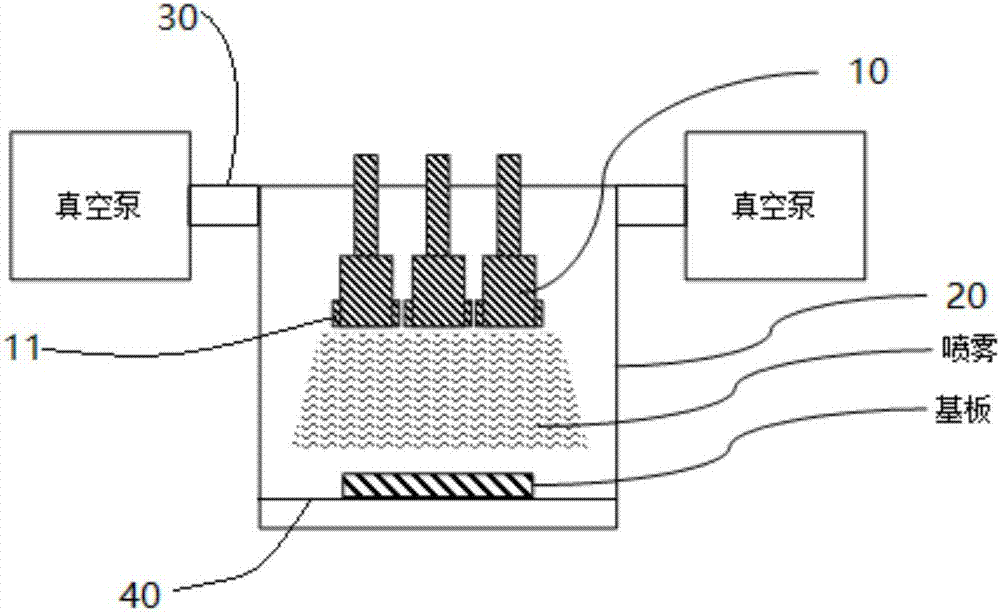

OLED and film deposition method thereof

A technology of electroluminescent devices and thin film deposition devices, which is applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve problems such as difficulty in ensuring the uniformity of the film, and achieve the effect of small size, uniform film thickness, and complete volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

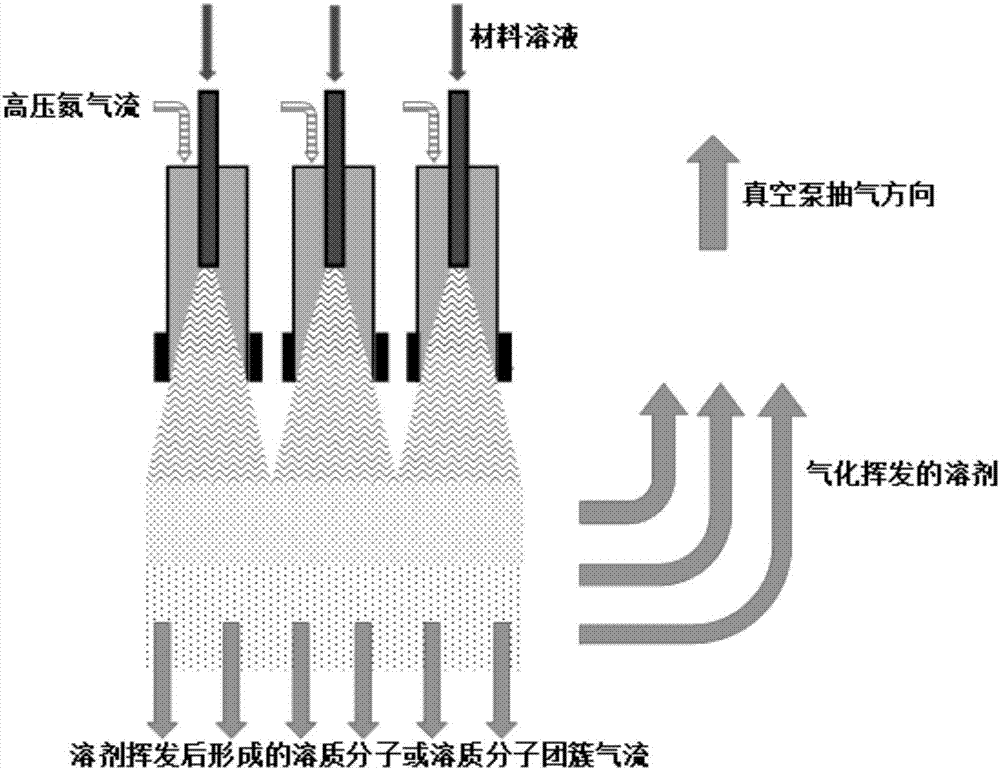

Method used

Image

Examples

Embodiment

[0036] The present embodiment is a manufacturing method of an organic electroluminescent device, which comprises an ITO anode, a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer and a cathode stacked in sequence, and its preparation method Including the following steps:

[0037] (1) Anode treatment: The substrate with the ITO electrode was ultrasonically cleaned in an alkaline cleaner and ultrapure water, then dried with nitrogen, vacuum baked at 100°C for 30 minutes, and treated with UV / ozone for 10 seconds.

[0038] (2) Hole injection layer deposition:

[0039] 2.1 Dissolving the hole injection layer material in a solvent to obtain a material solution, wherein the mass concentration of the hole injection layer material is 10 -3 g / L; in the present embodiment, the material of the hole injection layer is an arylamine-based compound QUPD, and the solvent is tetrahydrofuran; understandably, in other embodiments, it can also be ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com