Patents

Literature

303results about How to "Guarantee coating quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

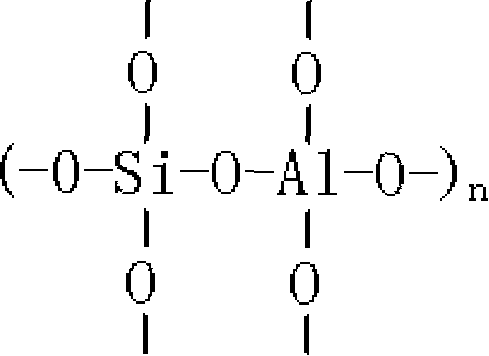

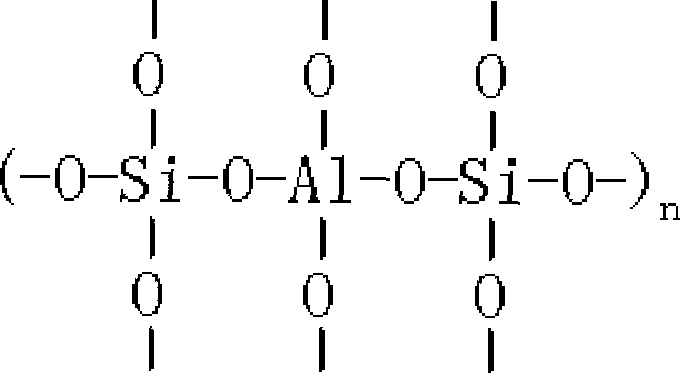

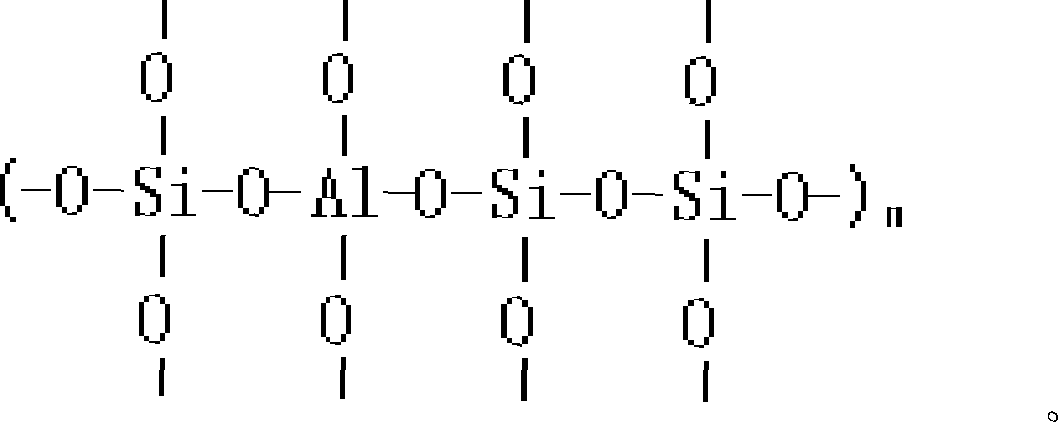

Polymer coating composite and preparation method thereof

InactiveCN101045832ALow costEasy to use on siteSolid waste managementCement productionPolymer scienceOxygen

This invention relates to a dope combination. The film coating it formed is amorphous gelatinous substance, base unit is three-dimensional network formed by connection of silicon - oxygen tetrahedron and aluminium - oxygen tetrahedron. end product takes electrovalent bond and covalent bond as main, vander waas bond as complement, possess linkage structure of organic heavy polymer, and double property of inorganic polymer and organic polymer. The unique performance supple the insufficiency of organic high molecular polymer. It possesses favorable performance of acid-proof, alkali-proof, impervious, antifreeze, seawater resistance and high temperature resistance.

Owner:袁景华 +1

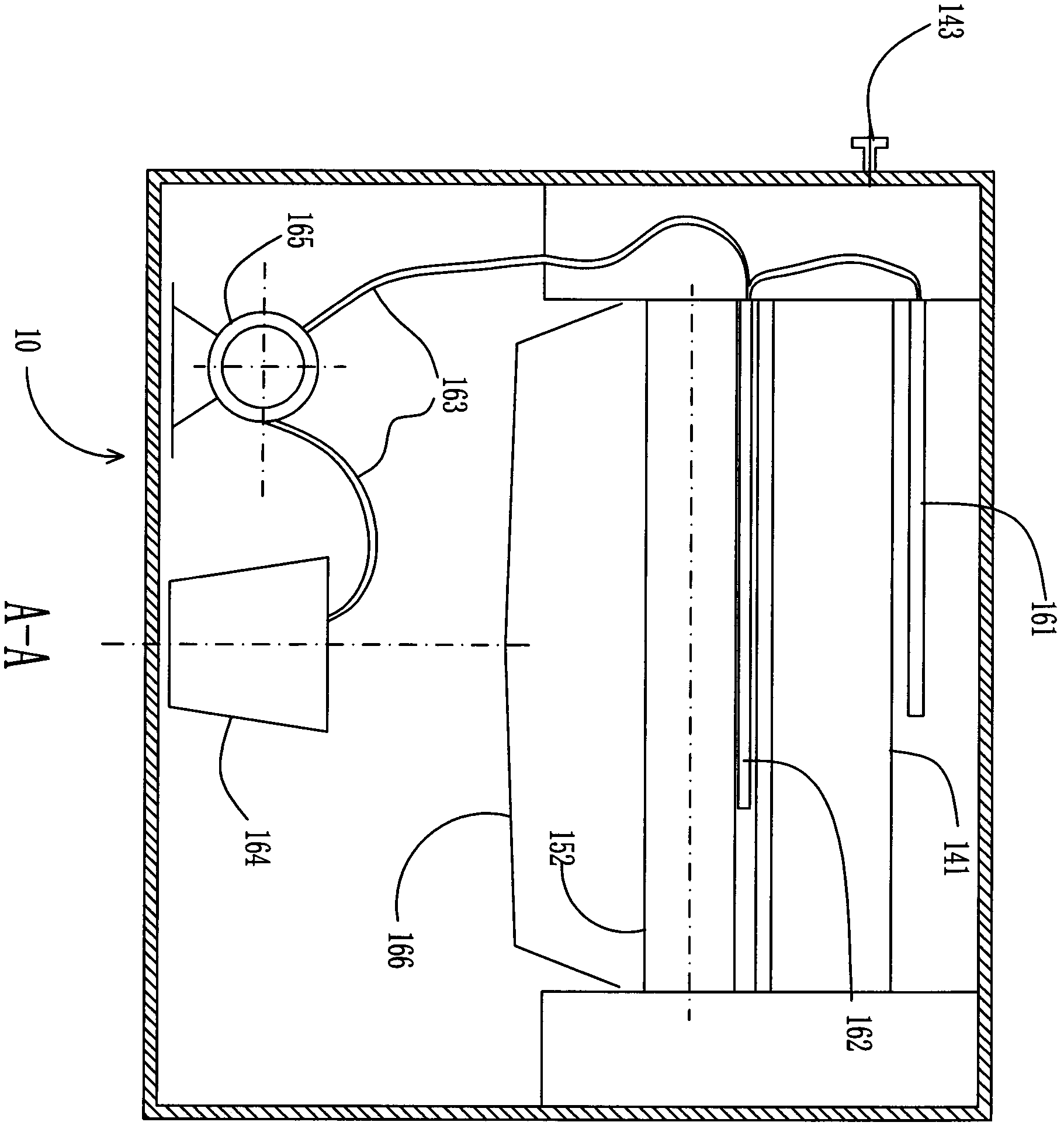

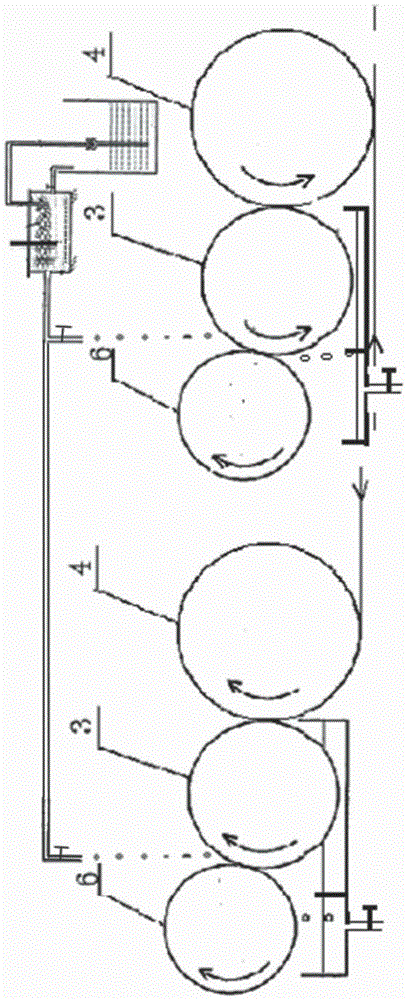

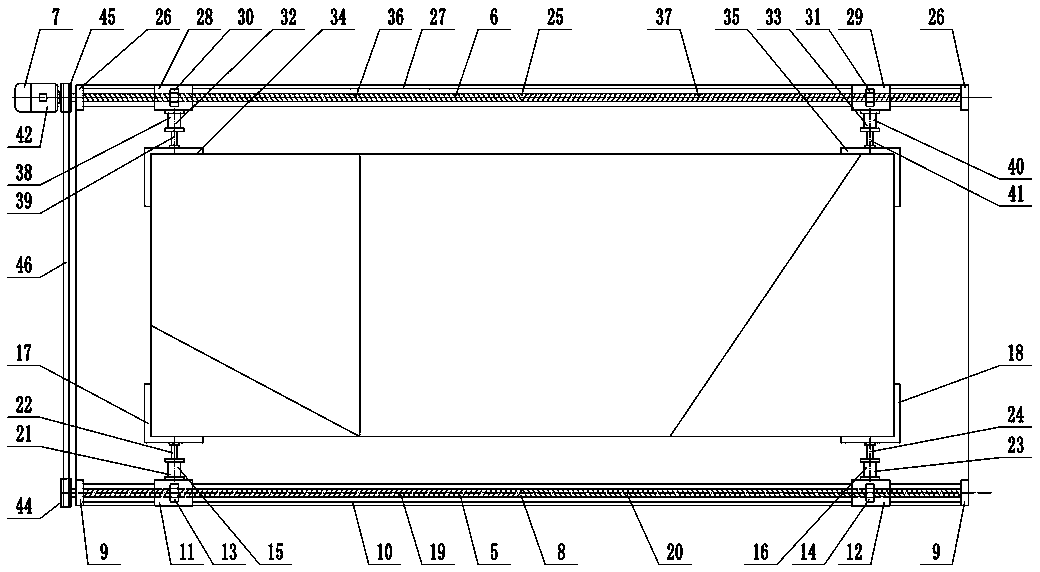

Continuous winding magnetic control sputtering vacuum coating device

InactiveCN101768726AComposable performancePrevent blowbyVacuum evaporation coatingSputtering coatingEngineeringControl room

The invention belongs to continuous coating device for solar selective absorption coating in plate-type solar apparatus, in particular relates to a continuous winding magnetic control sputtering vacuum coating device. The continuous winding magnetic control sputtering vacuum coating device comprises an unwinding chamber, a winding chamber, tension controlling chambers, a pre-processing chamber and craft chambers; the unwinding chamber and the winding chamber are respectively arranged at the head and tail ends of the device and respectively connected with a tension controlling chamber; the tension controlling chamber at one end of the unwinding chamber is connected with the pre-processing chamber; at least one craft chamber is arranged between the pre-processing chamber and the tension controlling chamber at one end of the winding chamber; one end of unwinding chamber, one end of winding chamber, two ends of tension controlling chambers, two ends of pre-processing chamber, and two endsof craft chambers are provided with flange plates of the same dimension, the unwinding chamber, the winding chamber, the tension controlling chambers, the pre-processing chamber and the craft chambers are connected into an integral by the flange plates. The invention provides a special coating device for long-term continuous solar selective absorption coating, and the device has the advantages ofhigh production efficiency, stable quality and outstanding film performance.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

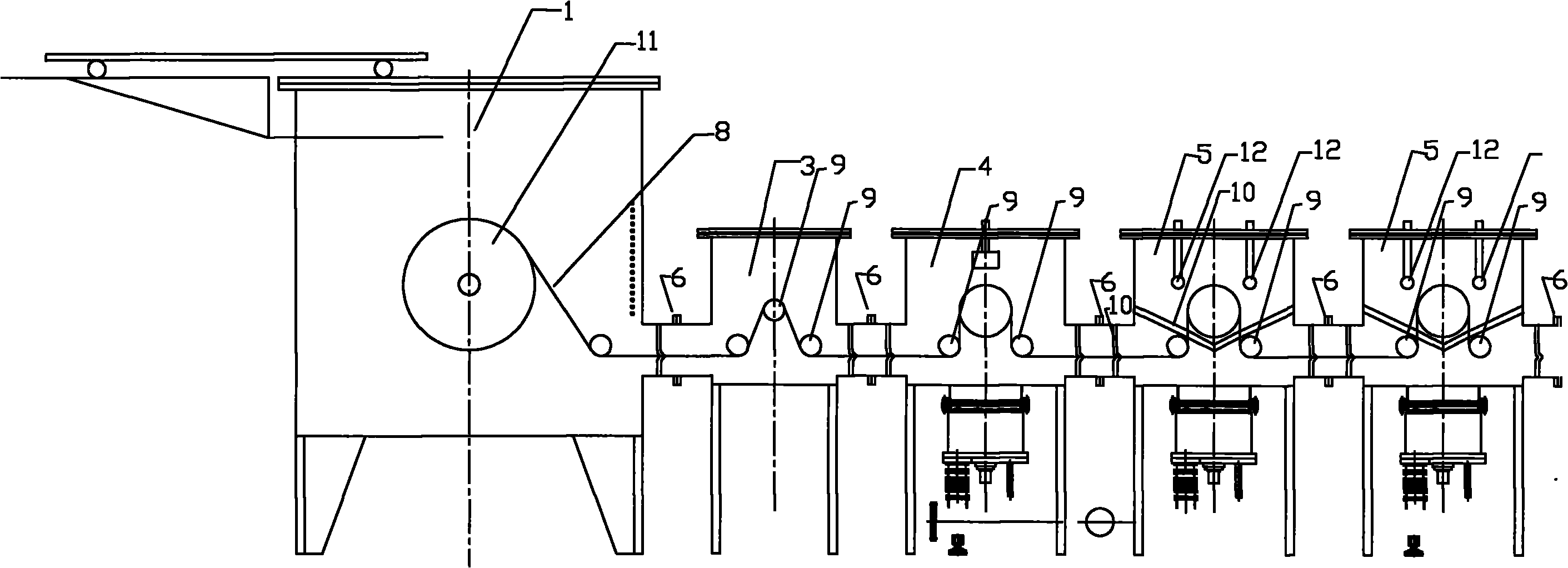

Automobile body color register coating process

InactiveCN103128042AGood coating effectImprove coating qualityPretreated surfacesSpecial surfacesPoint plottingSpray coating

The invention discloses an automobile body color register coating process. By means of the process steps of drawing confirming, automobile body cleaning, point plotting, location, contour line adhesion, polishing, roughening, cleaning, dust removing, shielding, protection, spray coating, shield removing, miscellaneous paint removing, drying and maintaining which are conducted successively, total planning is conducted to coating work by means of drawings before coating work, locating, wire drawing and other process construction processes are accurate and reliable, and the polishing and roughening processes are conducted before an non-color-register area is shielded. Particles produced in a polishing process are effectively prevented from being adsorbed to the shielded part of the non-color-register area, and a total coating effect and coating quality of the automobile body color register coating process are effectively improved.

Owner:LIUZHOU WULING MOTORS +1

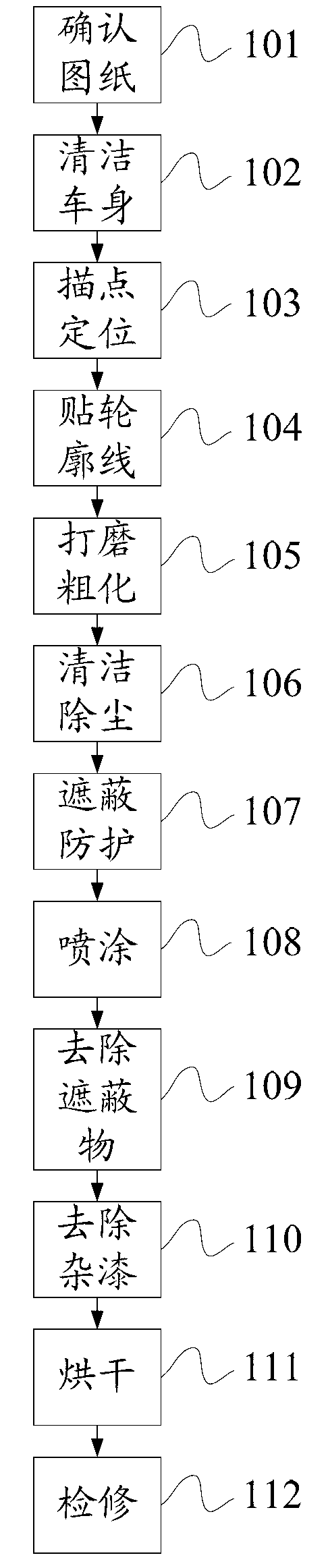

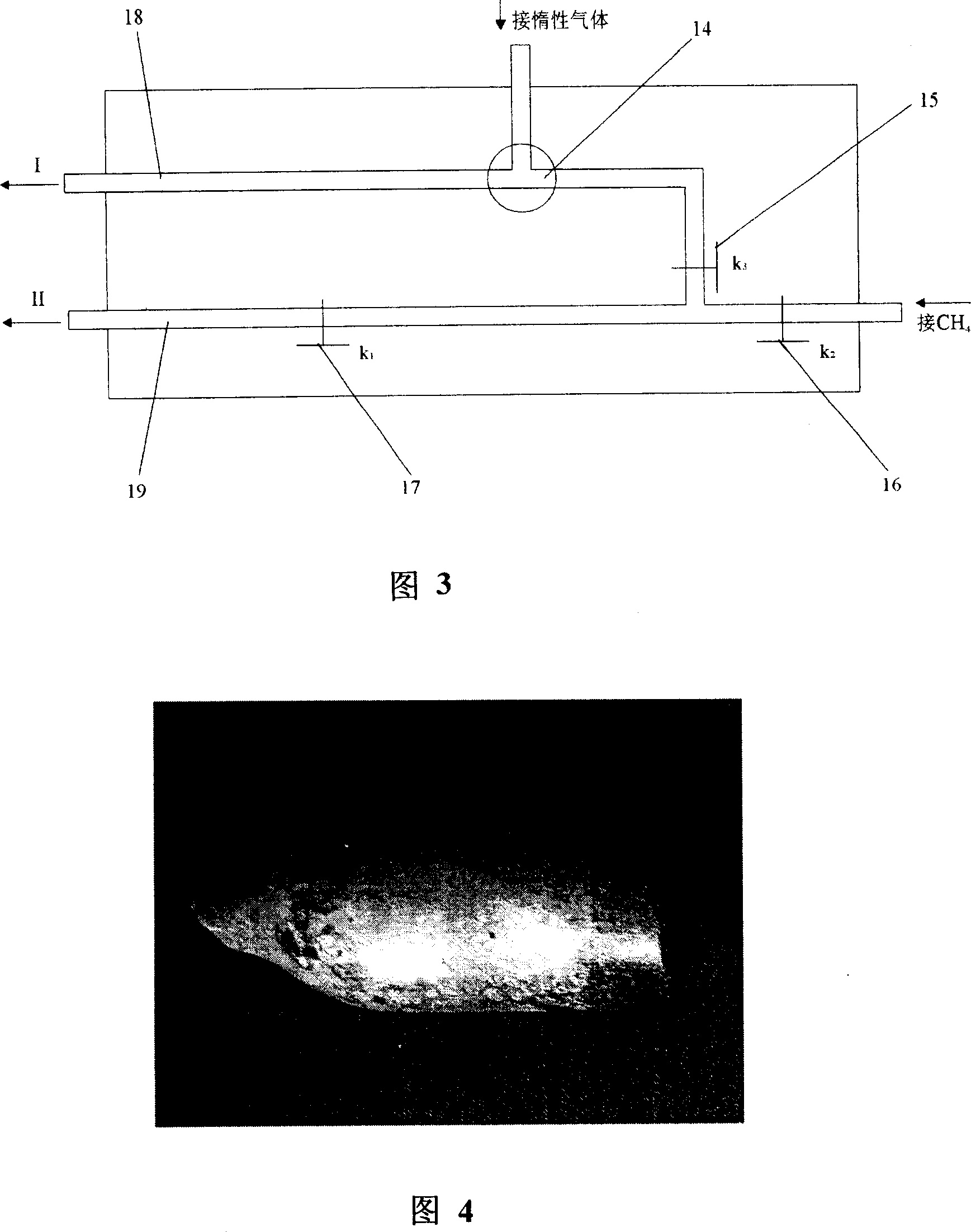

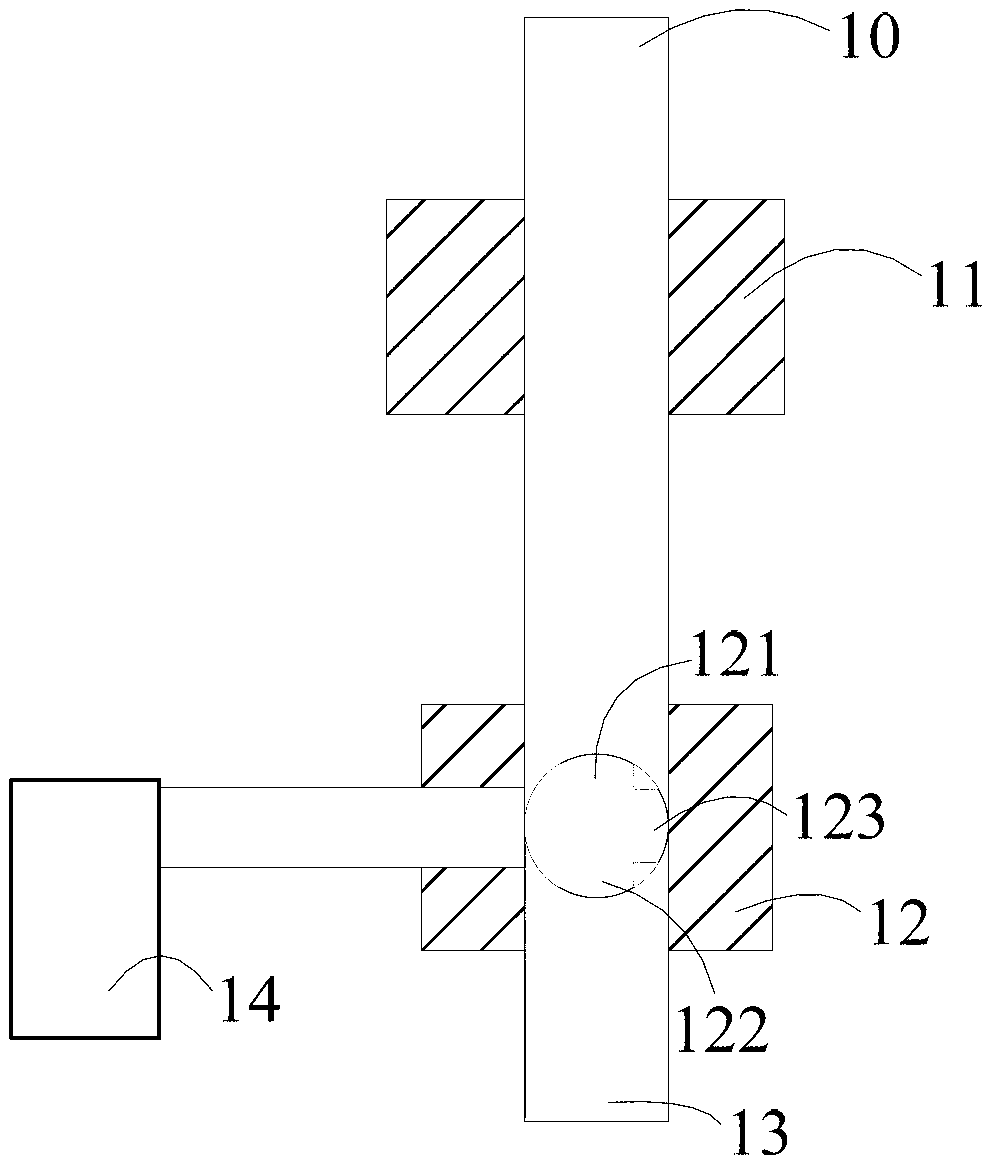

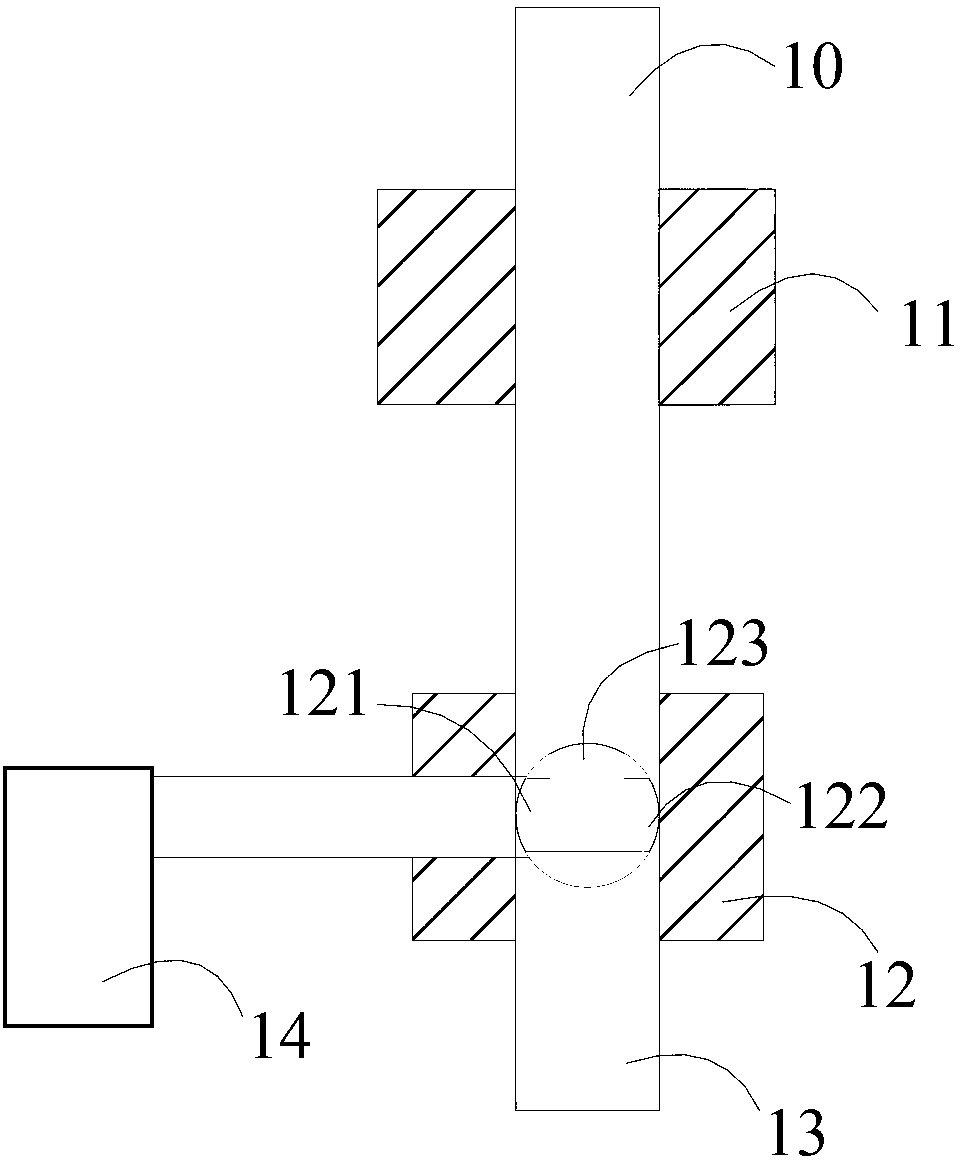

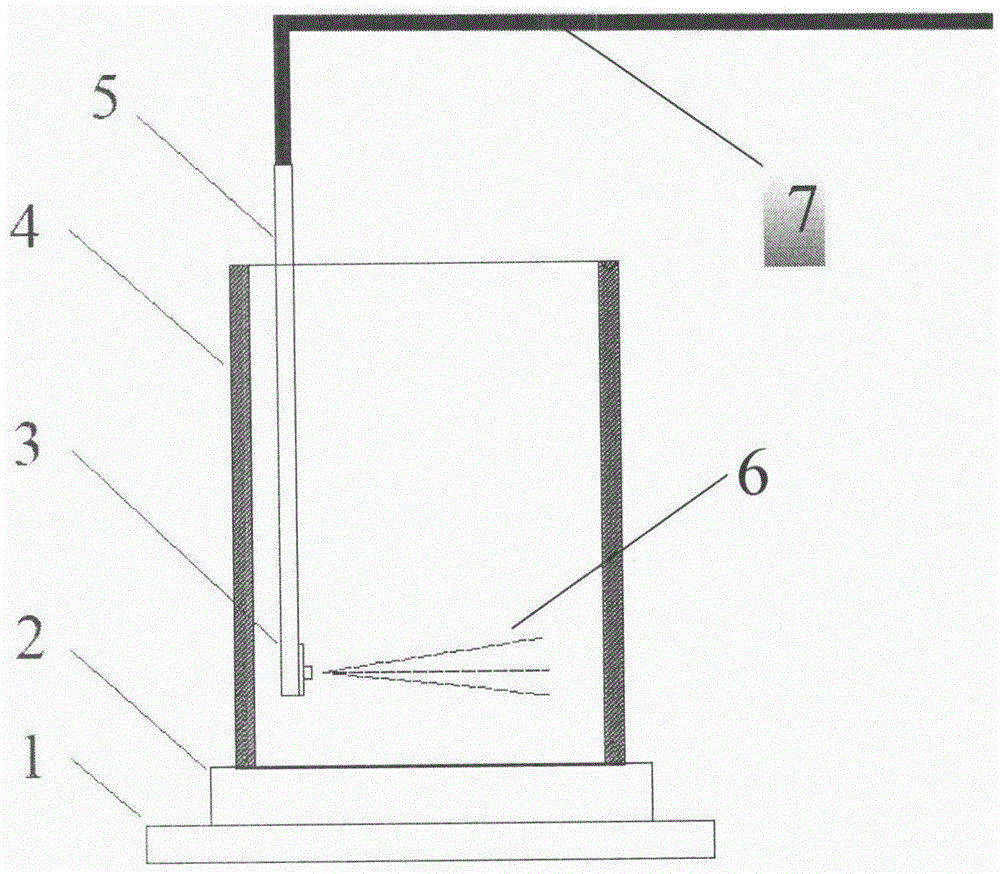

Carbon film coating method and device for quartz crucible for use in crystal growth

InactiveCN1962933AEvenly distributedHigh purityFrom frozen solutionsChemical vapor deposition coatingCarbon filmMethane gas

The invention discloses a quartz copple carbon film depositing method to grow crystal, which comprises the following steps: cleaning and drying the quartz copple; assembling the cleaned and dried quartz copple and film deposited device; heating sediment chamber with quartz copple at 1000-1060 Deg C; insulating; aerating high-purity inert gas into quartz copple and sediment chamber to drain the residual air; insulating at 1000-1060 Deg C; aerating methane gas; sedimenting carbon film on the inner wall of quartz copple; insulating at 1000-1060 Deg C for 40-60min; cooling slowly to indoor temperature. The carbon film depositing device is composed of heating furnace, sediment chamber to place deposited quartz copple and gas-supplying controller.

Owner:SICHUAN UNIV

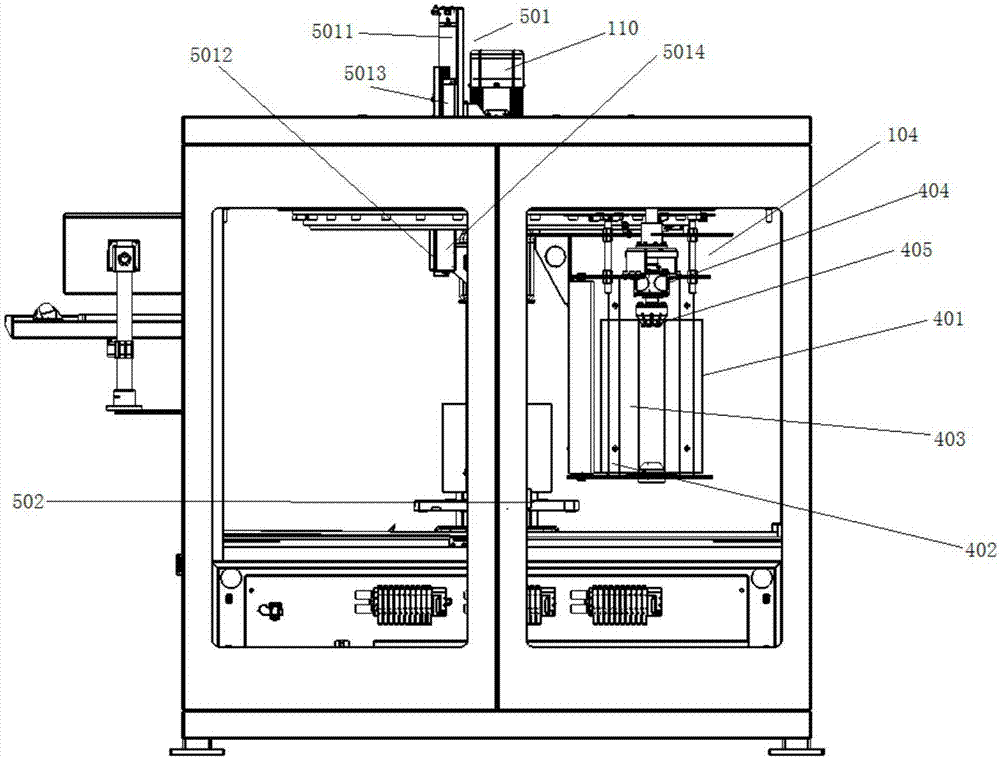

Frame seal glue coating device and method

ActiveCN103056064AImprove yieldGuarantee coating qualityLiquid surface applicatorsCoatingsControl unitAir bubble

The invention discloses a frame seal glue coating device. The frame seal glue coating device comprises a glue storage unit, an air bubble sensing unit, a flow direction control unit and a nozzle, wherein the glue storage unit is used for storing frame seal glue, and the air bubble sensing unit is used for sensing whether air bubbles are generated in the frame seal glue flowing to the nozzle from the glue storage unit; and the flow direction control unit controls the frame seal glue without the air bubbles to flow out of the nozzle so as to carry out a frame seal procedure, and controls the frame seal glue with the air bubbles not to reach the nozzle. The frame seal glue coating device provided by the invention can guarantee that the residual air bubbles are avoided in the frame seal glue in the frame seal procedure, thereby avoiding a glue suspending or glue breaking phenomenon of the frame seal glue which is coated on an array baseplate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

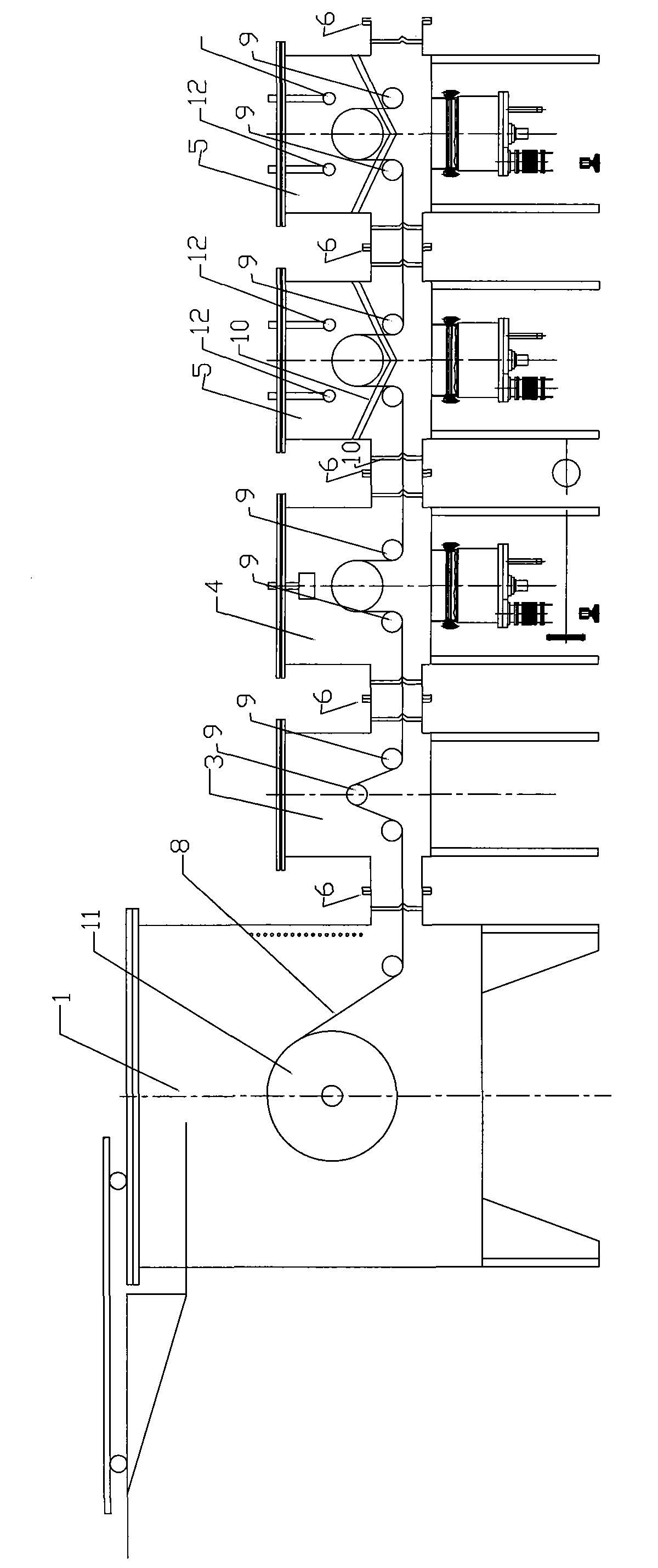

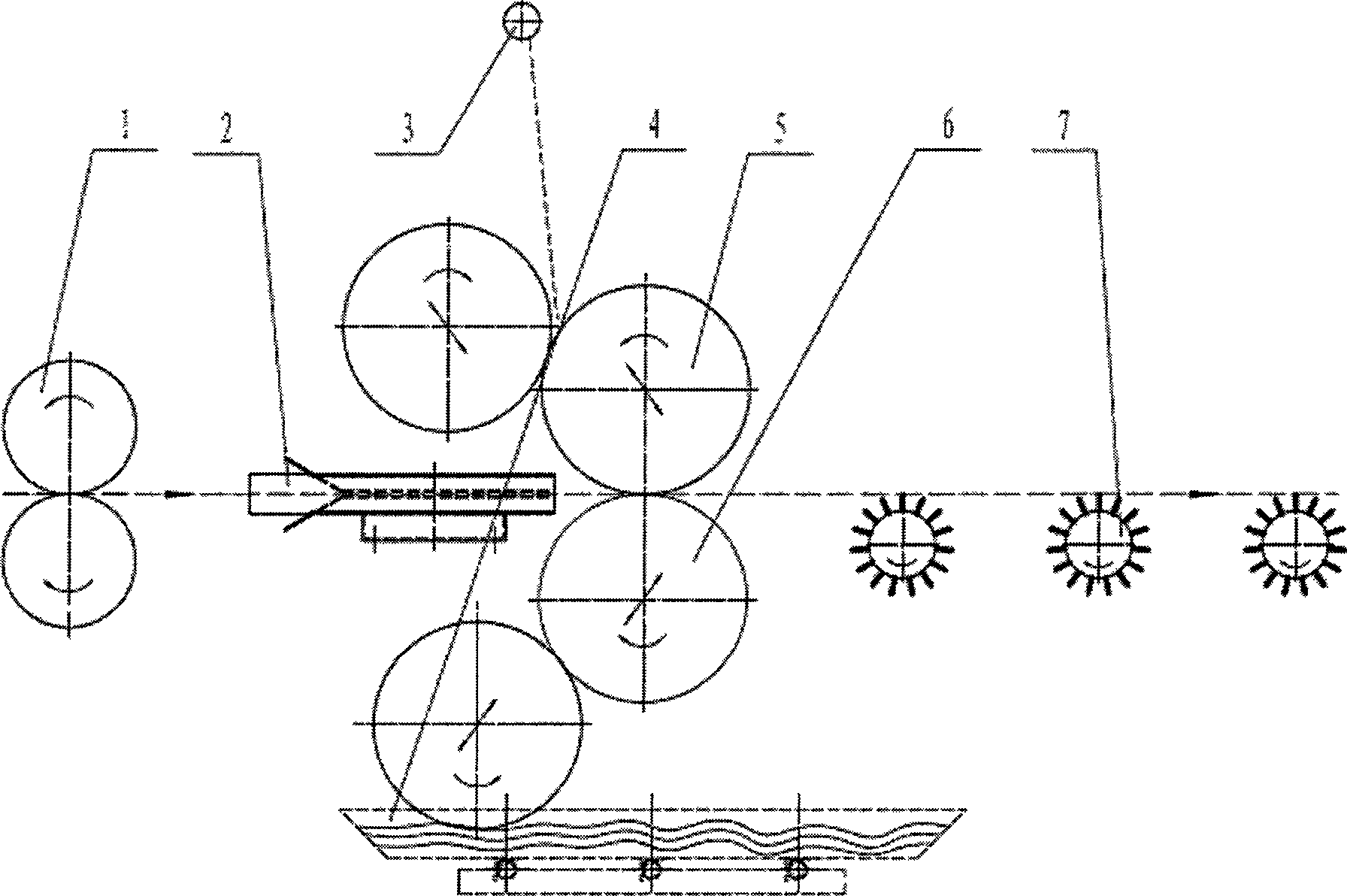

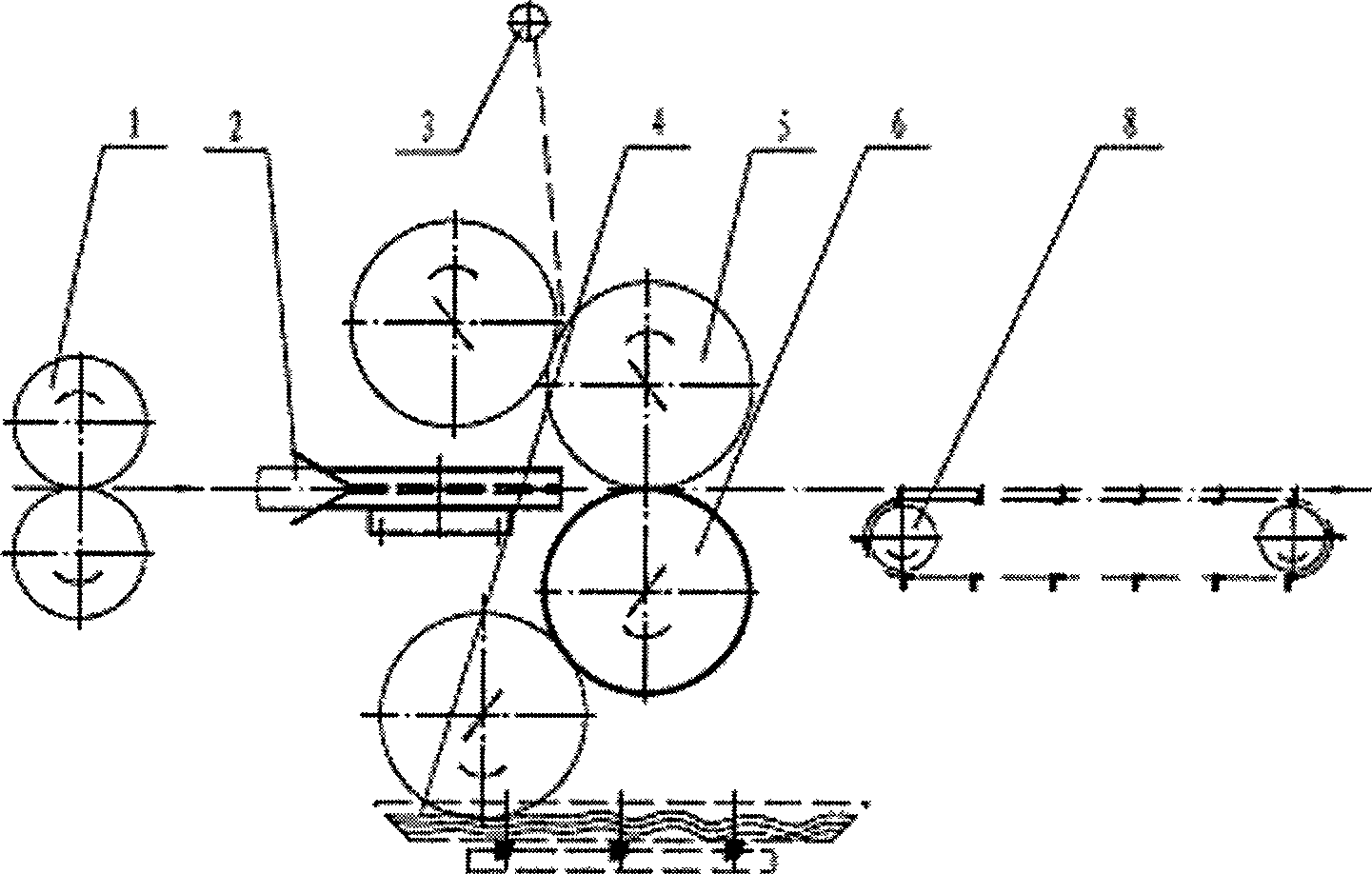

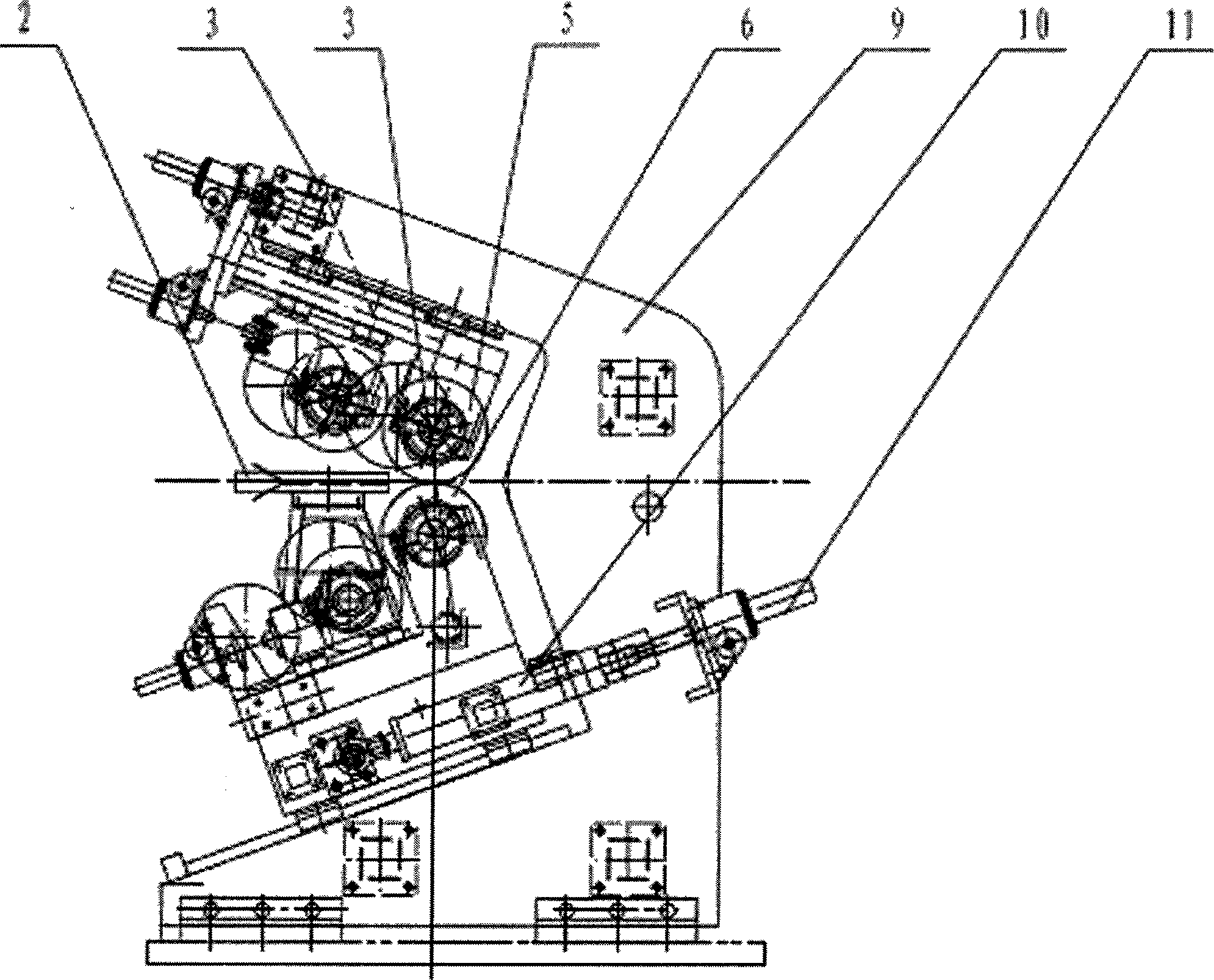

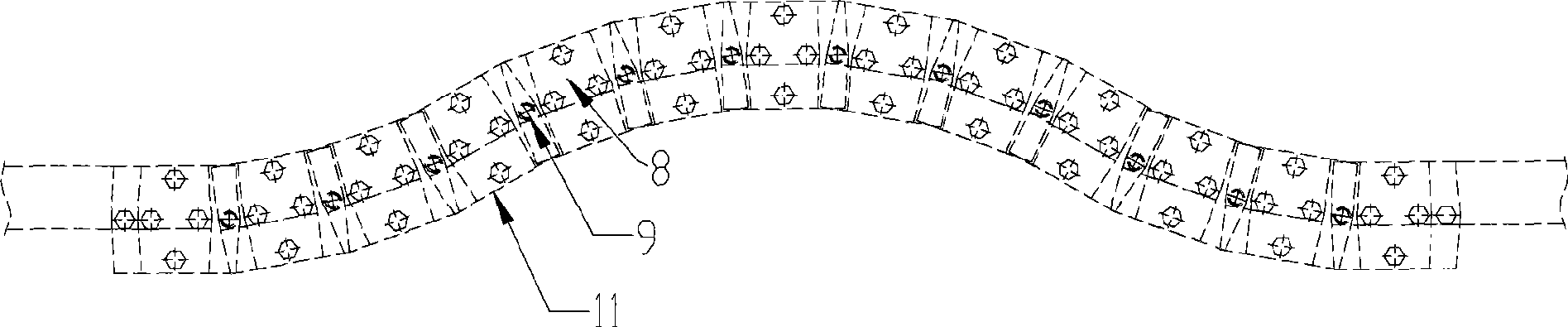

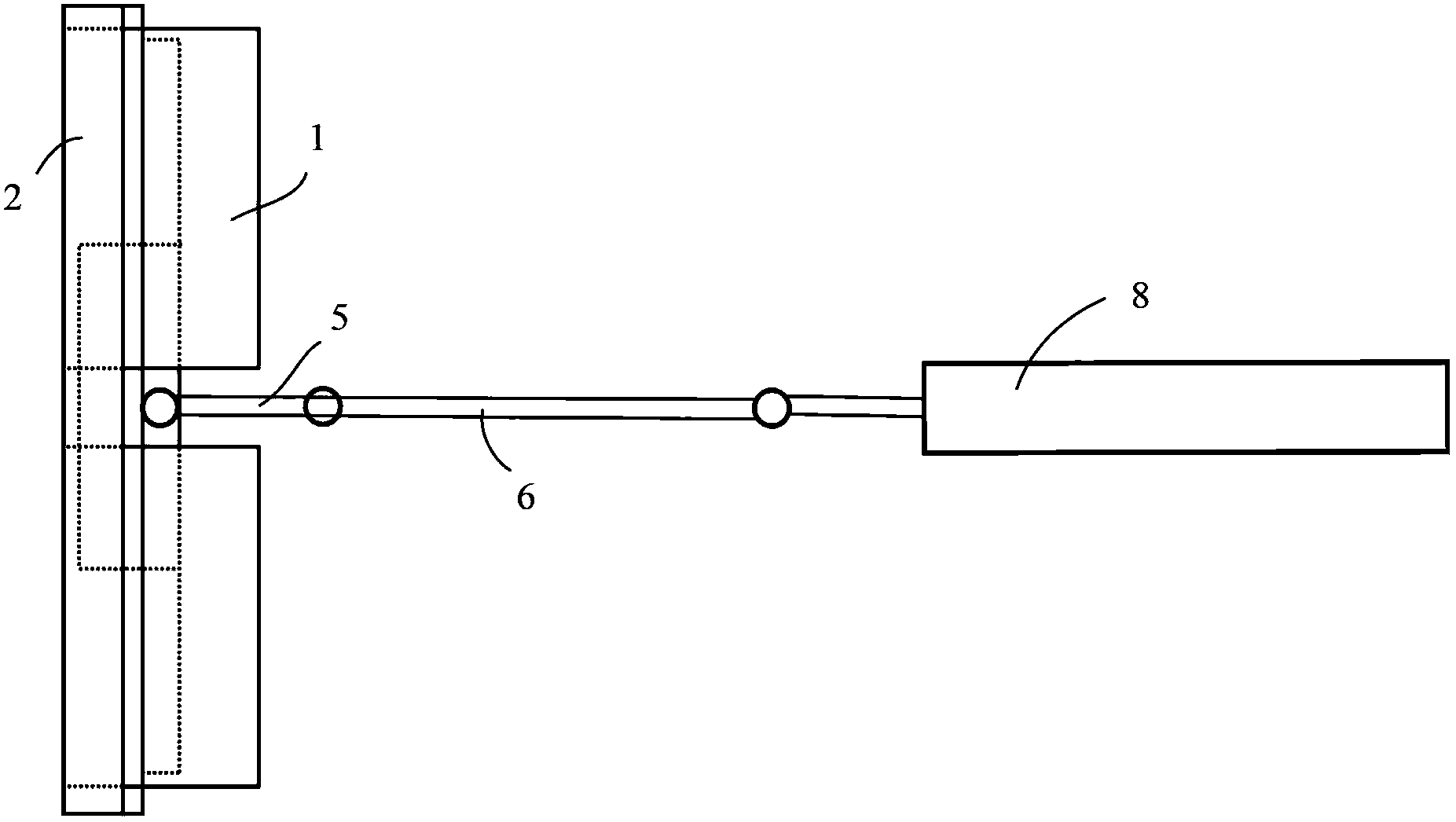

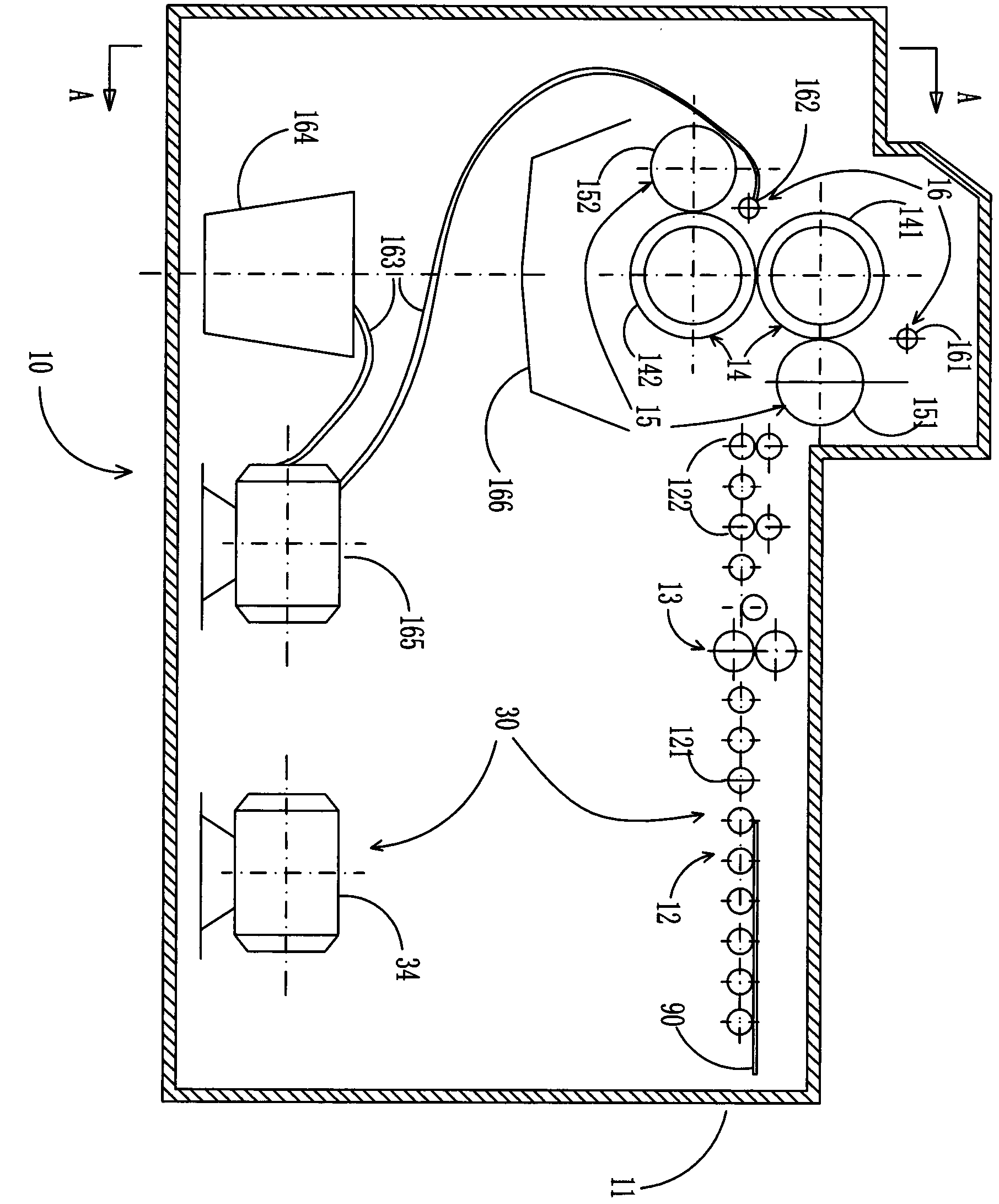

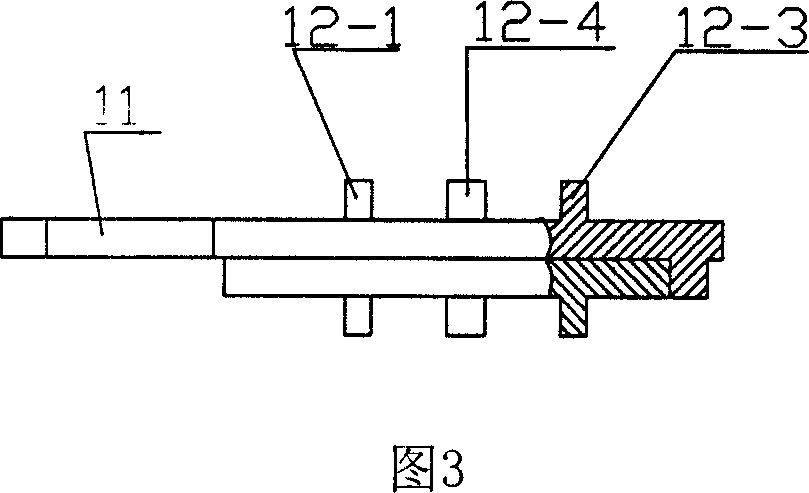

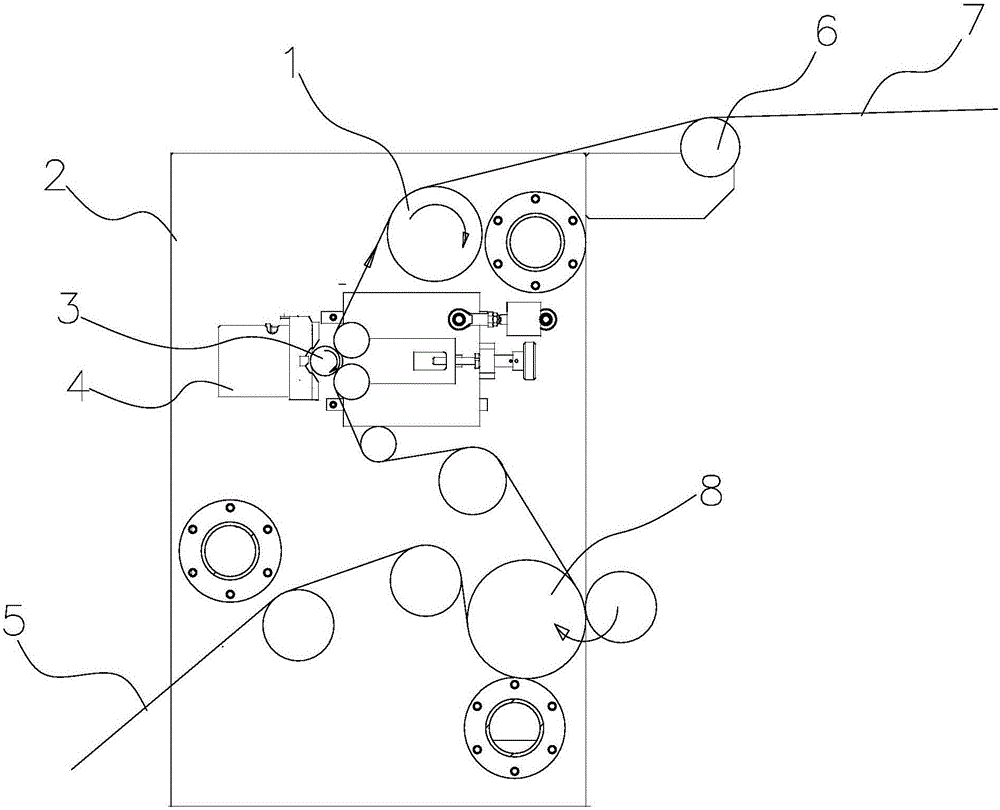

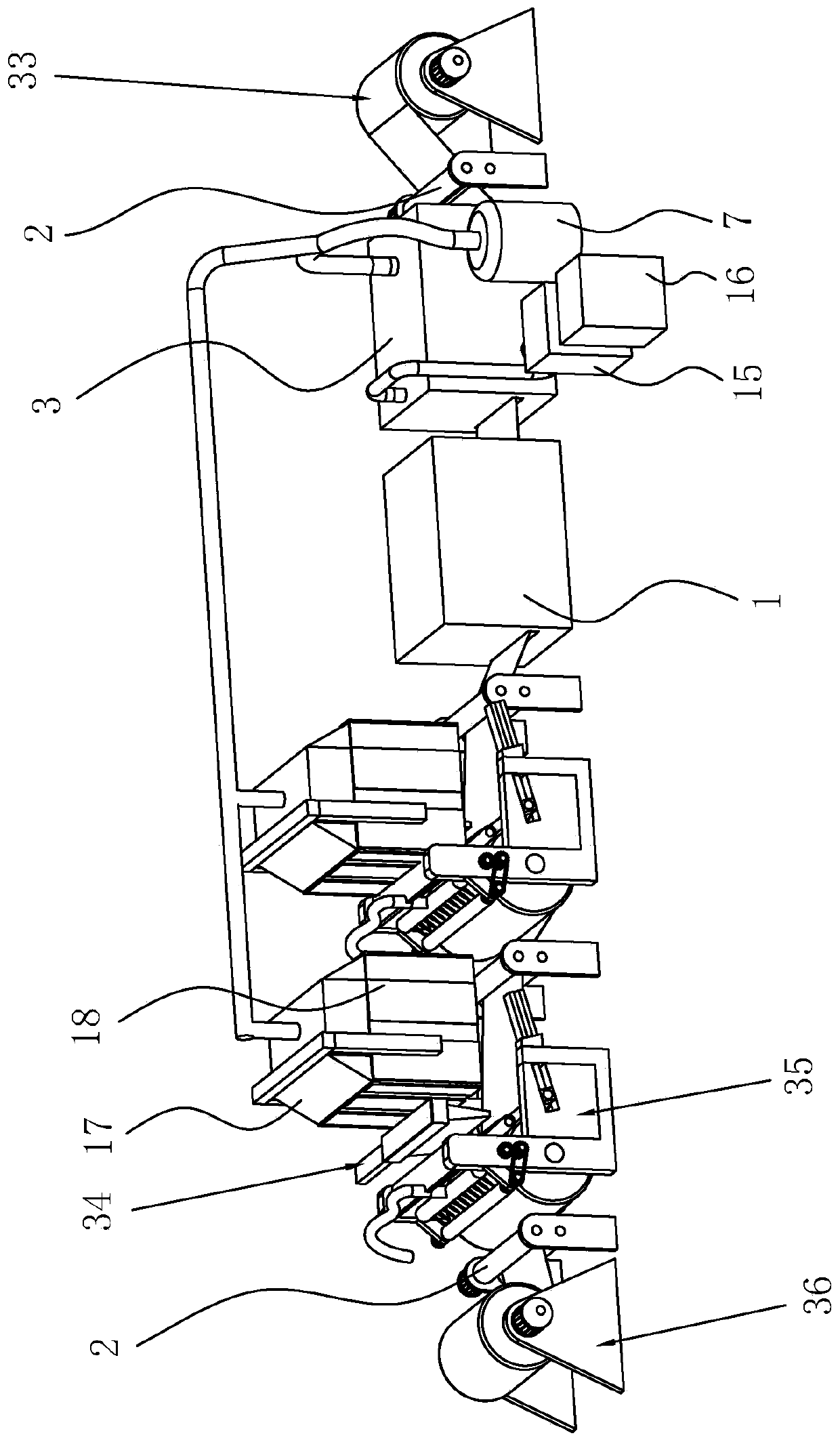

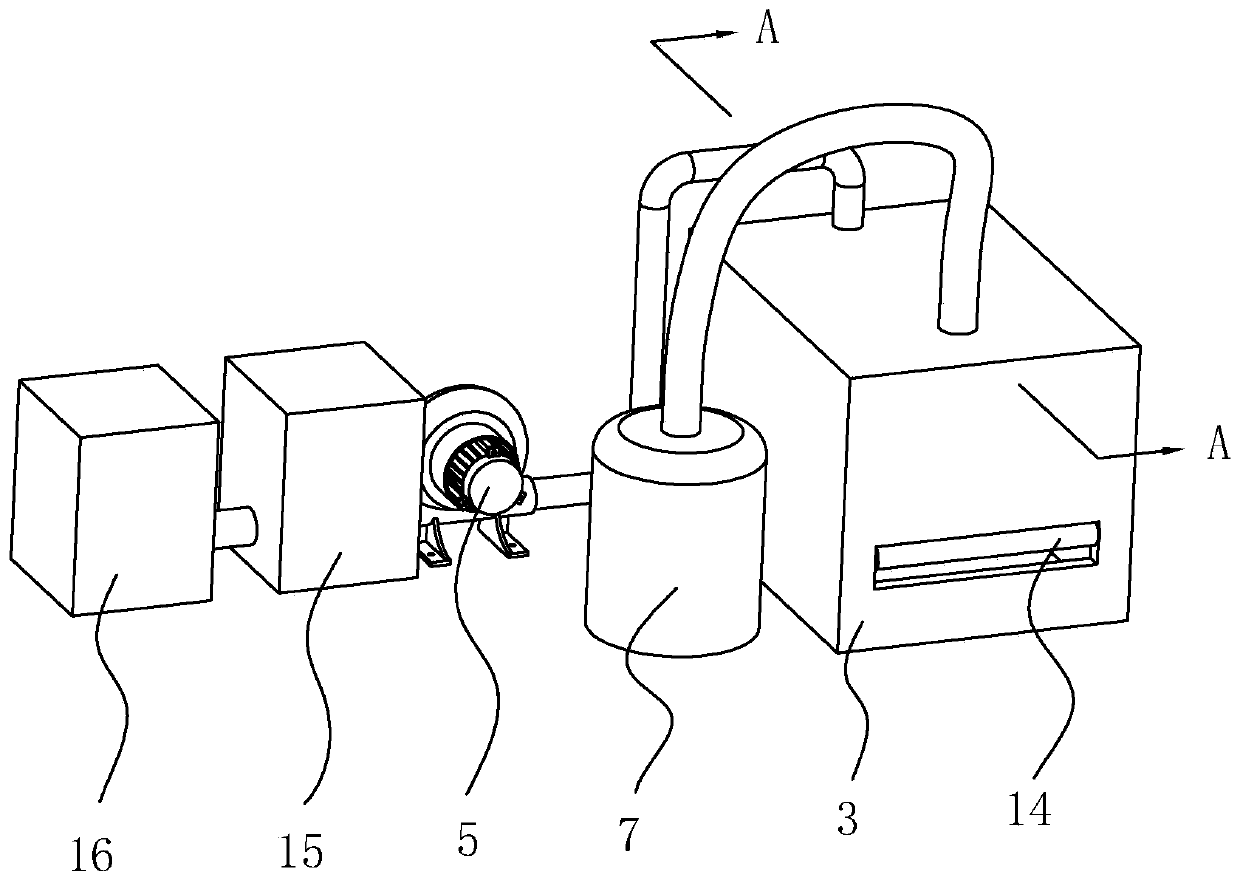

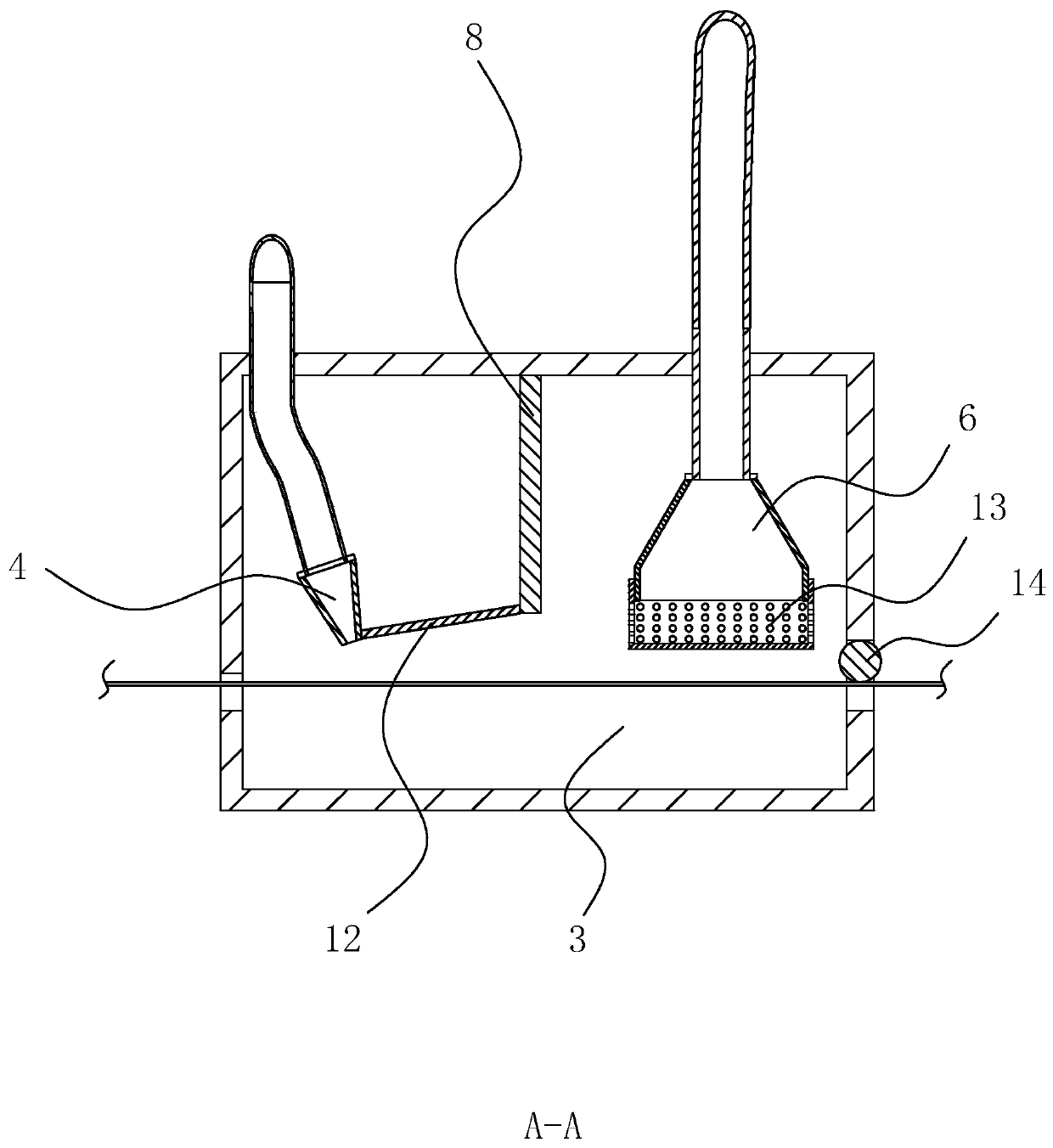

Single sheet type sheet metal roll coating mechanism

InactiveCN101474607AQuality improvementEasy curingLiquid surface applicatorsCoatingsSheet steelLacquer

The invention provides a single metal sheet roller coating mechanism, which is applicable to coating of chemical coatings. The invention is characterized in that the roller coating mechanism consists of a pair of pinch rolls 1, a material guiding section 2, a single-sheet roller coater, a pin-wheel-type conveyer 7 or a chain-type conveyer 8. An electric appliance is used to control synchronization of speed of the adopted pinch rolls 1, the single-sheet roller coater, the pin-wheel-type conveyer 7 or the chain-type conveyer 8, thereby ensuring coating quality. Inlet of the material guiding section 2 is provided with a horn-mouth-type structure, so as to facilitate leading in of steel plates; the material guiding section 2 and the steel plate can contact in a rolling way or a sliding way. The incoming materials can be carried by a lacquer disc or be sprayed by a spray nozzle on a spray tube. Each roller can be adjusted jointly or individually. A lower rolling system 6 can be rapidly adjusted by an oil cylinder. Such a structure mode can realize double-surface coating, thereby reducing material sticking to the maximum. Synchronization of front and rear conveying can ensure coating quality, save time and improve production efficiency.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

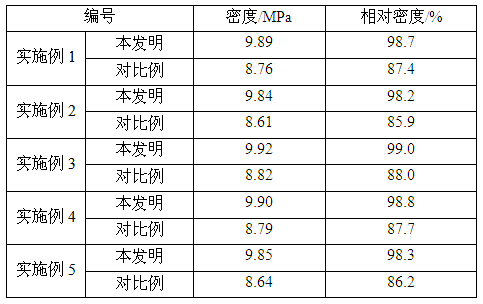

High-density molybdenum-niobium alloy target and preparation process thereof

InactiveCN105648407ALow costPrevent splashVacuum evaporation coatingSputtering coatingZirconium hydrideHydrogen atmosphere

The invention discloses a high-density molybdenum-niobium alloy target and a preparation process thereof. The preparation process comprises the following steps: firstly, the following components are weighed in percentage by weight: 5-15% of niobium powder, 0.1-0.8% of zirconium hydride and the balance of molybdenum powder; the components are molded through cold isostatic pressing after grinding and uniform mixing, and are sintered in vacuum; or, the components are sintered in vacuum after presintering in a hydrogen atmosphere; and finally, the machining is performed to obtain the high-density molybdenum-niobium alloy target. The high-density molybdenum-niobium alloy target is directly prepared by using a general powder metallurgy process and an activation effect of zirconium hydride, so that the process is simple, and the cost is low; and meanwhile, the particle splashing caused by air holes is prevented, the film plating quality is guaranteed, and the defects as thick structure and nonuniform components in a smelting foundary process, carburization and high cost in a hot pressing and hot isostatic pressing process and long flow and low yield in forging or rolling are overcome.

Owner:ZHENGZHOU UNIV

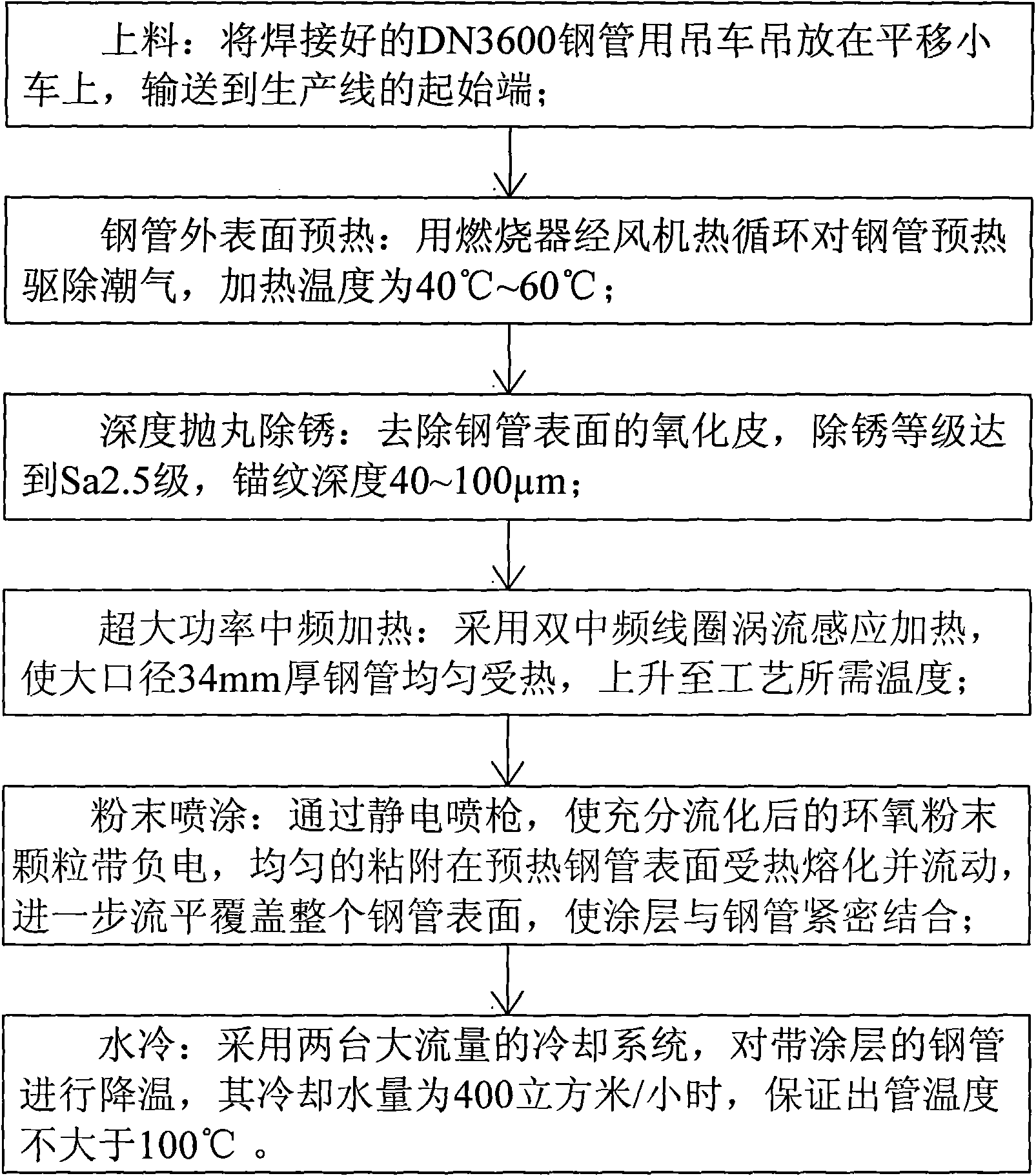

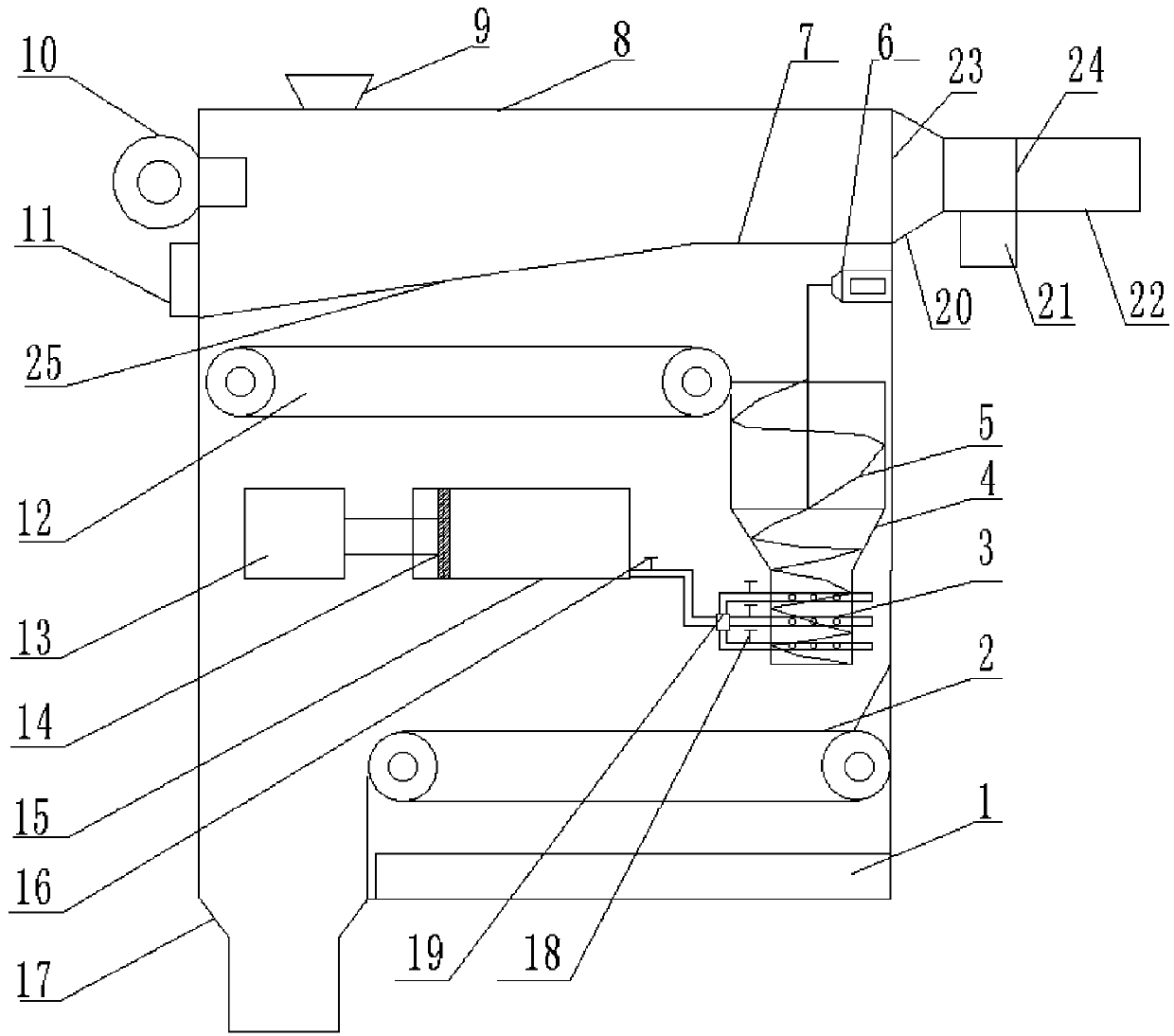

Method for carrying out outer anticorrosion on DN3600 buried steel tube by adopting molten epoxy powder

InactiveCN101602043AGuaranteed coating environmentGuaranteed coating effectPretreated surfacesCoatingsEpoxyMetallurgy

The invention relates to a method for carrying out outer anticorrosion on a DN3600 buried steel tube by adopting molten epoxy powder, and belongs to the field of anticorrosion of tube materials. A coating process comprises material loading, preheating of the outer surface of the steel tube, deep shot blasting and derusting, superlarge power medium-frequency heating, powder spraying and coating and water cooling. Aiming at the characteristics of large diameter and extremely-small rate of the wall thickness to the diameter of a large-diameter buried steel tube with DN3600 millimeter and more than DN3600 millimeter, the method optimizes the whole machining process, controls the velocity of temperature rising, heating and cooling through the control of a moving speed of the steel tube, ensures the coating environment and the coating effect of the steel tube and the adhesion effect of a coating layer and ensures that the quality of an outer anticorrosive coating layer of the large-diameter buried steel tube meets the relevant quality acceptance standards of the state.

Owner:SHANGHAI JIANZHIZHEN ANTI CORROSION TECH DEV

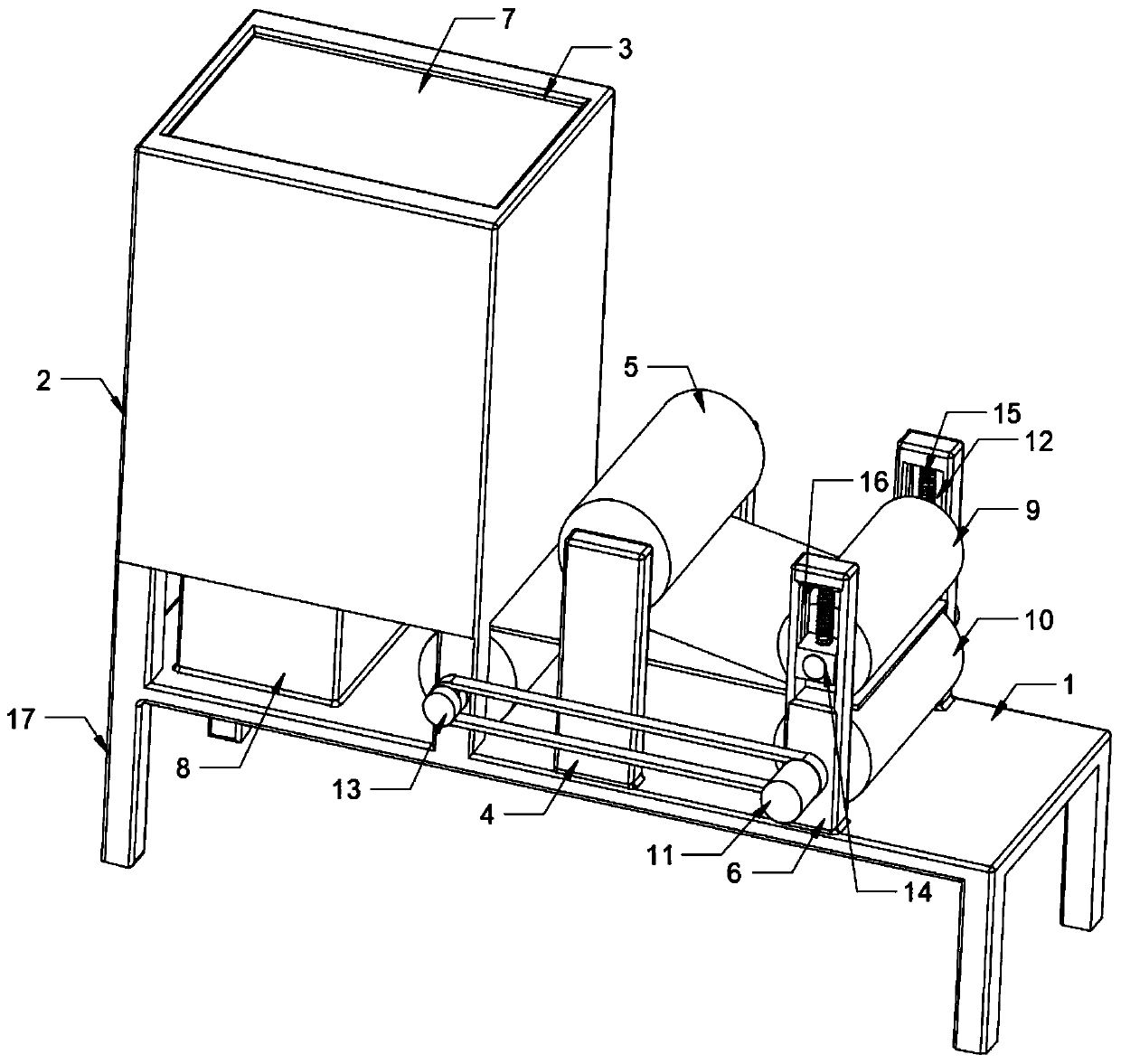

A seed coating machine provided with a dust collector

InactiveCN107771456AGuarantee coating qualityEasy to controlGas current separationCleaning using gasesLiquid wasteBiochemical engineering

The invention discloses a seed coating machine with a dust removal device, which belongs to the technical field of seed coating equipment, and solves the problem that the impurities in the seeds are coated together without impurity removal before seed coating, and the seed coating solution is wasted , including the box, the box is provided with a first filter screen below the feed inlet, a blower is provided on the side wall of the box body, the first filter screen is arranged in an inclined manner, and the end close to the blower is the low end of the first filter screen, The high end of the first filter screen is 8-10cm lower than the blower, the high end of the first filter screen is provided with a flat plate connected to the box, the first conveying device and the mixing bucket are arranged under the first filter screen, and the inside of the mixing tank is provided with Spiral feeder, with multiple spray heads on the lower part of the mixing barrel; an air storage tank and a medicine box under the first conveying device, and a second conveying device and a heating device under the stirring barrel; the side of the box connected to the flat plate A negative pressure device is arranged on the wall, and the negative pressure device includes a negative pressure cover and a negative pressure tube arranged on the negative pressure cover.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

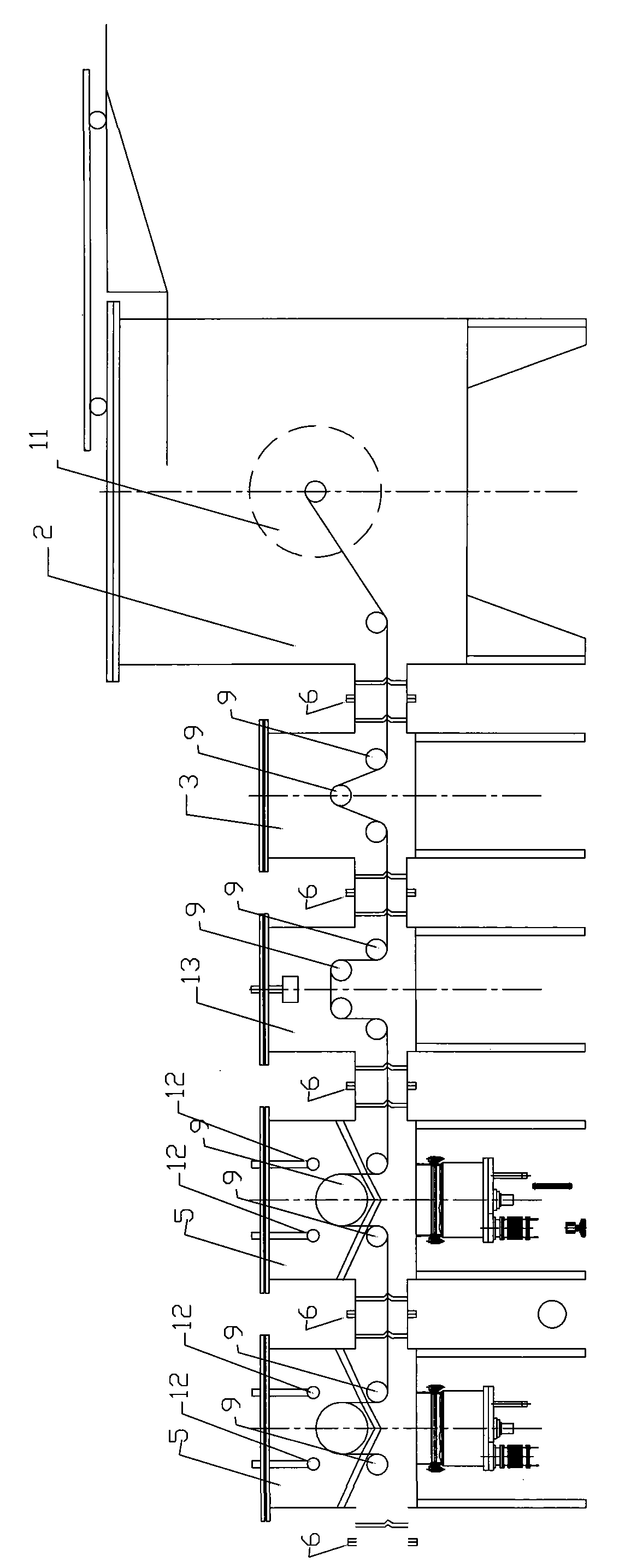

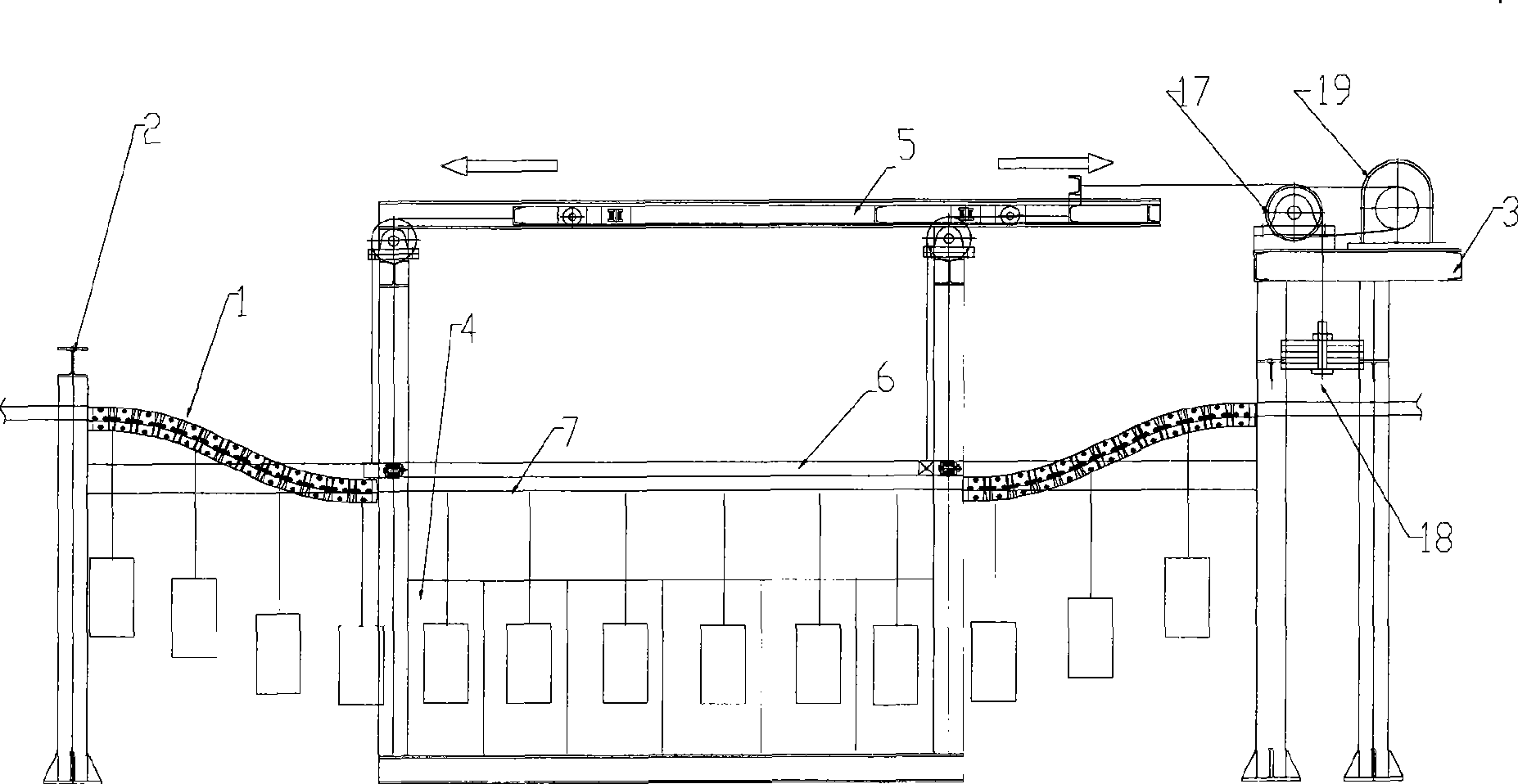

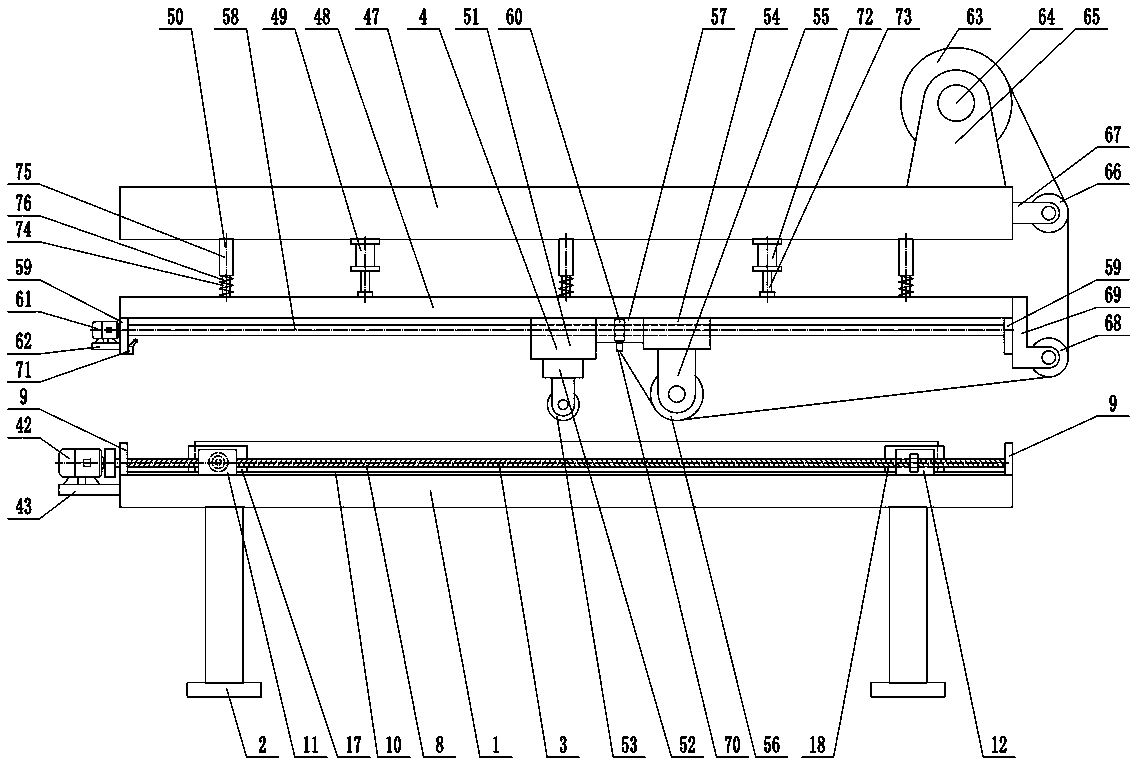

Flexible marching type continuous conveying system

InactiveCN101397090ALow investment costReduce labor intensityConveyorsCharge manipulationElectrophoresisDelivery system

The invention provides a flexible stepping-typed continuous conveying system. In the flexible conveying system, a traditional conveying chain track is shaped as a fixed chain track, based on which a flexible stepping-typed continuous conveying system which is really applicable to surface treatment and coating industry is developed; the key technique is composed of four parts: a flexible chain track, a horizontal translation pulley, an upper / lower lifting pulley and a stepping-typed continuous conveyor and the four parts form a whole flexible stepping-typed continuous conveying system equipment; the equipment can be applied to the pre-processing of a workpiece and can be widely applied to an electrophoresis dressing technique and a painting and coating technique; the flexible stepping-typed continuous conveying system can save effective equipment occupancy space, can effectively improve the productivity, greatly reduces the labor intensity and ensures the quality of the coated products.

Owner:SHENZHEN LIUSH MACHINERY EQUIP

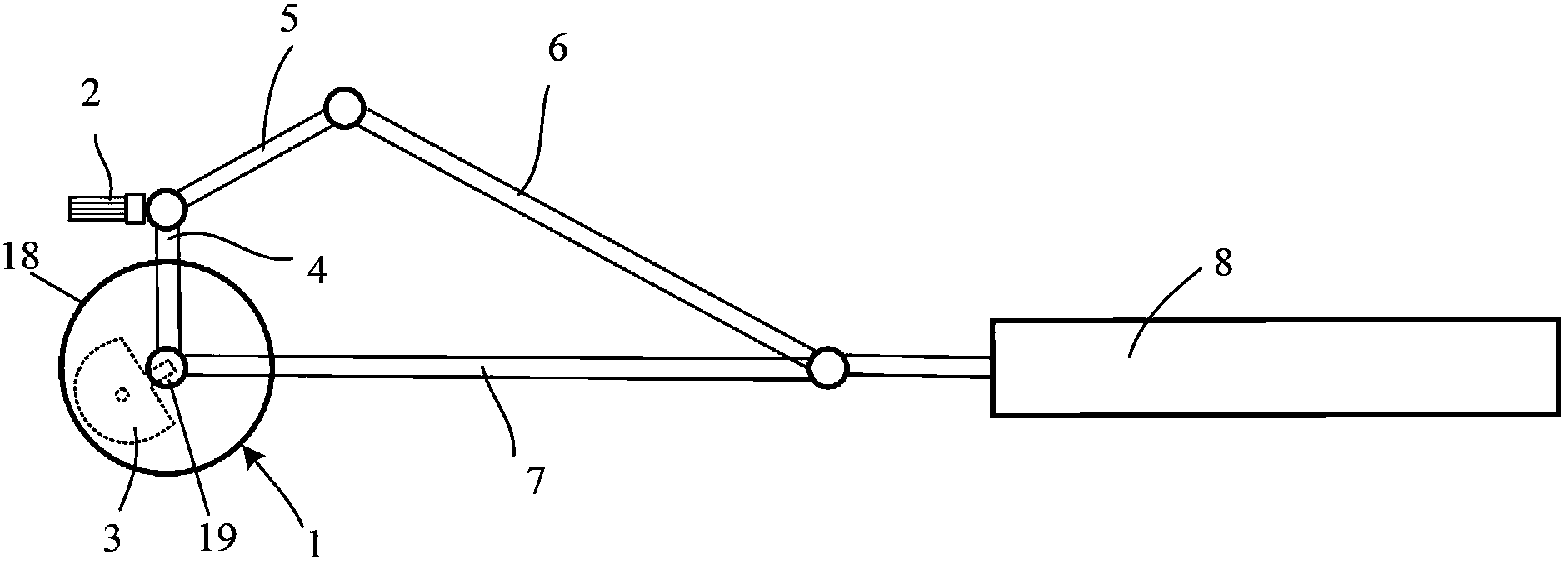

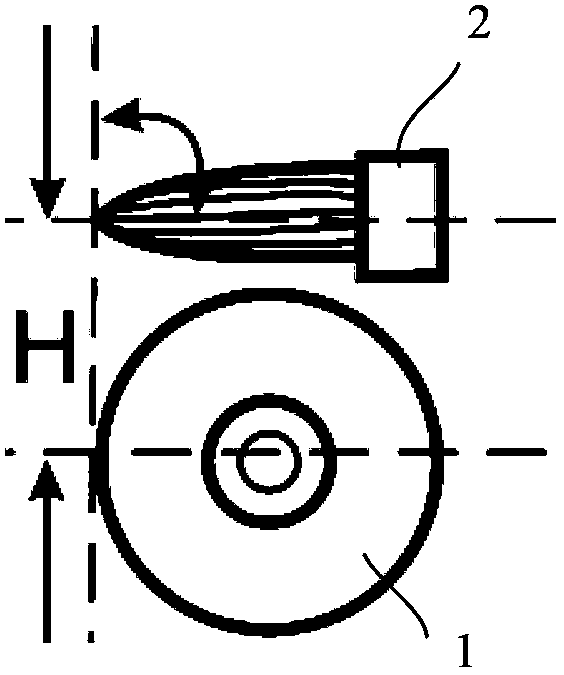

Painting brush coating and roller coating integrated device

ActiveCN103510689AGuaranteed constant angleFine brushing effectBuilding constructionsEngineeringGravity center

The invention provides a painting brush coating and roller coating integrated device. The painting brush coating and roller coating integrated device combines the advantages of the effects of brush coating and no dead corner with the advantage of coating efficiency of roller coating, so that while the coating quality is ensured, construction efficiency is improved, and coating period is shortened. The painting brush coating and roller coating integrated device is characterized by comprising a roller head, a brush head and a gravity constant device, the working position of the brush head is located above the roller head, the axial direction of the brush head is parallel with the axial direction of the roller head, the roller head comprises a roller core and a roller which is installed on the roller core in a freely rotary mode, the gravity constant device is connected with the brush head through a lever, the connection line of the gravity center of the gravity constant device and the supporting point of the lever deflects in the vertical direction, and the brush head and the gravity constant device are located on the same side of the lever, so that the gravity of the gravity constant device plays a role in hampering the brush head to enable the angle between the brush head and a working face to be constant.

Owner:NIPPON PAINT CHINA

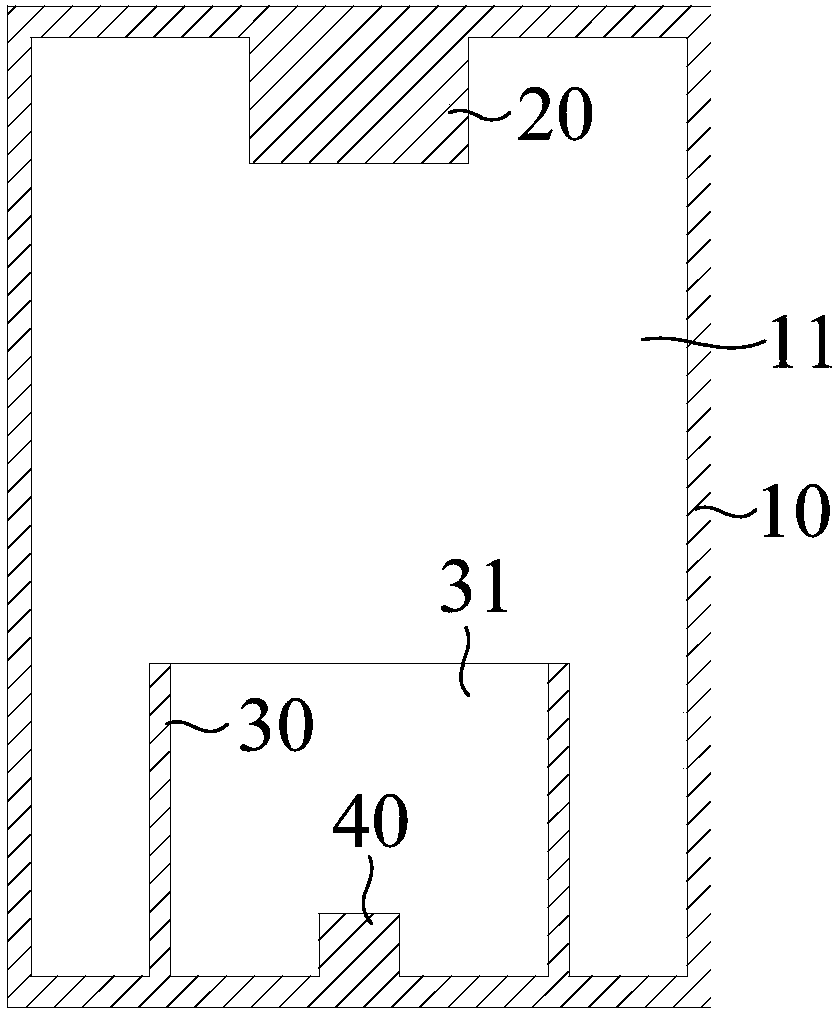

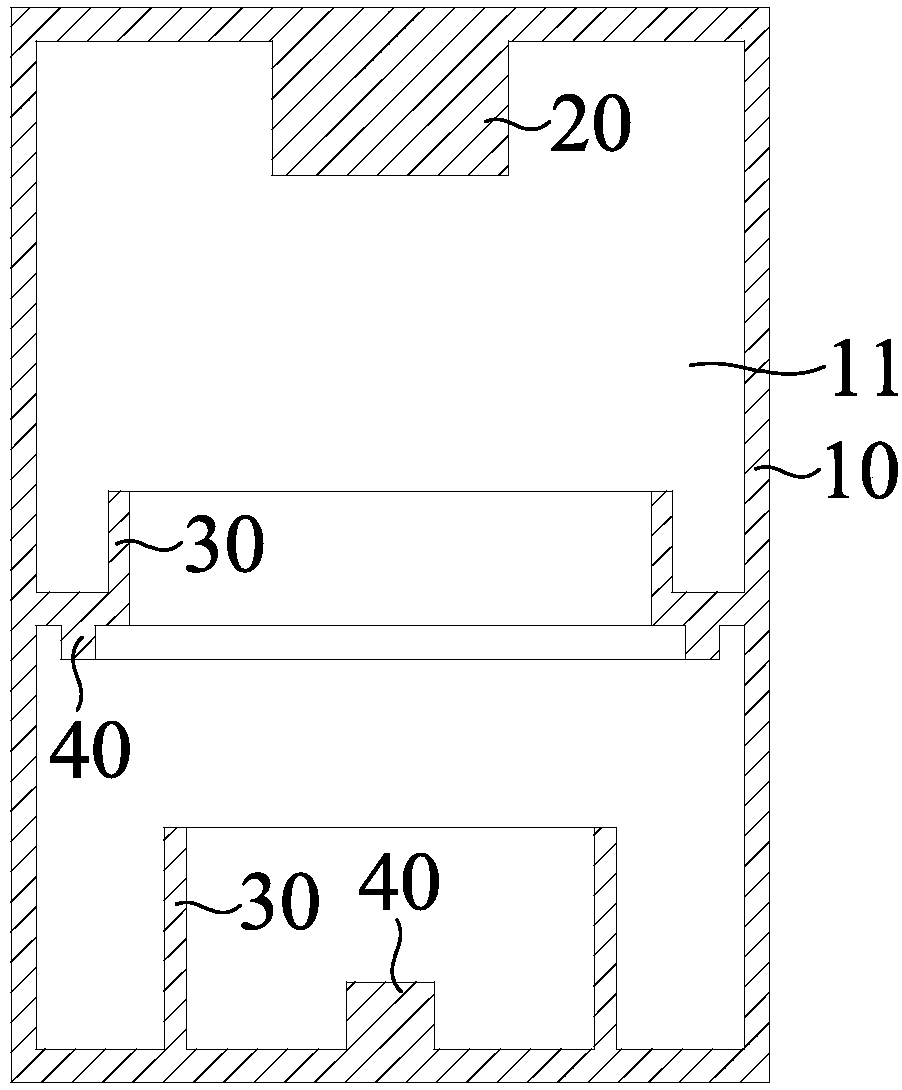

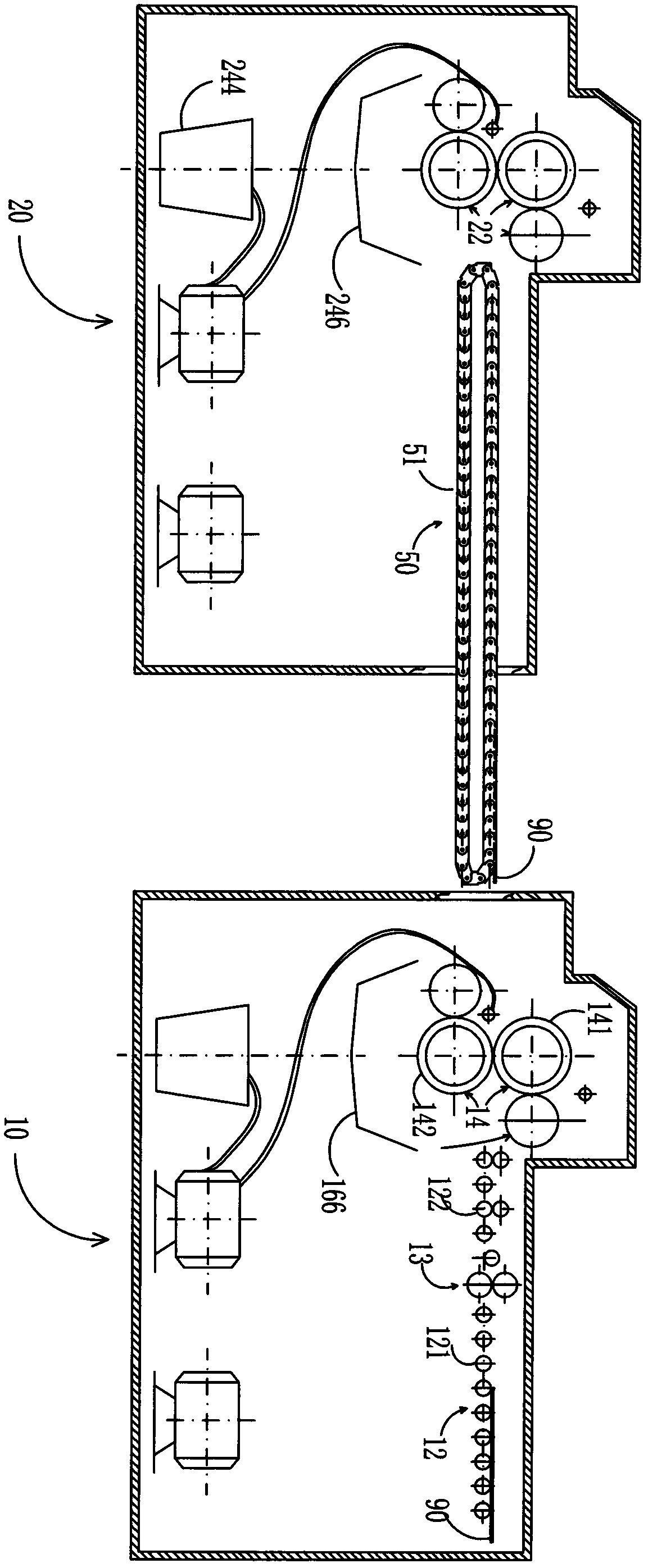

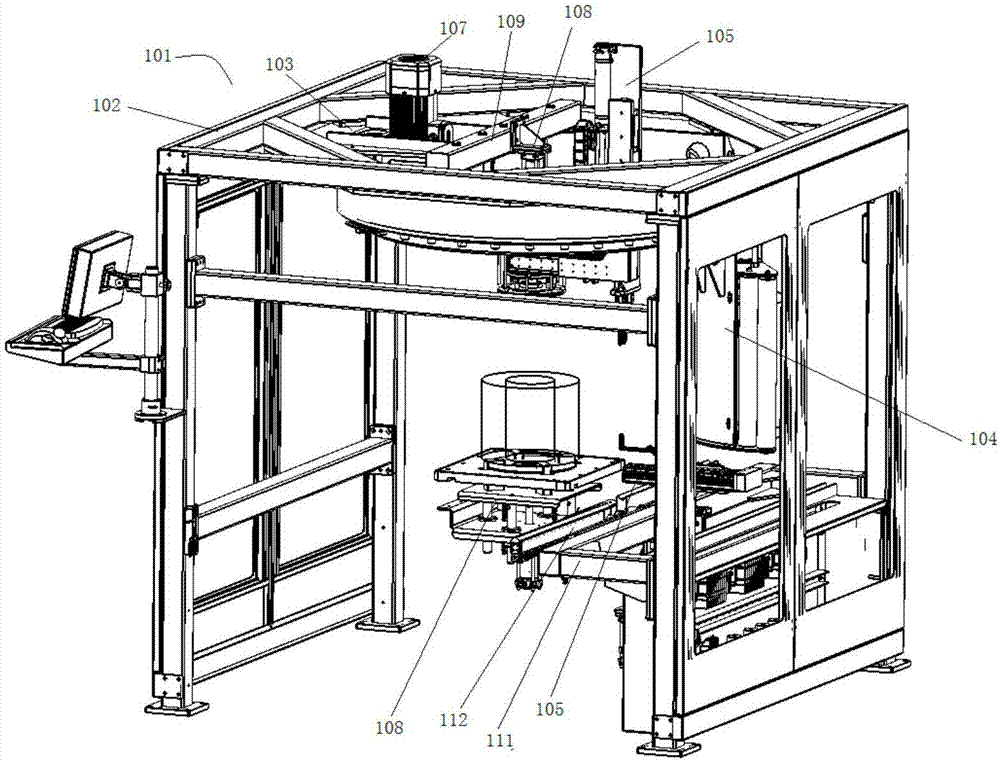

Physical vapor deposition equipment and physical vapor deposition method

InactiveCN107723675AImprove processing efficiencyImprove applicabilityVacuum evaporation coatingSputtering coatingGas phaseEngineering

The invention discloses physical vapor deposition equipment and a physical vapor deposition method. The physical vapor deposition equipment comprises a shell, a transmitting source, a bearing device and a power device. A vacuum coating chamber is formed in the shell, the transmitting source, the bearing device and the power device are located in the vacuum coating chamber, and the power device isconnected to the bearing device so that a to-be-coated product located on the bearing device can vibrate up and down, overturn from interior to exterior and rotate in the preset direction. When the physical vapor deposition equipment conducts coating, the step that a large amount of manual work is needed for manual hanging is omitted, the machining efficiency is greatly improved, the number of products machined at a time is tens of times of the number of products coated through an ordinary hanging tool manner, the machining cost is greatly reduced, and the automation degree in the coating process is higher; and meanwhile, the to-be-coated product can obtain a complete and comprehensive PVD clad layer, the applicability of the product is obviously improved, and the coating quality is further guaranteed.

Owner:DONGGUAN REVOLUTION PROD DESIGN

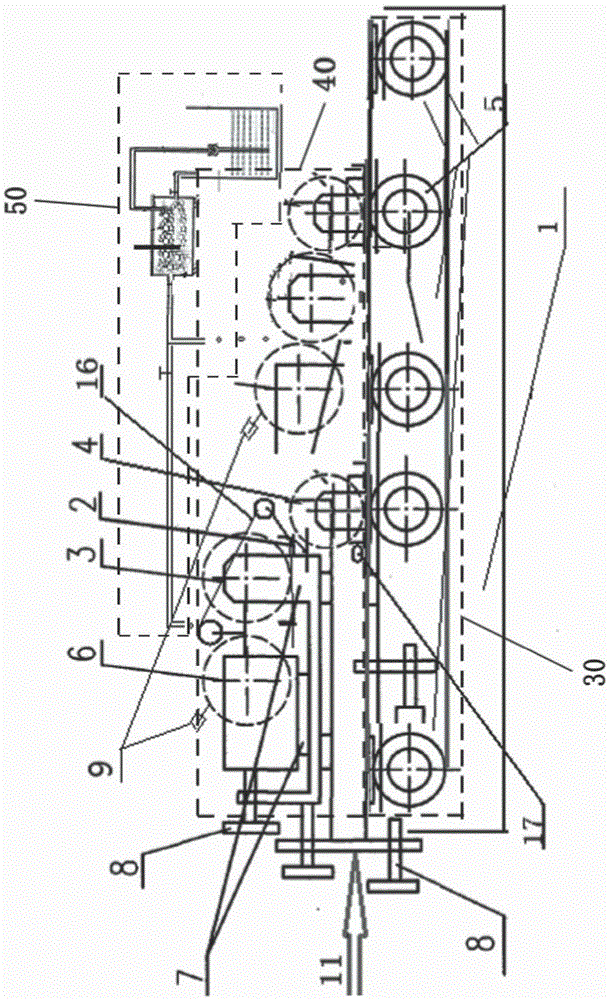

Printed circuit board solder resist ink coating technology and coating apparatus

InactiveCN102325427ALow efficiencyMeet quality requirementsNon-metallic protective coating applicationScreen printingResist

The invention provides printed circuit board solder resist ink coating technology and a coating apparatus. The coating technology comprises the following steps: a. coating solder resist ink at two sides of a circuit board for the first time by a first resist ink coating apparatus; b. coating the solder resist ink at two sides of the circuit board for the second time by a second resist ink coating apparatus, and using the solder resist ink to cover all lines and copper faces on the circuit board; c. drying the circuit board which goes through second solder resist ink coating. The coating apparatus comprises the first solder resist ink coating apparatus, the second solder resist ink coating apparatus, and a conveying mechanism provided between the first solder resist ink coating apparatus and the second solder resist ink coating apparatus. According to the coating technology and the coating apparatus, labor intensity of production personnel is substantial reduced, screen printing materials is saved, production cost is reduced, and labor productivity is effectively raised.

Owner:陈国富

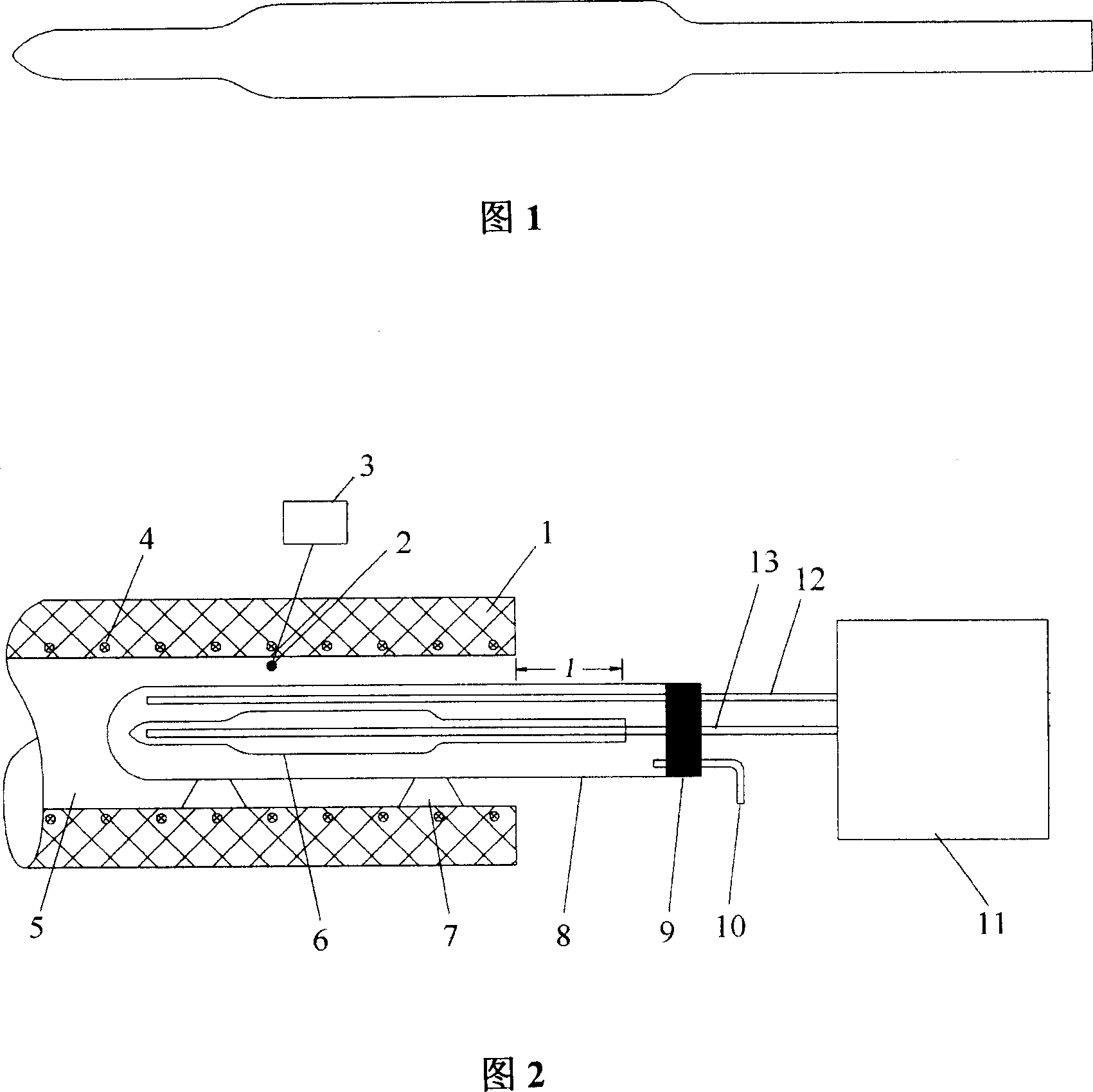

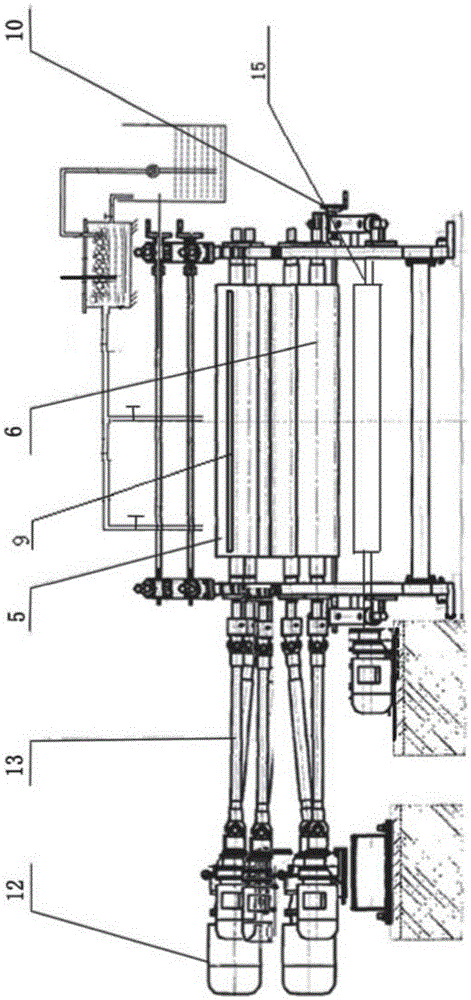

Roll coating device and coating technology

ActiveCN105396749AUniform thicknessImprove appearance qualityPretreated surfacesCoatingsElectric machineryProcess engineering

The invention discloses a roll coating device and a coating technology. The roll coating device comprises a base, and a driving system (30), a three-roll down-taking or up-feeding system (40) and a defoaming feeding system (50) which are sequentially connected, wherein the three-roll down-taking or up-feeding system (40) comprises sequentially arranged two sets of metering rolls (6), two sets of material taking rolls (3) and two sets of coating rolls (4); sliding block guide rails (7) are connected on the base (1); the metering roll 1 (6) is driven by a driving motor (12); and sharp knives (9) are connected on the metering rolls (6). The coating technology carried out through adopting the roll coating device is simple in operation and high in automation degree, the poor coating is easy and convenient to treat, and a coated product is high in adhesive force, can meet the bending requirement of stainless steel OT, can resist 5% acid alkali for 24 hours without change, can resist salt mist for 240 hours, and reaches the eight-grade standard; and compared with an oil coating, the coating adopted by the invention is non-combustible, unexplosive, VOC emission-free, non-toxic, harmless, safe and environment, and meets the national environmental protection policy and laws and regulations.

Owner:FUJIAN GANG HONG METAL TECH CO LTD

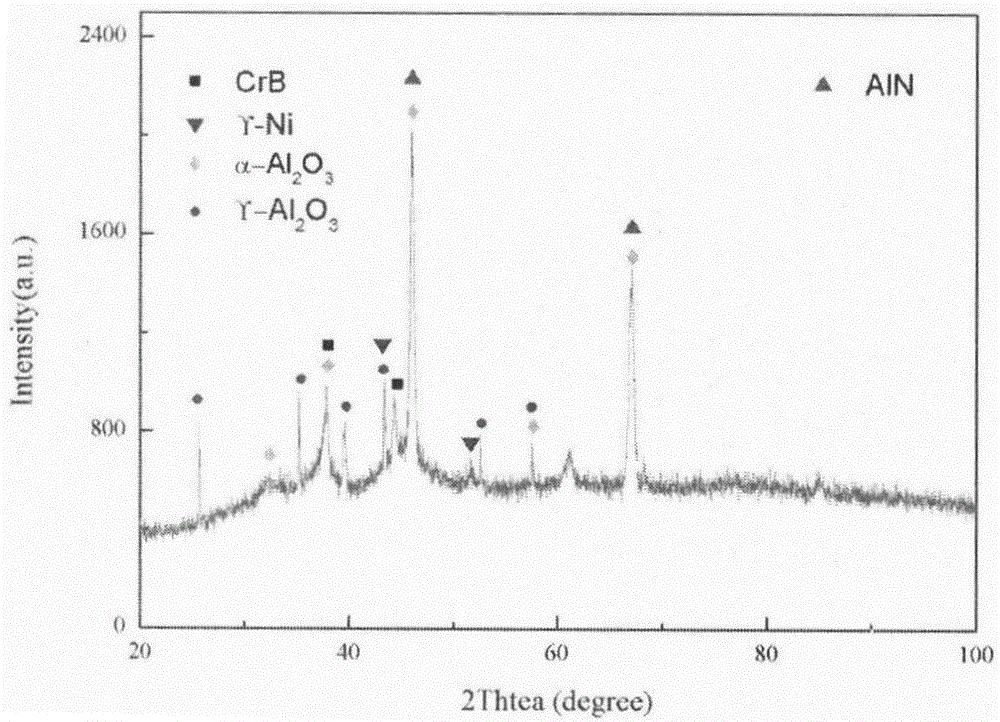

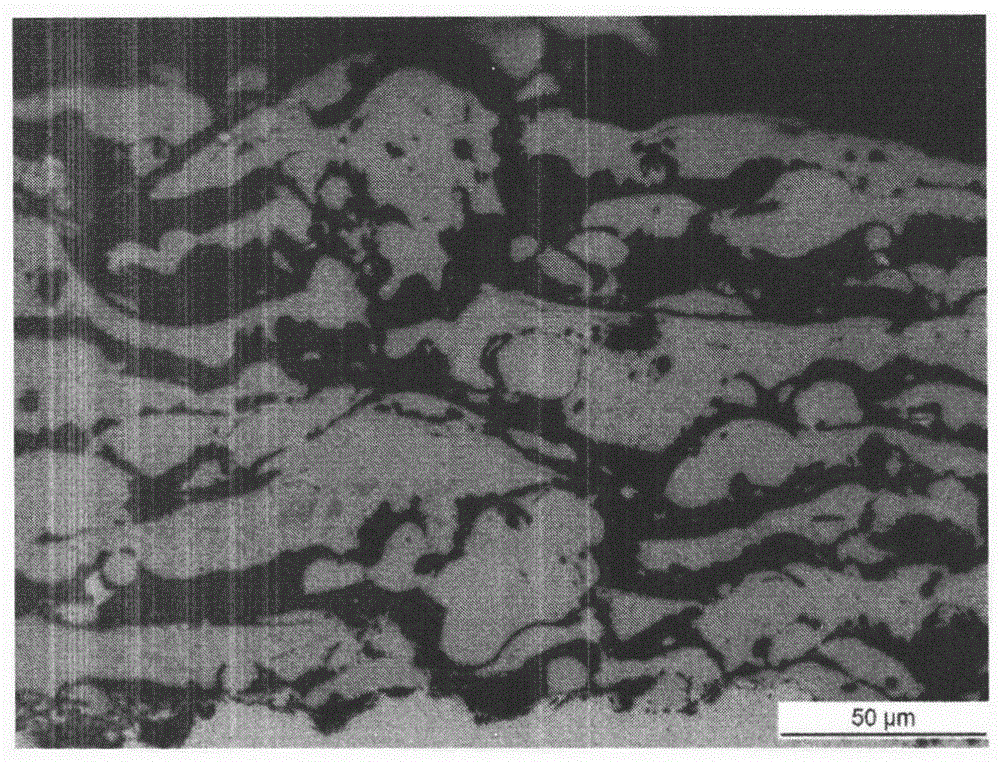

Preparation method of remanufactured coating for inner wall of air cylinder sleeve

InactiveCN106319430ARestoring service lifeAvoid stratificationMolten spray coatingThermal sprayingRestoration method

The invention relates to a preparation method of a remanufactured coating for the inner wall of an air cylinder sleeve. According to the preparation method, a thermal spraying mode is adopted; a base body of the inner wall of the air cylinder sleeve of a vehicle is remanufactured from a powdered material; the base body is made of carbon steel or stainless steel or other types of metal; the spraying powdered material is a metallic-nonmetallic composite and composite powder; after entering flame flow, the composite powder is deposited onto the base body through all or part of fusion and acceleration processes; and the composite powder is sprayed to the inner wall of the air cylinder sleeve of the vehicle, so that the composite coating is formed. By means of the method, defects existing in previous various air cylinder sleeve restoration methods are overcome. The thermal spraying method is adopted, and the high-performance composite coating is remanufactured on the inner wall of the cylinder sleeve; the service life of an engine of the vehicle is recovered; a mixed power gluing method is adopted in the spraying process, and the coating lamination phenomenon caused by density variation of the composite powder is effectively avoided; it is helpful to improve performance of the coating; and the service life of the coating is prolonged to a large extent.

Owner:YANGZHOU UNIV

Panel film laminating machine

PendingCN109333688APrecise angle of rotationAchieve clampingWood veneer joiningWood layered productsEngineeringMechanical engineering

The invention provides a panel film laminating machine, and belongs to the technical field of house and home production. The panel film laminating machine comprises a splicing clamping device and a gluing film laminating device. The splicing clamping device comprises a front splicing mechanism, a rear splicing mechanism and a splicing drive mechanism. The gluing film laminating device is arrangedon the upper side of a film laminating platform. A gluing sliding block and a film laminating sliding block of the gluing film laminating device are connected through a synchronous sliding block. A gluing film laminating lead screw and a gluing film laminating lead screw nut are in threaded connection. A gluing lifting support is arranged at the lower end of the gluing sliding block. A gluing roller is rotationally arranged on the gluing lifting support. The film laminating support is arranged at the lower end of the film laminating sliding block. A film laminating roller is rotationally arranged on the film laminating support. A film clamping device is arranged below the synchronous sliding block, and a clamping device travel switch is arranged on a left gluing film laminating lead screwsupport. By means of the panel film laminating machine, cut panels can be subjected to film laminating processing after being spliced and clamped again, the structure is reasonable, the film laminating effect is good, the panel film laminating machine can be applicable to different sizes of panels, applicability is high, and reliability is good.

Owner:奥凯家居(浙江)有限公司

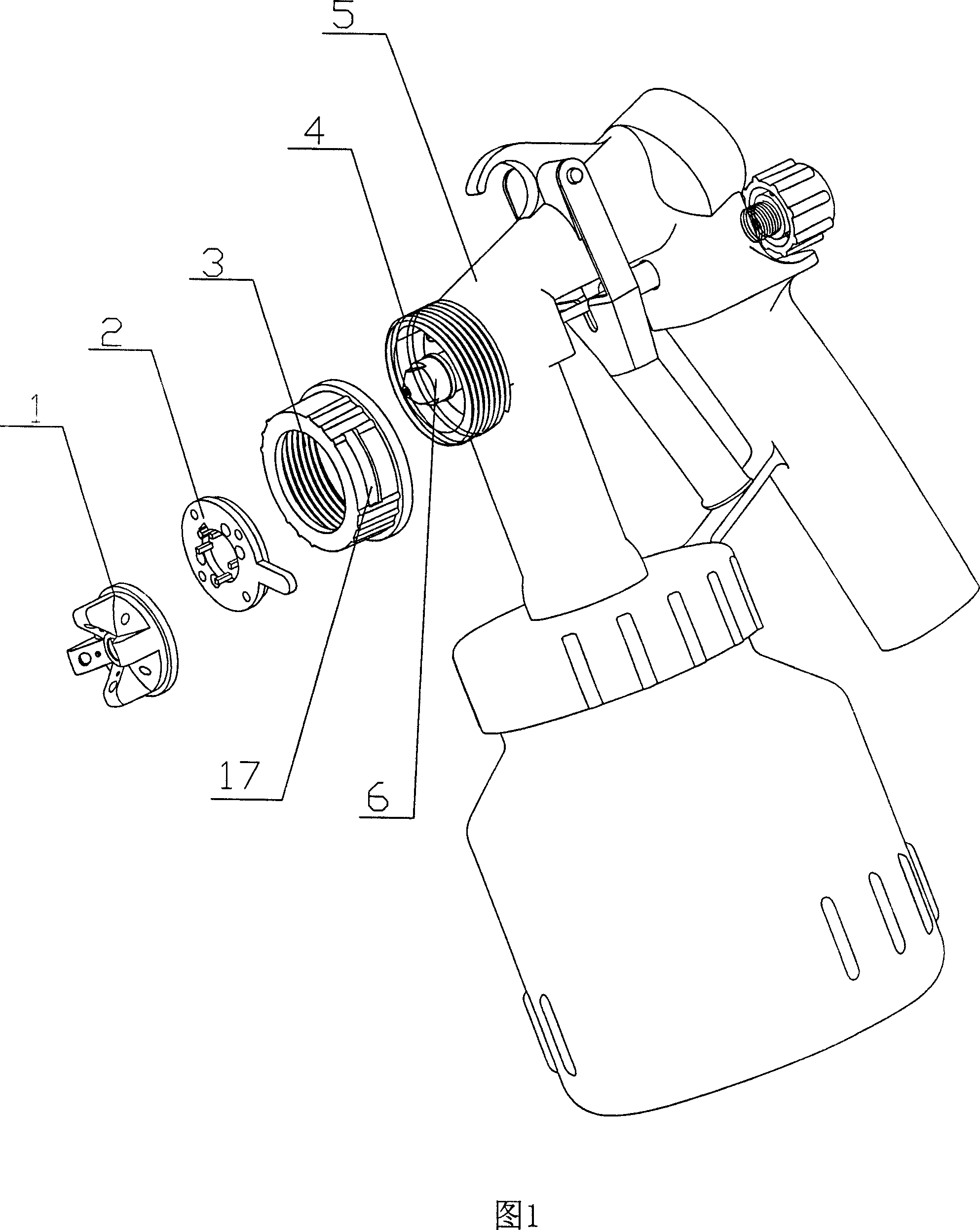

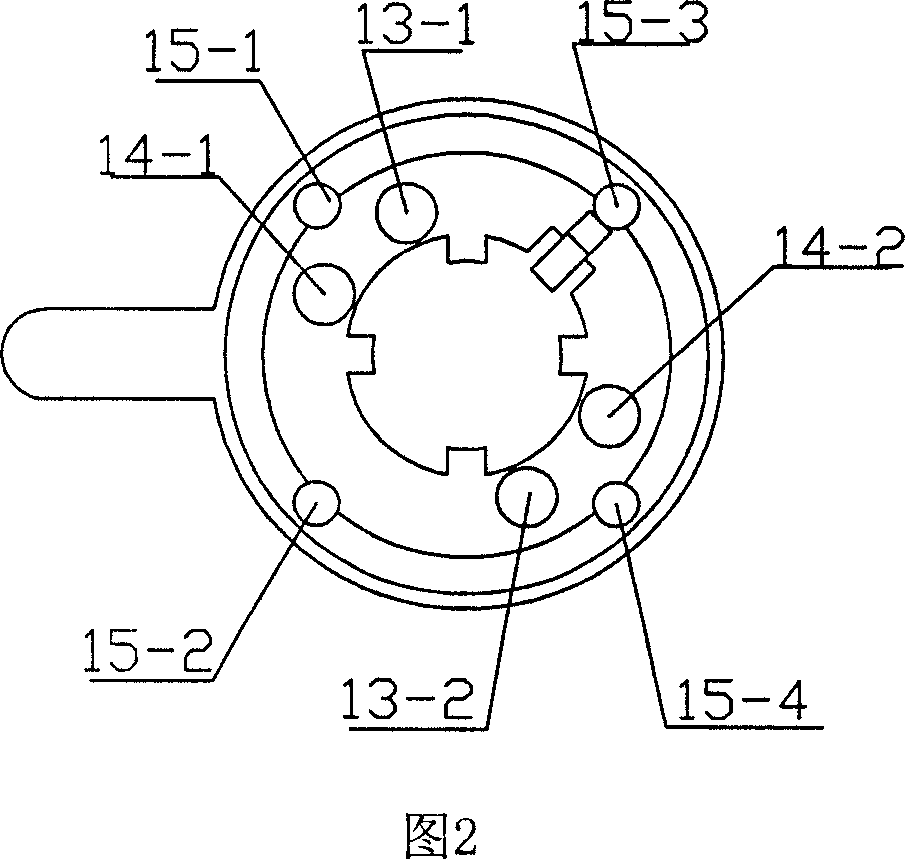

Easy-to regulate paint spraying gun

InactiveCN1931444AEasy and quick adjustmentGuarantee coating qualitySpray nozzlesLiquid spraying apparatusAirflowEngineering

The present invention relates to one kind of easy-to-regulate paint spraying gun and belongs to the field of painting equipment technology. The paint spraying gun has a gun body, a joint with inner channel to the spout with central hole, a nozzle fixed to the tip of the gun, surrounded with an annular space and with distributed air jet holes, an annular baffle with at least two set of holes and set between the annular space and the nozzle, a clamp nut with notch, and a shifting rod to stretch out from the annular baffle and through the notch. When the shifting rod is located in the first position or the second position, the upper and lower jet holes or the left and the right jet holes are made to communicate without annular space. The easy-to-regulate paint spraying gun may be regulated fast in the spraying form so as to ensure the painting quality.

Owner:潘晓明

Film laminating device for waterproof coiled material production

PendingCN111421943ARealize automatic deliveryImprove fitLaminationLamination apparatusEngineeringElectric control

The invention discloses a film laminating device for waterproof coiled material production. The film laminating machine comprises a supporting plate, a feeding box, a fixing frame, a film laminating shaft, a supporting frame, a pressing roller, a driving conveying roller, a servo motor and a driven conveying roller. A feeding box is fixedly mounted at one end of the top of a conveying supporting plate; a discharging groove in the vertical direction is formed in the top of the feeding box; according to the film laminating device for waterproof coiled material production, only a plurality of to-be-laminated waterproof coiled material bodies need to be stacked in the feeding box; the two ends of the waterproof coiled material at the bottommost feeding part are arranged on a supporting table and the driven conveying roller; an electric control mechanism is arranged to control a servo motor to work, so that the driving conveying roller and the driven conveying roller rotate; automatic conveying of materials can be achieved without manual alignment of the materials, and time and labor are saved; the pressing roller can press the laminated waterproof coiled materials through an arranged jacking spring, the laminating effect of a laminated film and the waterproof coiled materials is good, the film laminating quality is guaranteed, the subsequent pressing procedure is omitted, and the film laminating efficiency is improved.

Owner:山东正大防水材料股份有限公司

Film coating mechanism for yarn balls

ActiveCN107380507AAvoid the problem of not covering the surface of the yarn packageEnvelope realizationWrapping material feeding apparatusWeb rotation wrappingYarnElectric machine

The invention discloses a film coating mechanism for yarn balls. The film coating mechanism comprises a film coating support and a mounting plate arranged on the top of the film coating support, and further comprises a film feeding assembly and a film winding assembly. The film feeding assembly comprises an upper film clamping assembly arranged on the mounting plate and a lower film clamping assembly corresponding to the upper film clamping film assembly and arranged on the lower portion of the film coating support. A film coating gear ring is movably arranged in the middle of the mounting plate, a rotating motor is connected with one side of the film coating gear ring, the film winding assembly is arranged on one side of the film coating gear ring, and the film coating gear ring drives the film winding assembly to rotate. Coating films can be automatically conveyed to the side walls of the yarn balls through longitudinal moving and synchronous horizontal moving of the upper and lower film clamping assemblies, and film feeding is completed; right after each yarn ball is wrapped with one layer of coating film, the coating film is loosened, so that the problem that the coating films cannot cover the surfaces of the coating films is effectively avoided.

Owner:福德机器人(成都)有限责任公司

Method for preparing boron carbide coating through plasma spraying

ActiveCN103194714AReduce or even prevent churnAvoid churnMolten spray coatingDecompositionBoron carbide

The invention provides a method for preparing a boron carbide coating through plasma spraying. The method comprises the steps that: step (1), boron carbide powder and carbon powder are uniformly mixed; and the mixed powder is delivered into a plasma spraying device; step (2) the surface of a substrate requiring spraying is pretreated; step (3) plasma spraying is carried out on the surface of the substrate by using the plasma spraying device, such that the boron carbide coating is prepared. According to the invention, the coating is prepared through a carbon-doped B4C powder plasma spraying method. When jet flow is ejected, graphite powder take the priority to react with oxygen, such that B4C oxidation is avoided; with the addition of carbon, B4C high-temperature decomposition is inhibited, such that B4C loss under high temperature can be reduced or even prevented, and B4C coating with good performance can be obtained; with carbon doping, no impurity element is introduced into the coating, such that coating quality is ensured; also, with the addition of graphite powder, powder fluidity is increased, and spraying is facilitated.

Owner:SOI MICRO CO LTD

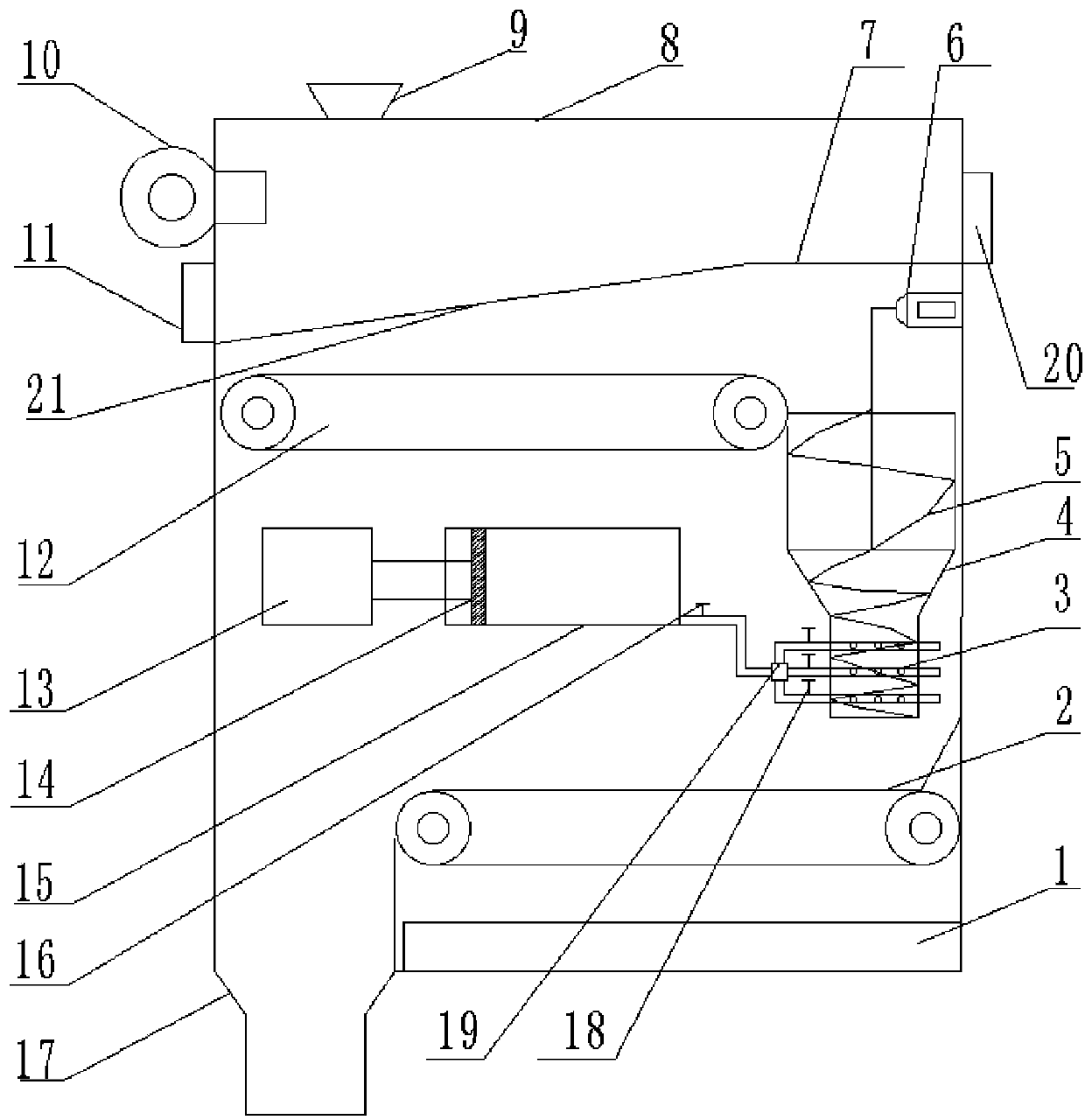

Seed coating machine with filtering device

InactiveCN107836161AGuarantee coating qualityEasy to controlSievingGas current separationLiquid wasteEngineering

The invention discloses a seed coating machine with a filter device, which belongs to the technical field of seed coating equipment, and solves the problem that the impurities in the seeds are coated together without removing impurities before seed coating, and the seed coating liquid is wasted , including a box body, the box body is provided with a filter screen under the feed port, and a blower is arranged on the side wall of the box body above the filter screen, and the blowing direction of the blower is the same as the transmission direction of the first conveying device. A first conveying device is arranged below the filter screen, and a stirring bucket is arranged at the output end of the first conveying device. The inside of the stirring bucket is provided with a spiral feed channel, and a motor that drives the spiral feed channel to rotate is arranged above the mixing bucket. A plurality of spray heads are arranged at the lower part of the barrel; an air storage tank and a medicine box are arranged under the first conveying device, and the outlet of the medicine box is connected with the spray head through a second pipeline; a second conveying device is arranged under the mixing bucket, so the A heating device is arranged below the second conveying device.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

Modified aqueous paint coating process for oil tank for petroleum cave depot/earthing storeroom

InactiveCN106311580ASolve the rustWon't fall offPretreated surfacesPolyurea/polyurethane coatingsPetroleumStorage tank

The invention discloses a modified aqueous paint coating process for an oil tank for a petroleum cave depot / an earthing storeroom. The process comprises the following operating steps of: (1) surface treatment before steel product coating; (2) environmental control; (3) coating construction; and (4) quality control. The invention formulates the coating process suitable for coating the oil tank in the petroleum cave depot / earthing storeroom with the modified aqueous paint. According to the process disclosed by the invention, the modified aqueous paint can be uniformly sprayed to the wall surface of a storage tank to satisfy the demand in the field of petroleum, so that the aqueous paint is in full contact with the oil tank. Moreover, the paint will not fall off from the oil tank, so that the coating quality is guaranteed, and the problem that the oil tank is rusted as an existing aqueous paint spraying method cannot achieve the using demand to lead to fall-off of the aqueous paint is solved.

Owner:TIANJIN ZHONGDE ENG DESIGN

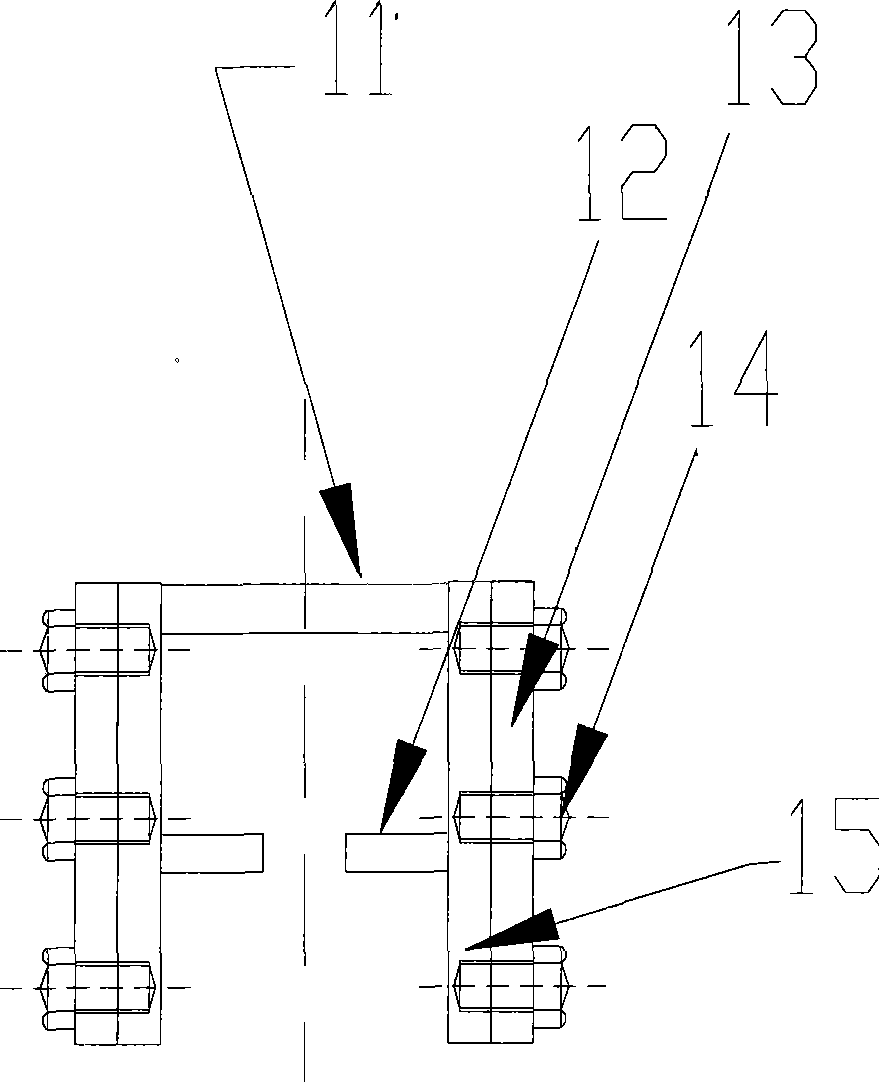

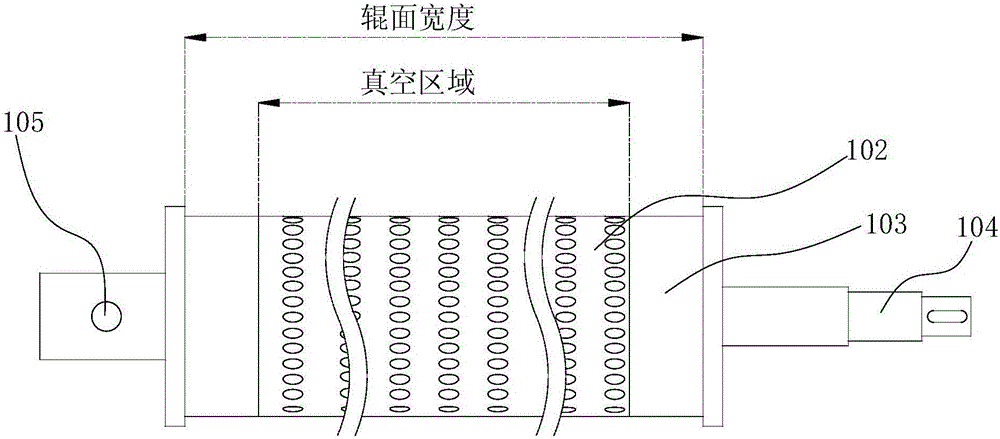

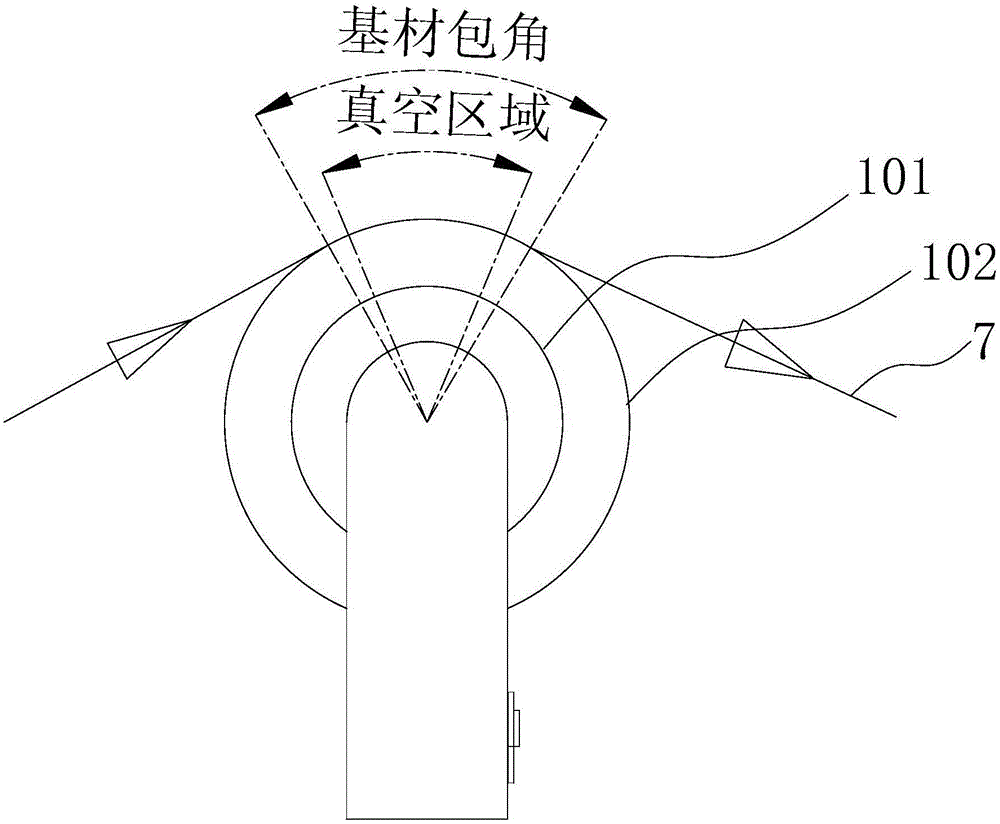

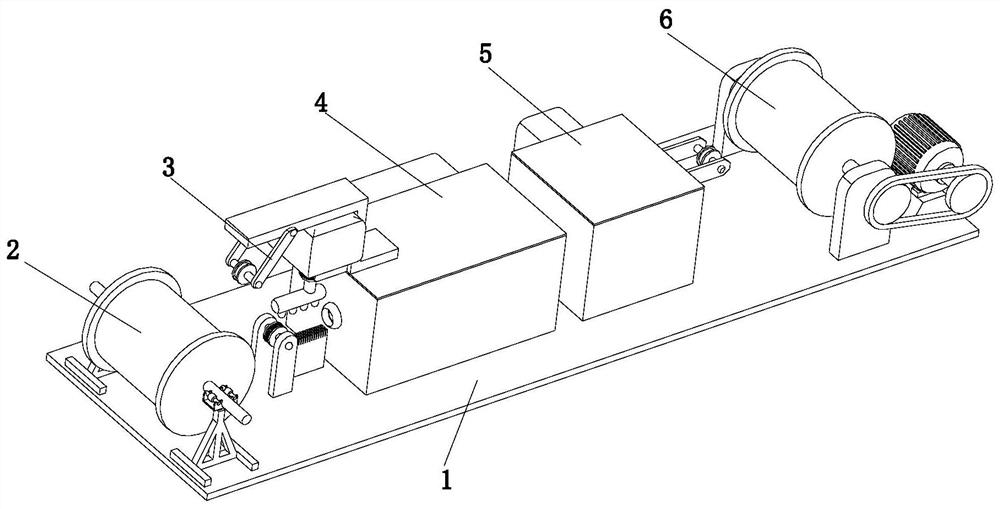

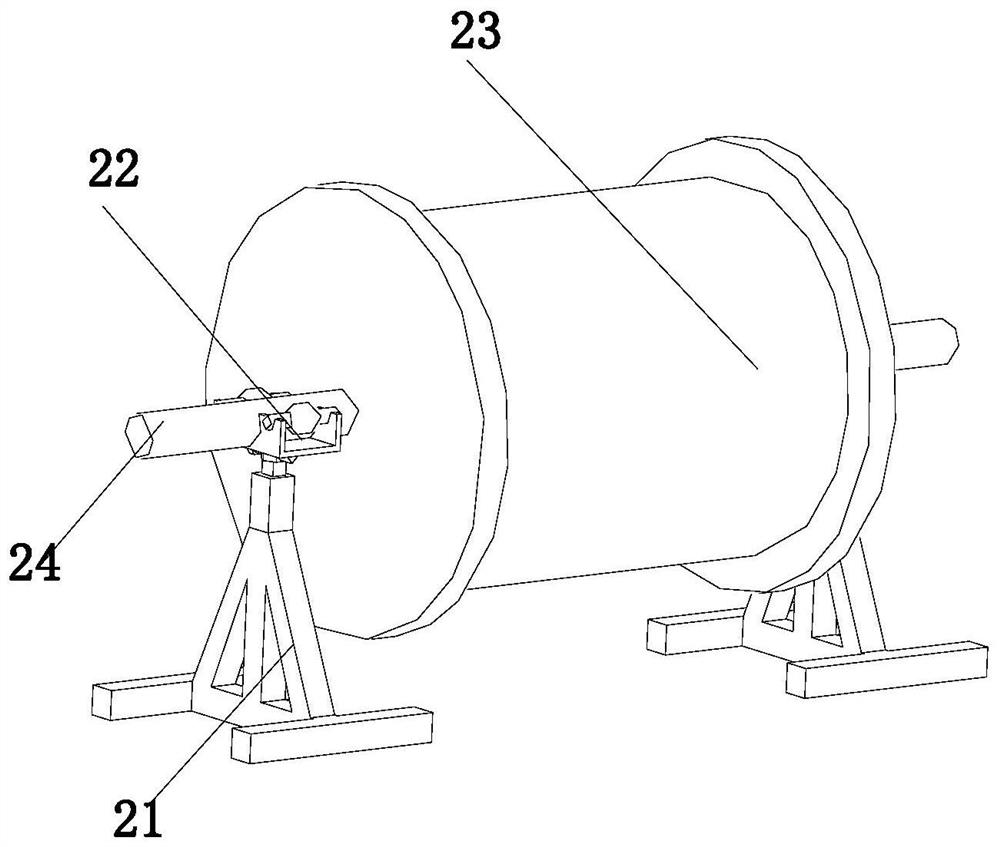

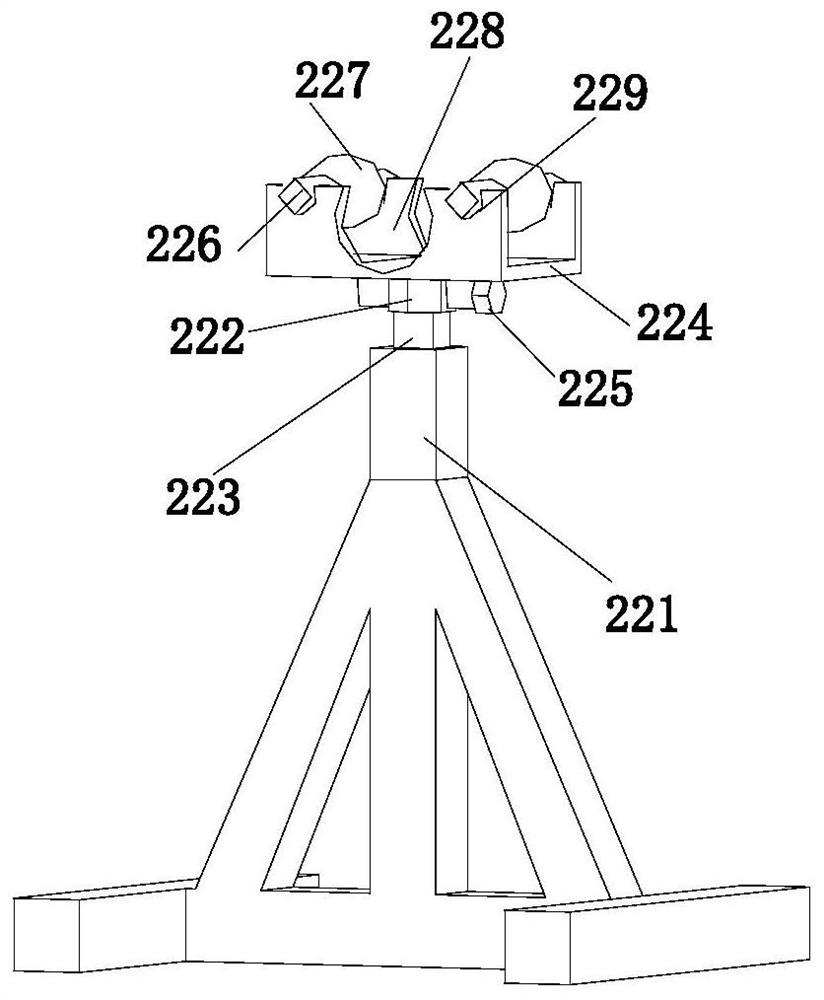

Compression roller device of winding mechanism of coating machine

PendingCN105903648AQuality assuranceReduce tensionLiquid surface applicatorsCoatingsEngineeringMachining

The invention discloses a compression roller device of a winding mechanism of a coating machine. The compression roller device comprises a tension adjusting roller fixed to a rack, wherein a compression roller abuts against one side of the tension adjusting roller; a base material winds round the tension adjusting roller for more than half a circle of the tension adjusting roller; and the base material is driven by a vacuum absorption roller to a dryer after being driven to a coating structure. The compression roller device of the winding mechanism of the coating machine has the advantage that the quality of products is not affected when the machining speed is increased.

Owner:SHENZHEN NEW KATOP AUTOMATION TECH

Enamelling machine for cable production

ActiveCN112133499APrevent beingQuality assuranceApparatus for feeding conductors/cablesInsulating conductors/cablesStructural engineeringElectric cables

The invention discloses an enamelling machine for cable production, and relates to the technical field of cable enamelling. The enamelling machine comprises a first mounting plate, a wire feeding assembly, a cleaning assembly, a paint spraying assembly, a drying assembly and a take-up assembly. The wire feeding assembly is fixedly arranged on one side of the first mounting plate. The cleaning assembly is fixedly arranged at the working end of the wire feeding assembly. The paint spraying assembly is fixedly arranged in the middle of the first mounting plate, the drying assembly is fixedly arranged beside the paint spraying assembly, and the take-up assembly is fixedly arranged on the other side of the first mounting plate. The working efficiency is improved, the automation degree is high,the quality of enameling operation is guaranteed, the labor intensity of workers is reduced, and the practicability of the device is greatly improved.

Owner:仪军电线电缆(惠州)有限公司

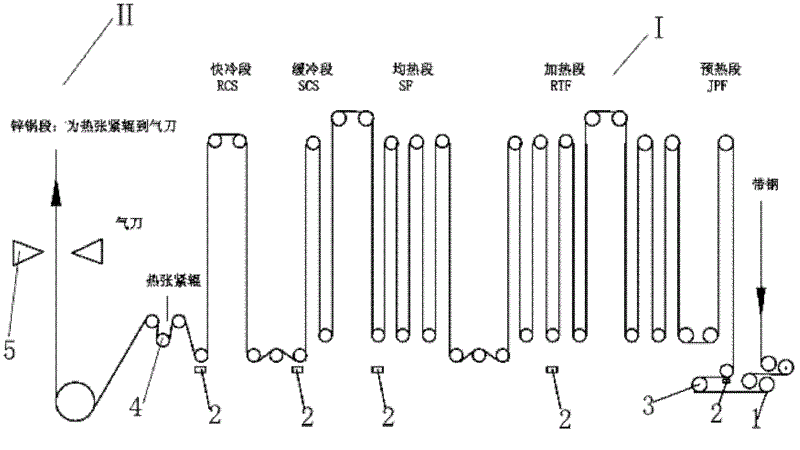

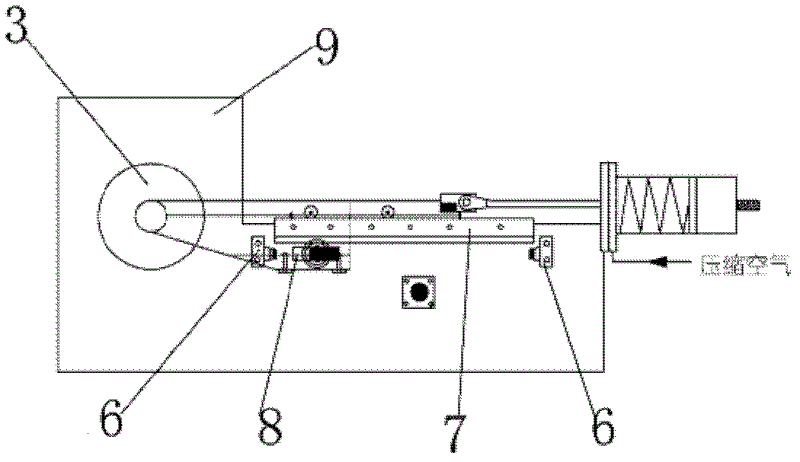

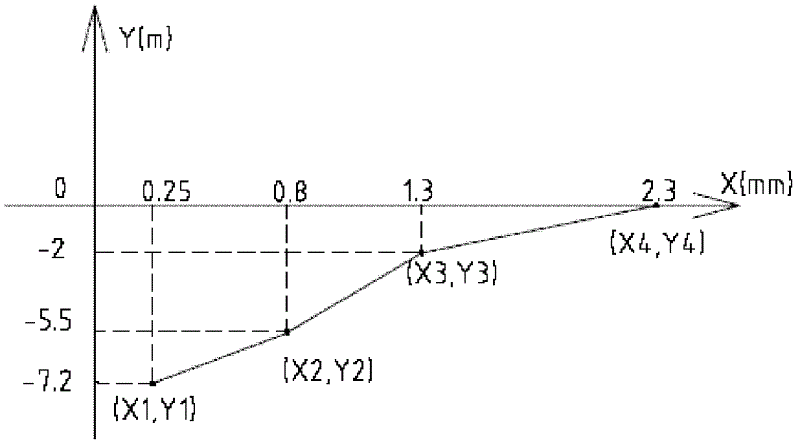

Method for tracking and controlling weld joints of band steel of continuous processing production line

ActiveCN102618813AEliminate downtimeReduce labor intensityHot-dipping/immersion processesProduction lineStrip steel

A method for tracking and controlling weld joints of band steel of a continuous processing production line is characterized in that the method is a control method combining dynamically compensating the length of band steel of a jumping roller in a furnace section with building a band steel expansion model in a zinc pot section to realize tracking and controlling welding joints in a process section. The length of the band steel of the jumping roller in the furnace section is dynamically compensated by means of adding the length, which is measured by a position sensor, of the band steel into the physical length of a preheating section (JPF) so that the weld joints are tracked and controlled; and an output factor is built according to the thickness of the band steel and a hot galvanizing process curve and is used as a variation value of the length of the band steel, and the variation value is added to the physical length of the zinc pot section so that the weld joints are tracked and controlled. Optimal tension switching moments of various sections of the furnace section are realized, proper tension is provided for the band steel, and accordingly a unit can produce qualified galvanized products. In addition, weld joint tracking control precision of the process section is greatly improved, the problem that the unit stops and is failed due to the fact that the band steel is collided with a baffle plate at the edge of an air knife when the weld joints pass through the air knife is completely avoided, and accordingly labor intensity of operators is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

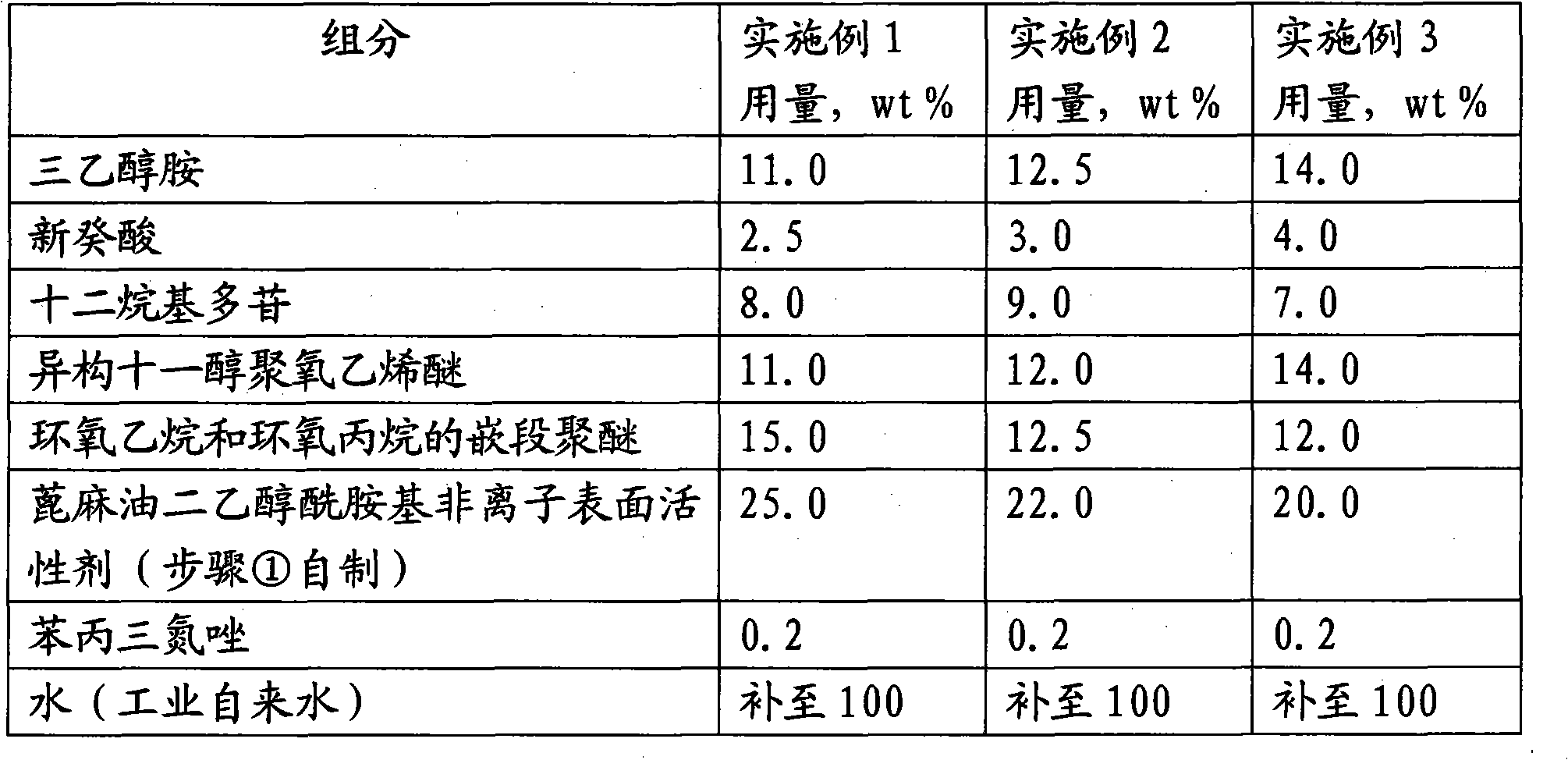

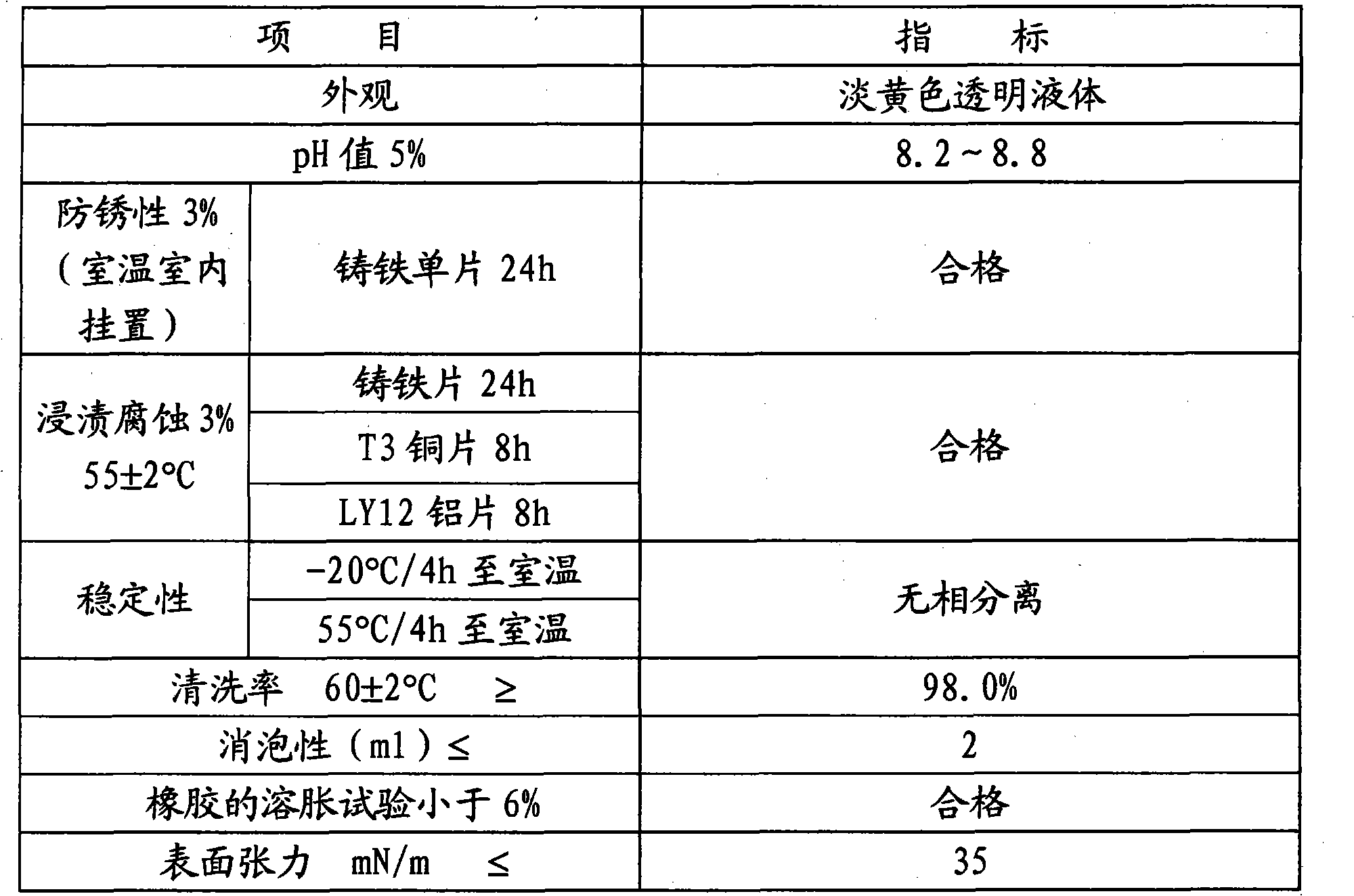

Metal cleaner used for coating production line and preparation method thereof

The invention relates to a metal cleaner used for a coating production line and a preparation method thereof. The metal cleaner consists of the following components in percentage by weight: 10 to 14 percent of triethanolamine, 2 to 4 percent of neodecanoic acid, 6 to 12 percent of dodecyl polyglycoside, 10 to 15 percent of heterogeneous XI alcohol ethoxylate, 10 to 15 percent of block polyether of ethylene oxide and propylene epoxide, 20 to 25 percent of caster oil diethanolamide-based non-ionic surfactant, 0.1 to 0.2 percent of styrene triazole and the balance of water. The appearance of the metal cleaner is transparent light yellow liquid; and when the metal cleaner is diluted at the concentration of 5 percent with water, the pH value is between 8.2 and 8.8. The metal cleaner is particularly suitable to be used for cleaning a metal workpiece on a coating production line before coating, meets the requirement on environmental protection, and has the characteristics of high cleaning performance, long service life, low foam, high compatibility with anti-rust oil and anti-rust paint, low influence on rubber plastic parts, high cost performance and capacity of replacing similar imported cleaner products.

Owner:常州市永丰油脂厂

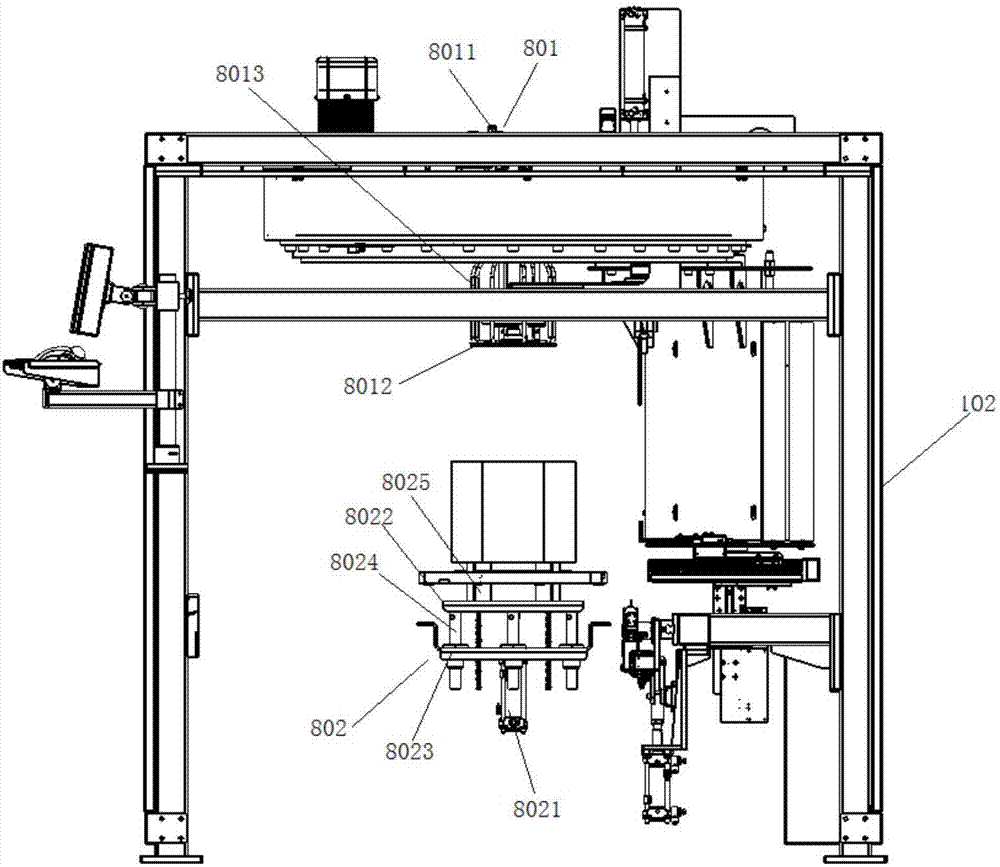

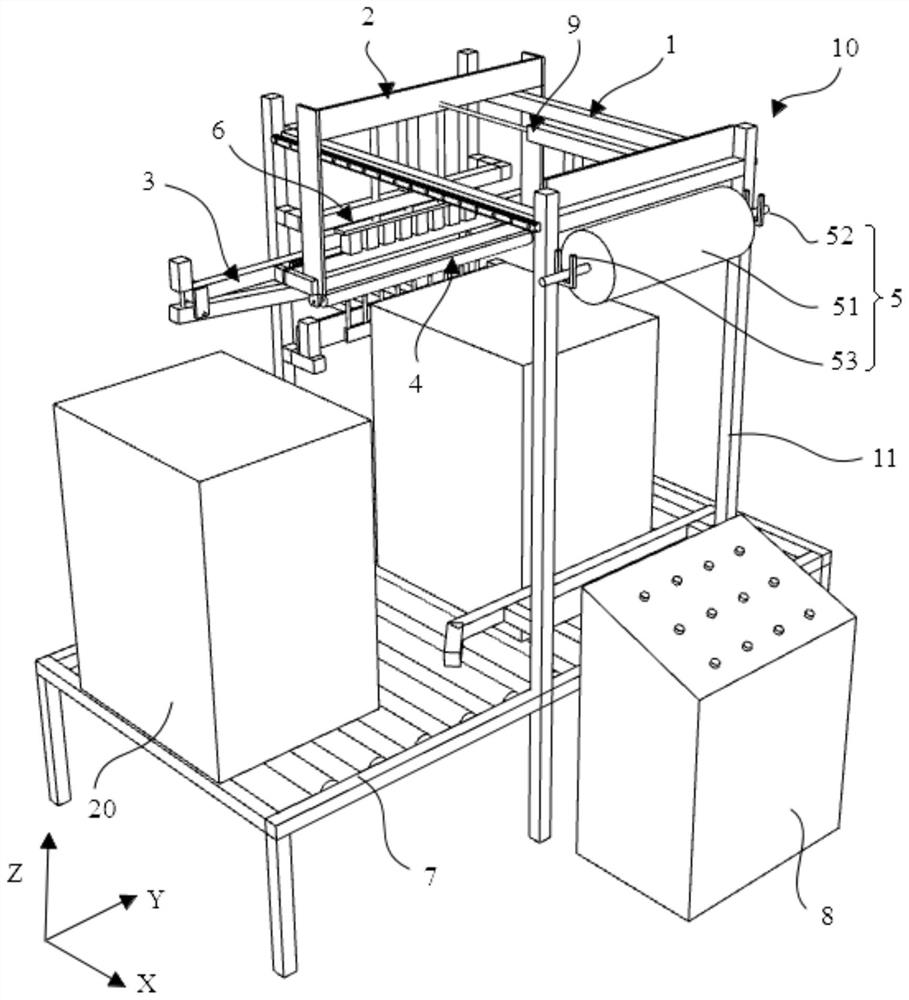

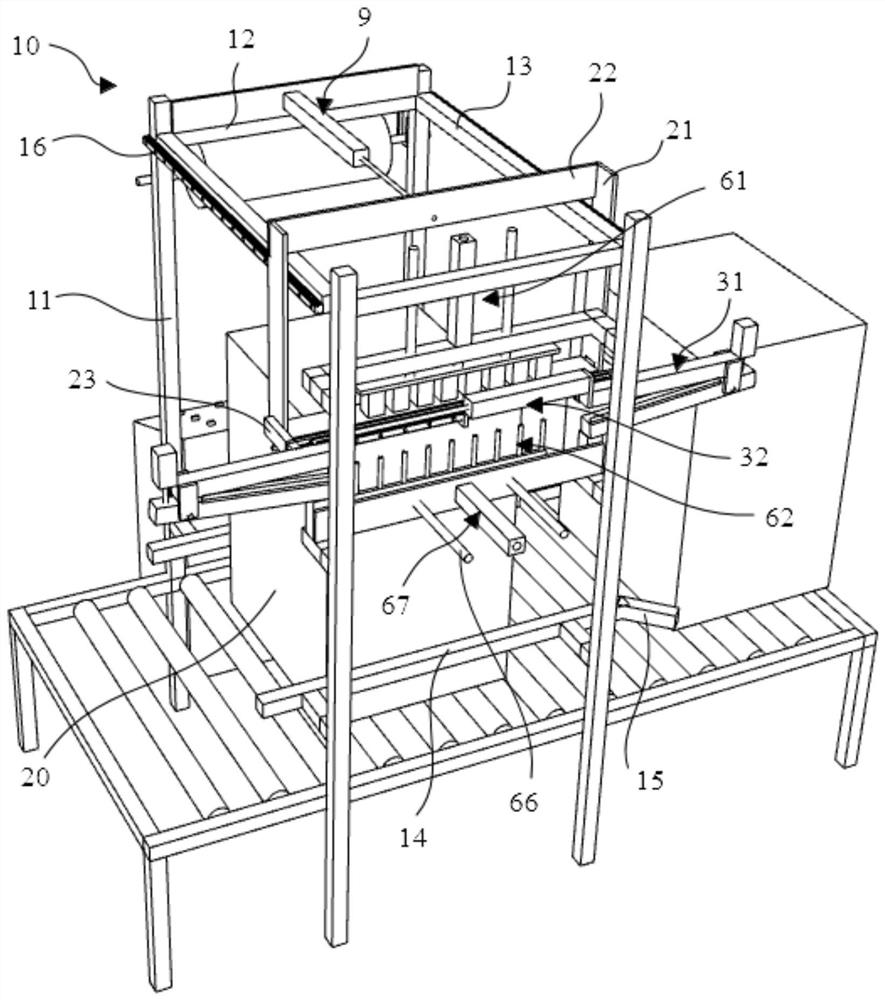

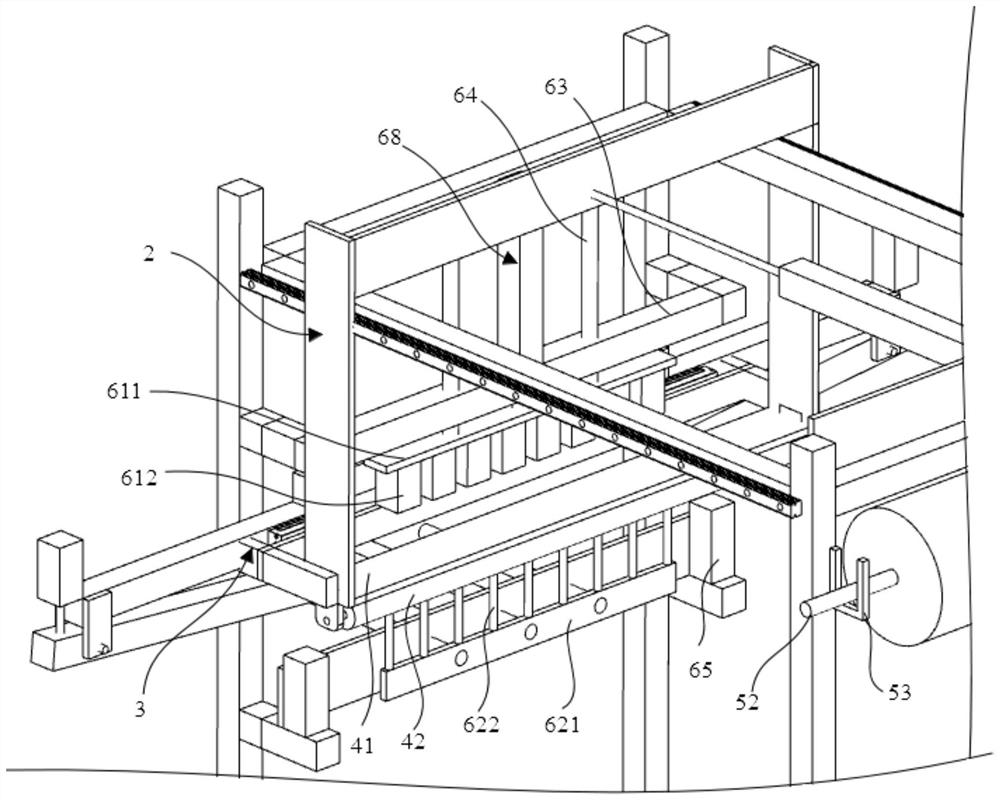

Film covering device and electric appliance packaging line

ActiveCN112722412AImprove lamination efficiencyHigh degree of automationPackagingCartonThin membrane

The invention belongs to the technical field of film covering, and particularly discloses a film covering device and an electric appliance packaging line. The film covering device comprises a rack, a thin film roll, a film clamping and cutting mechanism and a rolling assembly. The rack is provided with a first side and a second side which are oppositely arranged in a spaced manner in the X direction. The thin film roll is rotationally arranged on the first side of the rack. The film clamping and cutting mechanism is arranged on the rack in the manner of being capable of sliding in the X direction, and the film clamping and cutting mechanism is used for cutting a thin film and clamping the free end of the cut thin film roll. The rolling assembly is arranged on the rack and can move in the X direction and the Z direction relative to the rack, and the rolling assembly is used for pressing the thin film on the film covering surface. The electric appliance packaging line comprises the film covering device. According to the film covering device and the electric appliance packaging line, the film covering efficiency and the film covering quality to the upper surface of a carton can be improved.

Owner:QINGDAO HAIER INST OF IND INTELLIGENCE CO LTD +2

Rotating plasma spraying equipment

InactiveCN105018878AAvoid overall overheatingGuarantee coating qualityMolten spray coatingPhysicsEngineering

The invention relates to bore-rotating plasma spraying special equipment which comprises a powder, plasma gas, shielding gas, cooling air, cooling water inlet and backwater rotary conveying mechanism, an electric slip ring, a transmission mechanism, a coupling assembly and the like. Through the equipment, a bore plasma spraying gun can rotate 360 degrees continuously and endlessly, and stable transmission of powder, plasma gas, cooling air, cooling water inlet and backwater and current can be guaranteed. The equipment is suitable for plasma spraying of automobile engine cylinder bores, cylinder sleeves and other bore parts. The rotating plasma spraying equipment can make the bore gun rotate 360 degrees continuously and maximize the spraying distance by the utilization of centrifugal force so as to guarantee enough spraying distance, avoid overheating of workpieces, reduce internal stress and ensure coating quality.

Owner:北京联合涂层技术有限公司

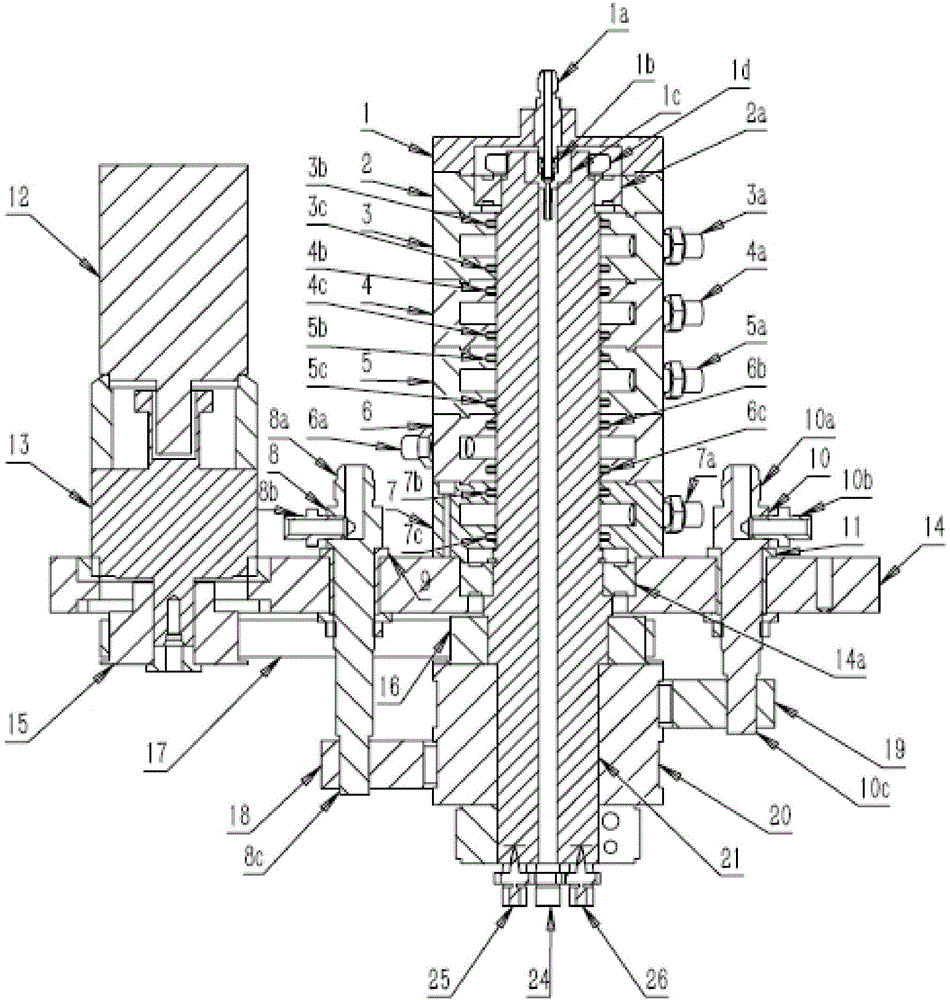

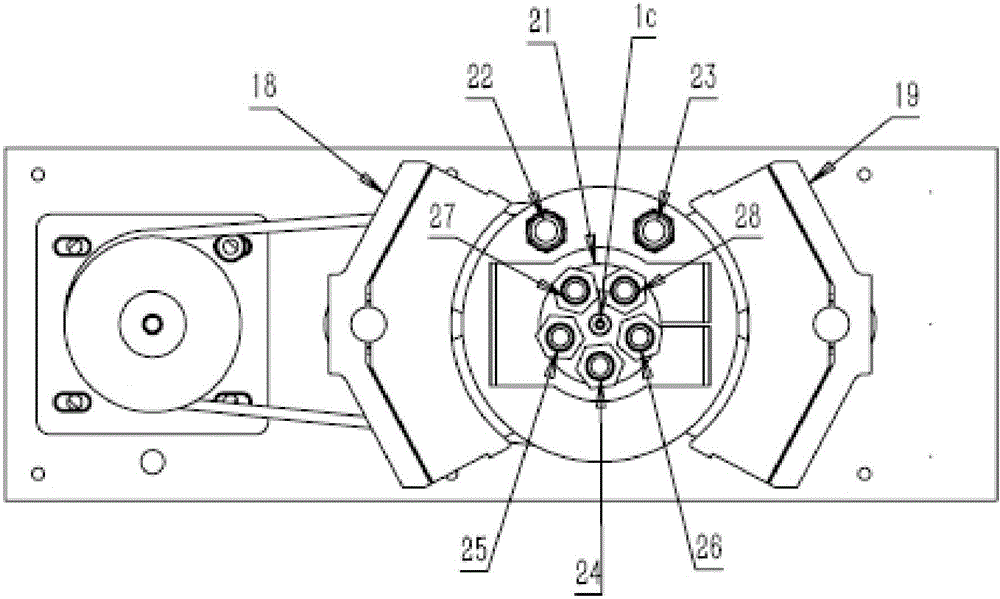

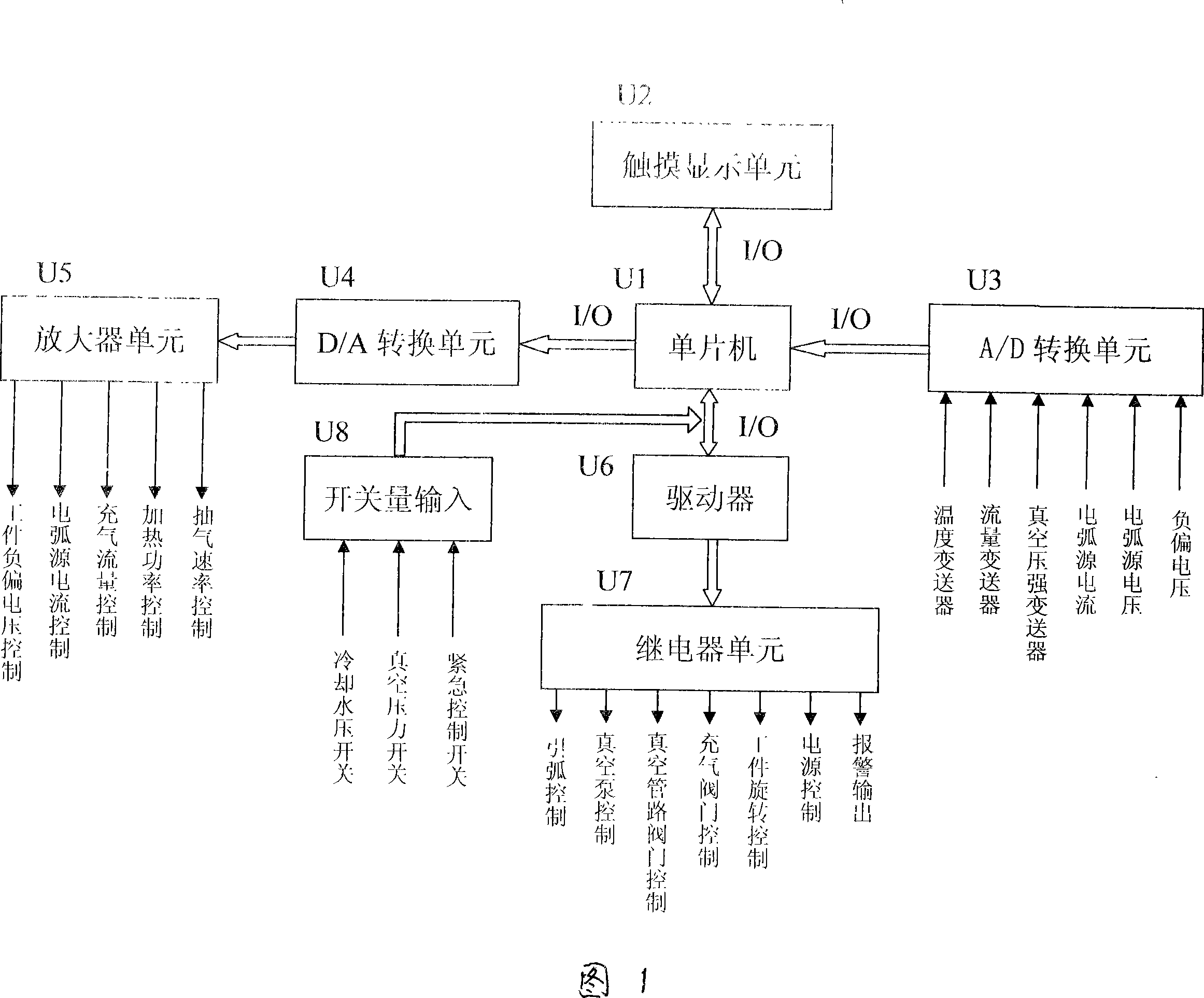

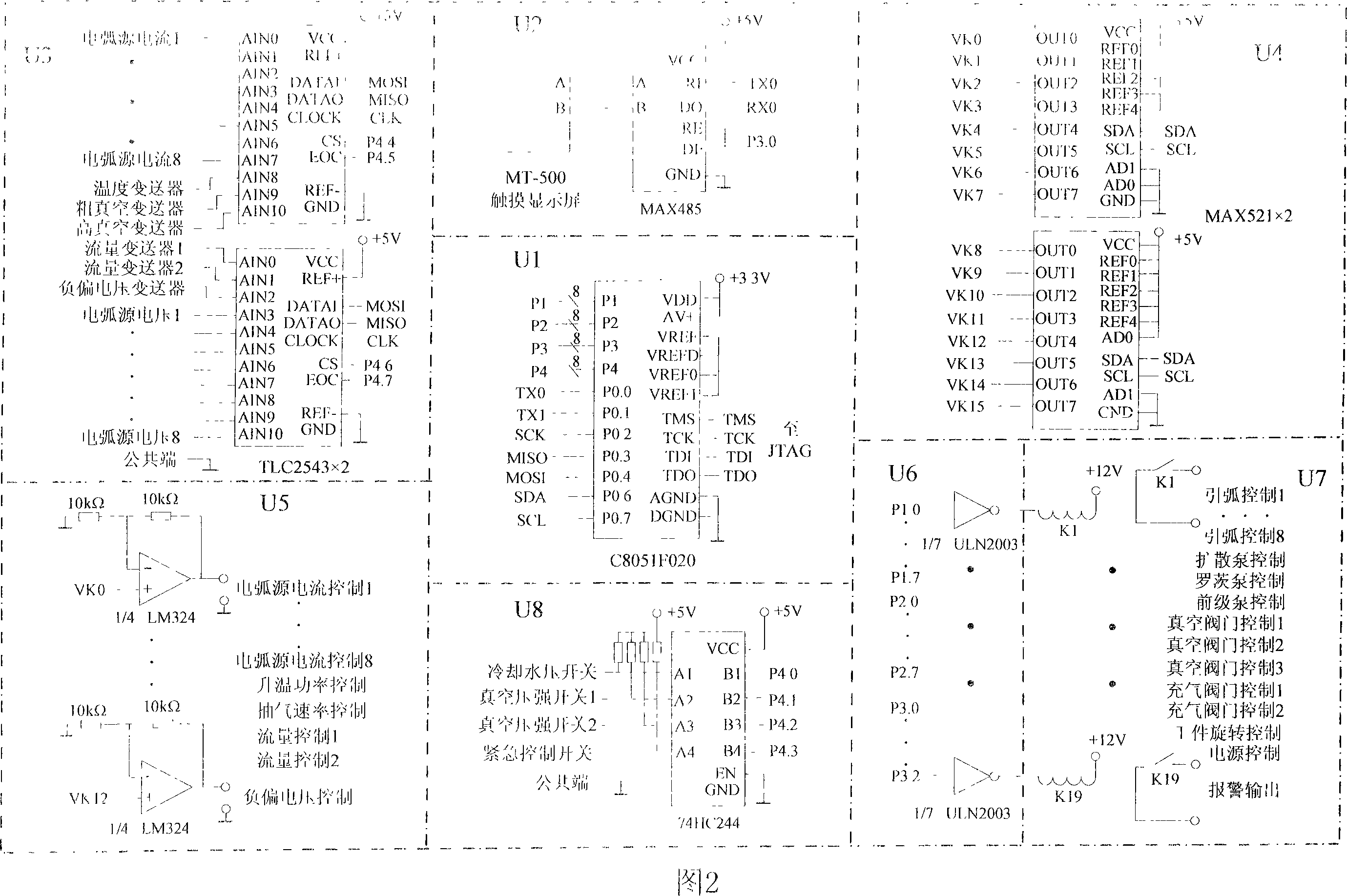

Vacuum multi sphere ion film coating machine intelligent integrated controller

InactiveCN101182634ARealize intelligent integrated controlReduce labor intensityComputer controlChemical vapor deposition coatingMicrocontrollerSolenoid valve

An intelligent integrated controller of a vacuum multi-arc ion plating machine comprises a singlechip, a touch display unit, an A / D conversion unit, a D / A conversion unit, an amplifier unit, a drive unit, a relay unit, and a switch value input unit. With the controller, an operator can input a prepared plating production technique via the touch display, and then the controller realizes the intelligent integrated control of the plating machine by controlling the vacuum pressure, the electric arc source current, the plating chamber temperature, the workpiece negative bias, and the aeration flow of the vacuum multi-arc ion plating machine and controlling the a vacuum pump, a solenoid valve and other devices according to the input technique. Thus, the vacuum plating technique is stabilized to guarantee the plating quality and the equipment safety.

Owner:湖南冶金职业技术学院

Multilayer laminating machine

ActiveCN111168968AImprove cleanlinessGuarantee the quality of coatingDirt cleaningCleaning using toolsStructural engineeringManufacturing engineering

The invention relates to a multilayer laminating machine comprising an unwinding device, a corona machine, laminating extrusion devices, calendering devices and a winding device. A plurality of groupsof laminating extrusion devices and calendering devices are provided, and a dust removal device is arranged between the unwinding device and the corona machine; dust collection devices are arranged at the exteriors of the laminating extrusion devices and the calendering devices; the dust removal device comprises a dust chamber with openings in the two ends of the lower part, and an air-blasting nozzle used for blowing dust is arranged in the dust chamber, and connected with an air blower; a dust suction nozzle used for sucking the dust is arranged in the dust chamber, and connected with a dust collector; and a separating plate is arranged between the air-blasting nozzle and the dust suction nozzle, and both openings of the air-blasting nozzle and the dust suction nozzle face the bottom wall of the dust chamber. According to the multilayer laminating machine, the dust adhering to the surface of base materials is blown through air flow sprayed out from the air-blasting nozzle, and flying dust in the dust chamber is sucked through the dust suction nozzle; the cleanliness of the base materials is improved, and the cleanliness of the base materials and lamination layers in the laminating process can be further ensured through the dust removal device, so that the laminating quality is ensured.

Owner:湖北金叶科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com