Patents

Literature

192results about How to "Avoid isolation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

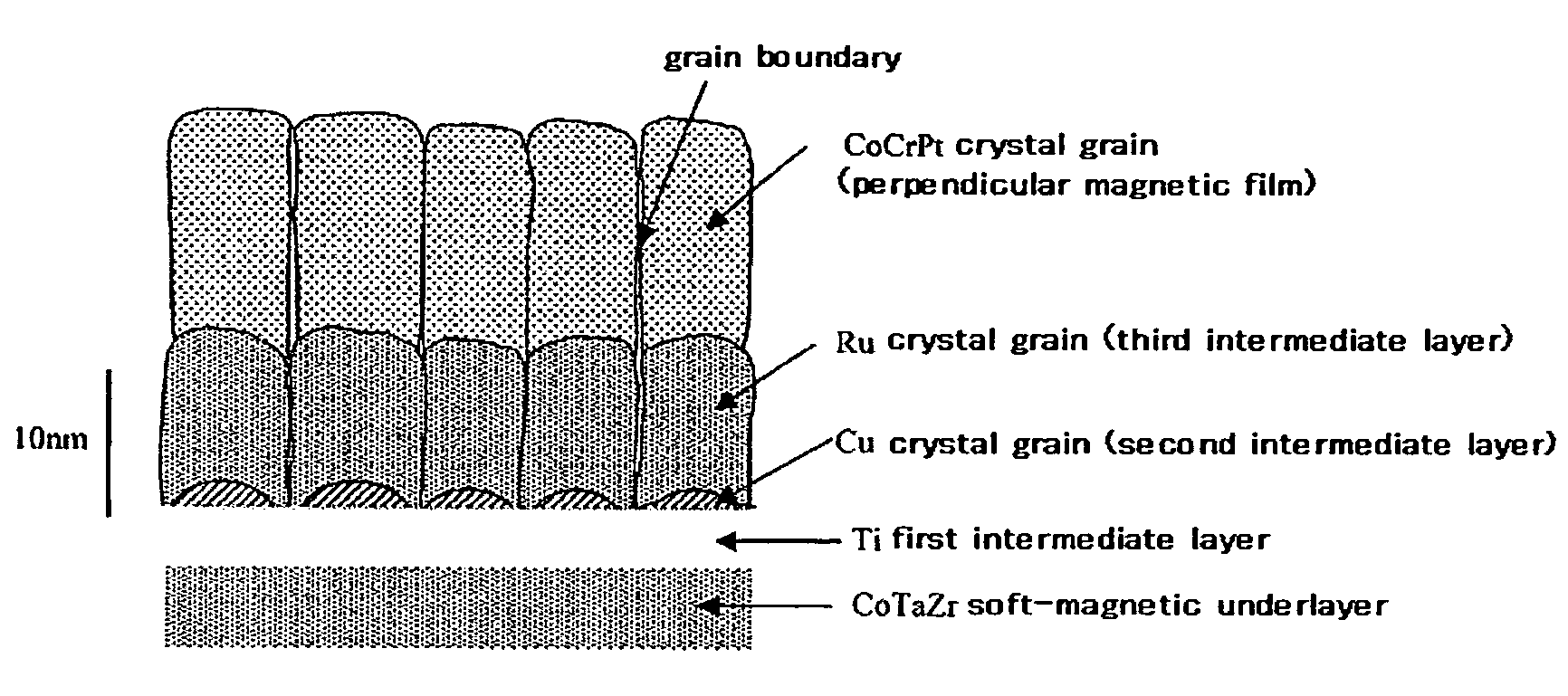

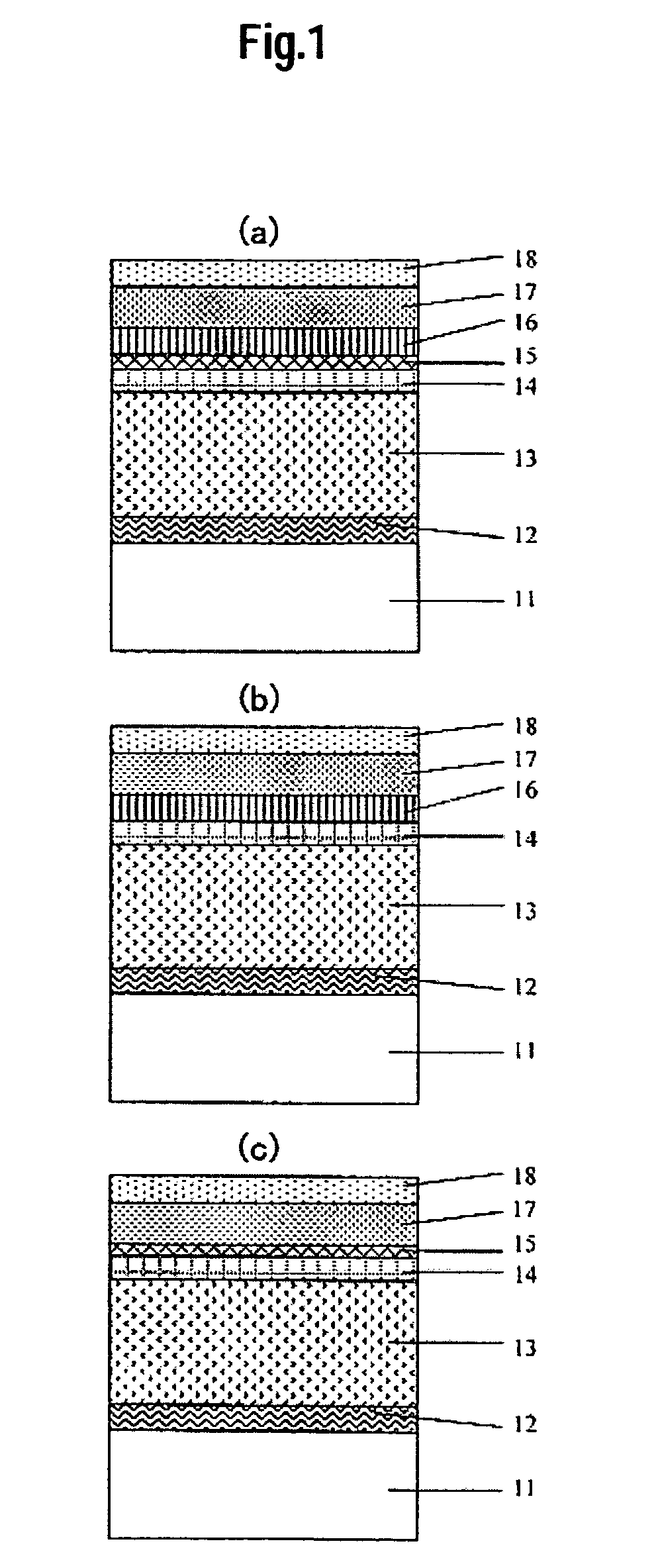

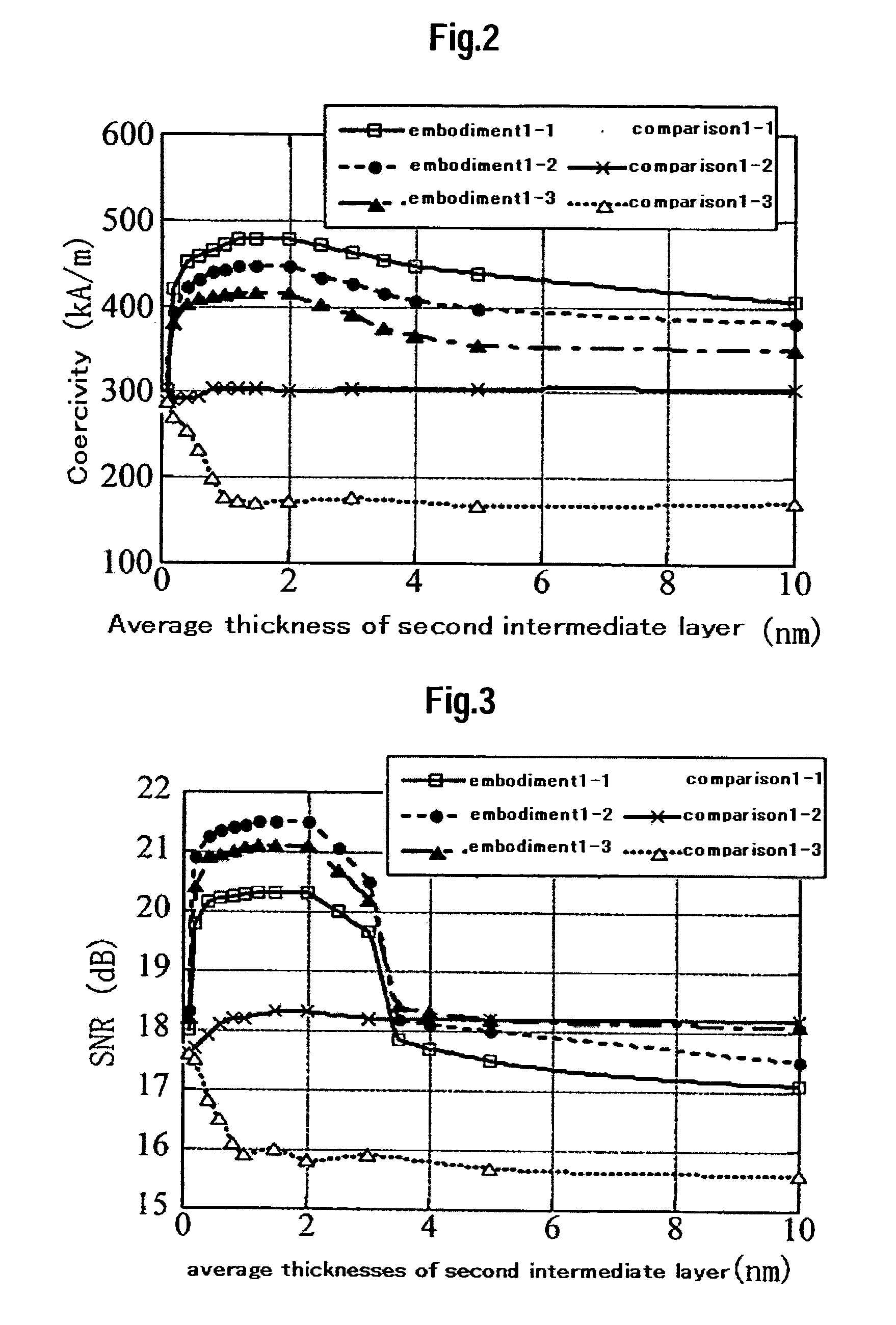

Perpendicular magnetic recording media and magnetic storage apparatus using the same

ActiveUS20050142388A1Excellent crystallographic texture and magnetic isolationExcellent write-abilityBase layers for recording layersRecord information storagePhysicsOxide

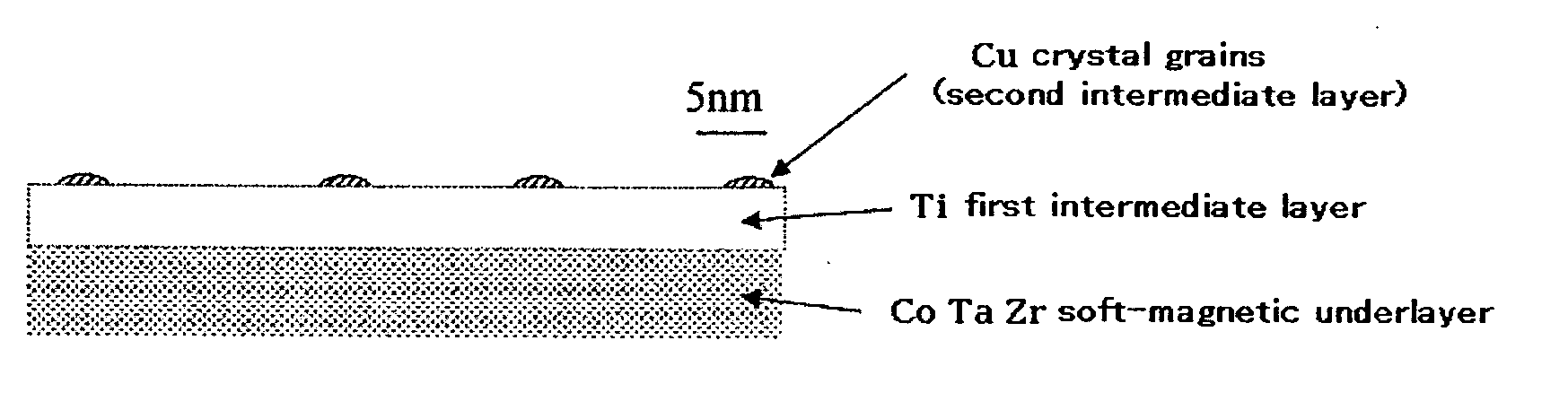

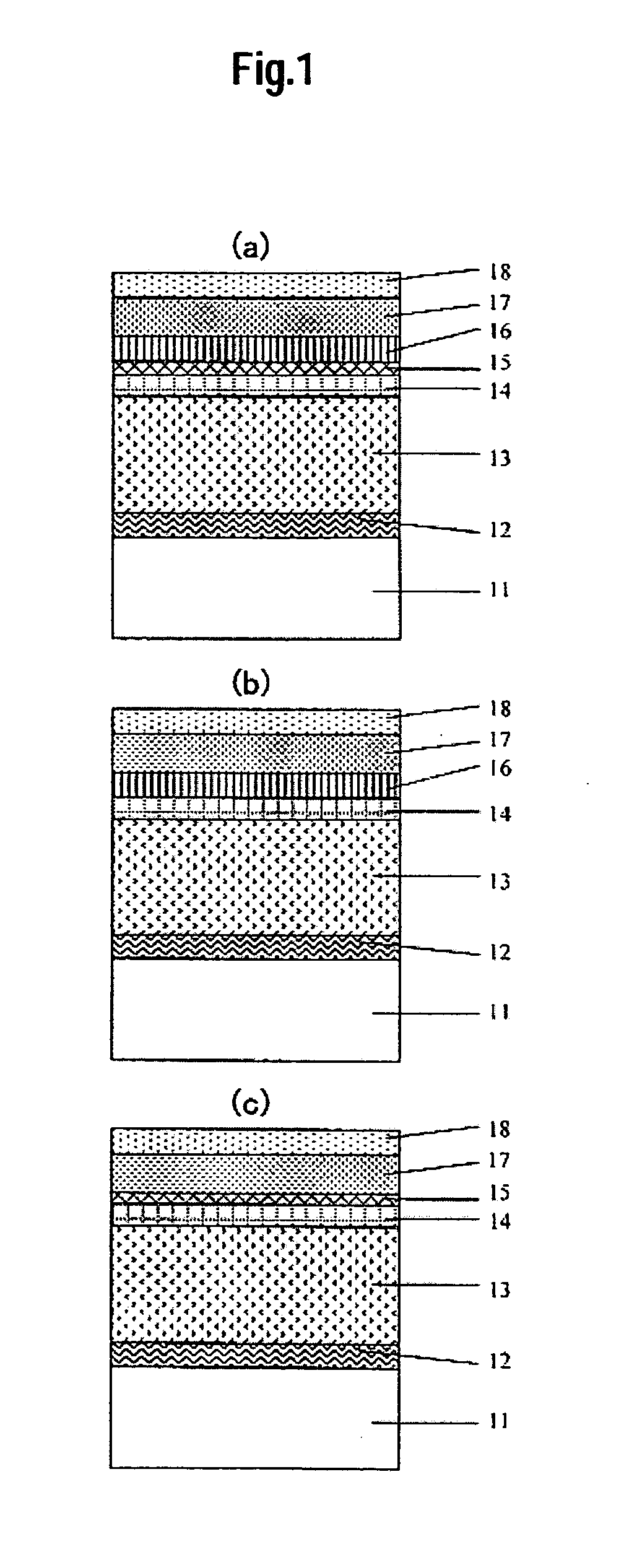

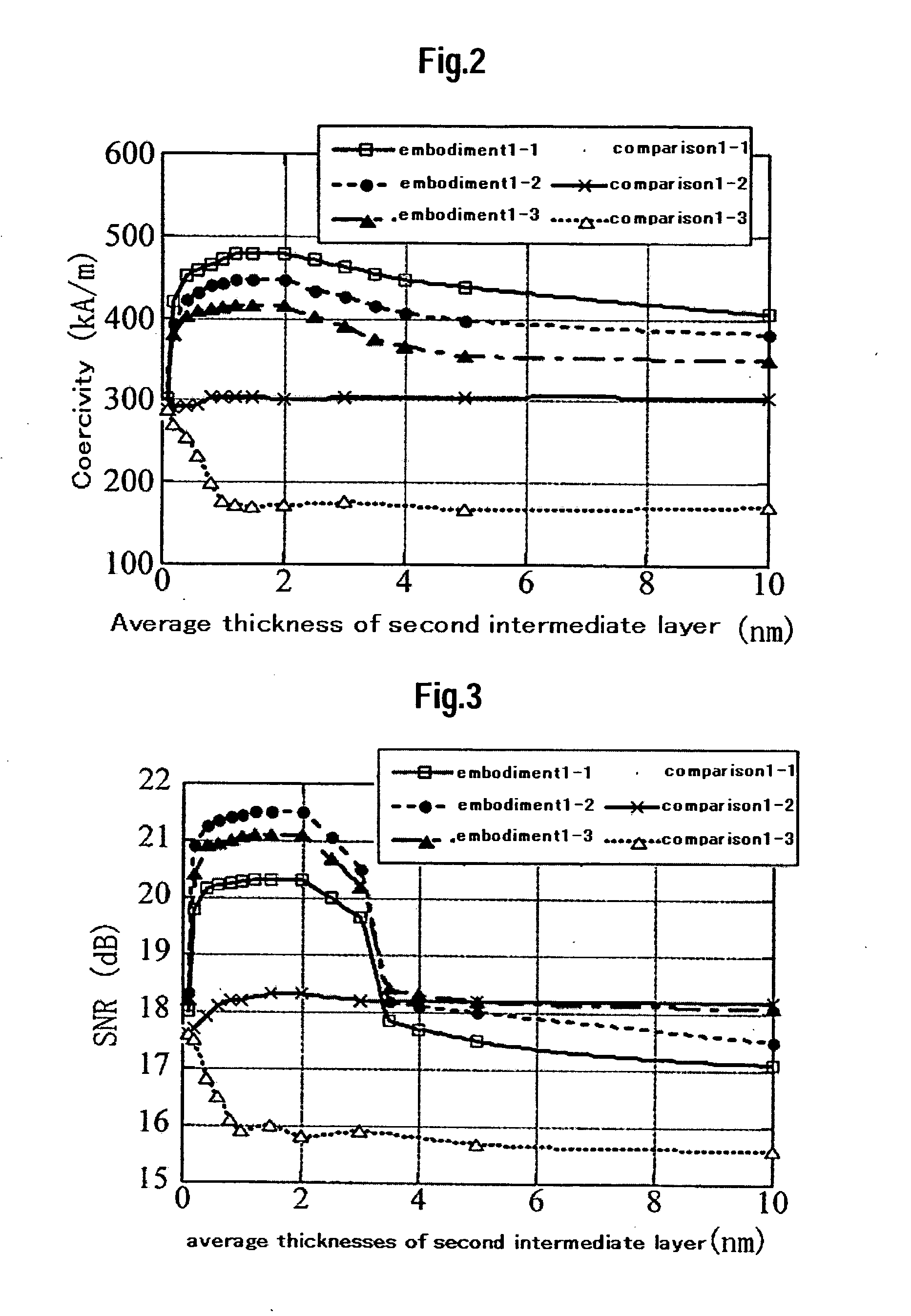

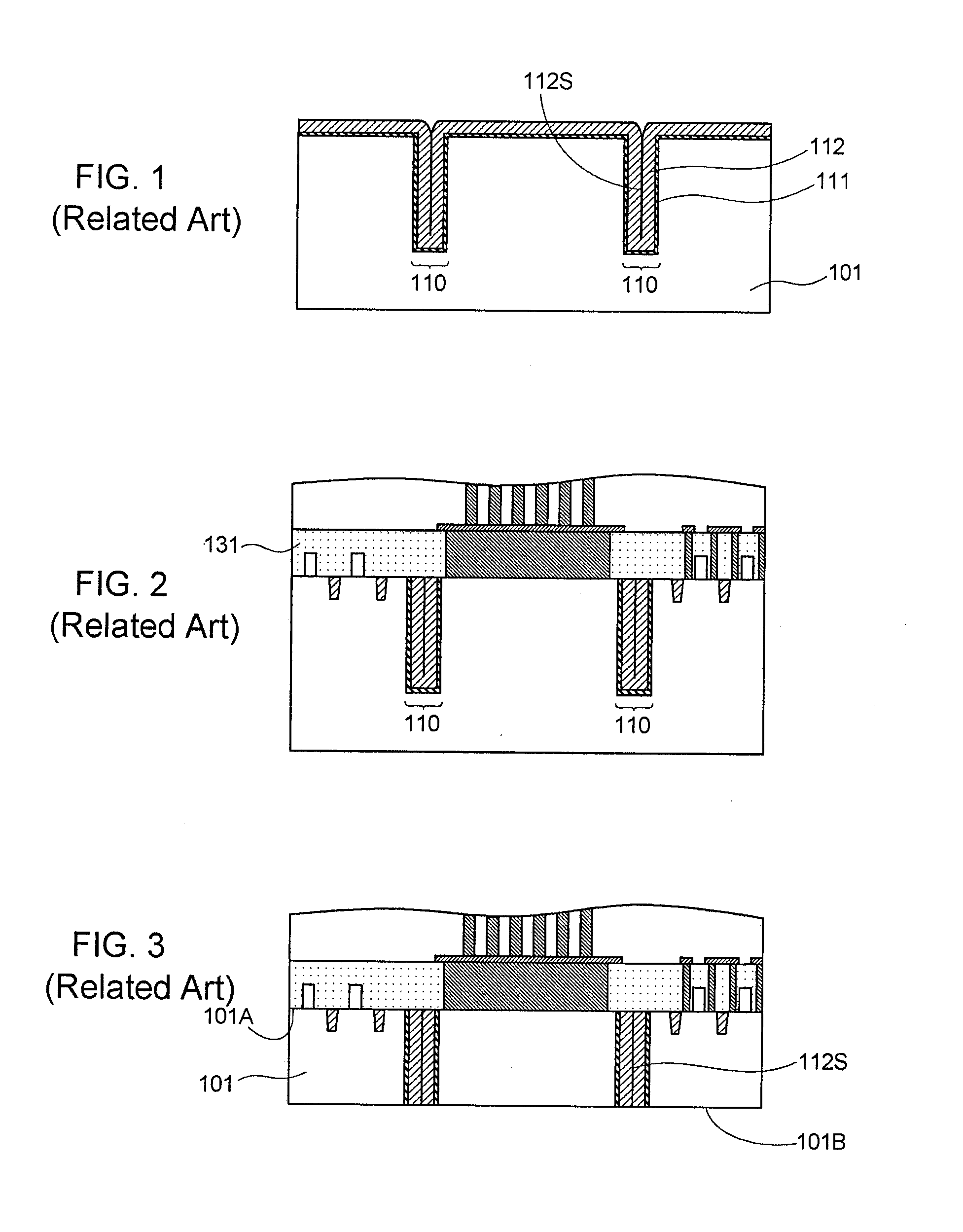

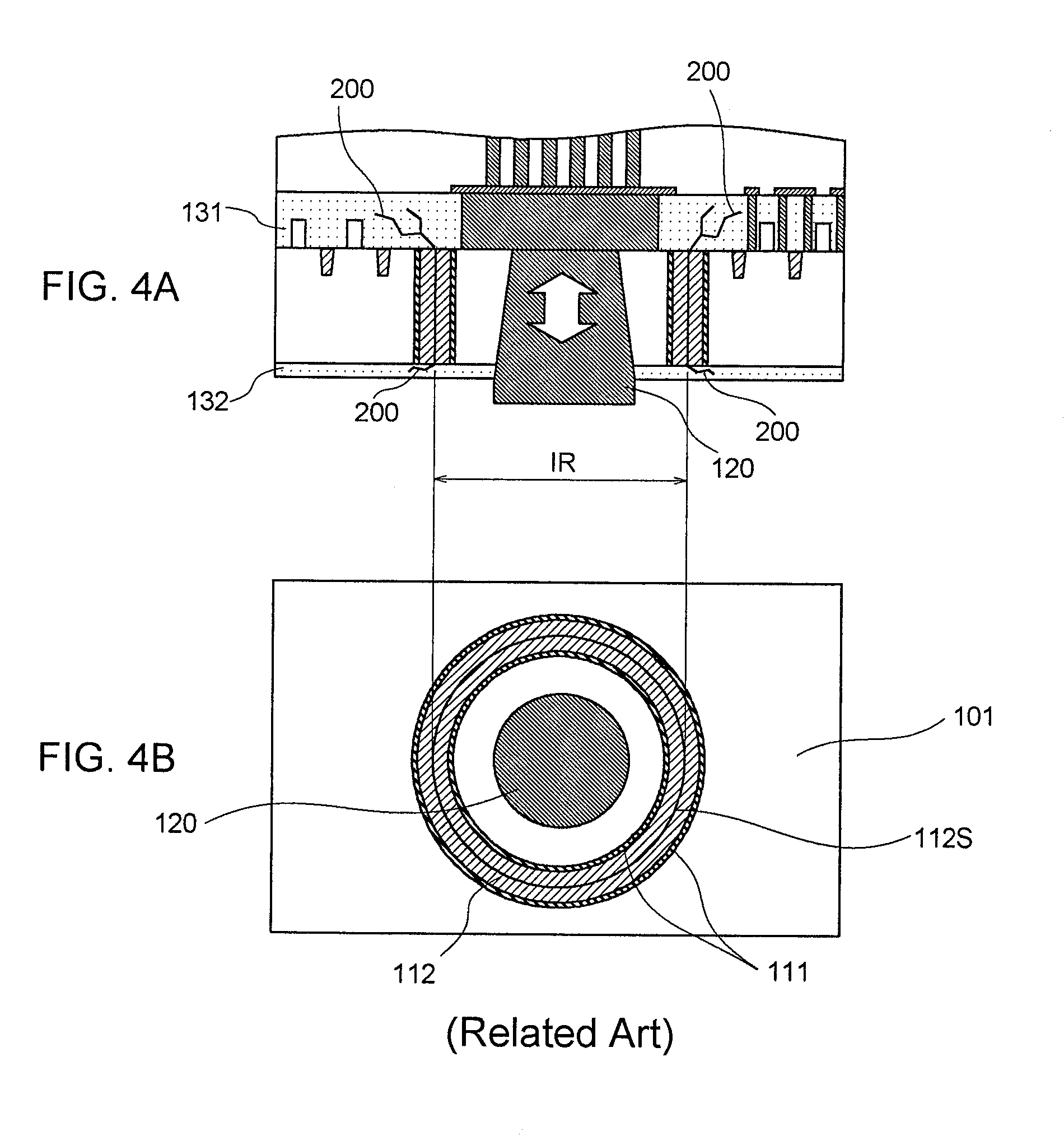

Embodiments of the invention provide a perpendicular magnetic recording medium that not only attains the magnetic isolation of crystal grains in a magnetic recording layer from one another in a region of the medium in which the thickness of an intermediate layer is equal to or smaller than about 20 nm but also exhibits excellent crystallographic texture and that exhibits small medium noise, excellent thermal stability, and high write-ability. In one embodiment, a perpendicular magnetic recording medium has at least a soft-magnetic underlayer, a first intermediate layer, a second intermediate layer, a third intermediate layer, and a magnetic recording layer successively formed on a substrate. The magnetic recording layer is composed of ferromagnetic crystal grains and oxides or nitrides, the third intermediate layer is composed of Ru or an Ru alloy, the second intermediate layer is composed of a metal or an alloy having the face-centered cubic lattice structure, and the first intermediate layer is composed of a metal or an alloy having the hexagonal close-packed structure.

Owner:WESTERN DIGITAL TECH INC

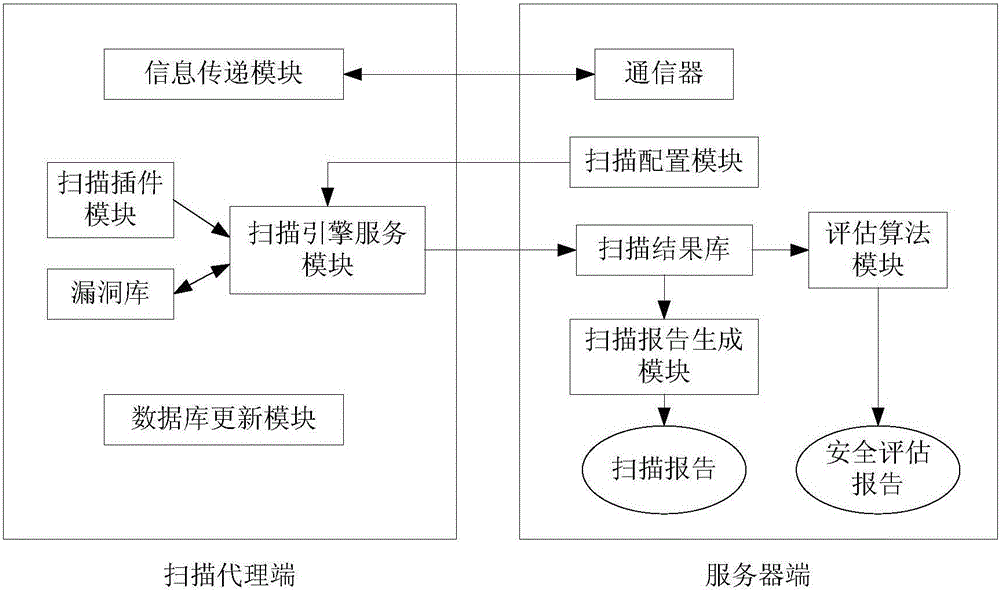

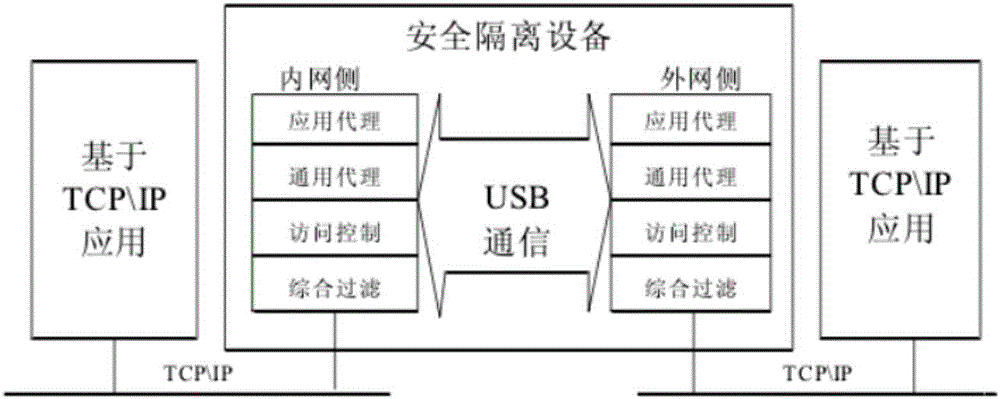

Electric power information network vulnerability threat evaluation model establishment method faced to electric power CPS risk evaluation and evaluation system based on the model

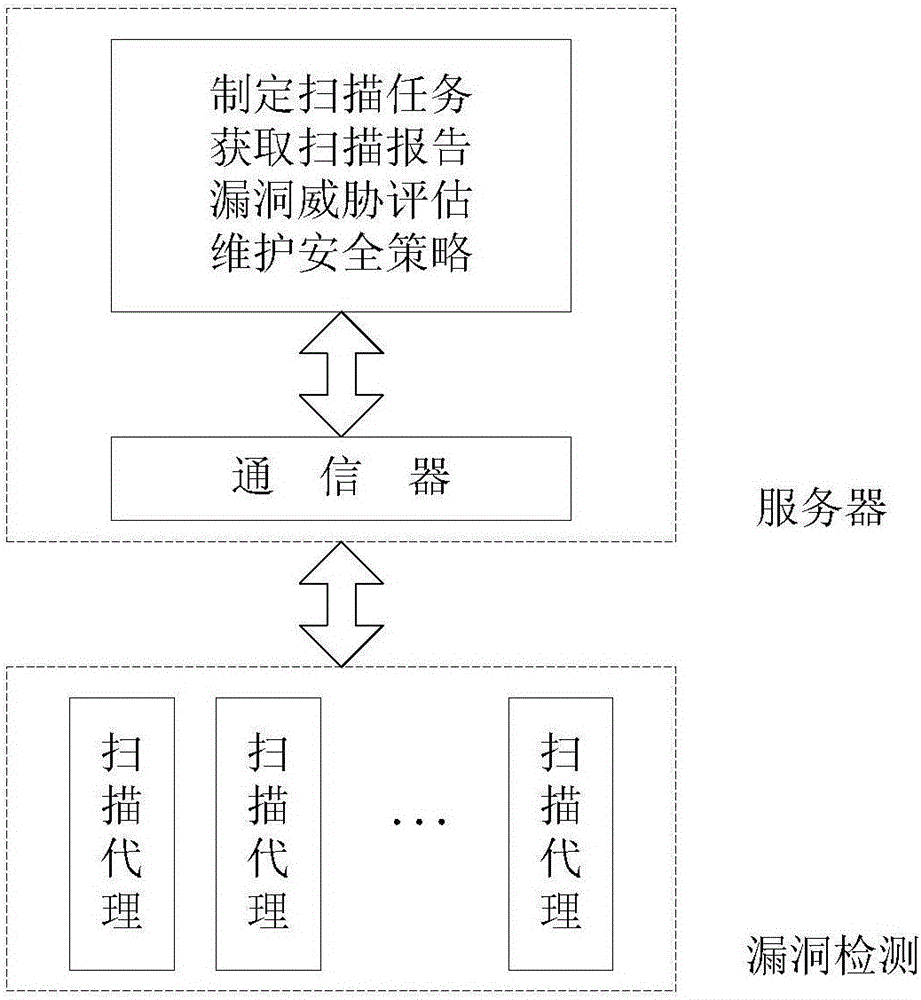

ActiveCN105763562AImprove accuracyImprove timelinessPlatform integrity maintainanceTransmissionDistributed structureStructure of Management Information

The invention discloses an electric power information network vulnerability threat evaluation model establishment method faced to electric power CPS risk evaluation and an evaluation system based on the model, the model selects three groups of security vulnerability evaluation factors including vulnerability distribution threat degree, access approach and utilization complexity; an analytic hierarchy process is adopted to establish a vulnerability threat degree evaluation model, and a parameter construction method is provided; on the basis of quantitative evaluation, the evaluation result defines a vulnerability threat level, and the objectivity of quantitative evaluation and visibility of qualitative evaluation are considered; and the system related to the invention comprises a vulnerability detection part and a server part which adopt distributed structure. According to the invention, a vulnerability scanning system and a security area of the electric power information network are combined, an electric power information network vulnerability threat evaluation algorithm based on CVSS and analytic hierarchy process is adopted to perform vulnerability threat evaluation, so that the system can be safer and more accurate for performing vulnerability scanning and safety evaluation on the electric power information network.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Perpendicular magnetic recording media and magnetic storage apparatus using the same

ActiveUS7368185B2Hindering magnetic decouplingReduce manufacturing costBase layers for recording layersRecord information storageMagnetic storageAlloy

Embodiments of the invention provide a perpendicular magnetic recording medium that not only attains the magnetic isolation of crystal grains in a magnetic recording layer from one another in a region of the medium in which the thickness of an intermediate layer is equal to or smaller than about 20 nm but also exhibits excellent crystallographic texture and that exhibits small medium noise, excellent thermal stability, and high write-ability. In one embodiment, a perpendicular magnetic recording medium has at least a soft-magnetic underlayer, a first intermediate layer, a second intermediate layer, a third intermediate layer, and a magnetic recording layer successively formed on a substrate. The magnetic recording layer is composed of ferromagnetic crystal grains and oxides or nitrides, the third intermediate layer is composed of Ru or an Ru alloy, the second intermediate layer is composed of a metal or an alloy having the face-centered cubic lattice structure, and the first intermediate layer is composed of a metal or an alloy having the hexagonal close-packed structure.

Owner:WESTERN DIGITAL TECH INC

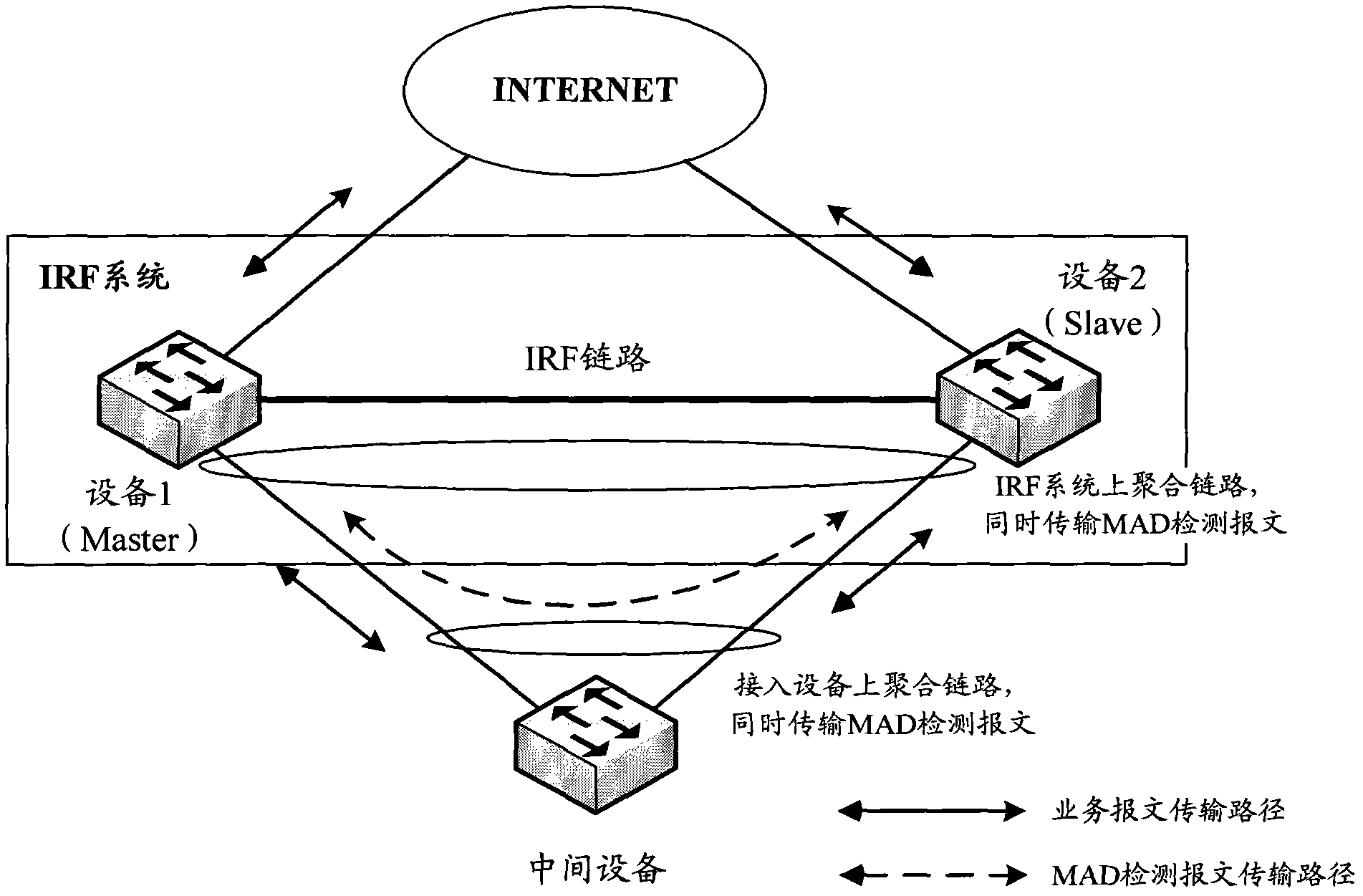

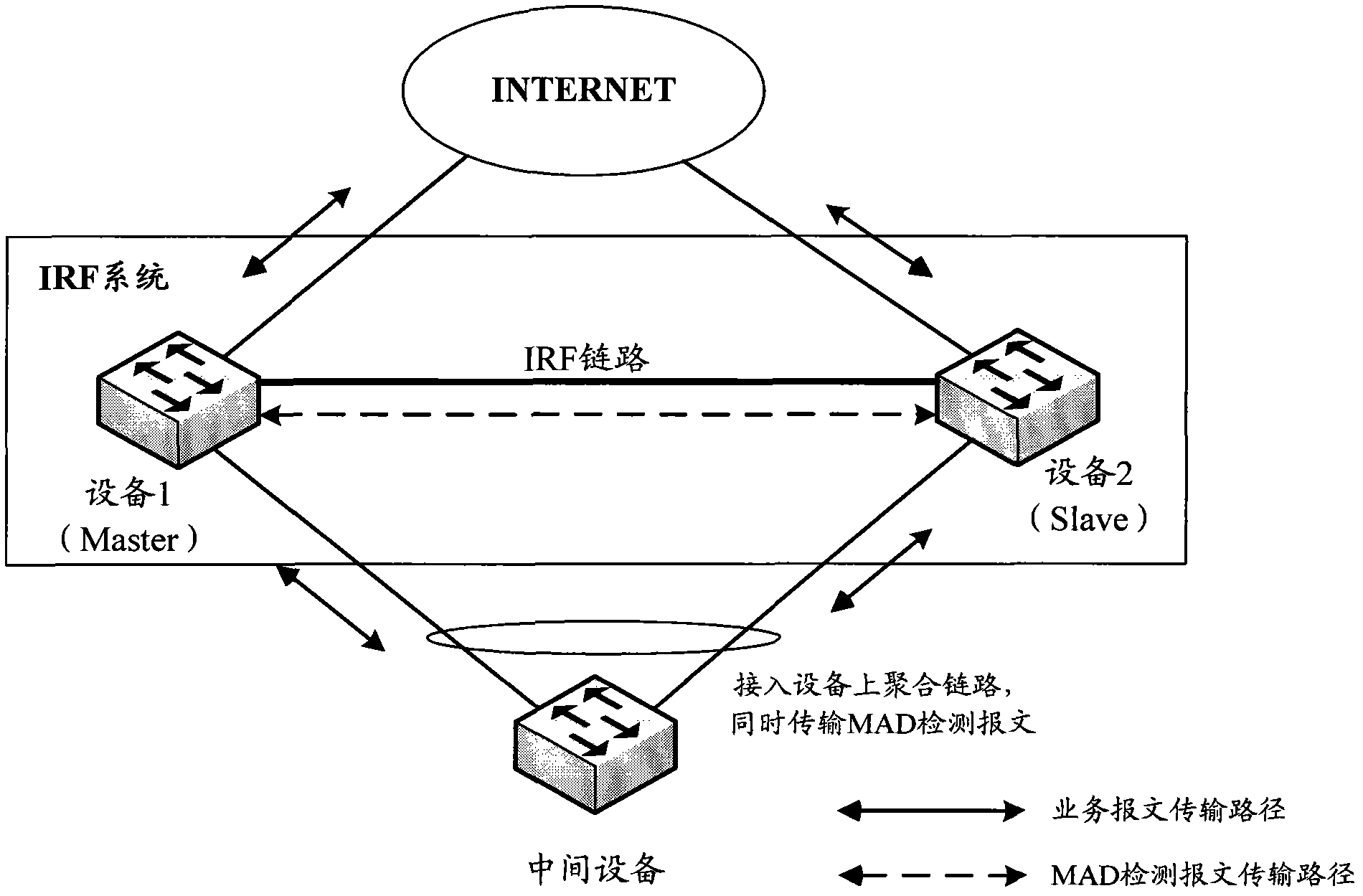

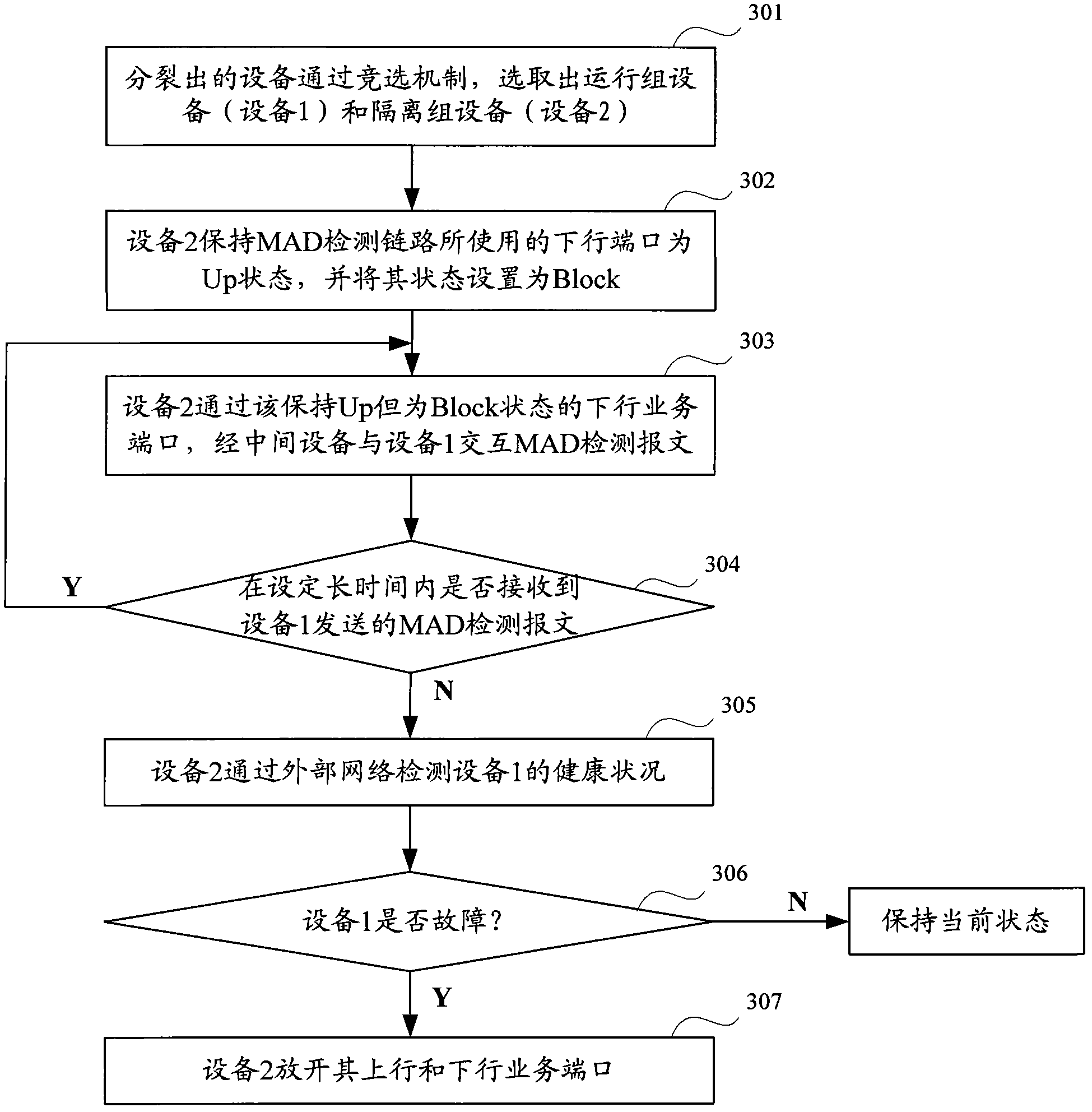

Fault processing method based on intelligent resilient framework (IRF) system and equipment thereof

The invention discloses a fault processing method based on an intelligent resilient framework (IRF) system and equipment thereof. The method comprises the steps that: when the equipment in the IRF system detects multi-active conflicts and determines that the equipment self is in a recovery state, a port of a multiple access device (MAD) detection link of the equipment self is kept up, in addition, the port is set into a block state, and the MAD detection messages are exchanged with operation state equipment through the MAD detection link; when the MAD detection messages sent by the operation state equipment are not received in the preset time, protocol messages are sent to the operation state equipment through other ports of the MAD detection link port, and response messages returned by the opposite end are waited; and when the response messages returned by the operation state equipment are not received in the preset time, the uplink service port is closed, and the downlink service port is opened. When the fault processing method and the equipment are adopted, the complete isolation between a user network and an external network caused by the current operation state equipment fault after the IRF cracking occurs can be avoided.

Owner:北京华三通信技术有限公司

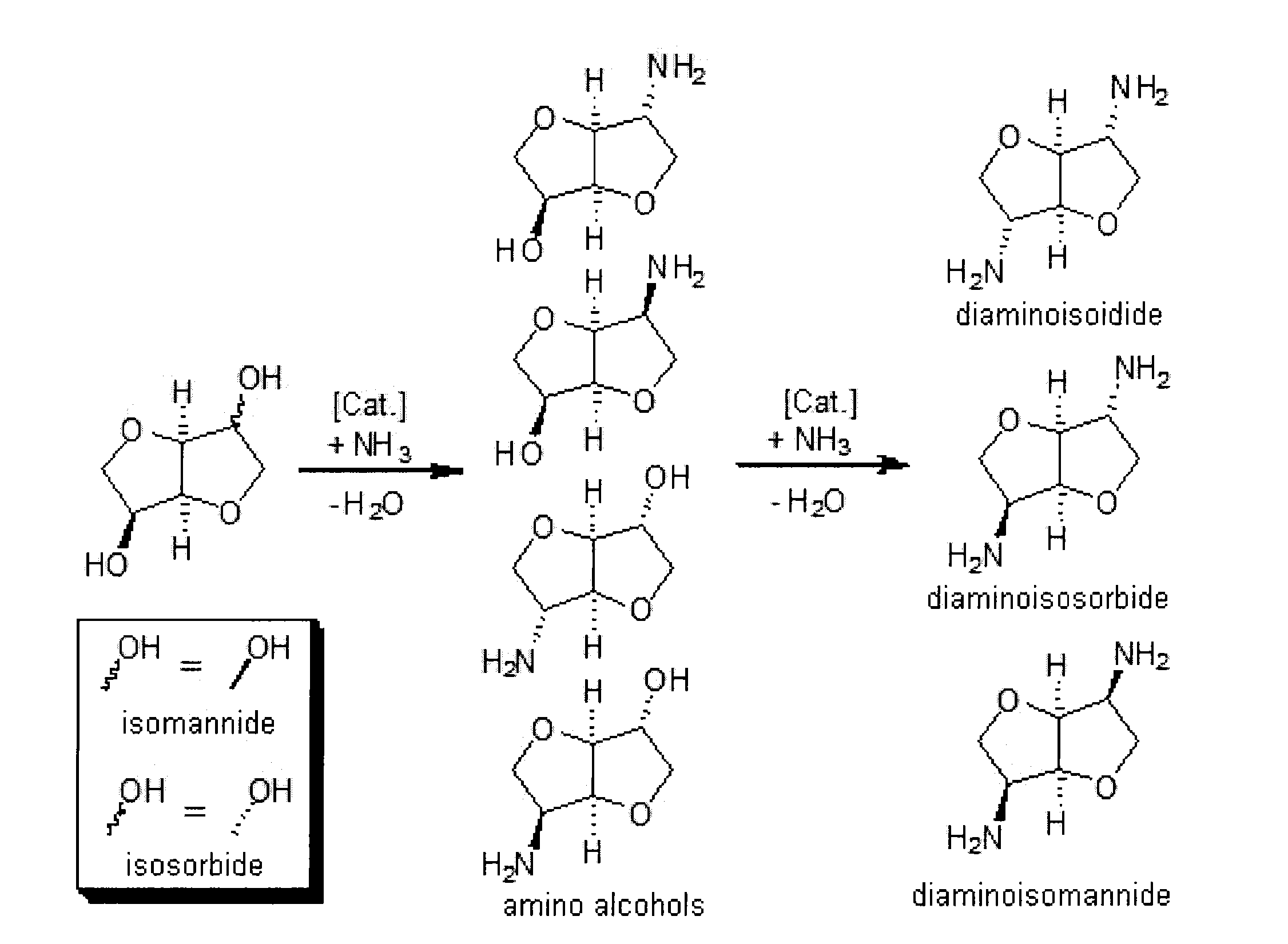

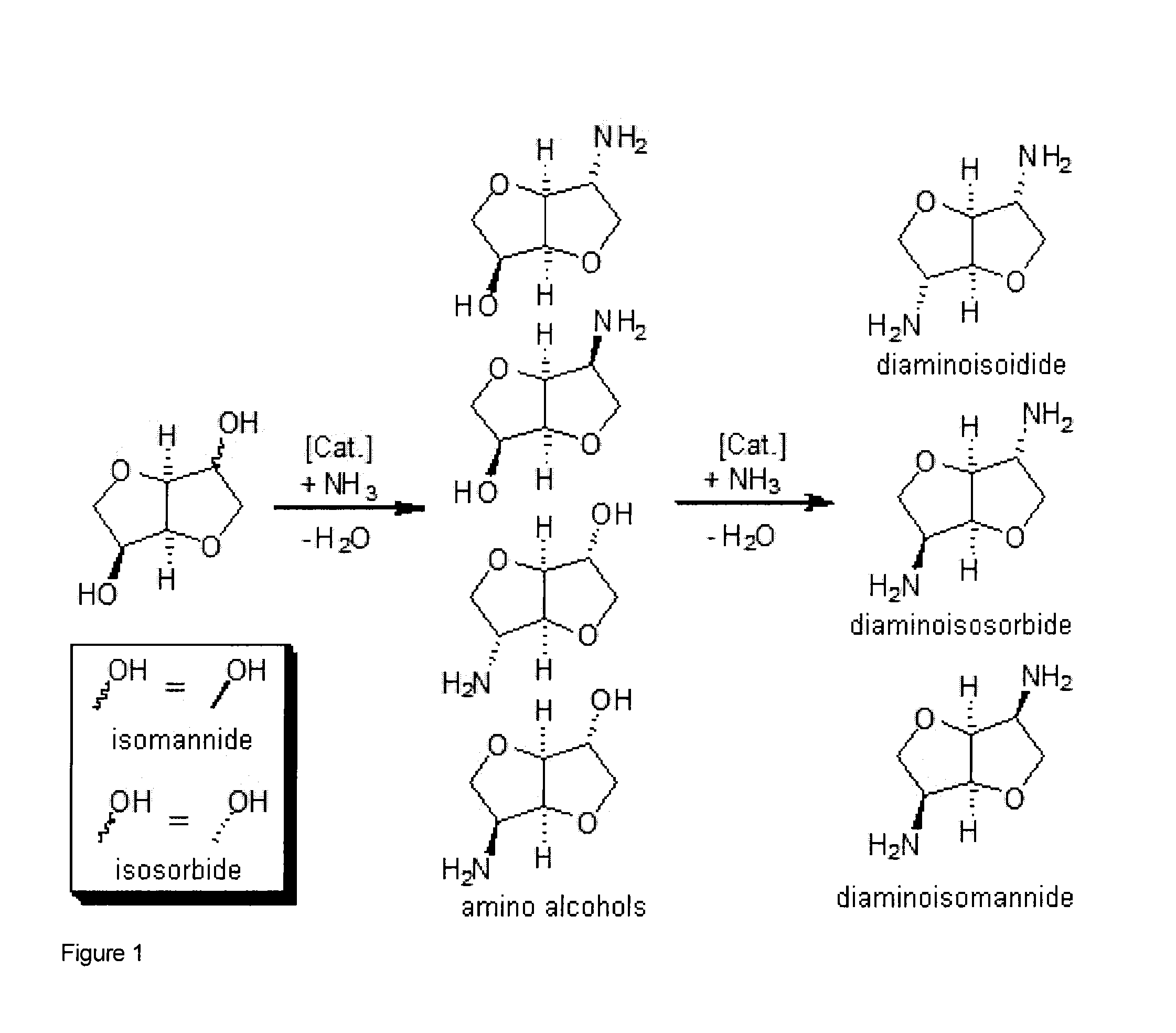

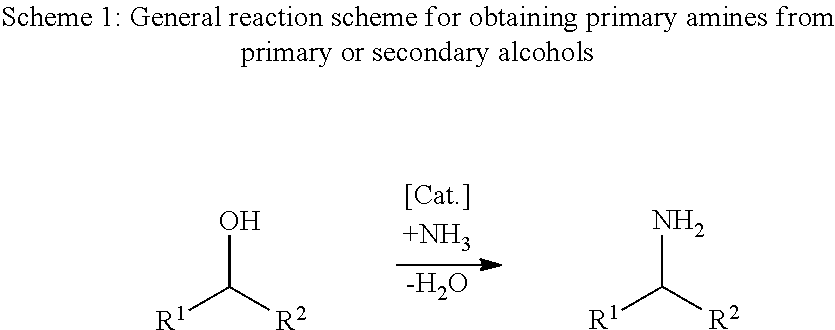

Process for the direct amination of secondary alcohols with ammonia to give primary amines

InactiveUS20130165672A1Isolation and purification of intermediatesAvoid isolationOrganic compound preparationAmino compound preparationAlcoholGas phase

The invention relates to a process for preparing primary amines which comprises the process stepsA) provision of a solution of a secondary alcohol in a fluid, nongaseous phase,B) contacting of the phase with free ammonia and / or at least one ammonia-releasing compound and a homogeneous catalyst and optionallyC) isolation of the primary amine formed in process step B),characterized in that the volume ratio of the volume of the liquid phase to the volume of the gas phase in process step B is greater than or equal to 0.25, and / or in that the ammonia is used in process step B) in a molar ratio based on the hydroxyl groups in the secondary alcohol of at least 5:1.

Owner:EVONIK DEGUSSA GMBH

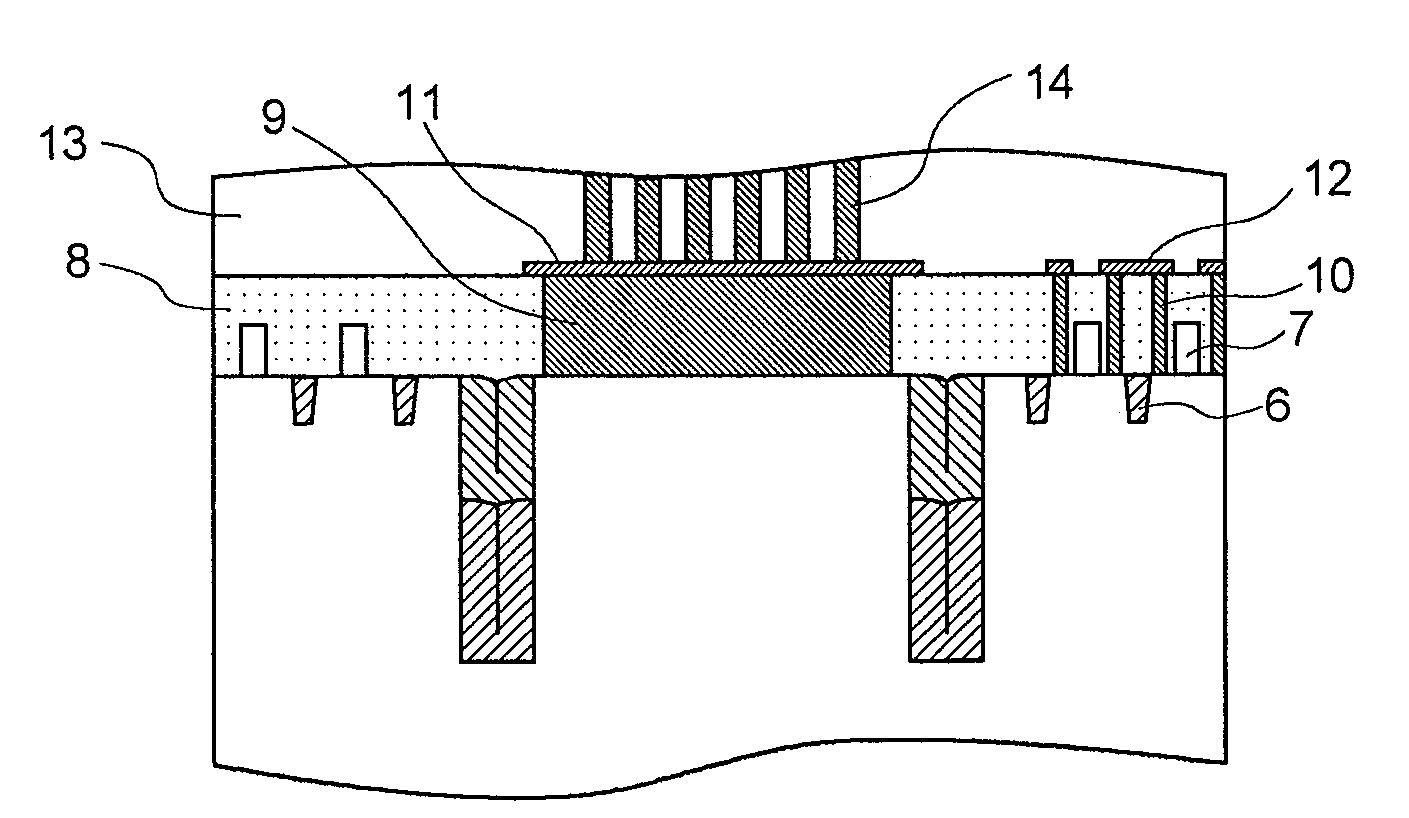

Method of manufacturing semiconductor device

InactiveUS20120315738A1High mechanical strengthImprove production yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The present invention provides a method of manufacturing a semiconductor device. An insulating-separating portion, which surrounds an electrode penetrating a substrate, is filled with a stacked structure of at least two stages, including a first stage of insulating film and a second stage of insulating film. When at least one of the first and second stages of insulating films has a seam, the seam is stopped by the region in the bottom of the second stage of insulating film that does not have a seam in at least the bottom thereof, thereby increasing mechanical strength. It is possible to prevent the inner region of the insulating-separating portion from being isolated.

Owner:PS4 LUXCO SARL

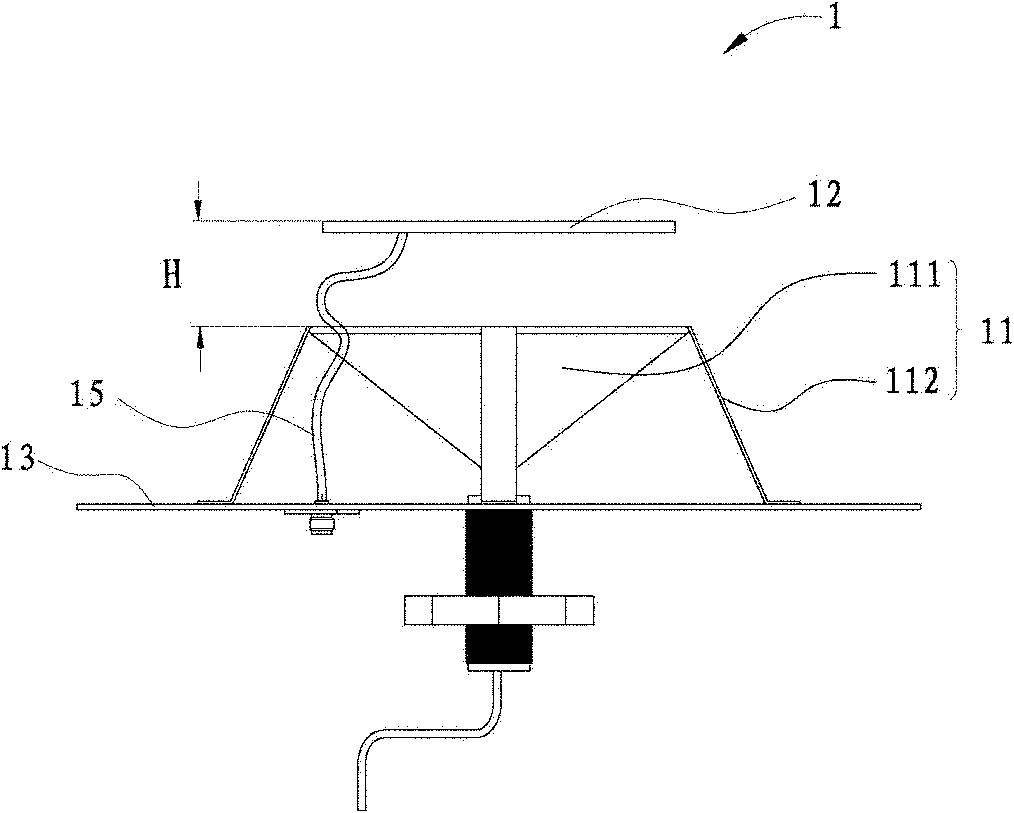

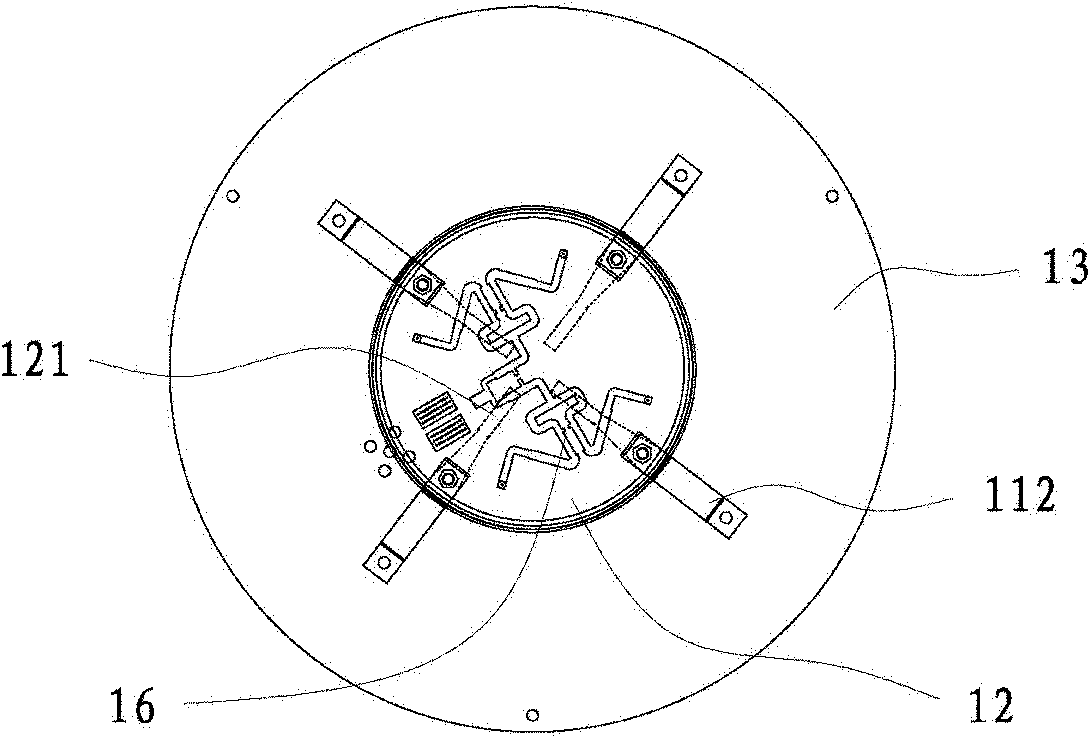

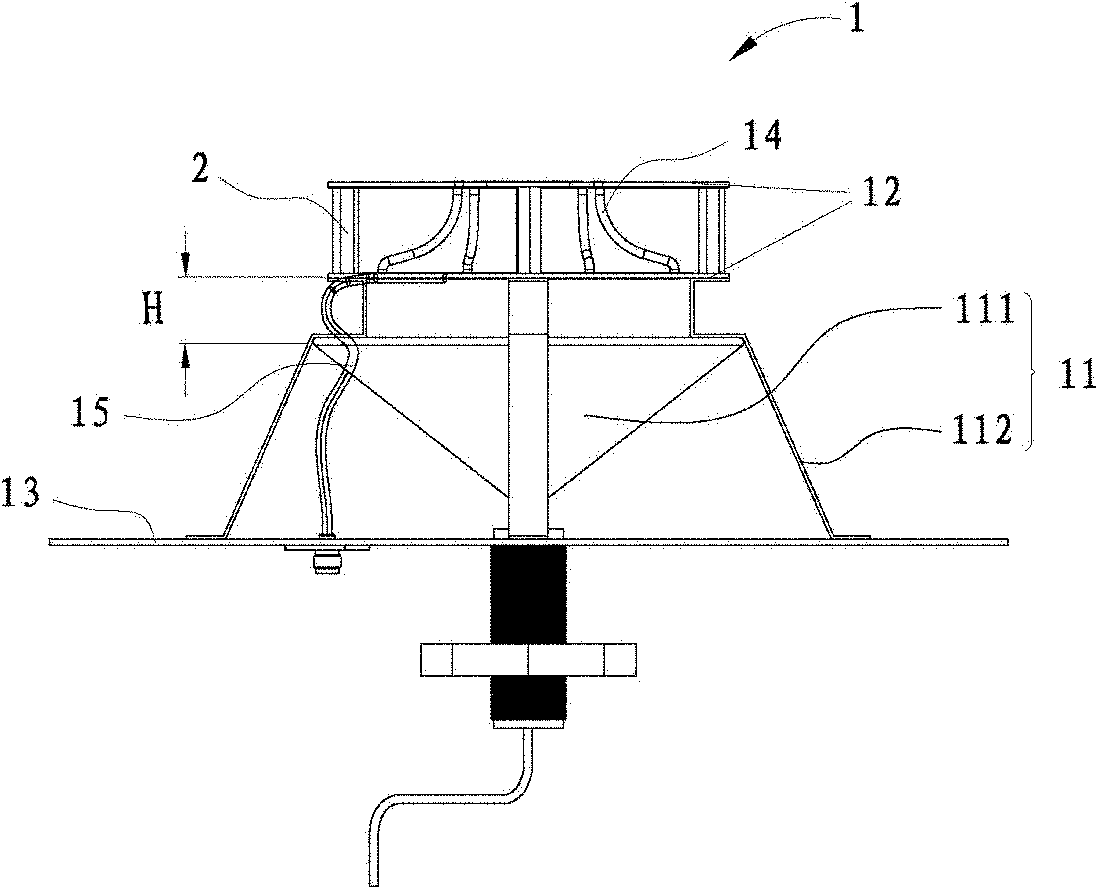

Dual-polarized indoor distributed antenna

InactiveCN102117973ARealize omnidirectional radiationImprove isolationRadiating elements structural formsAntenna earthingsPolarization diversityOptoelectronics

The invention discloses a dual-polarized indoor distributed antenna which comprises a vertically polarized omnidirectional radiation unit, and a horizontally polarized omnidirectional radiation unit, wherein the horizontally polarized omnidirectional radiation unit is provided with a plurality of ridge horn oscillators, and the horizontally polarized omnidirectional radiation unit and the vertically polarized omnidirectional radiation unit are arranged coaxially and arranged at an specific interval in the axial direction. Therefore, the consistency of all frequency points in the main raditiondirection of the horizontally polarized omnidirectional radiation unit and the vertically polarized omnidirectional radiation unit is guaranteed, the dual-polarized indoor distributed antenna can be possibly applied in polarity diversity of MIMO (multiple input and multiple output), the problem of orthogonal isolation of the horizontally polarized omnidirectional radiation unit and the verticallypolarized omnidirectional radiation unit is effectively solved, and the non-relevant requirement of an MIMO technology on the antenna is met.

Owner:MOBILE ANTENNA TECH SHENZHEN

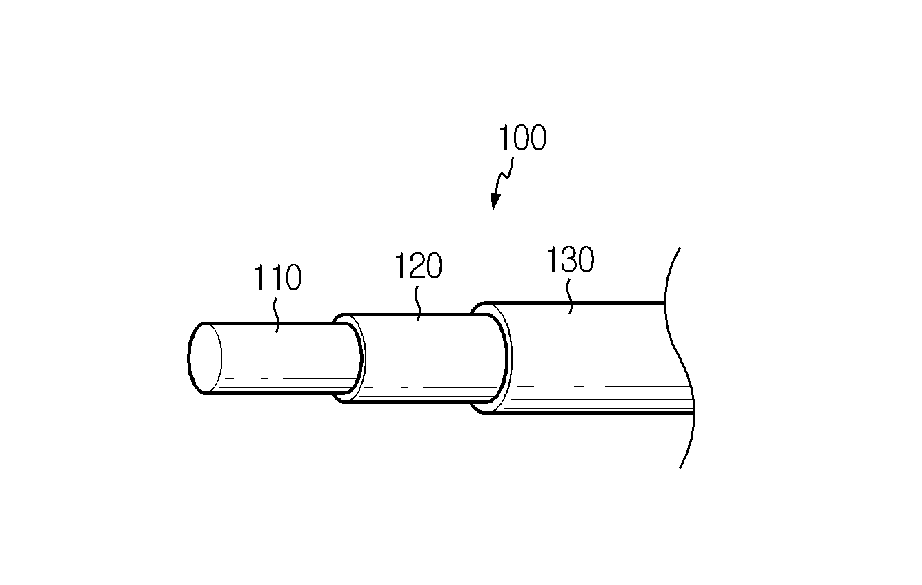

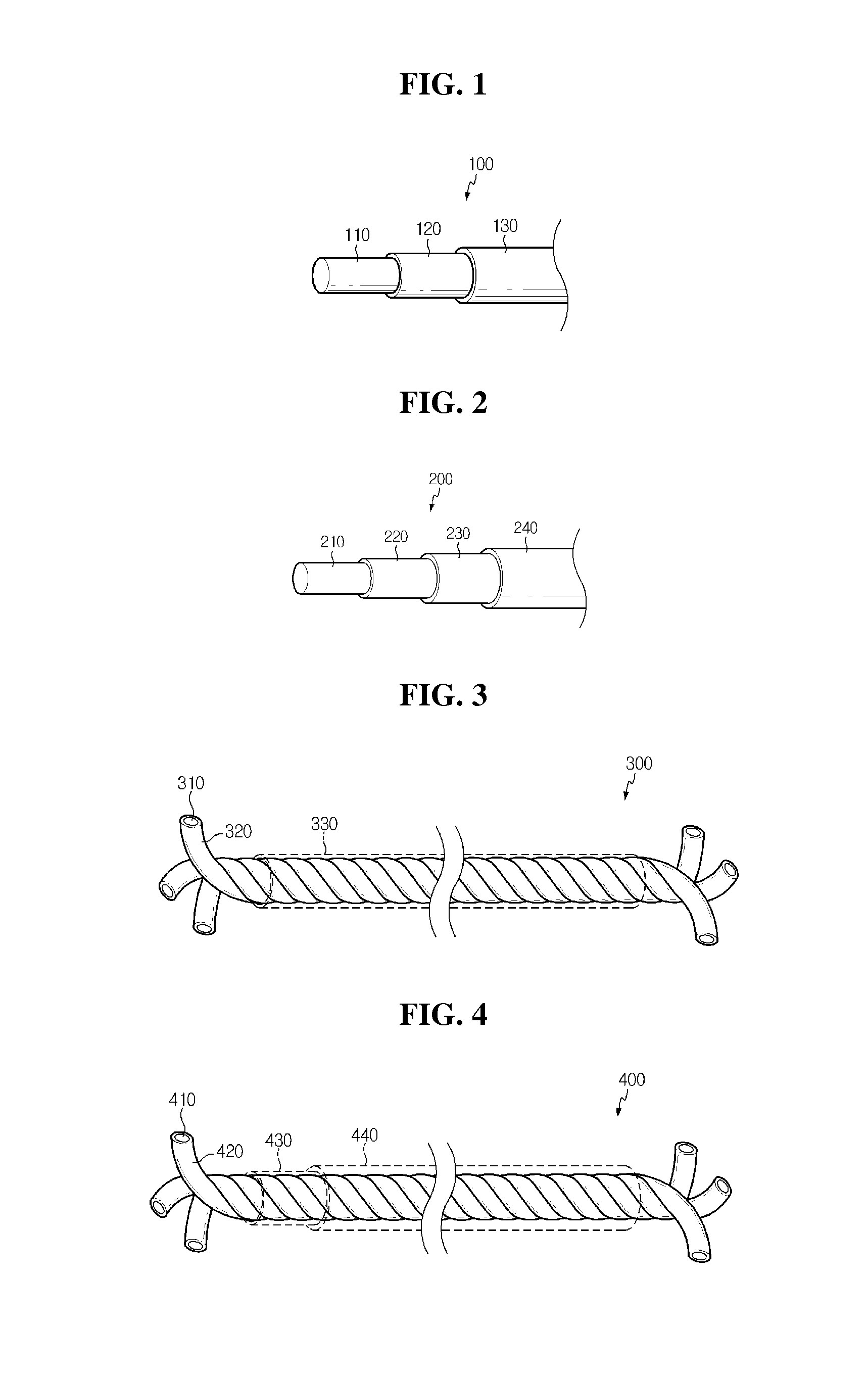

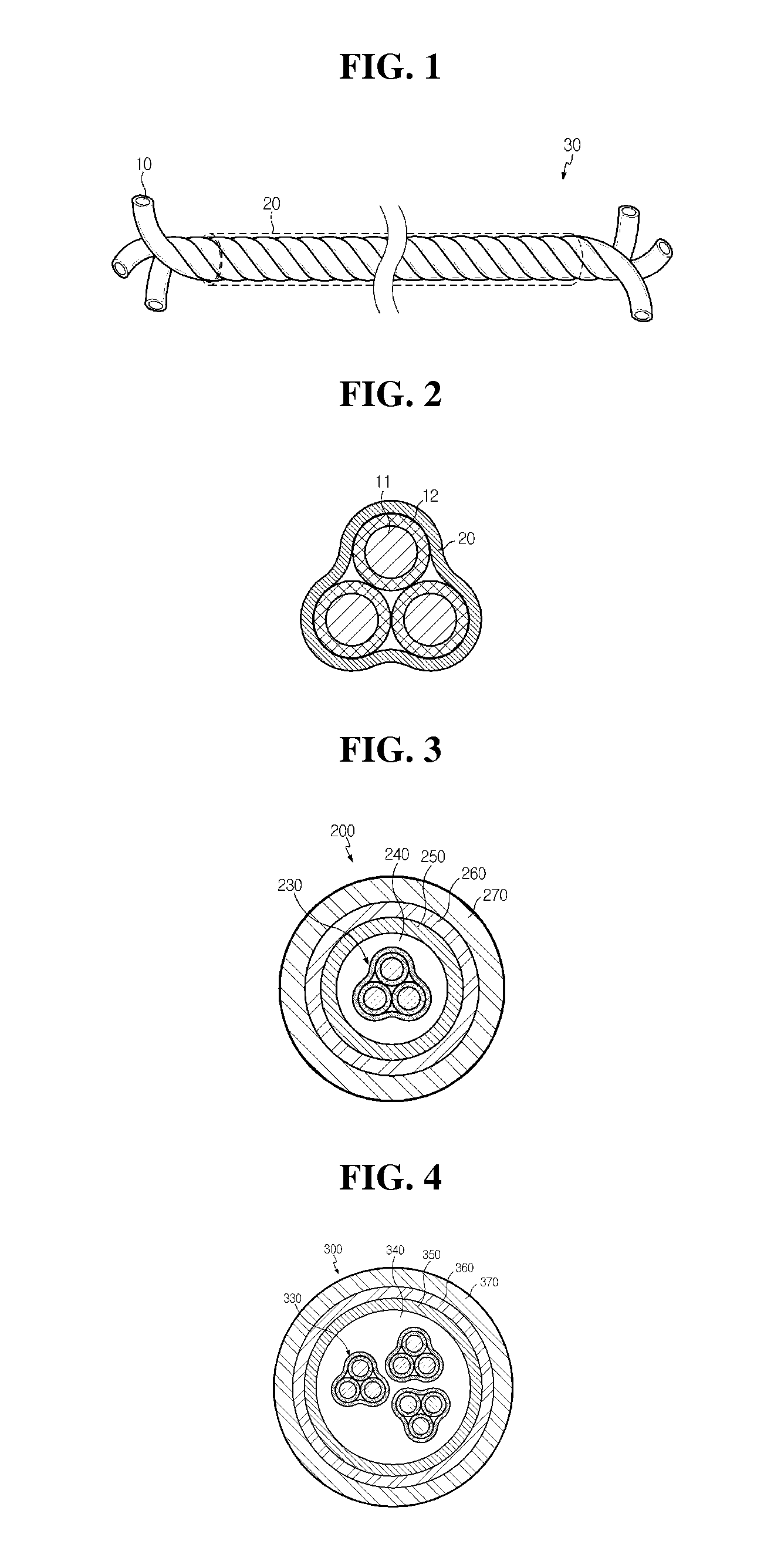

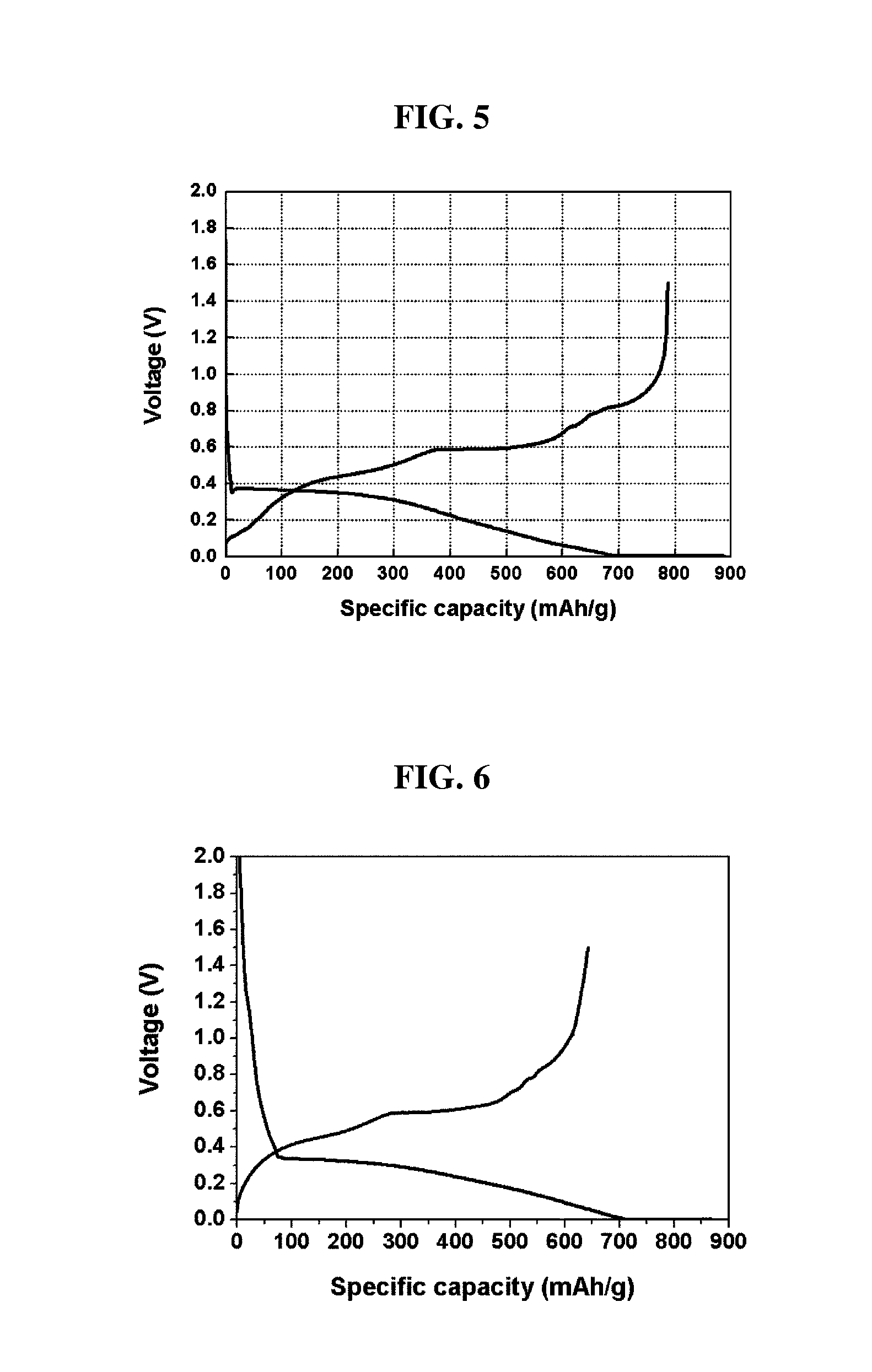

Anode for secondary battery and secondary battery having the same

ActiveUS20140170454A1High affinityAvoid isolationFinal product manufactureElectrode carriers/collectorsConductive materialsGraphite

The present invention relates to an anode for a secondary battery, comprising: a wire-type current collector; a metal-based anode active material layer formed on the surface of the wire-type current collector, and comprising a metallic active material; and a graphite-based anode composite layer formed on the surface of the metal-based anode active material layer, and comprising a mixture of a graphite-based active material, a conductive material and a first polymer binder.The anode of the present invention has the metal-based anode active material layer together with the graphite-based anode composite layer acting as a buffer, thereby preventing the metallic active material from being isolated or released even if excessive volume expansion occurs during charging and discharging processes. Also, the graphite-based anode composite layer has good affinity with an organic electrolyte solution to compensate the defect of the metallic active material having low affinity with an organic electrolyte solution.

Owner:LG ENERGY SOLUTION LTD

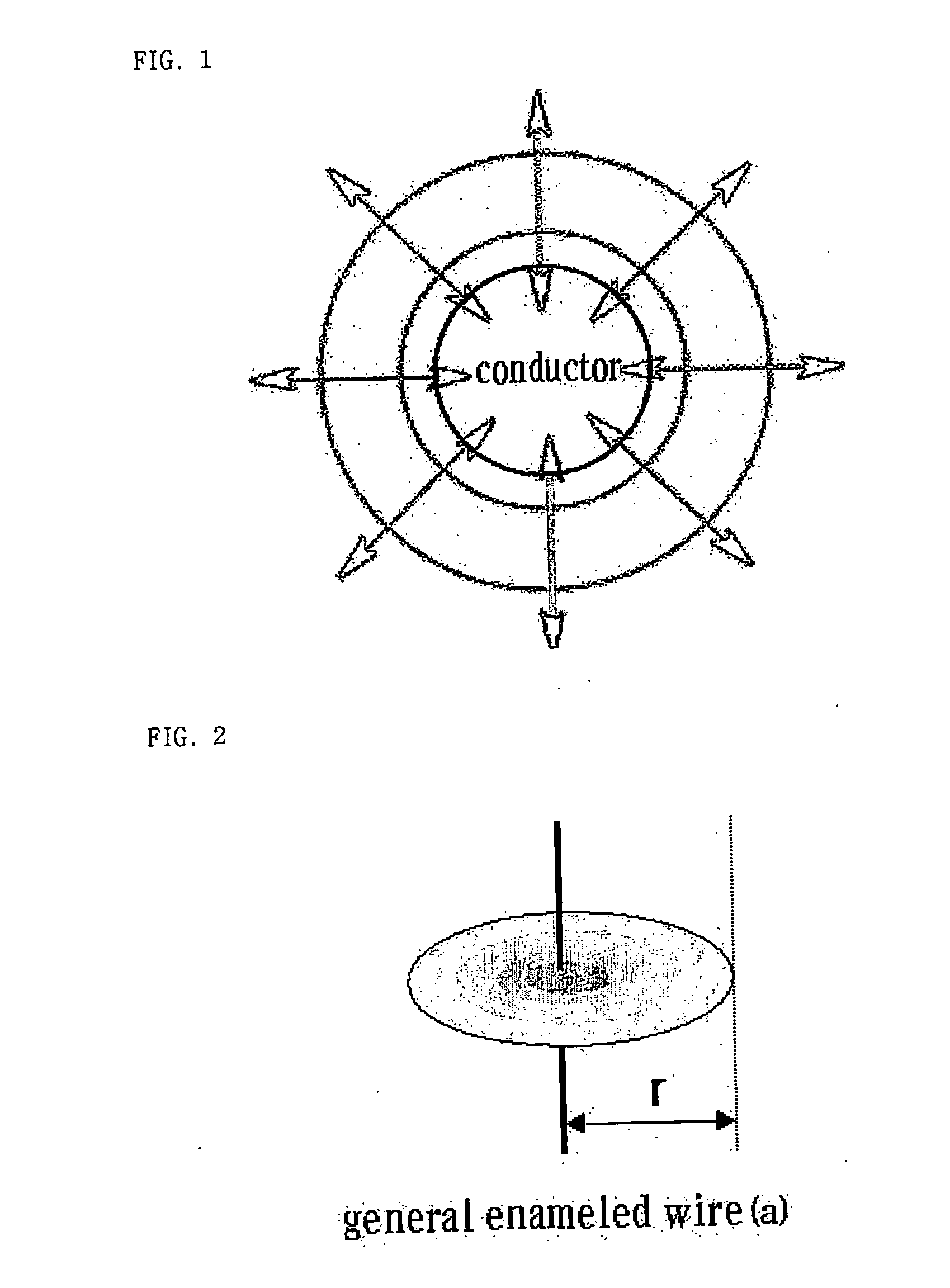

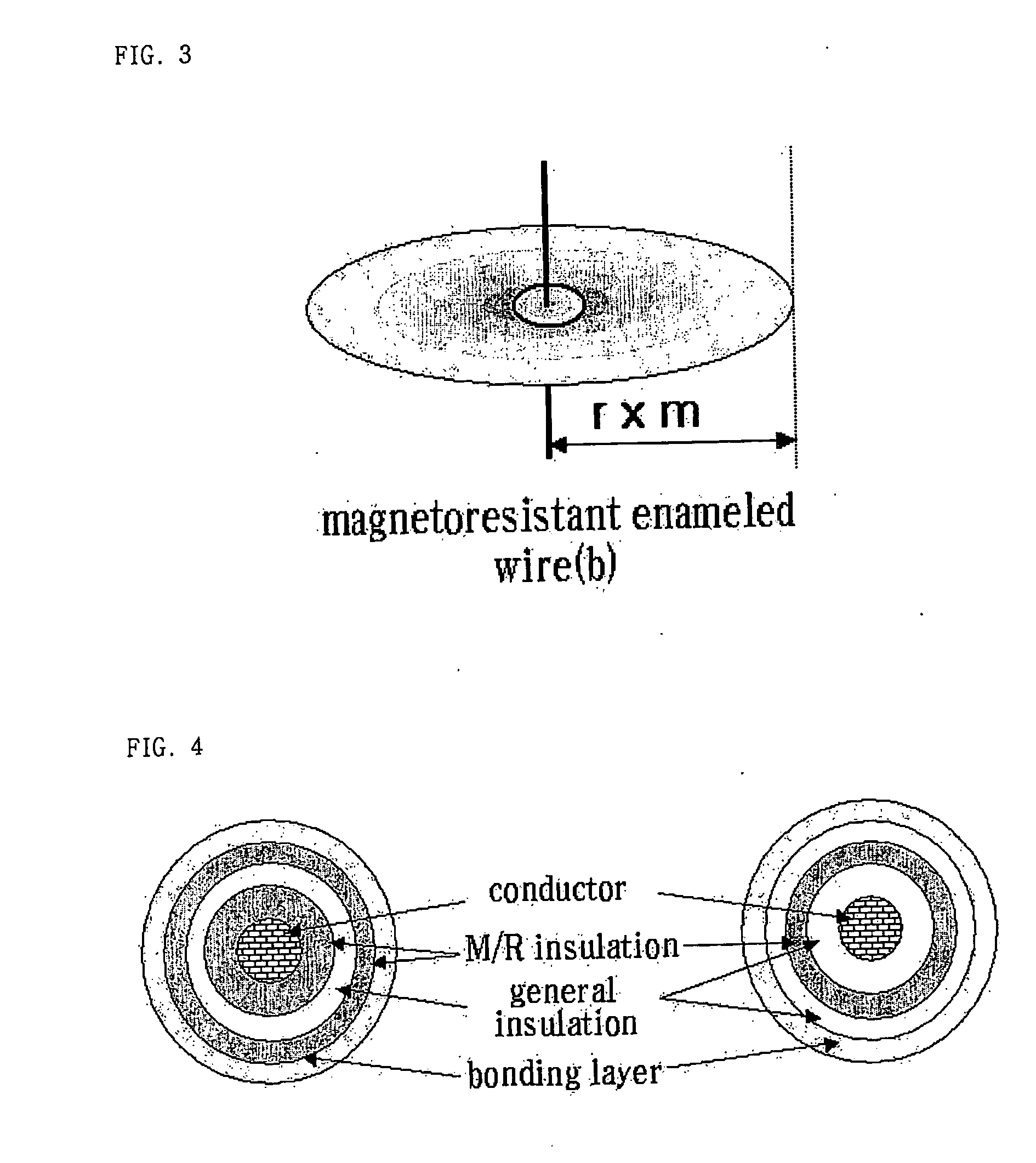

Enameled wire having magnetic reluctance properties and preparation method thereof, and coil using the same and preparation method thereof

InactiveUS20060165983A1Reduce energy lossAvoid temperature riseInsulated cablesTransformers/inductances detailsElectrical resistance and conductanceElectrical conductor

Disclosed herein is a magnetoresistant enameled wire coated with a material which shows improved conductivity by reducing resistance of a conductor since the wire exhibits effects similar to anisotropic magnetoresistance of magnetic materials when manufactured in the form of a coil. The material also shows effects similar to magnetoresistance exhibiting a strong magnetic flux density. Disclosed further are a method for manufacturing the magnetoresistant enameled wire, a magnetoresistant coil using the magnetoresistant wire, and a method for manufacturing the magnetoresistant coil.

Owner:WEDO

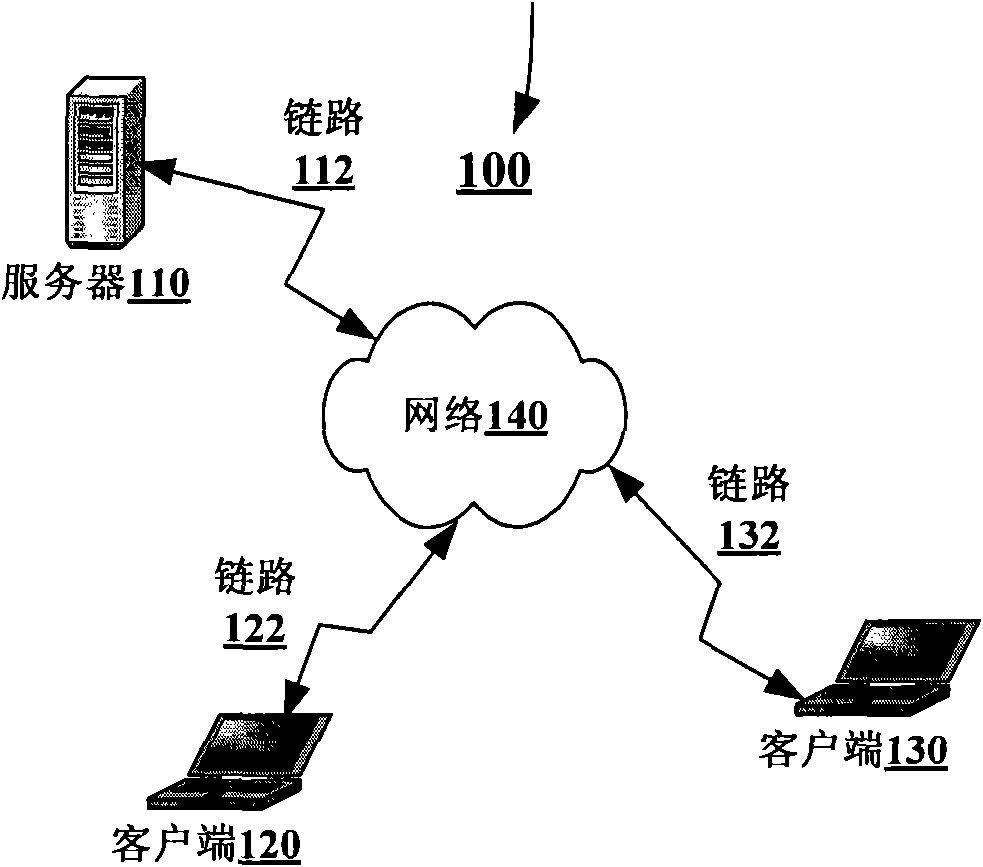

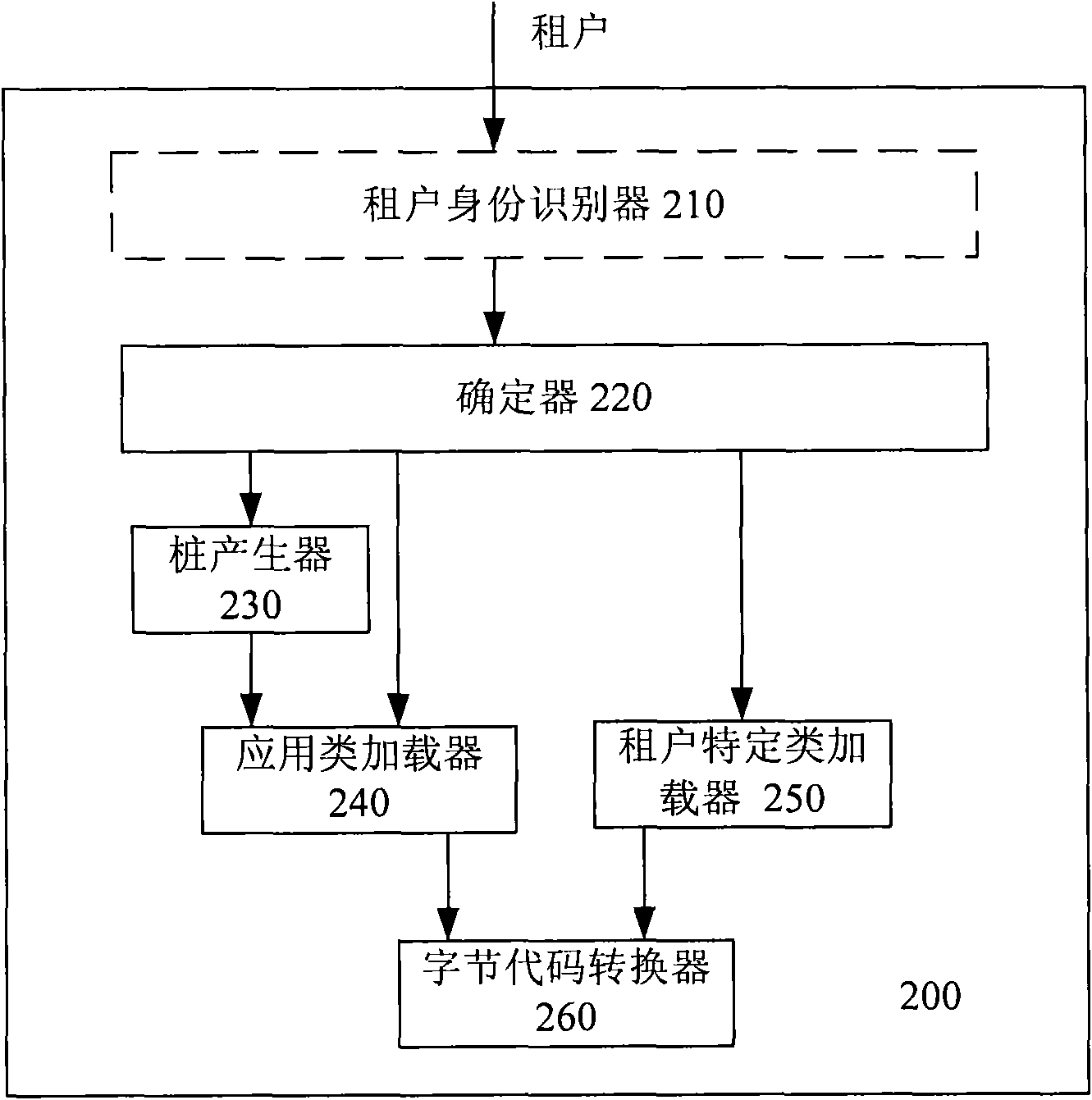

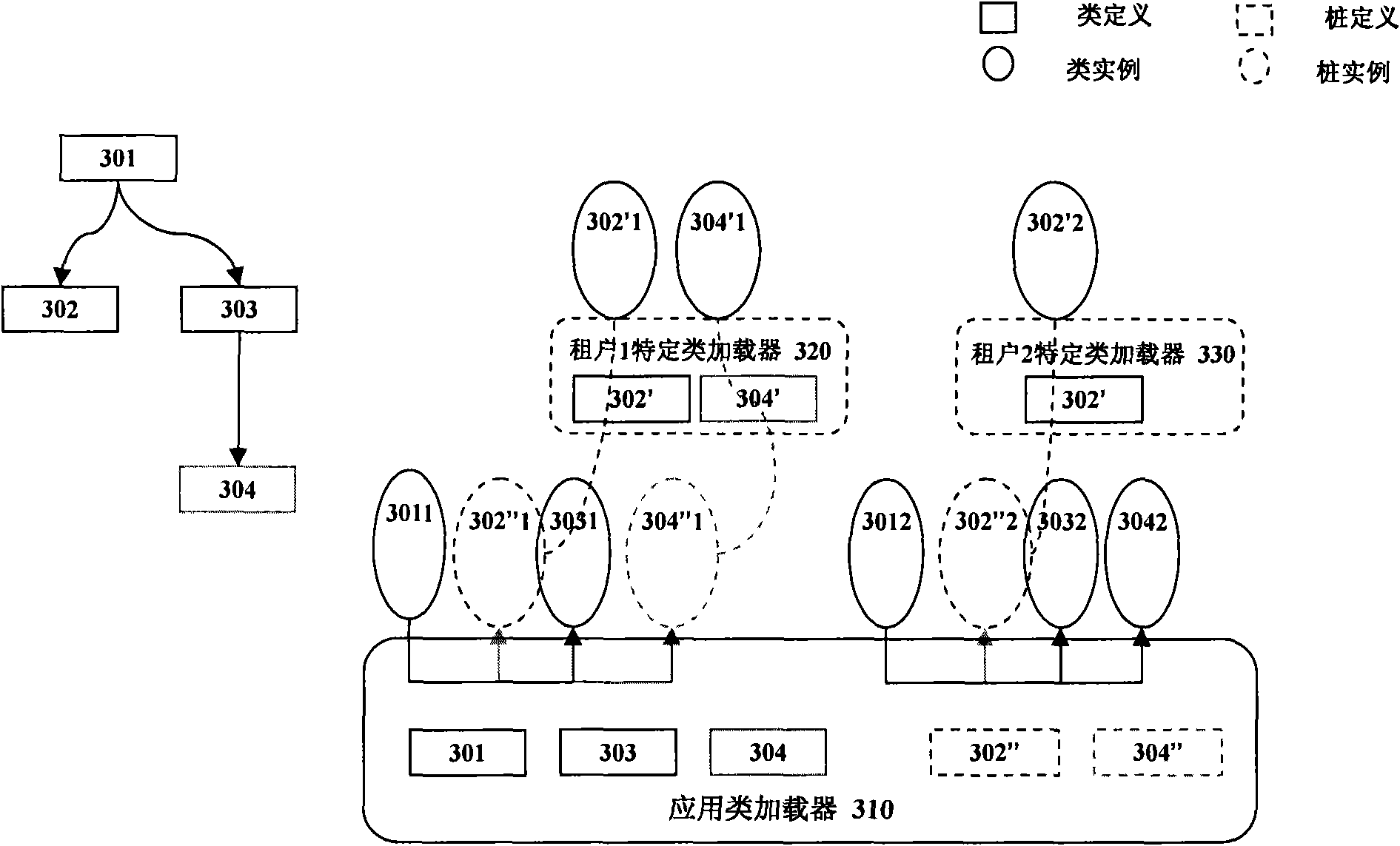

System and method for supporting multi-tenant separation/multi-tenant customization in JVM

InactiveCN101639770AAvoid isolationMeet individual needsSpecific program execution arrangementsApplication softwareByte

The invention discloses a system and a method for supporting multi-tenant separation / multi-tenant customization in a JVM. The system comprises a determiner used for determining which type of application program needs to be separated and / or which type of application program needs to be customized; a pile generator used for generating piles for the separated type and / or the customized type; a tenantpublic-use type loader used for loading the piles and the type requiring no separation and the type without being customized and a tenant specific type loader used for loading the separated type and / or the customized type; and a byte code converter used for converting the byte codes of the type which is referred to the separated type and / or the customized type into piles which are referred to theseparated type and / or the customized type. When necessary, the instances of the piles, the type requiring no separation, the type without being customized, and the separated type and / or the customized type are set up. Through the piles and / or the instances of the piles, the system and the method can realize communication with the type loaded by the tenant specific type loader and / or the instancethereof.

Owner:IBM CORP

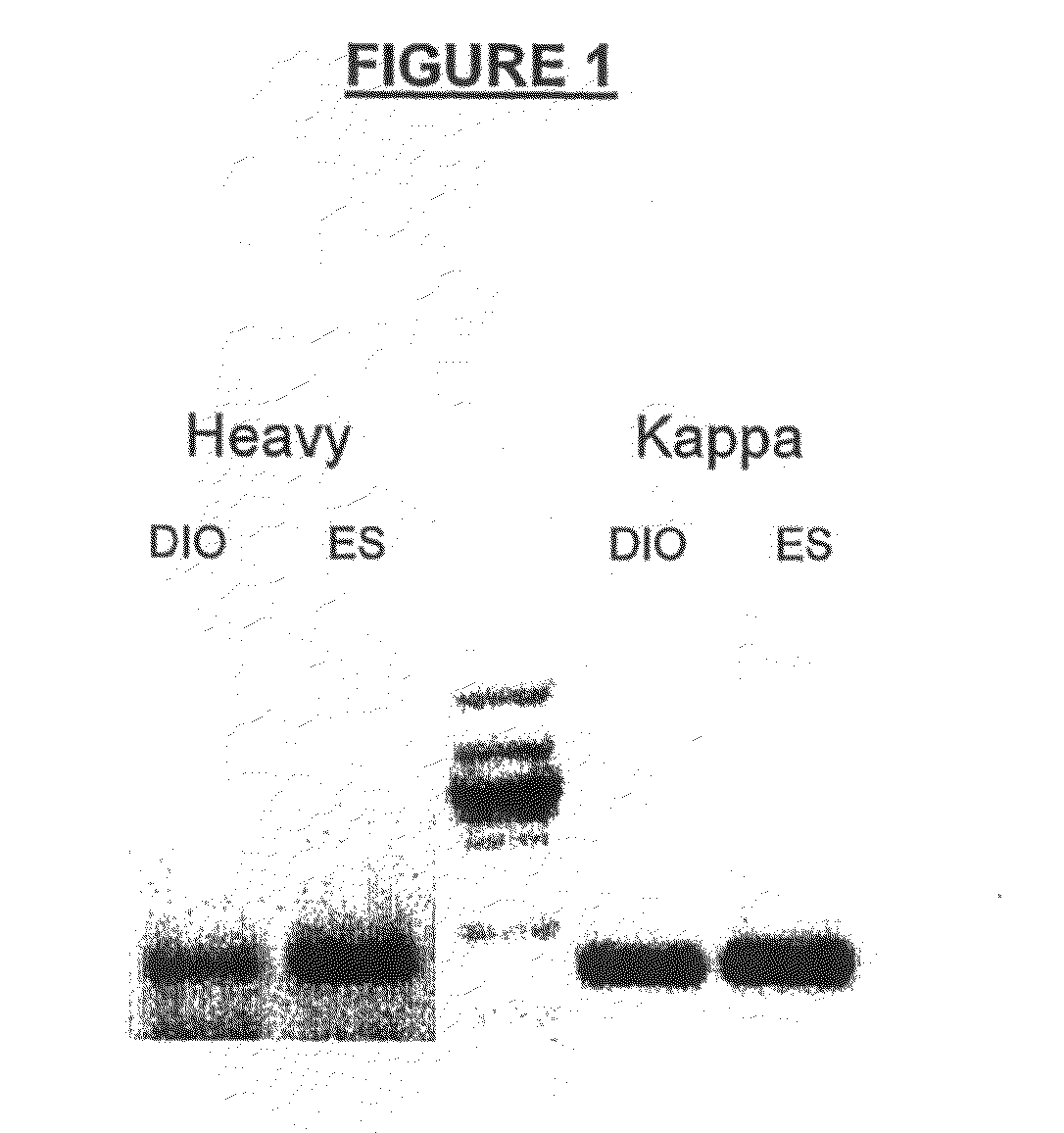

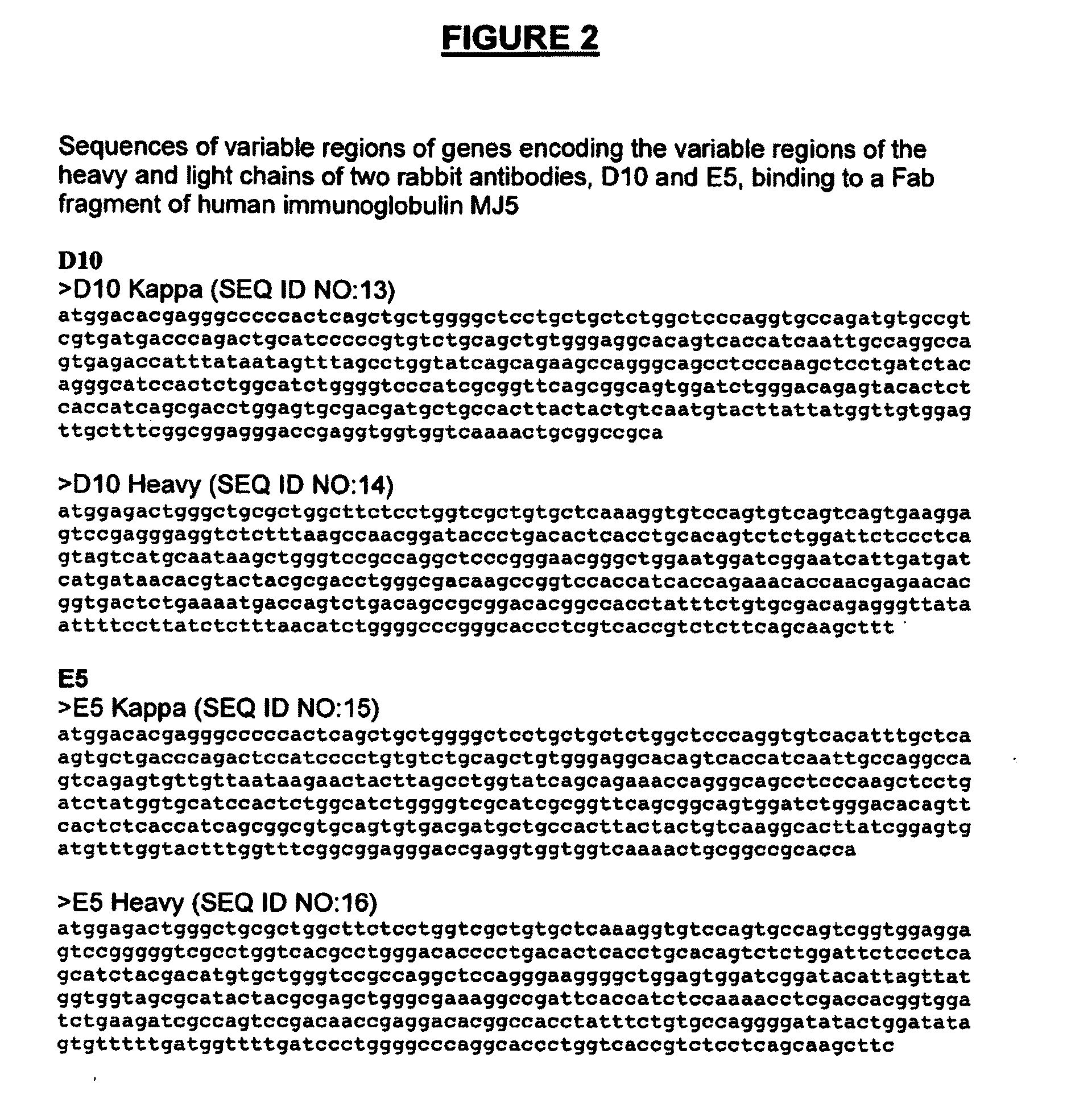

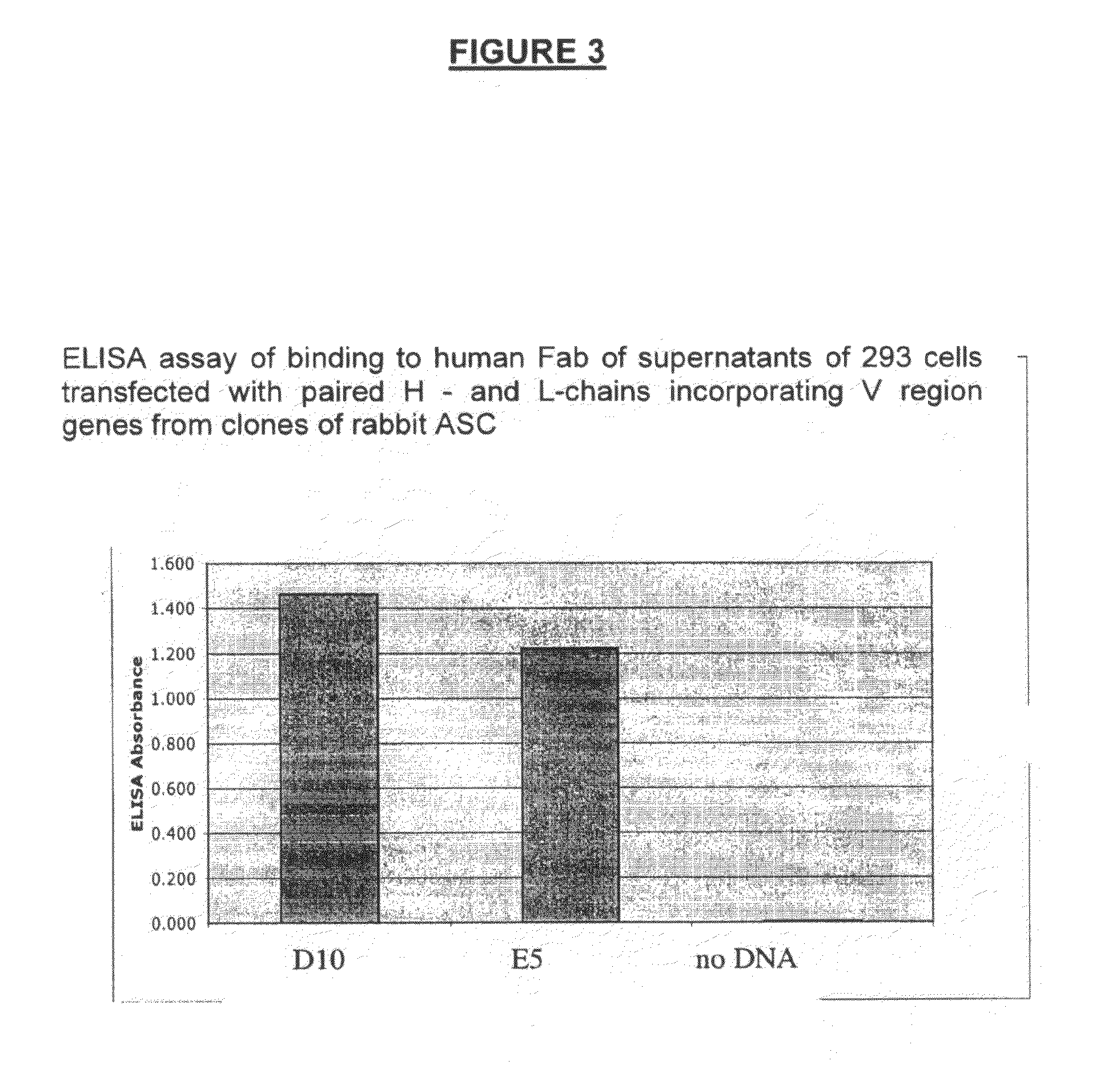

Methods of isolating cells and generating monoclonal antibodies

ActiveUS20100255496A1Increase concentrationEffective isolationAnimal cellsFused cellsAntibody-Secreting CellsMonoclonal antibody

The invention provides methods for isolating cells, particularly antibody-secreting cells that have a high likelihood of secreting antibodies specific for a desired antigen for the purpose of making monoclonal antibodies.

Owner:SCHRADER SABARIAH

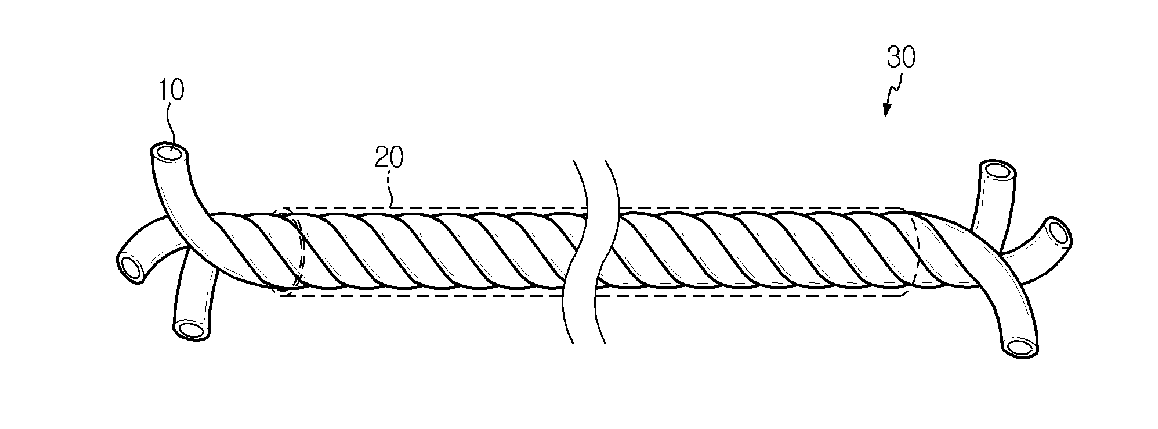

Anode for secondary battery and secondary battery having the same

ActiveUS20140170453A1Increase surface areaImproving the rate characteristics of a batteryFinal product manufactureElectrode carriers/collectorsOptoelectronicsSingle strand

The present invention relates to an anode for a secondary battery, comprising: a spiral anode having at least two anode wires which are parallel to each other and spirally twisted, each of the anode wires having an anode active material layer coated on the surface of a wire-type current collector; and a conductive layer formed to surround the spiral anode.The anode active material layer of the spirally-twisted has a thin thickness as compared with a single strand of an anode having the same anode active material. Therefore, Li ions can be easily diffused to enhance battery performance. Also, the anode of the present invention has a conductive layer on the surface thereof to prevent or alleviate the release of an anode active material which is caused by volume expansion during charging and discharging processes, and to solve the isolation of the anode active material.

Owner:LG ENERGY SOLUTION LTD

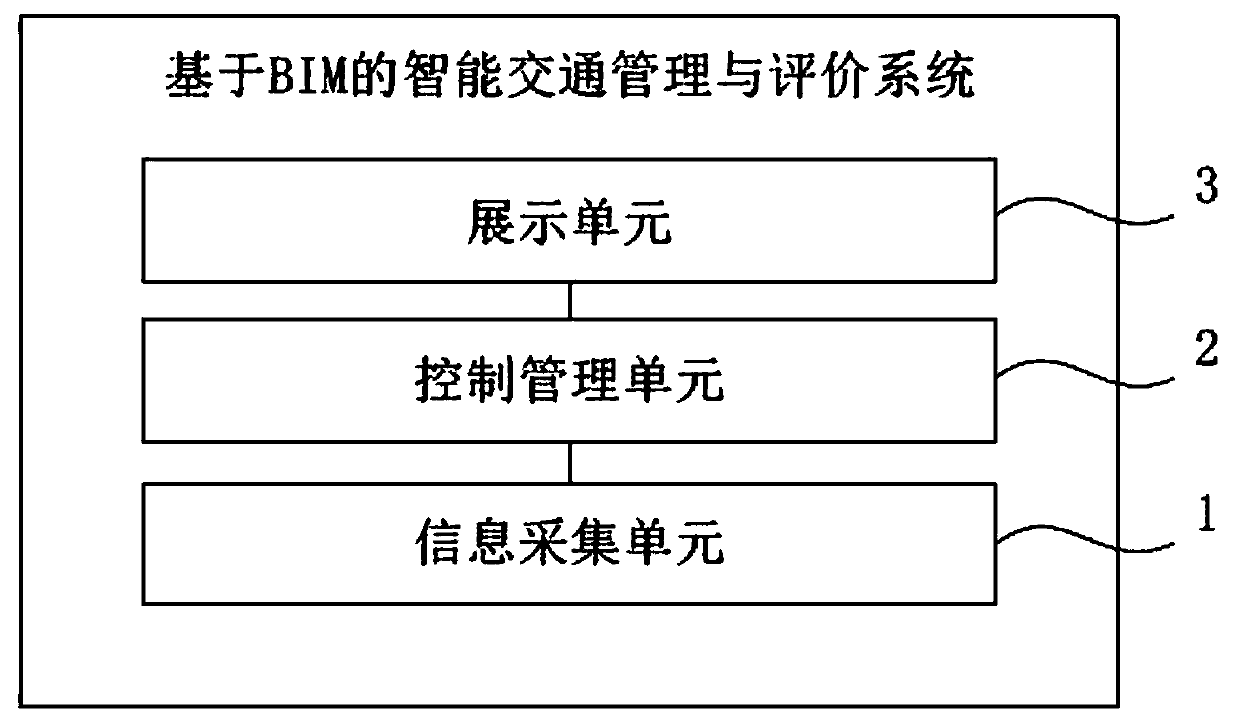

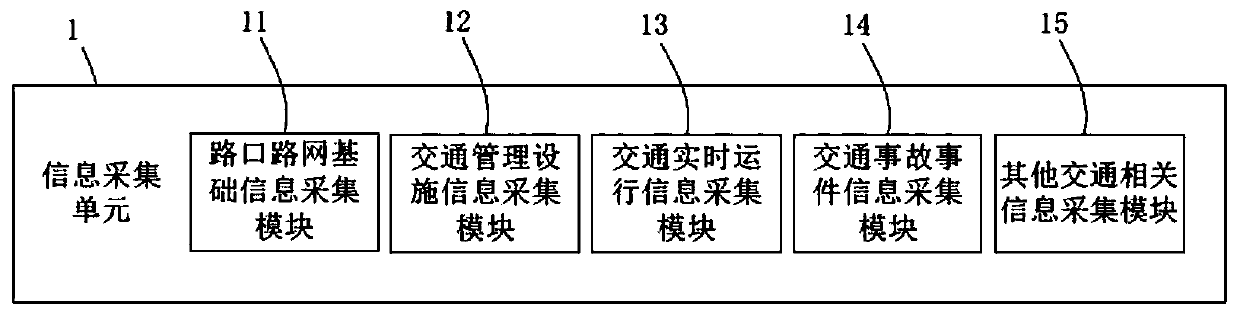

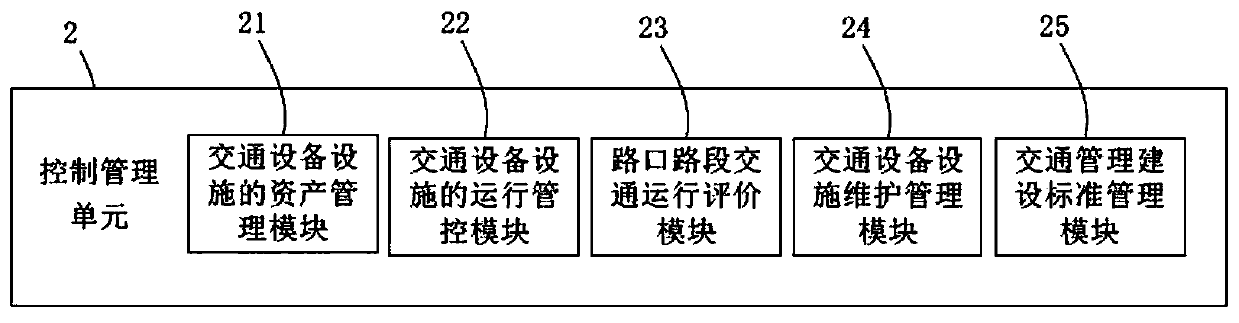

Intelligent traffic management and evaluation system based on BIM

ActiveCN111091312AAvoid isolationAvoid Duplicate Collection RequirementsArrangements for variable traffic instructionsDetection of traffic movementInformation sharingDigitization

The invention discloses an intelligent traffic management and evaluation system based on BIM. The invention relates to the technical field of intelligent traffic, and aims to solve the technical problems that a traditional intelligent traffic management system cannot quickly acquire digital achievements of urban traffic design and construction and is inconvenient for complete-cycle and all-aroundinformation sharing of design, construction and management. The invention discloses an intelligent traffic management and evaluation system based on BIM. The system comprises an information collectionunit based on BIM, a control management unit and a display unit. The invention provides an intelligent traffic management and evaluation system based on BIM. The BIM technology can be utilized to realize full-cycle information sharing and operation supervision of urban traffic from design to construction and then to later operation maintenance management, thereby avoiding self-integration of eachprocess, isolating information, avoiding repeated collection requirements of the information, realizing smooth transmission of the information, and providing accurate data support for traffic managers.

Owner:江苏广宇科技产业发展有限公司 +1

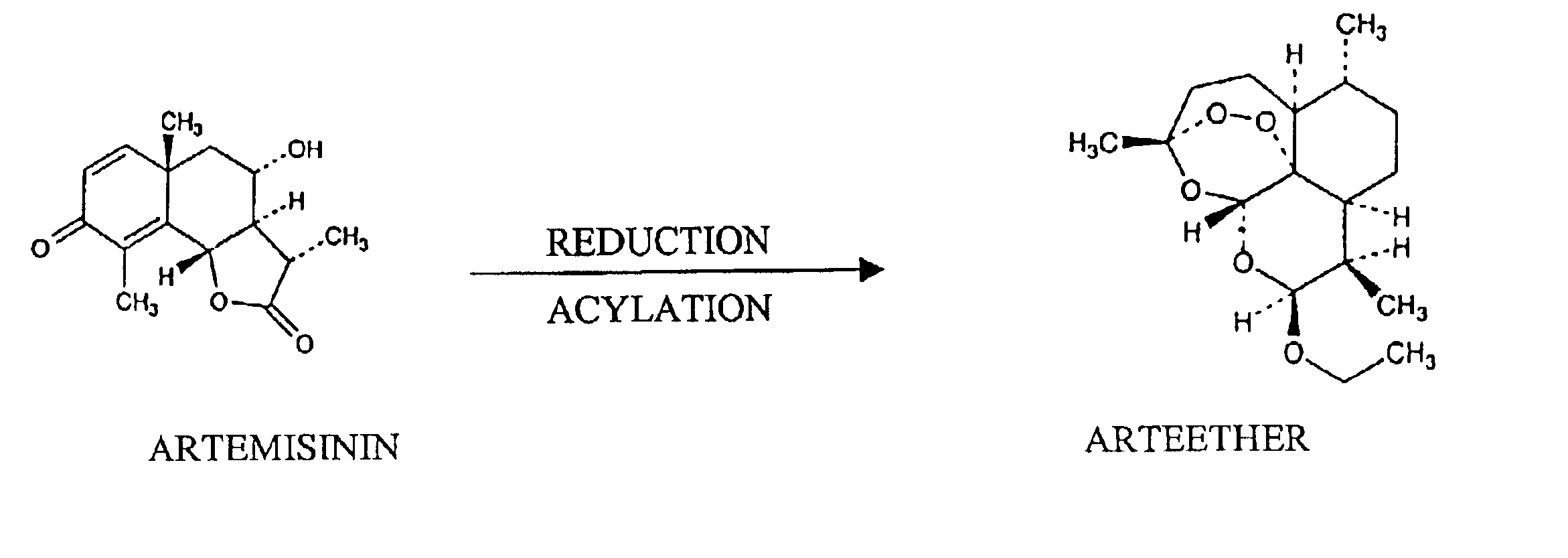

Single pot conversion of artemisinin into arteether

The present invention provides a method for the preparation of arteether from artemisinin in one pot in just about 4 hours comprising reduction of artemisinin into dihydroartemisinin by less quantity of sodium borohydride in ethanol at room temperature in the presence of a novel polyhydroxy catalyst, acylation of dihydroartemisinin in the presence of an acid catalyst, extraction of arteether from an aqueous reaction mixture using 1% ethyl acetate in n-hexane followed by workup and purification of the impure arteether to yield 80-86% (w / w) pure alpha, beta arteether.

Owner:COUNCIL OF SCI & IND RES

Non-Codeine Opioid Analgesic Process And Formulations

InactiveUS20090306119A1Prevent and minimise isolationAvoid isolationBiocideNervous disorderMedicineNon prescription

The invention is directed to the relief of pain using opioid analgesics other than codeine, preferably in combination with a non-steroidal anti-inflammatory agent. Treatment is by self-administration. Compositions for the treatments are provided. Compositions of opioid analgesics other than codeine adapted to avoid the problems of potential abuse are also provided. The compositions have potential use as both prescription and non-prescription medications.

Owner:KEANE MICHAEL

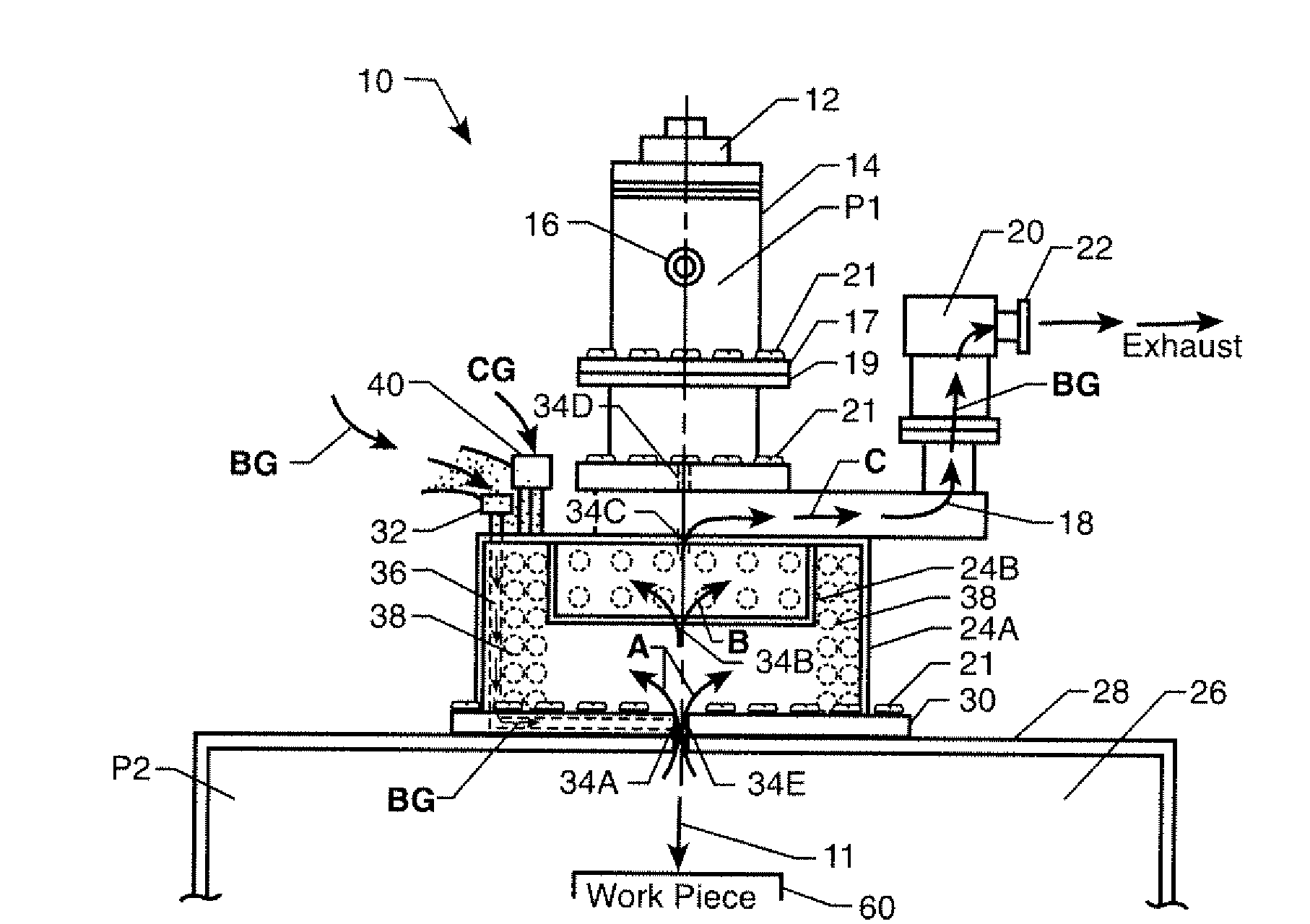

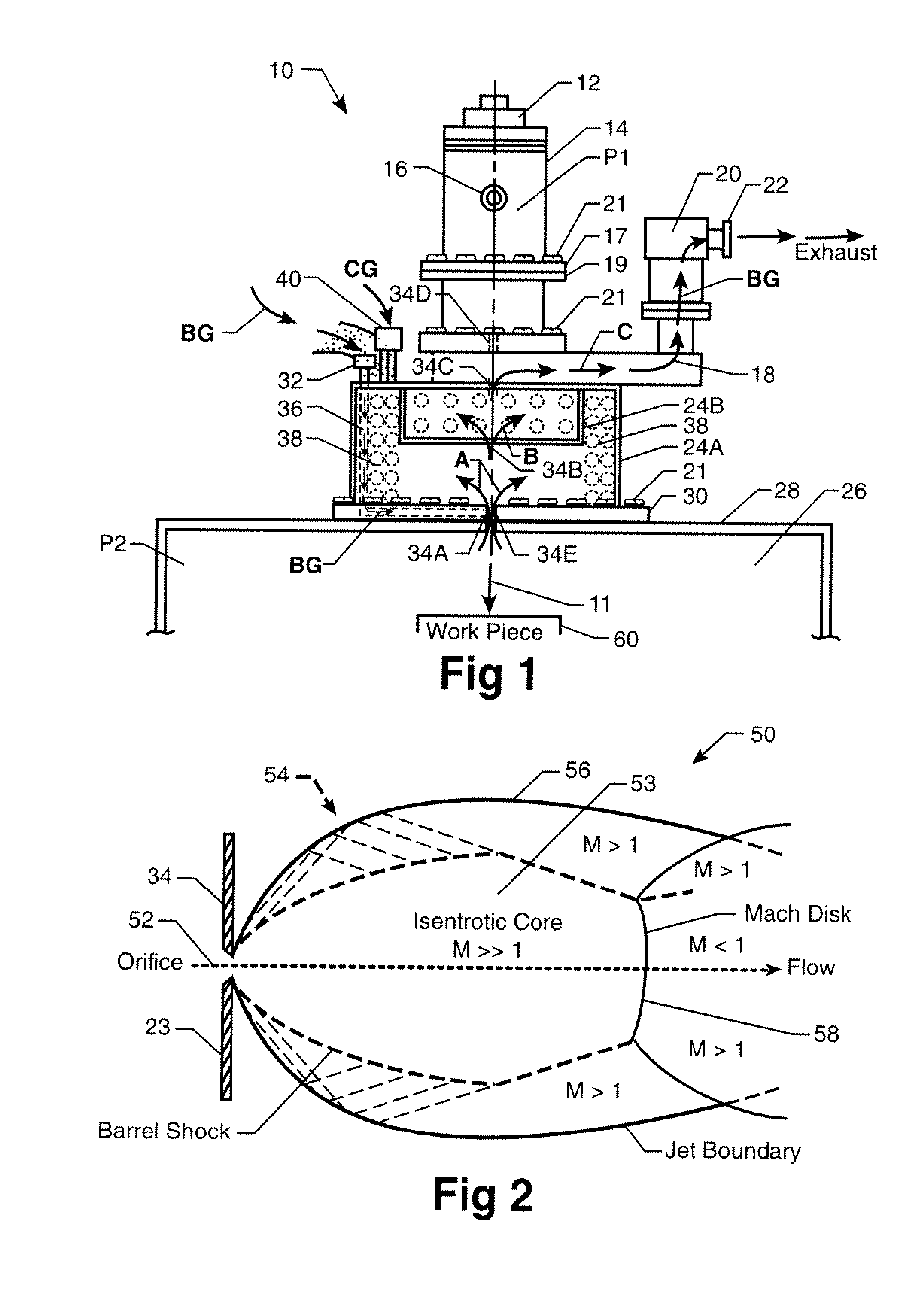

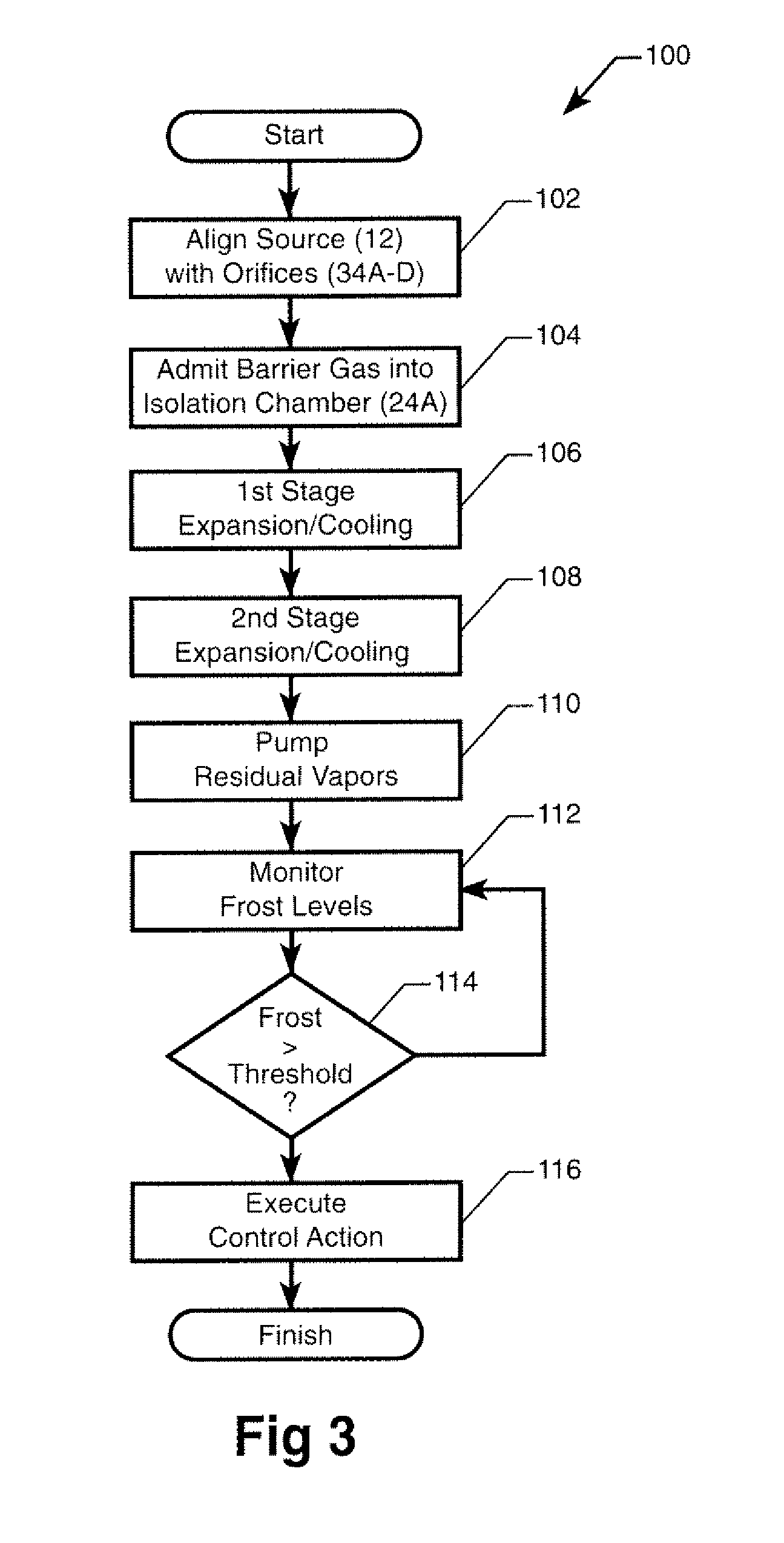

Vapor-Barrier Vacuum Isolation System

InactiveUS20100122901A1Increase pressureCost-effectiveCellsElectric discharge tubesVapor barrierAtmospheric air

A system includes a collimated beam source within a vacuum chamber, a condensable barrier gas, cooling material, a pump, and isolation chambers cooled by the cooling material to condense the barrier gas. Pressure levels of each isolation chamber are substantially greater than in the vacuum chamber. Coaxially-aligned orifices connect a working chamber, the isolation chambers, and the vacuum chamber. The pump evacuates uncondensed barrier gas. The barrier gas blocks entry of atmospheric vapor from the working chamber into the isolation chambers, and undergoes supersonic flow expansion upon entering each isolation chamber. A method includes connecting the isolation chambers to the vacuum chamber, directing vapor to a boundary with the working chamber, and supersonically expanding the vapor as it enters the isolation chambers via the orifices. The vapor condenses in each isolation chamber using the cooling material, and uncondensed vapor is pumped out of the isolation chambers via the pump.

Owner:NASA

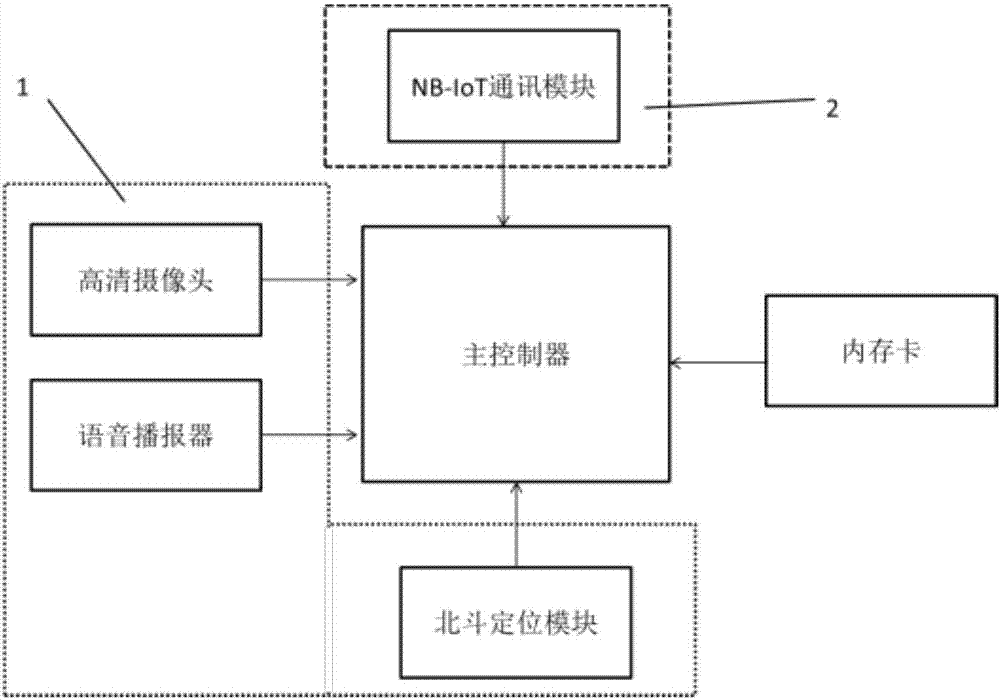

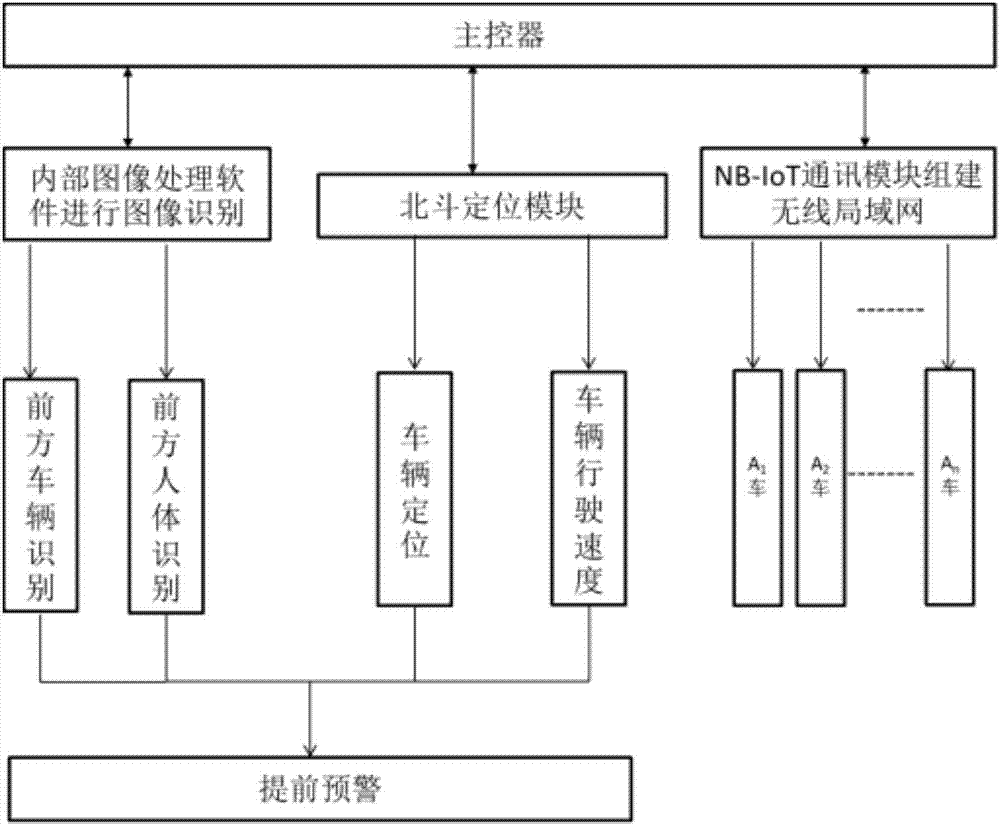

Intelligent networked automobile data recorder

PendingCN107204055AImprove visual effectsAvoid isolationRegistering/indicating working of vehiclesBiometric pattern recognitionEmergency situationsSafe driving

The invention discloses an intelligent networked automobile data recorder, and belongs to the field of electronic equipment of automobiles. The intelligent networked automobile data recorder comprises a main controller, a high-definition camera, and a memory card which is electrically connected with the main controller, wherein the main controller is in data communication with the high-definition camera. The intelligent networked automobile data recorder further comprises an image recognizing early-warning module and a wireless local area network self-building module; the image recognizing early-warning module is used for pre-determining the behaviors of vehicles and pedestrians in front, and timely warning in case of emergency in pre-determining; the wireless local area network self-building module is used for building wireless local area network of at least two automobiles in order to realize sharing and interaction of road condition information. With the adoption of the intelligent networked automobile data recorders, the road condition image information interaction of automobiles can be achieved, so that the viewing range of the automobile can be technologically expanded; in case of traffic accidents in road front, the route can be timely changed; in addition, the road front can be intelligently pre-determined, and warning information can be sent in advance, so that the accident occurrence rate is reduced, and a driver is helped to safely drive.

Owner:CHENGDU UNIV

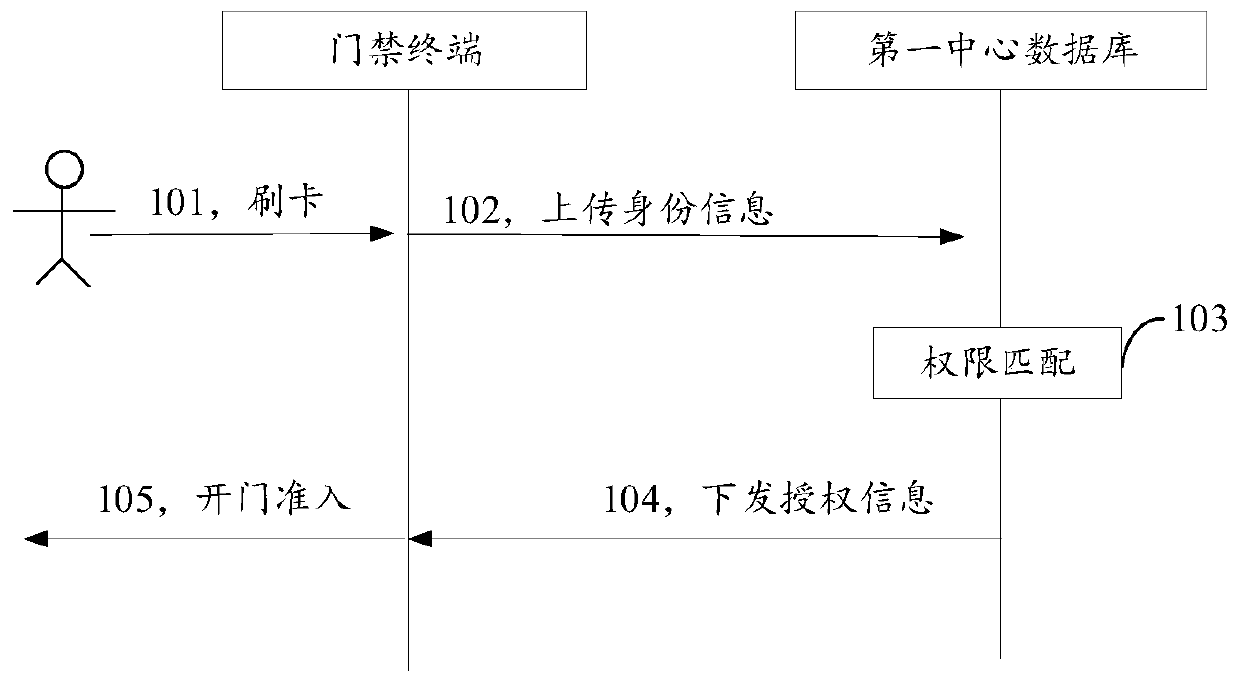

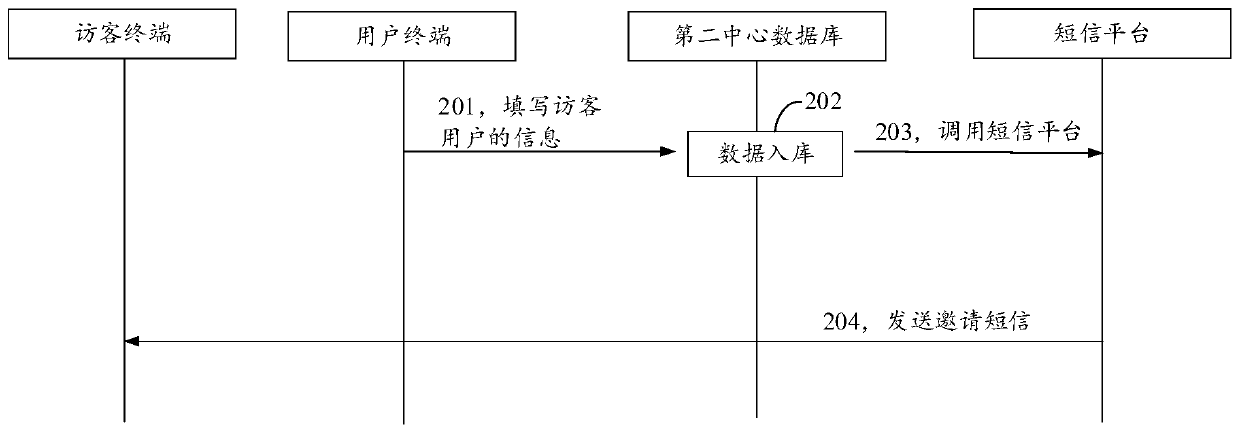

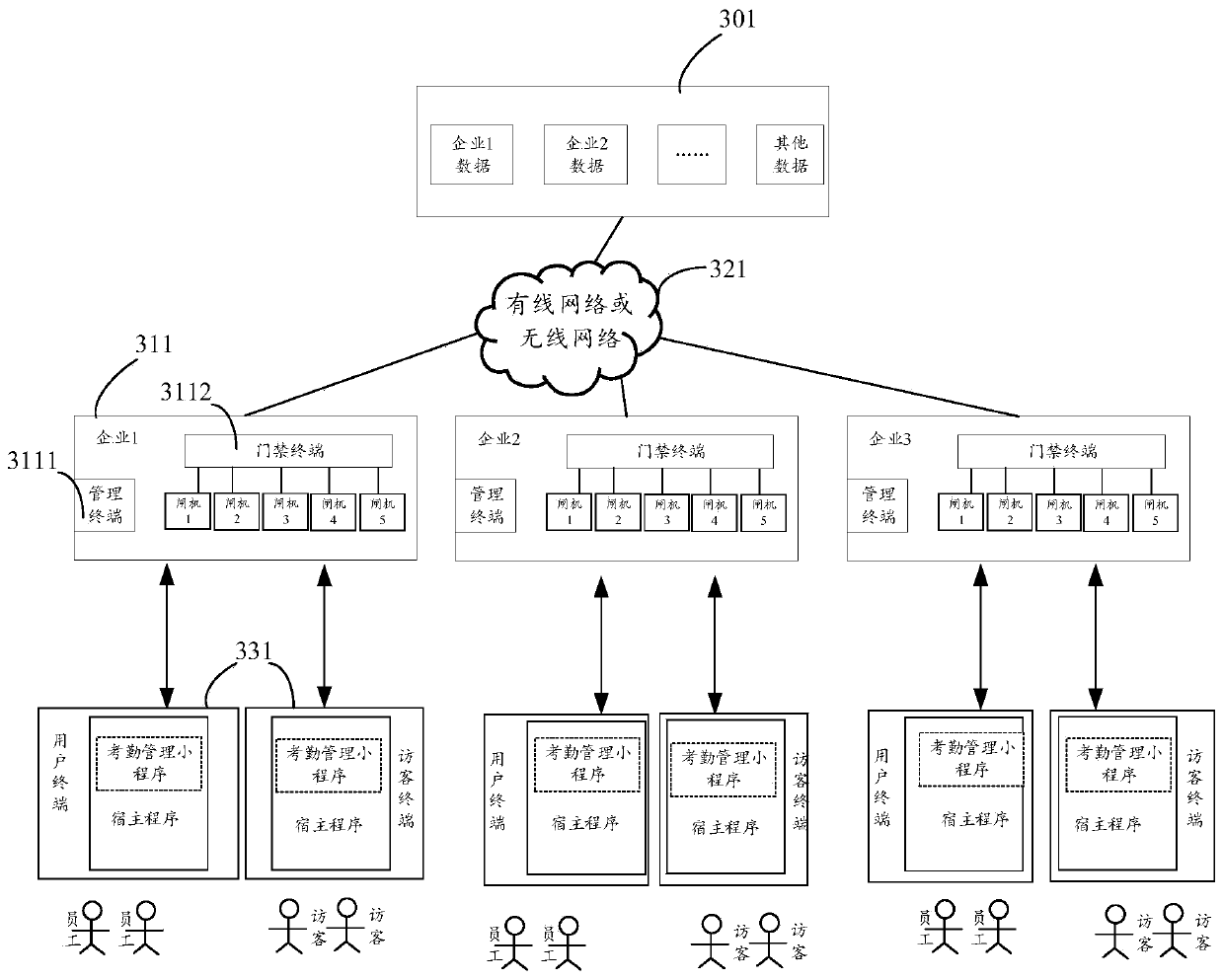

Visitor management system, visitor management method, equipment and storage medium

ActiveCN110148232AAvoid isolationReduce maintenance costsIndividual entry/exit registersData centerComputer terminal

The invention relates to a visitor management system, a visitor management method, equipment and a storage medium, belonging to the field of information acquisition and application. The visitor management system comprises a data center and at least one entrance guard terminal of an enterprise which is connected with the data center; wherein the data center is used for acquiring visitor biologicalinformation of a visitor account and an authenticated employee account to be accessed through a visitor management applet, and the visitor management applet is a program running depending on a host program; the data center is used for determining the entrance guard terminal corresponding to the authenticated employee account, and sending the visitor biological information of the visitor account tothe entrance guard terminal; the entrance guard terminal is used for receiving the visitor biological information of the visitor account sent by the data center, collecting target biological information of a target user, and releasing entrance guard restriction when the target biological information is matched with the visitor biological information. The visitor management method and the visitormanagement system can solve the problems of isolated information and complicated operation caused by that an entrance guard system and a visitor system are separately arranged, and an enterprise needsto maintain and manage two different systems at the same time.

Owner:TENCENT TECH (SHENZHEN) CO LTD

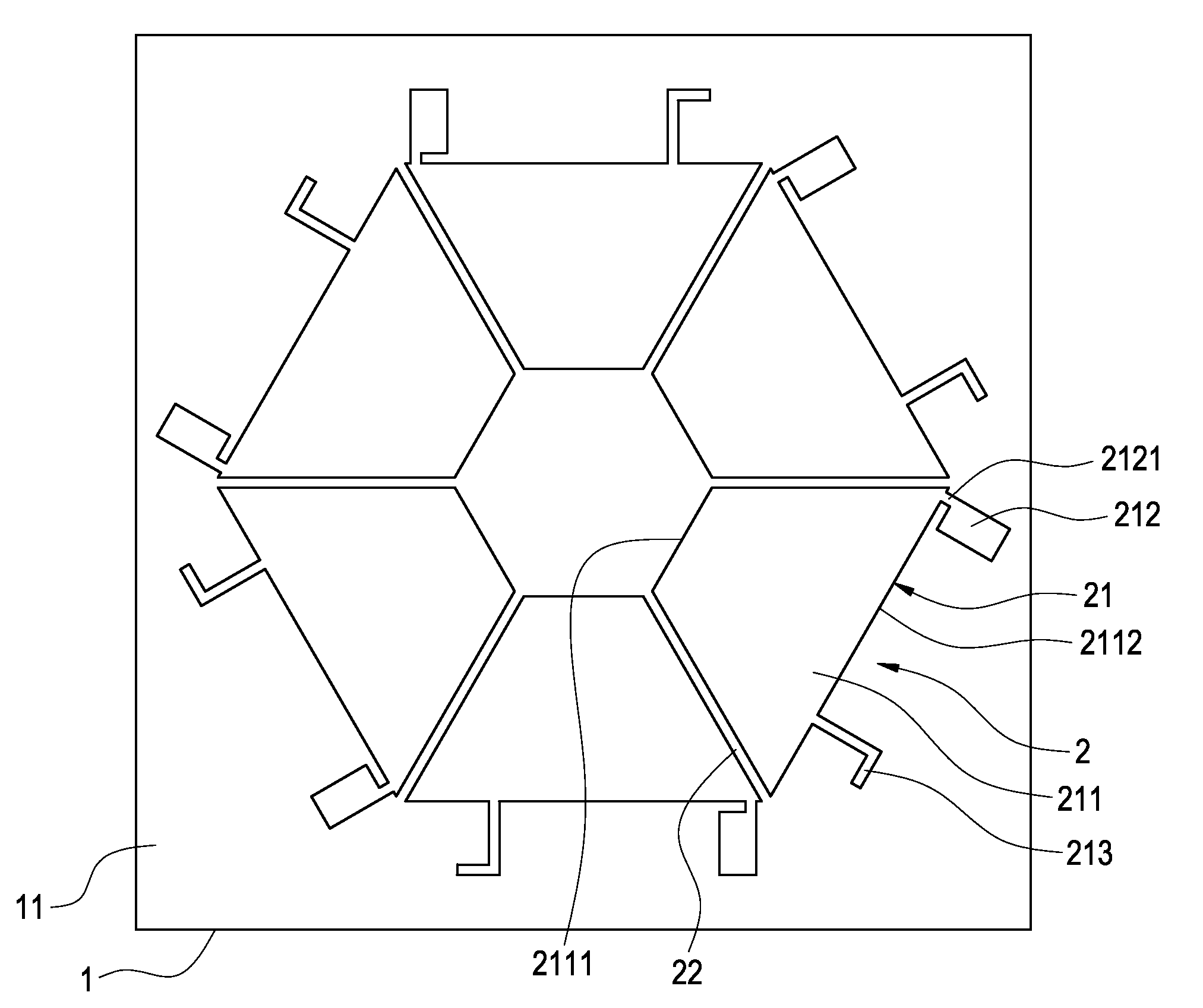

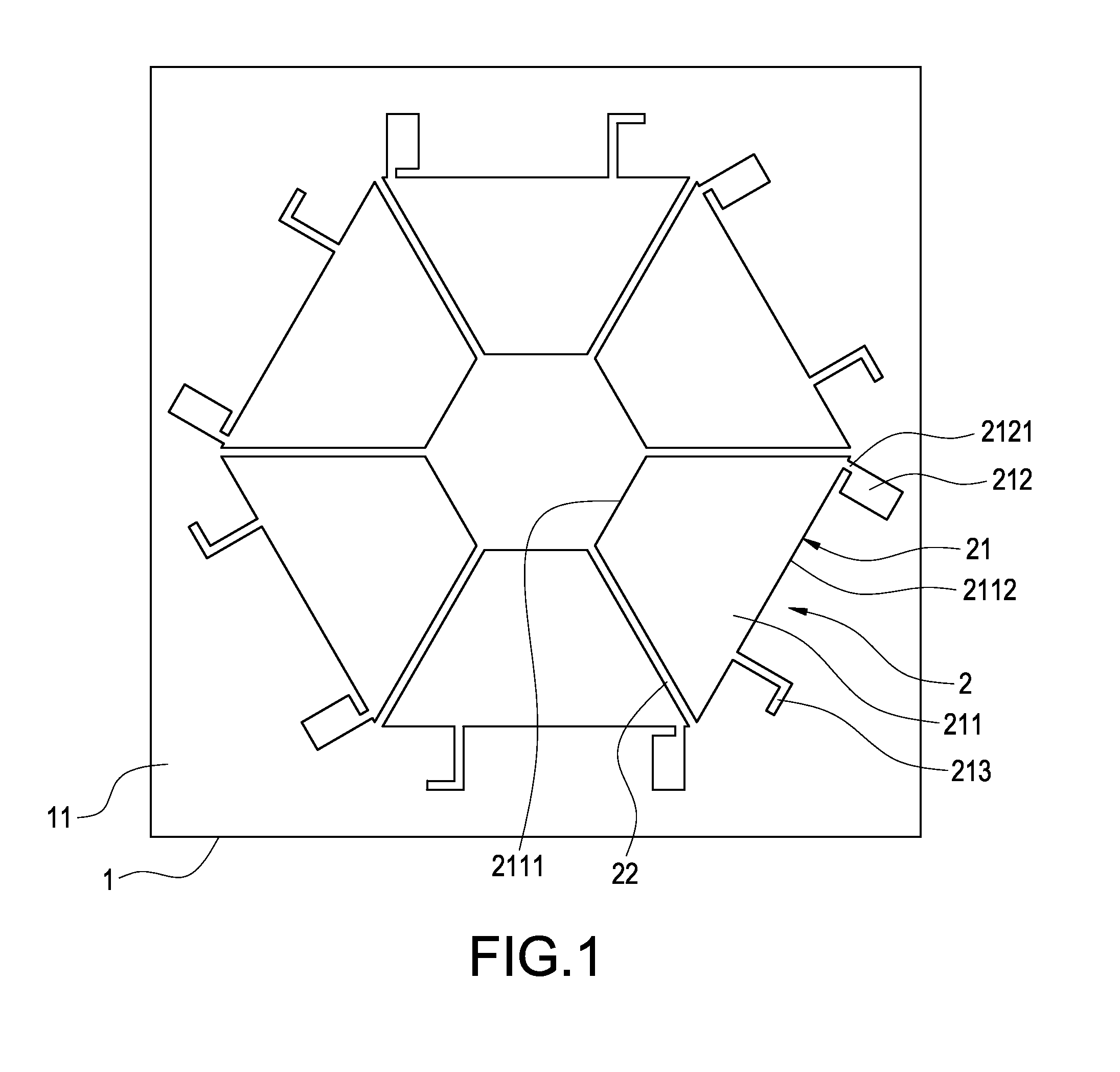

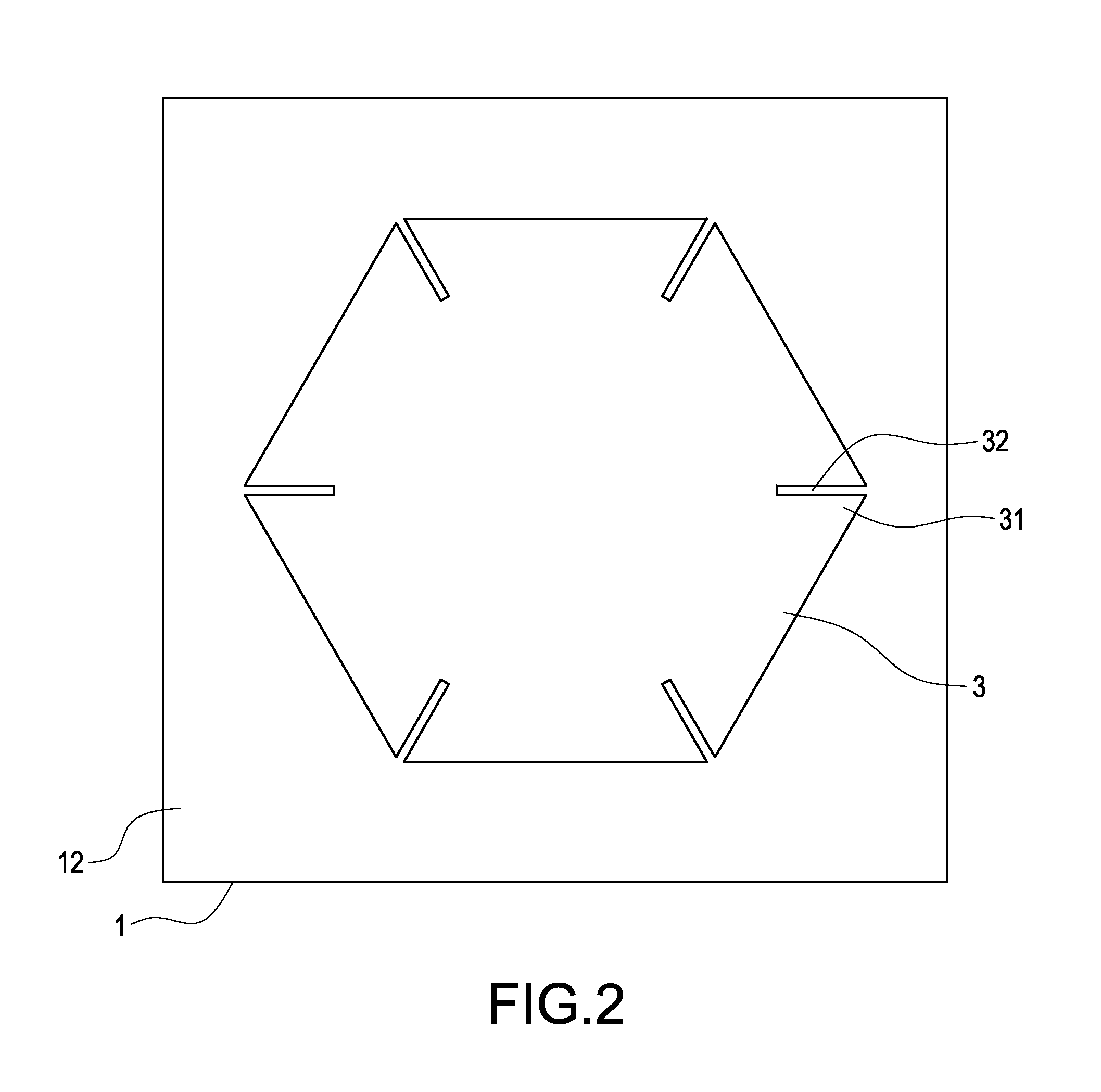

Planar array antenna structure

InactiveUS20150097751A1Increase performanceImprove performanceAntenna earthingsElongated active element feedRadiationElectrical and Electronics engineering

A planar array antenna structure includes a substrate, an array antenna, and a bottom ground portion. The substrate has a front surface and a rear surface. The array antenna is composed of a plurality of antenna units and disposed on the front surface of the substrate in a symmetrical and polygonal arrangement. A spaced slot is formed between every two antenna units. The bottom ground portion is polygonal and arranged on the rear surface of the substrate. The bottom ground portion has a plurality of included angles thereon, and one notch is formed between two included angles and the notches are correspondingly arranged to the spaced slots. Accordingly, the planar array antenna structure is used to generate high-gain radiation variations, effectively restrain the isolation between the radiators, and significantly increase overall performance of the antenna.

Owner:TECOM

Method for preparing modified acrylic resin finish

The invention relates to a process for preparing modified acrylic resin coating agent. Acrylic resin belongs to a film forming material, which is used most widely in leather coating materials and characterized by strong adhesive force, smooth film coating, brightness, bending resistance, good extensibility and stable structure. The acrylic resin has the disadvantages of 'hot sticking, cold brittleness', solvent intolerance, poor weather resistance and the like. The invention utilizes ethyl orthosilicate and acrylate monomers as raw materials, synchronously employs sol-gel method and non-soup emulsion polymerization under the condition that low molecular oligomer is taken as a stabilizing agent. In the process of preparing, no emulsifying agent is added, thereby avoiding the effects of isolation, elasticity, ageing resistance, exudation and the like of the emulsifying agent, achieving single and dispersed latex particles of which the surface is clean, enabling film build to have high water resistance and good physical-mechanical properties. Nanometer particle SiO2 generated by synchronously employing sol-gel method is capable of improving intensity, elasticity, ageing resistance and transparency of coating and endows leathers with good hand feeling.

Owner:SHAANXI UNIV OF SCI & TECH

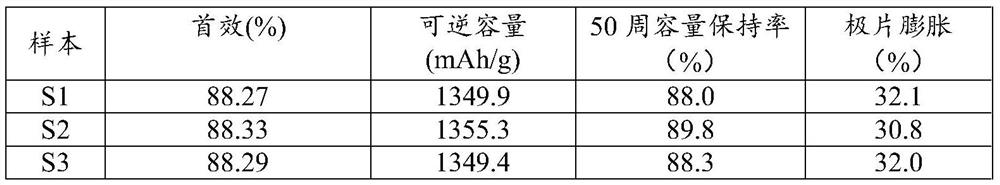

Silicon-oxygen composite negative electrode material, preparation method thereof and lithium ion battery

ActiveCN113066968AImprove stabilityLower pHNegative electrodesLi-accumulatorsSilicon oxygenLithium compound

The invention relates to a silicon-oxygen composite negative electrode material, a preparation method thereof and a lithium ion battery, the silicon-oxygen composite negative electrode material comprises a silicon-oxygen material and a composite coating layer coating the surface of the silicon-oxygen material, the composite coating layer comprises a carbon material and a lithium-containing compound, the carbon material has pores, and the pores are filled with the lithium-containing compound. The silicon-oxygen composite negative electrode material and the preparation method thereof are simple and low in cost, industrial production is easy to realize, the prepared silicon-oxygen composite negative electrode material has excellent electrochemical cycle and expansion inhibition performance, and the service life of a lithium ion battery can be prolonged.

Owner:BTR NEW MATERIAL GRP CO LTD +1

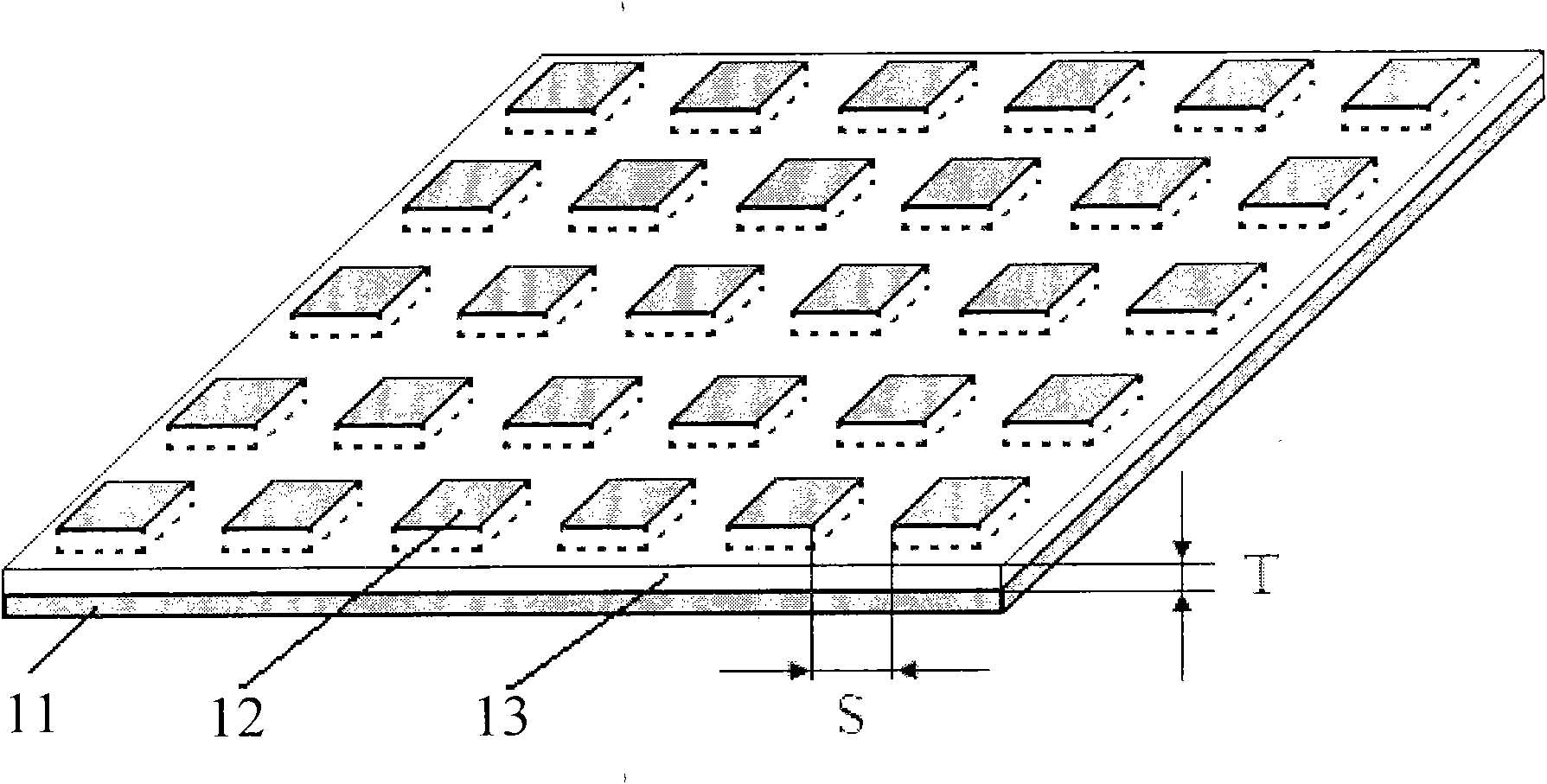

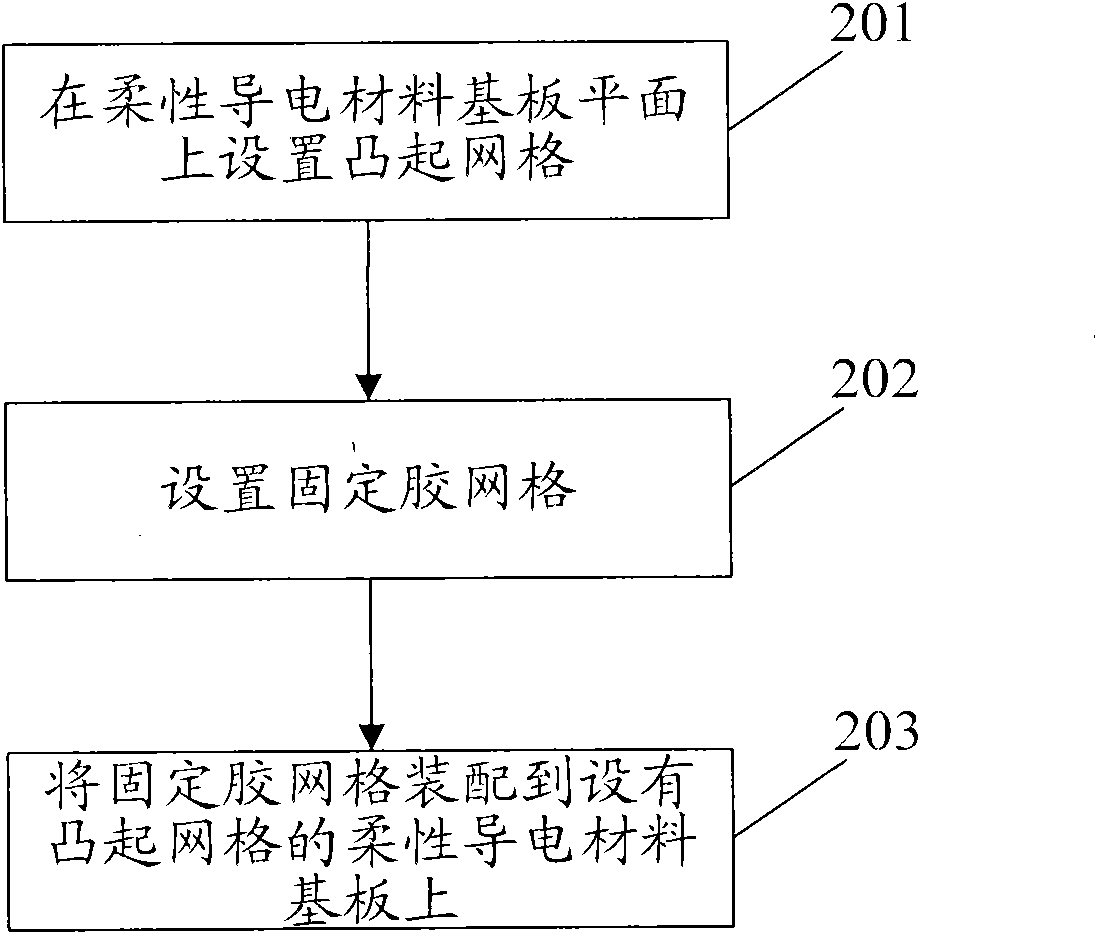

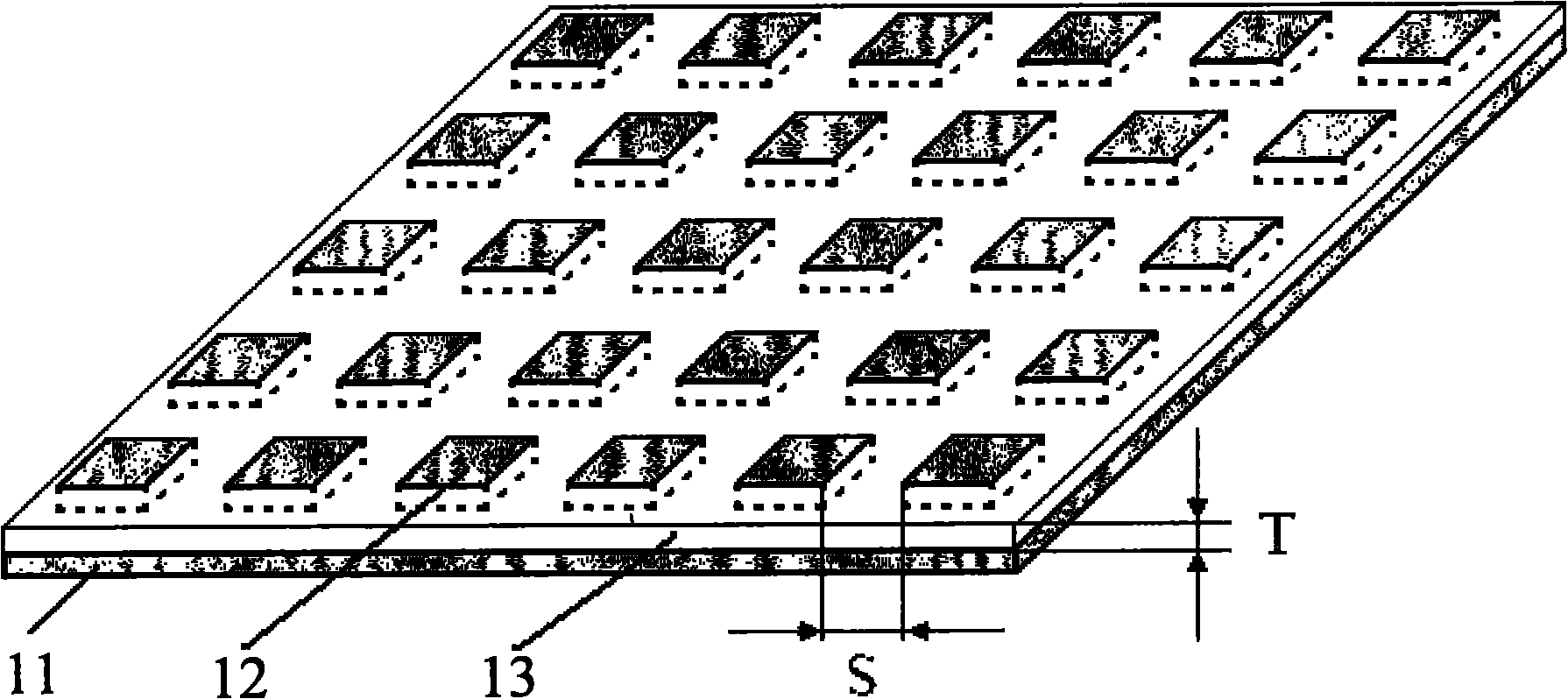

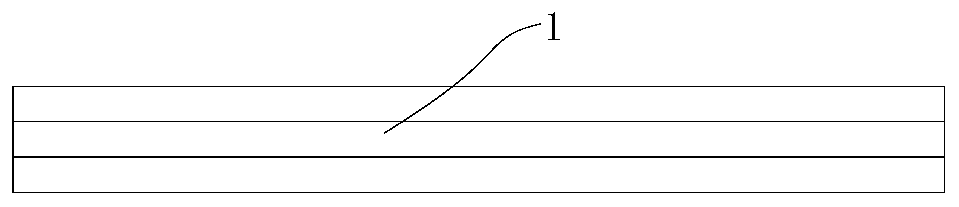

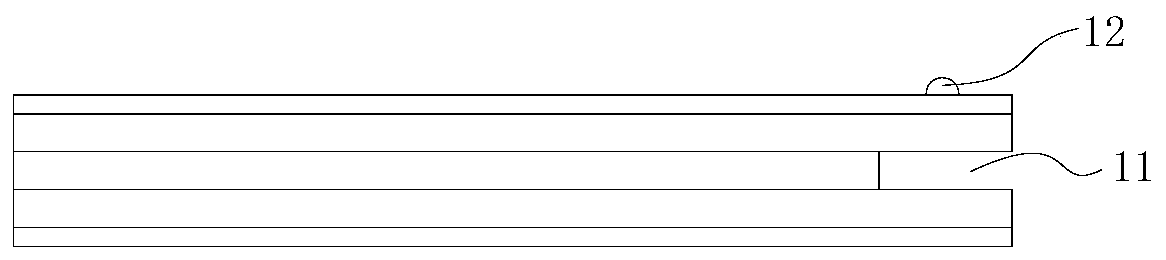

Flexible conducting material substrate and implementing method thereof

ActiveCN101888770AImprove conductivityIncrease contactMagnetic/electric field screeningRadiating elements structural formsConductive materialsEngineering

Owner:ZTE CORP

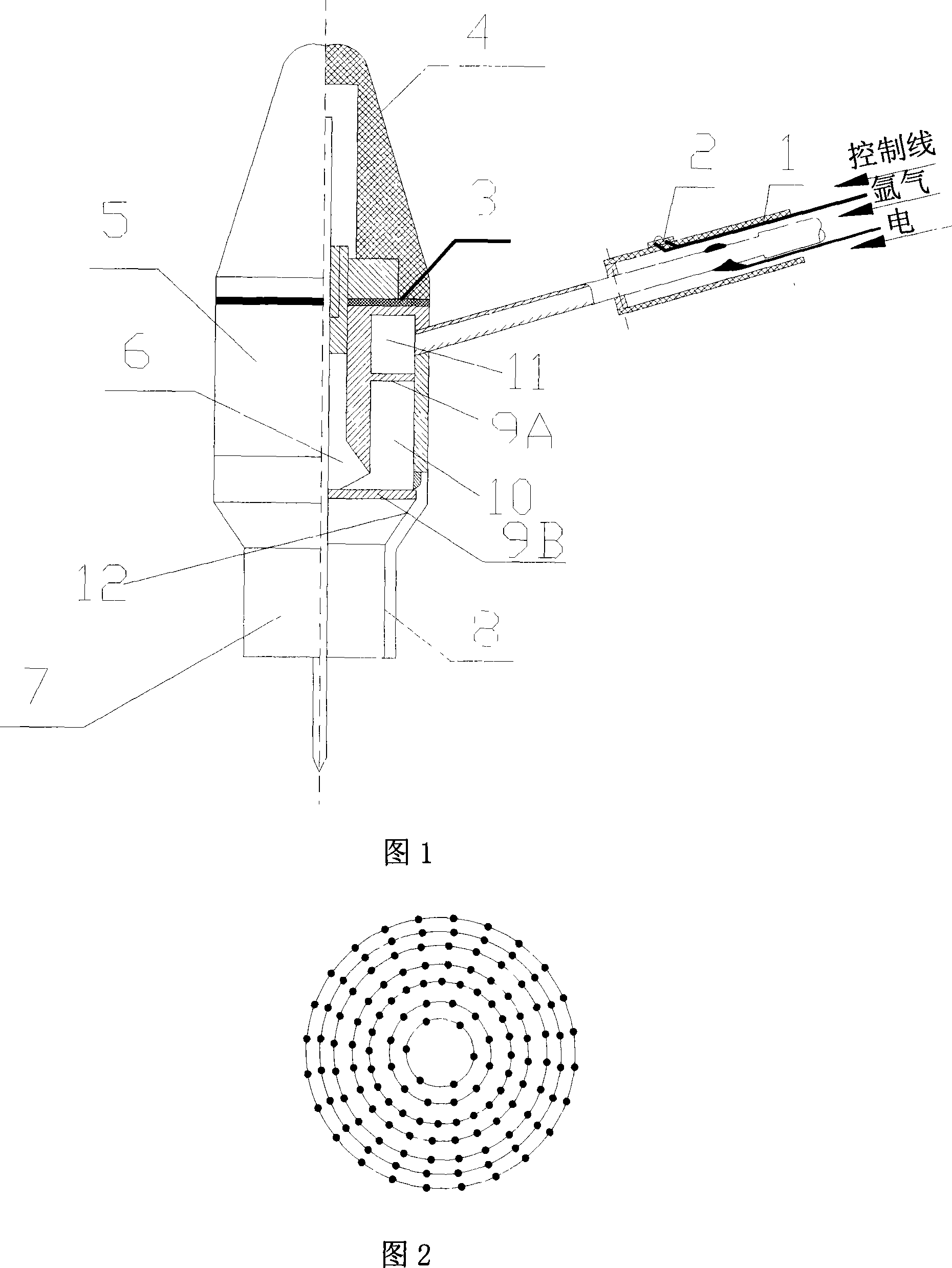

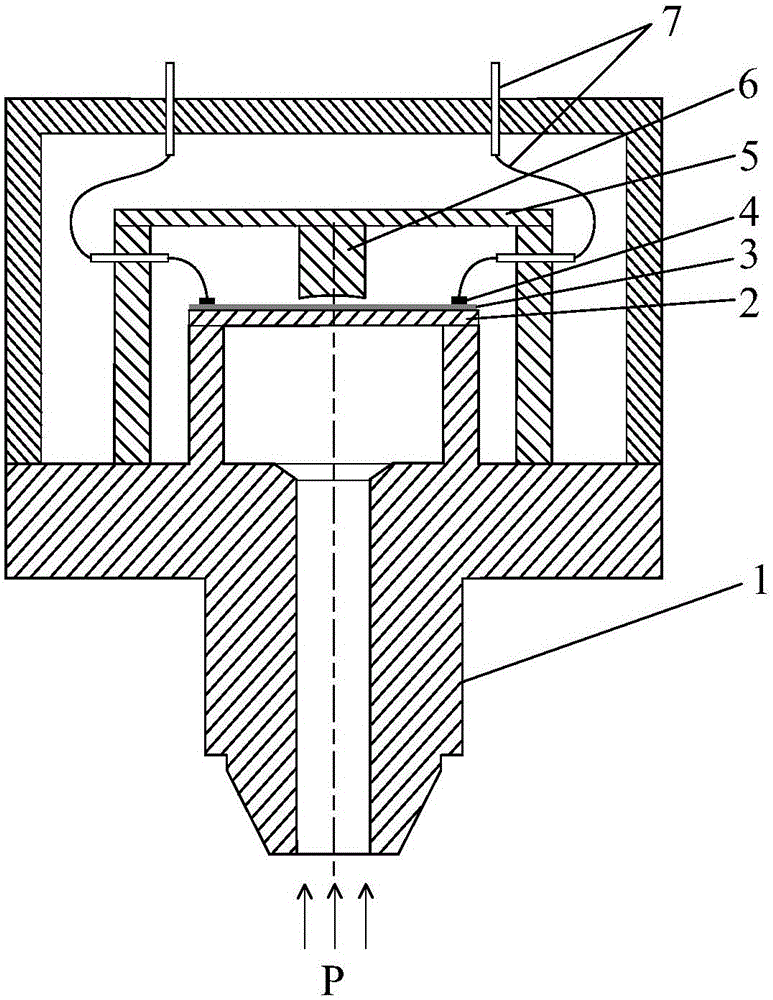

Cold air type argon-arc welding gun

InactiveCN101085489AEffective isolationAvoid isolationElectrode supporting devicesCold airHeat-affected zone

The invention relates to the argon cold air arc welding machine. It has top and down air chamber through the screen current and connected to the nozzle, and separated by rigid air lens with intersected through holes. The air lens is divided into top and down air chambers, forming effective isolation air multi layer post screening the current. It forms multi layer protective layer current. It has concentrated electric arc temperature, small thermal input, quick speed, and less thermal influence. It solves existing technical issues, avoids the location limitation of vacuum argon filling welding equipment. It realizes welding under natural conditions.

Owner:郭光耀

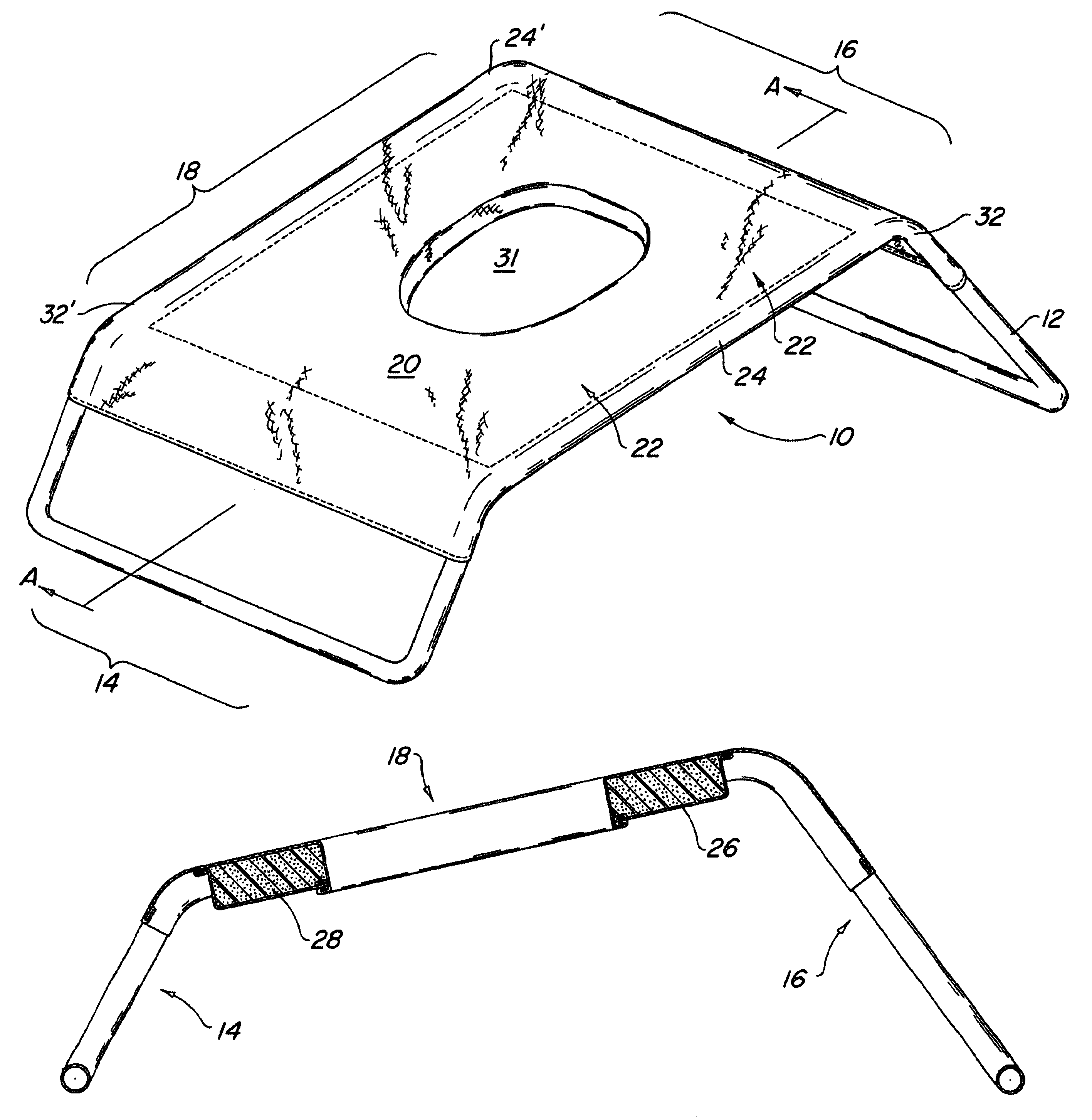

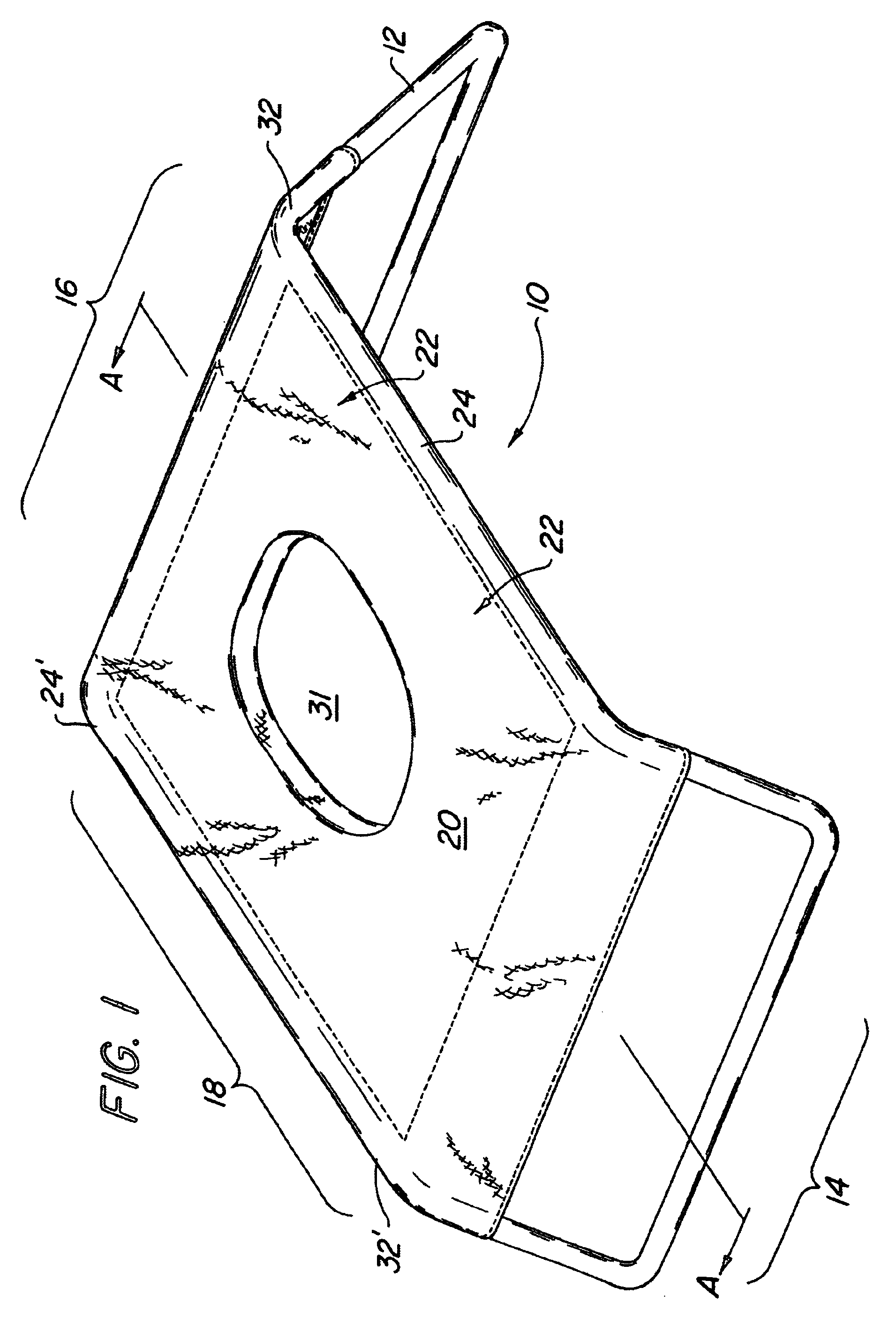

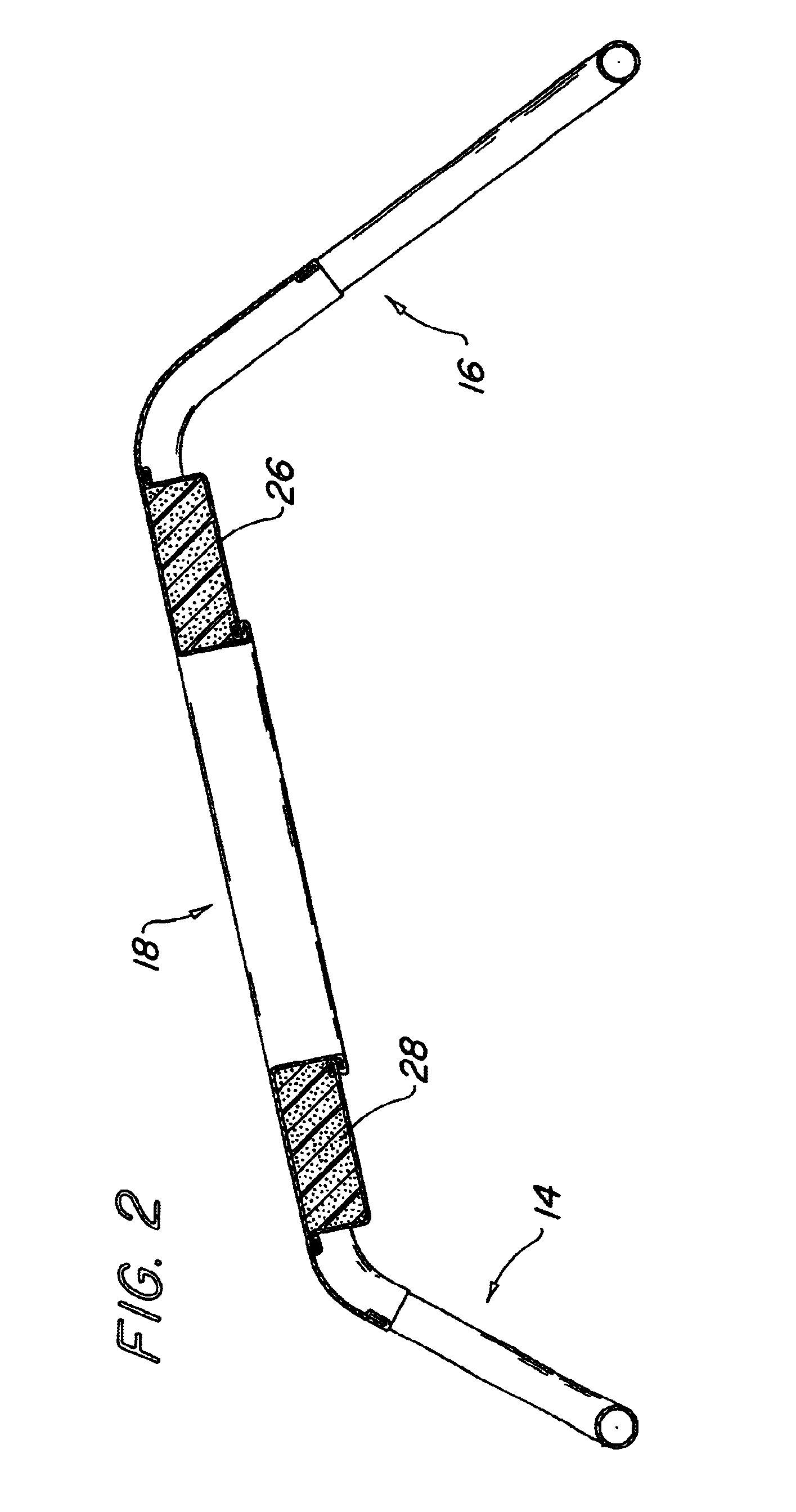

Facial support device

A facial support device having a frame and a cushion, or webbing, for supporting an individual's head, when the individual is reclining in a prone, face down position. The device of this invention is ergonomically designed to provide a gradual transition from the plane of an individual's reclining torso to his head, and thereby avoid or minimize stresses to the cervical spine, and to the musculature of the neck and back. This device includes an asymmetric opening associated with its cushion or webbing to permit unrestricted breathing by an individual when reclining in a face down position.

Owner:ALPA

High-temperature and large-range silicon-sapphire pressure sensor structure

The invention provides a high-temperature and large-range silicon-sapphire pressure sensor structure, which comprises a titanium alloy shell, two titanium alloy diaphragms, a connecting cylinder, a sapphire diaphragm, a monocrystalline silicon strain resistor and a metal wire. One titanium alloy diaphragm is combined with the sapphire diaphragm through vacuum sintering so as to form a sensitive element of a pressure sensor. A layer of monocrystalline silicon thin film with the thickness thereof to be 0.1-0.5 mum grows on the sapphire diaphragm in the heteroepitaxial manner. On an epitaxial film, the monocrystalline silicon strain resistor is prepared through the semiconductor plane process. The resistor forms a wheatstone bridge. The lower part of the other titanium alloy diaphragm is connected to a cylinder and the lower surface of the cylinder is provided with a spherical concave surface. The spherical concave surface completely fit the sapphire diaphragm during the deforming process. Meanwhile, the spherical concave surface is kept at a spacing of 5-10 mum from the sapphire diaphragm when there is no load. According to the technical scheme of the invention, upper and lower diaphragms form a separation type double-diaphragm structure. During the measurement process of a small-range pressure, the advantage of high sensitivity is realized. Meanwhile, the structure can be used for the measurement of large-range pressures.

Owner:BEIHANG UNIV +1

Flame-retardant separator and battery box

The invention discloses a flame-retardant separator. The flame-retardant separator comprises a separator body prepared from a flame-retardant material and a heat absorption material; the surface of the separator body is of a plane structure; and the separator body is provided with a mounting part matched with a battery box for mounting. The invention further provides a battery box adopting the flame-retardant separator. The flame-retardant separator and the battery box which are disclosed by the invention have the beneficial effects that by applying the separator prepared from the flame-retardant material to the battery box, separation, heat insulation and flame retardance can be effectively implemented and heat runaway and battery explosion are prevented so as to avoid an accident; and the separator occupies a small space, so that the battery box using the flame-retardant separator is simple in structure, high in space utilization rate, low in cost and good in safety performance.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

Lucid ganoderma cultivation method

ActiveCN105493884APromote growthStrong growthCultivating equipmentsMushroom cultivationLand resourcesGreenhouse

The invention discloses a lucid ganoderma cultivation method with flexible land selection and practicality and separating fungus rods and soil and a cement pool can be employed. The lucid ganoderma cultivation method comprises steps of land selection, greenhouse construction, cement pool construction and lucid ganoderma plantation in the cement pool. Flexible land selection can be achieved; the greenhouse can be permanently used and the cement pool has practicality. Standardized cultivation can be achieved; on one hand, the lucid ganoderma can be planted in a cement pool, so fungus rods can be fully separated from the soil and effects of pollutant sources, such as soil heavy metals and pesticide residuals in the soil on the fungus rods can be controlled; on the other hand, pollution to the soil by the fungus rods can be avoided and plantation land exchange for next time cultivation can be prevented; land resource can be effectively utilized and labor and material use can be reduced; the lucid ganoderma cultivation method has small pollution and high output; sporocarp is tidy and has no malformation; and conidial power can be easily collected and low cost is required.

Owner:JIANGSU DAOCHENG BIOTECH CO LTD

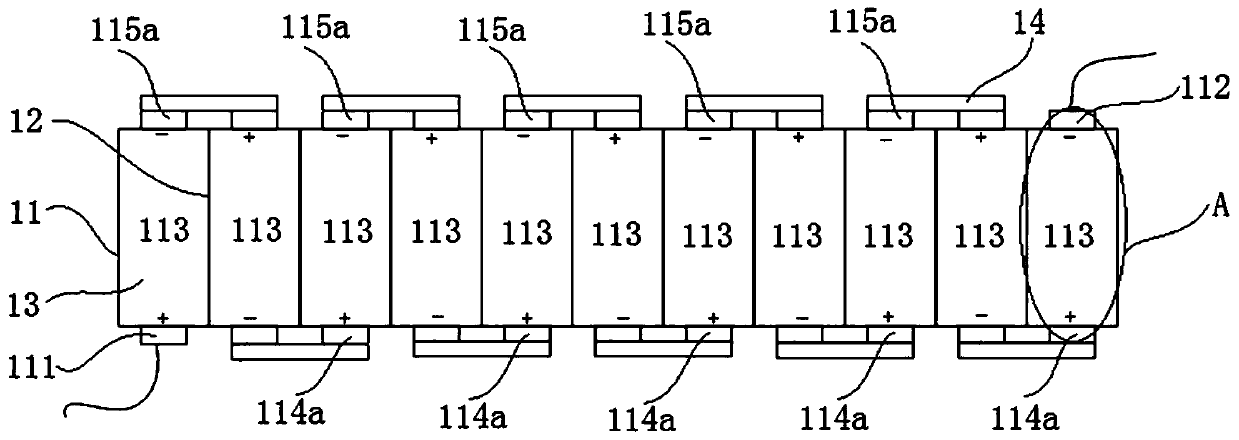

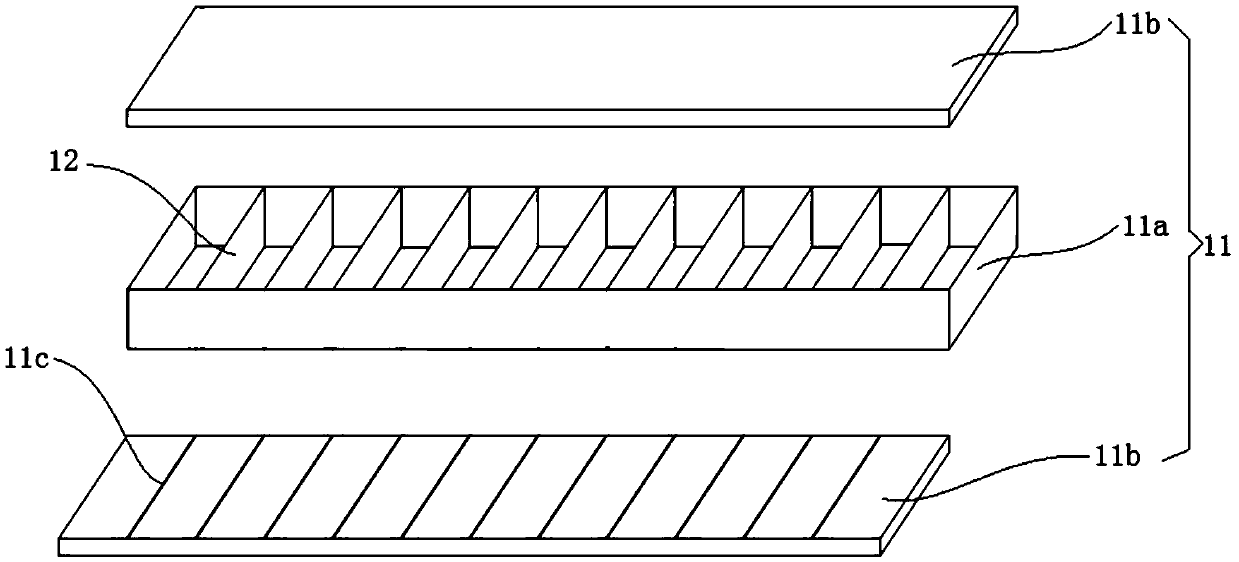

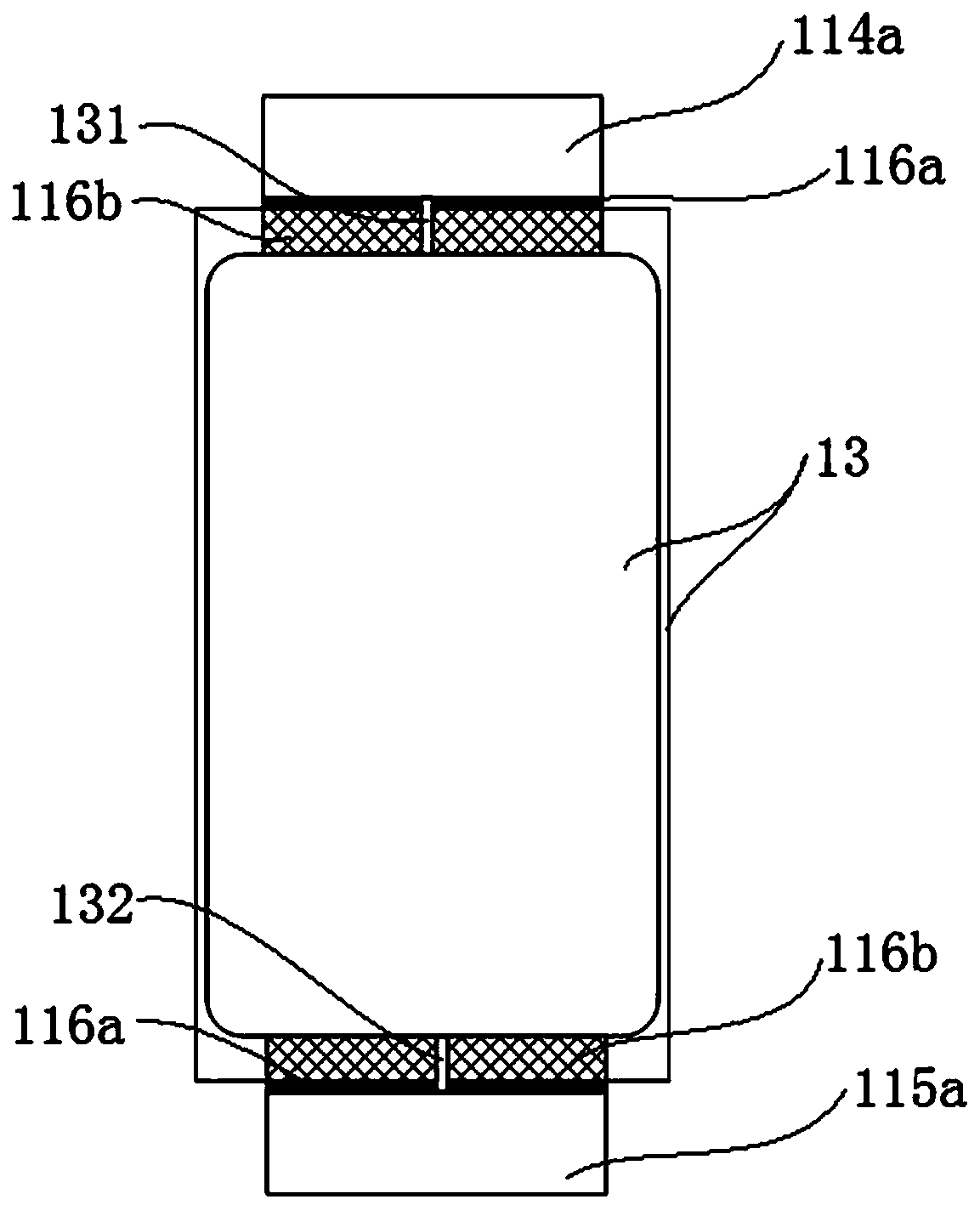

Battery module, battery device and electronic device

ActiveCN109686880AReduce volumeIncrease volumetric energy densityCell component detailsEngineeringApplication areas

The invention provides a battery module, a battery device and an electronic device, and belongs to the technical field of electronic technology applications. The battery module includes a battery module housing and at least one partition plate and N battery cells, and N is an integer greater than or equal to 2; the battery module housing is provided with a positive terminal and a negative terminal; at least one partition plate is located inside the battery module housing to divide the battery module housing into a plurality of chambers, and each partition plate is shared by two chambers adjacent to the partition plate; each of the battery cells is located in one chamber, and the N battery cells are powered by the positive terminal and the negative terminal. By adopting the module, and thebattery cells located in the adjacent chambers can be separated by the shared partition plate, which can avoid the isolation of the adjacent battery cells in the prior art through respective battery single housings, can avoid the waste of materials by the preparation of the battery module, can also reduce the space occupied by the battery module housing, reduce the volume of the battery module, and increase the volumetric energy density of the battery module.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

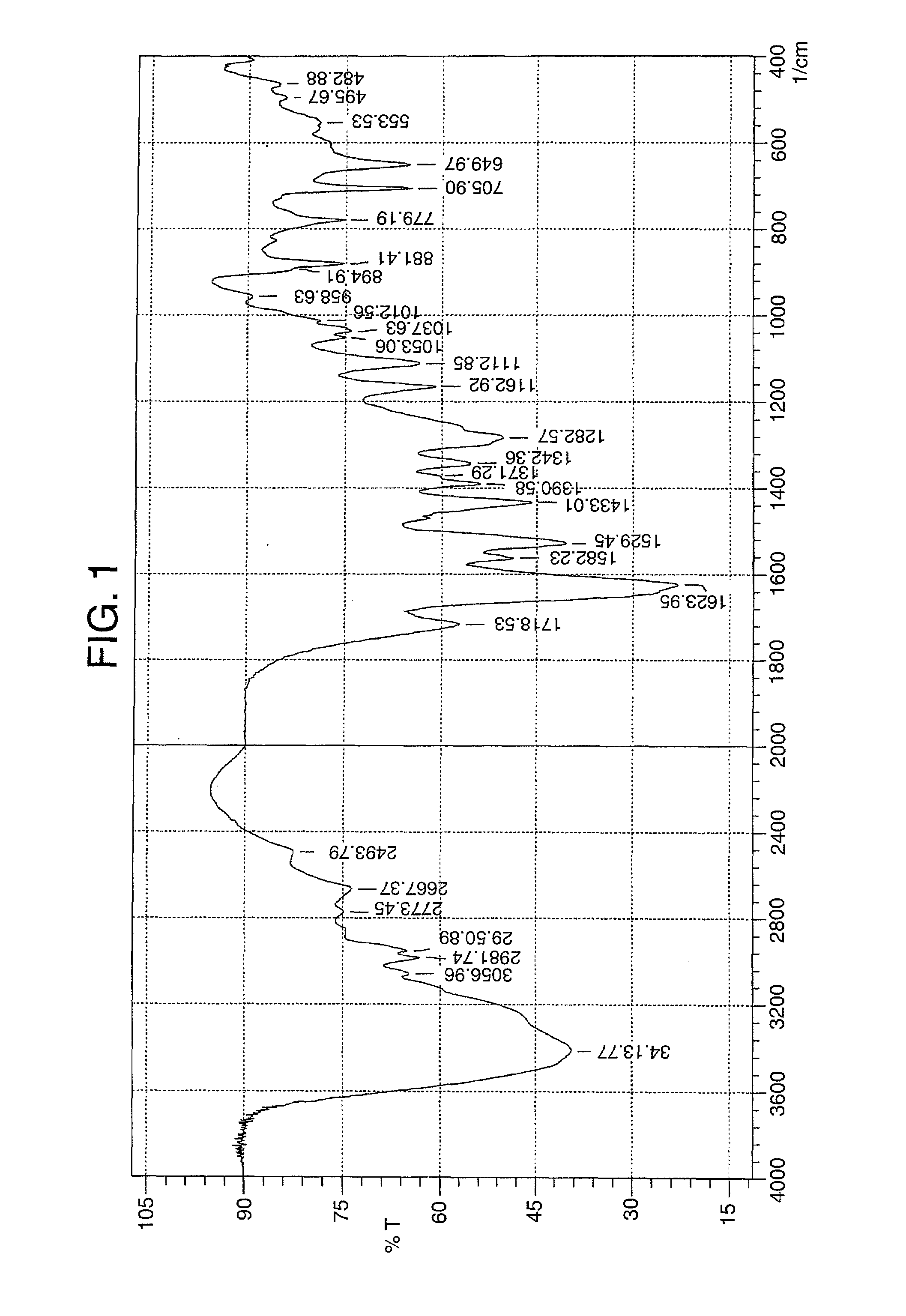

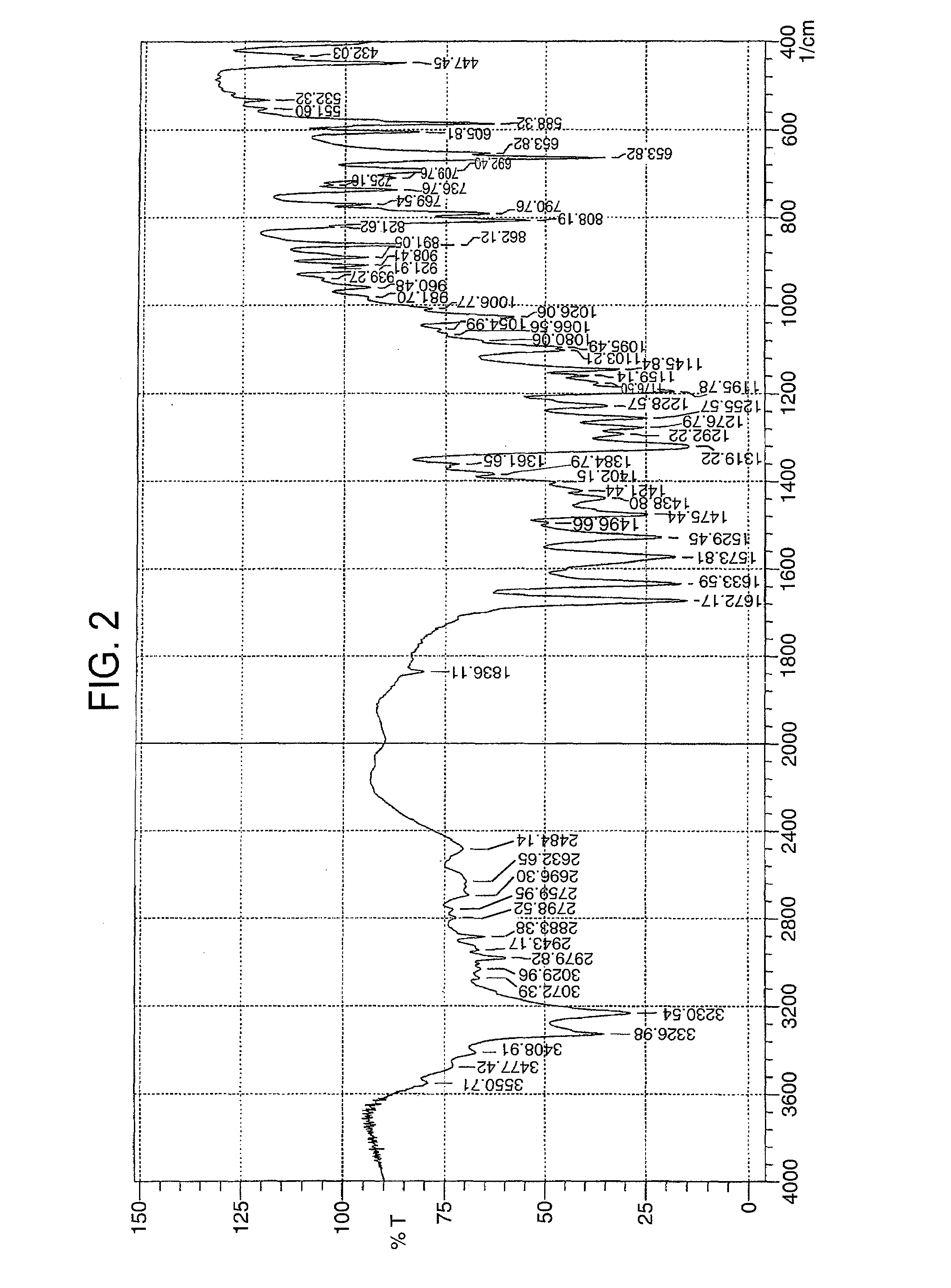

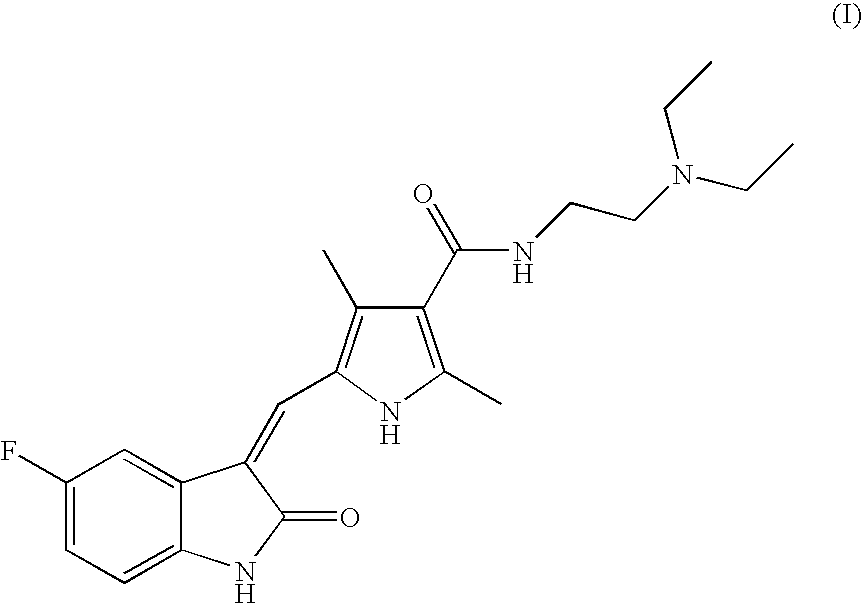

Process For Preparing A 3-Pyrrole Substituted 2-Indolinone Malate Salt

The invention relates to the malic acid salt of N-[2-(diethylamino)ethyl]-5-formyl-2,4-dimethyl-1H-pyrrole-3-carboxamide, to the use thereof as an intermediate for preparing the malic acid salt of sunitinib, and to pharmaceutical compositions comprising said malic acid salt of sunitinib.

Owner:MEDICHEM

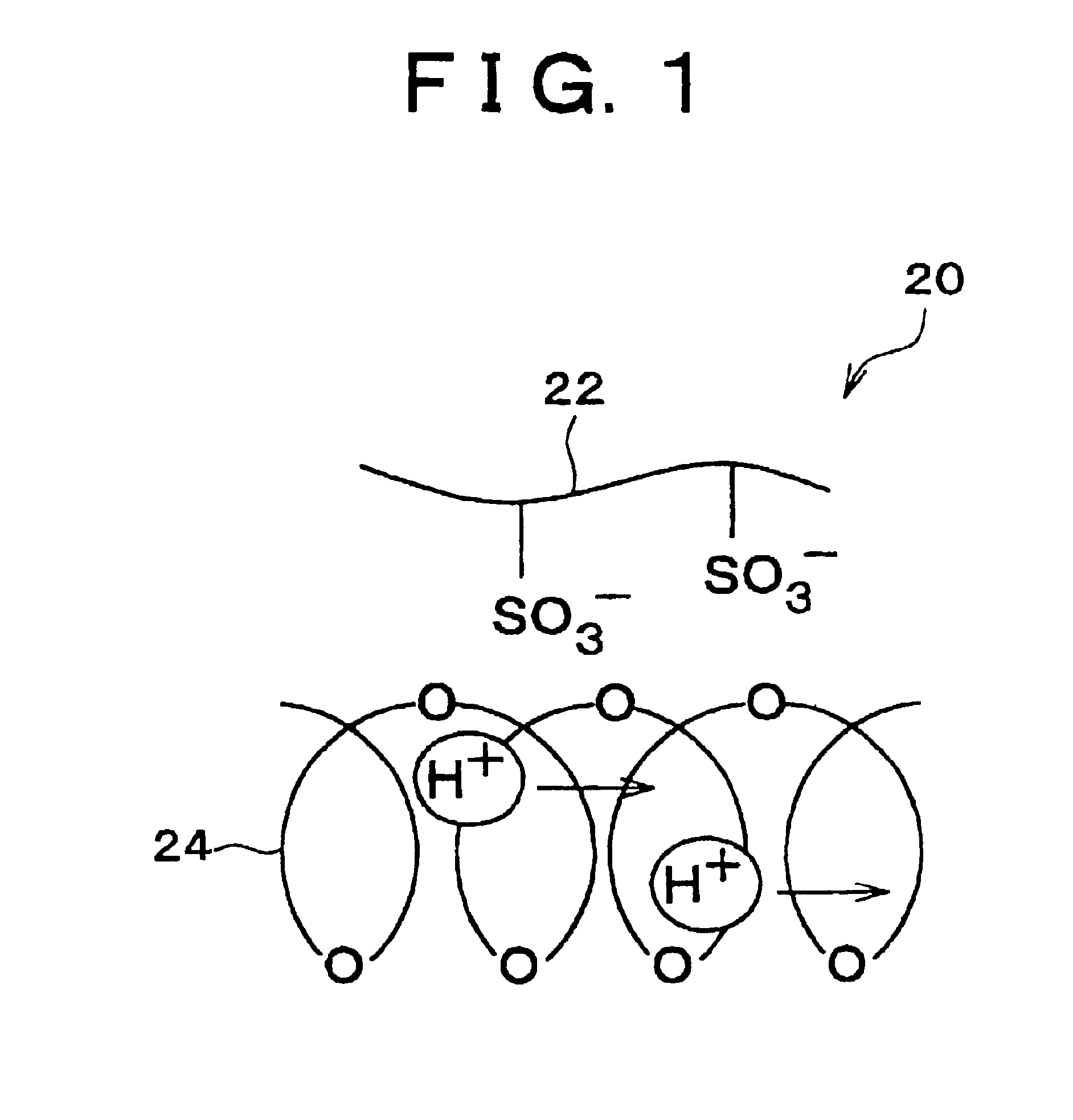

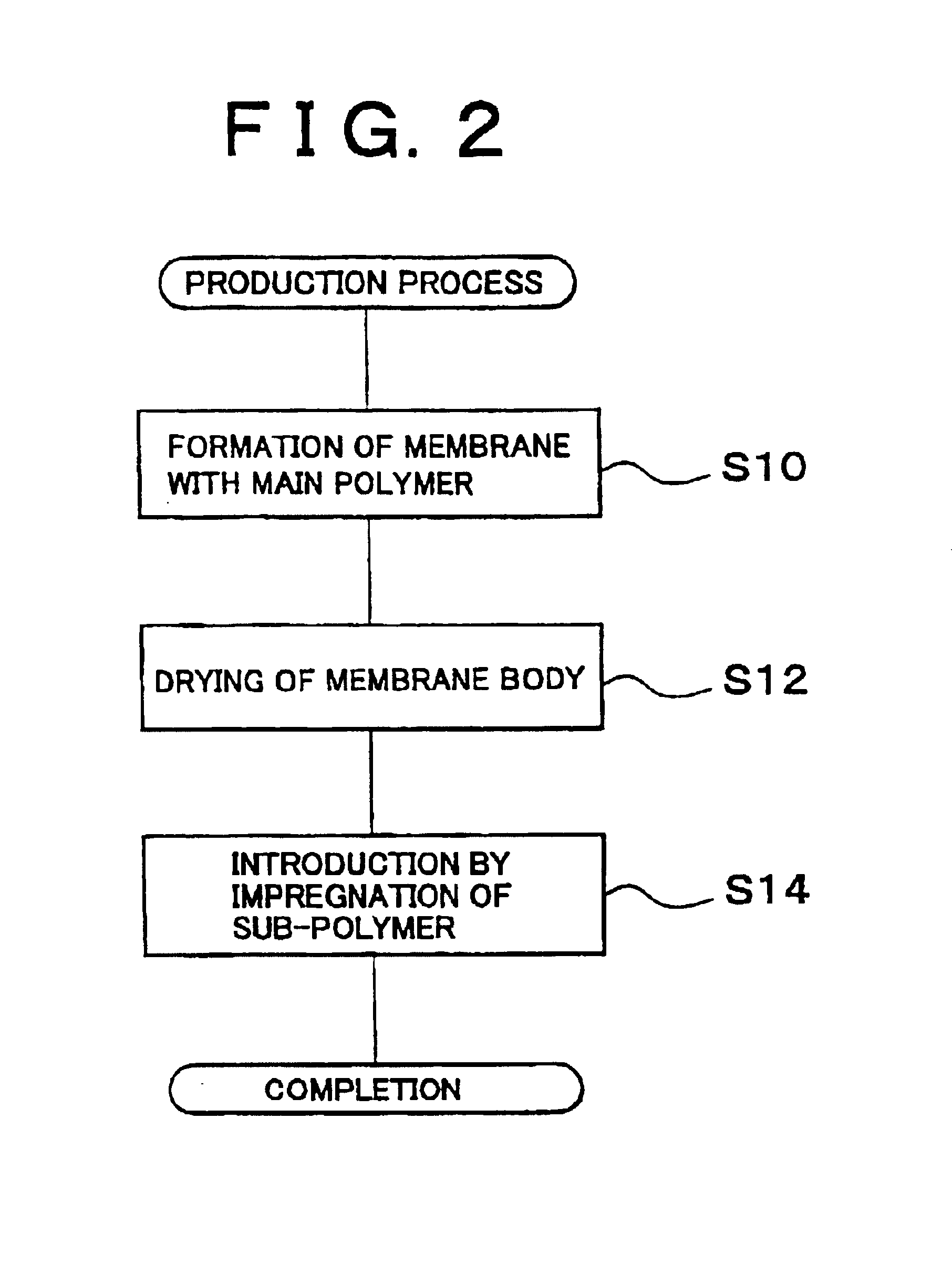

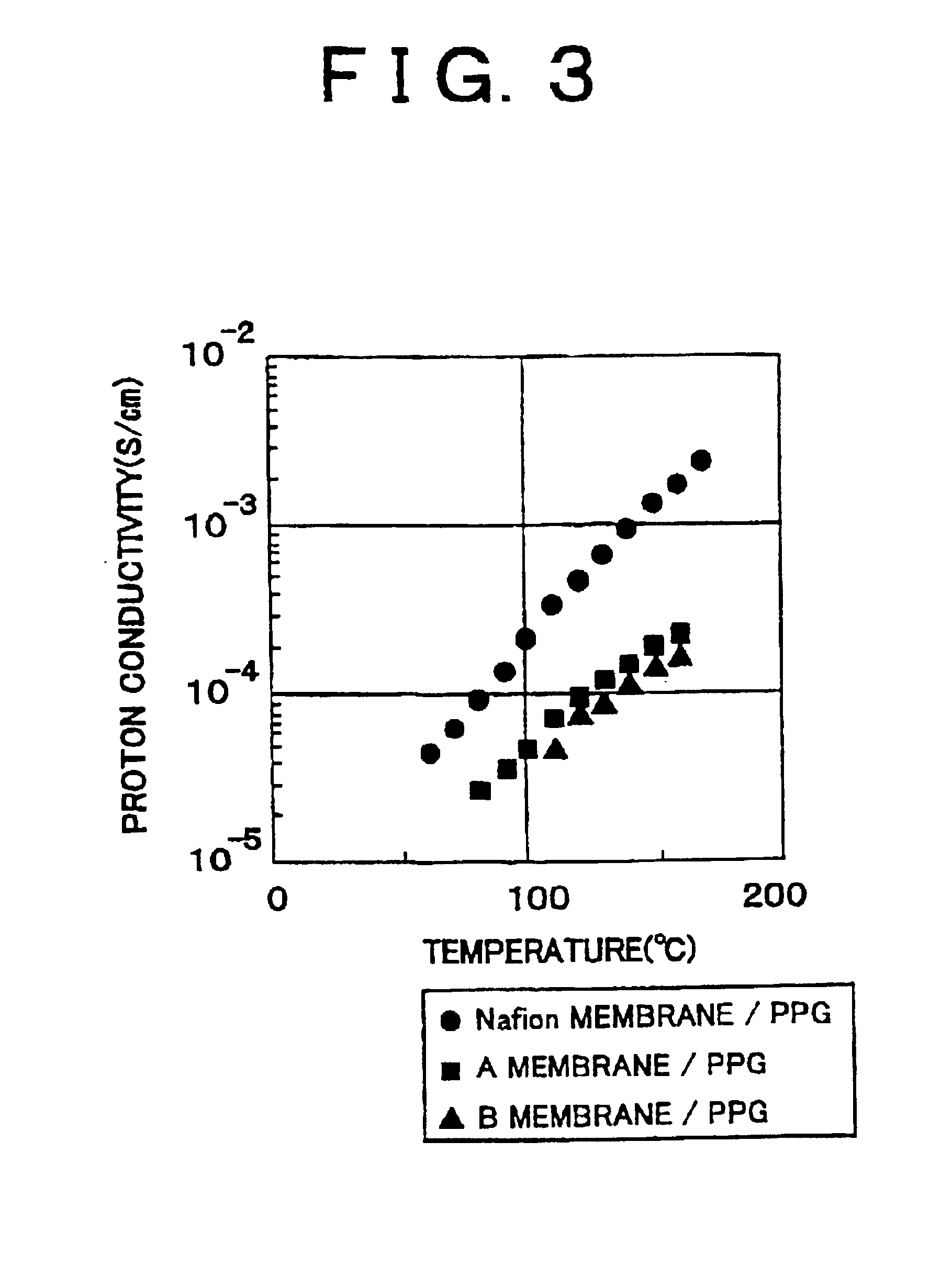

Polymer electrolyte membrane and method of production thereof

InactiveUS7060735B2Improve proton conductivityEfficient conductionSolid electrolytesIon-exchanger regenerationPolymer electrolytesBoiling point

A Polymer Electrolyte Membrane is formed by hot air drying of a membrane formed with an acidic main-polymer having proton conductivity and capability of forming an electrolyte membrane (S12), and then immersing it into a basic polymer solution to impregnate the membrane with the basic polymer (S14). The basic polymer is introduced in a large quantity into a site acting as a proton conduction pass of the main-polymer to take charge of the proton conduction. Since in the Polymer Electrolyte Membrane, a base polymer takes charge of proton conduction as compared with the case where proton takes charge of the proton conduction as a hydrate, the base polymer shows favorable proton conductivity even in a low humidity state at an elevated temperature exceeding boiling point of water.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com