Nano ceramic alloy material for strengthening surface of ductile iron roller with laser and preparation method thereof

A nano-ceramic alloy and roll surface technology, which is applied in the field of laser strengthening alloy materials, can solve the problems of not seeing nano-ceramic alloy materials, achieve superior laser processing performance, good machine use effect, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiment:

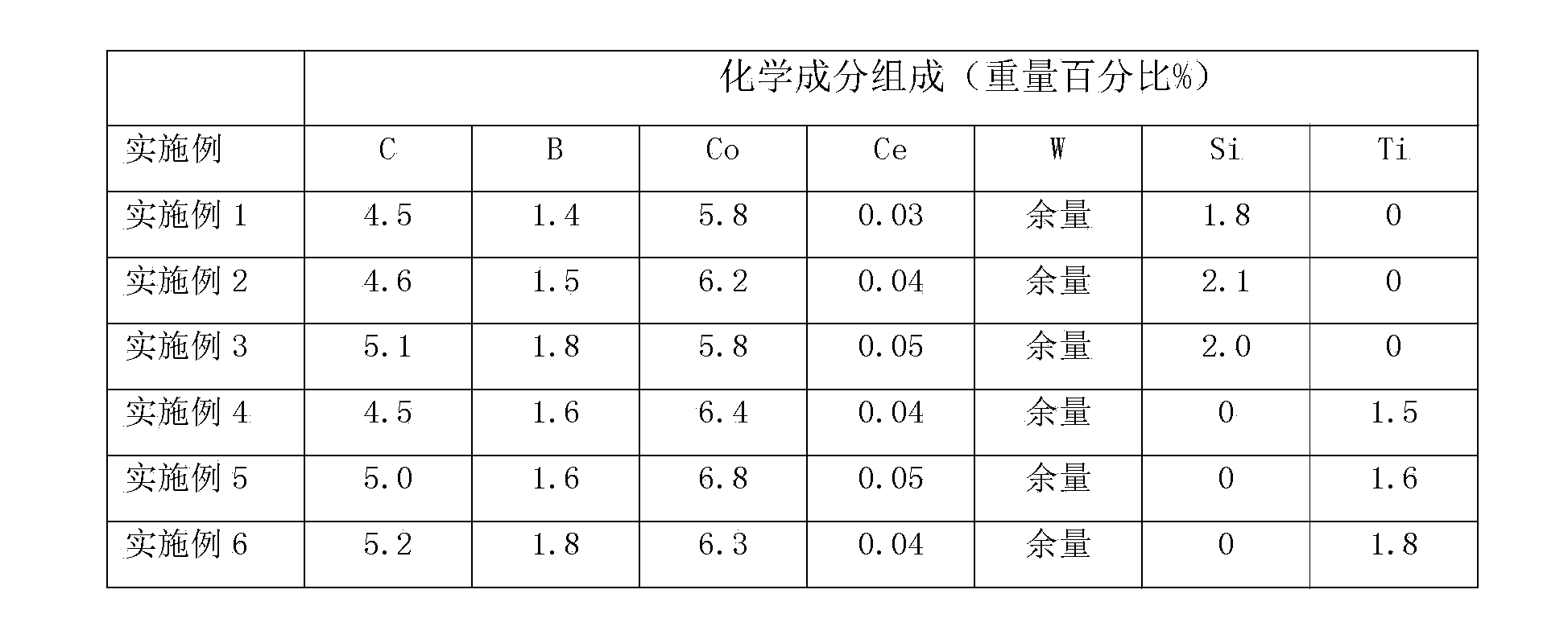

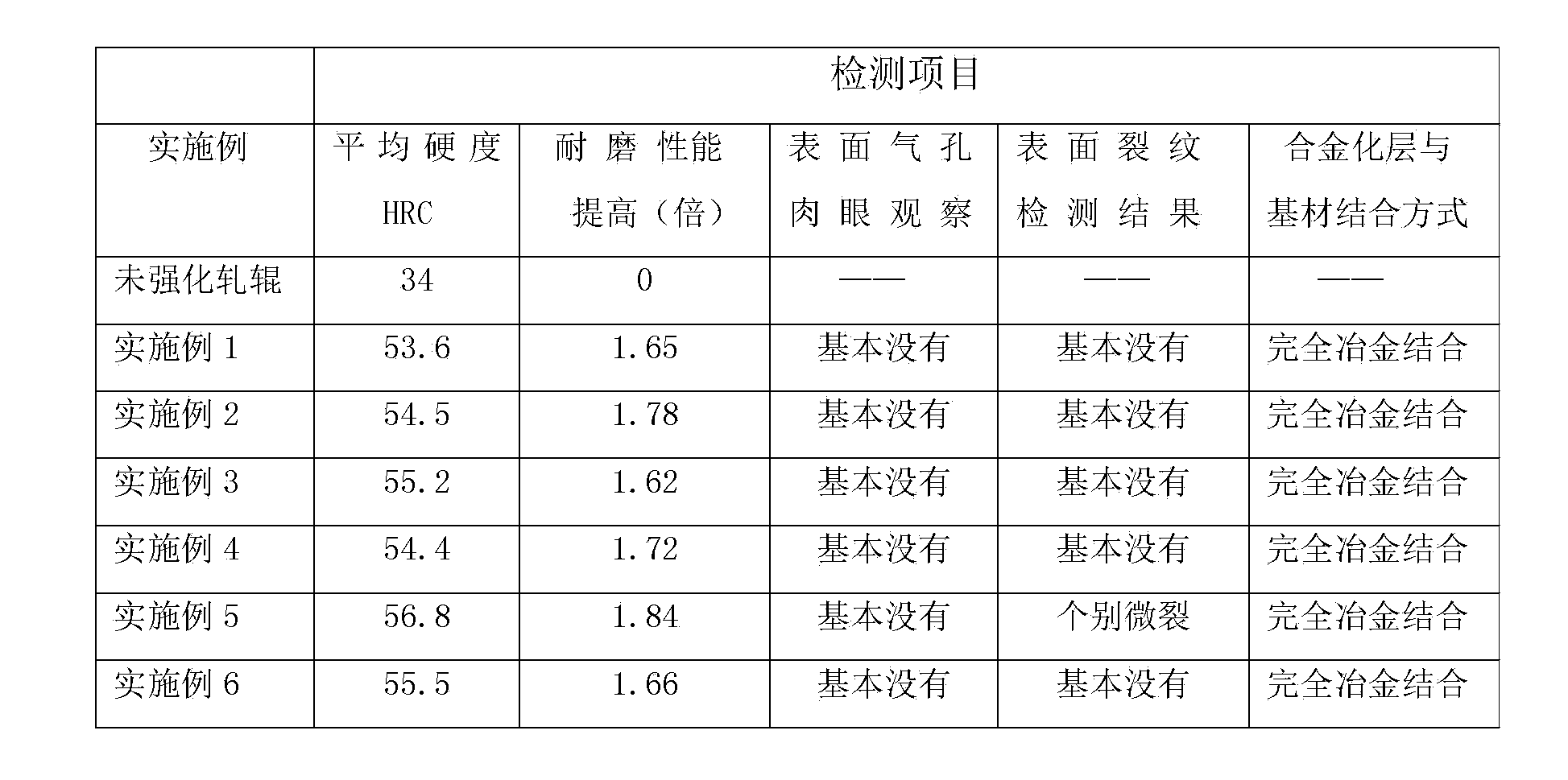

[0016] The invention provides a nano-ceramic alloy material for laser strengthening of the surface of a nodular iron roll, which is based on WC ceramic alloy, and its chemical composition is: C 4.0-5.5%, B 1.2-2.0%, Si 1.5- 2.5%, Co 4.0-14.0%, Ce 0.02-0.06%, W balance.

[0017] Another kind of nano-ceramic alloy material for laser strengthening of ductile iron roll surface is also based on WC ceramic alloy, and its chemical composition is as follows: C 4.0-5.5%, B 1.2-2.0%, Ti1.2-2.0% , Co 4.0~14.0%, Ce 0.02~0.06%, W balance.

[0018] In its preparation method, firstly, C, B, Co, Ce, and W elements are made into nano-ceramic alloy powder through spray pyrolysis, roasting, reduction, carbonization, and deoxidation, and then the average particle size is added to the powder by mechanical mixing. SiO below 0.3μm 2 or TiO 2 , Stir evenly that is the product. The chemical com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com