Horizontal screen sedimentation centrifuge

A settling centrifuge and screen technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve the problems of water removal capacity bottlenecks, simple safety devices, expensive maintenance costs, etc., to reduce the overall space, Guaranteed safe operation, the effect of a large overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

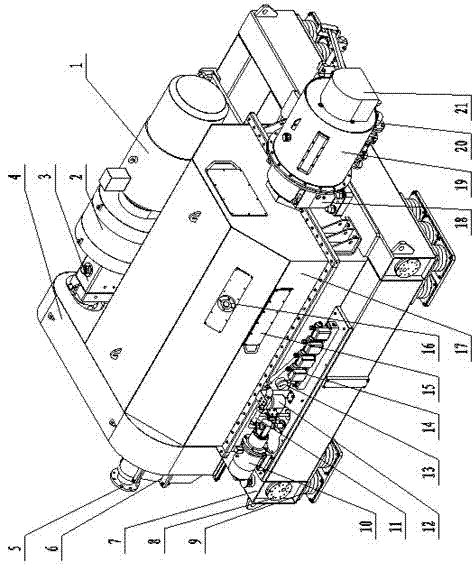

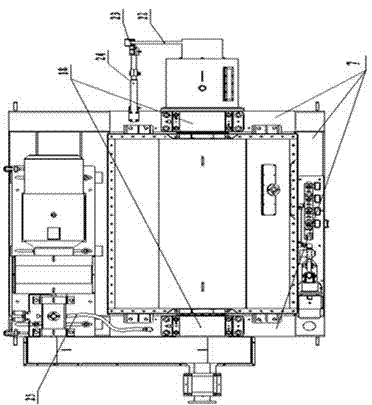

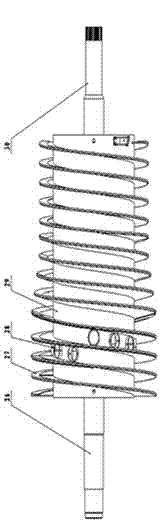

[0016] A horizontal screen sedimentation centrifuge is composed of five parts: driving device, rotor, lubricating device, differential, safety device, and base. Specifically, it is composed of motor 1, hydraulic coupler 2, countershaft seat 3, Transmission pulley cover 4, main pulley 5, feed pipe 6, feed pipe support 7, oil tank 8, cooler 9, rubber shock absorber 10, hydraulic pump 11, hydraulic pipeline 12, hydraulic filter 13, hydraulic gauge 14 , Hydraulic valve 15, transparent window 16, water injection pipe inlet 17, housing 18, bearing seat 19, high torque differential 20, safety box 21, torque rod 22, pressure sensor 23, sensor support rod 24, oil return pipe 25, Mandrel connecting pipe 26, screw pusher 27, feeding centrifugal port 28, mandrel 29, differential connecting pipe 30, feeding centrifugal bin 31, feeding baffle 32, belt pulley 33, hoop 34, lip Type sealing ring 35, bearing front baffle 36, angular contact ball bearing 37, bearing rear baffle 38, pulley connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com