particle sizes and different shapes; and the glass powder is low in melting point and small in heat expansion ratio, such that the circuit printing yield is high, and the conducting performance is good.

Owner:CHIZHOU HUASHUO ELECTRONICS TECH

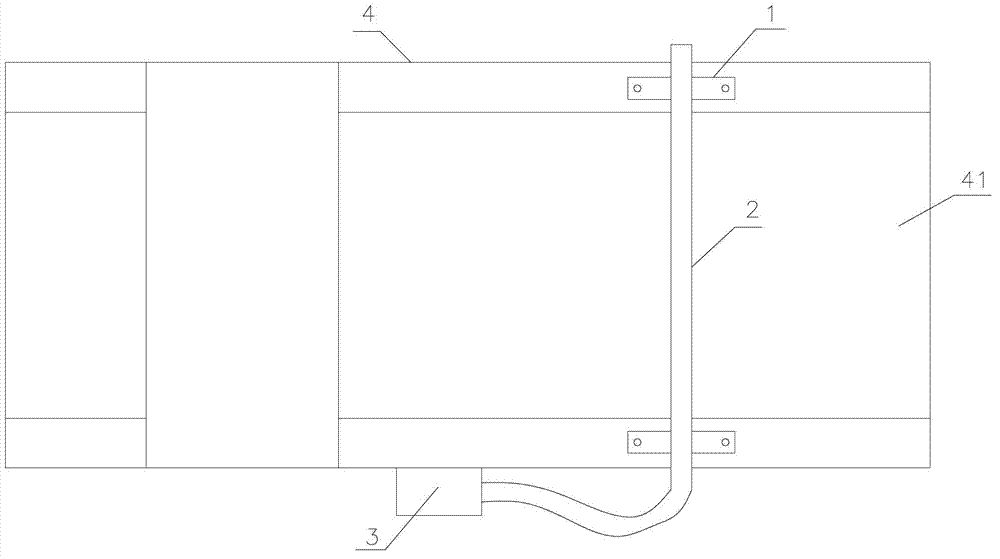

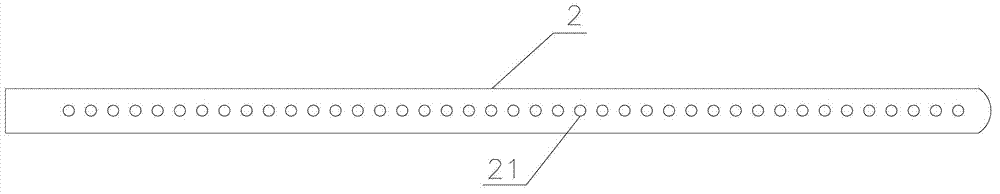

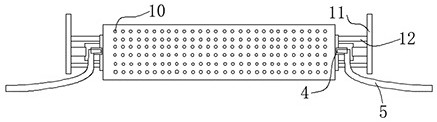

Silicon wafer surface cleaning device of solar cell printer

InactiveCN102806762AEasy to collectImprove printing yieldPrinting press partsSurface cleaningEngineering

The invention relates to a silicon wafer surface cleaning device of a solar cell printer. The silicon wafer surface cleaning device of the solar cell printer comprises a bracket, a blowing pipe and an air source; a pipe opening at one end of the blowing pipe is sealed; an pipe opening at the other end of the blowing pipe is open; the opened pipe opening of the blowing pipe is communicated with the air source through a pipeline; a plurality of blowing holes are arranged on the pipe wall of the blowing pipe; the air source is arranged on the solar cell printer; the brackets are arranged at the two sides of a conveyer belt of the solar cell printer, and the blowing pipe is arranged on the bracket. The silicon wafer surface cleaning device of the solar cell printer carries out cleaning work right opposite to a silicon wafer by adding the blowing pipe on the conveyer belt of the solar cell printer, blowing air through the air source and ventilating through the blowing holes, and can blow away silicon nitride particles and the like on the silicon wafer surface, so that the printing yield is improved, and collection of current on the silicon surface is increased, thereby improving the photoelectric conversion efficiency.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Rotary screen printing white ink and preparation method thereof

The invention provides rotary screen printing white ink and a preparation method thereof. The rotary screen printing white ink comprises the components in parts by mass: 15-30 parts of a polyurethane acrylate oligomer, 3-10 parts of an ultraviolet initiator, 40-55 parts of titanium dioxide, 5-10 parts of dipentaerythritol hexaacrylate, 10-20 parts of hexanediol diacrylate, 0.5-1 part of a dispersing agent, 0.5-2 parts of a leveling agent, 0.2-2 parts of an antifoaming agent and 0.1-0.5 part of a polymerization inhibitor, wherein the polyurethane acrylate oligomer comprises a bifunctional polyurethane acrylate oligomer and a hexafunctional polyurethane acrylate oligomer; and the defoaming agent is selected from one or more of a polyether defoaming agent, an amine defoaming agent and an amide defoaming agent. The rotary screen printing white ink shows a satisfactory printing effect when performing field printing and character printing at the same time, and has excellent and balanced drying speed and adhesion at the same time.

Owner:中山布瑞特环保油墨有限公司

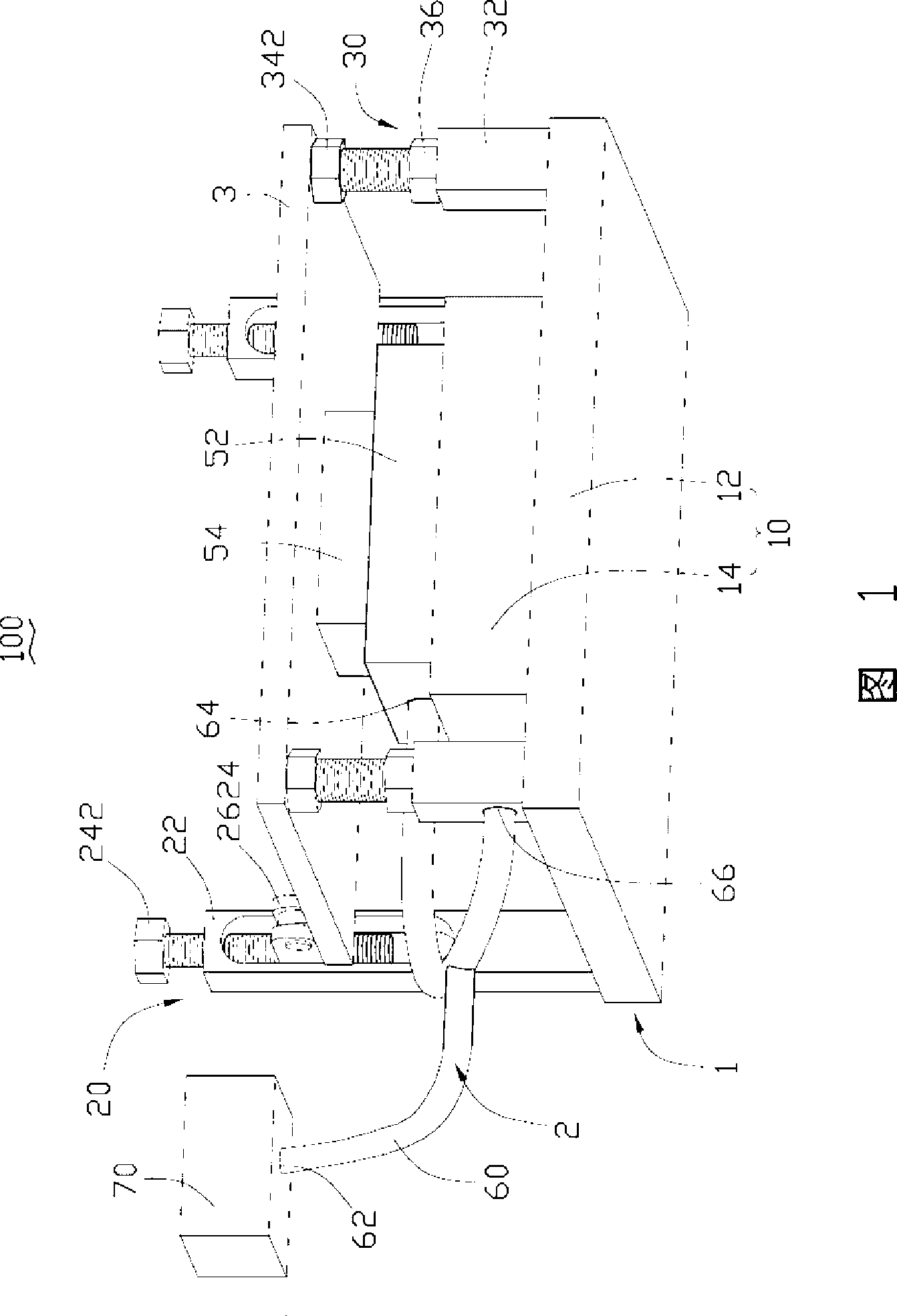

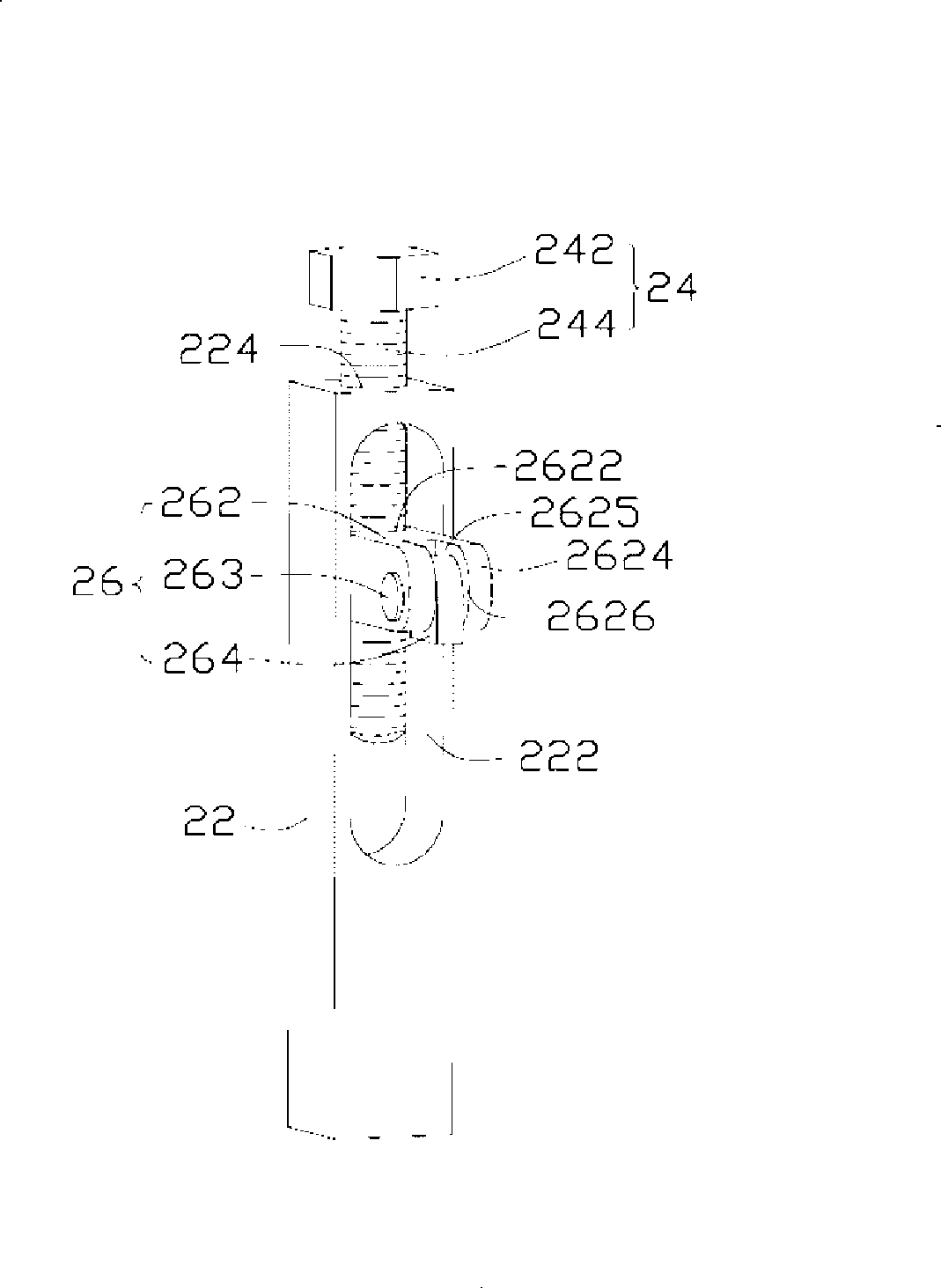

Positioning apparatus and print device using the positioning apparatus

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

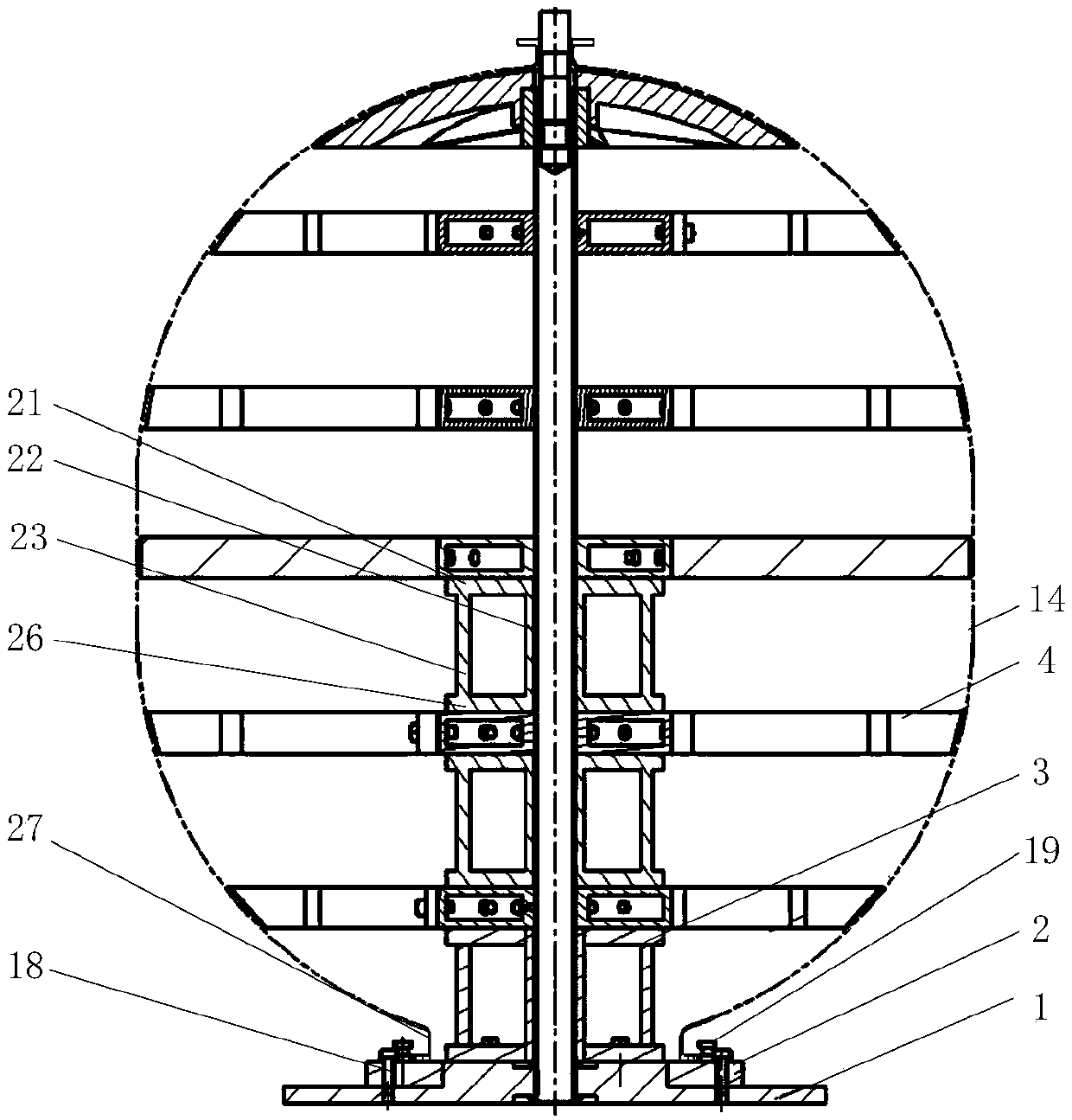

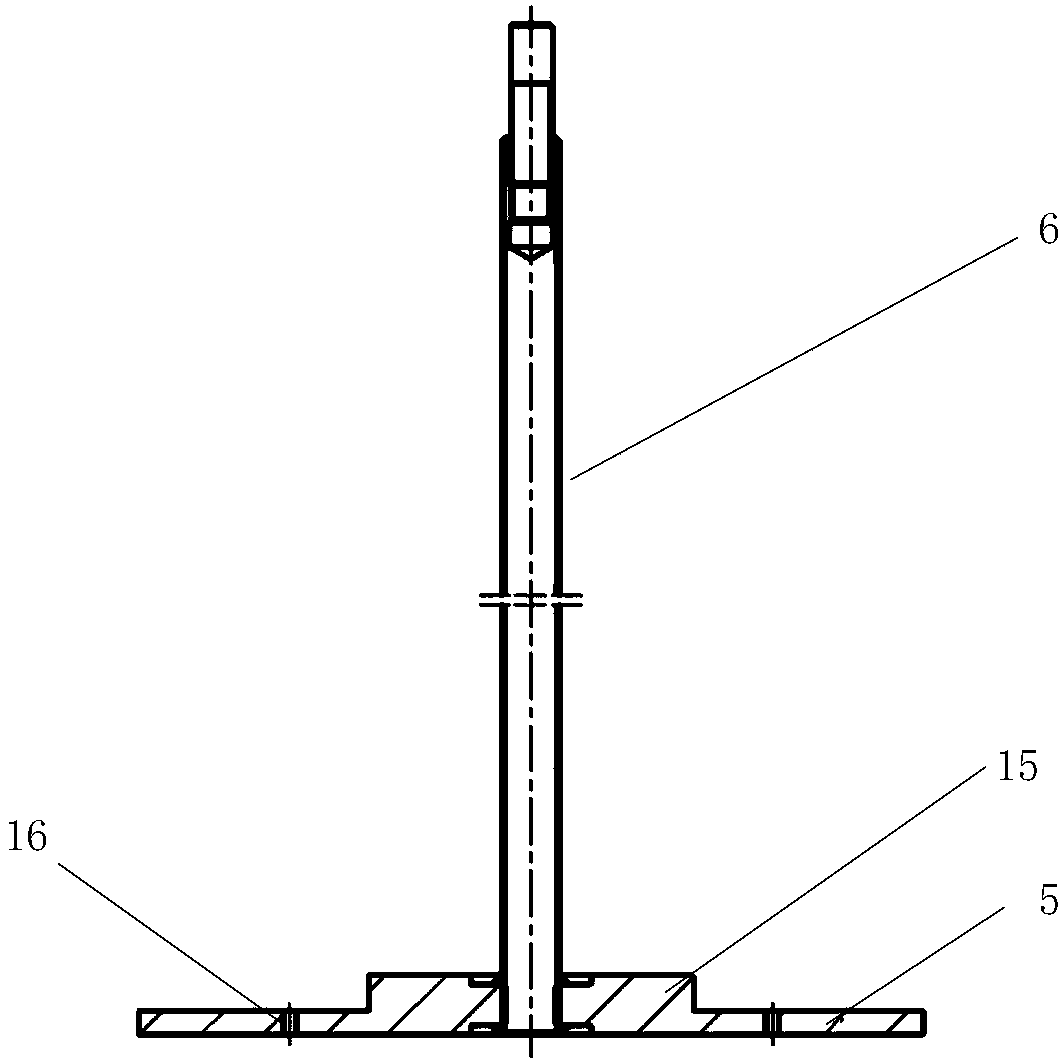

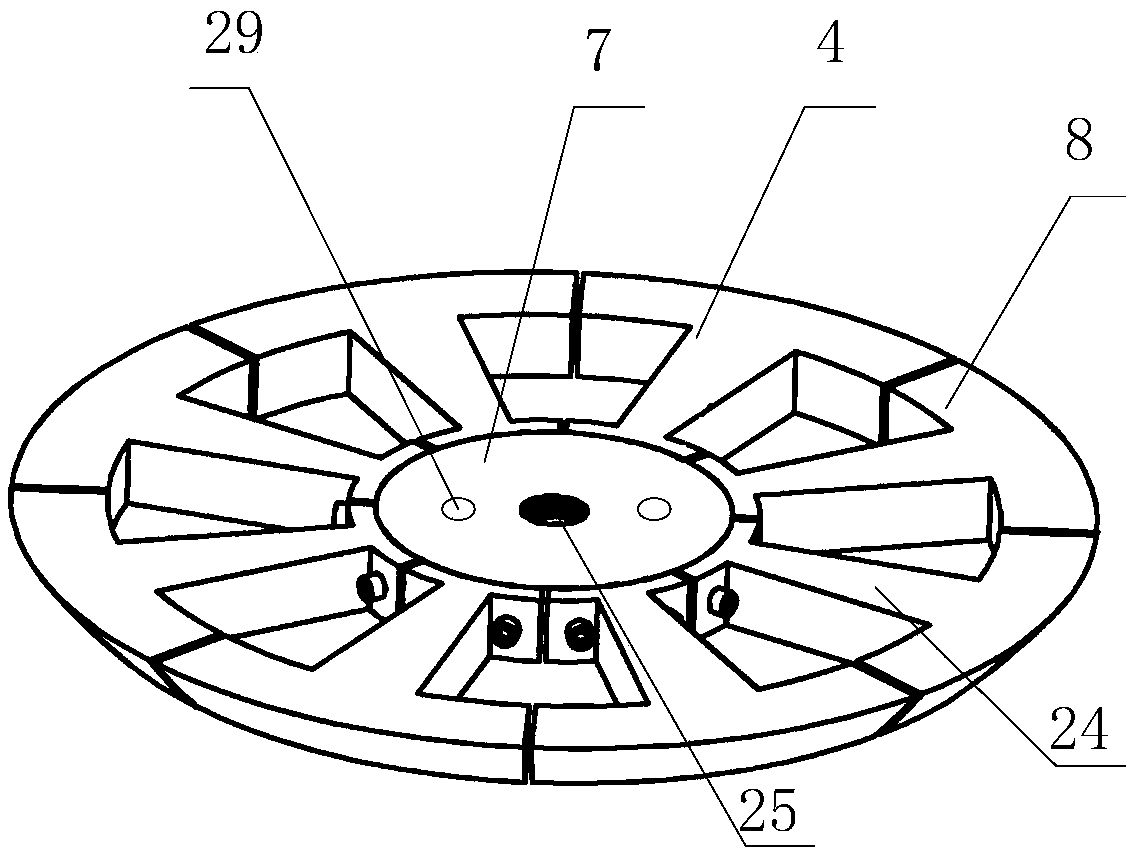

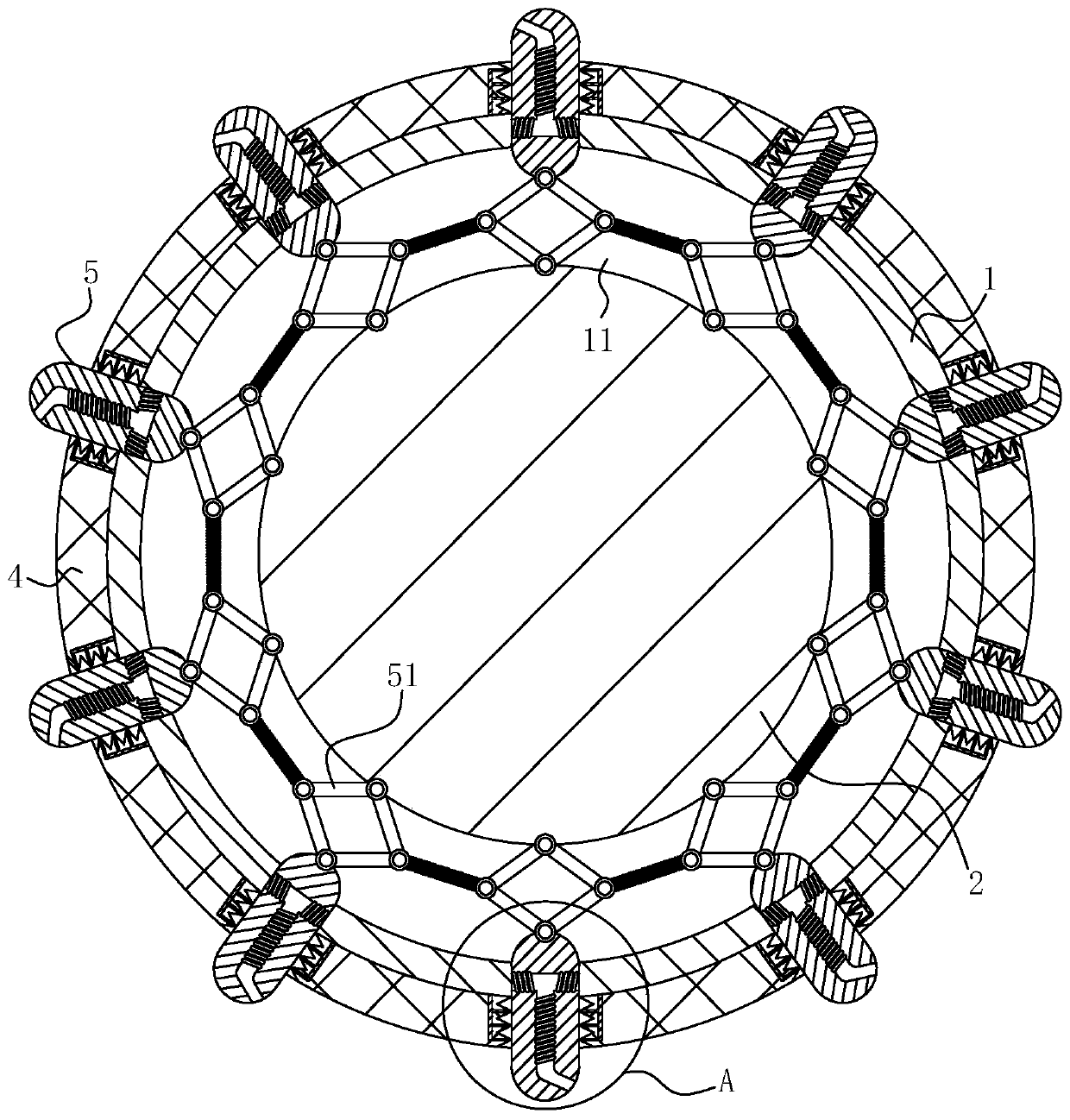

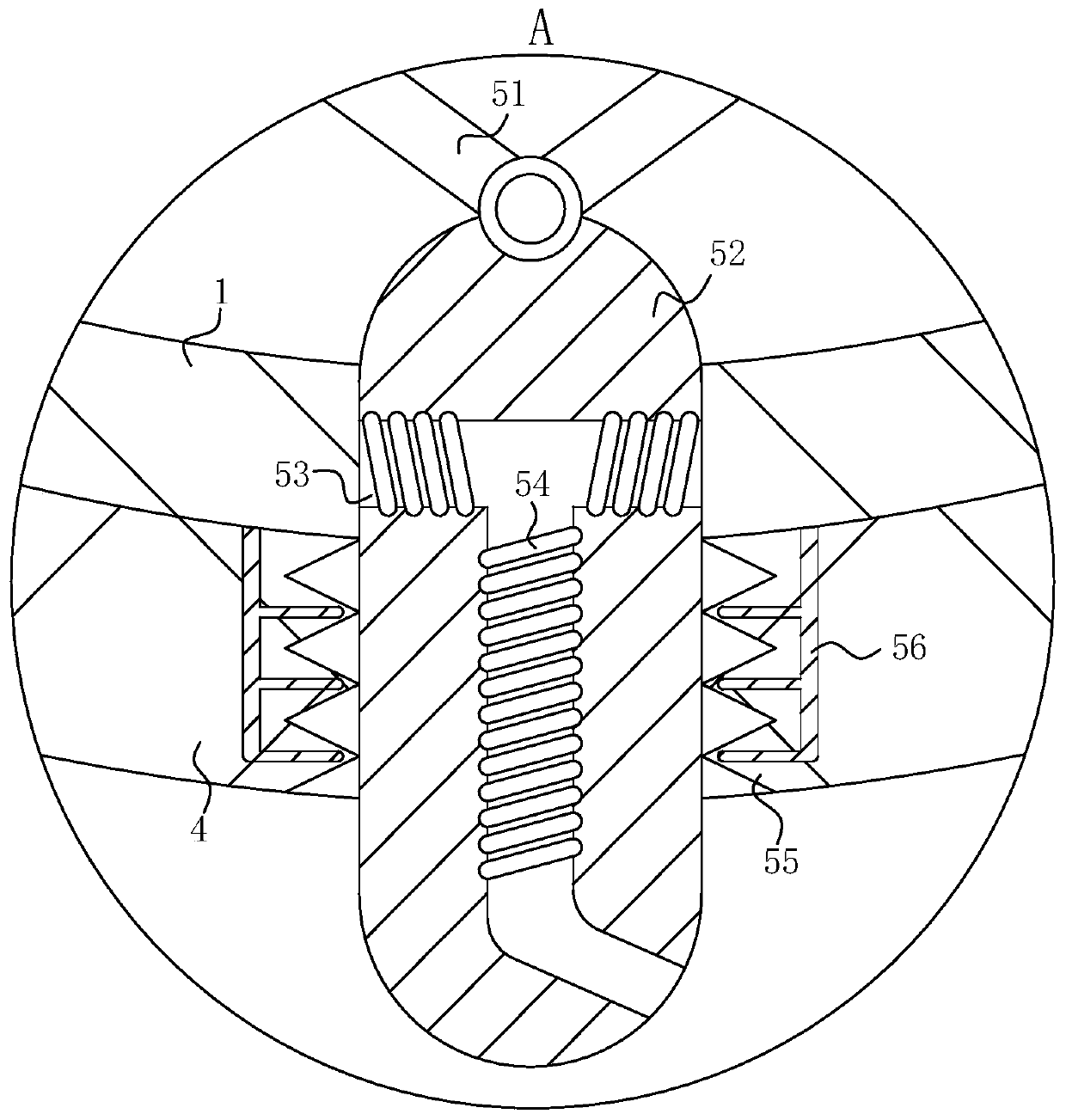

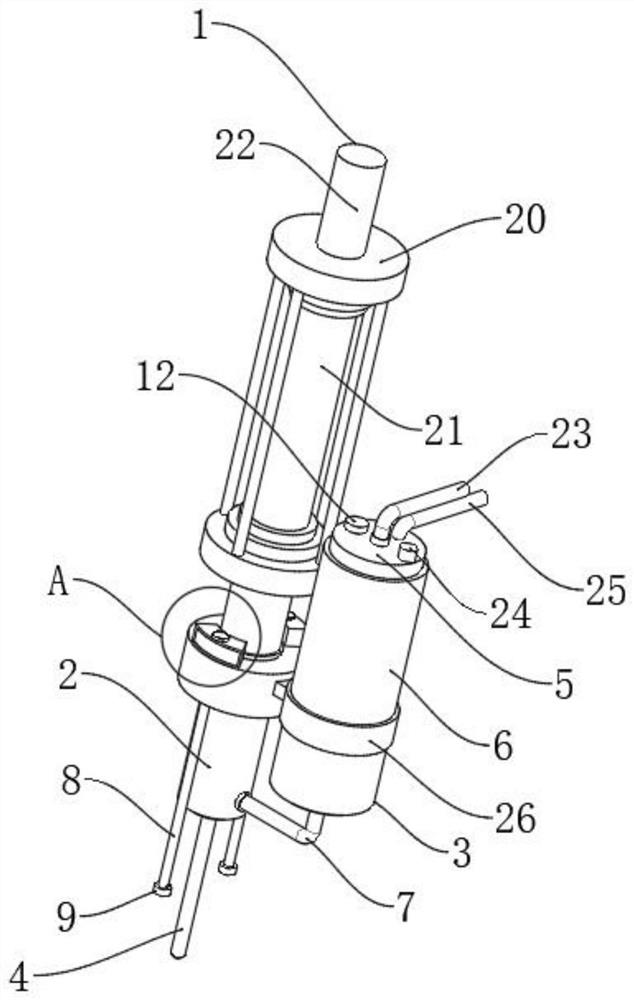

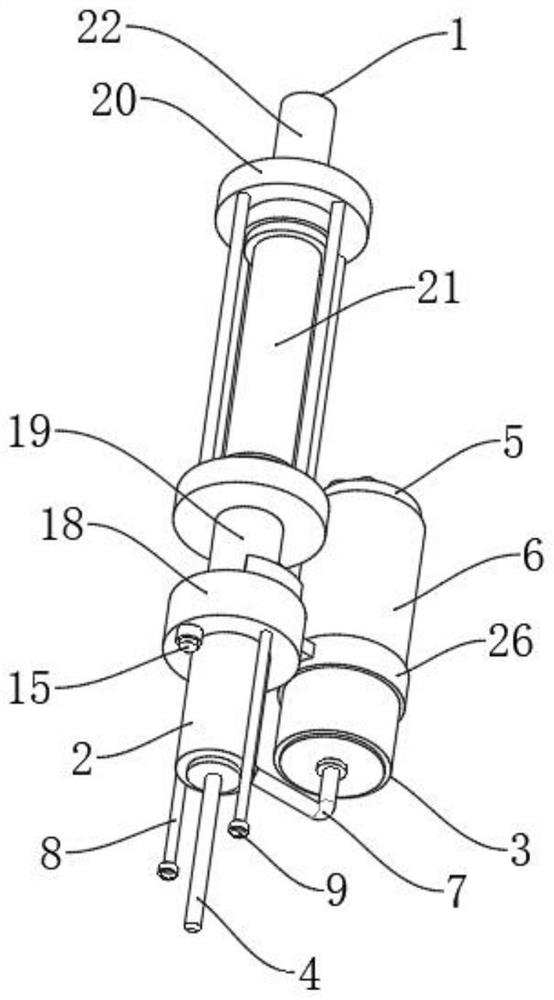

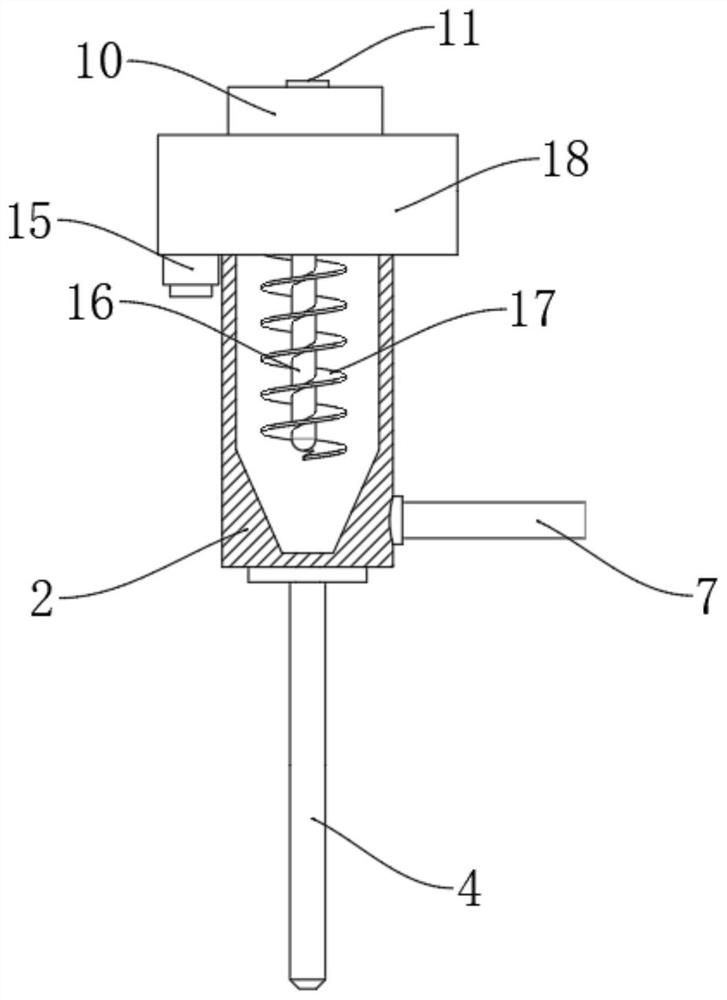

Additive manufacturing thin-wall rotating member anti-deformation device and application method thereof

ActiveCN109570501APlay a supporting roleImprove printing yieldAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringAdditive layer manufacturing

The invention discloses an additive manufacturing thin-wall rotating member anti-deformation device and an application method thereof. According to the characteristics that the cross-sectional size ofan additive manufacturing thin-wall rotating member changes continuously along with the change of height and the size of the thin-wall rotating member is larger, the size of a support frame further changes continuously, that is, a fixed screw rod is used as a vertical support frame in the vertical direction, and the outer diameters of transverse support rings change continuously along with the change of the size of the rotating member; and the outer diameter of the support ring at the vertical center position is the largest, and the outer diameters of the support rings are gradually reduced upward or downward, and the outer walls of the support rings are always in contact with the inner wall of the rotating member to play a supporting role. According to the additive manufacturing thin-wall rotating member anti-deformation device, the size of the device can be stably controlled within a range of manufacturing blanks, so that the printing yield is improved; and the device is an assemblypart, and can be disassembled integrally or in parts, so that cyclic utilization is convenient.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Method for coating water-transferring printing backing paper

InactiveCN102191719AAbsorbentSlow down soaking penetrationCoatings without pigmentsPulp material addition processesCelluloseChemical industry

The invention belongs to the chemical industry and in particular relates to a method for coating water-transferring printing backing paper. The method is characterized in that: the water-transferring printing backing paper is coated at one time by adopting a mixture prepared from the following components in the weight ratio of rubber powder to hydroxypropyl methylcellulose to polyacrylamide to water of 100:(1-5):(0.5-1):(250-350). The method comprises the following specific steps of: dissolving and stirring the rubber powder and the water in the ratio at the temperature of 85 to 95 DEG C at first; reducing the temperature to 45 to 55 DEG C, adding the proportionally prepared hydroxypropyl methylcellulose and stirring; after stirring, transferring the stirred glue into a reaction kettle of a high-speed stirrer, adding the proportionally prepared polyacrylamide and stirring. In the method, by adoption of one-time coating, the cost is lower and the yield rate is higher.

Owner:陈顺环

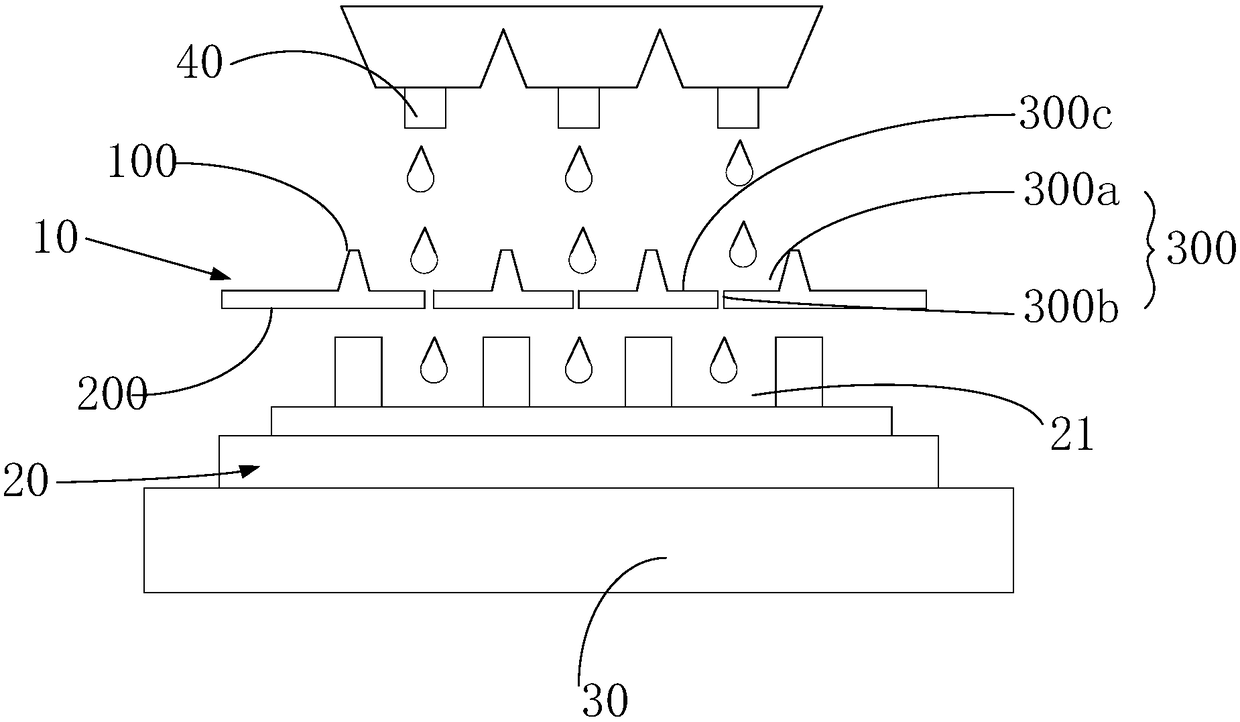

Guide plate, ink-jet printing method and device, display substrate and manufacturing method and device of display substrate

ActiveCN108382092AAvoid typographical errorsDrip correctlyDuplicating/marking methodsSolid-state devicesBiomedical engineeringInkjet printing

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

Printer and paper conveying mechanism thereof

A printing machine and its paper feeding mechanism. The paper feeding mechanism includes a frame, a bellows part, a conveying part, an exhaust part and a detection part. The bellows part includes a plurality of bellows arranged side by side in succession and transversely to the paperboard conveying direction, each bellows is connected to the suction source through a switching mechanism, and a pair of bellows are arranged above the end of the paper feeding stroke. Photoelectric sensor, during the paper feeding process, the position of the cardboard is checked by the photoelectric sensor, so as to control the action of the cutting mechanism, so that the suction source only needs to exhaust the bellows under the cardboard, which is beneficial to reduce energy consumption, and can choose a higher Low-power suction source equipment, and when the cardboard is sent crookedly, it can stop the machine in time to reduce waste and improve the printing yield.

Owner:湖南美奕机电科技有限公司

Preparation method of flame-retardant and waterproof adhesive for corrugated carton

ActiveCN110551470AReduce dosageImprove flame retardant performanceNon-macromolecular adhesive additivesGraft polymer adhesivesWater basedPolymer science

The invention belongs to the technical field of adhesives, and particularly relates to a preparation method of a flame-retardant and waterproof adhesive for a corrugated carton. The preparation methodspecifically comprises the following steps: (1) an organic silicon modified emulsion is prepared; (2) a white prepolymer emulsion is prepared; (3) an acrylic modified flame-retardant organic siliconemulsion is prepared; and (4) 110-120 parts of the acrylic modified flame-retardant organic silicon emulsion is put into a high-speed mixer, 1.5-2.3 parts of carnallite powder, 24-27 parts of polyhalite powder and 5-7 parts of a flame retardant are added, even stirring and mixing are conducted, and then the flame-retardant and waterproof adhesive is obtained. The prepared adhesive is transparent,high in adhesion and good in stability, water-based adhesive bonding, quick drying, and acid and alkali resistance are achieved, no organic solvent is contained, the poisonless, tasteless, non-combustible, environment-friendly and pollution-free effects are achieved, and pollution-free production can be achieved. The flame-retardant and waterproof adhesive is suitable for the carton not coated andpolished, and the corrugated carton is protected very well.

Owner:马鞍山市康辉纸箱纸品有限公司

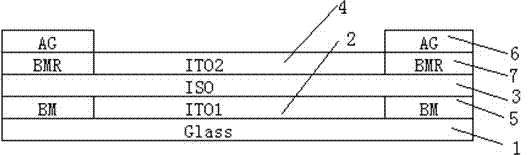

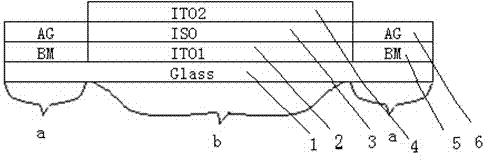

OGS touch screen structure and manufacturing method

InactiveCN104765496AReduce the number of layersImprove printing yieldInput/output processes for data processingEngineering

Owner:SHANDONG HUAXIN FUCHUANG ELECTRONICS SCI & TECH

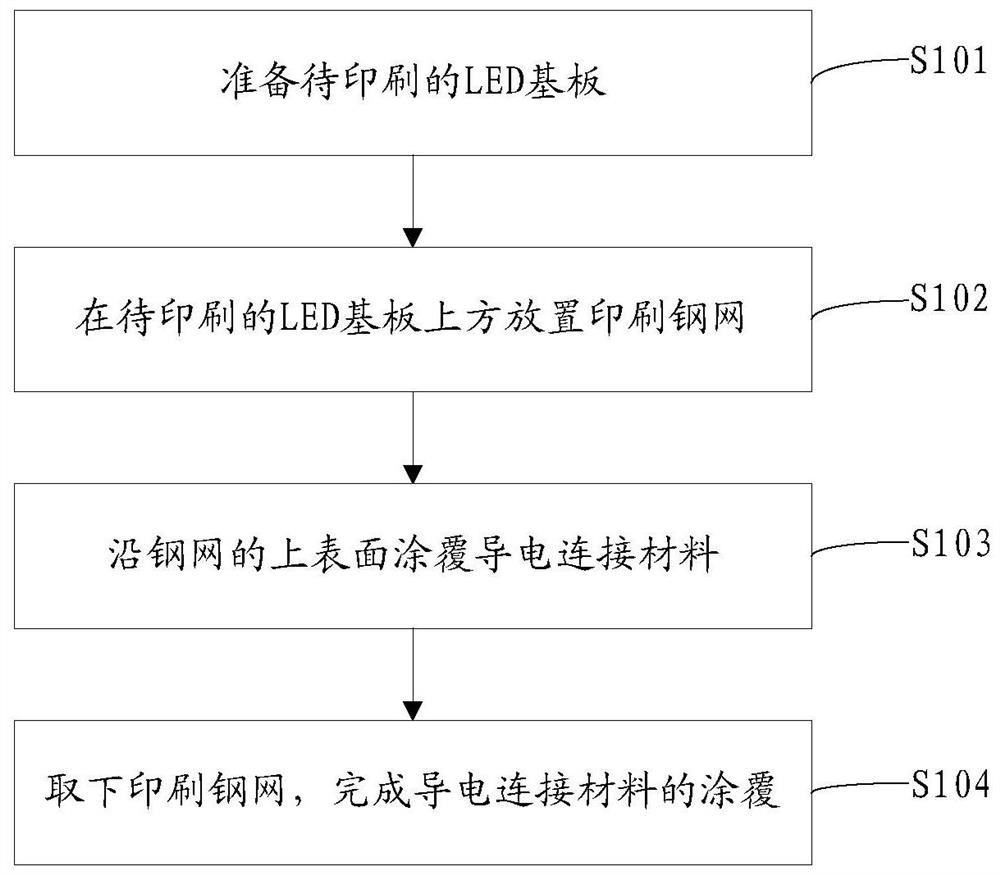

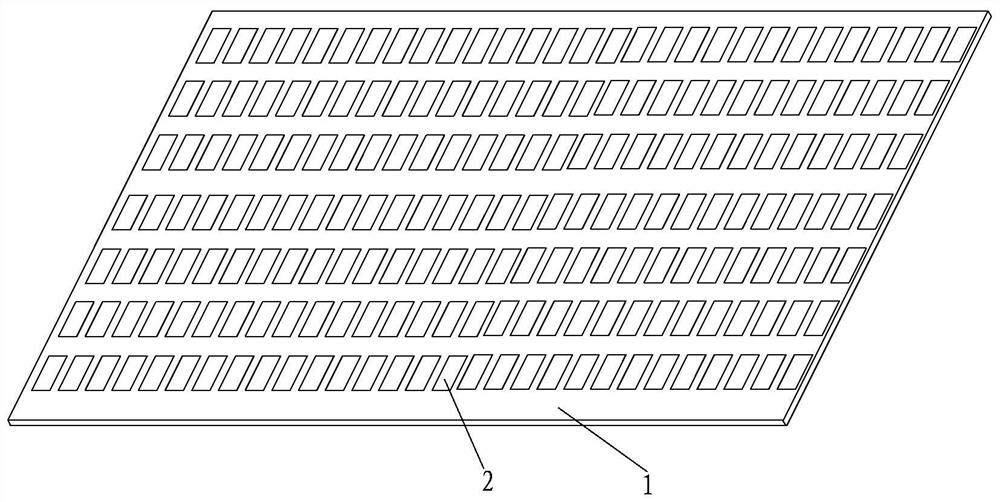

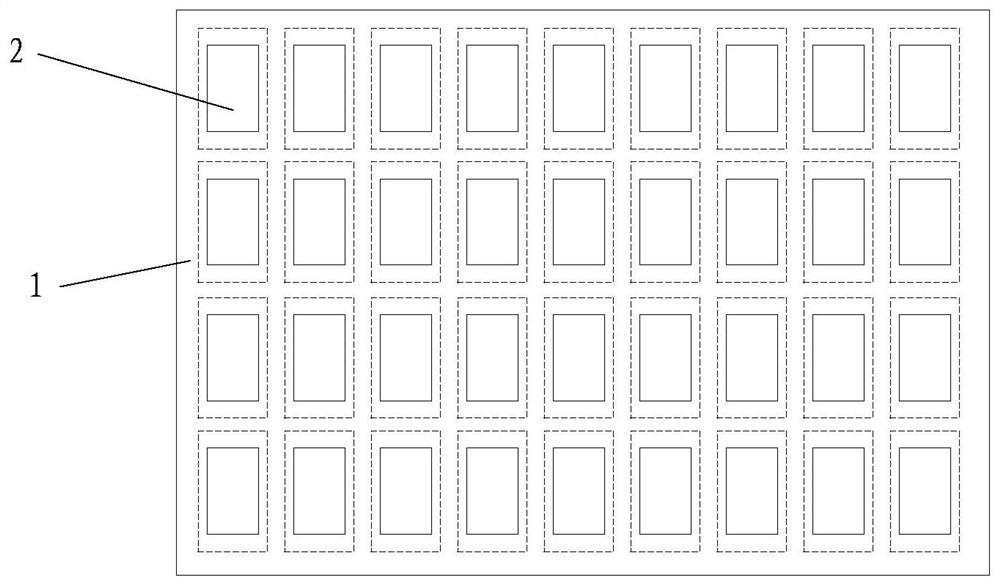

LED printing method

InactiveCN112951953AIncrease success rateImprove printing yieldScreen printersSemiconductor devicesAdhesive glueEngineering

The invention provides an LED printing method. The LED printing method comprises the steps: preparing an LED substrate to be printed; placing a printing net above an LED substrate to be printed, wherein the printing net is a blocky flat plate, a plurality of via holes penetrating through the upper surface and the lower surface of the flat plate are formed in the flat plate, and the hole diameters of the via holes are gradually increased in the direction from the upper surface to the lower surface of the flat plate, and the arrangement position of the via hole corresponds to a bonding pad area on the LED substrate; coating a conductive connecting material along the upper surface of the printing net, injecting the conductive connecting material into the via holes, and coating the conductive connecting material on the corresponding bonding pad areas; taking down the printing net, and completing the coating of the conductive connecting material. Therefore, the through holes of the printing screen are set to be big-end-down, the problem that glue and solder paste are not demolded is solved to a great extent, the success rate of LED installation is improved, and the LED printing yield is further improved.

Owner:SHENZHEN JUFEI OPTOELECTRONICS CO LTD

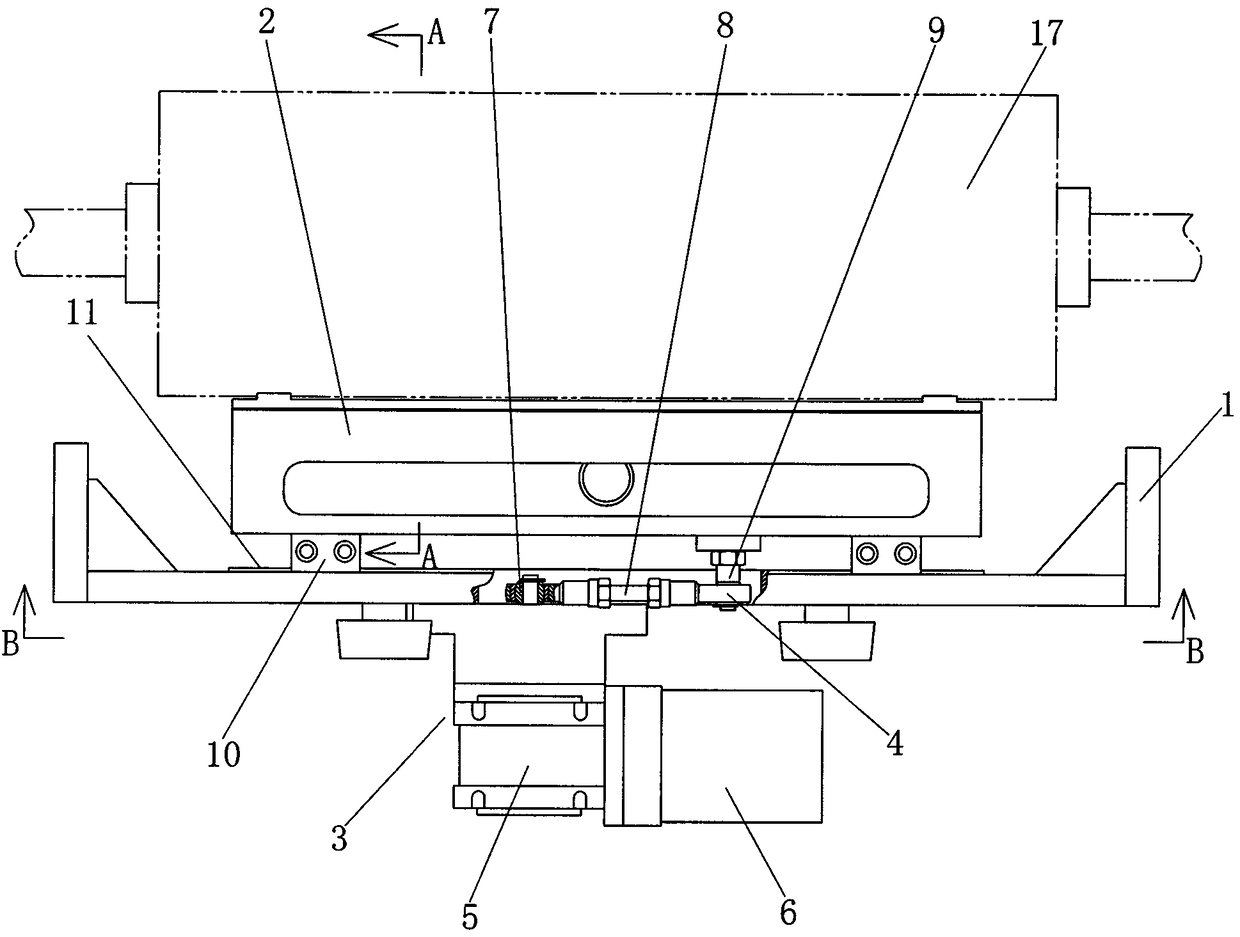

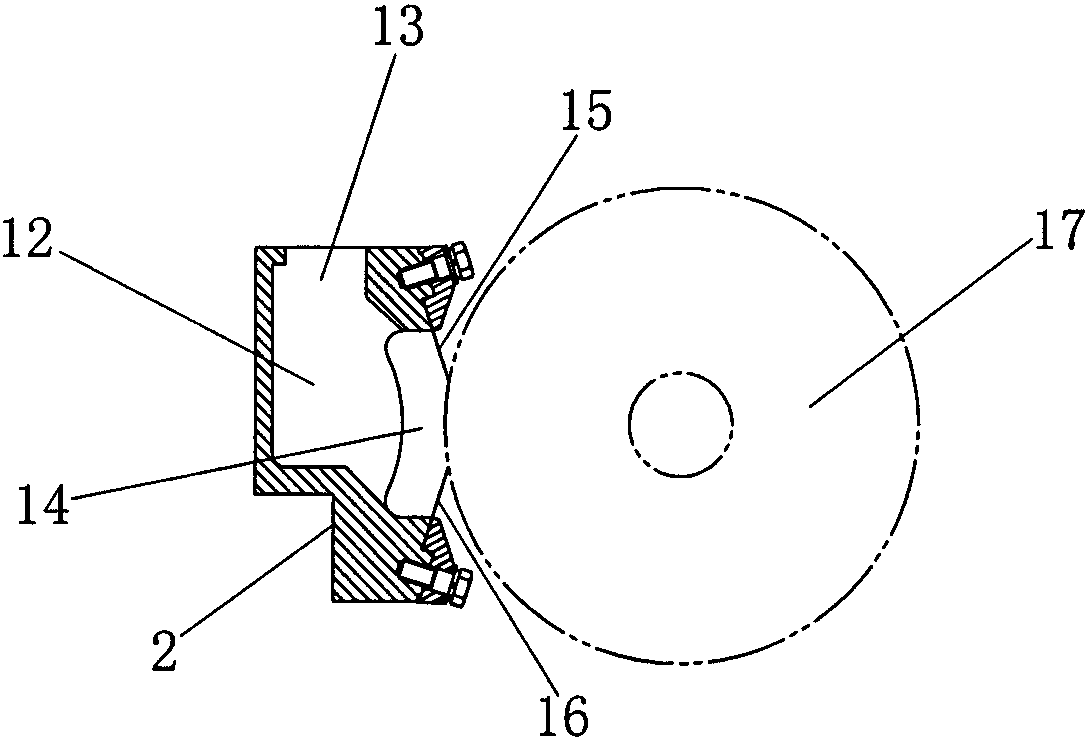

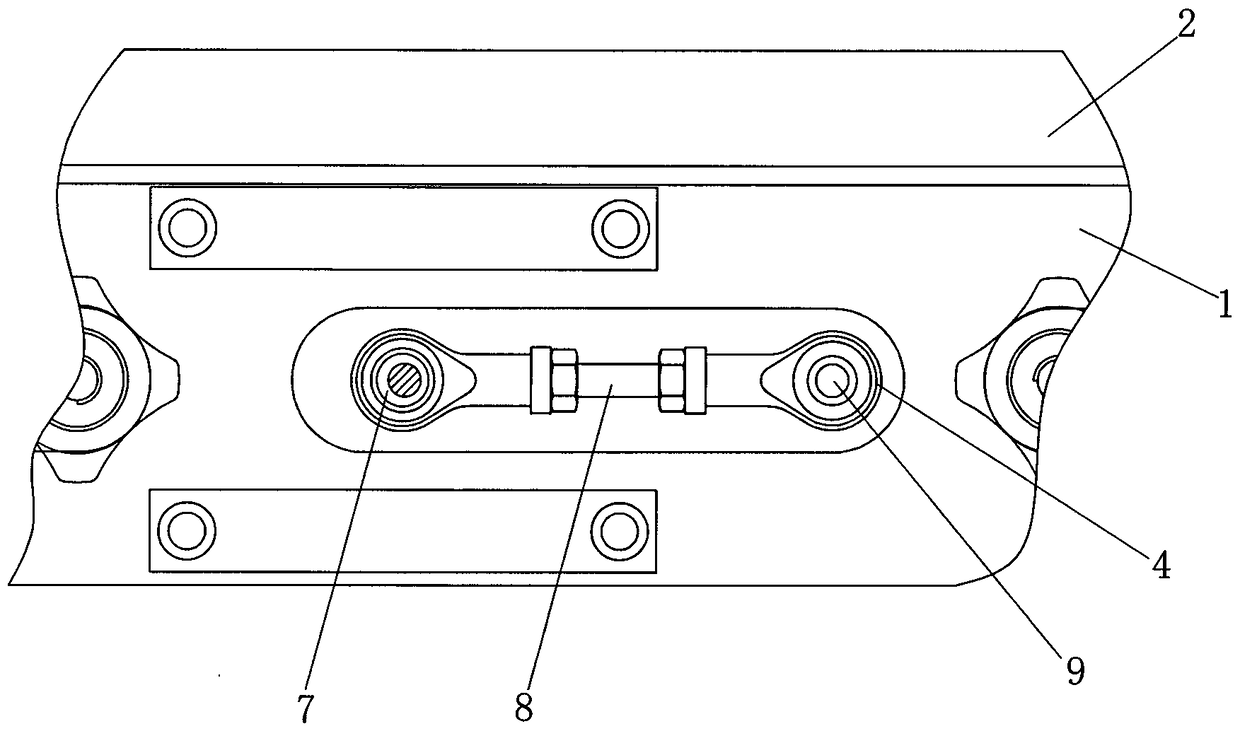

Reciprocating motion type sealed ink fountain of printing or coating machine

PendingCN108501510ADoes not affect delivery uniformityNo loss of print qualityScreen printersReciprocating motionEngineering

The invention discloses a reciprocating motion type sealed ink fountain on a printing or coating machine. The reciprocating motion type sealed ink fountain on the printing or coating machine solves the problems that an existing sealed ink fountain are fixed, a scraper and an anilox roller on the existing sealed ink fountain are also fixed, so that the scraper has a high change frequency, printingcost is increased, and scraper consumption is serious, and other problems are also solved. According to the technical scheme, the reciprocating motion type sealed ink fountain on the printing or coating machine comprises an ink fountain frame for being fixed on the printing or coating machine and a sealed ink fountain arranged on the ink fountain frame. The reciprocating motion type sealed ink fountain is characterized in that the sealed ink fountain is matched on the ink fountain frame in a transversely sliding mode and is positioned at the front side of the ink fountain frame; a reciprocating motion driving mechanism is mounted on the ink fountain frame; and the driving end of the reciprocating motion driving mechanism is connected with the sealed ink fountain.

Owner:SHANTOU OLGER PACKING MACHINERY

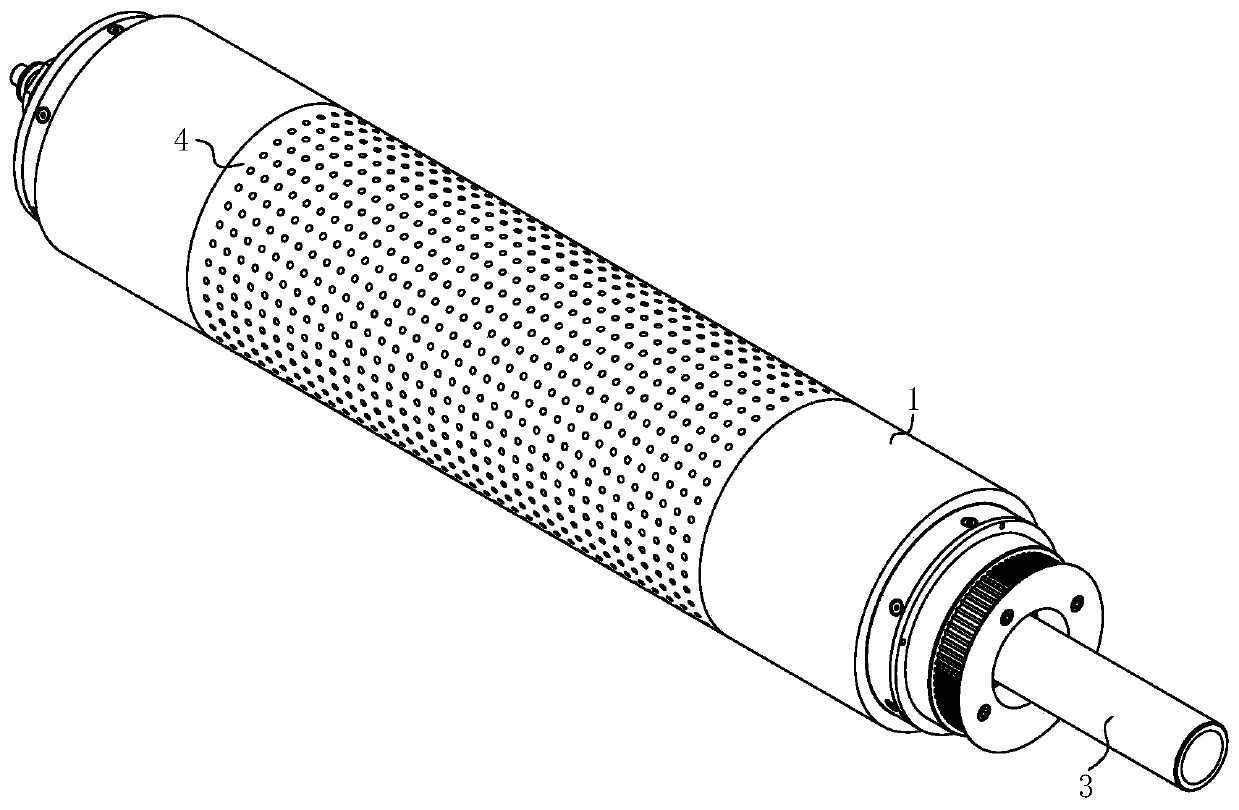

Printing rubber roller

ActiveCN110254033AUniform printingImprove printing yieldRotary pressesRubber ringPulp and paper industry

The invention belongs to the field of printing equipment accessories, and particularly relates to a printing rubber roller. The printing rubber roller comprises a installation roller, a brake roller, a liquid conveying pipe, a rubber ring and a spraying mechanism, wherein the installation roller is fixedly arranged on the outer side of the brake roller; a liquid storage cavity is formed in a position between the installation roller and the brake roller; the liquid conveying pipe is fixedly connected to the right end of the installation roller; the rubber ring is fixedly embedded in the outer end wall of the middle of the installation roller; the liquid conveying pipe communicates with the liquid storage cavity; the spraying mechanism is arranged in the liquid storage cavity; the spraying mechanism comprises a hinged frame, a sliding rod and a liquid flowing hole; the inner end of the hinged frame is uniformly and fixedly arranged on the outer surface of the brake roller; the hinged frame is provided with a torsion spring; and the outer end of the hinged frame is fixedly connected with the sliding rod. The printing rubber roller is mainly used for solving the problems that a printing rubber roller in the prior art is not able to imprint fabric at the first time when the fabric is dyed to result in increasing the imprinting difficulty because dye is dried and solidified quickly, thereby reducing the yield is greatly.

Owner:岳阳市大地印务有限公司

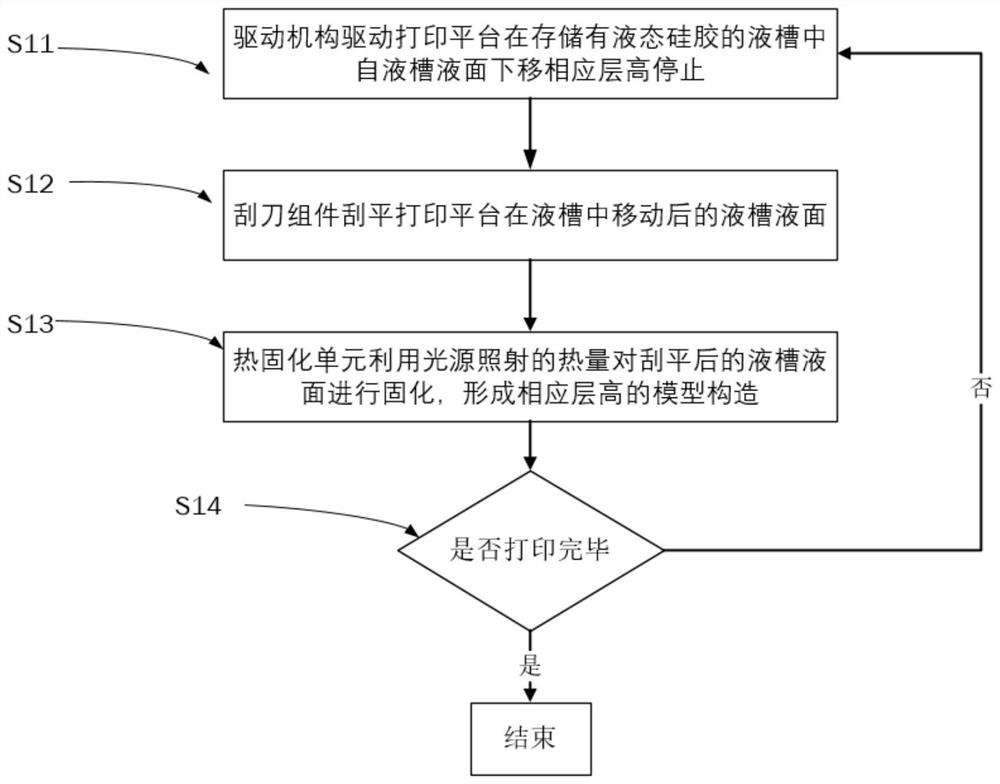

Thermocuring printing method and printing device thereof

InactiveCN113547747ANot prone to collapseImprove printing qualityAdditive manufacturing apparatus3D object support structuresLiquid tankIndustrial engineering

The invention discloses a thermocuring printing method and device, and belongs to the technical field of 3D printing. The method comprises the steps that a driving mechanism drives a printing platform to move downwards by a corresponding layer height from the liquid level of a liquid tank in the liquid tank where a thermocuring fluid material is stored to stop; a scraper assembly scrapes the liquid level of the liquid tank after the printing platform moves in the liquid tank; a thermocuring unit cures the leveled liquid level of the liquid tank to form a model structure with the corresponding layer height; whether printing is finished or not is judged, and if yes, ending is carried out; and if not, the steps are repeated. The device part comprises the printing platform, the liquid tank, a refrigerator, the scraper assembly, the thermocuring unit and a driving unit. The device has the advantages of high printing fineness and high printing quality.

Owner:REGENOVO BIOTECH

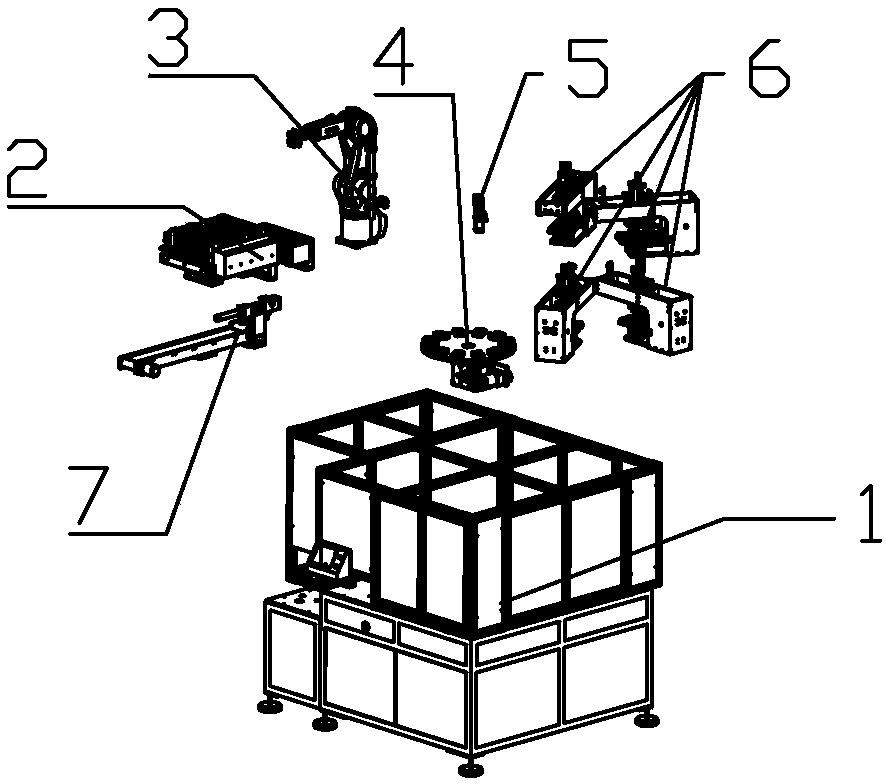

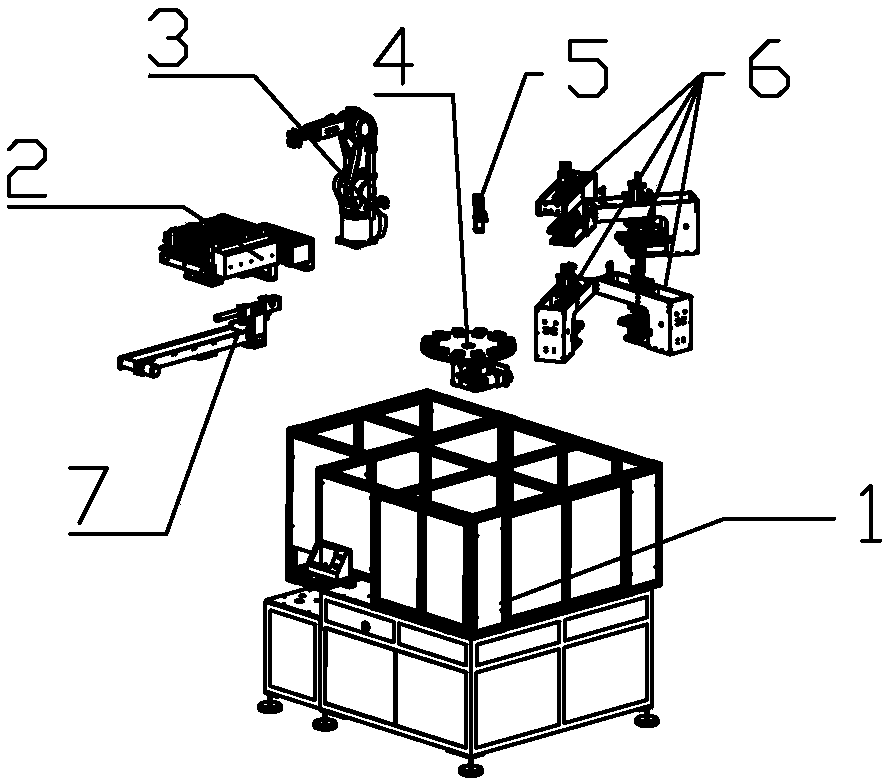

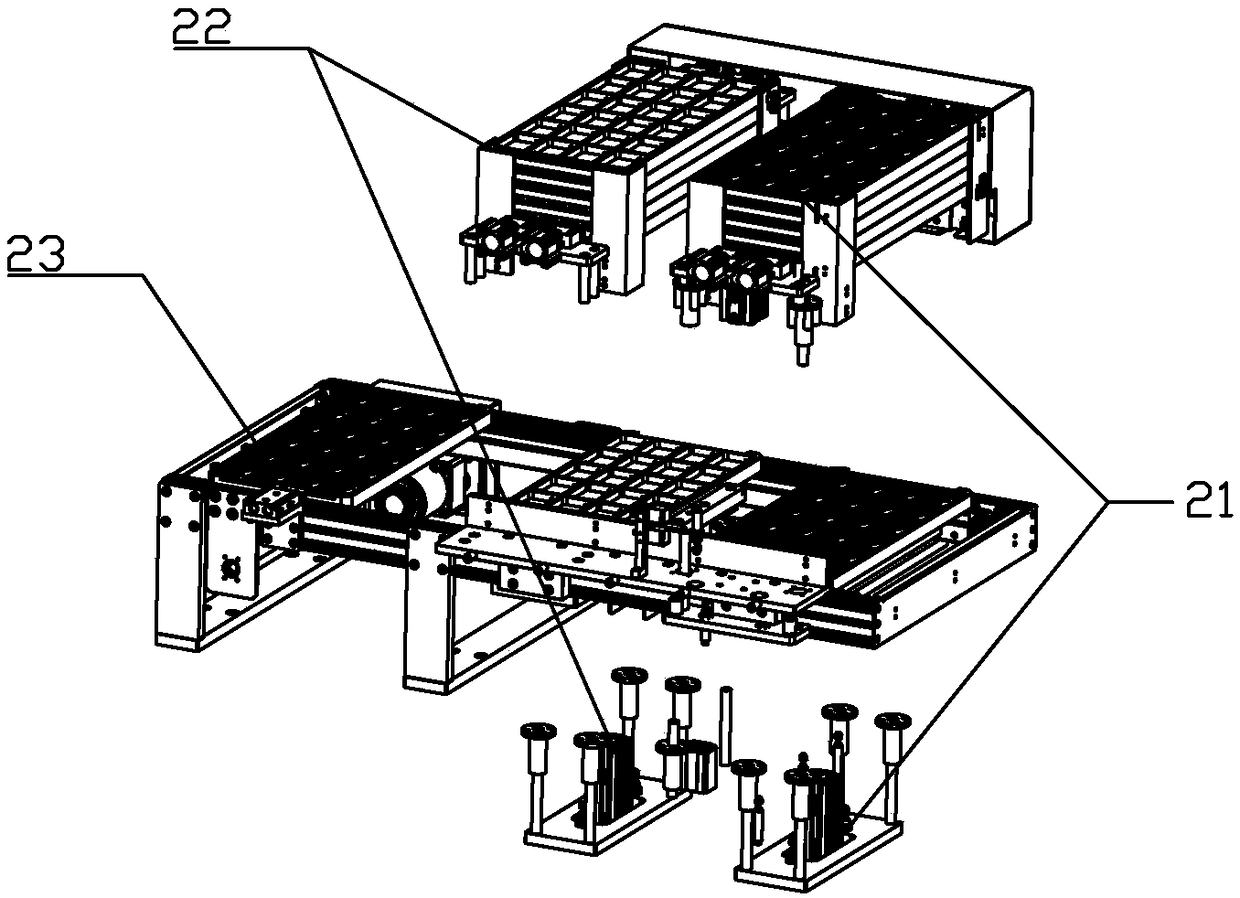

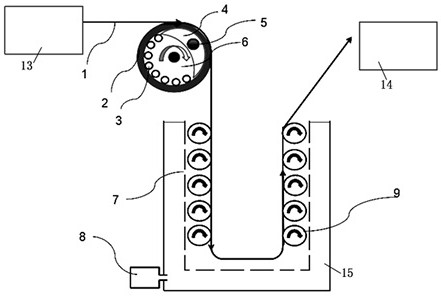

Printer with chromotography

InactiveCN108608727AHigh degree of intelligenceImprove printing yieldRotary pressesOther printing apparatusEngineeringMechanical engineering

The invention provides a printer with chromatography. The printer with chromatography comprises a rack assembly and a workpiece tray feeding and tray-changing device on the rack assembly. The workpiece tray feeding and tray-changing device comprises a full-tray feeding box assembly, an empty-tray collecting box assembly and a conveyer belt assembly, and the full-tray feeding box assembly and the empty-tray collecting box assembly are arranged on the conveyer belt assembly. The printer with chromatography has the advantages that the workpiece tray feeding and tray-changing device performs feeding conveniently and precisely, the printer with chromatography is operated fully automatically and is high in intelligent degree, and the printing yield is high.

Owner:吴连根

A kind of manufacturing method of large and medium-sized pottery

ActiveCN108582416BMeet the needs of customizationImprove printing efficiencyCeramic shaping apparatusClaywaresProcess engineeringCeramic

The invention discloses a large and medium chinaware manufacturing method. Compared with a traditional method, such subsequent treatment processes as outer surface finishing, finish carving treatmentand / or colored drawing treatment and glazing of large and medium chinaware ceramic blanks and production of chinaware outer profile surfaces belong to simultaneous asynchronous treatment spaced by specific space-time intervals, so that the problem of performing subsequent processes one by one after completion of previous treatment procedures in the traditional method is overcome, and saving of a lot of time and delication of the artistic effect can be both considered. In addition, the method can finish complex shapes, is more suitable for manufacturing of large and medium artistic shape chinaware, meanwhile, greatly enriches the shaping range of large and medium chinaware, and greatly reduces the manufacturing cost of large artistic porcelains.

Owner:湖南筑巢智能科技有限公司

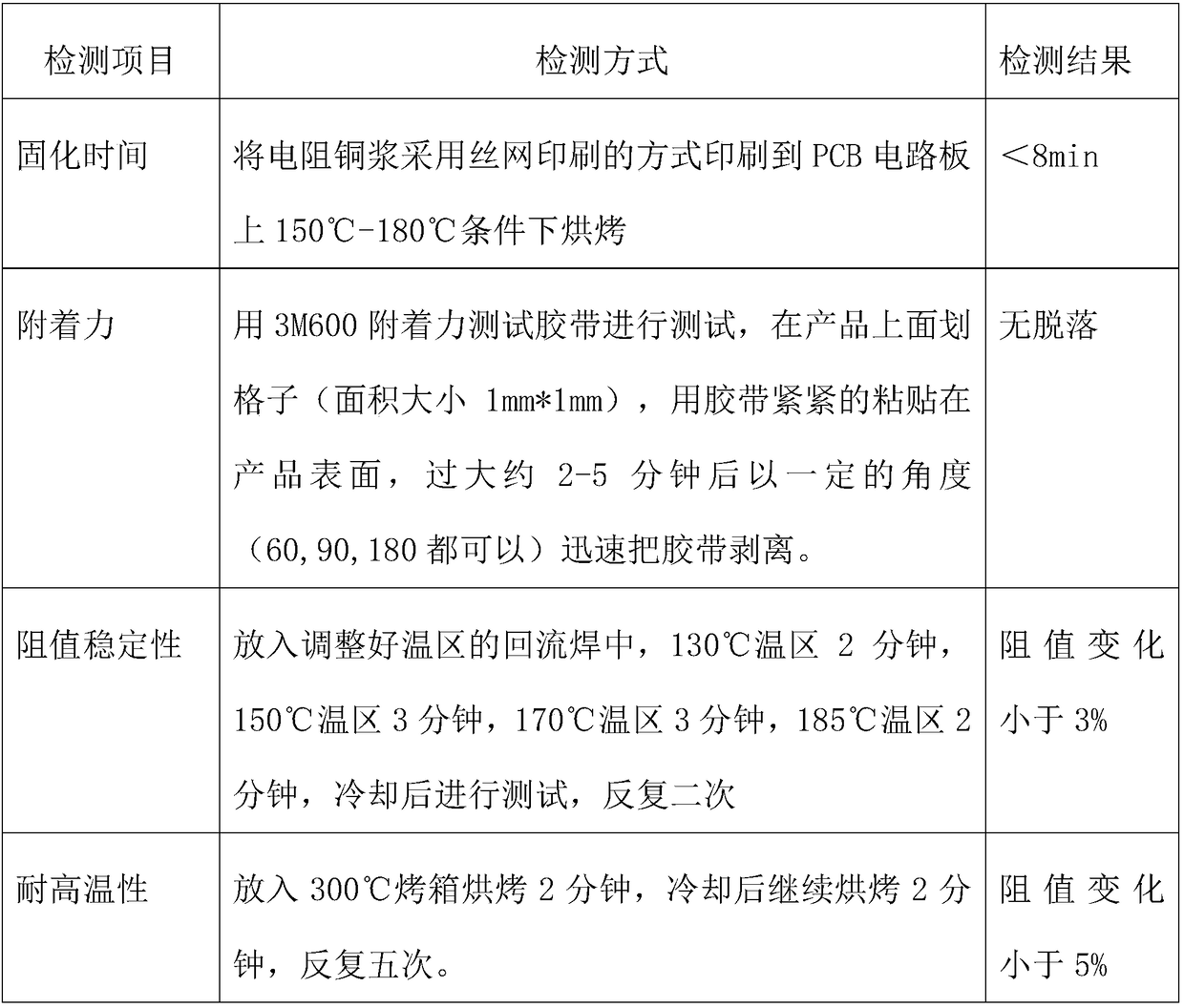

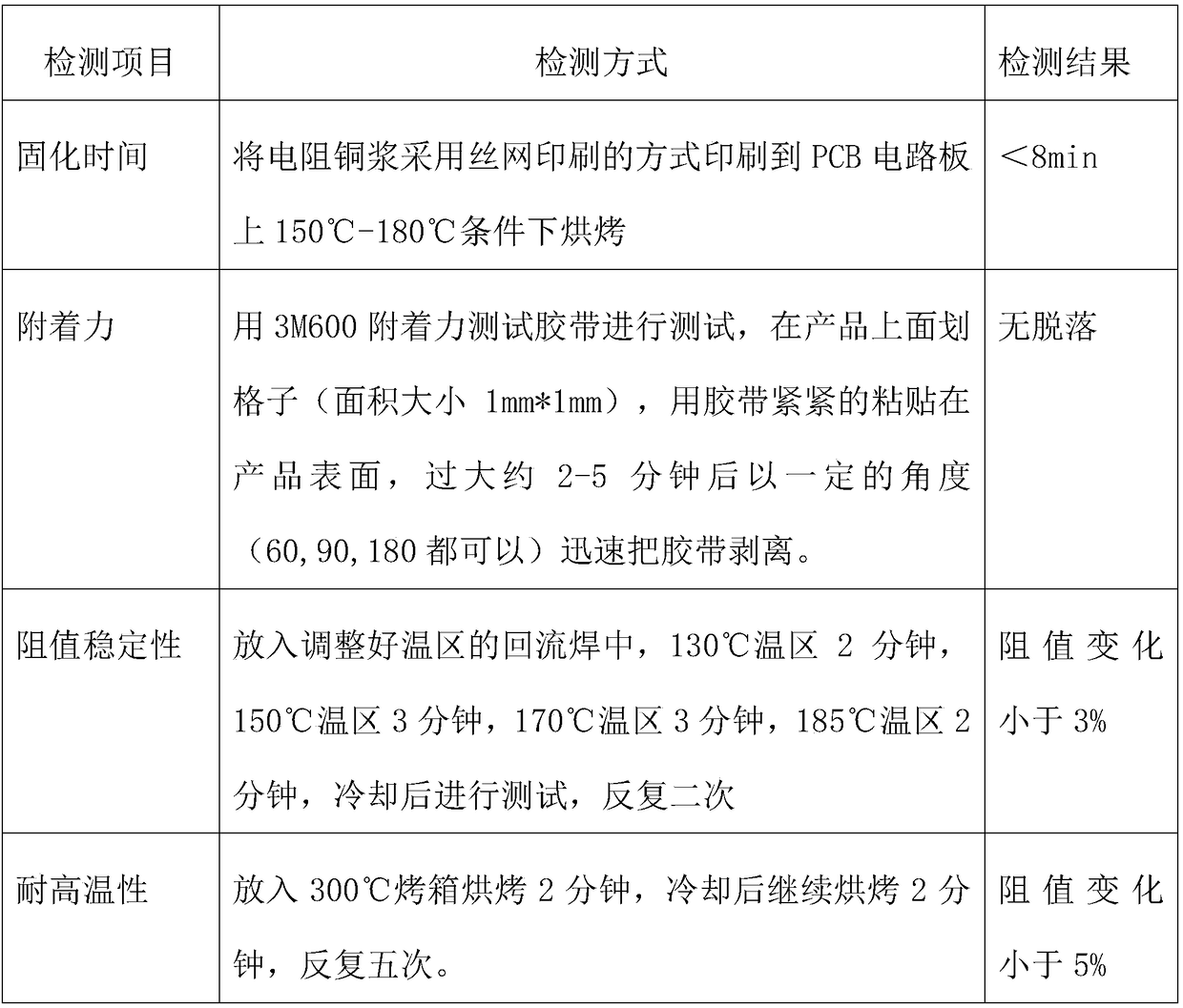

Resistance copper slurry and preparation method thereof

InactiveCN109206976AGood printabilityShort curing timeInksMetallic pattern materialsResistAcrylic resin

The invention discloses resistance copper slurry and a preparation method thereof, and belongs to the technical field of electronic slurry. The resistance copper slurry is mainly prepared from the following components in parts by weight: 12-16 parts of trimethylolpropane triacrylate, 25-28 parts of N-vinyl pyrrolidone, 3-6 parts of bivalent acid ester, 38-45 parts of epoxy acrylic resin, 2-5 partsof fatty alcohol polyoxyethylene ether, 1-3 parts of a surfactant, 8-13 parts of an initiator and 80-100 parts of silver-coated copper powder. The resistance copper slurry has the advantages of excellent printability, short curing time, strong adhesion force, high temperature resistance, moisture resistance, resistance to solder resist ink erosion, and stable resistance value. The preparation method of the resistance copper slurry is simple in process, easy to prepare and high in production efficiency; the produced product has good quality and low production cost.

Owner:郑胜

Chromaticity printing technique of in-mold label injection molding sheet material

ActiveCN100588555CReduce printing timesGuaranteed printing accuracyPattern printingOther printing apparatusPunchingAdhesive

Owner:BYD PRECISION MFG

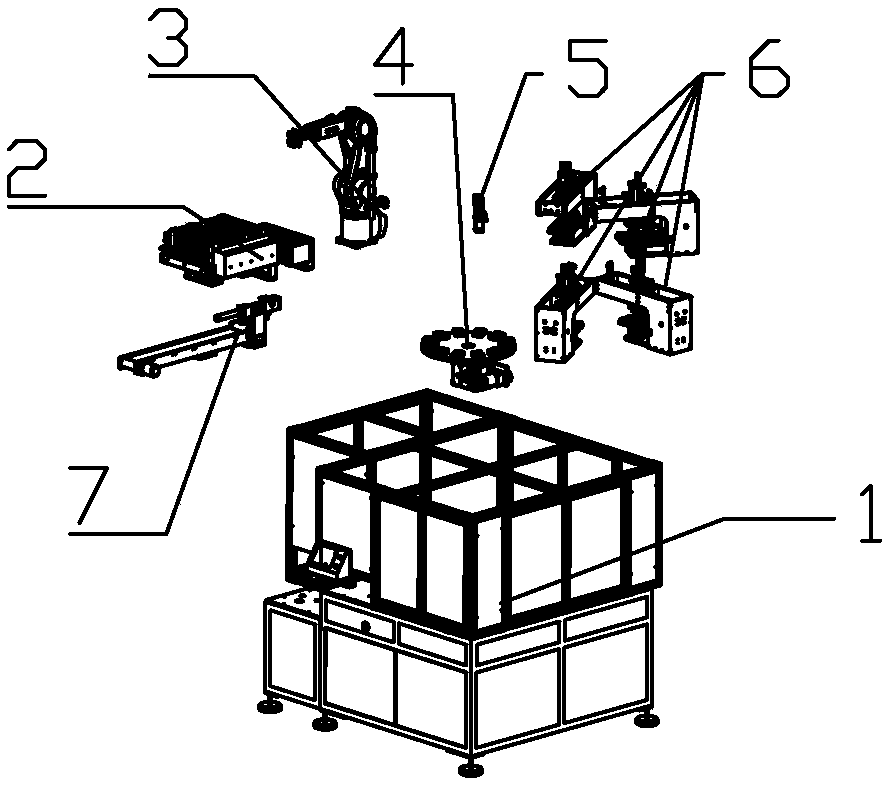

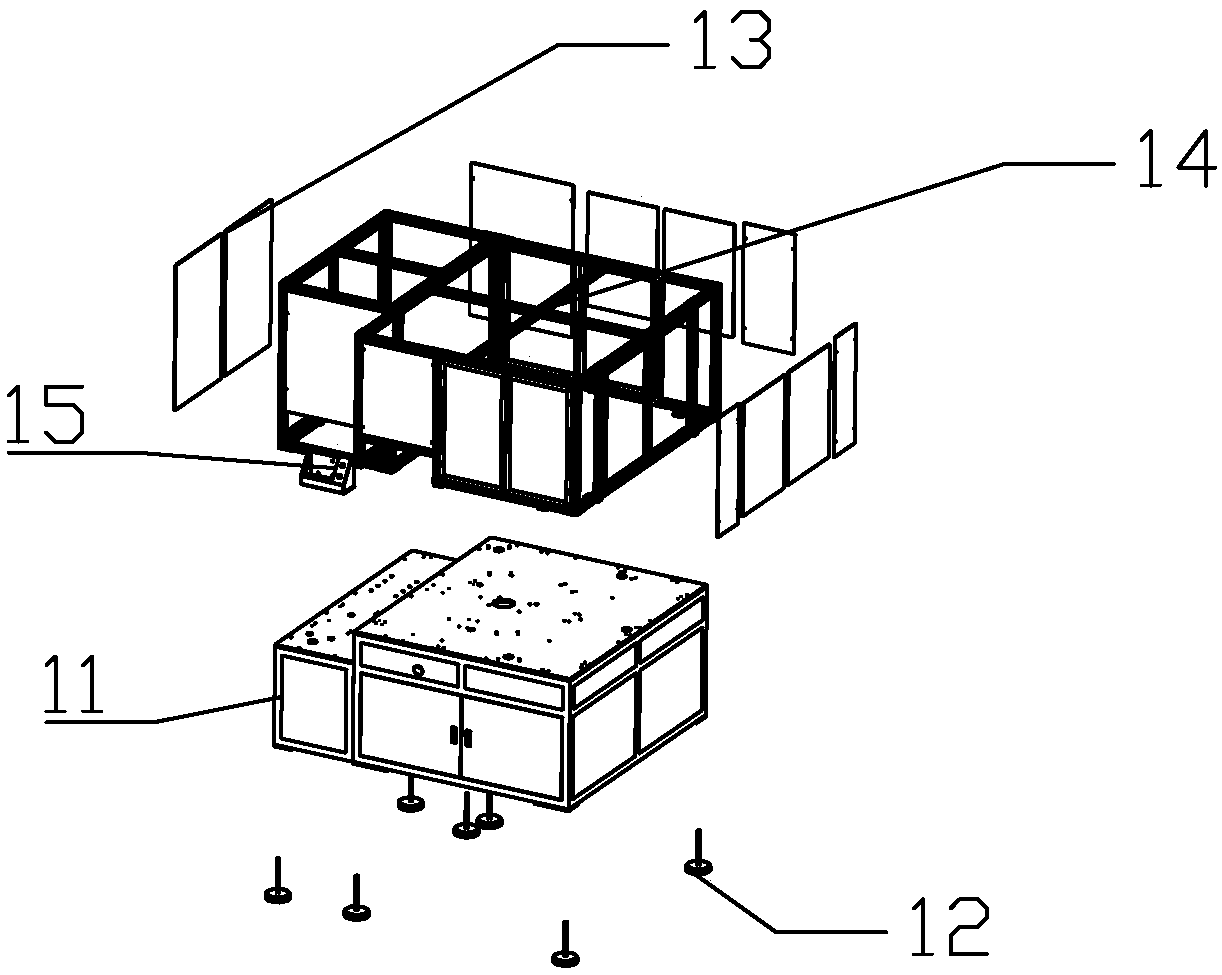

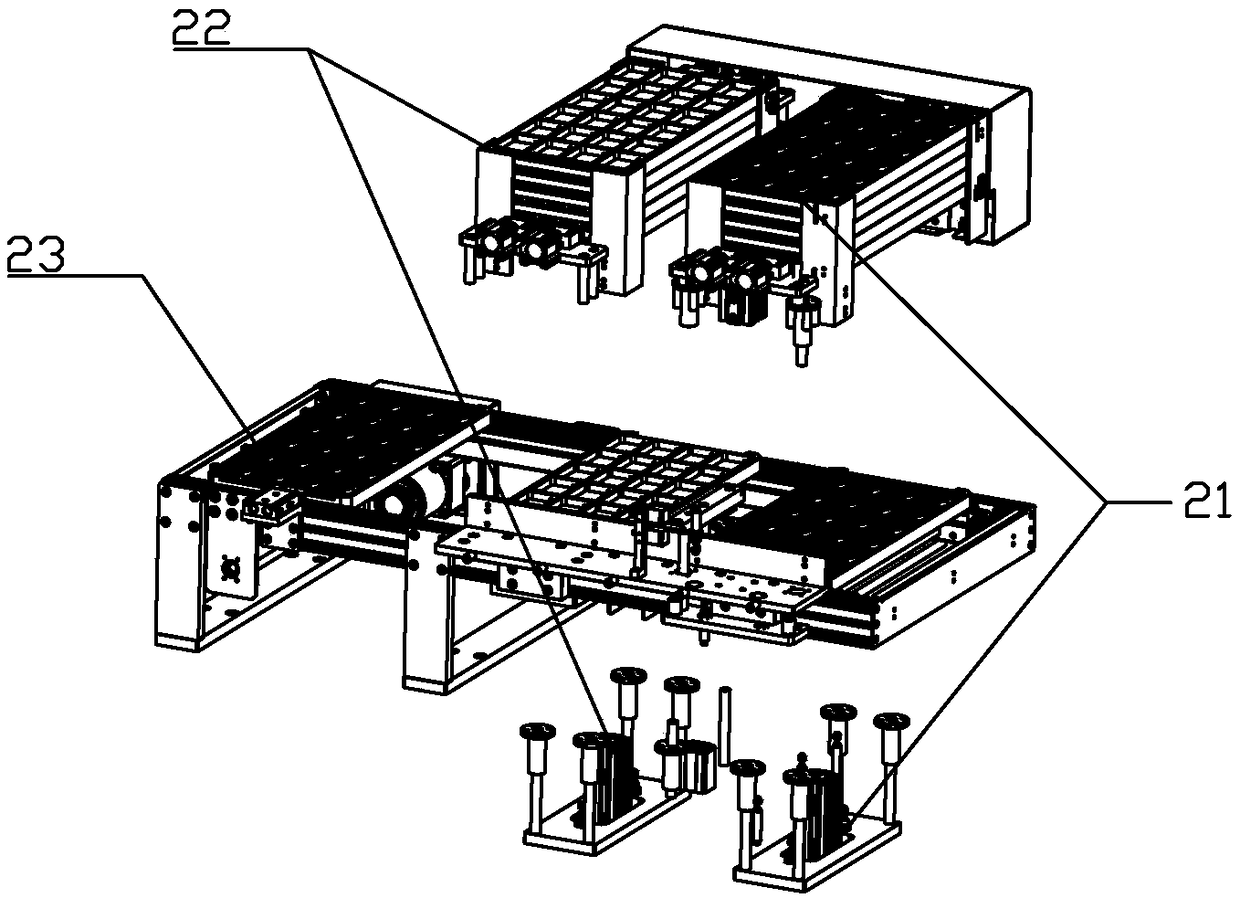

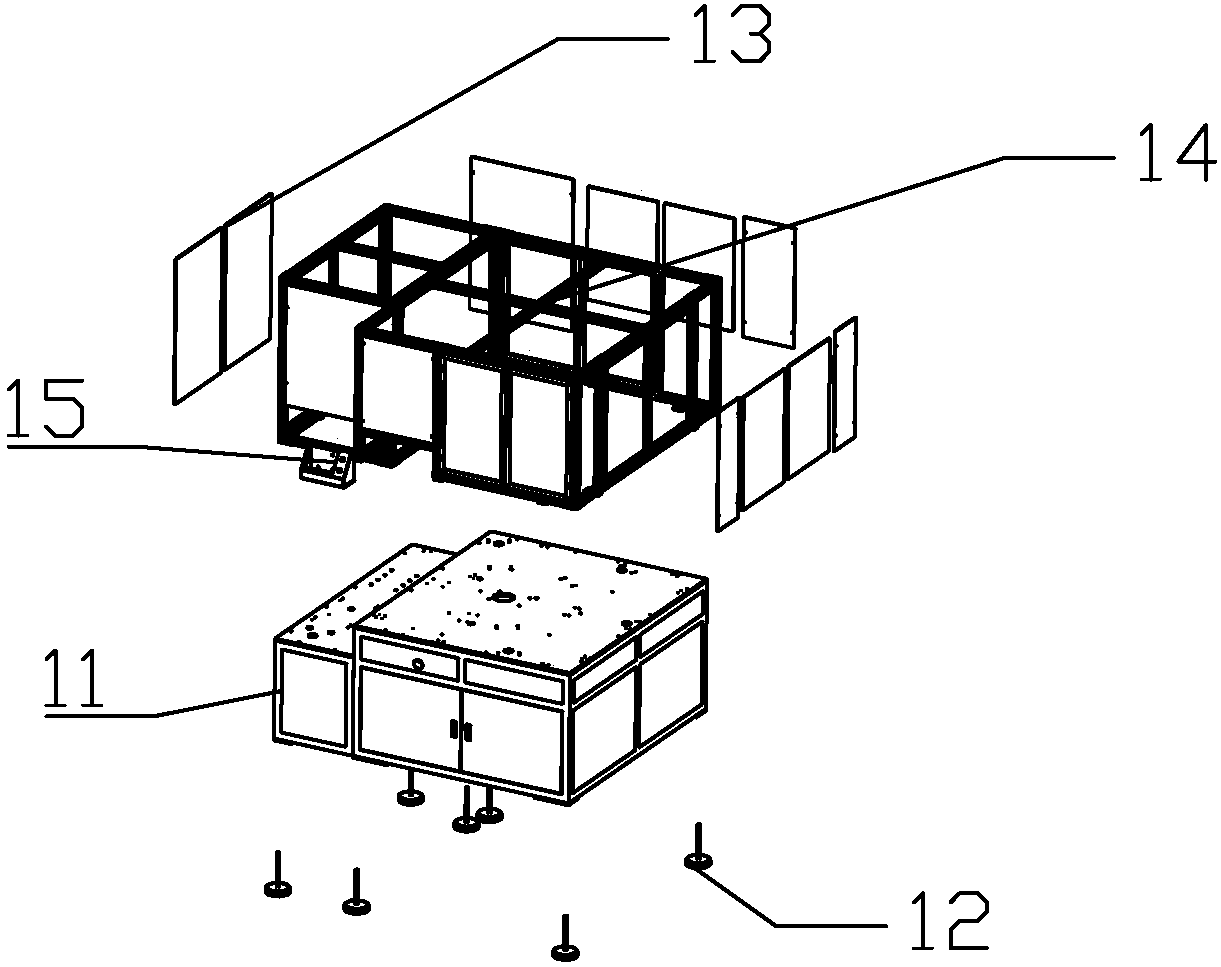

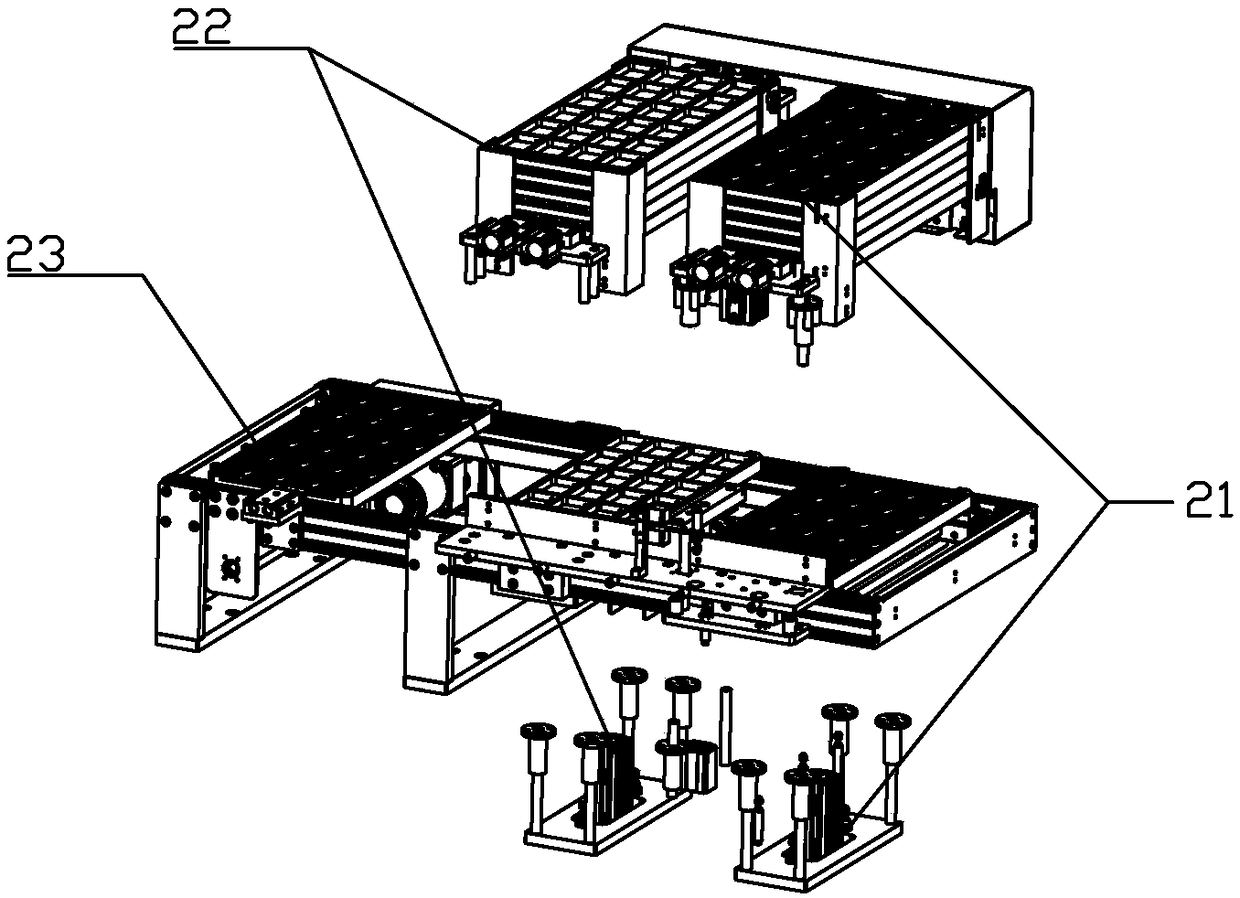

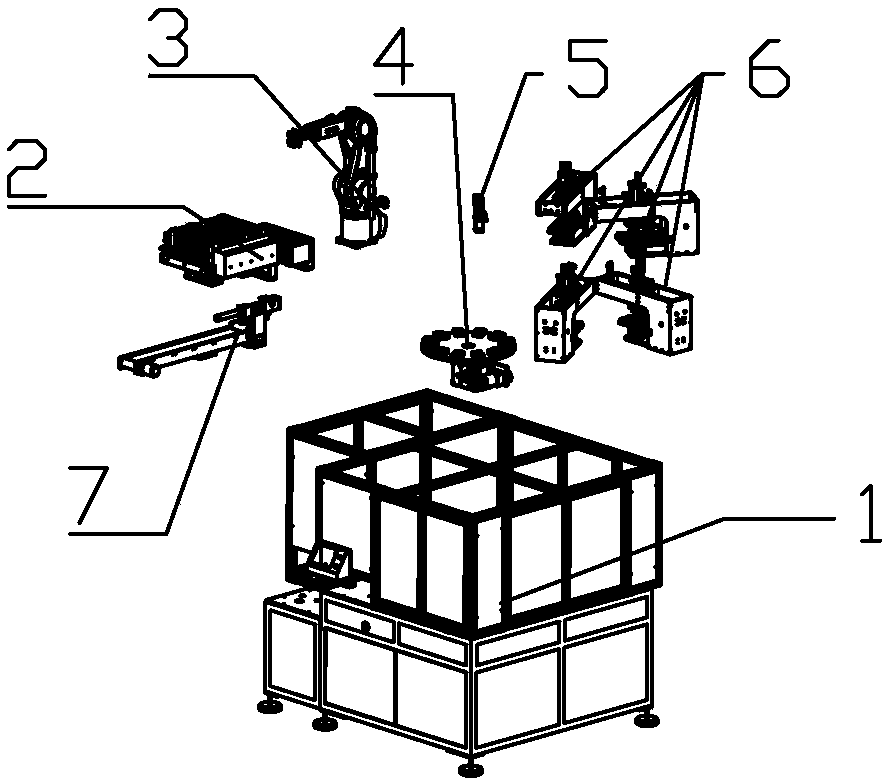

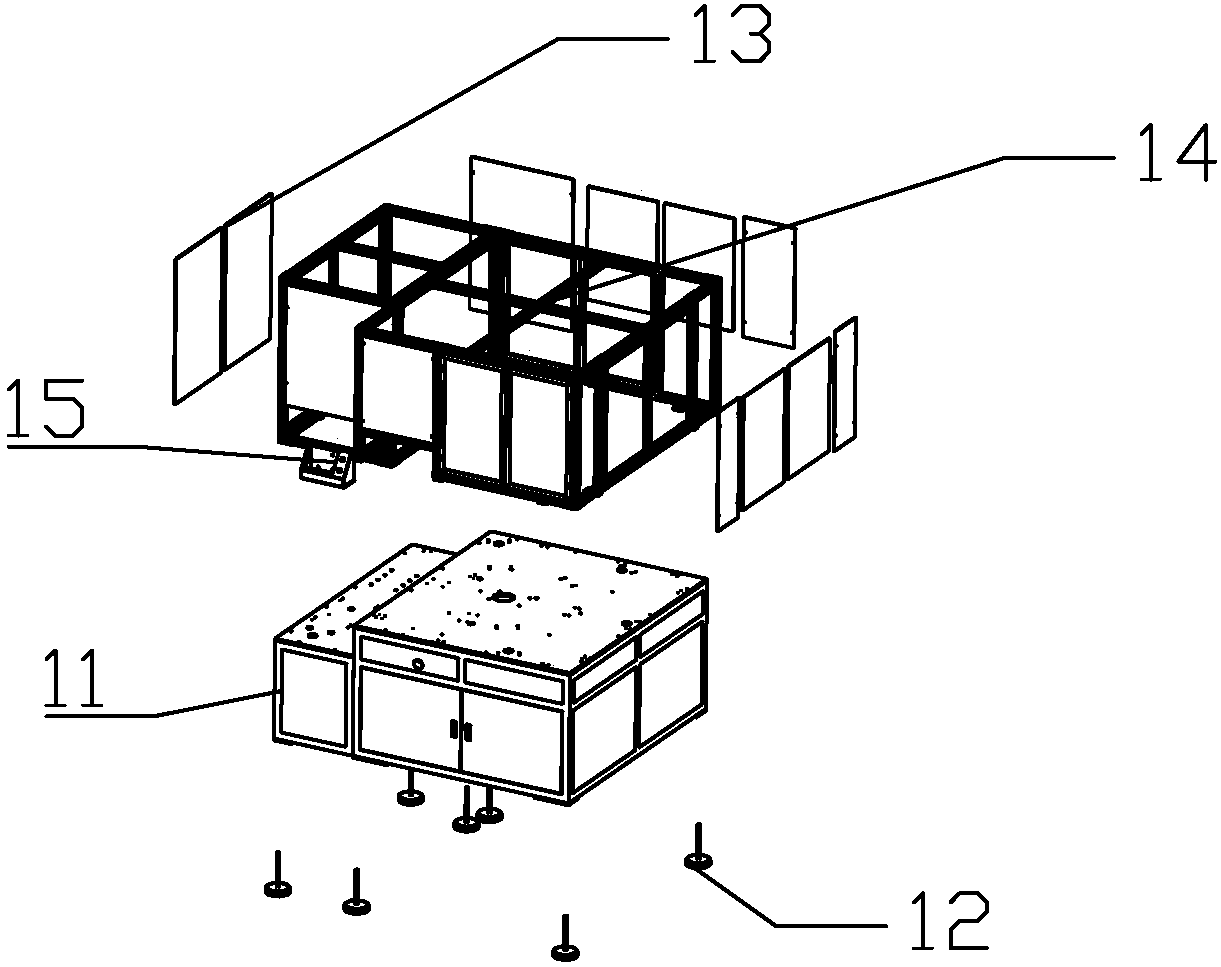

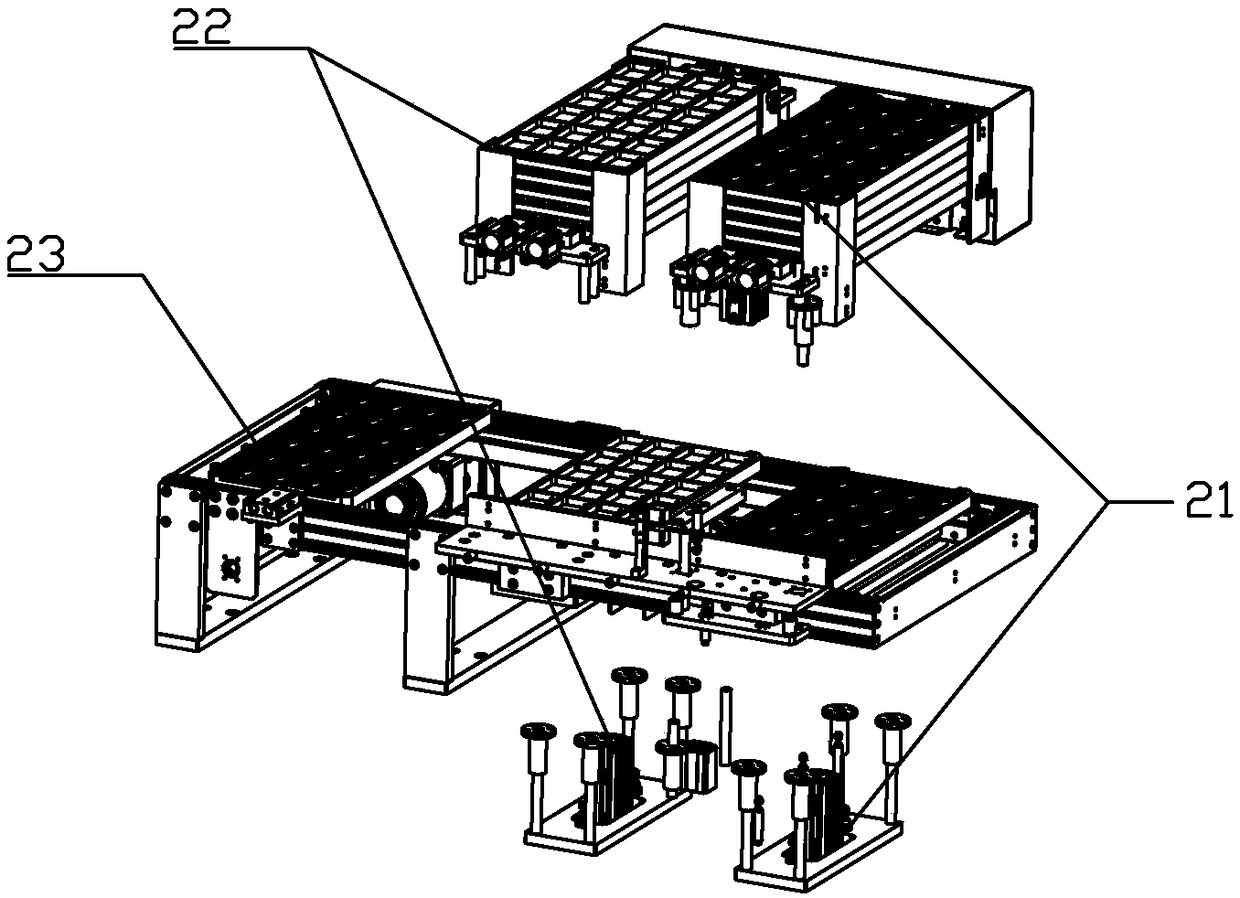

Intelligent printer with chromatography

InactiveCN108582984AEasy to printEasy and accurate printingRotary pressesOther printing apparatusEngineeringManipulator

The invention relates to the field of intelligent printing equipment, in particular to an intelligent printer with chromatography. The intelligent printer with chromatography comprises a rack assembly, a material disc feeding and disc replacing device, a mechanical arm feeding device, a 12-indexing disc device, a pressing locating device, a printing device and a product discharging device, and thematerial disc feeding and disc replacing device, the mechanical arm feeding device, the 12-indexing disc device, the pressing locating device, the printing device and the product discharging device are arranged on the rack assembly. The intelligent printer with chromatography has the beneficial effects that feeding of the material disc feeding and disc replacing device is convenient and precise,the feeding position of the mechanical arm feeding device is precise, and a workpiece is precisely located by the pressing locating device; the 12-indexing disc device is precise in action, the printing device is precise in polychrome printing, and the product discharging device is convenient for discharging; and the intelligent printer with chromatography achieves full-automatic operation, and ishigh in intelligent degree and high in printing finished product rate.

Owner:吴连根

Chromatic printing machine

InactiveCN108501512APrecise color printingHigh degree of intelligenceRotary pressesOther printing apparatusPrinting inkEngineering

The invention relates to the field of intelligent printing equipment, and discloses a chromatic printing machine. The chromatic printing machine comprises a rack assembly and a duodecimal index platedevice and four printing devices which are arranged on the rack assembly; the four printing devices are regularly arranged over the duodecimal index plate device; and each printing device comprises amoving wire assembly, a printing head assembly and a printing ink table assembly, the moving wire assemblies are fixed to the rack assembly, the printing head assemblies and the printing ink table assemblies are arranged on the moving wire assemblies, and the printing head assemblies are connected with the printing ink table assemblies. The chromatic printing machine has the advantages that the duodecimal index plate device acts precisely, and the printing devices are precise in chromaticity printing and high in printing finished product rate.

Owner:吴连根

High-yield SMT process for solder paste printing

PendingCN114222444AImprove printing yieldGuaranteed accuracyPrinted circuit assemblingTypewritersSolder pasteManufacturing engineering

The invention discloses a high-yield SMT process for solder paste printing, relates to the technical field of SMT, and aims to solve the problems that existing solder paste printing mostly adopts silk-screen printing, the printing precision is low, and printing correction is inconvenient. The solder paste jet printing machine head comprises a first base, a second base and a feeding mechanism, the feeding mechanism is located at the upper end of the second base, the first base is connected with the second base in a welded mode, a material supplementing barrel is installed at the lower end of the first base, a printing spray rod is installed at the lower end of the material supplementing barrel, and the feeding mechanism comprises a material storage barrel and a constant-temperature heating sleeve. The constant-temperature heating sleeve is located on the outer side of the material storage barrel, the material storage barrel is connected with the constant-temperature heating sleeve in a glued mode, a material conveying pipe is installed between the material storage barrel and the material supplementing barrel, the material conveying pipe is fixed to the material storage barrel and the material supplementing barrel in a sealed mode, and negative-pressure dust suction rods are installed on the two sides of the lower end of the first base. A negative pressure dust suction nozzle is arranged at the lower end of the negative pressure dust suction rod, and dust collection boxes are installed on the two sides of the upper end of the first base.

Owner:苏州合宏世纪电子有限公司

Intelligent printer

InactiveCN108501515AHigh degree of intelligenceImprove printing yieldRotary pressesOther printing apparatusManipulator

The invention relates to the field of intelligent printing equipment. An intelligent printer comprises a rack assembly, and a tray loading and replacing device, a manipulator charging device, a twelvedial device, a pressing and positioning device, a printing device and a product discharging device arranged on the rack assembly. The intelligent printer has the advantages that the tray loading andreplacing device is convenient and precise to load, the manipulator loading device is precise in loading position, the pressing and positioning device positions a workpiece precisely, the twelve dialdevice is precise to act, the printing device is precise in polychrome printing, and the product discharging device is convenient to discharge; and the intelligent polychrome printer is full-automaticto operate, high in degree of intelligence and high in printing rate of finished products.

Owner:吴连根

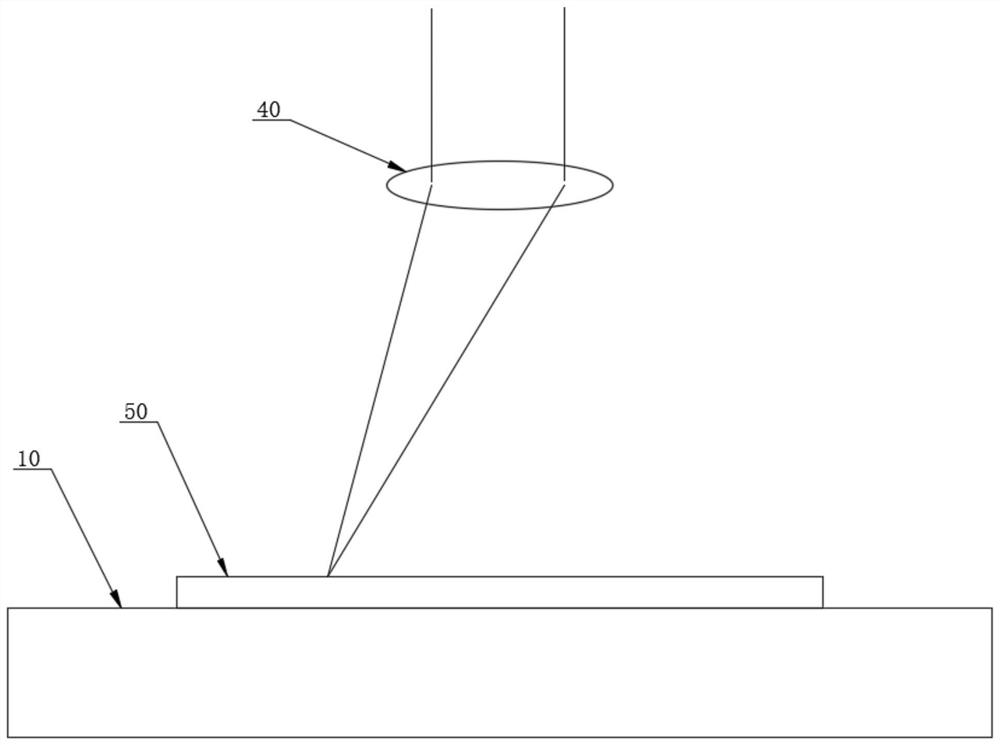

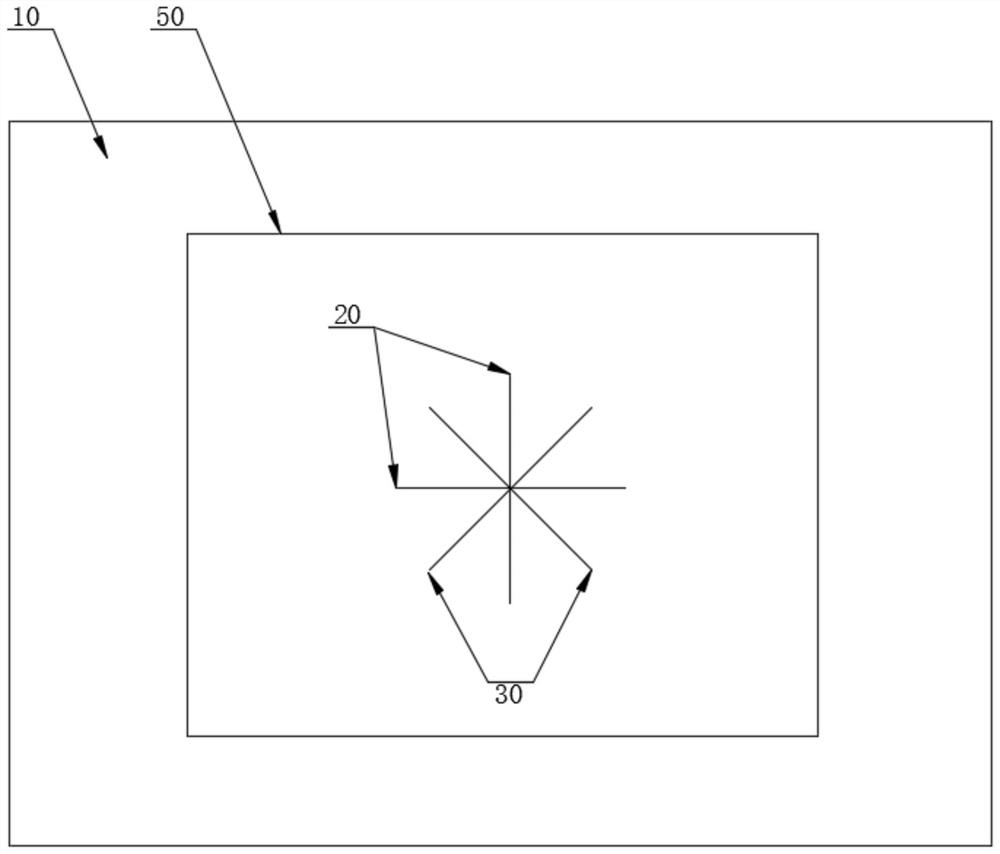

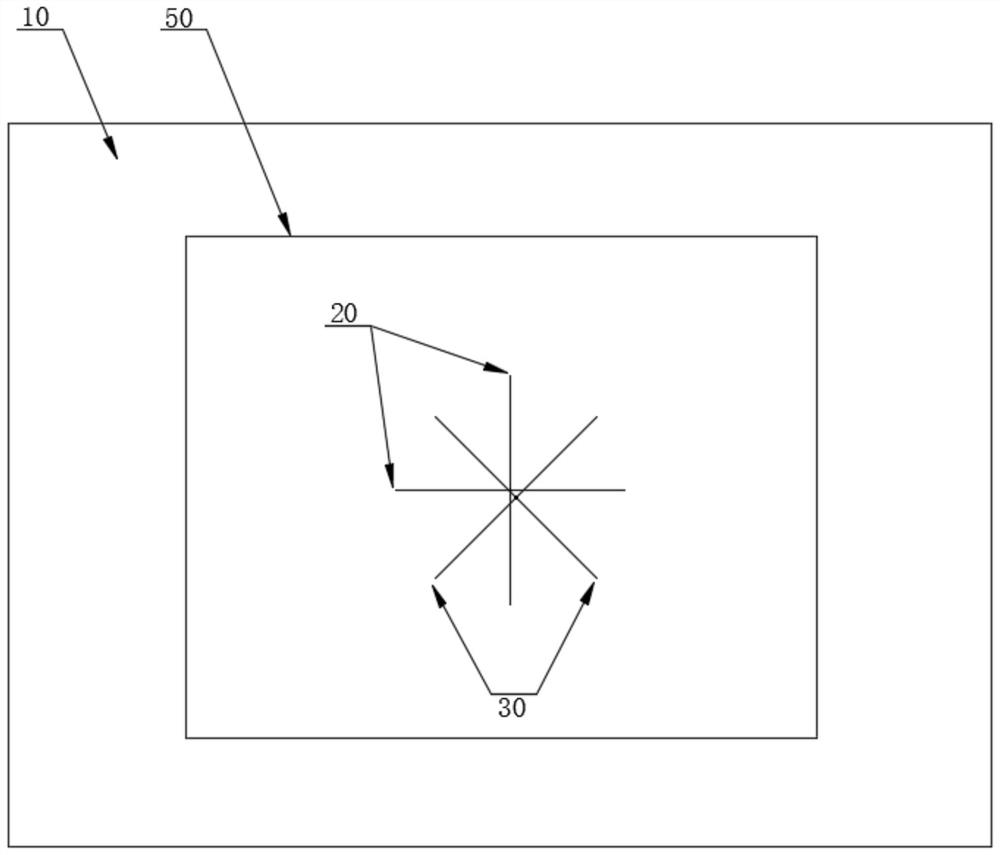

A 3D printing laser galvanometer level detection method

The invention relates to a method for detecting the level of a 3D printing laser vibrating mirror. After confirming that the printing platform is in a horizontal state, establish a cross coordinate, control the laser to print the first cross-shaped track on the printing platform, and then control the rotation of the cross coordinate to 0‑90° to control The laser continues to print the second cross-shaped track on the printing platform, and finally observe whether the intersection of the first cross-shaped track and the second cross-shaped track coincides to judge whether the vibrating mirror is installed horizontally. When the intersection of the first cross-shaped track and the second cross-shaped track coincides, the vibrating mirror is installed horizontally; when the intersection of the first cross-shaped track and the second cross-shaped track does not coincide, the vibrating mirror is not installed horizontally, This can achieve the purpose of quickly and automatically detecting whether the galvanometer is installed horizontally, thereby avoiding manual testing, greatly reducing labor costs and testing time, and improving printing yield and work efficiency.

Owner:HANS LASER TECH IND GRP CO LTD +1

Storage box

PendingCN114715709AReduce the probability of uneven windingImprove printing yieldScreen printersPhotovoltaic energy generationEngineeringMaterial storage

The invention relates to a material storage box which comprises adsorption guide rollers, a material storage box body and an air draft device, and the adsorption guide rollers are arranged outside the material storage box body and close to an opening of the material storage box body and in the material storage box body. The adsorption guide roller located outside the storage box body and the adjacent vertical row of adsorption guide rollers located on one side of the storage box body are driving rollers which move intermittently, the vertical row of adsorption guide rollers located on the other side of the storage box body are driven rollers which move continuously, and the rotating speed of the driven rollers is smaller than that of the driving rollers; the adsorption guide roller comprises a roller body with an air draft hole, an air draft device with an air draft pipeline is arranged on the side edge of the adsorption guide roller, and the air draft device corresponds to the air draft hole. According to the storage box, continuous printing can be guaranteed, base materials at the printing procedure can be printed on the same straight line all the time, the probability of printing deviation is reduced, the probability that the base materials entering the curing section of the drying oven are unevenly wound due to deviation can be effectively reduced, and the sheet printing yield is increased.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com