Tubular centrifuge and method thereof for keeping balance of rotating drum

A tubular centrifuge and drum technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of drum wear, rotation axis deviating from the vertical position, and inability to separate materials, to avoid rotating drums. Drum imbalance, optimized centrifugation effect, improved residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

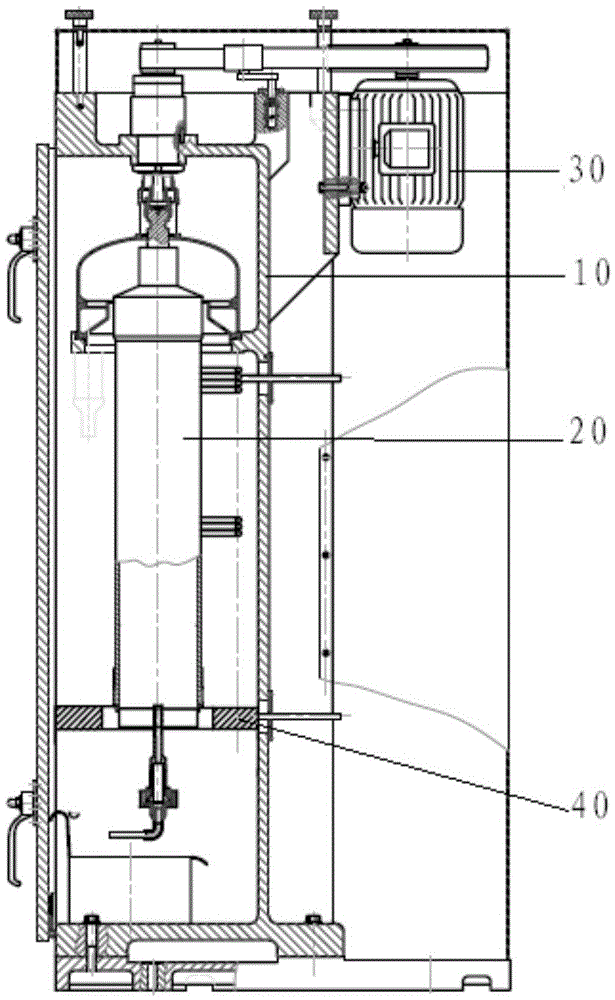

[0039] Such as figure 1 As shown, Embodiment 1 discloses a tubular centrifuge, including a frame 10, a drum 20 and a driving device 30, the driving device 30 is arranged on the frame 10, and the driving device 30 is connected with the drum 20 for driving The drum 20 rotates itself in the vertical direction around the axis of the drum.

[0040] The tube centrifuge also includes: an induction device, which is used to monitor whether the rotation axis of the drum deviates from the vertical direction, and generates a drum position signal when the rotation axis of the drum is detected to deviate from the vertical direction; magnetic reset The device 40, the magnetic resetting device 40 is fixed on the frame 10 and connected with the drum 20, the magnetic resetting device 40 is also connected with the induction device and receives the drum position signal. When the sensing device detects that the rotation axis of the drum deviates from the vertical direction, the magnetic resetting...

Embodiment 2

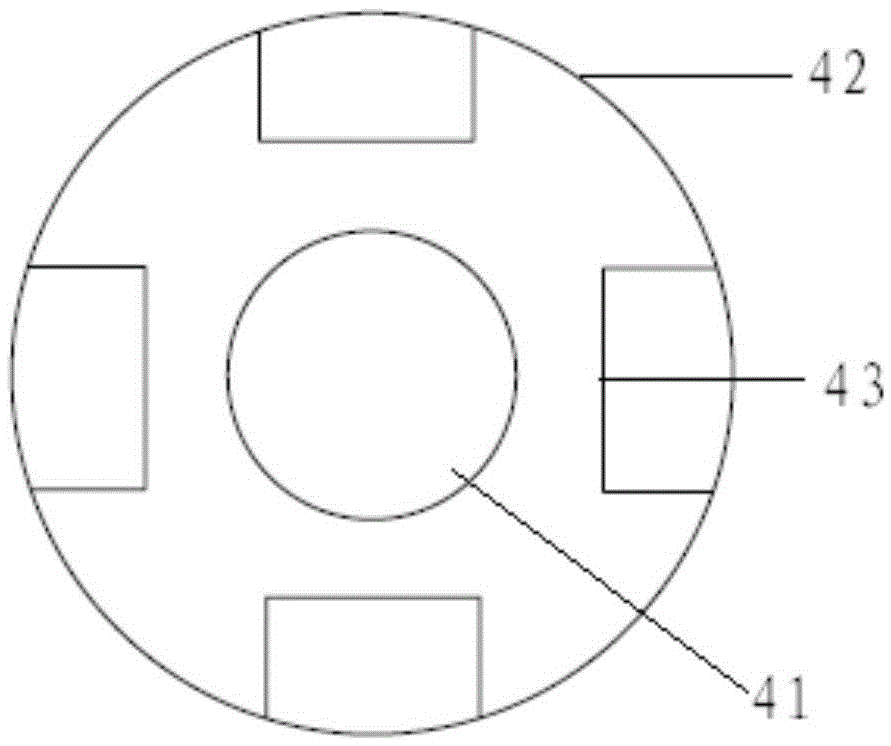

[0043] Such as figure 2 As shown, the difference between the second embodiment and the first embodiment is that the magnetic reset device 40 in the tubular centrifuge disclosed in the second embodiment includes: a magnetic rotor 41, the magnetic rotor 41 is arranged on the drum and is connected with the drum Coaxial arrangement; a stator disk 42, the stator disk 42 is fixed on the frame, the stator disk 42 and the magnetic rotor 41 are coaxially arranged, and there is a gap between the stator disk 42 and the magnetic rotor 41, and the stator disk 42 is provided with four Winding 43, and the four windings 43 are evenly distributed on the stator plate 42; a control device, the control device is connected with the induction device and receives the drum position signal sent by the induction device, and the control device is connected to the four windings 43 respectively.

[0044] When the induction device senses that the rotation axis of the drum deviates from the vertical direct...

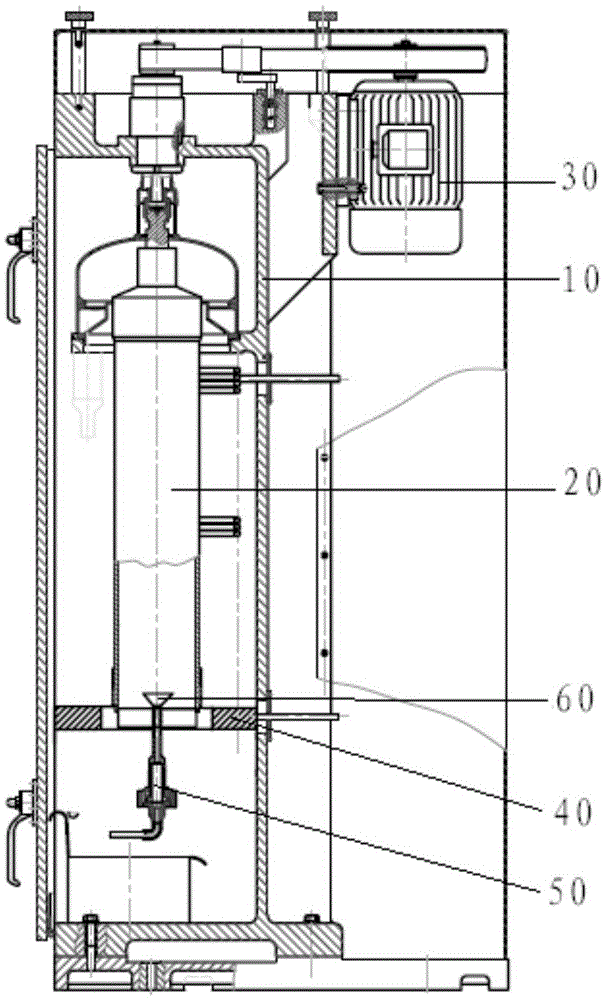

Embodiment 3

[0048] The difference between Embodiment 3 and Embodiment 1 is that the tubular centrifuge disclosed in Embodiment 3 also includes: an alarm device, which is connected to the sensing device; When all segments deviate from the vertical direction, the alarm device sends out a first alarm signal; when the sensing device senses that the angle of rotation axis of the drum deviates from the vertical direction is greater than the first angle, the alarm device sends out a second alarm signal.

[0049] When within the first period of time, the drum does not restore balance under the action of the magnetic reset device, then the operator can take countermeasures in time according to the first alarm signal, such as emergency shutdown, replacement of the magnetic rotor or repair of the unbalanced drum Manual reset, etc. When the angle of rotation axis of the drum deviates from the vertical direction is greater than the first angle, the magnetic reset device can no longer restore the balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com