Gravity acceleration centrifuge

A technology of gravity acceleration and centrifuge, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inconvenient maintenance, poor purification effect, low centrifugal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

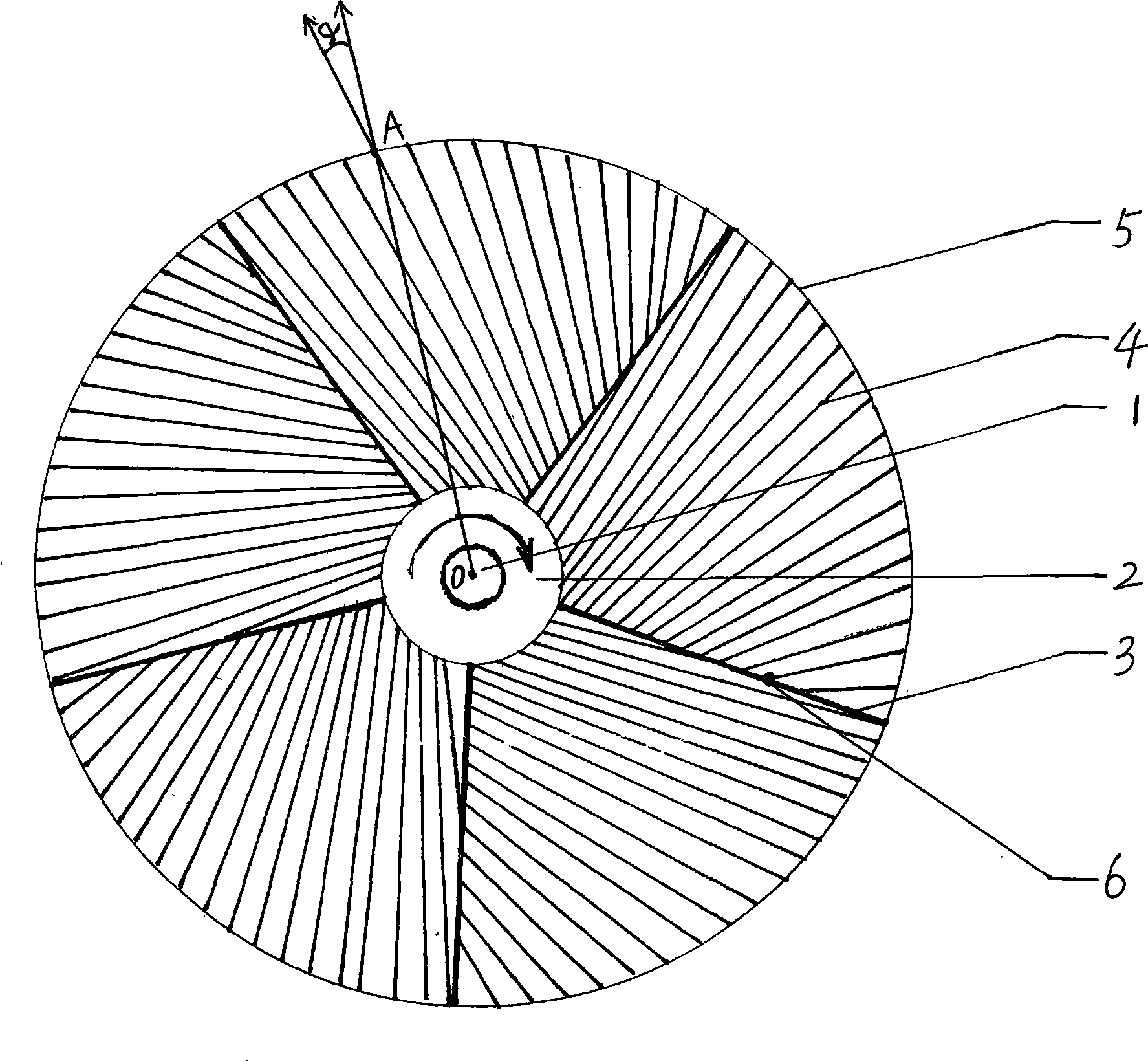

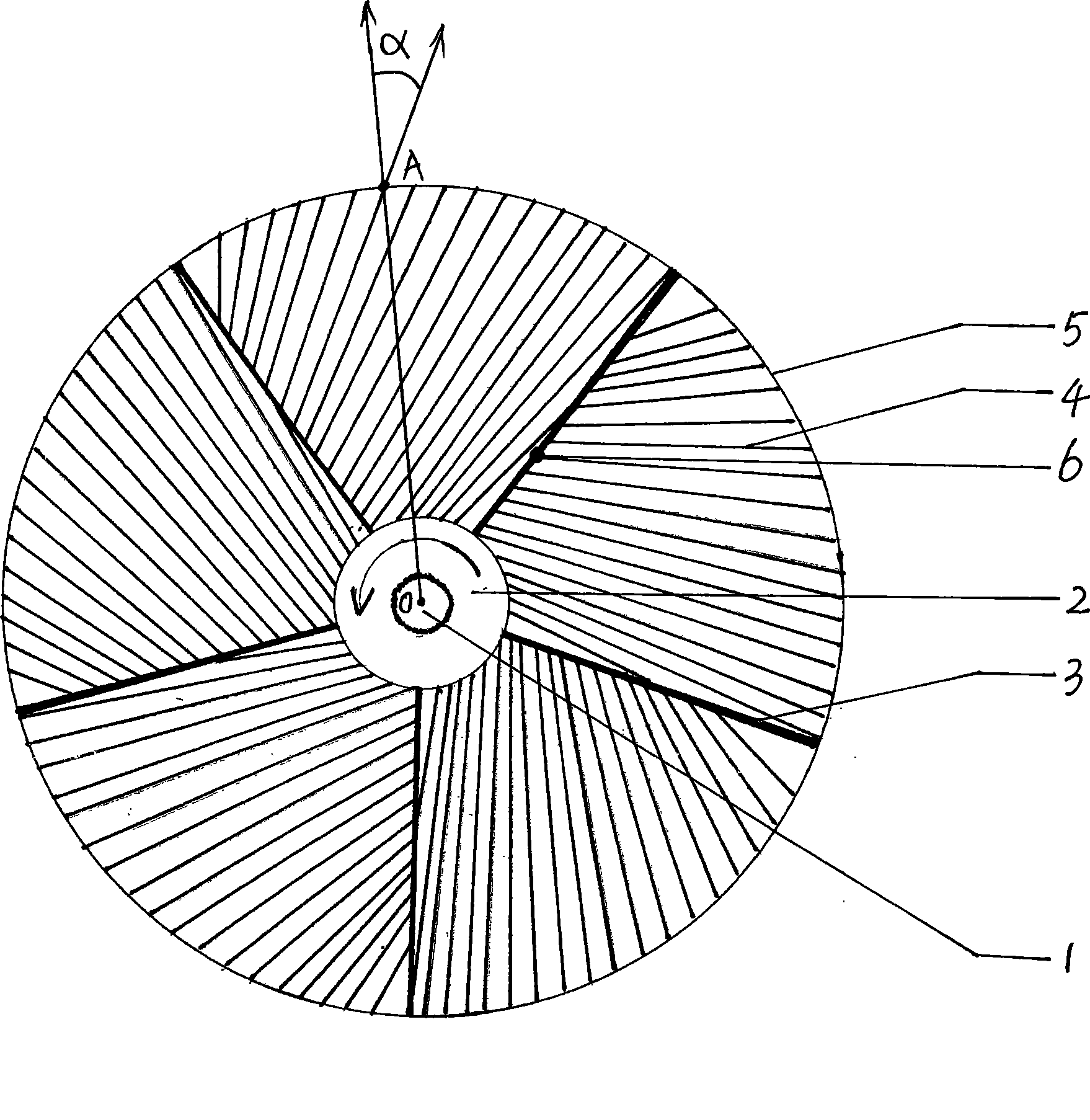

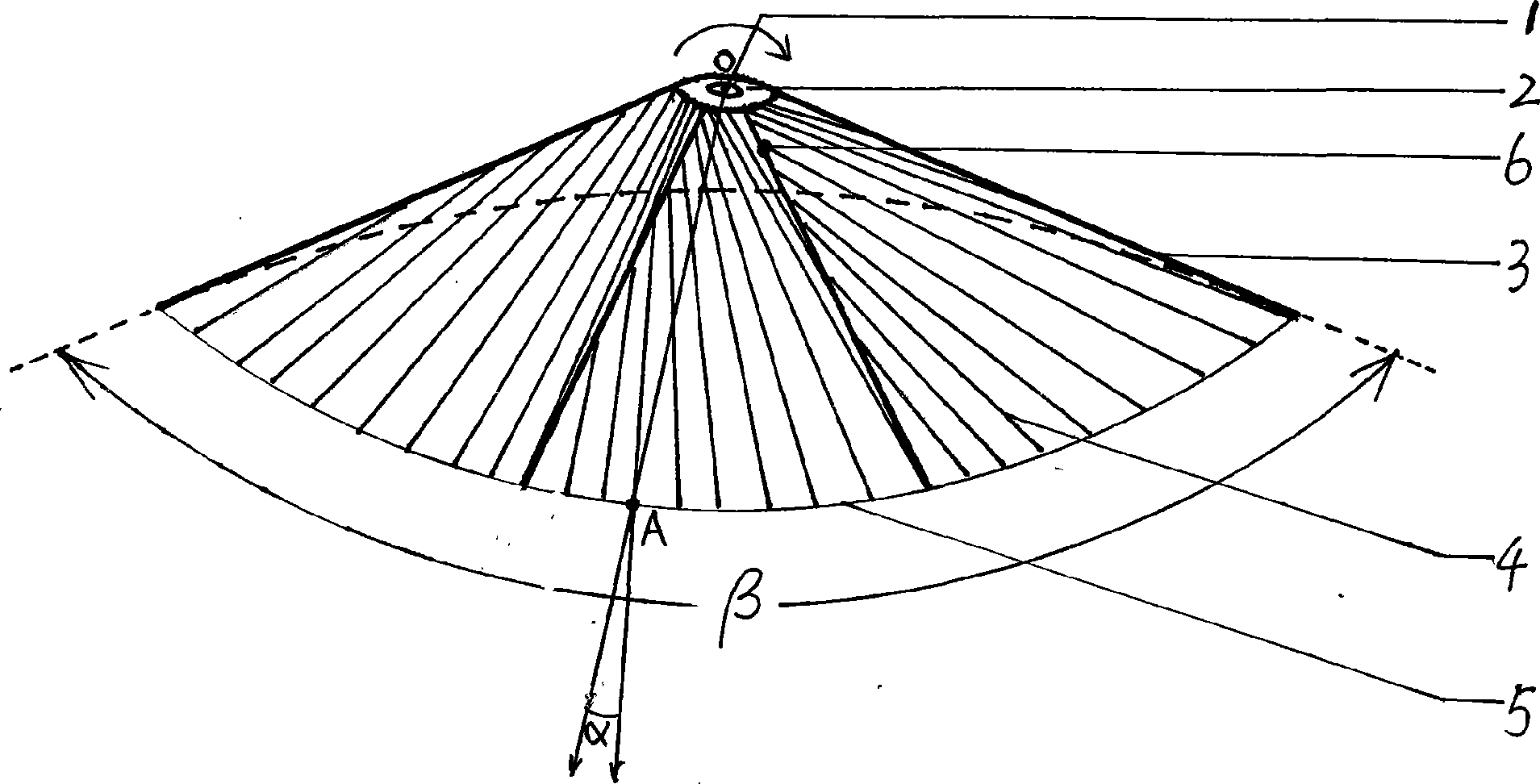

[0026] figure 1 , figure 2 As shown, the gravitational acceleration centrifuge is a flat disk structure, including an inner disk 2 , a main frame 3 , centrifugal wires 4 , and an outer ring 5 . The transmission connection hole 1 is in the center of the inner disk 2; the transmission connection hole 1 is used for assembly with the transmission system, and the centrifuge speed t: 360 rpm≤t≤7200 rpm. The inner disk 2 and the outer ring 5 are connected by five main skeletons 3 distributed uniformly and fan-shaped in a straight line. The inner endpoints of the main skeletons 3 are connected to the inner disk 2 and the outer endpoints are connected to the outer ring 5; There are M centrifugal wires 4 distributed by a certain elevation angle, and M is 19, and the centrifugal wires 4 of the present embodiment are 95 altogether. The centrifugal wire 4 takes the main skeleton on one side or the inner disk 2 between the two main skeletons as the starting point 6, and is set in the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com