Patents

Literature

153results about How to "Improve centrifugal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

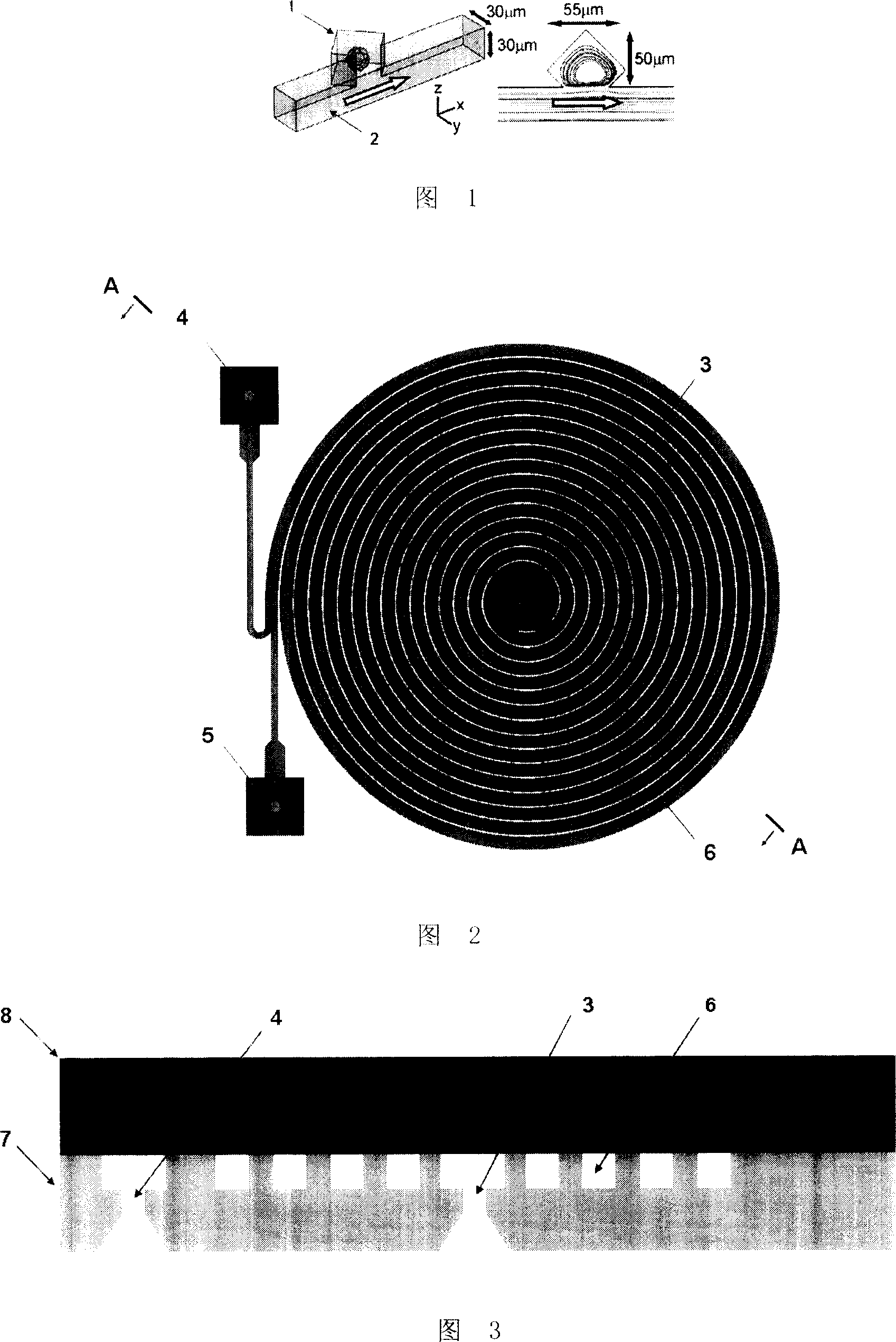

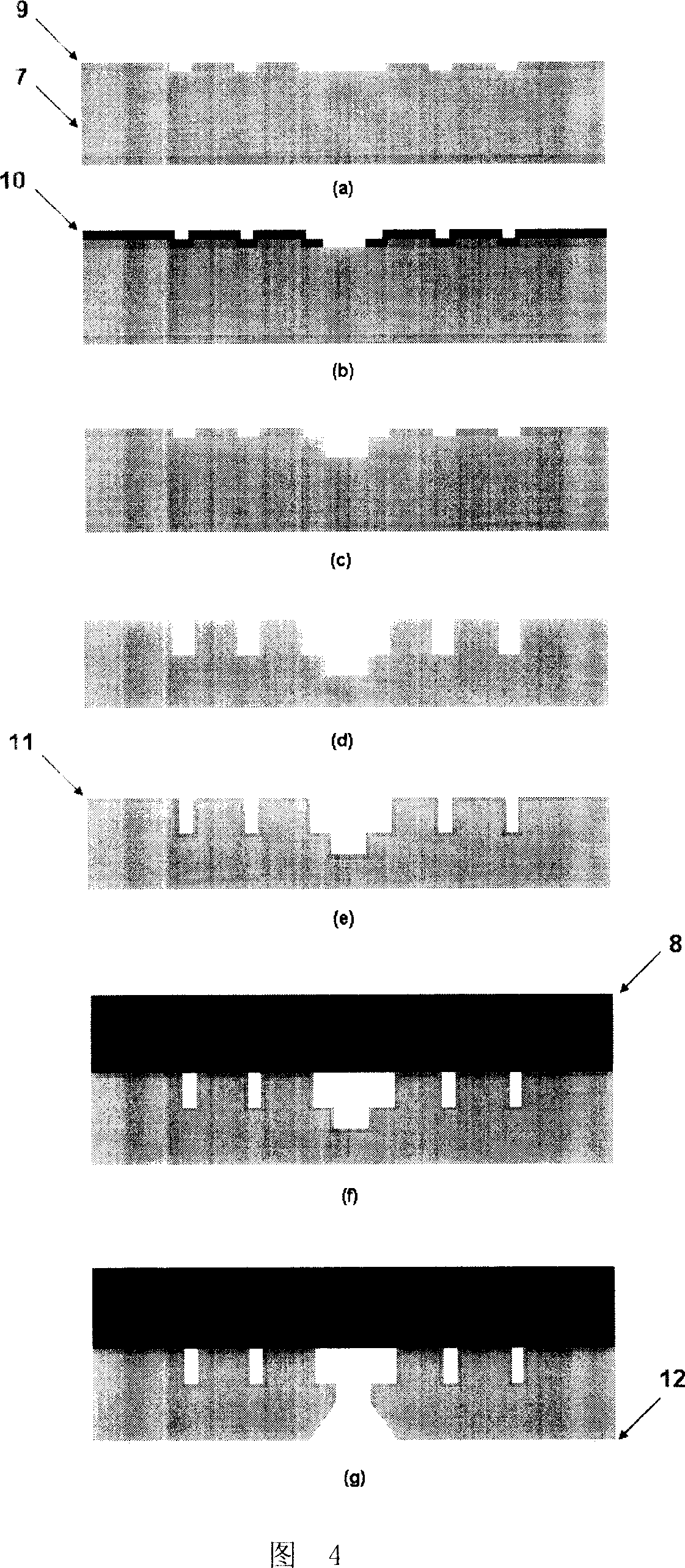

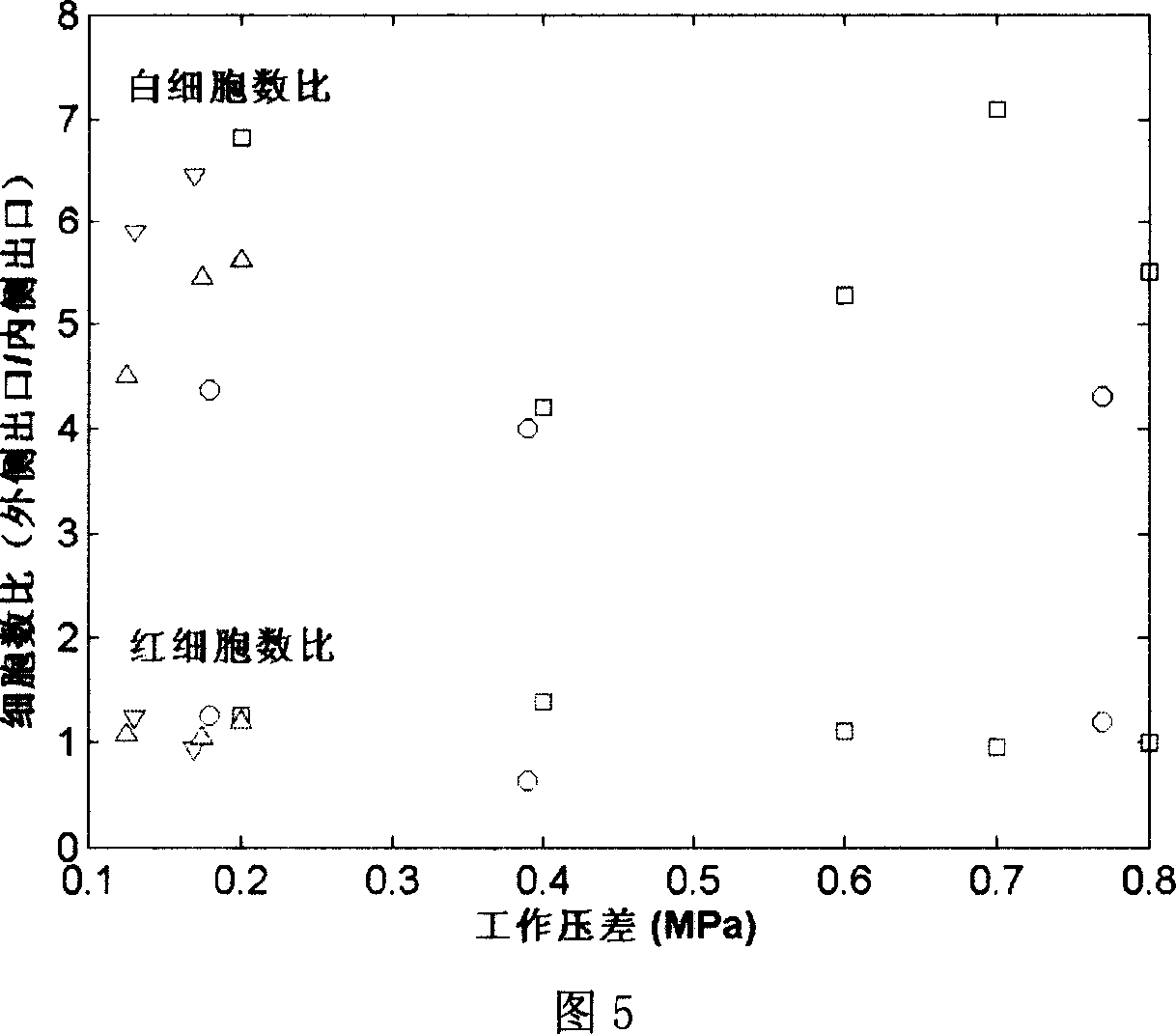

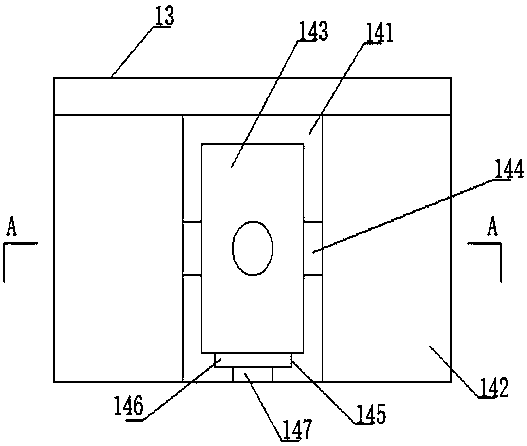

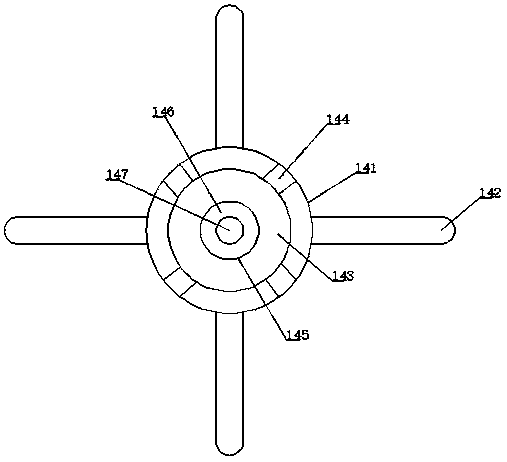

Microfluid centrifugal chip and its processing method

The invention relates to the making of a micro flow centrifugal chip. It comprises the chip base and cover plate, the base composed of a bended and continuous extending micro slot channel, with the curvature radius ranging 20-1000 micron, at least one inlet at the center of the micro slot channel, at least two outlets at the tail of the micro slot channel. It has a micro slot channel with micro curvature radius spinal, generating clutch acceleration speed to realize the centrifugal operation. It applies to micro processing, being able to realize excellent centrifugal effect, low in cost, and quick.

Owner:PEKING UNIV

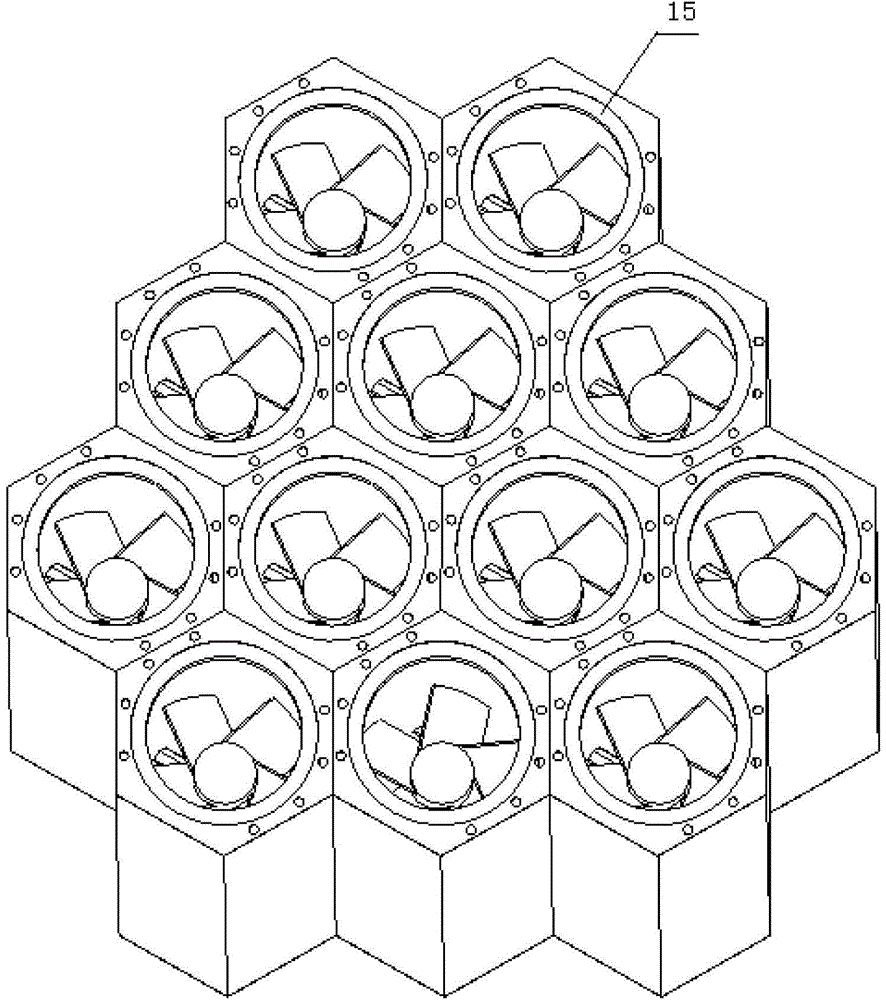

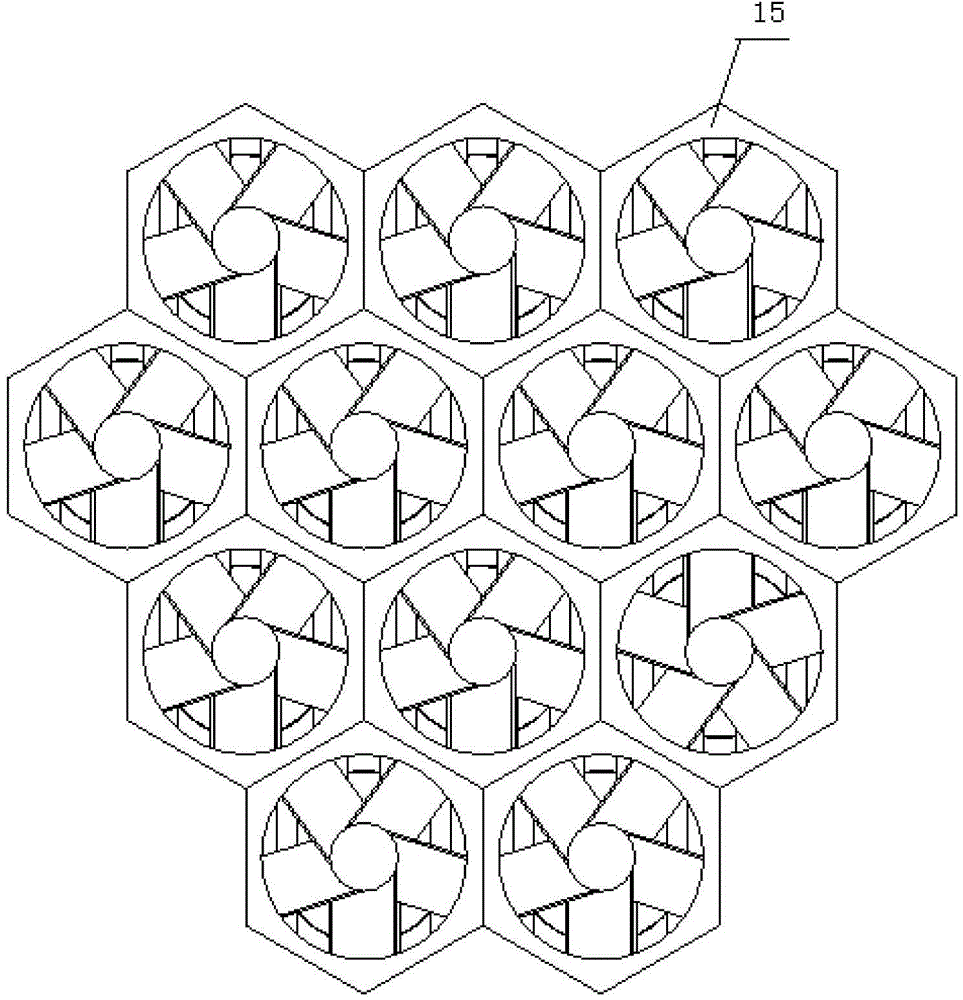

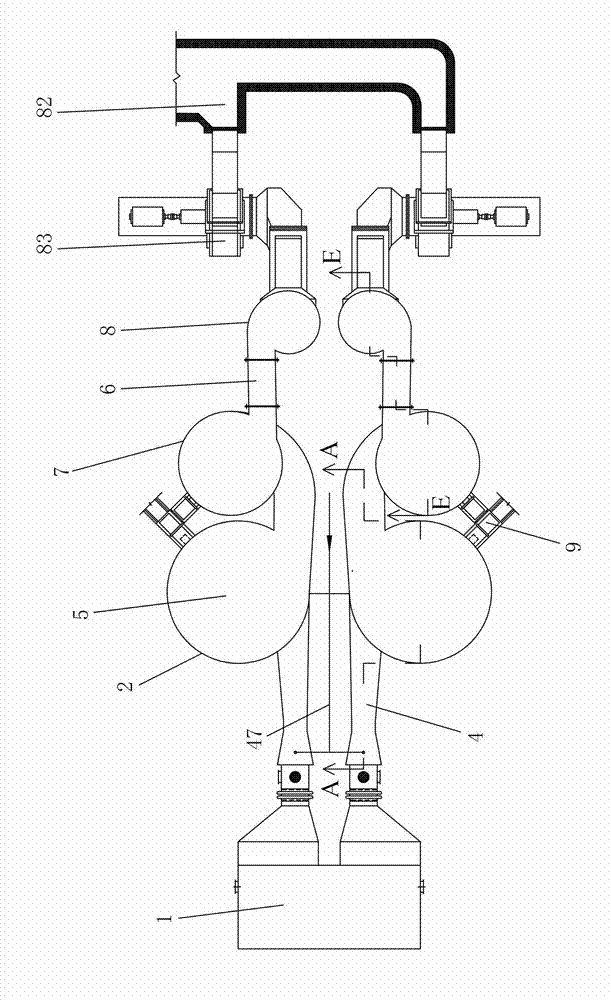

Phase-change dust-removing and mist-removing paralleling device of high-efficiency pneumatic pipe bundle and application

The invention relates to a phase-change dust-removing and mist-removing paralleling device of a high-efficiency pneumatic pipe bundle and an application. The phase-change dust-removing and mist-removing paralleling device comprises a plurality of phase-change dust-removing and mist-removing devices of the high-efficiency pneumatic pipe bundle, which are connected together in parallel; each of the phase-change dust-removing and mist-removing device comprises a hollow drum body with the openings at the two ends, a drum-body upper sealing plate, a drum-body lower sealing plate, a cyclone section, a pipe-bundle type water-mist distributing section and a water blocking section. The paralleling device has the advantages that the plurality of phase-change dust-removing and mist-removing devices are connected together in parallel, so that a user can assemble and adjust according to the treating capability needed practically, single phase-change dust-removing and mist-removing devices can be connected by adopting bonding, welding or hole grooves and the like; the manufacture is convenient and the waste-gas treating range is greatly expanded.

Owner:AEROSPACE ENVIRONMENTAL ENG

Centrifuge, rotor for centrifuge, and sample container for centrifuge

InactiveUS20130316889A1Low costIncrease capacityRotary centrifugesLaboratory glasswaresBiomedical engineeringCentrifuge

Owner:KOKI HLDG CO LTD

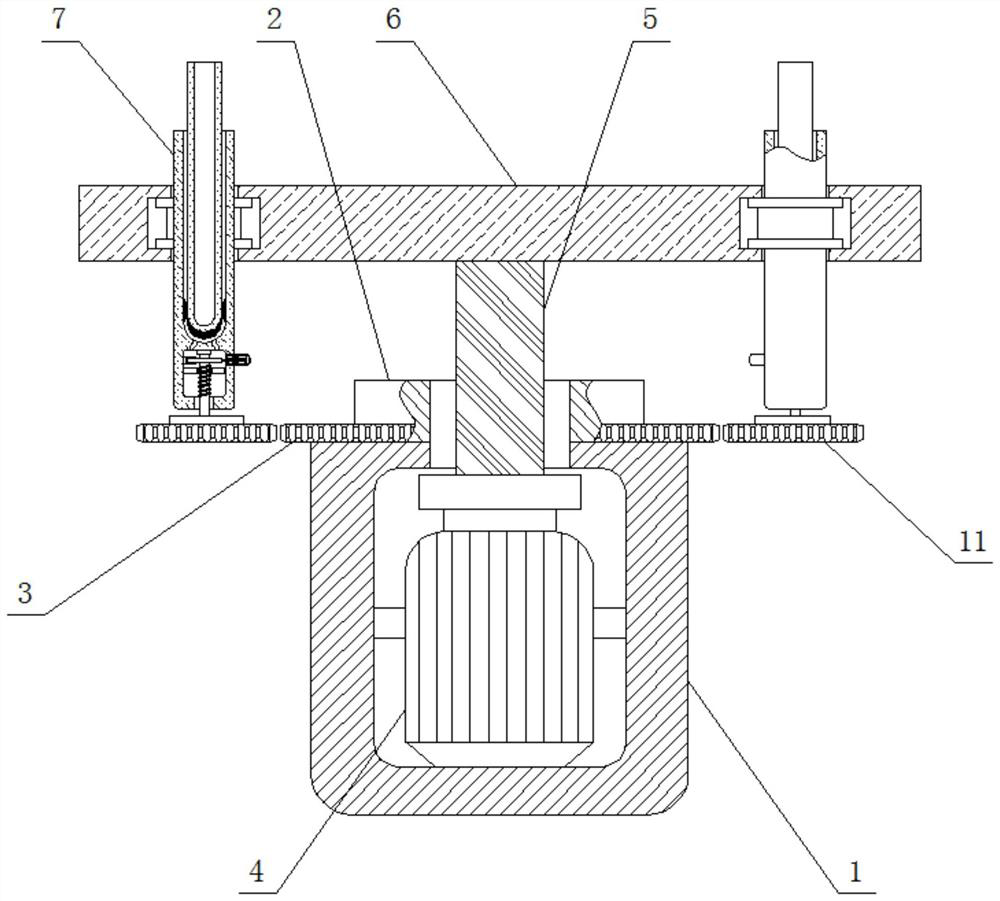

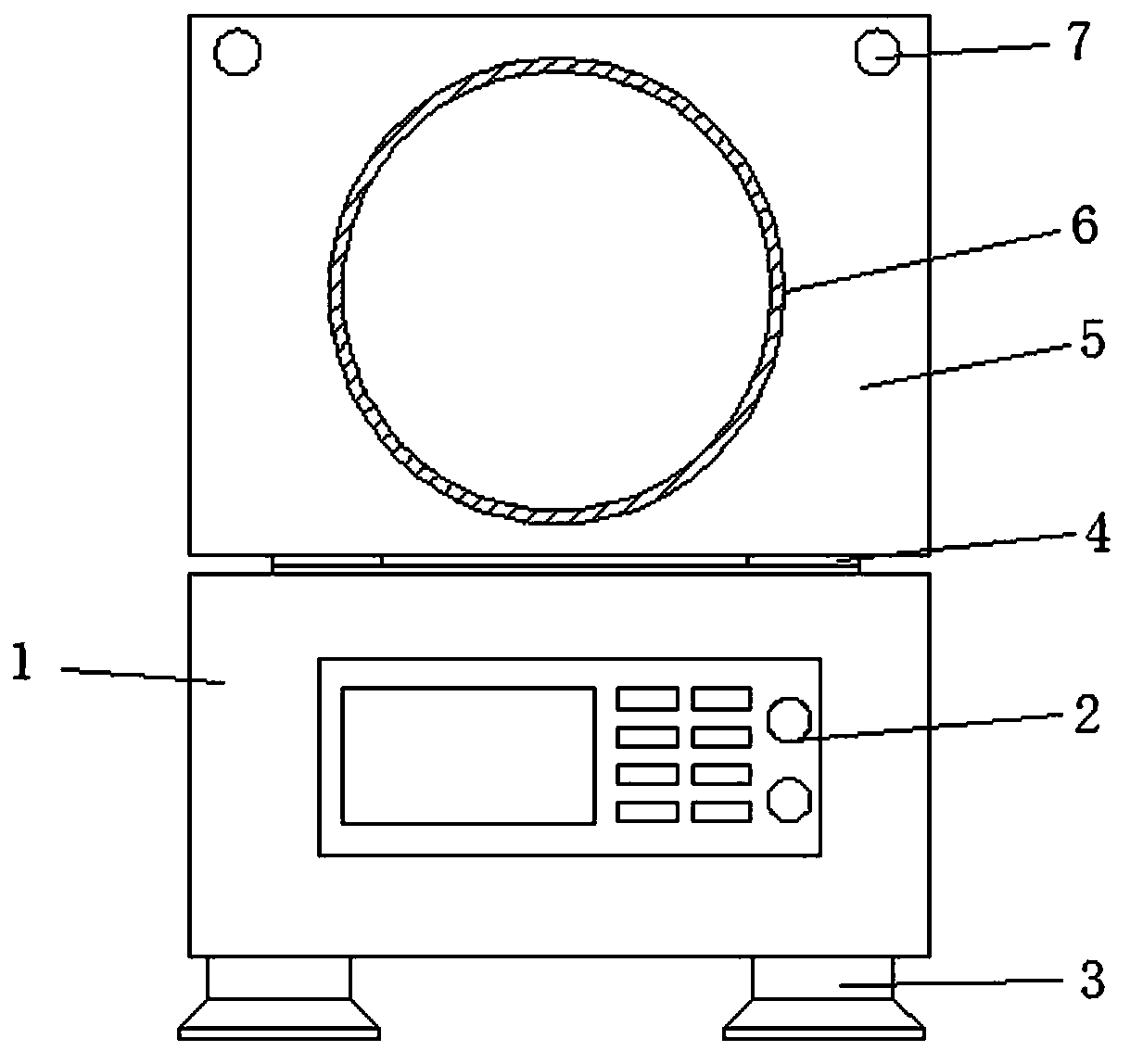

Stem cell rapid centrifuge capable of preventing centrifugal pollution

InactiveCN112170025AImprove stabilityImprove adsorption capacityBioreactor/fermenter combinationsEngine sealsElectric machineryEnvironmental engineering

The invention provides a stem cell rapid centrifuge capable of preventing centrifugal pollution, and belongs to the technical field of cell centrifuges. The problems that when an existing centrifuge is used, part of operators easily forget to close a sealing cover on the centrifuge and then press a key on a control panel, and once the sealing cover is forgotten to be closed, the exterior environment is polluted during centrifuging of stem cells are solved. The stem cell rapid centrifuge comprises a shell, and a centrifugal motor is installed on the bottom end face of the interior of the shell.When the sealing cover is forgotten to be closed before centrifugal work, a shielding mechanism is always located on the front side of a control key on a control panel due to the fact that the shielding mechanism does not obtain tension, therefore a worker cannot press the control key on the control panel at the moment and then is reminded to close the sealing cover, after the sealing cover is closed, the control key on the control panel lose the shielding effect and then is pressed so that the sealing cover cannot be forgotten to be closed, and the phenomenon that the exterior environment ispolluted during centrifuging of stem cells is effectively avoided.

Owner:鲁乐

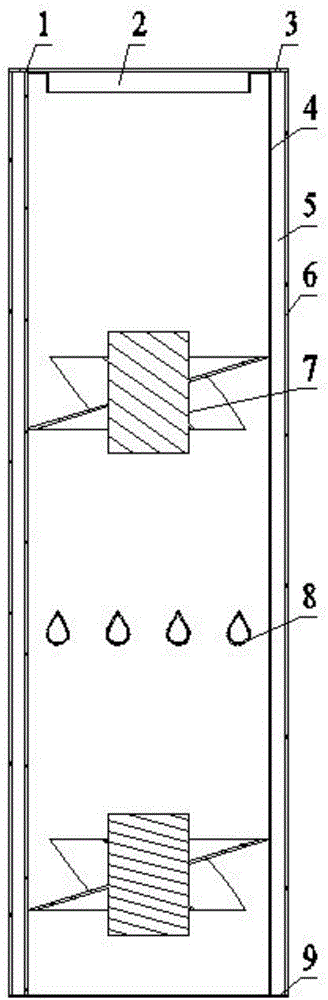

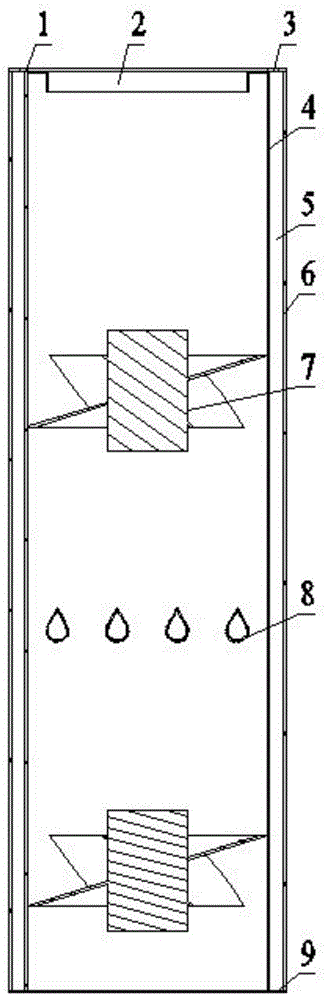

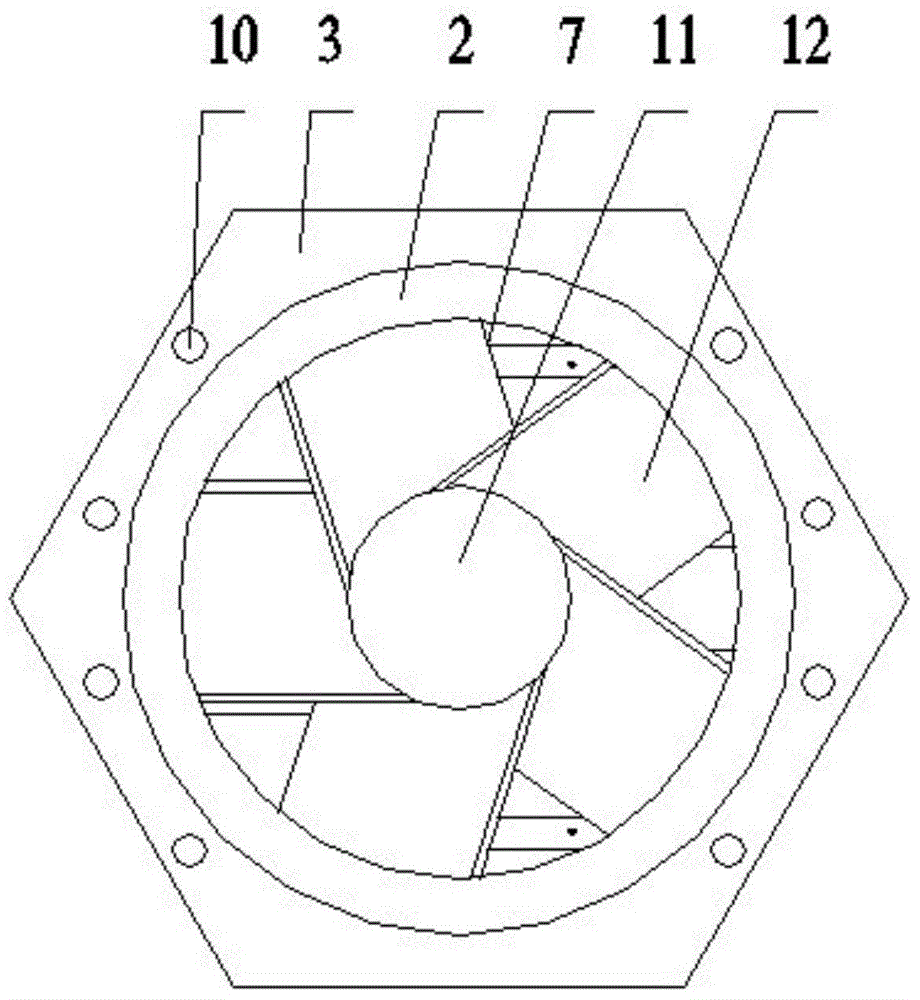

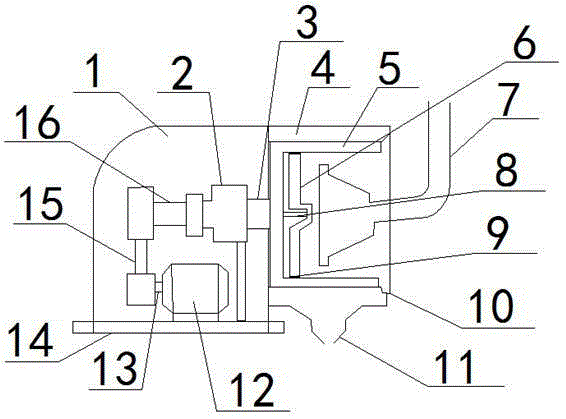

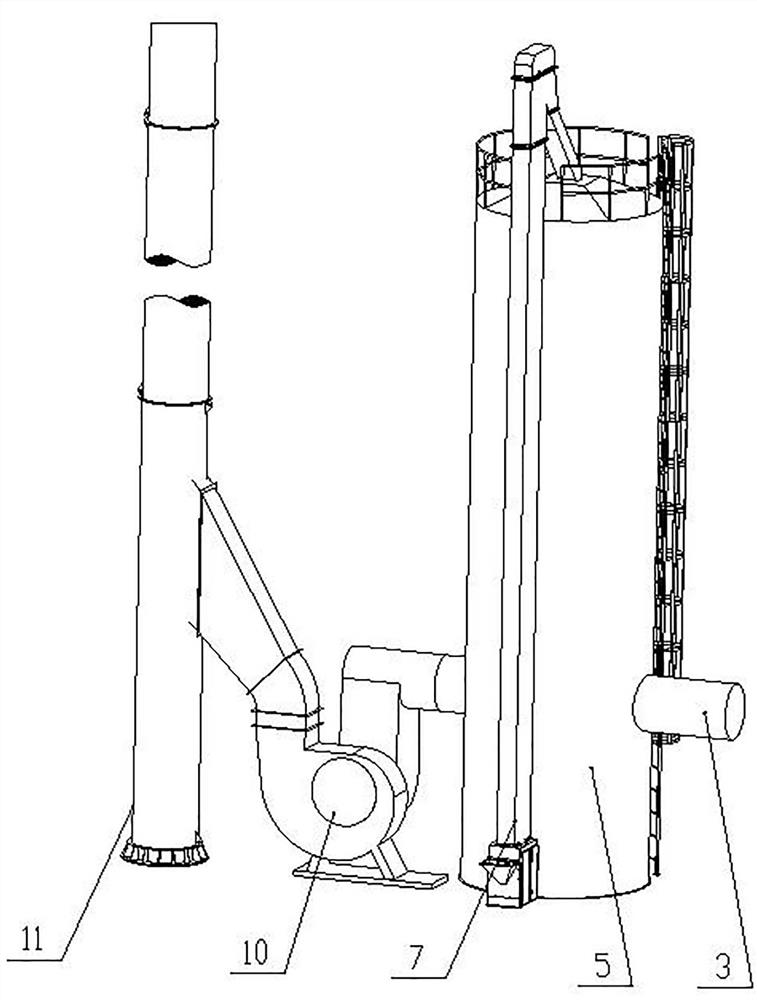

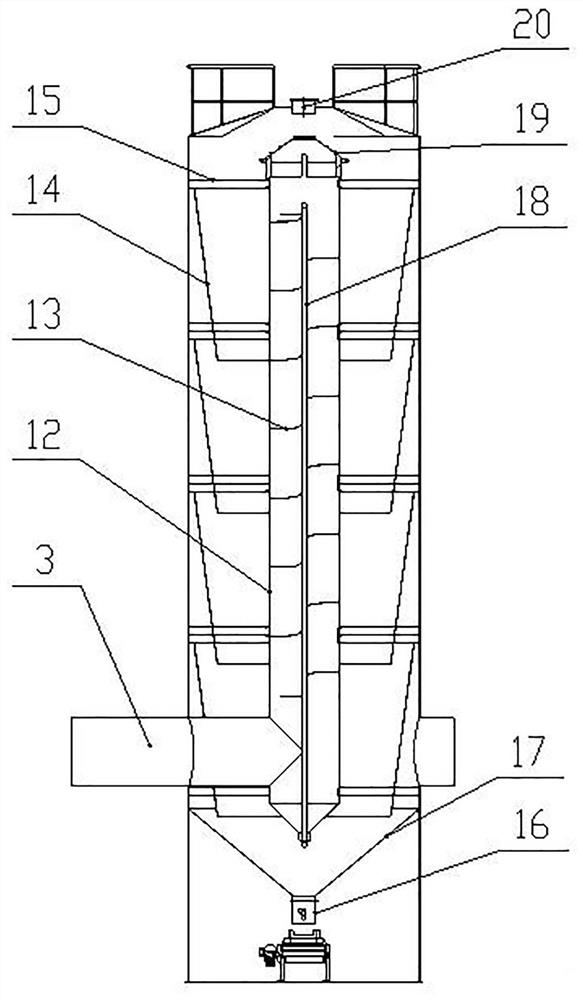

High-efficiency pneumatic pipe bundle phase-change dedusting and demisting device and application

InactiveCN104923020AImprove centrifugal effectHelp to separate and captureCombination devicesElectricityEngineering

The invention relates to a high-efficiency pneumatic pipe bundle phase-change dedusting and demisting device and application. The device comprises a hollow barrel with two ends open, an upper barrel sealing plate, a lower barrel sealing plate, rotational flow sections, pipe-bundle-type water mist distribution sections and a water retaining section, the rotational flow sections of more than two stages are arranged coaxially in the inner-layer barrel from bottom to top at intervals, each pipe-bundle-type water mist distribution section is arranged coaxially between each two corresponding rotational flow sections, and the water retaining section is coaxially arranged on the inner-layer barrel below the upper barrel sealing plate in an outer-edge-sealed manner. The device can effectively remove liquid drops, dust and superfine dust of smoke systems or industrial waste gas systems, is good in demisting and dedusting effect and is lower in energy consumption and more energy saving when compared with wet-type electric dedusting. In addition, by the device, arrangement space is saved, and power equipment is omitted; the device has good dedusting and demisting effect while energy consumption is lowered, and can be applied to dedusting and demisting of industrial tail gas.

Owner:AEROSPACE ENVIRONMENTAL ENG

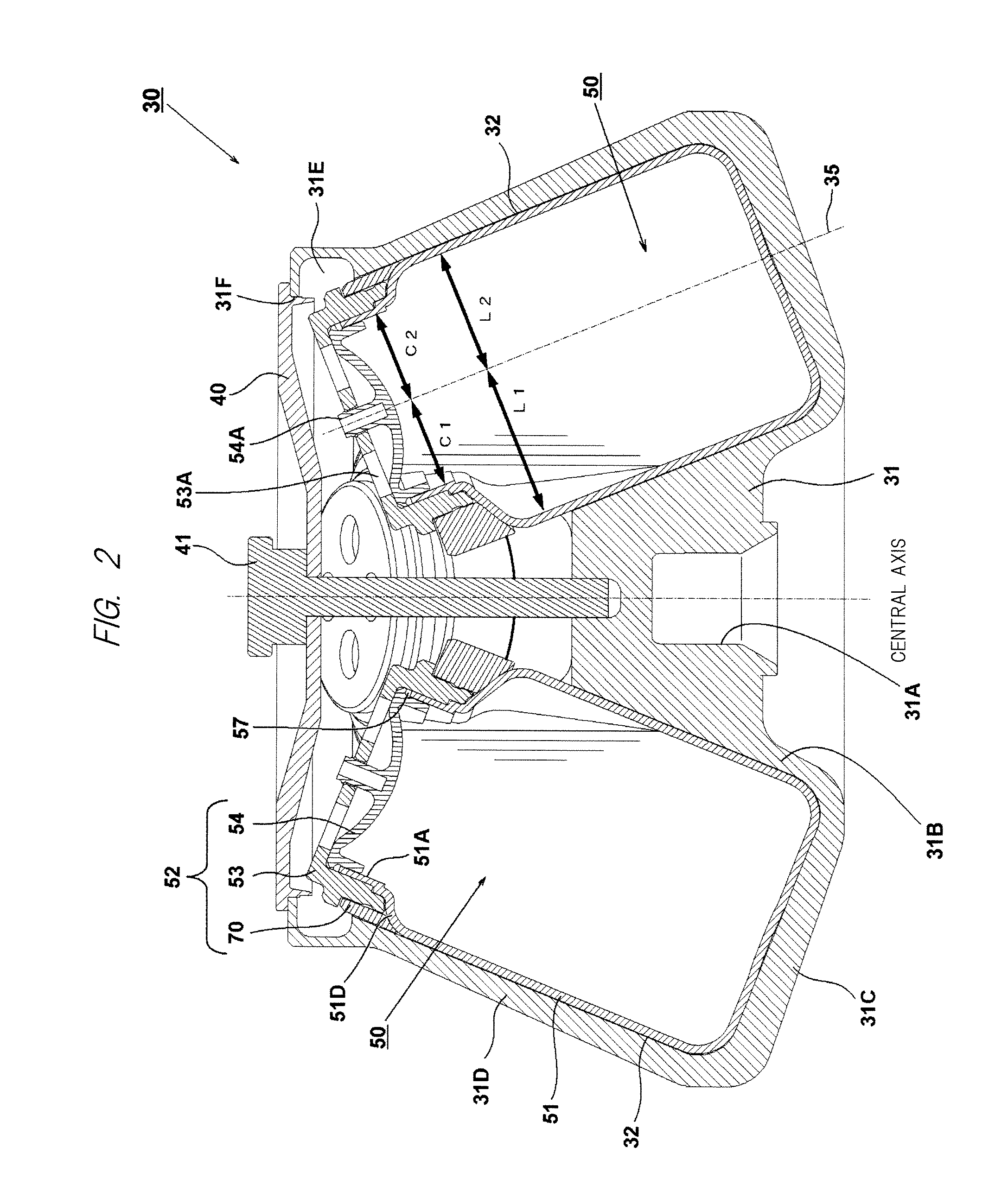

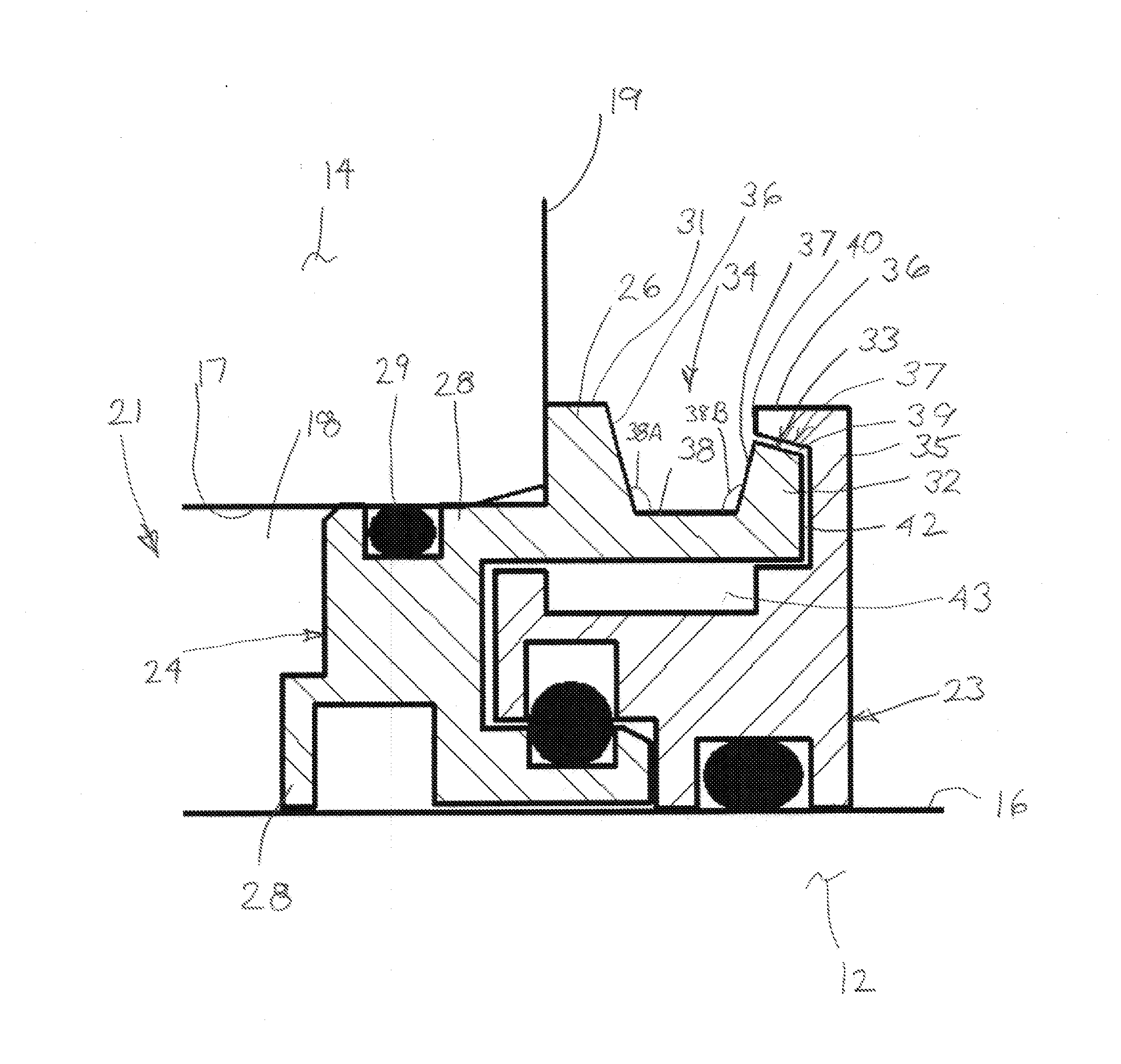

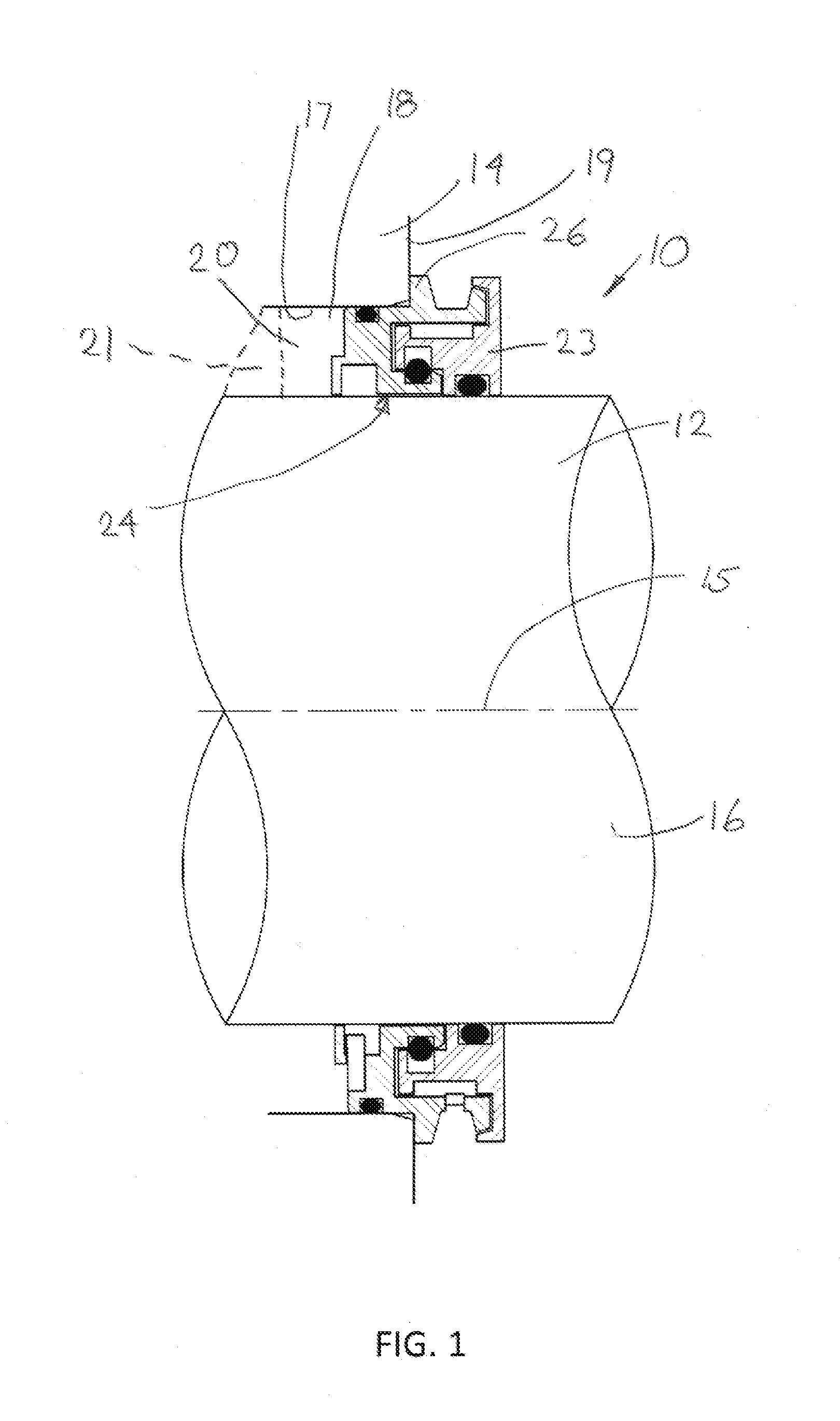

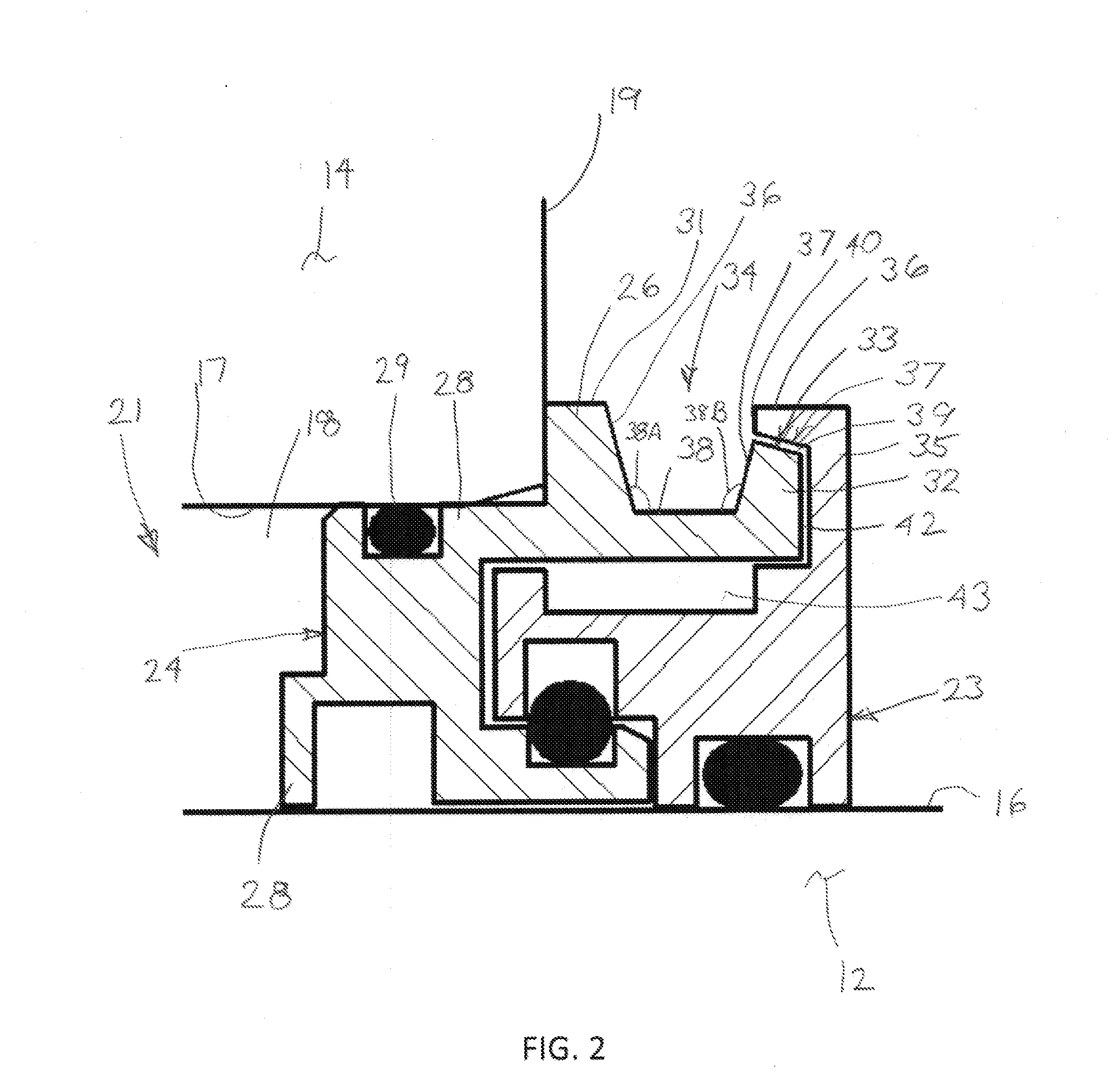

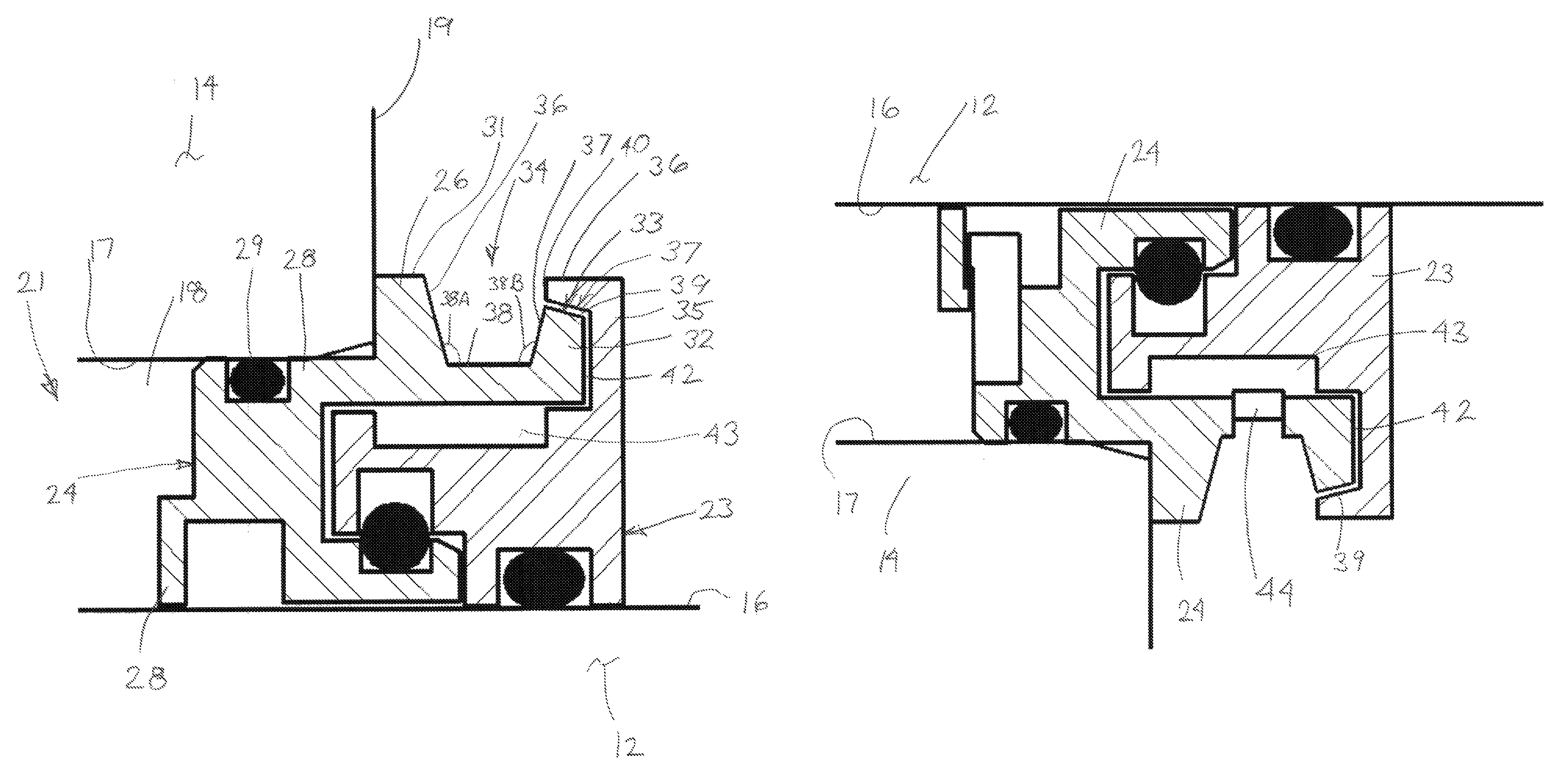

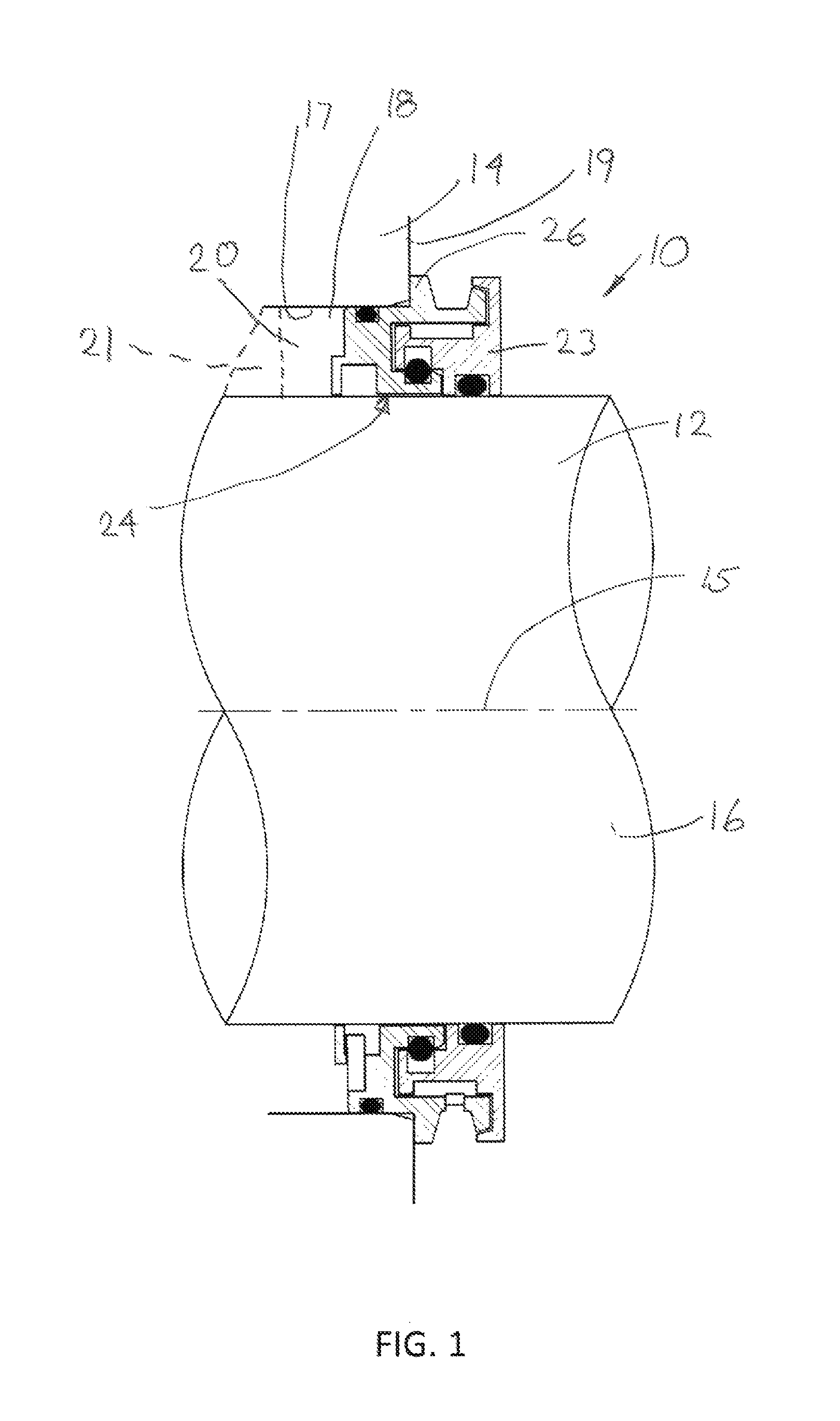

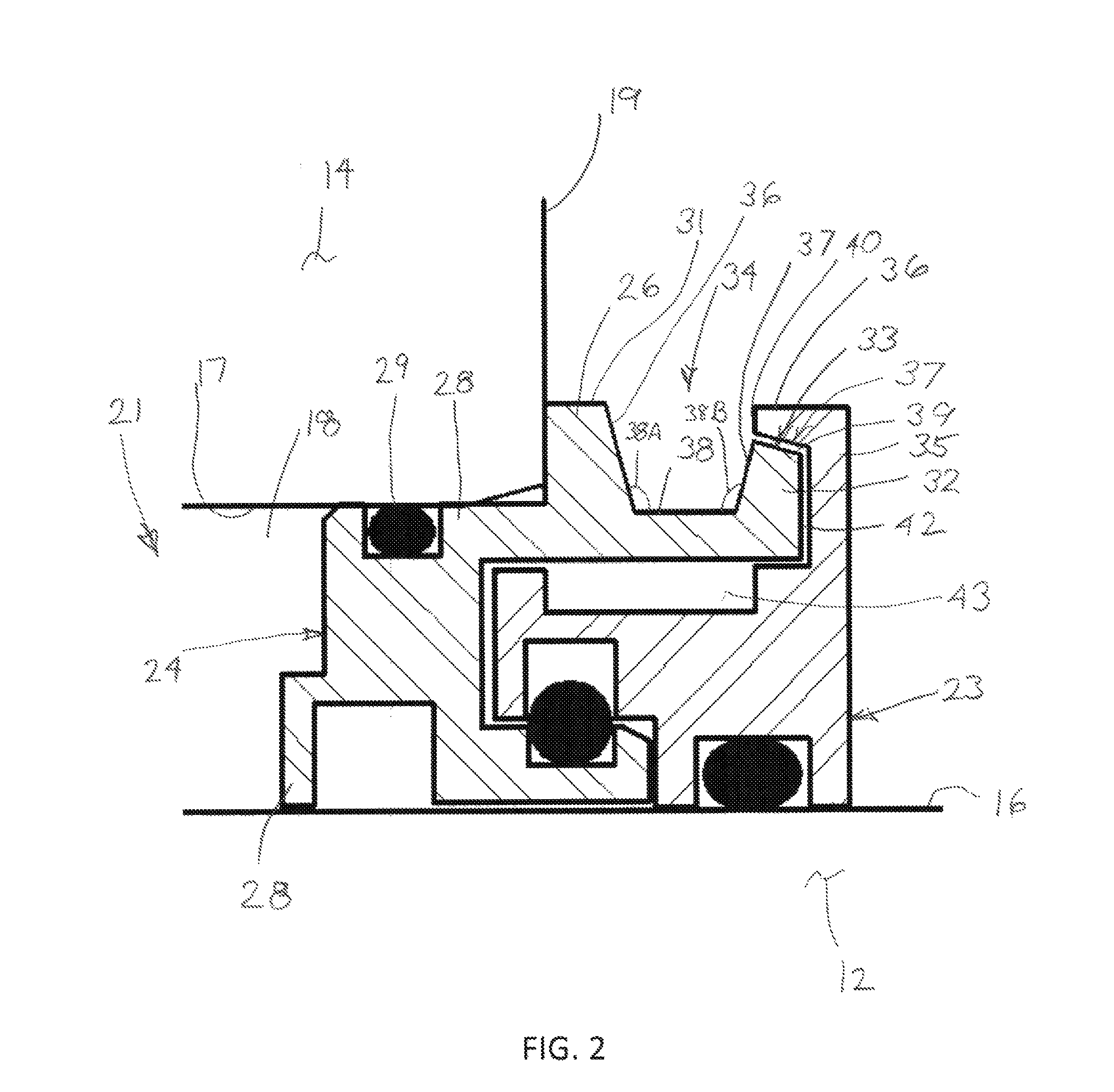

Bearing isolator seal for rotating shaft

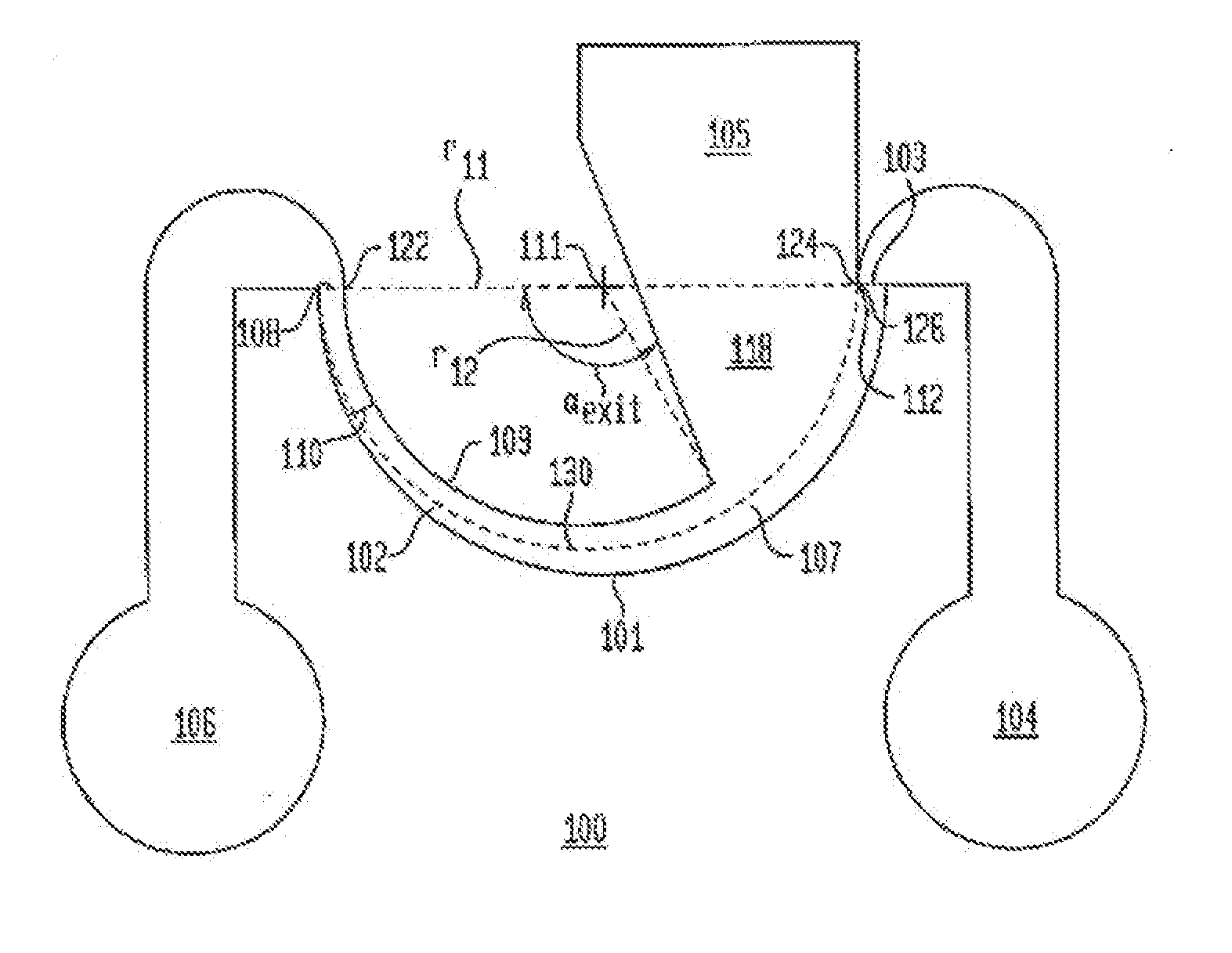

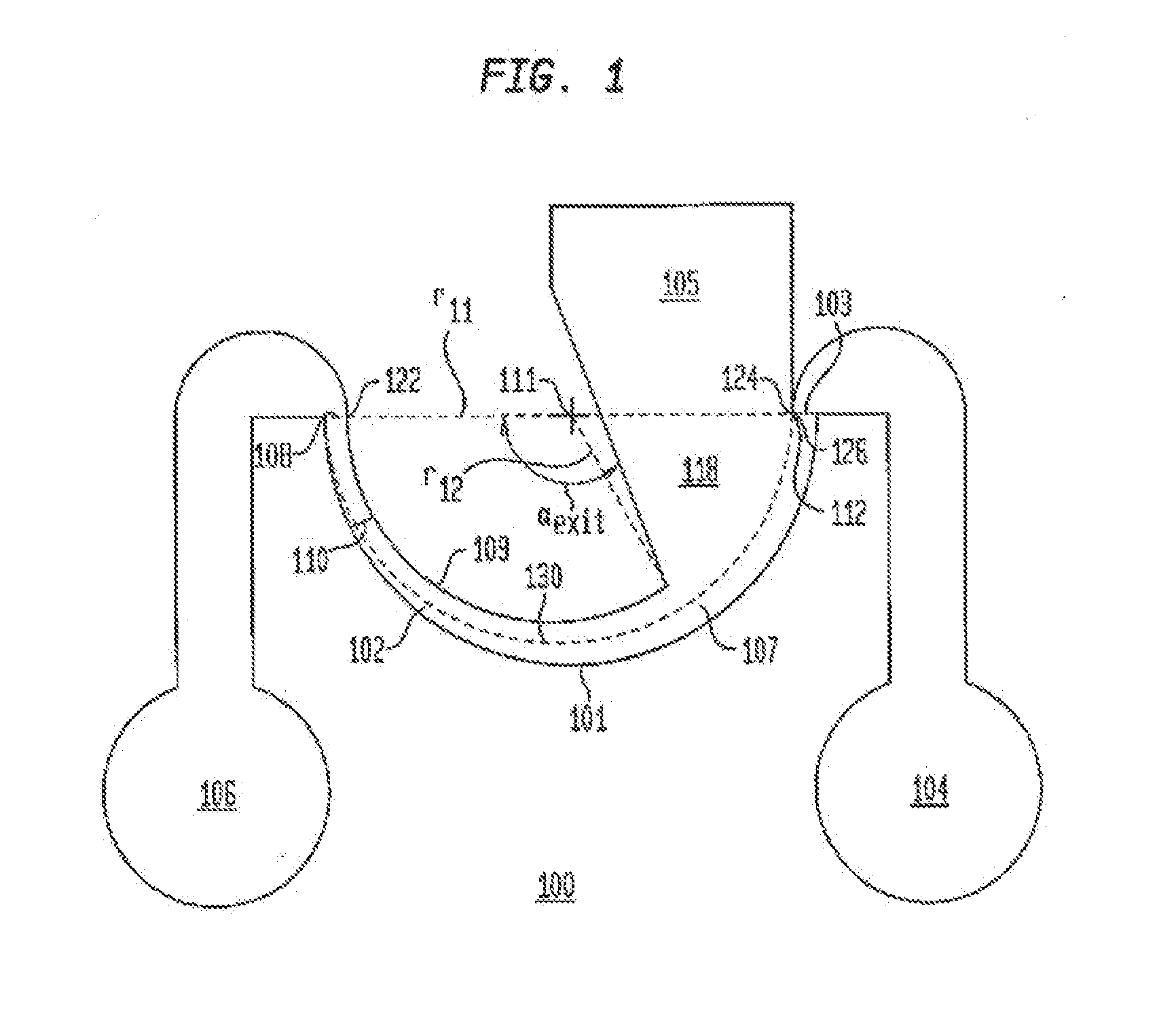

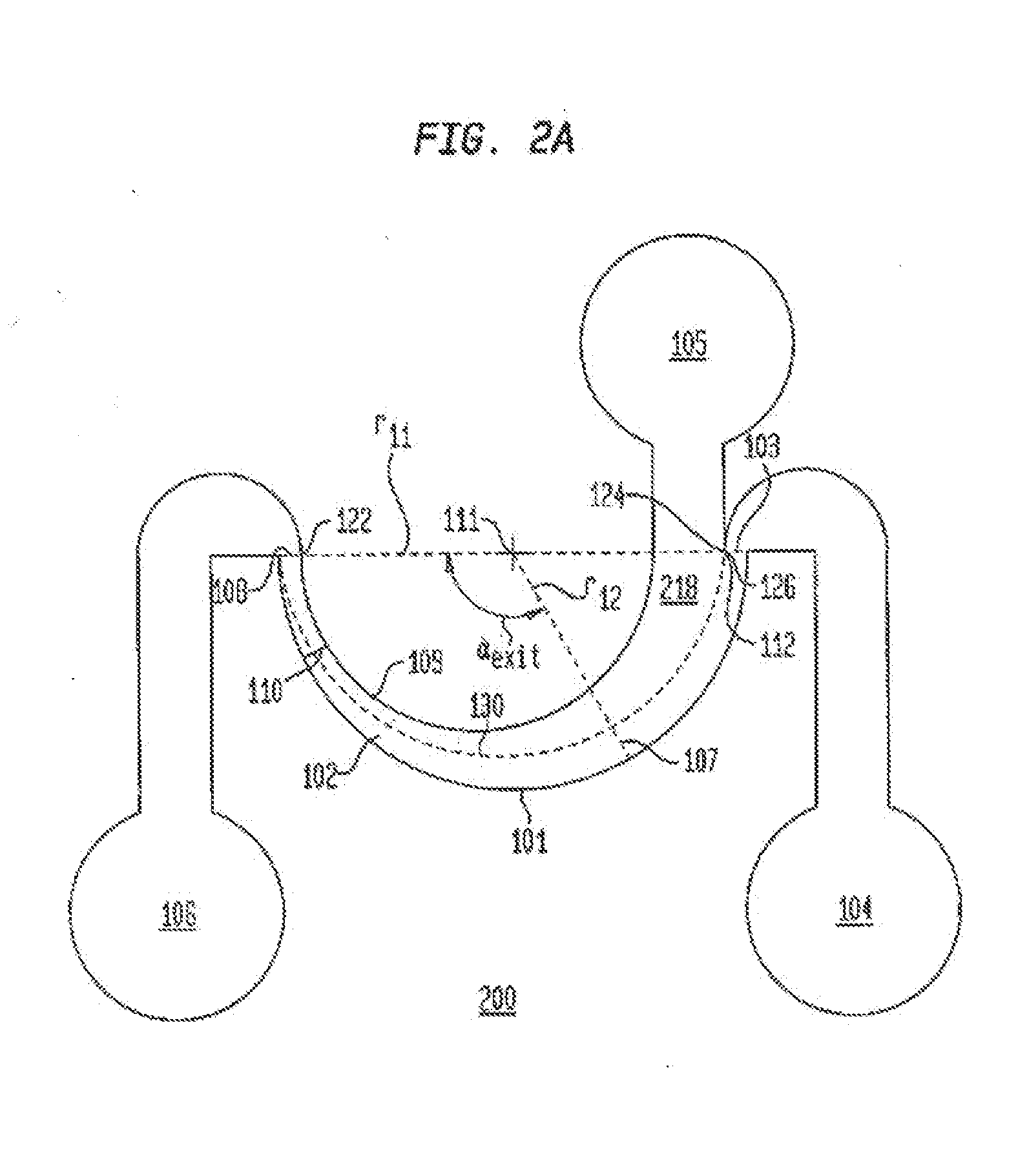

A bearing isolator seal includes a rotor and stator wherein the stator has inboard and outboard radial projections which define a groove bounded by groove side faces and a groove bottom face. The rotor extends radially and then axially so as to lie closely adjacent to the terminal end of the outboard radial projection on the stator to define an entrance passageway. The bearing isolator seal includes a surface geometry which is believed to result in improved exclusion of contaminants, particularly from high velocity water spray, wherein the entrance passageway is angled to increase the rotational effects of exclusion during shaft rotation, and wherein the groove side faces are also angled to assist in redirecting spray and other contaminants away from the passageway.

Owner:FLOWSERVE MANAGEMENT CO

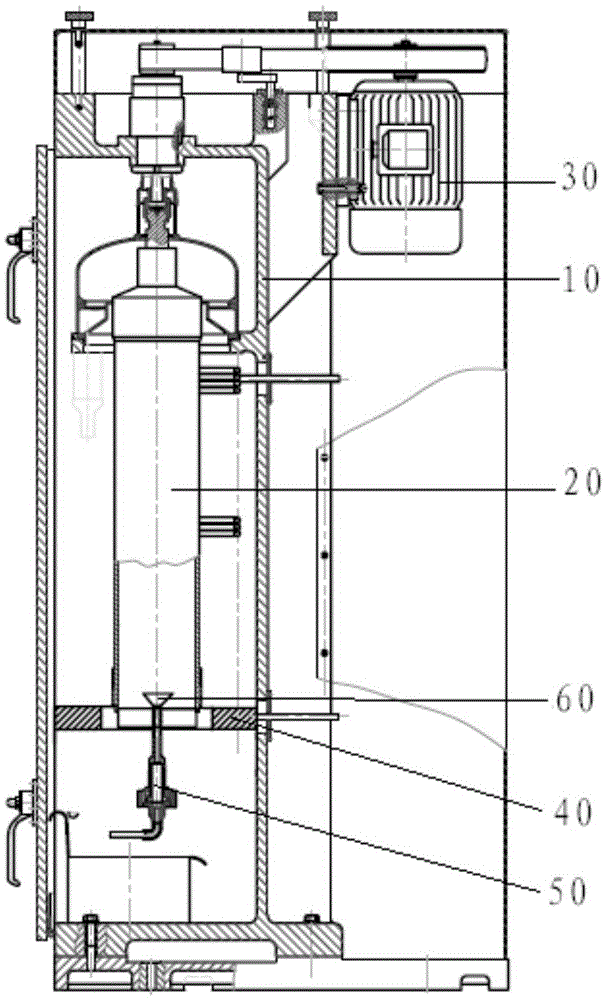

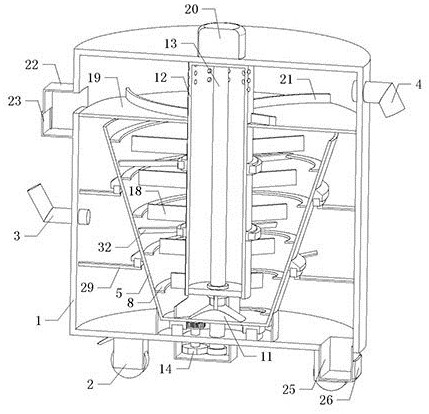

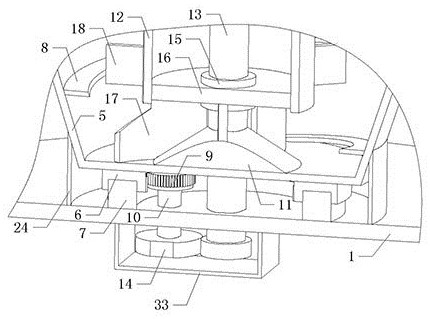

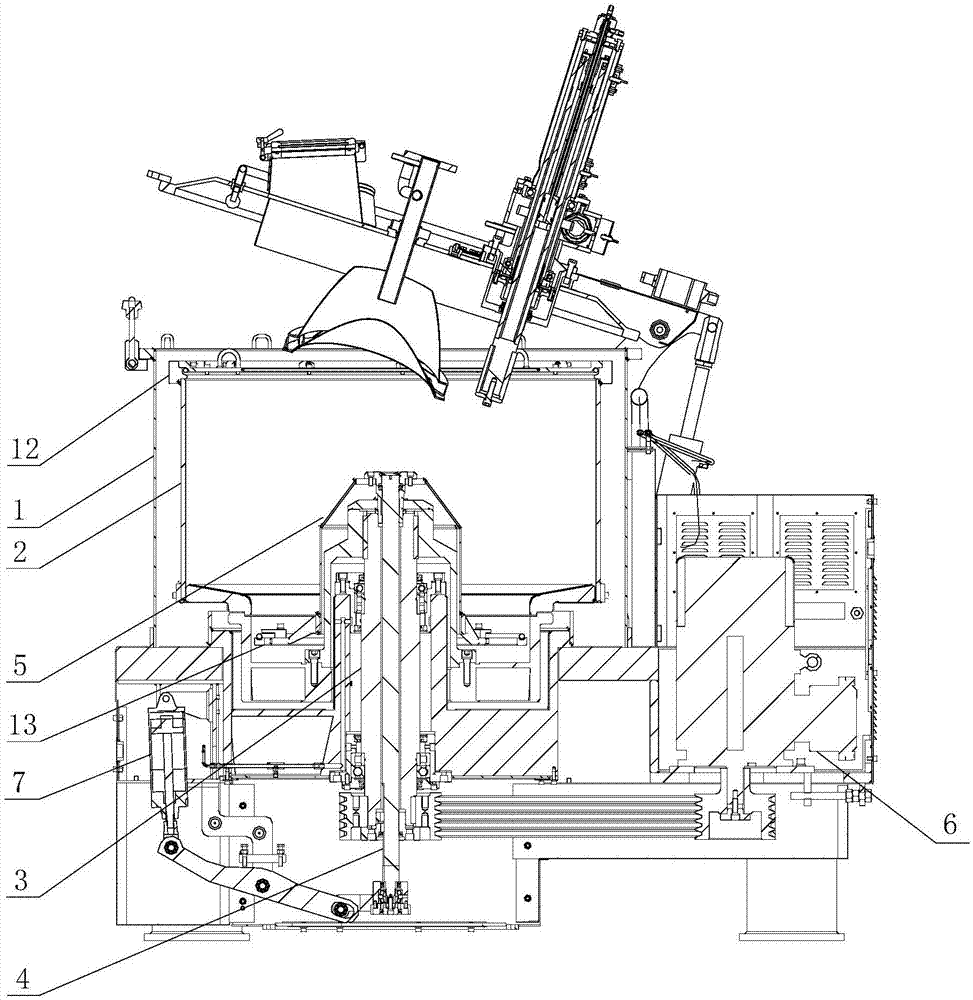

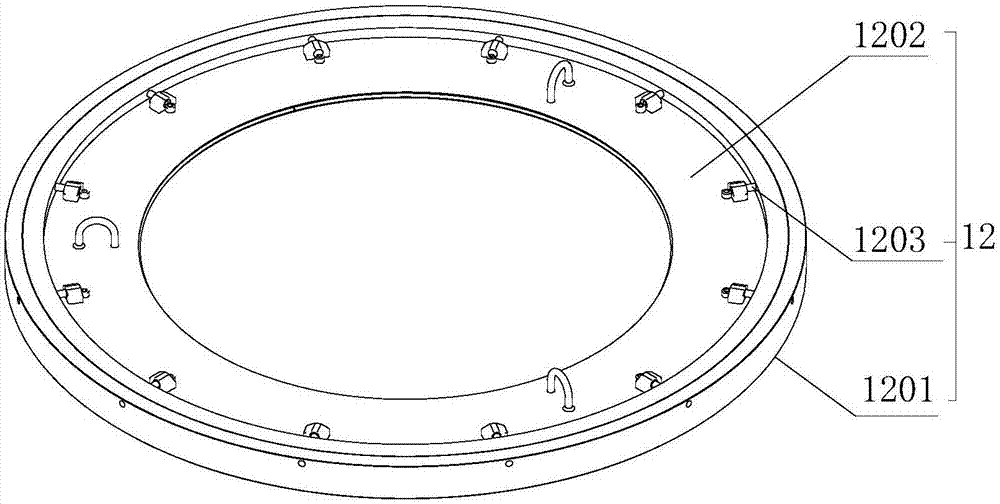

Compact type self-cleaning centrifuge

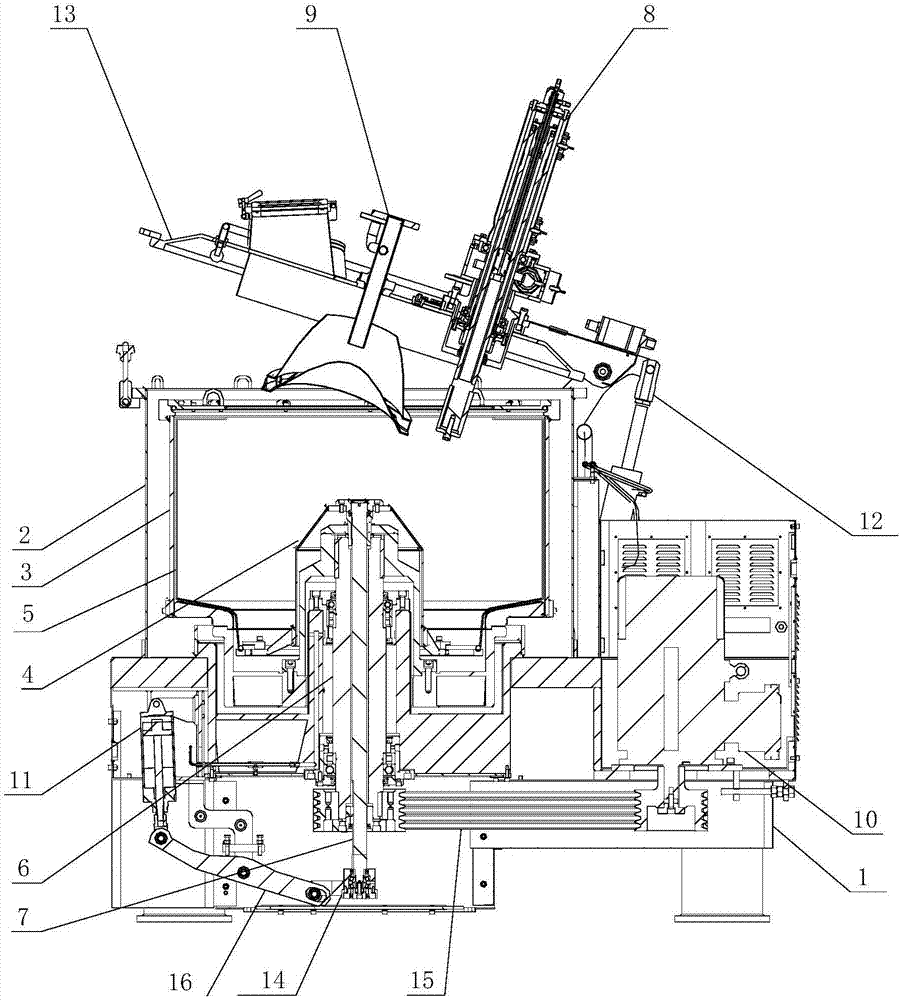

The invention discloses a compact type self-cleaning centrifuge which comprises a base, a shell, a drum, a lifting cover, a filtration bag, a main shaft, a lifting shaft, a scraping mechanism, a distribution mechanism, a first driving mechanism, a second driving mechanism and a third driving mechanism. The compact type self-cleaning centrifuge is simpler and more compact in structure through arrangement for the structure of the shell and parts in the corresponding positions in the shell, so that the overall height is greatly lowered. In addition, the lifting shaft and the main shaft are matched, the lifting cover can rotate synchronously with the drum and lift up and down relative to the drum at the same time, accordingly the filtration bag is pulled to retract up and down to remove materials stained on the wall of the drum and the filtration bag, and the purposes of self cleaning and improvement of the centrifugal effect of the centrifuge are achieved.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

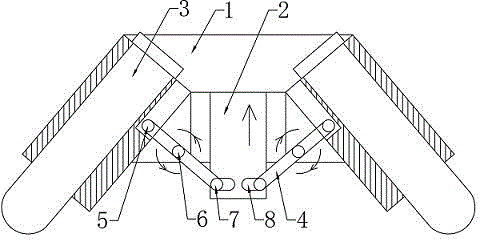

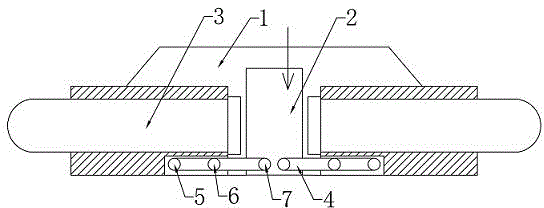

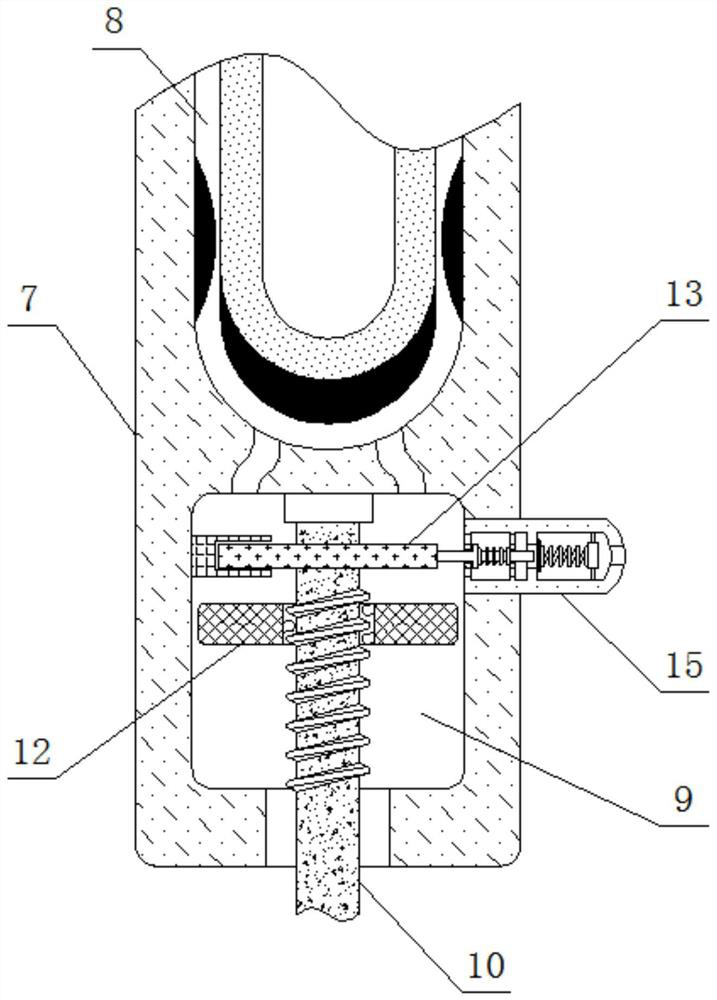

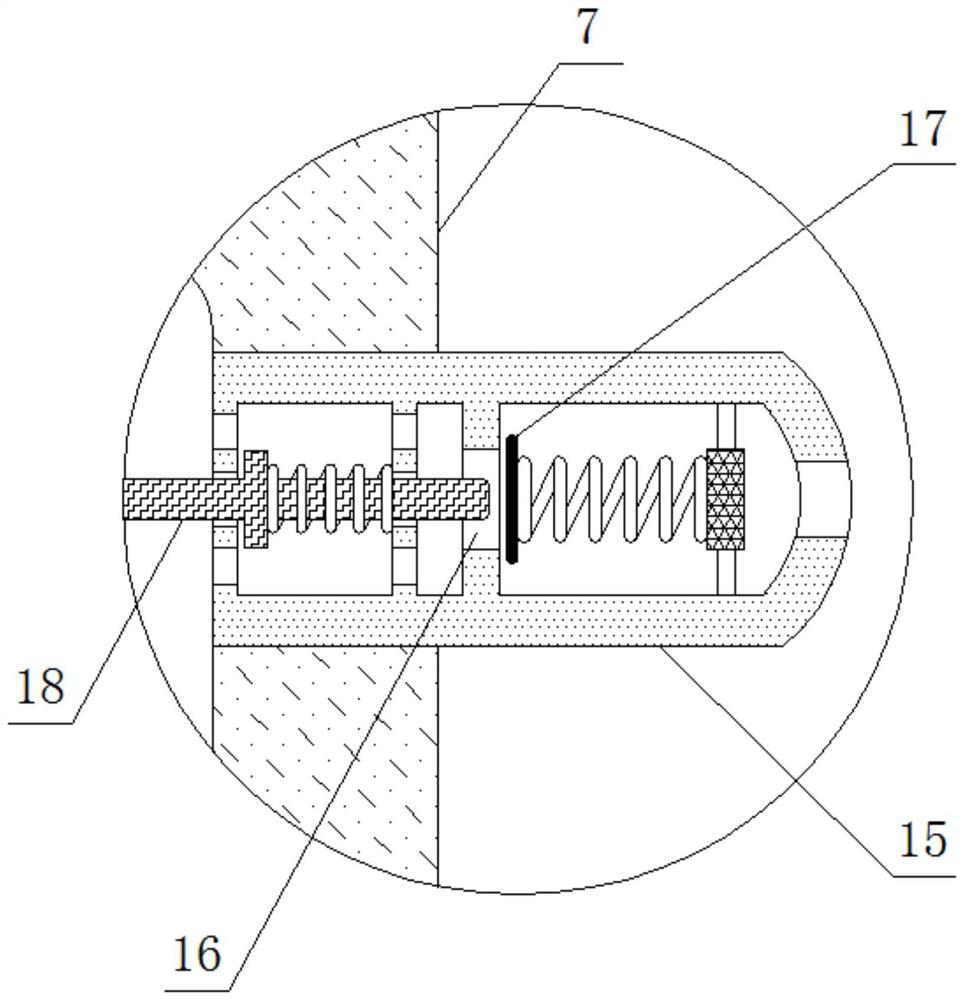

Self-closing pressing centrifuge rotating disc

The invention relates to a self-closing pressing centrifuge rotating disc. The technical scheme of the invention is that the centrifuge rotating disc comprises a rotating disc main body, a link mechanism and a pressing column, wherein a movable test tube groove is formed in the rotating disc main body; the middle end of the link mechanism is connected with the rotating disc main body; one end of the link mechanism is provided with a left connecting point connected with the test tube groove, and the other end of the link mechanism is provided with a right connecting point connected with the pressing column. The centrifuge rotating disc aims to be used for slantly placing test tubes before the centrifuge is utilized, the test tubes are enforced to be horizontally placed for centrifugation because of the centrifugal effect in the using process, and the centrifuge can be opened by directly pressing the pressing column.

Owner:苏州培英实验设备有限公司

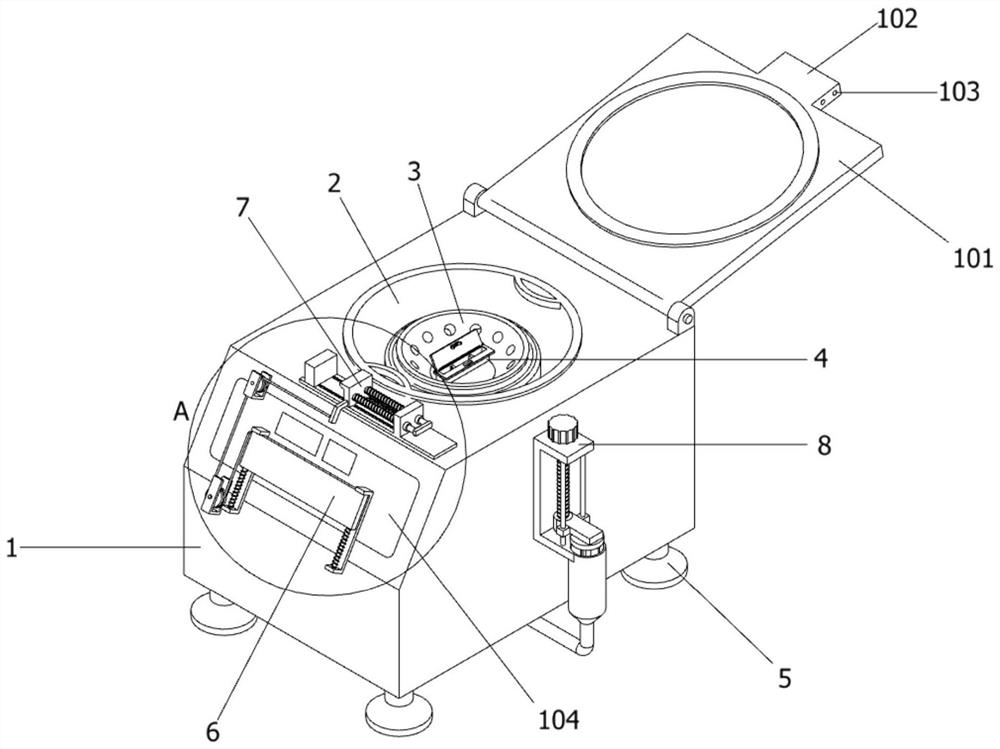

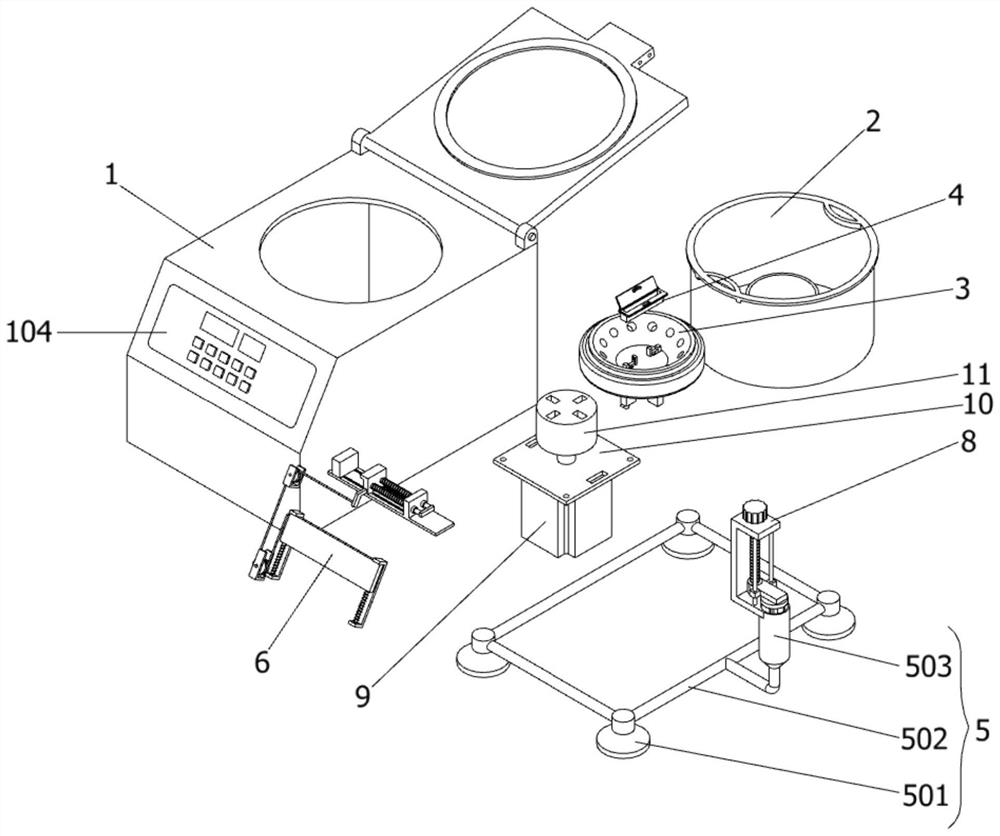

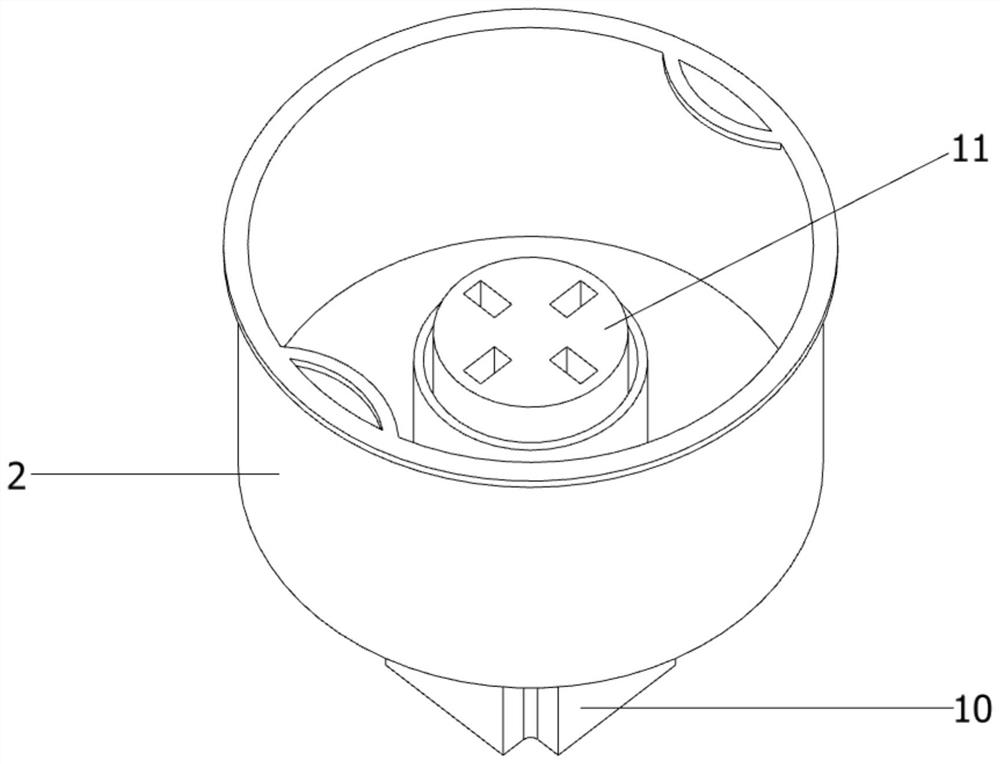

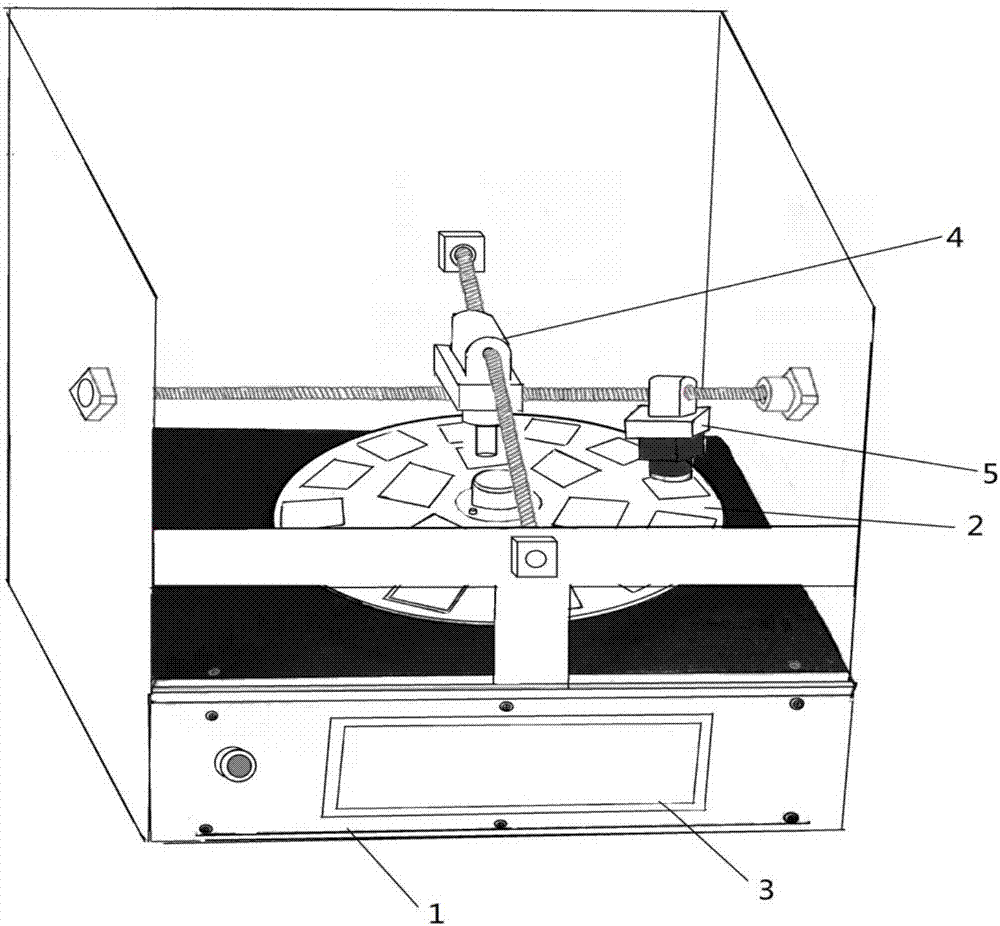

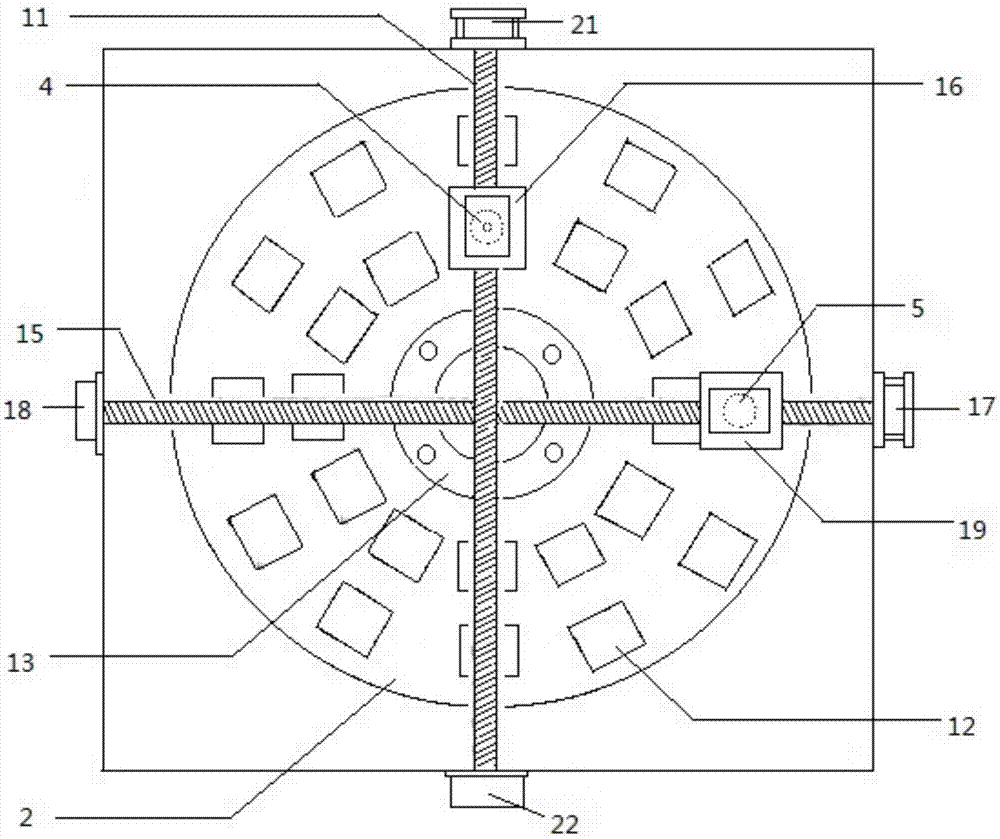

Blood type detection device based on microfluidic chips and STM32

ActiveCN107247150AIntelligent speed controlQuick responseBiological testingAgainst vector-borne diseasesBrushless motorsMedicine

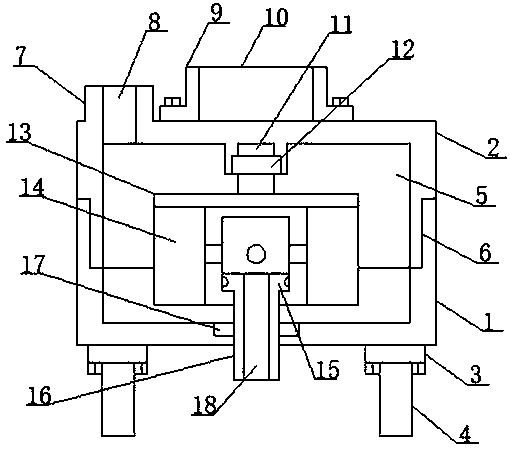

The invention relates to a blood type detection device based on microfluidic chips and STM32. The device comprises a base, an eccentric device and a positioning device. A switch and a touch screen are arranged at the right front end of the base. The eccentric device comprises an eccentric rotating disc and a direct-current brushless motor. The direct-current brushless motor is installed in the middle of the base and is connected with a rotating disc connecting shaft, the rotating disc connecting shaft sequentially penetrates upwards through an upper partition plate and a rubber pad and is connected with the eccentric rotating disc, and an inner ring and an outer ring of 24 clamping grooves used for containing the microfluidic chips are formed in the eccentric rotating disc. According to the device, an STM32 controller serves as a core, and positioning and eccentric operation are completed through the two crossed ball screws on the upper portion and a working table. With the combination of an embedding type, the microfluidic technology, movement control, optical detection and other technologies, the blood type detection device has the advantages of being accurate in positioning, high in speed and efficiency, intelligent, flexible, convenient to use and the like.

Owner:HEBEI UNIV OF TECH

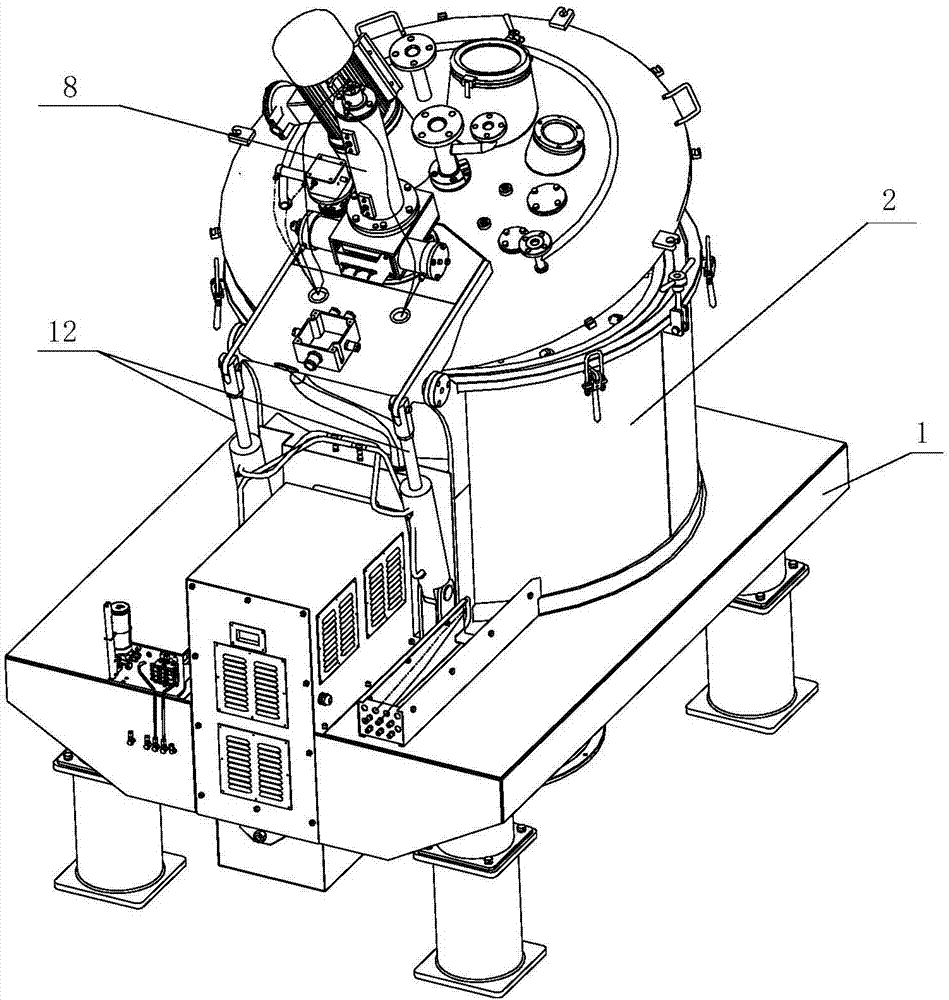

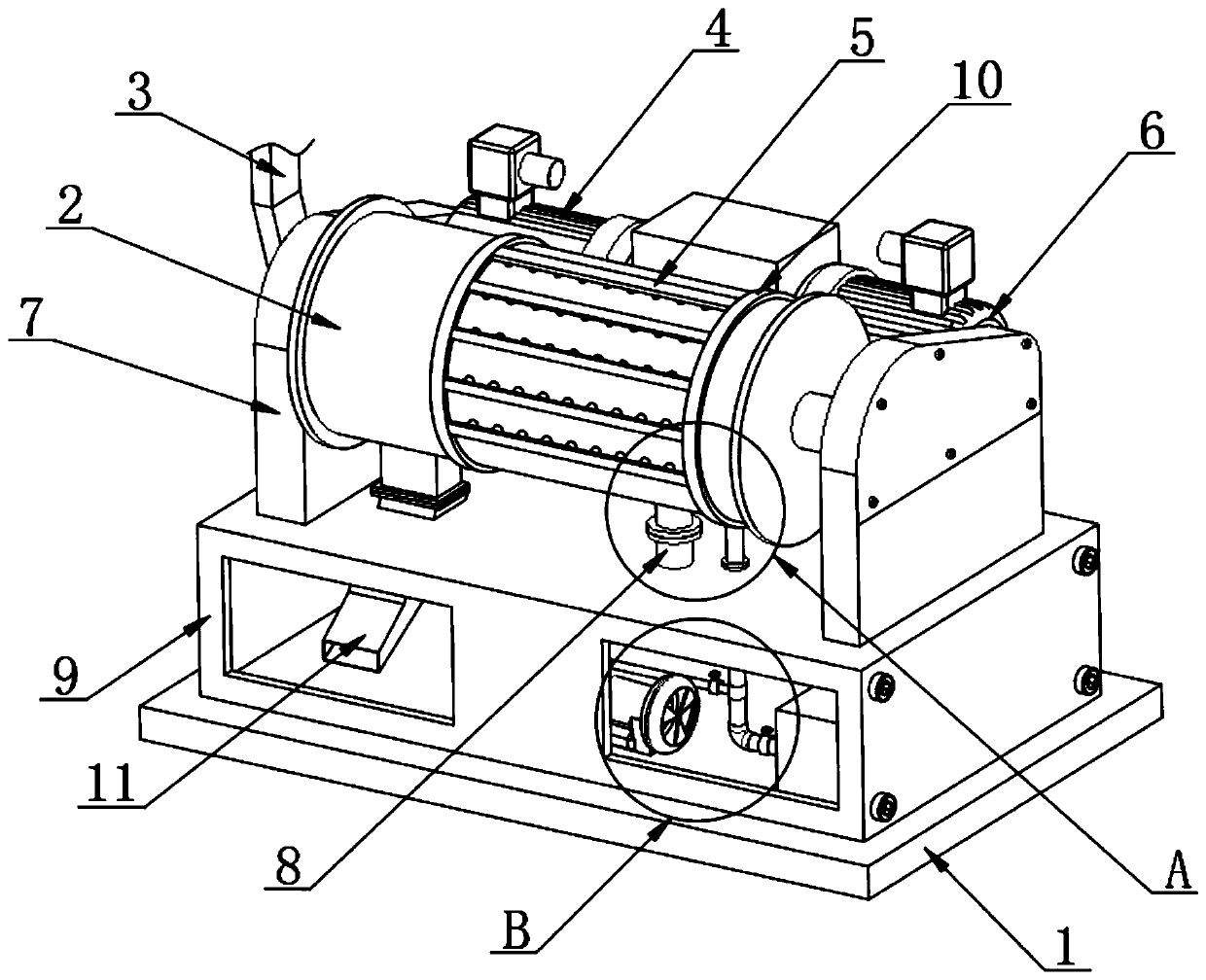

Tubular centrifuge and method thereof for keeping balance of rotating drum

The invention discloses a tubular centrifuge and a method thereof for keeping balance of a rotating drum. The tubular centrifuge comprises a frame, the rotating drum and a driving device; the driving device is arranged on the frame, is connected with the rotating drum, and is used for driving the rotating drum to rotate around the axis of the rotating drum in the vertical direction; an induction device is used for monitoring if the rotating axis of the rotating drum is deviated from the vertical direction and generating a rotating drum position signal when monitoring that the rotating axis of the rotating drum is deviated from the vertical direction; and a magnetic return device is fixed on the frame, is connected with the rotating drum, is connected with the induction device, receives the rotating drum position signal, and drives the rotating drum to enable the rotating axis of the rotating drum to return to the vertical direction according to the rotating drum position signal. The tubular centrifuge can effectively guarantee the rotating axis of the rotating drum to be always in the vertical direction, enables the rotating drum to keep the balance state, and effectively guarantees stable operation.

Owner:SHANGHAI DAIBAO MACHINERY EQUIP CO LTD

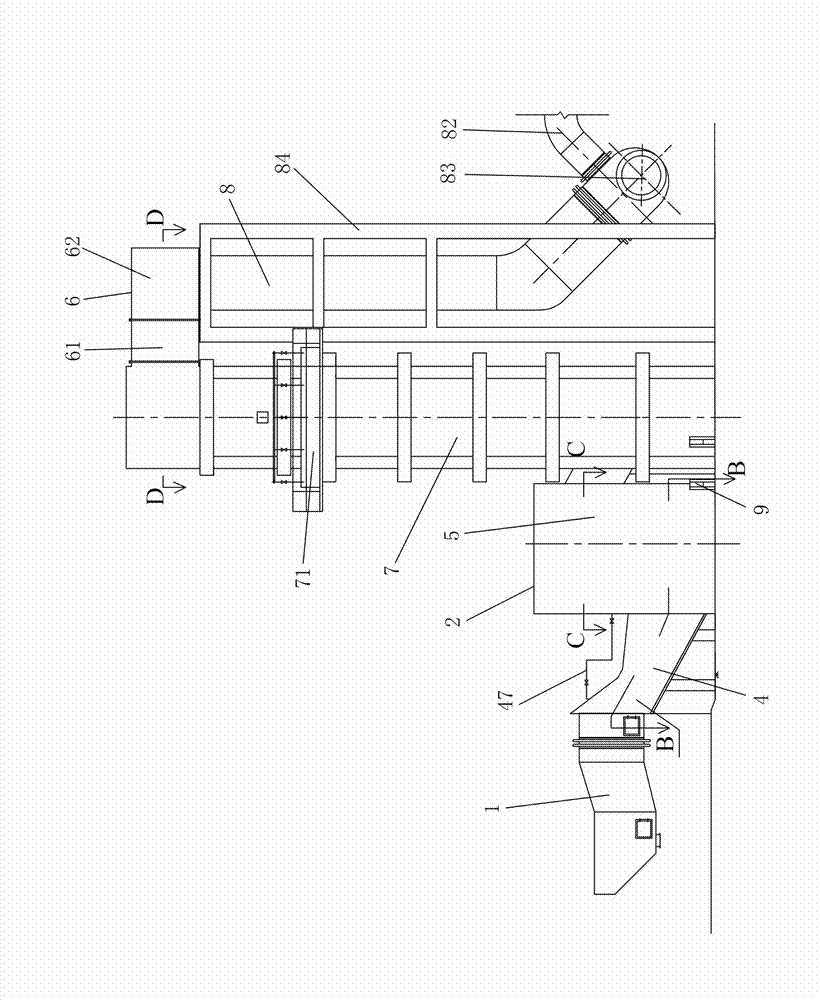

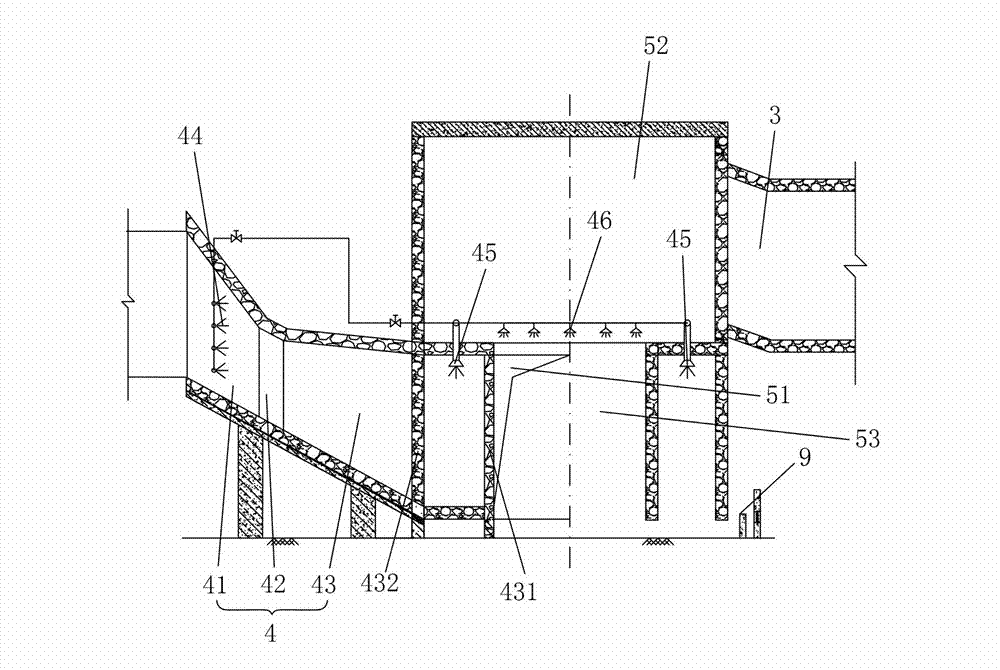

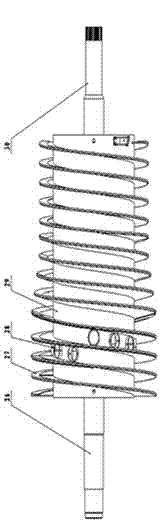

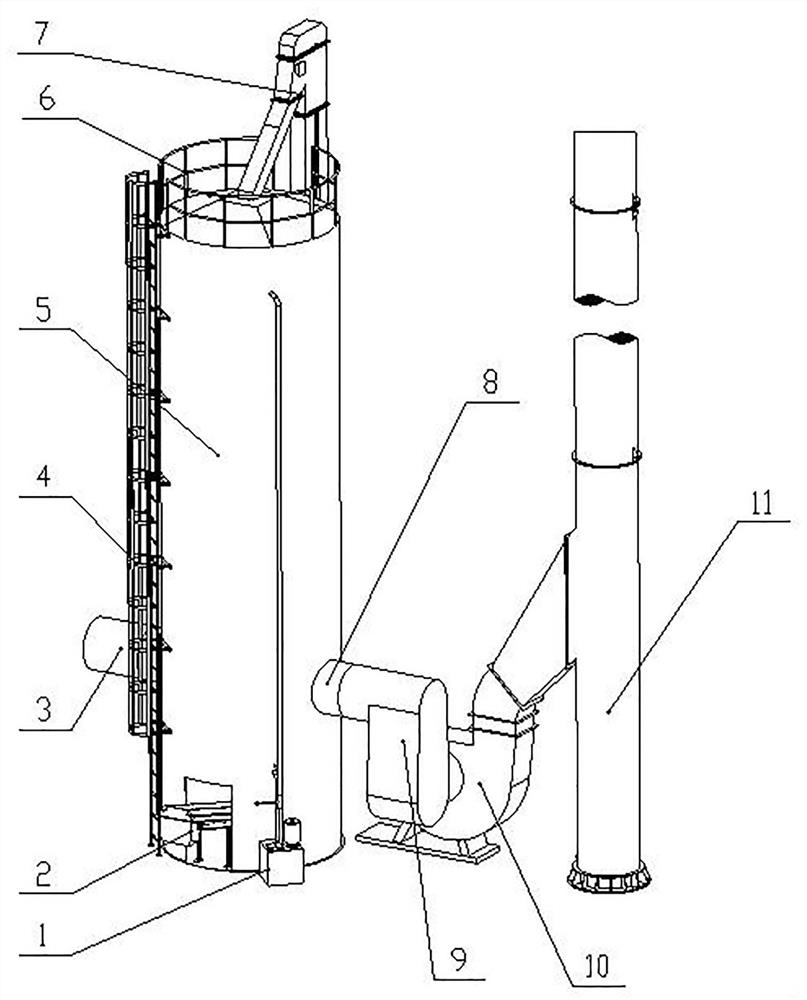

Spiral venturi scrubber and wet-method desulphurization and denitration dust-collecting system

InactiveCN102886189AHigh speed flowImprove centrifugal effectCombination devicesDust controlProcess engineering

The invention discloses a spiral venturi scrubber comprising a venturi pipe and a first water-sealing type water discharging device, wherein the venturi pipe is formed by connecting a retractable pipe, a compressed throat pipe and a spiral gradually-expanded pipe in sequence; the retractable pipe and the spiral gradually-expanded pipe are internally and respectively provided with first and second spraying and washing devices; and the bottom of the scrubber is provided with a water outlet which is connected with the first water-sealing type water discharging device. The invention further discloses a wet-method desulphurization and denitration dust-collecting system comprising a main desulphurization dust-collecting tower, a secondary desulphurization dust-collecting tower, a dehydrator and the spiral venturi scrubber; and the scrubber is communicated with the bottom end of the main desulphurization dust-collecting tower through a connecting flue; the top of the main desulphurization dust-collecting tower is communicated with the top of the secondary desulphurization dust-collecting tower through the dehydrator; and an air inlet of the secondary desulphurization dust-collecting tower is higher than the bottom surface of the dehydrator. The spiral venturi scrubber has the advantages of small volume, low energy consumption, high dust-collecting efficiency, good desulphurization and denitration effects and the like.

Owner:CHANGSHA ENVIRONMENTAL PROTECTION COLLEGE

Bearing isolator seal for rotating shaft

ActiveUS9140366B2Reduce the possibilitySmooth rotationEngine sealsSupports/enclosures/casingsEngineeringSurface geometry

A bearing isolator seal includes a rotor and stator wherein the stator has inboard and outboard radial projections which define a groove bounded by groove side faces and a groove bottom face. The rotor extends radially and then axially so as to lie closely adjacent to the terminal end of the outboard radial projection on the stator to define an entrance passageway. The bearing isolator seal includes a surface geometry which is believed to result in improved exclusion of contaminants, particularly from high velocity water spray, wherein the entrance passageway is angled to increase the rotational effects of exclusion during shaft rotation, and wherein the groove side faces are also angled to assist in redirecting spray and other contaminants away from the passageway.

Owner:FLOWSERVE MANAGEMENT CO

Solid-liquid separation device for primary sewage treatment

InactiveCN107935108AEasy dischargeImprove filtering effectWater/sewage treatment by centrifugal separationMoving filtering element filtersCentrifugationEngineering

The invention discloses a solid-liquid separation device for primary sewage treatment. The device comprises a bottom hollow case and a top hollow case, wherein the bottom of the bottom hollow case isprovided with a plurality of connecting plates through screw bolts; one support rod is arranged in the center of the bottom of each connecting plate. The centrifugal force principle is used to realizethe filtering effect; by using the device, the bottom hollow case and the top hollow case can be freely combined or dismounted, so that inside filtered sundries can be conveniently discharged. In addition, through a centrifugal filtering rotating mechanism arranged in the device, when inside sewage rotates to generate an eddy current phenomenon, the eddy current enables impurities in the sewage to generate the centrifugation phenomenon, so that the impurities can move towards the outer side; liquid in the sewage can enter the inside of a hollow structure for the centrifugal filtering rotatingmechanism through a filter hole for the centrifugal filtering rotating mechanism; under the gravity effect, the liquid in the sewage can be discharged out through a main liquid discharging pipeline;when an electric motor rotates faster, when the generated centrifugal force effect is stronger, the filtering effect is better; the practicability is higher.

Owner:湖南涟钢建设有限公司

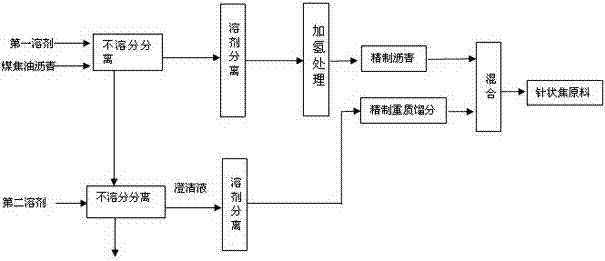

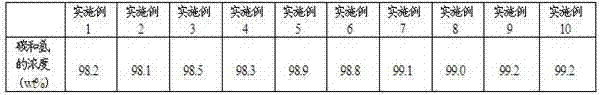

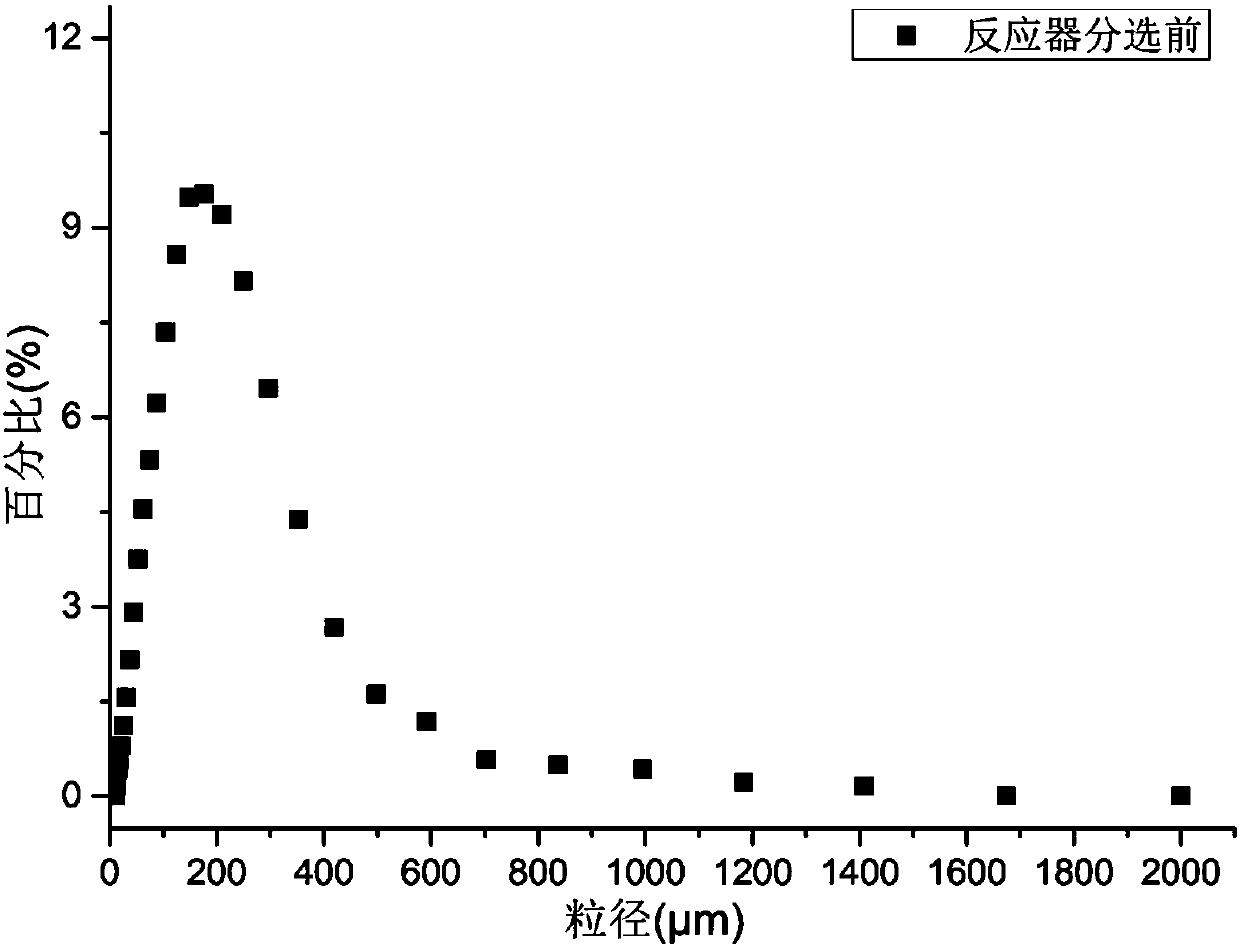

Process for preparing needle coke raw material by using coal-tar pitch and through heavy-phase circulation

ActiveCN103087747AHigh yieldEfficient separationWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCokeProcess engineering

The invention relates to a process for preparing a needle coke raw material by using coal-tar pitch and through heavy-phase circulation. The process comprises the steps that: (1) coal-tar pitch is sufficiently mixed with a first solvent; first solvent insoluble matters are removed from the mixture with a physical separation method, such that a first clarified liquid is obtained; (2) the first solvent is removed by separation; the obtained residual component is subjected to hydrogenation, such that refined pitch is obtained; (3) the first solvent insoluble matters and a second solvent are sufficiently mixed; second solvent insoluble matters are removed from the mixture with a physical separation method, such that a second clarified liquid is obtained; (4) the second solvent in the second clarified liquid is removed by separation, such that a refined heavy component is obtained; and (5) the refined pitch and the refined heavy component are mixed, such that the raw material used for preparing needle coke is obtained. With the process provided by the invention, the obtained needle coke raw material has high polyaromatic condensed polycyclic aromatic content, such that needle coke product yield is effectively improved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Aerodynamic separation nozzle

InactiveUS20130174602A1Increase pressureHigh speedRefrigeration componentsSteam engine plantsTemperature controlGas phase

Multiple designs and methods for aerodynamic separation nozzles and systems for integrating multiple aerodynamic separation nozzles into a single system are disclosed herein. These aerodynamic separation nozzles utilize a combination of aerodynamic forces and separation nozzle structure to induce large centrifugal forces on the fluids that in combination with the structure of the nozzle are used to separate heavier constituents of the fluid from lighter constituents, and more particularly to separate a first or liquid phase from gaseous phases. In some embodiments a number of separation nozzles are combined into a single system suitable for dynamic processing of a process gas. In other embodiments the separation nozzles are temperature controlled to condition the incoming gas to a temperature in order to encourage a phase change in certain constituents of the gas to occur within the nozzle to further enhance separation.

Owner:TENOROC

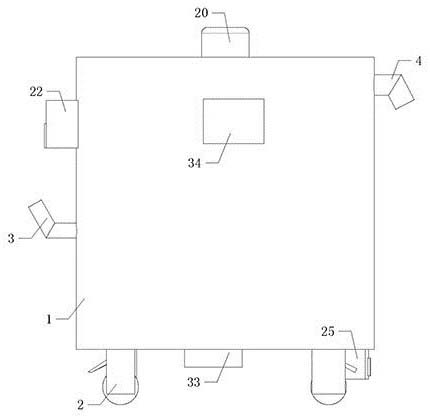

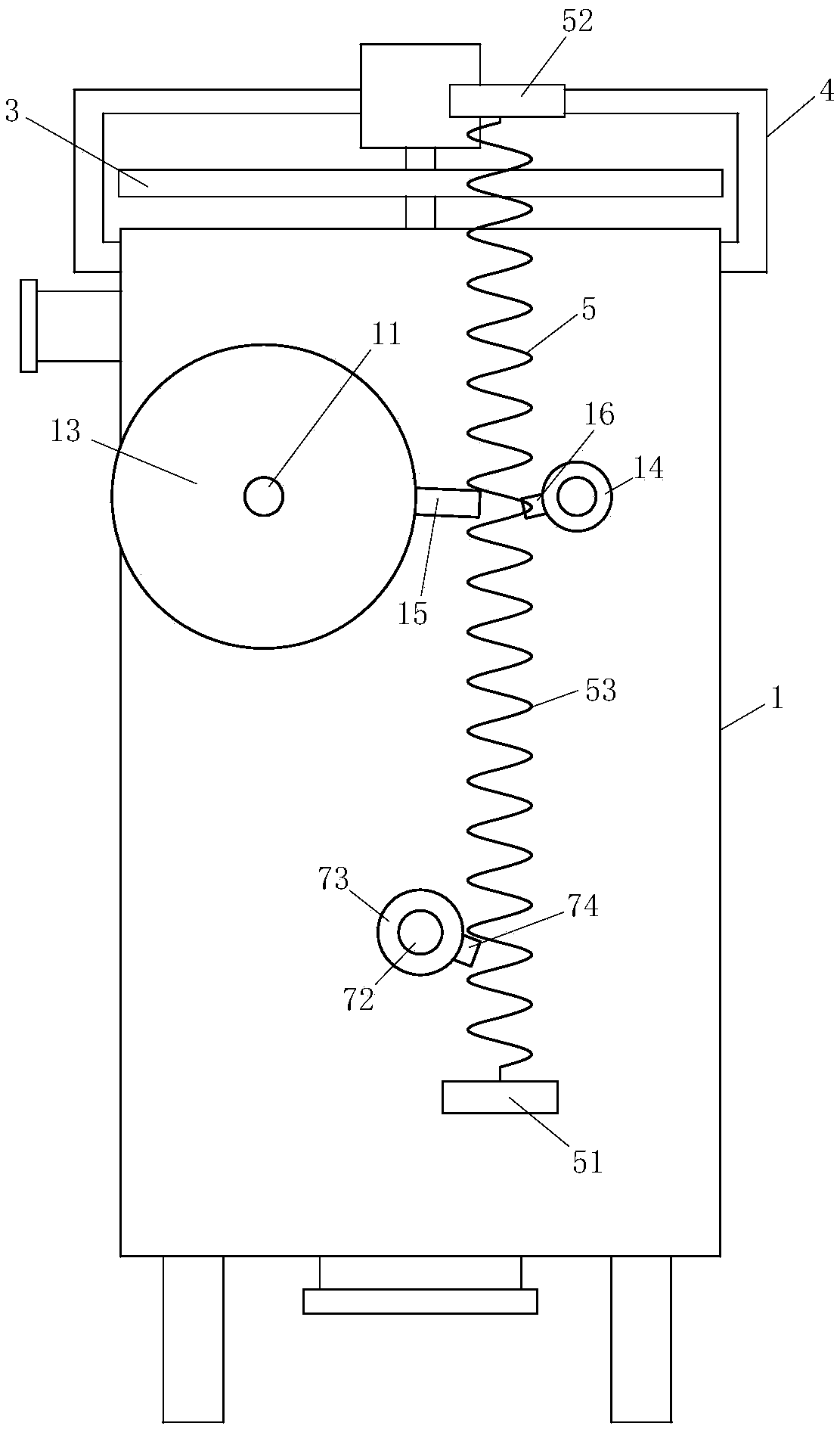

Movable small wastewater treatment equipment

ActiveCN111924996AEasy to cleanSynchronous cleaningWater/sewage treatment by centrifugal separationSpecific water treatment objectivesSewageWater treatment

The invention relates to the technical field of environmental protection equipment. The invention relates to wastewater treatment equipment, in particular to movable small wastewater treatment equipment. Sewage is subjected to purification treatment, particle impurities in sewage can be conveniently and effectively separated, the particle impurities in the sewage are prevented from blocking equipment, normal operation of the equipment is guaranteed, meanwhile, the particle impurities in the sewage are subjected to multi-section purification treatment, the particle impurities can be effectivelyprevented from causing overstock damage to the equipment, the equipment is conveniently protected, and practicability and reliability are improved. The equipment comprises a treatment bin, four groups of self-locking universal wheels, a water inlet pipe, an overflow pipe, a centrifugal hopper and a first annular chute, the four sets of self-locking universal wheels are evenly installed at the bottom of the treatment bin, the water inlet pipe is installed on the left side of the treatment bin, the overflow pipe is installed on the upper right side of the treatment bin, the centrifugal hopper is located on the lower side in the treatment bin, the bottom of the centrifugal hopper is sealed, and the first annular sliding groove is formed in the bottom of the centrifugal hopper.

Owner:海普欧环保集团有限公司

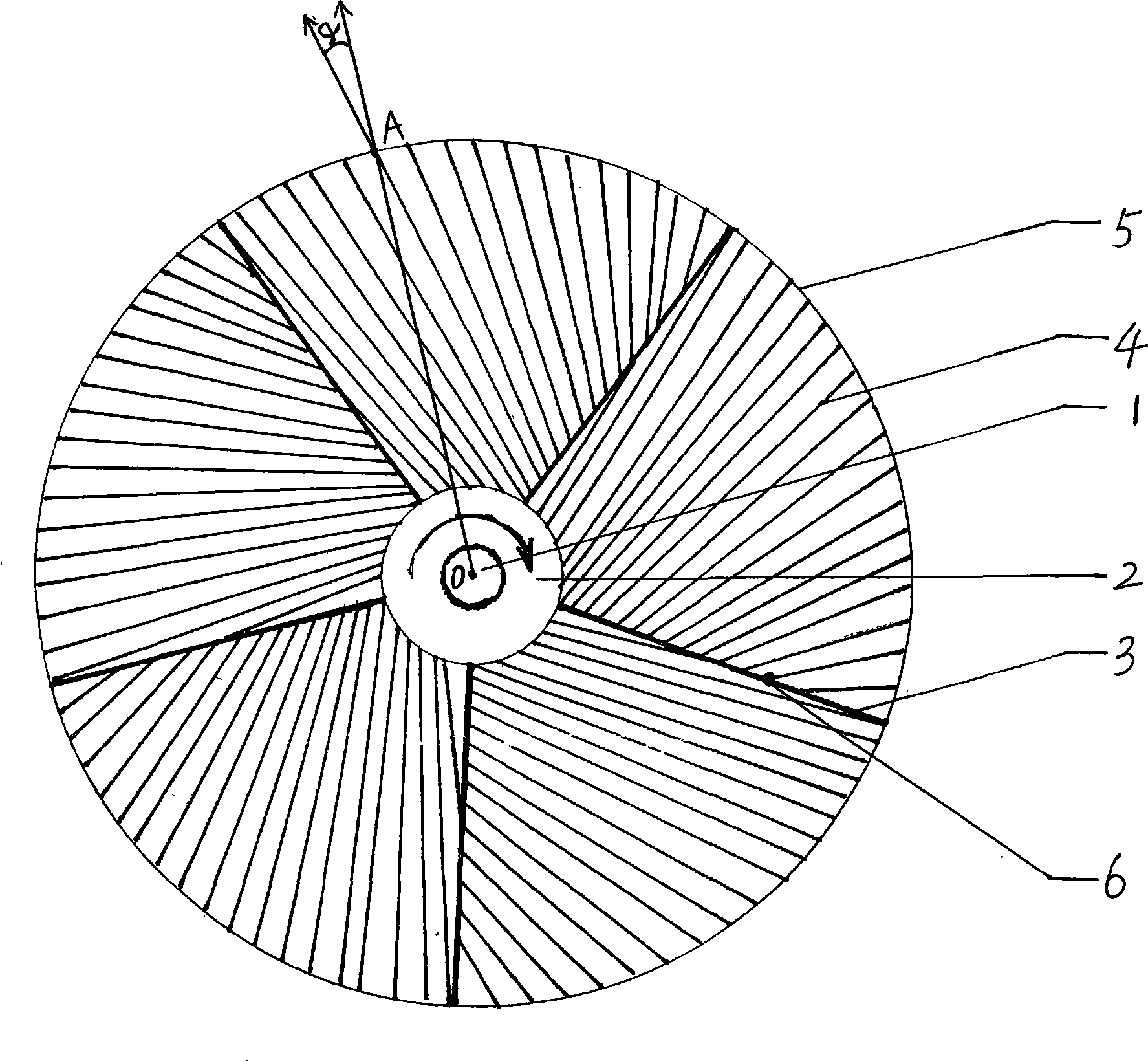

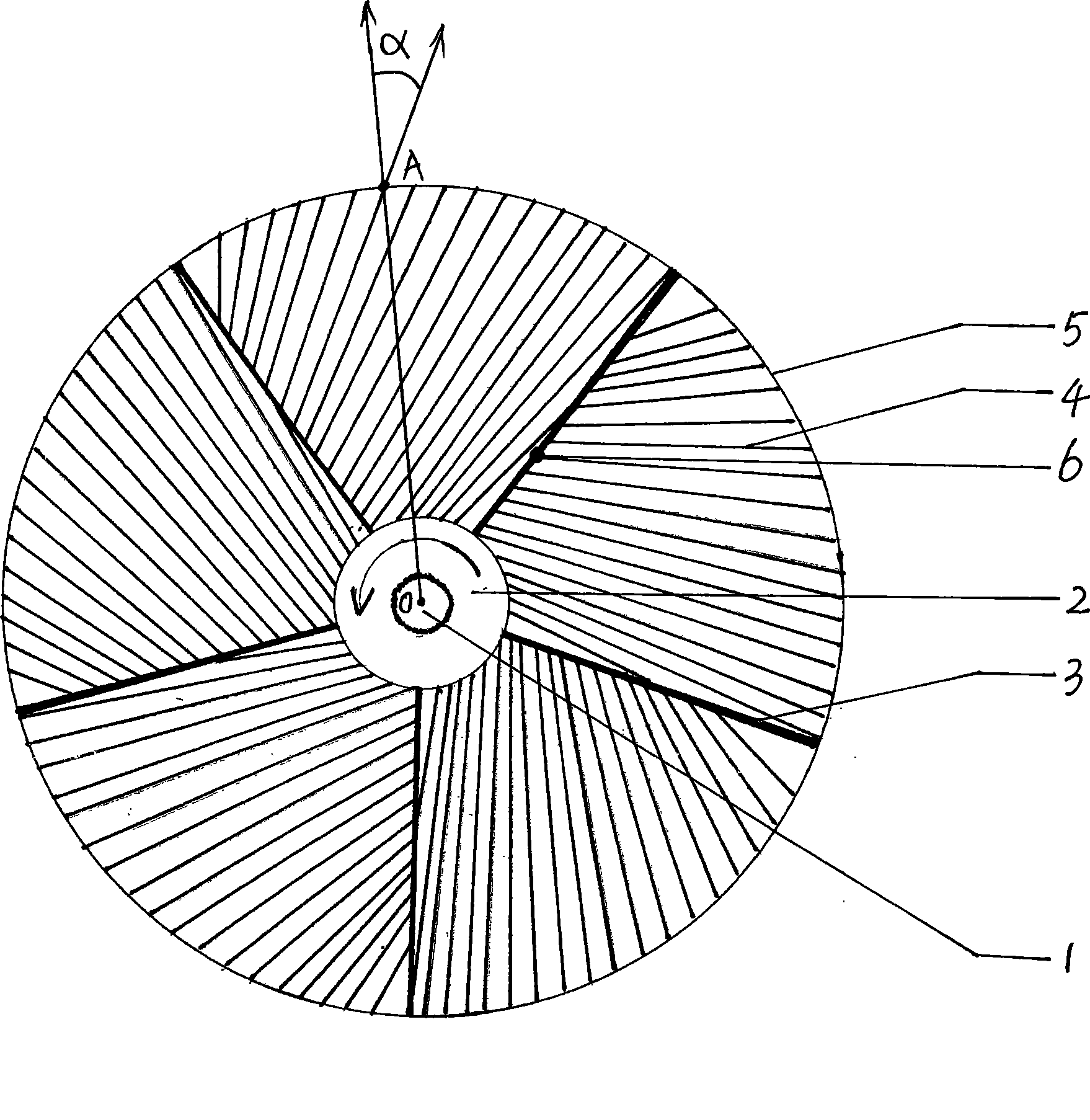

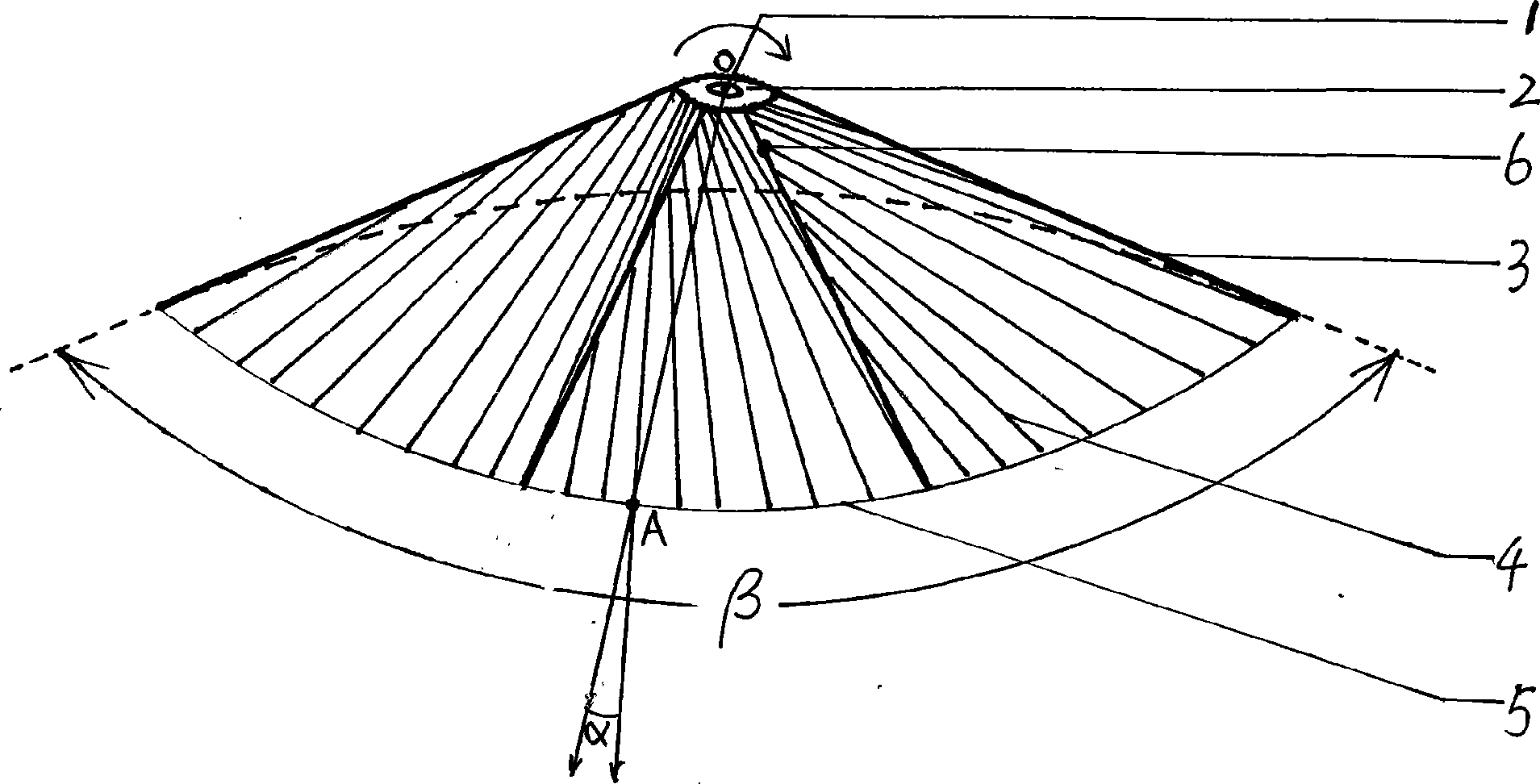

Gravity acceleration centrifuge

InactiveCN101422674AIn line with the principle of centrifugal mechanicsEasy to handleDispersed particle separationElevation angleConvex structure

The invention discloses a gravity acceleration centrifuge. An inside plate is connected with an external ring by a main frame; the sector area between adjacent main frames has centrifugal wires which are distributed according to a certain elevation angle; the centrifugal wires are arranged along the direction which is opposite to the rotating direction of the centrifuge by taking a side main frame and the inside plate between two main frames as the starting point; the other end of the centrifugal wire is connected with the external ring at the adjacent main frames or between two main frames; the inside plate is disc-shaped, polygonal or similar polygonal; and the main frames, the inside plate and the external ring have concave and convex structures which are used for positioning the centrifugal wires. The gravity acceleration centrifuge is connected with a transmission system of a purification or dehumidification device and strongly suction wind by an exhaust fan; when smoke particles, dusts and vaporous particles strike the main frames and the centrifugal wires of the centrifuge, as the distribution angle of the centrifugal wires is the same as the centrifugal direction of the smoke particles, dusts and vaporous particles which meets the centrifugal force theory, the system wind resistance is effectively reduced; the centrifugal purification efficiency is obviously enhanced; the structure is simple; the maintenance is convenient; and the service life is long.

Owner:唐道远

Centrifuge for automatically separating pulp and dregs

The invention discloses a centrifuge for automatically separating pulp and dregs. The centrifuge comprises a machine bin for fixing a gearbox and a stepping motor, and a liquid collecting bin for filtering, wherein the stepping motor is connected to the gearbox through a driven shaft; a liquid outlet is formed right below the liquid collecting bin; a feeding tube for conveying a material is arranged at the outer side of the liquid collecting bin; the output end of the gearbox is connected to a filtering frame in the liquid collecting bin through a rotating shaft, so that the gearbox drives the filtering frame to rotate; the filtering frame has a frame structure of which the outer end is provided with an opening and the middle is provided with a filtering screen; the output end of the feeding tube extends into the filtering frame from the opening end of the filtering frame; a dreg outlet is formed in the bottom part of the liquid collecting bin at the outer part of the opening end of the filtering frame. According to the centrifuge, a washing plate reciprocates in the filtering frame, so that the material on the filtering screen can be removed without stopping the centrifuge, and as a result, the working efficiency can be greatly improved.

Owner:ANHUI HUAIHUA

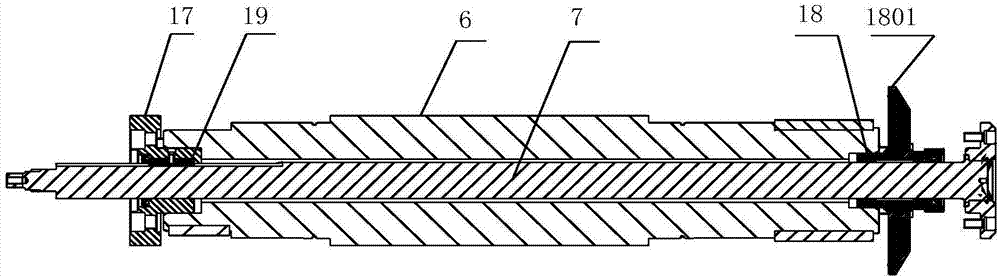

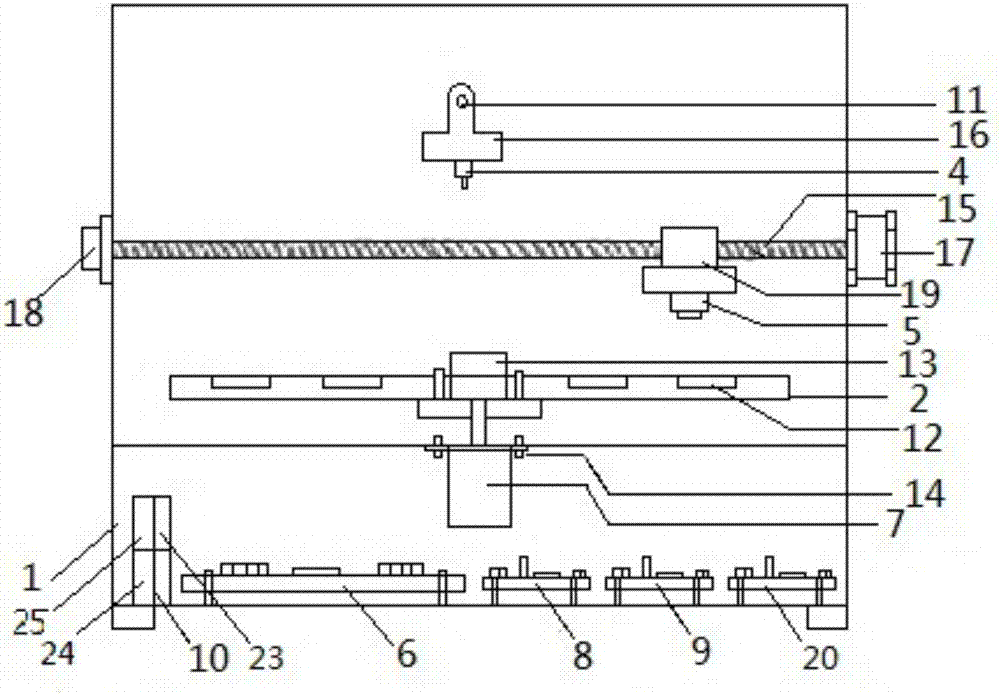

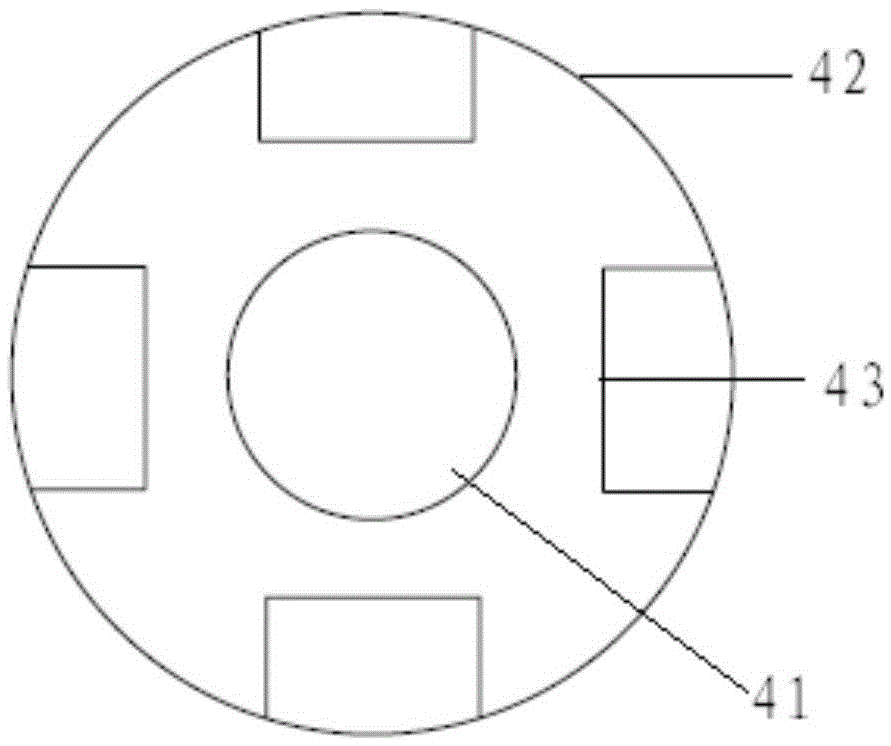

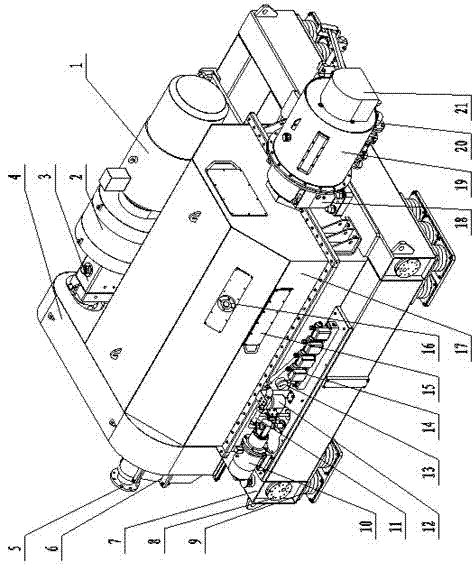

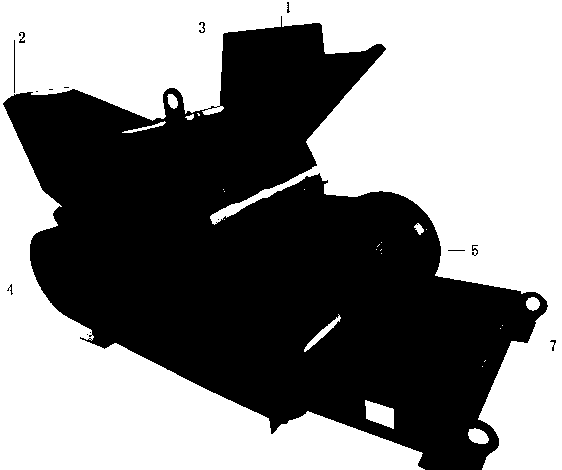

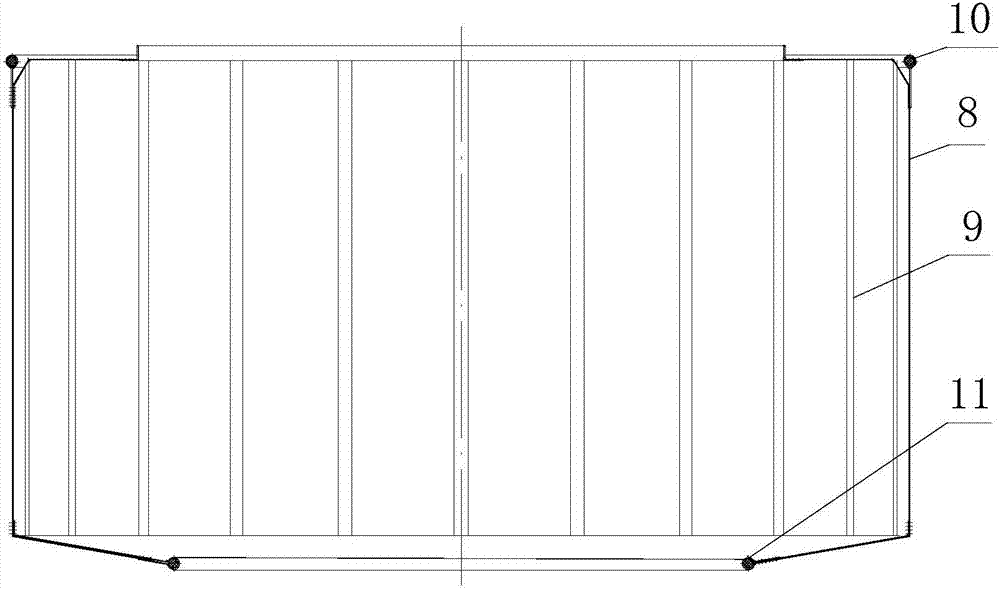

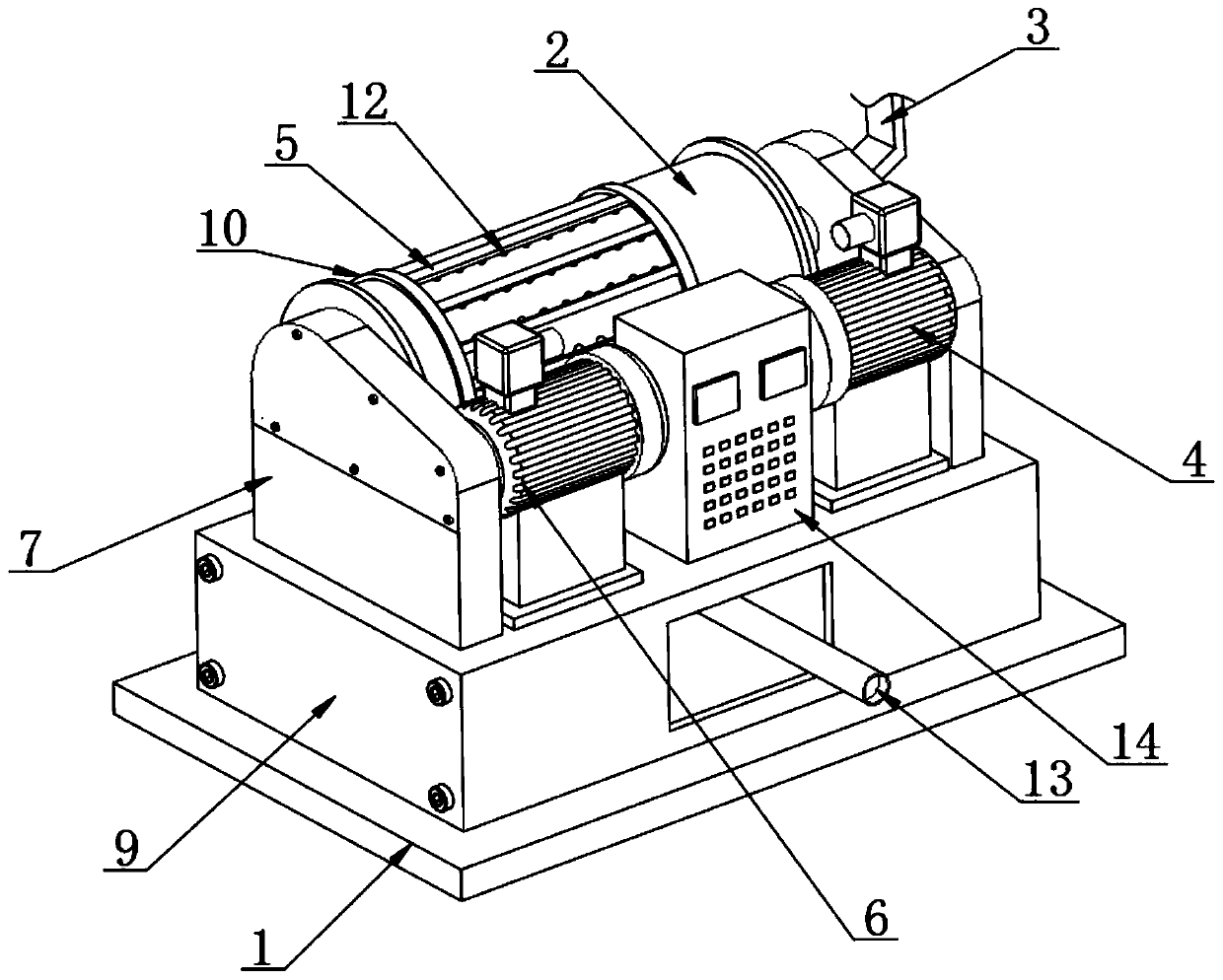

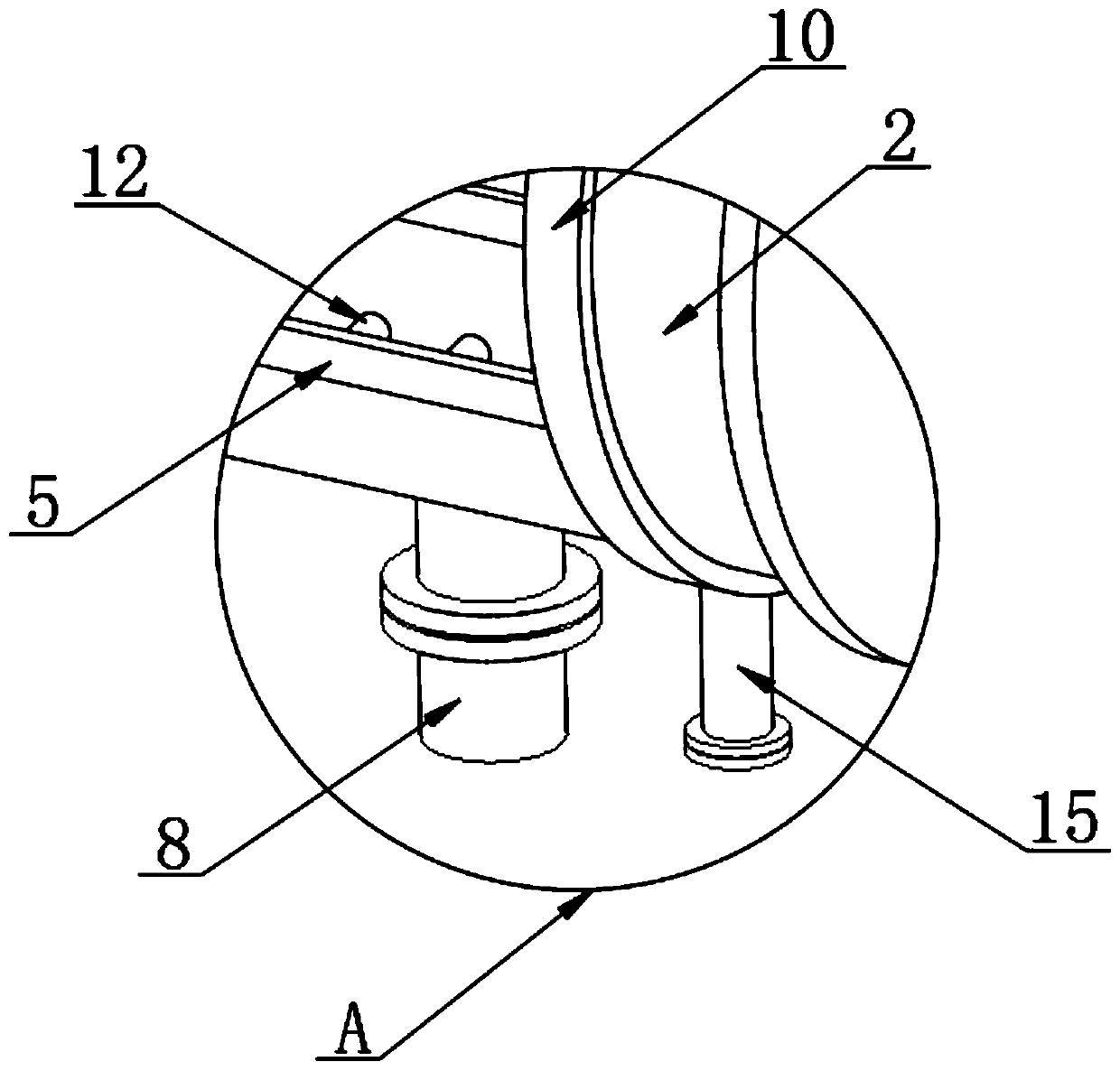

Horizontal screen sedimentation centrifuge

InactiveCN103801463AImprove centrifugal effectPlay a protective effectRotary centrifugesPropellerEngineering

The invention discloses a horizontal screen sedimentation centrifuge, and belongs to the field of centrifugal equipment. The horizontal screen sedimentation centrifuge is composed of a driving device, a rotor, a lubricating device, a differential mechanism, a safety device and a base, wherein the base can provide stable mounting points for the whole machine and guarantees stable and firm running of equipment, the rotor is the core of the centrifuge, and materials are separated through the rotor; the differential mechanism provides large torque differential for a spiral propeller; the safety device can make the spiral propeller break away from differential in the instantaneous overload process, normal running of the whole machine is guaranteed, and a feedback value is used for regulating material inlet amount; the driving device provides power for the centrifuge; the lubricating device is used for filling lubricating oil for the equipment, and sufficient lubrication of all lubricating points of the whole machine is guaranteed. The horizontal screen sedimentation centrifuge has the advantage that because the centrifuge is a filtering type screen centrifuge, the dehydrating rate can be increased by 14 percent to 24 percent.

Owner:山东联重机械有限公司

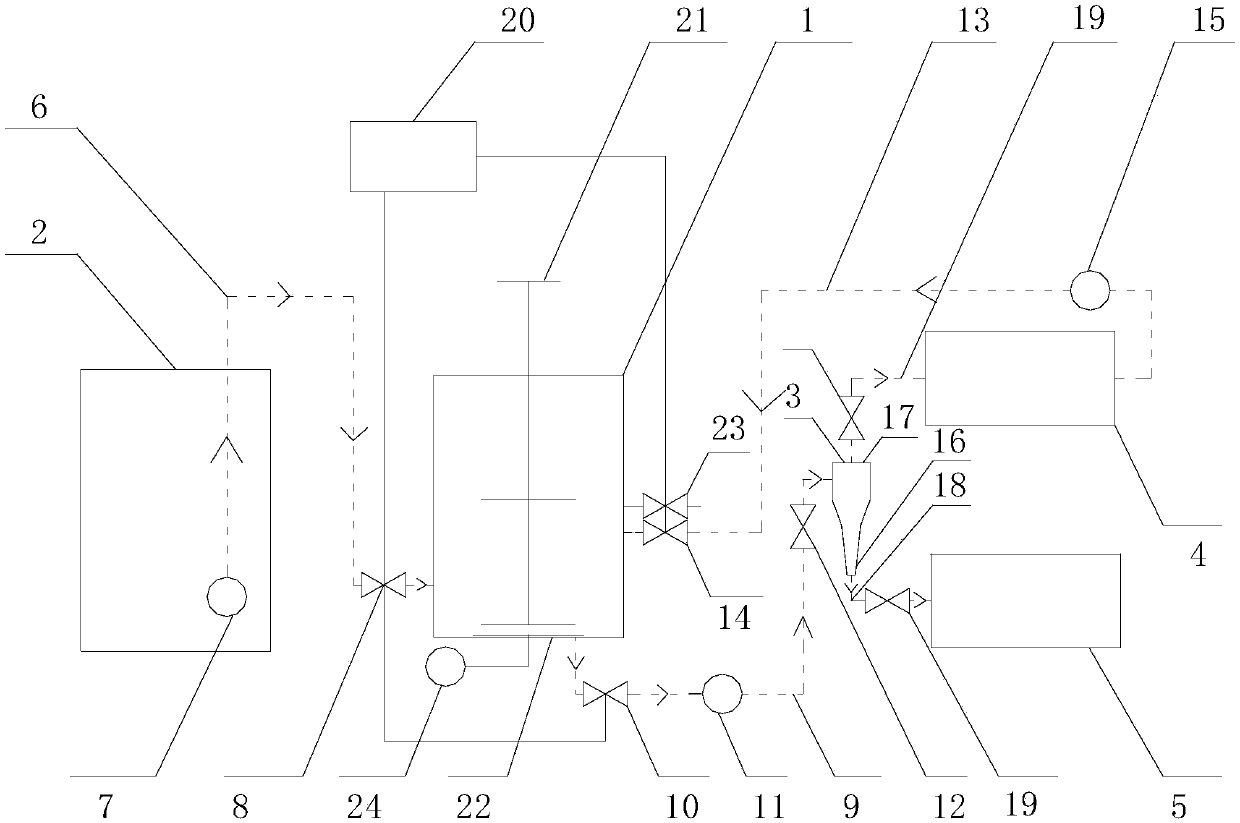

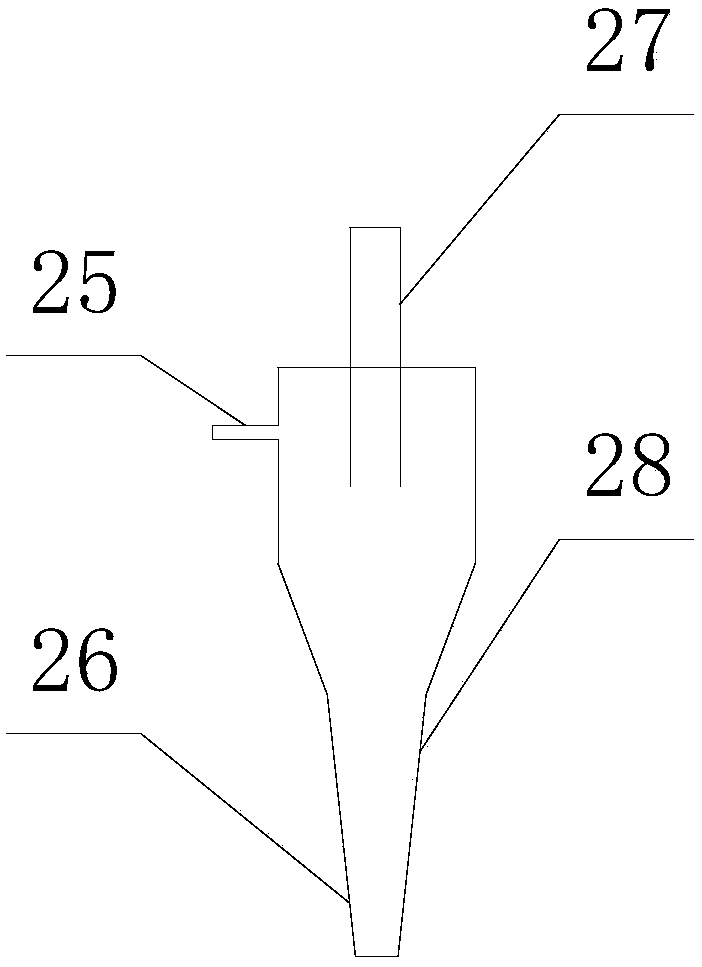

Device using cyclone separator to sort granular sludge and floc sludge, and use method thereof

PendingCN107857363AReasonable structural designHigh degree of automationReversed direction vortexTreatment with aerobic and anaerobic processesAutomatic controlSludge

The invention relates to a device using a cyclone separator to sort granular sludge and floc sludge, and a use method thereof. The device comprises an SBR reactor, a regulating water tank, a main bodycyclone, a floc sludge storage tank, a granular sludge storage tank, a supporting member and an automatic control system; the SBR reactor and the main body cyclone are fixedly arranged on the supporting member, and the regulating water tank is connected with the SBR reactor through a first pipeline; the SBR reactor is connected with the main body cyclone through a second pipeline; the SBR reactoris connected with the floc sludge storage tank through a third pipeline; the bottom flow opening of the main body cyclone is connected with the granular sludge storage tank in series through a fourthpipeline; the overflow opening of the main body cyclone is connected with the floc sludge storage tank in series through a fifth pipeline; and the automatic control system includes a time controller.The device has the advantages of reasonable structure design, reliability in running, low production and operation cost, convenience in later stage maintenance, and high automation degree, and can beused to solve many problems in the prior art.

Owner:BEIJING DRAINAGE GRP CO LTD

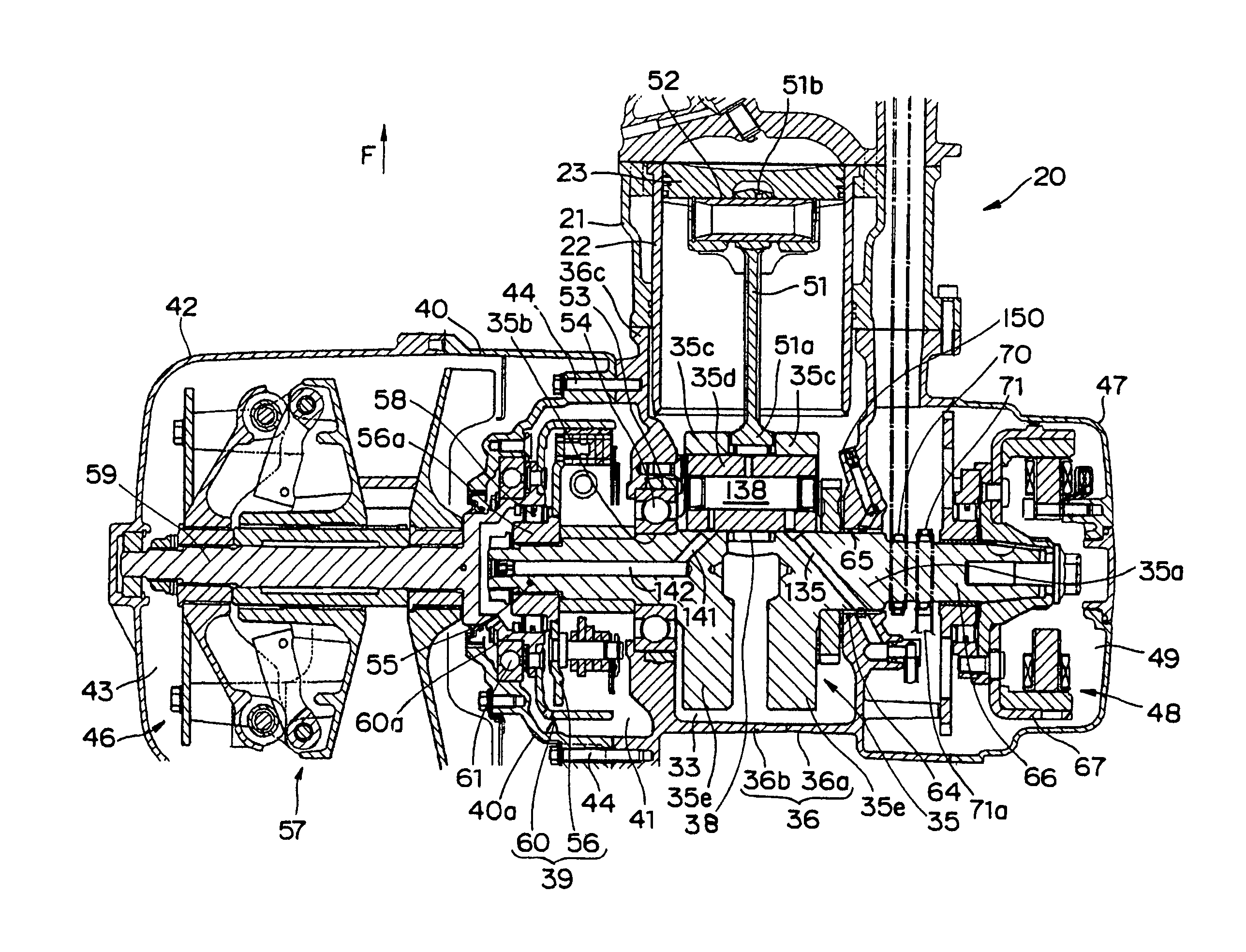

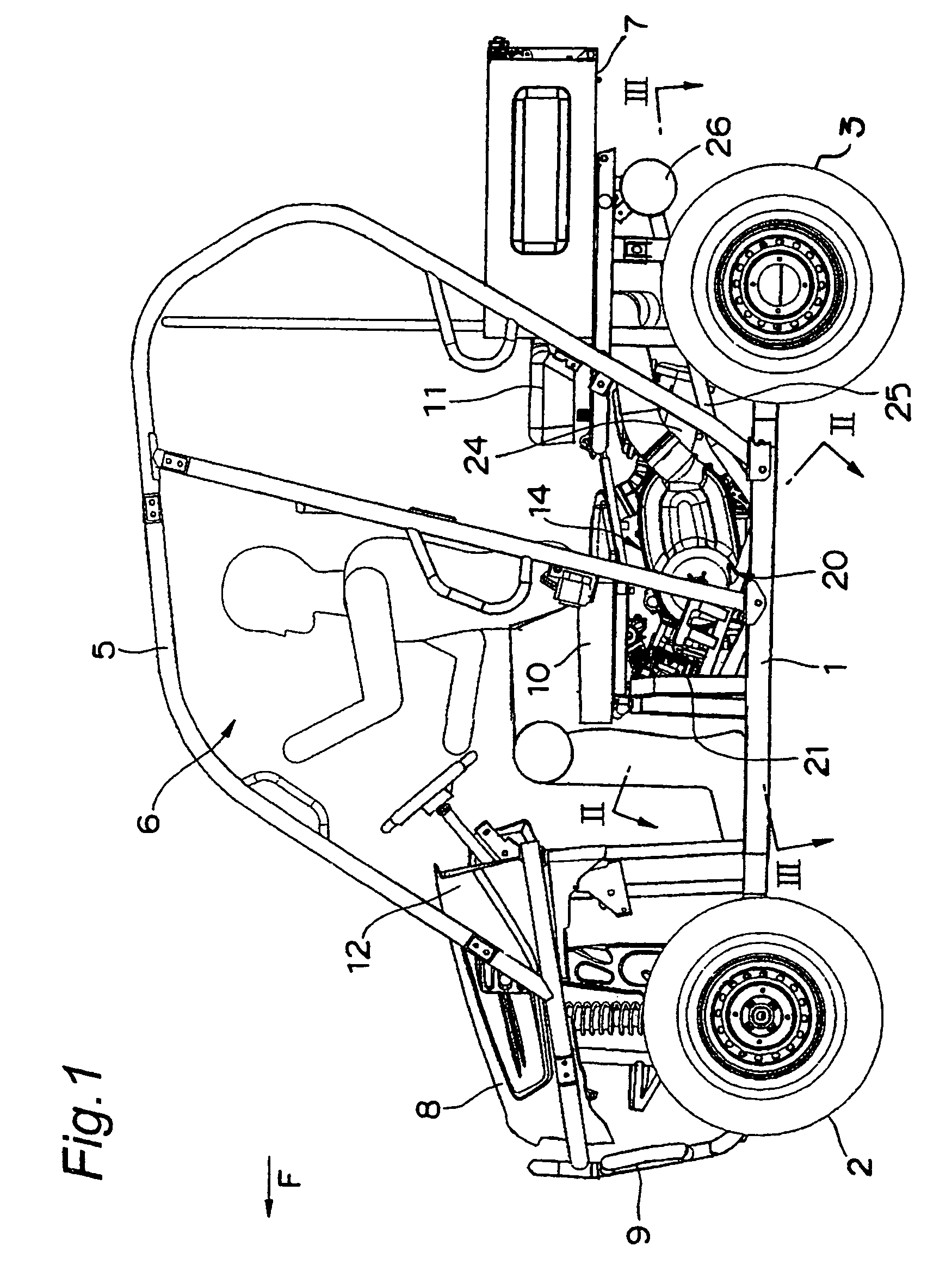

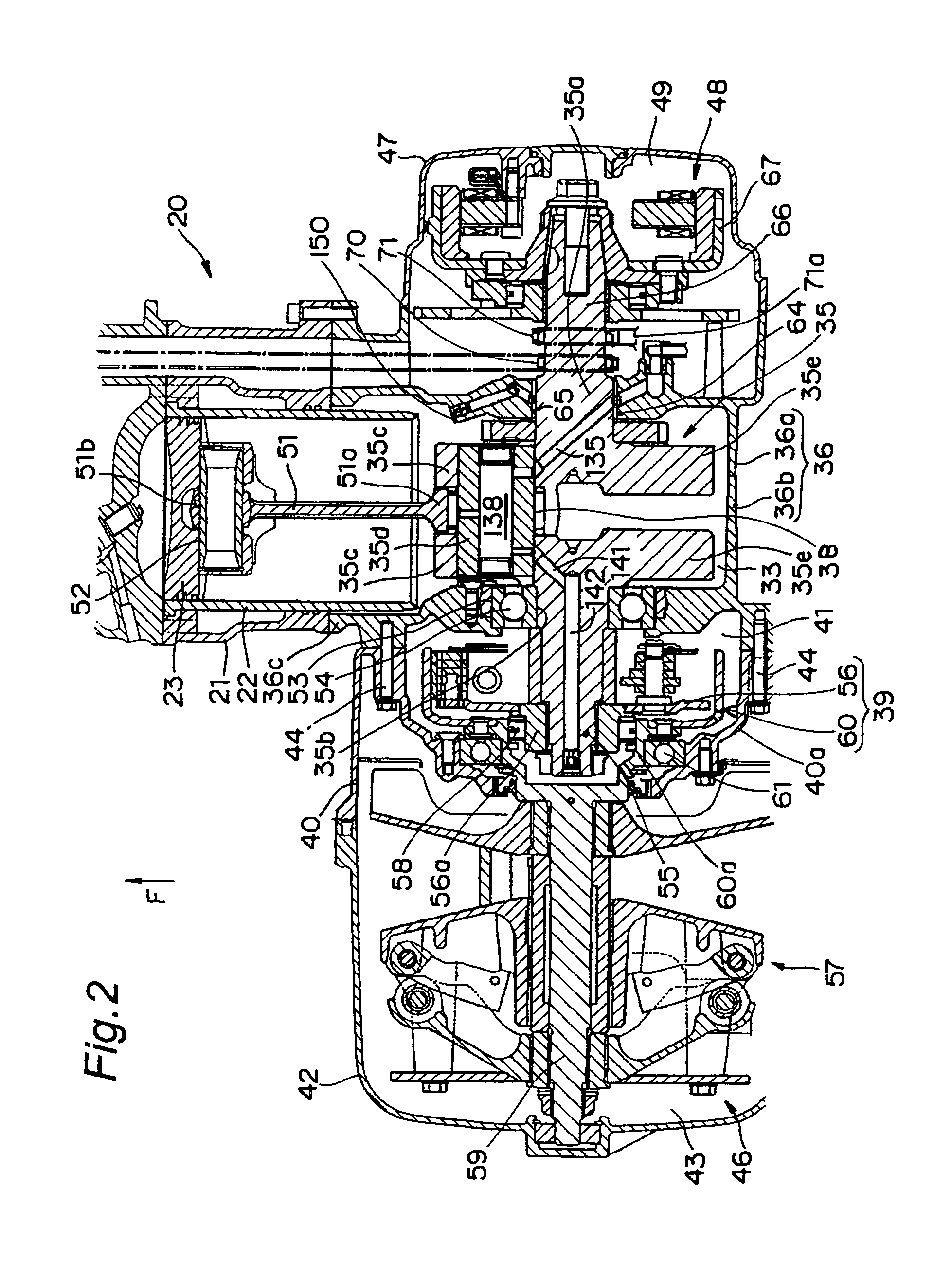

Engine with centrifugal clutch

ActiveUS8083045B2Generating large amountImprove centrifugal effectLubrication of auxillariesLubricant conduit arrangementsBall bearingCrankpin

An engine with a centrifugal clutch which can efficiently cool and lubricate the centrifugal clutch. The engine supports a pair of journal portions of a crankshaft by a bearing such as a ball bearing, a roller bearing, or the like, as well as a bearing metal. There is provided first oil supplying means formed in the crankshaft. The first oil supplying means has an oil passage for the first oil supplying means which is communicated with a main oil passage through an oil hole formed in the bearing metal and extends through a fitting portion of a crankpin to reach the centrifugal clutch.

Owner:KAWASAKI MOTORS LTD

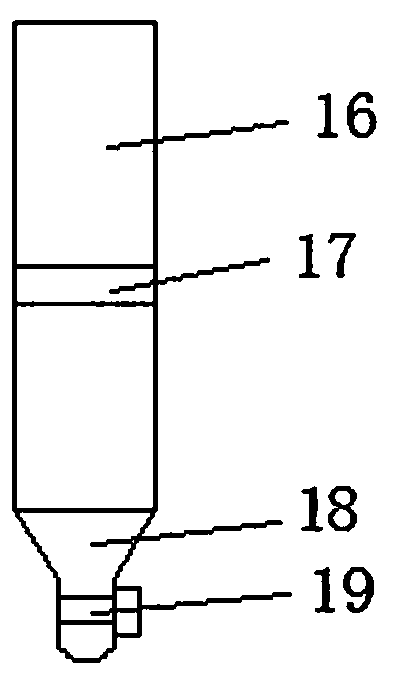

Cell research centrifugal equipment for fixing test tube through negative pressure

The invention relates to the technical field of biological cells, and discloses cell research centrifugal equipment for fixing a test tube through negative pressure. The cell research centrifugal equipment comprises a motor, the top of the motor is rotatably connected with a rotating shaft penetrating through a fixed table, the top of the rotating shaft is fixedly connected with a storage plate, storage cylinders arranged at equal intervals are inserted into the tops of the storage plate, storage grooves are formed in the tops of the storage cylinders, air cavities are formed in the lower portions of the interiors of the storage cylinders, threaded rods are rotatably connected to the inner top walls of the air cavities, pinions are fixedly connected to the bottoms of the threaded rods, andthe threaded rods is sleeved with pistons and ratchet wheels. When the pistons reach the bottom wall of the air cavity, the pistons stop moving downwards, the threaded rods drive the storage cylinders to rotate on the storage plate under the action of the pinions, so that the effect that the centrifugal test tube rotates while revolving around the center of the storage plate is achieved, the movement of the centrifugal test tube is more variable and complex, and the centrifugal effect of biological cells is better.

Owner:广州硕泰科技有限公司

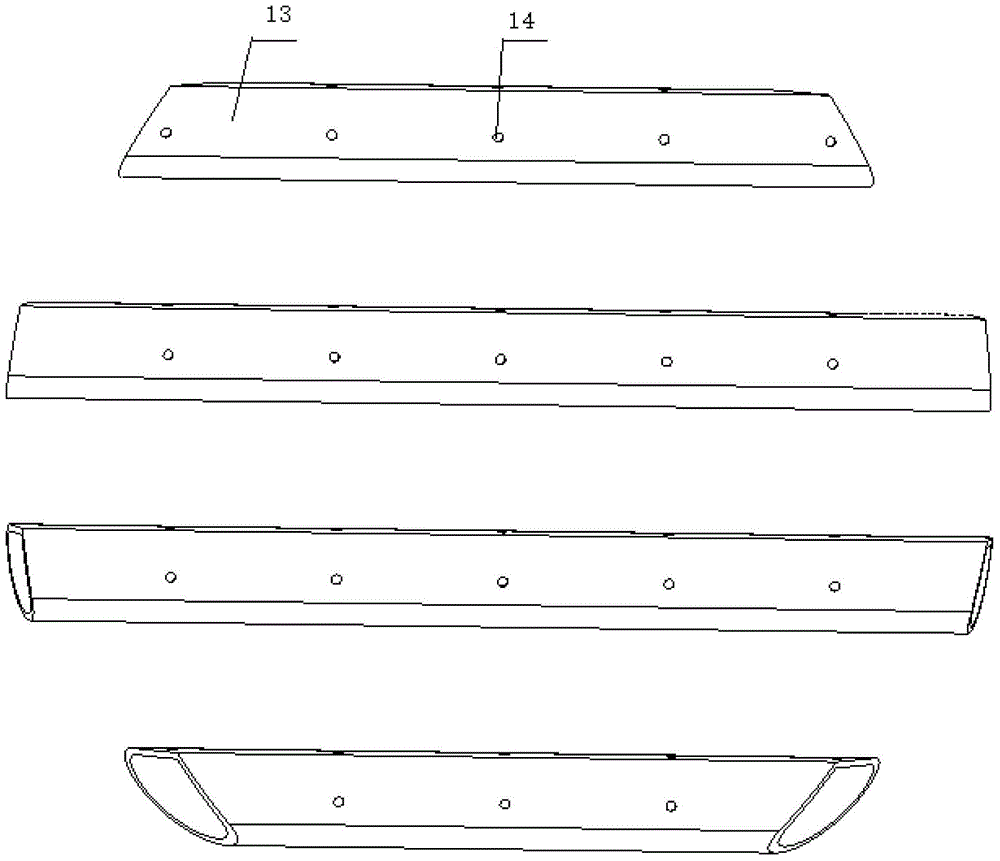

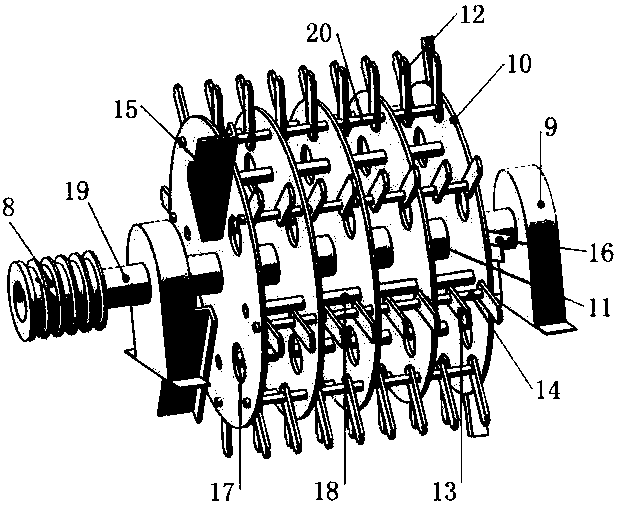

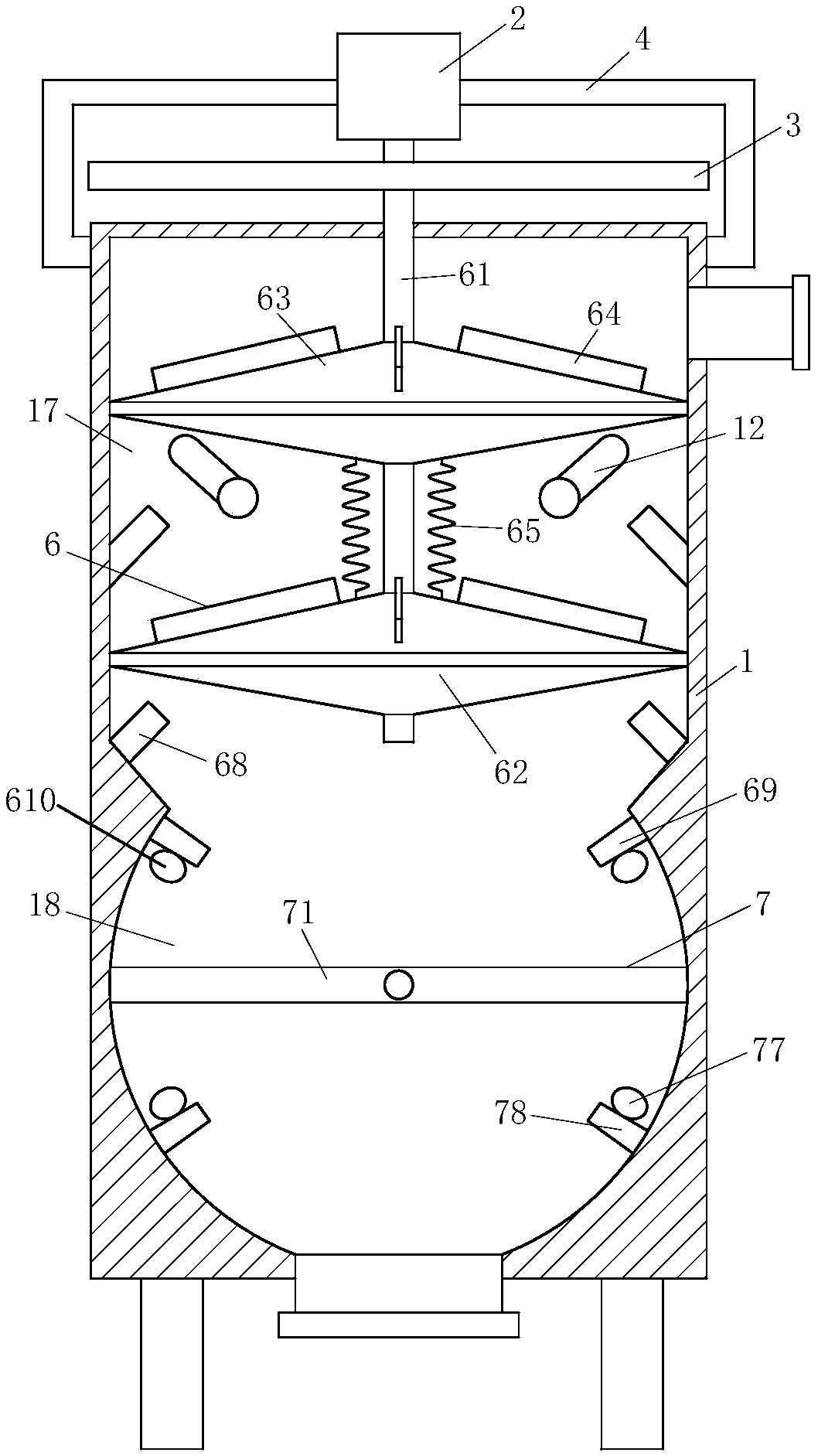

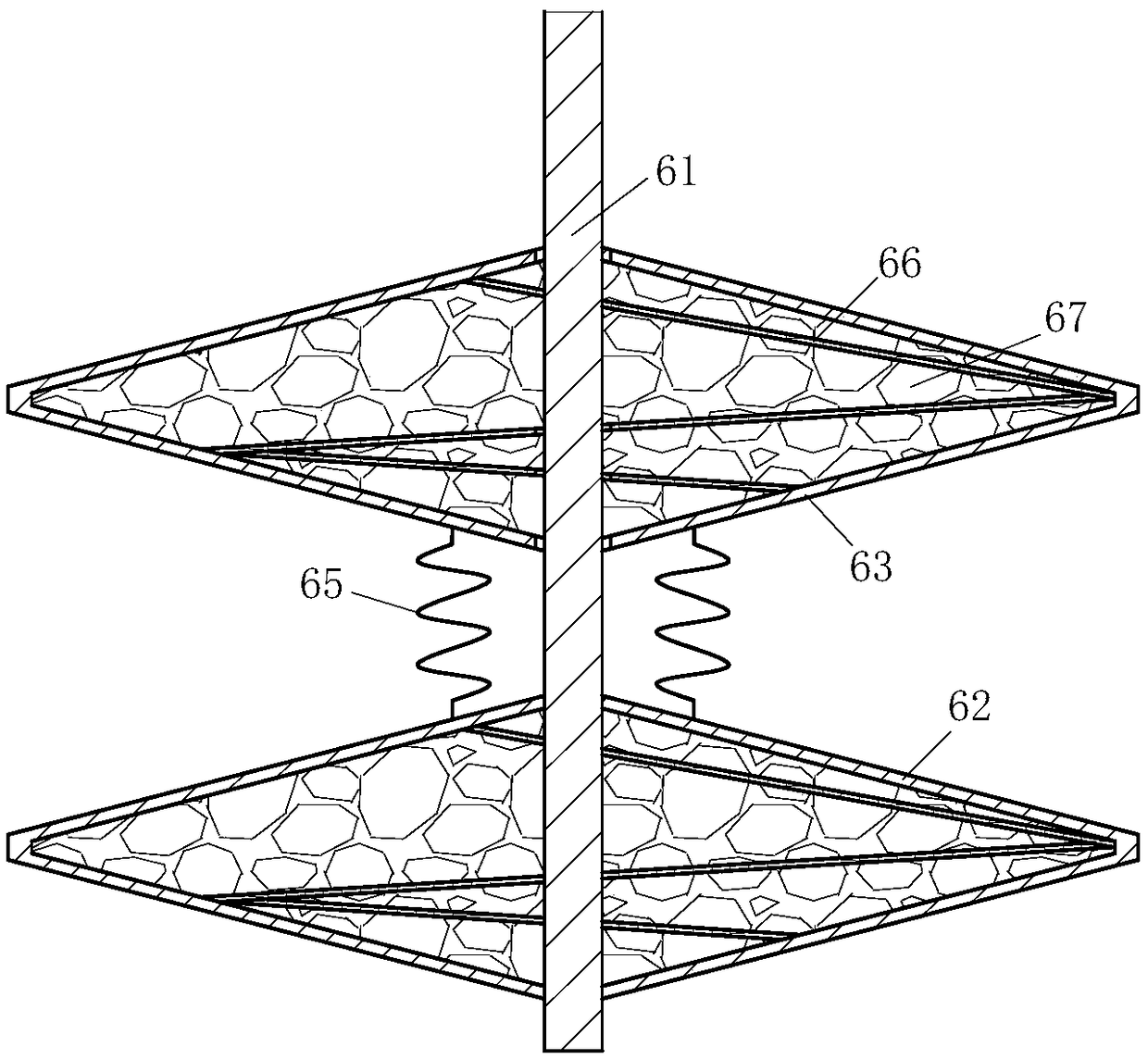

Axial-flow type pulverizer

PendingCN108372007AImprove centrifugal effectAvoid paste machineFeeding-stuffGrain treatmentsEngineeringMechanical engineering

The invention relates to an axial-flow type pulverizer which comprises a shell with a feeding hole and a discharge hole, and a main shaft arranged in the shell, wherein a plurality of rotor plates arefixedly arranged on the main shaft, a plurality of cutting blades distributed along the circumferential direction are arranged on the rotor plates located at the feeding hole, a plurality of materialthrowing plates distributed along the circumferential direction are fixedly arranged on the rotor plates located at the discharge hole, a plurality of hammers and blades are coupled between adjacentrotor plates by hinge pins, the blades are arranged along a spiral line coaxial with the main shaft, and air holes are formed in the rotor plates. According to the invention, material is cut off by the cutting blades, is cut up with a blade, and is smashed with the hammers; the whole processing process is performed step by step, so as to avoid machine pasting and blockage; and meanwhile, wind flowin the shell is realized due to the arrangement of the air holes, so as to enhance the material centrifugal effect and further improve the smashing effect.

Owner:赵兴朋

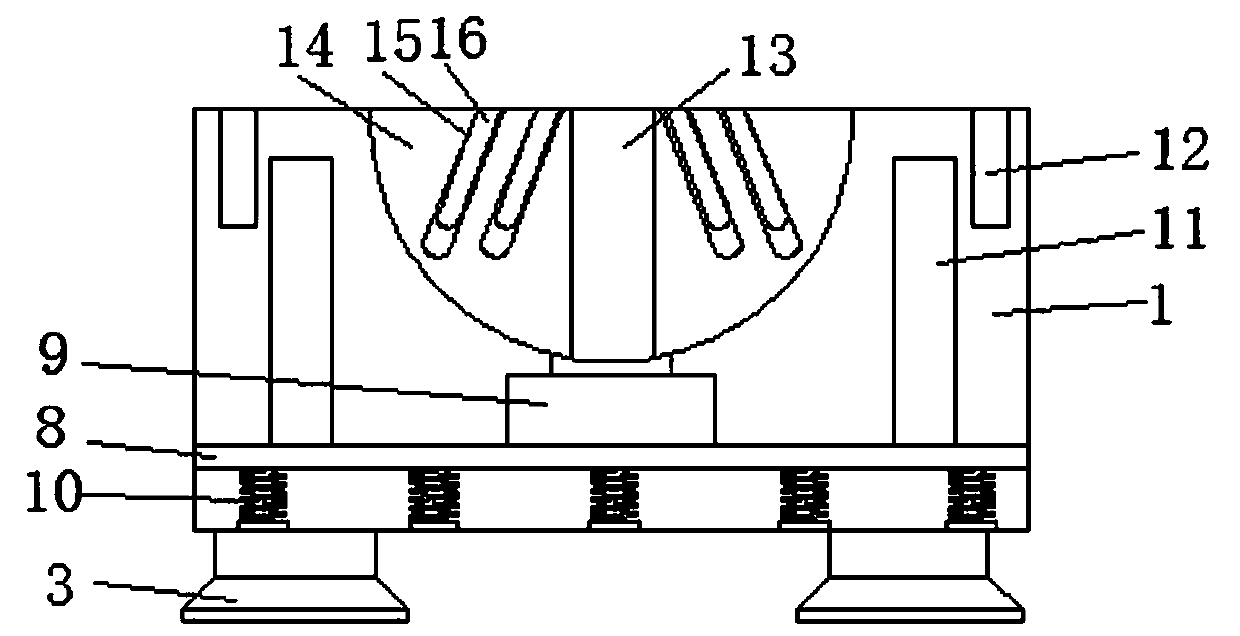

Centrifugal machine for pharmaceutical manufacturing

InactiveCN109530101AImprove sealingFirmly connectedEngine sealsNon-rotating vibration suppressionVolumetric Mass DensitySolid particle

The invention discloses a centrifugal machine for pharmaceutical manufacturing. The centrifugal machine comprises a machine case, a case cover, a centrifugal bin and a centrifugal tube, wherein a baseis arranged at the bottom of the machine case, the base is fixedly connected with the machine case through bolts, a controller is arranged on the surface of the machine case, the controller is fixedly connected with the machine case through bolts, a hinge is arranged at the upper part of the machine case, the case cover is arranged on the upper part of the hinge, the case cover is rotationally connected with the machine case through the hinge, a supporting plate is arranged in the machine case, a motor is arranged on the upper portion of the supporting plate, and the motor is fixedly connected with the supporting plate through bolts. According to the centrifugal machine for pharmaceutical manufacturing, the motor is started through the controller to drive a connecting shaft to rotate so as to enable the centrifugal bin to rotate, liquid with different densities in the centrifugal tube is separated by centrifugal force, a separation screen arranged inside the centrifugal tube can separate solid particles in the liquid, the liquid separation is facilitated, a liquid outlet is opened by rotating a control valve, the internal separated liquid is discharged and solid-liquid separationis realized.

Owner:江苏特克菲勒生物科技有限公司

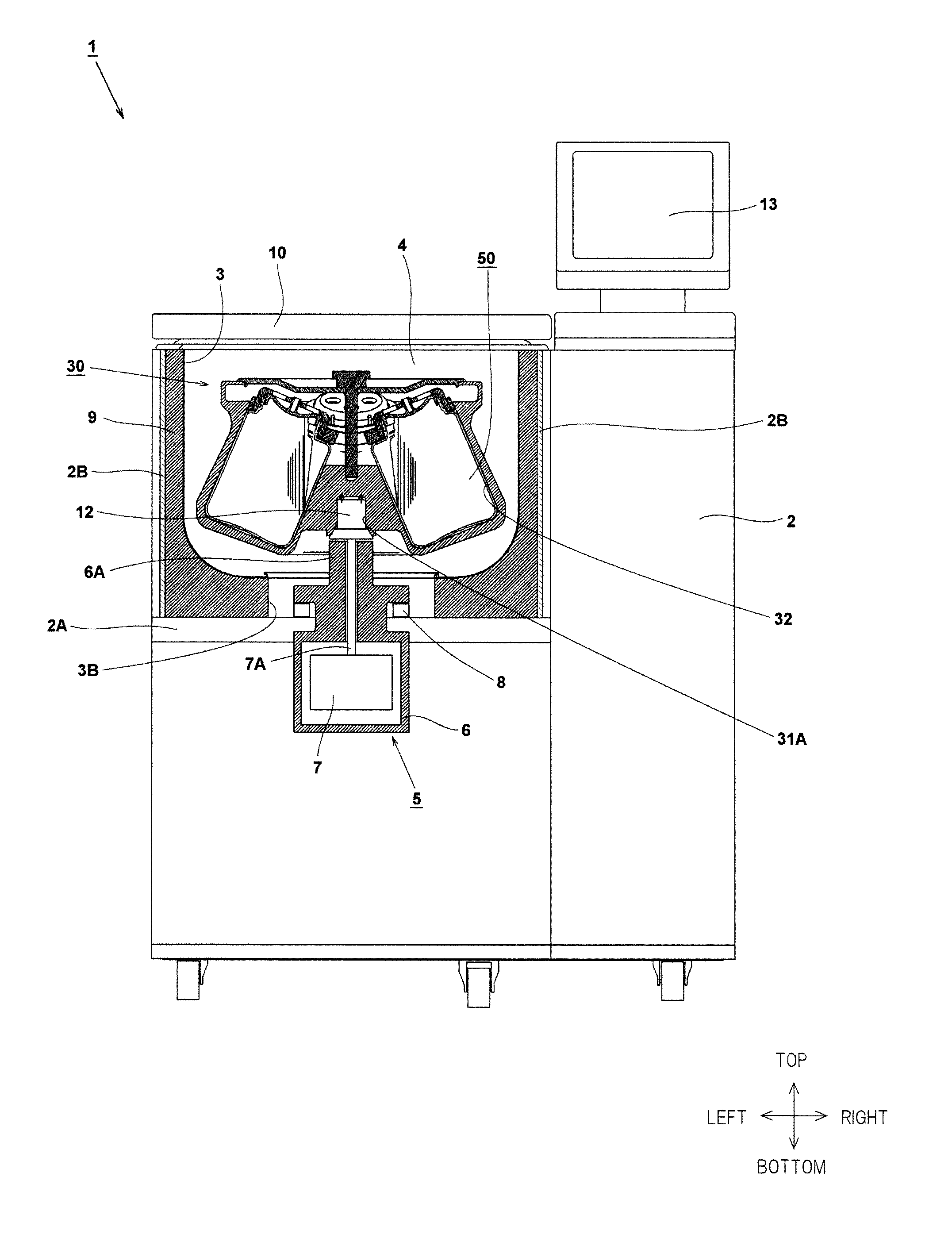

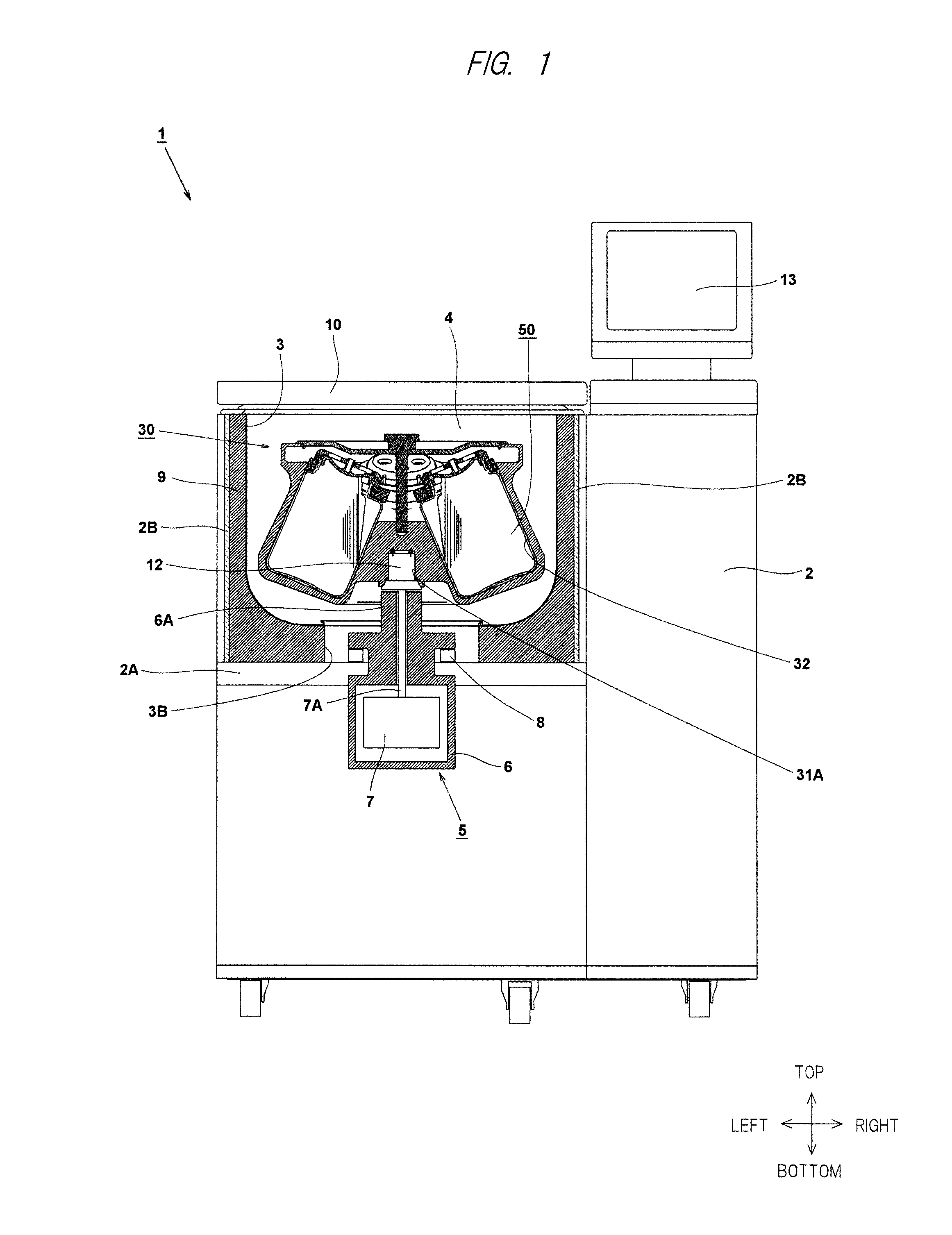

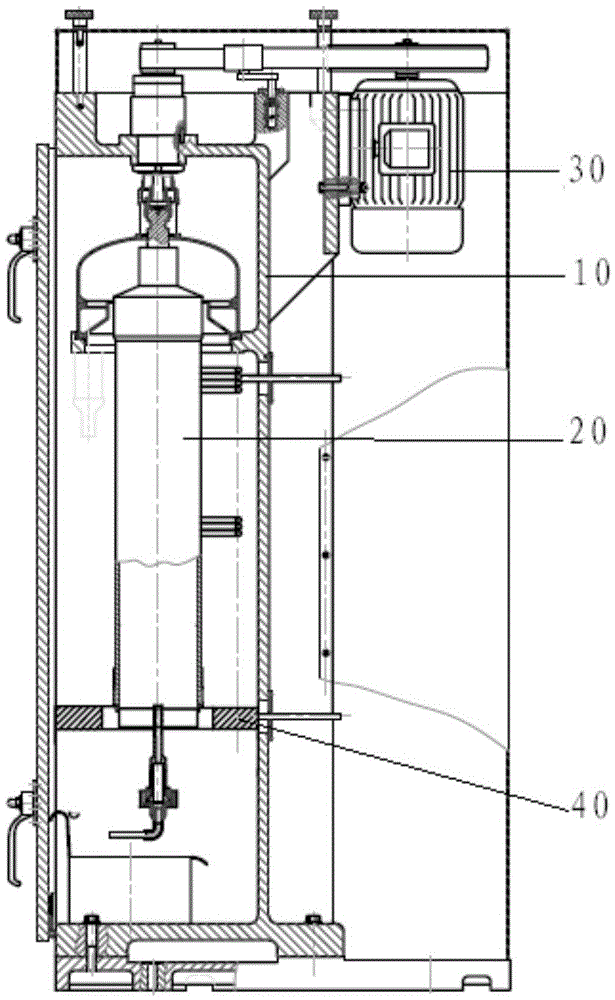

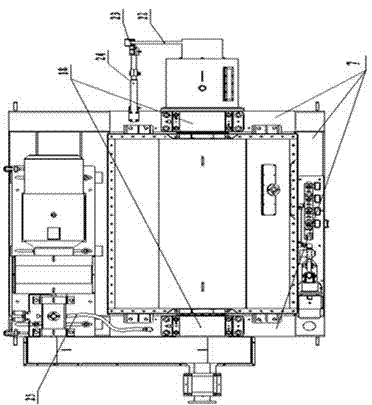

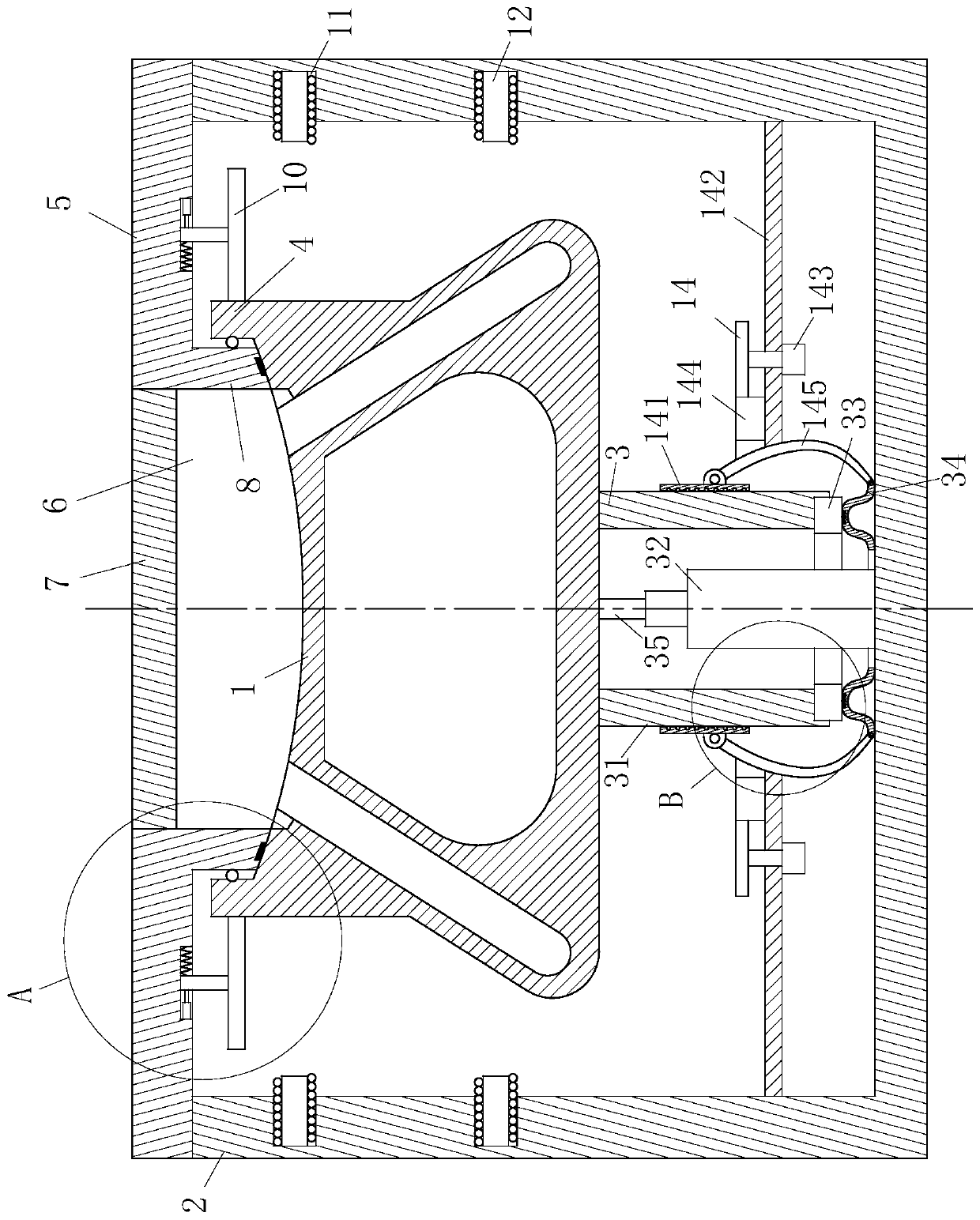

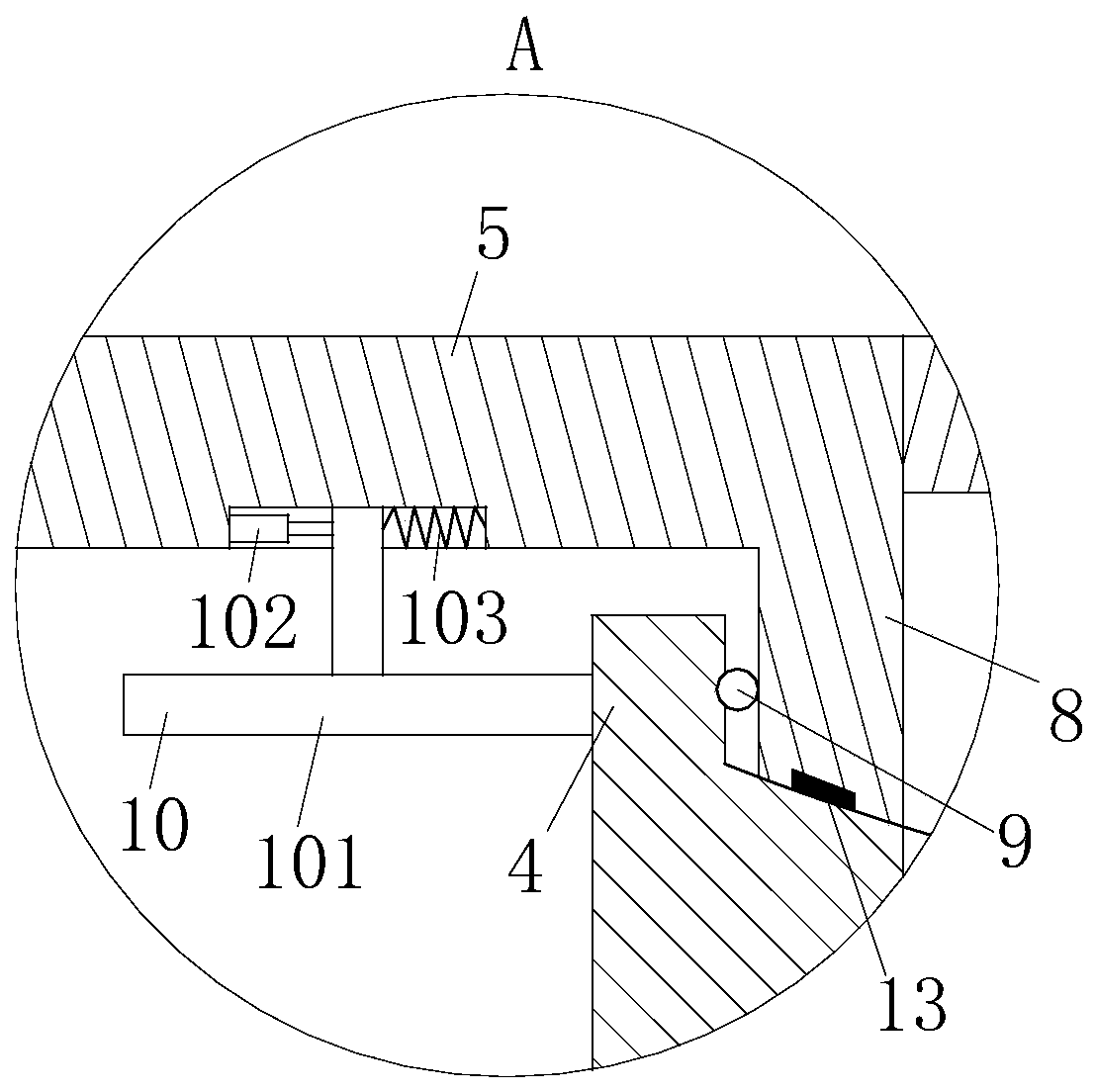

Filter bag reinforced self-cleaning type centrifugal machine

ActiveCN106955796AAchieve self-cleaningImprove centrifugal effectCentrifugesEngineeringUltimate tensile strength

The invention discloses a filter bag reinforced self-cleaning type centrifugal machine. The filter bag reinforced self-cleaning type centrifugal machine comprises a shell, a rotary drum arranged in the shell, a power device arranged in the shell for driving the rotary drum to rotate and a filter bag located in the rotary drum, wherein the outer wall of the filter bag clings to the inner wall of the rotary drum; the structure of the power device for driving the rotary drum to rotate is arranged into one comprising a main shaft, a lifting shaft, a lifting cover, a first driving mechanism and a second driving mechanism; by arranging the structures of the main shaft, the lifting shaft, the lifting cover, the first driving mechanism and the second driving mechanism, in the process of driving the rotary drum and the filter bag to synchronously rotate, the filter bag can be pulled to shrink and stretch, and accordingly, materials attached to the wall of the filter bag directly fall off, so that the purposes of realizing filter bag self-cleaning and improving the centrifugal effect are achieved; and at the same time, a plurality of reinforcing strips are arranged on the outer surface of the filter bag so as to improve the tensile strength of the filter bag, and the filter bag can closely cling to the inner wall of the rotary drum after being reset.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

Centrifugal machine for disinfection bath foam preparing

InactiveCN111438003AIncrease centrifugal forceIncrease the centrifugal force fromRotary centrifugesSprayerHigh pressure water

The invention discloses a centrifugal machine for disinfection bath foam preparing, and relates to the technical field of disinfection bath foam preparing. A base is included. A machine case is arranged at the upper end of the base. Side plates are correspondingly arranged on the two sides of the upper surface of the machine case. A machine barrel is arranged between the two side plates. An annular pipe is arranged on the outer surface of the machine barrel in a surrounding manner. One side face of the annular pipe communicates with a connecting pipe. The inner side face of the connecting pipecommunicates with sprayers. The lower surface of the annular pipe communicates with a conveying pipe. An outer drum is arranged in the machine barrel and internally rotationally connected with an inner drum. Through the design of the double drums, the centrifugal force of the centrifugal machine is increased, accordingly, the material centrifuging effect is improved, and solid particles and liquid in liquid materials are more thoroughly separated; and meanwhile, through the link action of an electric air heater and a high-pressure water pump, residual solid particles adhering into the centrifugal machine can be dried and separated, cleaning is easy, operation is simple, and the cleaning efficiency is high.

Owner:山东消博士消毒科技股份有限公司

Table centrifuge

The invention belongs to the technical field of centrifuges, and particularly relates to a table centrifuge. A rotor, a machine case and a controller are included. The rotor is connected to the centerpart of the machine case through a drive module, and a first annular boss is arranged at the upper portion of the rotor. A case cover is arranged at the upper portion of the machine case. An anti-leakage cover is arranged at the middle portion of the case cover, and a second annular boss is arranged at the lower end of the case cover. Balls are connected between the second annular boss and the first annular boss. The case cover is further provided with an auxiliary rotation module. The drive module comprises a sleeve, a first motor, a conical roller bearing and an adjusting gasket, wherein the sleeve is connected to the axis position of the bottom of the rotor, the first motor is arranged at the axis line of the rotor, and the output end of the first motor is connected with the bottom ofthe rotor through a connecting rope. A rope is twisted to a certain degree to drive the rotor to rotate, the situation that vibration generated during motor work is transmitted to the rotor is avoided, the rotor rotation stability is improved, and accordingly the centrifuging effect and work quality of the centrifuge are improved.

Owner:梁山新翔新材料有限公司

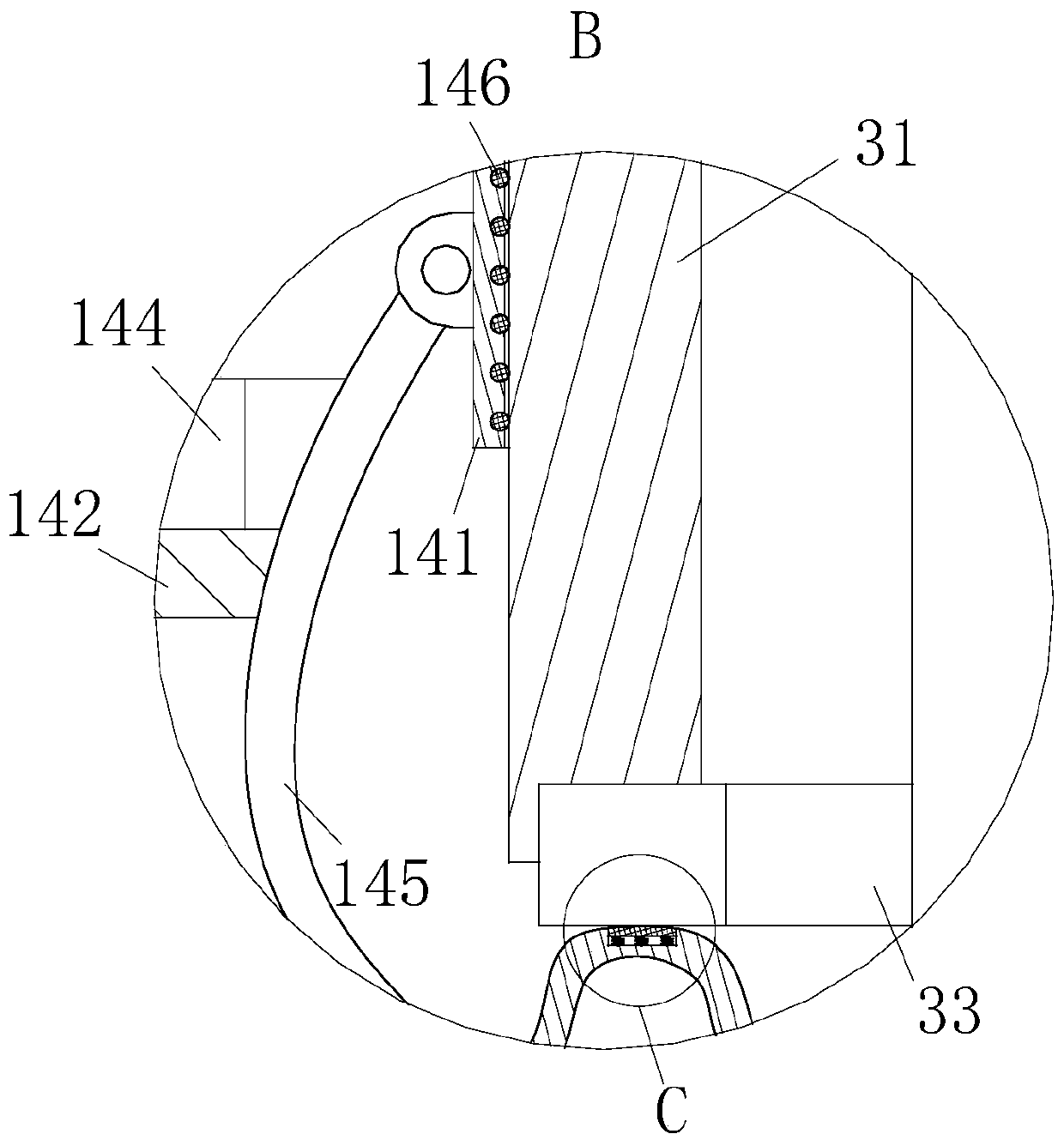

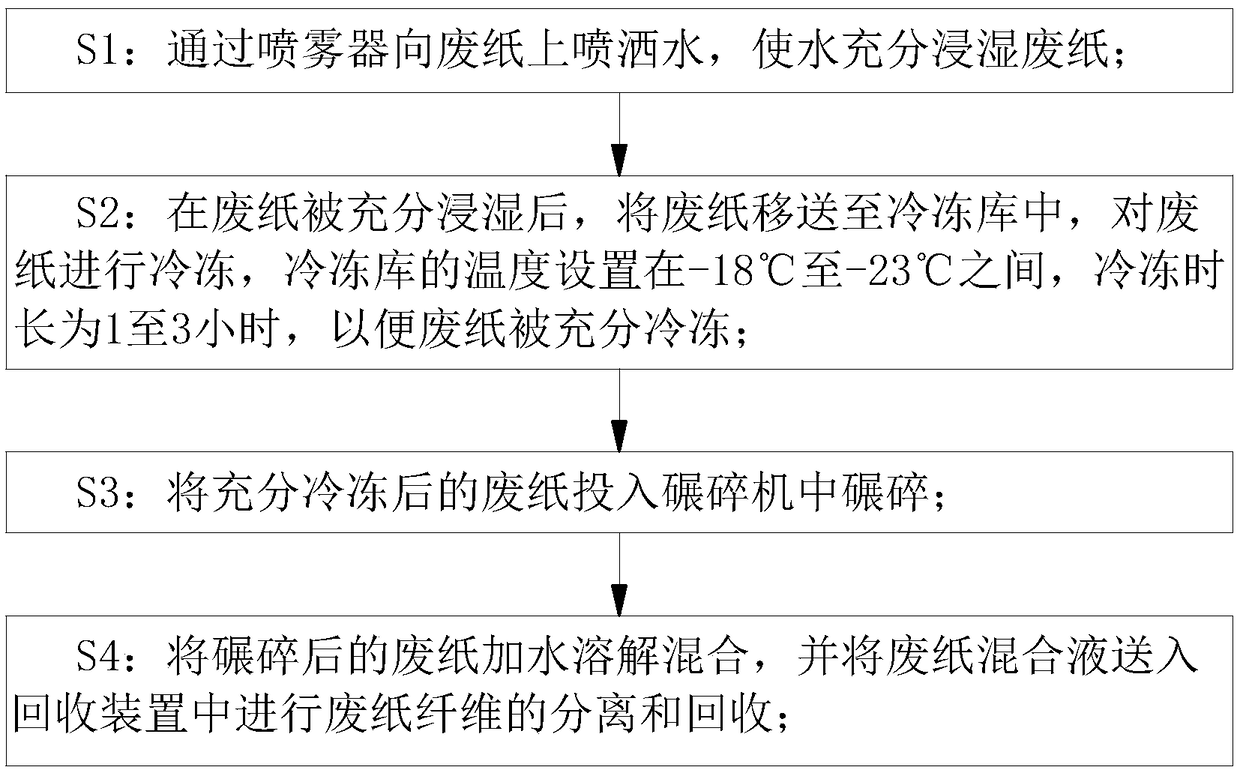

Paper pulp recycling method

InactiveCN109457525ACentrifugal accelerationFull recoveryPaper recyclingFiltration circuitsRecovery methodFiber

The invention belongs to the technical field of waste paper recycling, in particular to a paper pulp recycling method. A recycling device adopted in the process comprises a recycling tank, and furthercomprises supporting legs, a feed inlet, a discharge outlet, a motor, a worm wheel, a mounting frame, a transmission mechanism, a primary filtration unit, a secondary filtration unit and a controller, wherein the controller is used for controlling the work of the recycling device, the supporting legs are installed at the bottom of the recycling tank, water is sprayed to waste paper with a sprayerand is frozen, the water turns into ice after being frozen, at the moment, the volume is increased, the waste paper is opened and torn, and meanwhile the waste paper becomes brittle after being frozen so as to be more easily smashed sufficiently; a crushing mill is used for crushing; and when the crushing mill crushes ice blocks, the waste paper is crushed through the ice blocks, at the moment, the crushed ice blocks further tear the waste paper, the smashing effect is improved, the fiber content of the dissolved waste paper is greatly improved, and the extraction rate of the fibers in the waste paper is improved.

Owner:崔雪柯

Flue gas waste heat recovery device

PendingCN112880459AExtend the pathImprove efficiencyRecuperative heat exchangersDrying gas arrangementsExhaust fumesFlue gas

The invention relates to a flue gas waste heat recovery device which comprises an outer shell, a vertical inner air duct and a circulating water system. An air inlet pipe is arranged on one side of the outer shell, an air outlet pipe and the circulating water system are arranged on the other side of the outer shell, the air inlet pipe is communicated with the vertical inner air duct, and a spiral blade is arranged in the vertical inner air duct. The spiral blade is of a spiral rising structure around a circulating water vertical pipe, and four receiving hoppers which are connected up and down are arranged in the outer shell. In industrial production, waste heat of waste gas accounts for a large amount of heat losses, high-temperature flue gas exhausted by an asphalt mixing plant contains a large amount of water vapor and carries a large amount of waste heat, the waste heat in the flue gas can be recycled, a large amount of energy can be saved, fuel is saved for subsequent stone drying, and air pollution is greatly reduced. And meanwhile, the production cost of enterprises can be reduced, and important practical significance is also achieved for meeting the strategic requirements of energy conservation and emission reduction.

Owner:CA LONG ENG MACHINERY CO LTD

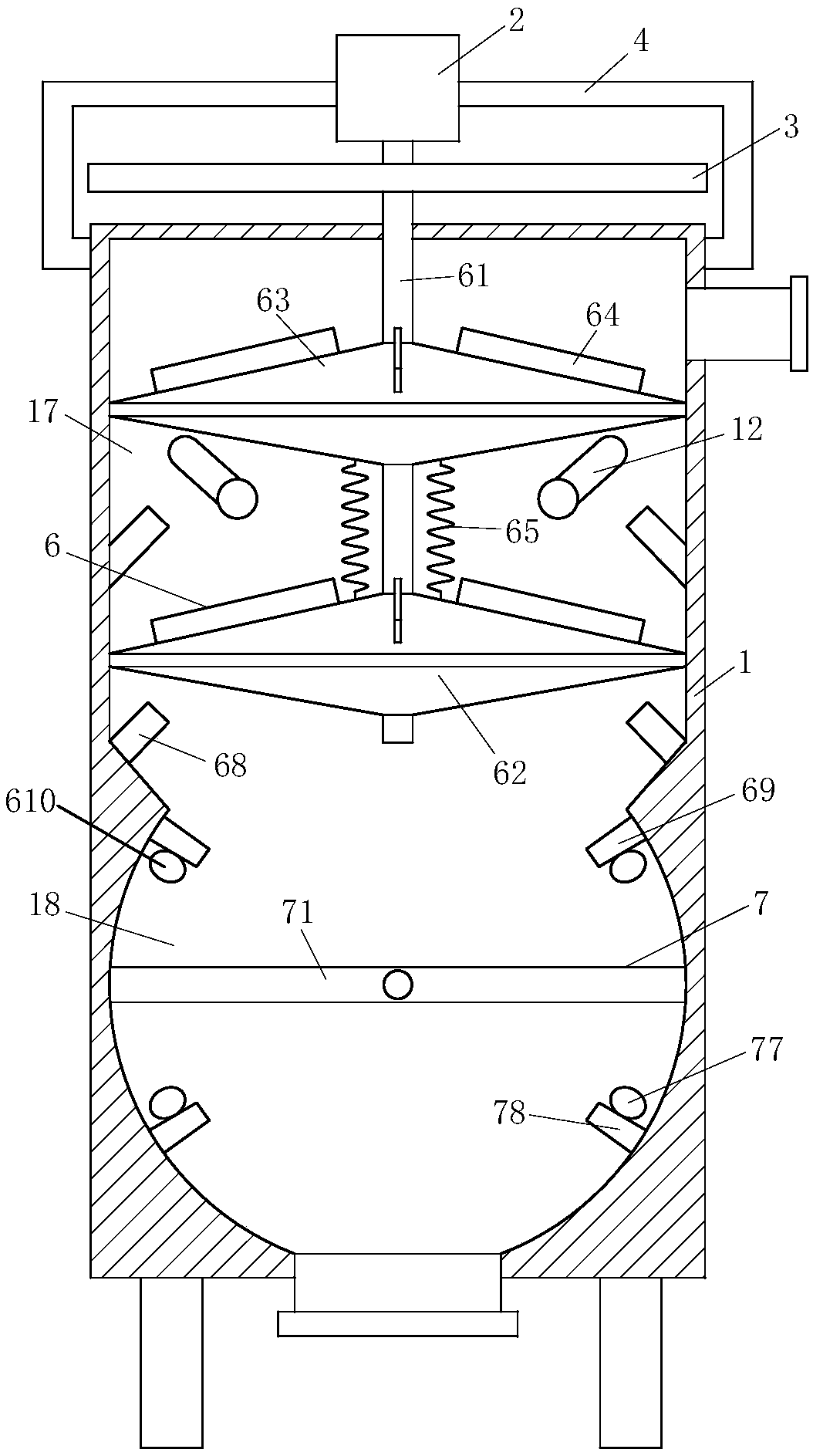

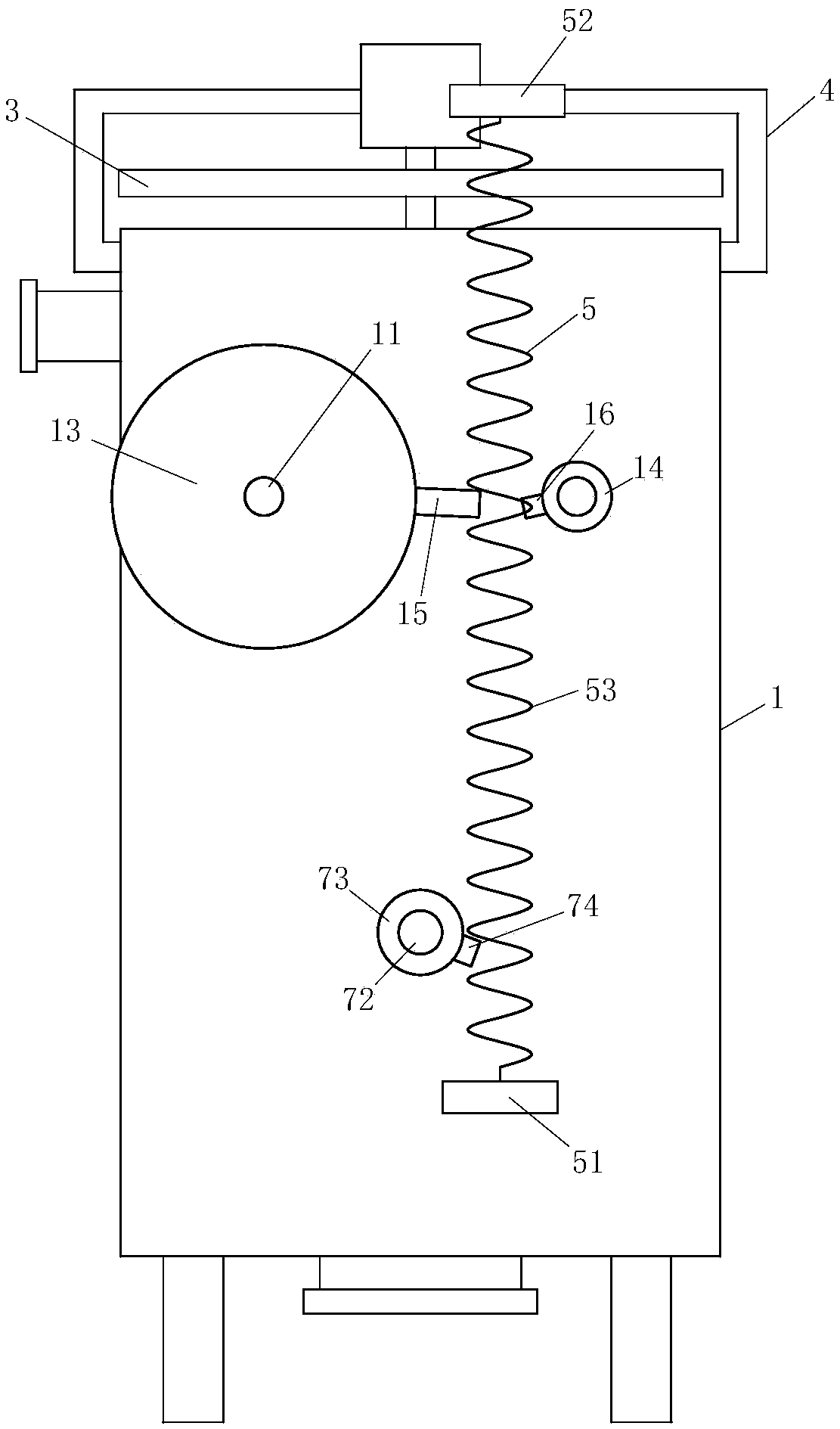

Paper pulp recycling device

InactiveCN109338783AHigh recovery rateFast recyclingPaper material treatmentFiberPulp and paper industry

The invention belongs to the technical field of paper making equipment, and particularly relates to a paper pulp recycling device. The device comprises a recycling tank, supporting legs, a feeding inlet, a discharging outlet, a motor, a worm gear, a mounting rack, a transmission mechanism, a primary filtering unit, a secondary filtering unit and a controller. The controller is used for controllingthe recycling device to work; the supporting legs are installed at the bottom of the recycling tank; the feeding inlet is formed in the upper portion of the side wall of the recycling tank, and the discharging outlet is formed in the bottom wall of the recycling tank; by arranging the motor, the primary filtering unit and the secondary filtering unit, paper pulp is stirred, broken and mixed through stirring blades, and therefore the waste paper fiber recycling rate is increased; the paper pulp is repeatedly filtered through a filter net, the filter net is obliquely arranged according to the Zshape, rotating centrifugal force can be effectively utilized, the centrifuging effect can be accelerated, and the separating efficiency is improved, so that the waste paper fiber recycling speed canbe increased, and the time needed by recycling and separating is shortened.

Owner:崔雪柯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com