Cold air type argon-arc welding gun

A argon arc welding torch and air-conditioning technology, applied in arc welding equipment, electrode characteristics, welding equipment, etc., can solve the problems of small heat affected area, easy oxidation and nitridation of metals, and concentrated arc temperature, so as to avoid oxidation or nitridation. phenomenon, the effect of small welding deformation and stable airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

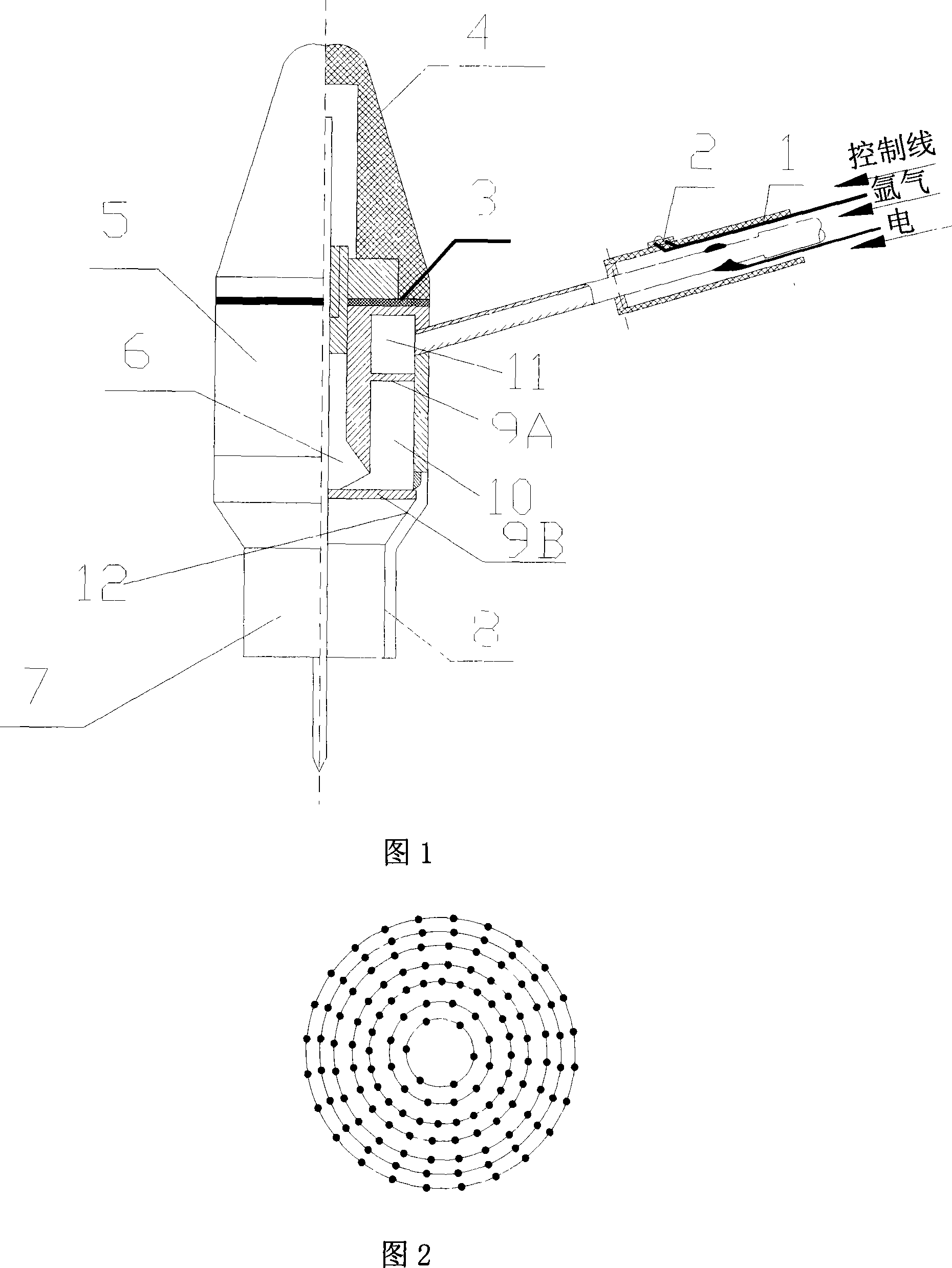

[0013] Fig. 1 has described the gun body that has nozzle and the handle that connects gun body, tungsten electrode nut and electrode chuck form a best embodiment of cold gas type argon arc welding torch. It consists of handle 1, button 2, sealing gasket 3, electrode nut 4, gun body 5, electrode chuck 6, tungsten electrode 7, nozzle 8 and gas lens 9, as well as control lines, argon arc pipes, cables, etc. composition. The handle 1 that button 2 is housed is electrically connected with the control line in the form of the prior art, and its pipeline is the passage that enters argon. An electrode nut 4 and a nozzle 8 are fixedly connected to the upper and lower ends of the gun body 5 integrally connected by brazing with a copper tube. The electrode nut 4 is sealed and connected to the gun body 5 through the gasket 3 . A tapered reflective wall 12 is formed on the upper end of the nozzle 8 made of ceramics or high-temperature-resistant non-metallic insulating material. In the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com