Patents

Literature

245results about How to "Prevent being" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

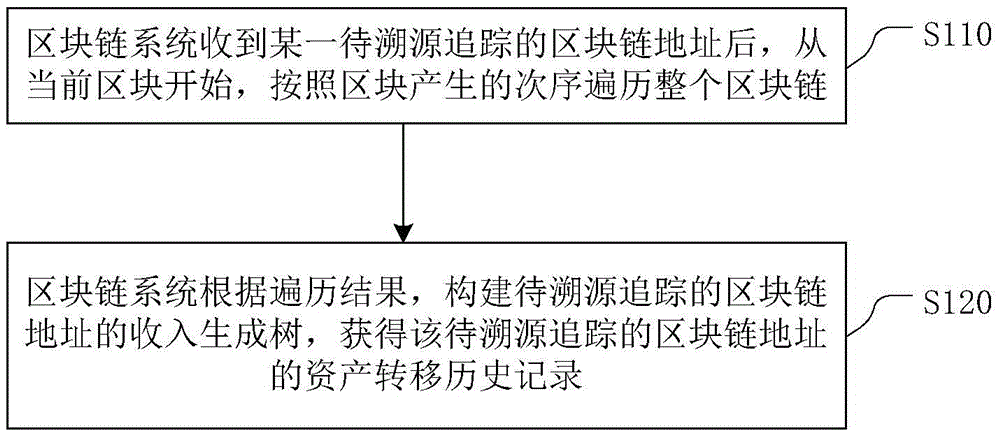

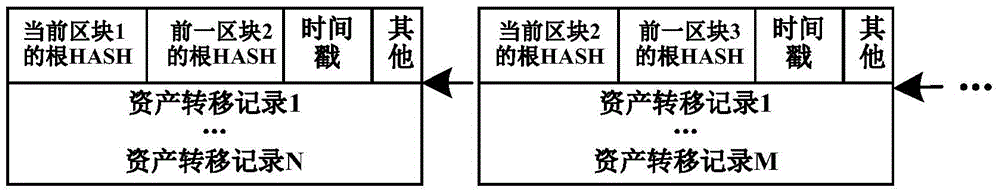

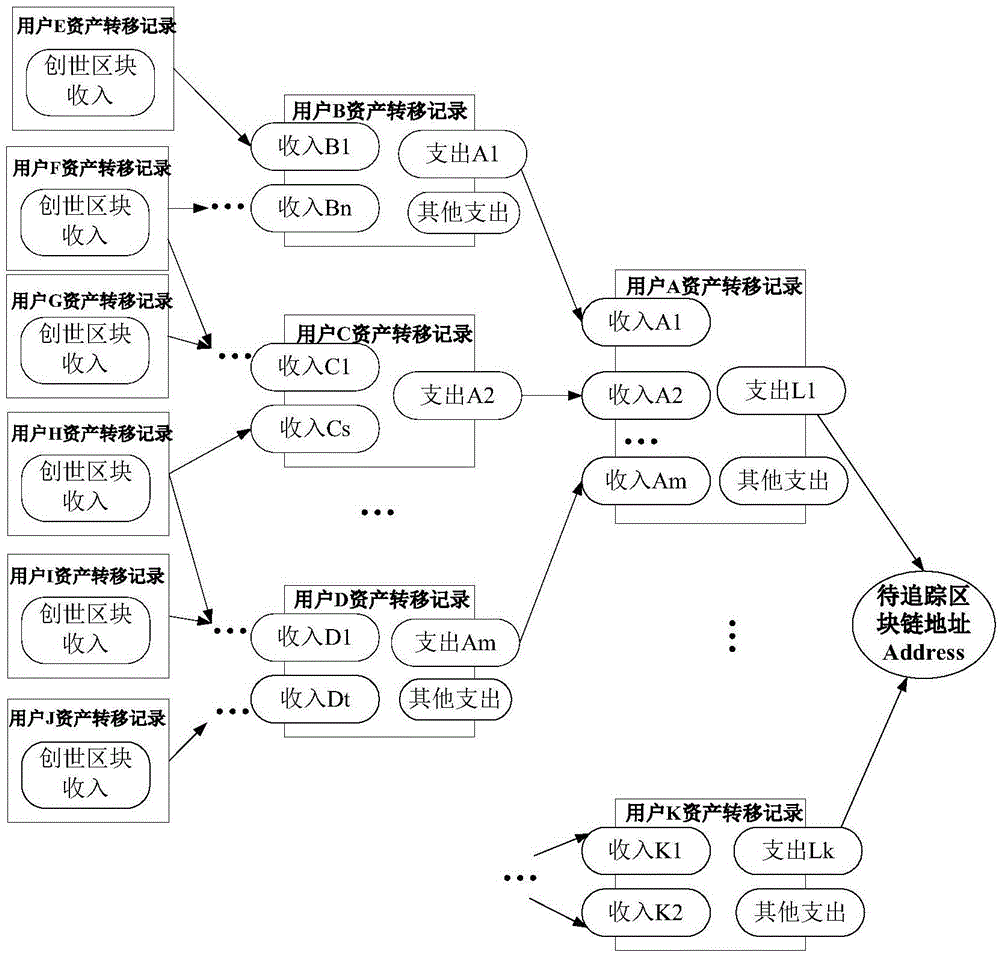

Block chain tracing method

The invention relates to a tracking method on internet, and provides a block chain tracing method. The method comprises the following steps: after receiving, by a block chain system, the address of a block chain to be traced, traversing the whole block chain by the block chain system according to the block generation sequence from the current block; and constructing, by the block chain system, an incoming generation tree and an outgoing generation tree of the address of the block chain to be traced according to the traversing result, so as to obtain an asset transformation history of the address of the block chain to be traced. The method is conducive to tracing the illegal using behaviors and illegal users of the block chain system so as to prevent the block chain system from becoming a tool utilized by the lawbreakers, so that basis is provided for the wider application of the block chain technology; and the method is mainly used for providing an audition function.

Owner:BUBI BEIJING NETWORK TECH CO LTD

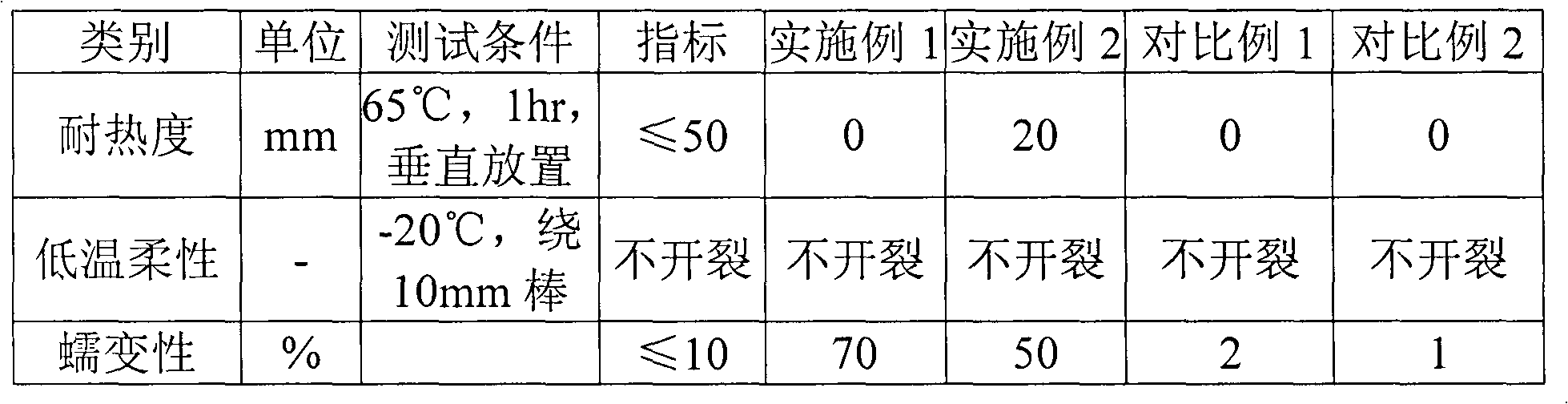

Modified asphalt composition with creeping characteristic and preparation method thereof

InactiveCN102020859AAvoid rapid agingExtended service lifeBuilding insulationsBituminous waterproofingMaterials science

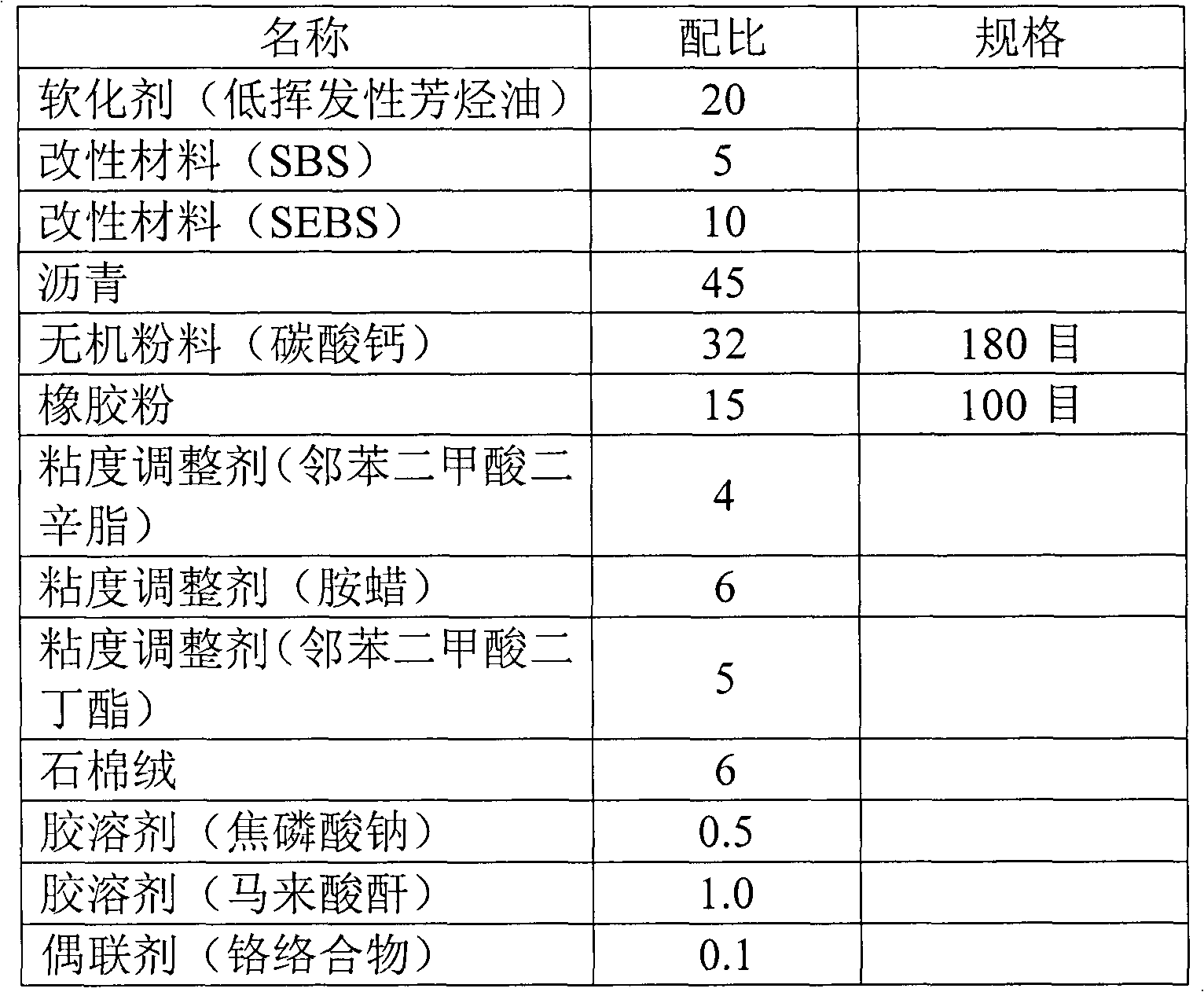

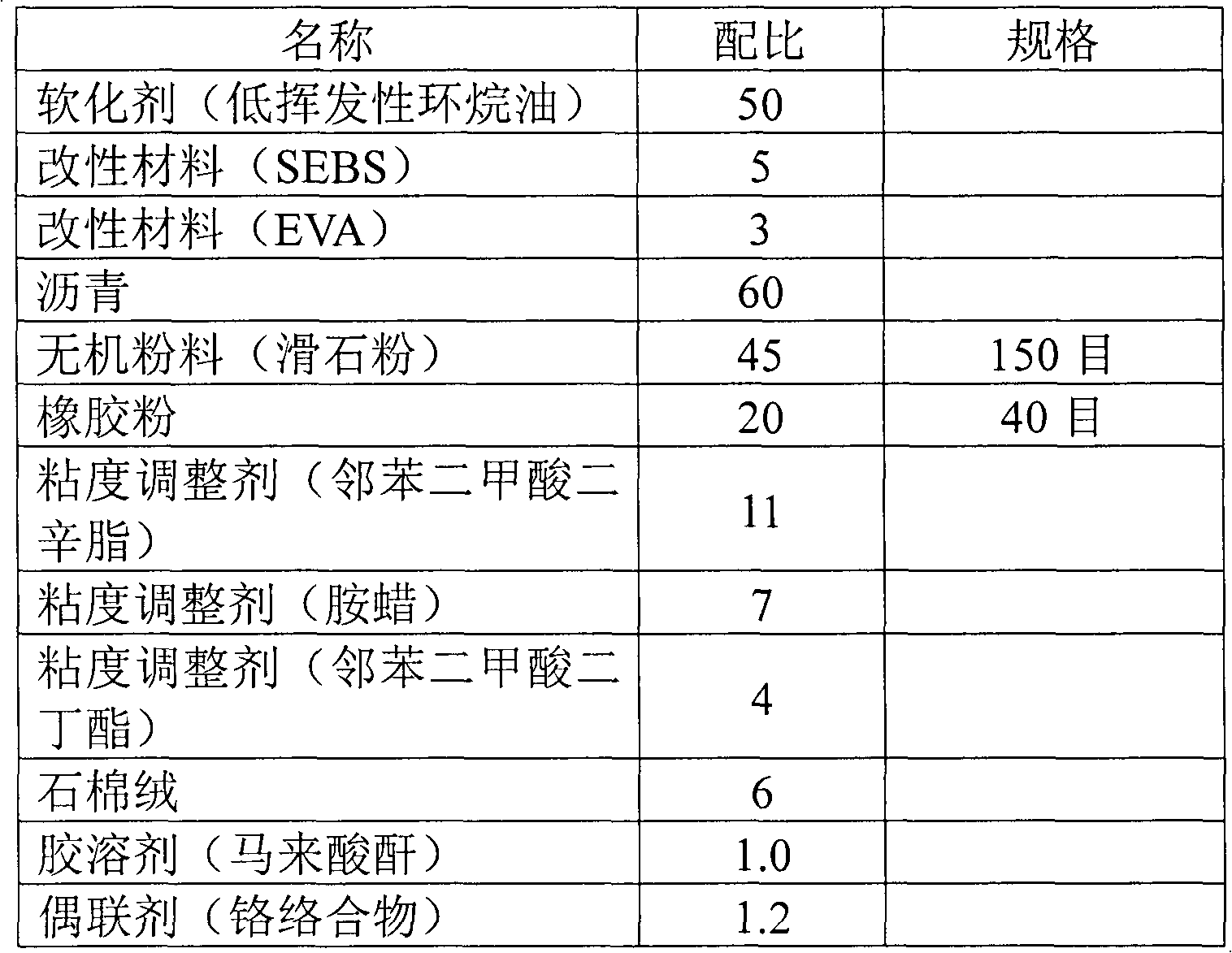

The invention provides a modified asphalt composition with a creeping characteristic, which comprises the following components in parts by weight: 15-60 parts of asphalt, 3-15 parts of modifying material, 5-30 parts of rubber powder, 15-60 parts of softening agent, 15-60 parts of inorganic powder, 3-25 parts of viscosity regulating agent, 0.3-1.5 parts of peptizing agent and 0.1-2 parts of coupling agent. A preparation method of the modified asphalt composition comprises the following steps of: adding the softening agent into a reaction kettle, heating to 170 to 200 DEG C, adding the modifying material, agitating, adding the asphalt and the rubber powder, and agitating for 1-2 h to obtain an intermediate raw material; levigating the intermediate raw material to 150-250 meshes, and putting back to the reaction kettle; and finally, adding the inorganic powder, the viscosity regulating agent, the peptizing agent and the coupling agent into the reaction kettle, agitating and dispersing uniformly. The modified asphalt composition has the characteristics of excellent water-proof performance, strong binding capability and continuous binding capability, large elongation percentage and good low-temperature flexibility.

Owner:ZHEJIANG WOPUMAN HIGH NEW MATERIALS

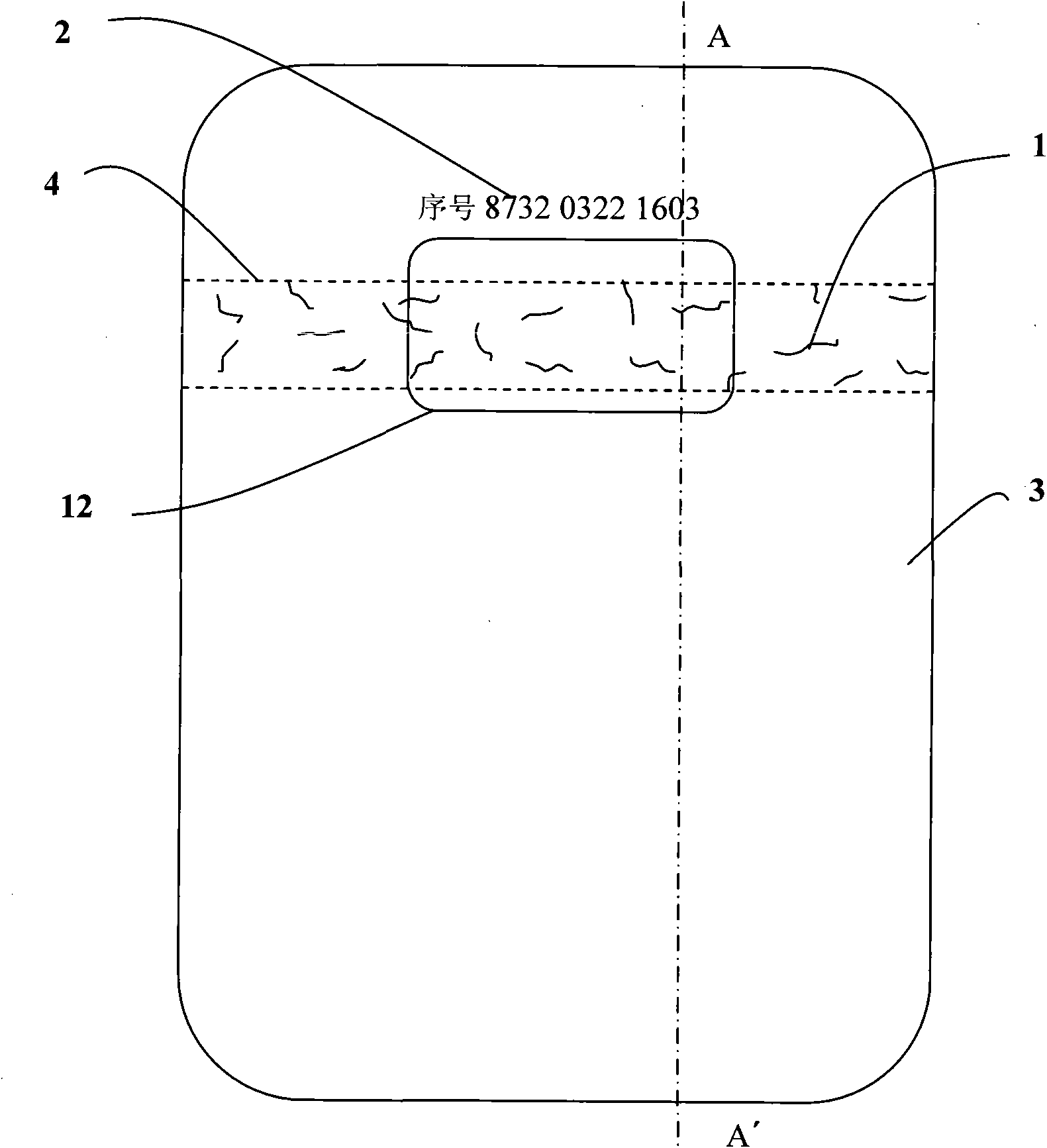

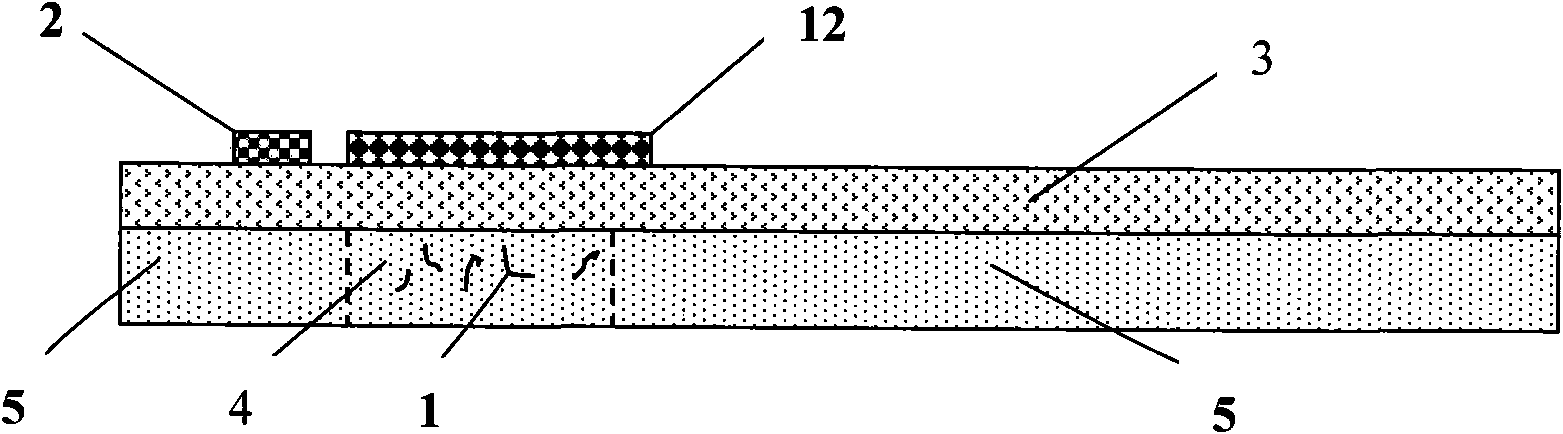

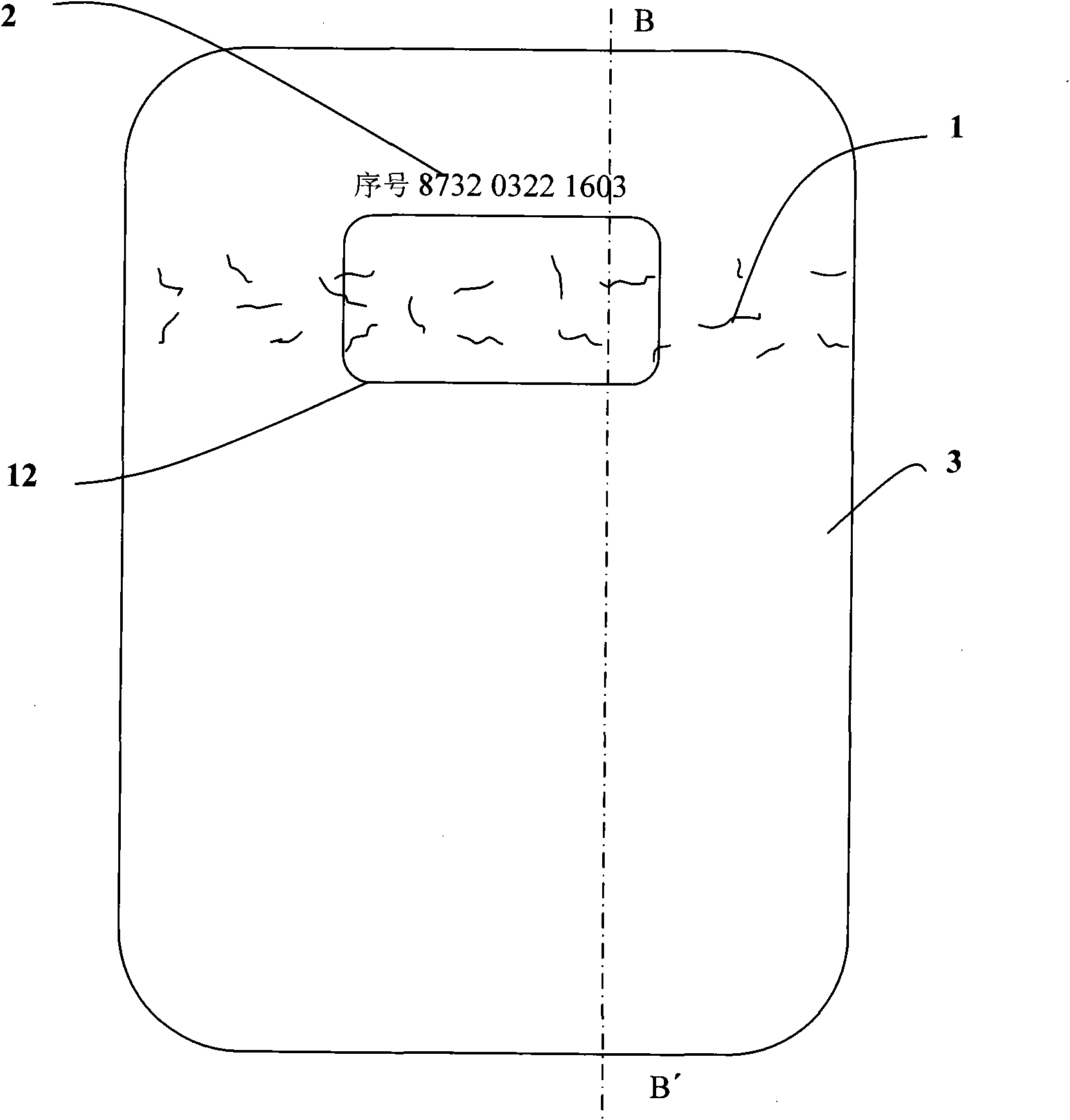

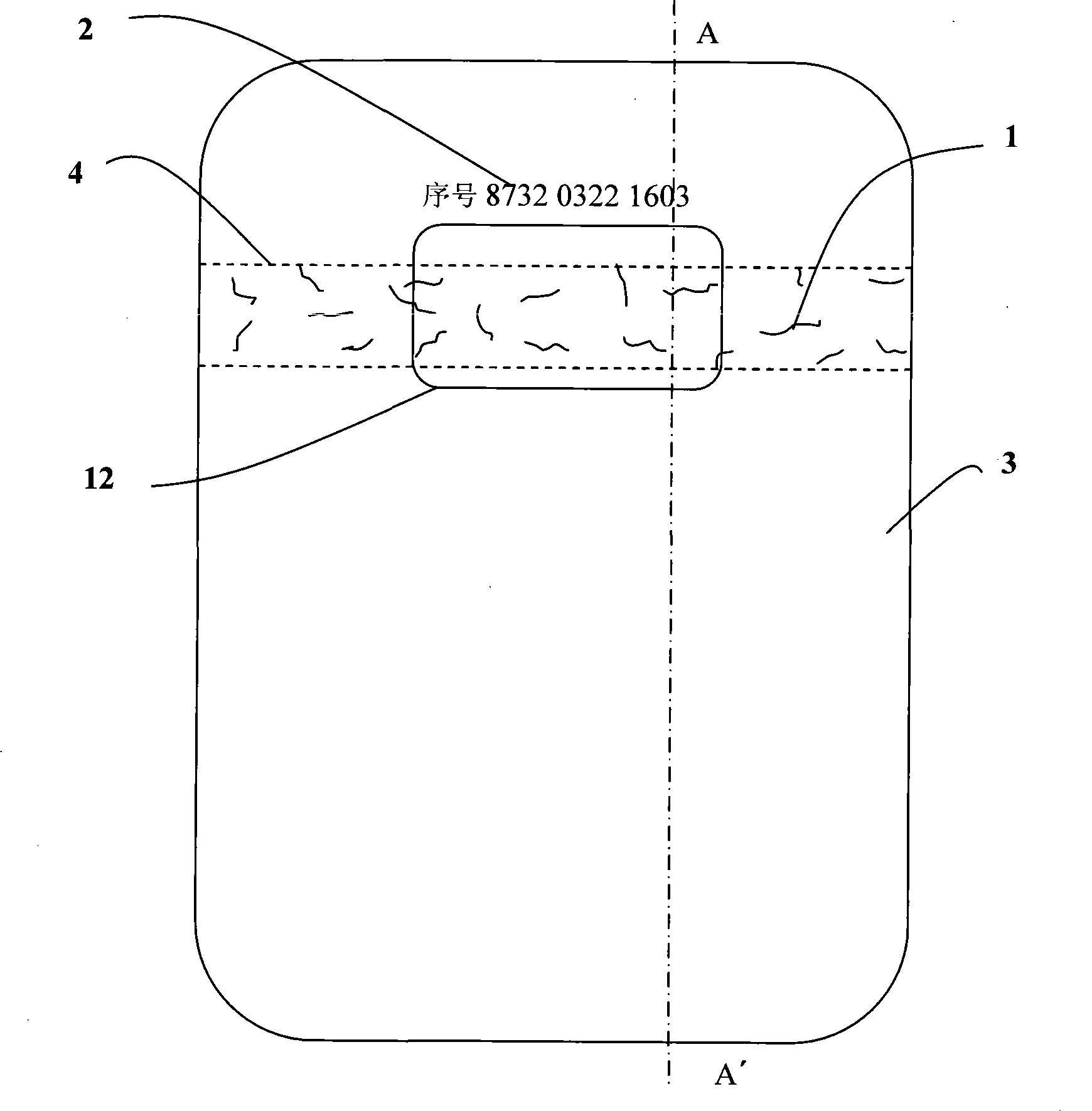

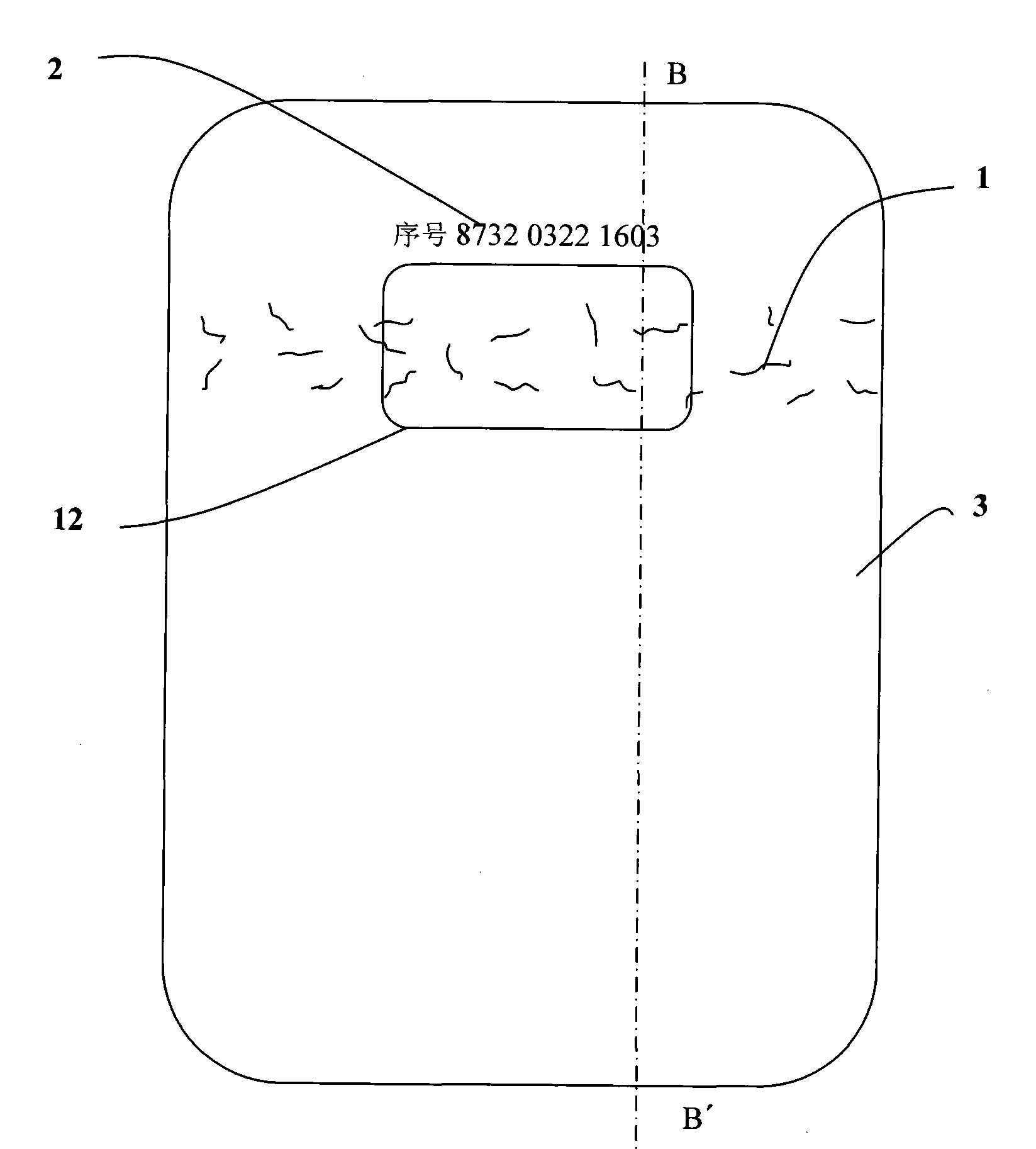

Local grain anti-counterfeiting print

ActiveCN101556750AEasy to produceReduce manufacturing costStampsIdentification meansTelephone networkFiber

The invention provides a local grain anti-counterfeiting print, fiber grains are directly fabricated at a local region on the print, randomly distributed characteristic information of fiber is scanned, collected and stored in a database of a computer anti-counterfeiting inquiry system connected to a telephone network or / and the Internet for the masses to check truth; the print can be produced by utilizing fibreless grain materials including current standard paper, films and the like, can avoid specific paper making and film making, lightens the influence of the fiber on the aesthetic sensibility of the print, and can prevent a fake producer from continuing to use the print after uncovering the print.

Owner:HAINAN PPK NETWORK TECH

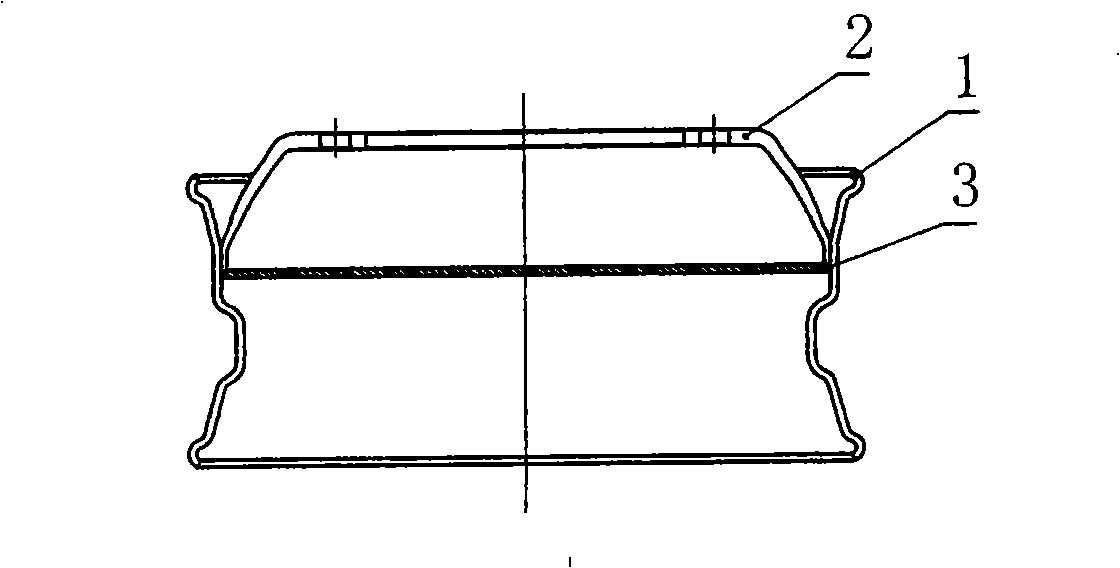

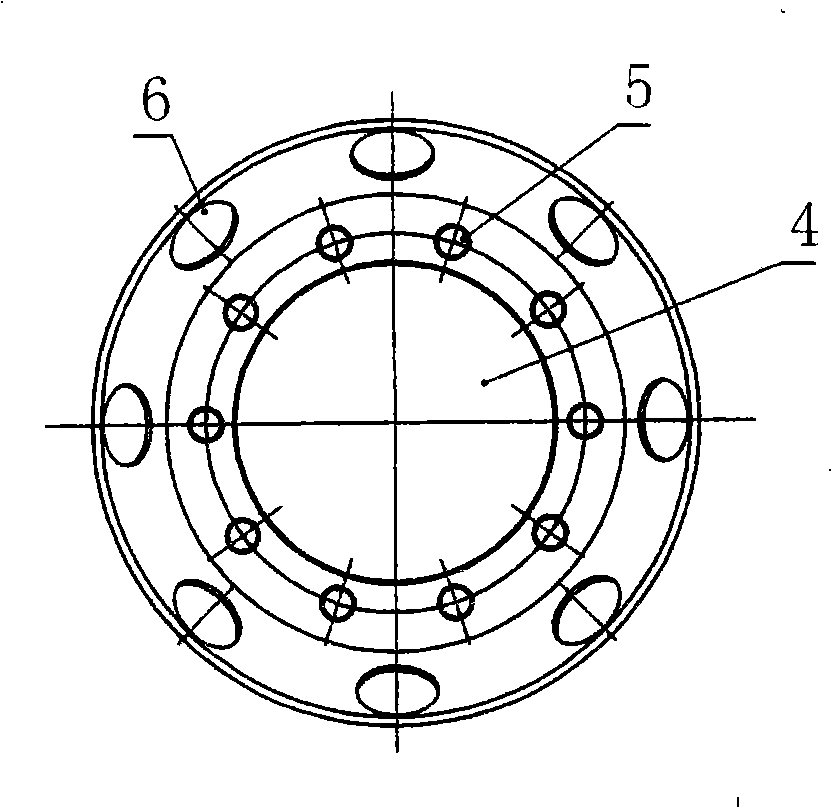

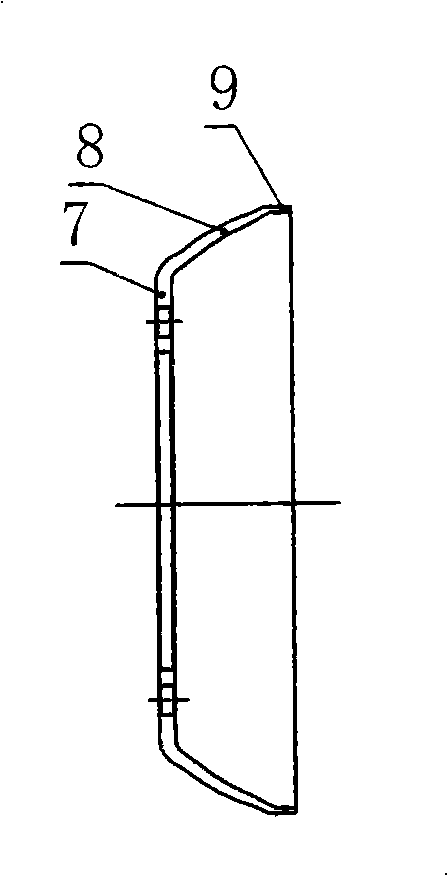

Process for manufacturing steel spoke

The invention relates to a manufacturing technique of a steel wheel rib, which adopts cylinder stock to replace the traditional sheet. The manufacturing technique adopts the technique steps that: the cylinder stock is prepared; the cylinder stock is rolled on a roll forming machine to form a cup in-process material with symmetric axial direction, big diameter at two ends and small diameter at a middle groove; the cup in-process material is cut off at the centre to form two same bowl in-process materials; the bottoms of the bowl in-process materials on a spinning machine are spin-formed to a plane, so as to ensure the whole workpiece to be a bowl intermediate product; a central technique hole is punched; a transition curved segment and a tangential path are spun; a central hole / a bolt hole and a wind-punching hole are punched; the lathe work includes central hole processing / a plane / an excircle / an end plane mounting, letter pressing and other working procedures. The cylinder stock can be directly prepared with a steel pipe, and also with a steel belt circle / welding technology. Compared with the traditional manufacturing technique, the manufacturing technique for the steel wheel rib can avoid the steel plate at the periphery of blanking disc type stock from wasting material, and reduce the waste material generated from the pre-punching central hole working procedure, thereby greatly improving the utilization ratio of the material.

Owner:JIAXING STONE WHEEL

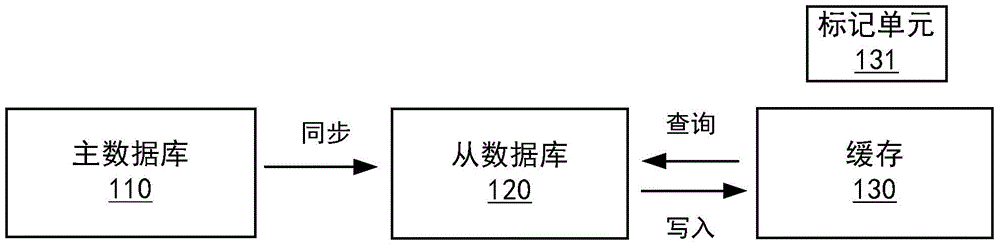

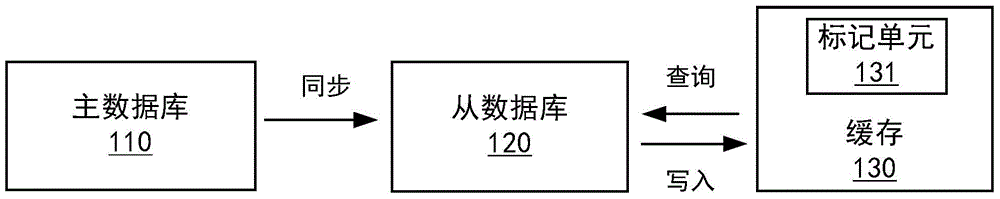

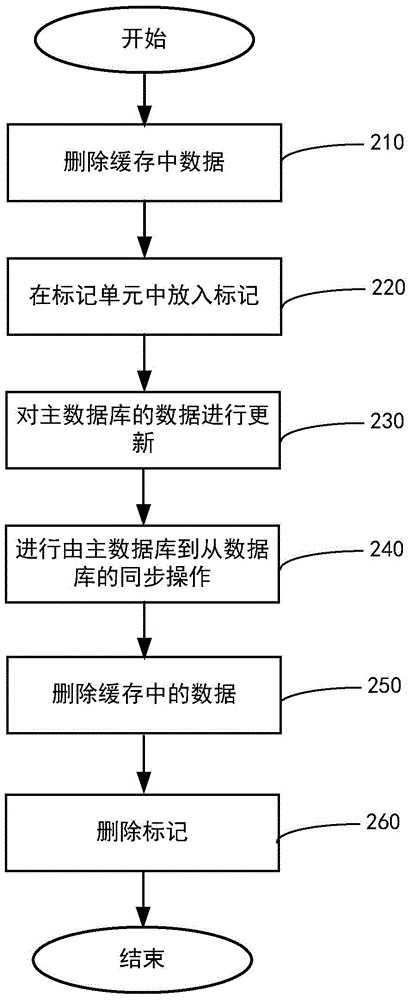

Distributed service system as well as data updating method and data query method thereof

ActiveCN103955486APrevent beingEliminate the risk of data inconsistenciesDatabase updatingSpecial data processing applicationsData synchronizationDistributed services

The invention provides a data updating method of a distributed service system. The system comprises a main database, a slave database and a cache. The method comprises the following steps of a, deleting data in the cache; b, placing a mark into a marking unit; c, updating data of the main database; d, deleting data in the cache again, and synchronizing the data in the main database to the slave database; e, deleting the mark. The invention also discloses a data query method of the distributed service system and the distributed service system. Consistency of data in the cache and data in the databases is ensured, and the risk of data inconsistency caused by high concurrency and main-slave synchronization delay is eliminated.

Owner:BEIJING 58 INFORMATION TECH

Local grain anti-counterfeiting print

ActiveCN101556750BEasy to produceMitigate the impact of aestheticsStampsIdentification meansFiberThe Internet

Owner:HAINAN PPK NETWORK TECH

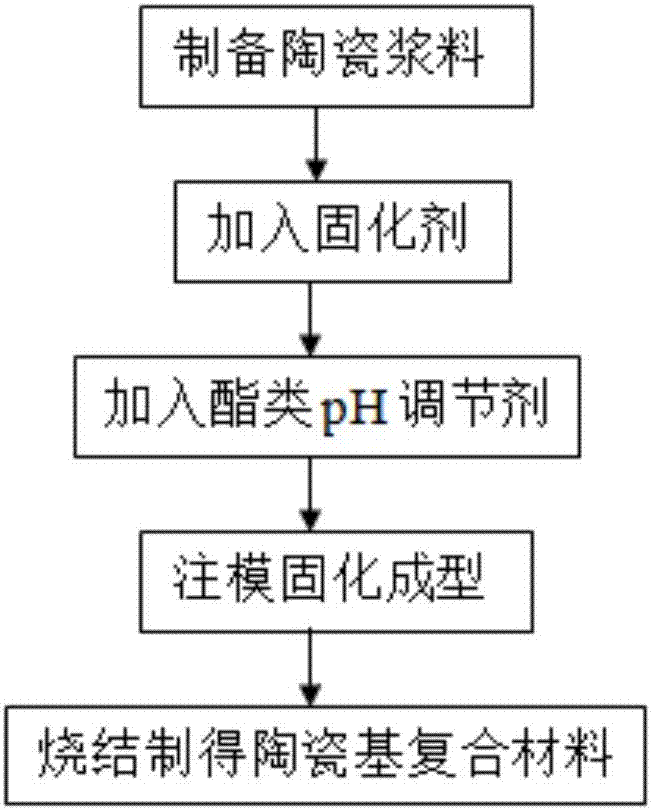

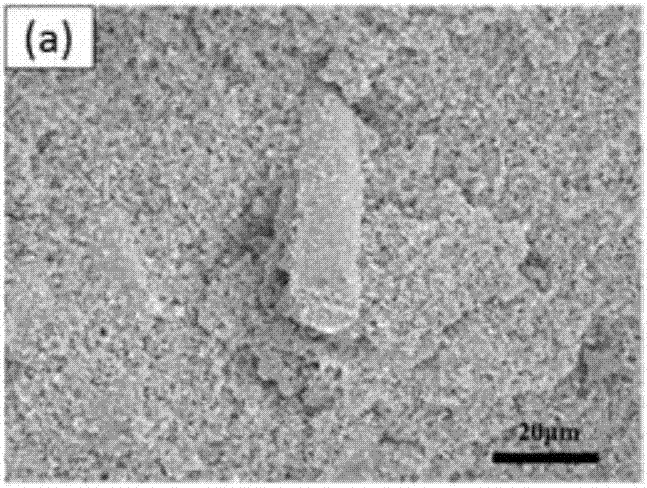

Method for rapidly preparing inorganic fiber-enhanced ceramic composite material

The invention belongs to the technical field of inorganic non metal, and concretely relates to a method for rapidly preparing an inorganic fiber-enhanced ceramic composite material. The method comprises the following steps: ceramic powder, inorganic fiber, a dispersant and deionized water are uniformly mixed through ball milling, the uniform ceramic slurry with negative electricity is on the surface of ceramic powder particles; a curing agent containing high-valence counter ions is added and is subjected to ball milling; an esters pH conditioning agent is added in the obtained slurry; then the material is stirred under vacuum condition and is degassed, the material is slowly injected into a nonporous die, then is demoulded through water-bath heating to obtain a wet blank, the wet blank is dried to the dried blank; and the ceramic composite material is obtained through sintering. According to the prepared inorganic fiber-enhanced ceramic composite material, compared with the ceramic without inorganic fiber, the bending strength at room temperature is increased by about 30%, the ceramic composite material is uniform and consistent, the time required by the method is short, an organic matter is not required for being added, rubber discharge is not required, and the ceramic composite material having complex shape is obtained.

Owner:HUAZHONG UNIV OF SCI & TECH +2

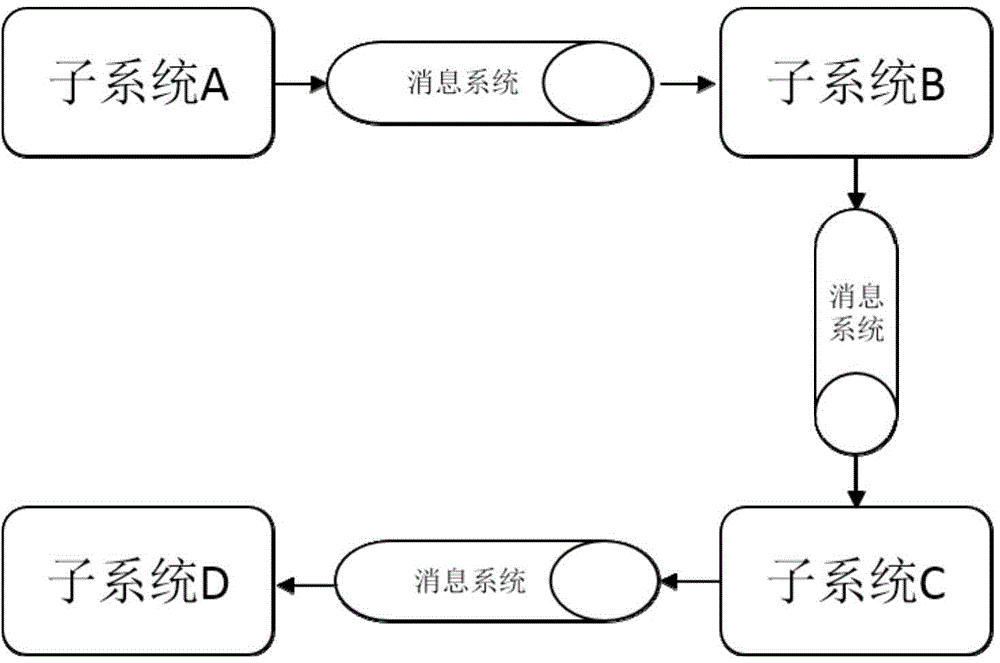

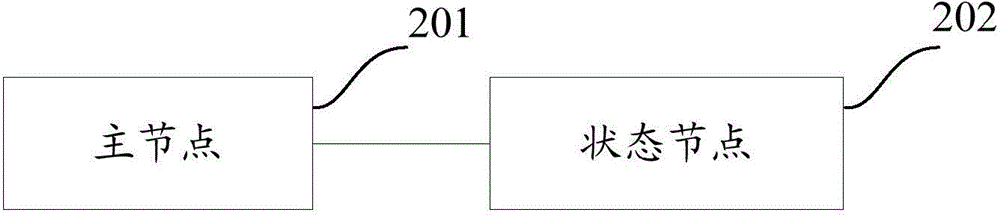

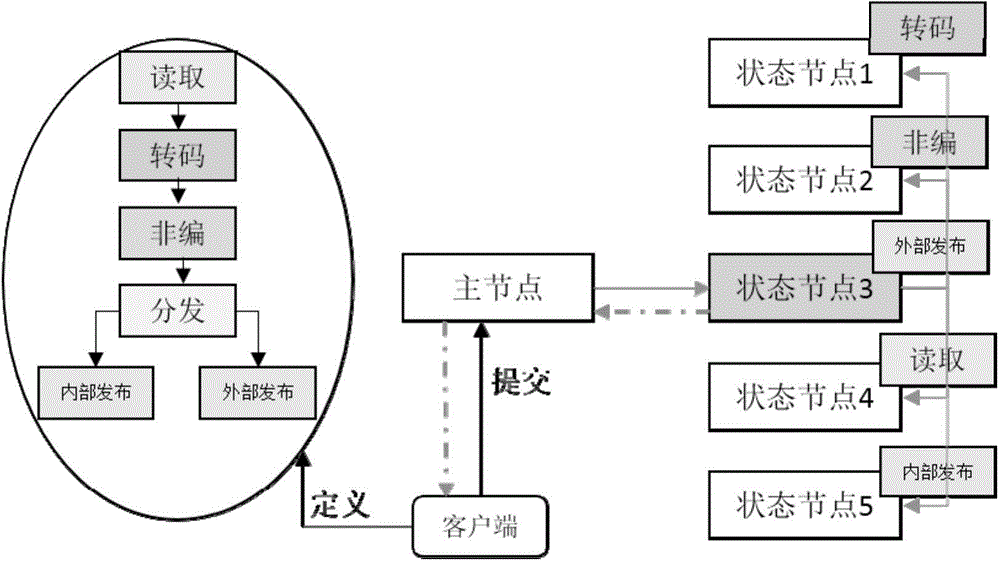

Distributed workflow device and method for processing workflow by distributed workflow device

ActiveCN104102949AAvoid Single Points and BottlenecksImprove stabilitySpecial data processing applicationsWorkflow processSoftware engineering

The embodiment of the invention provides a distributed workflow device and a method for processing workflow by the distributed workflow device, wherein the distributed workflow device concretely comprises a main node and state nodes in a cluster; the main node is used for allocating one corresponding state node to a workflow definition submitted by a user; the workflow definition provides a task interface, and the task interface can be used for calling a sub system for executing a corresponding workflow task; each state node is used as a management calling node for compiling the workflow definition into the workflow task and the corresponding task interface, and distributing the workflow task and the corresponding task interface to the corresponding state node; and the state nodes are also used as task executing nodes for executing the workflow task by the corresponding sub system called by the task interface. The distributed workflow device and the method provided by the embodiment have the universality, and the workflow processing stability and throughput can be improved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

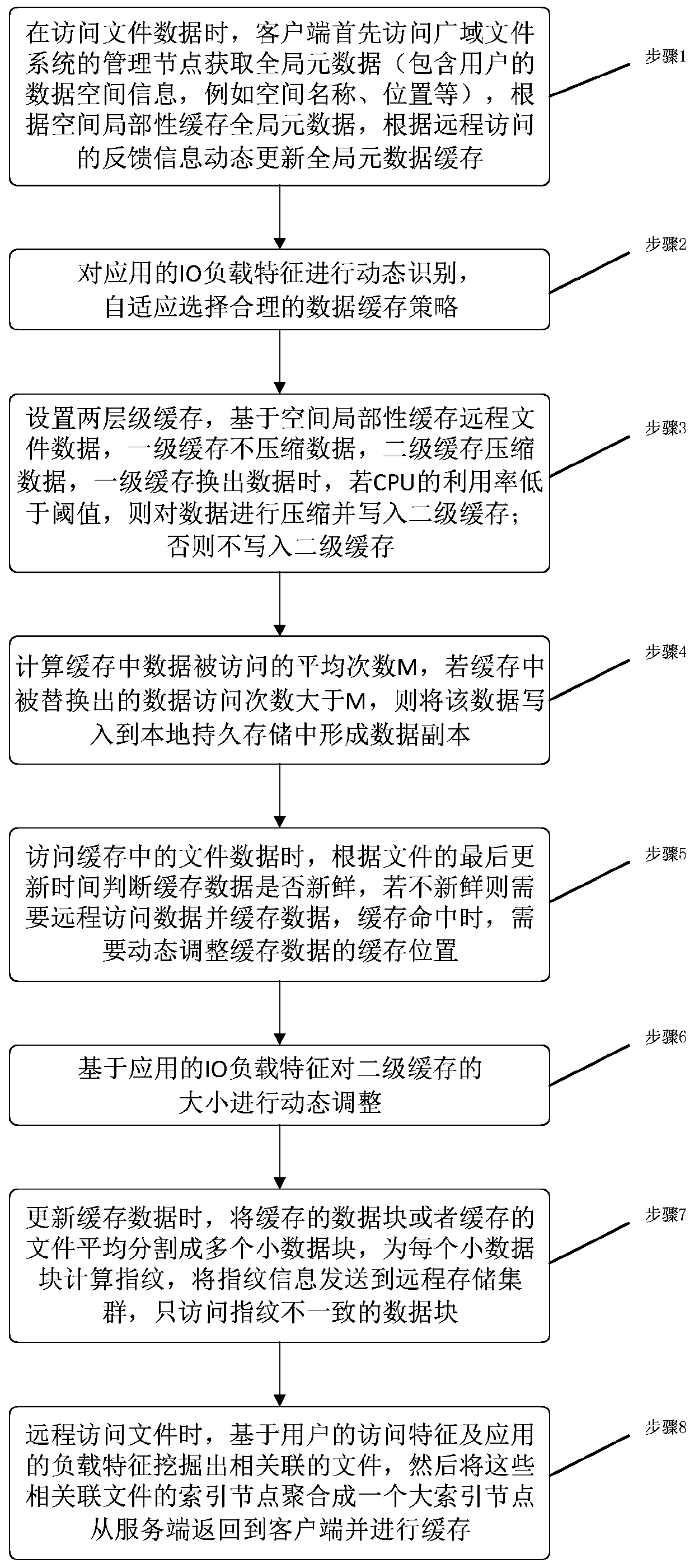

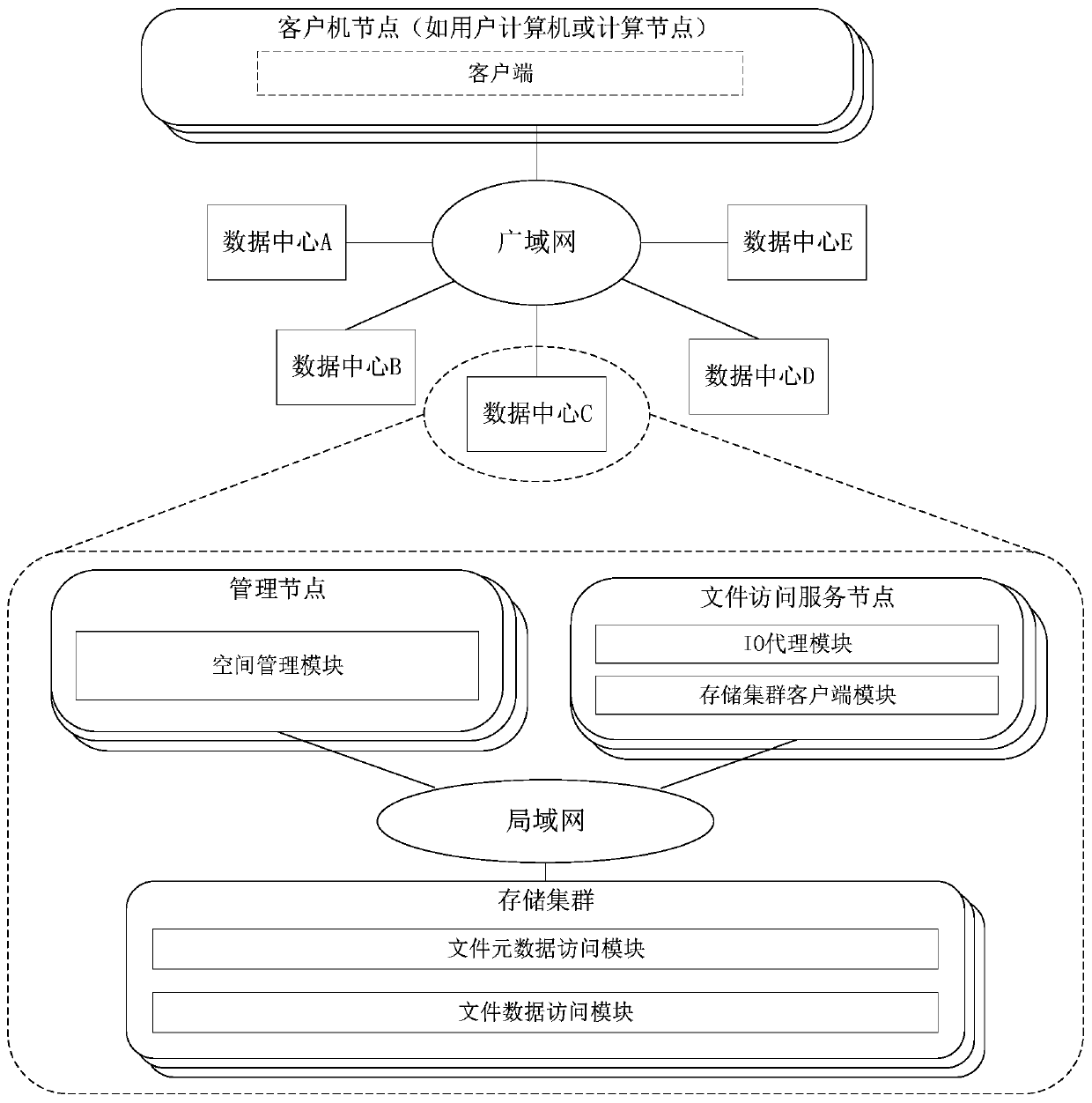

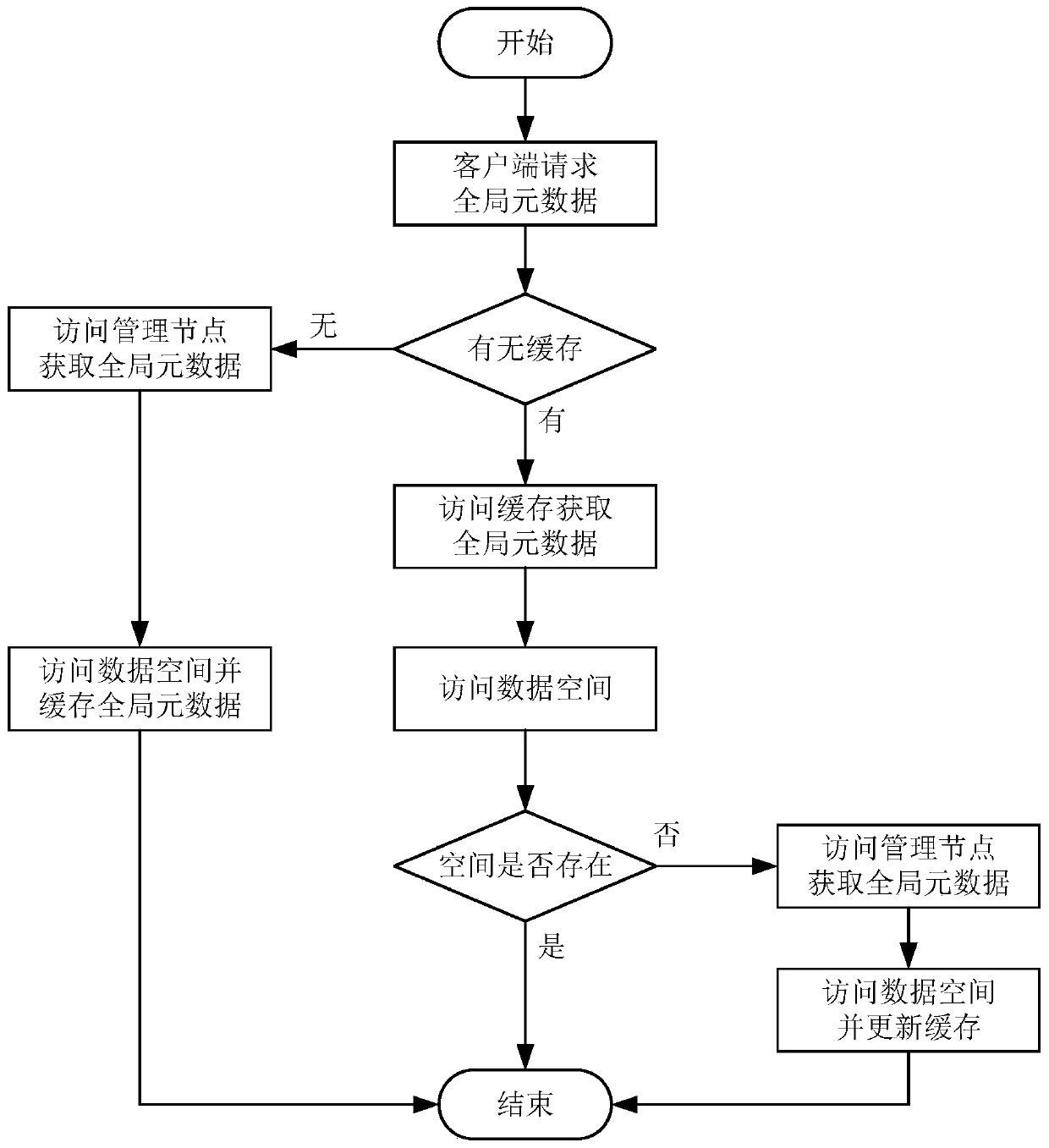

Remote file data access performance optimization method based on efficient caching of client

ActiveCN110188080AReduce the amount of remote actual transmissionPrevent beingFile access structuresSpecial data processing applicationsAdaptive compressionGranularity

The invention provides a remote file data access performance optimization method based on the efficient caching of a client. The method comprises the steps of caching the global metadata and the filedata on the client based on a locality principle; caching the file data by adopting a mixed caching strategy based on the data block and the file as granularity; performing adaptive compression on thecache according to the use state of the computing resource; locally generating a copy file for the frequently accessed data; dynamically adjusting the size of the cache based on the IO load characteristics of the application; carrying out the fine-grained updating on the overdue cache data; and mining an associated file based on the access characteristics of the user and the load characteristicsof the application, and aggregating the index nodes of the associated file into a large index node and caching the large index node at the client. According to the method, the remote file data accessperformance can be remarkably improved.

Owner:BEIHANG UNIV

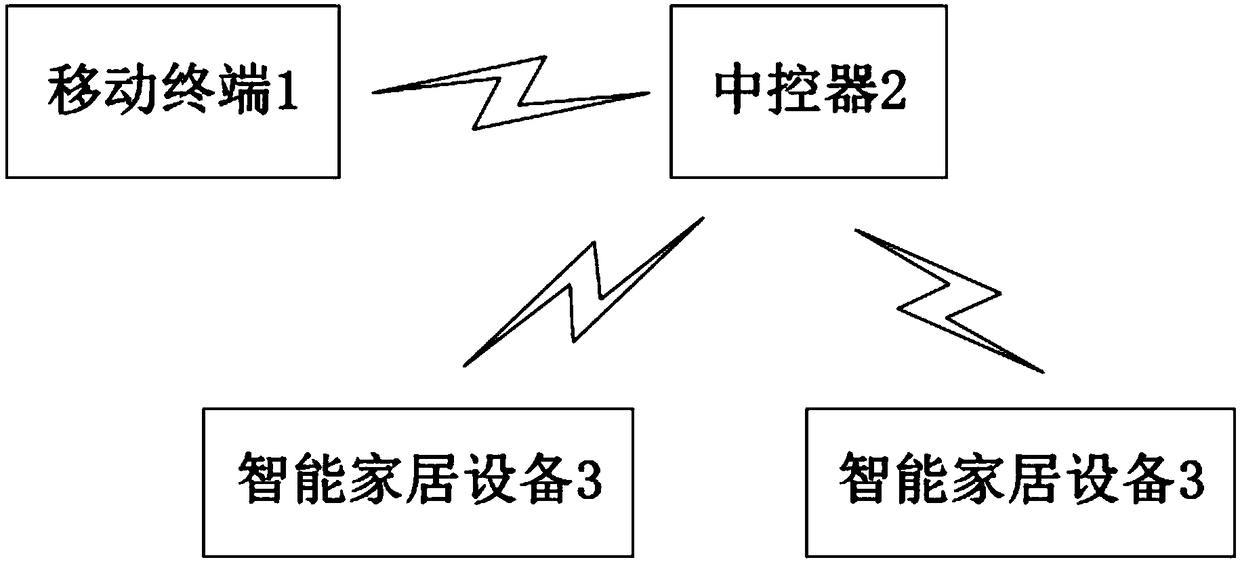

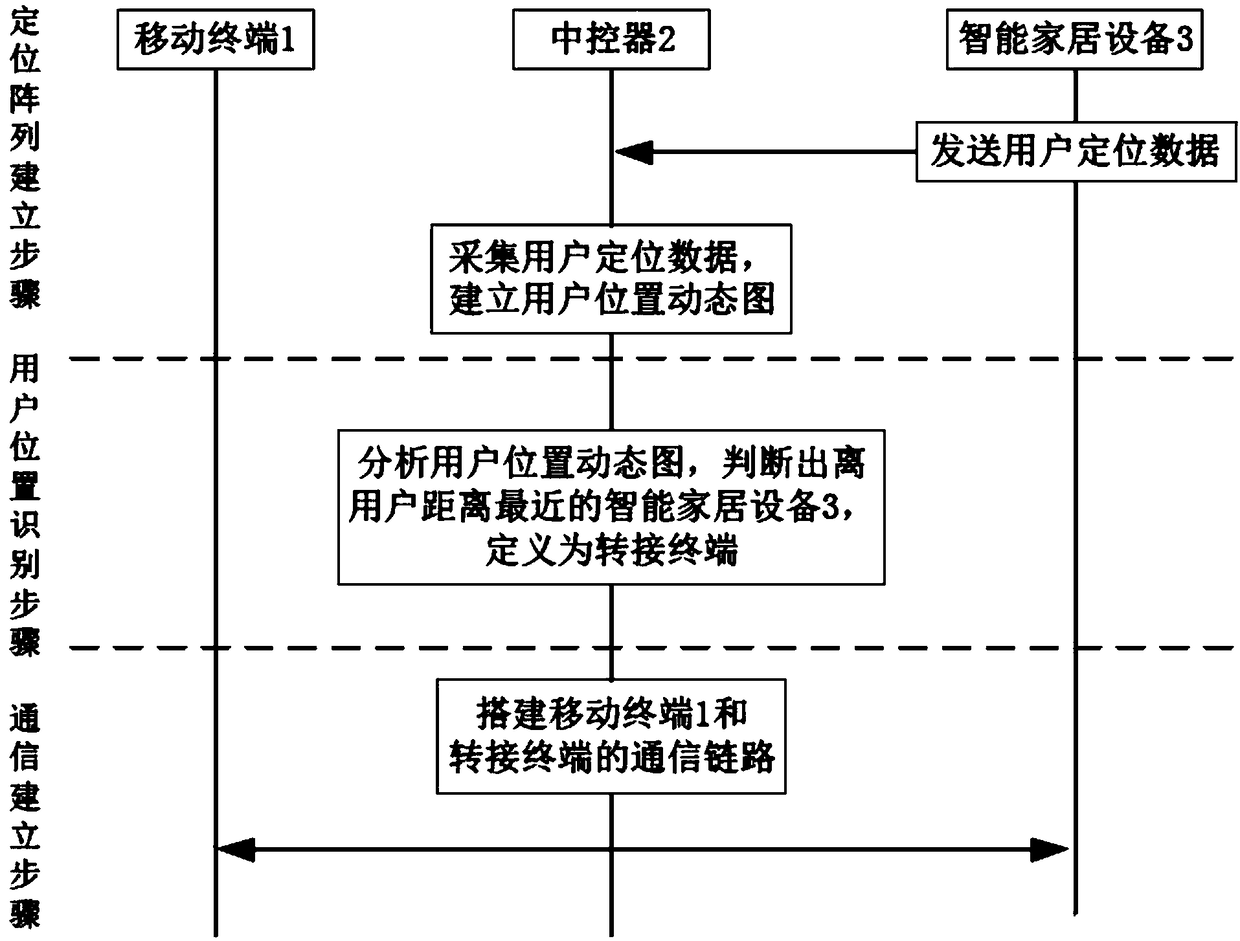

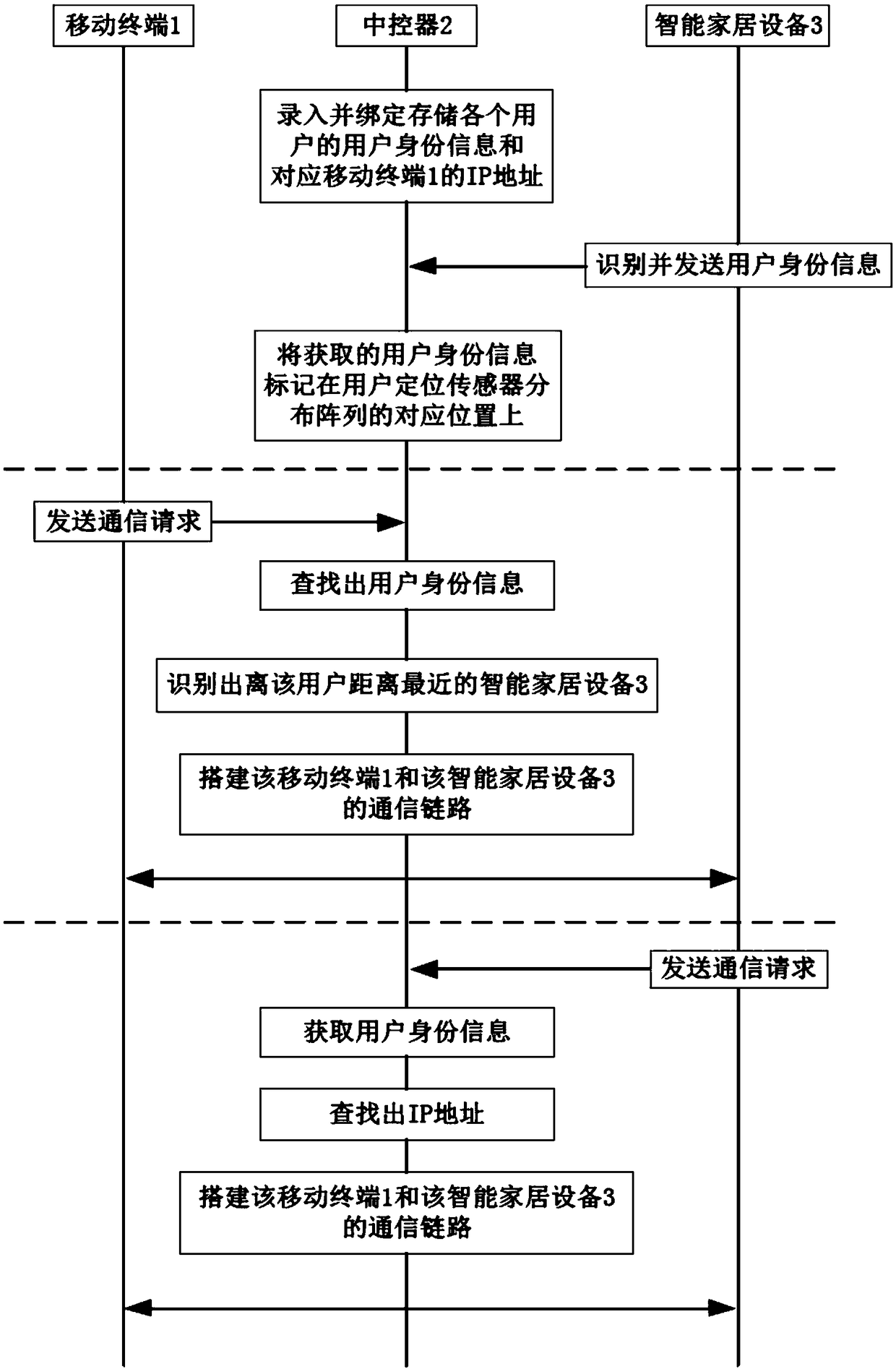

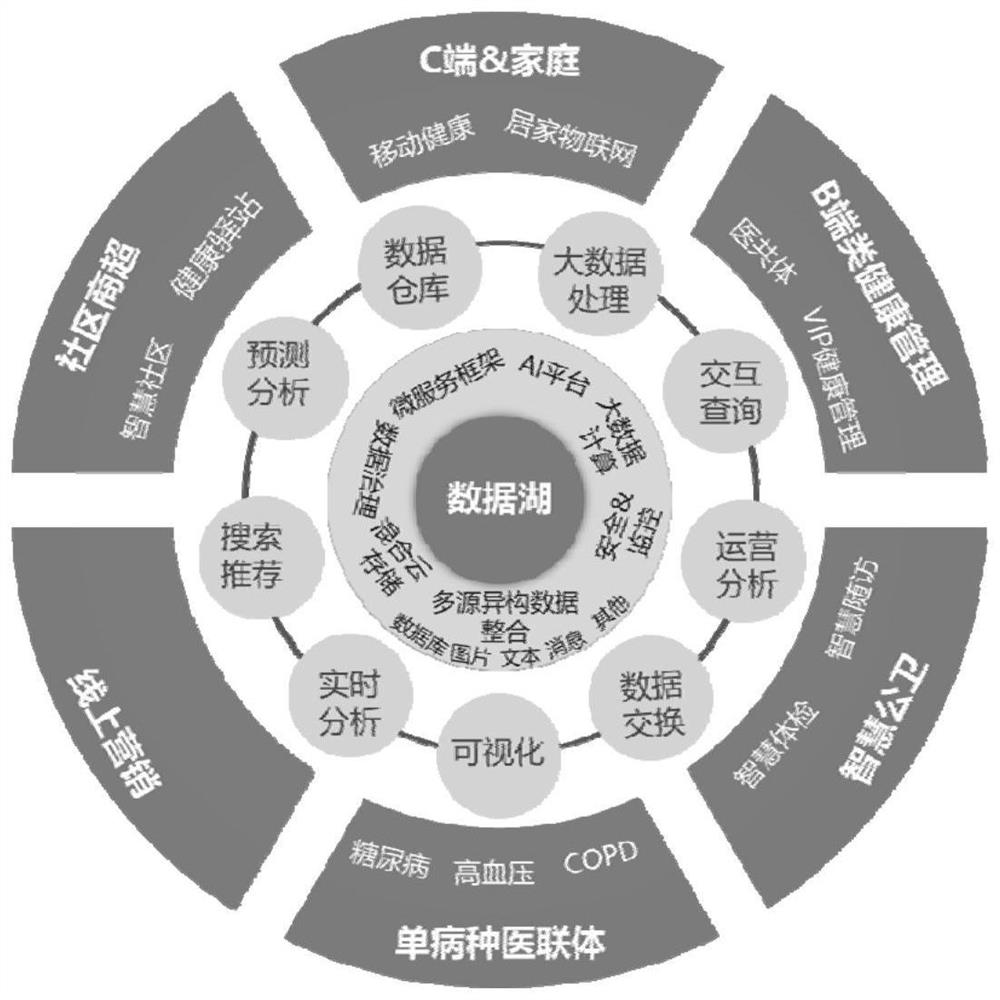

Communication method and system based on home smart interconnection

ActiveCN108900502APrevent beingIncrease communication timeSpeech recognitionLocation information based serviceTelecommunications linkComputer terminal

The invention discloses a communication method and system based on home smart interconnection. A central controller determines the smart home device closest to a user by analyzing a user position dynamic map. The smart home device is defined as a transfer terminal. A communication link is established between a mobile terminal and the transfer terminal. The transfer terminal is connected to the mobile terminal via the communication link and establishes a synchronous call. Therefore, a call or information is transferred to the smart home device closest to the user, and the user can answer the call or obtain the information through the smart home device. Thus, the user can answer the call or obtain the information timely without the mobile terminal after arriving at home. For example, the user can answer the call or obtain the information by the smart home device during cooking when it is not convenient for the user to operate the mobile terminal, so convenience is brought to the user.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

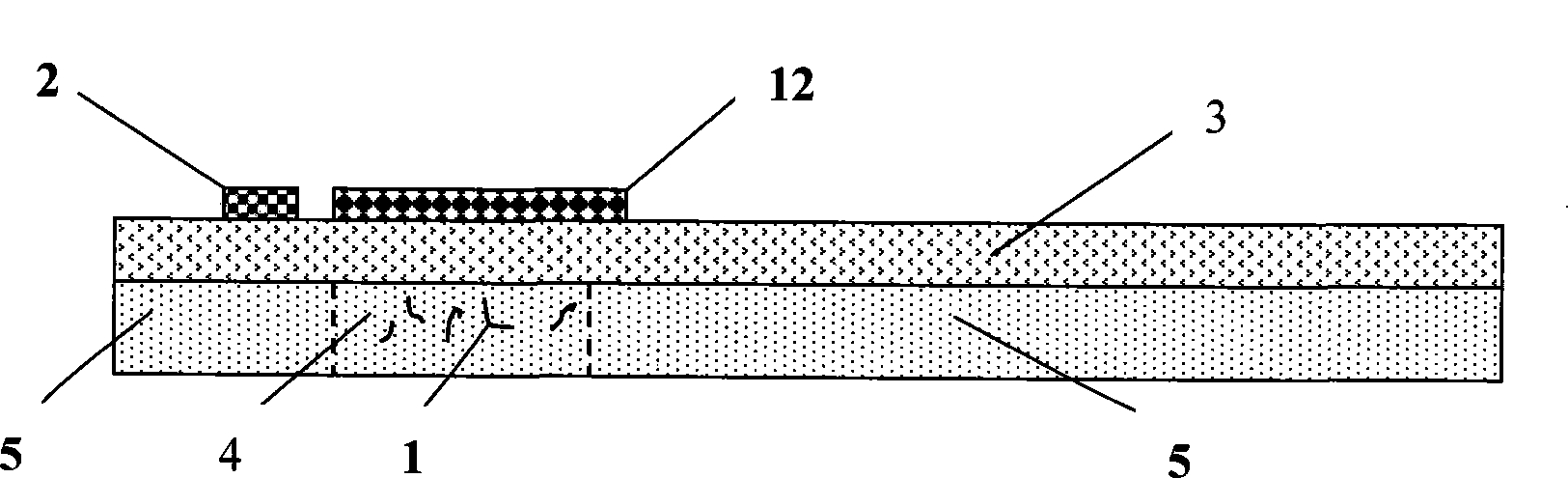

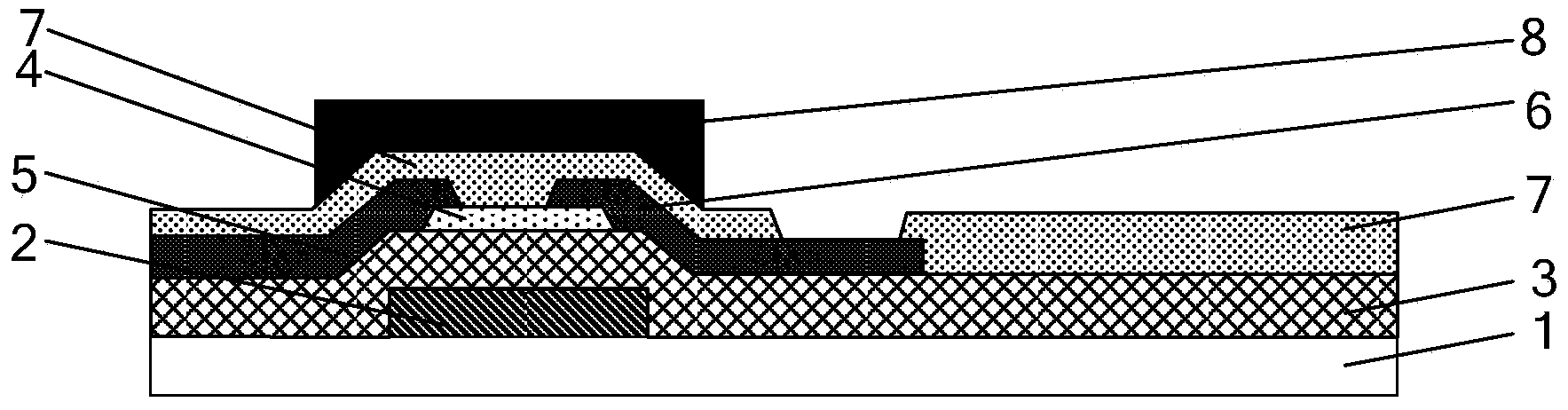

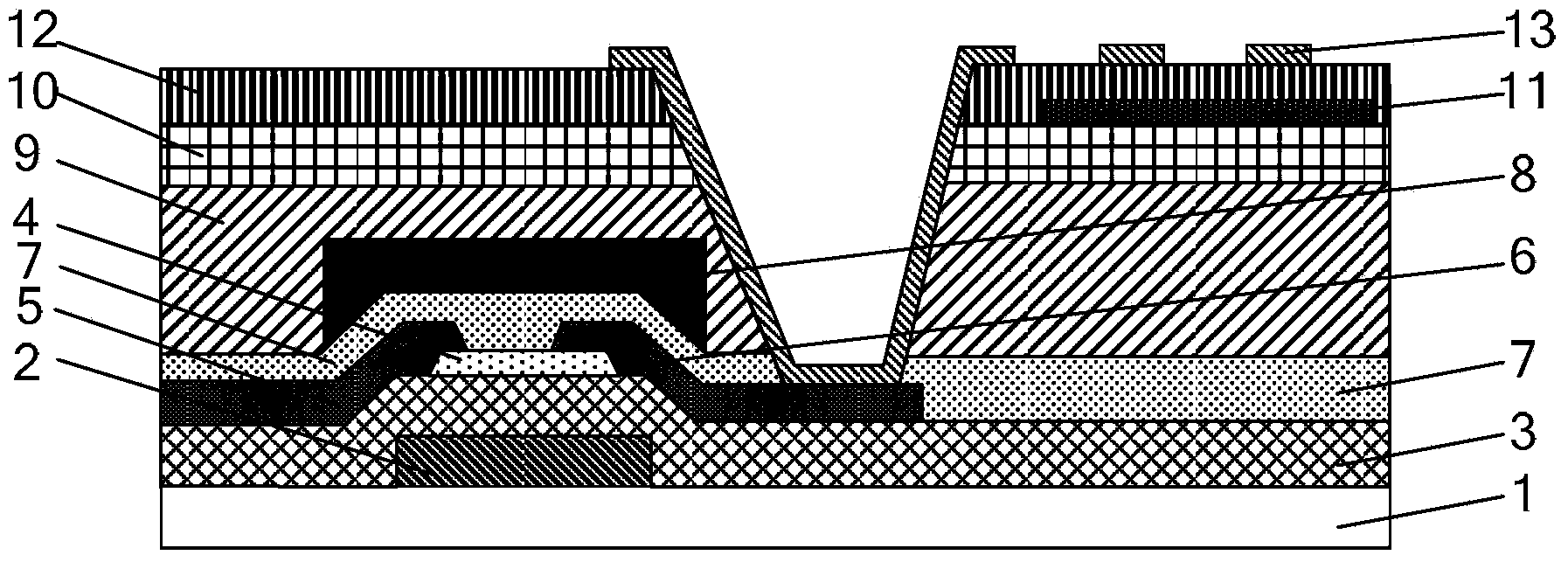

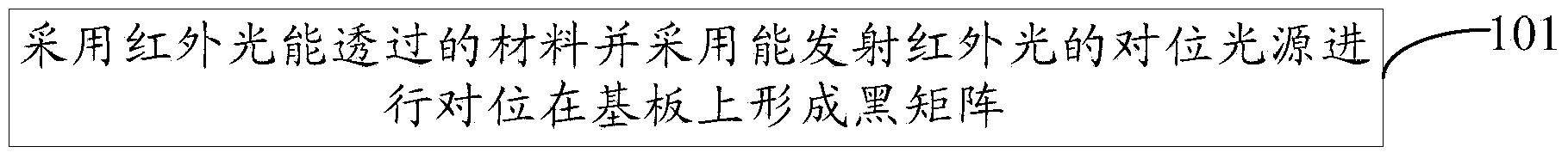

COA substrate, manufacturing method thereof and display device

InactiveCN104297980AAccurateImprove display qualityPhotomechanical apparatusNon-linear opticsManufacturing technologyDisplay device

The embodiment of the invention provides a COA substrate, a manufacturing method thereof and a display device, and relates to the field of the display technology. The problem that in an existing COA substrate, a black matrix cannot be aligned with a pattern of a layer structure in front of the black matrix when the black matrix is formed is solved. The display quality of the display device is improved, and the produced display device is prevented from becoming a defective good. The COA substrate comprises the black matrix made of materials through which infrared light can transmit. An aligning light source for aligning the black matrix with the pattern of the layer structure in front of the black matrix is the infrared light. The COA substrate is applied to the manufacturing technology of the display device.

Owner:BOE TECH GRP CO LTD

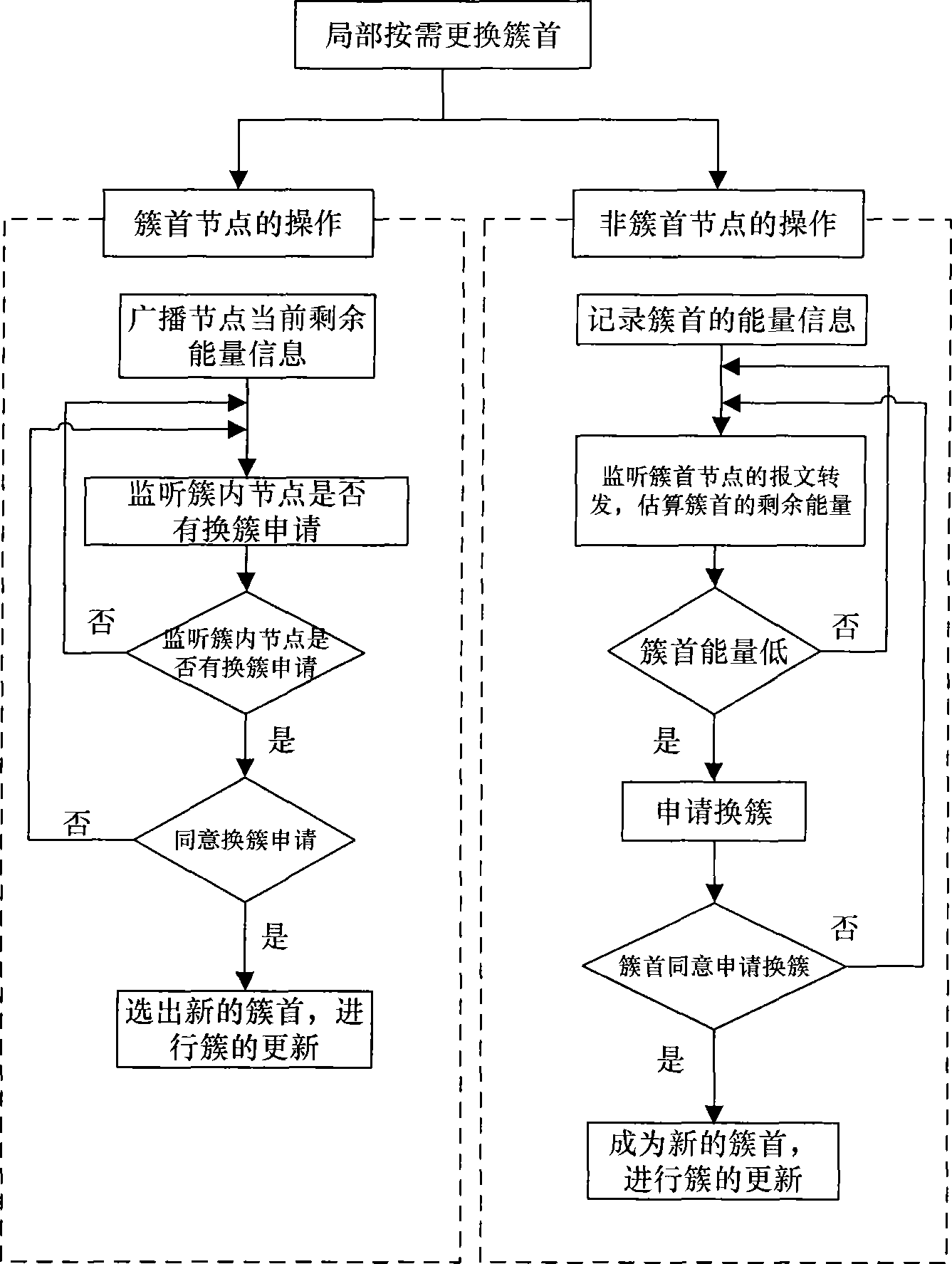

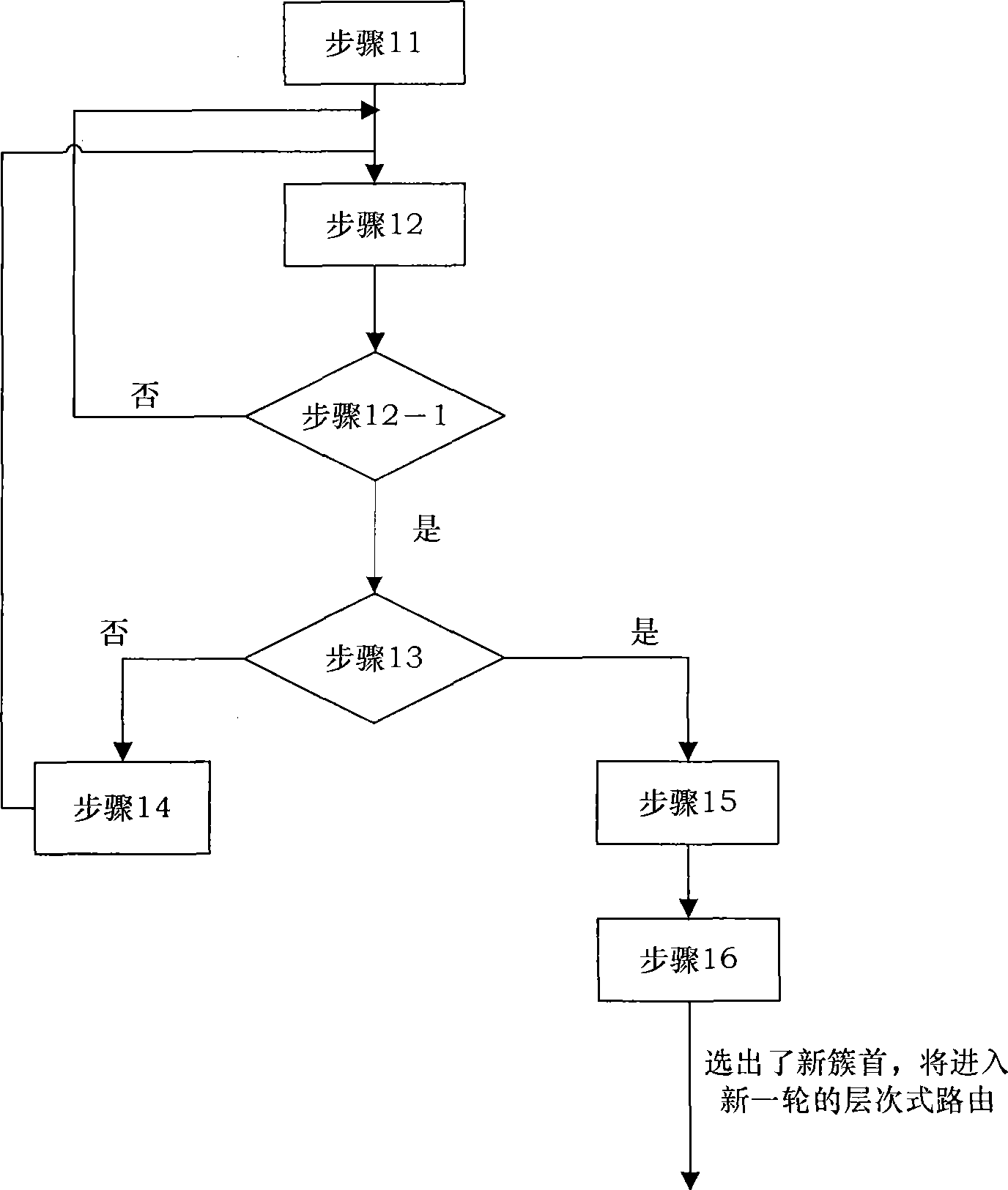

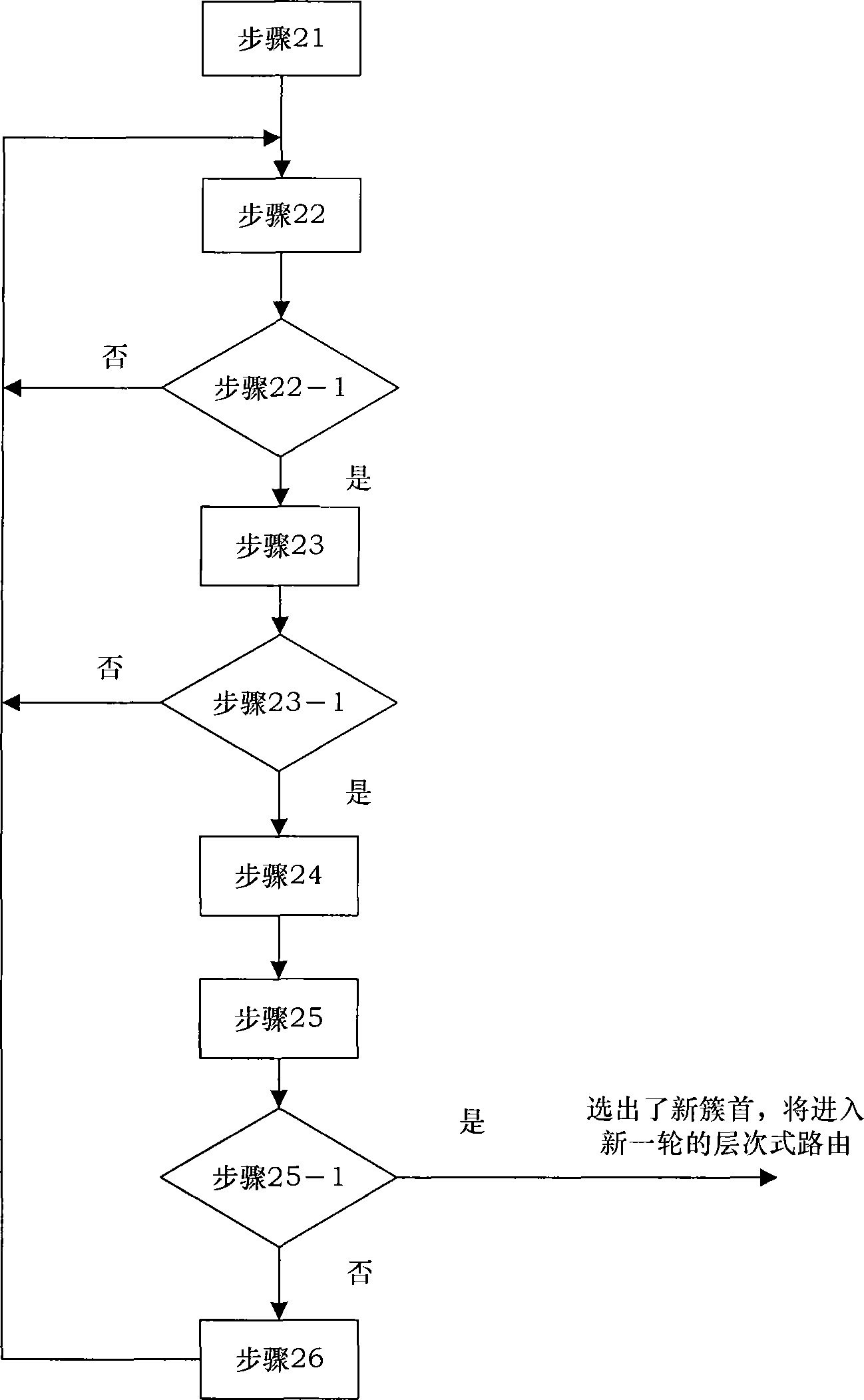

Partial on demand cluster head replacement method for wireless sensor network clustered routing

InactiveCN101426293APrevent beingReduce consumptionEnergy efficient ICTNetwork traffic/resource managementNetwork packetSelf-energy

The present invention discloses a method for replacing partial required cluster-head of cluster-based routing of wireless sensor network. Through the method, the cluster-head replacing in the cluster-based hierarchy-type routing in the wireless sensor network can be realized. Furthermore the problems such as energy consumption of normal whole network cluster changing are reduced through the partial required cluster-head replacing. The technical scheme adopted by the invention is that the data package transmission of cluster-head is monitored all the time by the non-cluster-head node in the cluster thereby estimating the residual energy of the cluster head. An cluster application is initialized according to the magnitude relationship between the estimated cluster-head residual energy and the self energy of non-cluster-head node thereby realizing partial required cluster-head replacing. The cluster-head replacement according to the invention uses cluster as a unit. The conditions whether each cluster should replace the cluster, when to change the cluster and which new node is selected for the cluster head are all independent from each other, thereby reducing the energy consumption when the whole network is changed with cluster timely, and obtaining an energy equalization of the whole network.

Owner:BEIHANG UNIV

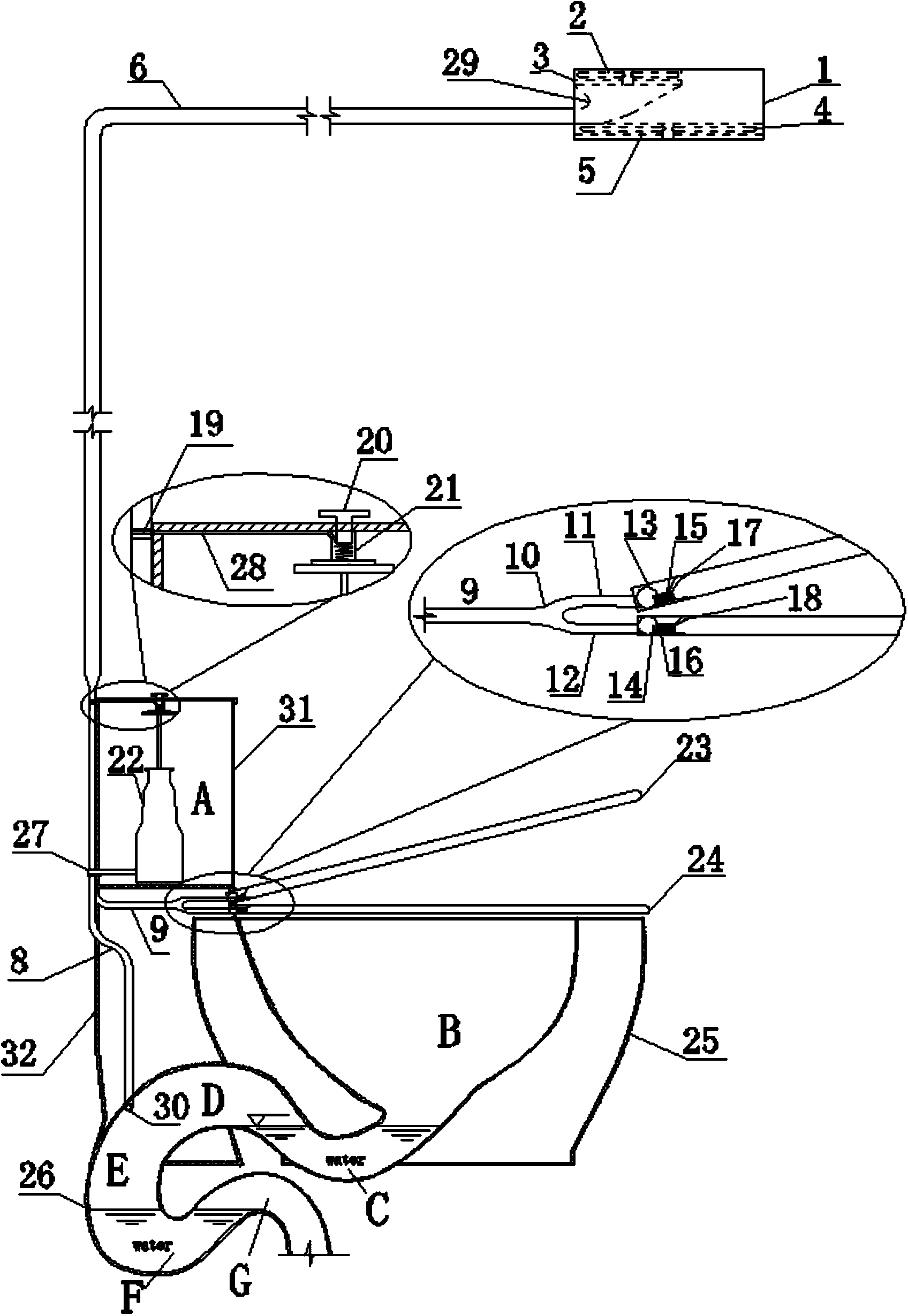

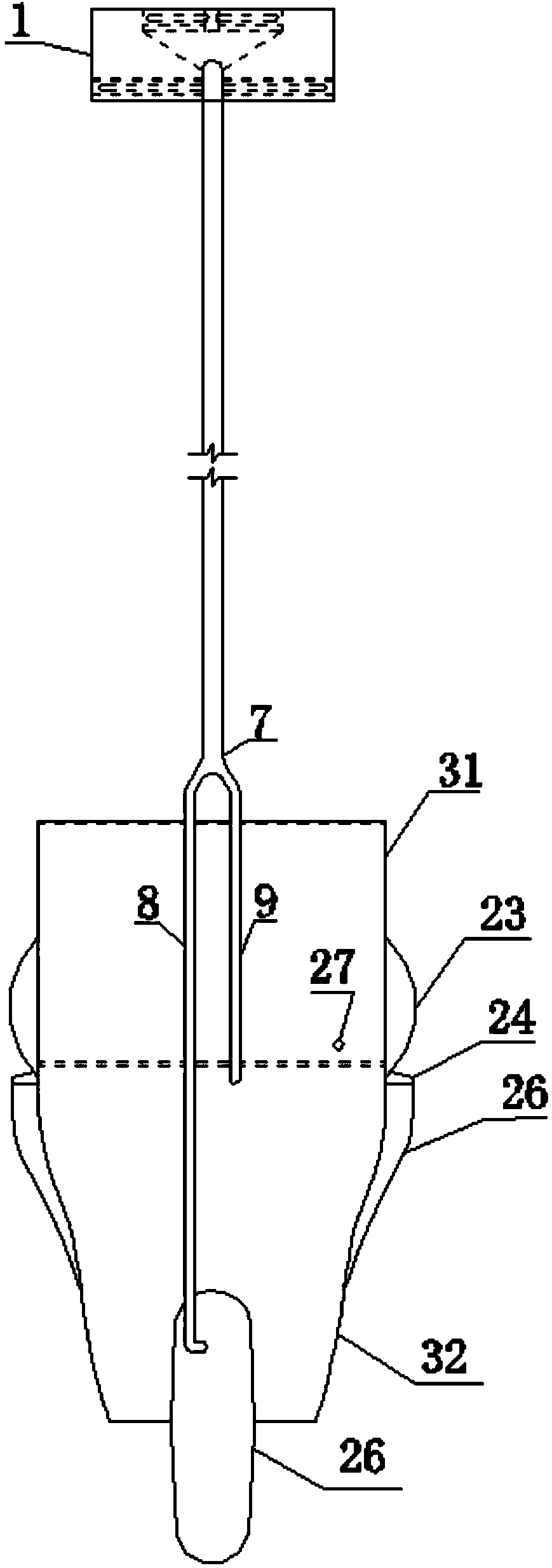

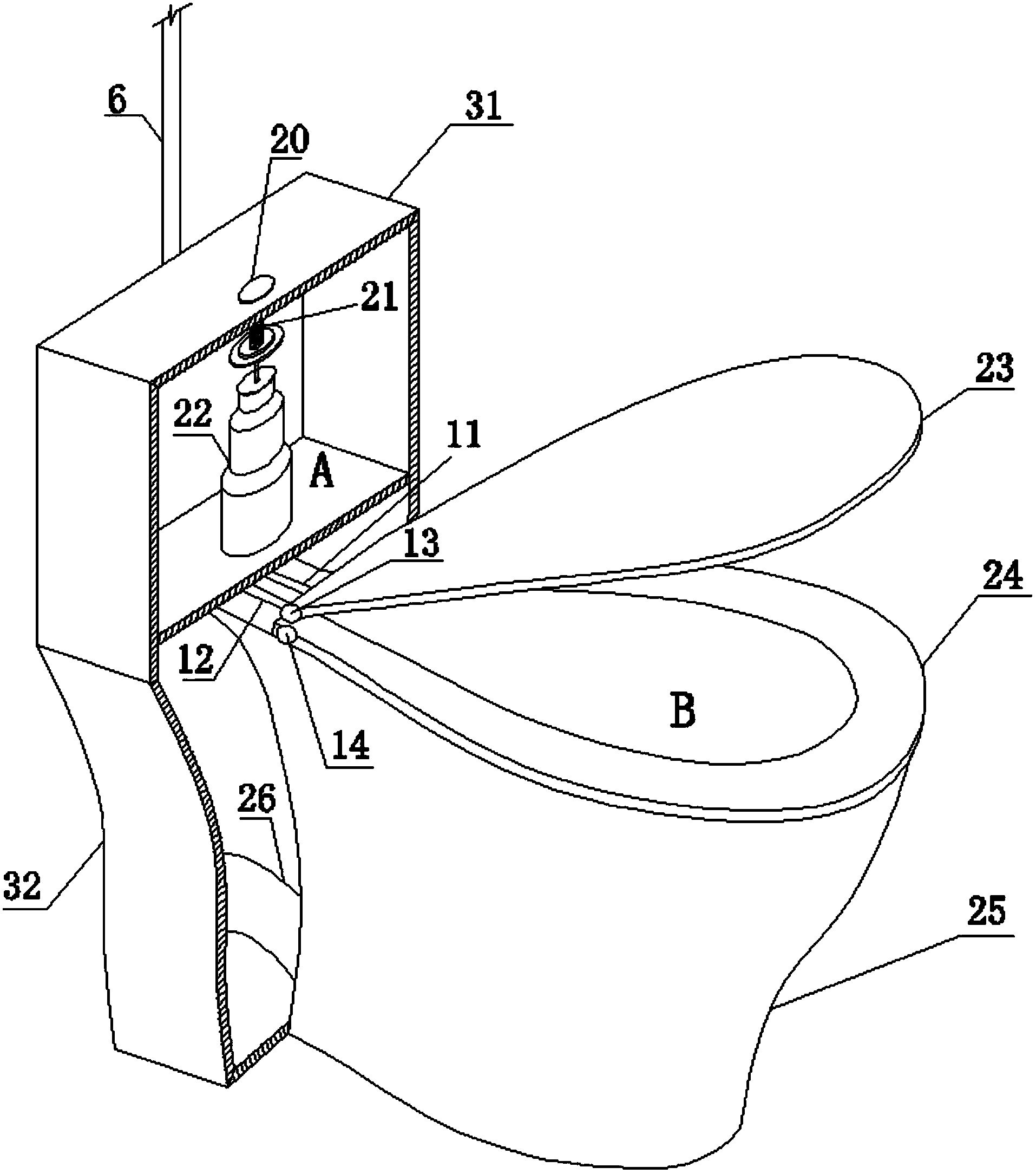

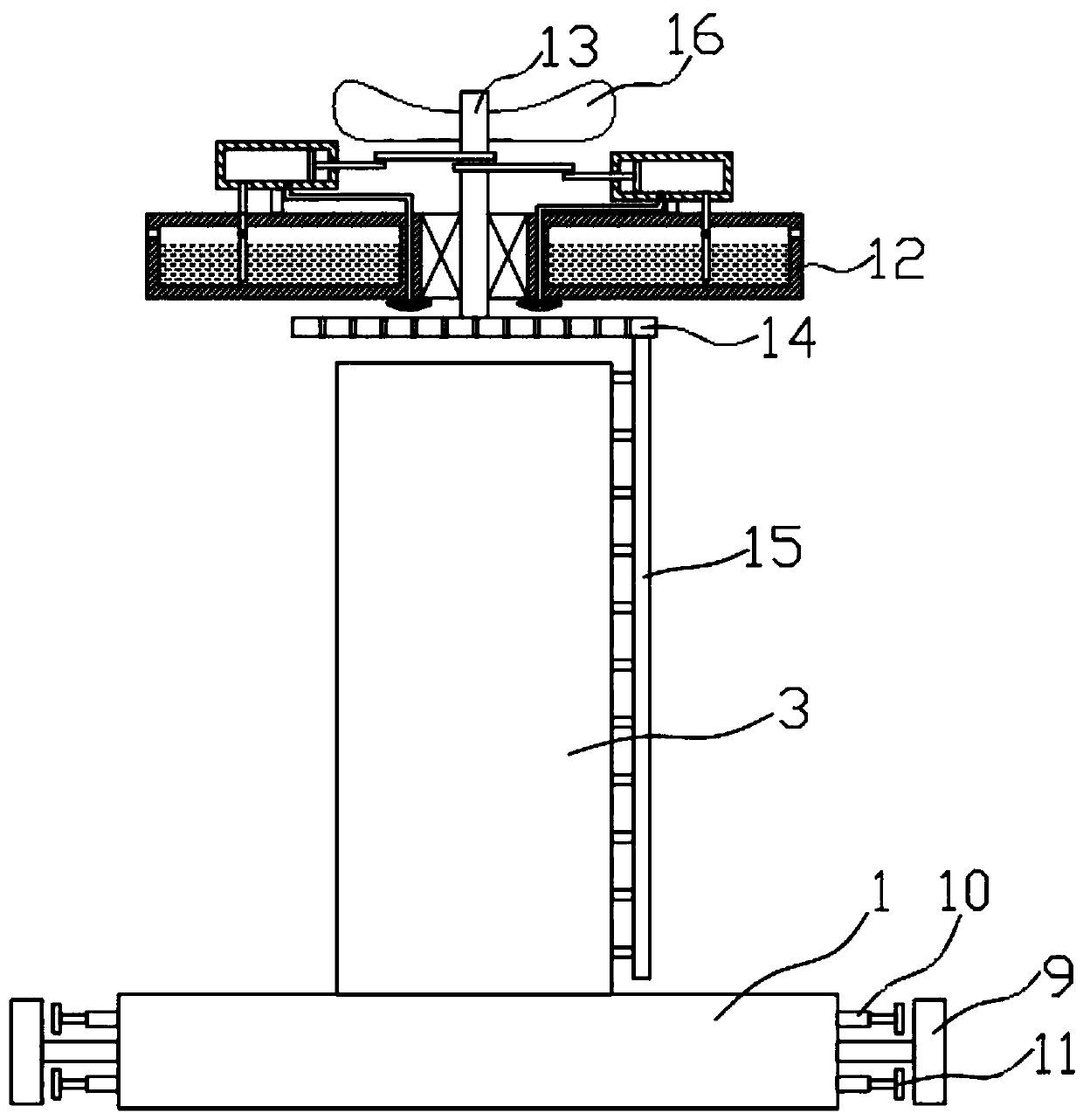

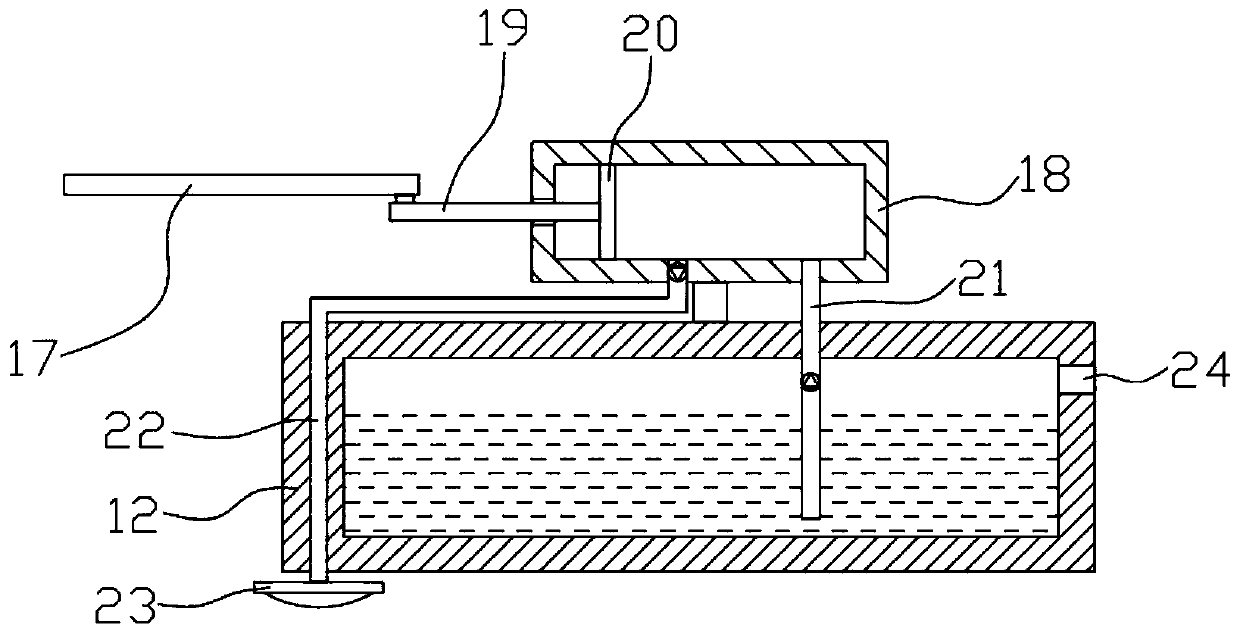

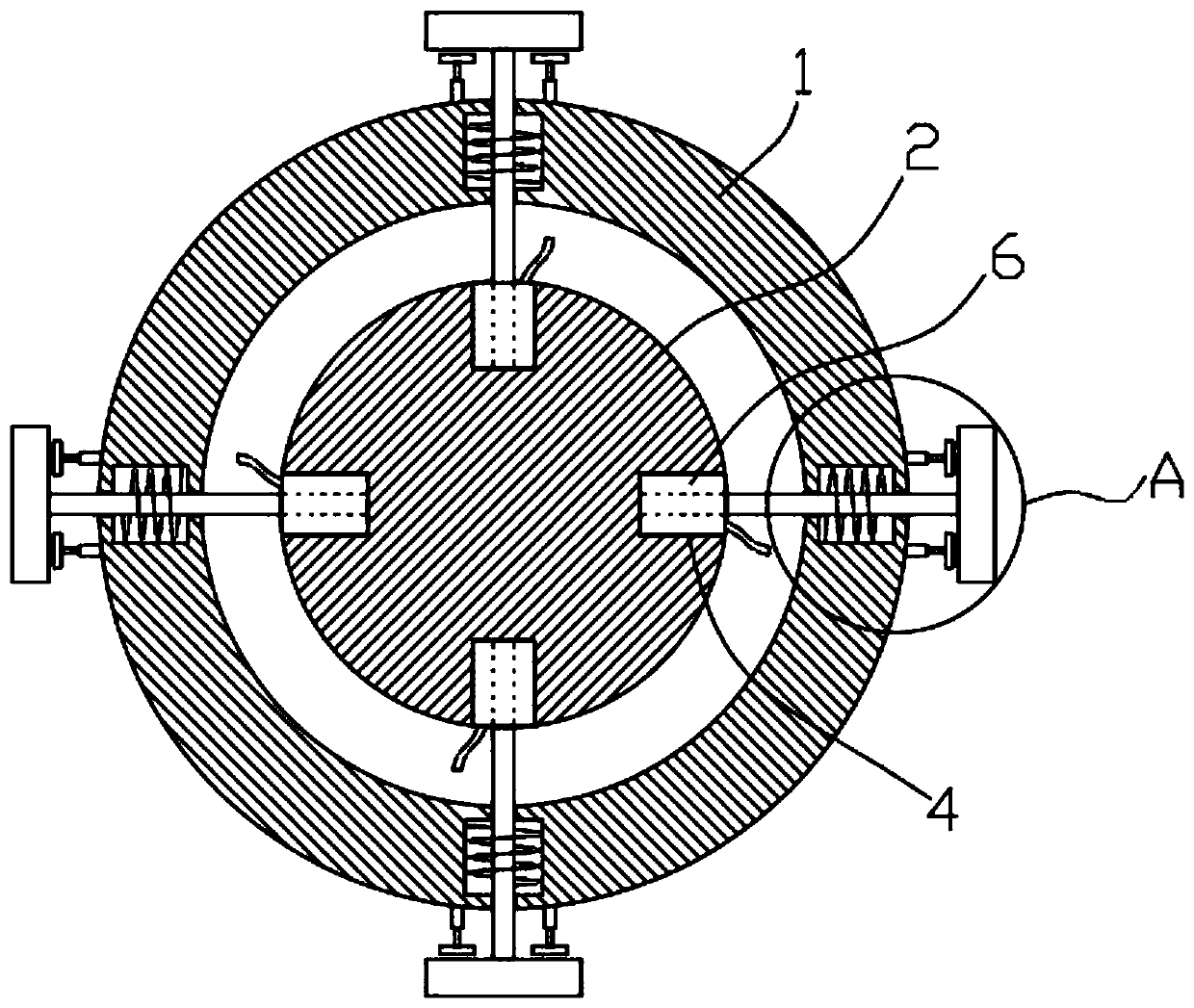

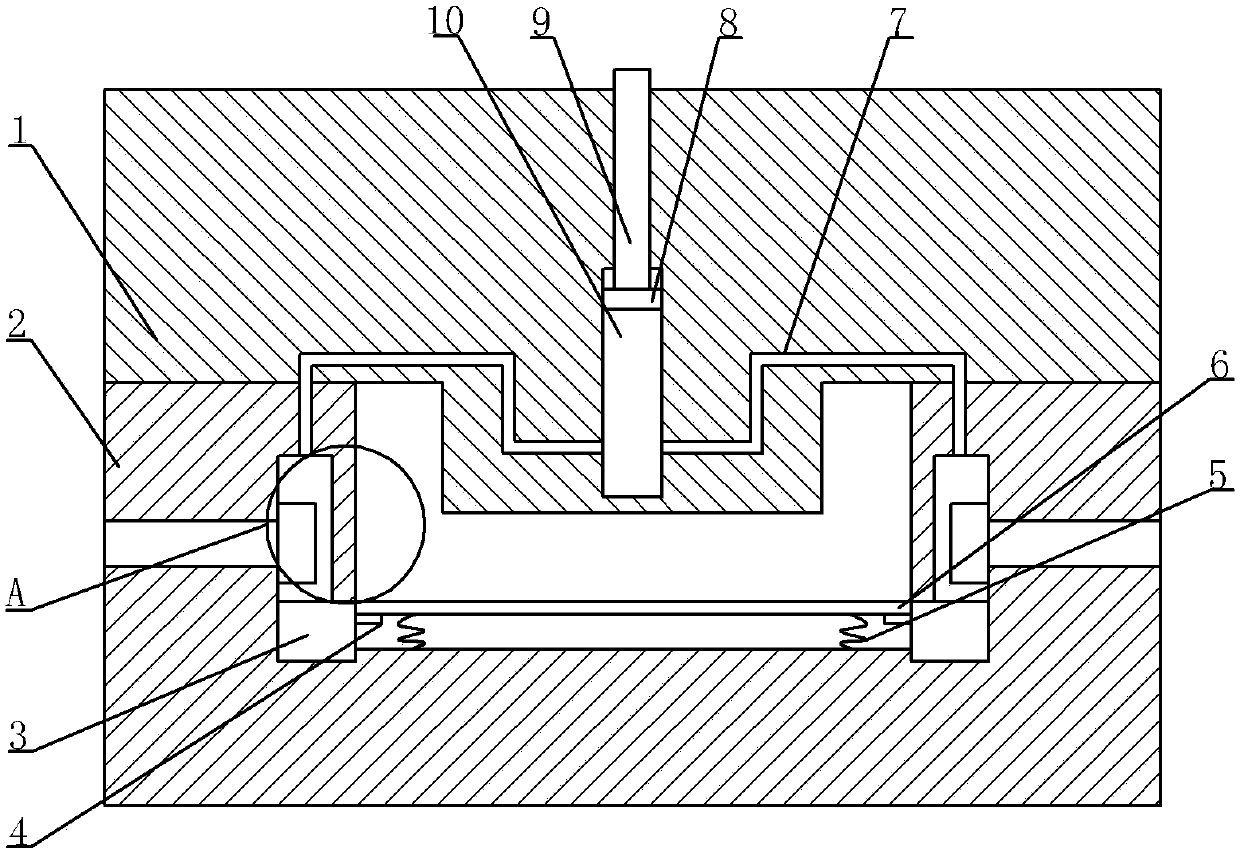

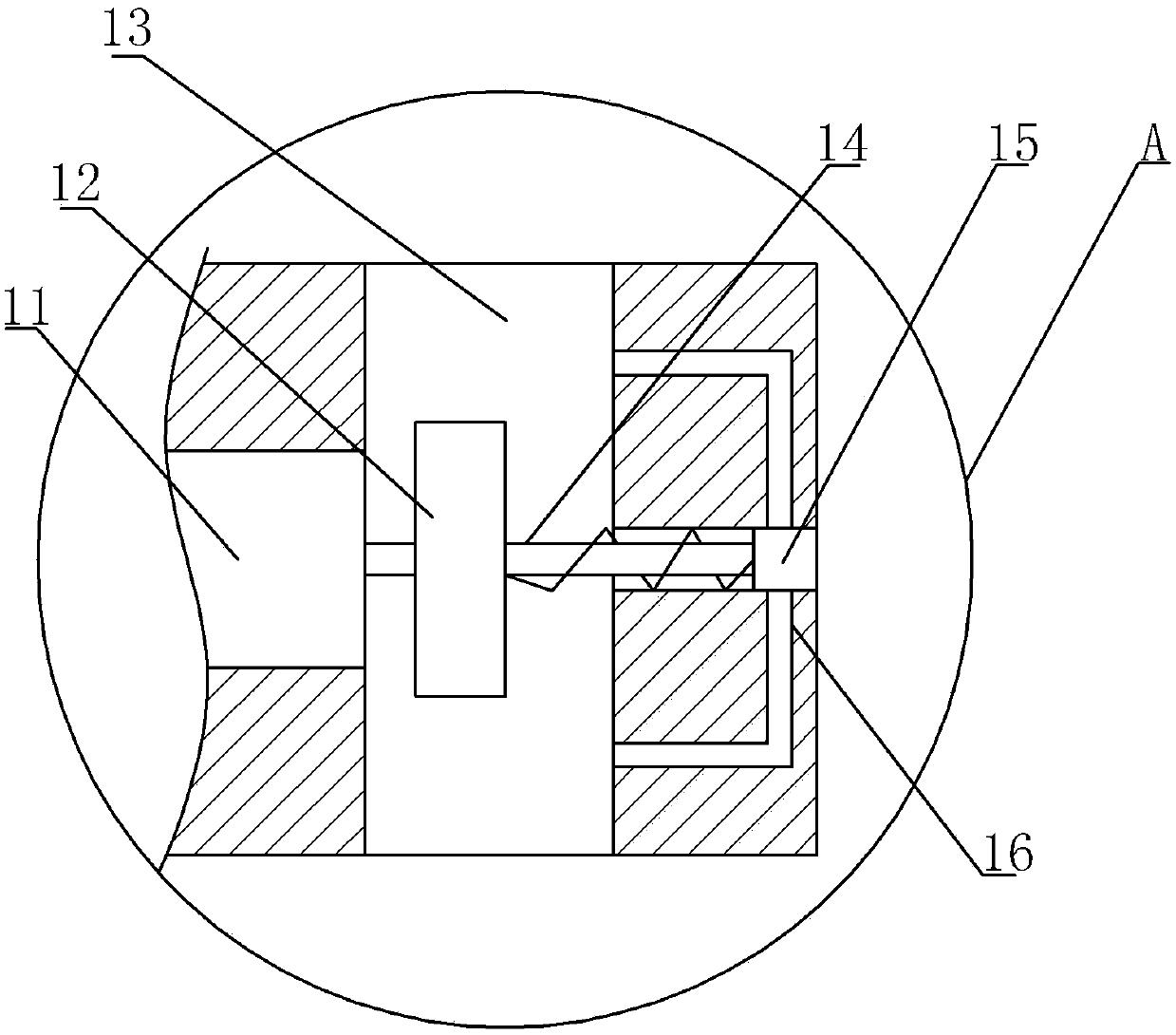

Closestool capable of conducting air exhaust deodorization and vacuum-assisted flushing

InactiveCN103615039ADoes not increase the use of bathroom spaceAchieve exhaust and deodorizationFlushing devicesBathroom coversDaily livingVacuum assisted

The invention provides a closestool capable of conducting air exhaust deodorization and vacuum-assisted flushing, and belongs to the technical field of daily living articles. The closestool is improved on the basis of a traditional closestool so that the disadvantages and the defects in the prior art in terms of the closestool deodorization technology and the vacuum-assisted flushing can be overcome, and a double-layer air exhaust fan serves as a power source for an air exhaust deodorization system of the whole closestool and a vacuum-assisted flushing system of the whole closestool. The air exhaust deodorization technology which saves energy and is environmentally friendly is provided for air exhaust deodorization of the closestool. Flushing is assisted by vacuum so that water resources can be saved. An existing air exhaust device in a toilet is improved and combined with the closestool to form a set of system, namely, the closestool capable of conducting air exhaust deodorization and vacuum-assisted flushing. The air exhaust deodorization effect and the vacuum-assisted flushing effect can be achieved while no excessive devices are additionally arranged on the closestool to occupy space in the toilet. The closestool is improved so that the closestool can have the air exhaust deodorization function and the vacuum-assisted flushing function, odorous gas can not be left after people relieve the bowels due to the air exhaust deodorization function, and water resources are saved due to the vacuum-assisted flushing function.

Owner:BEIJING UNIV OF TECH

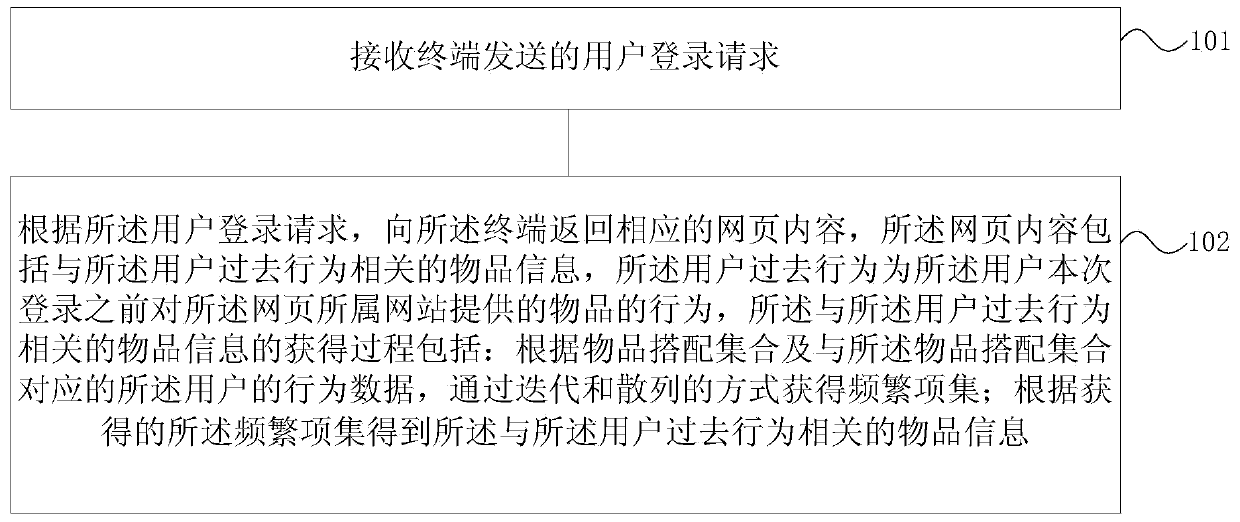

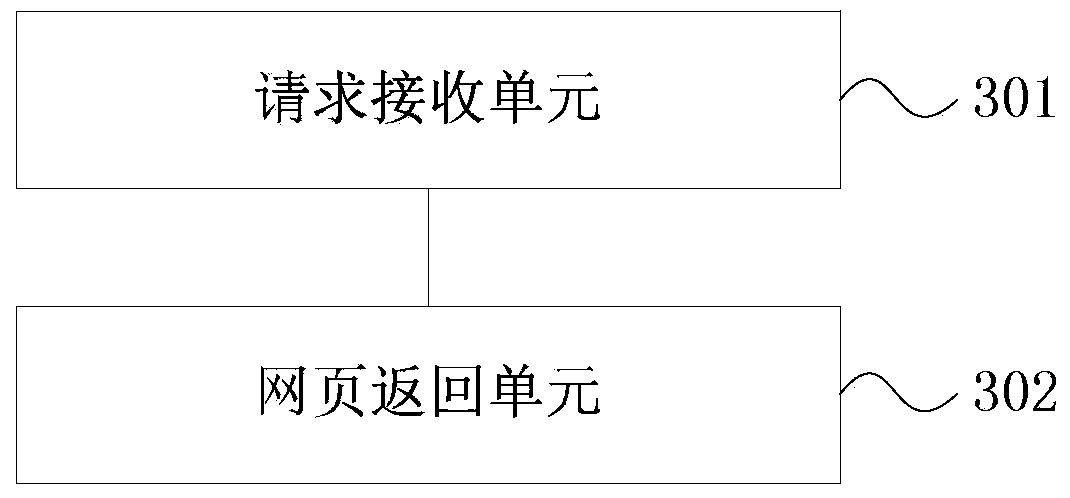

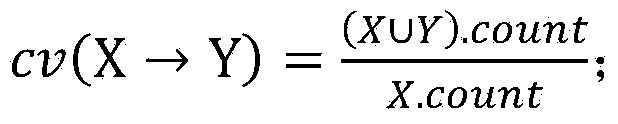

Method and device for providing information

ActiveCN103744904AImprove computing efficiencyImprove practicalitySpecial data processing applicationsComputer terminalData mining

The invention relates to the technical field of computers, in particular to a method and a device for providing information. The method comprises the steps of receiving a user login request sent by a terminal; returning a corresponding webpage content to the terminal according to the user login request, wherein the webpage content include article information related with user's past behaviors which are behaviors of articles provided by a website webpage belongs to before the user logs in this time. The obtaining process of the article information related with the user's past behaviors comprises the steps of obtaining a frequent item set according to an article matching set and user behavior data corresponding to the article matching set in iteration and hash modes; obtaining the article information related with the user's past behaviors according to the obtained frequent item set. By adopting the method, the frequent item set is obtained in iteration and hash modes, and the practicability of provided information is improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Ultra-wide bandwidth beam low profile back cavity antenna structure

ActiveCN110311206AAvoid damagePrevent beingAntenna supports/mountingsVibration dampingEngineeringAirbag

The invention discloses an ultra-wide bandwidth beam low profile back cavity antenna structure which comprises a mounting ring plate. An antenna base is arranged in the mounting ring plate. A cylindrical antenna casing is fixedly connected with the upper end of the antenna base. The mounting ring plate has a plurality of shock absorbing mounting units distributed circumferentially equiangularly around the antenna casing. The upper end of the antenna casing is provided with a pneumatic self-cleaning unit. Each shock absorbing mounting unit comprises a circular slot arranged on the antenna baseand a cavity formed in the mounting ring plate, and the slot corresponds to the cavity in position. An inserted rod is inserted in each slot. The outer wall of one end, which is located in the slot, of each inserted rod is fixedly connected with an expansion airbag. According to the invention, the pneumatic self-cleaning unit can automatically clean the antenna casing by using the wind power, which prevents manual cleaning and reduces energy consumption; and the shock absorbing mounting units are arranged, which can be used for shock absorption when the wind is large, so as to avoid damage.

Owner:江苏维航精仪科技有限公司

Cleanable injection mold

The invention relates to the technical field of mold machining, and discloses a cleanable injection mold. The cleanable injection mold comprises an upper mold and a lower mold; the upper mold is a convex mold; the lower mold is a concave mold; when the convex mold is clamped with the concave mold, a molding cavity is formed between the convex mold and the concave mold; the convex mold is providedwith an injection molding way communicating with the molding cavity; a cooling cavity is formed in the bottom of the concave mold, and is provided with a slide plate; a pressure spring is arranged atthe bottom of the slide plate; one-way valves are arranged on two sides of the cooling cavity; air cavities communicating with the external are arranged on two sides of the cooling cavity; rotating shafts are arranged in the air cavities; spiral blades are fixed on the rotating shafts; the convex mold is provided with a cooling way and a collecting cavity; a pressing plate is arranged in the collecting cavity; a pushing rod slidingly connected with the convex mold is fixed on the pressing plate; an air way and a closing block are arranged on the side wall of the molding cavity; the closing block is provided with a connecting rod; and the connecting rod is connected with the rotating shafts through one-way clutches. The cleanable injection mold is simple in structure, can remove dust of themolding cavity, scrapes off impurities in the molding cavity, and meanwhile, can cool plastic melts.

Owner:CHONGQING YINSHENG MOLD

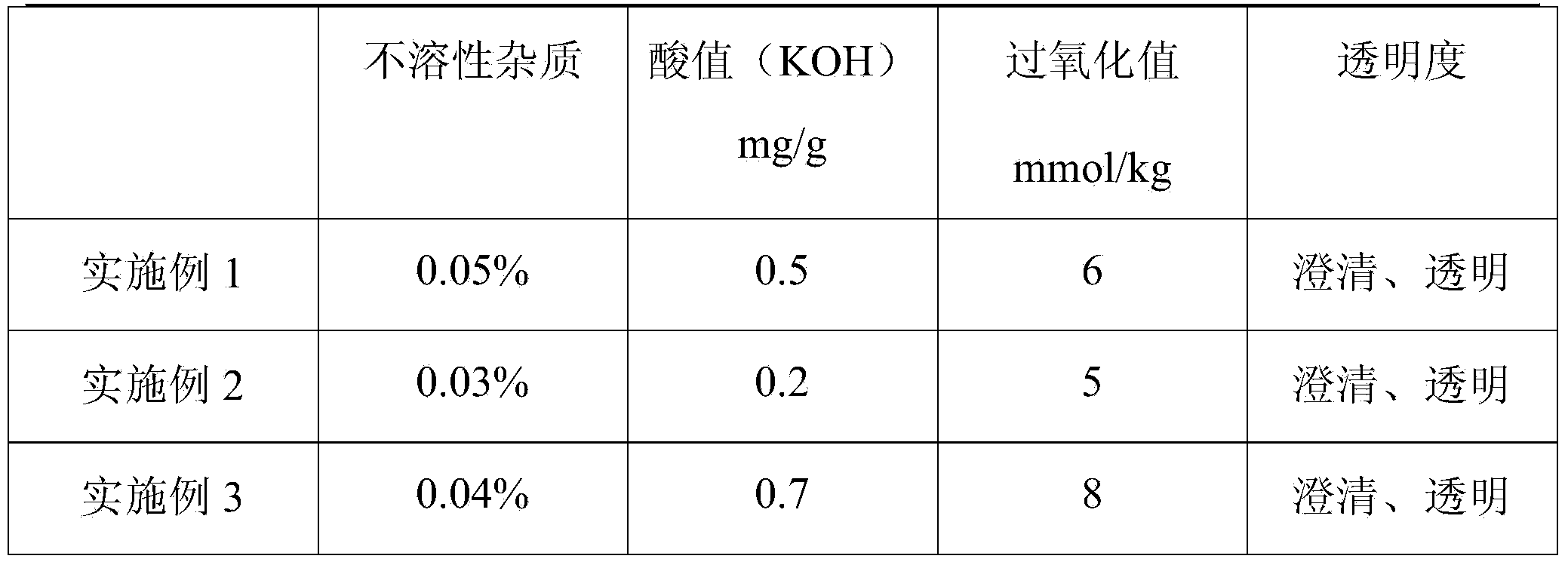

Oil and fat refining process

InactiveCN104232298ASettling fastReduce oil contentFatty-oils/fats refiningSocial benefitsOil and grease

The invention provides an oil and fat refining process which comprises the following steps: a degumming and alkali refining process, a decoloring process and a deodorizing process, wherein a proper amount of phosphoric acid is added in the degumming and alkali refining process, so that non-hydrated phospholipid is converted into hydrated phospholipid, the sedimentation velocity of the phospholipid is accelerated, the oil content of oil feet is reduced, and the hydration effect is enhanced; and a clay regeneration process is added in the decoloring process, so that waste clay is prevented from becoming an industrial waste residue, and an even more important fact is that the recycling of the clay not only has better social benefit in environmental protection and treatment of three wastes, but also has certain economic benefit.

Owner:ANHUI ZHONGSHENG EDIBLE OIL TECH

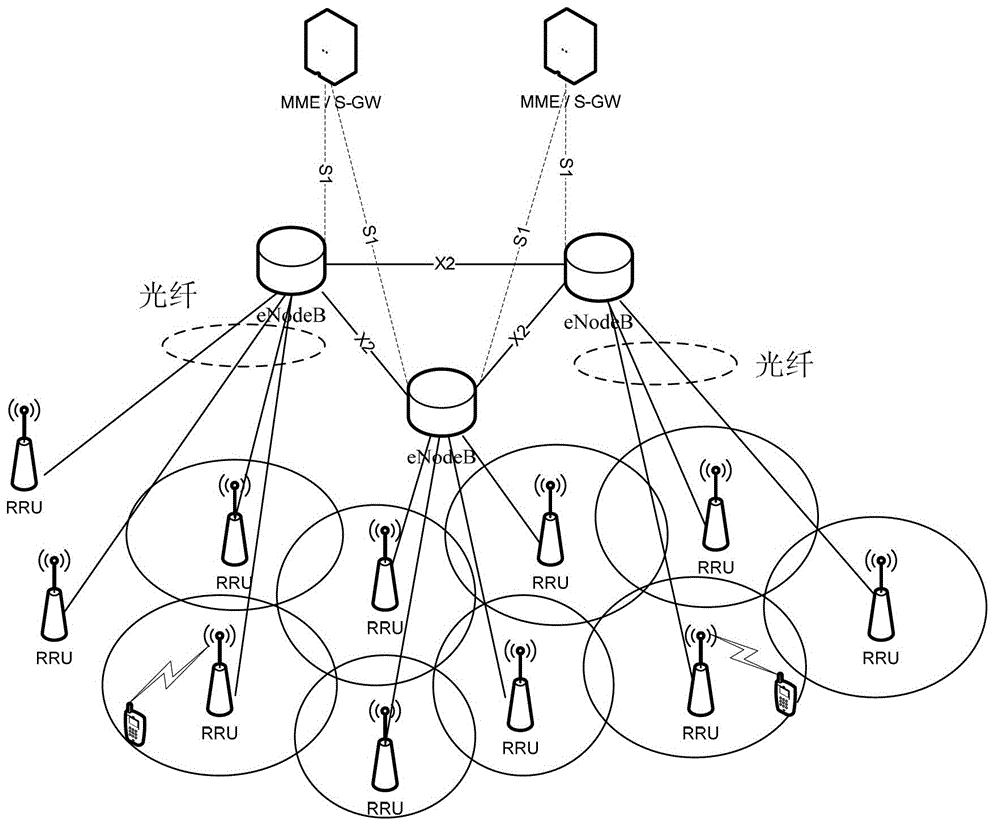

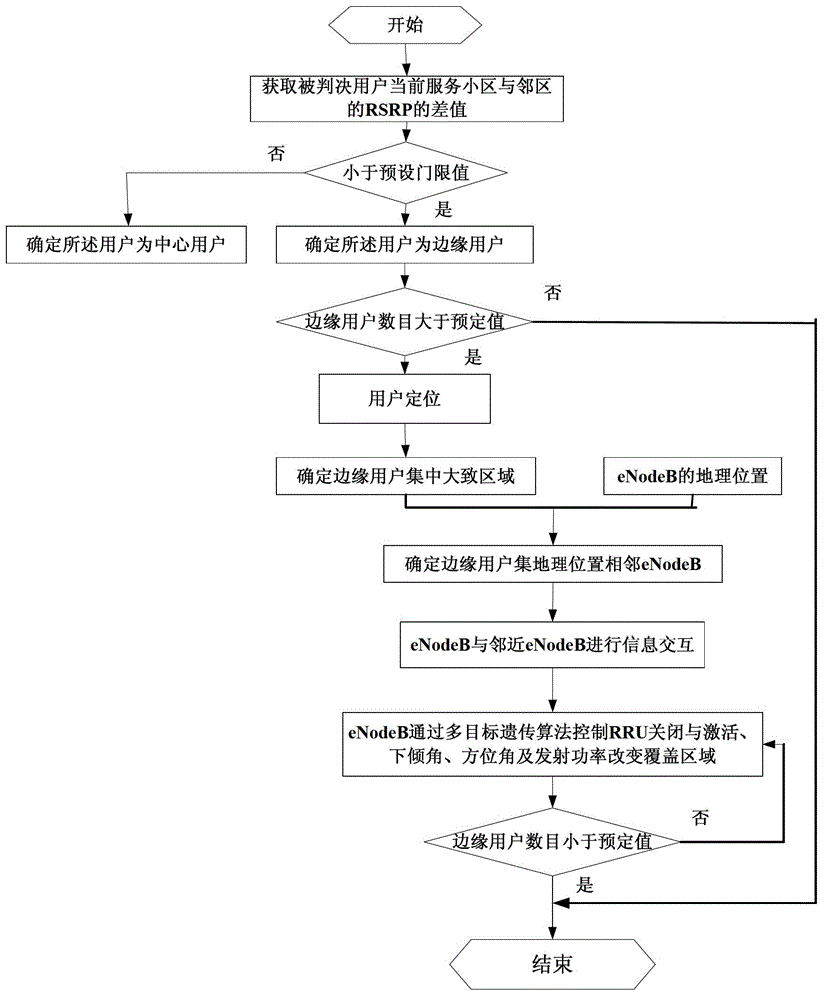

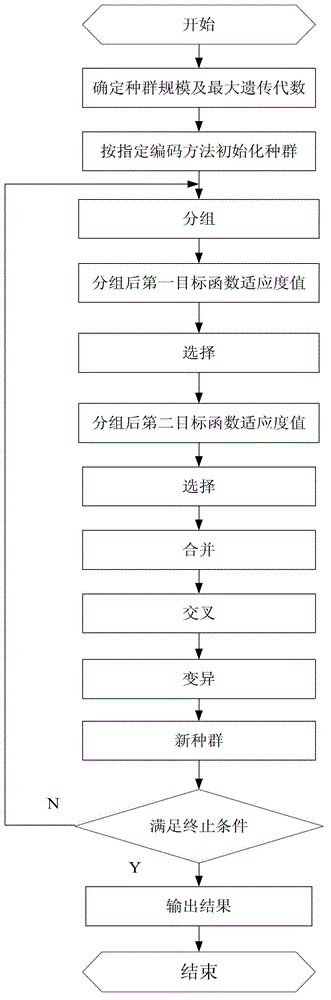

Method for improving performance of cell edge users by using multi-objective genetic algorithm

ActiveCN102752767AControl transmit powerReduce the numberNetwork planningQuality of serviceGeolocation

The invention discloses a method for improving the performance of cell edge users by using a multi-objective genetic algorithm, and relates to the field of communication. The method for improving the performance of the cell edge users by using the multi-objective genetic algorithm can reduce the number of edge users to the greatest extent and greatly improve the service quality and the satisfaction degree of the users. The method comprises the following steps: enabling a base station to judge whether a user is a cell edge user or not according to measurement reports of the user; enabling the base station to determine the geographical positions of the edge users in coverage; enabling the base station to determine the base station which is in the vicinity of a cell edge user set according to the geographical positions of the edge users and the geographical position of the base station; enabling the base station to exchange information with the neighboring base station through X2; and enabling the base station to generate a coverage adjusting strategy through the multi-objective genetic algorithm according to the obtained information, and adjusting the activation and the closing of an RRU (radio remote unit), the transmission power and the declination angle and the azimuth angle of an antenna to change the coverage, thereby ensuring that users in the inter-cell overlapping region are as few as possible.

Owner:XIAMEN UNIV +1

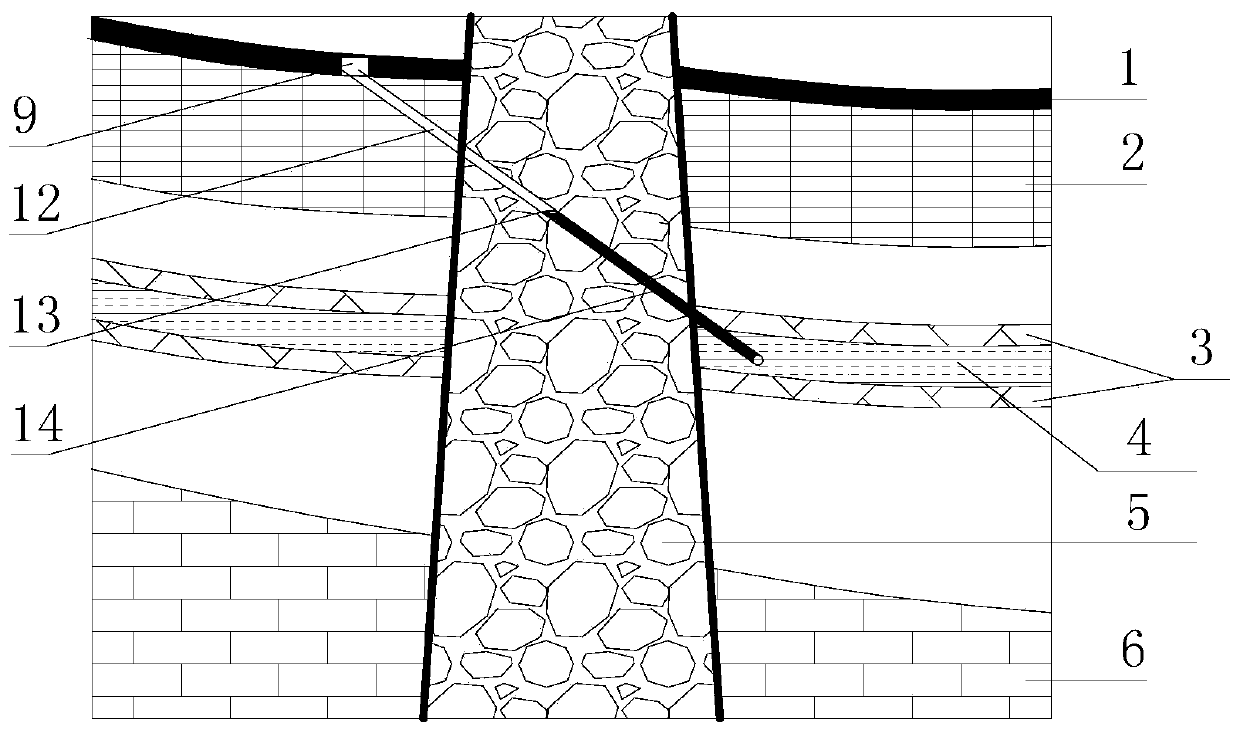

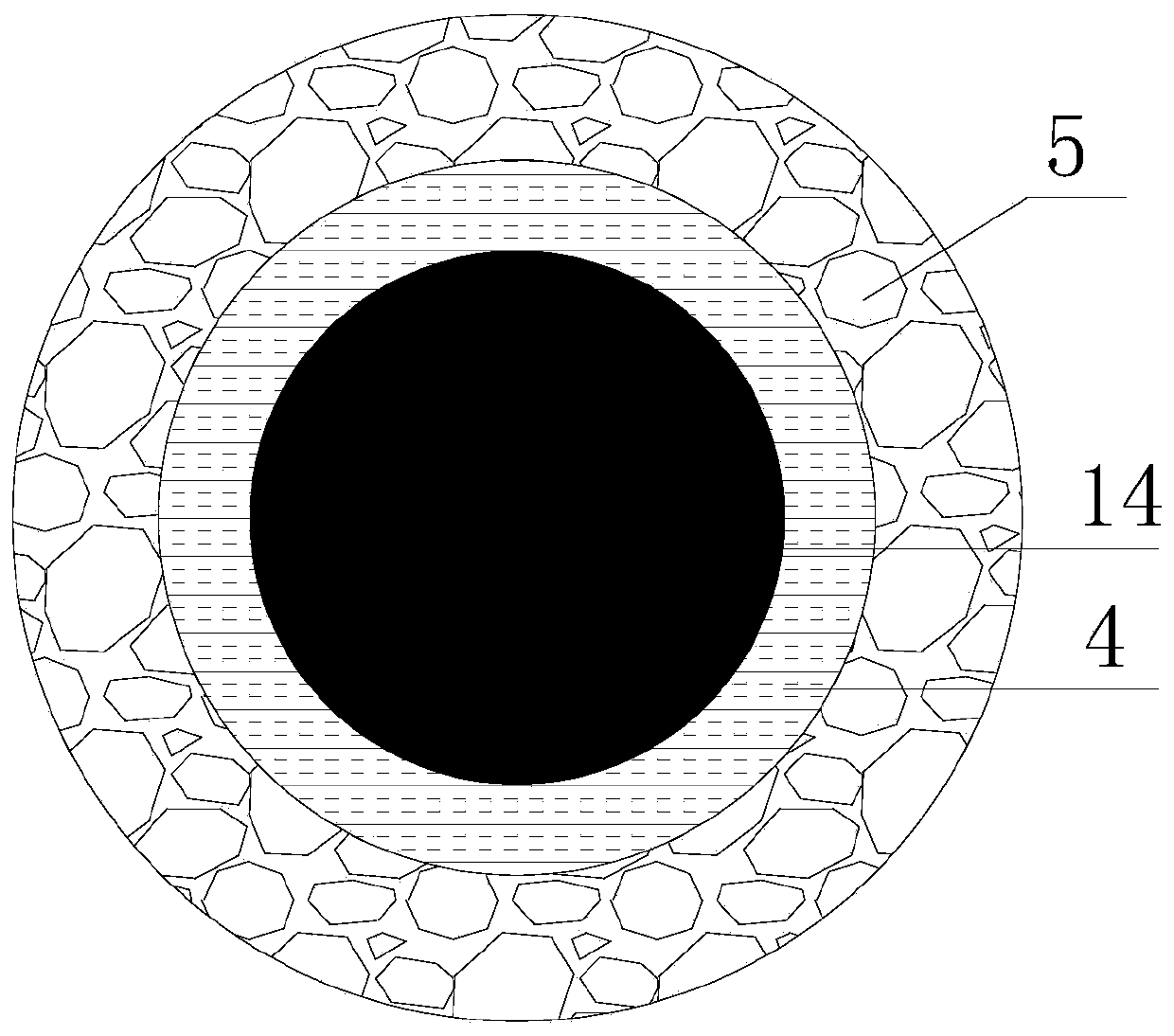

Working face collapse column grouting waterproof treatment method

InactiveCN111075482APrevent beingImprove water barrier effectUnderground chambersSealing/packingDrill holeCoal

The invention relates to the technical field of coal mine disaster treatment, in particular to a working face collapse column grouting waterproof treatment method. The method comprises the following steps that a working face cut opening is pushed, and pushing is stopped until the safe distance between the working face cut opening and the collapse column is kept; two grouting auxiliary roadways anda plurality of grouting drill nests are tunneled at the positions, corresponding to the collapse column, of a transportation crossheading, and a plurality of corresponding grouting drill nests are tunneled at the positions, corresponding to the collapse column, of an air return crossheading; and inclination grouting drill holes are constructed in the grouting auxiliary roadways and the grouting drill nests in the transportation crossheading, inclination grouting drill holes are constructed in the grouting drill nests in the air return crossheading, and the final hole layers of all the grouting drill holes are controlled to be located in a bottom plate aquifer between the two bottom plate water-resisting layers of the coal seam. The method is not only suitable for preventing the situationthat the non-water-guide collapse column is activated and guides water due to mining influence, but also can reinforce the water-guide collapse column in a multi-layer grouting mode, the water insulation capacity can be improved, and it is ensured that no water damage accident occurs when the coal face is pushed over.

Owner:NORTH CHINA INST OF SCI & TECH +4

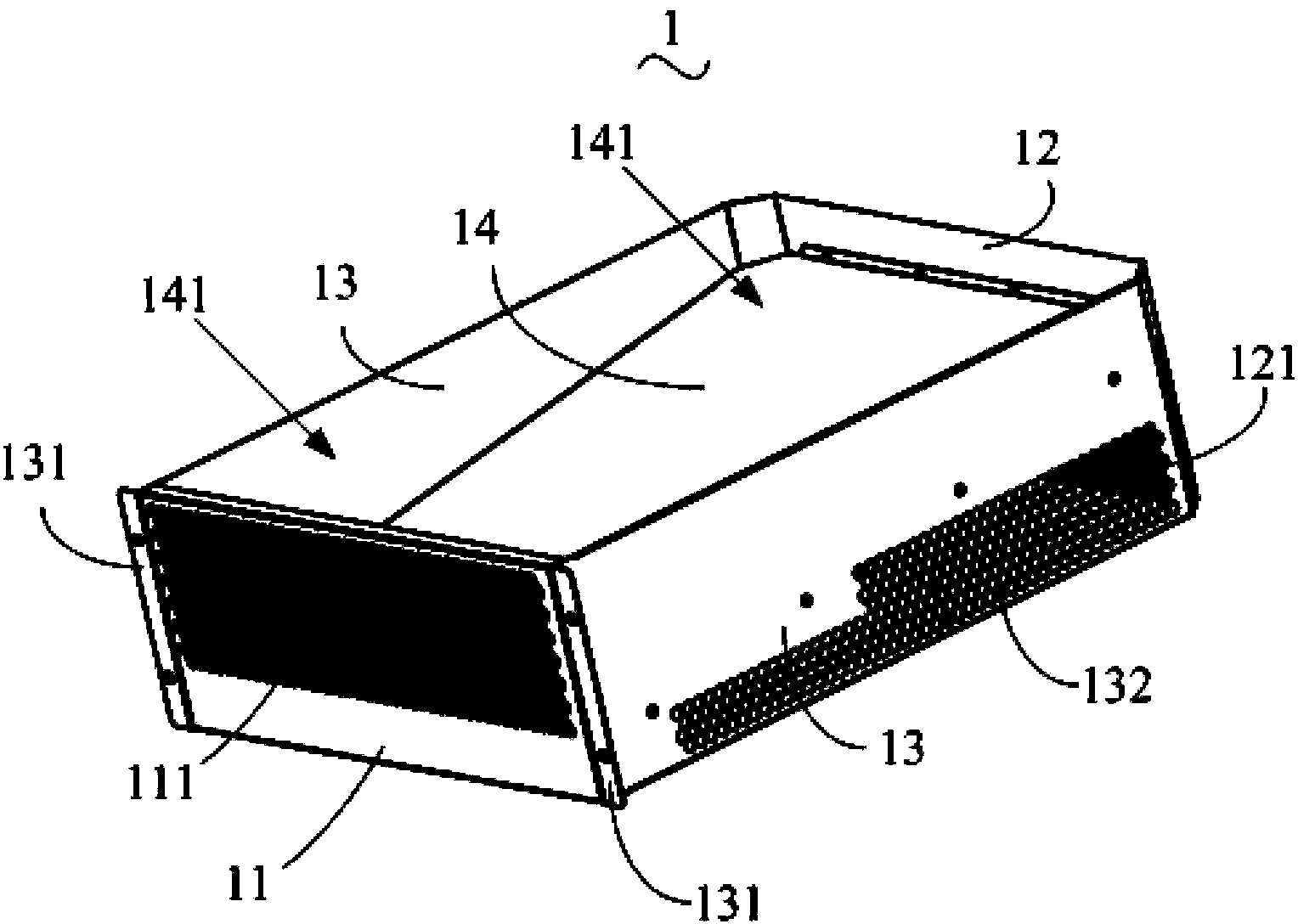

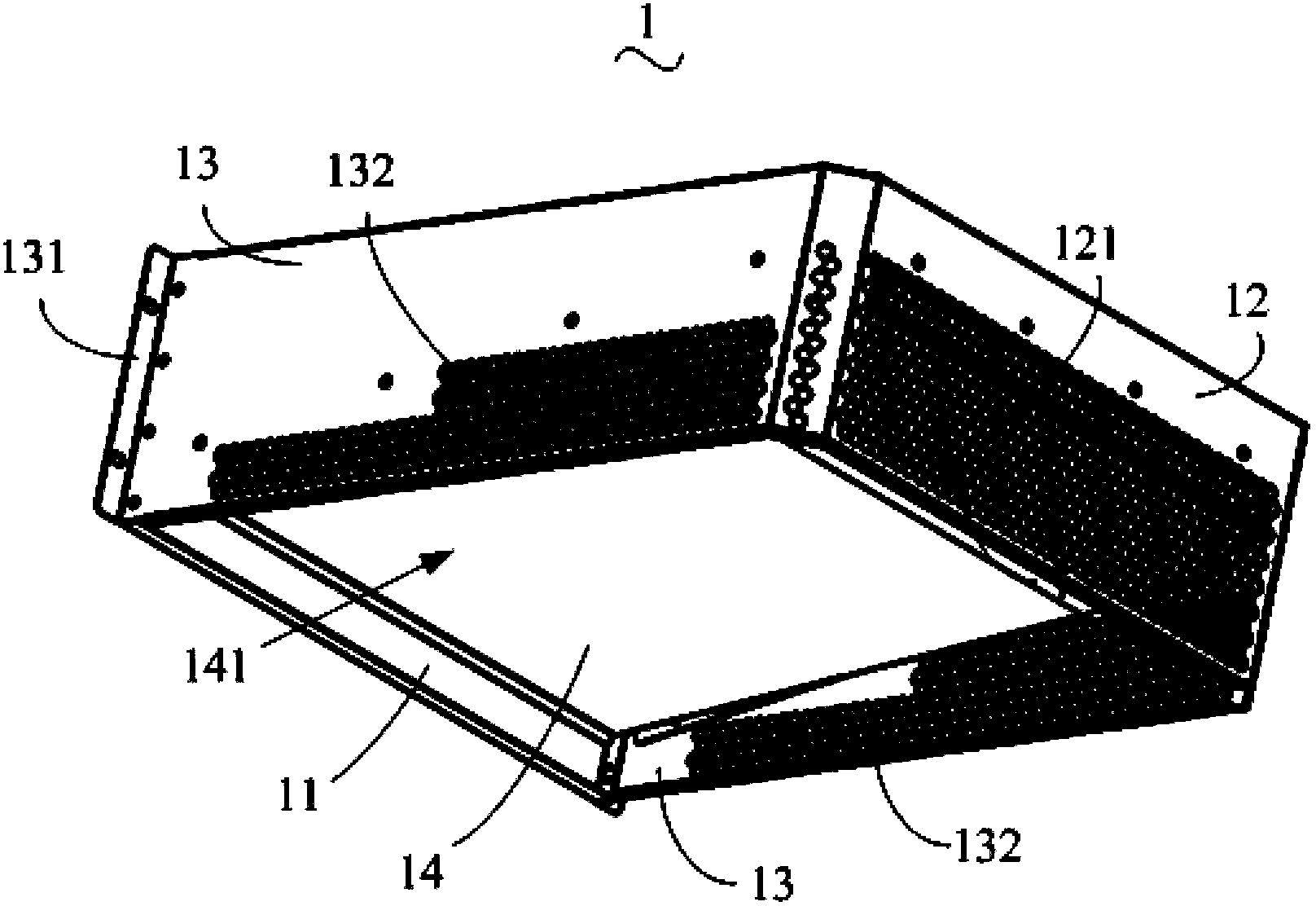

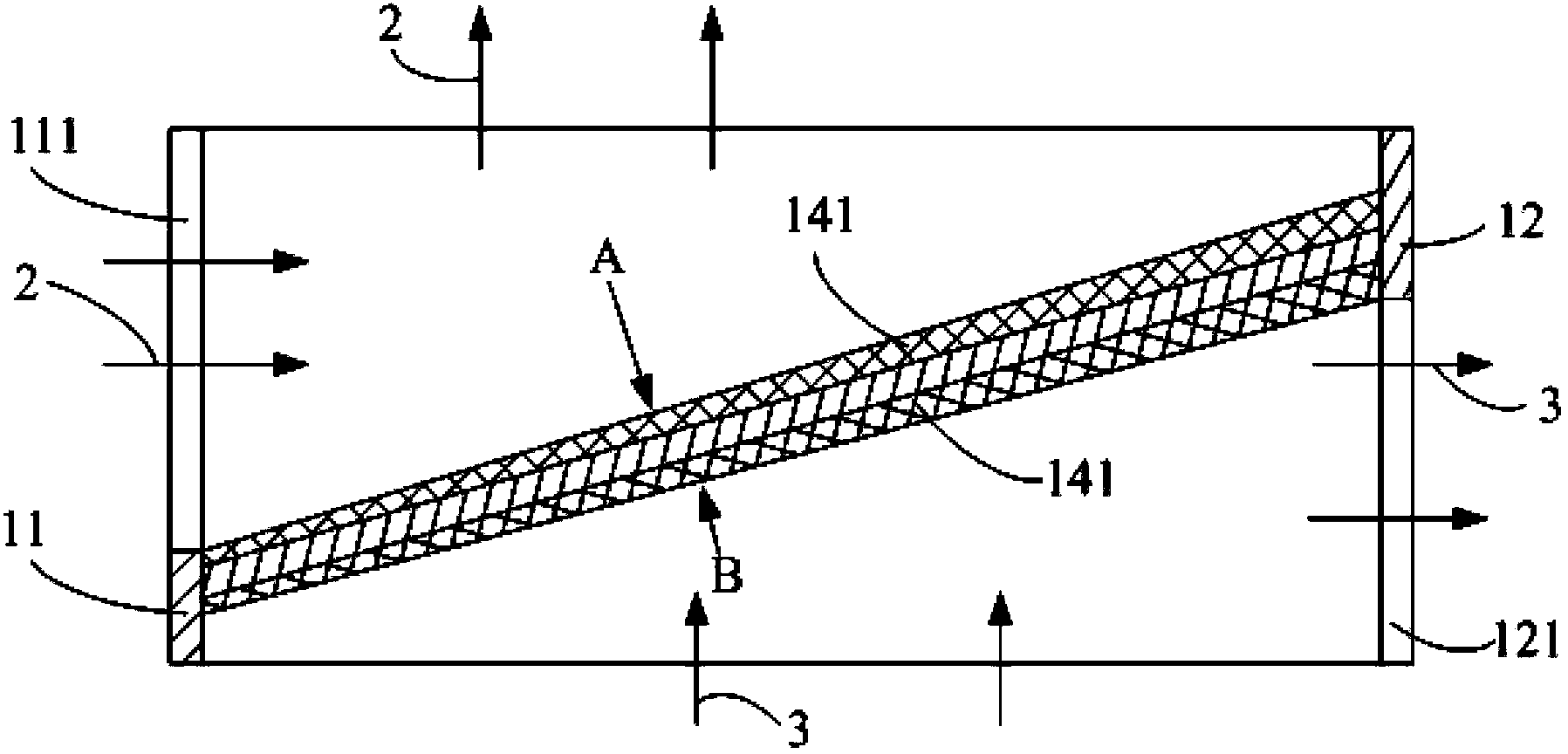

Air guide insertion box for forced air cooling type machine cabinet and forced air cooling type machine cabinet

ActiveCN104349649AReduce heatingAvoid heatingModifications for standard racks/cabinetsThermal insulationForced-air

Disclosed are an air deflecting subrack for a forced air cooling cabinet, and forced air cooling cabinet, the air deflecting subrack comprising a front vertical plate having vent holes, a back vertical plate having vent holes, two side vertical plates having lugs, and an air deflecting transverse plate configured to isolate the wind area; the front vertical plate, the back vertical plate, the two side vertical plates, and the air deflecting transverse plate are fixedly connected integrally so as to differentiate and deflect the cold and hot airflows at the two sides of the air deflecting transverse plate; and the surface of the air deflecting transverse plate is provided with a thermal insulation layer made of thermal insulation material. The present invention has better heat dissipation and good sound absorption effects.

Owner:ZTE CORP

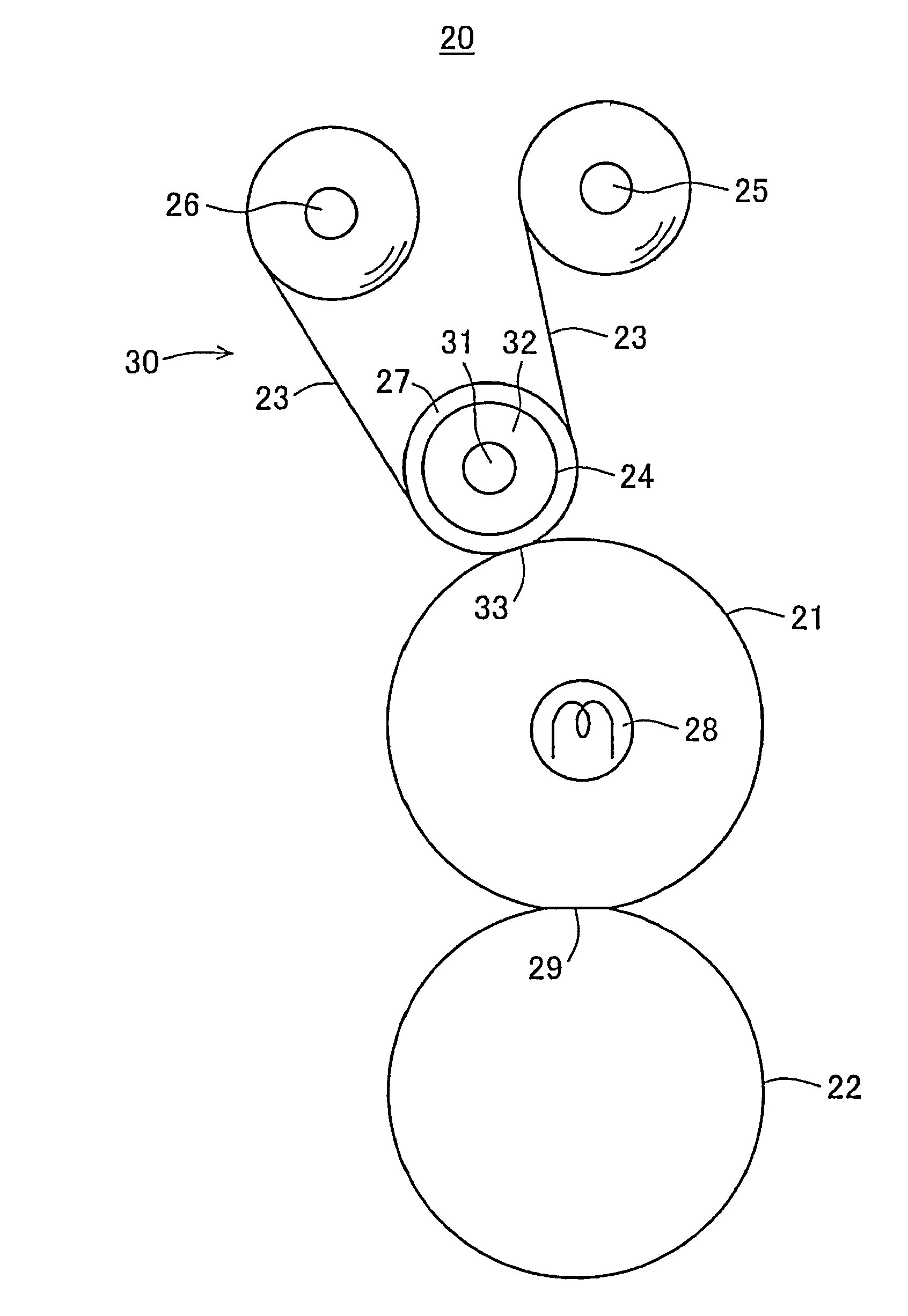

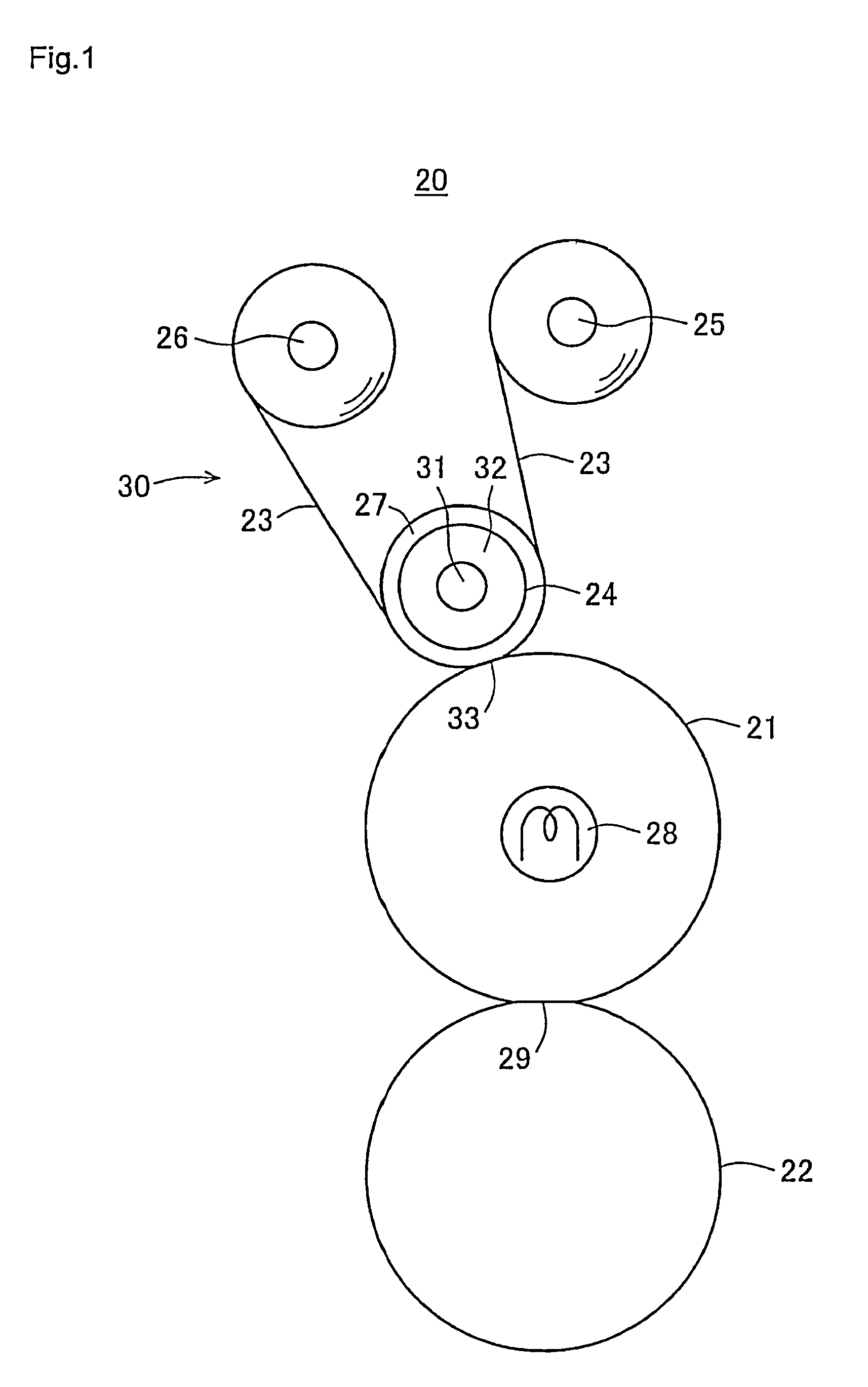

Fuser unit with cleaning mechanism and image forming apparatus having the same

InactiveUS7630675B2Prevent beingPrevent travelElectrographic process apparatusBand shapeImage formation

Owner:SHARP KK

Preparation method and utilization method of catalyst originated from waste

ActiveCN107983362AWon't happenAvoid pollutionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivation methodNitrate

The invention relates to a preparation method and a utilization method of a catalyst originated from waste. The preparation method which is a one-step activation method comprises the following steps:mixing one or more of KOH or K2CO3,Fe3<+>, manganese nitrate and nickel nitrate in proportion in sludge or biomass; fully stirring the mixture; then carrying out an anaerobic pyrolytic reaction on thestirred sludge or biomass at 650-900 DEG C to obtain activated coke in one step; and then cleaning the activated coke with clean water, and dehydrating and airing the same to obtain the catalyst. Thecatalyst powder or a formed substance used at 100-360 DEG C can obtain the denitration efficiency of over 80%. The catalyst can promote tar cracking, no tar is discharged in the preparation process and energy is self-supplied; and the catalyst which is deactivated is pollution-free.

Owner:TONGJI UNIV

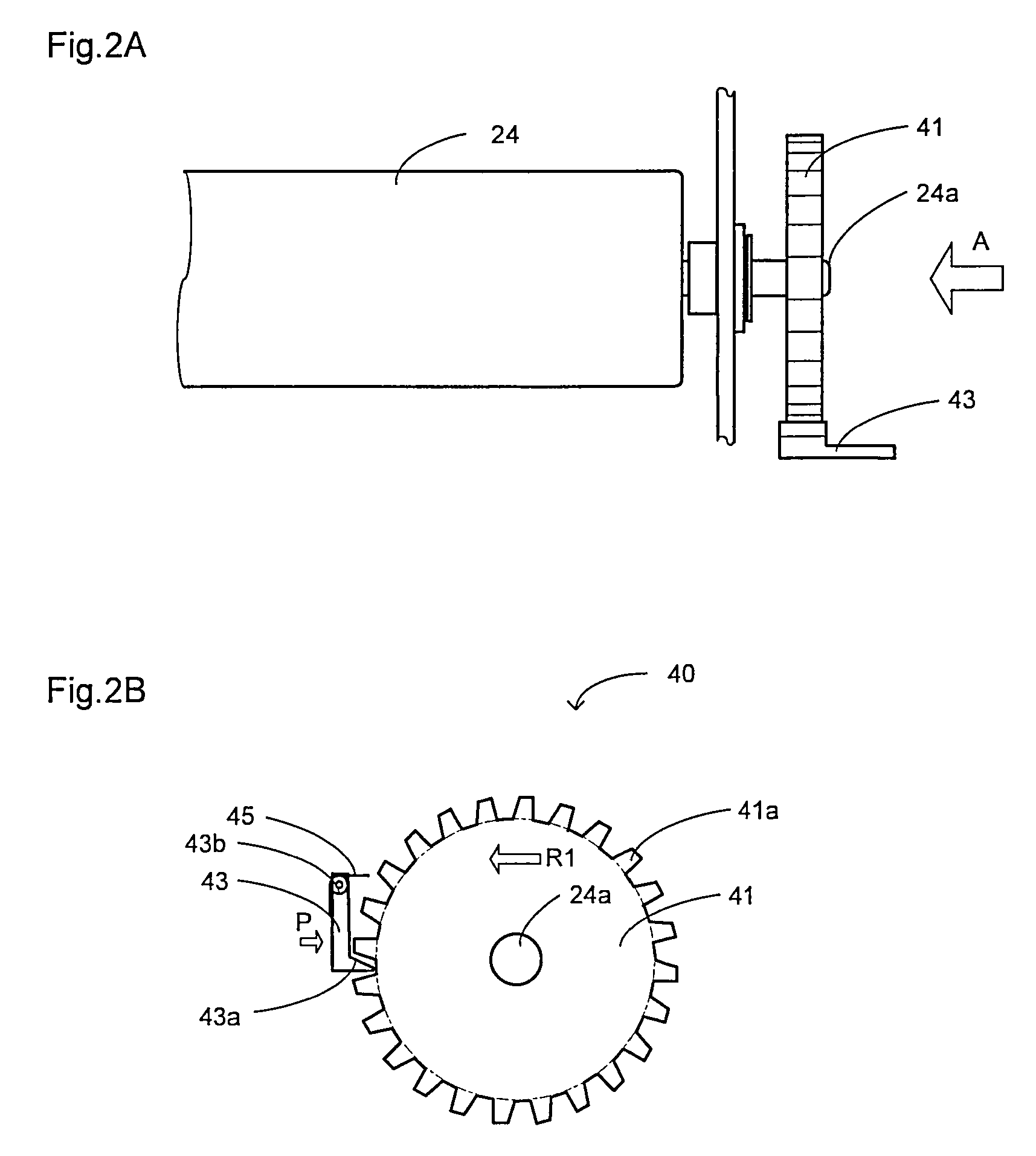

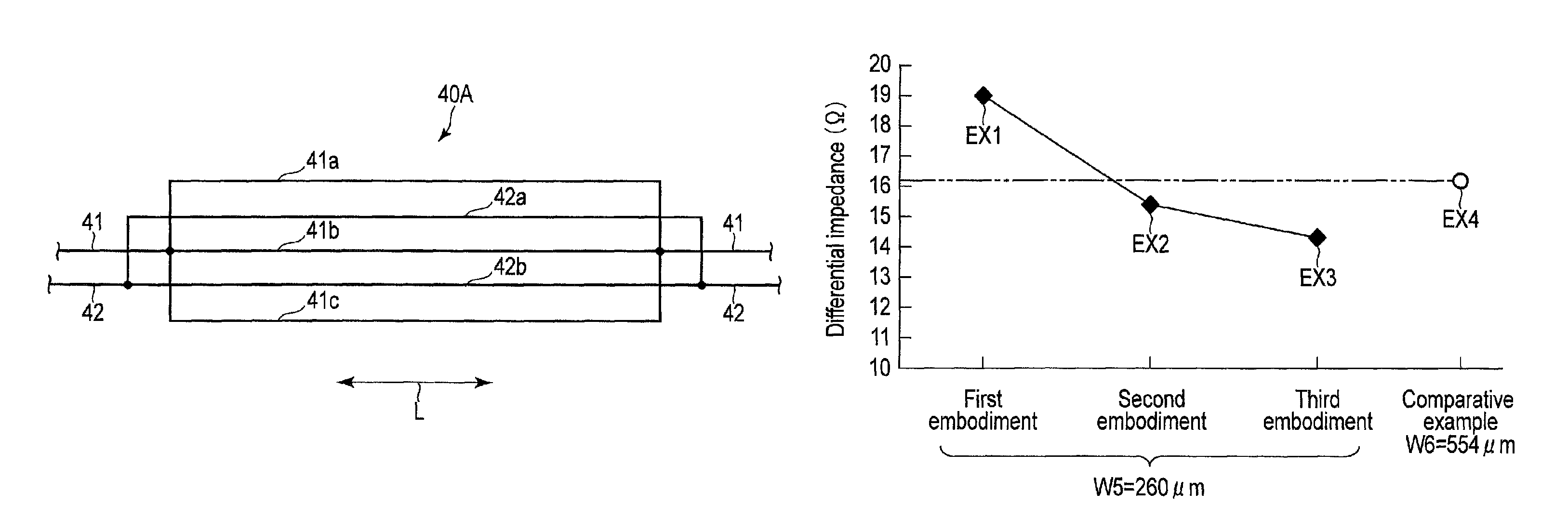

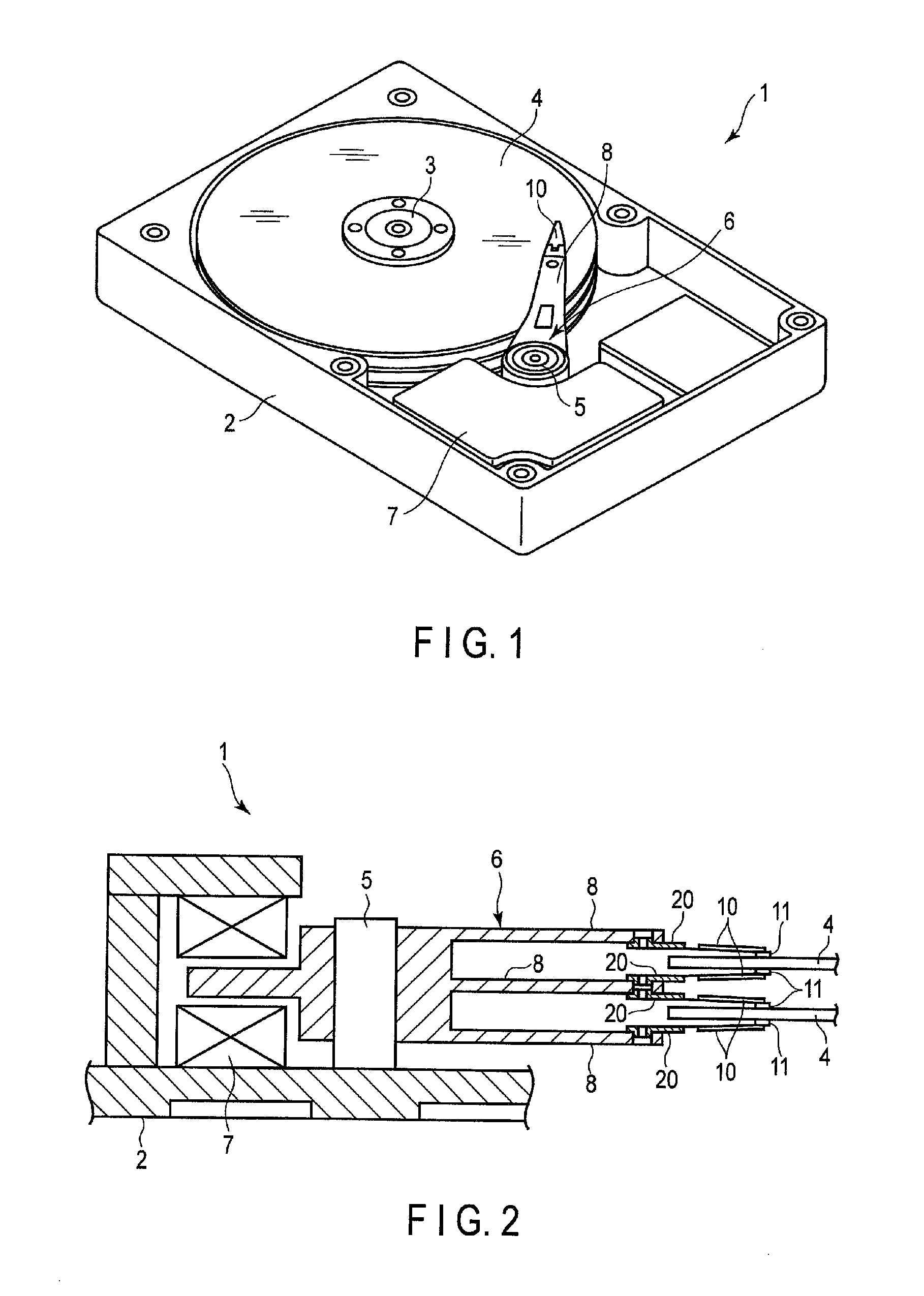

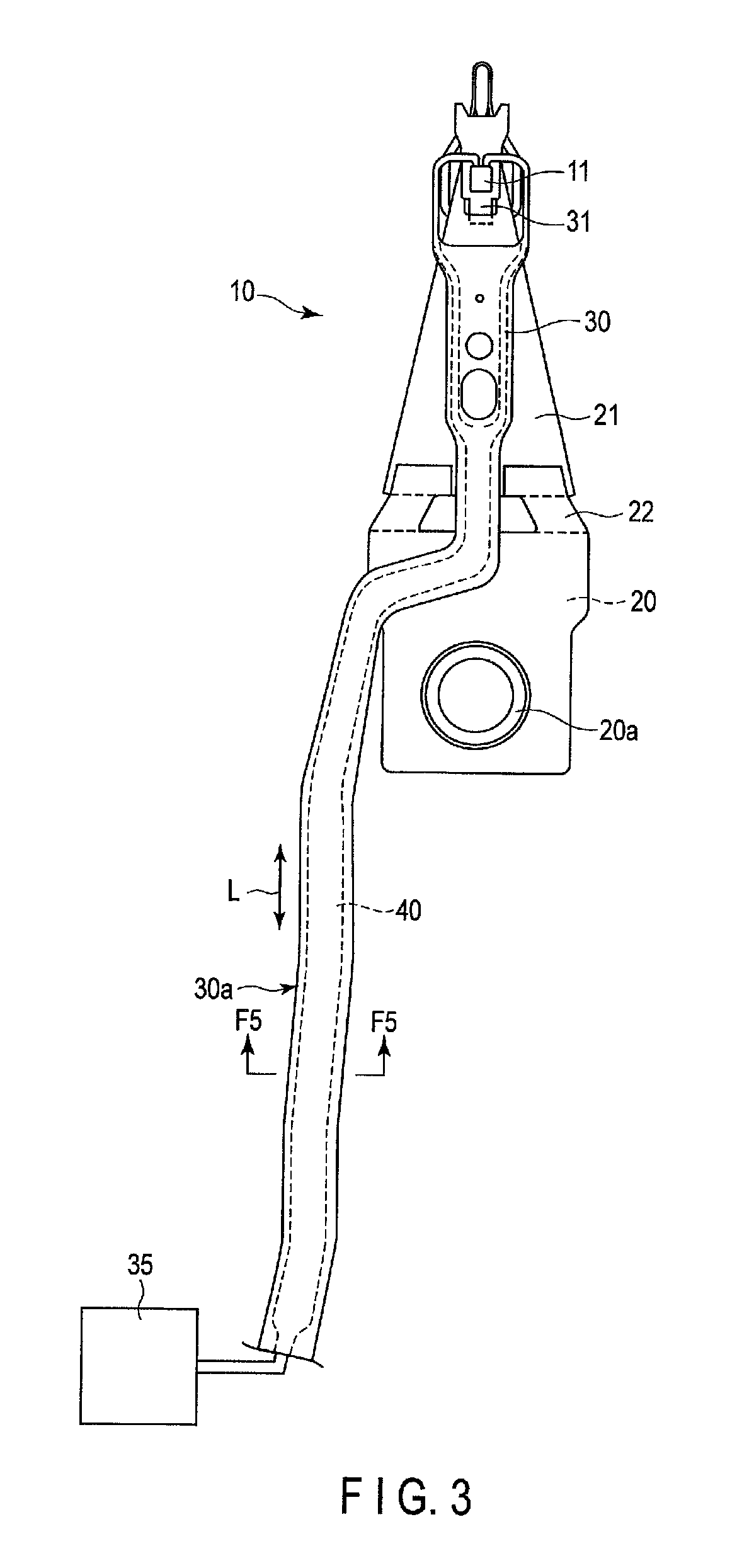

Interleaved circuit of flexure for disk drive

ActiveUS8705210B2Lower impedancePrevented from becoming wideRecord information storageIntegrated arm assembliesElectrical conductorEngineering

An interleaved circuit has first branch conductors branching from a first conductor, second branch conductors branching from a second conductor, a metal base having an opening, an insulating layer formed on the metal base, an electrically insulating first cover resin layer, and an electrically insulating second cover resin layer. The first branch conductors are formed on the insulating layer. The first branch conductors are covered by the first cover resin layer. The second branch conductors are formed on the first cover resin layer. The second branch conductors are individually located between the first branch conductors. The second branch conductors are covered by the second cover resin layer.

Owner:NHK SPRING CO LTD

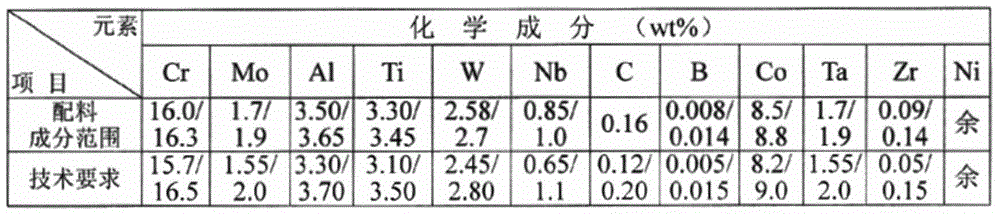

Method for preparing K438 alloy by adopting K438 alloy return material

InactiveCN103556004AIncrease profitReduce wasteIncreasing energy efficiencyChemical compositionIngot

The invention relates to a method for preparing a K438 alloy by adopting a K438 alloy return material. The technical scheme is as follows: the preparation method comprises the following steps of carrying out purifying treatment on the K438 alloy return material; smelting the K438 alloy return material into a return material charge bar; regulating the chemical components of the return material charge bar; smelting the return material charge bar into a finished product K438 alloy ingot. The method disclosed by the invention can be used for producing the K438 alloy which meets the requirement for usage of a product, increases the utilization ratio of materials and reduces the waste of precious metal resources.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

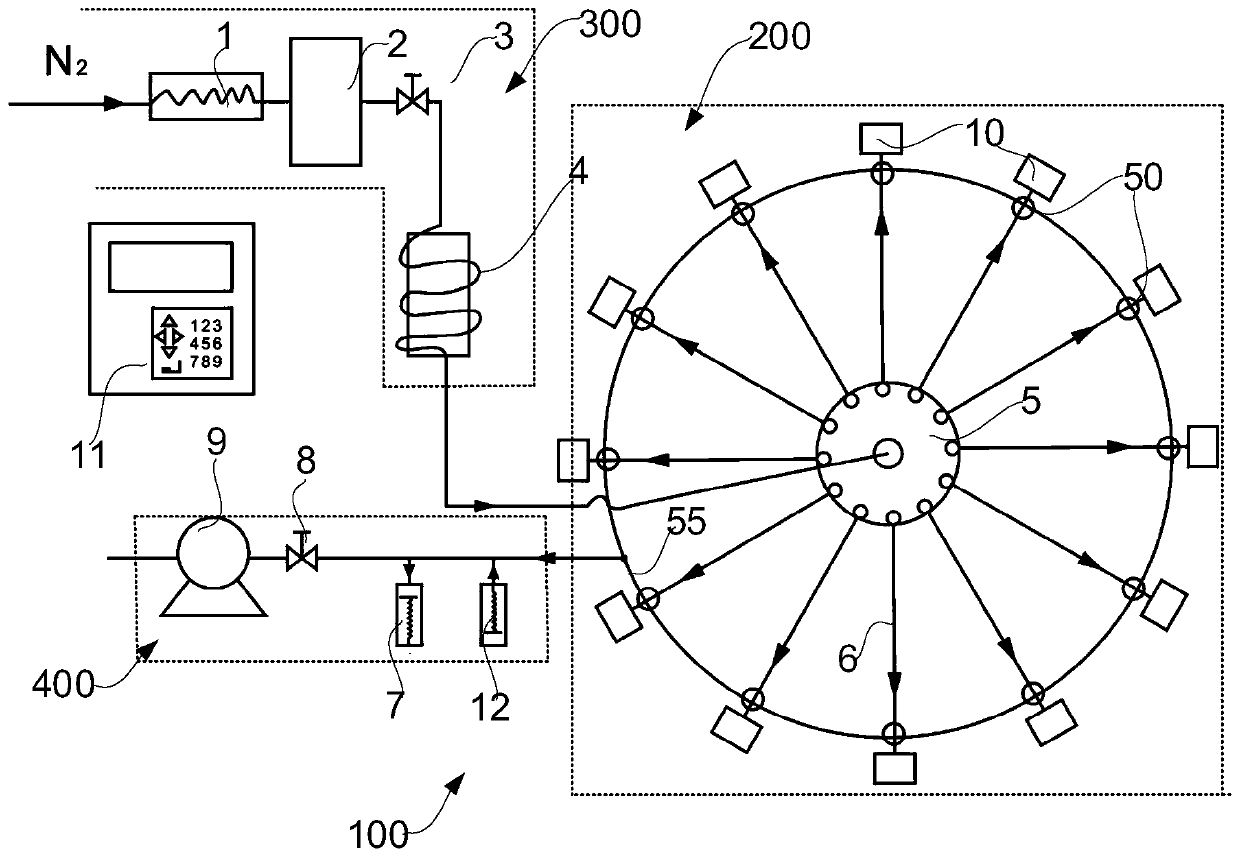

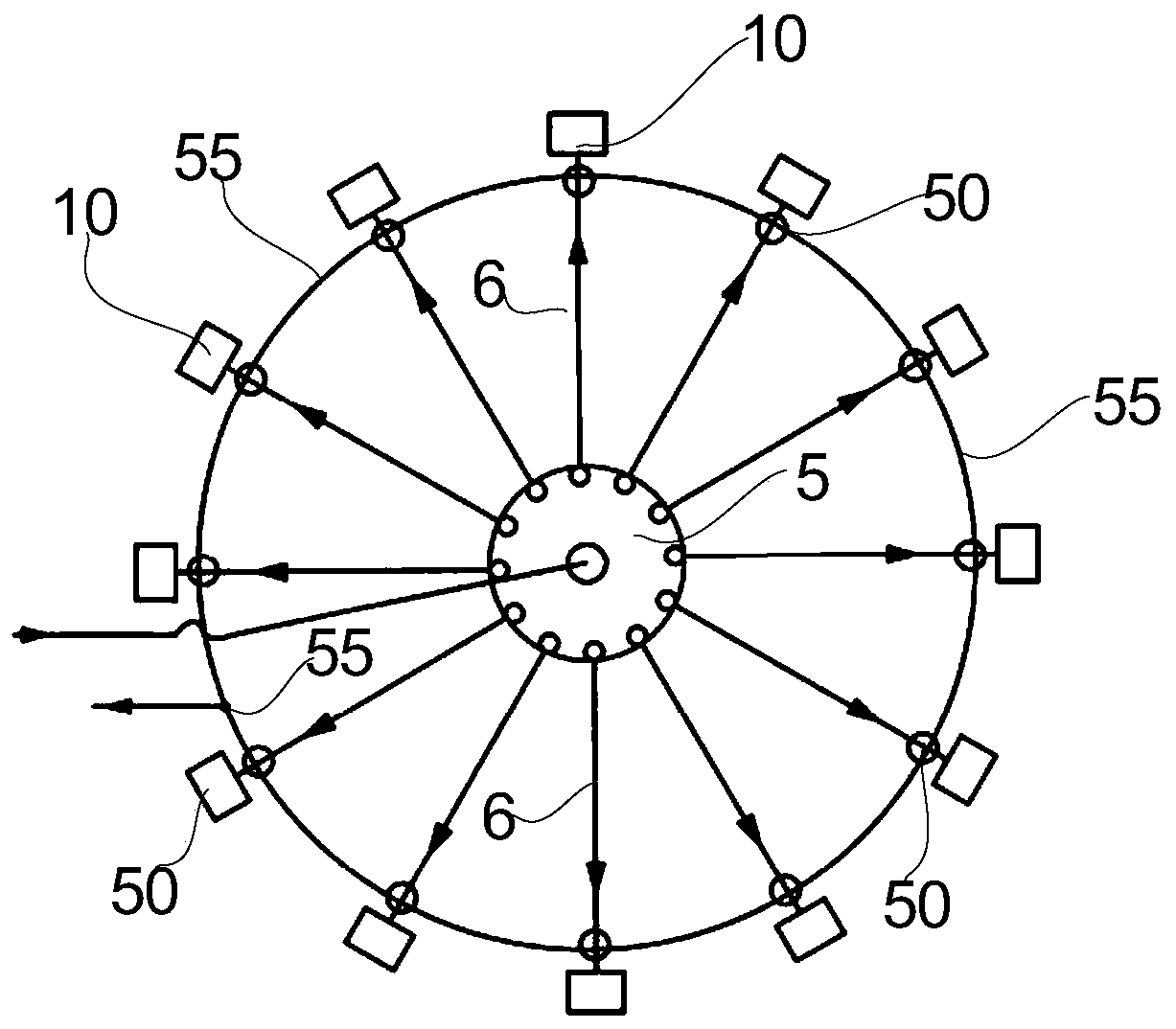

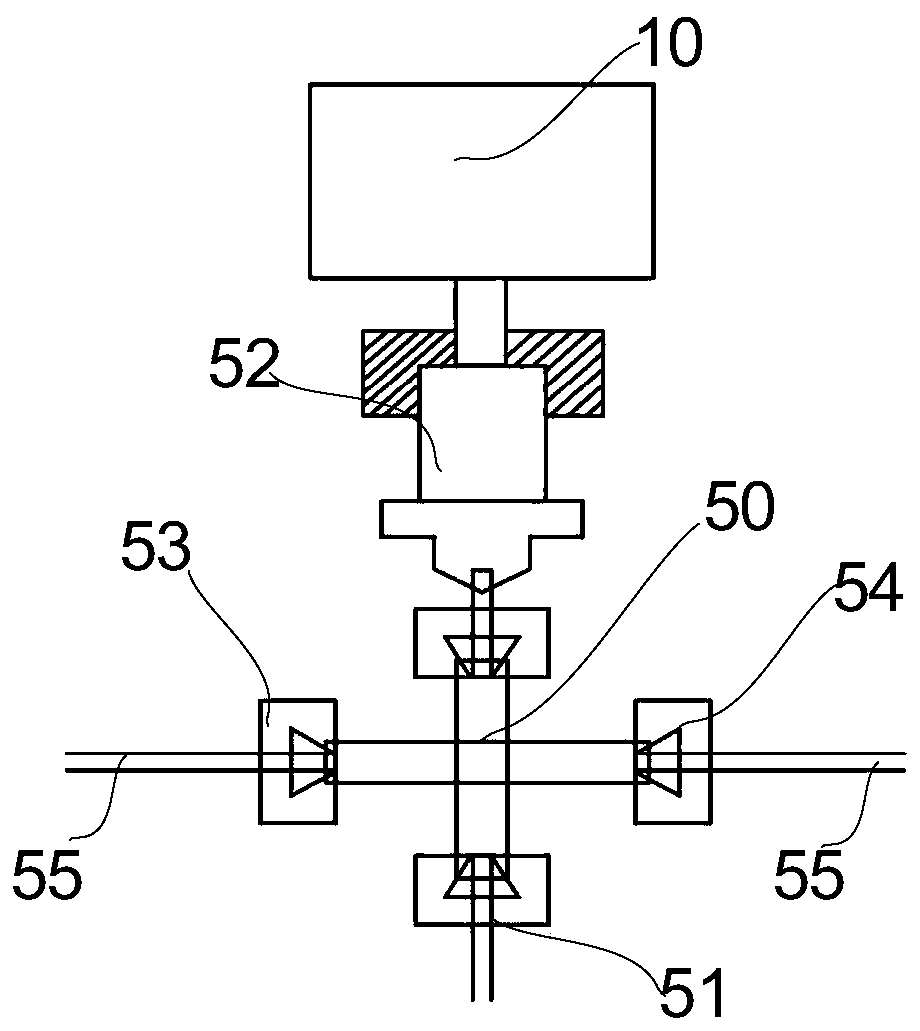

Gas bag cleaning device and method

InactiveCN109772828AReduce consumptionPrevent beingHollow article cleaningLine tubingProcess engineering

The invention discloses a gas bag cleaning device and method. The gas bag cleaning device comprises a fixing device, an inflating device and a gas pumping device, wherein the fixing device is providedwith a gas distributor and gas connectors of gas bags, the gas distributor is connected with the gas connectors through pipelines, the gas distributor is connected with the two or more pipelines, each pipeline corresponds to the corresponding gas connector, and the gas connectors are mutually connected; the inflating device is connected with the gas distributor through a pipeline so as to fill the gas bags with gas through the gas connectors; and the gas pumping device is connected with the fixing device through a pipeline and used for pumping out gas in the gas bags and the fixing device. The gas bags in the market can be cleaned through the gas bag cleaning device and method and thus can be recycled. In this way, consumption of the gas bags in the analyzing and sampling processes can bereduced, the cost is saved, and the situation that the gas bags become secondarily polluted solid pollutants can also be avoided as much as possible.

Owner:刘斌

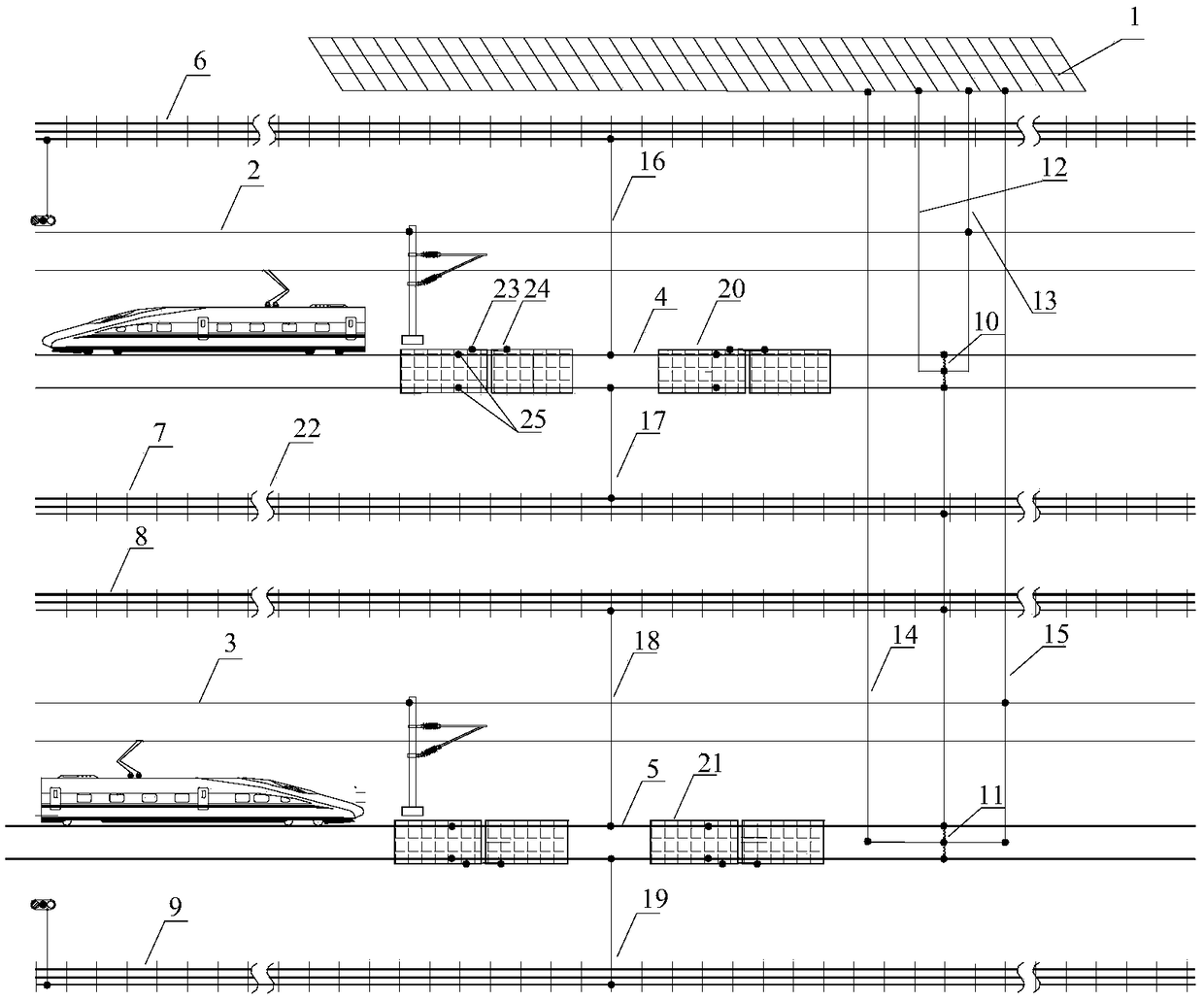

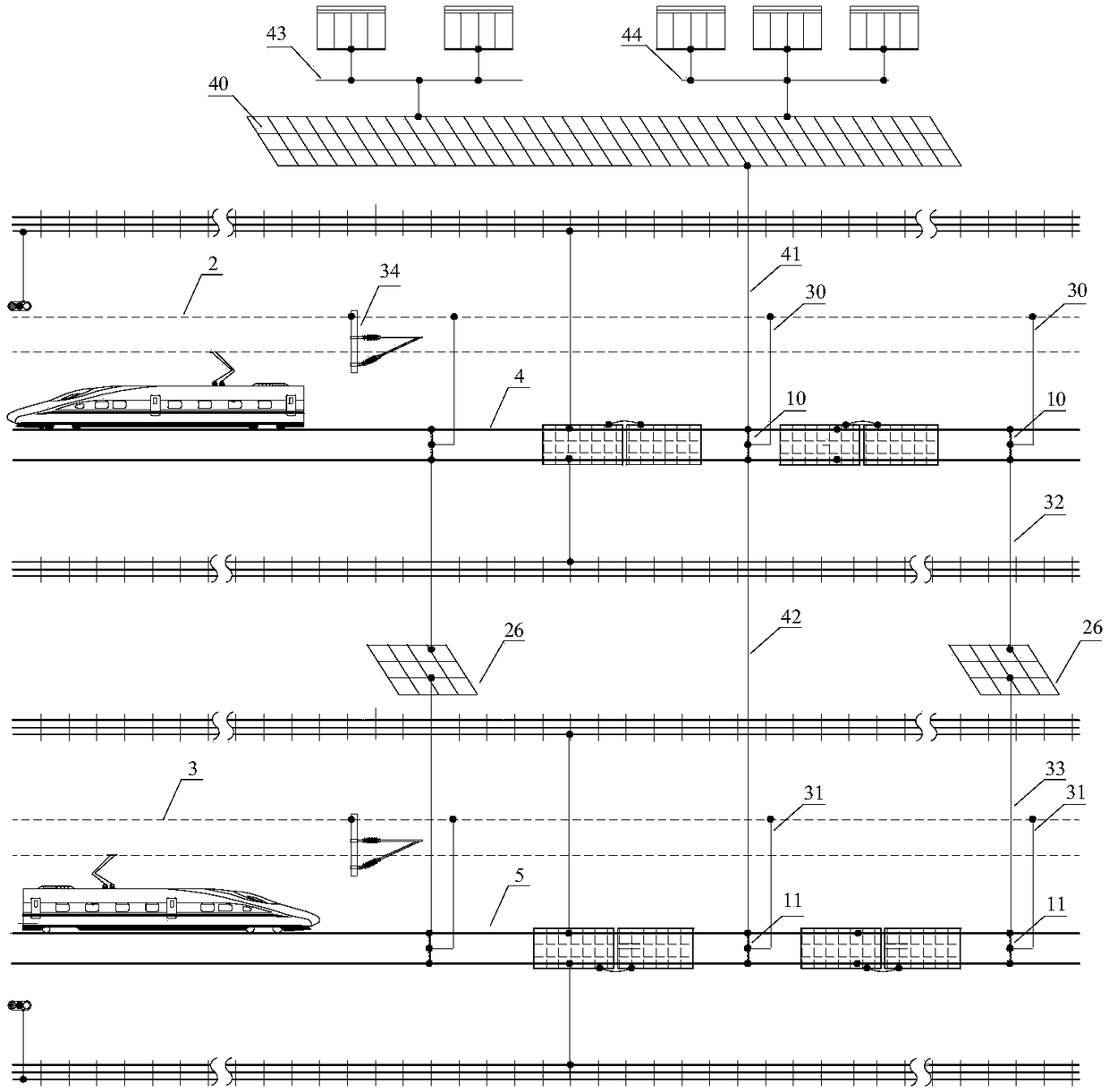

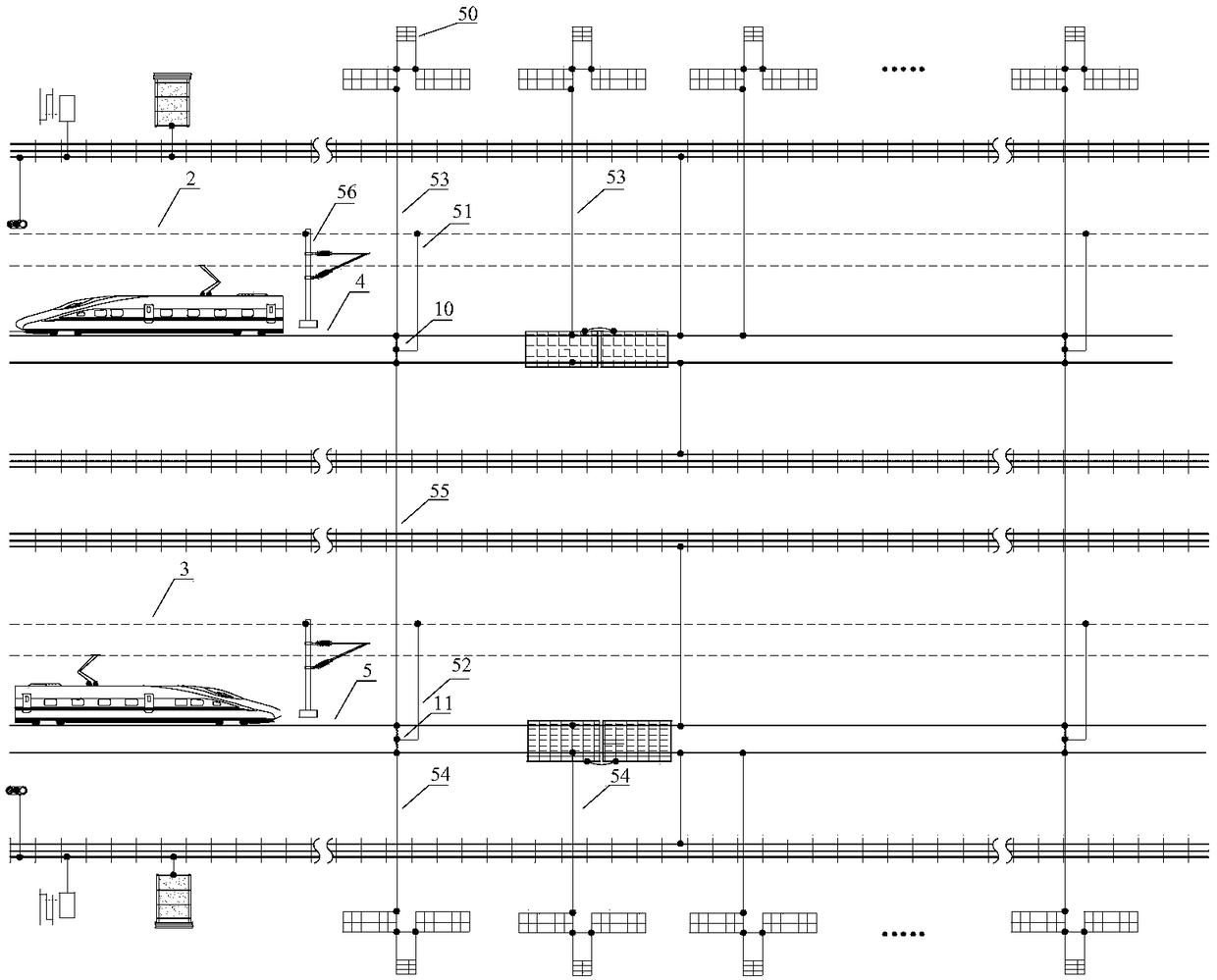

Integrated grounding system applied to urban rail transit adopting alternate current traction power supply system

ActiveCN108790957ASolve traffic grounding issuesEnsure safetyRail devicesHarmonic reduction arrangementElectrical resistance and conductanceElectrical conductor

The invention provides an integrated grounding system applied to urban rail transit adopting an alternate current traction power supply system. The grounding problem of the urban rail transit adoptingthe alternate current traction power supply system is solved, and the safety of equipment and personnel is ensured. The traction power supply system working ground (current returning access) is constituted by an upward steel rail, a downward steel rail, a catenary current returning line and the ground, and an upward steel rail conductor and a downward steel rail conductor are completely and transversely connected at the 500-600 m interval. The working ground (current returning access) is in single-point reliable connection with grounding devices of an integrated ground network of stations along a line, an interval air shaft ground network, a contact transverse channel ground network, a traction substation ground network, a tunnel, a bridge and the like, an equipotential platform is constructed while the grounding resistance of the system is reduced, and meanwhile, the situation that all systems are connected with the strong electricity working ground to become the strong electricity system current returning access is avoided.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

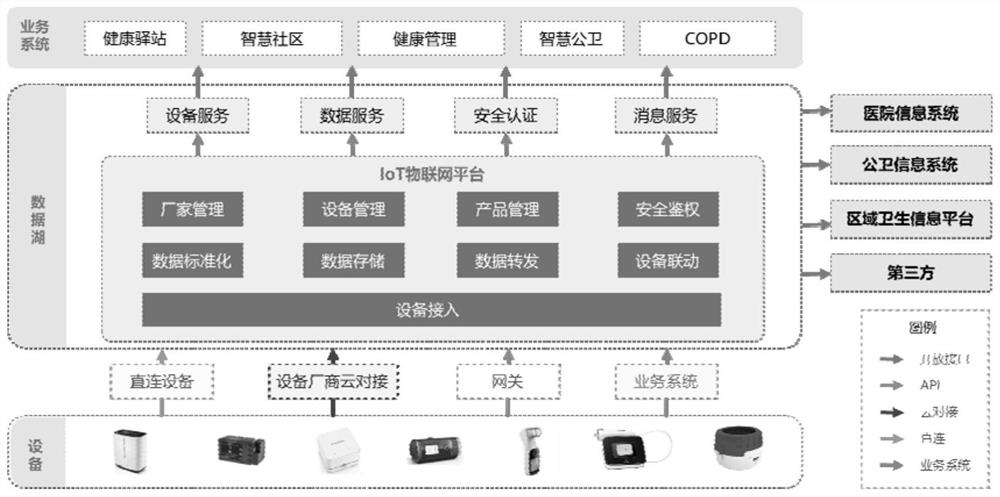

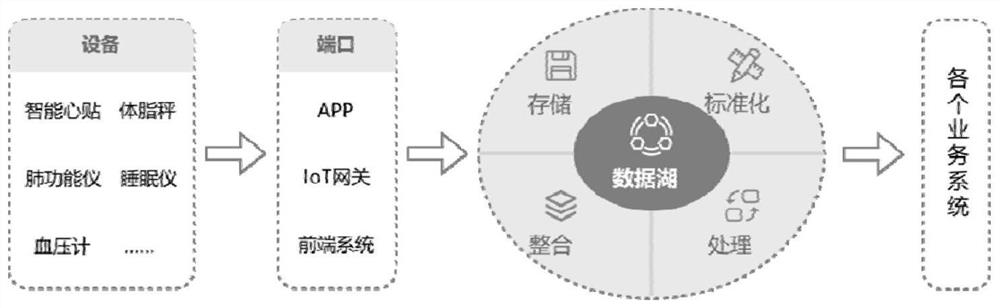

Data processing method, device, system and equipment and storage medium

PendingCN112820366ARealize multiplexingPrevent beingRelational databasesSpecial data processing applicationsService systemData storage system

The invention discloses a data processing method, device, system and equipment and a storage medium. The method comprises the following steps: receiving Internet of Things data reported by an Internet of Things terminal device; according to a preset rule sent by a service system, target Internet of Things data in the Internet of Things data being determined, wherein the preset rule is a condition for indicating storage processing of the Internet of Things data; and storing the target Internet of Things data to a storage position corresponding to the preset rule, thereby effectively realizing multiplexing of a data storage system in a multi-service system, effectively reducing the cost of the data storage system and the service system, and meanwhile, effectively preventing the data corresponding to the service system from becoming islanding data.

Owner:BOE TECH GRP CO LTD

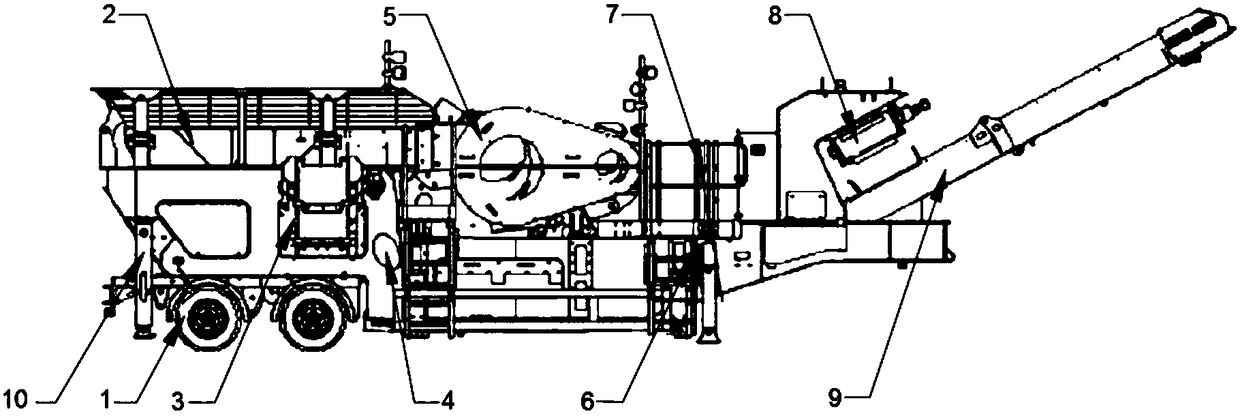

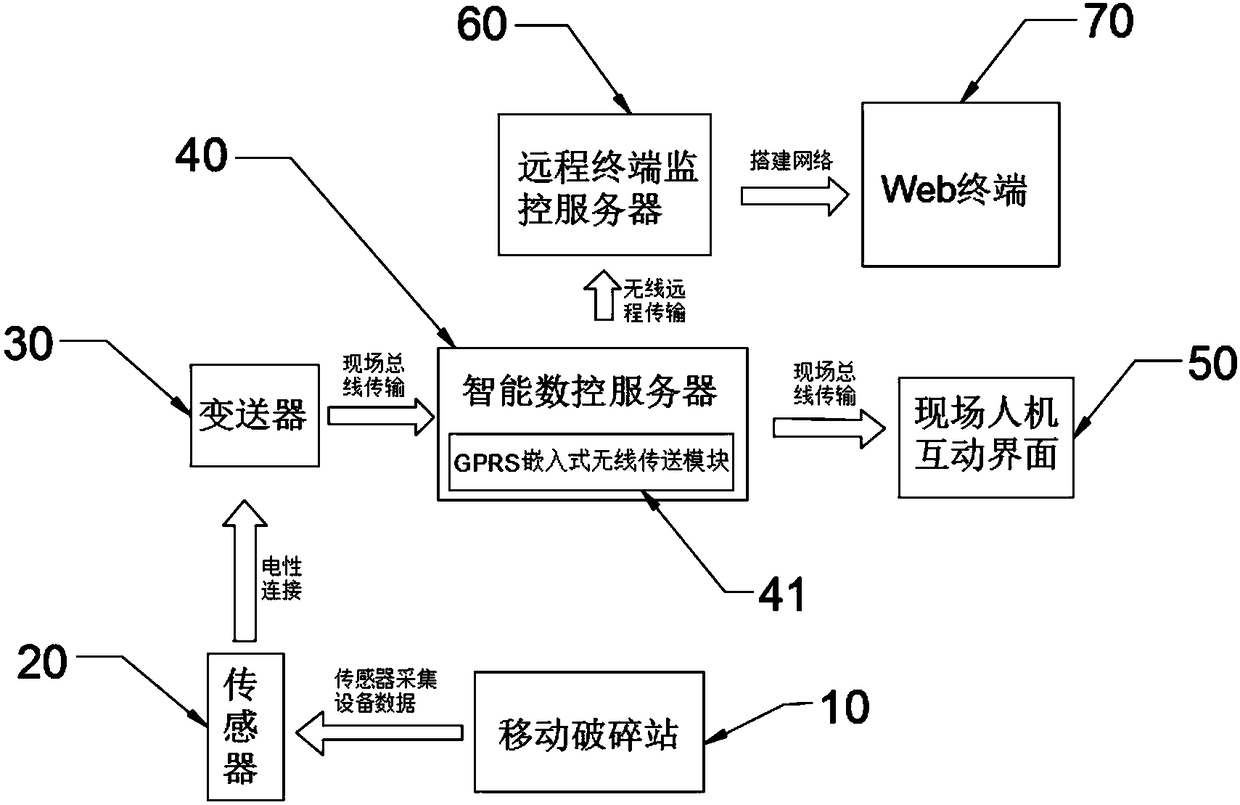

Intelligent movable crushing station having remote monitoring function

InactiveCN109277173ALow costAvoid isolationGrain treatmentsAgricultural engineeringMonitoring system

The invention discloses an intelligent movable crushing station having remote monitoring function, which includes: a movable crushing travel system, a rod-vibrating feeding machine, a side belt machine, a blanking hopper device, a jaw crusher, a hydraulic lifting system, an electric-control system, an iron remover, a jaw crusher discharge main belt machine, and a weighing device disposed in the jaw crusher discharge main belt machine. The jaw crusher discharge main belt machine is installed under a discharge outlet of the jaw crusher. The iron remover is installed at the upper side of the middle part of the jaw crusher discharge main belt machine. The discharge outlet of the rod-vibrating feeding machine is arranged above the inlet of the jaw crusher. The side belt machine is installed under the jaw crusher discharge main belt machine. The hydraulic lifting system is disposed at the lower part of the movable crushing station and is connected to a main framework through a support assembly. The electric-control system is disposed on a platform above the jaw crusher discharge main belt machine. The intelligent movable crushing station has a complete set of comprehensive monitoring system, thus achieving remote monitoring of the movable crushing station.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD +1

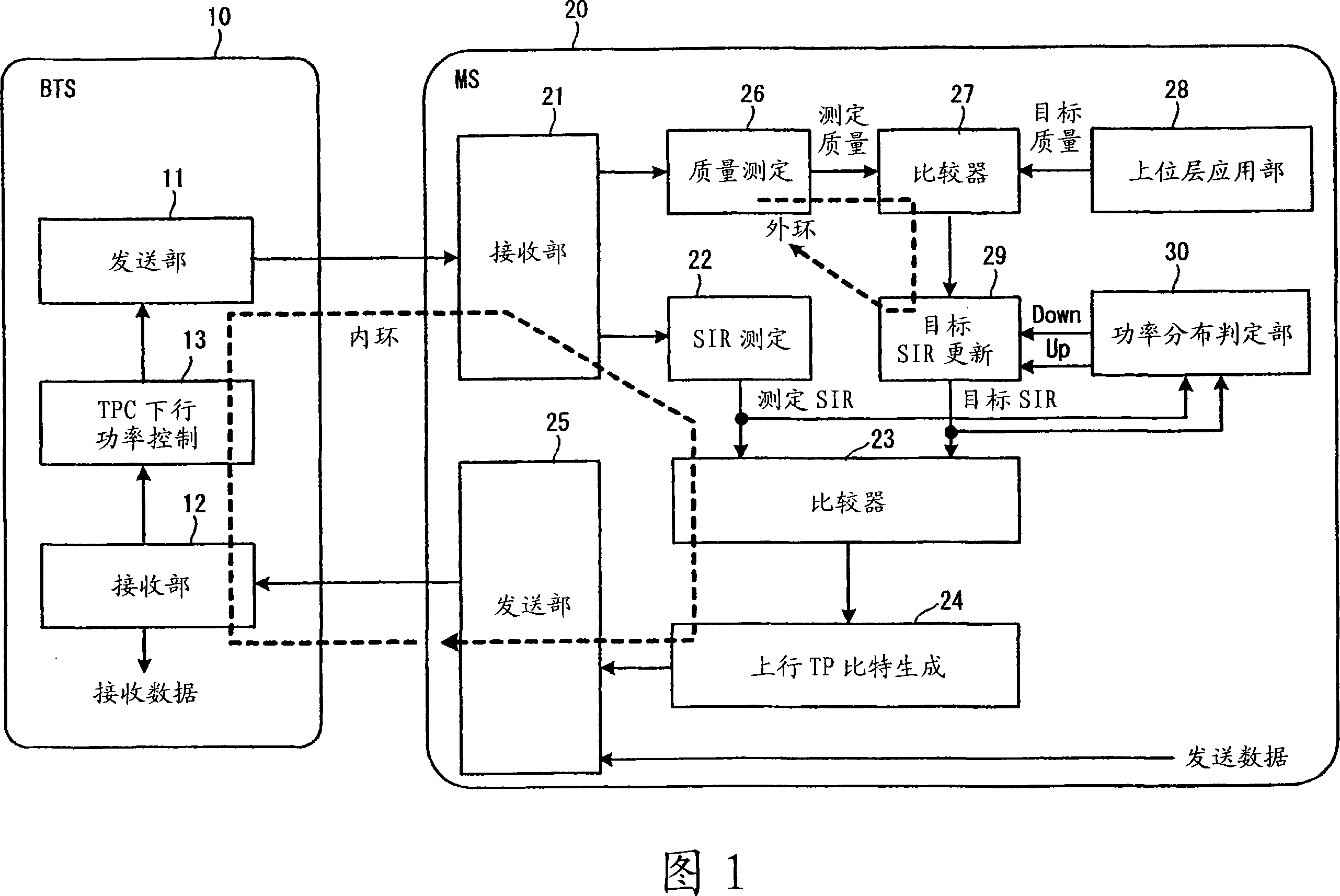

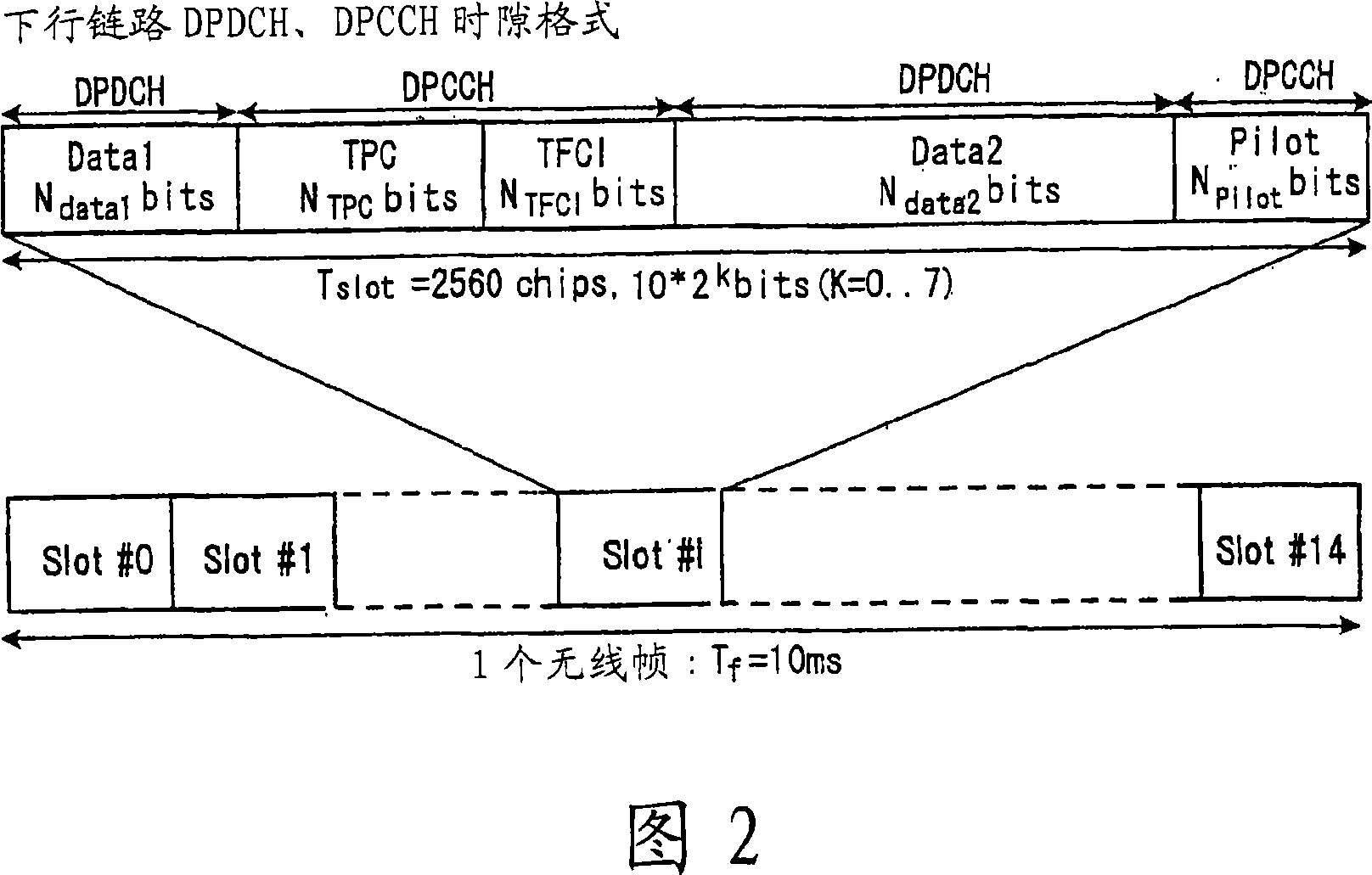

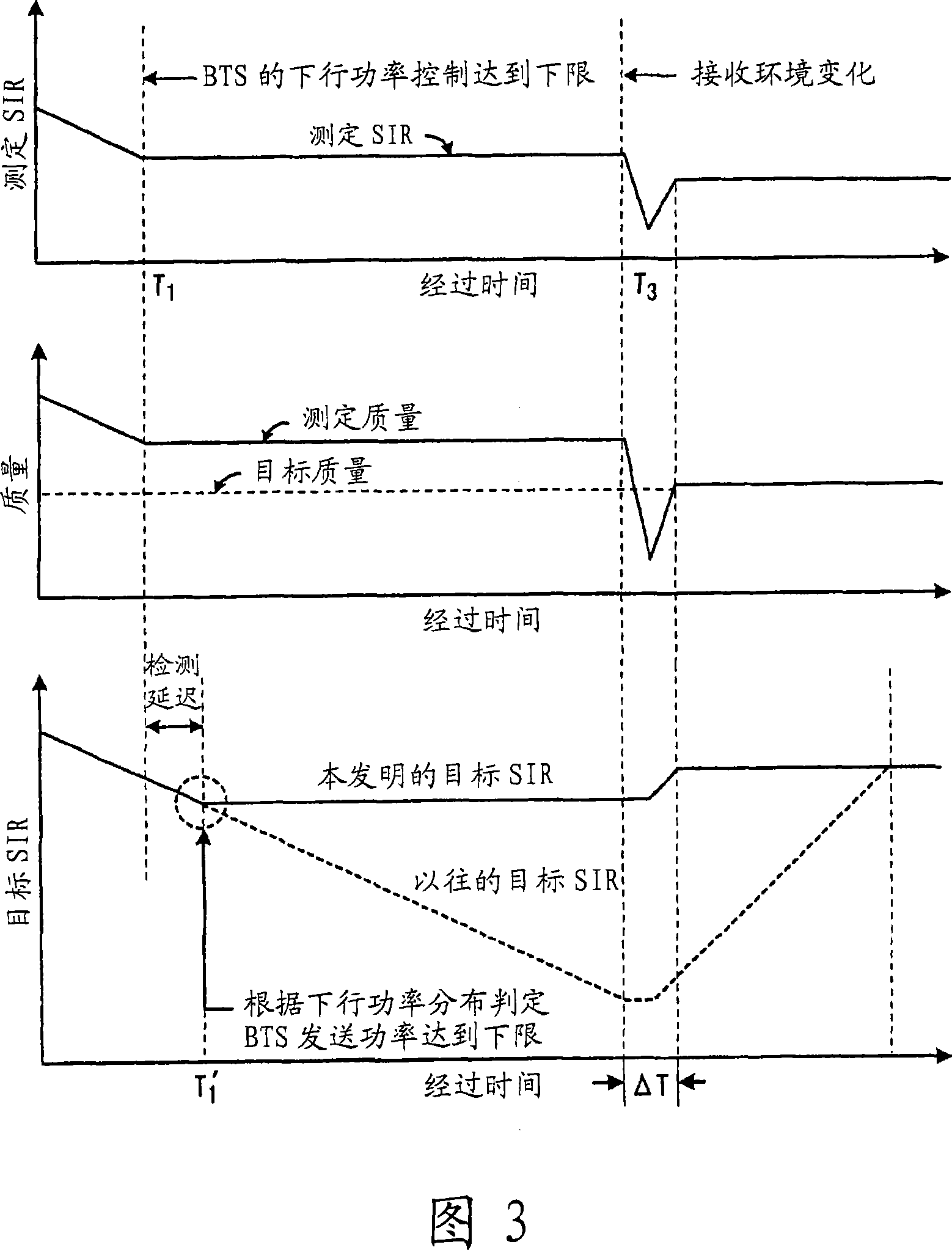

Transmission power control unit and transmission power control method

On the receiving side, a measured quality of received data and a target quality are compared and a target SIR is variably controlled. At the same time, the target SIR and a measured SIR are compared, transmission power control information (TPC information) made by based on the comparison results is transmitted to a transmitting side and transmission power is controlled on the transmitting side based on the transmission power control information. Furthermore, whether the transmission power has reached a limit is monitored on the receiving side, and when it reaches the limit, the target SIR is fixed at the latest value not to be revised. When the communication environment changes and transmission power can be controlled, variable control of the target SIR is restarted.

Owner:FUJITSU LTD +1

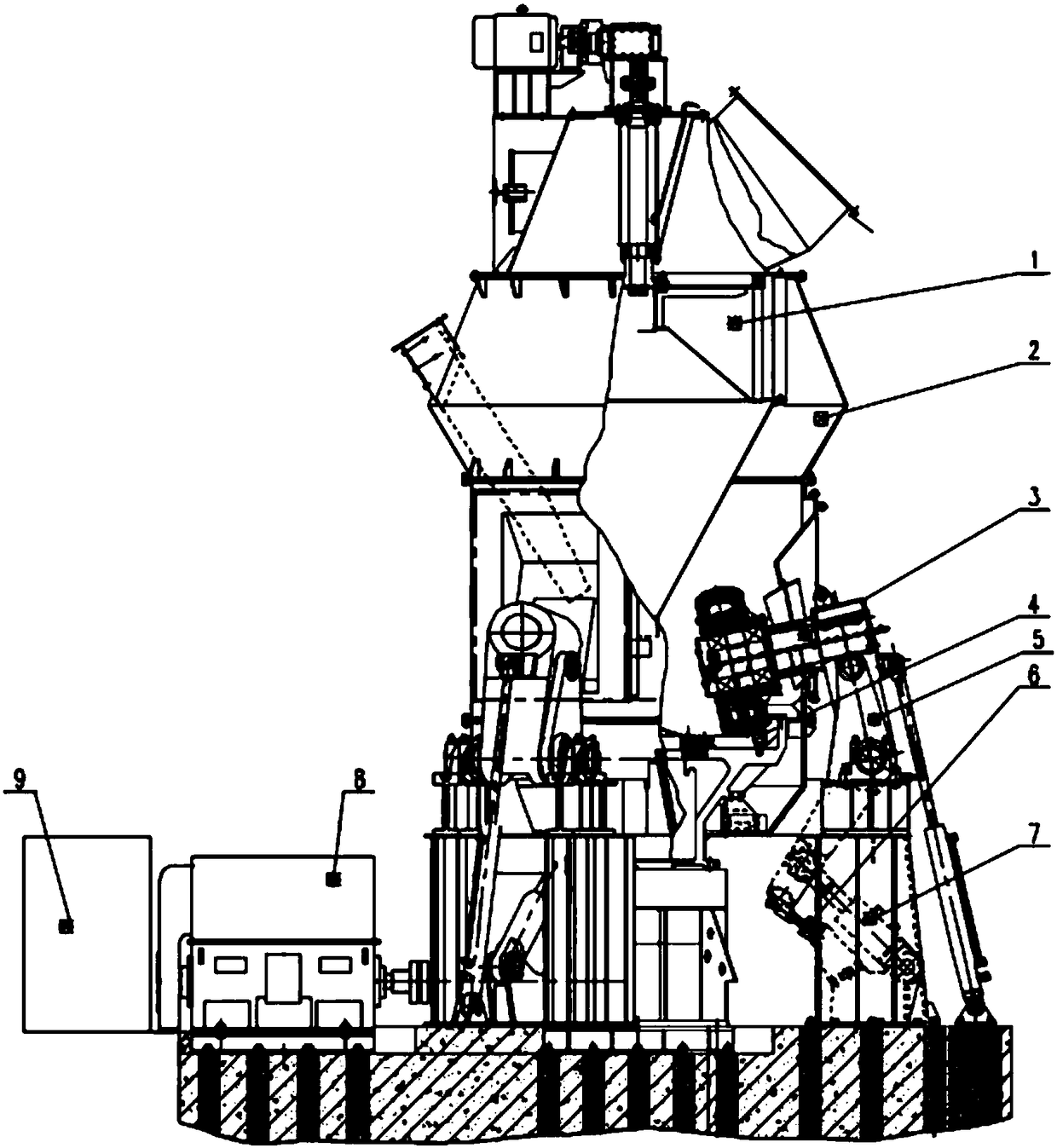

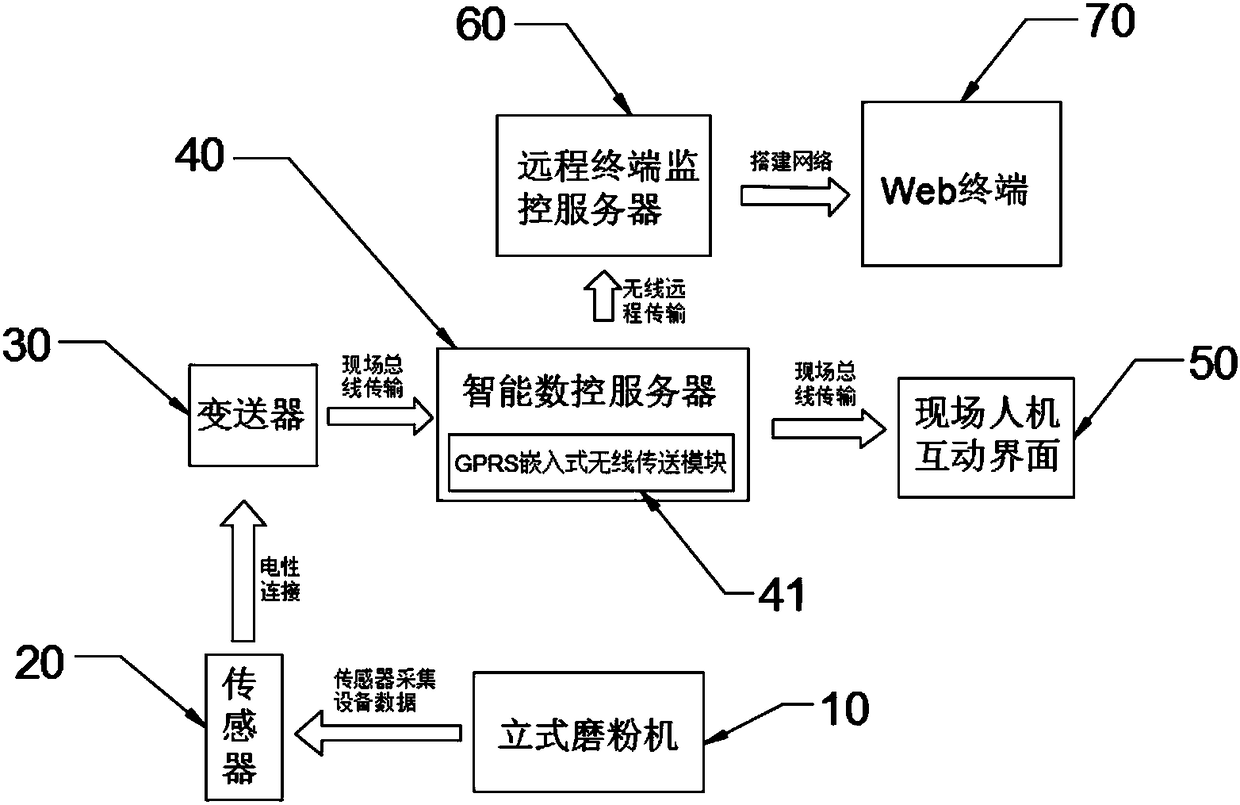

Intelligent vertical grinding mill having remote monitoring function

InactiveCN109277147ALow costImprove real-time performanceGrain treatmentsNumerical controlAgricultural engineering

The invention discloses an intelligent vertical grinding mill having remote monitoring function, which includes: a separator, a housing, a grinding roller device, a grinding disc device, a transmission arm, a position limiting device, a compressing inspection and hydraulic device, a transmission system, and a hydraulic lubricating system. The separator is installed on the upper part of the housing. The grinding roller device is installed in the middle-lower part of the housing. The grinding disc device is installed below the grinding roller device. The transmission arm is installed on a transmission portion of the grinding roller device. The compressing inspection and hydraulic device is installed under the transmission arm. The position limiting device is located in the compressing inspection and hydraulic device. The transmission system is installed on a base. The hydraulic lubricating system is connected to a main machine through an oil path. The vertical grinding mill, sensors, a transmitter, an intelligent numerical control server, a field man-machine interaction interface, a remote terminal monitoring server, and a WEB terminal form the whole monitoring system together. By means of a set of complete comprehensive monitoring system, remote monitoring on the vertical grinding mill is achieved.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com