Composite light guide plate

A light guide plate and surface layer technology, which is applied in the field of light guide plates, can solve the problems affecting the durability and light guide performance of the light guide plate, cannot meet the needs of laser engraving outlets, and poor water absorption performance of the plate, so as to improve the utilization rate of light sources and laser processing performance Good, low coefficient of water expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

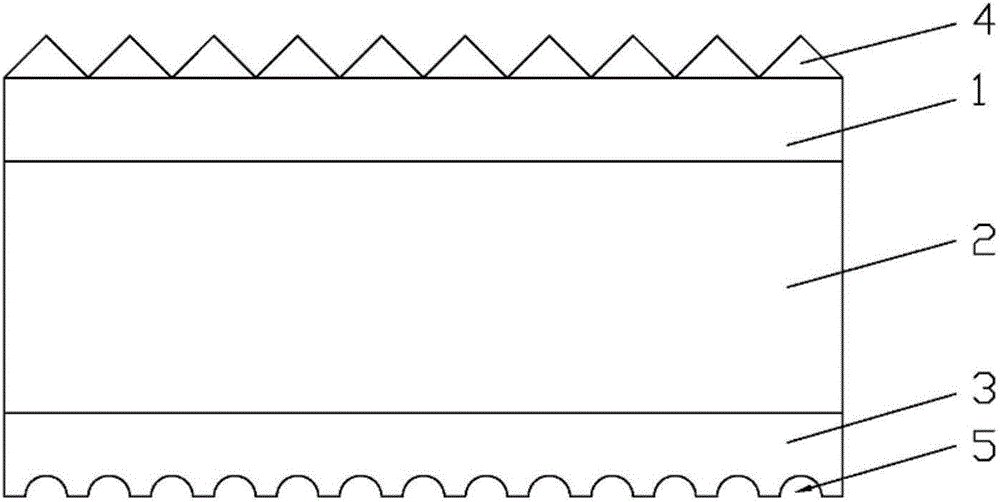

[0022] A composite light guide plate, comprising MS surface layer (1), PS base layer (2), MS bottom layer (3) from top to bottom, said MS surface layer (1), PS base layer (2), MS bottom layer (3) Composite connection is adopted in a co-extrusion film compound method, the MS bottom layer (3) is provided with a light guide dot layer (5) carved by laser, and the MS surface layer (1) is provided with a mold The thermoformed prism array surface layer (4).

[0023] The thickness of the PS matrix layer (2) is 60% of the total thickness of the composite light guide plate.

[0024] The prisms in the prism arrangement surface layer (4) are formed into V-shaped polygonal rhomboids, the distance between the peaks of two adjacent V-shaped polygonal rhomboids is 30um, and the height range of the prisms is 15um.

[0025] In the specific production, the prepared MS plate raw materials and PS plate raw materials are selected and put into two screw extruders respectively. After the screw is me...

Embodiment 2

[0029] A composite light guide plate, comprising MS surface layer (1), PS base layer (2), MS bottom layer (3) from top to bottom, said MS surface layer (1), PS base layer (2), MS bottom layer (3) Composite connection is adopted in a co-extrusion film compound method, the MS bottom layer (3) is provided with a light guide dot layer (5) carved by laser, and the MS surface layer (1) is provided with a mold The thermoformed prism array surface layer (4).

[0030] The thickness of the PS matrix layer (2) is 96% of the total thickness of the composite light guide plate.

[0031] The prisms in the prism arrangement surface layer (4) are formed into V-shaped polygonal rhomboids, the distance between the peaks of two adjacent V-shaped polygonal rhomboids is 500um, and the height range of the prisms is 150um.

[0032] In the specific production, the prepared MS board material and PS board material are selected and put into two screw extruders respectively. After the screw is melted, it...

Embodiment 3

[0036] A composite light guide plate, comprising a MS surface layer (1), a PS base layer (2), and an MS bottom layer (3), the MS surface layer (1), PS base layer (2), and MS bottom layer (3) adopt a common Composite connection in extruded film, the MS bottom layer (3) is provided with a light guide dot layer (5) carved by laser, and the MS surface layer (1) is provided with diamonds formed by hot pressing of molds. Mirror arrangement finish (4).

[0037] The thickness of the PS matrix layer (2) is 45% of the total thickness of the composite light guide plate.

[0038] The prisms in the prism arrangement surface layer (4) are formed into V-shaped polygonal rhomboids, the distance between two adjacent V-shaped polygonal rhomboids is 350um, and the height range of the prisms is 100um.

[0039] In the specific production, the prepared MS board material and PS board material are selected and put into two screw extruders respectively. After the screw is melted, it enters the co-ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com