Table centrifuge

A centrifuge and desktop technology, applied in the field of centrifuges, can solve the problems of affecting the centrifugal effect, uneven weight of the rotor, and vibration of the rotor, and achieve the effect of improving the effect, reducing friction, and reducing jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

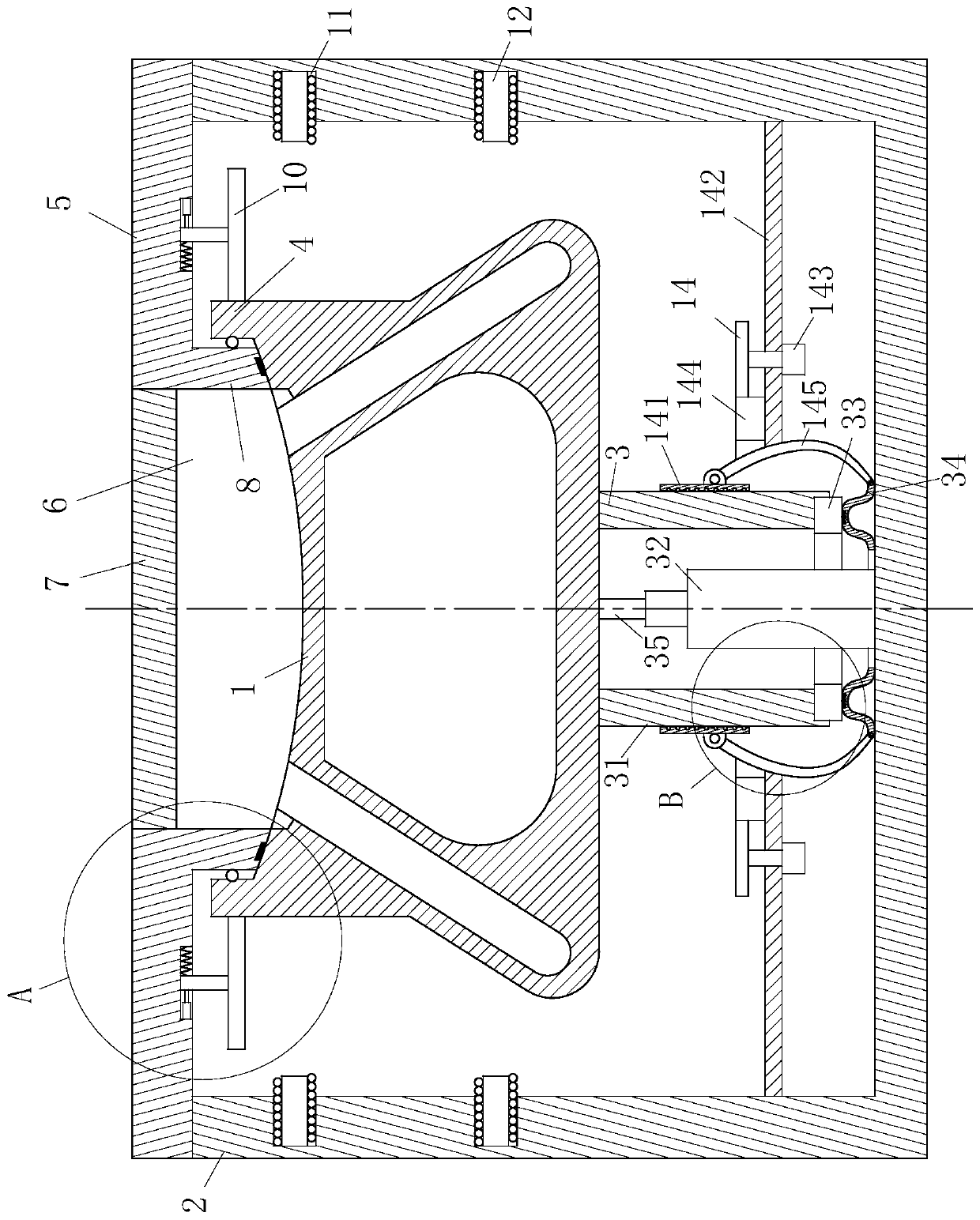

[0025] use Figure 1-Figure 6 A desktop centrifuge according to one embodiment of the present invention will be described below.

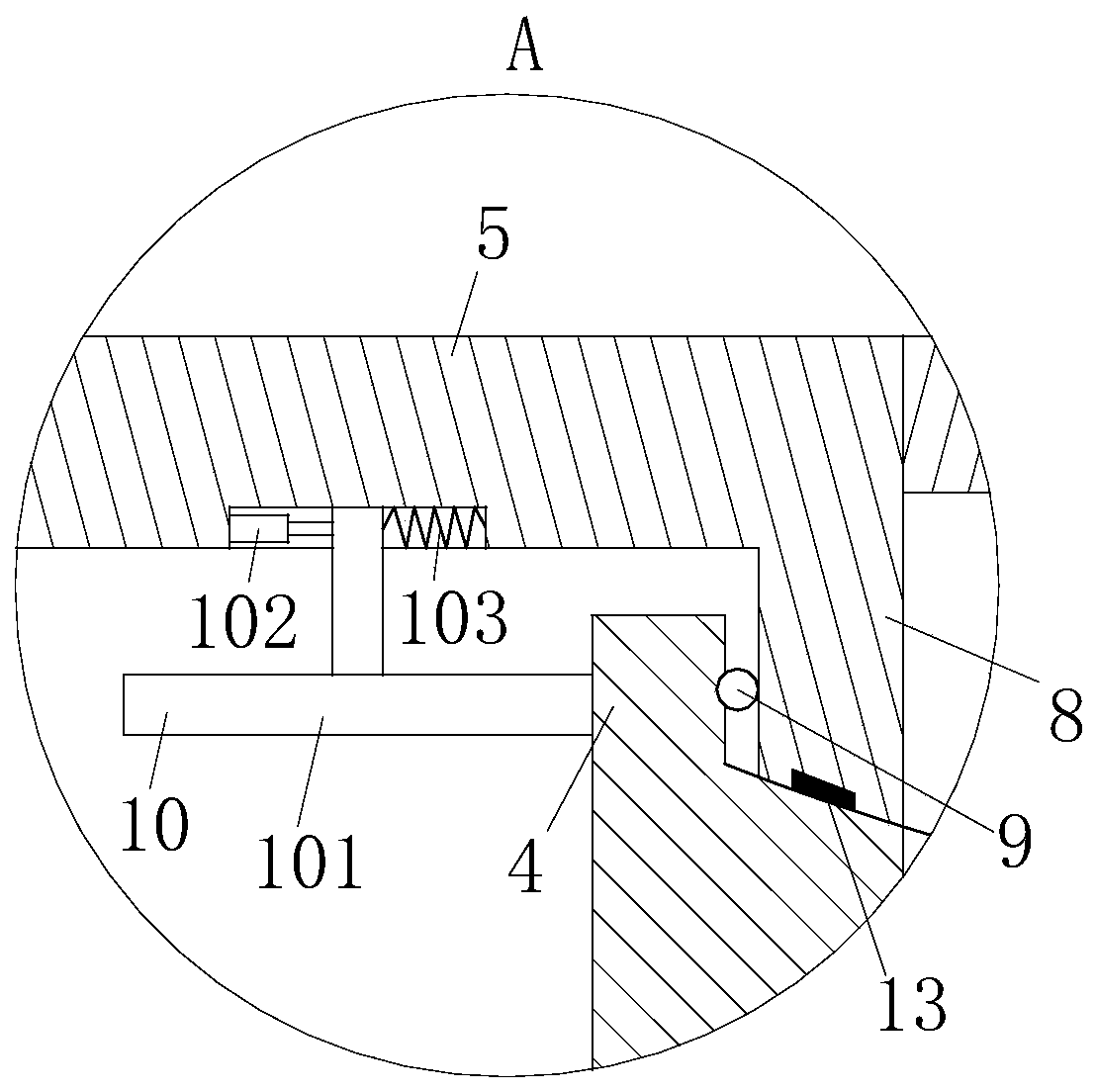

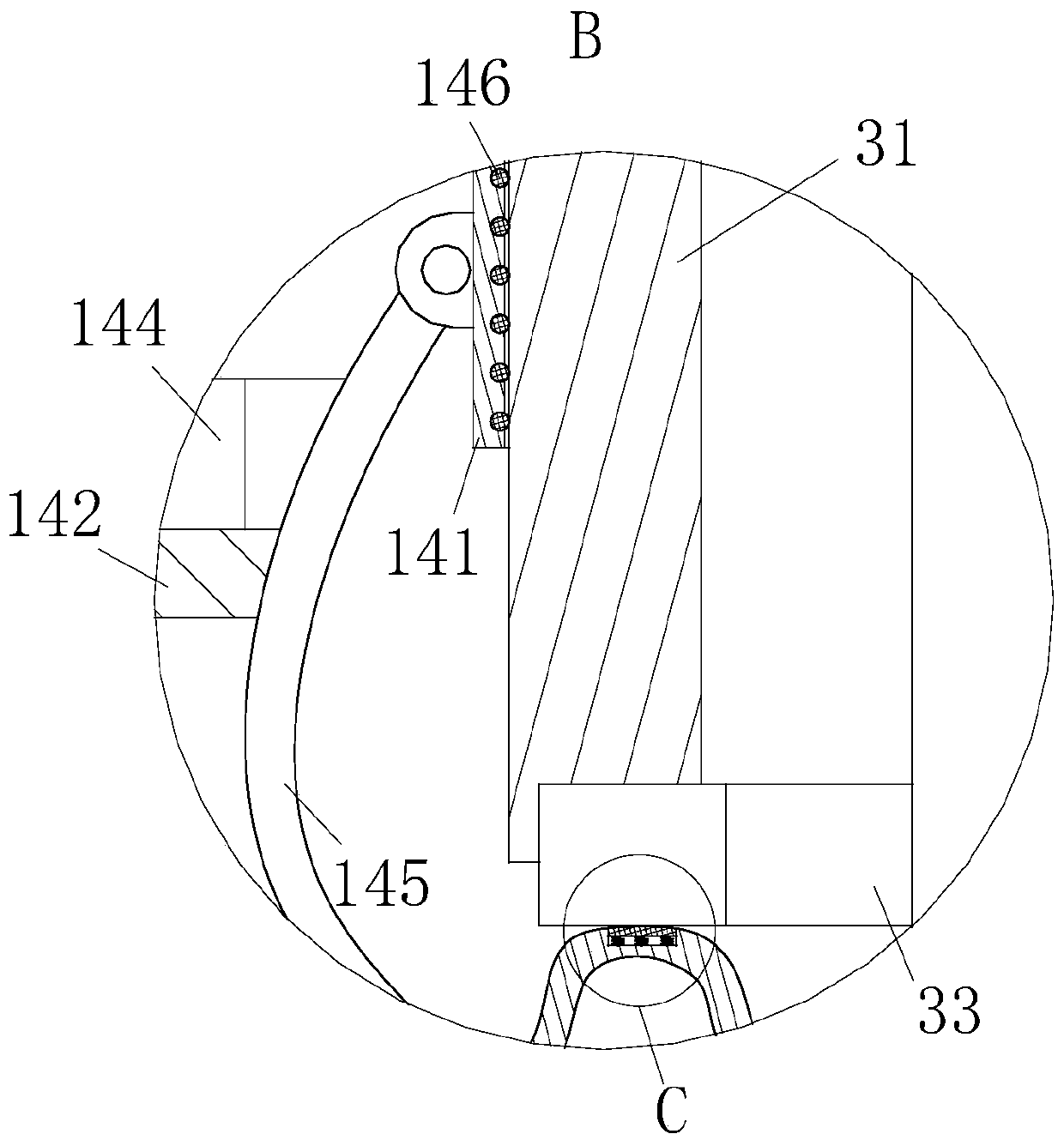

[0026] Such as figure 1As shown, a desktop centrifuge according to the present invention includes a rotor 1, a cabinet 2 and a controller; the rotor 1 is connected to the center of the cabinet 2 through a drive module 3, and the rotor 1 is provided with a container for holding test tubes. The upper part of the rotor 1 is an arc surface, and the upper part of the rotor 1 is provided with a No. 1 annular boss 4; the upper part of the chassis 2 is provided with a case cover 5; the middle part of the case cover 5 is provided with a No. 1 through hole 6 corresponding to the middle part of the rotor 1 , the No. 1 through hole 6 is provided with an anti-leakage cover 7, and the lower end of the case cover 5 is provided with a No. 2 annular boss 8 in contact with the arc surface of the rotor 1; the No. 2 annular boss 8 and the No. 1 annular boss 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com