Centrifuge for automatically separating pulp and dregs

An automatic separation and centrifuge technology, applied in the field of centrifuges, can solve problems such as frequent shutdowns and affect work efficiency, and achieve the effects of improving work efficiency, prolonging life, and preventing burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

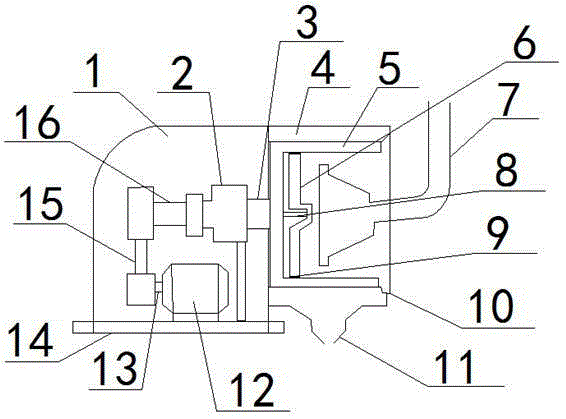

[0017] refer to figure 1 As shown, a centrifuge for automatic separation of pulp and residue includes a machine compartment 1 for fixing a gearbox 2 and a stepper motor 12 and a liquid collection bin 4 for filtering, and the stepper motor 12 passes through a driven shaft 16 Connected with the gearbox 2, a liquid outlet 11 is provided directly below the liquid collection bin 4, and a feed pipe 7 for transferring materials is provided outside the liquid collection bin 4, and the output end of the gearbox 2 passes through the rotating shaft 3 is connected with the filter frame 5 located in the liquid collection bin 4, and drives the filter frame 5 to rotate; the filter frame 5 is a frame-shaped structure with an outer end opening and a filter screen in the middle, and the output end of the feed pipe 7 is from The opening end of the filter frame 5 protrudes into the filter frame 5 ; a slag outlet 10 is provided at the bottom of the liquid collection bin 4 outside the opening end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com