Multifunctional roller coater

A roll coater and multi-functional technology, applied in printing machines, rotary printing machines, printing, etc., can solve problems such as air bubbles, poor adjustment accuracy, and increased adjustment difficulty, so as to ensure coating quality, coating thickness, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

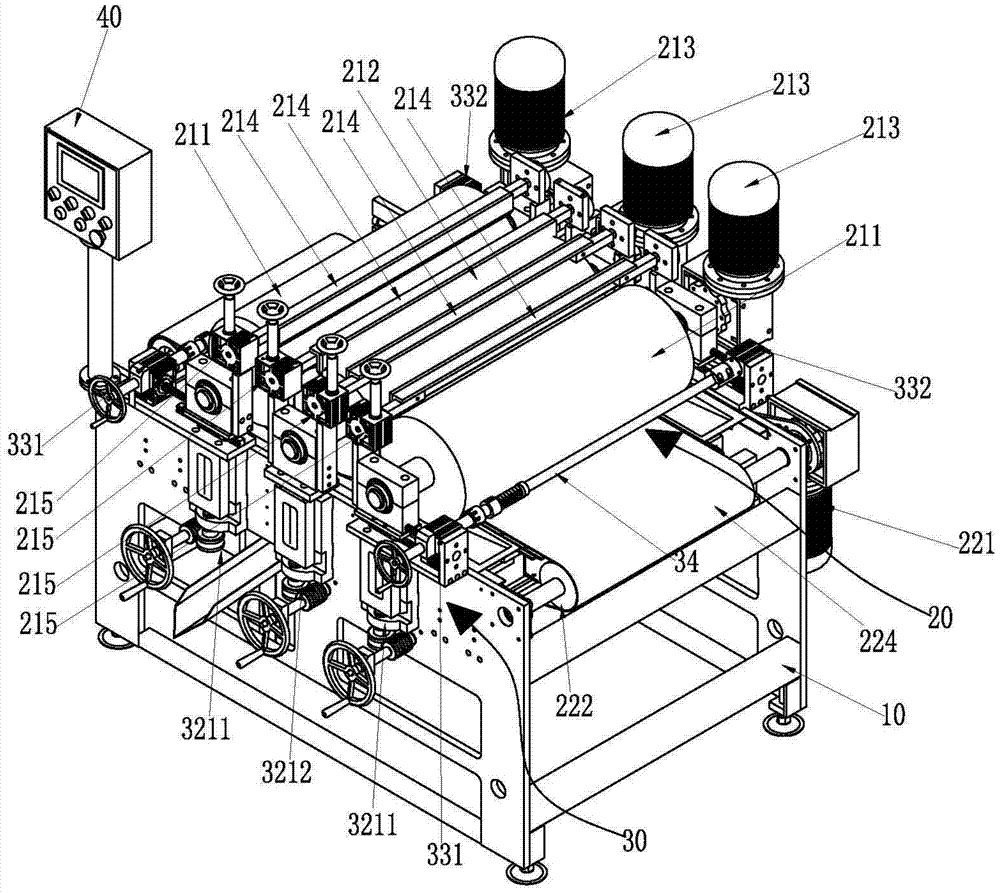

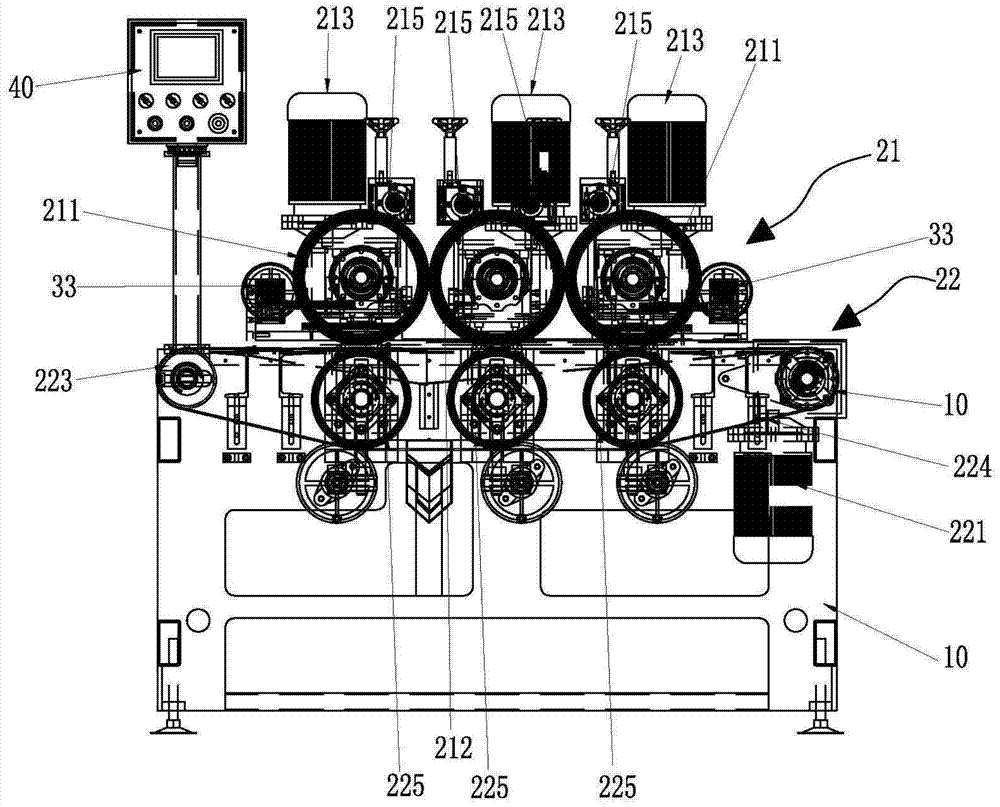

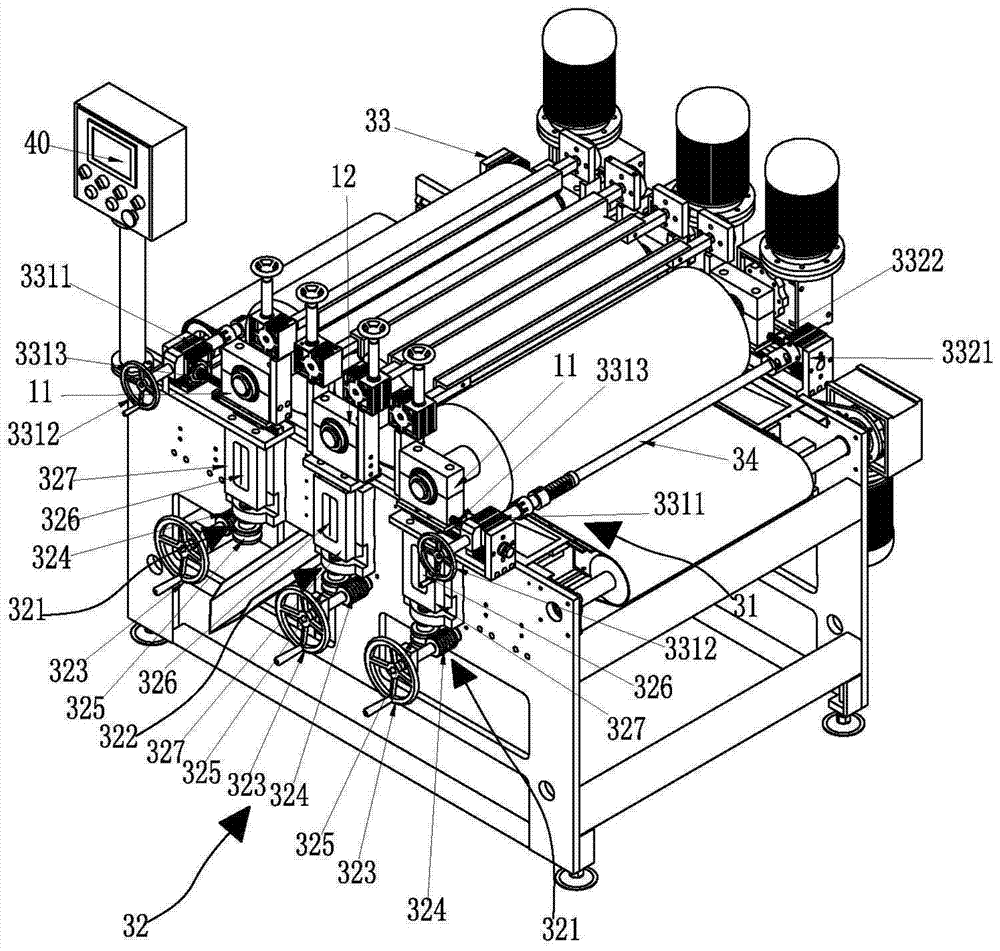

[0064] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, a multifunctional roller coating machine, including a frame 10, a coating system 20, a roller adjustment system 30 and a control system 40.

[0065] Wherein, the above-mentioned coating system 20 , roller adjustment system 30 and control system 40 are installed on the frame 10 .

[0066] The coating system 20 includes a roller set 21 and a transmission mechanism 22 , and the roller set 21 and the transmission mechanism 22 are installed on the frame 10 .

[0067] The roller set 21 is provided with three rollers, including two steel wheels 211 and a soft rubber transfer wheel 212, the soft rubber transfer wheel 212 is installed between the two steel wheels 211, and each roller is connected correspondingly There is a motor 213 that drives the rollers to rotate. The two steel wheels 211 are one or both of mirror steel wheels or pattern steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com