A ring-pull material suitable for laser processing and its preparation method

A laser, aluminum substrate technology, applied in epoxy resin coatings, devices for coating liquids on surfaces, coatings, etc. The effect of reducing VOCS emission, improving adhesion and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

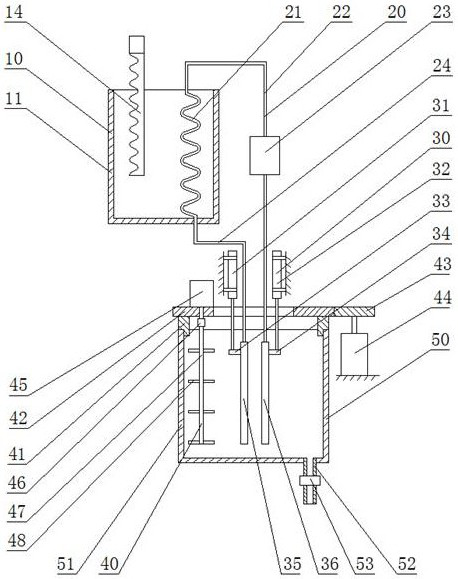

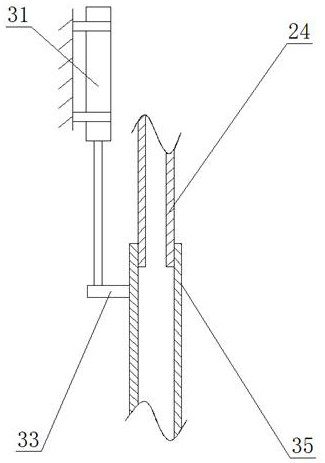

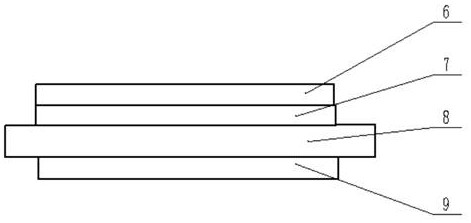

Image

Examples

Embodiment 1

[0031]The high temperature resistant inner coating of the present embodiment comprises the following raw materials in parts by weight: 40 parts of epoxy resin, 11 parts of amino resin, 2 parts of high temperature resistant organic pigment, 16 parts of aromatic hydrocarbon solvent, 10 parts of ethylene glycol monobutyl ether, 3 parts of n-butanol, 10 parts of propylene glycol methyl ether acetate.

[0032] The epoxy outer coating comprises the following raw materials in parts by weight: 25 parts of ethylene glycol monobutyl ether, 5 parts of dibasic ester mixture, 15 parts of propylene glycol methyl ether acetate, 1 part of n-butanol, and 15 parts of aromatic hydrocarbon solvent , 8 parts of nano graphite powder.

[0033] The passivation stock solution includes the following raw materials in parts by weight: 0.1 part of hydrofluoric acid, 20 parts of nitric acid, and 10 parts of trivalent chromium.

[0034] A method for preparing a pull ring material suitable for laser process...

Embodiment 2

[0037] The high-temperature-resistant inner coating of this embodiment includes the following raw materials in parts by weight: 42 parts of epoxy resin, 12 parts of amino resin, 1 part of high-temperature-resistant organic pigment, 0.1 part of dispersant, 18 parts of aromatic hydrocarbon solvent, ethylene glycol alone 15 parts of butyl ether, 5 parts of n-butanol, and 16 parts of propylene glycol methyl ether acetate.

[0038] The epoxy outer coating comprises the following raw materials in parts by weight: 18 parts of ethylene glycol monobutyl ether, 8 parts of dibasic ester mixture, 20 parts of propylene glycol methyl ether acetate, 3 parts of n-butanol, and 18 parts of aromatic hydrocarbon solvent , 7 parts of nano graphite powder.

[0039] The passivation stock solution includes the following raw materials in parts by weight: 0.8 parts of hydrofluoric acid, 25 parts of nitric acid, and 4 parts of trivalent chromium.

[0040] A method for preparing a pull ring material sui...

Embodiment 3

[0043] The high temperature resistant inner coating of the present embodiment comprises the following raw materials in parts by weight: 46 parts of epoxy resin, 13 parts of amino resin, 5 parts of high temperature resistant organic pigment, 0.5 part of dispersant, 15 parts of aromatic hydrocarbon solvent, ethylene glycol mono 14 parts of butyl ether, 2 parts of n-butanol, 13 parts of propylene glycol methyl ether acetate.

[0044] The epoxy outer coating comprises the following raw materials in parts by weight: 15 parts of ethylene glycol monobutyl ether, 7 parts of dibasic ester mixture, 18 parts of propylene glycol methyl ether acetate, 4 parts of n-butanol, 20 parts of aromatic hydrocarbon solvent , 6 parts of nano graphite powder.

[0045] The passivation stock solution includes the following raw materials in parts by weight: 0.8 parts of hydrofluoric acid, 27 parts of nitric acid, and 5 parts of trivalent chromium.

[0046] A method for preparing a pull ring material sui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com