Compression roller device of winding mechanism of coating machine

A technology of winding mechanism and pressing roller device, which is applied in the coating field, can solve problems such as easy shrinkage, increase the tension of the coating area, and affect product quality, and achieve the effect of small tension, guaranteed coating quality, and high tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

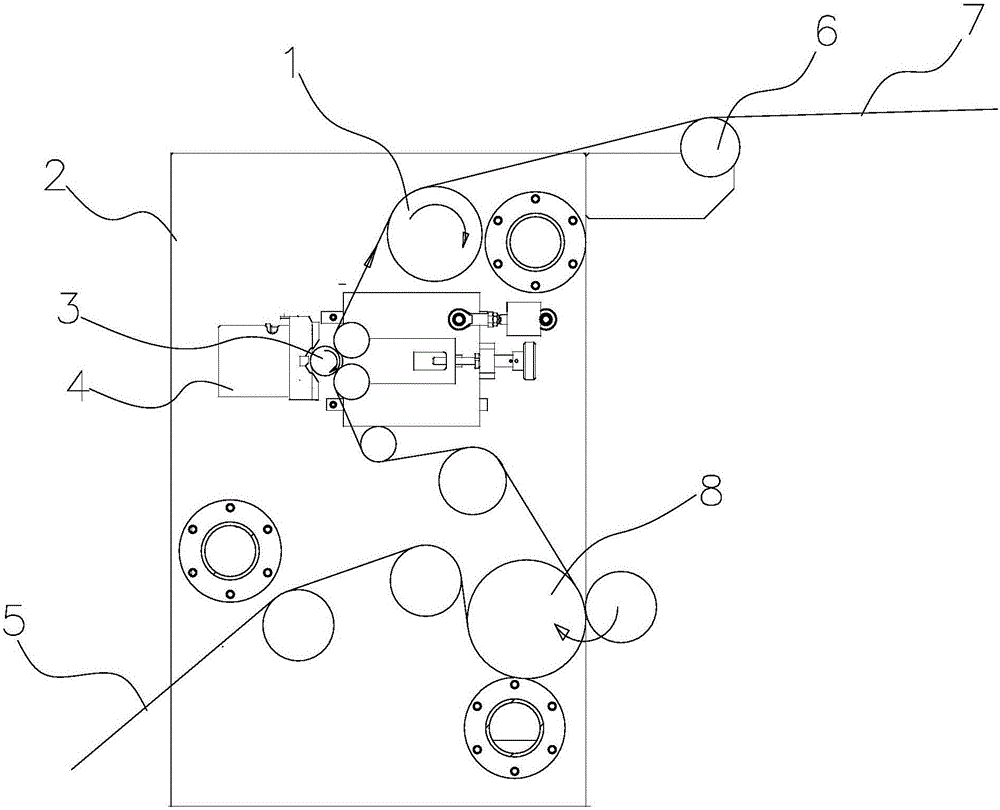

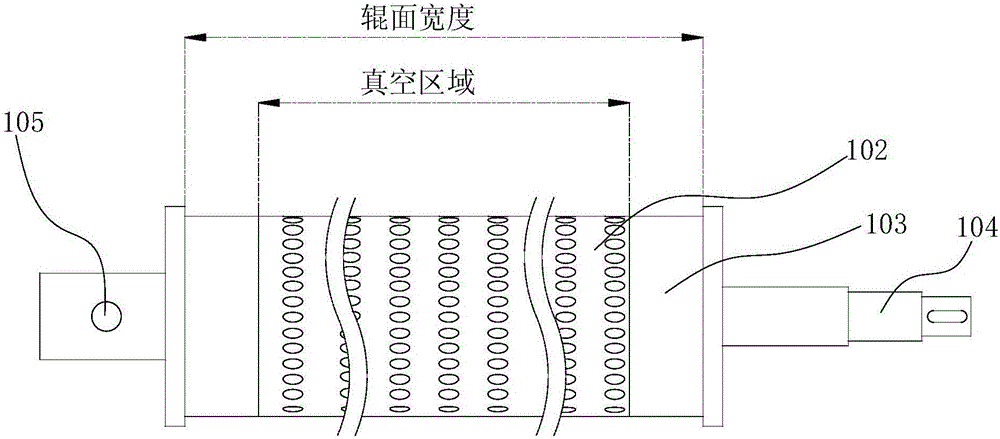

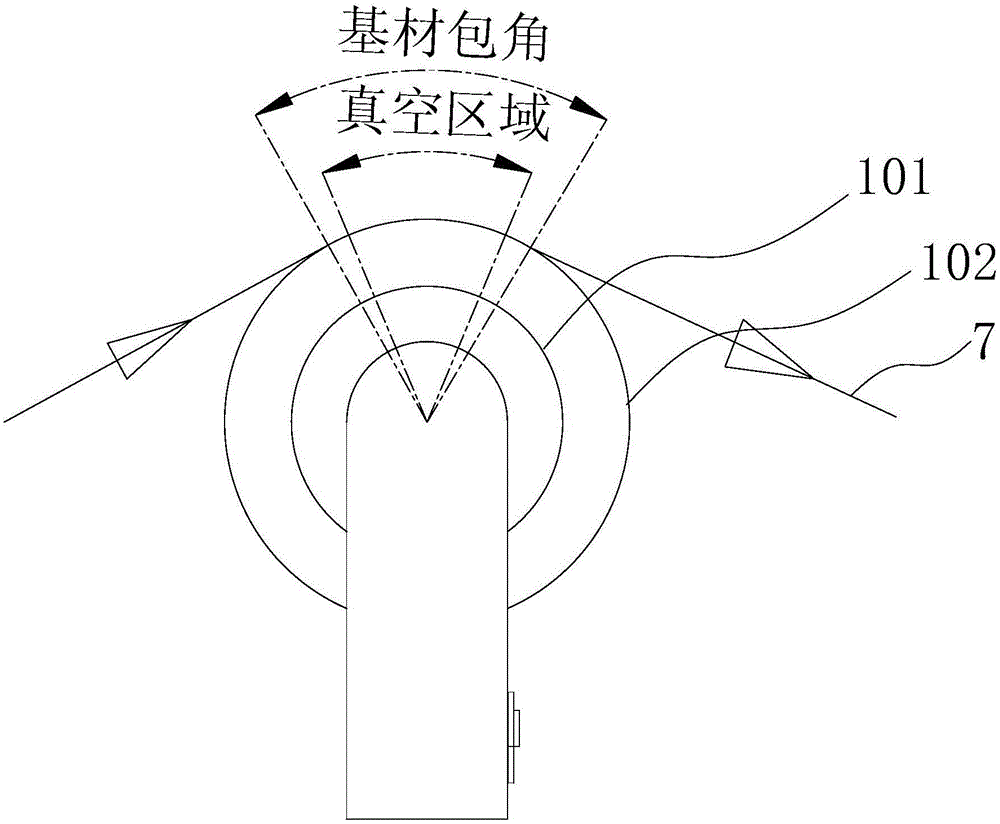

[0019] For the pressure roller device of a coating machine winding mechanism in this embodiment, please refer to the Figure 1 to Figure 3 , including a tension adjustment roller 8 fixed on the frame 2, one side of the tension adjustment roller 8 is pressed against a pressure roller, and the tension adjustment roller 8 goes around the base material 5 that exceeds half a circle of the tension adjustment roller 8, so After the substrate 5 is transferred to the coating structure, it is coated into a coating film 7 and is transferred to the oven by the vacuum adsorption roller 1; the tension adjustment roller 8 and the vacuum adsorption roller 1 are both driving rollers.

[0020] After the substrate 5 of this device bypasses the tension adjustment roller 8, a "tension cutoff" is formed. After the substrate 5 coated in the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com