Patents

Literature

139 results about "Flushing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of flushing time In its simplest form, the flushing time is defined as the time needed to drain a volume V through an outlet A with current velocity v ( Figure 15.1 ).

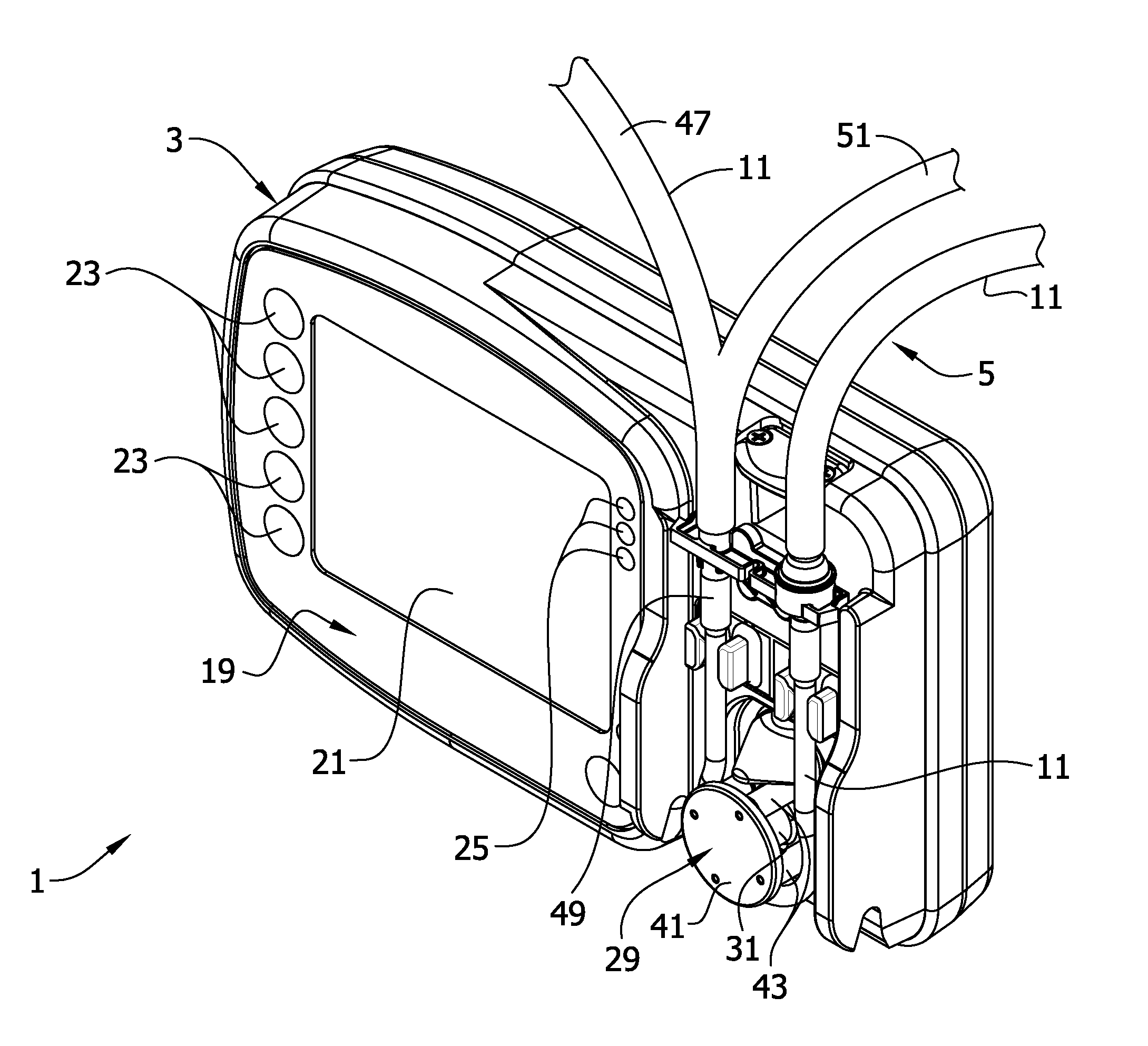

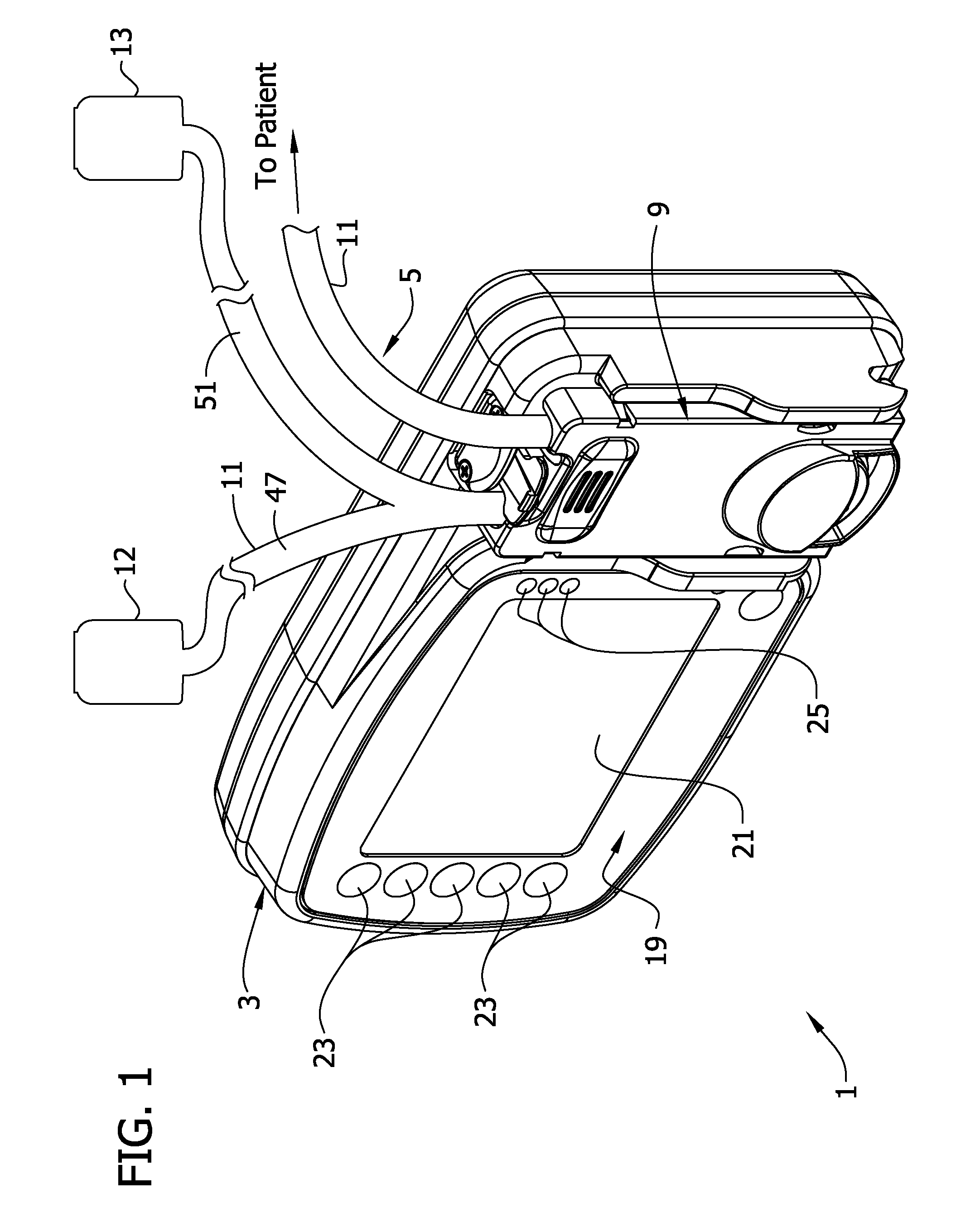

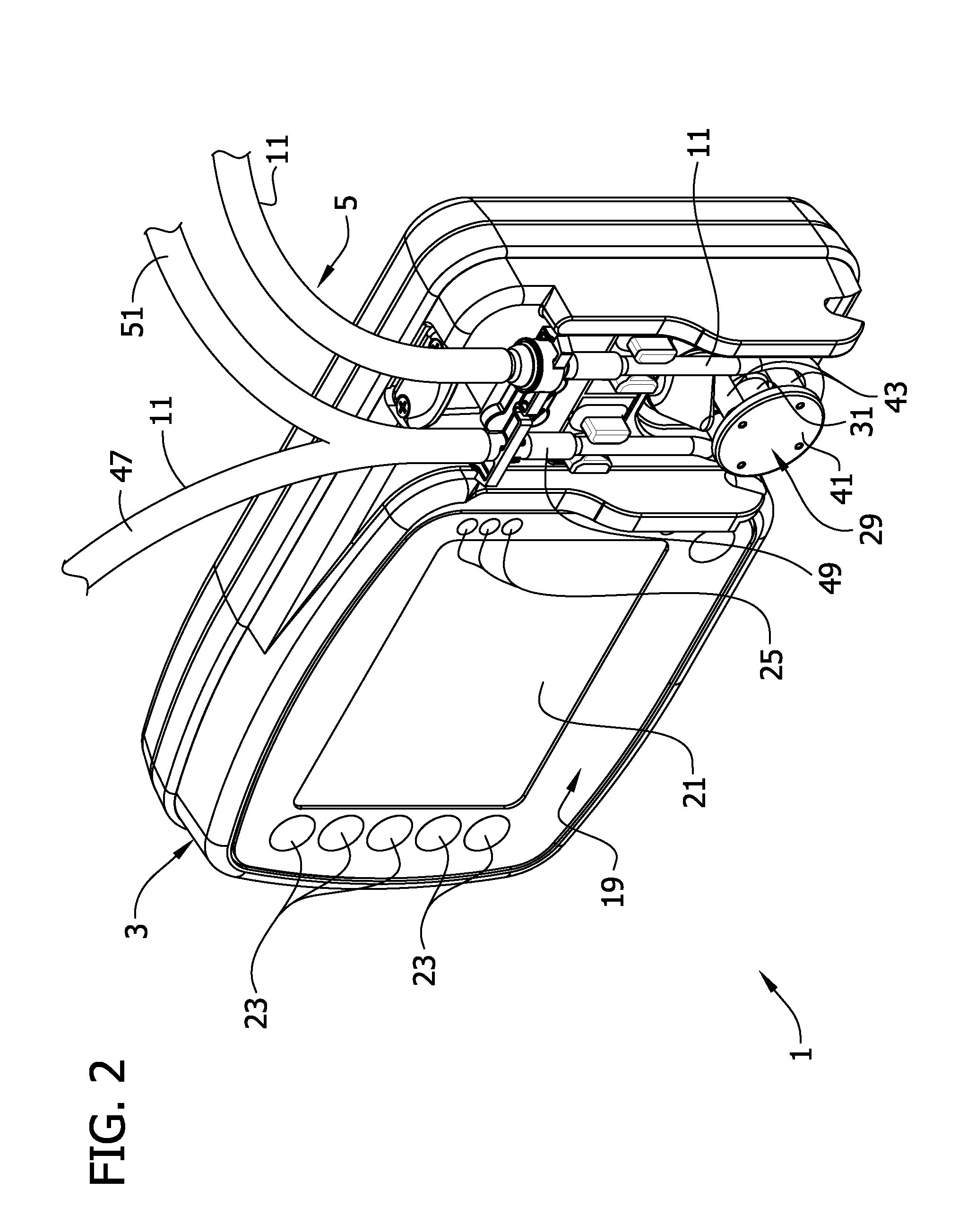

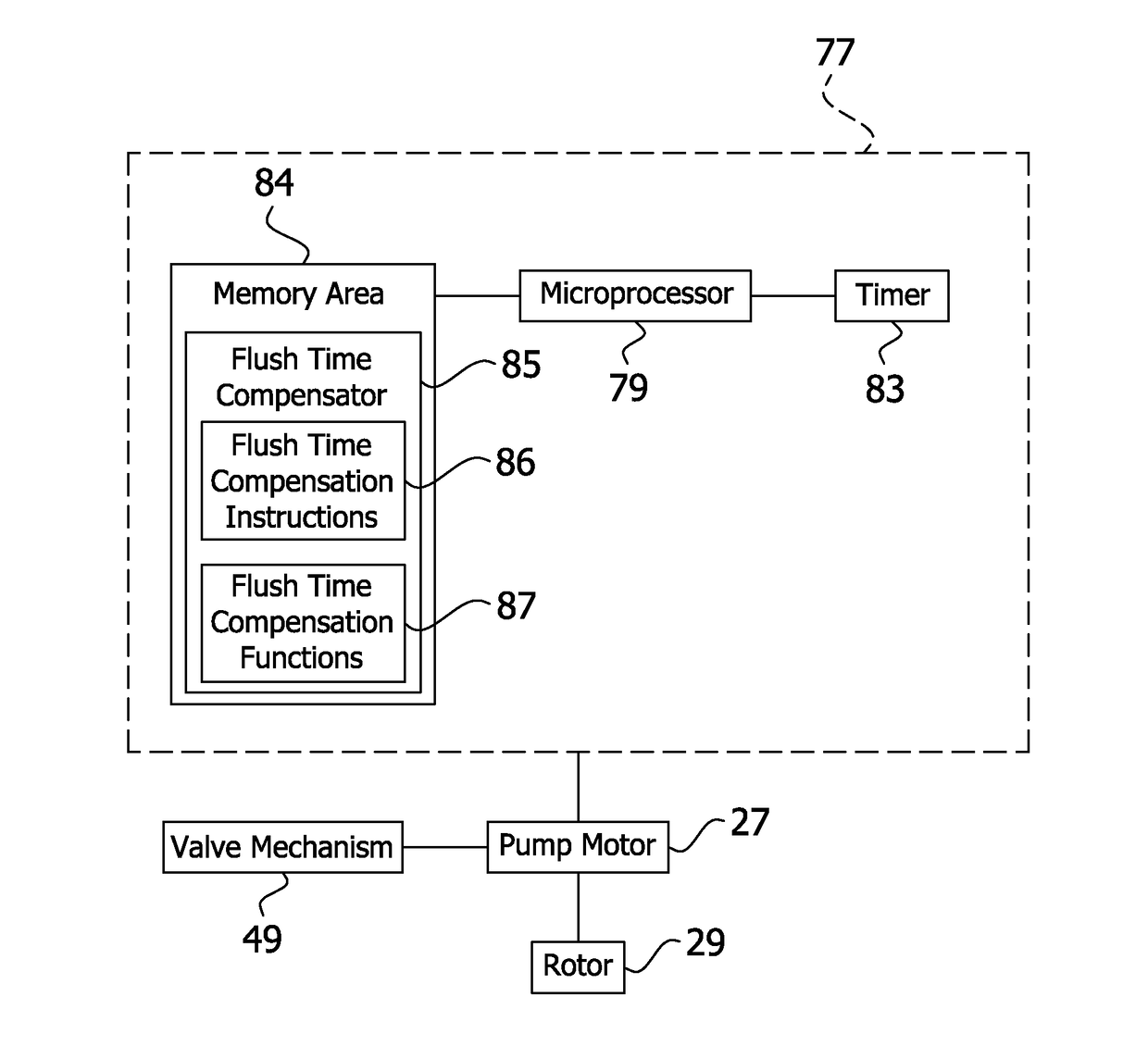

Feeding Rate Compensated Pump and Related Methods Therefor

A pumping apparatus for use with a pump set to deliver fluid through the pump set to a subject includes a pumping device capable of acting on the pump set to produce a fluid flow within the pump set. A controller is in communication with the pumping device for controlling operation of the pumping device in a feeding configuration and in a flushing configuration. The controller is adapted to store a selected flow rate and a desired fluid volume of a first fluid in the memory and at least one of a flush rate and flush volume of a second fluid. A flush time compensator is capable of being run for determining a compensated feeding configuration of the first fluid based on an amount of time the controller will operate the pump device in the flushing configuration and the desired fluid volume of the first fluid.

Owner:KPR U S LLC

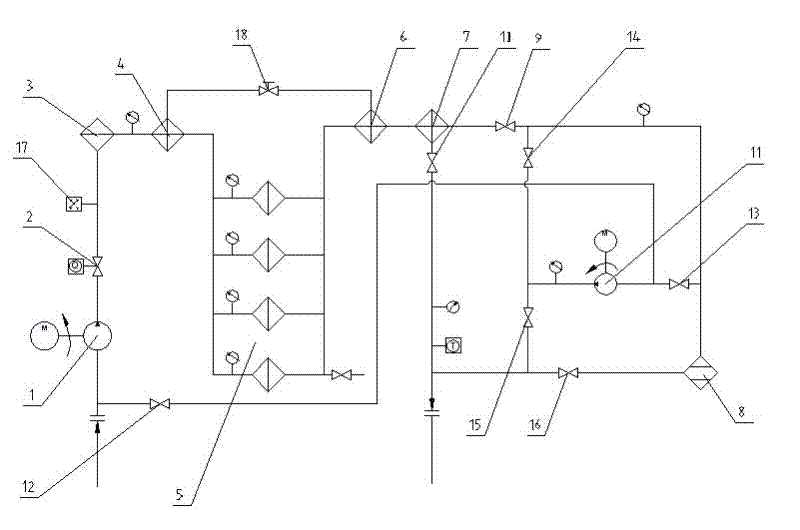

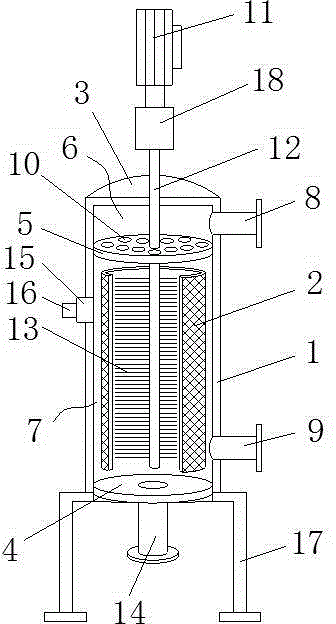

High-flow flushing device

InactiveCN102389886AReduce rinse timeGuaranteed flushing qualityHollow article cleaningFlushing timeTurbine

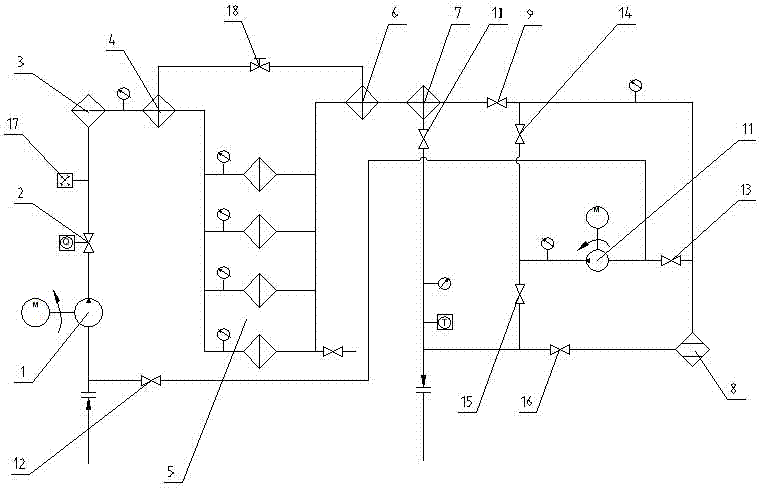

The invention relates to a high-flow flushing device which comprises a main oil pipeline and an auxiliary oil pipeline, wherein the main oil pipeline is provided with a main oil pump; the auxiliary oil pipeline is provided with an auxiliary oil pump; the main oil pipeline and the auxiliary oil pipeline are linked with each other; various filters, heaters and other protecting devices and valves are serially connected to the main oil pipeline; a plurality of pipelines with valves are linked with the auxiliary oil pipeline; and the valves are controlled to open and close, thereby achieving various flushing and filtering purposes. The high-flow flushing device has the beneficial effects that the high-flow flushing device can be used for shortening the flushing time for the steam turbine oil, ensuring the flushing quality of a steam turbine oil system, controlling and promoting the cleanness of turbine oil, and improving a working condition of a project for flushing and purifying the steam turbine oil.

Owner:ZHENJIANG KENENG ELECTRIC POWER EQUIP

Ground water back pouring cyclic utilization method

InactiveCN101298945ACreate pollutionIncrease pressureOther heat production devicesGeothermal energy generationFlushing timeGroundwater recharge

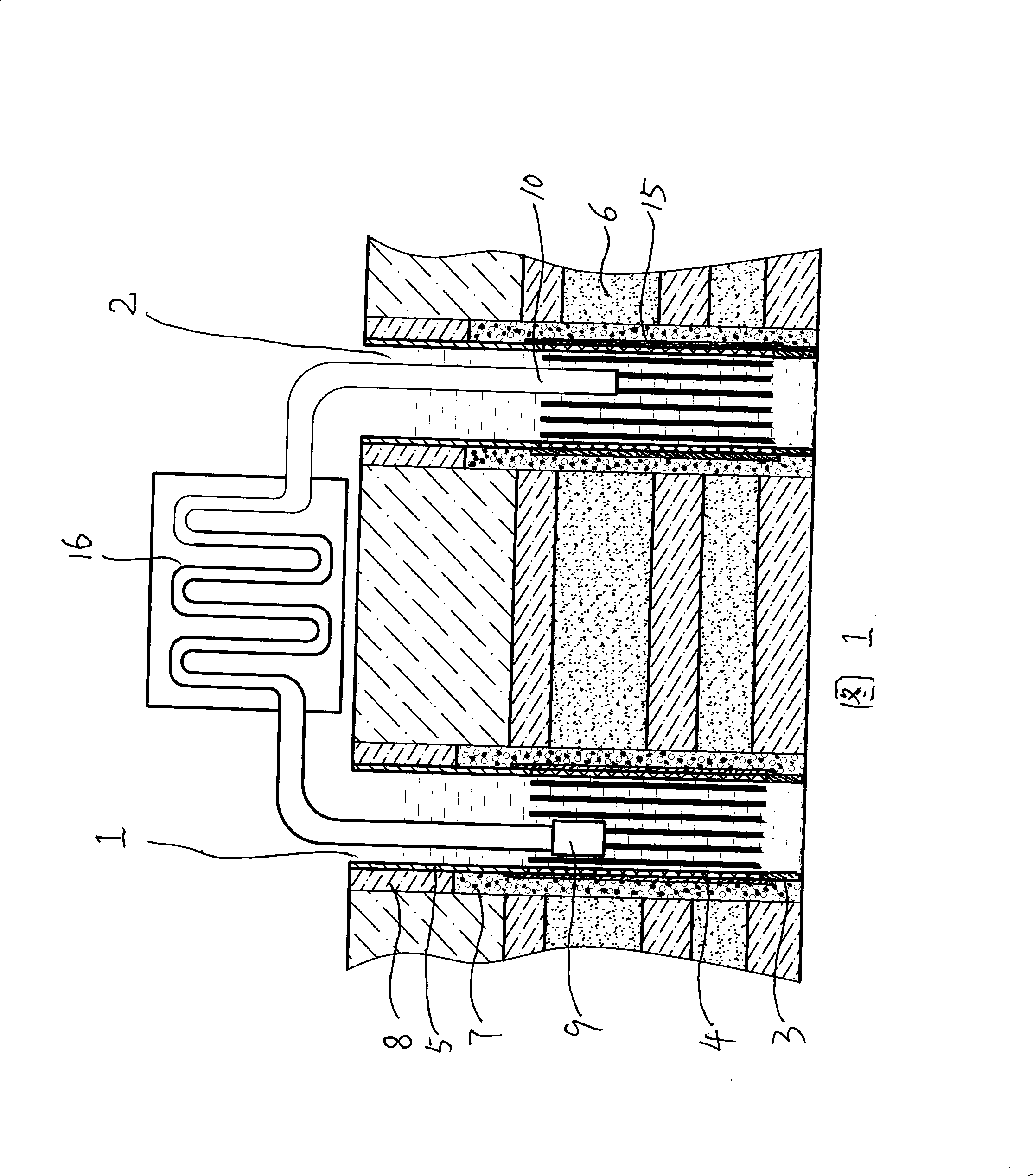

The invention belongs to the technical field of the groundwater recharge cyclic utilization method, particularly discloses a groundwater recharge cyclic utilization method, which is characterized by determining the depth of the pumping well and drilling a recharge well borehole having the same depth with the pumping well in the precipitation action radius of the pumping well, according to the local hydrogeology. The well pipe is fixed in the borehole according to the sequence of a sedimentation pipe, a strainer and a case pipe, then filter material, the killing well and the flushing are filled in turn, finally a pumping device and a recharging device are arranged, which forms a circular loop in the water pumping and recharging process. In the flow process of the groundwater, the temperature rises or lowers; and flushing is performed again after killing well, the flushing time is short and complete, and the groundwater does contact with the outside, which does not pollute the groundwater after recharging. The invention not only is suitable for the puaternary system stratal configuration, also suitable for the tertiary stratal configuration of the pottery and the Minghua town.

Owner:刘娇娜

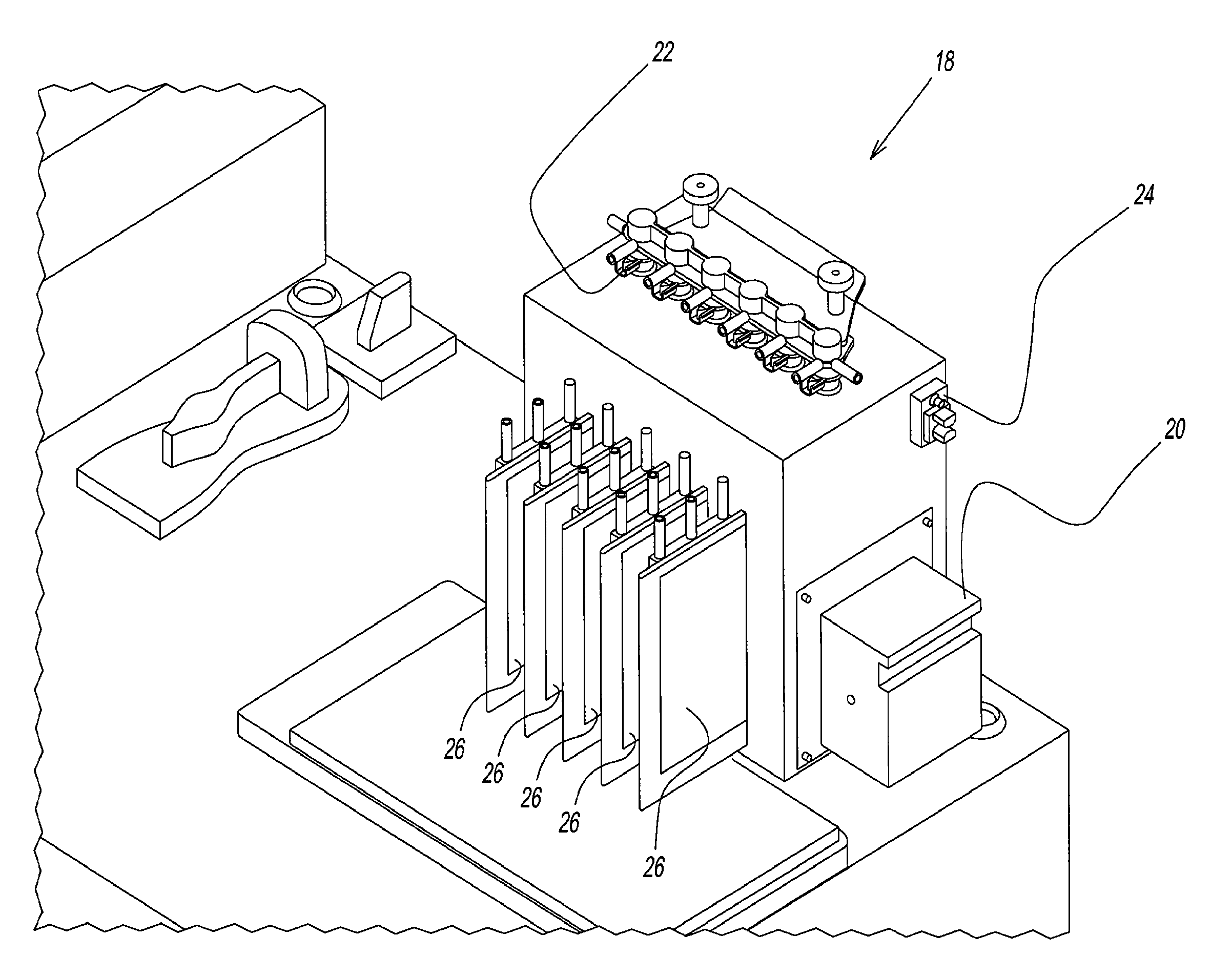

Automated aseptic liquid collection workstations and collection devices therefore

An automated liquid collection workstation is provided. The workstation includes a processor, a peristaltic pump, a valve actuator, and an algorithm. The peristaltic pump and the valve actuator are in electrical communication with the processor. The valve actuator can move a plurality of valves, when disposed therein, among an off position, a flush position, and a collection position. The algorithm is resident on the processor and is configured to: move all of the valves to the off position and place the pump in an off state when no sampling or flushing is required, move all of the valves to the flush position and place the pump in an on state for a predetermined flush time period when flushing is required, and move a respective one of the valves to the collection position, move any of the valves upstream of the respective valve to the flush position, and place the pump to the on state for a predetermined collection time period when collection is required.

Owner:ALFA WASSERMANN INC

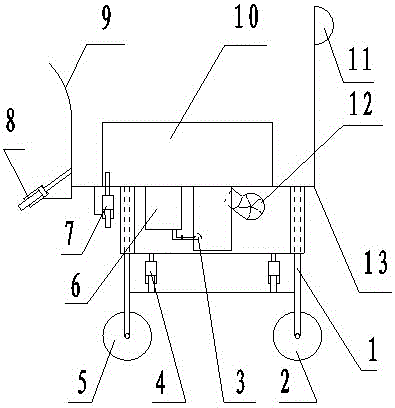

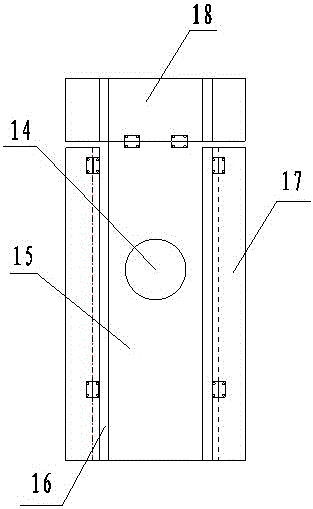

Autonomous navigation remote control toilet robot

ActiveCN105729481AReduce labor costsImprove work efficiencyWheelchairs/patient conveyanceManipulatorVehicle frameSprayer

The invention provides an autonomous navigation remote control toilet robot. The autonomous navigation remote control toilet robot comprises a trolley, a battery, a drive motor, a corner motor and a platform. The trolley is provided with travelling wheels and steering wheels. A lifting oil cylinder, a telescopic oil cylinder and a tilting oil cylinder are arranged on a frame of the trolley. A guide groove is formed in one end face of the platform, and an electric heating water tank and an air heater are arranged on the other end face of the platform. The trolley enters a toilet and reaches the location of a sewer through a tracking camera or GPS positioning mode; a sealing lid is opened; a lifting guide pipe rises to be in sealed connection with a magnetic guide pipe on the trolley in an attracted mode; after a user goes to the toilet, a magnetic valve on the electric heating water tank is opened through induction of an infrared induction device; hot water flushes the ass via a sprayer, and the flushing time is set through a remote controller; the air heater is started after the ass is flushed, and hot air dries the flushed ass by a hot air pipe; the lifting guide pipe is separated from the magnetic guide pipe, descends and returns to the initial location; and the sealing lid is closed, so that the user finishes using the toilet.

Owner:SHANDONG UNIV OF TECH

Cleaning method of low-temperature multiple-effect seawater desalination evaporator

ActiveCN101614502APromote recoveryReduce drug consumptionMetallic material coating processesFlush cleaningFlushing timeCleaning methods

The invention relates to a cleaning method of a low-temperature multiple-effect seawater desalination evaporator, which belongs to the technical field of thermal seawater desalination. The method comprises the steps as follows: washing by water with the temperature being 20 to 30 DEG C and the flushing time being 30 to 60 minutes; carrying out precleaning by pre-cleaning liquid with the pre-cleaning time being 30 to 120 minutes; carrying out acid cleaning by pickling fluid containing pickling inhibitor with the acid cleaning time being 2 to 12 hours; adjusting pH value to 6.5 to 7.5 by alkali liquor; washing by water; carrying out passivation by passivating liquid with the passivation time being 2 to 12 hours. The method has the advantages that the performance of a low-temperature multiple-effect seawater desalination evaporator can be better recovered after the cleaning, and the method is economic, practical, simple and effective. The method is particularly applicable to the cleaning to low-temperature multiple-effect seawater desalination evaporators, and also applicable to the cleaning to heat exchangers and evaporators for seawater medium.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

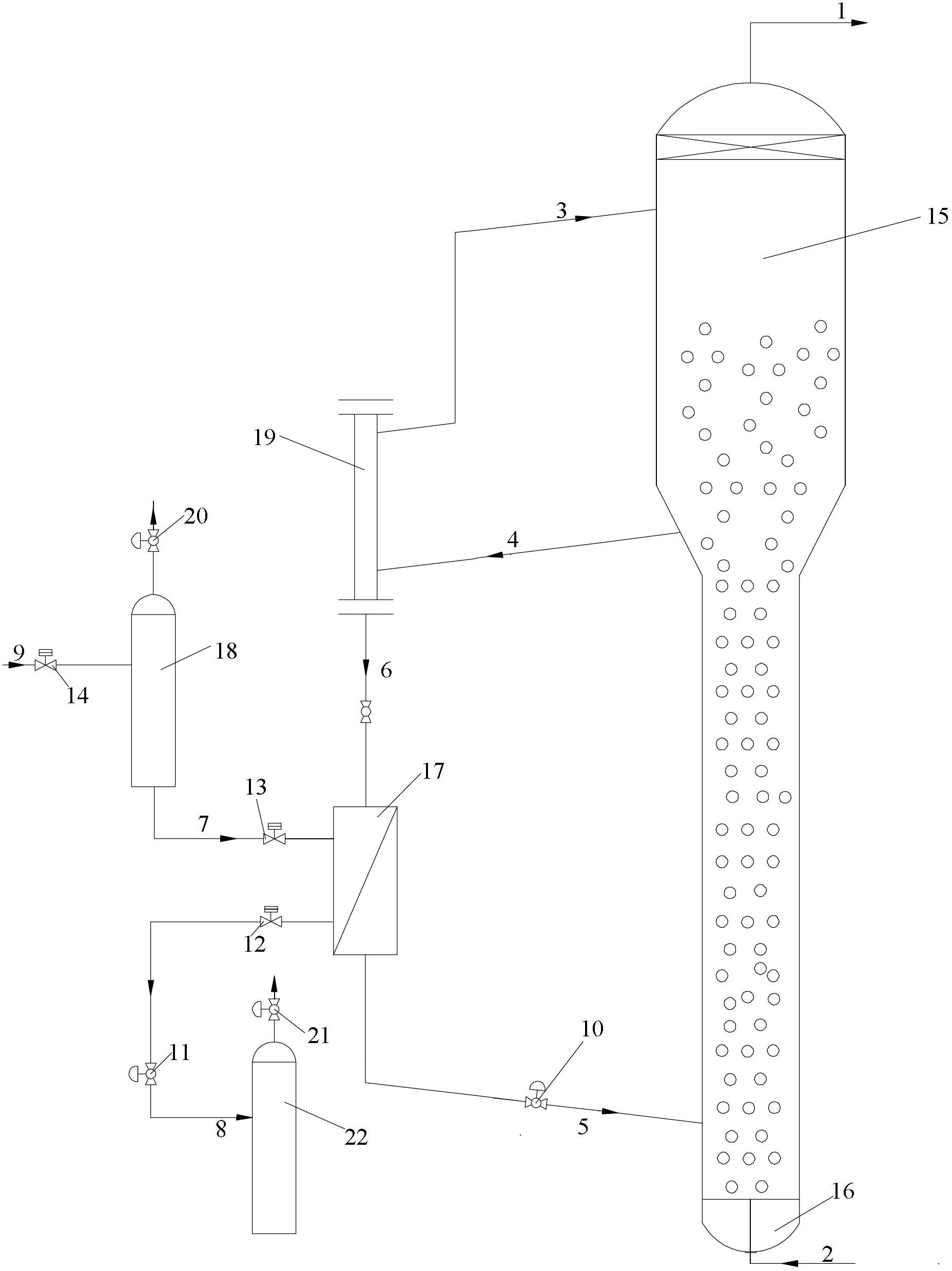

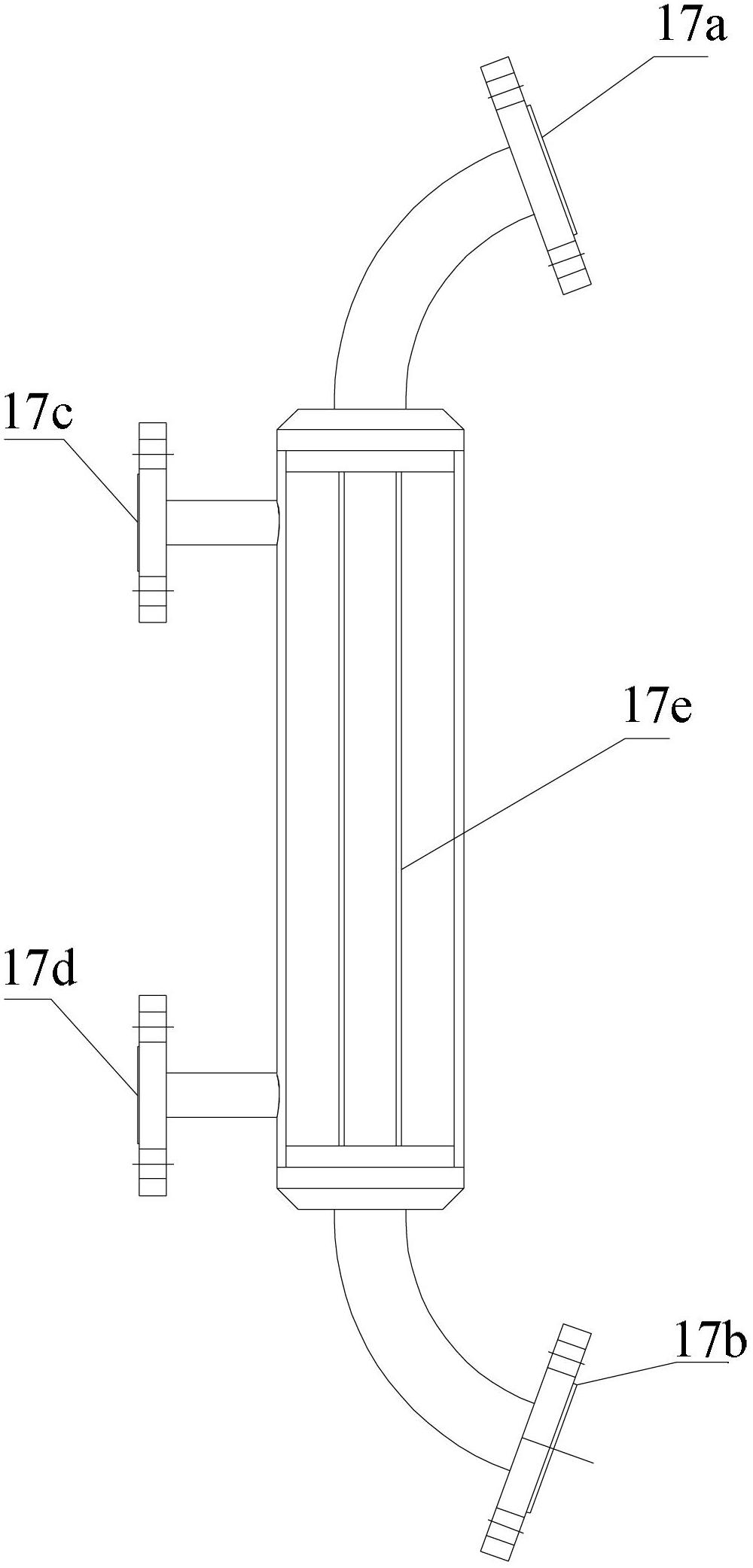

Fischer-Tropsch wax and catalyst filtering and back-flushing method for Fischer-Tropsch synthetic slurry bed reactor

ActiveCN102688724AGuarantee continuous and stable operationAchieve regenerationHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionWaxFlushing time

The invention provides a Fischer-Tropsch wax and catalyst filtering and back-flushing method for a Fischer-Tropsch synthetic slurry bed reactor. The method comprises the following steps of: 1, in production mode, opening a clear solution extracting system, and extracting Fischer-Tropsch wax to a crude wax product buffer tank with set pressure; 2, in the production mode, when the back-flushing time interval value reaches a set value, opening a back-flushing system to back-flushing a filter element; and 3, when the back-flushing time reaches a set value, closing the back-flushing system, and newly extracting the Fischer-Tropsch wax to the crude wax product buffer tank with the set pressure. By automatically controlling a filter system and the back-flushing system and automatically back-flushing the filter element according to the time period or the back-flushing operation pressure difference, the Fischer-Tropsch wax can be stably and effectively extracted from the reactor for a long period, and stable and continuous operation of the Fischer-Tropsch synthetic slurry bed reactor is realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

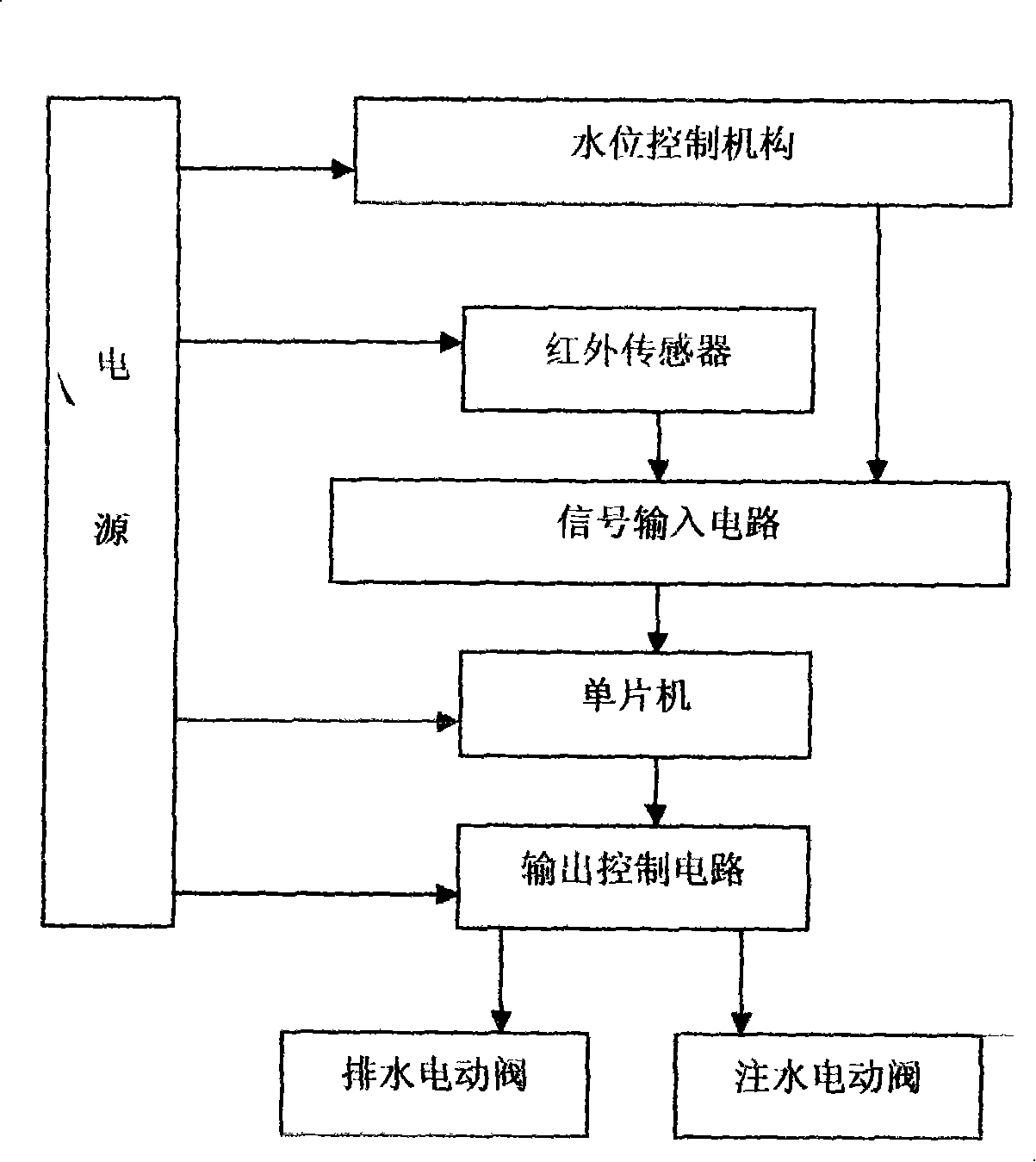

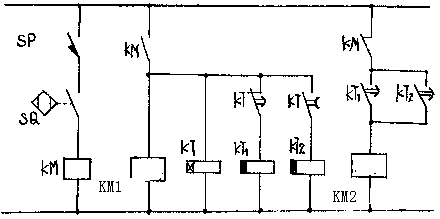

Intelligent water saving toilet and intelligent flushing control method

InactiveCN101289874AGuaranteed water savingPrevent water leakageFlushing devicesWater leakageAutomatic control

The invention discloses an intelligent water-saving closestool and an intelligent toilet-flushing control method to overcome the problems that the prior closestool has water leakage and great randomness of manual operation and can not automatically control flushing time and flushing quantity. The intelligent water-saving closestool comprises a water tank as well as a water inlet pipe, a drain valve and a drain opening arranged inside the water tank, wherein the water inlet pipe is connected with a water injection pipe and a pressure pipe through a teejunction; a hydraulic cylinder which is used to open and close the drain valve is arranged between the pressure pipe and the drain valve; the water injection pipe and the pressure pipe are respectively provided with a water injection electric valve and a drain electric valve, and are in electrical connection with an infrared sensor through a signal input / output circuit and an output control circuit. The intelligent water-saving closestool and the intelligent toilet-flushing control method not only can completely solve the water leakage phenomenon of a closestool, but also can realize automatic toilet flushing according to required water quantity; moreover, the closestool and the method can keep the water tank in a seeper-free state when the closestool is not used.

Owner:赵丕君

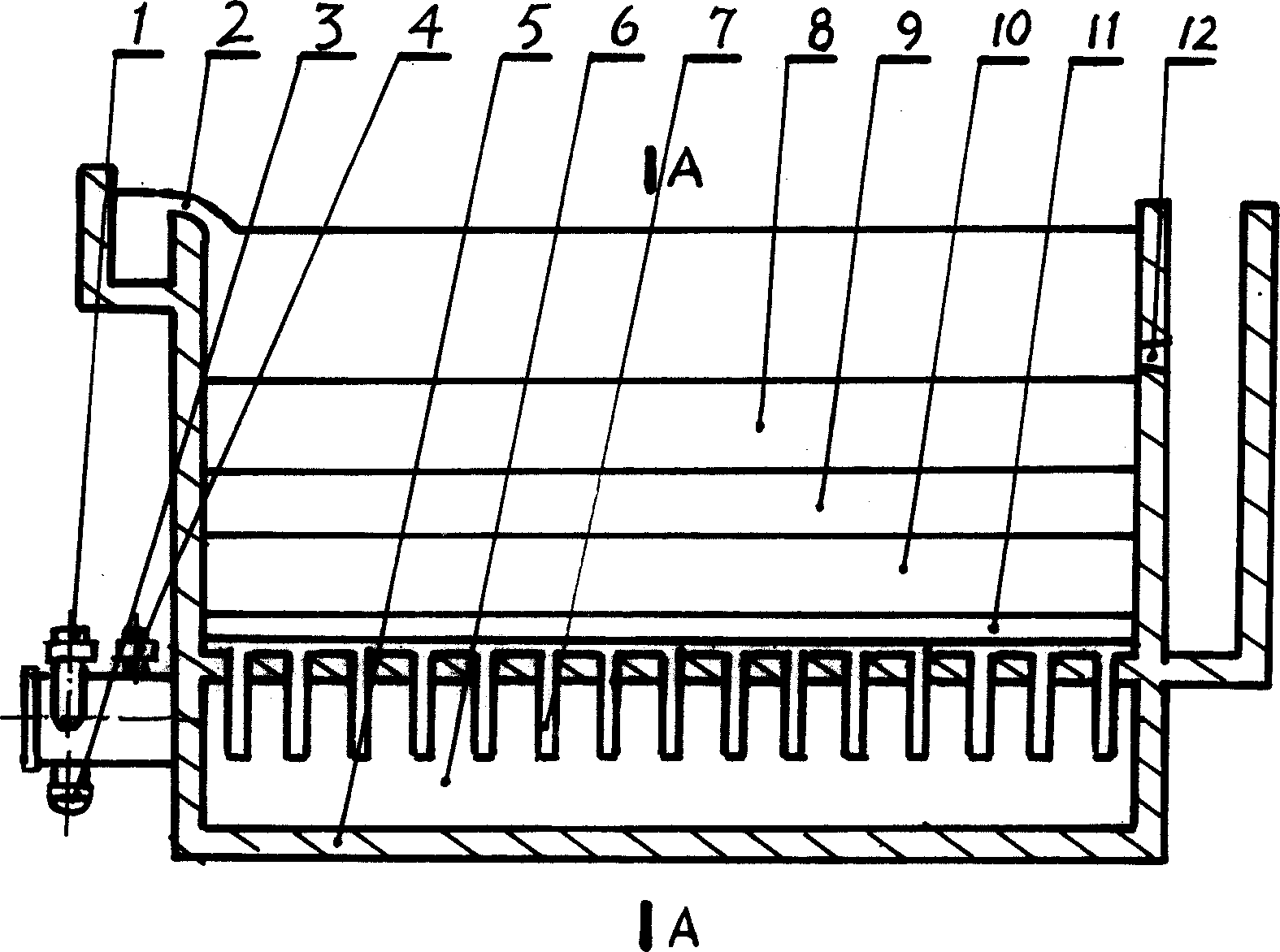

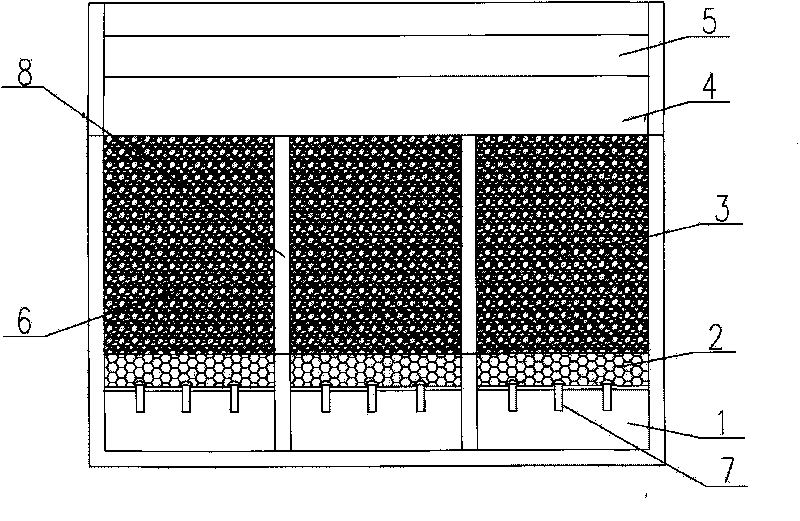

Tilting plate type filtering pool

ActiveCN1683052AReduce backwash water consumptionShort timeLoose filtering material filtersGravity filtersFlushing timeWater quality

The present invention relates to a filter characterizing mutually arranged filter elements, and is especially tilting plate type filtering pool for use in water works. The tilting plate type filtering pool consists of filtering pool, reverse flush system, filtering system, sewage draining system and water influent and effluent system. The reverse flush system includes reverse flush valve, flushing air valve, water and air distributing transverse pipes, water distributing longitudinal pipes and air distributing longitudinal pipes; the filtering system includes anthracite layer, quartzite layer, coarse sand layer and pebble layer; the water influent and effluent system includes overflow weir plate, water effluent valve and water canal; and the sewage draining system includes tilting plate valve and canal. The present invention has less reverse flush water amount, short reverse flush time, high water effluent quality, low cost and other advantages.

Owner:杜加富

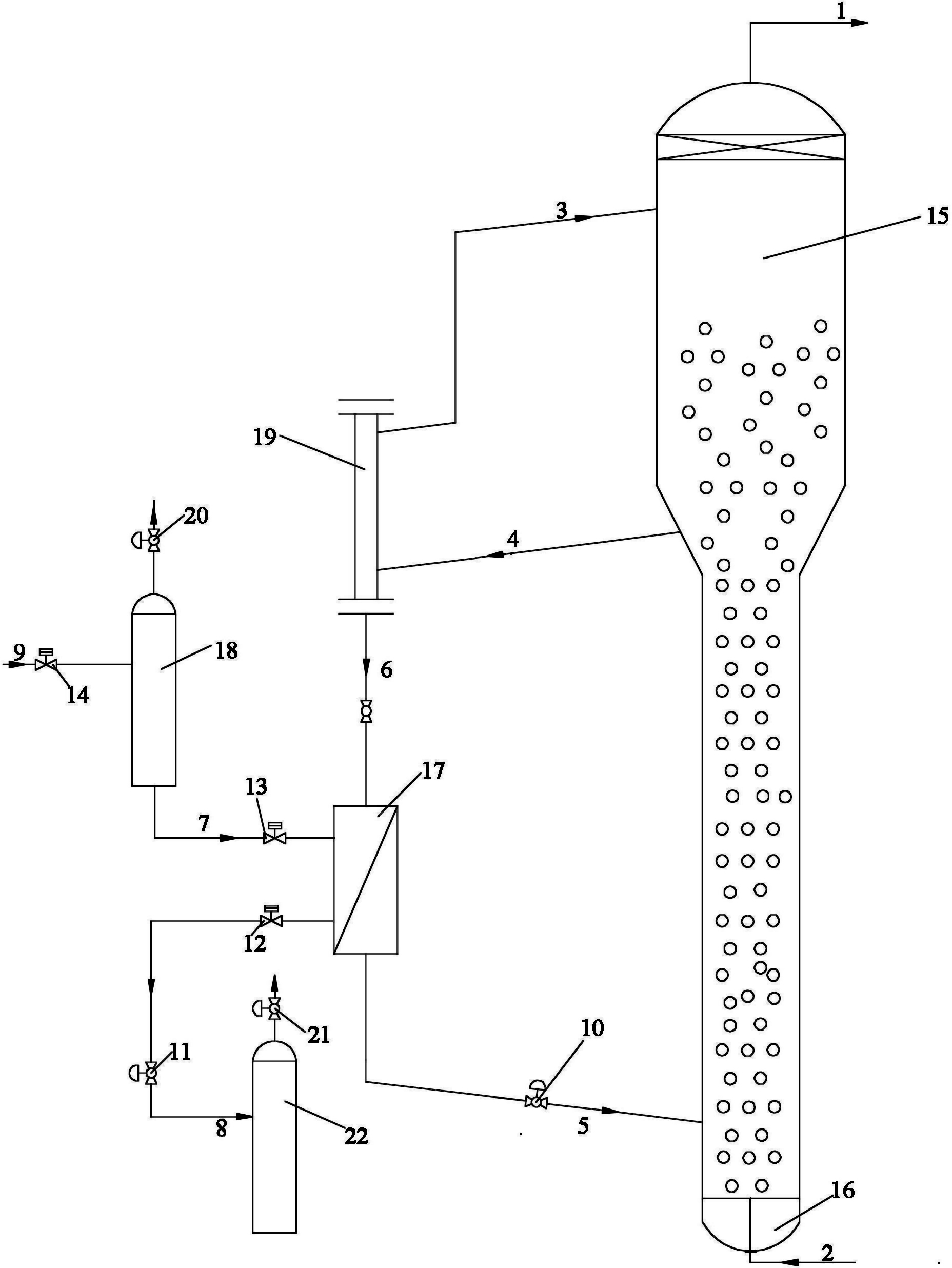

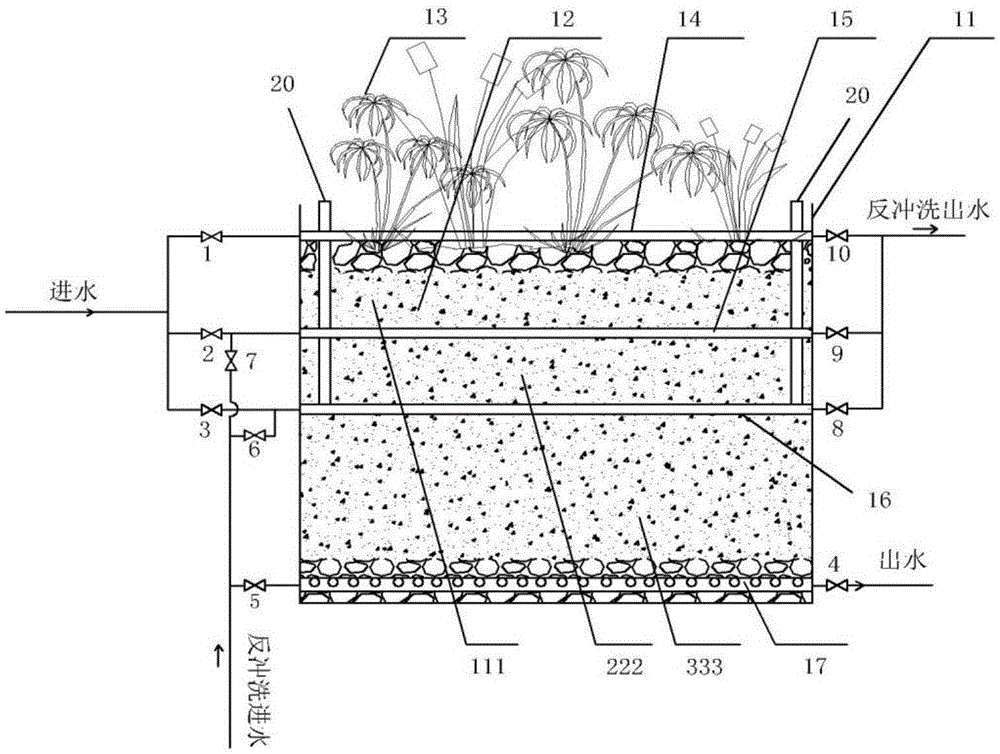

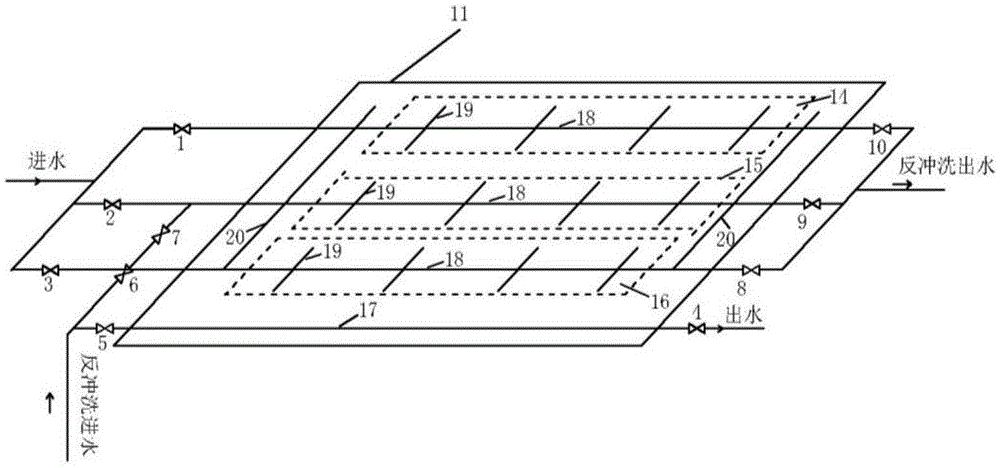

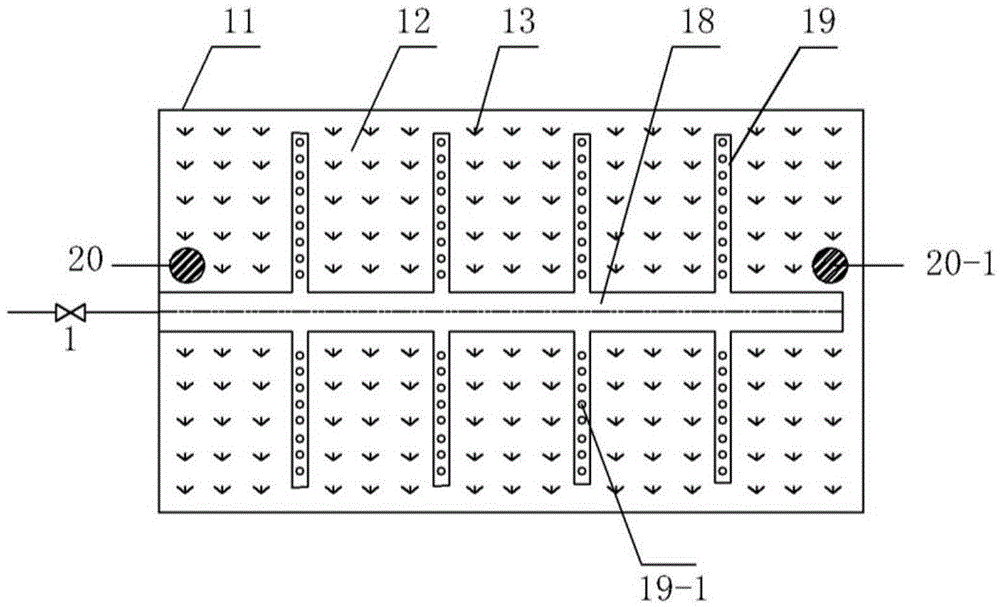

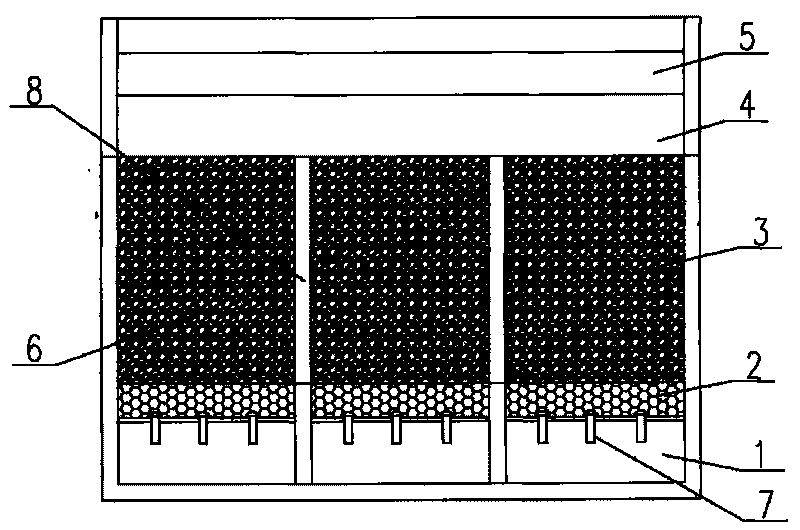

Anti-blocking water distribution and back-flushing method and device for constructed wetland

ActiveCN105600938AAlleviate concentrated blockageExtended service lifeSpecific water treatment objectivesSustainable biological treatmentFlushing timeConstructed wetland

The invention discloses an anti-blocking water distribution and back-flushing method and device for a constructed wetland. Water distribution pipes are arranged in layers on the surface layer of the constructed wetland and inside filler and connected with an incoming water source through valves respectively; the water distribution pipe in the filler is connected with an air pipe through an intermediate pipe; and the top of the air pipe is communicated with the atmosphere. When the device runs in the wetland, constant water distribution is realized layer by layer from top to bottom by controlling the on / off of the valves, and the yielding water is collected and discharged by a water-out pipe at the bottom of the wetland; and in back flushing, the water-out and distribution pipes are used as back-flushing layered water feed and collection pipes. The parameters such as back-flushing strength and back-flushing time are set according to the actual blocking degree of each layer of the wetland, and the back-flushing water is discharged nearby; the phenomenon that the filler close to the water distribution positions is easily blocked together in the constructed wetland can be effectively solved, the filler of each layer is fully utilized, and the service life is prolonged; due to the back-flushing way, the back-flushing efficiency is improved, the distribution of back-flushing water is optimized, and the operation is simple; and since an additional back-flushing pipe is not needed, the cost is lowered.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Cleaning method of low-temperature multiple-effect seawater desalination evaporator

ActiveCN101614502BPromote recoveryReduce drug consumptionMetallic material coating processesFlush cleaningFlushing timeCleaning methods

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

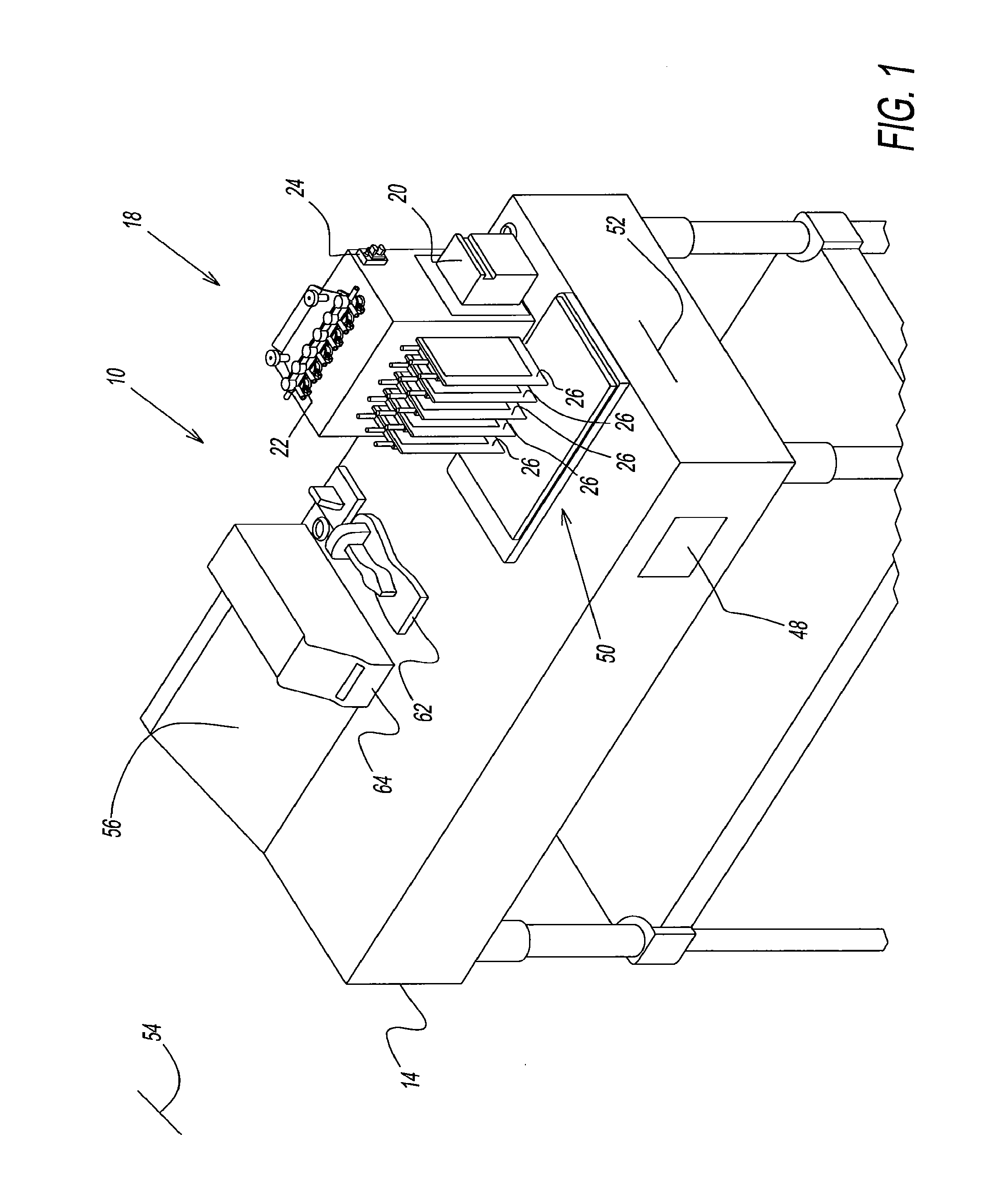

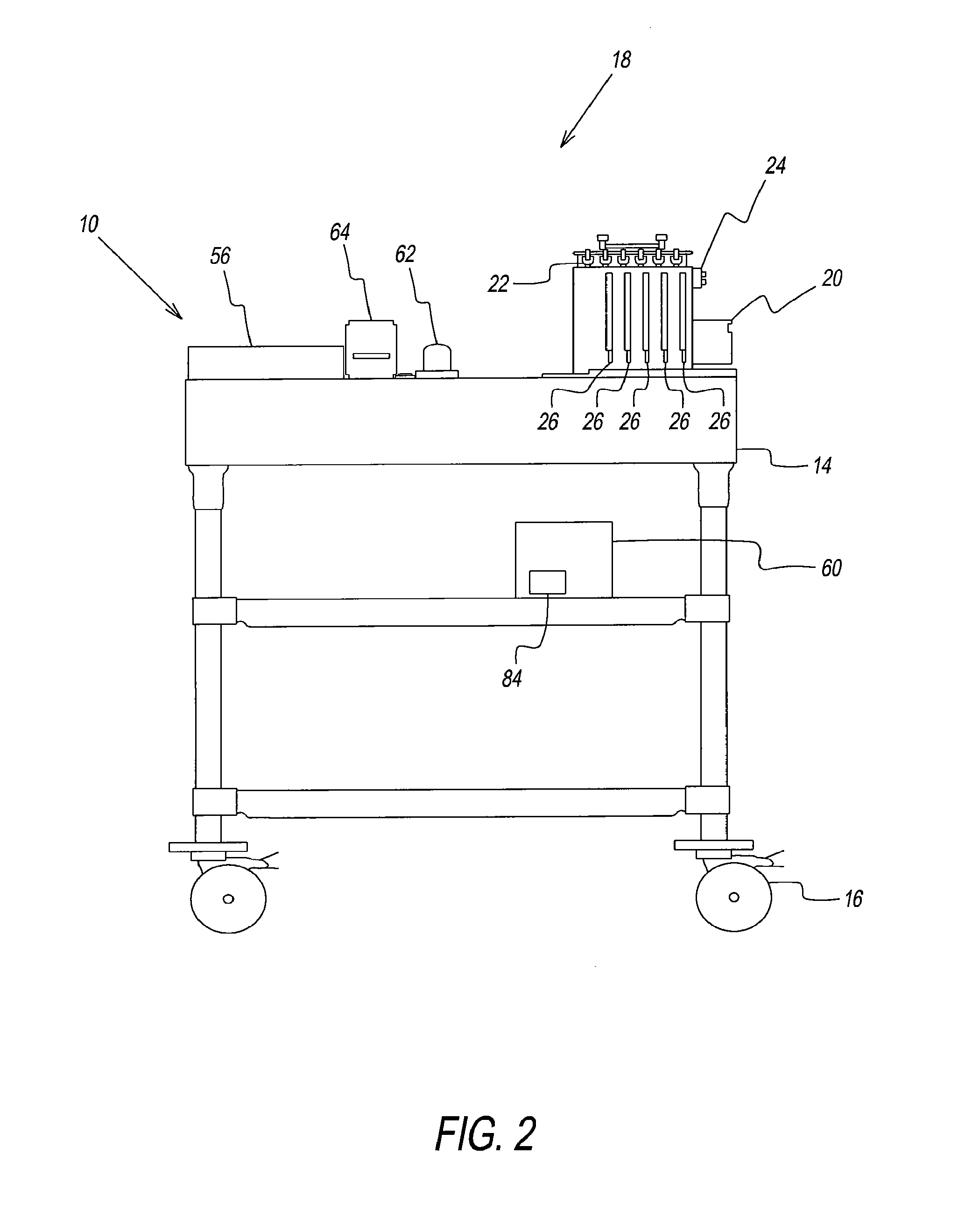

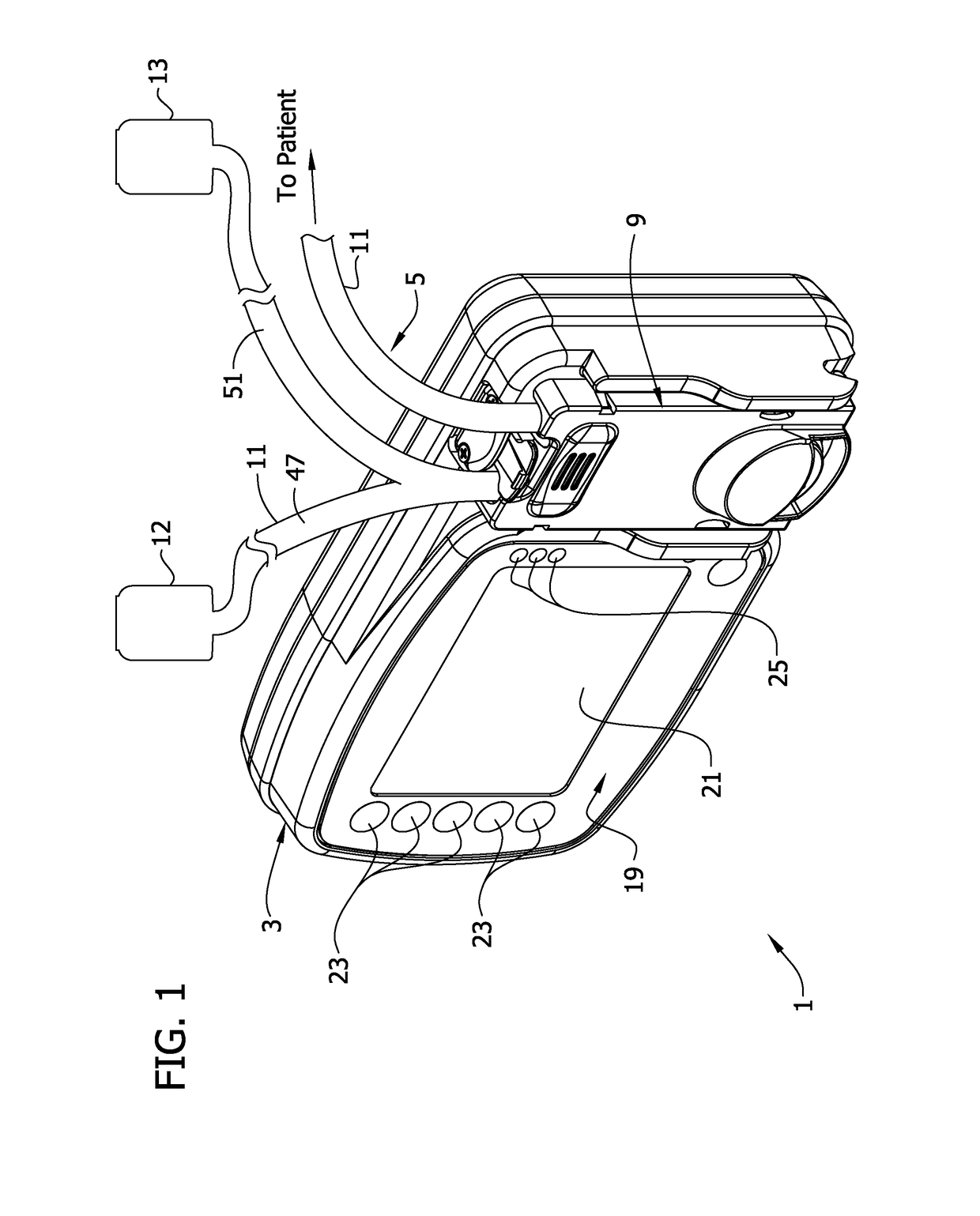

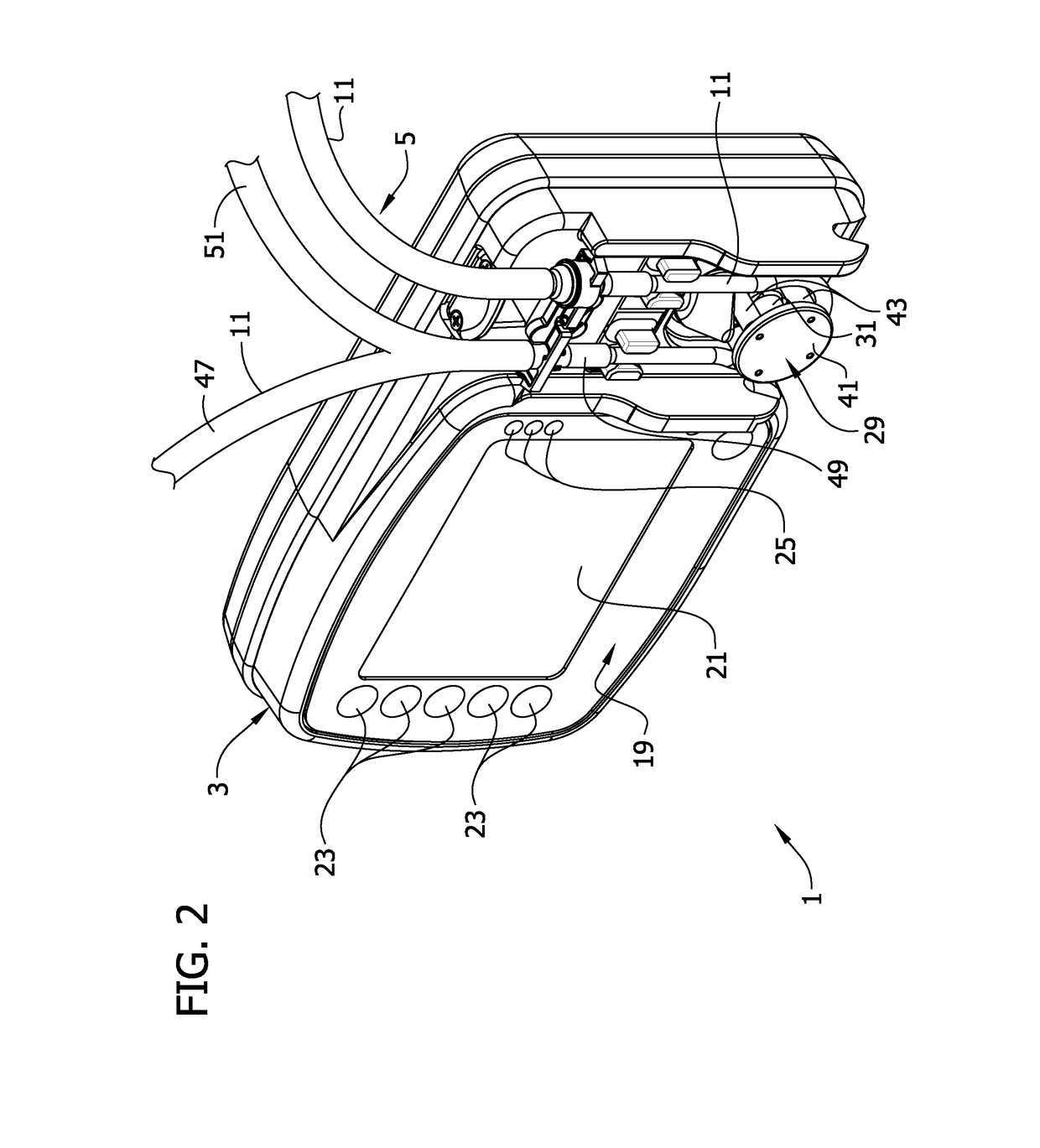

Feeding rate compensated pump and related methods therefor

A pumping apparatus for use with a pump set to deliver fluid through the pump set to a subject includes a pumping device capable of acting on the pump set to produce a fluid flow within the pump set. A controller is in communication with the pumping device for controlling operation of the pumping device in a feeding configuration and in a flushing configuration. The controller is adapted to store a selected flow rate and a desired fluid volume of a first fluid in the memory and at least one of a flush rate and flush volume of a second fluid. A flush time compensator is capable of being run for determining a compensated feeding configuration of the first fluid based on an amount of time the controller will operate the pump device in the flushing configuration and the desired fluid volume of the first fluid.

Owner:KPR U S LLC

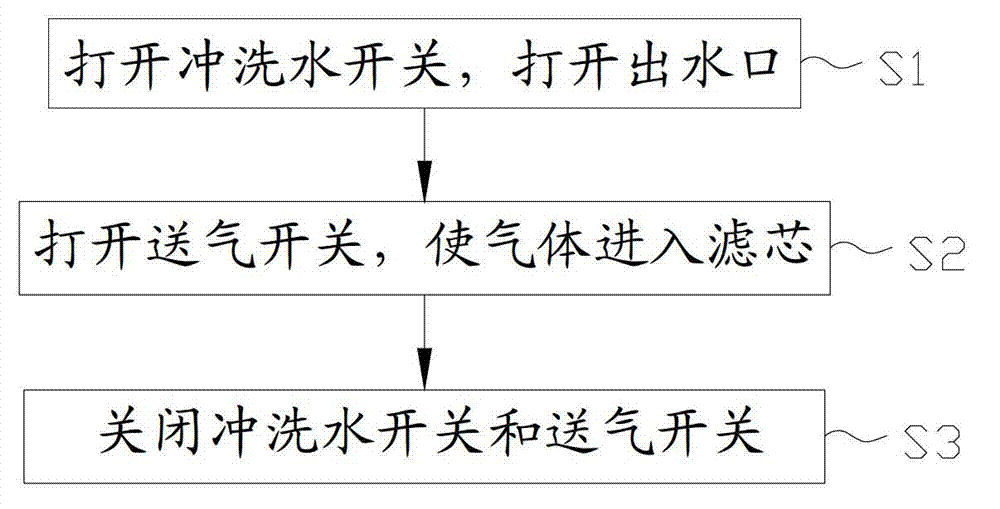

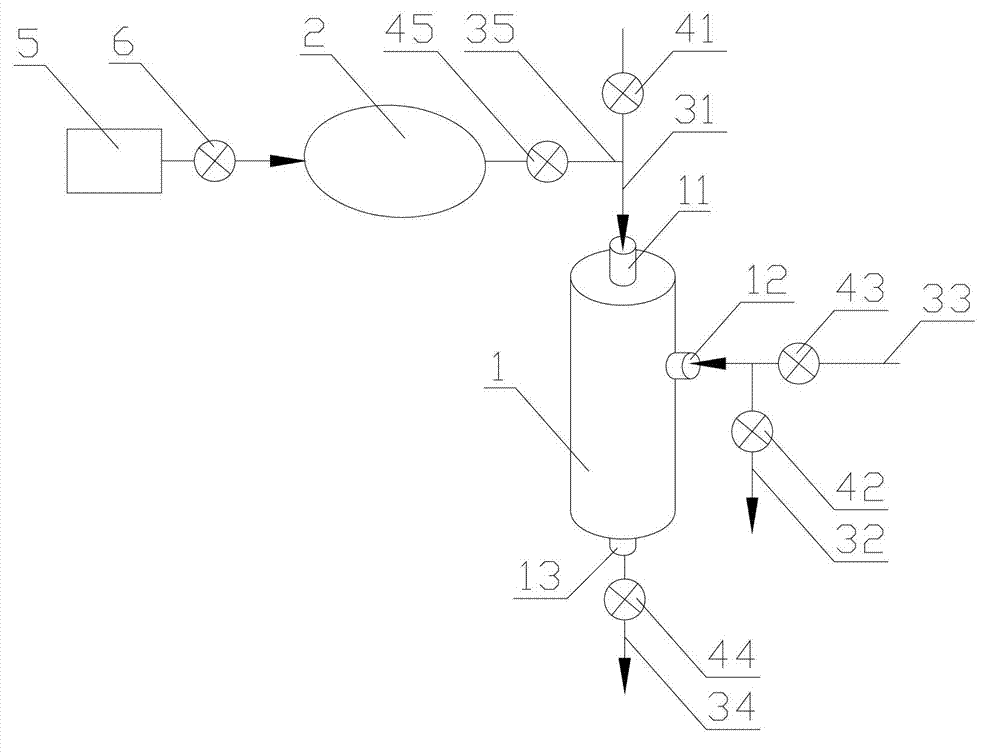

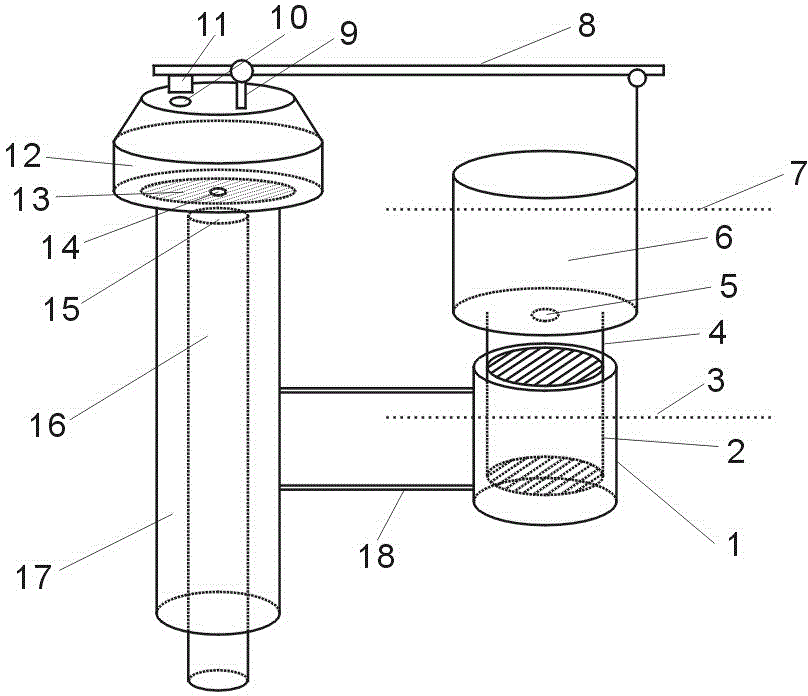

Internal-pressure type ultrafiltration membrane flusher and flushing method

InactiveCN103084069AReduce cloggingIncrease water fluxSemi-permeable membranesFlushing timeInternal pressure

The invention discloses an internal-pressure type ultrafiltration membrane flushing method and a flusher. The flusher provided by the invention comprises a flushing water pipe and a flushing water switch, a sewage discharge pipe and a sewage discharge switch, and further comprises an air storage tank and an air supply pipe, as well as an air supply switch arranged on the air supply pipe, wherein the air supply pipe is connected to the water inlet of a filter element. Under the action of pressure, the air in the air storage tank passes through the filter element and gaseous-liquid two phase flows are formed in the filter element; and the acting manner and the acting intensity of the single water phase with the attachments inside the membrane filaments are changed; therefore, flushing of the filter element can be finished well. Compared with the traditional flushing way, the flusher is capable of completing back flushing of the filter element better and more thoroughly; therefore, the water flux of the filter element after flushing is improved, stoppage of the ultrafiltration membrane is retarded, the service lives of the ultrafiltration membrane and the filter element are prolonged, the total water flux of the filter element is improved, and simultaneously, the flushing time is saved and the back flushing water is saved.

Owner:SHENZHEN CHENGDELAI IND CO LTD

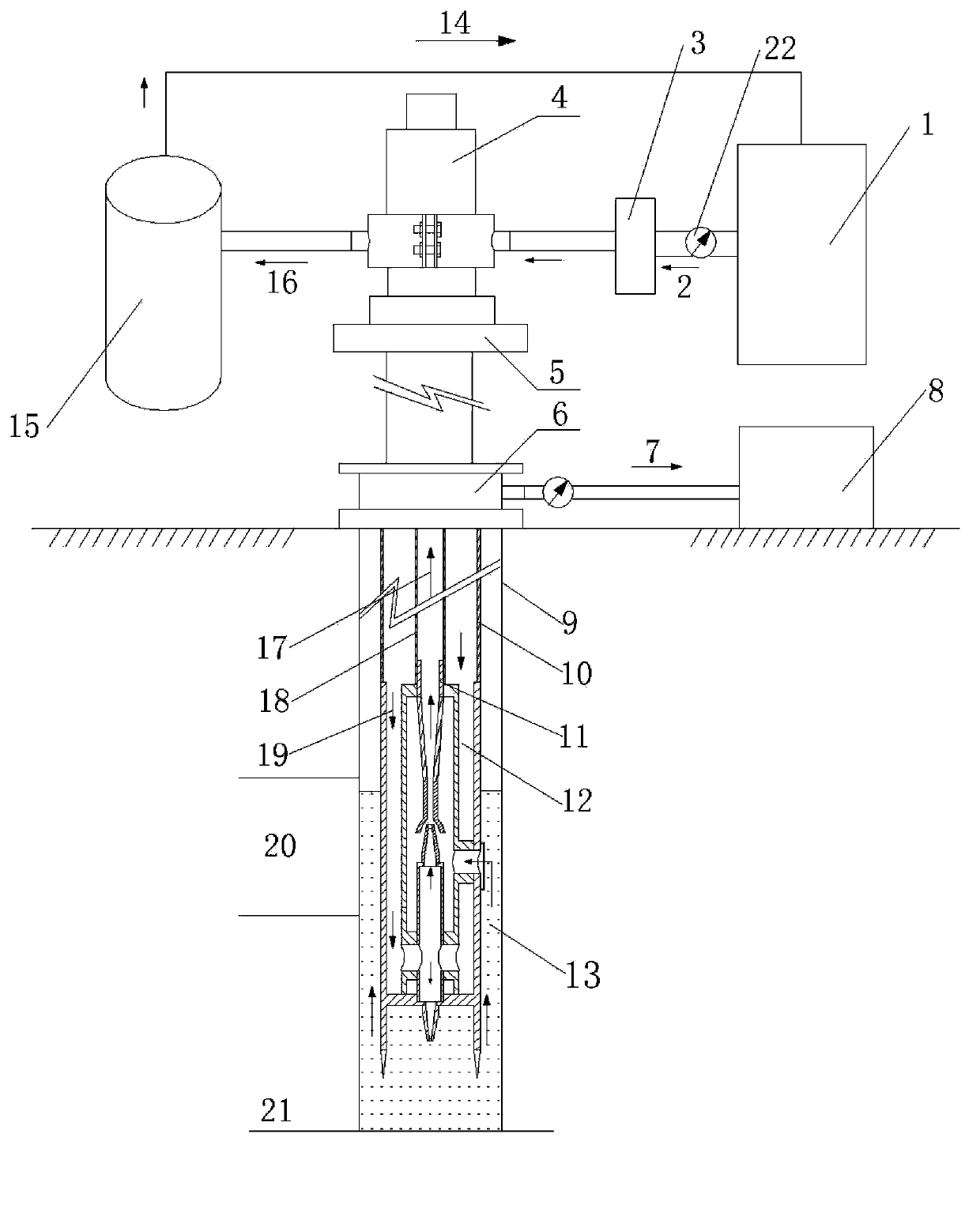

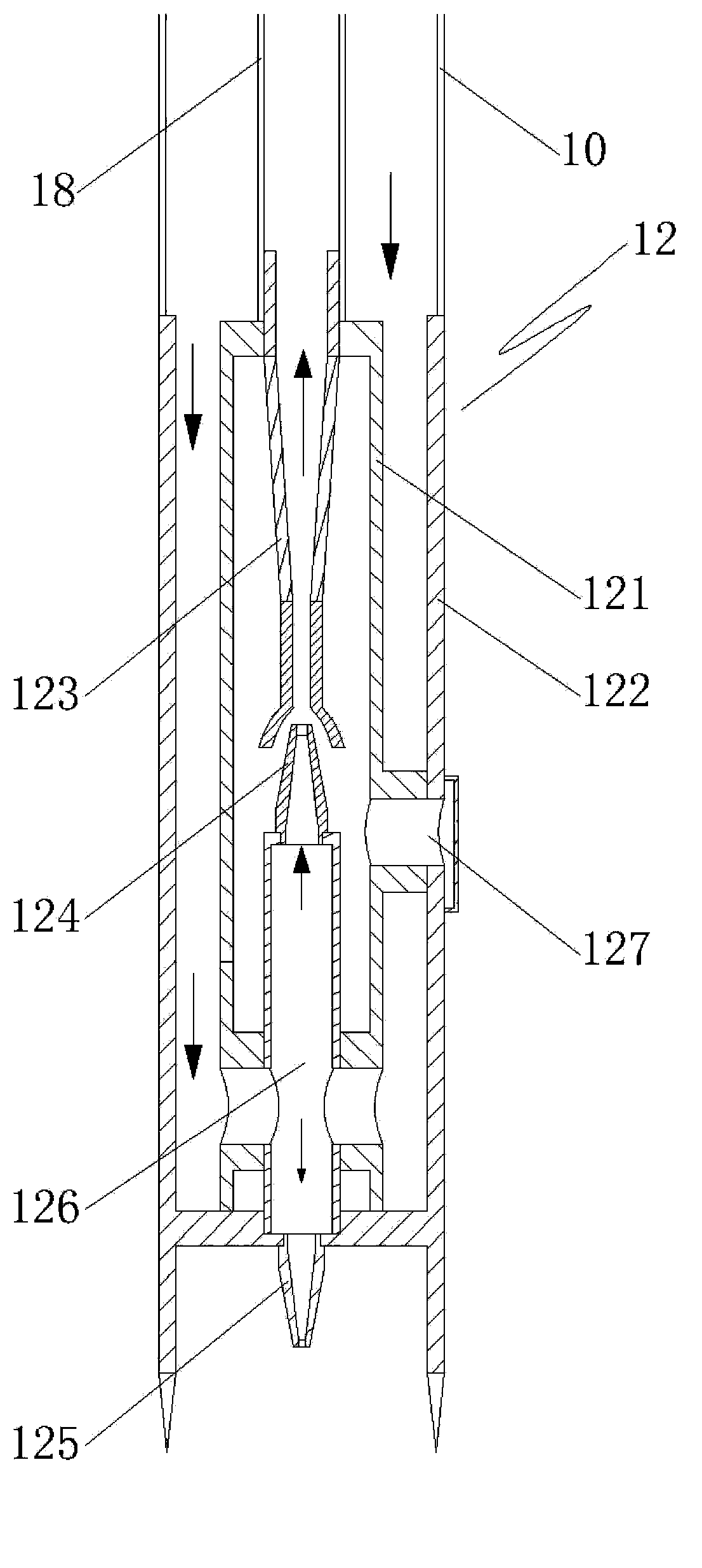

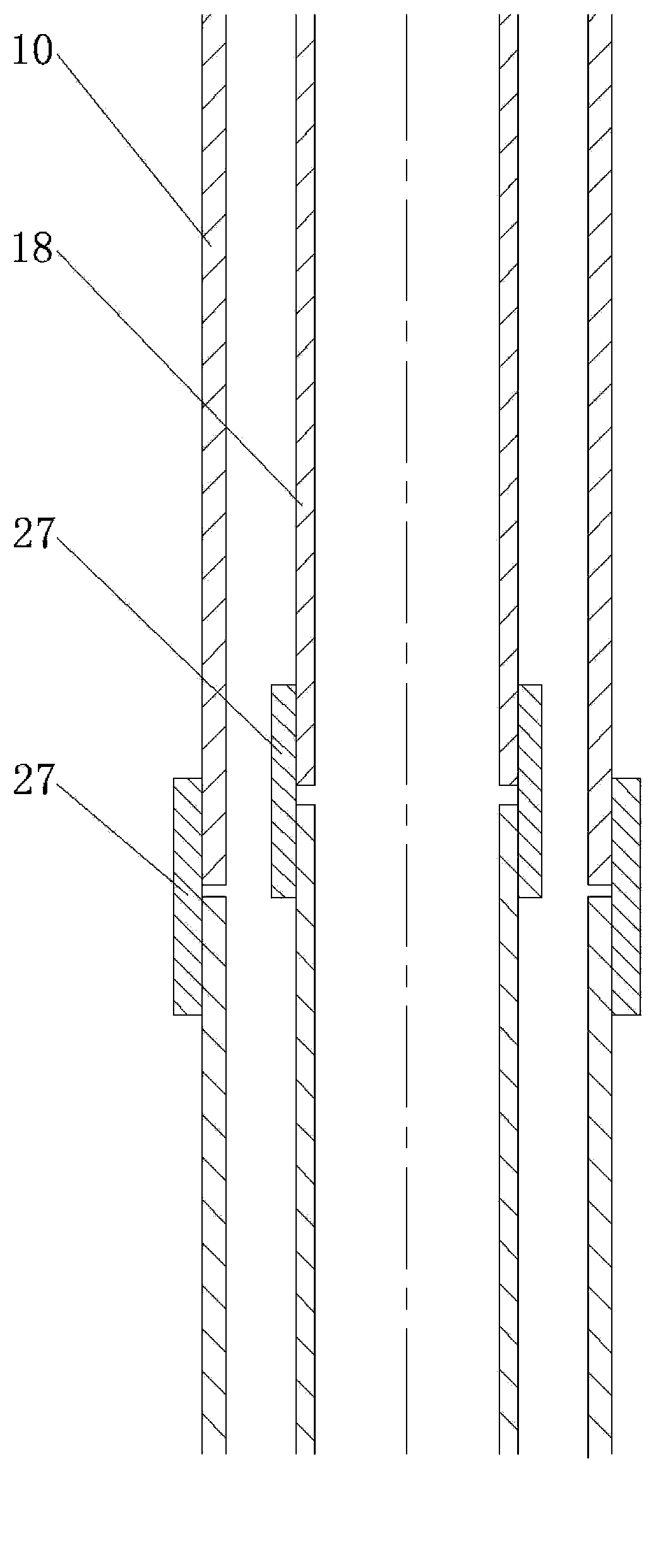

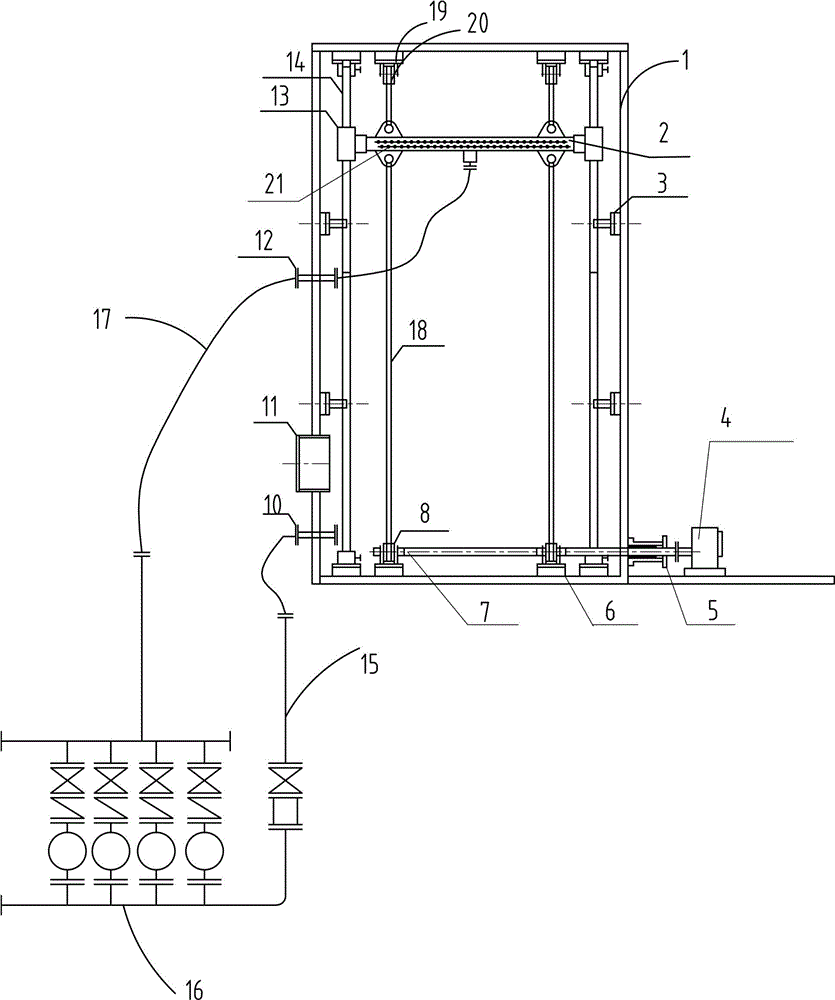

Concentric-tube pulverized coal discharging system and method for coal-bed gas well

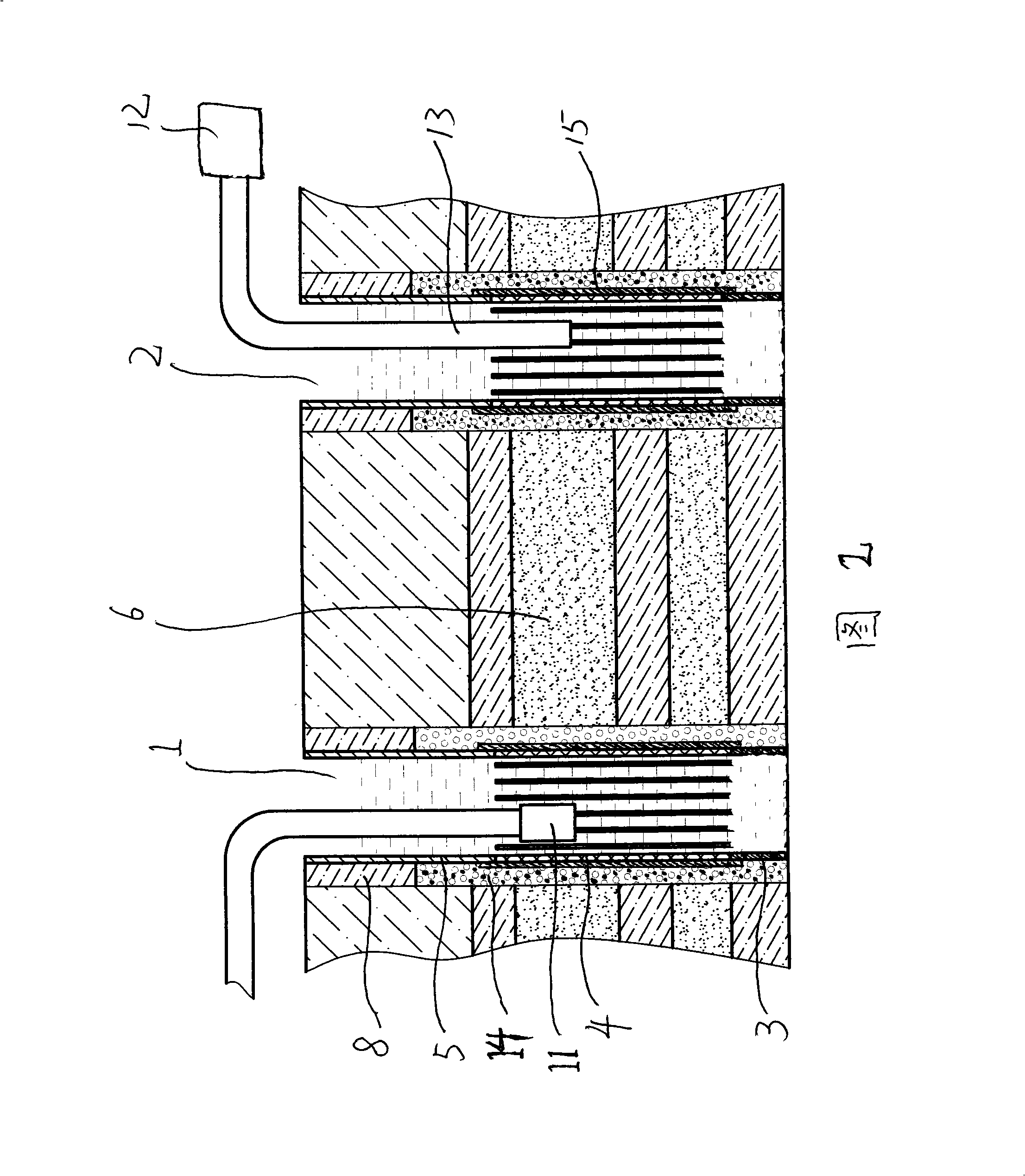

ActiveCN103867148AImprove the efficiency of workover operationsWon't breakFlushingFlushing timeProcess engineering

The invention discloses a concentric-tube pulverized coal discharging system for a coal-bed gas well and belongs to the technical field of coal-bed gas well and oil-gas field development. The system comprises a ground portion and a down hole portion. The ground portion comprises a three-plunger reciprocation pump (1), a concentric-tube coal discharging system well head unit (4), a well head casing spool (6) and a solid-liquid separation unit (15). The down hole portion comprises an outer oil tube (10), an inner oil tube (18) and a concentric-tube hydraulic jet pulverized coal flushing unit (12). The ground mechanism delivers high-pressure power liquids to the down hole mechanism which performs pulverized coal flushing. The invention further discloses a coal-bed gas well concentric-tube pulverized coal discharging method using the system. By means of the system and the method, the concentric-tube hydraulic jet pulverized coal flushing unit is arranged, so that pulverized coal of the coal-bed gas well bottom can be flushed thoroughly, the pulverized coal flushing time is greatly shortened, the coal-bed gas repair efficiency is greatly improved, the operation time is shortened, and damage to coal beds of the well bottom can be prevented.

Owner:PETROCHINA CO LTD +2

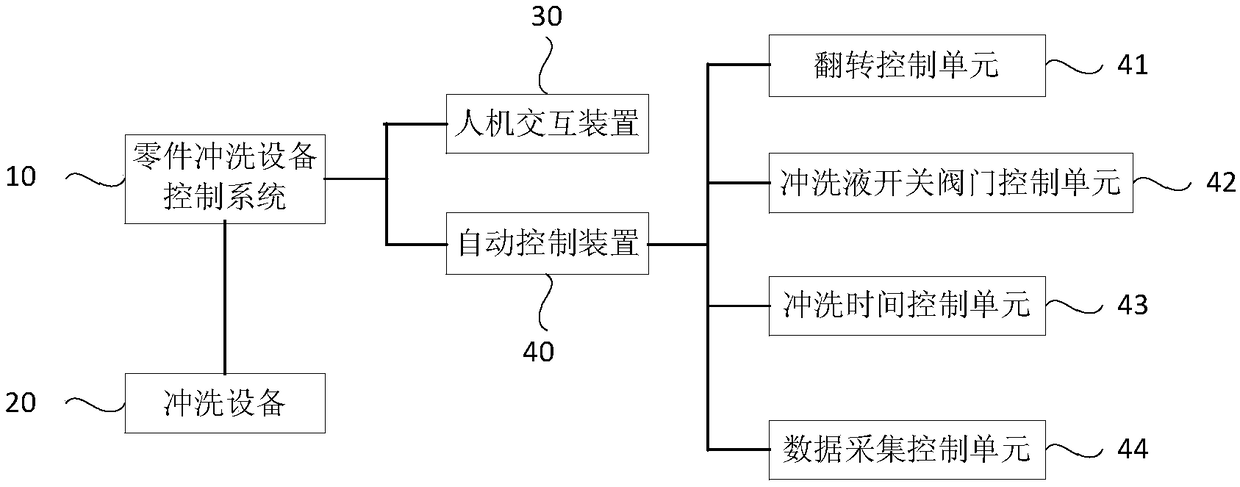

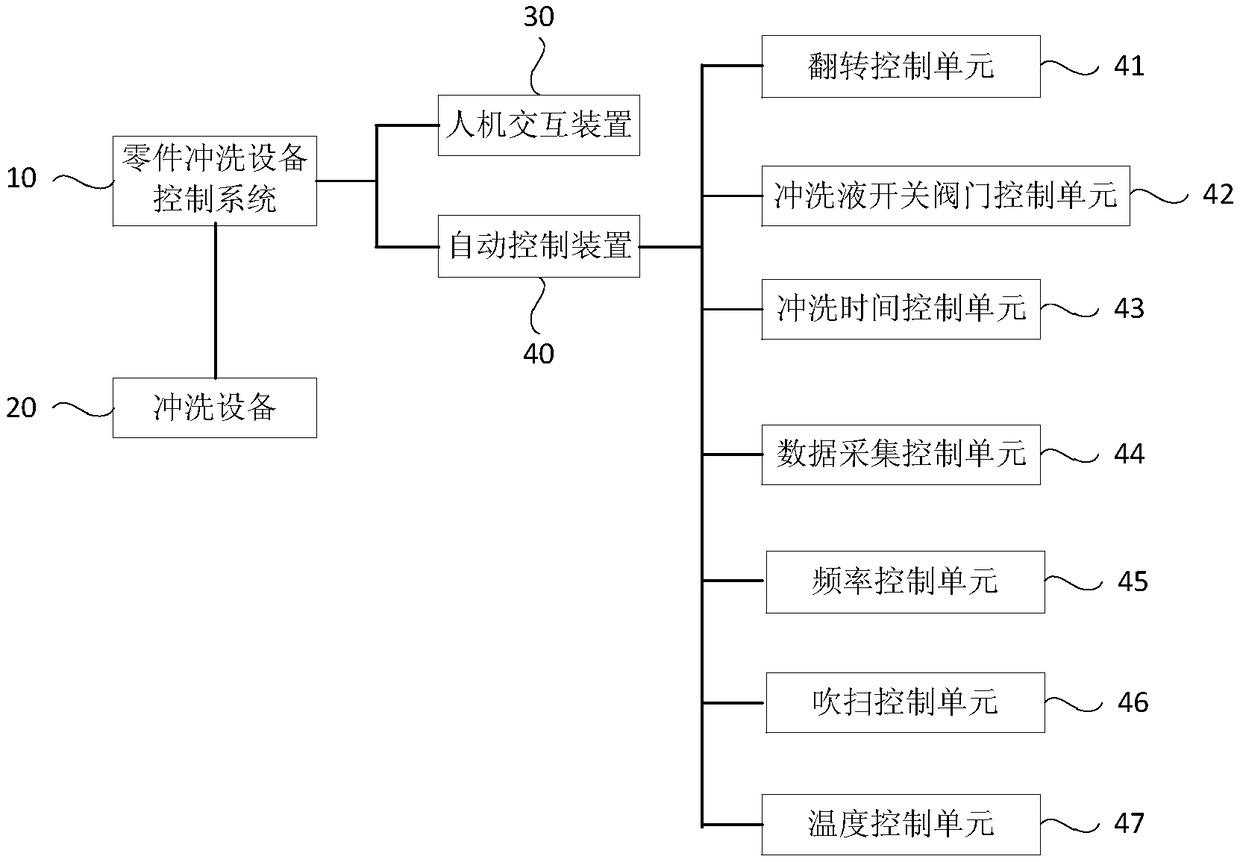

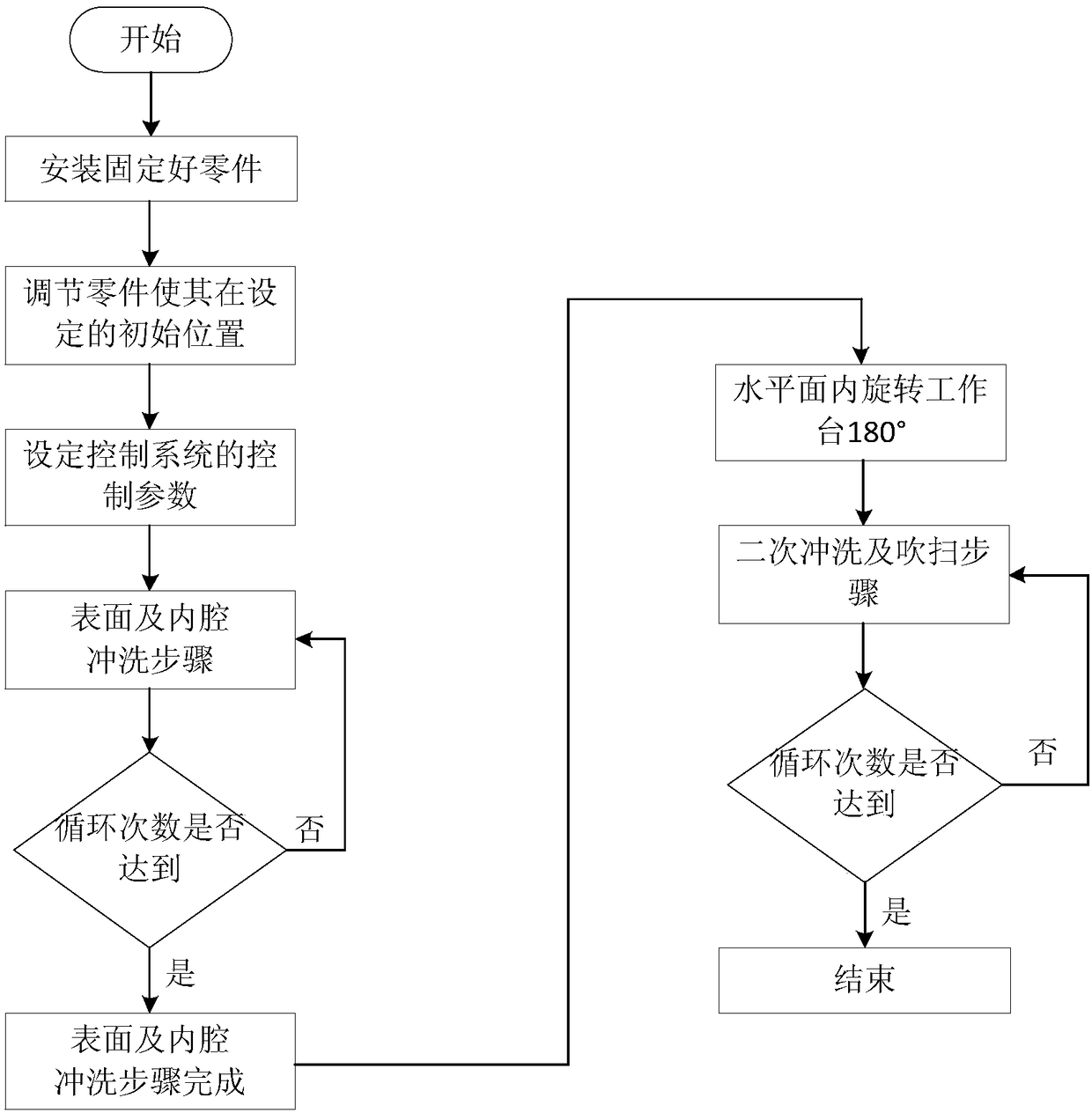

Part flushing equipment control system, part flushing system and part flushing method

ActiveCN108722962AReduce human interventionImprove washing effectCleaning using gasesCleaning using liquidsAutomatic controlAnalysis data

The invention discloses a part flushing equipment control system for controlling part flushing equipment. The control system comprises an automatic control device for intelligently controlling all executing mechanisms of the part flushing equipment and a man-machine interaction device for receiving an externally input instruction and switching the work modes of the automatic control device. The automatic control device comprises a turnover control unit, a flushing fluid switch valve control unit, a flushing time control unit, a flushing fluid pressure control unit and a data collecting controlunit. The invention further discloses a part flushing system including the part flushing equipment control system and a part flushing method. According to the part flushing equipment control system,the part flushing system and the part flushing method, the part flushing process is automatically controlled, human intervention is reduced, and the flushing effect is better due to the controllability of all flushing parameters. A more efficient and energy-saving flushing scheme can be set by analyzing related data of data collection.

Owner:CHINA HANGFA SOUTH IND CO LTD

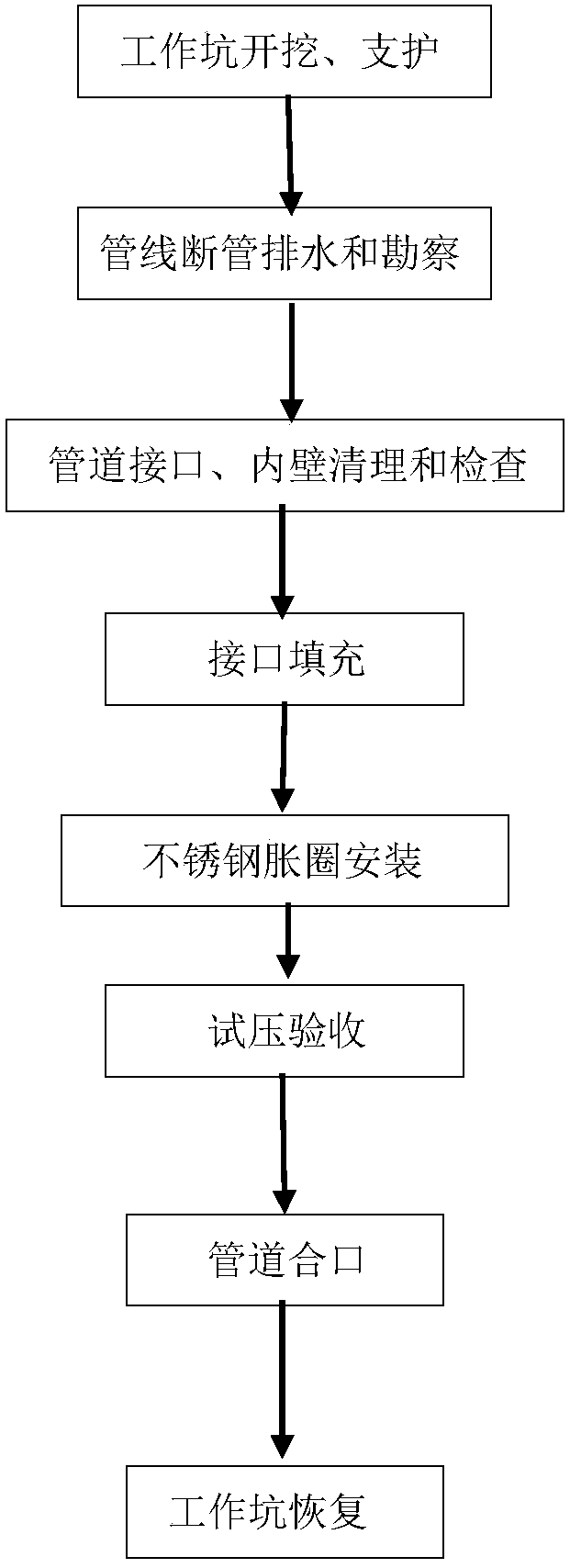

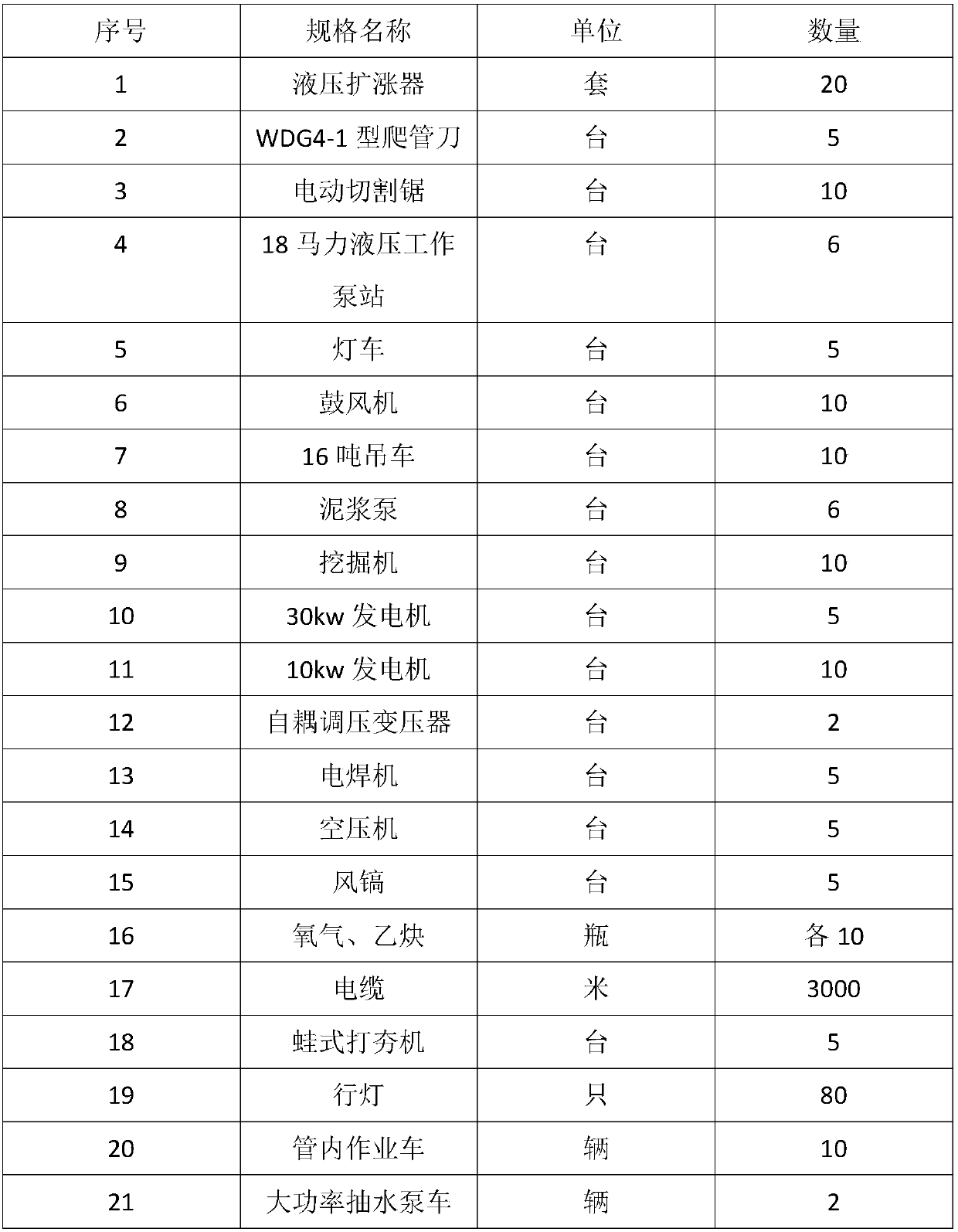

Internal expansion ring method pipe joint repair construction method

InactiveCN107763362AReduce construction intensityReduce construction areaPipe laying and repairPipe elementsState of artFlushing time

The invention discloses an internal expansion ring method pipe joint repair construction method, solves the problem of incapability of quickly and effectively repairing pipes in the prior art, and achieves such effects as high construction speed, no construction limitation from the ground and the environment, low cost and no limitation to the joint repair from the pipes. The internal expansion ring method pipe joint repair construction method comprises the following steps: working pits are excavated along pipelines in a construction site by every other set distance; the pipes are cut for breakage in the working pits to drain water remained in the pipes; pipe joints are cleaned and filled; sealing strips are bonded on the inner walls of the pipes in the pipe joints; internal expansion ringsare clamped in annular grooves of the sealing strips, and set pressure is applied to the internal expansion rings; two ends of the pipelines are blocked, and the pipe flushing time is set; steel pipes are arranged in the breakage places of the pipes to join the broken pipes; and the working pits are backfilled to recover pavements.

Owner:济南普利市政管网工程有限责任公司

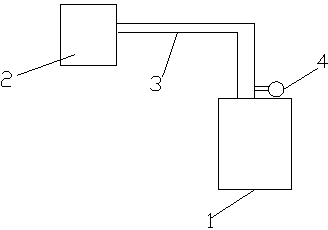

Closestool with automatic flushing and deodorization functions

The invention relates to a closestool with the automatic flushing and deodorization functions. The closestool comprises a closestool seat, a closestool cover, a closestool water tank, a flushing module, a deodorization module and a control circuit used for automatically starting the flushing module and the deodorization module and controlling the flushing time, wherein the control circuit comprises a closestool starting circuit, a deodorization starting circuit, a flushing mode selection circuit used for confirming the flushing time and a flushing starting circuit. According to the invention, the circuits are controlled, so that the flushing module and the deodorization module are automatically started and the flushing time is controlled, and the phenomenon that people are in contact with various bacteria is avoided; the flushomg time can be selected according to defecating or urinating, so that not only can the thorough flushing be guaranteed, but also the water resource is saved; in addition, the sewer can be cleaned when odor of the closestool is eliminated, so that better thorough deodorization effect is realized.

Owner:洁盟科技有限公司

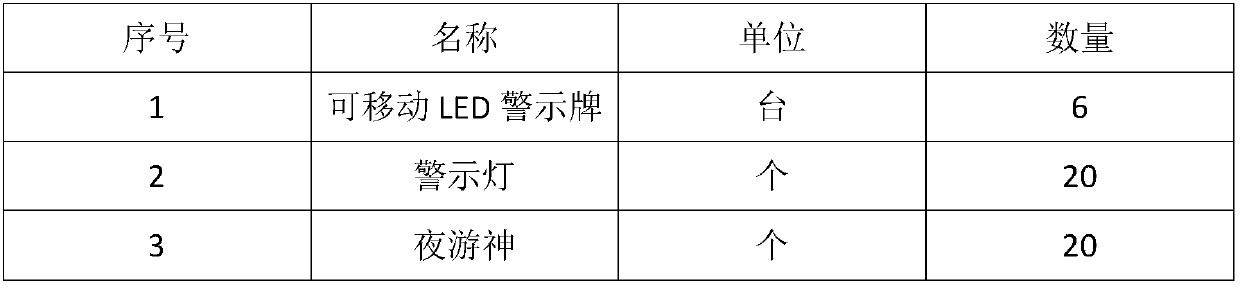

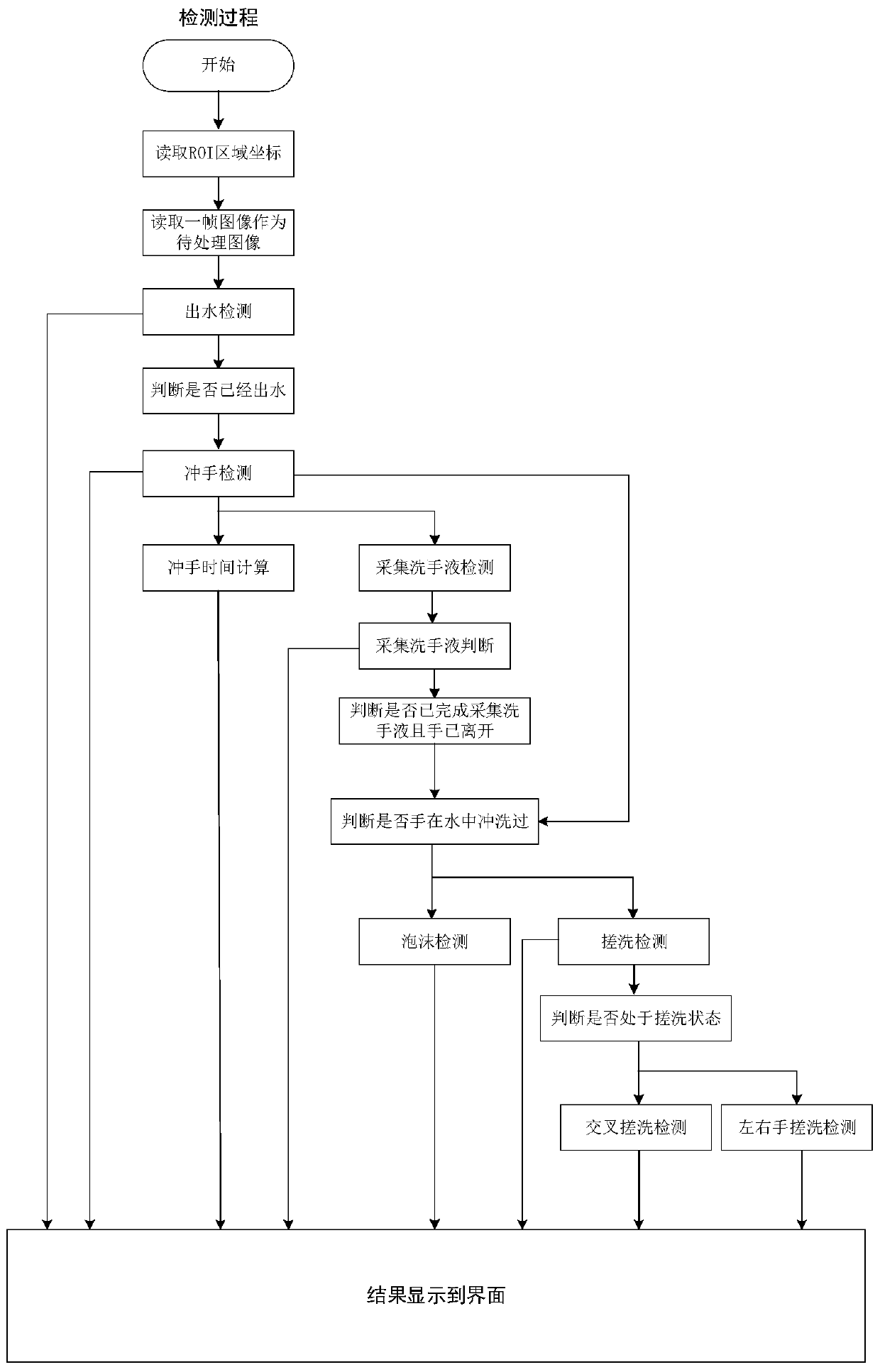

A method for automatically detecting standardization of a hand washing and disinfecting process based on computer vision

ActiveCN109726668ALow hardware requirementsEasy to superviseImage enhancementImage analysisFlushing timeHand sanitizer

The invention provides a method for automatically detecting standardization of a hand washing and disinfecting process based on computer vision. The method comprises the following steps: S1, fixing acamera at a position where a pool area can be completely shot; S2, carrying out process normalization automatic detection on the to-be-processed image, wherein whether a faucet discharges water or notis detected; Detecting whether the hand is flushed in water or not and detecting the flushing time of the hand in water; Detecting whether the hand sanitizer is collected or not; Whether enough foamis generated in the scrubbing process of the hand or not is detected; Detecting whether the two hands have mutual scrubbing actions or not in the scrubbing process; detecting Whether ten fingers are crossed and scrubbed with each other in the scrubbing process of the two hands; Detecting whether the left hand back and the right hand back are scrubbed or not in the scrubbing process of the hands; And S3, displaying each normative detection result in the step S2 on a display interface. The method solves the problems that the method for detecting whether the hand washing is qualified or not through microbiology sampling is high in cost, long in period and easy to interfere.

Owner:DALIAN MARITIME UNIVERSITY

Sewage treatment filter

InactiveCN104906852AAutomatically identify the degree of depositionSimple structureStationary filtering element filtersFlushing timeSewage

The invention relates to a sewage treatment filter including a filter body, a filter net is arranged in the filter body, a sewage cavity is between a cover body and a stationary plate, a clear water cavity is between the stationary plate and a bottom cover, a water inlet pipe is arranged on the outer wall of the upper side of the filter body, a water outlet pipe is arranged on the outer wall of the lower side of the filter body, the water inlet pipe is communicated with the sewage cavity, the water outlet pipe is communicated with the clear water cavity, a plurality of water inlet holes are arranged on the stationary plate, the water inlet holes are communicated with the sewage cavity and the clear water cavity, an electric motor is arranged on the upper end of the filter body, the electric motor drives a transmission shaft to rotate, the transmission shaft extrudes into the filter body, a stainless steel brush is arranged on the transmission shaft, the stainless steel brush can clean the inner wall of the filter net, the bottom cover is provided with a sewage drain valve in penetration manner, and cleaned impurities are discharged by the sewage drain valve. The sewage treatment filter has simple structure and reasonable design, and can achieve automatic back flush, the flush time is short, efficiency is high, and filtering performance is good.

Owner:安庆市紫韵电子商务有限公司

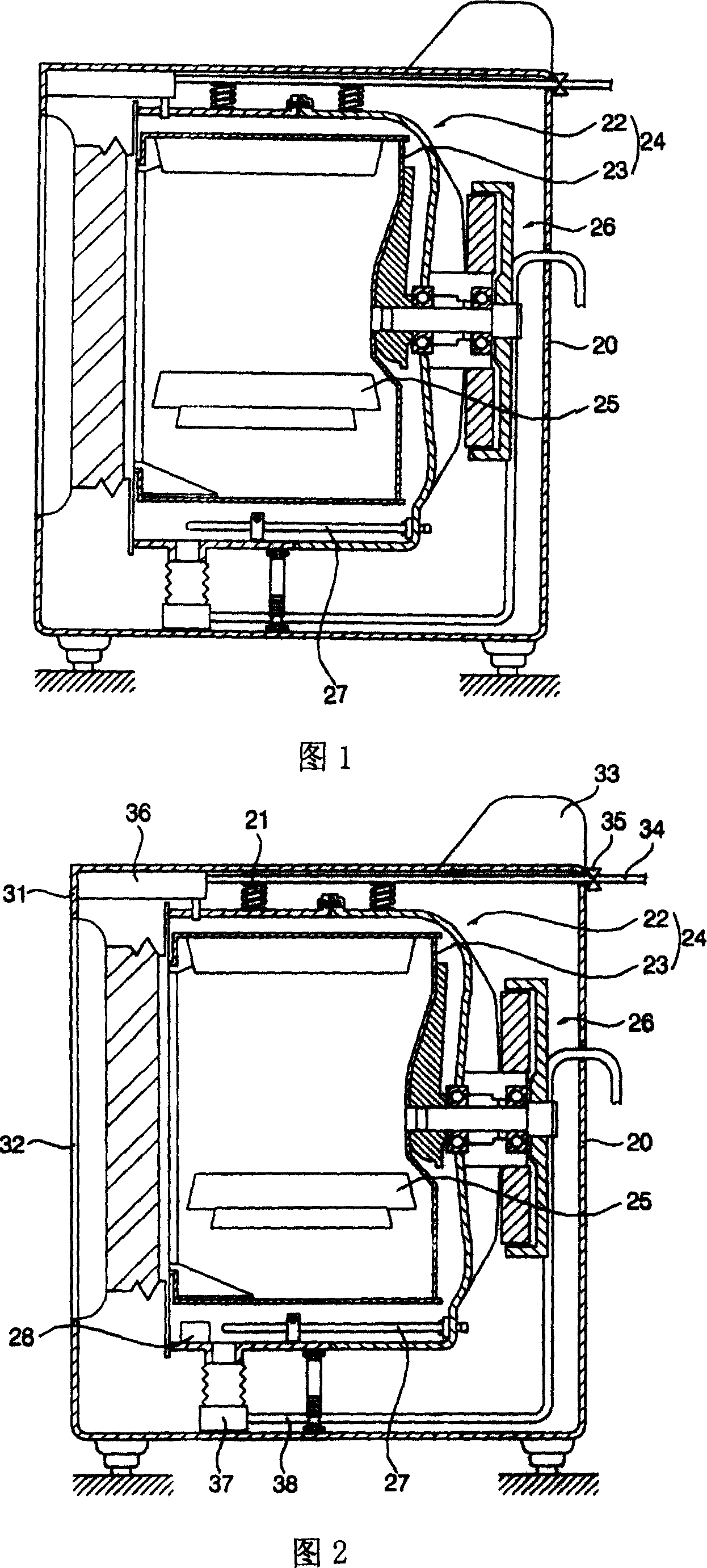

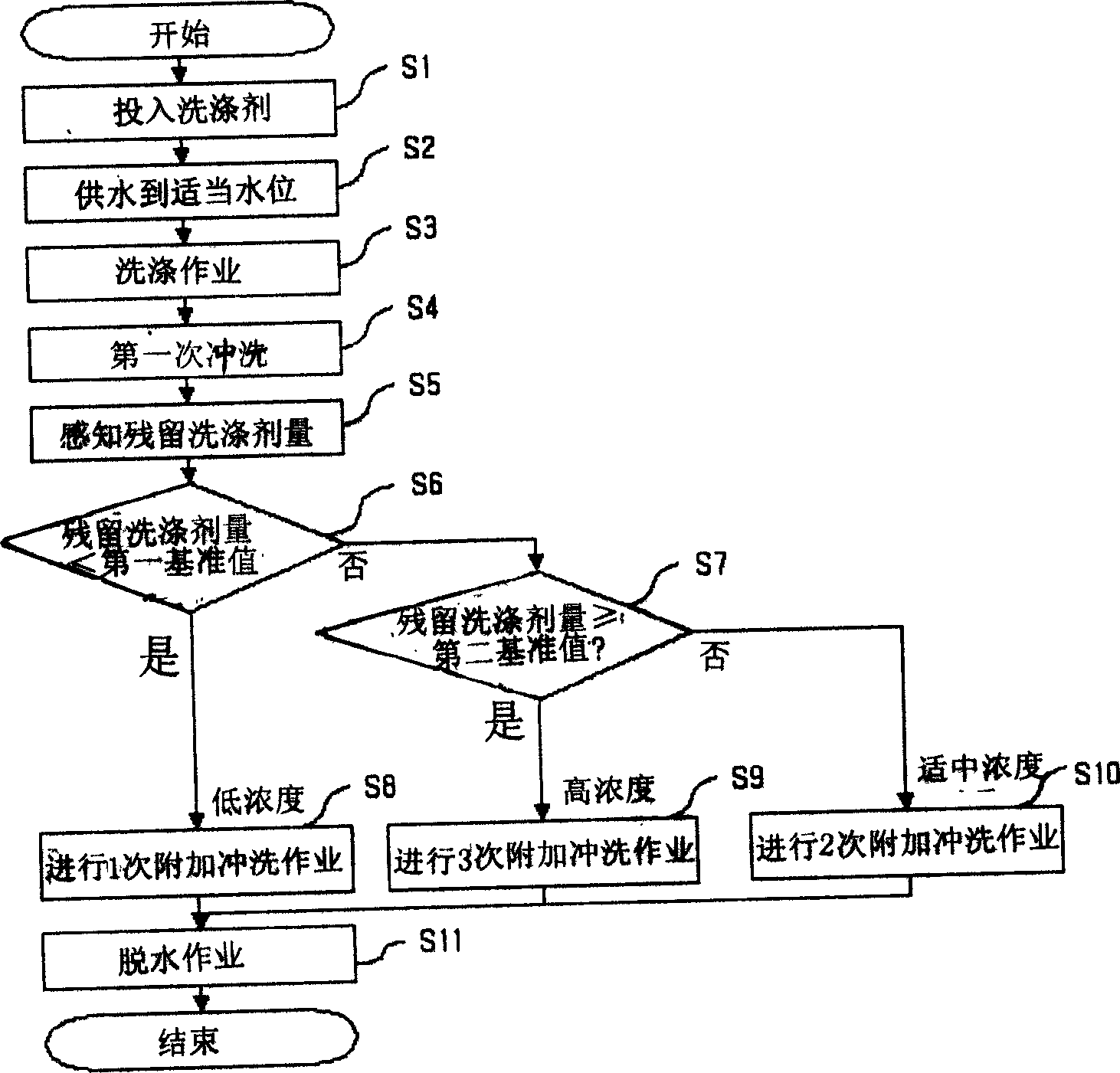

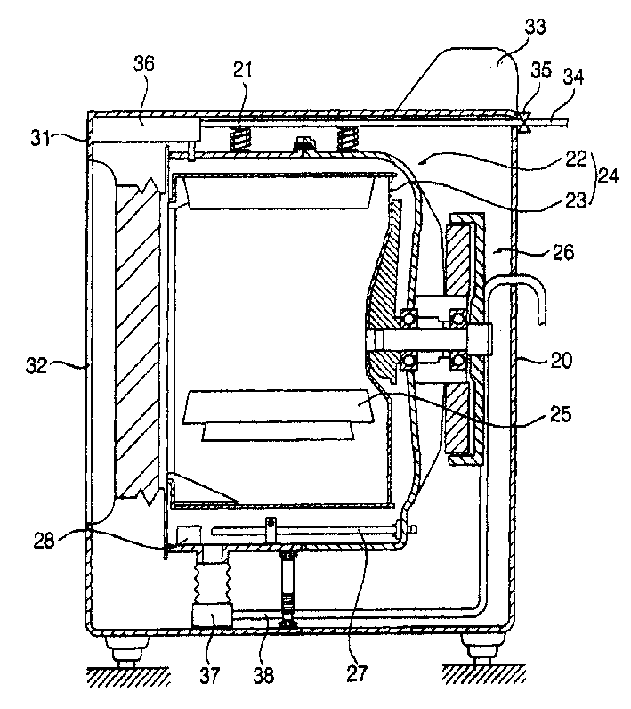

Flushing method for drum washing machine

InactiveCN1566437AAvoid wastingImprove comfortControl devices for washing apparatusTextiles and paperFlushing timeEngineering

The invention provides a flushing method for a cylinder washing machine, which includes the following four steps: 1. supplying water and detergent to the washing groove; 2. flushing for the first time after washing is complete; 3. comparing the sensed detergent residual amount in the washing water to the reference value, then determining additional flushing times; 4. flushing according to the comparative results in step 3. The invention can effectively prevent energy waste, improve flushing effect and comfort feelings of washings, and also can prevent skin diseases caused by residual detergent.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

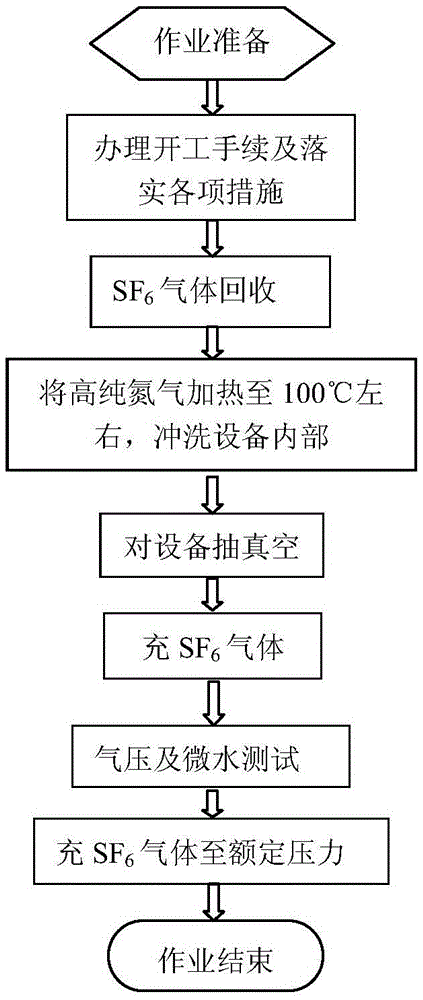

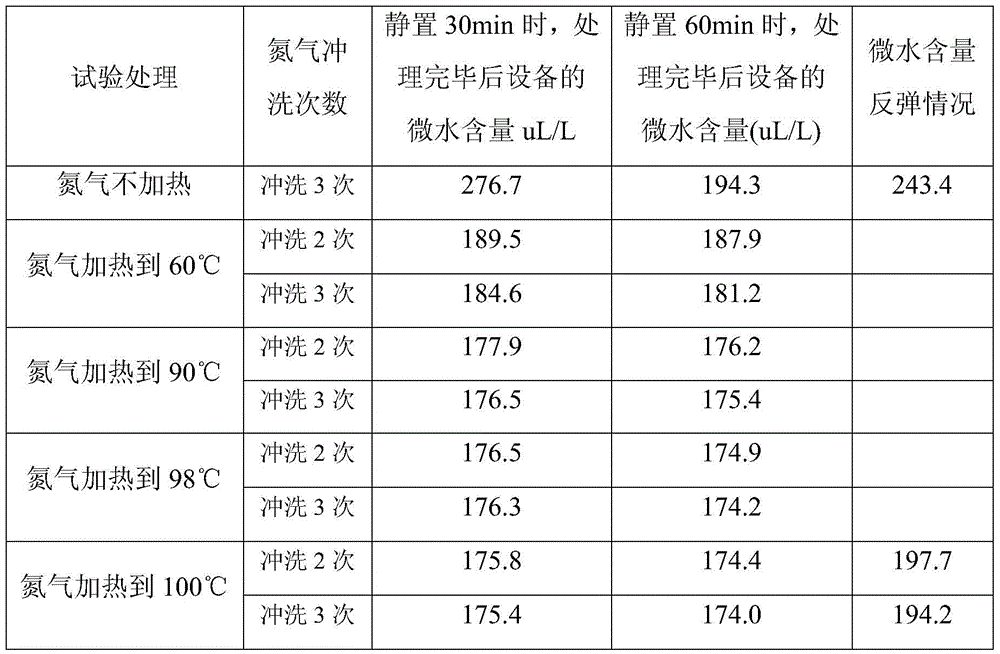

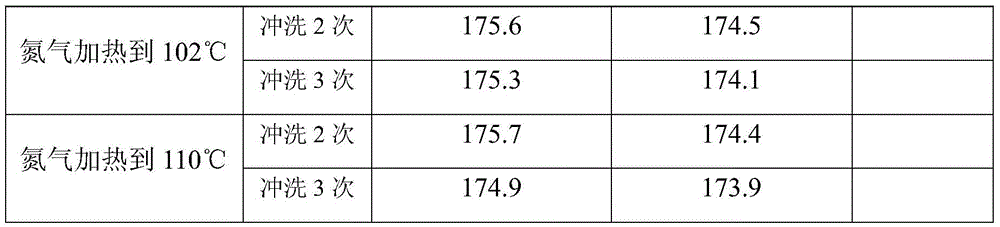

Treatment process aiming at moisture standard exceeding in SF6 device

ActiveCN105536448AImprove solubilityImprove exchange efficiencyDispersed particle separationFlushing timeTemperature control

The invention relates to a treatment process aiming at moisture standard exceeding in an SF6 device. The process comprises: before nitrogen inflation for flushing the SF6 device, heating nitrogen to 98-102 DEG C through a gas temperature control system; inflating nitrogen into the SF6 device for flushing for 30 min; discharging nitrogen through a vacuum duct after flushing; performing flushing twice; inflating SF6 gas into the SF6 device; performing an air-pressure-and-moisture test; and inflating SF6 gas into the SF6 device till a rated pressure is reached. Through the process, time of nitrogen standing in the SF6 device is effectively shortened, and flushing times with nitrogen during the flushing process is reduced, thereby improving the treatment effect and efficiency of moisture standard exceeding in the SF6 device. Through treatment of moisture standard exceeding, the moisture content in coil devices can be effectively inhibited from rebounding.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

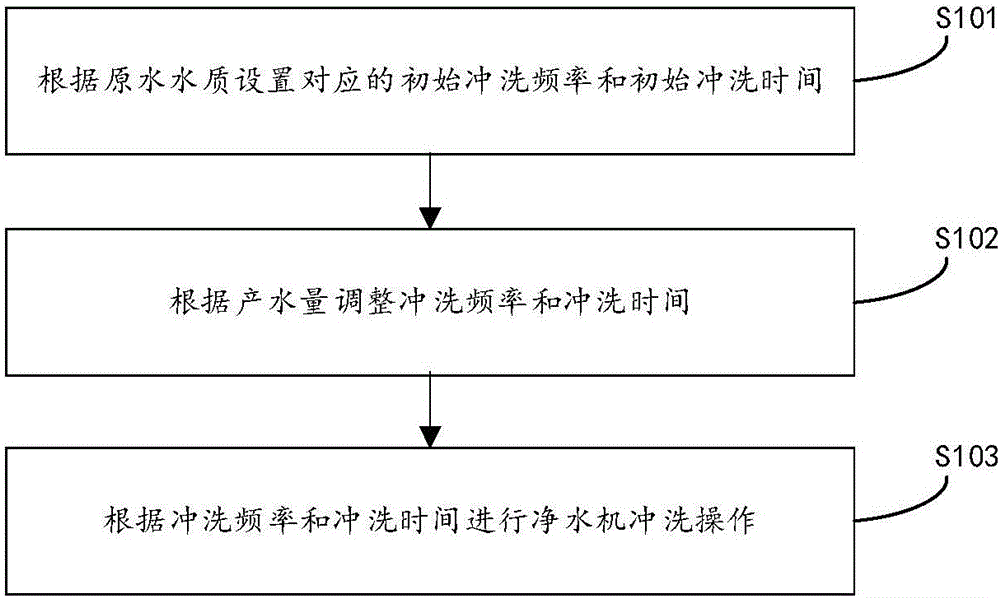

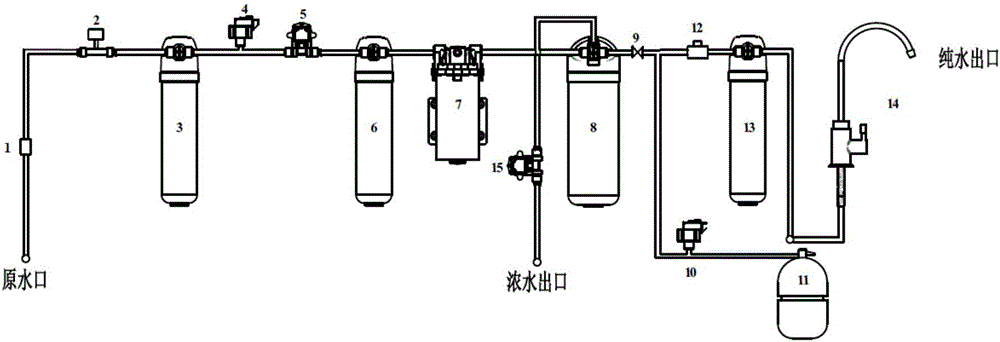

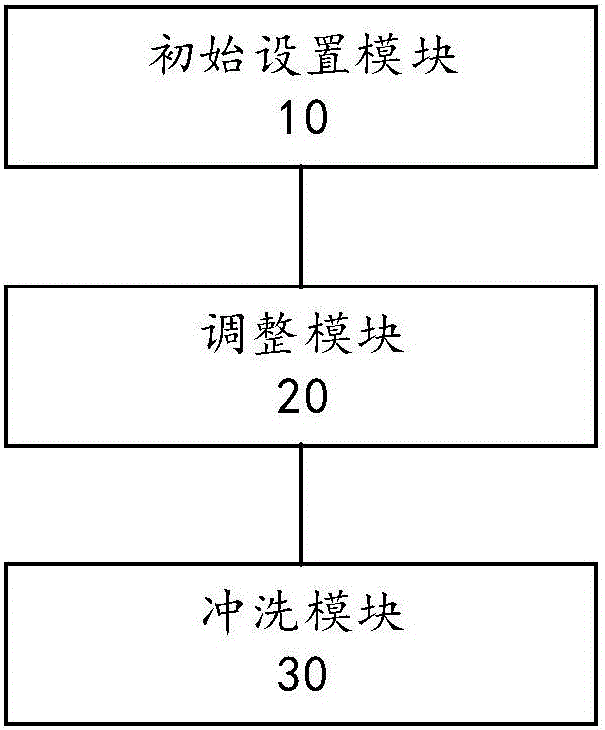

Water purifier flushing method and device

InactiveCN106178955ARealize automatic adjustmentHigh recovery rateWater treatment parameter controlSpecific water treatment objectivesFlushing timeWater quality

The invention discloses a water purifier flushing method and a device, wherein the method comprises the following steps: setting corresponding initial flushing frequency and initial flushing time according to the quality of raw water; adjusting the flushing frequency and flushing time according to water yield; and performing flushing operation of a water purifier according to the flushing frequency and the flushing time. By applying the technical scheme, the automatic adjustment of the water purifier flushing mode through the quality detection of raw water and the detection of water yield, so that the water purifier flushing mode can adapt to the quality demand of water in different regions. Through the variable flushing mode, the water yield throughout slowdown speed of RO membranes can be obviously reduced, and the recovery rate of the water purifier is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Resin regeneration and post-flushing method of steam generator drainage sewage purification system in nuclear power station

InactiveCN106391147AReduce consumptionReduce rinse timeIon-exchanger regenerationFlushing timeNuclear power

The invention belongs to the technical field of nuclear power station sewage purification, in particular relates to a resin regeneration and post-flushing method of a steam generator drainage sewage purification system in a nuclear power station. The defects in the prior art are overcome, the regeneration and post-flushing time of resin in the steam generator drainage sewage purification system is shortened, and the residual amount of regeneration liquid after a resin bed is flushed is reduced, and it is ensured that the residual regeneration liquid is not introduced into system after the resin regeneration process. The method comprises the following steps: step 1, regenerating cation resin; step 2, performing flushing after the cation resin is regenerated; step 3, regenerating anion resin; step 4, performing combined flushing.

Owner:JIANGSU NUCLEAR POWER CORP

Bottle cultivation method for ombre mushroom

InactiveCN104429612AHigh biotransformation rateIncrease productionCultivating equipmentsMushroom cultivationFlushing timeSocial benefits

The invention discloses a bottle cultivation method for ombre mushroom. The processes include preparing ombre mushroom cultivation medium, putting into a bottle, autoclaving, inoculation and the like, and further include picking up of the ombre mushroom and removing of mushroom roots. All the processes are executed by machines, both labors and energy are saved, and is benefit for the expanding of production scale and the increasing of yield. Meanwhile high and stable yield is realized and good social benefit is achieved. The water-retaining property of cultivation bottles is much better than that of cultivation bags. The flushing time of each batch is cut down by 3 to 5 days, the time of occupying mushroom houses is greatly saved, and the utilization rate of mushroom houses is increased. Meanwhile, the hypha of the cultivation medium is rapid in growing speed, high in biotransformation rate, high in output and low in manufacture cost.

Owner:上林县明珍源桑枝菌业有限公司

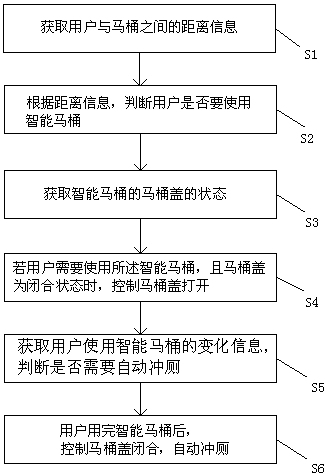

Control method used for intelligent closestool

The invention provides a control method for an intelligent toilet, comprising the following steps: acquiring distance information between a user and the toilet; judging whether the user wants to use the intelligent toilet according to the distance information; acquiring the distance information of the intelligent toilet The state of the toilet lid: if the judgment result in the step S2 is that the user needs to use the smart toilet, and the toilet lid is closed in the step S3, control the opening of the toilet lid. Obtain information about changes in the use of the smart toilet by the user, and determine whether automatic toilet flushing is required. The invention can intelligently open and close the toilet lid; by judging the pressure, the current state of the user using the toilet is determined, and according to the actual situation of the user, the toilet is only flushed after the user has used up the toilet, which can precisely control the flushing time and avoid Early toilet flushing and waste of water resources. At the same time, it improves the user experience and makes the toilet more intelligent.

Owner:董思言

Constant force float auxiliary flushing time control valve

ActiveCN105821944AIncrease the use of functionsSimple structureFlushing devicesWater storageFlushing time

The invention discloses a constant force float auxiliary flushing time control valve, which comprises: a water cup, a constant force float, a low water level line, a connecting rod, an adjustment hole, a water storage chamber, a high water level line, a lever arm, a fulcrum, a pressure relief Holes, blockages, equal pressure chambers, spring pressure membranes, pressure guide holes, sealing ports, water inlet pipes, water outlet pipes, and fixed brackets, use the buoyancy of the constant force float in the water cup to close the pressure relief holes, which solves the unreasonable structure of the current flushing valve , Unstable performance and problems that cannot be widely used.

Owner:GUANGDONG HEGII SANITARY WARES CO LTD

Technology for improving color and luster, and juice loss of cooled meat

InactiveCN108056151ASolve the problem of whiteningSolve water problemsMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsBiotechnologyFlushing time

The invention relates to a technology for improving color and luster, and juice loss of cooled meat, specifically discloses a cooling flushing, modified atmosphere packaging and cold-chain transportation technology of pork and belongs to the technical field of processing of agricultural products. The technology comprises the following technological steps: (1) carrying out cooling flushing; carrying out flushing on slaughtered and split two-part pork, wherein the flushing temperature is 4+ / -1 DEG C, 6+ / -1 DEG C, 8+ / -1 DEG C, 10+ / -1 DEG C and 12+ / -1 DEG C respectively, the relative humidity is 80 to 85 percent, the air speed is 3.5+ / -0.5m / s and the flushing time is 12h; after flushing, irradiating and sterilizing by utilizing an ultraviolet lamp; (2) carrying out modified atmosphere packaging; cutting the flushed cooled meat and carrying out the modified atmosphere packaging after cutting; (3) carrying out cold-chain transportation; transporting the packaged cooled pork under the conditions that the temperature is 8+ / -1 DEG C, 12+ / -1 DEG C and 16+ / -1 DEG C, wherein the transportation time is 3h, 6h, 9h, 12h and 15h. According to the technology provided by the invention, the cooled pork treated through the cooling flushing, modified atmosphere packaging and cold-chain transportation technology has good color and luster and water-retaining property; the meat is fresh and tender andhas good elasticity; the problems that the pork turn white and water is discharged after enterprise slaughtering and transportation are solved and the technology has wide industrial production value.

Owner:海南罗牛山食品集团有限公司

High-pressure water online flushing device for condenser

InactiveCN105258550AShorten maintenance timeLower water costsFlush cleaningFlushing timeSpray nozzle

The invention discloses a high-pressure water online flushing device for a condenser. The high-pressure water online flushing device comprises a transmission system and a high-pressure water flushing device, wherein the high-pressure water flushing device comprises at least one high-pressure water pump unit, a water supply pipe arranged between the high-pressure water pump unit and the condenser, a water spraying pipe communicated with the high-pressure water pump unit through a water inlet pipe and parallel high-precision nozzles arranged on the water spraying pipe; and the transmission system comprises a vertical guide rail positioned on the condenser and a sleeve arranged on the vertical guide rail in a sliding manner, and the two ends of the water spraying pipe are connected to the sleeve and move up and down along the vertical guide rail with the help of a driving device. After the high-pressure water online flushing device is adopted, work can still be carried out when the condenser is not in a halt state, so that the unit maintenance time is saved. Through adopting the high-precision nozzles, positioning is accurate. The sleeve of the transmission system regularly moves, and the flushing coverage rate of a cooling water pipe reaches 100%. The parallel high-precision nozzles simultaneously work, single flushing time is shortened, and the flushing efficiency is greatly improved.

Owner:江苏壹泰节能环保科技有限公司

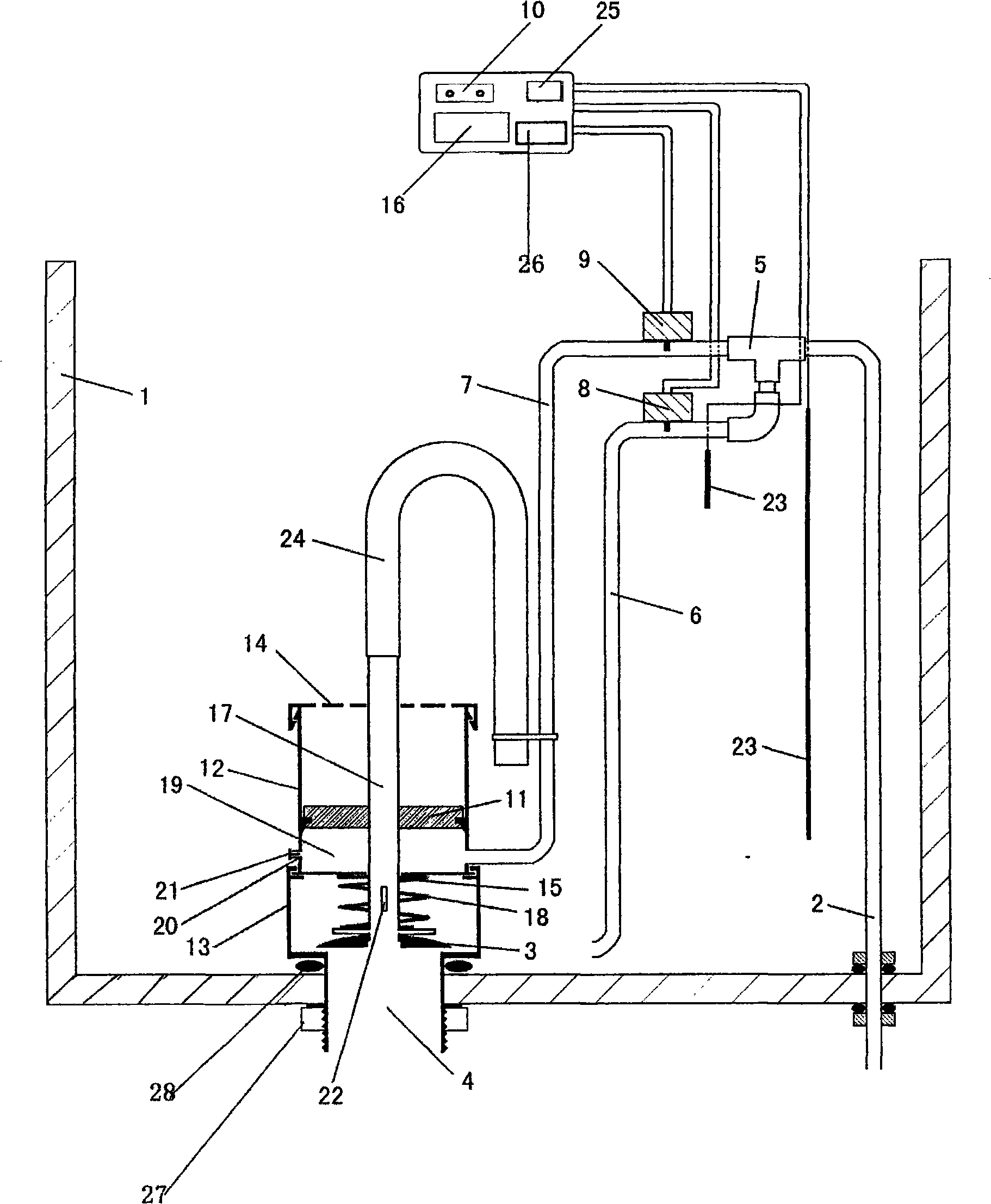

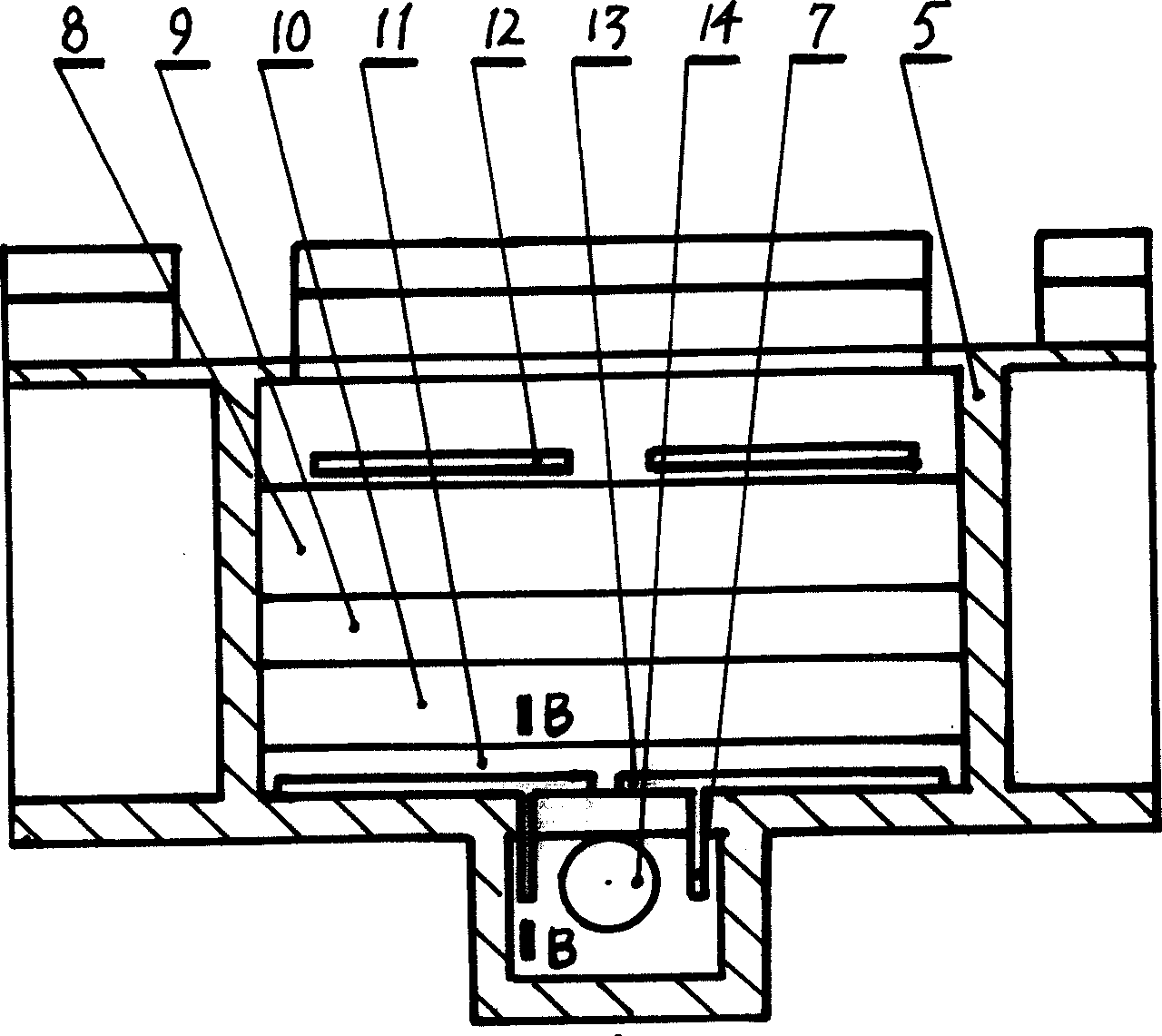

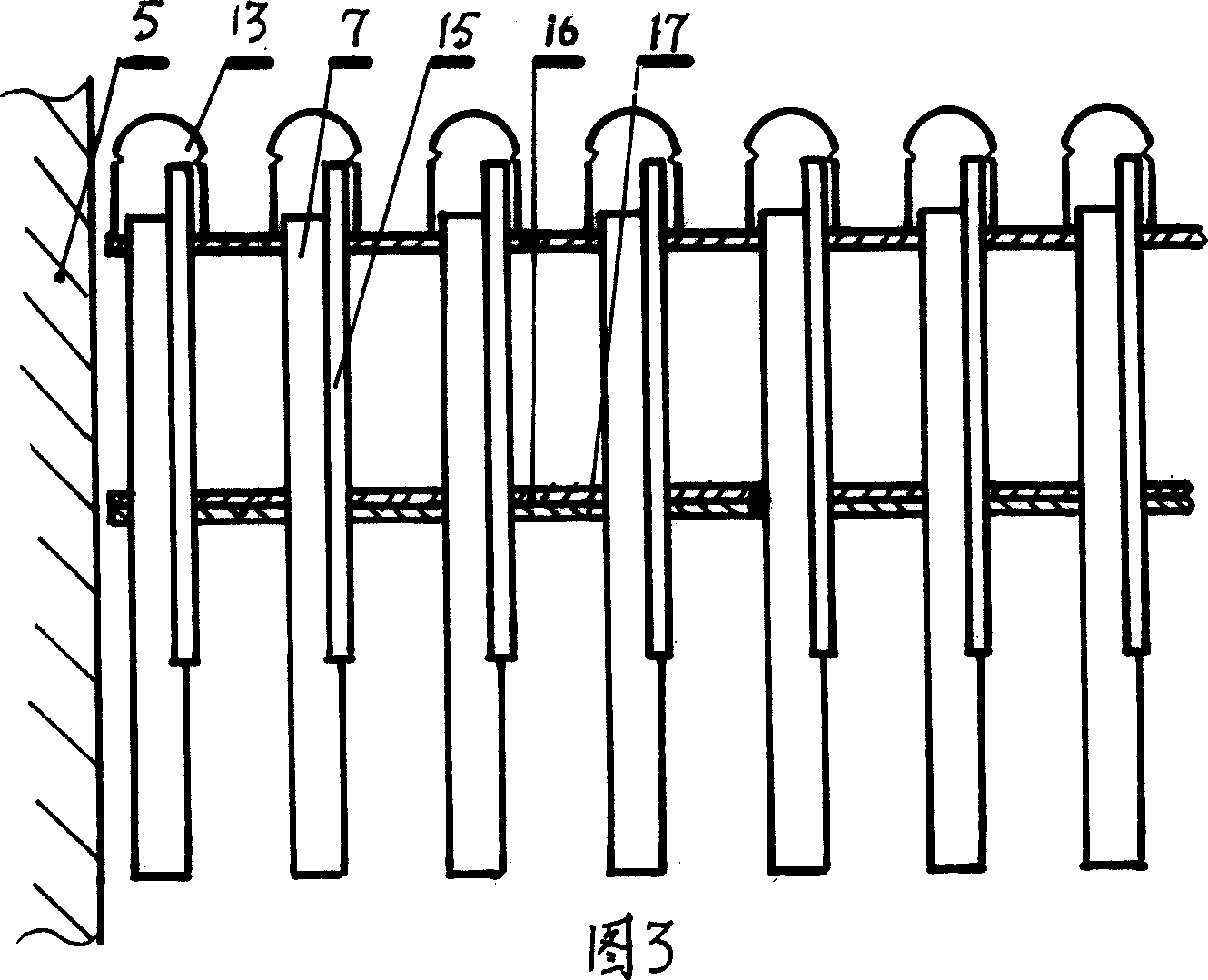

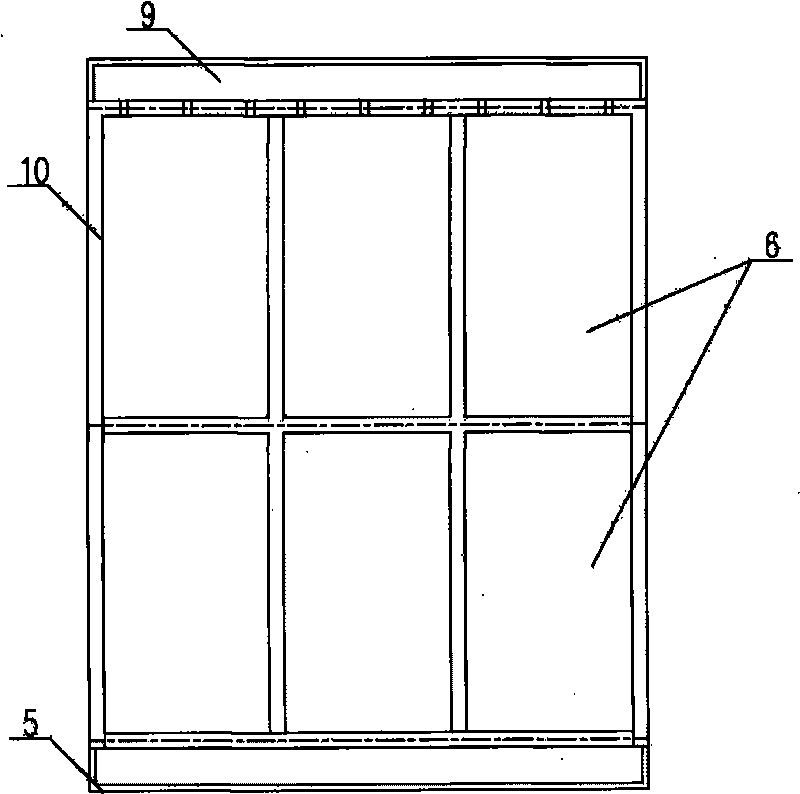

Upward-flow biological aerated filter

InactiveCN101734787AIncrease productivityKeep aliveSustainable biological treatmentBiological water/sewage treatmentFlushing timeBiochemical engineering

The invention discloses an upward-flow biological aerated filter, which is provided with a biofilter (10). The filter is characterized in that the biofilter (10) is separated into a plurality of sub-grid areas (6) equal in size through baffles (8), and each sub-grid area (6) is correspondingly provided with an independent flushing device. By adopting a sub-grid structure, the filter and a gas-water system can be arranged to be a plurality of units, and the bottom of the filter is provided with the independent flushing devices to flush sub-grids one by one so as to shorten flushing time, save water and gas for flushing and ensure better flushing effects. The filter has the advantages of improving flushing efficiency, ensuring uniform flushing intensity, maintaining biofilm activity, preventing blockage and improving the production efficiency of the biological aerated filter.

Owner:大连恒基新润水务有限公司

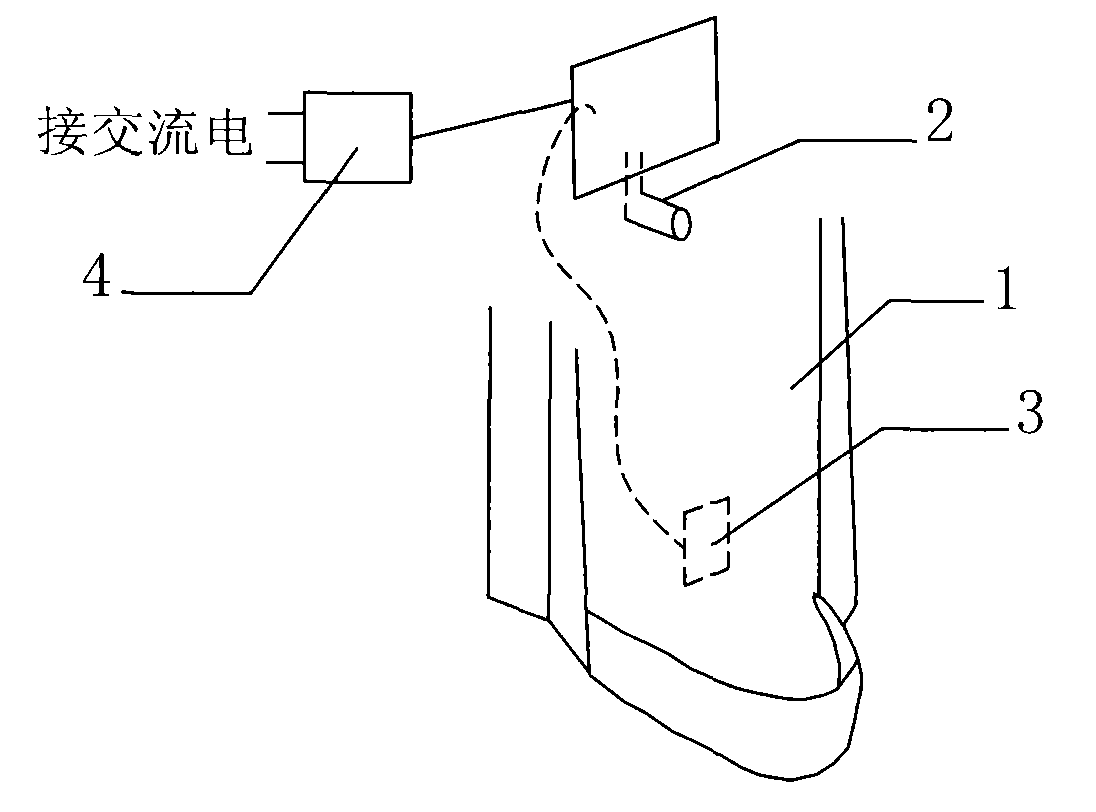

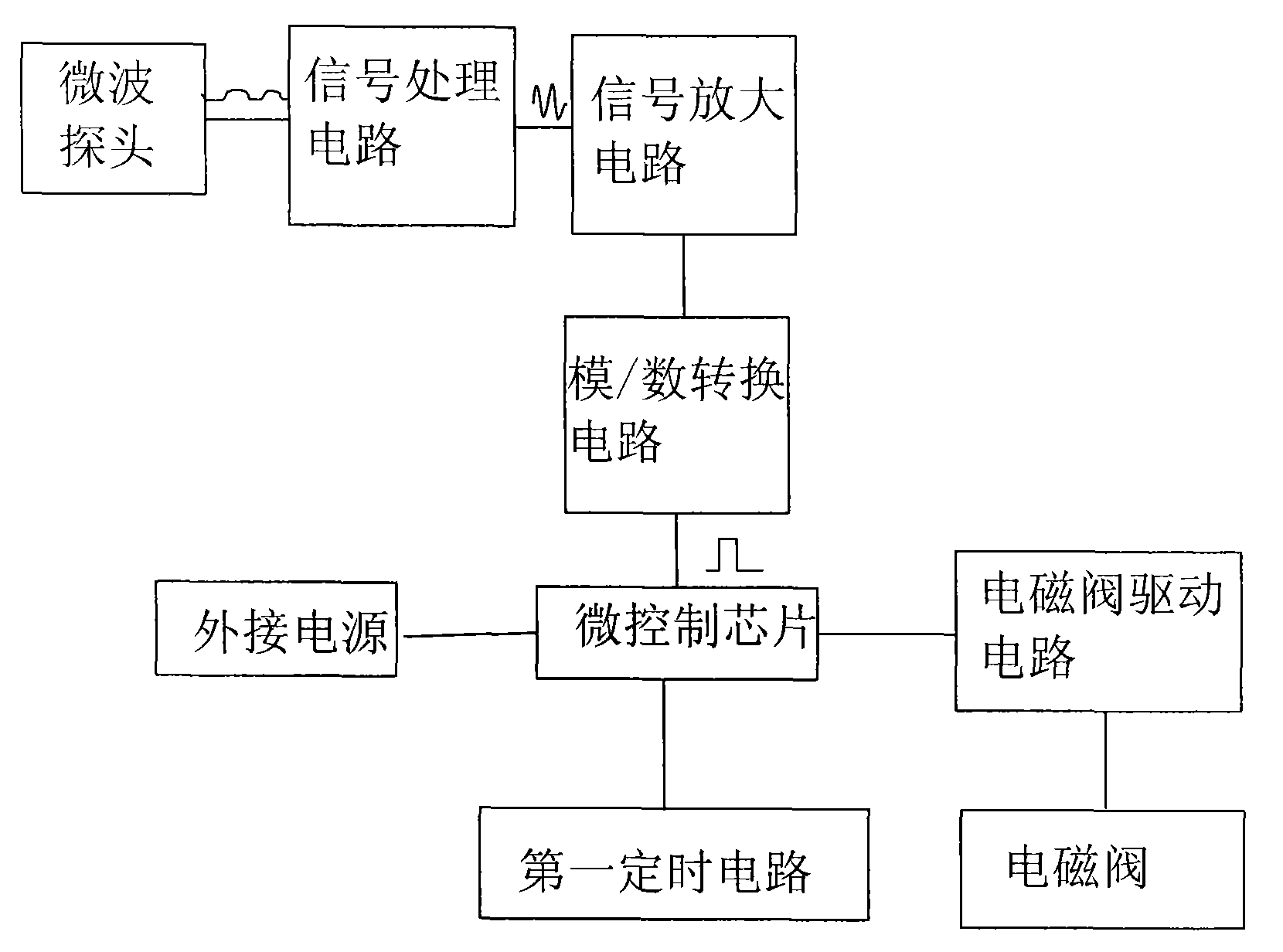

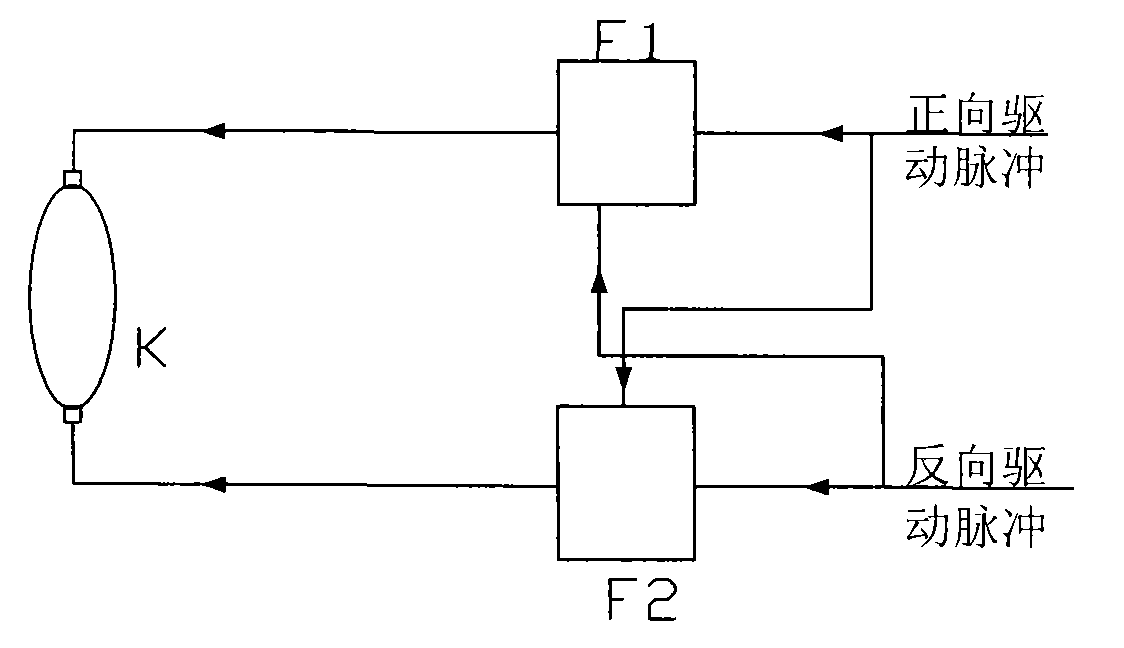

Microwave sensing automatic urinal

InactiveCN101550721AAvoid misuseAvoid surface reflectionsUrinalsFlushing devicesFlushing timeSignal processing circuits

The invention disclosed a microwave sensing automatic urinal, comprising a urinary hopper, a flushing pipeline and a microwave probe arranged at the ceramics back of urinary hopper. The microwave probe is connected with a controller sequentially through a signal processing circuit, a signal amplifying circuit and an analog / digital converting circuit; the controller is connected with an electromagnetic valve through an electromagnetic valve driving circuit, and also connected with a timing circuit for controlling water flushing time; and power supply of the whole circuit is supplied by an external power source. The microwave sensing automatic urinal utilizes Doppler effect of microwave to closely detect the flowing liquid with a detection range of about 90 mm; only the urinate instead of a human body is detected so as to prevent incorrect operation and avoid surface reflection and influence of external factors; the microwave probe is arranged at the ceramics back of urinary hopper so that the problem of installing the automatic sensing urinal in a narrow space is solved. Accumulated water is unlikely to generate, and influence of humidity at the front side is avoided.

Owner:XIAMEN OLT SCI & TECH ELECTRONICS DEVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com