Chromaticity printing technique of in-mold label injection molding sheet material

A technology of color register printing and in-mold labeling, applied in printing process, printing, post-processing of printing, etc., can solve the problems of easy rubbing of ink on the surface of keys, low yield rate, etc., so as to improve the printing yield rate and reduce the number of printings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

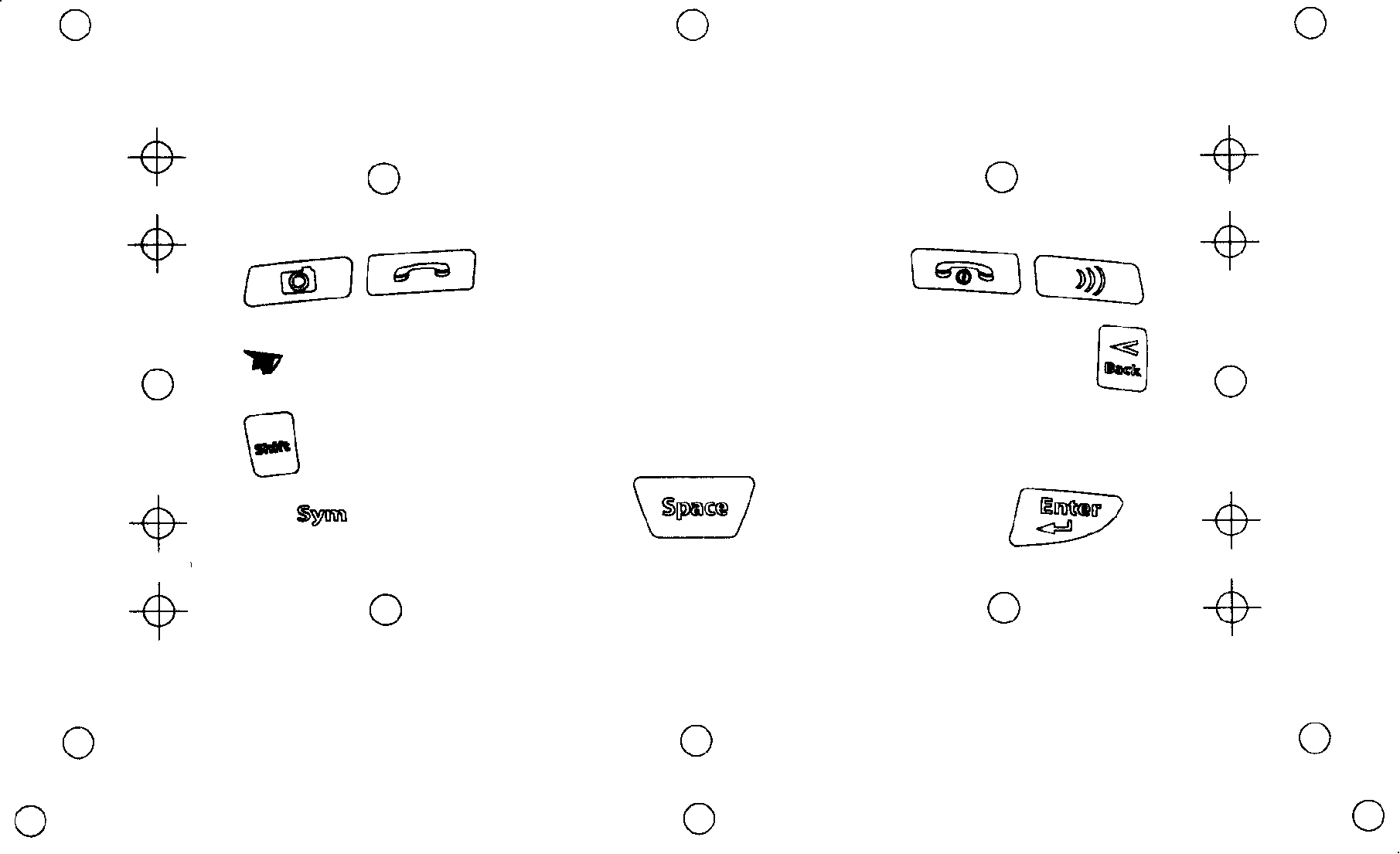

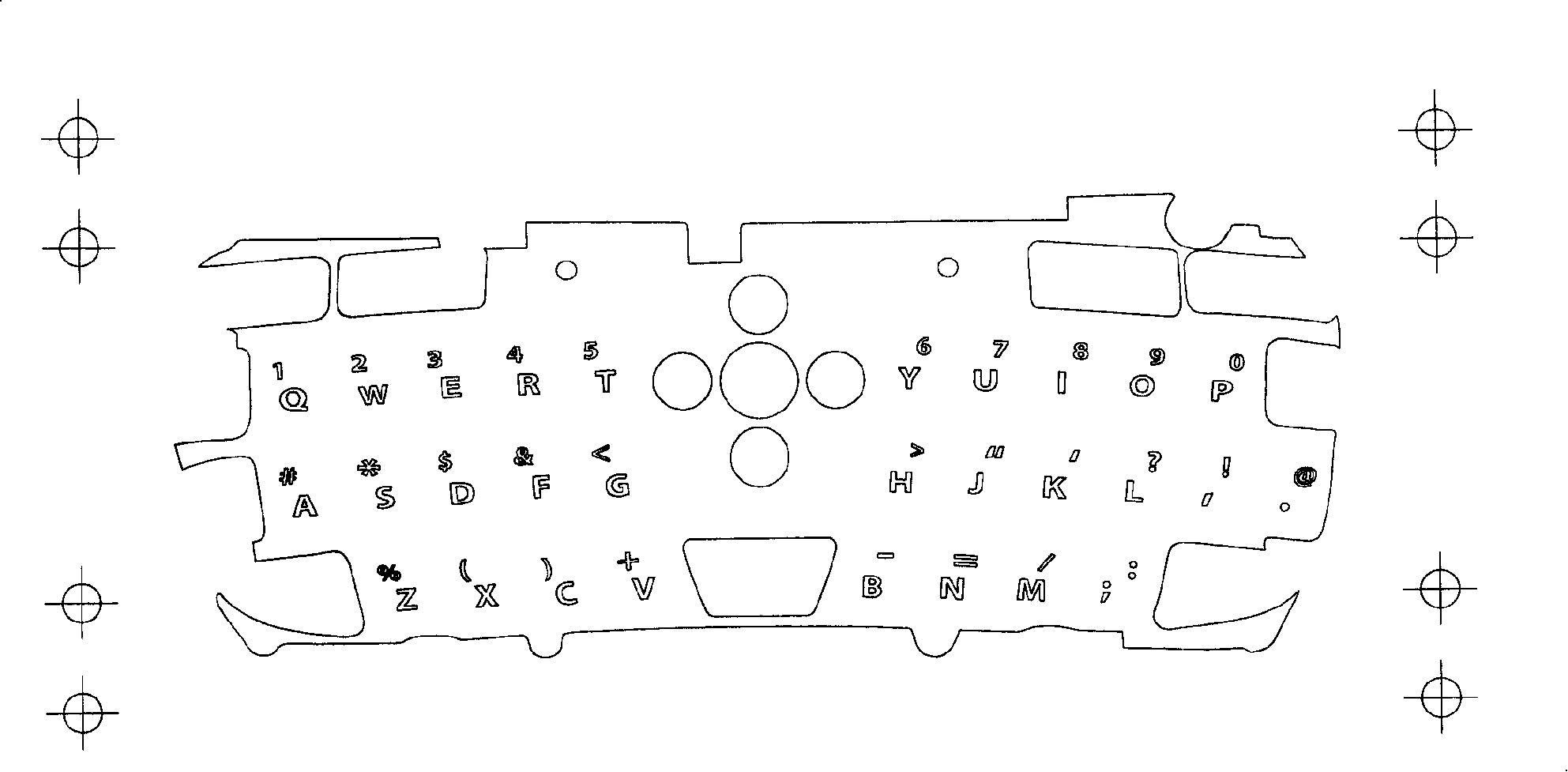

[0029] This embodiment takes mobile phone keypad printing as an example to illustrate the overprint printing process of the present invention. The mobile phone keyboard is mainly produced by printing, molding, injection molding and trimming the formable sheet. In the production of mobile phone keyboards, the mobile phone keyboard is first printed, and then the printed sheet is put into the molding mold, and the sheet is formed into a keyboard shape by hot pressing, and then the formed keys are filled by injection molding. It can be made after trimming.

[0030] Printing of mobile phone keyboard: (1) Put the sheet on the printing table, print the background color of the keyboard, with symbols, characters or patterns in the background color, wherein the symbols, characters and patterns are each a hollow unit, and print There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com