Closestool capable of conducting air exhaust deodorization and vacuum-assisted flushing

A vacuum-assisted, flushing toilet technology, which is applied to water supply devices, flushing equipment with water tanks, sanitary equipment for toilets, etc., can solve the problems of water storage reduction, water tank volume compression, and limited vacuum effect, and achieve air pressure reduction. The effect of small size, noise reduction and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

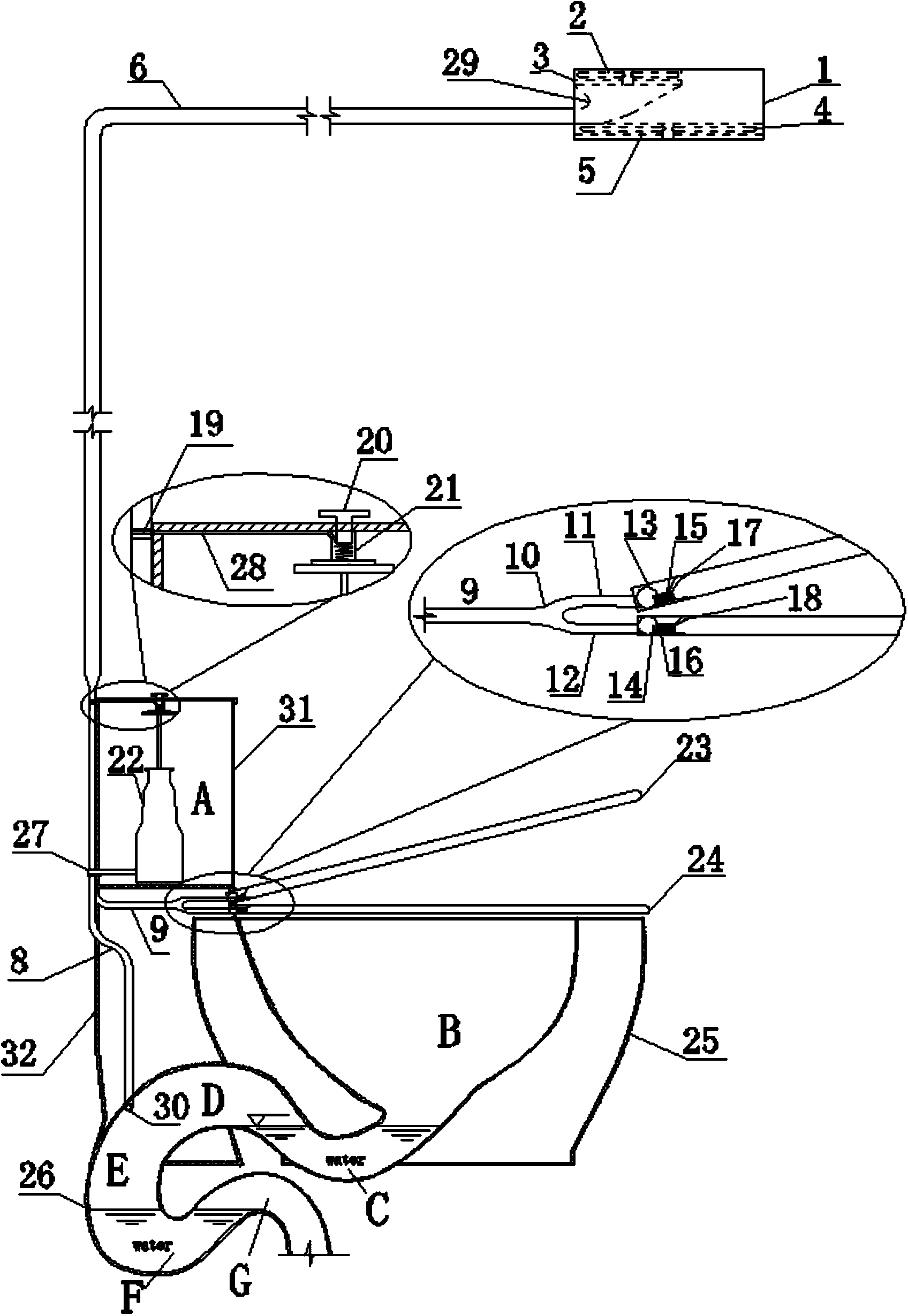

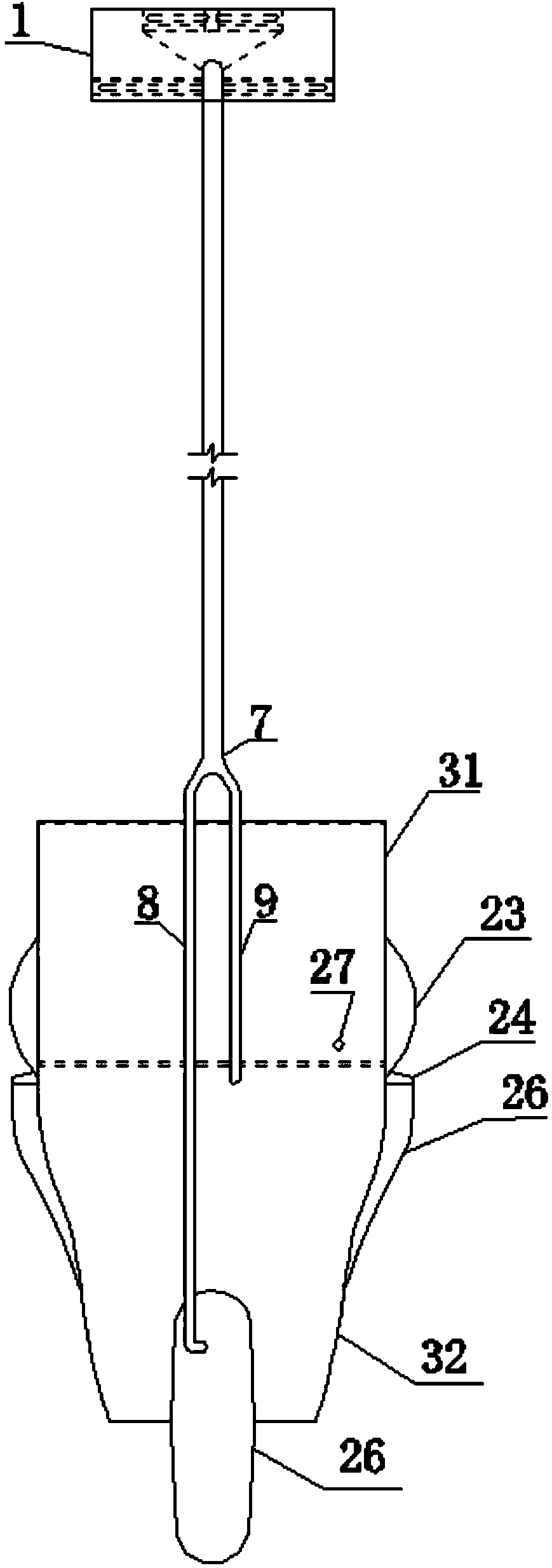

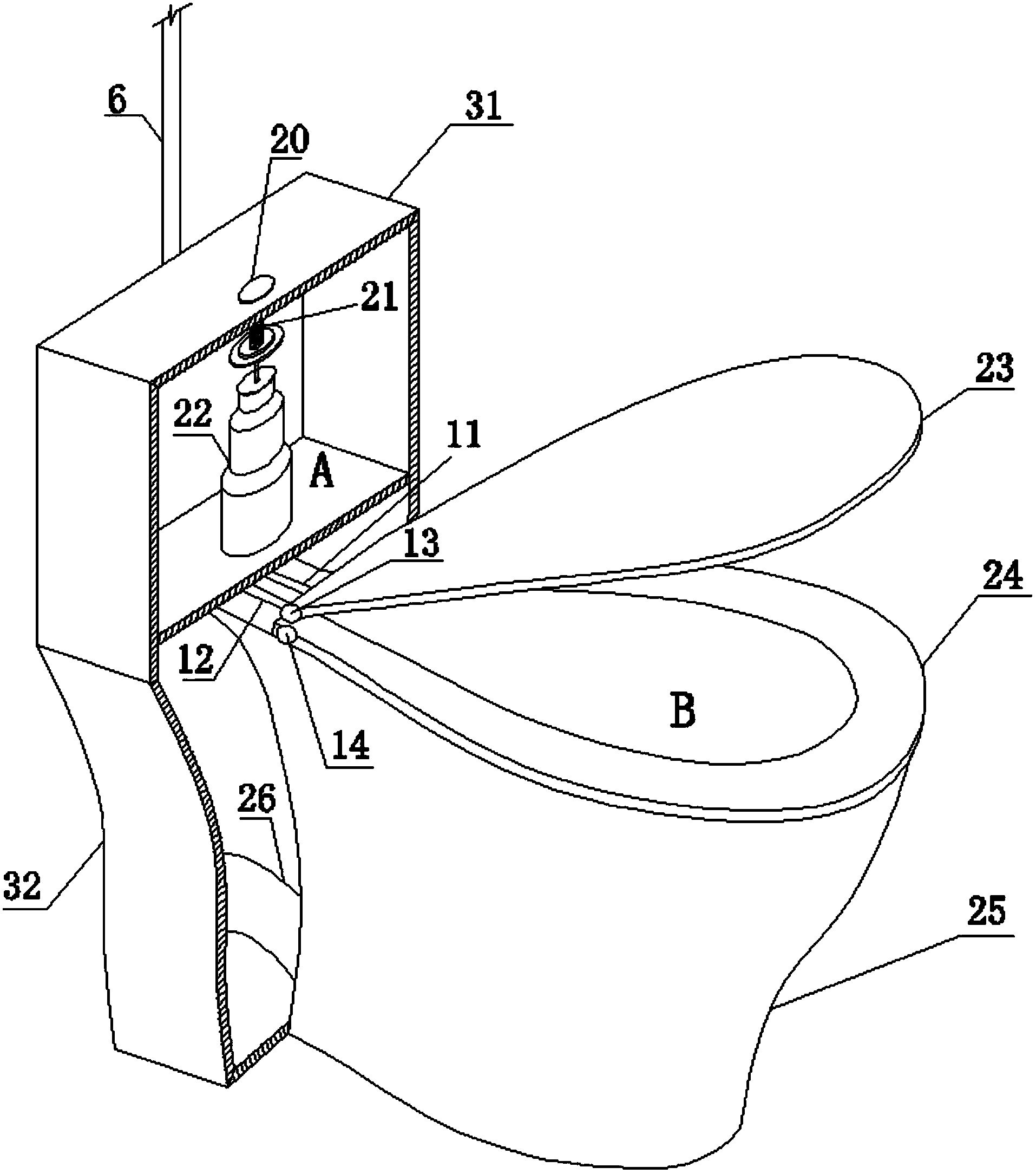

[0030] Attached below Figure 1 to Figure 7 The embodiments of the present invention are described in detail.

[0031] The structure diagram of the toilet of the present invention is as follows Figure 1 to Figure 7 As shown, the overall structure of the toilet is mainly composed of an exhaust air suction system, a drainage system, a toilet and a control system, and the exhaust air suction system is used in the toilet's exhaust air deodorization and vacuum-assisted water pumping procedures.

[0032] The specific implementation steps are as follows:

[0033] When the toilet is not in use, pass the toilet exhaust fan switch k 2 The lower fan 4 controlling the double-layer exhaust fan 1 exhausts and ventilates the toilet.

[0034] When the toilet is in use, the upper shaft 13 can be rotated by opening and closing the toilet cover 23 to control the operation of the exhaust air suction system.

[0035] Step 1: When using the toilet, open the toilet cover 23, and the upper shaft 13 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com