High performance back sprayer

A high-performance, sprayer technology, which is applied to spray devices, liquid spray devices, and devices for catching or killing insects, etc., can solve problems such as the inability to meet the spraying needs of tall fruit trees, short battery life, and insufficient spray pressure. To achieve the effect of compact structure, accurate injection and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

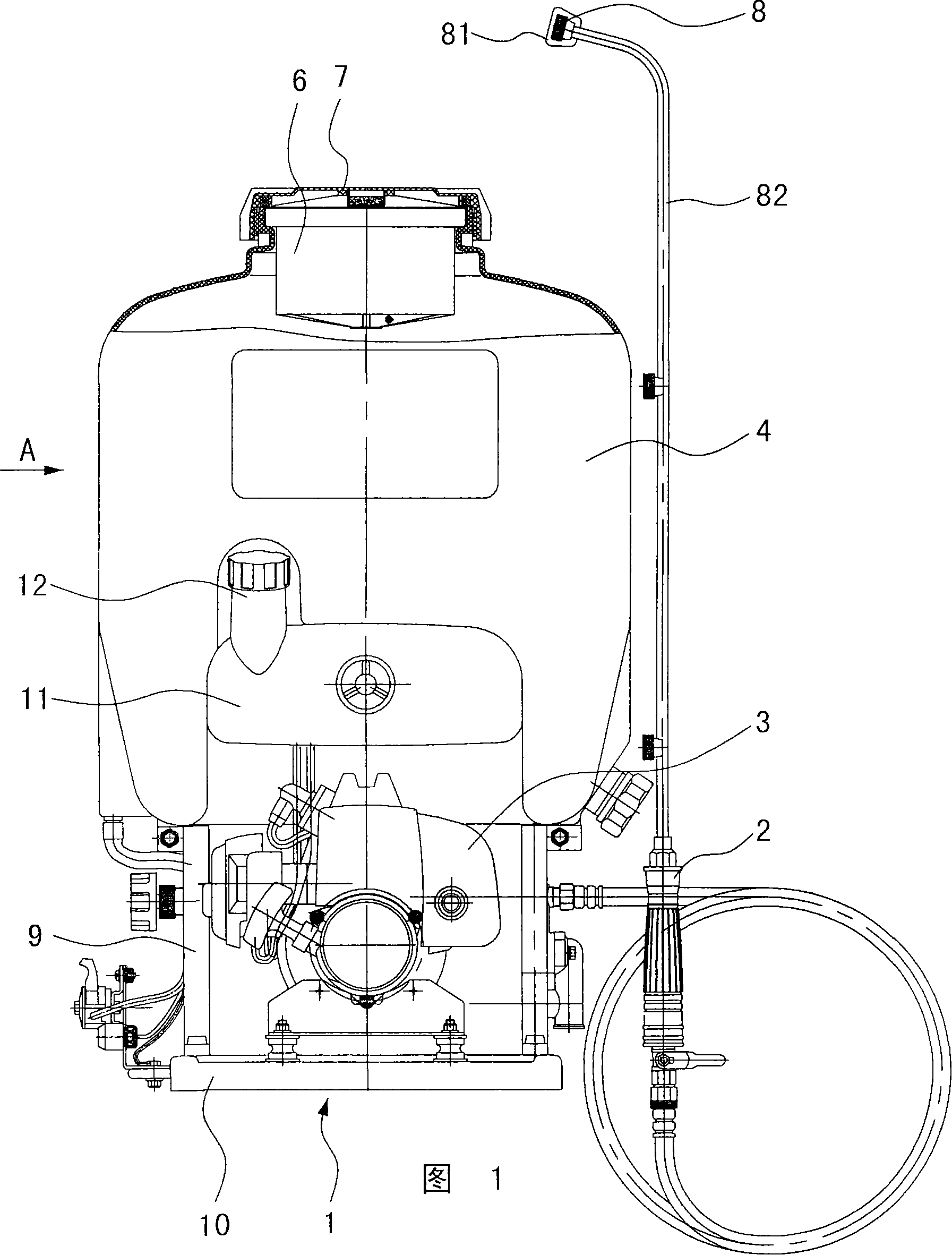

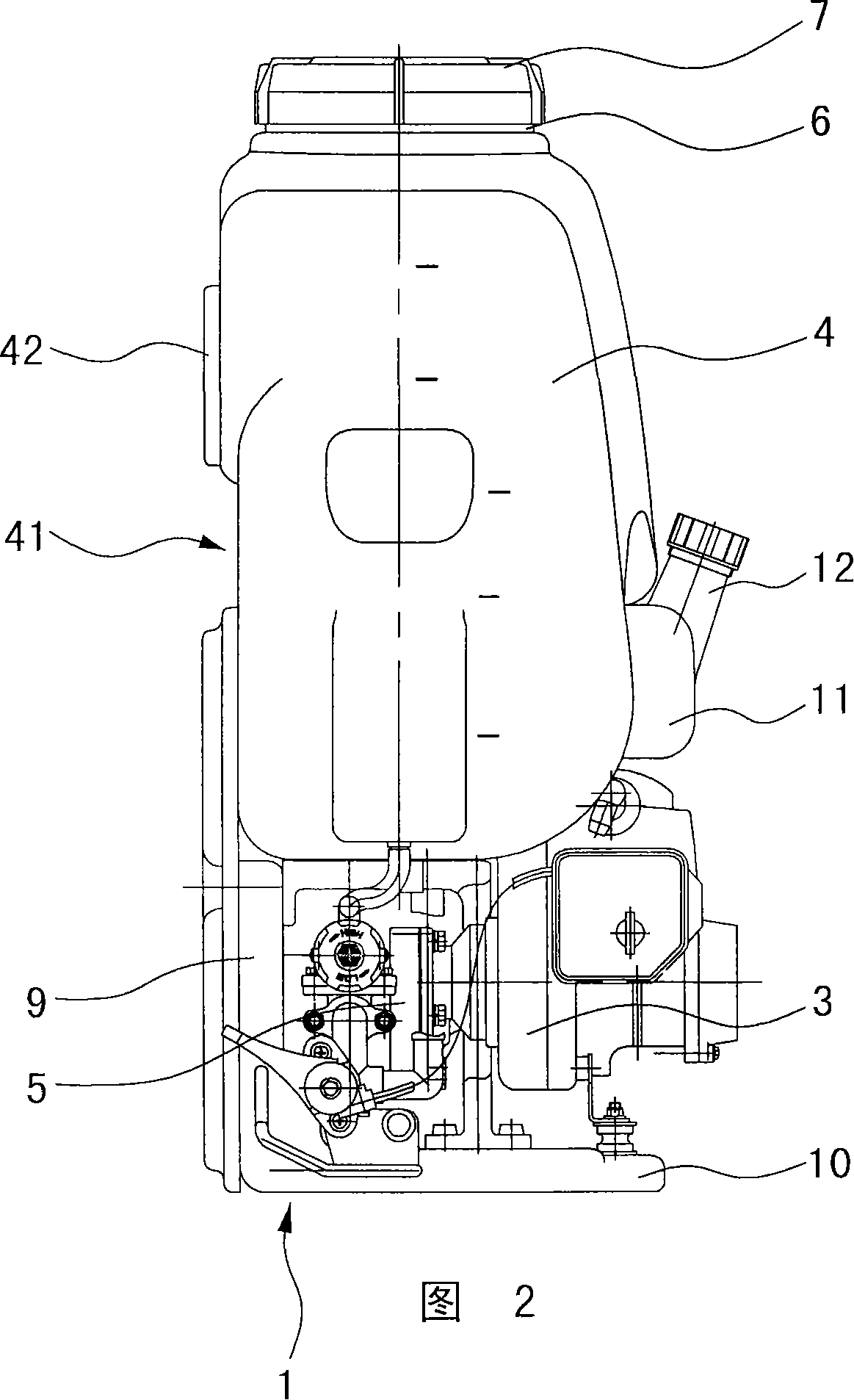

[0009] The invention discloses a high-performance backpack sprayer, as shown in Fig. 1 and Fig. 2, there is a liquid medicine box 4, and a water inlet 6 is formed on the box body, and a water filling cover 7 is installed on the water inlet, and a water filling cover 7 is installed on the lower part of the box body The pump and the power driving the pump, the water outlet of the pump is connected to the spray gun assembly 2, and the liquid medicine is sprayed out through the nozzle 8. Its main technical feature is that an open bracket 9 is installed on the lower part of the box body 4, and the bracket is connected to the base 10, and the bracket and the base Form assembly frame 1, described power is gasoline engine 3, and gasoline engine 3 feet are fixed on the base 10, and fuel tank 11 is installed on the wall surface of casing 4, and fuel tank 11 has filler nozzle 12, and gasoline engine 3 drives pump 5. This scheme installs open (not closed) support 9 at the bottom of liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com