Patents

Literature

85results about How to "Small droplet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Measuring Analyte Concentrations in Liquids

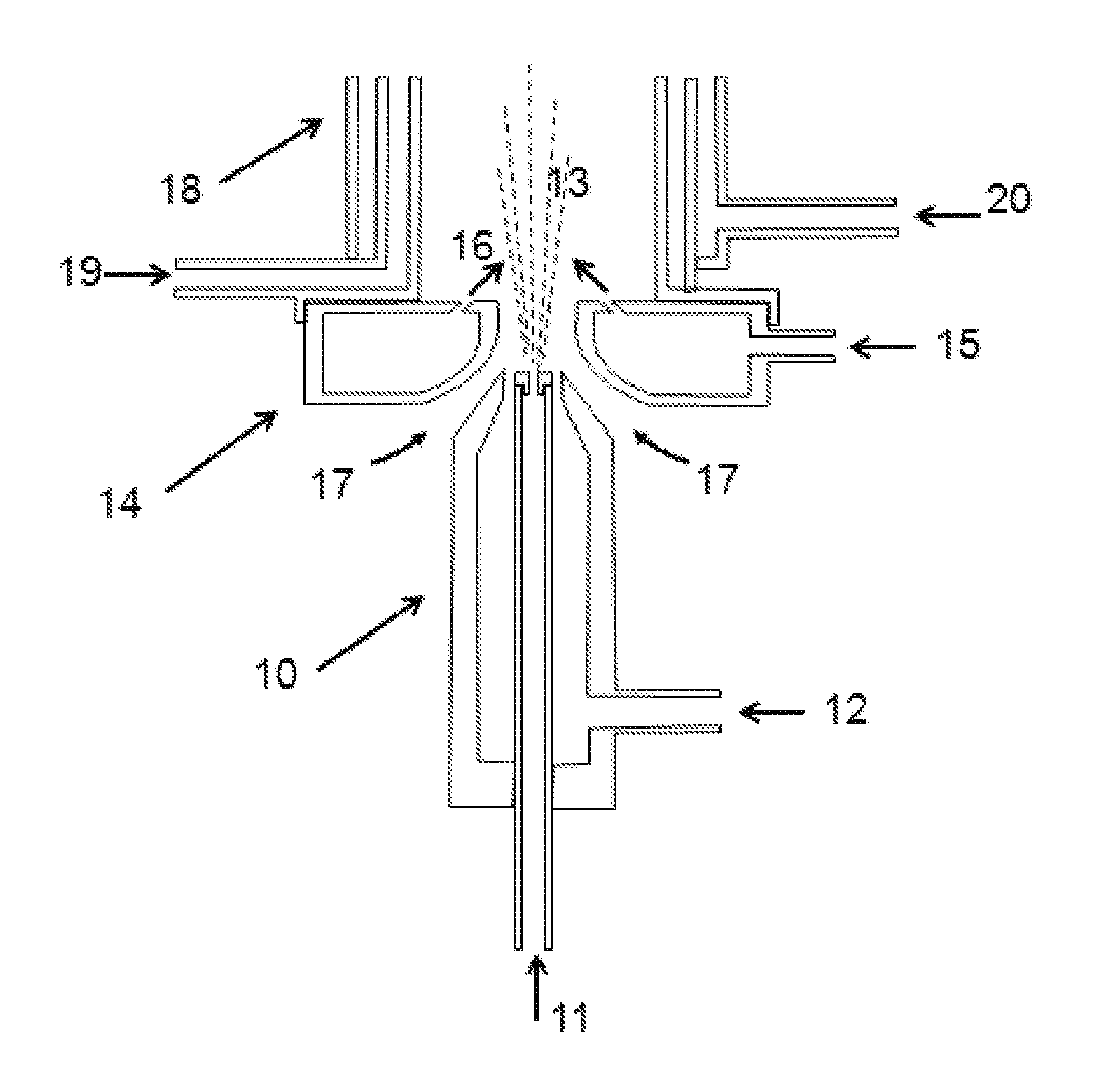

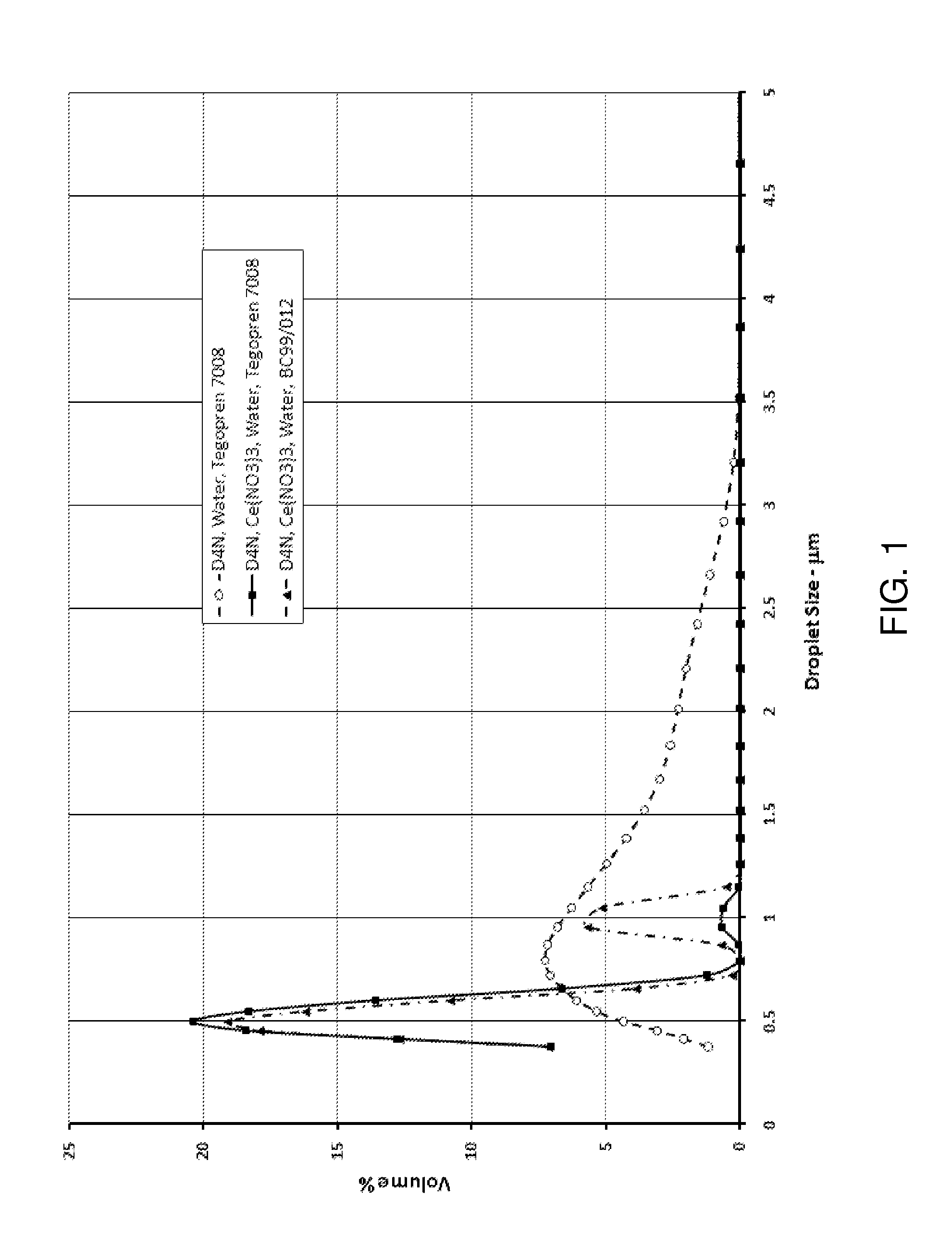

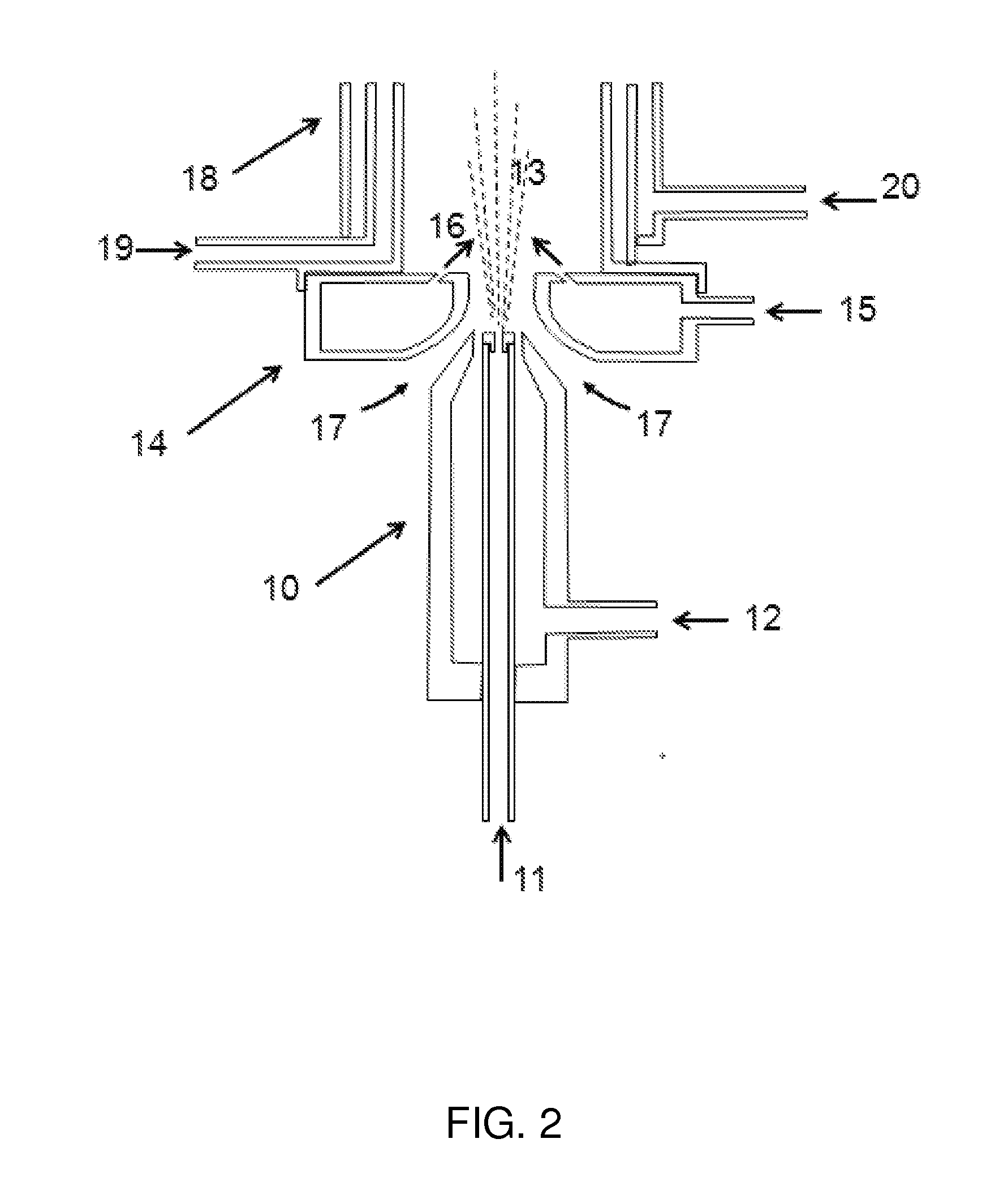

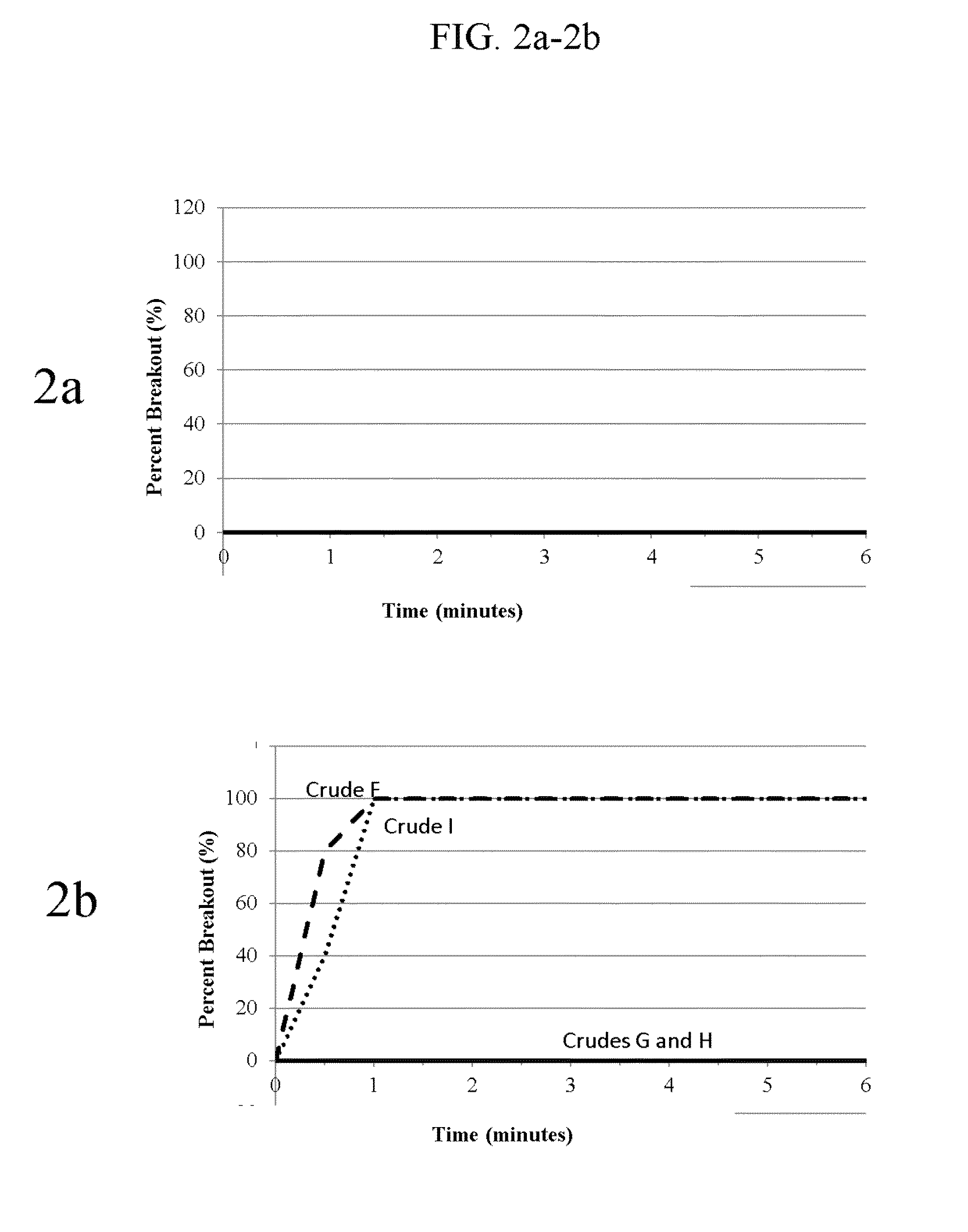

InactiveUS20080137065A1Higher kinetic energy mixingSmall dropletSamplingComponent separationElectrical mobilityDroplet size

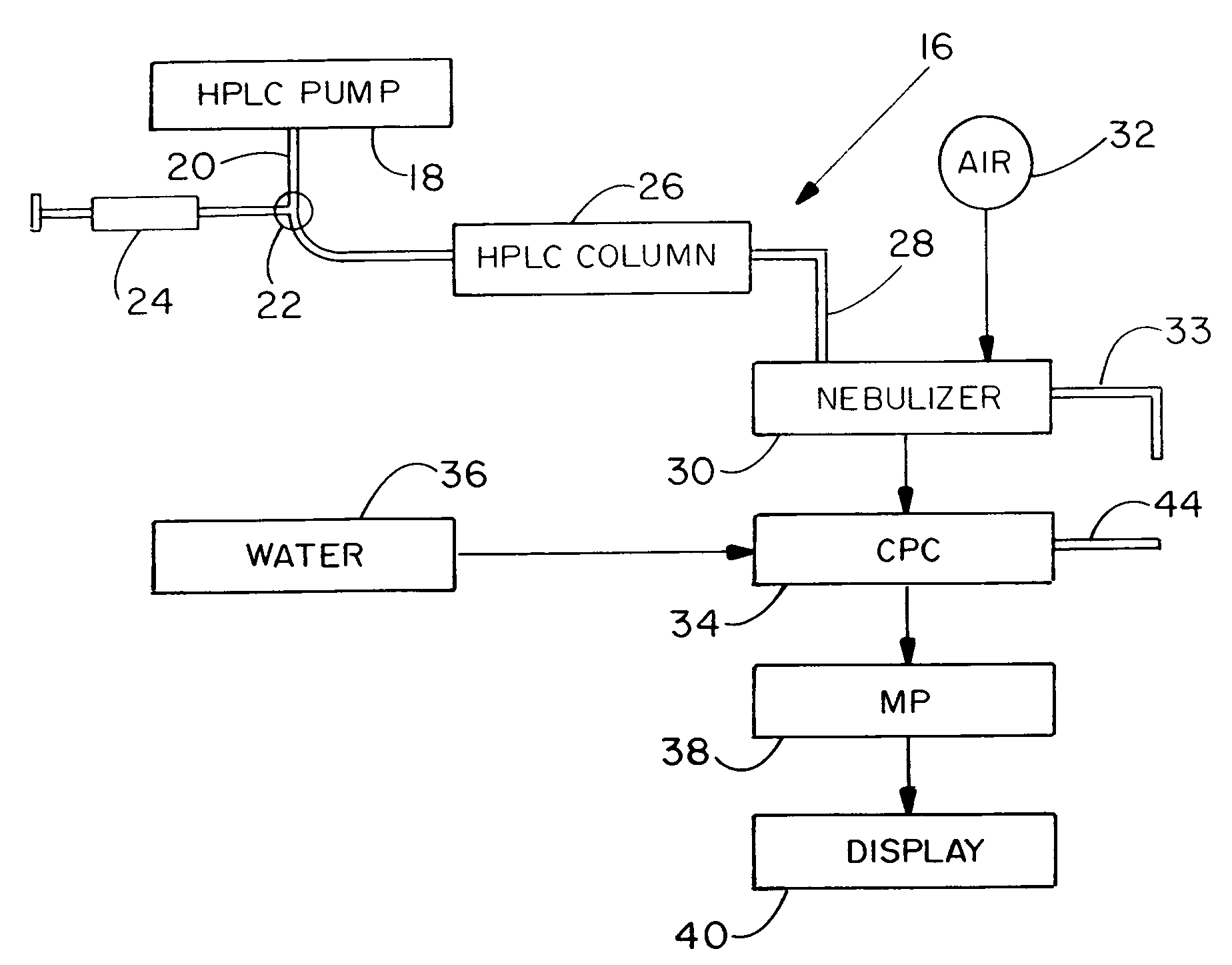

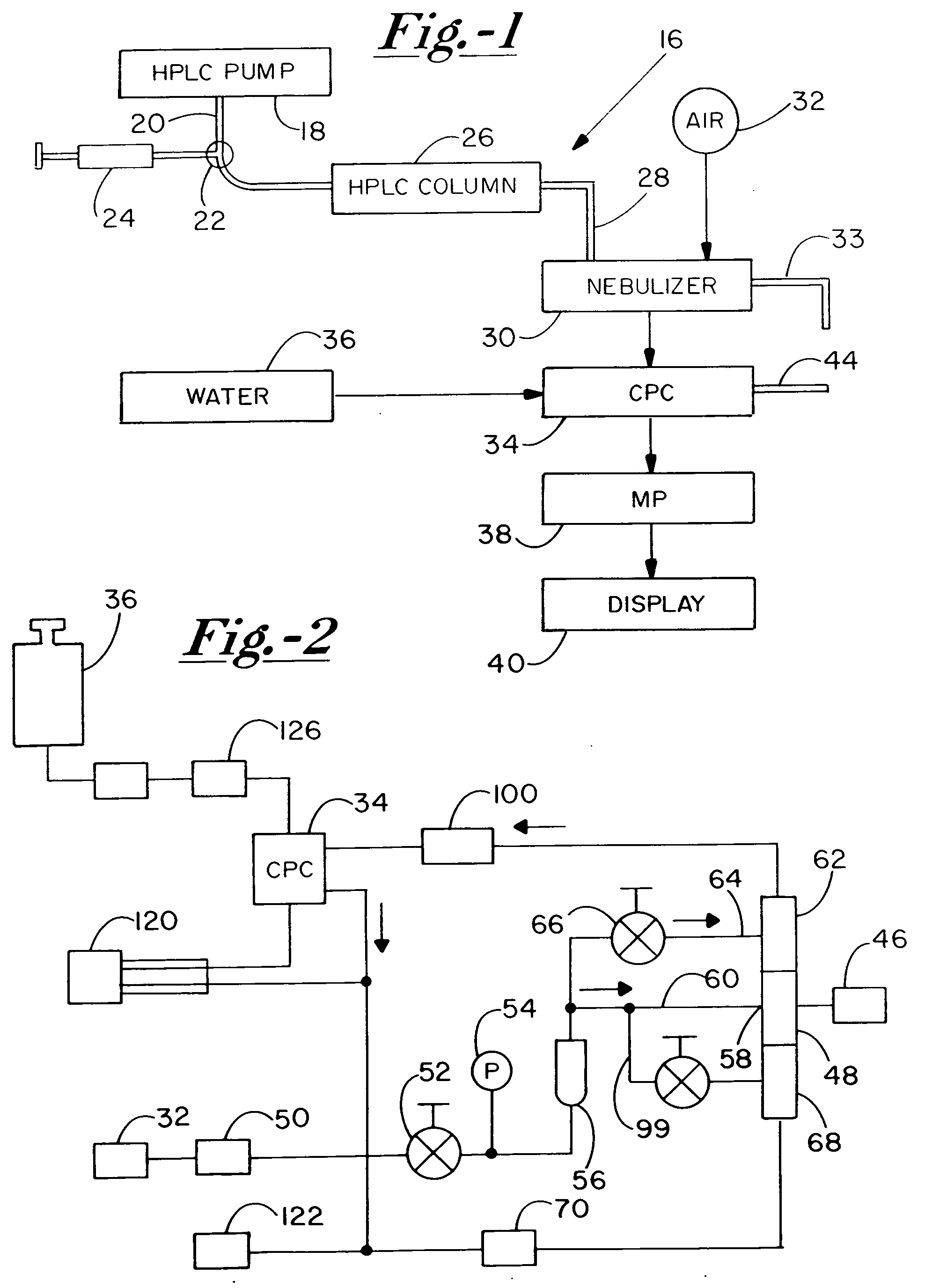

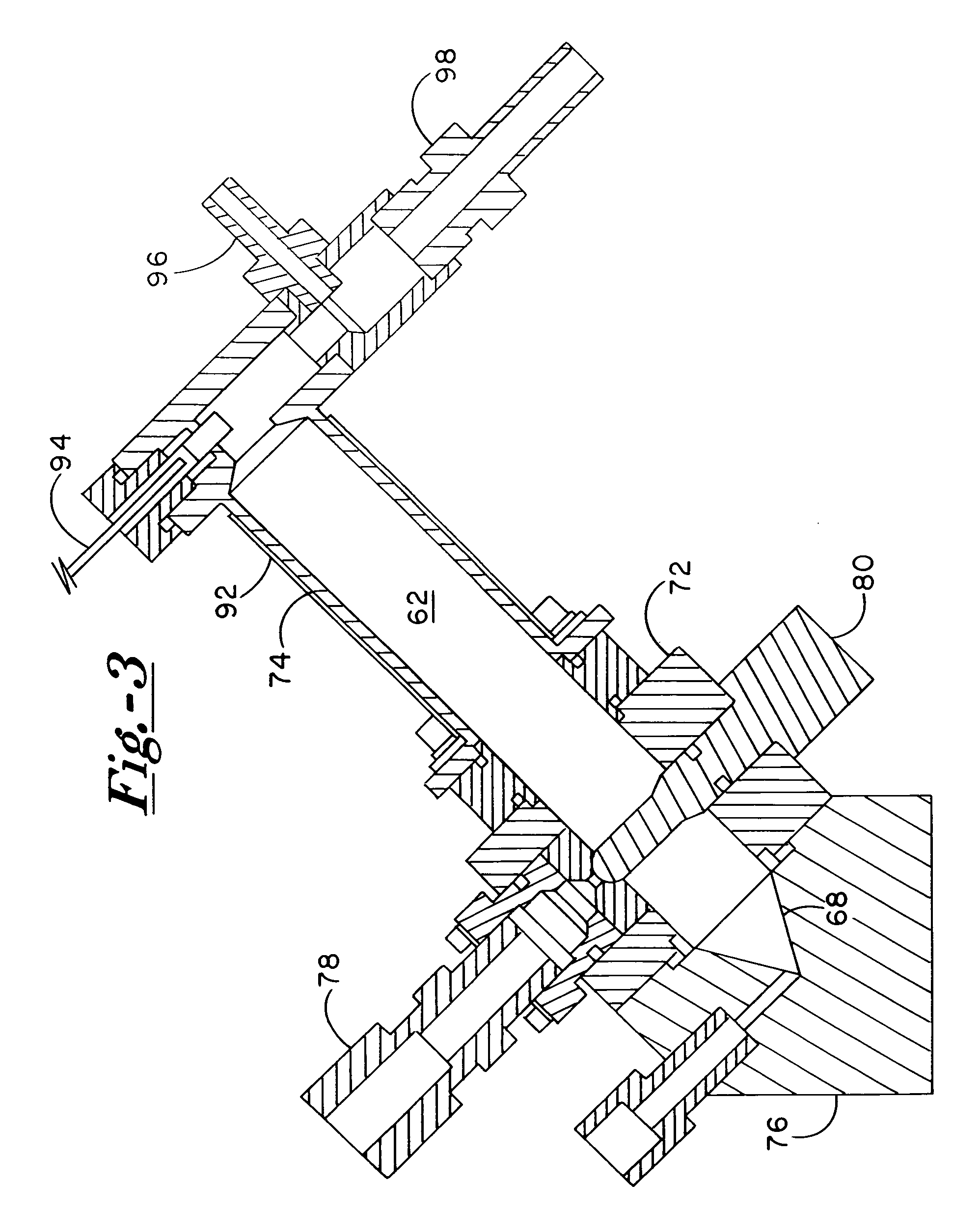

A high performance liquid chromatography system employs a nebulizer with a flow restriction at the exit of its mixing chamber to produce finer droplets, and an adjustable impactor for increased control over droplet sizes. Downstream of the mixing chamber, the nebulizer can incorporate tubing that is permeable to the sample liquid, to promote aerosol drying through perevaporation. A condensation particle counter downstream of the nebulizer uses water as the working medium, and is adjustable to control threshold nucleation sizes and droplet growth rates. A particle size selector employing diffusion, electrostatic attraction or selection based on electrical mobility, is advantageously positioned between the nebulizer and the CPC.

Owner:TSI INC

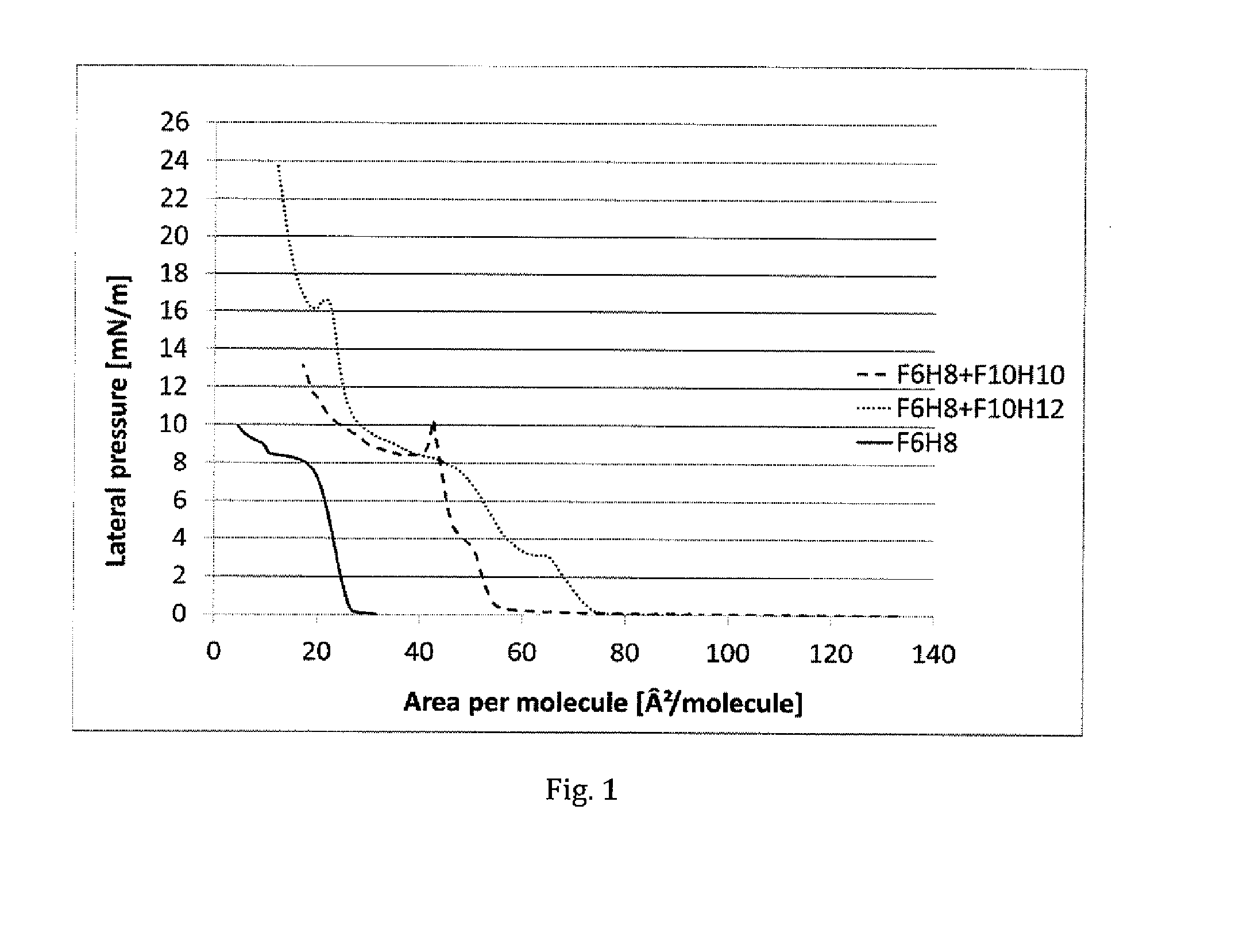

Compositions comprising mixtures of semifluorinated alkanes

ActiveUS20150224064A1Effective timeTune viscosityBiocideHalogenated hydrocarbon active ingredientsAlkaneKERATOCONJUNCTIVITIS SICCA

The invention provides novel compositions comprising at least two or more semifluorinated alkanes. The compositions can be used as medicines that are topically administered to an eye or ophthalmic tissue, such as for use in the treatment of keratoconjunctivitis sicca (dry eye) and / or meibomian gland dysfunction and symptoms associated therewith. The invention further provides kits comprising such compositions.

Owner:NOVALIQ GMBH

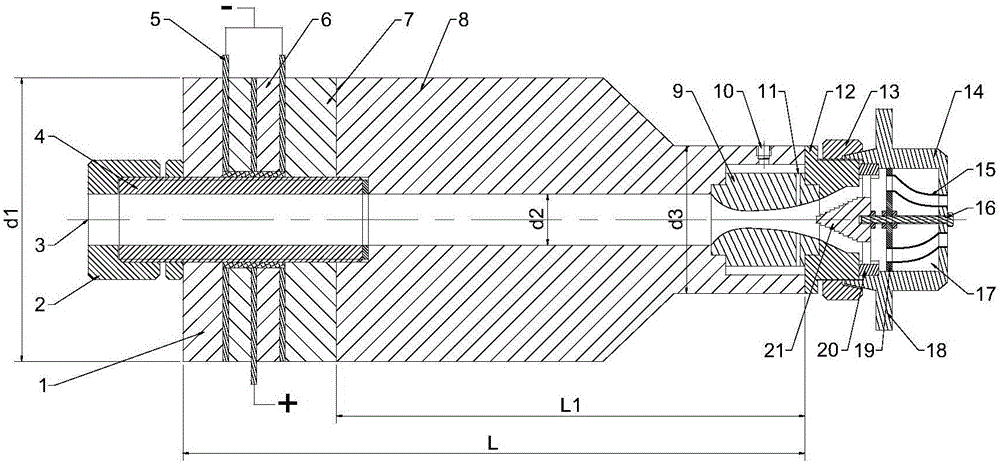

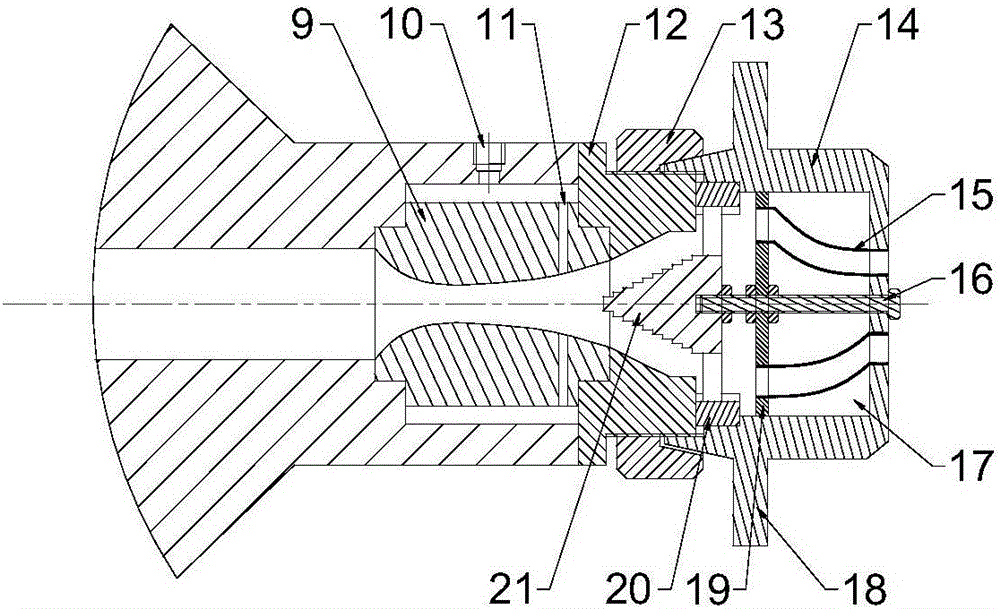

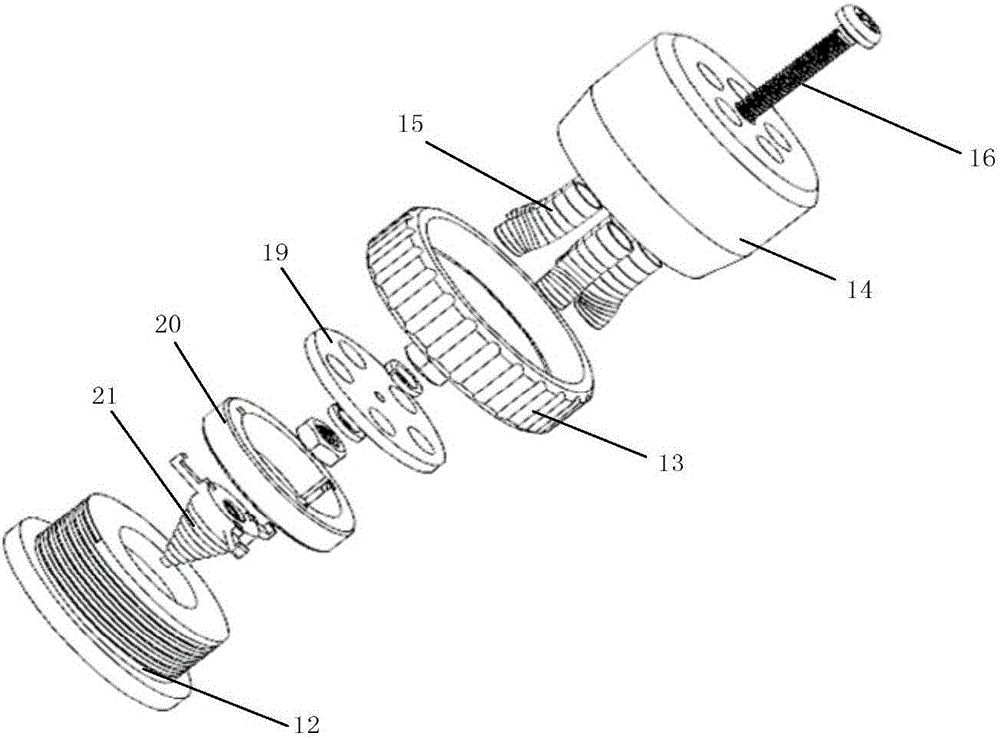

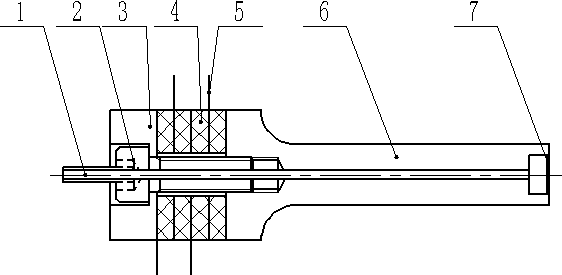

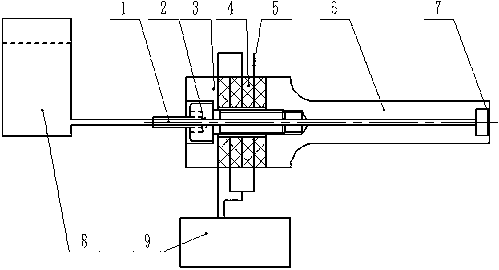

Piezoelectric two-phase flow ultrasonic atomization spraying nozzle

InactiveCN105834054ALarge amount of atomizationSmall dropletLiquid spraying apparatusElectricitySpray nozzle

The invention provides a piezoelectric two-phase flow ultrasonic atomization spraying nozzle. The piezoelectric two-phase flow ultrasonic atomization spraying nozzle comprises a piezoelectric vibrator, an amplitude-change pole, a second end cover and a first end cover; the piezoelectric vibrator and the amplitude-change pole are connected through a connecting bolt; an air inlet connector is installed at the tail of the connecting bolt; the second end cover is fixed to the front end of the amplitude-change pole; a laval type valve element is fixed into a step hole of the amplitude-change pole and a groove of the second end cover; a liquid inlet hole is formed in the hole wall face of the step hole of the amplitude-change pole; a plurality of flow guide holes are formed in the positions, close to an outlet, of the laval type valve element in the radial direction; the first end cover is threaded connection to the second end cover; a radial positioning ring is arranged at the position of a clamping groove in the back end of the first end cover; a step type taper valve is installed on the radial positioning ring; the step type taper valve and a vibration separating plate are connected through an adjusting bolt; a resonance chamber is formed between the vibration separating plate and the top end of the first end cover; and a plurality of flexible pipes are arranged in the resonance chamber. According to the piezoelectric two-phase flow ultrasonic atomization spraying nozzle, a large number of superfine fog drops are generated under the low-energy working condition, and the shortcoming that large pulverization amount, small grain size, low power dissipation and directed spraying cannot be considered at the same time through in the traditional technology is overcome.

Owner:JIANGSU UNIV

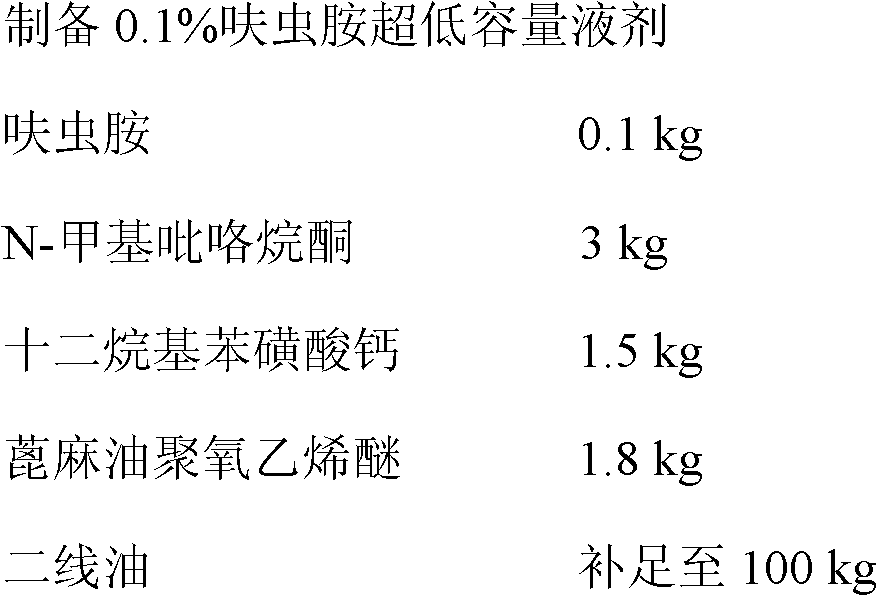

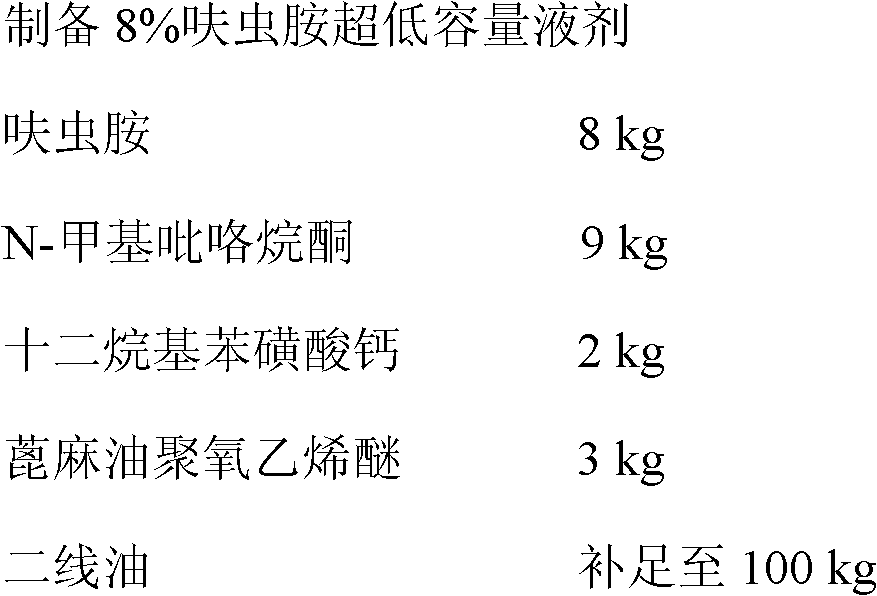

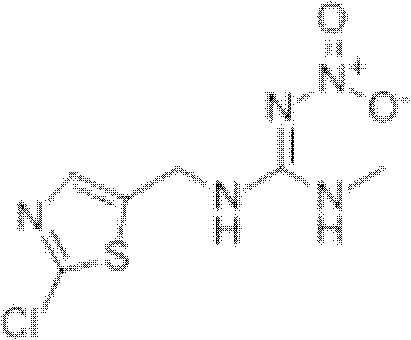

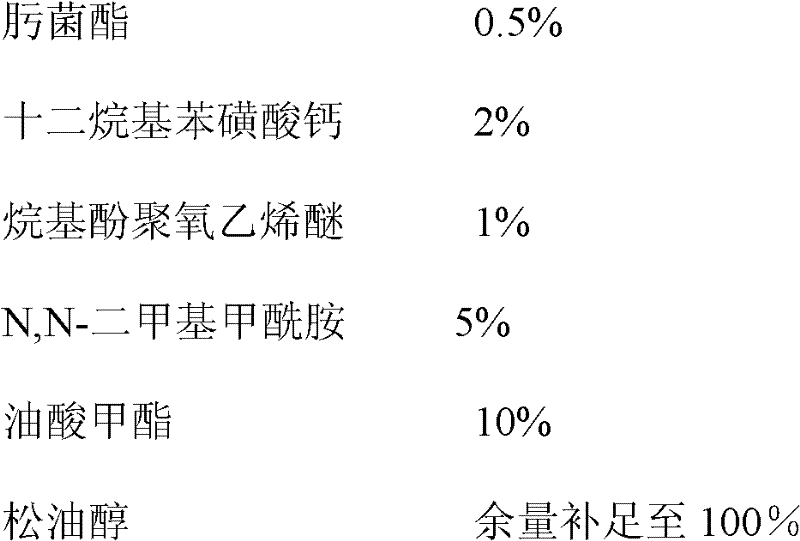

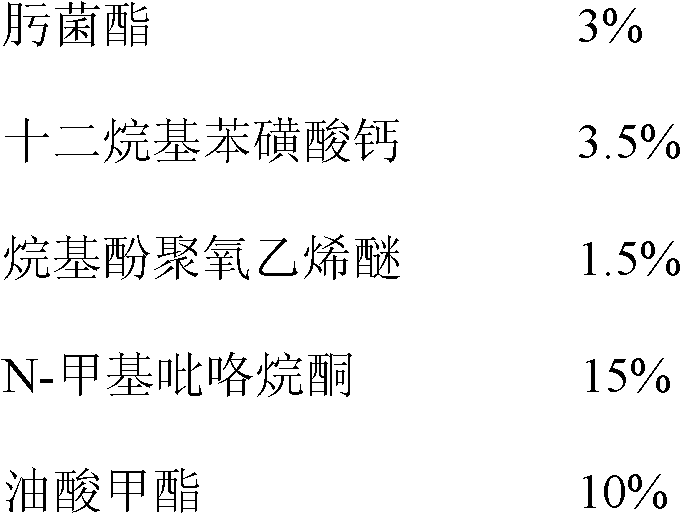

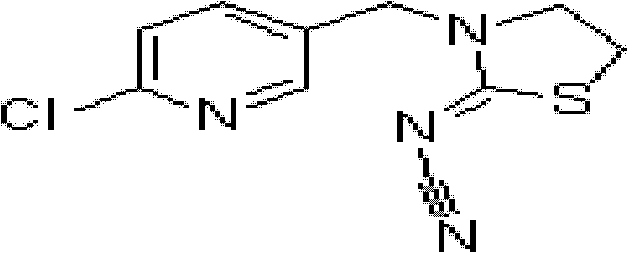

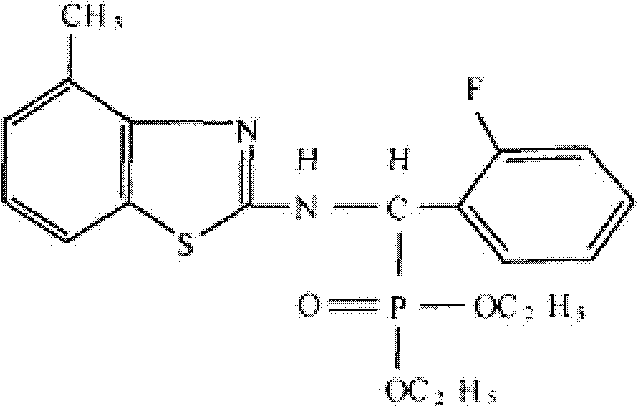

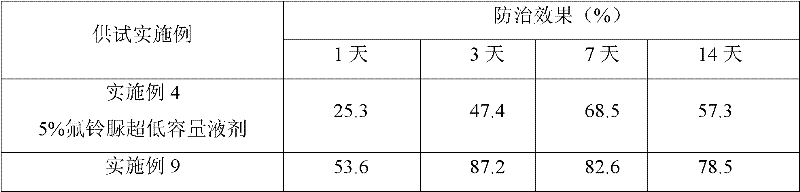

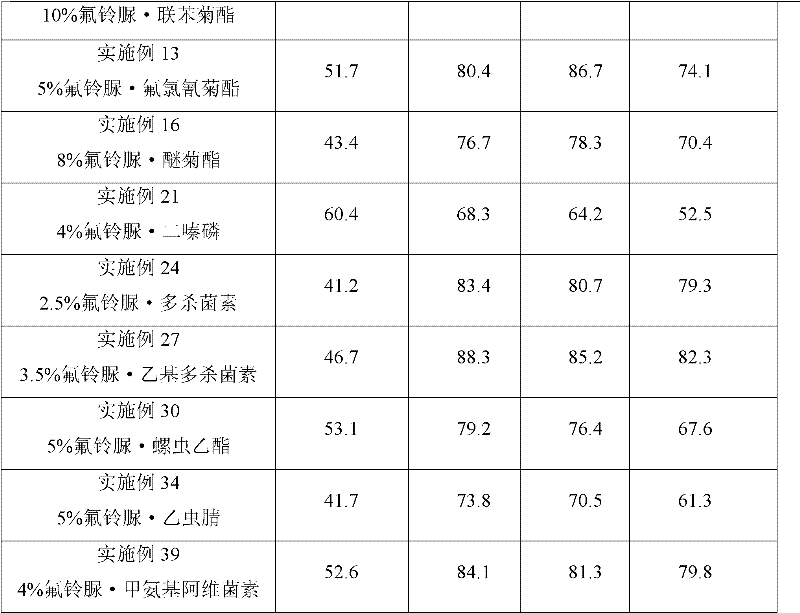

Ultra-low-capacity liquid containing dinotefuran

The invention discloses ultra-low-capacity liquid containing dinotefuran, which takes the dinotefuran or a combination of the dinotefuran and an active component II as an active ingredient. Other components comprise assistants and solvents which are complemented to form ultra-low-capacity liquid with content being 100 percent. The active component II is any one of imidaclothiz, high-efficacy cypermethrin, cypermethrin, ethofenprox, tolfenpyrad, flonicamid, chlorantraniliprole and the like. The ultra-low-capacity liquid containing the dinotefuran can be used for preventing and controlling cropinjurious insects such as rice plant hoppers, rice leaf folders, brown plant hoppers, white back plant hoppers, small brown plant hoppers, rice stem borers, rice thrips and the like, and has the advantages of convenience in production, water saving, high working efficiency, good efficacy, long efficacy duration, synergistic interaction and the like.

Owner:GAUNGXI TIANYUAN BIOCHEM

A kind of ultra-low volume liquid preparation containing thiamethoxam

The invention discloses an ultra-low-capacity liquid preparation containing thiamethoxam, which uses thiamethoxam, or the compound of thiamethoxam and active component II as the active ingredient, and supplements the rest to 100% with auxiliary agents and solvents. Low-volume liquid preparation; active component II is beta-cypermethrin, pymetrozine, chlorantraniliprole, flubendiamide, tofenpyrad, azadirachtin, buprofezin, abamectin, and emamectin Any one of plain benzoate and diazinon. The invention can be used to control crop pests such as rice planthopper, rice leaf roller, brown planthopper, white-backed planthopper, striatellus striatellus, stem borer and rice thrips, and has the advantages of convenient processing, water saving, high work efficiency and good drug effect , long-lasting, synergistic and other advantages.

Owner:GAUNGXI TIANYUAN BIOCHEM

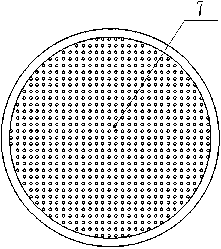

Ultrasonic vibration atomizer

InactiveCN103056061ASimple structureLarge power capacityLiquid spraying apparatusLiquid mediumEngineering

The invention discloses an ultrasonic vibration atomizer which comprises a liquid delivery pipeline, a bolt, a rear cover plate, a piezoelectric ceramic wafer, an electrode piece, an amplitude changing rod and a mesh vibration plate. The rear cover plate, the piezoelectric ceramic wafer, the electrode piece and the amplitude changing rod are sequentially sleeved on the bolt and connected and clamped through the bolt, the liquid delivery pipeline is connected at the rear end of the bolt, and the mesh vibration plate is arranged at the front end of the amplitude changing rod. An energy converter is of a sandwich type structure, and the ultrasonic vibration atomizer has the advantages of large power capacity, tiny and uniform in fogdrop after atomizing, effective in liquid medium atomizing, easy to control atomizing amount and the like.

Owner:SUZHOU UNIV OF SCI & TECH

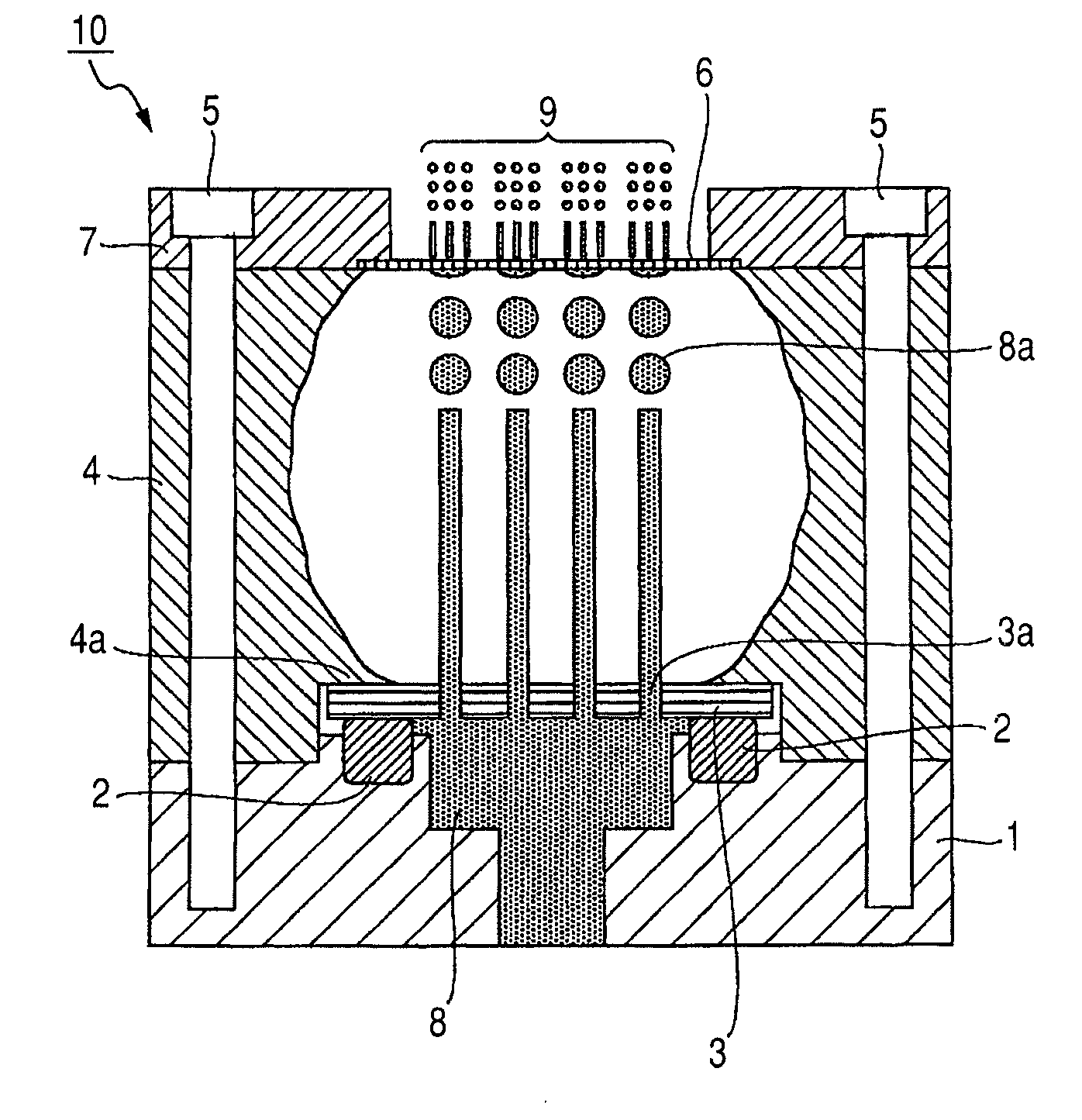

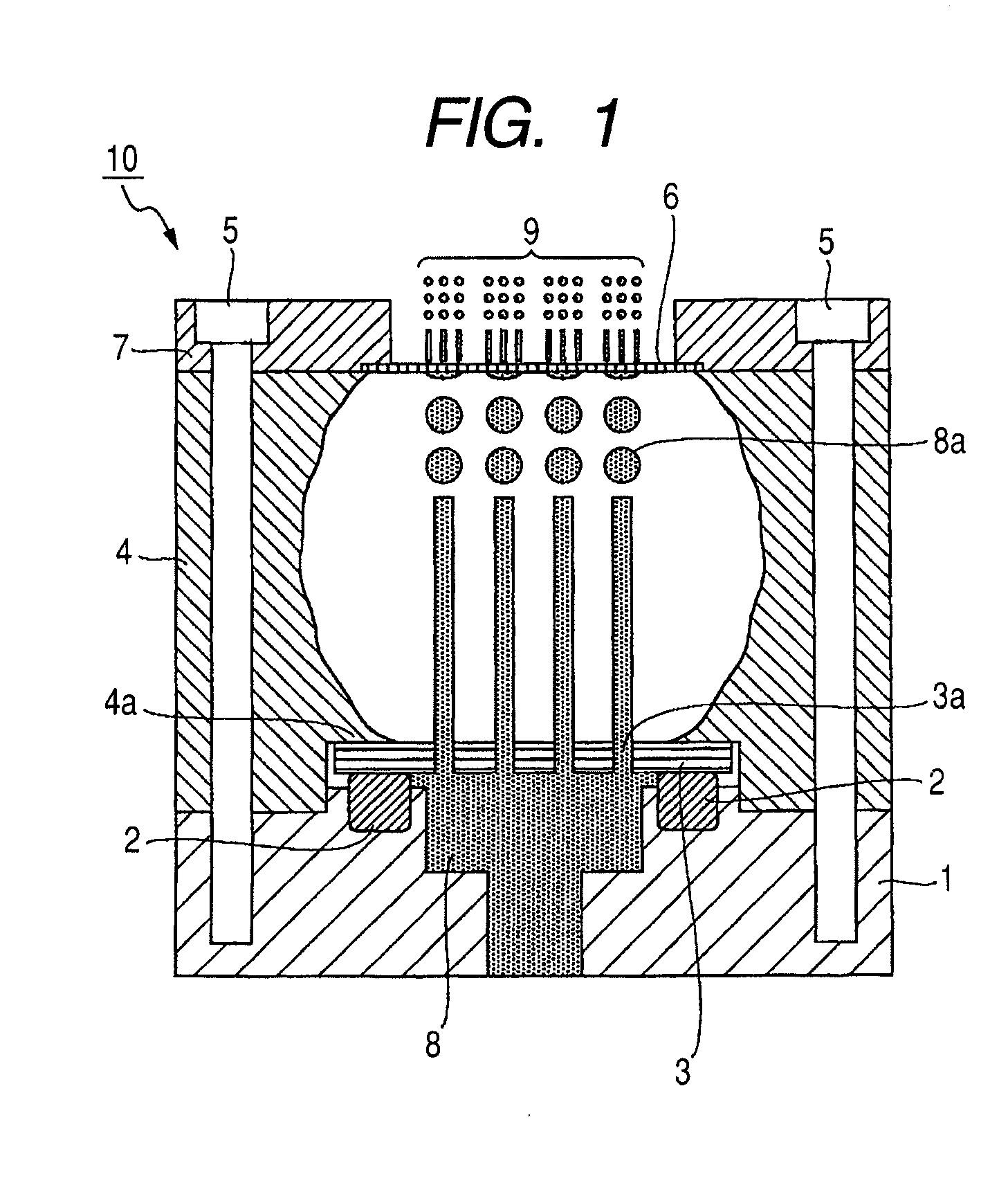

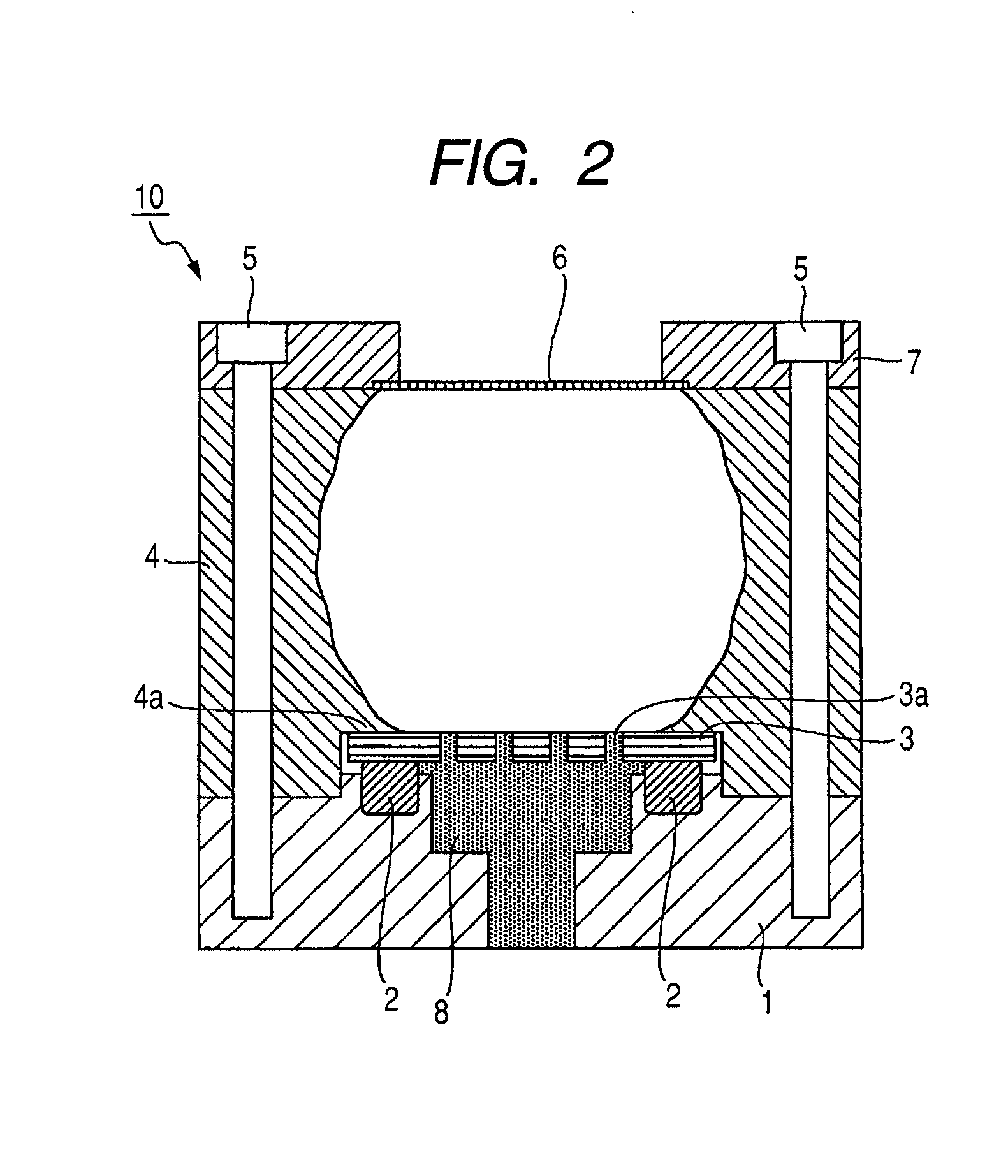

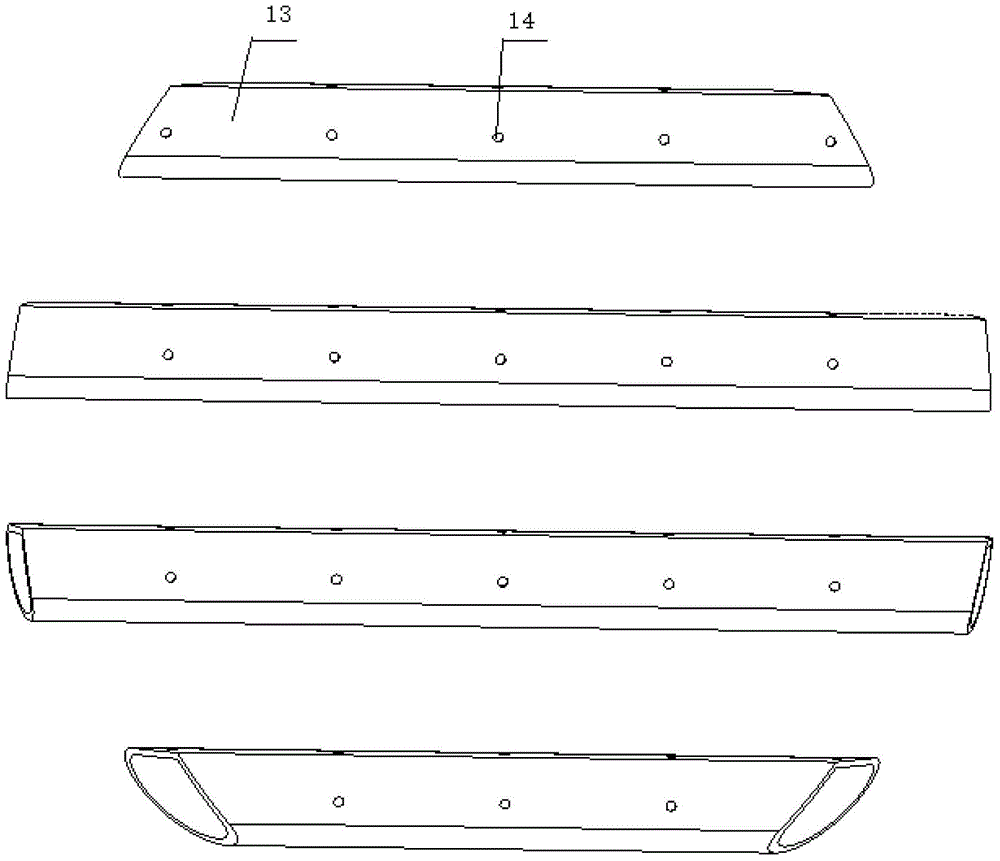

Discharge head and droplet discharging device

InactiveUS20100083956A1Small dropletReduce maintenanceMedical devicesLiquid spraying apparatusVena contracta diameterEngineering

A discharge head 10 for discharging droplets from discharge ports can withstand high water pressure and is provided with a first orifice plate 3 having first discharge ports 3a and a second orifice plate 6 having second discharge ports. The first orifice plate 3 and the second orifice plate 6 are separated from each other in the liquid discharge direction of the discharge head 10 and disposed opposite to each other. The diameter of the discharge ports of the second orifice plate 6 is smaller than the diameter of the discharge ports 3a of the first orifice plate 3 so that very fine droplets 9 are discharged from the discharge head 10 as the liquid discharged from the discharge ports 3a of the first orifice plate 3 is split by the second discharge ports.

Owner:CANON KK

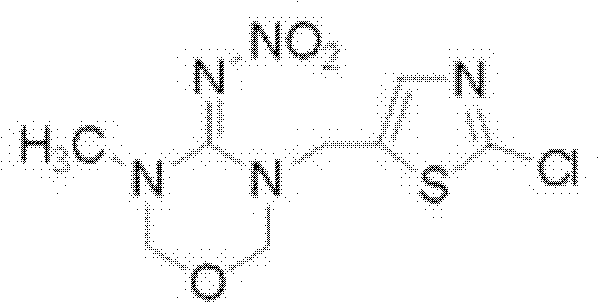

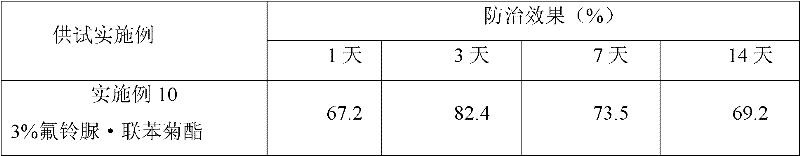

A kind of ultra-low volume liquid preparation containing clothianidin

The invention discloses an ultra-low-volume liquid preparation containing clothianidin, which uses clothianidin, or clothianidin and active component II as the active ingredient, and supplements the rest to 100% with auxiliary agents and solvents. Low-volume liquid preparation; active component II is any one of beta-cypermethrin, beta-cyfluthrin, chlorantraniliprole, flubendiamide, abamectin or emamectin benzoate. The invention can be used to control crop pests such as rice planthopper, rice leaf roller, brown planthopper, white-backed planthopper, striatellus striatellus, stem borer and rice thrips, and has the advantages of convenient processing, water saving, high work efficiency and good drug effect , long-lasting, synergistic and other advantages.

Owner:GAUNGXI TIANYUAN BIOCHEM

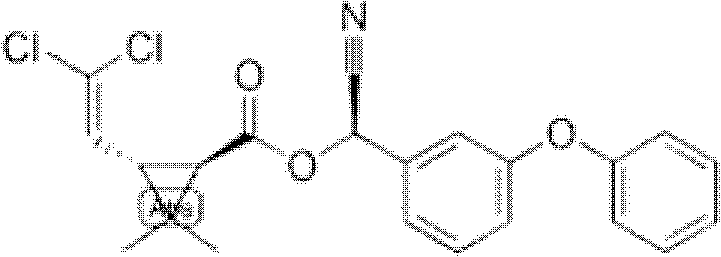

Super low volume liquid formulation containing trifloxystrobin

InactiveCN102379292AImprove ergonomicsImprove efficiencyBiocideFungicidesAdditive ingredientFlusilazole

The super low volume liquid formulation containing trifloxystrobin is prepared by using trifloxystrobin or trifloxystrobin and an active ingredient B as active components and adding auxiliary agent and solvent. The active ingredient B is selected from epoxiconazole, flusilazole, difenoconazole, propiconazole, myclobutanil, tebuconazole, tricyclazole, metalaxyl, chlorothalonil, carbendazim, prochloraz, isoprothiolane and fenoxanil. Weight percentage of each ingredient is as below: trifloxystrobin 0.5-15%, active ingredient B 0-20%, auxiliary agent 1-15% and solvent supplying to 100%. The invention has advantages of simple processing, high work efficiency, water saving, long persistent period, no target resistance generation, little environmental pollution and cooperation synergy, etc; and super low volume spraying, low volume spraying or super low volume electrostatic spraying can control a plurality of diseases of paddy rice, wheat, corn, vegetable, tobacco, tea tree, fruit tree and cotton, etc.

Owner:GAUNGXI TIANYUAN BIOCHEM

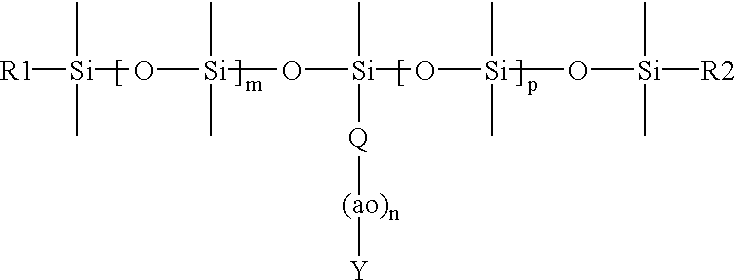

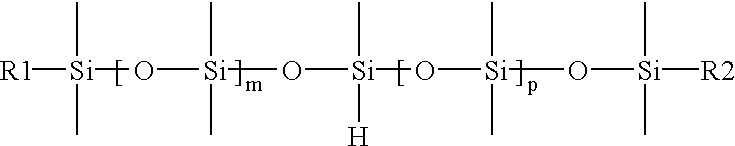

Binder resin and synergist composition including a parting agent and process of making lignocellulosic articles

InactiveUS20020121327A1MinimizationReduce moisture contentPaper/cardboard articlesWood working apparatusCellulosePyrrolidine

A method for preparing compression molded or pressed lignocellulosic articles is disclosed. The method involves forming a binder resin by combining a polyisocyanate component with a parting agent and preferably a synergist. The parting agent is the reaction product of an isocyanate compound and an isocyanate-reactive compound of the general structure R--(ao).sub.n--Y where: R is a hydrophobic group containing alkyl, alkaryl, polyaryl, or siloxane moieties; (ao) is an alkylene oxide or mixture of alkylene oxides; n is from 1 to 25; and Y represents a monofunctional isocyanate-reactive group. A resinated lignocellulosic mixture is formed by combining the binder resin with lignocellulosic particles. Then a compression molded or pressed lignocellulosic article is formed by compressing the resinated lignocellulosic mixture at an elevated temperature and under pressure. It is particularly preferred that the binder resin further include a synergist of either a C.sub.1-4 N-alkylpyrrolidone, gamma-butyrolactone, or a mixtures of them. The most preferred synergist is N-methyl-2-pyrrolidine.

Owner:BASF CORP

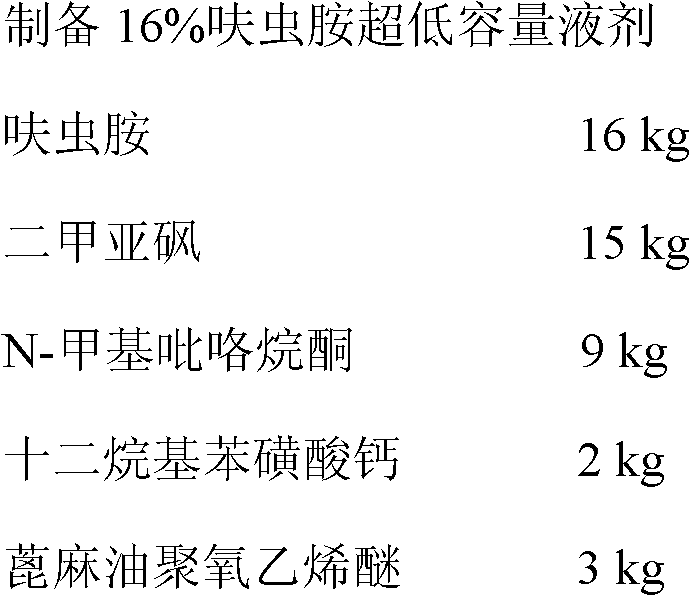

A kind of ultra-low volume liquid preparation containing thiacloprid

The invention discloses an ultra-low-volume liquid preparation containing thiacloprid, which uses thiacloprid, or a compound of thiacloprid and active component II as the active ingredient, and supplements the rest to 100% with additives and solvents. Low-volume liquid formulation; active ingredient II is beta-cypermethrin, pymetrozine, chlorantraniliprole, flubendiamide, tofenpyrad, azadirachtin, buprofezin, abamectin or emamectin Any of the plain benzoates. The invention can be used to control crop pests such as rice planthopper, rice leaf roller, brown planthopper, white-backed planthopper, striatellus striatellus, stem borer and rice thrips, and has the advantages of convenient processing, water saving, high work efficiency and good drug effect , long-lasting, synergistic and other advantages.

Owner:GAUNGXI TIANYUAN BIOCHEM

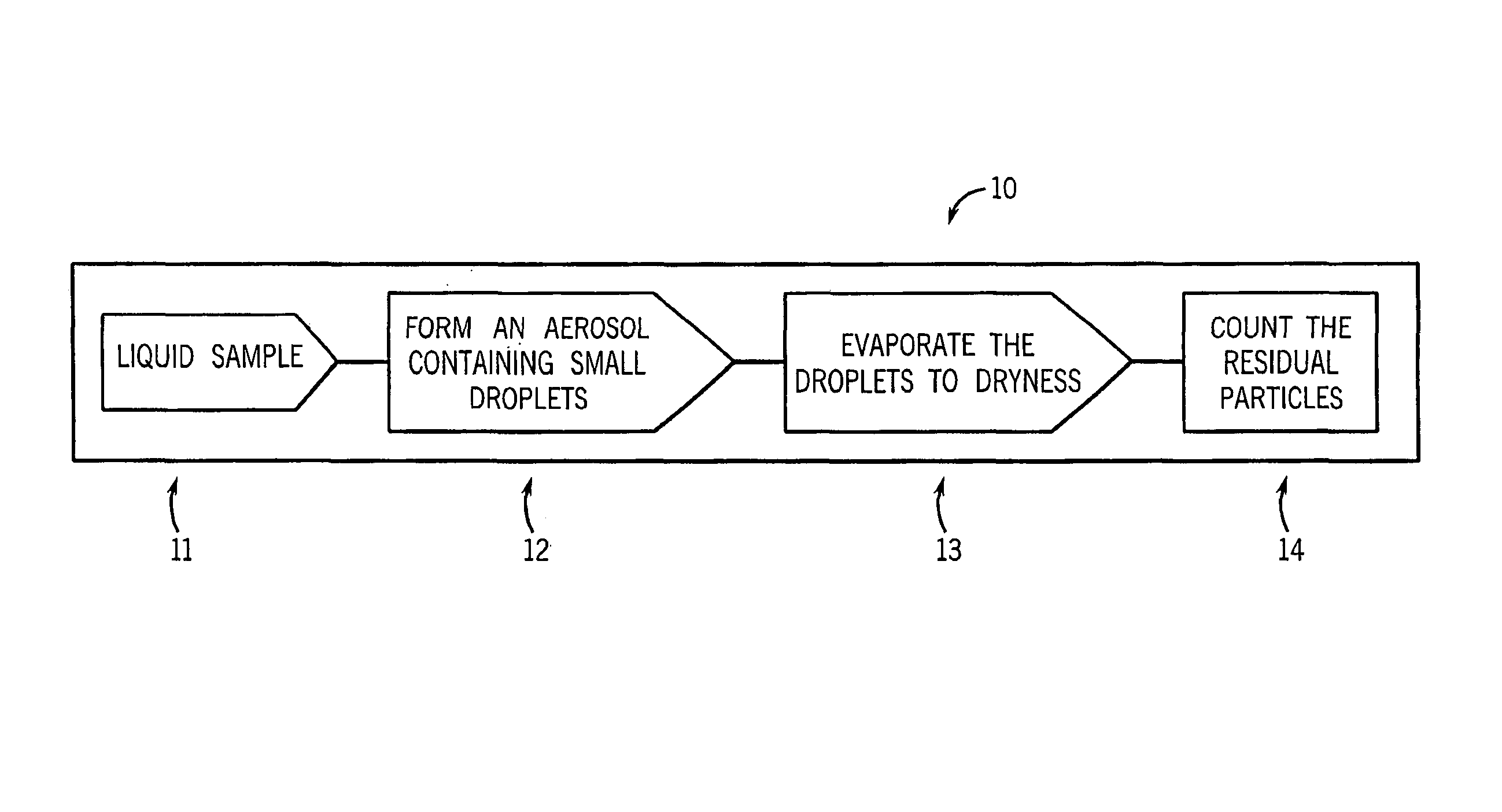

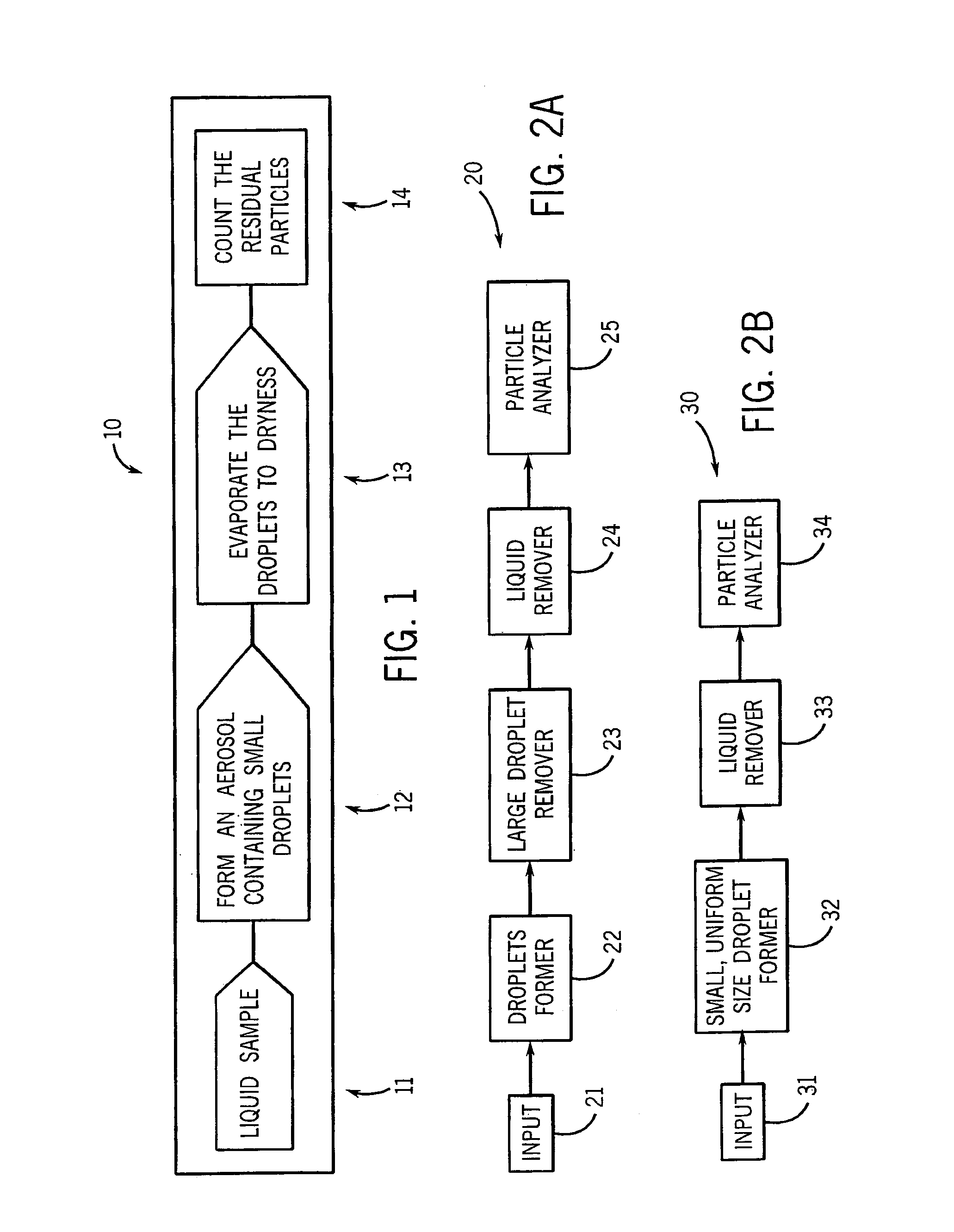

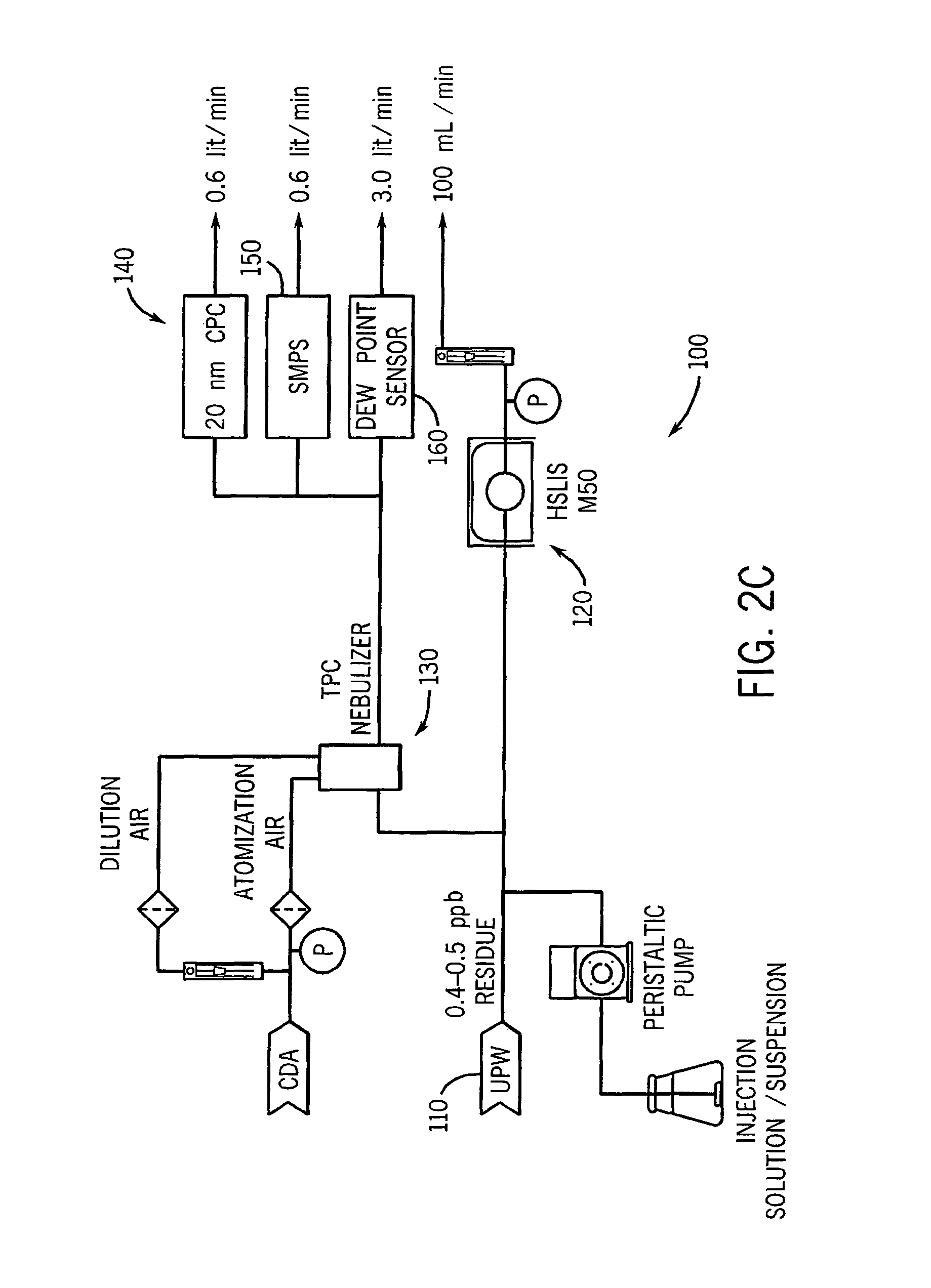

Residue concentration measurement technology

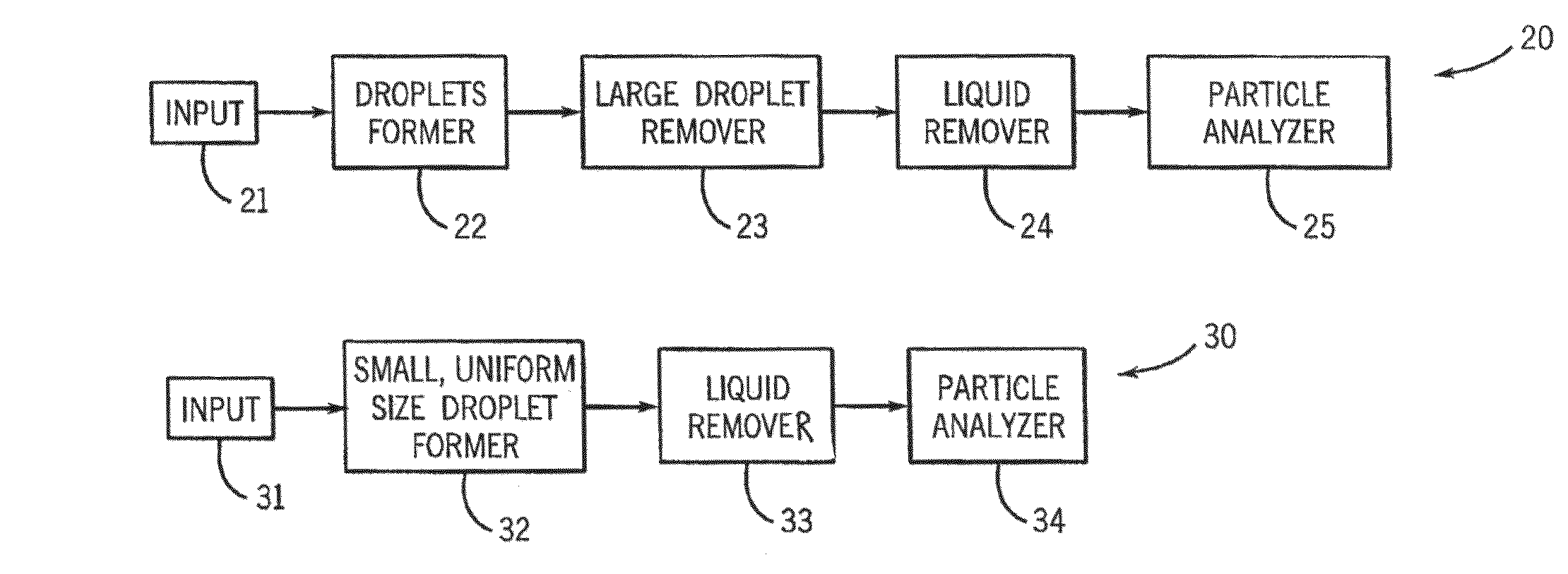

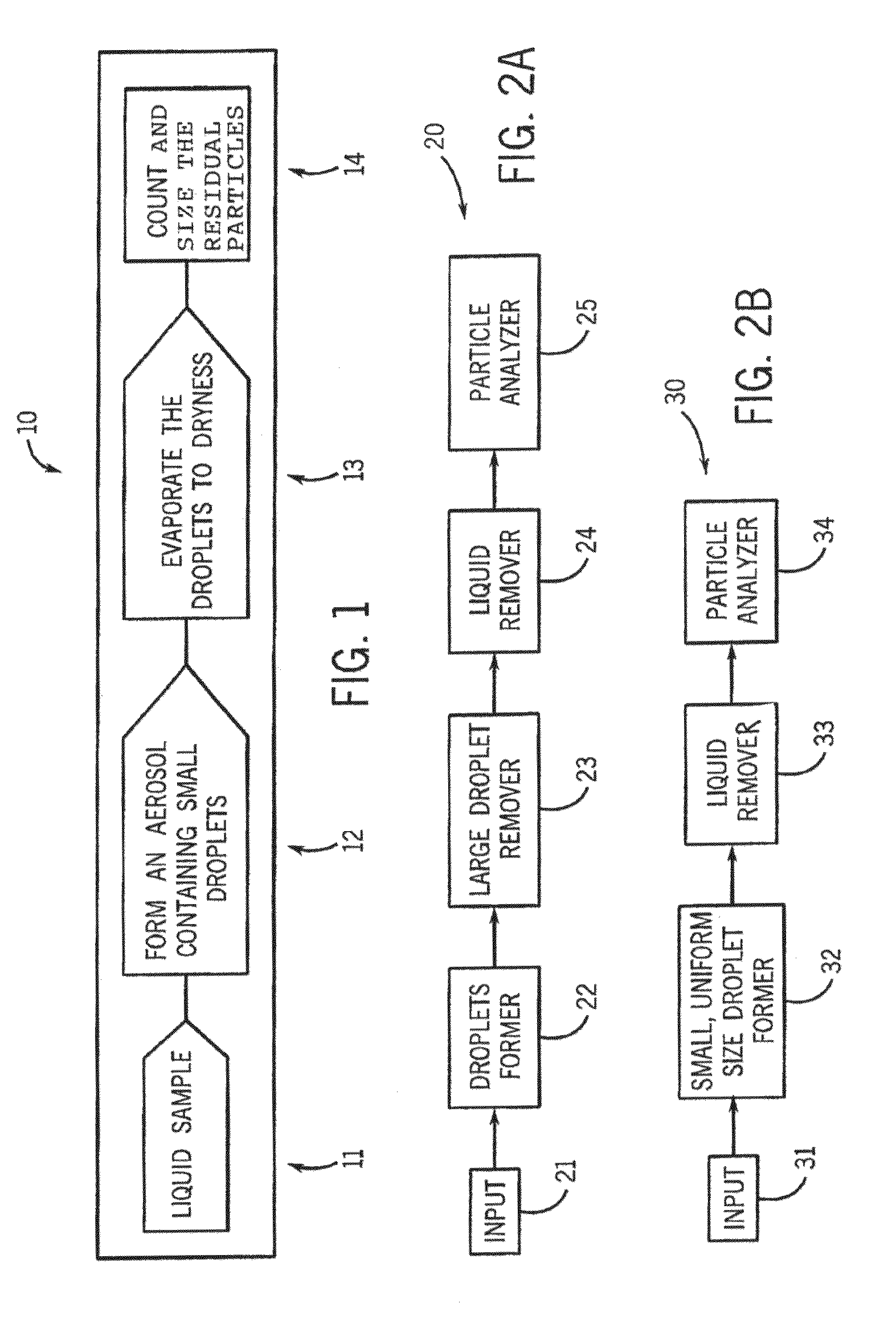

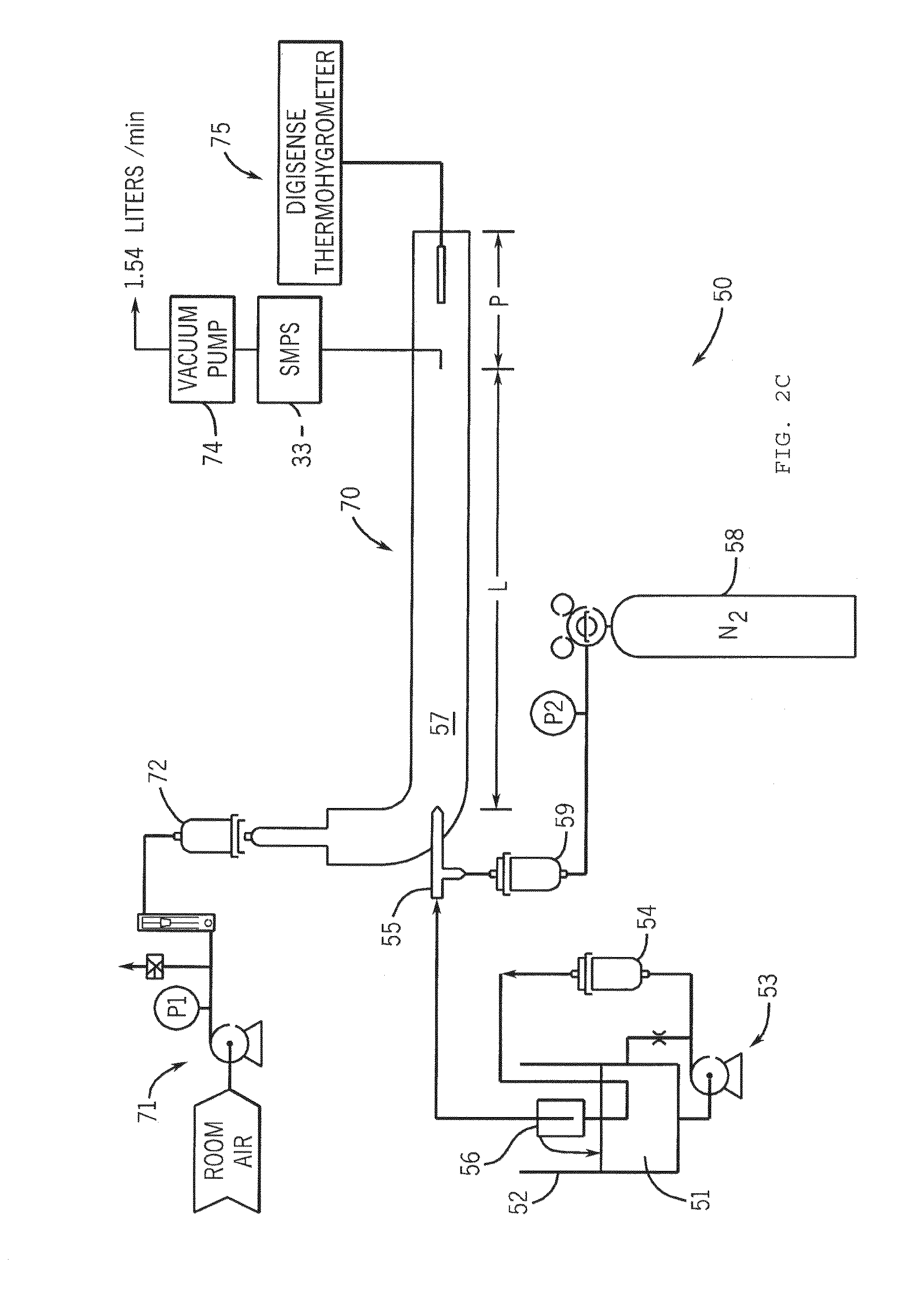

ActiveUS8573034B2Higher kinetic energy mixingSmall dropletComponent separationFlow propertiesParticulatesColloid

A method and apparatus for measuring dissolved residue concentrations and particulate residue particle concentrations and size distribution in liquids, particularly colloidal suspensions. The method involves separating dissolved and particulate residues in liquids for subsequent analysis of the residue species. The method includes the steps of forming an aerosol from the liquid sample to be analyzed, evaporating the droplets in the aerosol to dryness, detecting and sizing the particles, and determining the liquid volumetric inspection rate. An apparatus for separating dissolved and particulate residues in liquids for determination of the concentrations of the two residue species as well as the size distribution of the particulate species is also disclosed. The apparatus includes a droplet former, a dryer communicatively connected to the droplet former, and a detector communicatively connected to the evaporator for detecting and sizing particles.

Owner:CT ASSOCS

Aqueous emulsion non-silicon defoamer and preparation method thereof

ActiveCN101780383BImprove surface activityEnhanced defoamingTransportation and packagingMixingWater basedEmulsion

The invention discloses an aqueous emulsion non-silicon defoamer and a preparation method thereof. The defoamer consists of a material with defoaming activity, an emulsifying material and a dispersion medium, wherein the material with defoaming activity consist of alkynol, higher aliphatic alcohol and glyceryl polyether; the emulsifying material consists of anionic emulsifier and non-ionic emulsifier; and the dispersion medium consists of water and glycol. The defoamer of the invention has excellent defoaming and anti-foaming functions and high wettability and stability and is particular suitable for water-based paint, oil ink and other systems.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

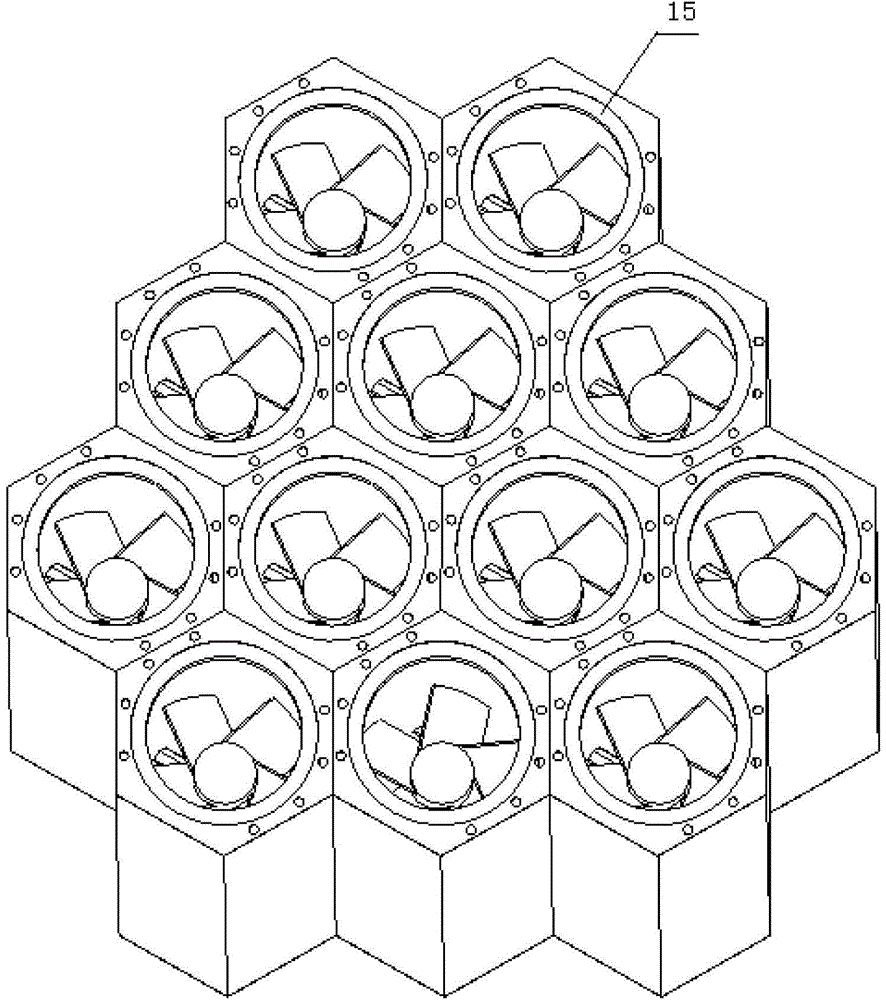

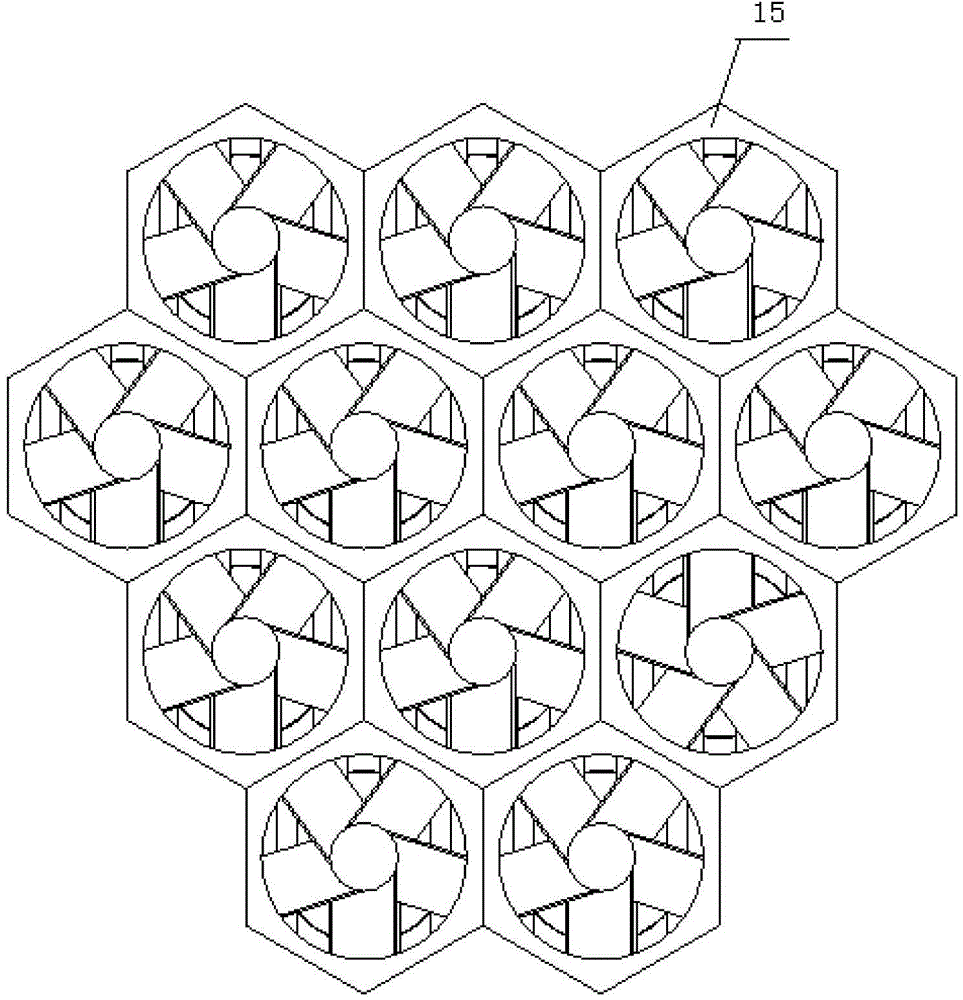

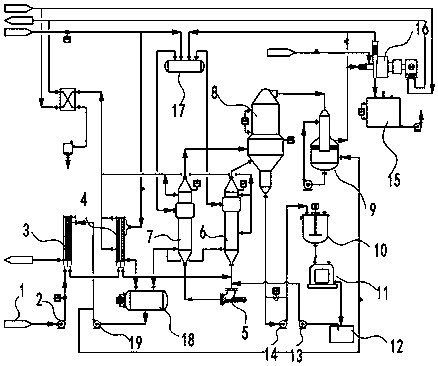

Phase-change dust-removing and mist-removing paralleling device of high-efficiency pneumatic pipe bundle and application

The invention relates to a phase-change dust-removing and mist-removing paralleling device of a high-efficiency pneumatic pipe bundle and an application. The phase-change dust-removing and mist-removing paralleling device comprises a plurality of phase-change dust-removing and mist-removing devices of the high-efficiency pneumatic pipe bundle, which are connected together in parallel; each of the phase-change dust-removing and mist-removing device comprises a hollow drum body with the openings at the two ends, a drum-body upper sealing plate, a drum-body lower sealing plate, a cyclone section, a pipe-bundle type water-mist distributing section and a water blocking section. The paralleling device has the advantages that the plurality of phase-change dust-removing and mist-removing devices are connected together in parallel, so that a user can assemble and adjust according to the treating capability needed practically, single phase-change dust-removing and mist-removing devices can be connected by adopting bonding, welding or hole grooves and the like; the manufacture is convenient and the waste-gas treating range is greatly expanded.

Owner:AEROSPACE ENVIRONMENTAL ENG

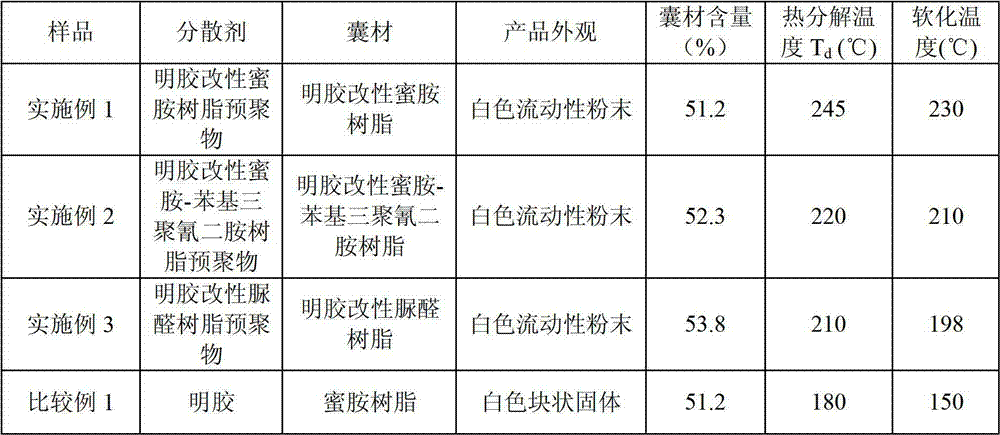

Heatproof microencapsulated essence and its preparation method

InactiveCN102787016ANarrow particle size distributionSmall particle size distributionEssential-oils/perfumesMicroballoon preparationPolymer scienceDecomposition

The invention discloses a heatproof microencapsulated essence used for thermoplastic high polymer materials, and its preparation method. The heatproof microencapsulated essence treats an oil-soluble liquid essence as a capsule core, a gelatin modified amino resin prepolymer as an emulsification dispersant and a gelatin modified amino resin composite material as a wall material. The preparation method of the heatproof microencapsulated essence comprises the processes of prepolymerization, emulsifying dispersion and microcapsule coating. The heat decomposition temperature and the softening temperature of the microencapsulated essence can reach above 200DEG C, mechanical performances comprising the heat resistance, the toughness and the like of the microencapsulated essence are excellent, and the microencapsulated essence has a long-lasting fragrance; and the particle size of the microencapsulated essence is 1-10mum, so the microencapsulated essence can be easily and uniformly dispersed in the high polymer materials.

Owner:HEFEI UNIV OF TECH +1

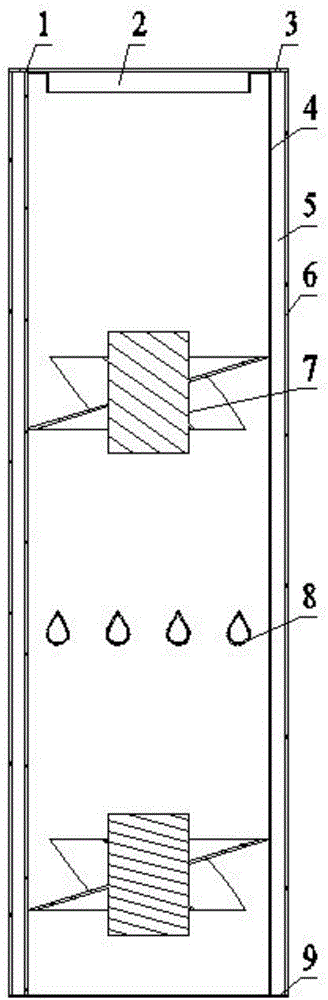

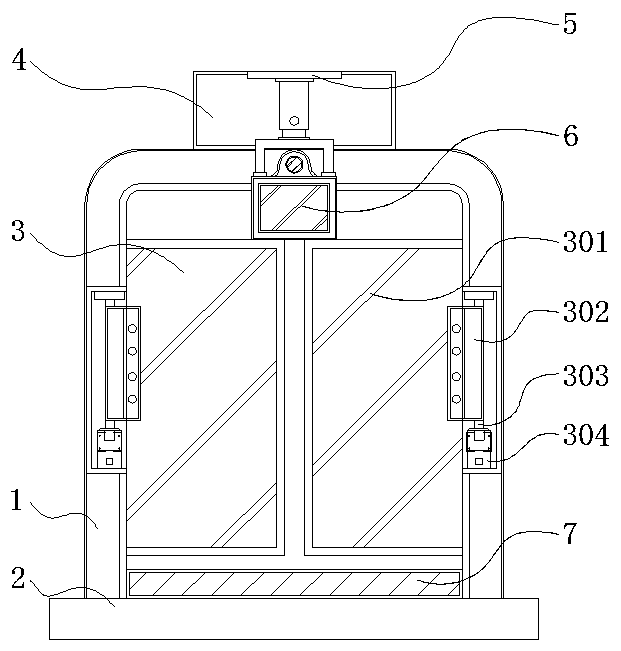

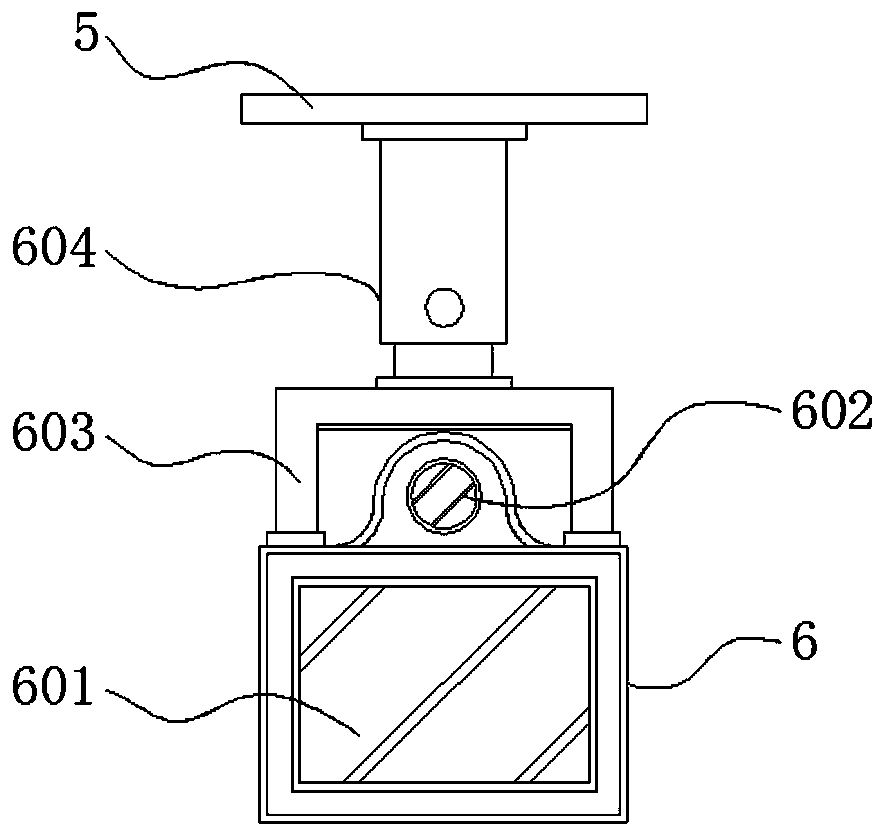

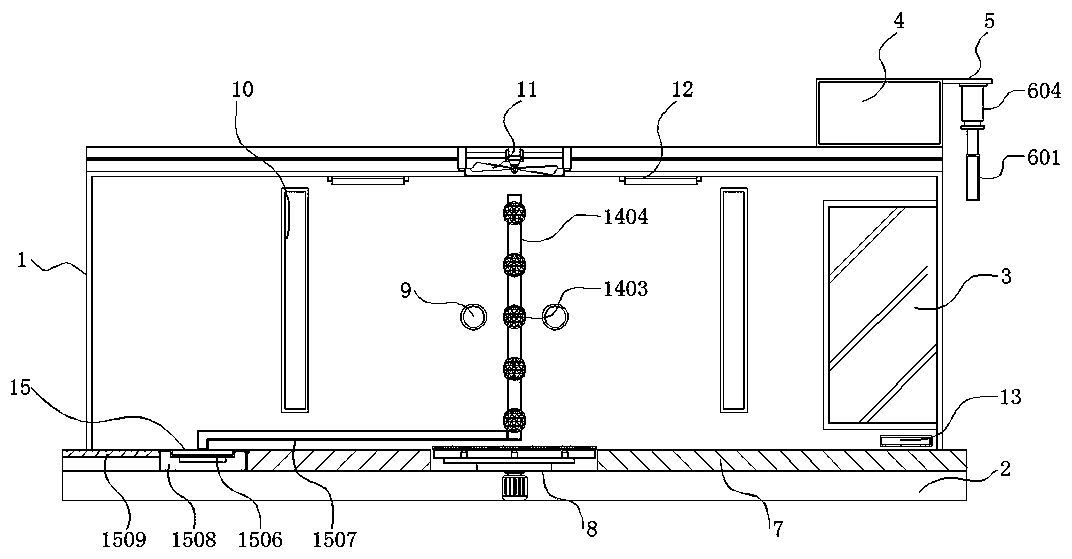

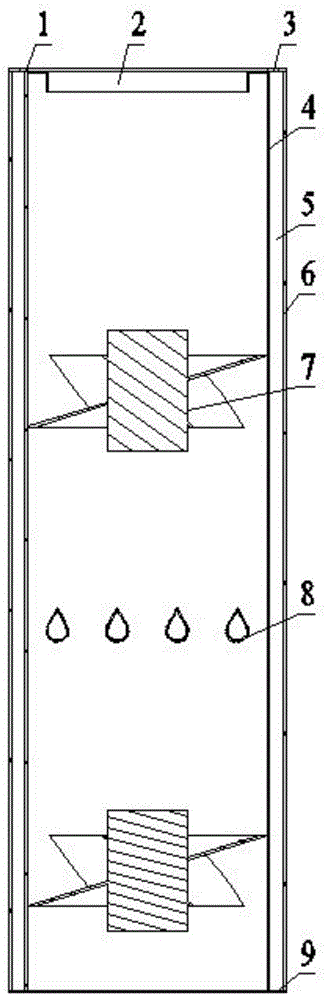

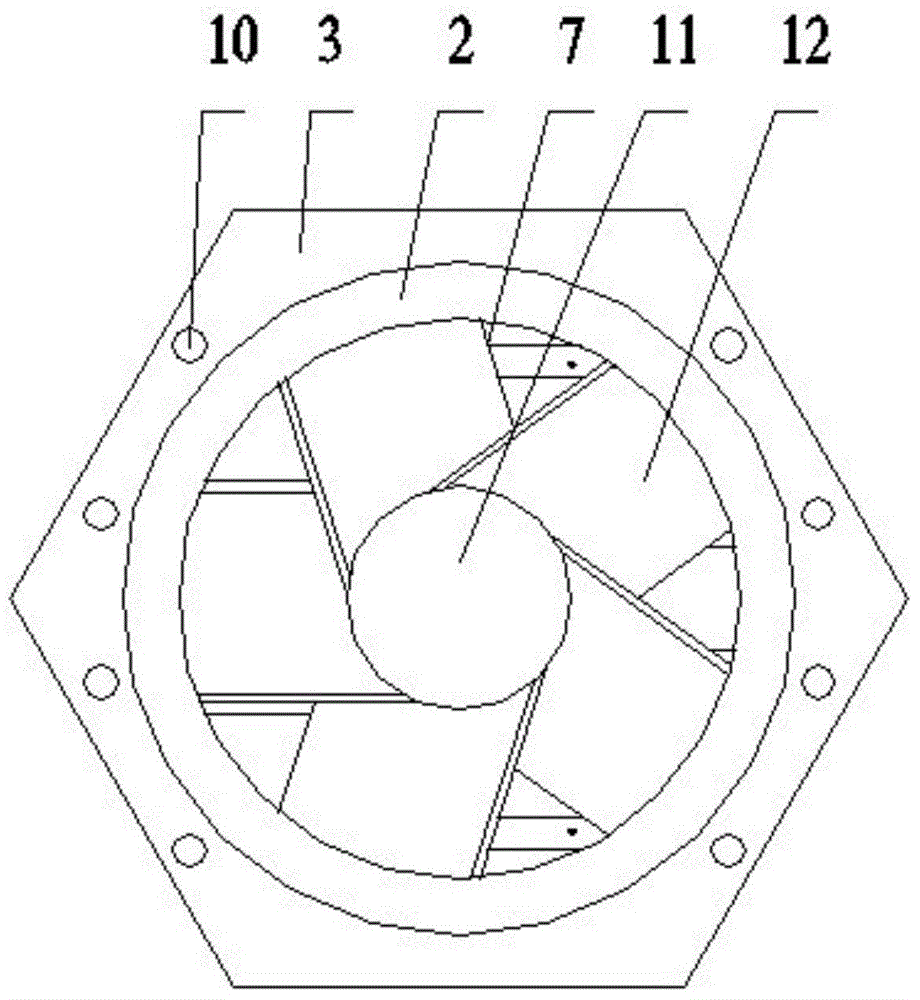

Intelligent passage capable of efficient disinfection, sterilization, temperature control and face recognition

InactiveCN111485797AEasy to recordFacilitate face recognitionCharacter and pattern recognitionLavatory sanitoryTemperature controlUltraviolet irradiation

The invention relates to the technical field of disinfection passages, and discloses an intelligent passage capable of efficient disinfection, sterilization, temperature control and face recognition.The intelligent passage comprises a passage main body, a face recognition mechanism and a conveying belt, wherein a base is fixed below the passage main body; a gate mechanism is mounted at an entrance of the passage main body; a control box is fixed above the entrance of the passage main body; a fixing plate is connected to the outer side of the control box; the face recognition mechanism is mounted below the fixing plate; the conveying belt is arranged at the bottom of the interior of the passage main body; a rotation mechanism is mounted at the bottom of the middle of the interior of the passage main body; and indication lights are arranged on both sides of the top of the rotation mechanism and embedded in the inner wall of the passage main body. The intelligent passage disclosed by theinvention has the beneficial effects that through the conveying belt, users can be conveyed stably and at a constant speed, so that poor disinfection effects caused by different walking speeds of theusers can be prevented, and injuries to human bodies because of long-term ultraviolet irradiation can be avoided.

Owner:湖南马王堆制药有限公司

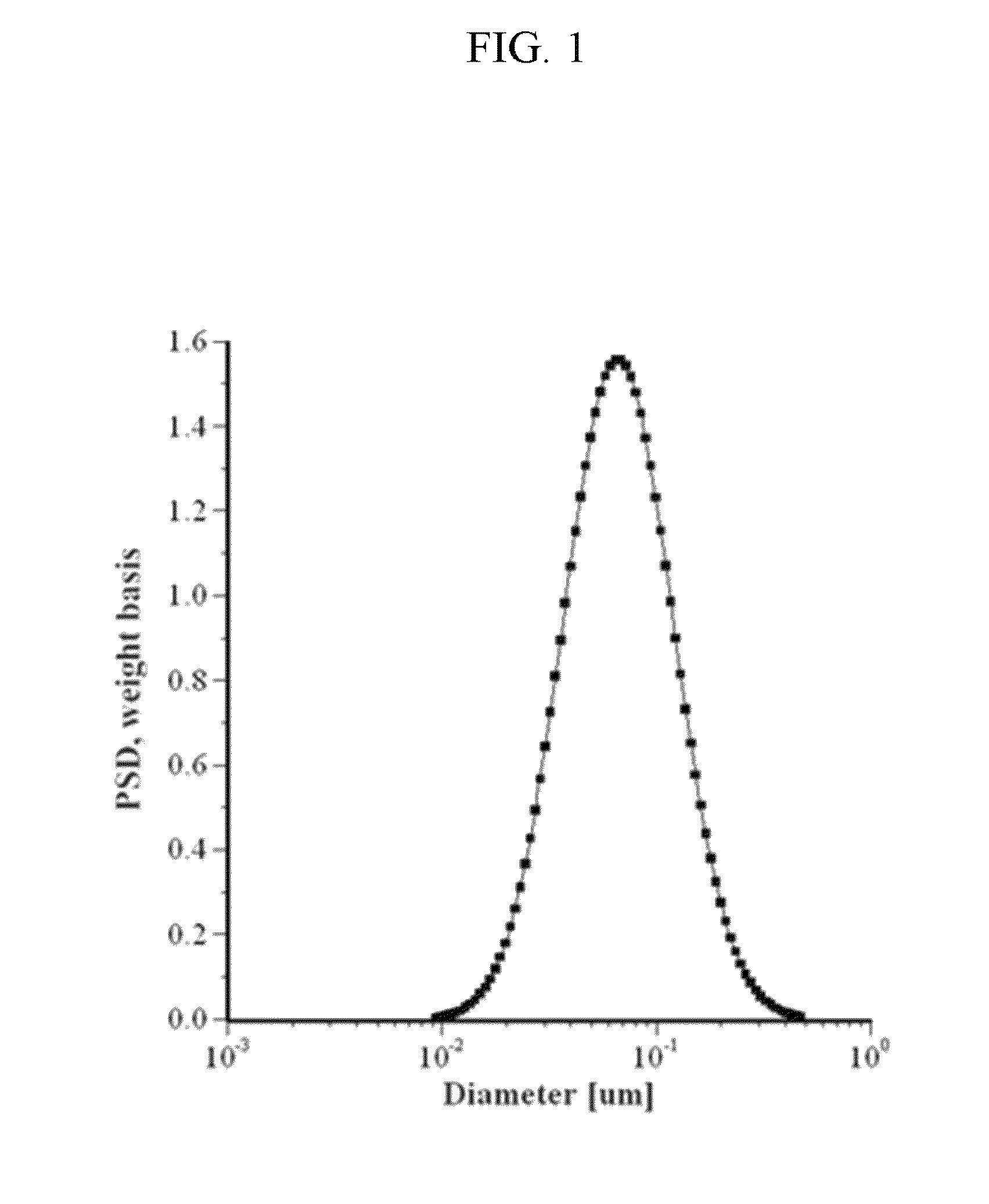

Particle concentration measurement technology

ActiveUS8272253B2Higher kinetic energy mixingSmall dropletComponent separationNanoparticle analysisParticulatesChemical physics

A method and apparatus for measuring particle concentration and size distribution of particles in liquids. The method involve separating dissolved and particulate residues in liquids for determination of the size and concentration of the particulate species. The method includes the steps of forming an aerosol from the liquid sample to be analyzed, evaporating the droplets in the aerosol to dryness, and detecting the particles. An apparatus for separating dissolved and particulate residues in liquids for determination of the size and concentration of the particulate species is also disclosed. The apparatus includes a droplet former, a dryer communicatively connected to the droplet former, and a detector communicatively connected to the evaporator for detecting particles.

Owner:CT ASSOCS

High-efficiency pneumatic pipe bundle phase-change dedusting and demisting device and application

InactiveCN104923020AImprove centrifugal effectHelp to separate and captureCombination devicesElectricityEngineering

The invention relates to a high-efficiency pneumatic pipe bundle phase-change dedusting and demisting device and application. The device comprises a hollow barrel with two ends open, an upper barrel sealing plate, a lower barrel sealing plate, rotational flow sections, pipe-bundle-type water mist distribution sections and a water retaining section, the rotational flow sections of more than two stages are arranged coaxially in the inner-layer barrel from bottom to top at intervals, each pipe-bundle-type water mist distribution section is arranged coaxially between each two corresponding rotational flow sections, and the water retaining section is coaxially arranged on the inner-layer barrel below the upper barrel sealing plate in an outer-edge-sealed manner. The device can effectively remove liquid drops, dust and superfine dust of smoke systems or industrial waste gas systems, is good in demisting and dedusting effect and is lower in energy consumption and more energy saving when compared with wet-type electric dedusting. In addition, by the device, arrangement space is saved, and power equipment is omitted; the device has good dedusting and demisting effect while energy consumption is lowered, and can be applied to dedusting and demisting of industrial tail gas.

Owner:AEROSPACE ENVIRONMENTAL ENG

Manufacture of synthetic silica glass

InactiveUS20130045854A1Reduce nitrogen oxide emissionsLower Level RequirementsSilicaGlass shaping apparatusEmulsionSilicon dioxide

Methods are described for manufacturing silica-based glass, in which silica precursor material is supplied to a synthesis flame in the form of an emulsion. The methods involve the steps of: forming an emulsion of an aqueous phase in a non-aqueous liquid silica precursor material; supplying the emulsion as a spray of droplets into a synthesis flame, whereby the precursor material is converted in the flame into a silica-containing soot; and collecting the soot on a substrate, either as a porous soot body for subsequent consolidation to glass or directly as a substantially pore-free glass.

Owner:HERAEUS QUARTZ UK

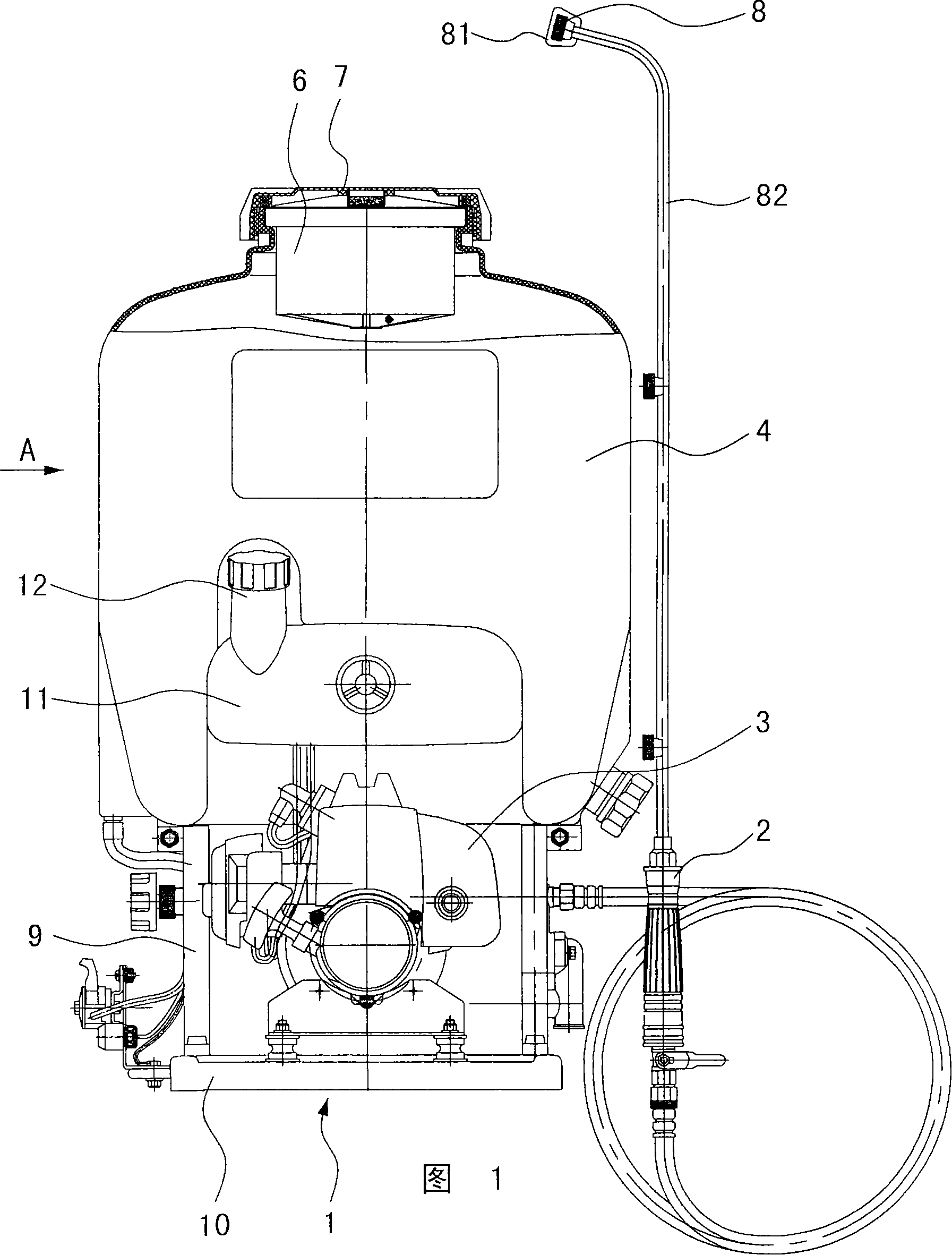

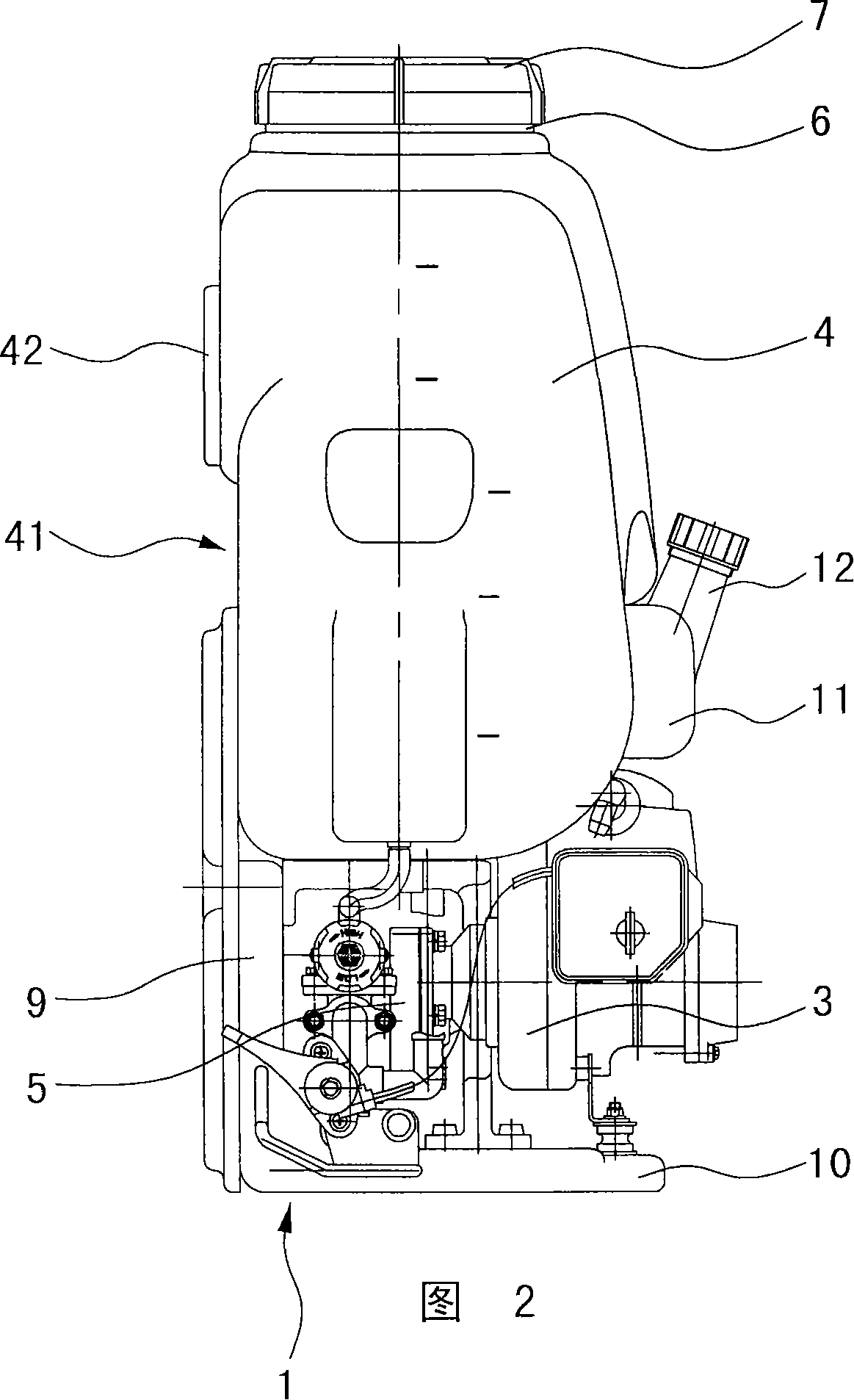

High performance back sprayer

InactiveCN101157072AHigh work pressureExtended service lifeLiquid spraying apparatusInsect catchers and killersSprayerWorking pressure

The invention relates to a high-performance knapsack spraying machine, which comprises a pesticide liquid box body, a water filling opening is made on the box body, a water filling cover is arranged on the water filling opening, a pump and a power diving the pump are arranged at the lower part of the box body, a spray gun component is connected with a water outlet opening of the pump, and the pesticide liquid is sprayed through a spray head. The knapsack spraying machine is characterized in that an open supporting frame is arranged at the lower part of the box part, the supporting frame is connected with a bottom seat, an assembly machine frame is composed of the supporting frame and the bottom seat, the power is a gasoline engine, the bottom feet of the gasoline engine are fixed on the bottom seat, an oil tank is arranged on the wall surface of the box body, the oil tank is provided with a zerk, and the pump is driven by the gasoline engine. Compared with the prior art, the proposal has the characteristics that firstly the gasoline engine continuously works; secondly, the power of the gasoline engine is large, and the working pressure is high; thirdly, the operation is convenient, without the inflation; fourthly, the service life is long; fifthly, the open supporting frame is favorable for installation and working, and the assembly and disassembly and the maintenance are also convenient; sixthly, the pesticide liquid box body, the pump, and an engine are connected into an integrated style, the volume is small, and the moving is flexible; seventhly, the application range is wide.

Owner:梁小恩

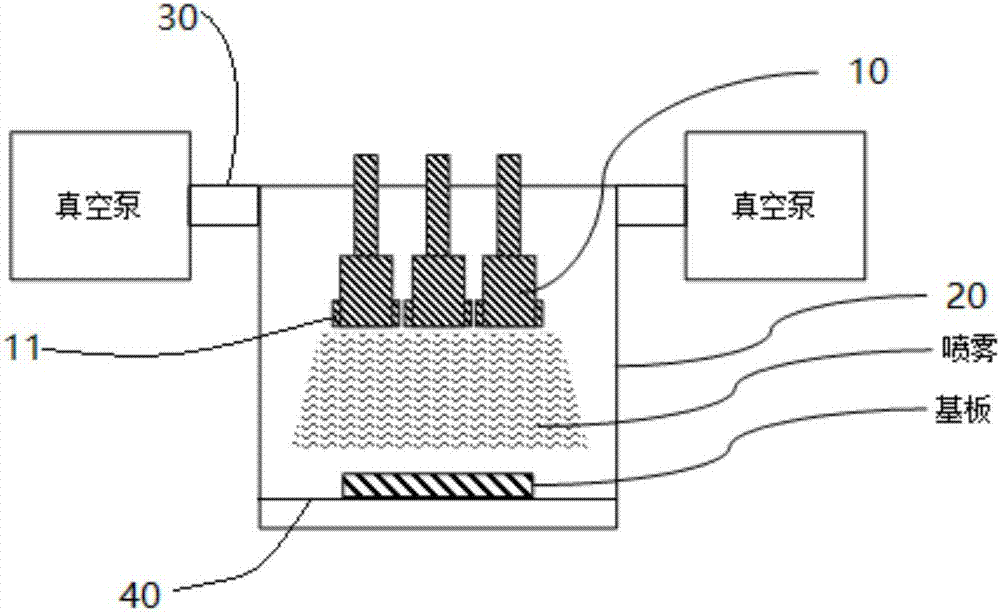

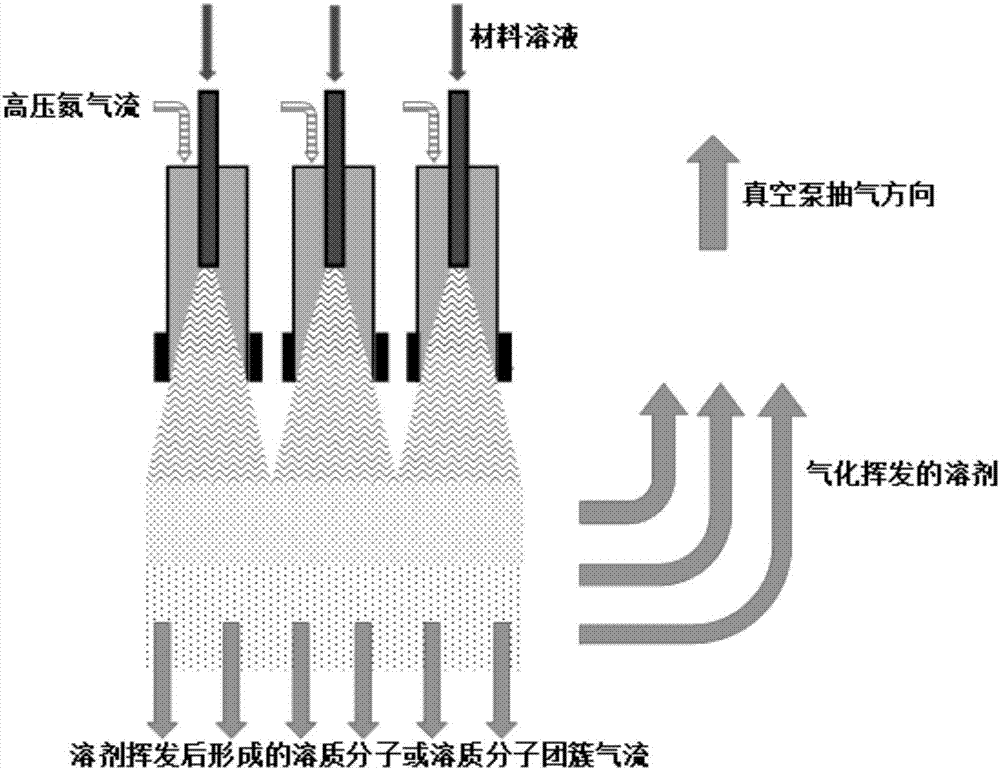

OLED and film deposition method thereof

ActiveCN107359277AUniform thicknessSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceSolvent

The invention relates to an OLED and a film deposition method thereof. The film deposition method comprises the following steps of: preparing a material solution: dissolving a material to be deposited in a solvent to obtain the material solution; and providing an atomization device comprising an atomization system, a cavity, a vacuum tube and a support plate; and depositing: placing a substrate on the support plate, switching on a vacuum device, vacuuming the cavity through the vacuum tube, and atomizing the material solution through the atomization system to deposit the material solution on the substrate. The film deposition method of the OLED utilizes a combination of vacuum and a spray process to deposit the film of the OLED, does not need to heat and sublimate the material to be deposited at a high temperature, and is suitable for materials hard to sublimate or liable to thermally decompose. Further, droplets formed by spray are small, and the vacuum environment allows the solvent to be uniformly volatilized, thereby forming a uniform film thickness.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

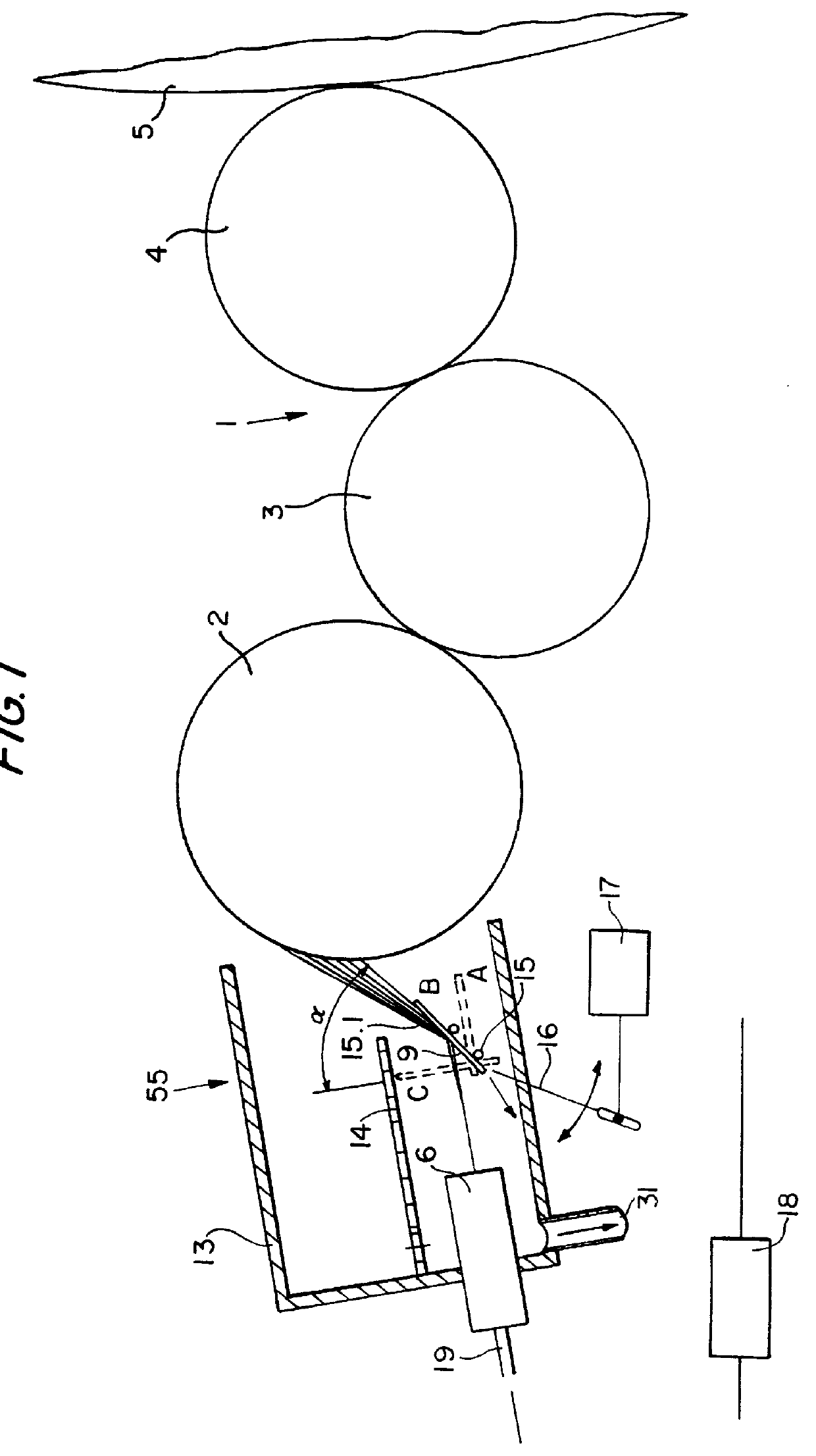

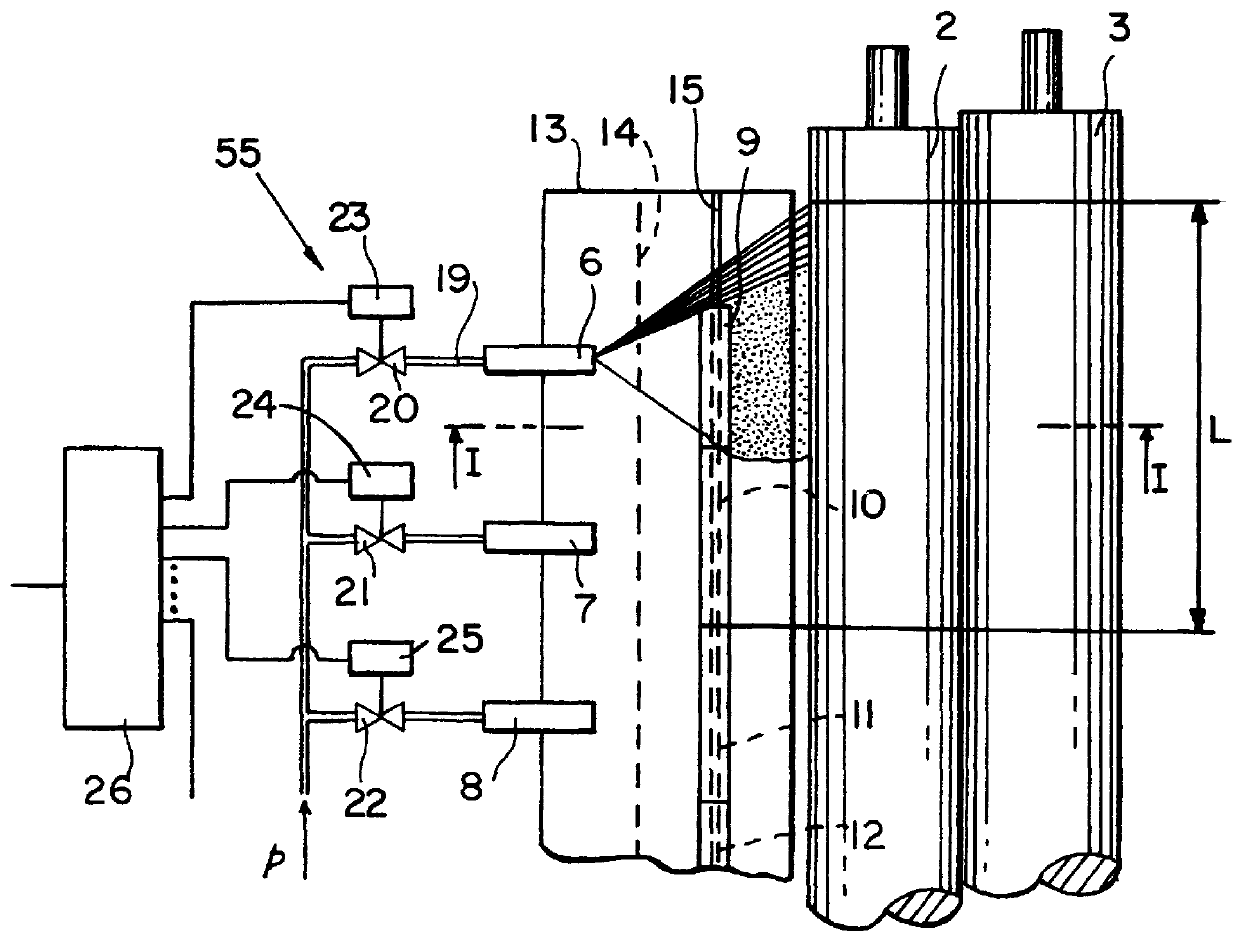

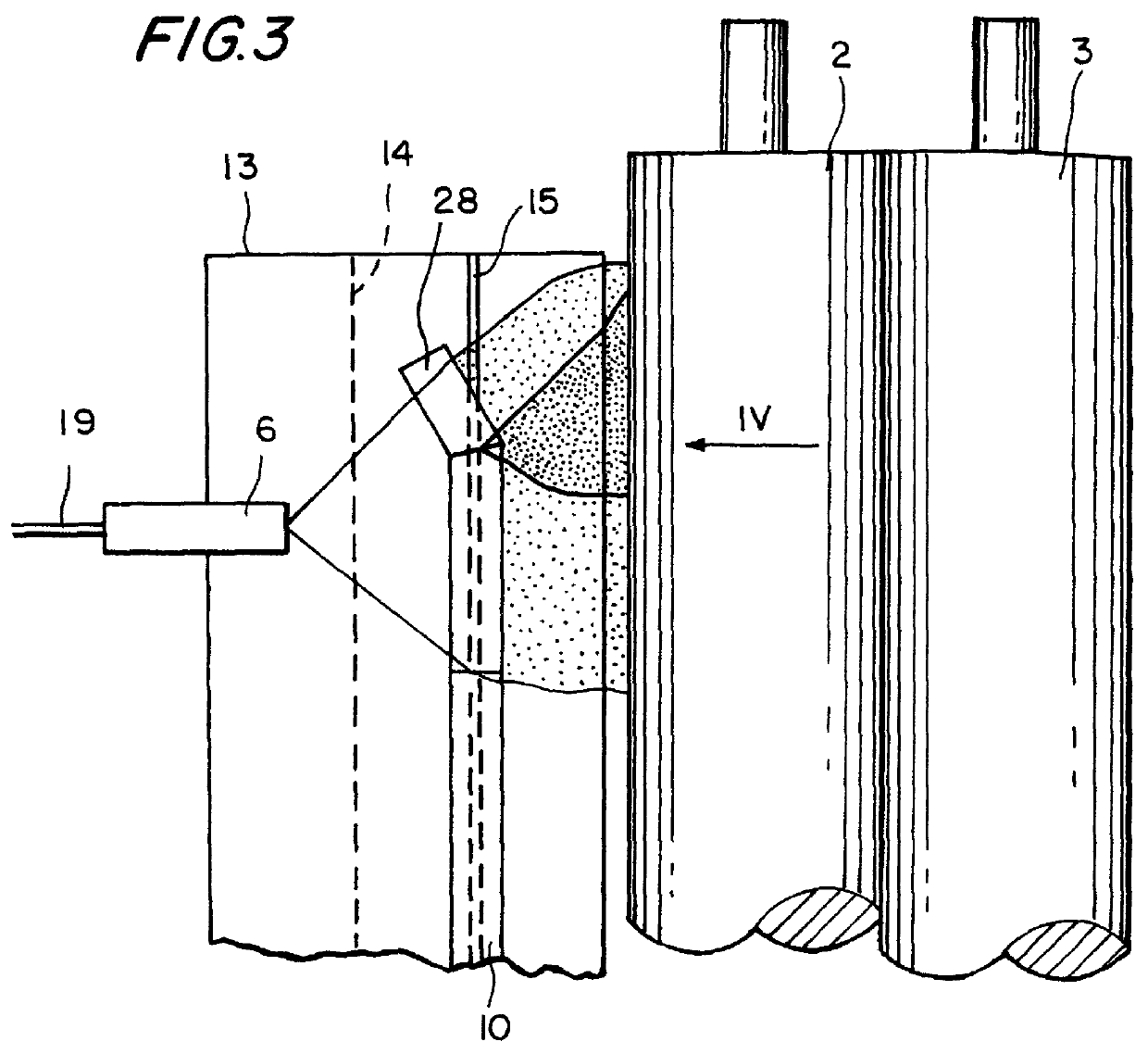

Device for applying wetting agent to a cylinder of a rotary printing machine

InactiveUS6089153ASmall dropletDecrease in atomizationOffice printingRotary lithographic machinesSmall dropletEngineering

An economical device for applying a wetting agent in the form of small droplets to a cylinder includes nozzles which are supplied continuously with pressurized wetting agent arranged along the cylinder. An adjustment element in the spray area of the nozzles doses the wetting agent application that is maximally one printed page wide.

Owner:M A N ROLAND DRUCKMASCHINEN AG

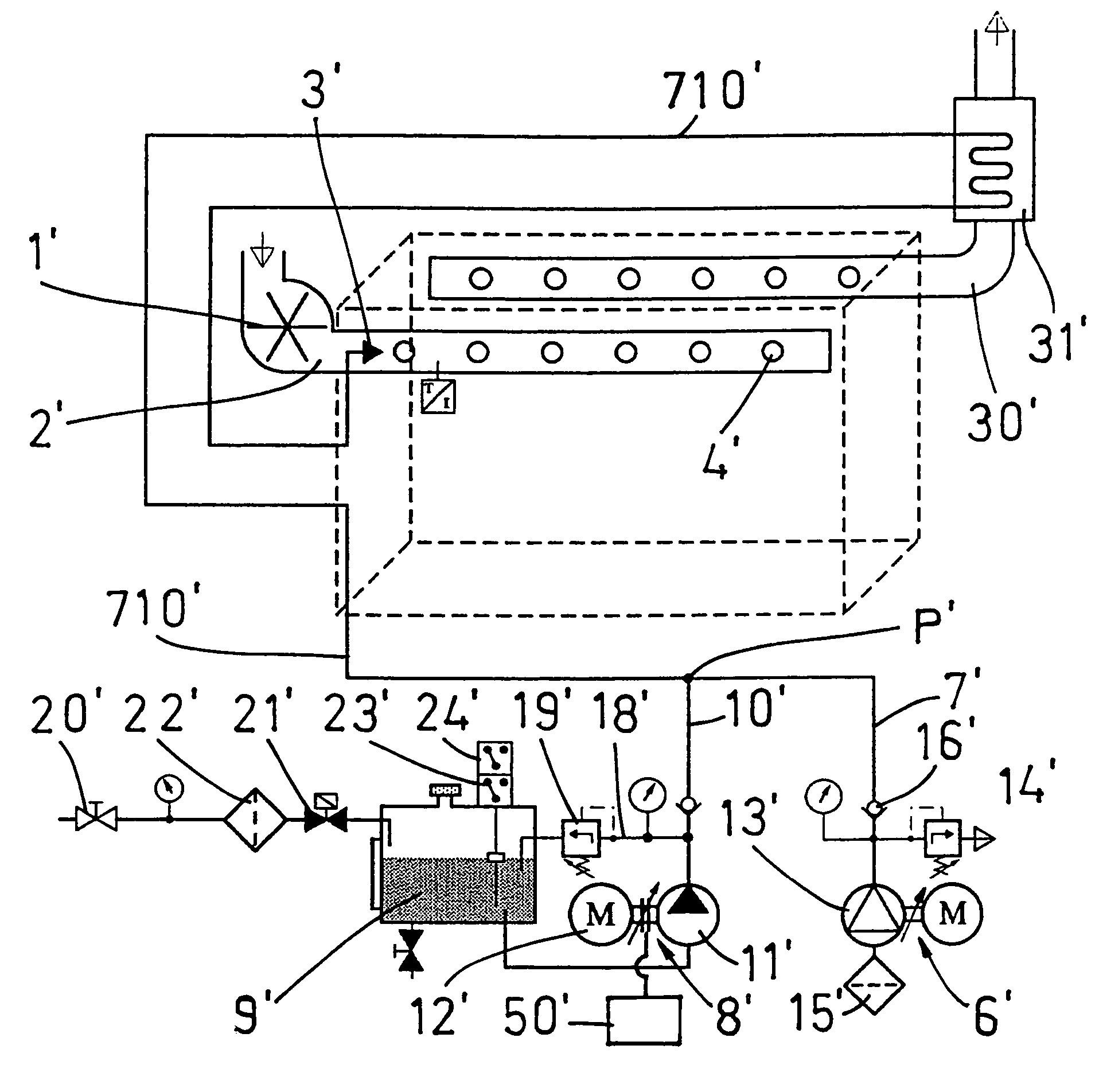

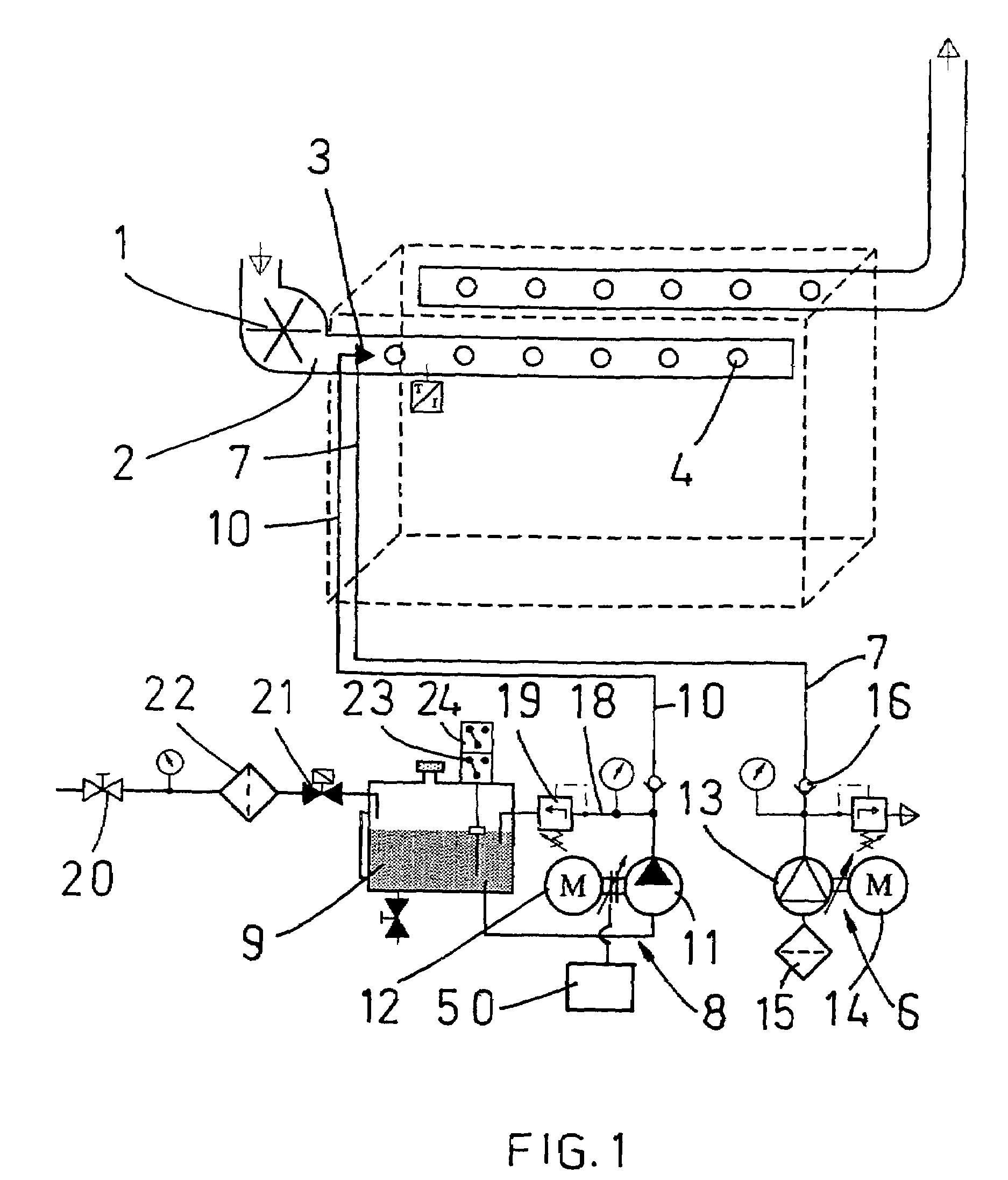

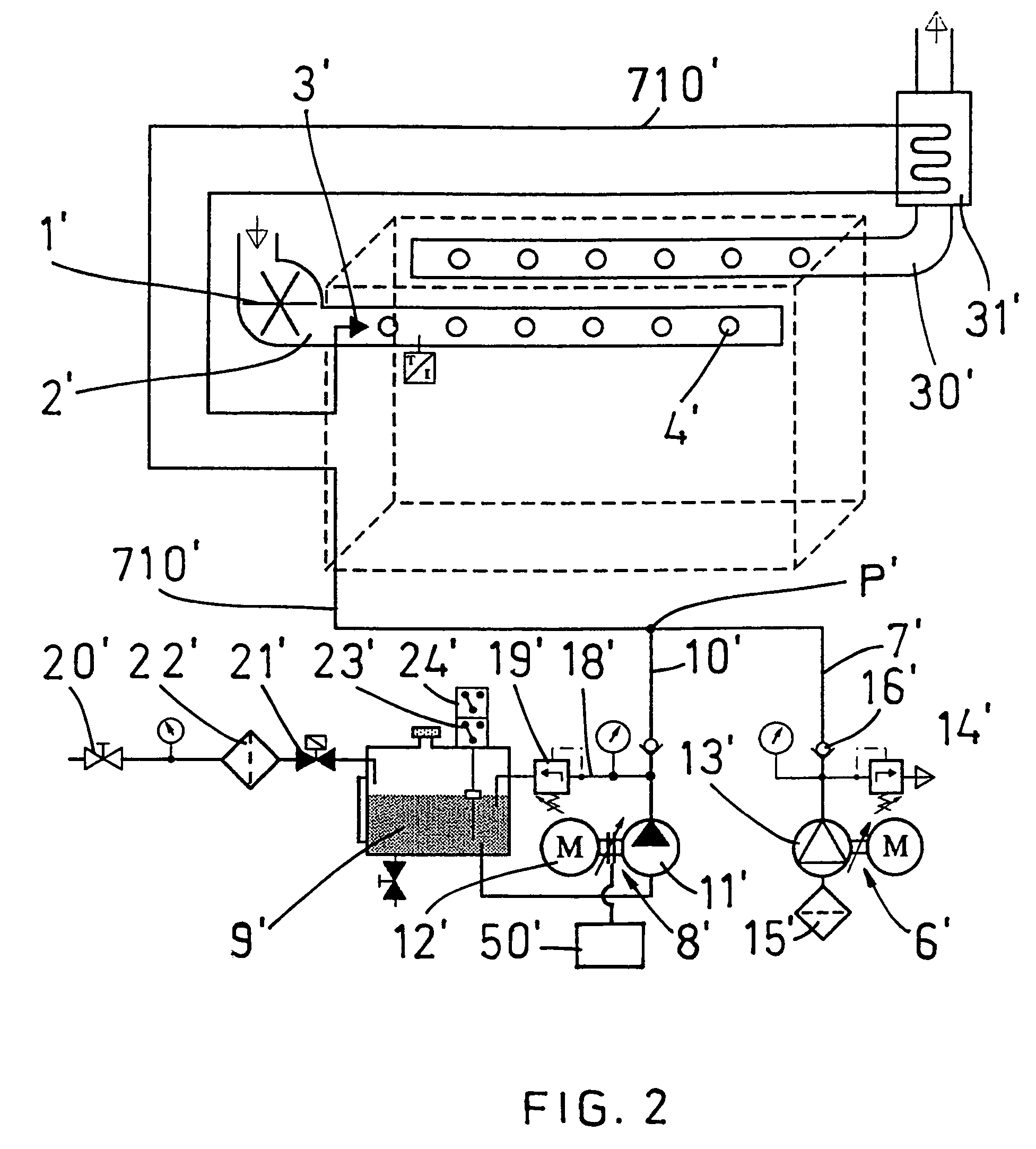

Method and apparatus for reducing combustion engine emissions

InactiveUS7231893B2Reduce nitrogen emissionsEasy to installInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberProduct gas

The invention relates to a method for cleaning exhaust gases from a combustion engine, in which method humid air is fed into the combustion chamber of the combustion engine. In order to reduce nitrogen emissions effectively, particularly when a diesel engine is running at partial power, and in order for the method to be very accurately adjustable to meet the requirements of each particular engine application and use, in accordance with the invention, a mixture of gas and aqueous mist is fed with a spray head (3) into a space (2), which leads to the combustion chamber. The method can be readily implemented by an apparatus, which can be mounted in a small space without having to make substantial changes in the combustion engine. The invention also relates to an apparatus for cleaning exhaust gases from a combustion engine.

Owner:MARIOFF CORP OY

Method for preparing compact-type porous ceramic-based titanium electrothermal film

ActiveCN105693287ANo pollutionSimple preparation processHeating element materialsCeramicwarePolyvinyl butyralPolyvinyl alcohol

The invention belongs to a preparation method of a titanium film, belongs to the field of electrothermal films and particularly relates to a method for preparing a compact-type porous ceramic-based titanium electrothermal film. The method comprises the following steps of: mixing and ball-grinding titanium or titanium hydride powder, a polyving akohol aqueous solution or a polyvinyl butyral ethanol solution in a certain ratio so as to obtain uniform and stable titanium slurry; then spraying the titanium slurry on a porous ceramic base, drying at a low temperature, and performing high-temperature sintering in the presence of inert gas or under high-vacuum protection, thereby obtaining the compact-type porous ceramic-based titanium electrothermal film. The preparation method is low in preparation process cost, high in production efficiency, high in operability and free from environmental pollution, and conforms to the sustainable development policy; the prepared compact-type porous ceramic-based titanium electrothermal film has the advantages of high electrothermal conversion efficiency, safety, no toxicity, better atomization effect, small driving voltage and the like, and can be applied to electrothermal devices of compact-type medical atomization devices and the like.

Owner:XIANGTAN UNIV

Device for producing hydrated lithium hydroxide on basis of MVR and production method thereof

InactiveCN108298569ASmall amount of lithiumReduce fouling frequencyEvaporation with vapour compressionEvaporator accessoriesLithium hydroxideForced circulation

The invention discloses a device for producing hydrated lithium hydroxide on the basis of MVR. The device includes a raw material tank, a condensate water preheater, a vapor preheater, a forced circulation evaporator, a thickener, a centrifugal machine, a compressor and a vapor separating bag. Raw materials in the raw material tank are conveyed into the condensate water preheater through a feedingpump, and the condensate water preheater is communicated with the vapor preheater through a pipe; the raw materials in the vapor preheater are conveyed into the forced circulation evaporator througha pipe, and the forced circulation evaporator comprises a first heater, a second heater and a crystal separator. The device has the advantages that the interior of a heat exchanging pipe of a forced circulation heater is polished, the adhesive force of crystals adhering to a wall in a solution can be effectively reduced, it is ensured that the flow velocity of the solution in the heat exchanging pipe can reach 2.5 m / s or above, and meanwhile the pipe wall is flushed to further reduce the scaling frequency in the heat exchanging pipe; at the same time, the superheat degree of an outlet of the heater is lowered, flash evaporation and pipe blockage are effectively prevented from occurring in the pipes, and a pipe blockage situation caused by locally massive crystallization due to an excessively high superheat degree is reduced.

Owner:SHANGHAI ZHONGTENG ENVIRONMENTAL PROTECTION TECH CO LTD

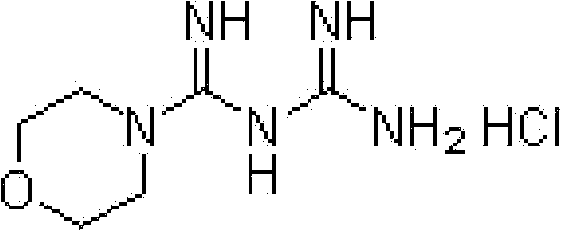

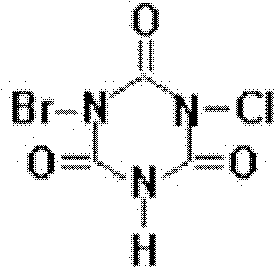

Dufulin-containing ultra low volume liquid formulation

ActiveCN102657219AReduce control effectGood control effectBiocideDisinfectantsActive componentElectro spray

The invention relates to a Dufulin-containing ultra low volume liquid formulation, which is prepared by using Dufulin or Dufulin and an active component II as active components and adding an auxiliary agent and a solvent. The active component II is any one selected from the group consisting of ningnanmycin, moroxydine hydrochloride, amino-oligosaccharin, chlorobromoisocyanuric acid and lentinan. The invention has advantages of simple processing, high work efficiency, water conservation, long persistent period, targets which are not easy to generate drug resistance, low environmental pollution, synergist effects and the like. Through ultra low volume spray, low volume spray or ultra low volume static electro-spray, a plurality of diseases of crops such as paddy rice, tobacco, corn, cotton, orange, capsicum, tomato, rape and the like can be prevented and cured.

Owner:GAUNGXI TIANYUAN BIOCHEM

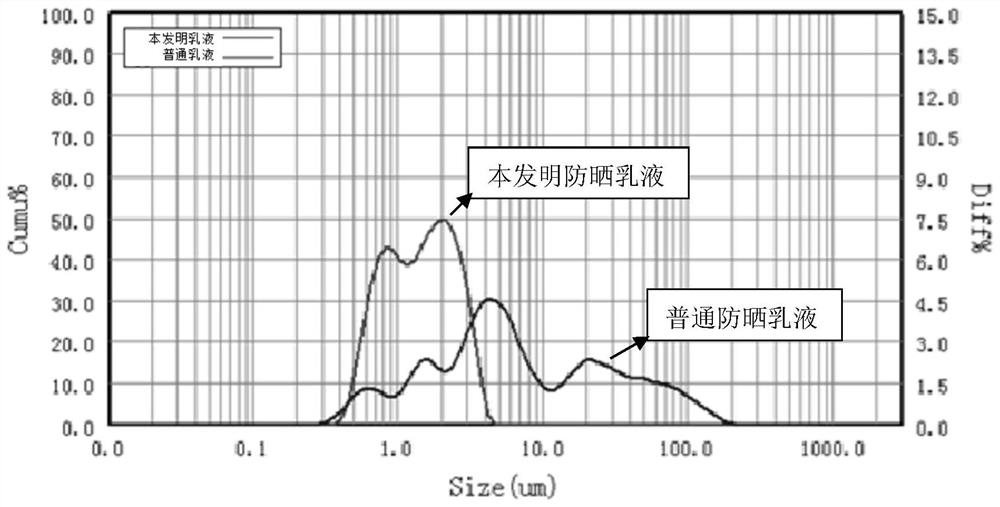

Composition for increasing sunscreen value of sunscreen emulsion and preparation method of composition

InactiveCN112137906AImprove stabilityReduce dosageCosmetic preparationsToilet preparationsBenzoic acidSunscreen agents

The invention discloses a composition for increasing the sunscreen value of a sunscreen emulsion and a preparation method of the composition. Water, octyl polymethylsiloxane, ethylhexyl triazinone, diethylaminohydroxybenzoyl hexyl benzoate, diethylhexyloxyphenol methoxyphenyl triazine, ethylhexyl methoxycinnamate, octocrilene, Tween 60 or tribehenin PEG-20 ester or polyglycerol-3 diisostearate andglyceryl stearate citrate combined components are adopted. A prepared emulsion preform in a sub-micro stable state is transferred into an ultrasonic cell disruptor for treatment, a treated water phase preform phase is added, homogenizing and uniform stirring are carried out to obtain a target product. According to the emulsion prepared by the method, the usage amount of an emulsifier and a sunscreen agent can be reduced, the cost is saved, and the influence of large usage amount of the raw materials on skin, such as irritation, is reduced; The prepared emulsion is smaller in liquid drop and more uniform in sunscreen component distribution, the sunscreen value of the sunscreen emulsion is increased, the skin feeling is fresher, and meanwhile, the stability is better.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

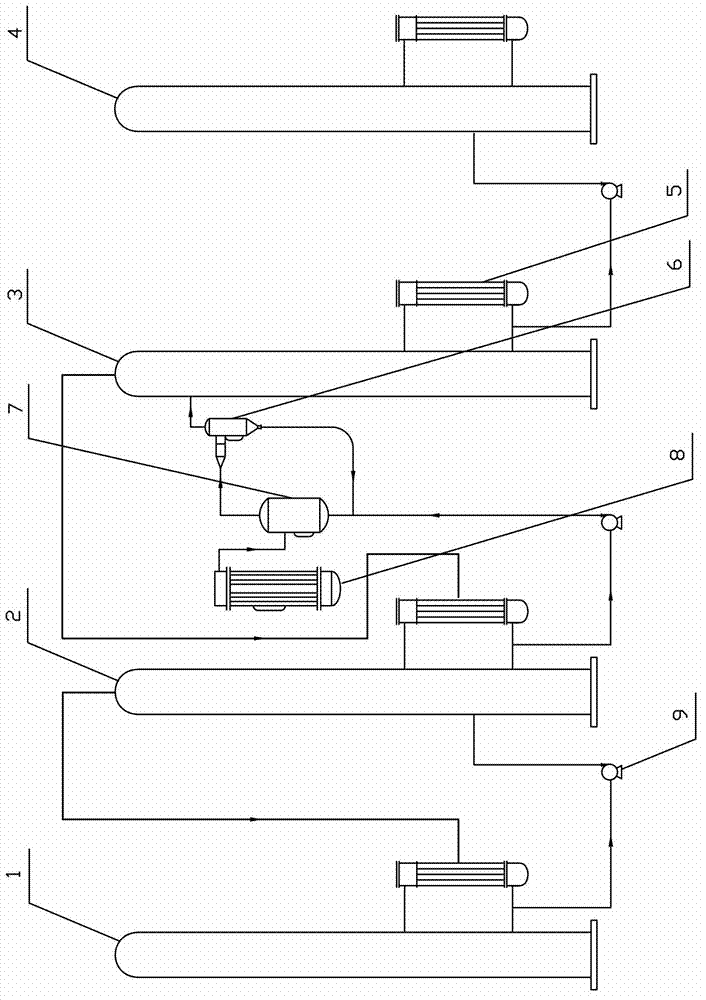

DMF (dimethyl formamide) recovery device and method in production of synthetic leather

ActiveCN102964262ASmall dropletReduce gas volumeCarboxylic acid amide separation/purificationVapor–liquid separatorReboiler

The invention discloses a DMF (dimethyl formamide) recovery device and method in production of synthetic leather. The device comprises a first-level concentration tower, a second-level concentration tower, a rectifying tower and a deacidification tower, wherein the four towers are all provided with a reboiler; a gas outlet at the top of the rectifying tower is connected with the reboiler of the second-level concentration tower through a pipeline; a gas outlet at the top of the second-level concentration tower is connected with the reboiler of the first-level concentration tower through a pipeline; the rectifying tower is connected with a feed device; the feed device comprises a gas-liquid separator arranged on the rectifying tower, a flash tank connected with the gas-liquid separator and a feed heater connected with the flash tank; and a discharge port of the second-level concentration tower is connected with the flash tank through a discharge pump. According to the invention, since the gas-liquid separator performs gas-liquid separation during the feed of the rectifying tower, the liquid droplets carried by the ascending gas and the gas carried by the descending liquid are greatly reduced, the recovery rate of DMF is improved, and the recovery is more thorough; and meanwhile, the production cost of the synthetic leather can be lowered, and more economic benefits are brought to enterprises.

Owner:QUANZHOU WANHUA SEWANG MICRO FIBER CO LTD

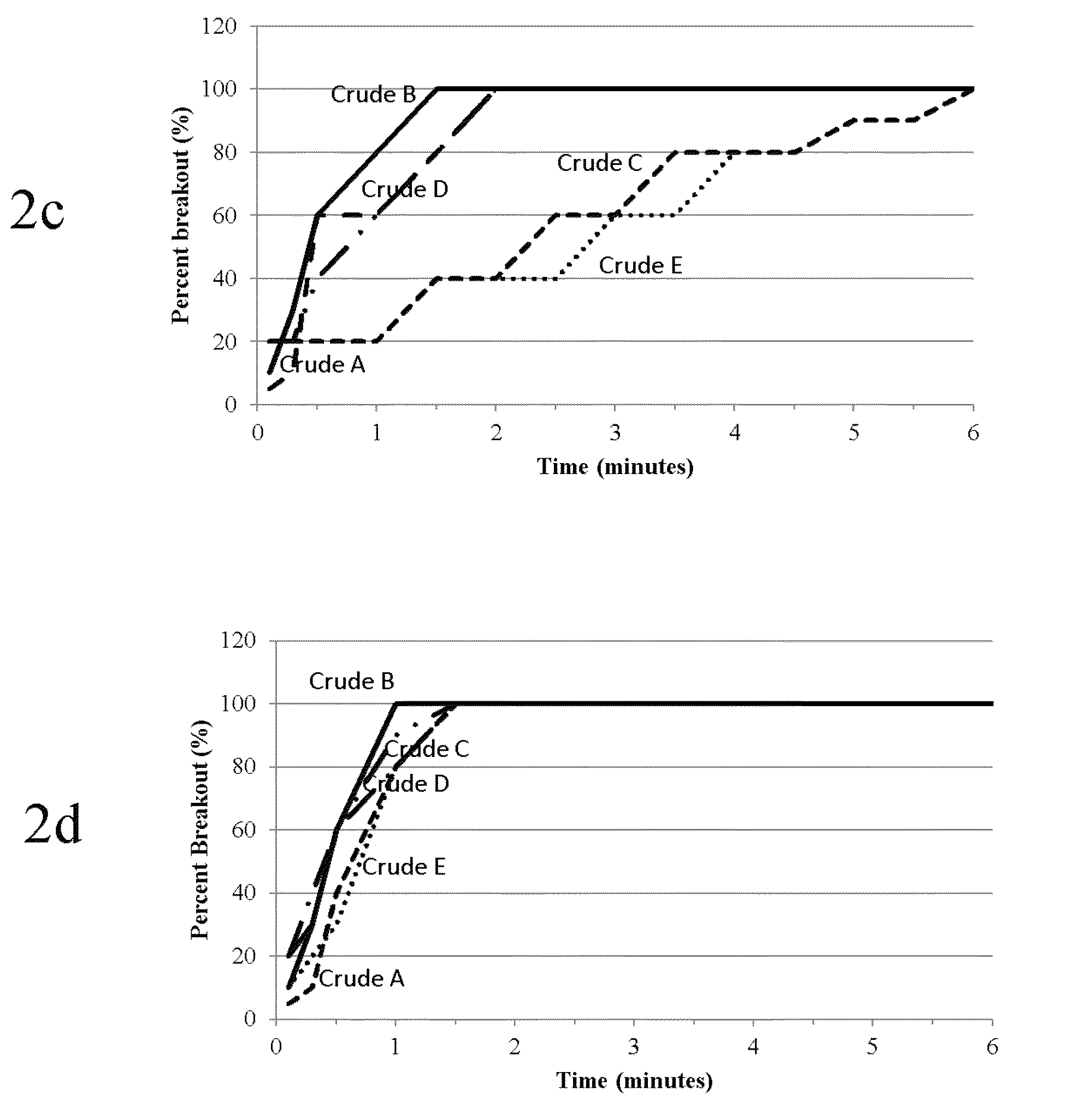

Demulsifier composition and method of using same

ActiveUS9353261B2Improve permeabilityPromote recoveryDewatering/demulsification with chemical meansRefining by water treatmentDemulsifierWater soluble

Owner:CHAMPIONX USA INC

Ultra-low volume liquid agent containing hexaflumuron

ActiveCN102379306AImprove ergonomicsImprove efficiencyBiocideAnimal repellantsAdditive ingredientAbamectin

An ultra-low volume liquid agent containing hexaflumuron of the invention takes hexaflumuron, or hexaflumuron and active component B as active ingredient, the active ingredient is 0.1% to 30% and the rest is auxiliary agent and solvent to make 100% ultra-low volume liquid agent. The active component B is any one of bifenthrin, ethofenprox, cyfluthrin, diazinon, abamectin, emamectin benzoate, pleocidin, spinetoram, spirotetramat and ethiprole. The invention has simple and convenient production, high working efficiency, less water amount, long effective period, uneasy drug resistance of target, low environment pollution and strong synergism. Insects to wheat, corn, vegetables, tobacco, tea plant, fruit plant, cotton, wood and sugarcane can be prevented by ultra-low volume spray, low volume spray and low volume static electric spray.

Owner:GAUNGXI TIANYUAN BIOCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com