Intelligent movable crushing station having remote monitoring function

A mobile crushing and remote monitoring technology, which is applied in the field of mining equipment, can solve problems such as inaccurate monitoring of faults in mobile crushing stations, and achieve the effects of information sharing, optimized management and production, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

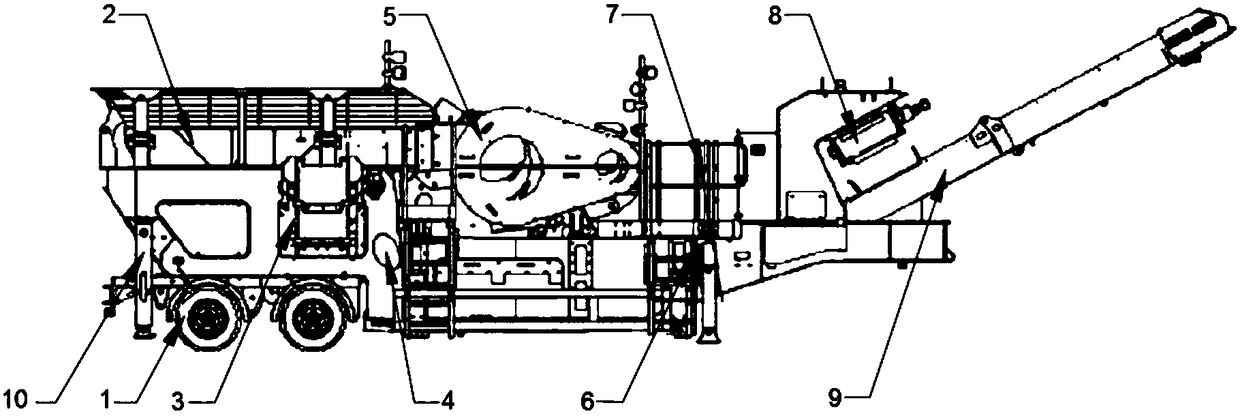

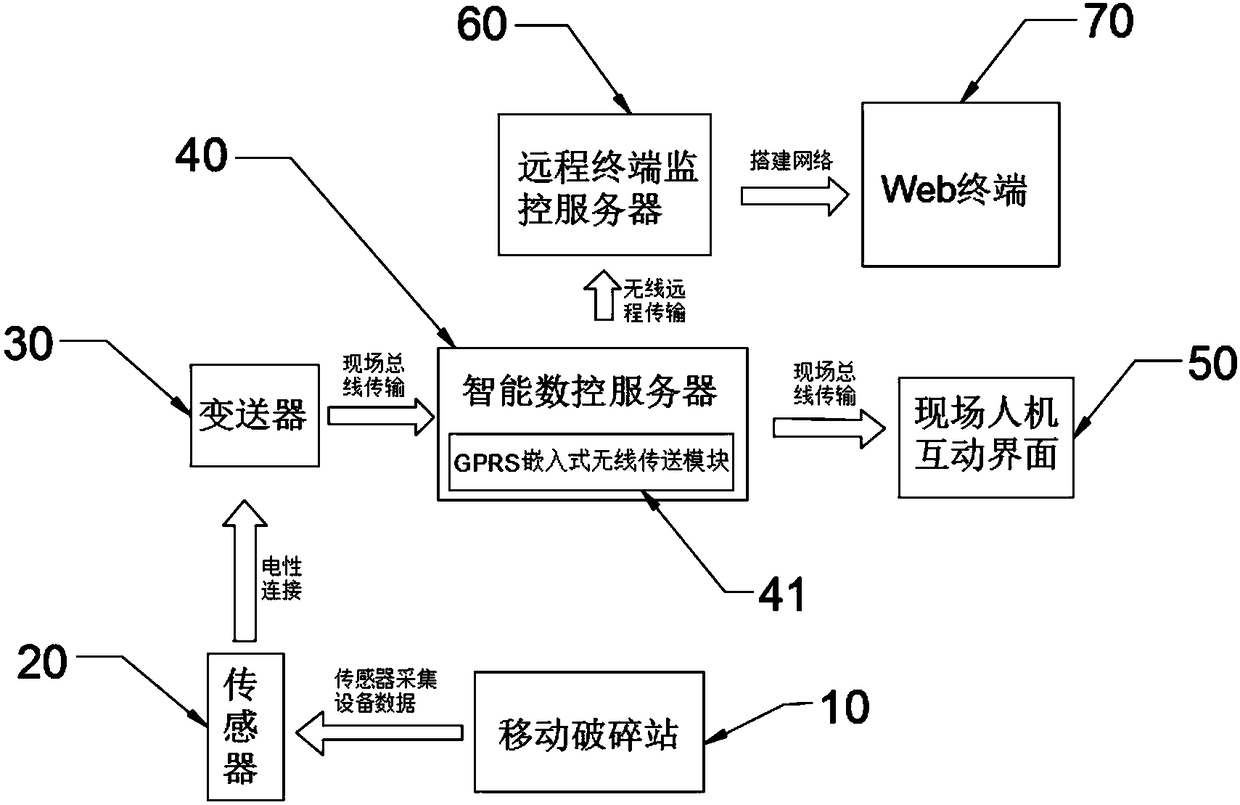

[0021] Example: such as Figure 1-2 As shown, the present invention provides an intelligent mobile crushing station with a remote monitoring function, including a mobile crushing walking system 1, a rod vibrating feeder 2, a side belt conveyor 3, a lower hopper device 4, a jaw crusher 5, Hydraulic lifting system 6, electric control system 7, iron remover 8, jaw crusher discharge main belt conveyor 9 and the weighing scale inside the jaw crusher discharge main belt conveyor 9; jaw crusher discharge main belt conveyor 9 is installed on the jaw crusher The lower part of the discharge port of the jaw crusher 5, the iron remover 8 is installed above the middle part of the main belt conveyor 9 of the jaw crusher, and the discharge port of the rod vibrating feeder 2 is installed above the feed port of the jaw crusher 5, and the side The belt conveyor 3 is installed under the rod vibrating feeder 2, the hydraulic lifting system 6 is located at the lower part of the mobile crushing sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com