Flame-retardant separator and battery box

A battery box and separator technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve problems such as the threat of thermal runaway and explosion of battery cells, and achieve thermal runaway and battery explosion prevention, isolation prevention, and high space utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

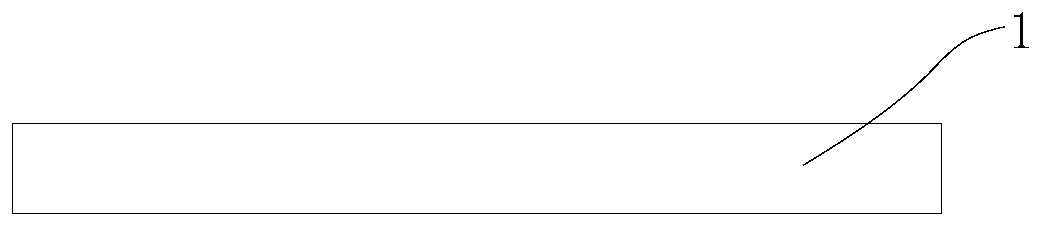

[0028] Such as figure 1 As shown, in this embodiment, the separator body 1 is made of flame-retardant materials and heat-absorbing materials. The part of the separator body 1 in contact with the surface of the battery cell 3 is a planar structure. The installation part that is installed with the battery box. The installation part in this embodiment is an integral structure with the partition body 1, which is a rectangular planar structure. The installation groove provided on the inner bottom surface of the corresponding battery box is a concave groove, but the partition board The thickness of the installation part of the main body is slightly larger than the width of the concave groove. The partition body 1 is inserted into the concave groove by external force, and the connection is made by the damping between the two. If it needs to be replaced, it can be pulled out by external force and replaced.

[0029] The flame-retardant partition in this embodiment is a single-layer str...

Embodiment 2

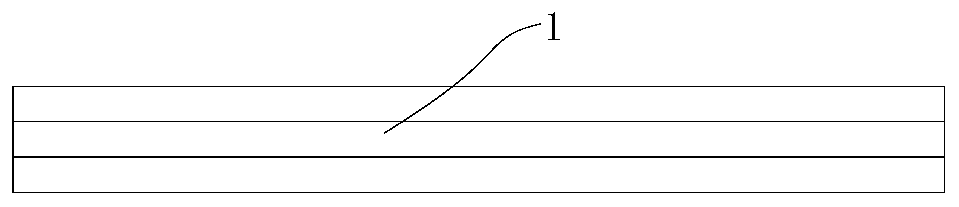

[0038] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is: the flame-retardant partition in this embodiment is a multi-layer structure;

[0039] In this embodiment, the partition body 1 adopts a three-layer composite structure, and its shape is rectangular. Among them, in order to achieve the effect of rapid flame retardancy, preferably, the flame retardant can be an organic or inorganic highly flame-retardant material. Organic flame retardants are represented by bromine, nitrogen, red phosphorus and compounds, and inorganic flame retardants are represented by antimony trioxide, magnesium hydroxide, aluminum hydroxide, and silicon.

[0040] In this embodiment, the same flame retardant material can be used for the three layers of the partition body 1, or different flame retardant materials can be used, and the selection criteria of the heat absorbing material are the same as in the first embodiment.

[0041] Therefore, in this embodiment, n...

Embodiment 3

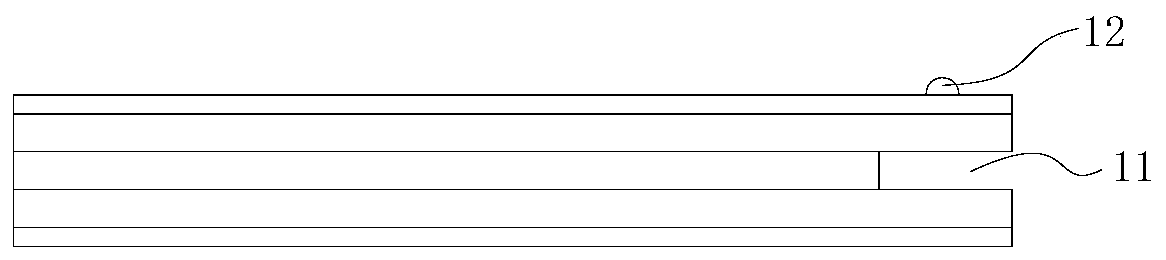

[0043] Such as image 3 , 4 As shown, the difference between this embodiment and Embodiment 1 is that: the flame-retardant partition in this embodiment is a multi-layer structure; and the installation part is different;

[0044] In this embodiment, the flame-retardant partition 1 adopts a five-layer composite structure, the shape is rectangular, and the thickness of each layer is 1 mm. The flame-retardant materials used in the middle three layers are zinc borate, aluminum hydroxide, and magnesium hydroxide. There is also a layer of flame retardant made of organic or inorganic high flame retardant material on both sides of the middle layer. The thickness of the flame retardant is 0.5mm. The flame retardant can be organic or inorganic high flame retardant material. Organic flame retardant Agents are represented by bromine, nitrogen, red phosphorus and compounds, and inorganic flame retardants are represented by antimony trioxide, magnesium hydroxide, aluminum hydroxide, and sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com