Intelligent 3D printing substrate leveling system and 3D printer

A printing-based and intelligent technology, applied in the field of 3D printing, can solve the problems of heavy molding substrate, time-consuming and labor-intensive, and affect the printing efficiency of 3D printers, and achieve the effect of improving printing efficiency, improving printing yield, and ensuring adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

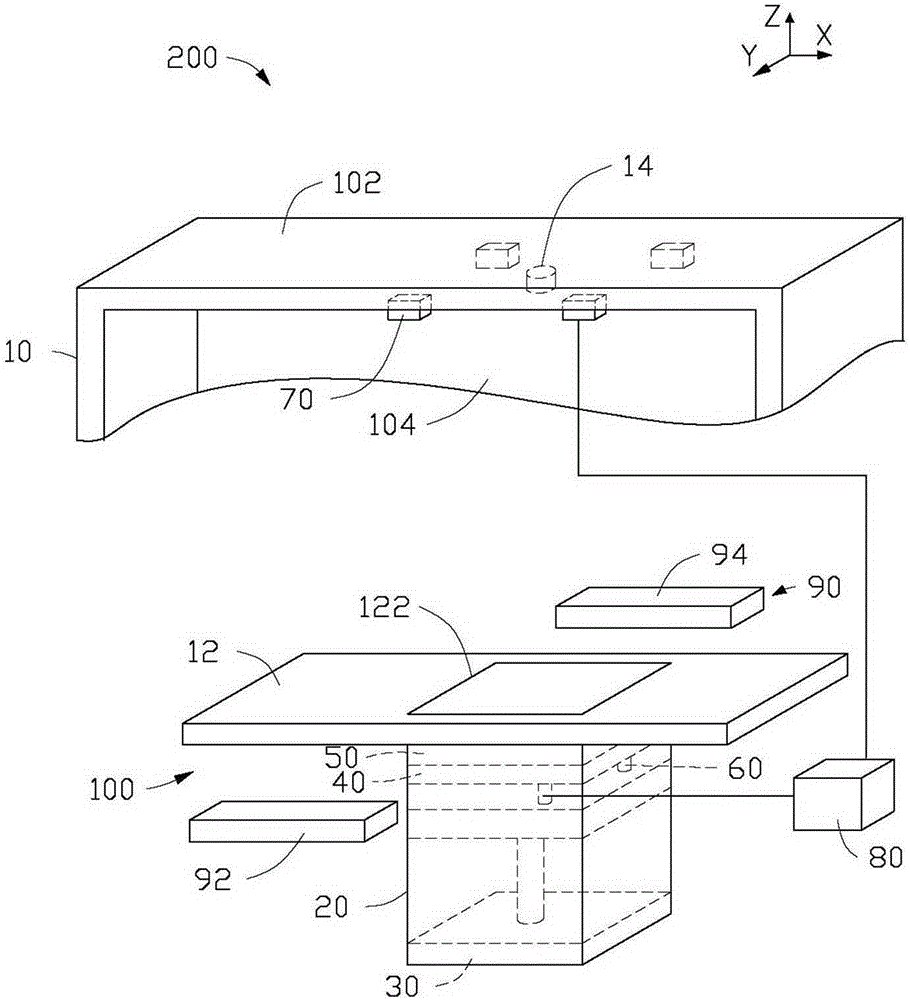

[0024] see figure 1 , is the 3D printer 200 provided in the first embodiment of the present invention. The 3D printer 200 includes a sealed chamber 10 , a workbench 12 , a laser device 14 , and an intelligent leveling system 100 for a 3D printed substrate. In this embodiment, the sealed chamber 10 is a hollow rectangular parallelepiped structure, including opposite top walls 102 and bottom walls (not shown in the figure), and four walls connecting each other end to end and vertically connecting the top wall 102 and the bottom wall. a side wall 104. The workbench 12 , the laser device 14 , and the 3D printed substrate intelligent leveling system 100 are all accommodated in the sealed chamber 10 . The workbench 12 defines a through hole 122 , and the laser device 14 is located above the workbench 12 . Specifically, the laser device 14 is fixed on the top wall 102 and aligned with the workbench 12 .

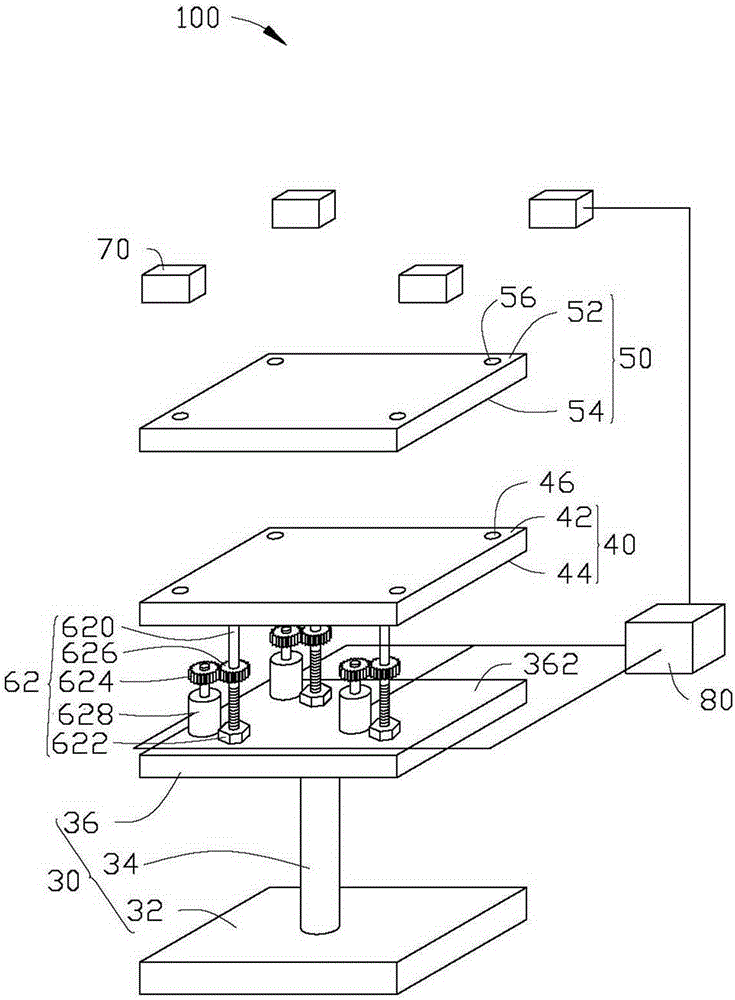

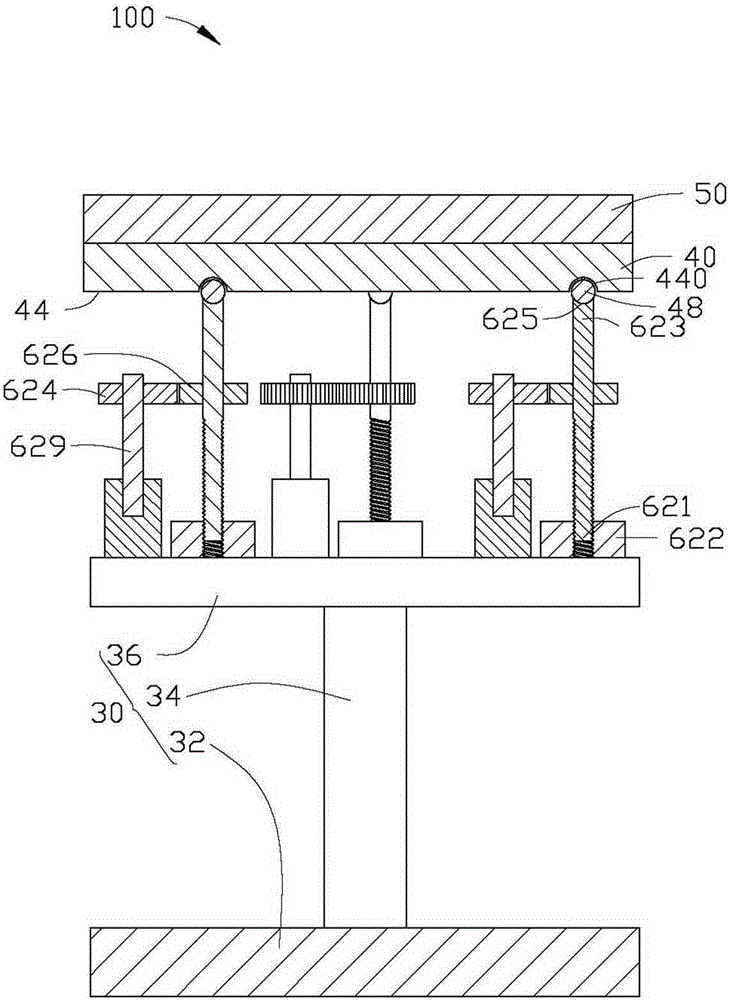

[0025] The 3D printed substrate intelligent leveling system 100 includes a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com