Pilot proportional reversing valve

A proportional reversing valve and pilot-operated technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem that the number and technical indicators of proportional reversing valves cannot meet user requirements, and can not achieve neutral function and Problems such as transition state function and affecting the left and right movement of the spool of the proportional directional valve can solve the problem of external leakage, reduce the external leakage link, and increase the working pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

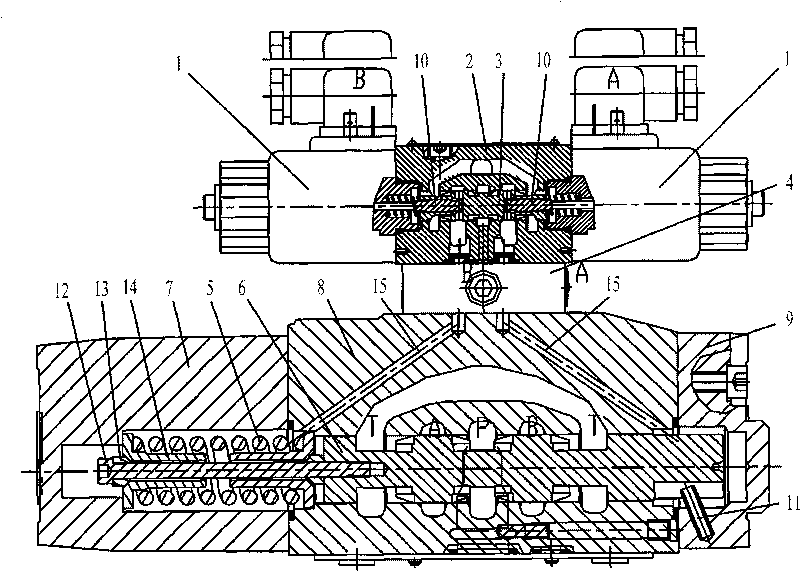

[0027] refer to figure 1 , a pilot-operated proportional reversing valve, which includes a main valve body 8, a quantitative decompression valve 4 installed on the main valve body 8, and a pilot control valve installed on the quantitative decompression valve 4; the pilot control valve includes a pilot control valve The valve body 2, and the left and right proportional electromagnets 1 respectively installed at both ends of the pilot valve body 2; on the pilot valve body 2 at the upper position of the left and right proportional electromagnets 1, working oil ports B and A are respectively made, The left and right proportional electromagnets 1 convert an electrical signal into a proportional pressure output signal. A pilot valve core 3 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com